Patents

Literature

1137 results about "Overhead crane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of parallel runways with a traveling bridge spanning the gap. A hoist, the lifting component of a crane, travels along the bridge. If the bridge is rigidly supported on two or more legs running on a fixed rail at ground level, the crane is called a gantry crane (USA, ASME B30 series) or a goliath crane (UK, BS 466).

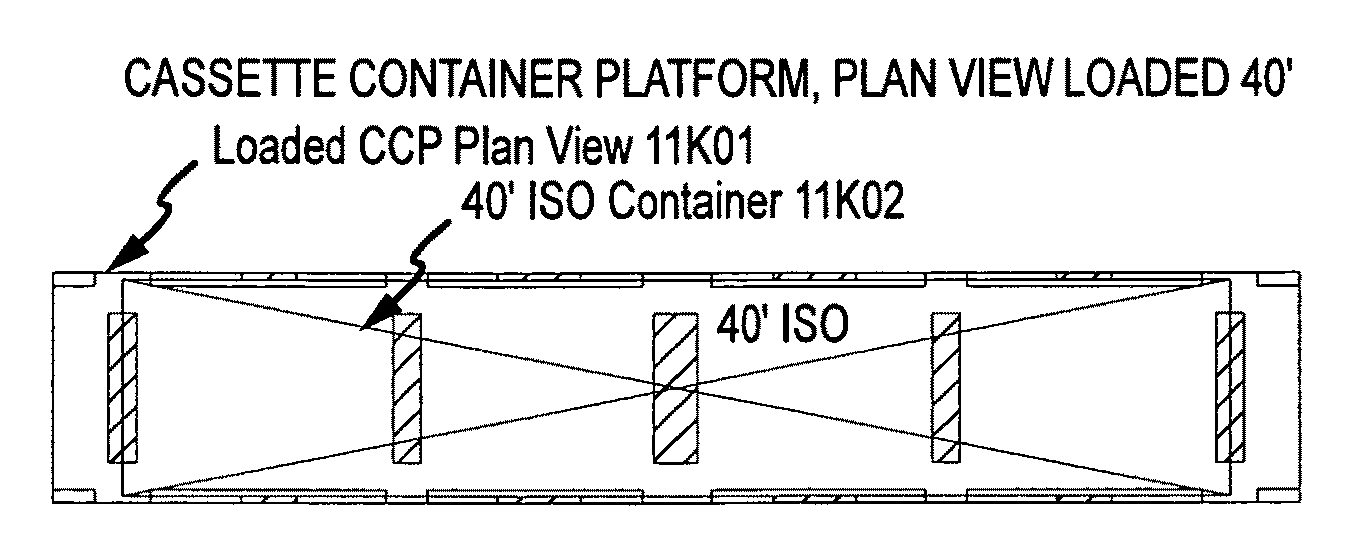

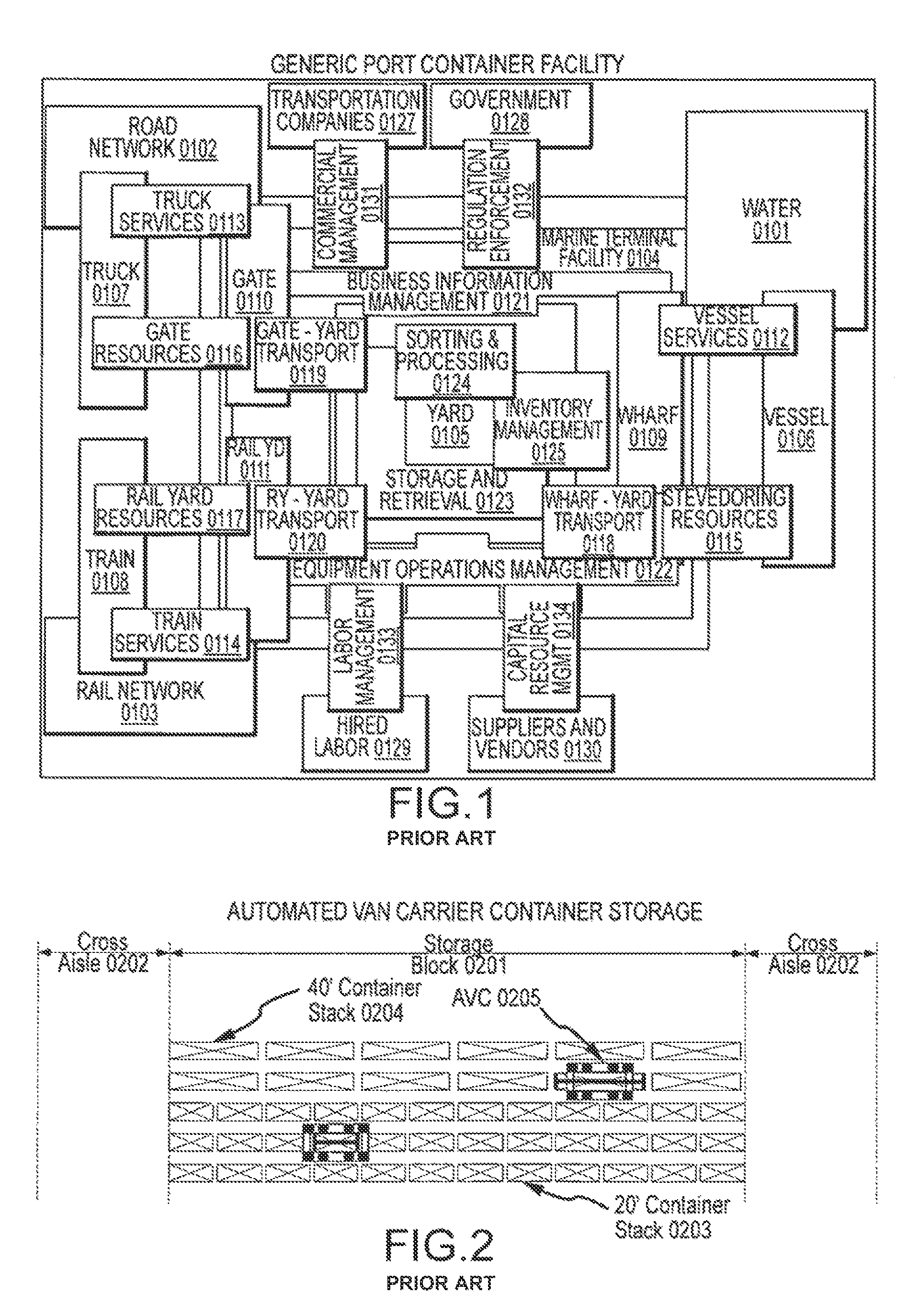

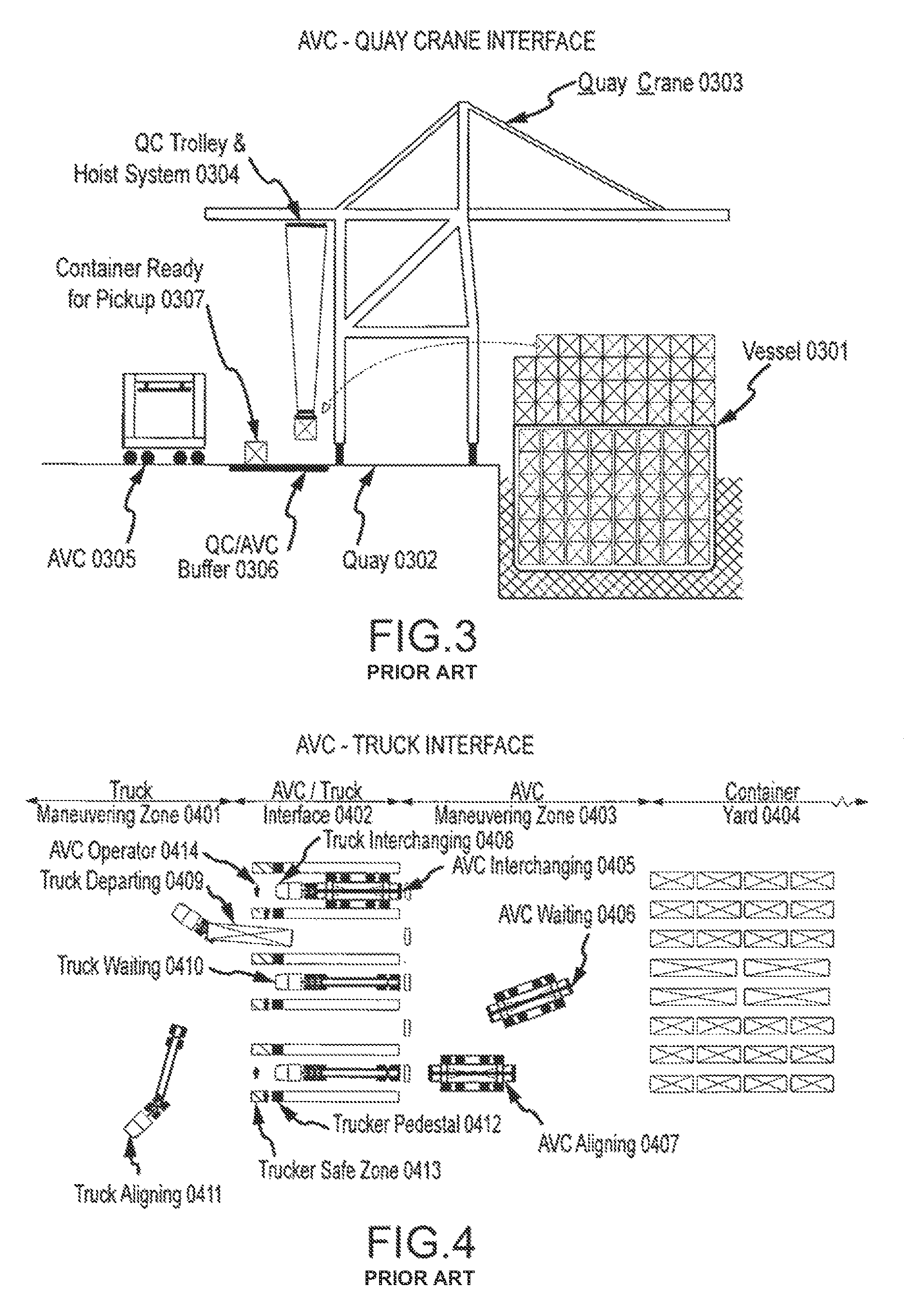

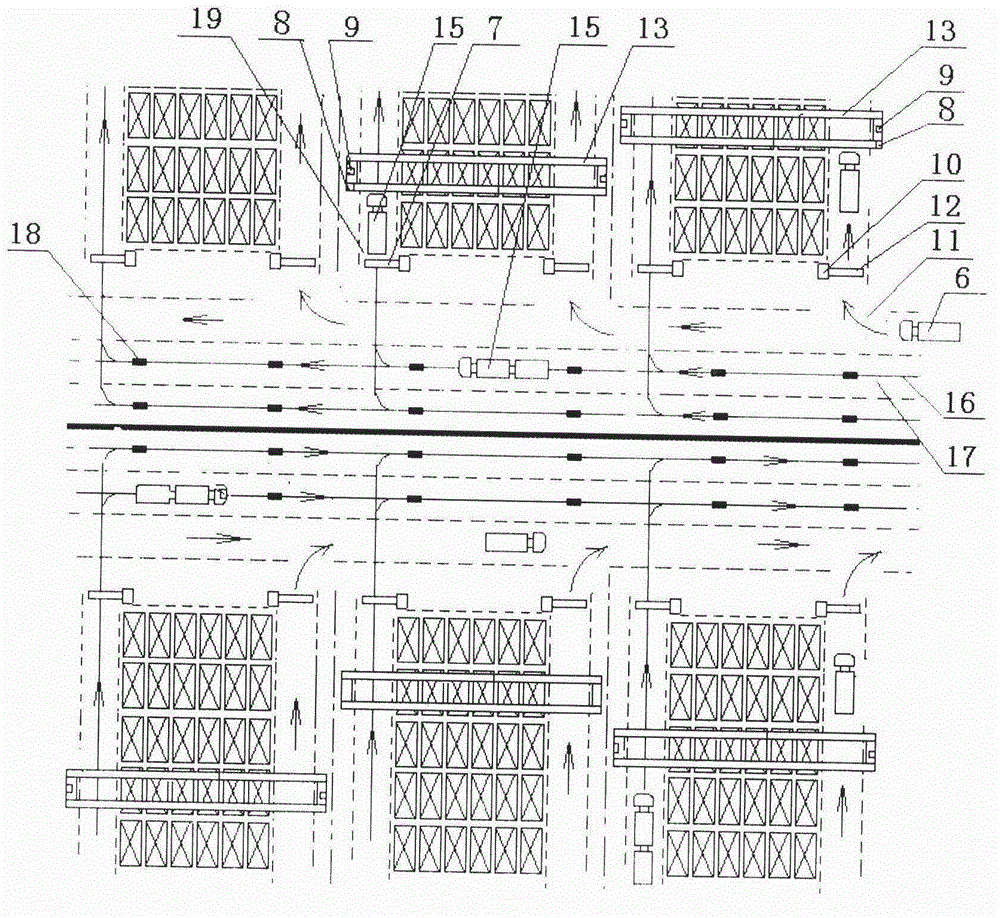

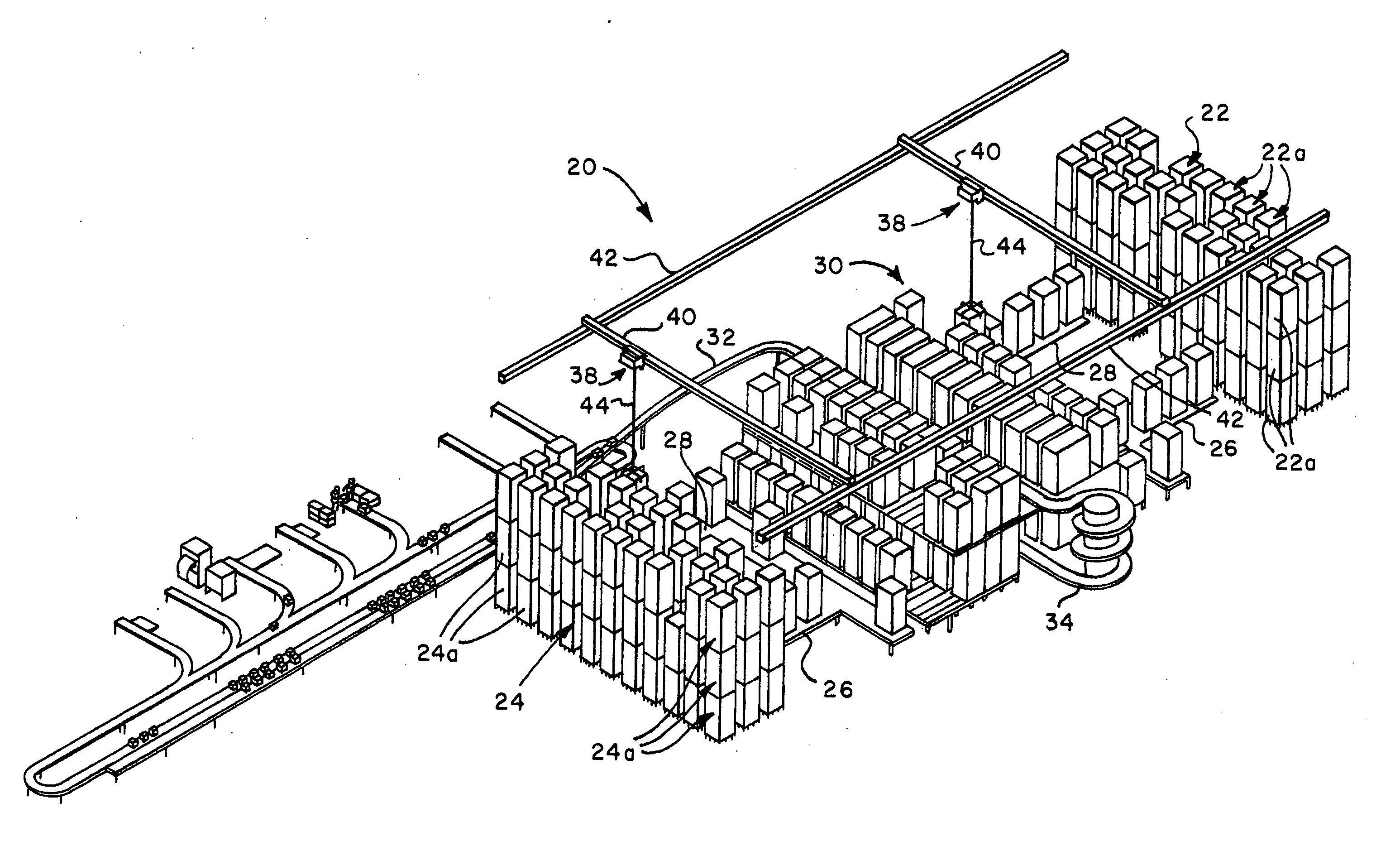

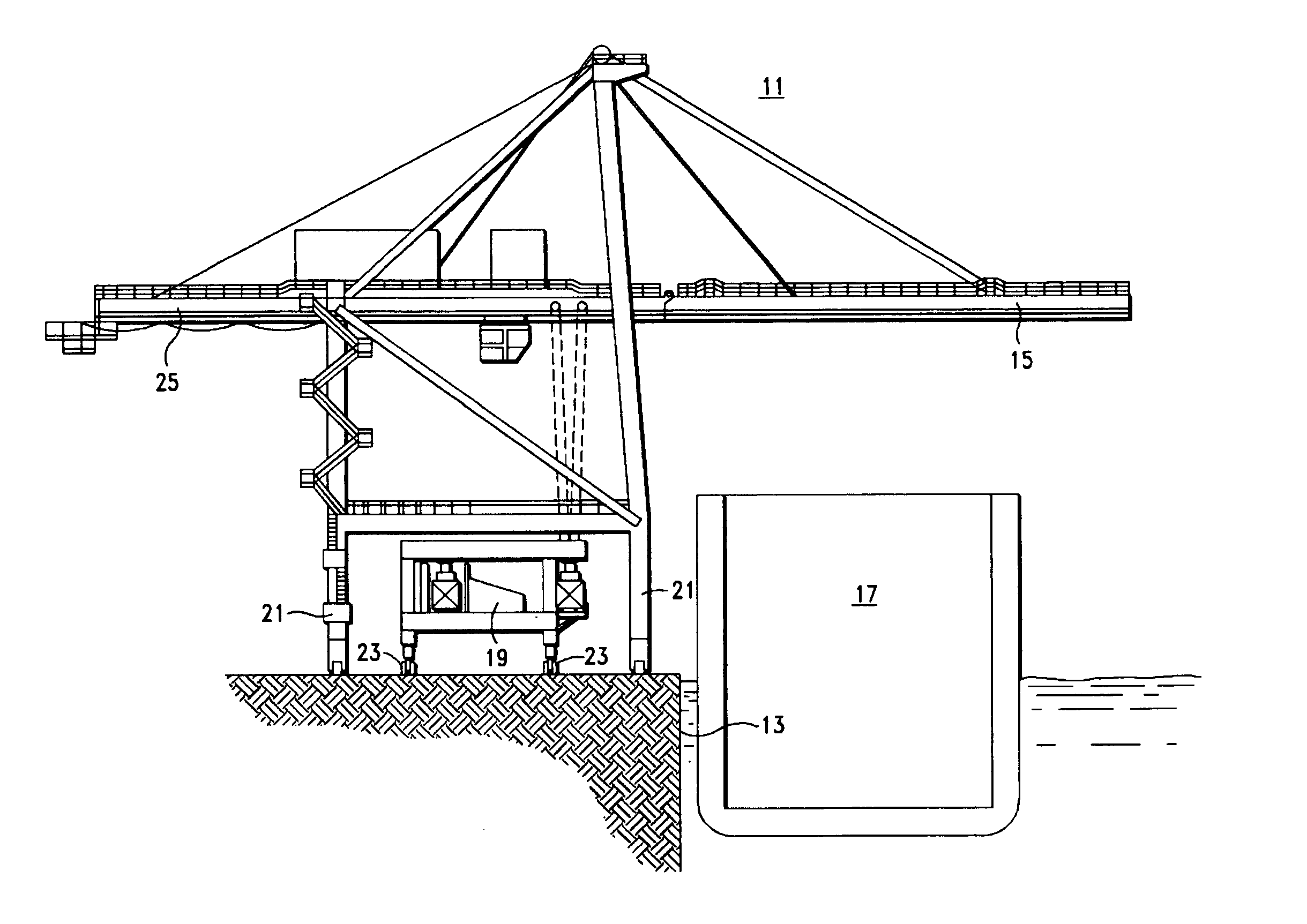

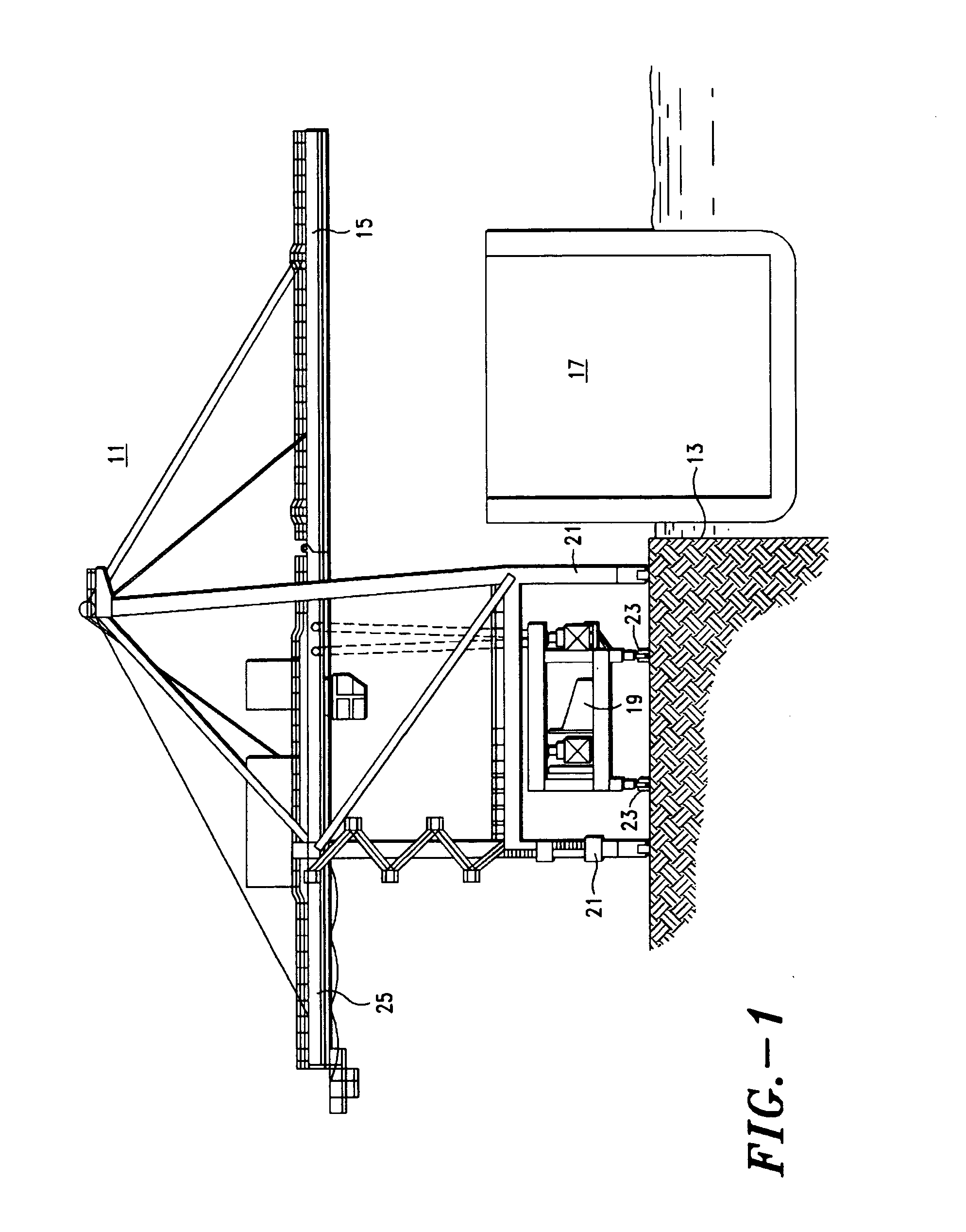

Automated marine container terminal and system

InactiveUS7972102B2Reduced footprintLow costCargo handling apparatusPassenger handling apparatusAutomated guided vehicleOverhead crane

A storage area is accessed by automated guided vehicles which receive and unload containerized loads. On the waterside, loads are exchanged between the vehicles and ships using quay cranes. On the ground transportation side, loads are exchanged between the vehicles and truck or rail carriers using semi automated or automated remote-controlled bridge cranes. Within the storage area, loads are exchanged between the vehicles and the storage facilities using automated stacking cranes. The vehicles are adapted to receive a cassette storage platform which in turn receives standard ISO containers. The vehicles also are adapted to receive one or more alternative platforms including a coning platform for workers to manage container coning, a reefer access and maintenance platform, and a worker transport platform.

