Cold and hot fatigue test method and device for engine cylinder cover assembly

A technology for engine cylinder head and fatigue test, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of low efficiency of cold and heat fatigue test, and achieve the effects of easy control, simple operation and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

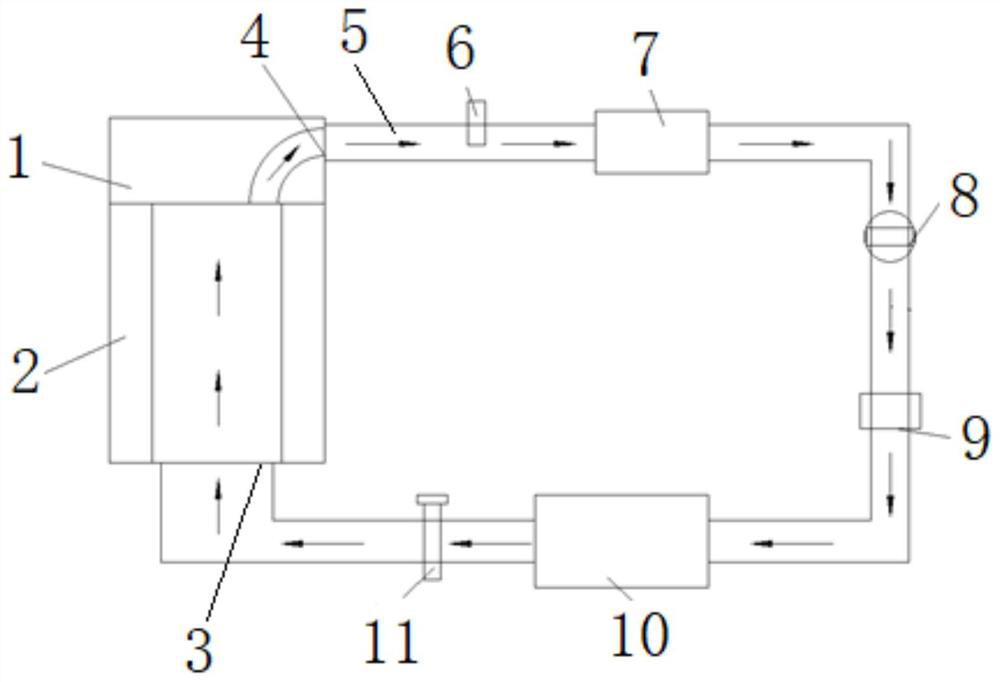

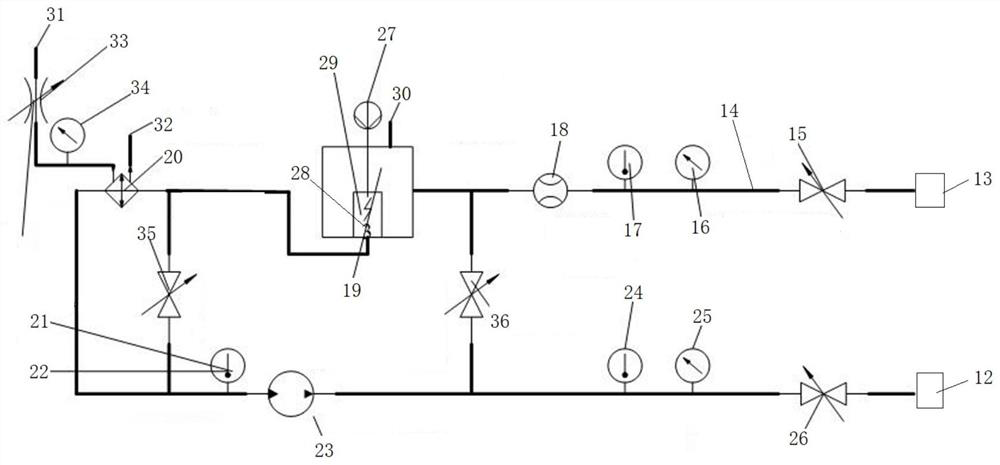

[0043] The present application will be described in further detail below in conjunction with the accompanying drawings and embodiments.

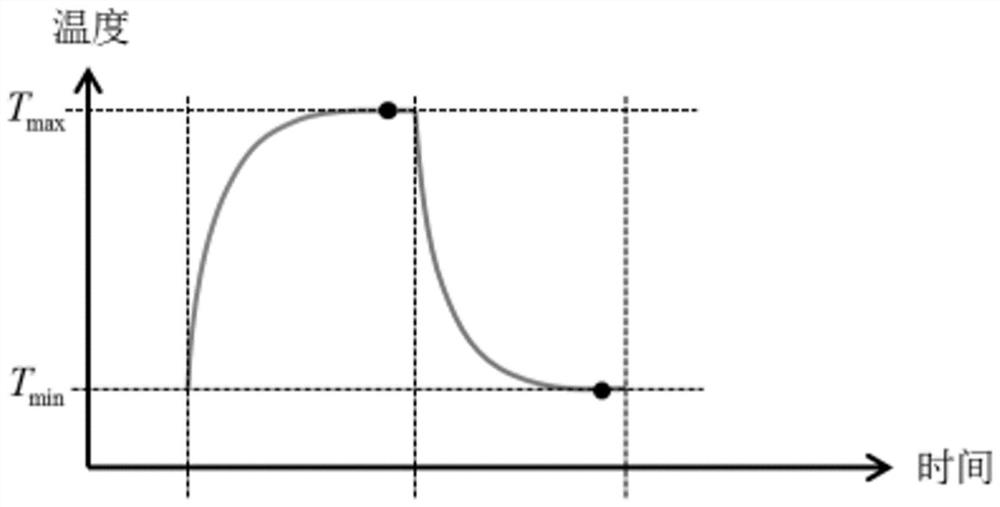

[0044]Thermal fatigue is divided into low-cycle thermal fatigue and high-cycle thermal fatigue. When the engine is started, the fire surface is directly impacted by high-temperature and high-pressure gas, and the temperature is very high, while the temperature on the side with cooling water is relatively low, which limits the thermal expansion of the fire surface and generates strong compressive stress. Under high temperature conditions Plastic deformation occurs; when the engine stops, tensile stress is generated due to cold contraction. Due to the repeated action of the alternating stress of thermal expansion and cold contraction, the fire surface will eventually fail due to thermal fatigue due to cracks. Therefore, the start-stop cycle of the engine belongs to low-cycle thermal fatigue, which is characterized by large temperature and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com