Owner:MARINE TERMINALS CORP

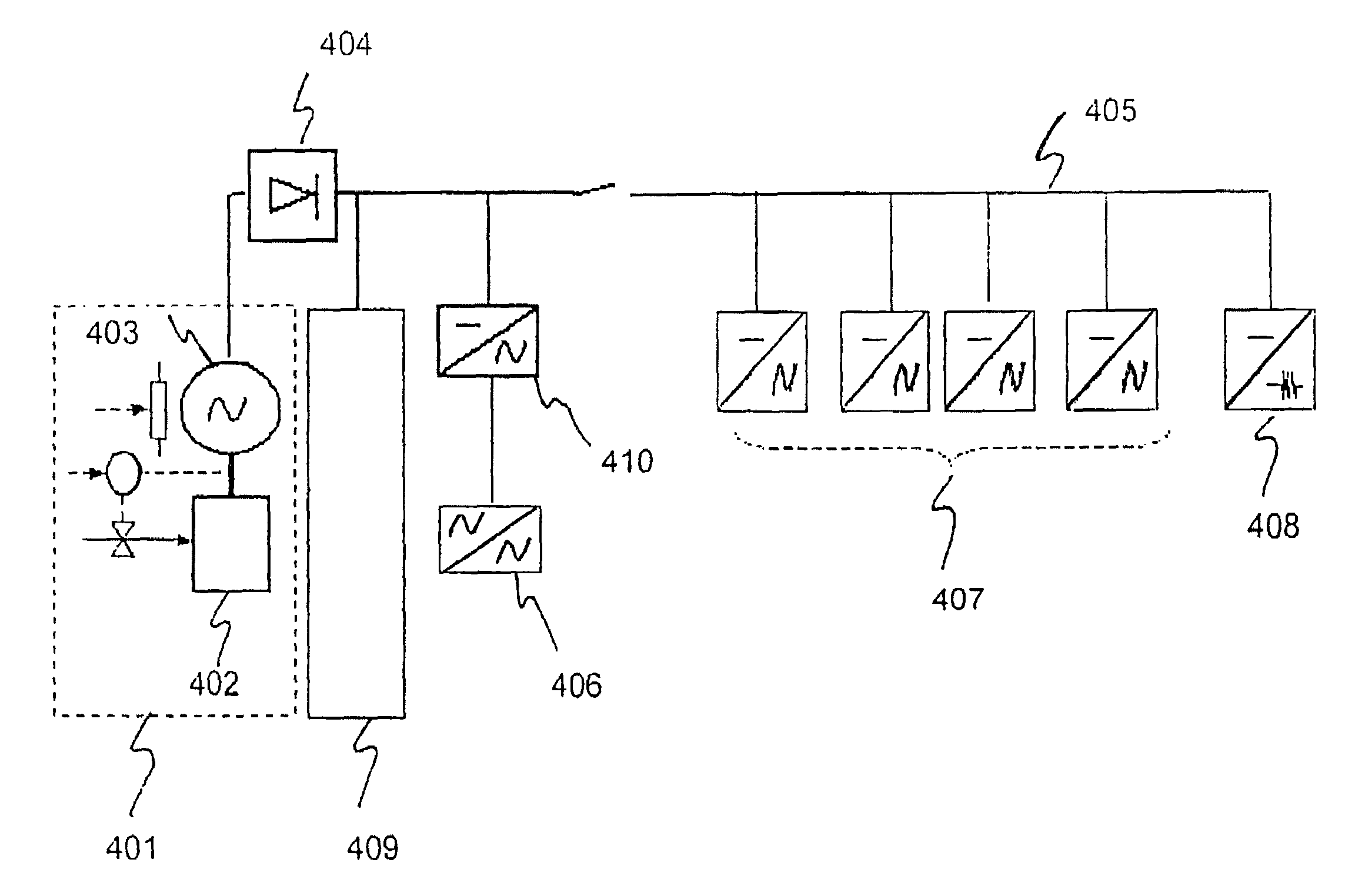

Load-lifting apparatus and method of storing energy for the same

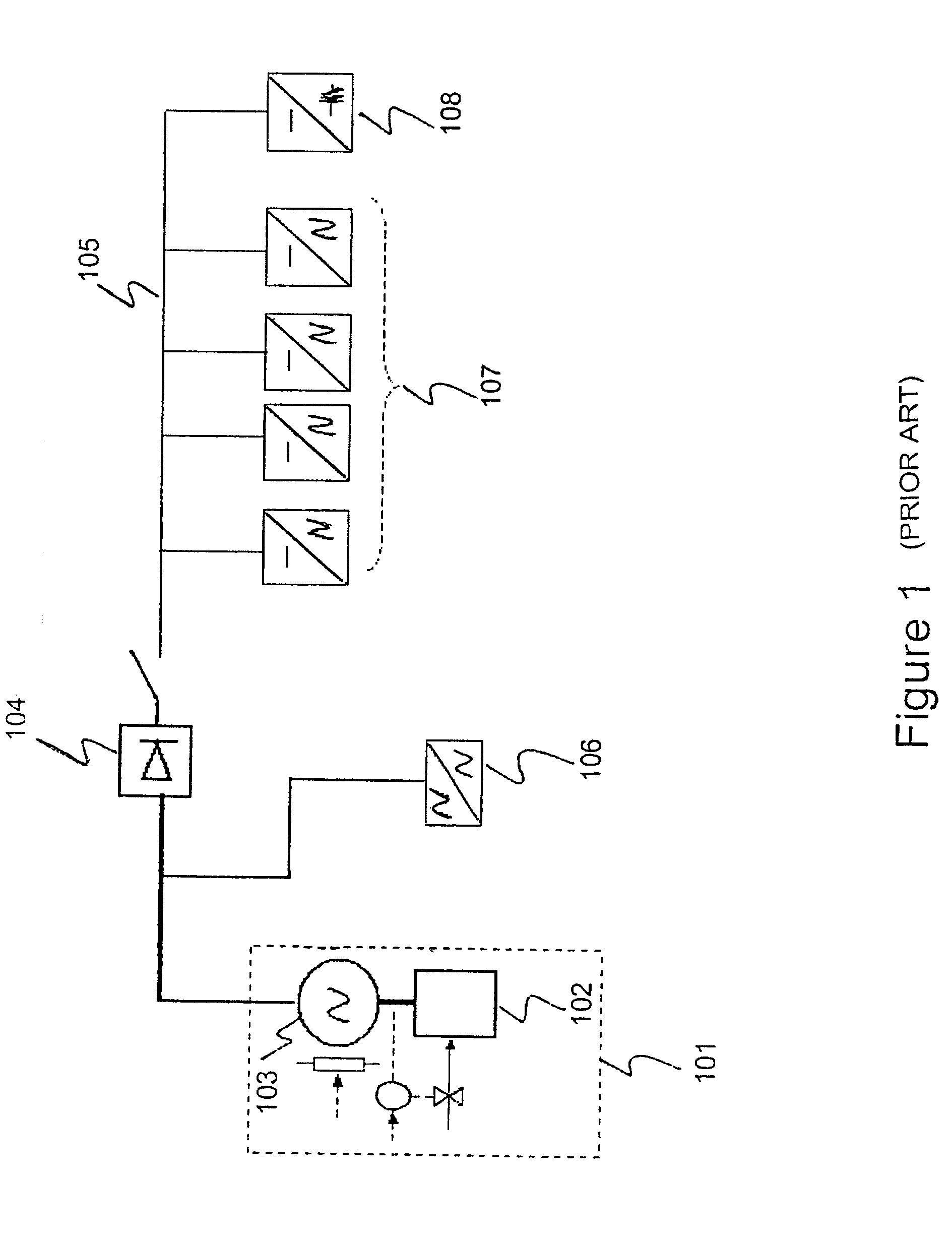

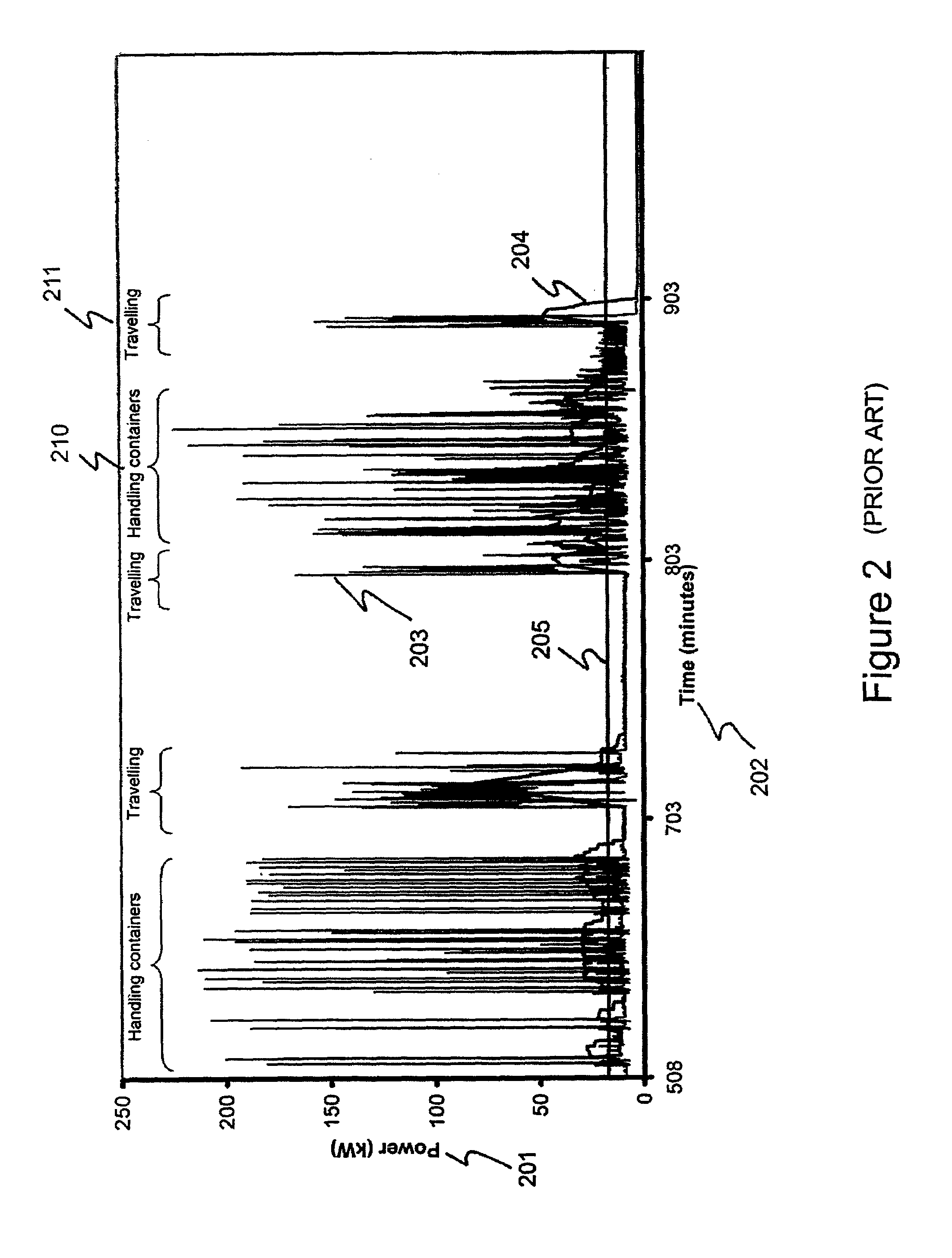

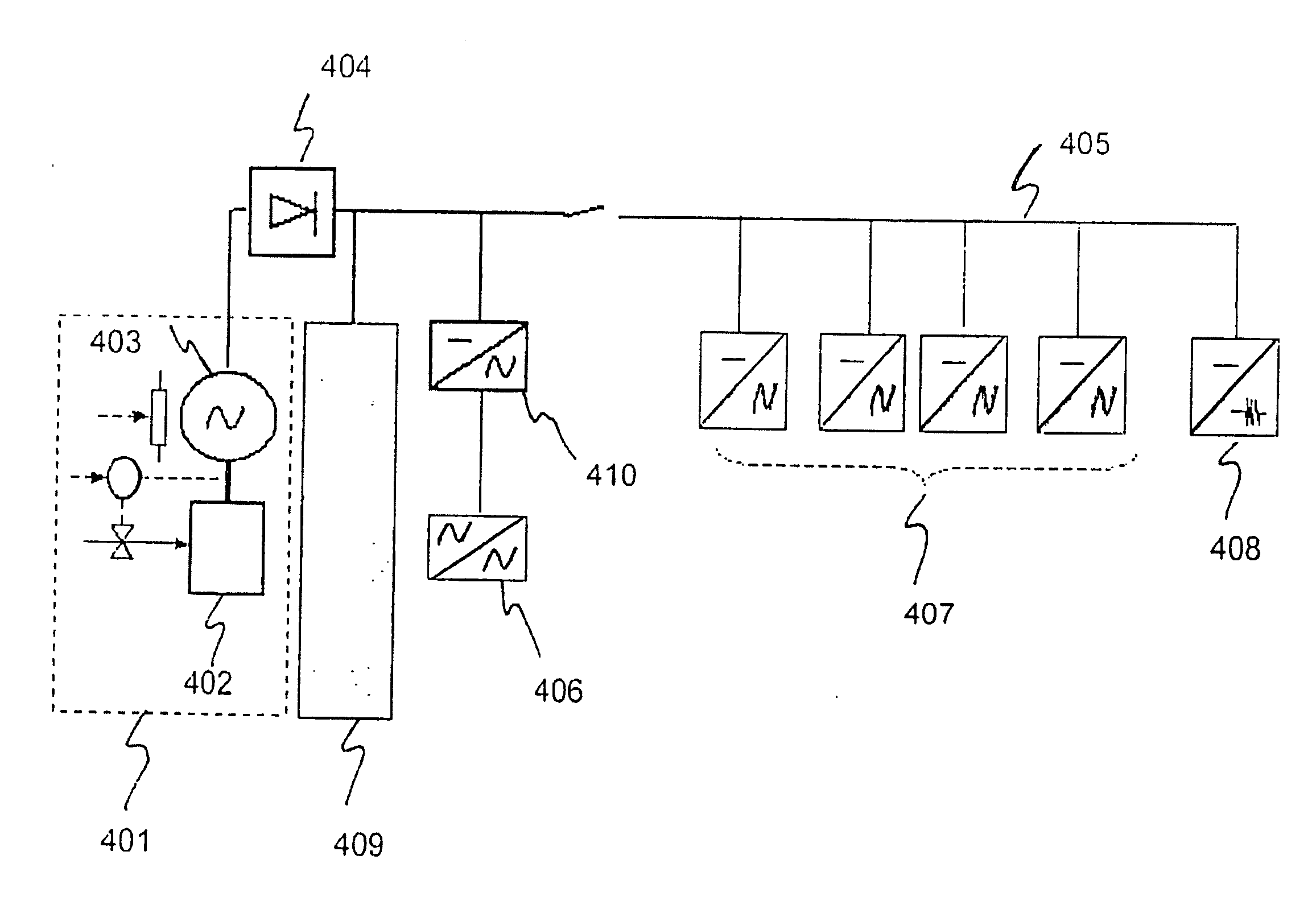

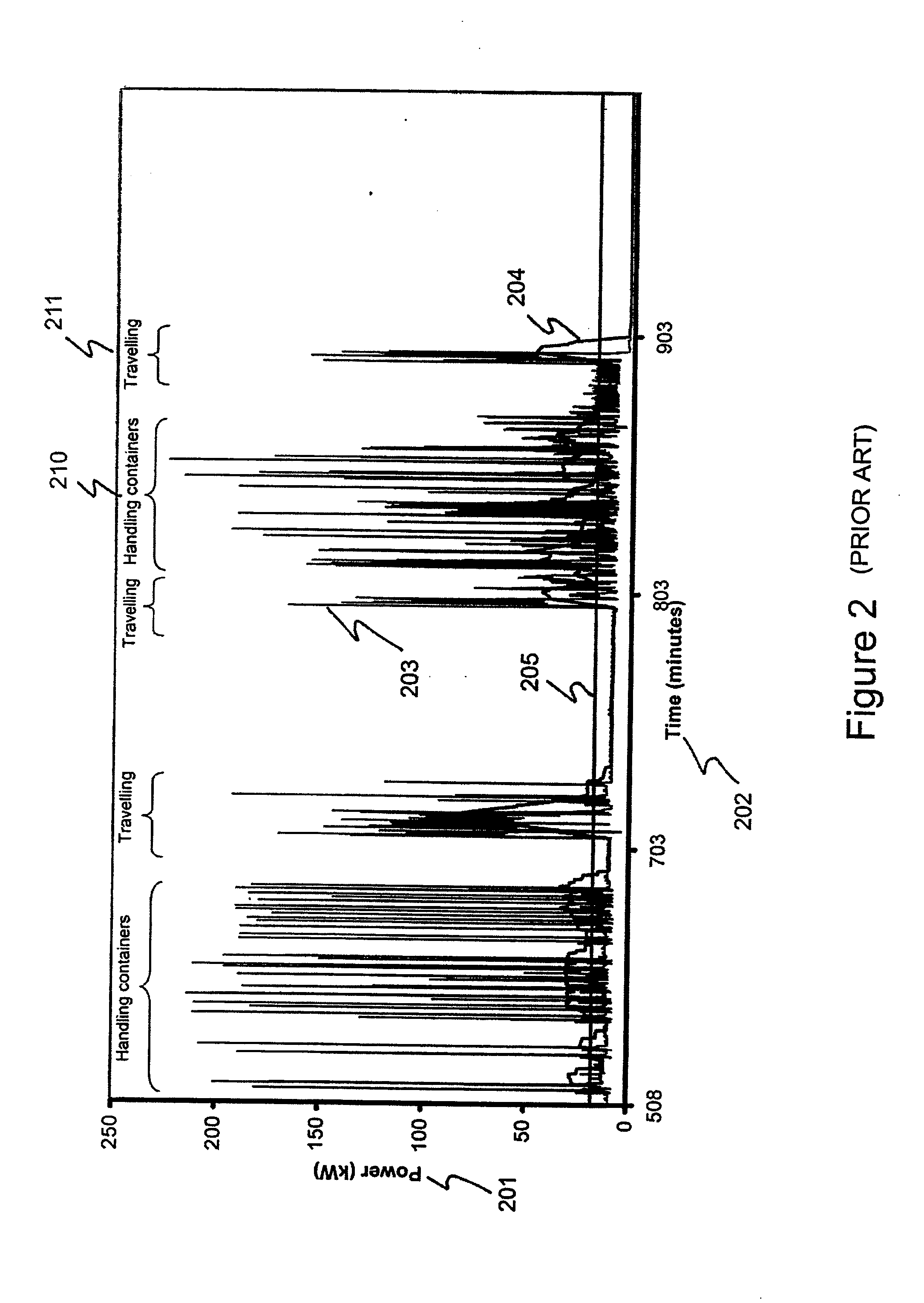

ActiveUS7554278B2Small sizeAlleviate power rating requirementDc motor stoppersDynamo-electric converter controlRegenerative brakeContainer crane

A load-lifting apparatus has one or more prime power sources, one or more energy storage systems and regenerative braking. Regenerative energy is recovered when the load-lifting apparatus lowers its load. The elements of the prime power sources, energy storage devices and electrical components may be distributed to provide stability for the load-lifting apparatus. The general power architecture and energy recovery method can be applied to cranes, rubber-tired gantry cranes, overhead cranes, mobile cranes, ship-to-shore cranes, container cranes, rail-mounted gantry cranes, straddle carrier cranes and elevators. In such an architecture, the energy storage system helps alleviate the power rating requirement of the prime power source with respect to the peak power requirement for lifting a load.

Owner:MI JACK CANADA

Load-lifting apparatus and method of storing energy for the same

ActiveUS20080048497A1Improve fuel efficiencyLower noxious prime power emissionBatteries circuit arrangementsDc motor stoppersPower ArchitectureContainer crane

A load-lifting apparatus has one or more prime power sources, one or more energy storage systems and regenerative braking. Regenerative energy is recovered when the load-lifting apparatus lowers its load. The elements of the prime power sources, energy storage devices and electrical components may be distributed to provide stability for the load-lifting apparatus. The general power architecture and energy recovery method can be applied to cranes, rubber-tired gantry cranes, overhead cranes, mobile cranes, ship-to-shore cranes, container cranes, rail-mounted gantry cranes, straddle carrier cranes and elevators. In such an architecture, the energy storage system helps alleviate the power rating requirement of the prime power source with respect to the peak power requirement for lifting a load.

Owner:MI JACK CANADA

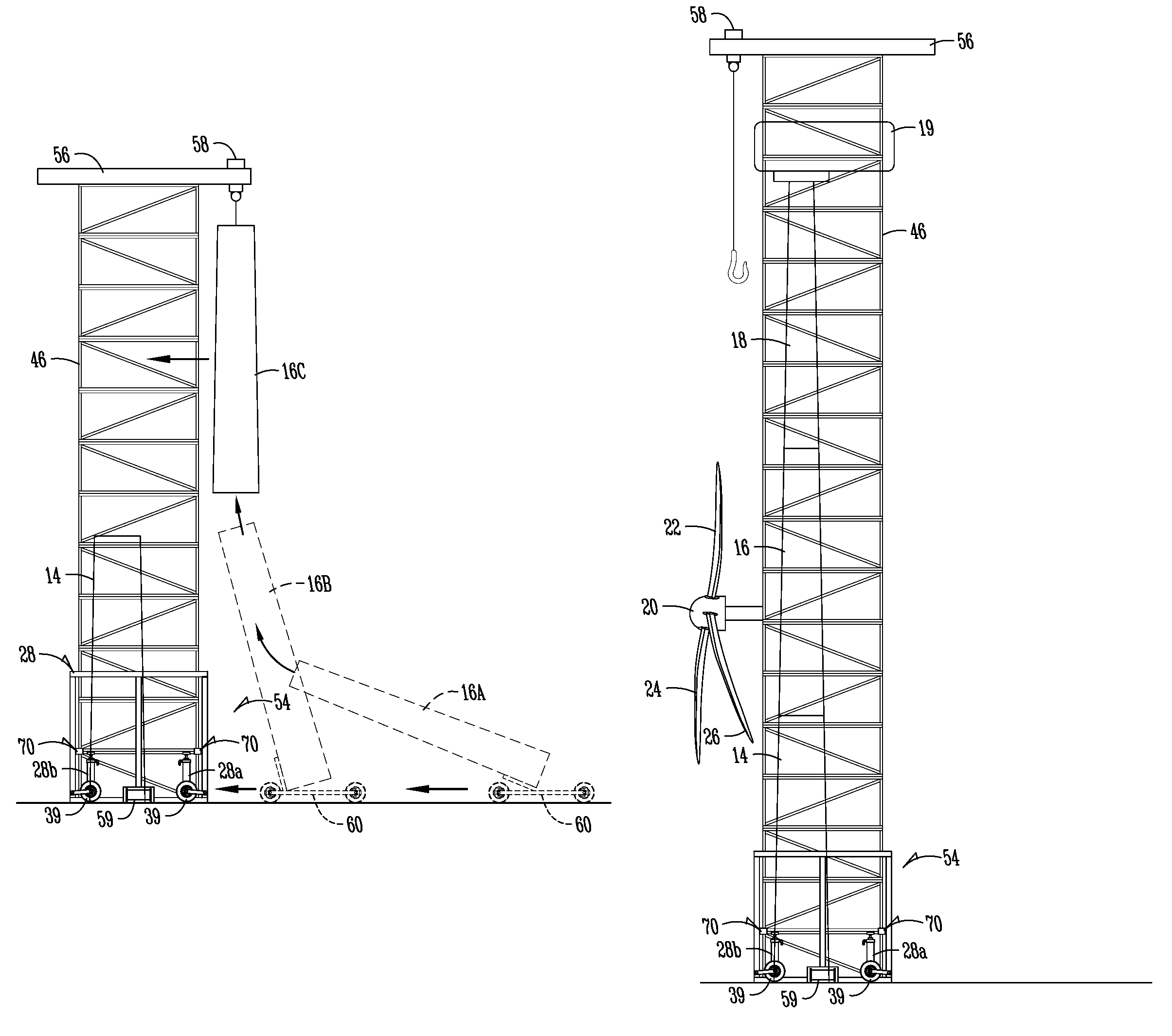

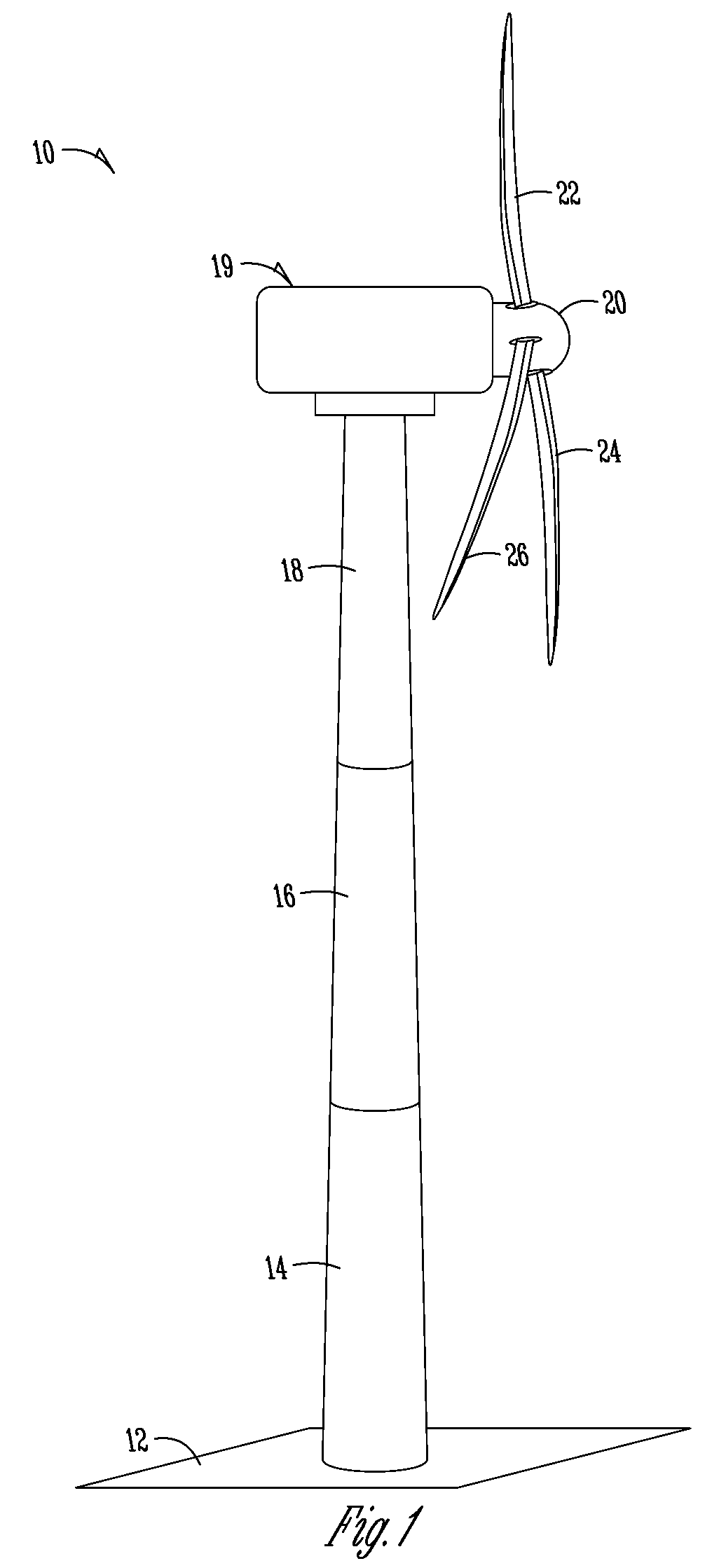

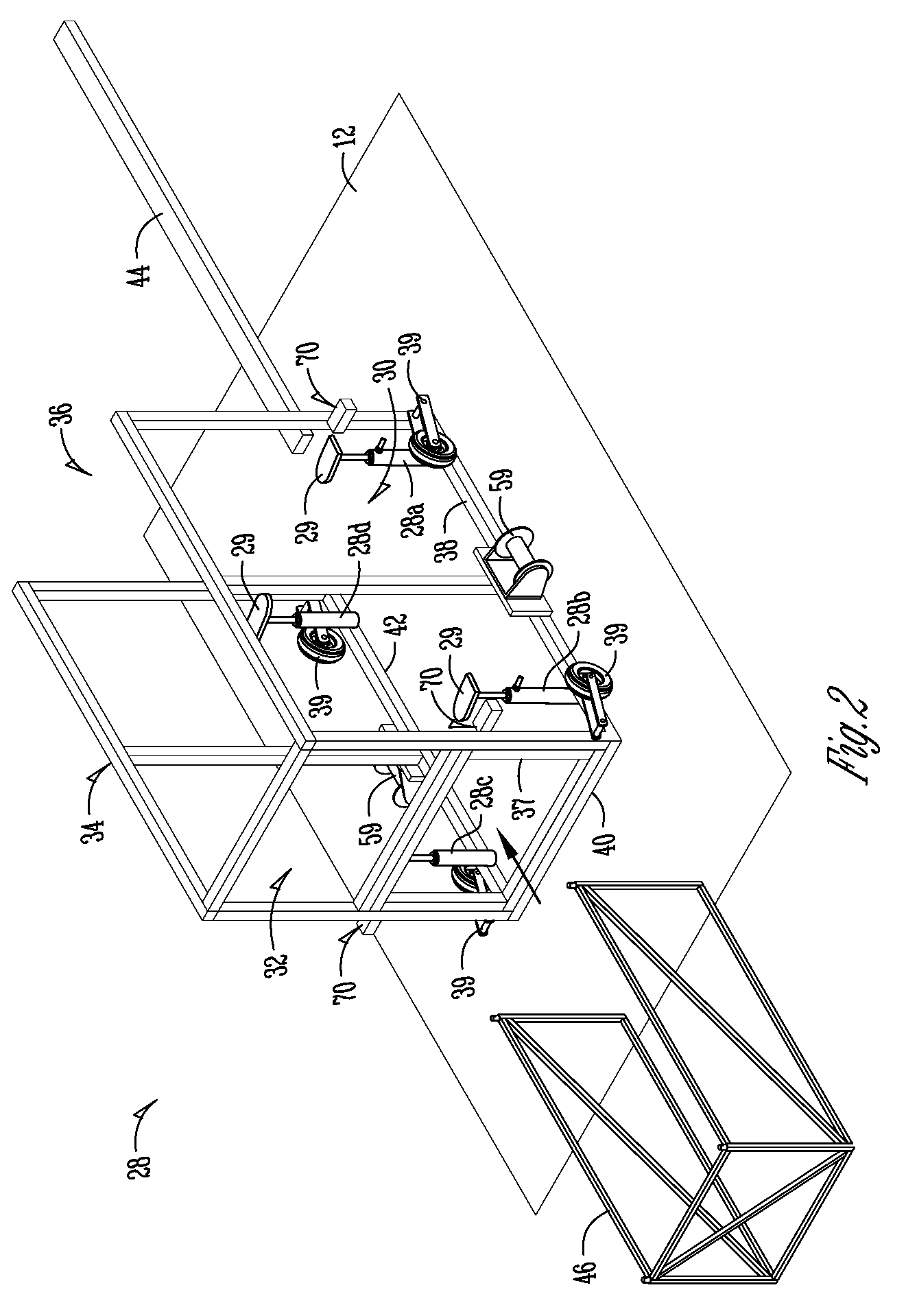

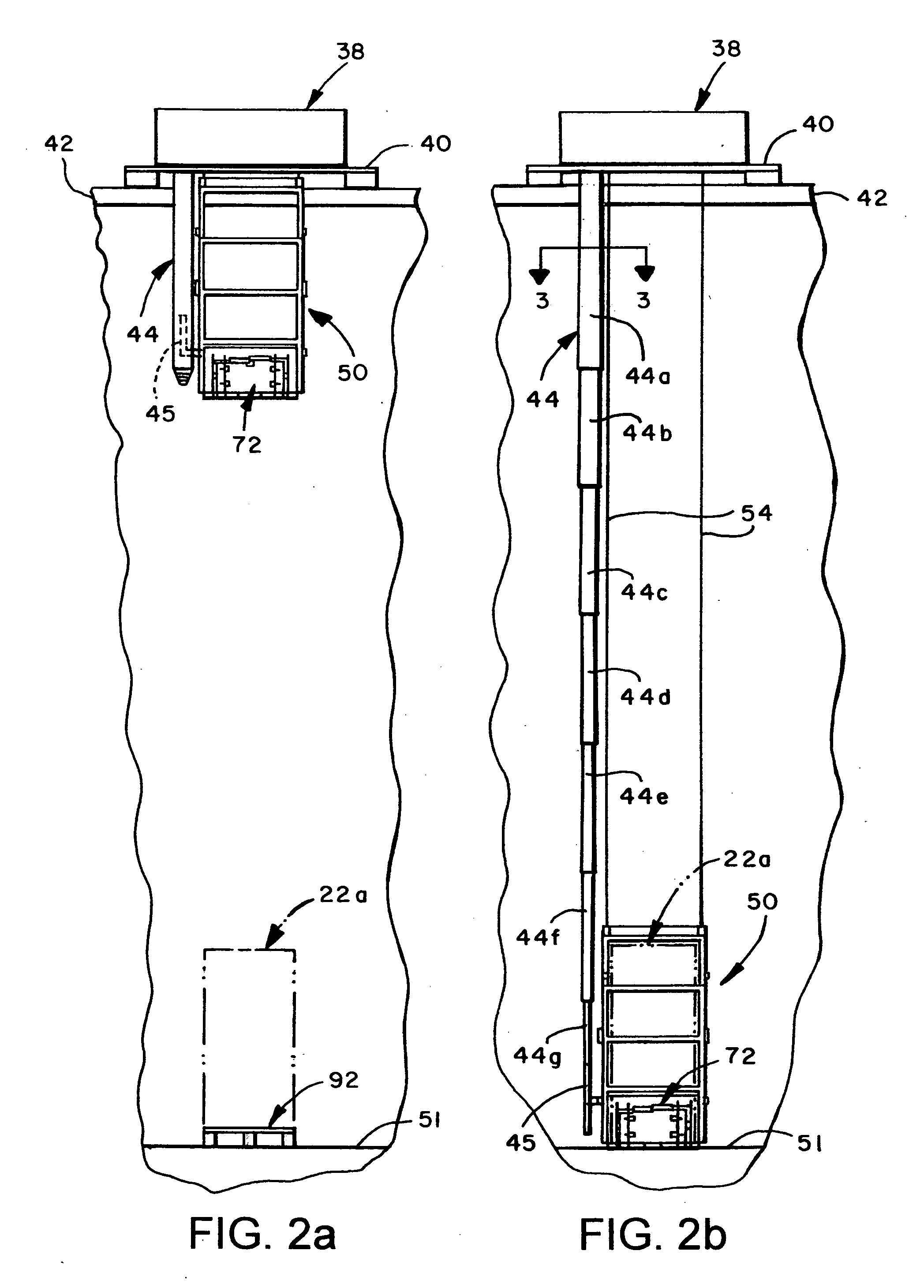

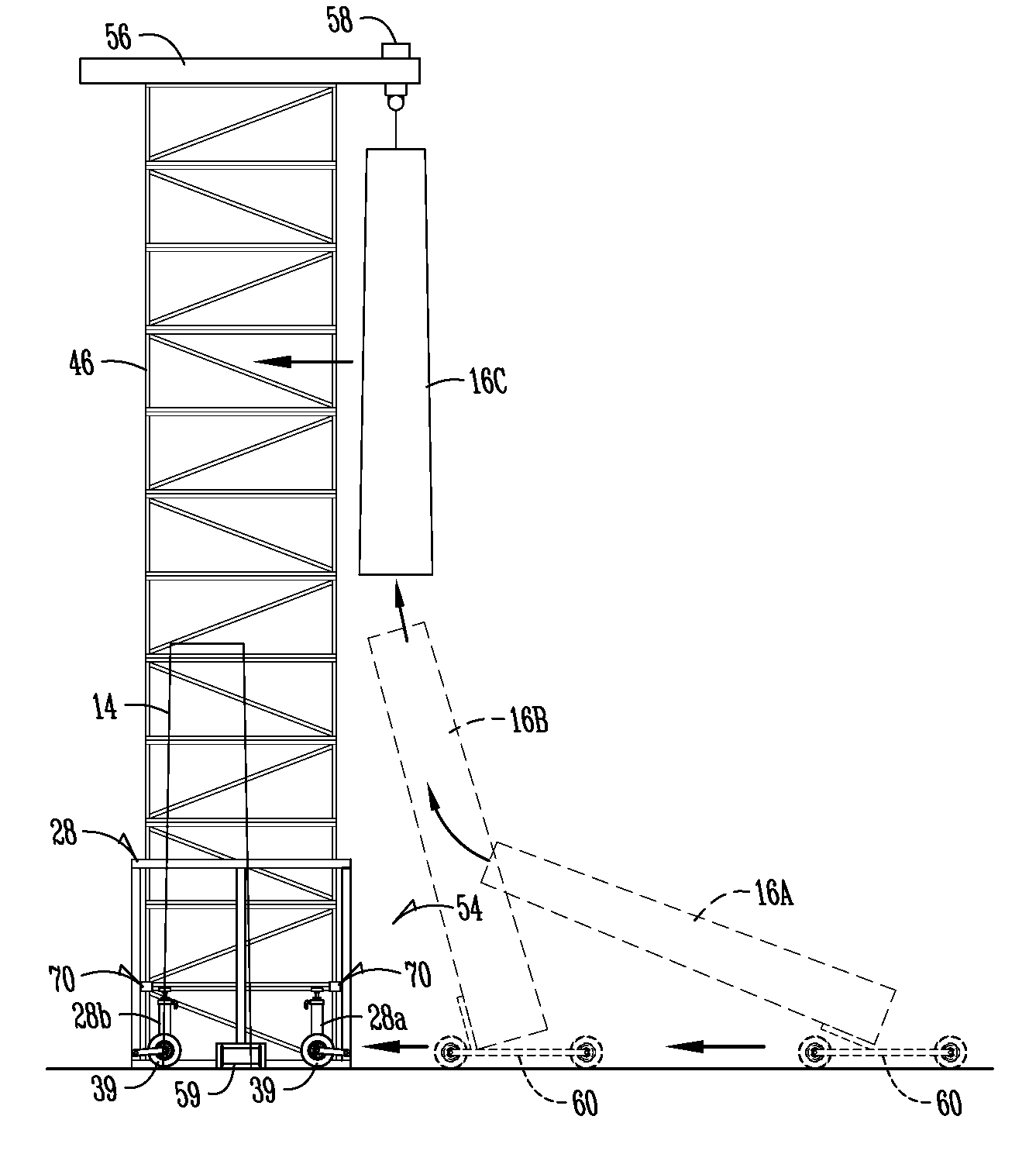

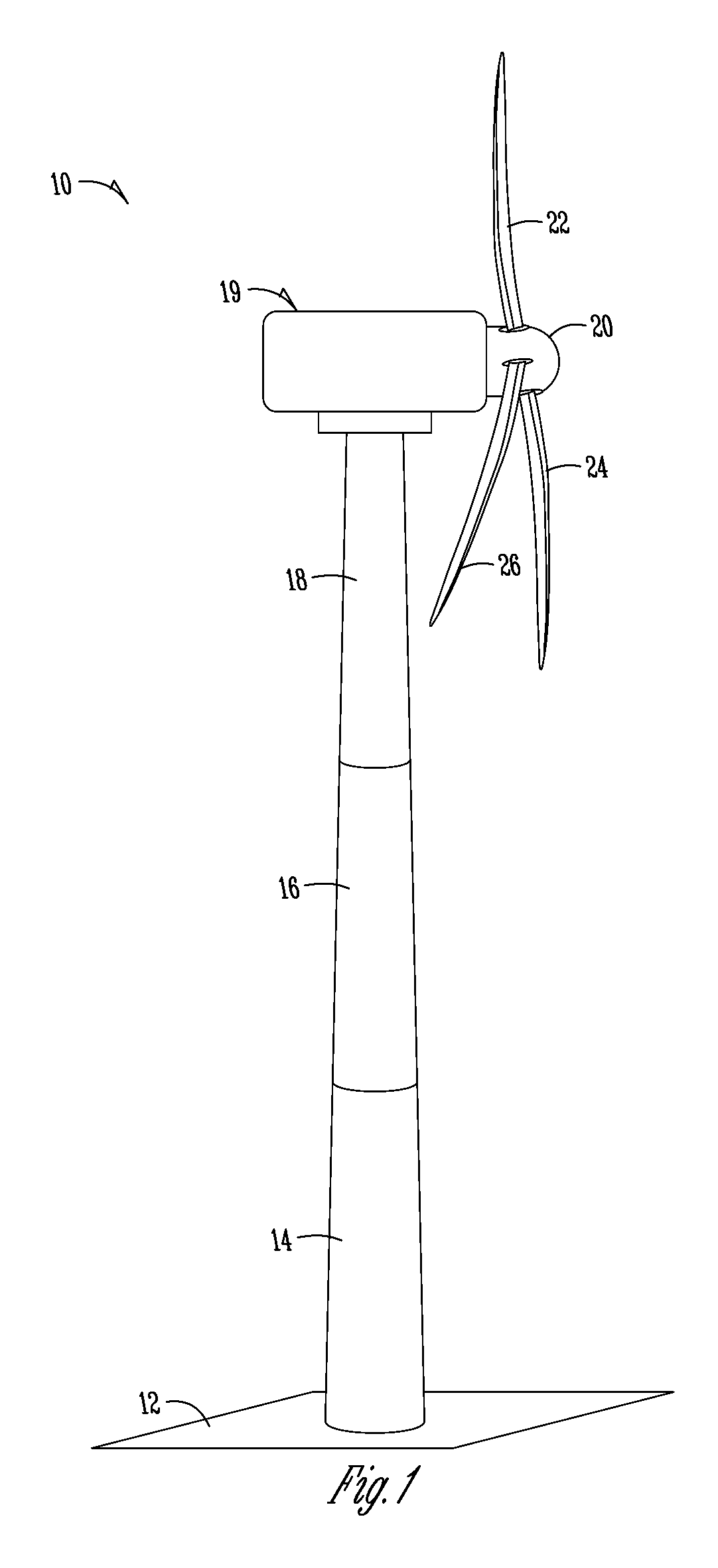

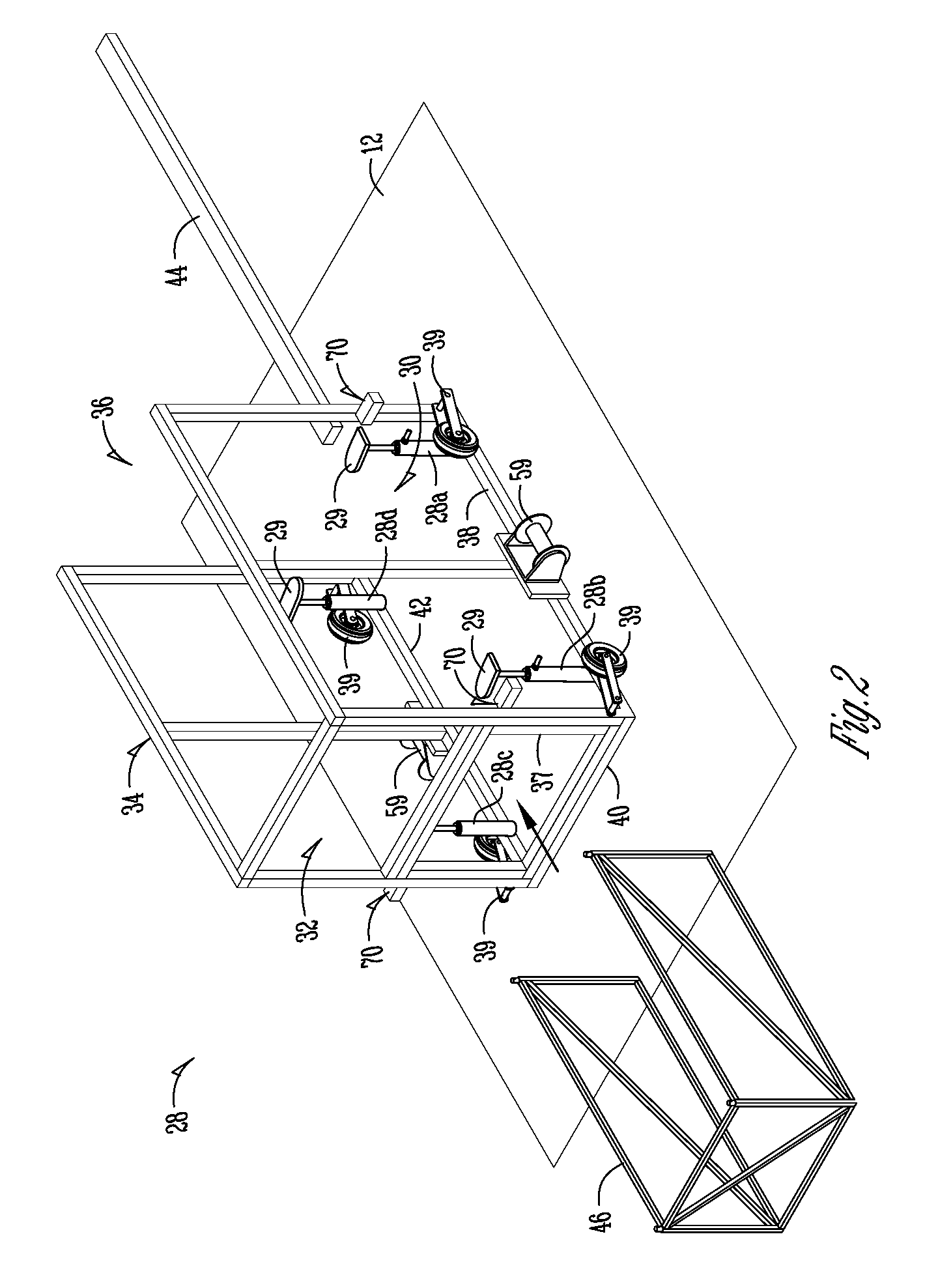

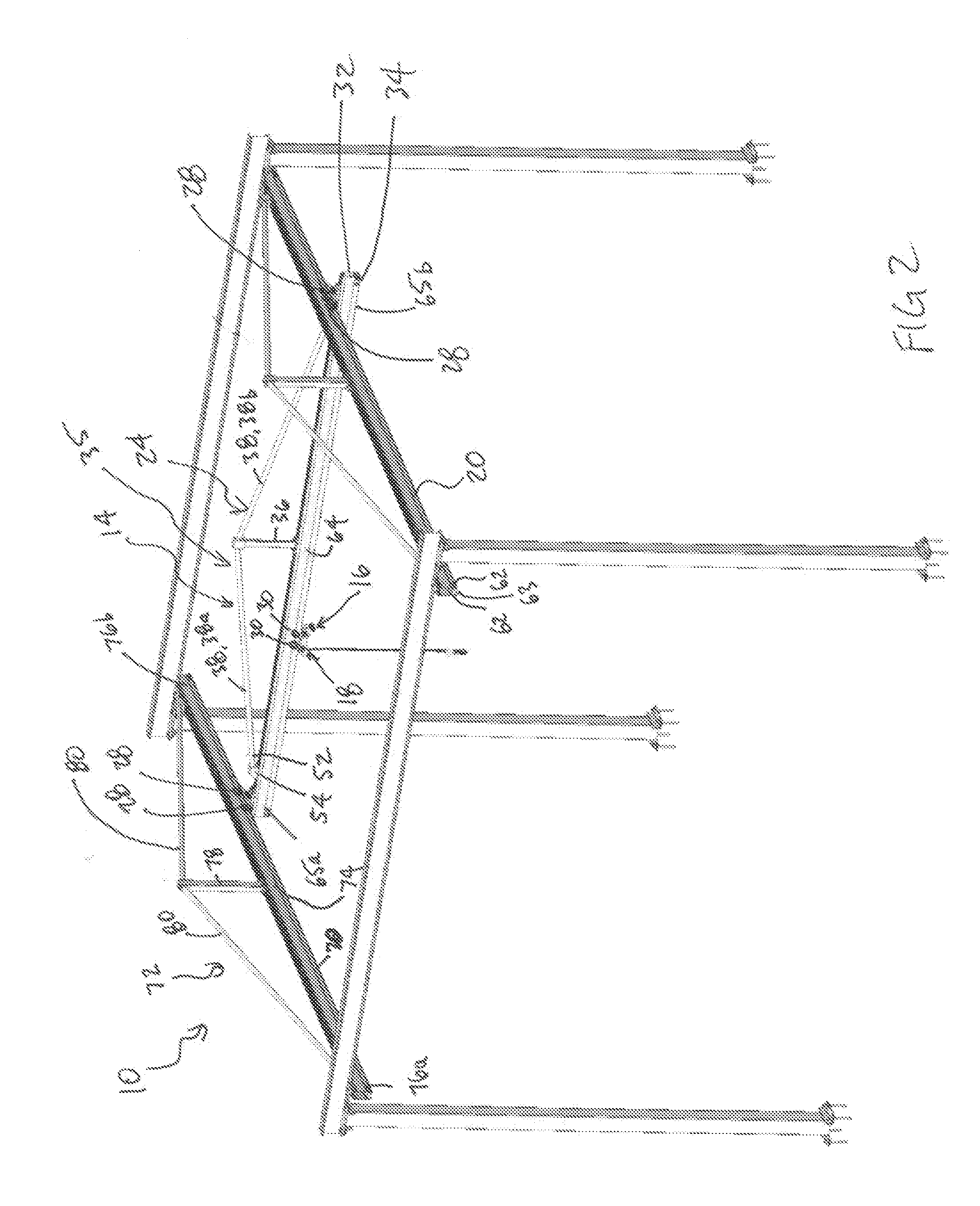

Wind turbine erector

A wind tower erection device and method for erecting wind turbine towers which avoid the need for using expensive cranes. The device and method employs a stacker unit for anchoring to the wind turbine foundation, a plurality of intermediate modules, and a mechanical actuator for raising the intermediate modules vertically. The stacker unit has a receptacle allowing for lateral sliding of intermediate modules inside of the stacker unit. In one embodiment, the stacker unit has a receptacle for lateral sliding of intermediate modules inside of the stacker unit. The stacker unit and the intermediate modules each have at least one open side to for positioning of tower sections within the stacker unit and stacked intermediate modules. A bridge crane section is initially placed on top of the stacked intermediate modules. The bridge crane is raised vertically as additional intermediate modules are added at the bottom, thereby allowing wind tower sections to be winched into place using the crane, each being added on top of the other as the stacked intermediate modules increase to the necessary height.

Owner:VORHIES ROGER W

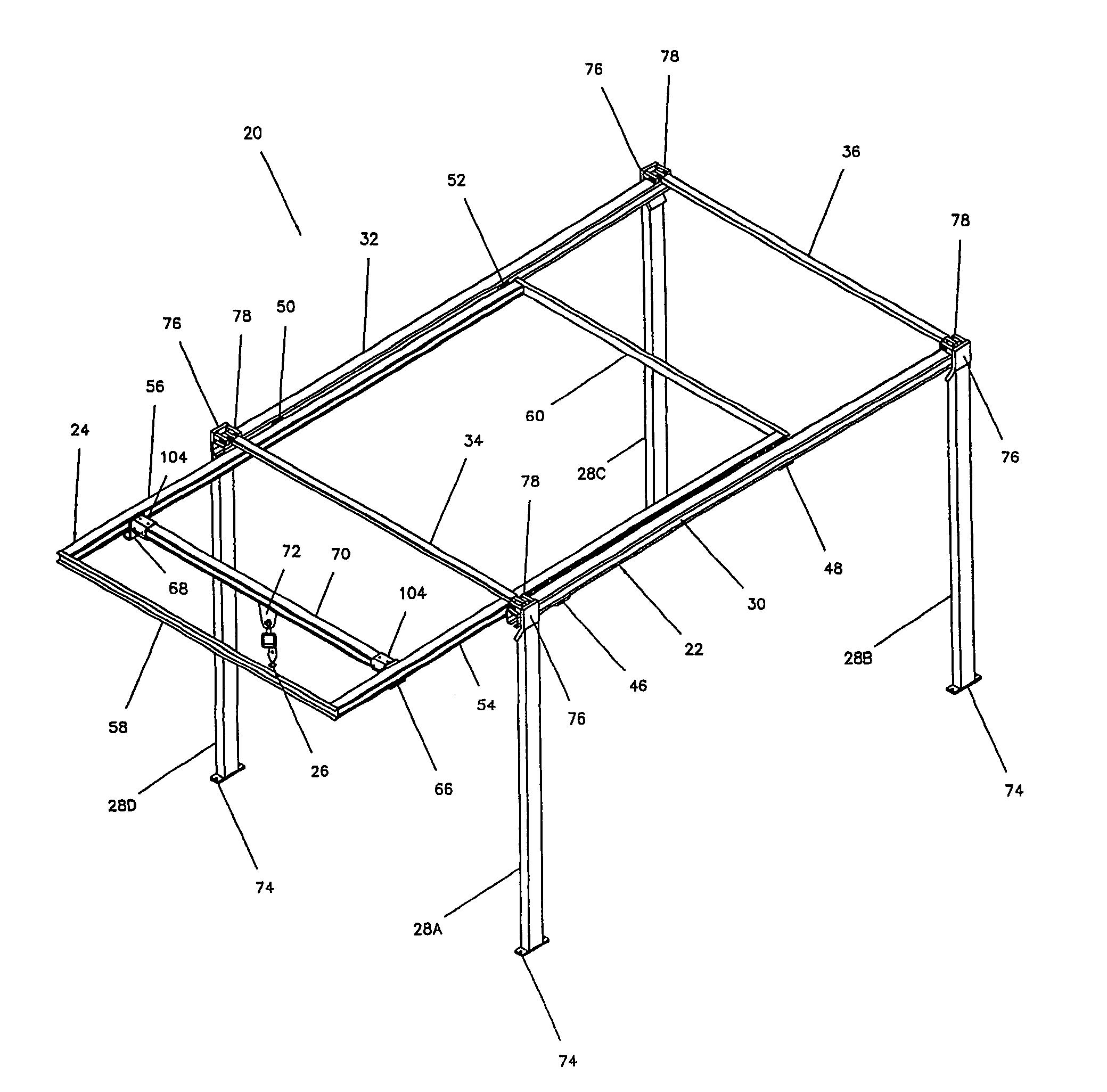

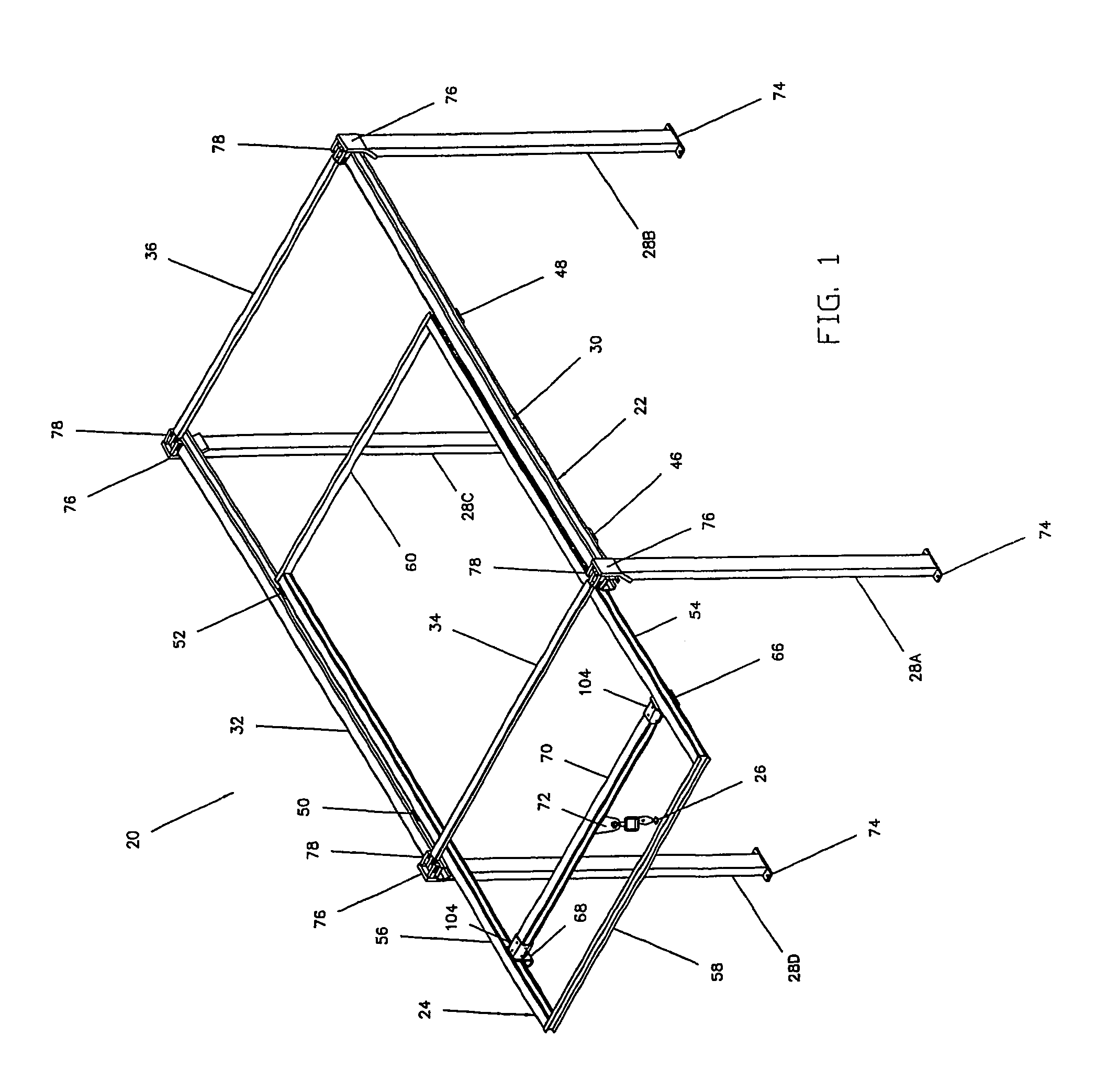

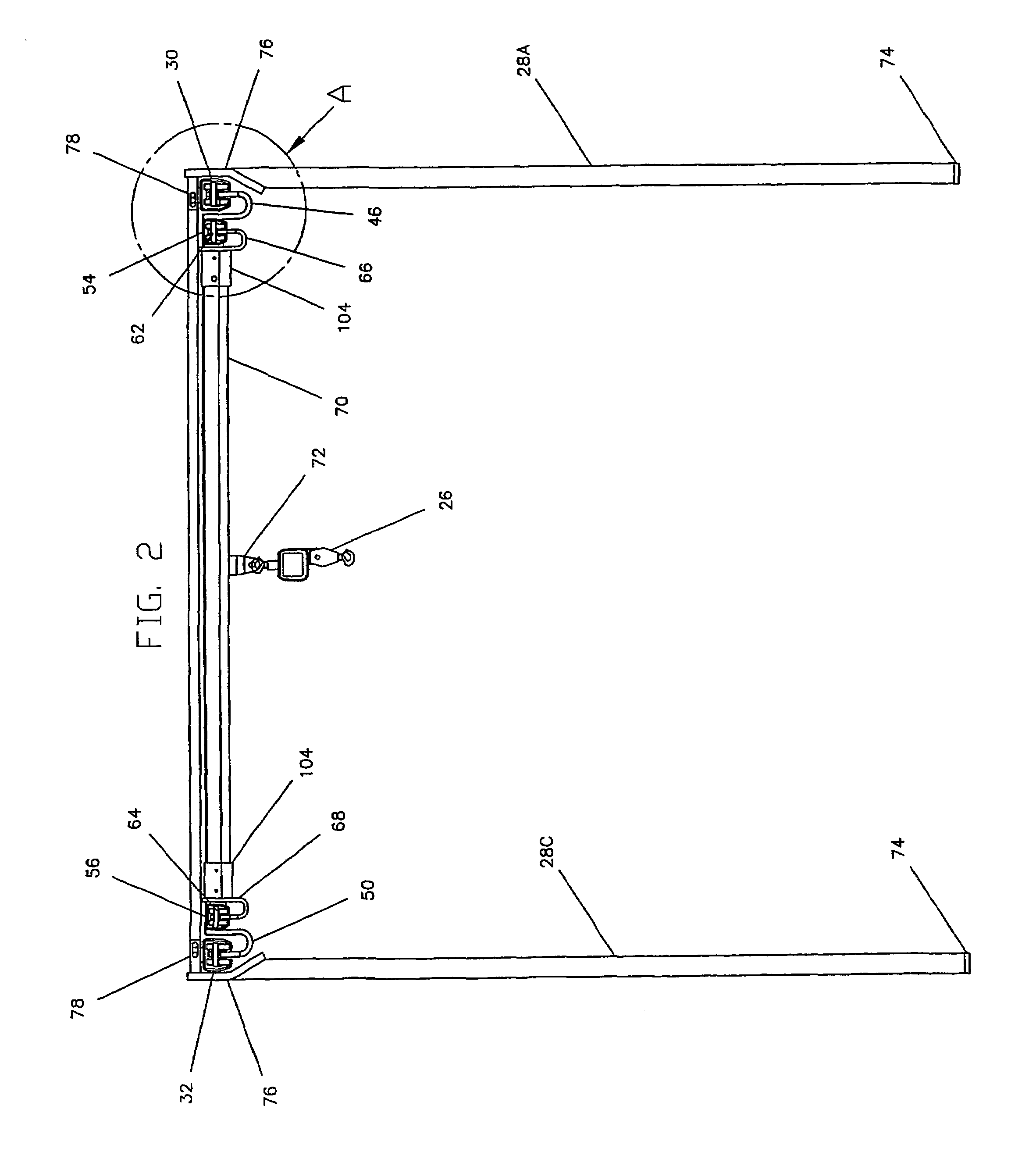

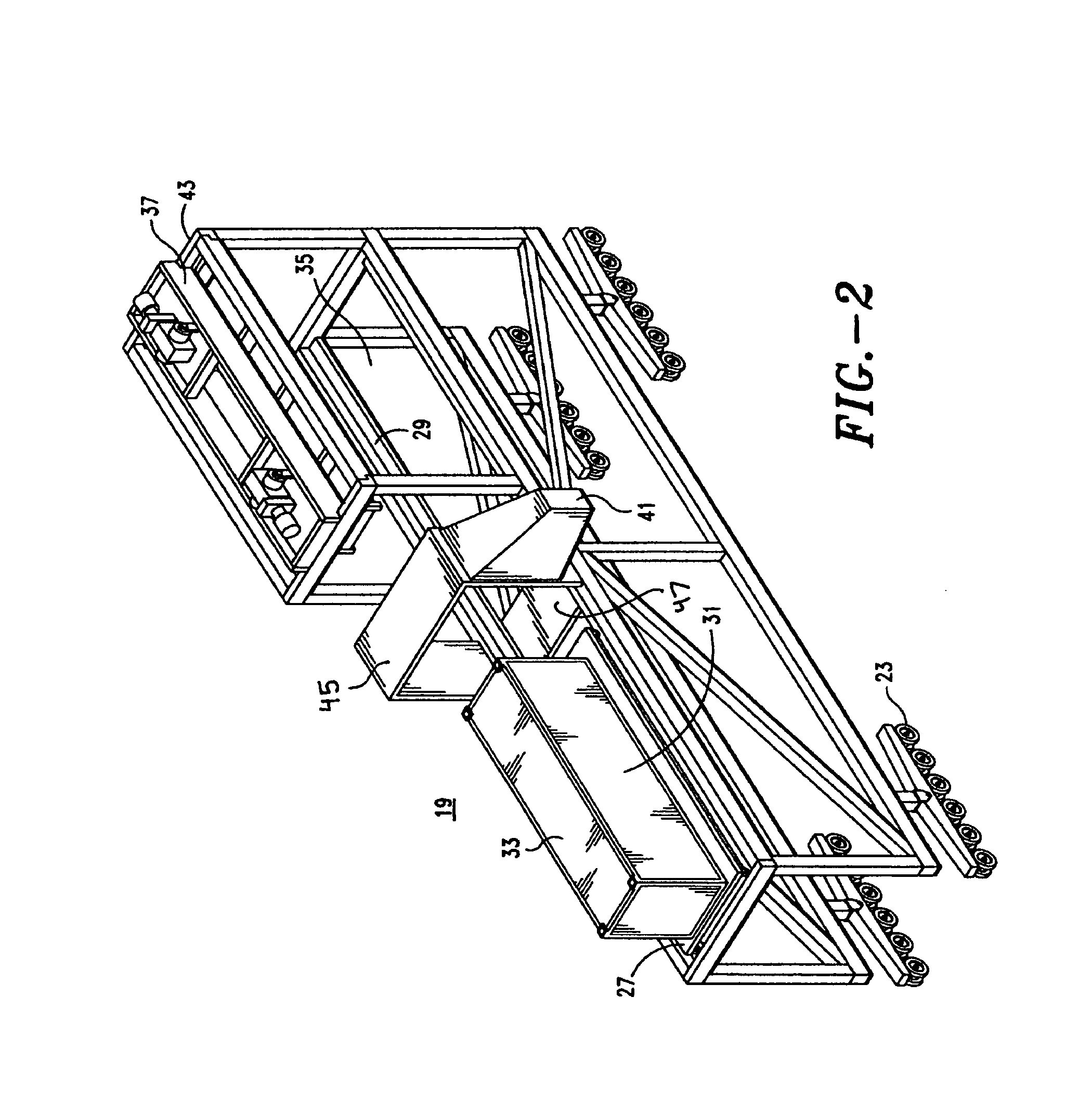

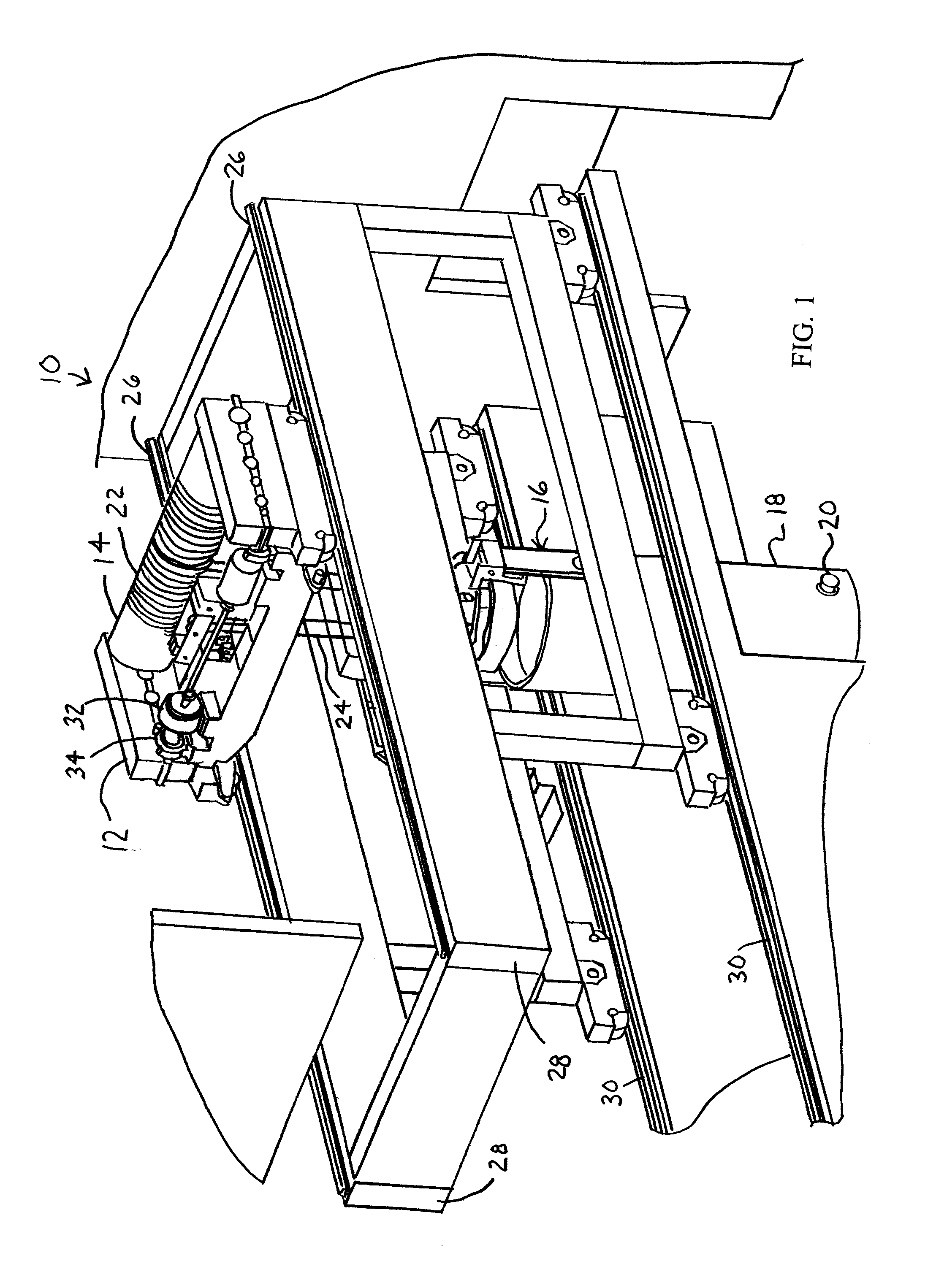

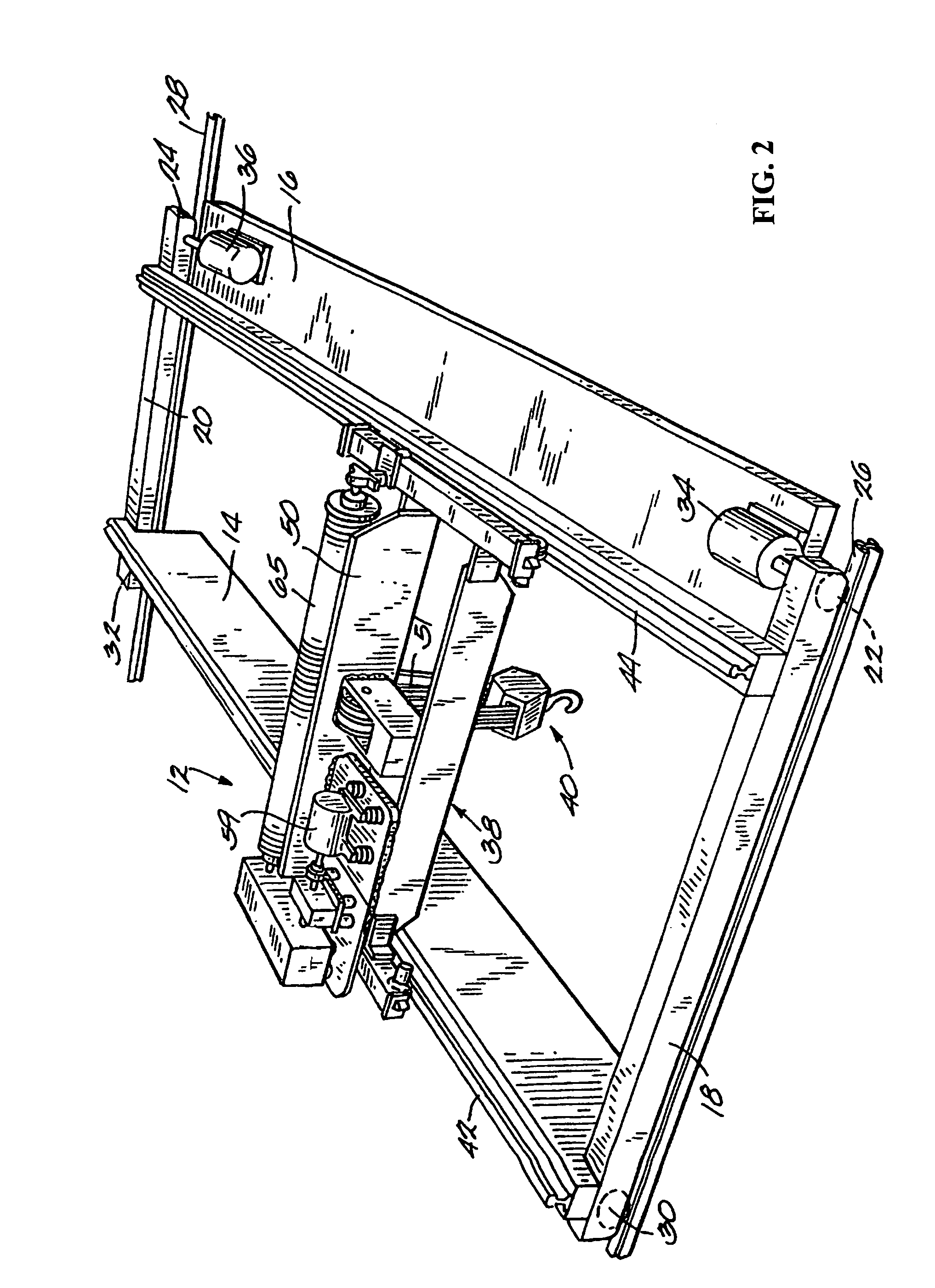

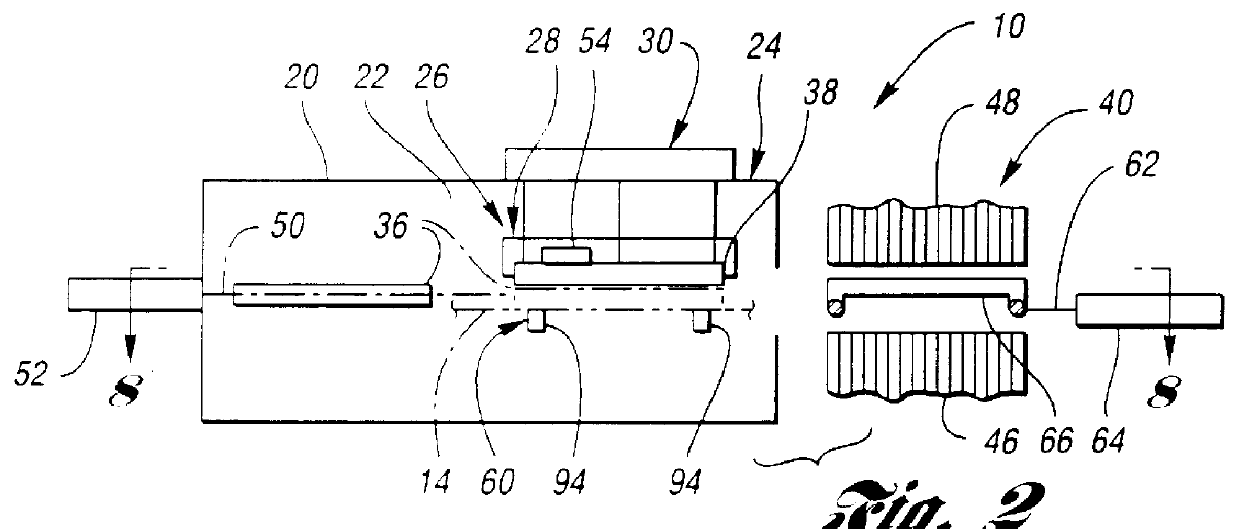

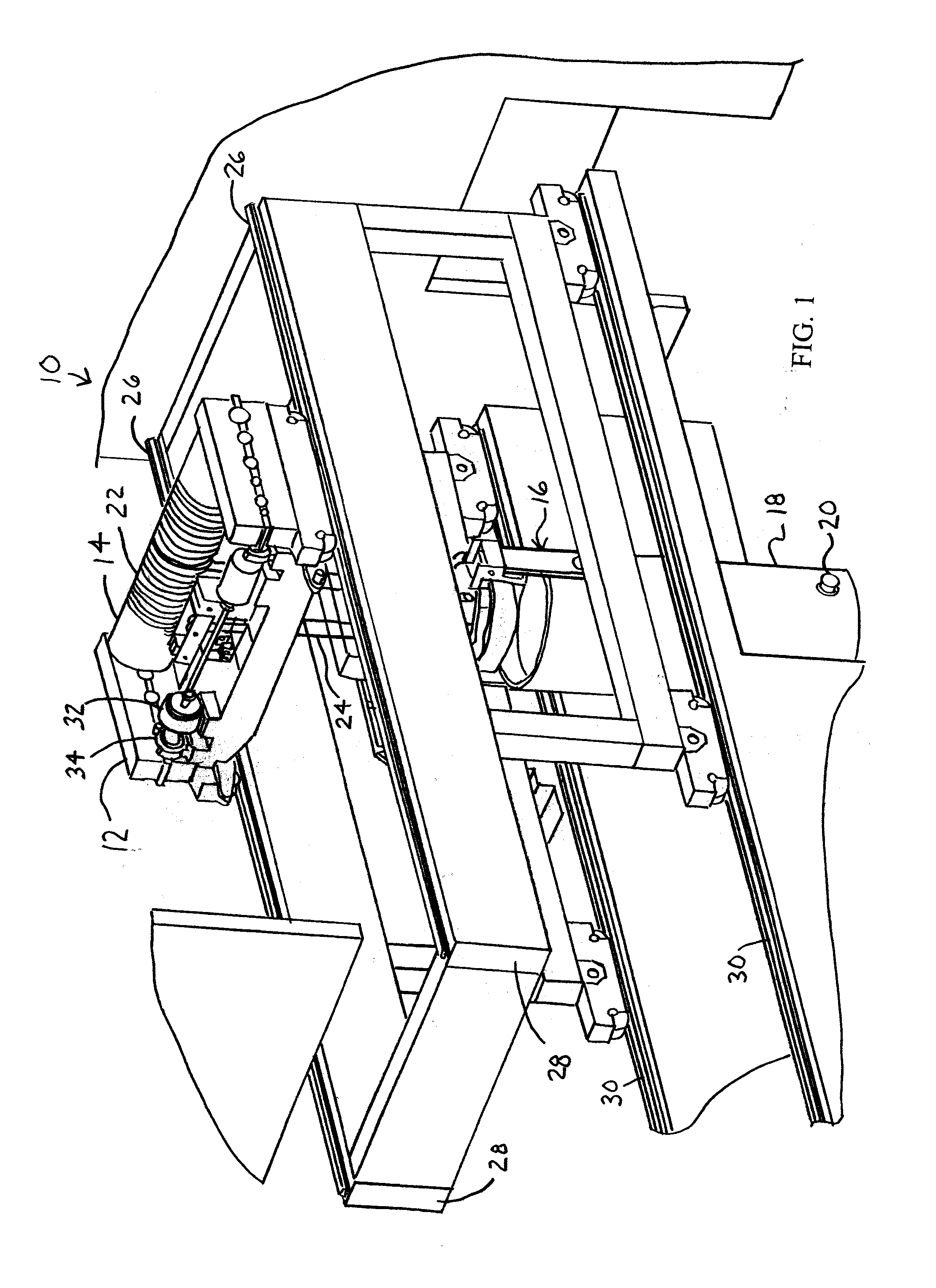

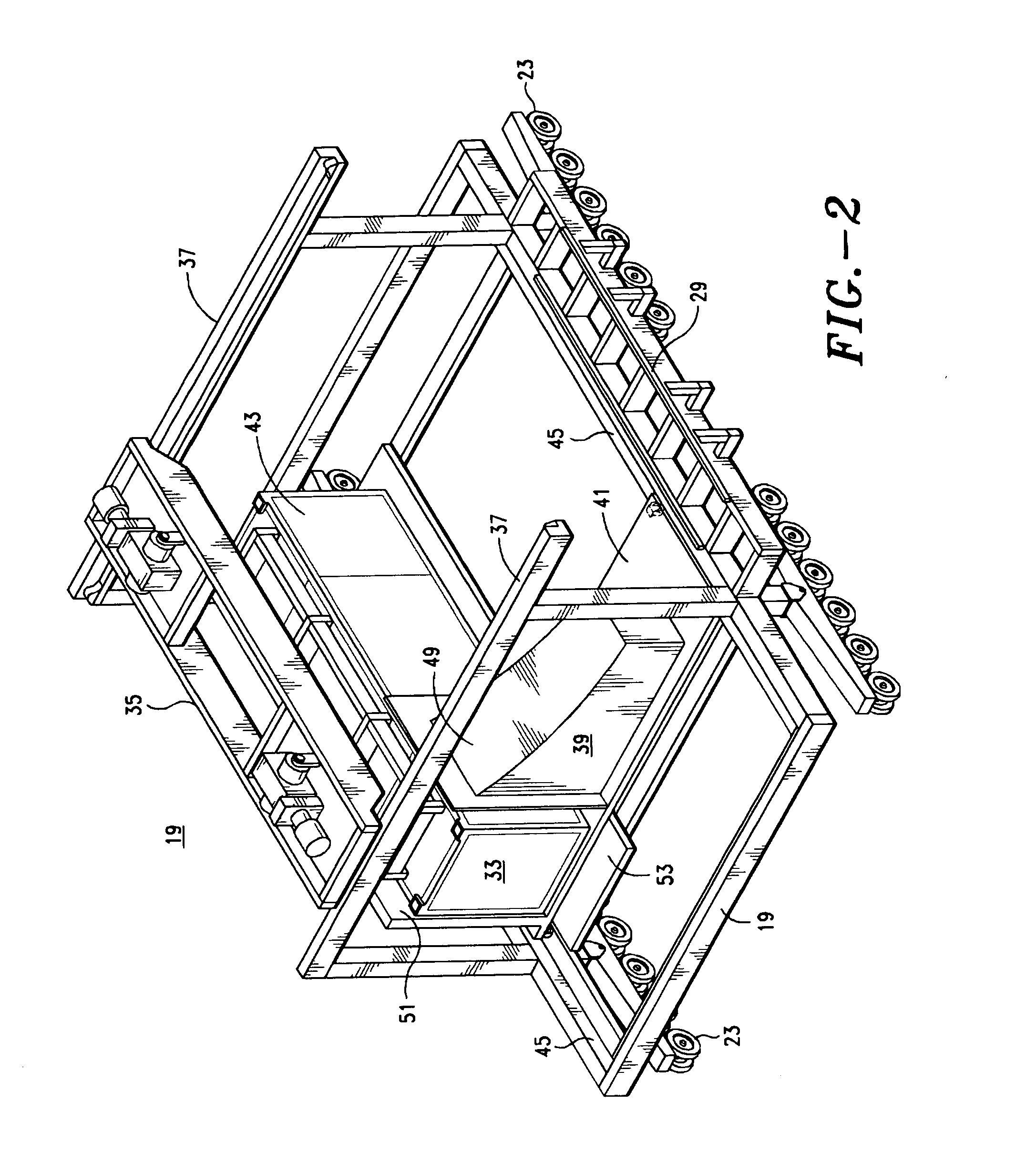

Low headroom telescoping bridge crane system

A telescoping bridge crane system arranged to be mounted over a floor of a structure, e.g., a vehicle trailer, and including a pair of enclosed mounting tracks for slidably supporting a runway frame. Trucks are located within the tracks. Each truck includes a hanger. The runway frame also includes two enclosed tracks which are directly supported by the hangers and located beside and parallel to the mounting tracks. A bridge section is mounted between the enclosed tracks of the runway frame by another pair of trucks. The a bridge section supports an extremely low headroom hoist assembly including an actuator, a cable, plural rotatable sheaves and a hook.

Owner:TRANSOL

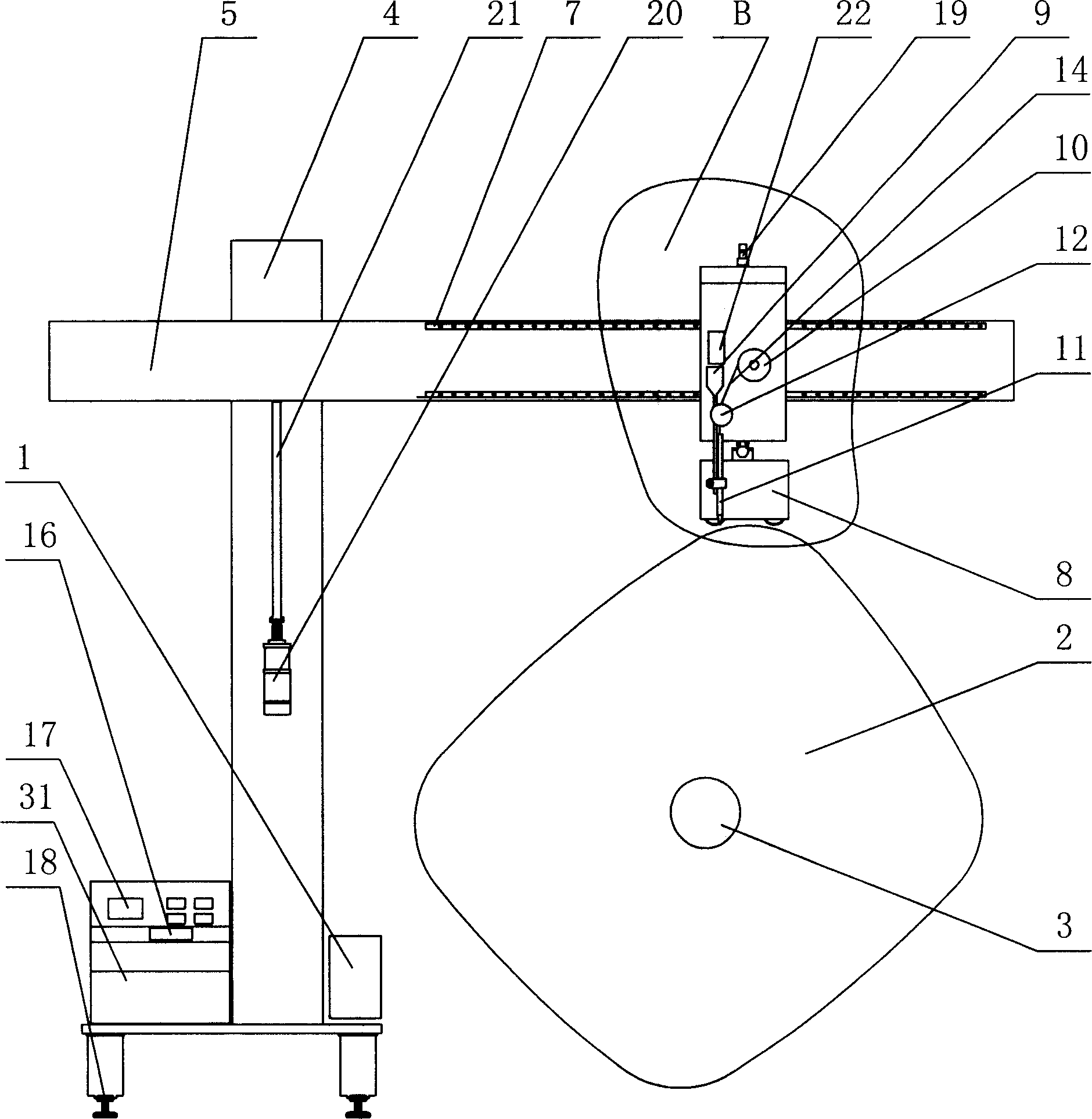

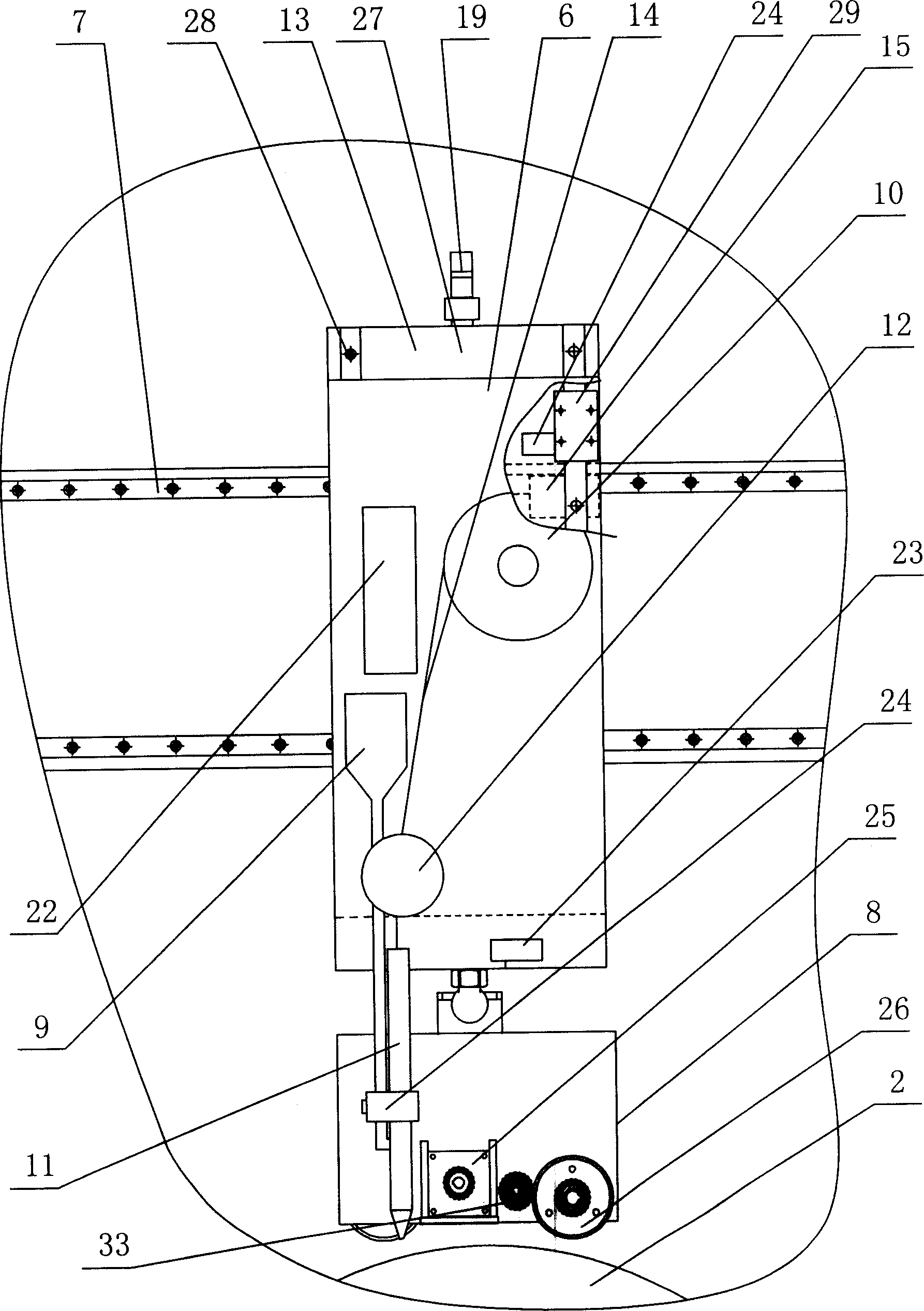

Automatic welding machine for annular seam in specially shaped tank

InactiveCN1672848AQuality assuranceFully automatedWelding/cutting auxillary devicesArc welding apparatusBogieDrive motor

The automatic welding machine for annular seam in specially shaped tank includes welding machine, specially shaped tank, rotating device installed on the tank, overhead crane track on the side of the tank, support on the overhead crane track, and welding platform on the support. The present invention features the horizontal track fixed on the welding platform with installed horizontal sliding plate, the longitudinal track installed on the other side of the sliding plate with installed longitudinal sliding plate, welding wire disc with wound welding wire and welding wire transmission unit on the longitudinal sliding plate, bogie with welding gun, driving motor and distance sensor connected to control via cable and fixed to the lower part of the longitudinal sliding plate, and the controller connected also to the driving motor in the bogie and the rotating device on the tank. The present invention has the features of automatic welding, high efficiency and good welding effect.

Owner:刘宪福

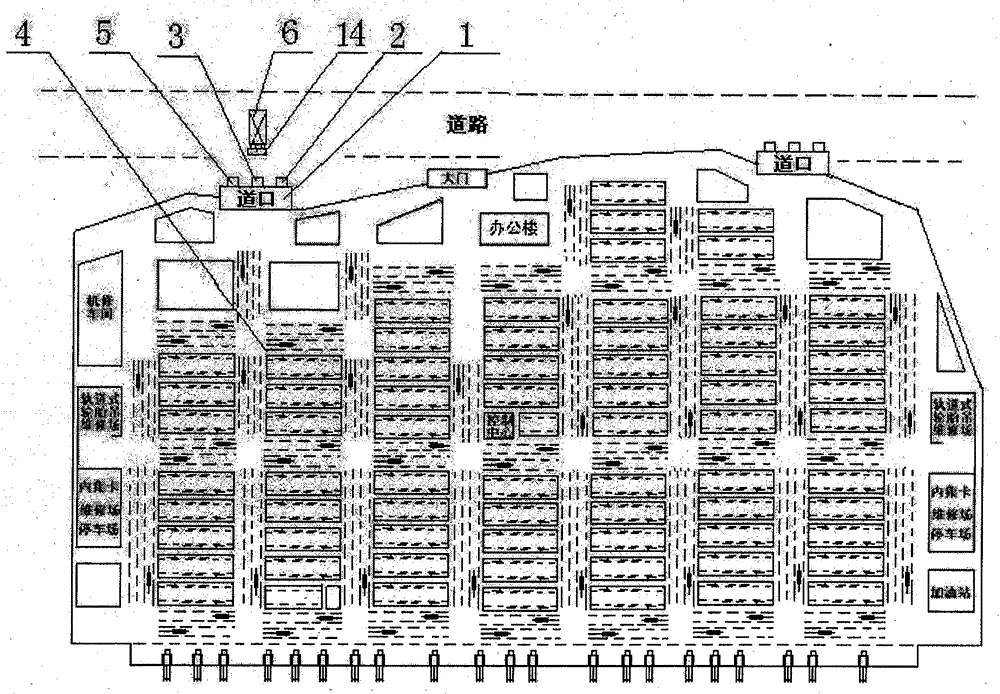

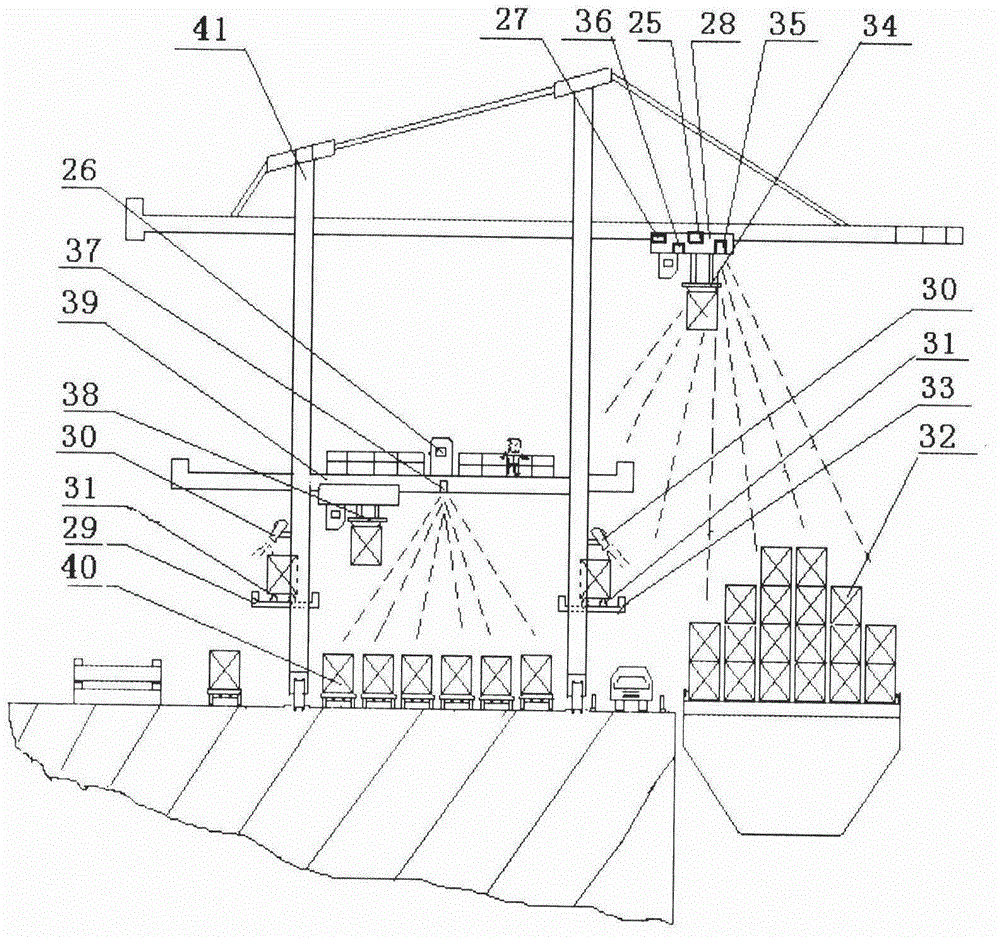

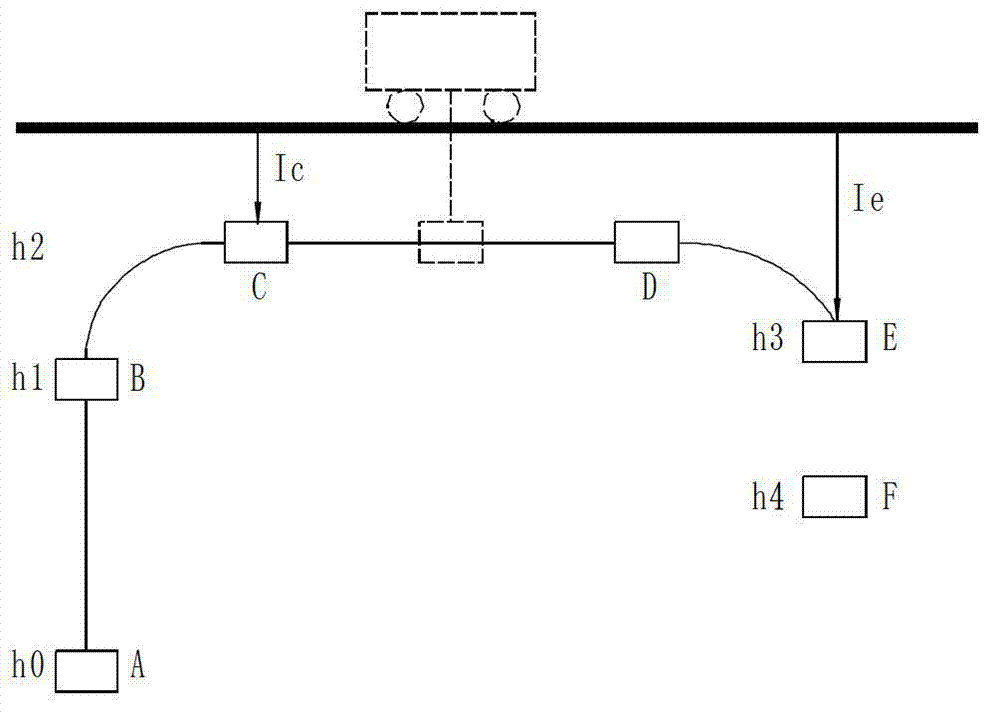

Container automated wharf loading and unloading system and method

InactiveCN104058261AAnti-collisionAvoid collisionStorage devicesPosition/course control in two dimensionsOn boardAutomated guided vehicle

The invention discloses a container automated wharf loading and unloading system and method. Containers on board are loaded or unloaded through a double-trolley and double-platform bridge crane; an automated guided vehicle refitted by a common truck, on which a metal magnetic detector, a GPS (global positioning system) reader-writer, a laser collision avoidance system and an image display system are arranged, travels along a metal enamel leading line through the metal magnetic detector; the GPS reader-writer reads radio frequency card address positions on the ground; the laser collision avoidance system and the image display system measure collision avoidance functions of people and objects; a rail tyre crane travels through rails when conveying the containers and travels through tyres during site changing; guide vehicle and outer truck lanes exist in a site and do not disturb each other; an outer truck is guided through the GPS reader-writer when entering a wharf; a common container wharf is transformed into a full-automatic container loading and unloading wharf through the equipment improvement.

Owner:NANTONG TONGLEI SOFTWARE

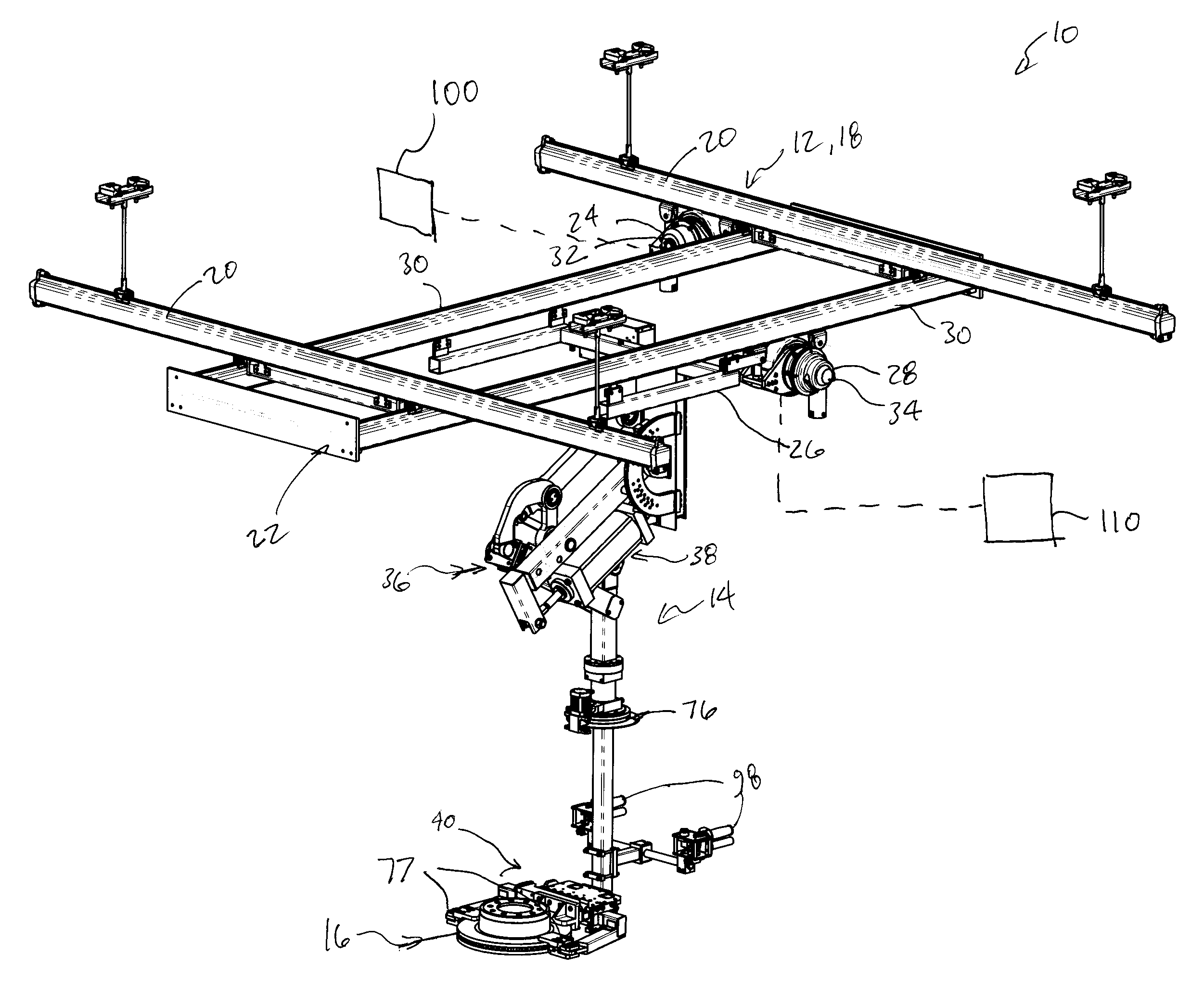

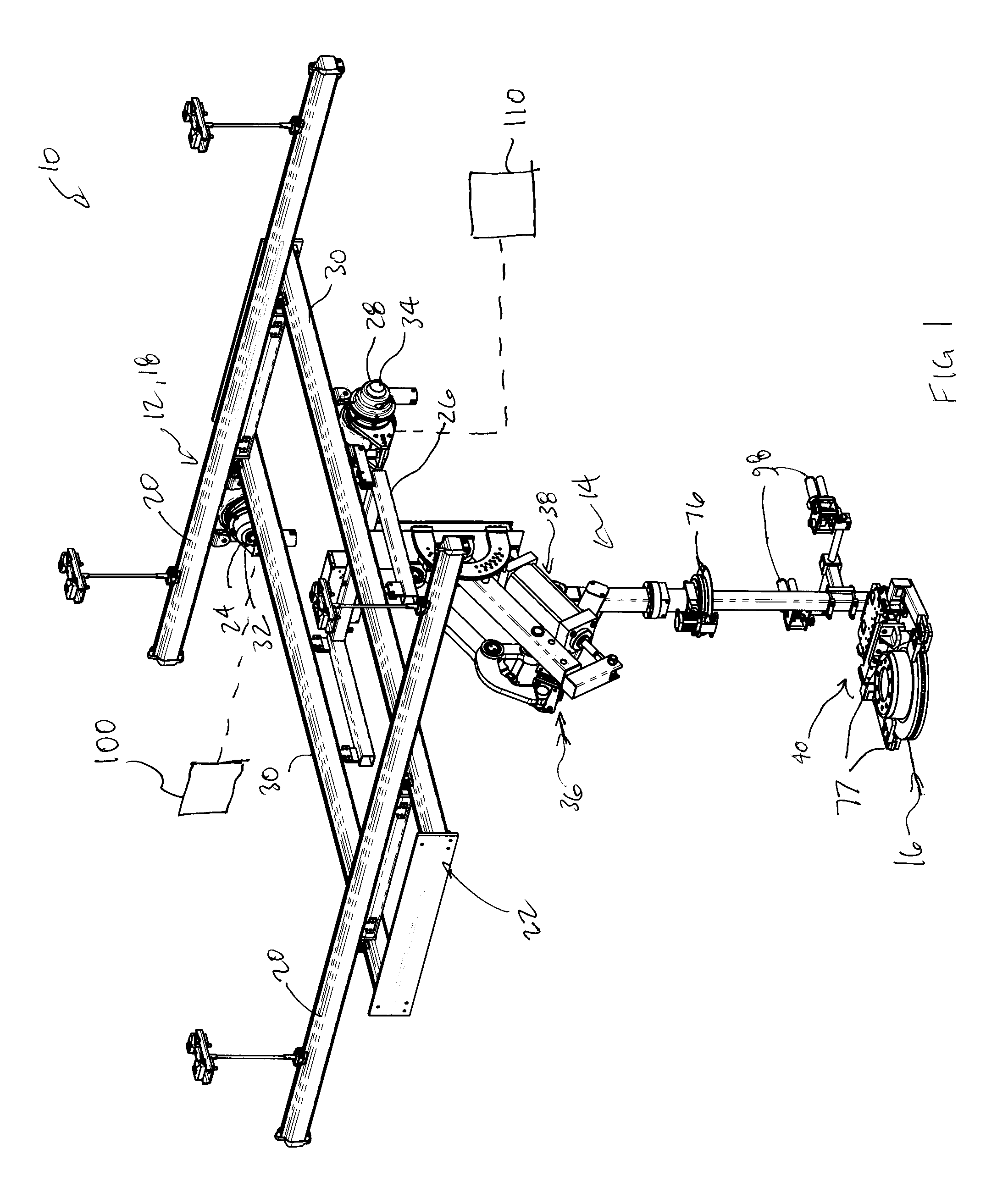

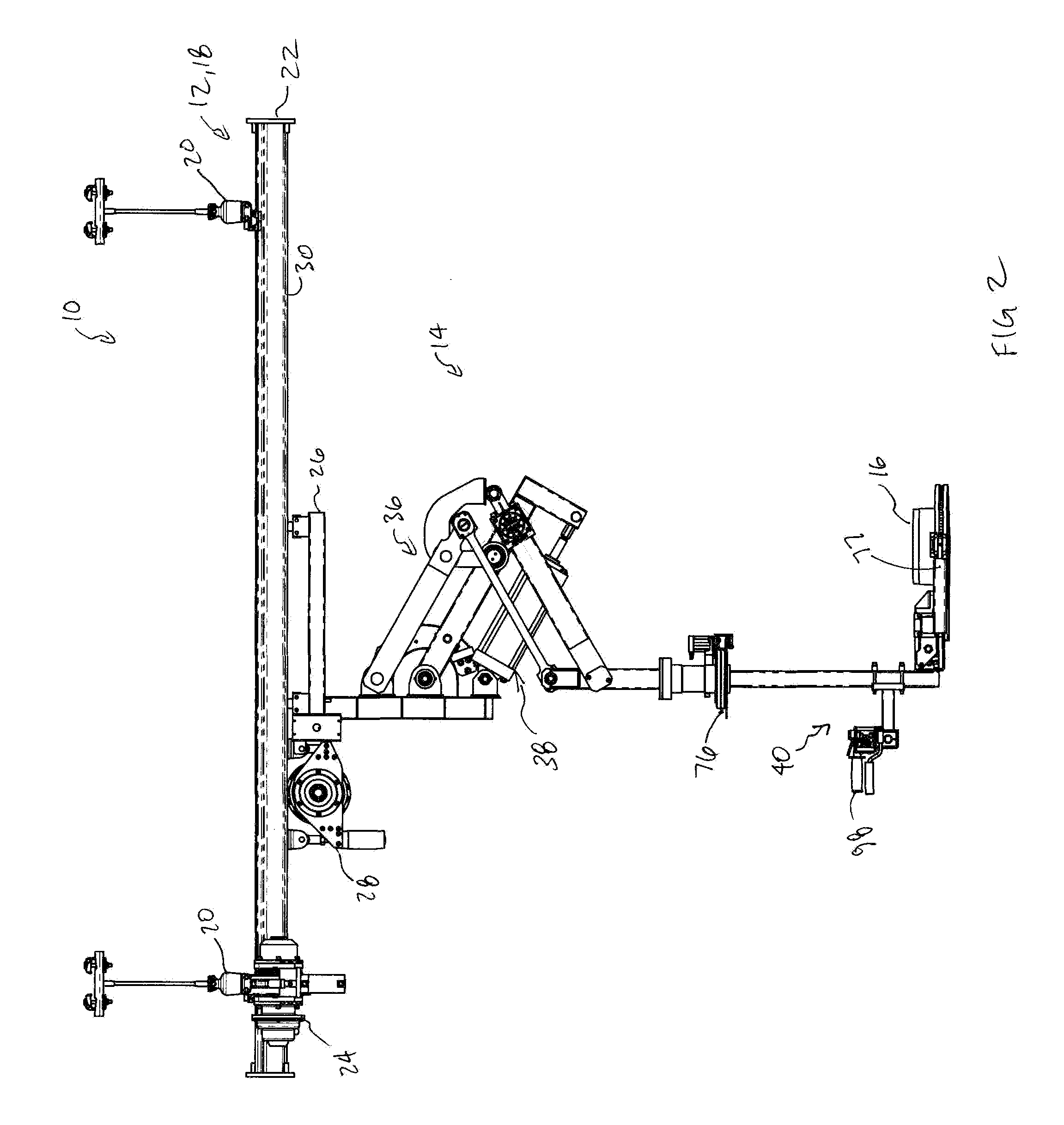

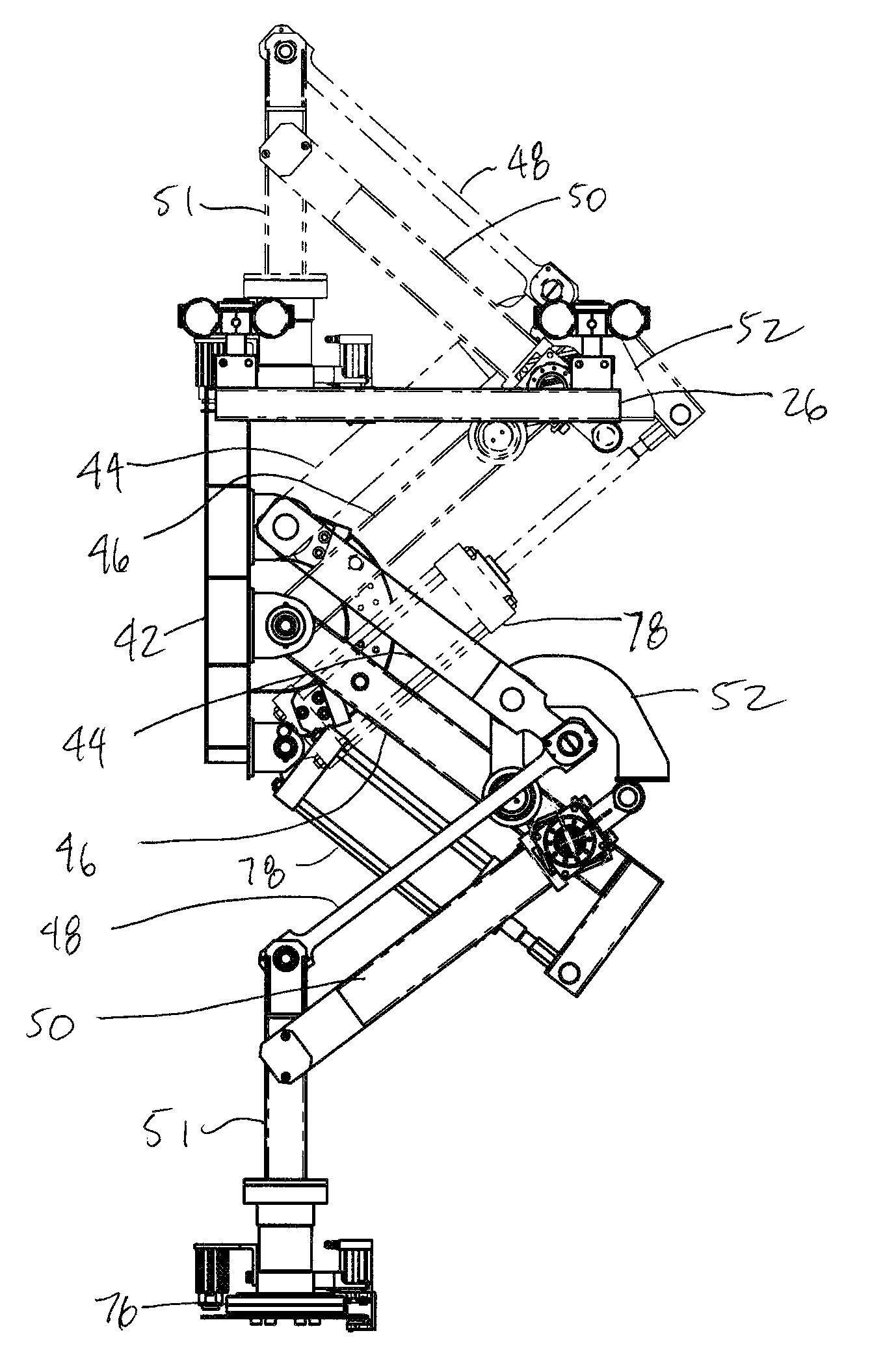

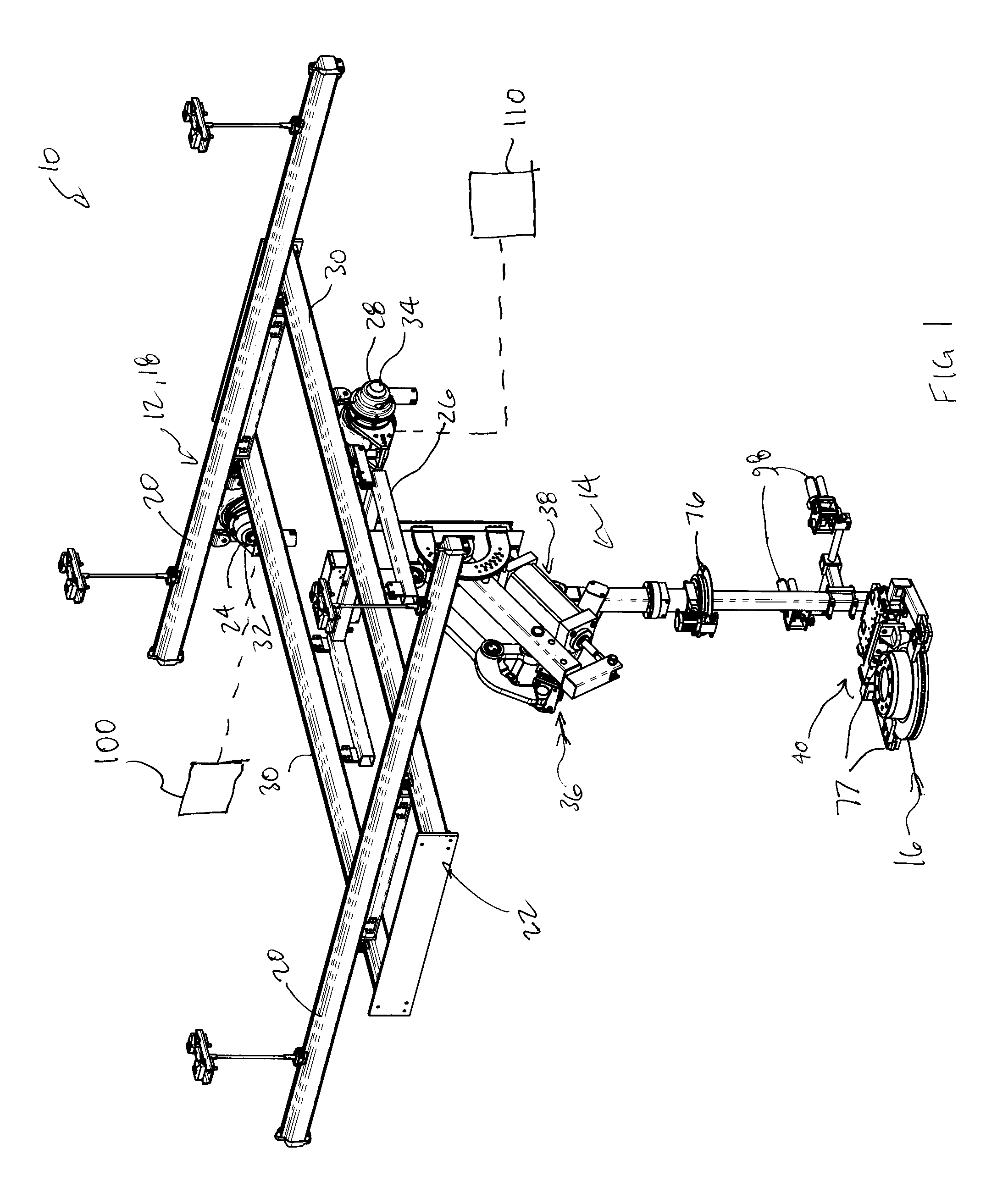

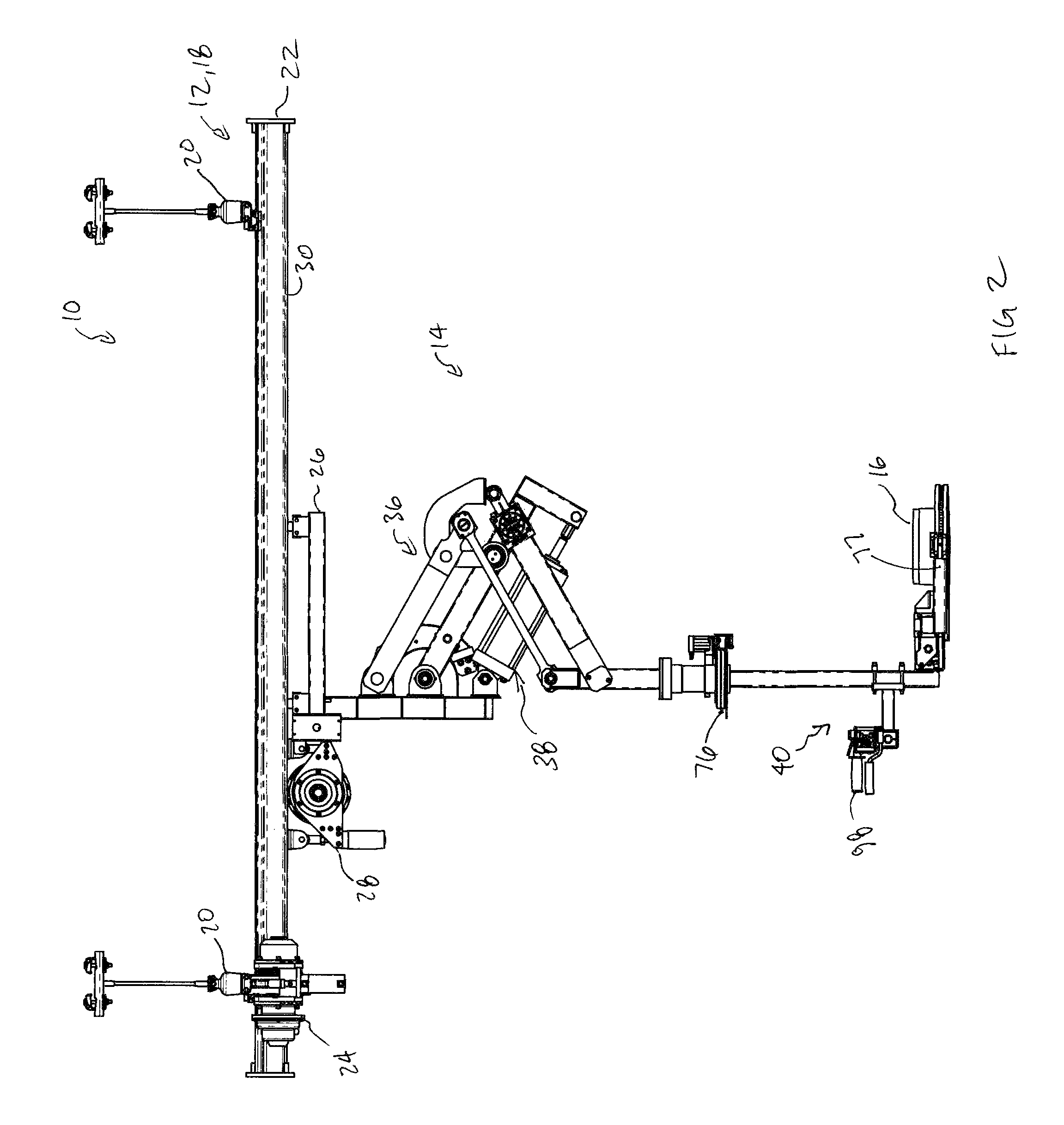

Compound-arm manipulator

ActiveUS20090283490A1Large range of motionReduced footprintProgramme-controlled manipulatorCurtain suspension devicesTransport systemRange of motion

In a first aspect, the invention is directed to a manipulator that is relatively compact and has a relatively large range of motion. The manipulator includes a linkage that folds back on itself, which reduces the footprint of the linkage. In a particular embodiment, the manipulator includes a linkage and a load balancing device. The linkage includes a first link, a second link, a third link and a fourth link. The first link and second links are rotatably connected to a base about first and second connection axes. The third and fourth links are connected to the first and second links respectively about third and fourth connection axes respectively. The third and fourth links are rotatably connected to a lift arm about fifth and sixth connection axes respectively, wherein the fifth and sixth connection axes are horizontally displaced from the third and fourth connection axes in the direction of the first and second connection axes. The load balancing device is configured to support the linkage in a selected position against a load and configured to permit the load to be moved upwards or downwards with a selected amount of force on the lift arm. The manipulator may be provided as part of a load maneuvering system that further includes a transport system that may be similar to that used on an overhead crane.

Owner:GIVENS RAY

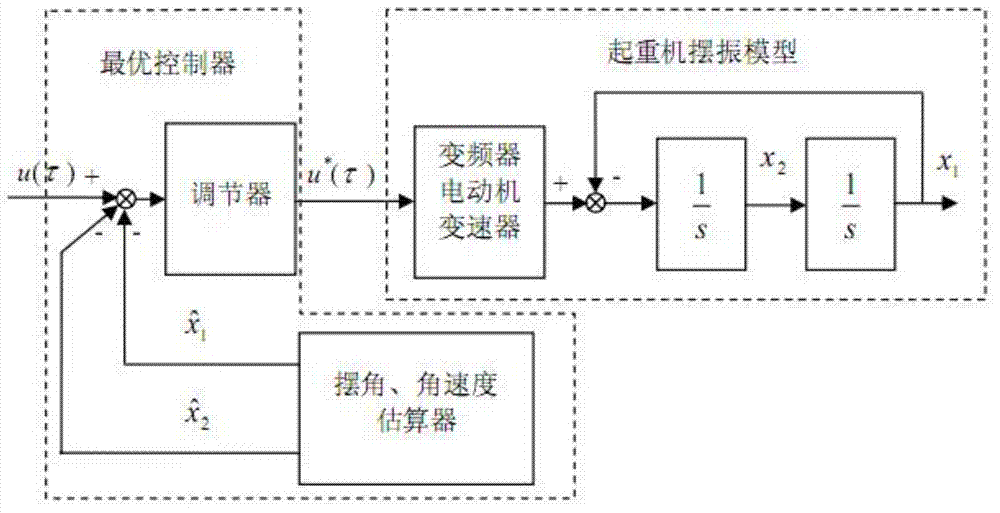

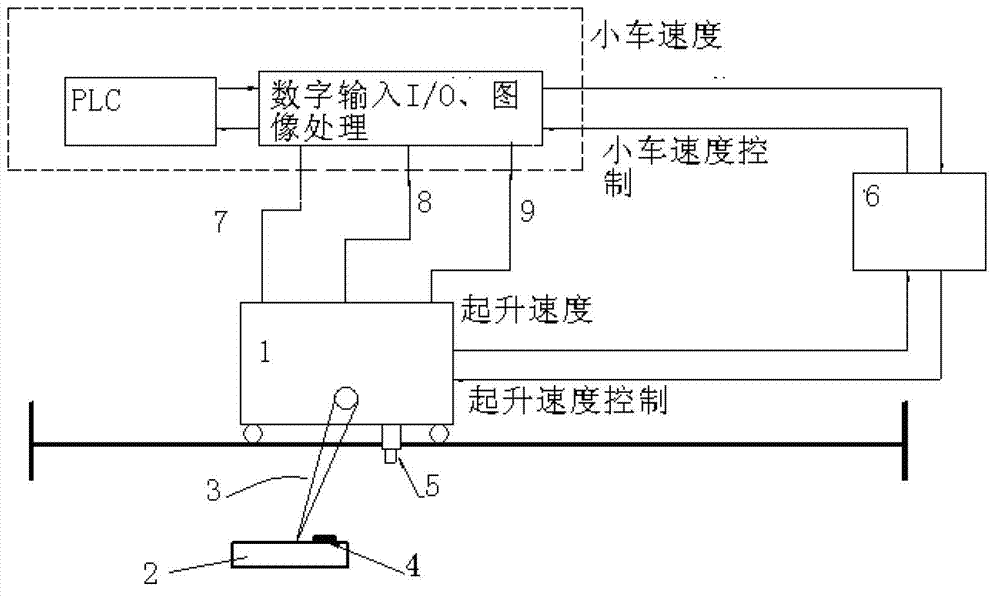

Spreader anti-sway controlling method of overhead traveling crane

InactiveCN102849625AEasy to handleRealize the purpose of electrical optimization controlLoad-engaging elementsMotor driveTransverter

The invention relates to a spreader anti-sway controlling method of an overhead traveling crane. The spreader has 5 measuring parameters: a trolley position of a supporting spreader, a spreader cable length, a spreader cable swing angle, a trolley speed, and a spreader elevation speed. The 5 measuring parameters are respectively measured by 2 absolute encoders, a video camera system, and an incremental encoder. The trolley speed and the spreader elevation speed serve as input signals and act upon an AC servo motor driven by the trolley and the spreader through a frequency converter, such that the entire spreader system can work harmonically. A controlling strategy and the treatment upon the collected signals are realized by a whole PLC processor. A controlling method and a controlling strategy are provided. With the video camera system, through spreader real-time monitoring, spreader swing angle which is the position and the cable length are obtained. Trolley position information and cable length information are obtained by using the encoders. The signals are read by using the absolute encoders. Feedback signals are acquired by the incremental encoder. The controlling method provide by the invention has the advantages of higher controlling precision and higher data processing speed.

Owner:无锡大力起重机械有限公司

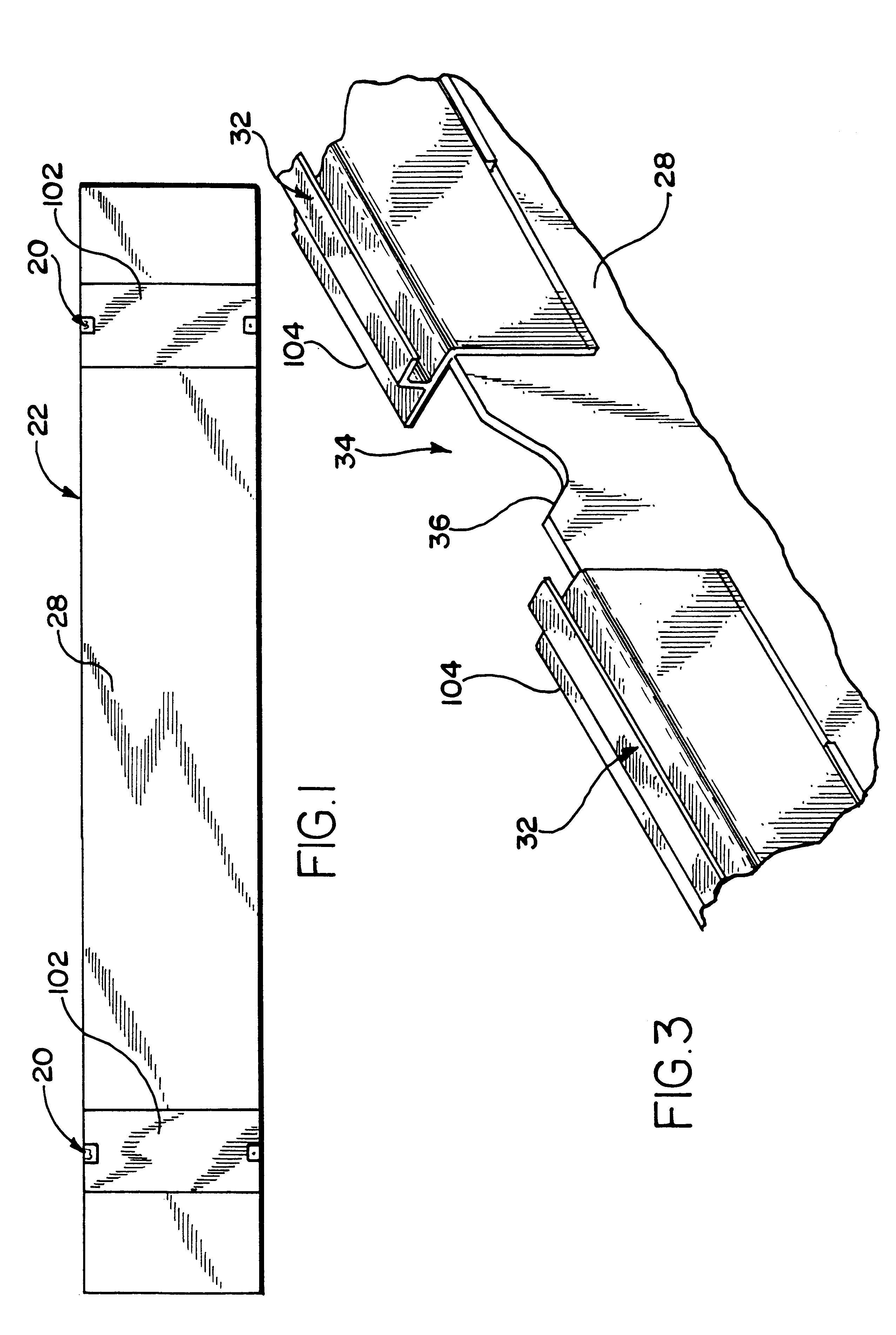

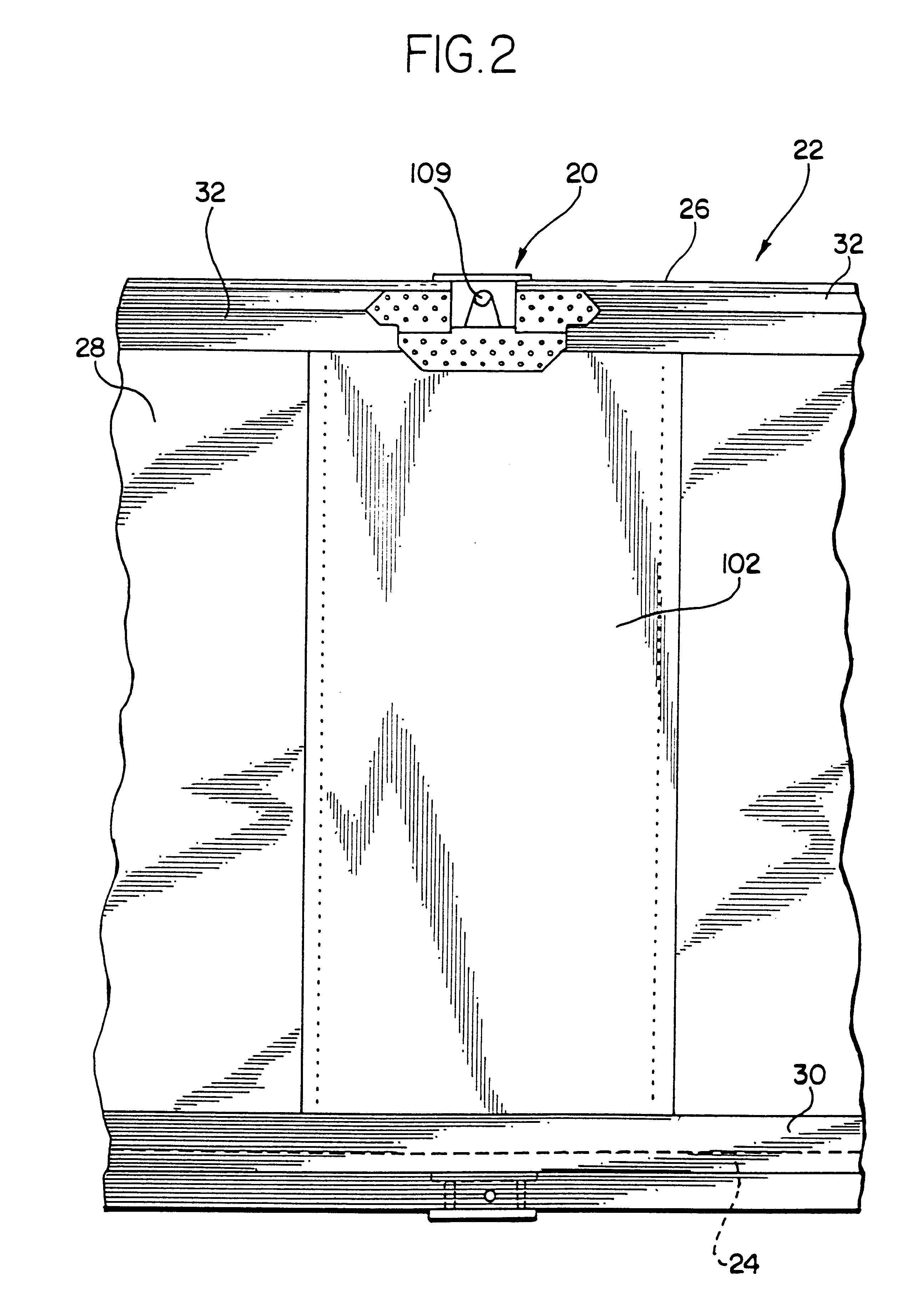

Material handling system

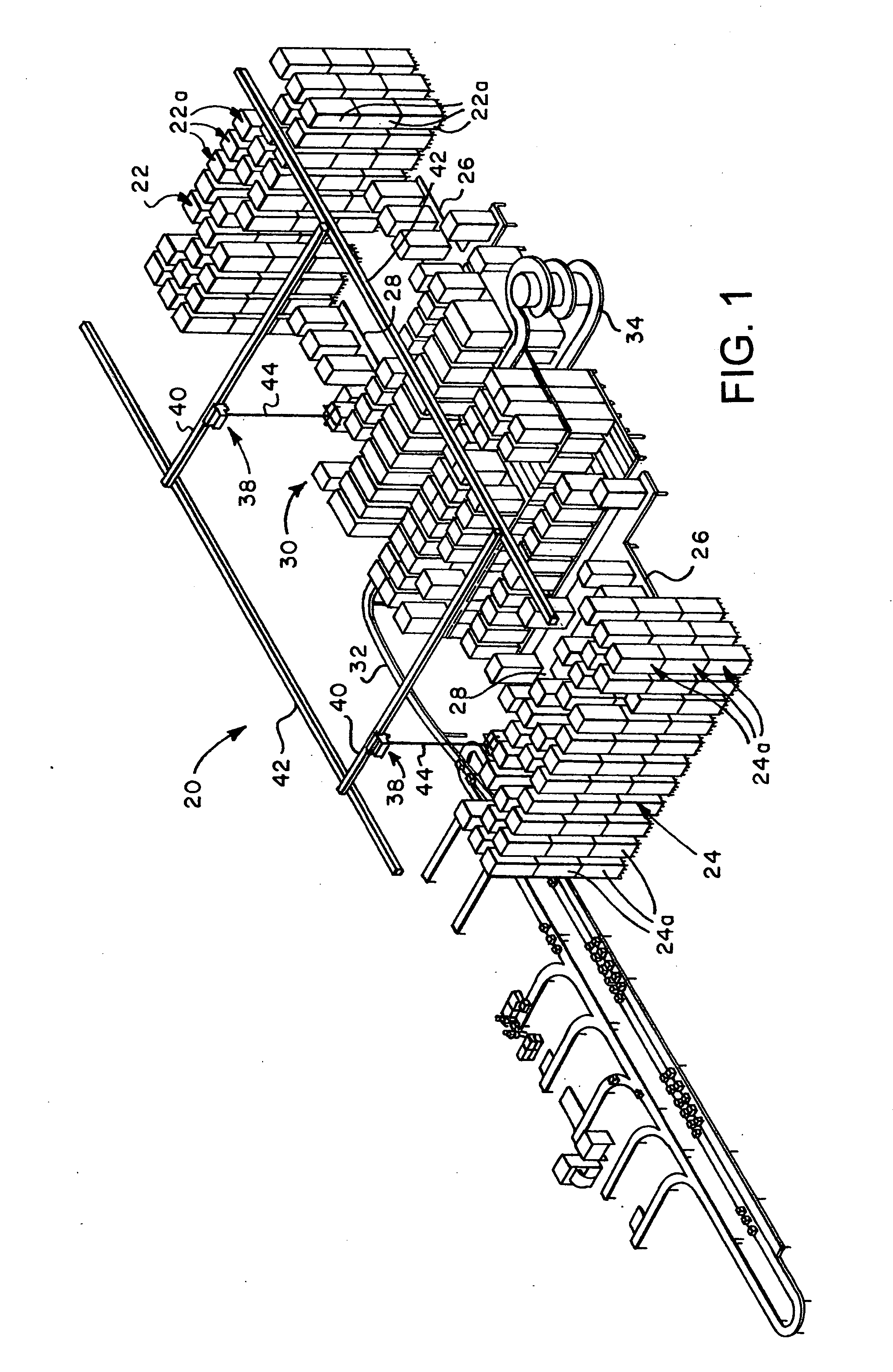

InactiveUS20060056951A1High density storageReduced activityLifting devicesStorage devicesEngineeringOverhead crane

A material handling system for placing and retrieving palletized loads in densely spaced storage areas utilizing an overhead bridge crane connected to a pallet load handling device by way of lifting cables and a stabilizing mast assembly. The pallet handling devices may include vertically or horizontally movable pallet engaging fork mechanisms mounted on a generally rectangular frame which is operable to be lowered over a pallet load and engaged therewith by way of the fork mechanisms. The pallet handling device frame may be split and interconnected by actuator mechanisms to facilitate ease of placing the handling devices over a pallet load and releasing the load from the handling device.

Owner:WILLIAMSON JEFFREY TODD

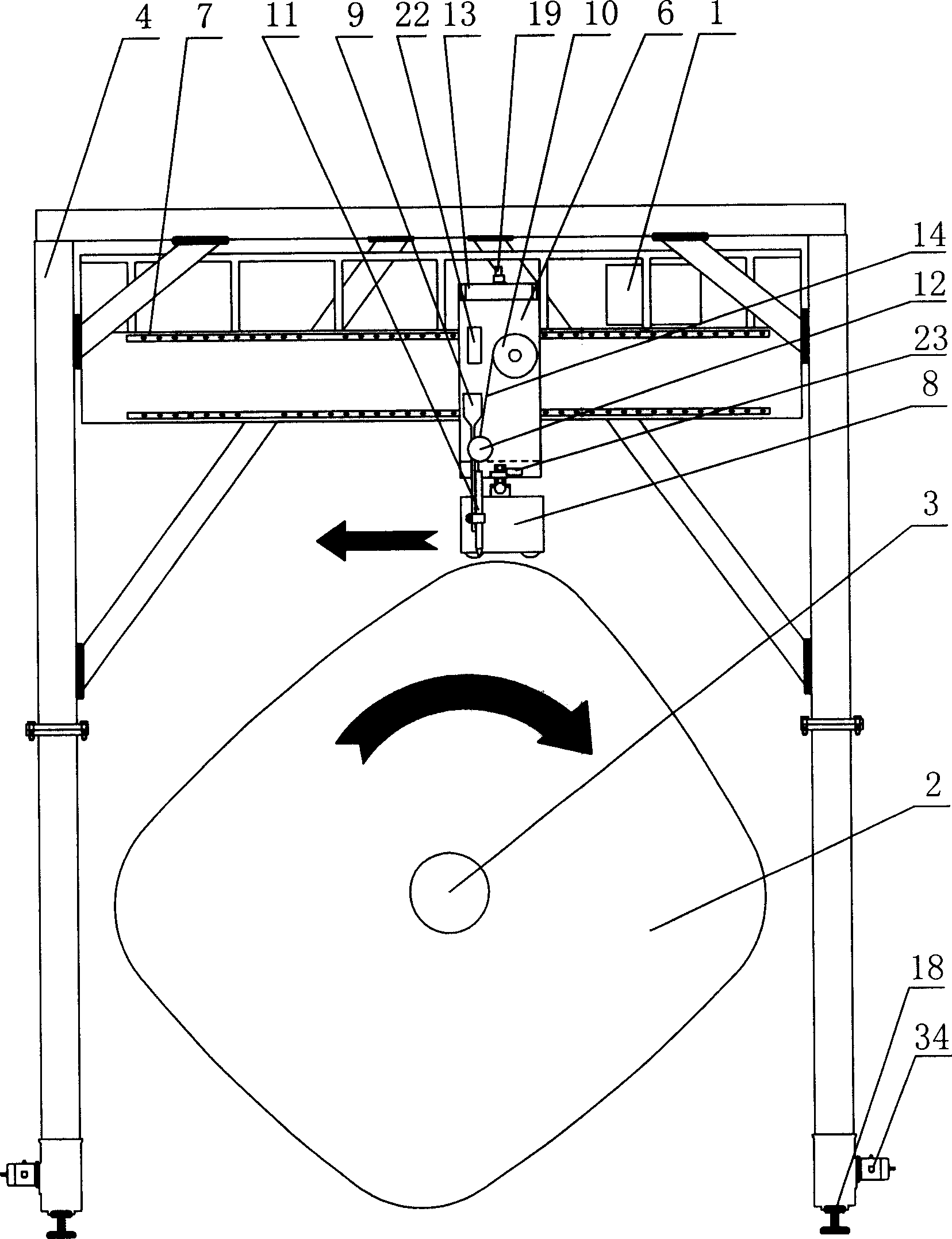

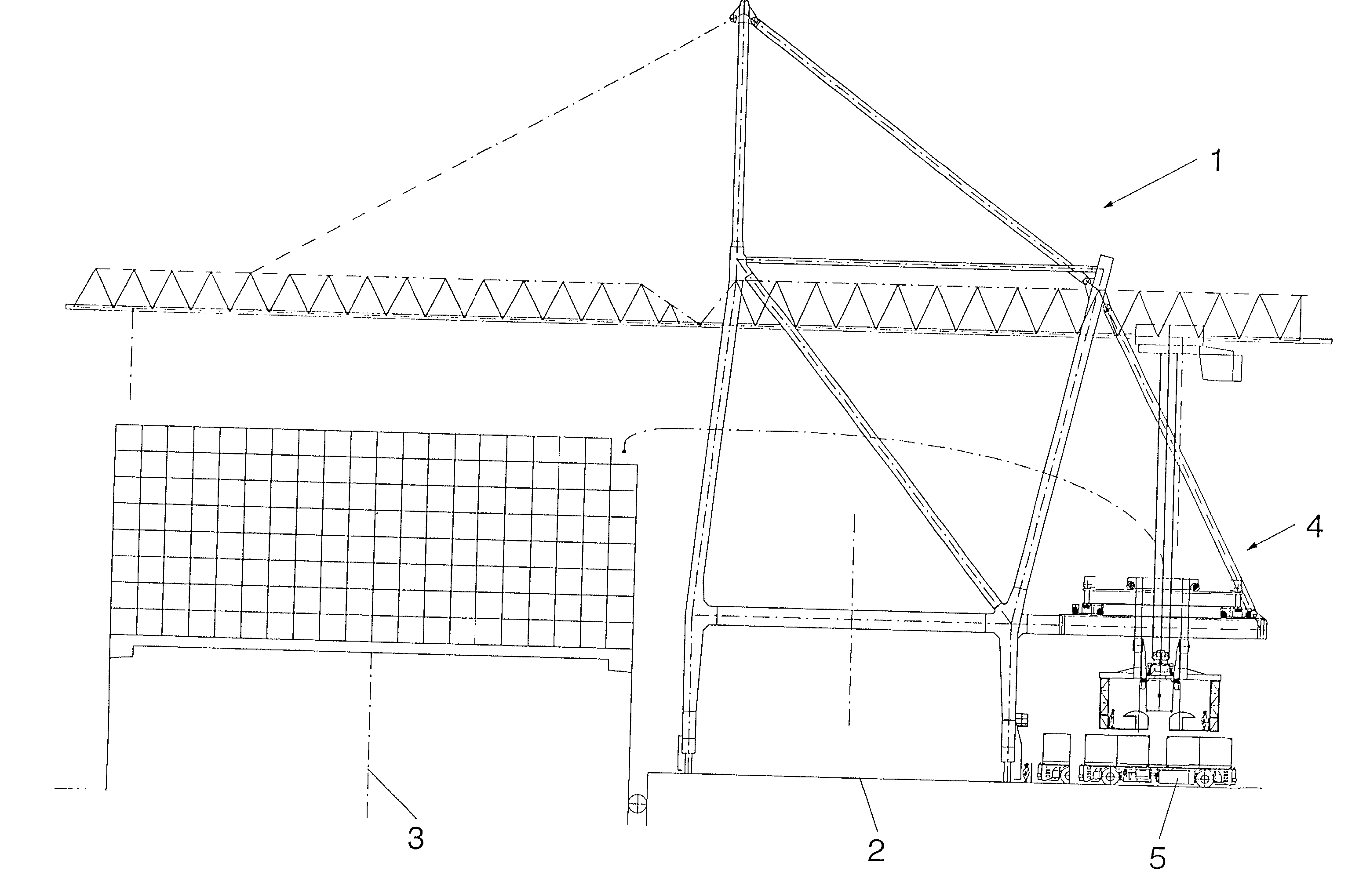

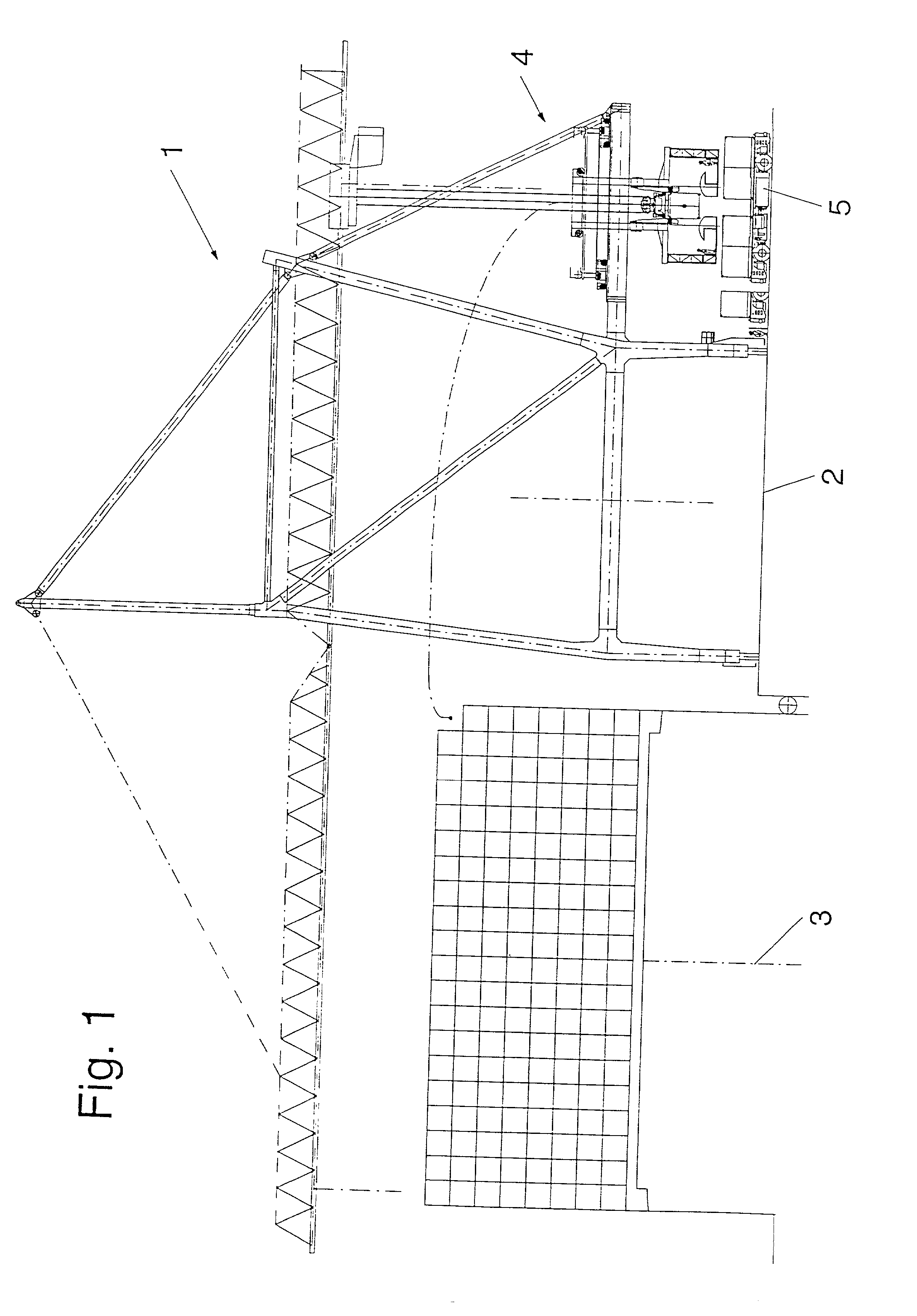

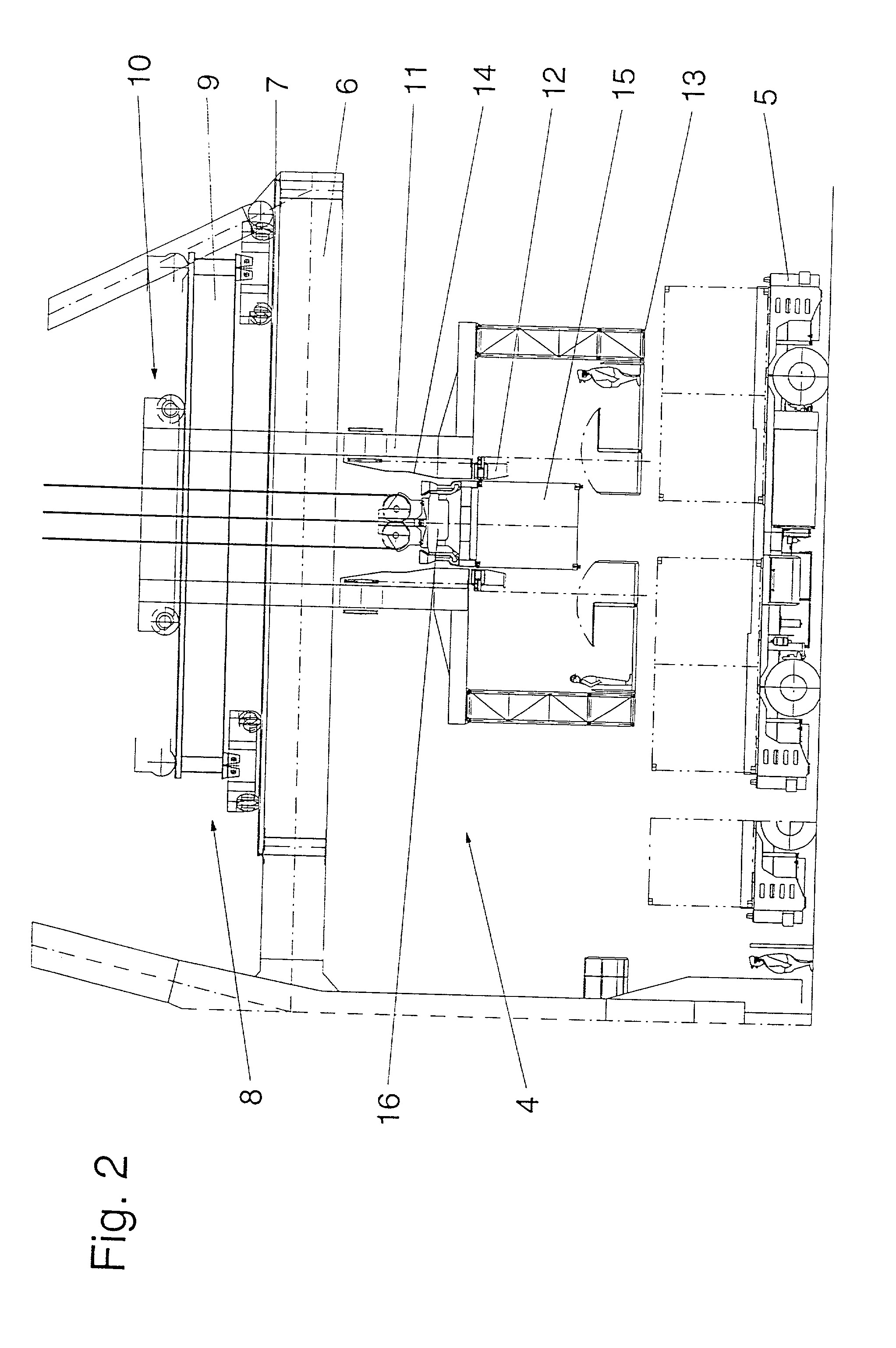

Loading device for ISO containers

InactiveUS20020044854A1Avoid bottlenecksEffective maneuveringCargo handling apparatusBase supporting structuresOverhead craneVertical axis

A loading device for ISO containers in a container terminal with a container bridge for the loading and unloading of ships and with automatic incoming and outgoing transfer of the containers by means of automatic guided vehicles, with at least one container load suspension device in the form of a spreader and devices for the intermediate positioning of the container within the loading device to allow the installation or removal of the twistlocks, and with platforms for the workers performing this task. The loading device consists of a polar bridge crane, which can rotate around its center vertical axis, and which is designed as a bridge crane with a trolley capable of traveling on a crane bridge supported on a circular track located in the rear area of the land-side rail of the container bridge.

Owner:ROCKWELL SOFTWARE +1

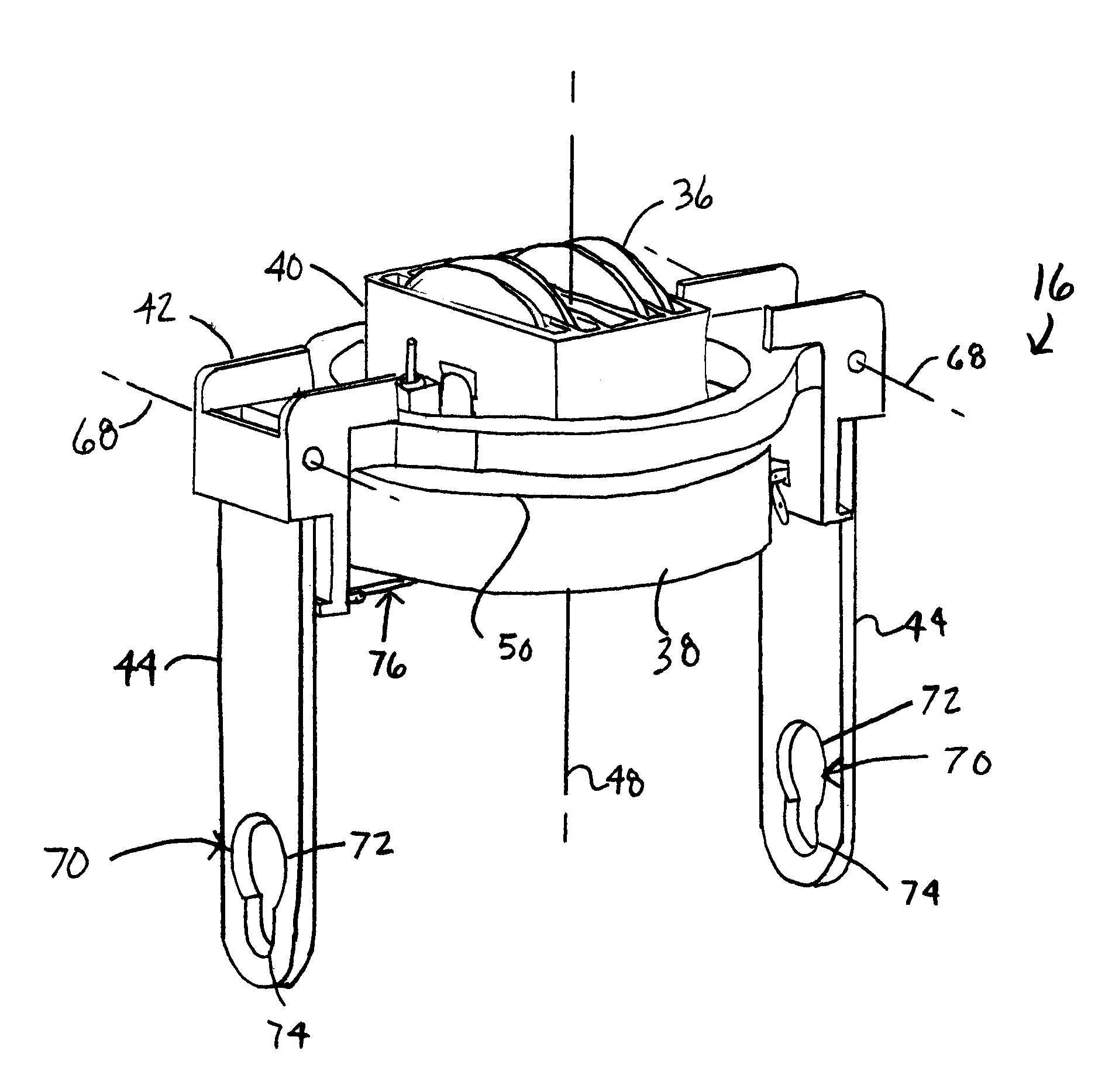

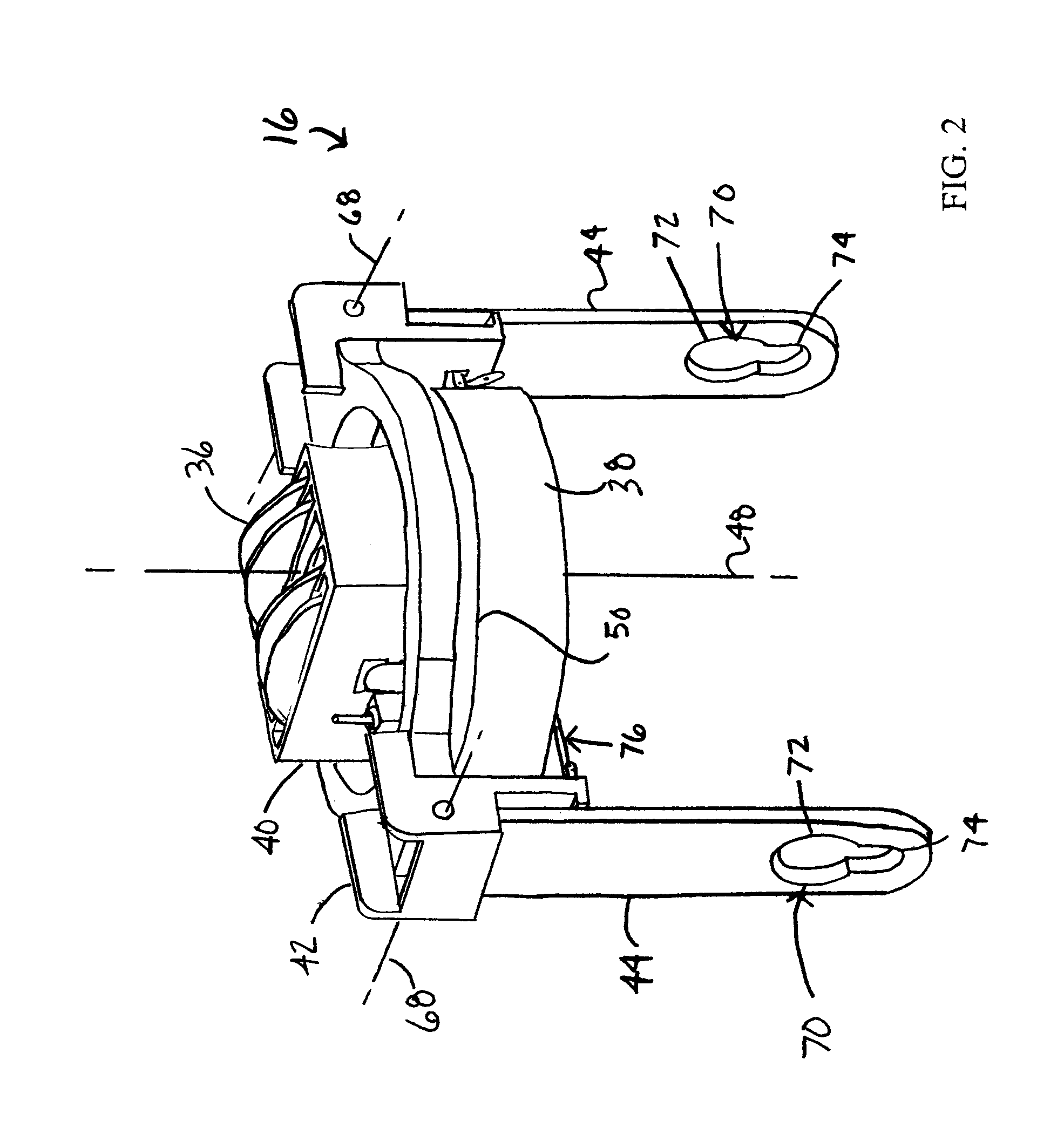

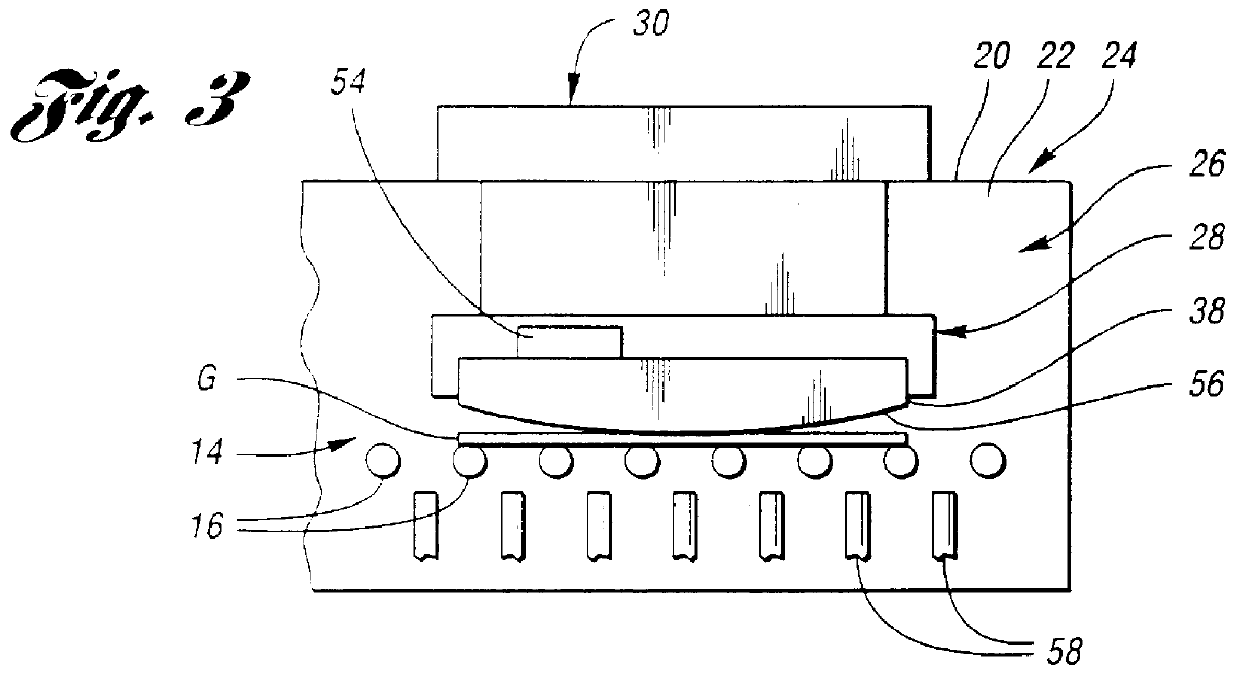

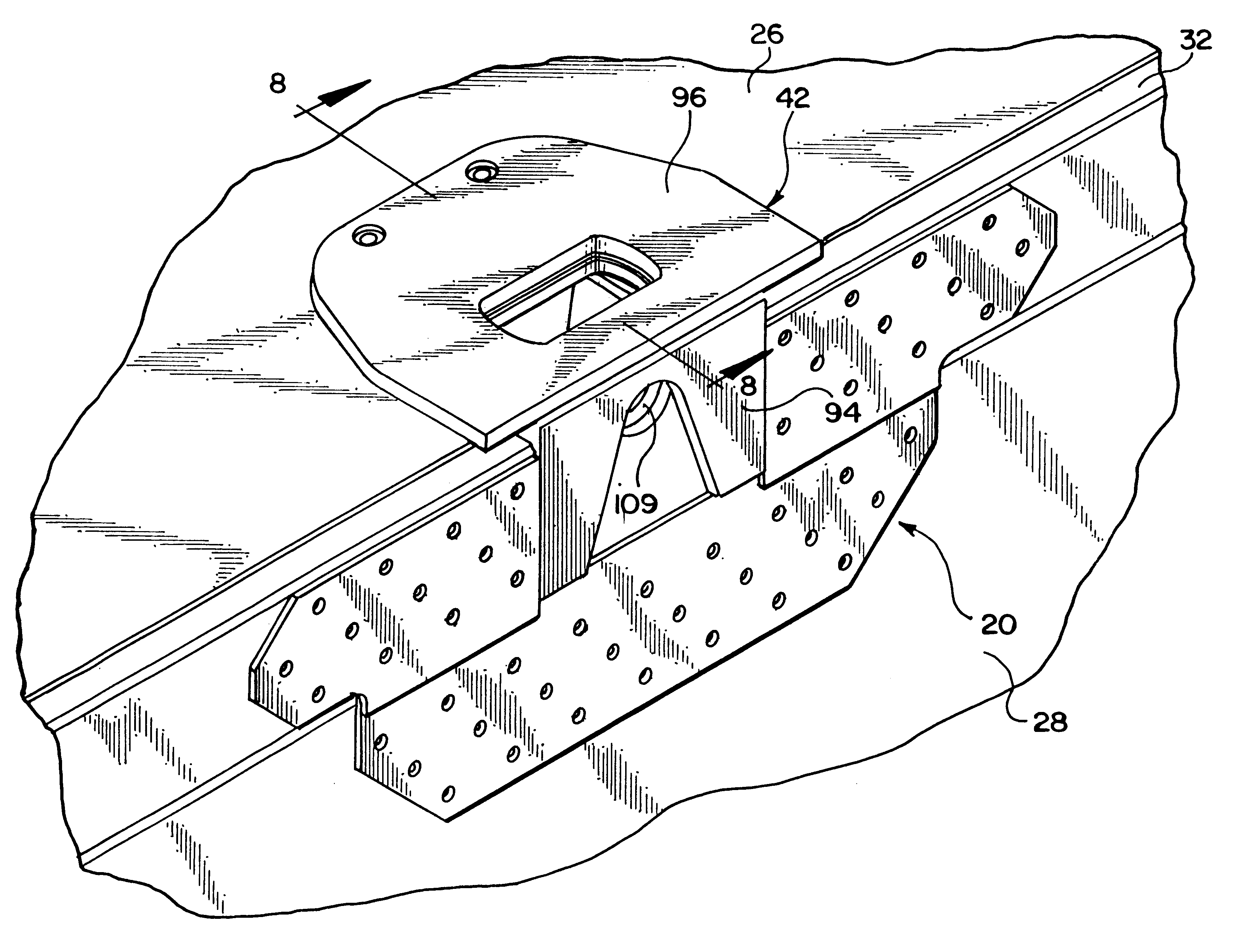

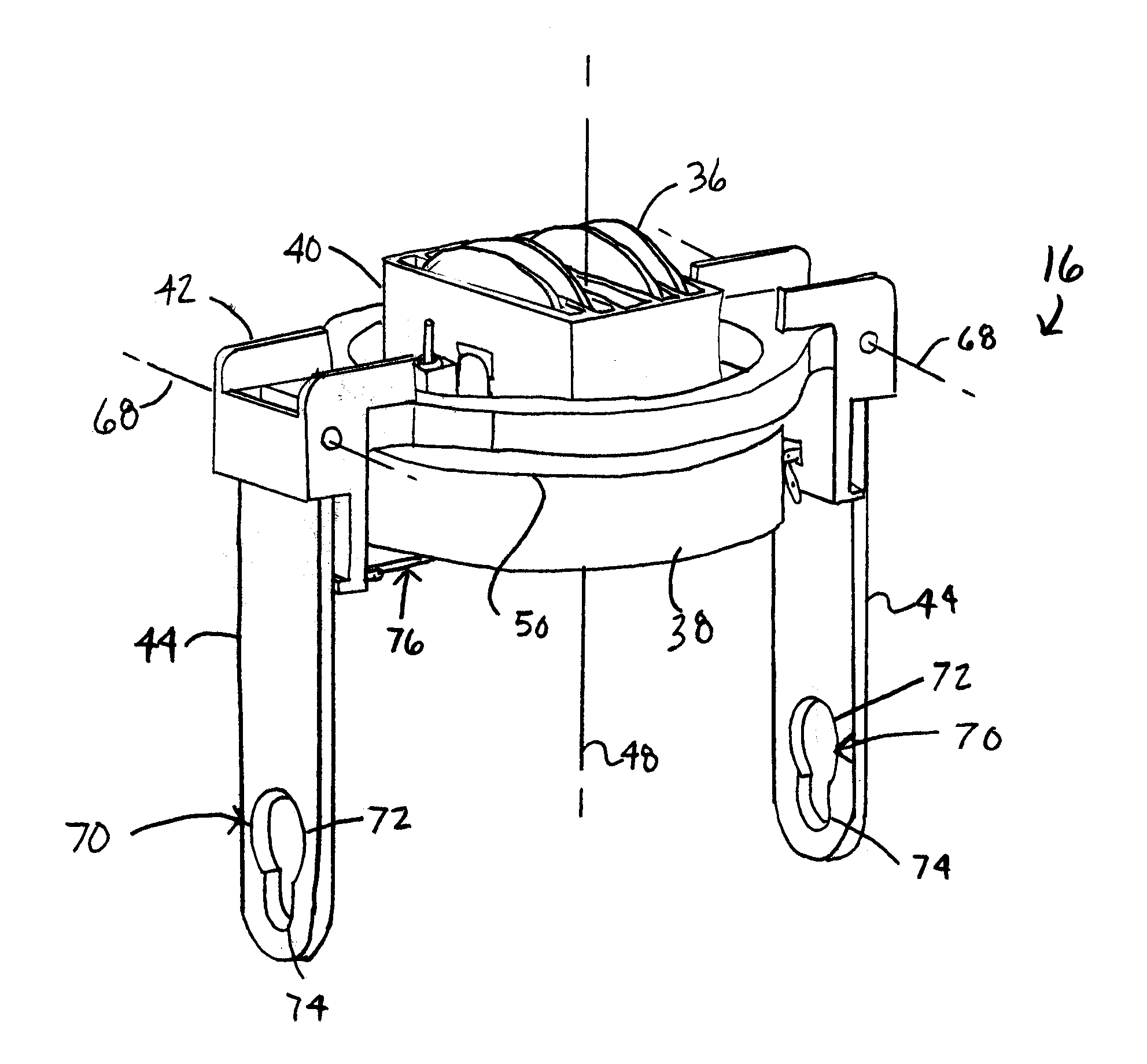

Bottom block assembly with pivoting trunnion paddles

ActiveUS7775571B2Nuclear engineering problemsNuclear engineering solutionsHorizontal axisOverhead crane

A bottom block assembly for an overhead crane includes a main bottom block, an outer frame carried by the main bottom block and rotatable relative to the main bottom block about a vertical axis of rotation, and a pair of paddles carried by the outer frame and downwardly extending from the outer frame on opposed sides of the main bottom block. Upper ends of the paddles are pivotably secured to the outer frame about horizontal axes so that lower ends of the paddles pivot toward and away from each other. The paddles are pivotable between a closed position wherein each of the paddles is substantially vertical and an open position wherein the lower end of each of the paddles is outwardly pivoted away from a vertical central axis. Each of the paddles has a keyhole-shaped closed-section opening near its lower end.

Owner:MHE TECH

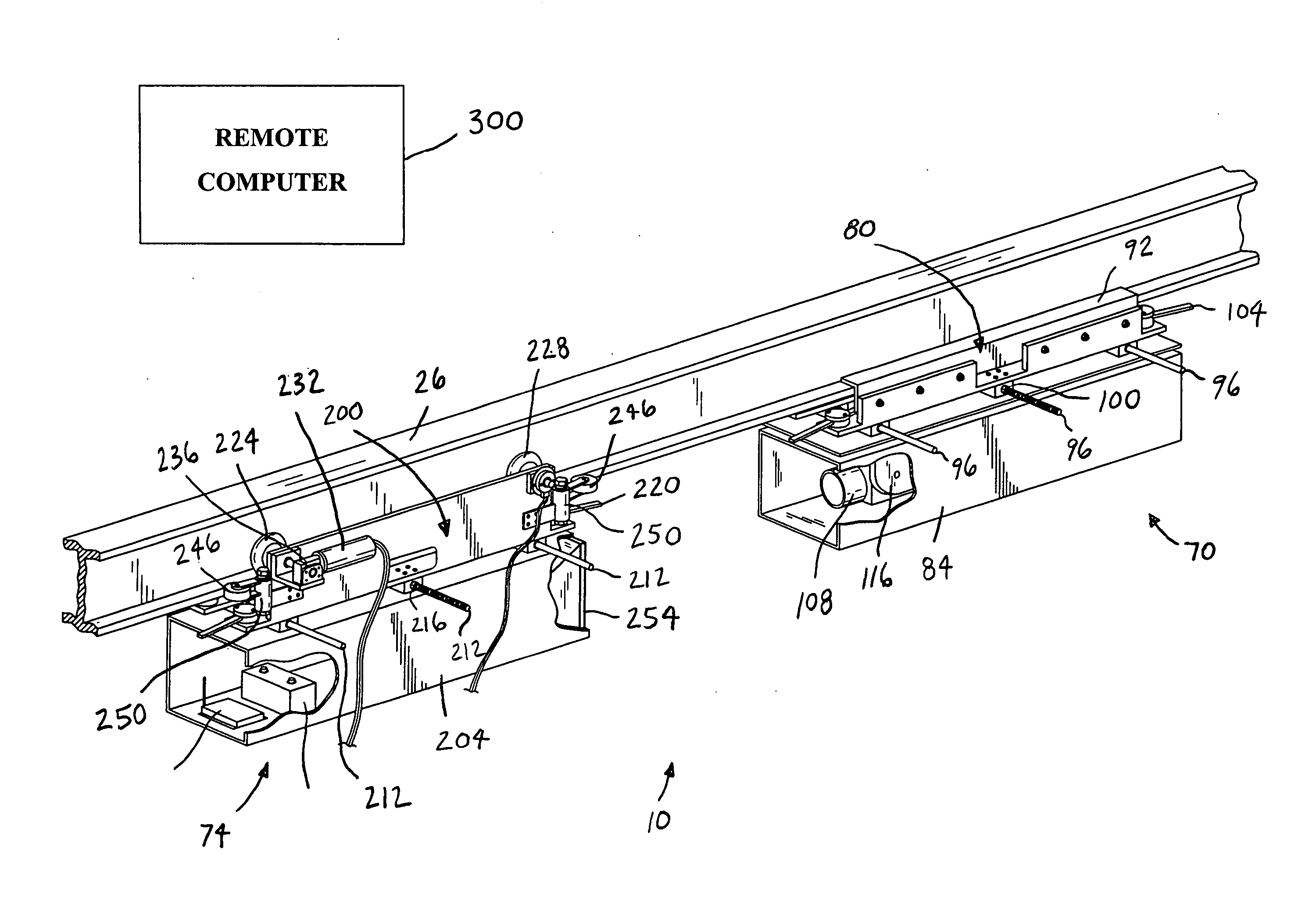

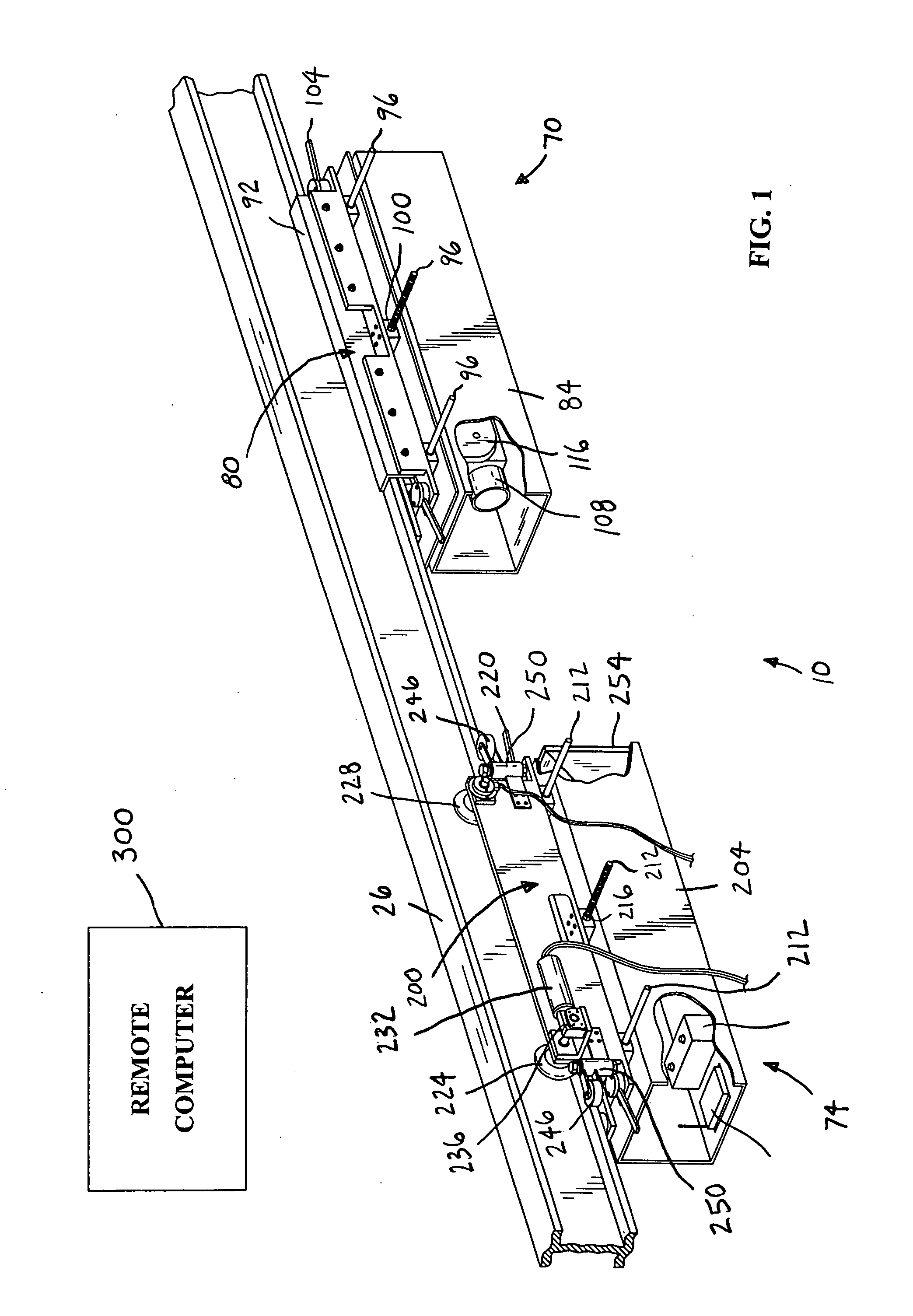

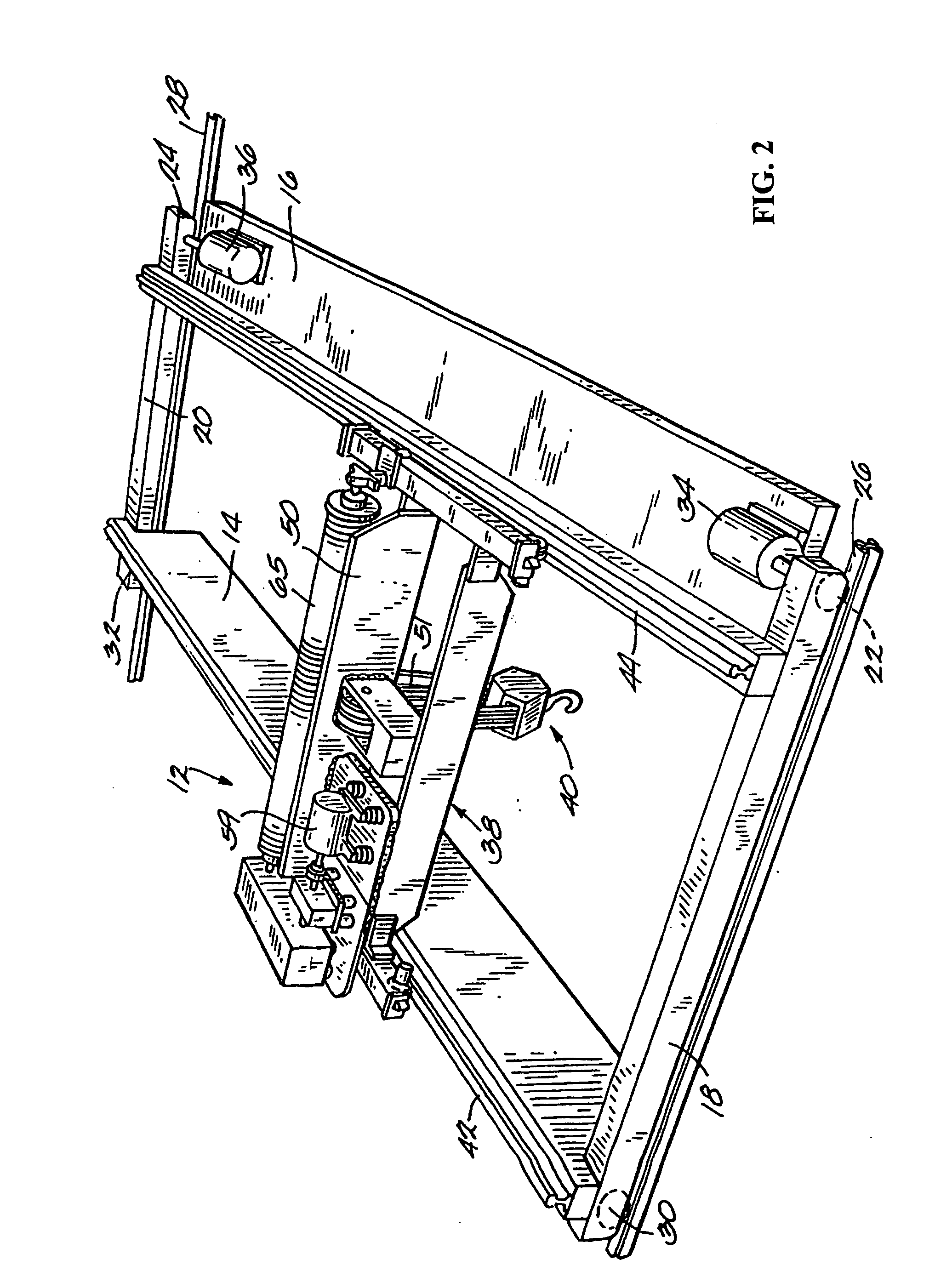

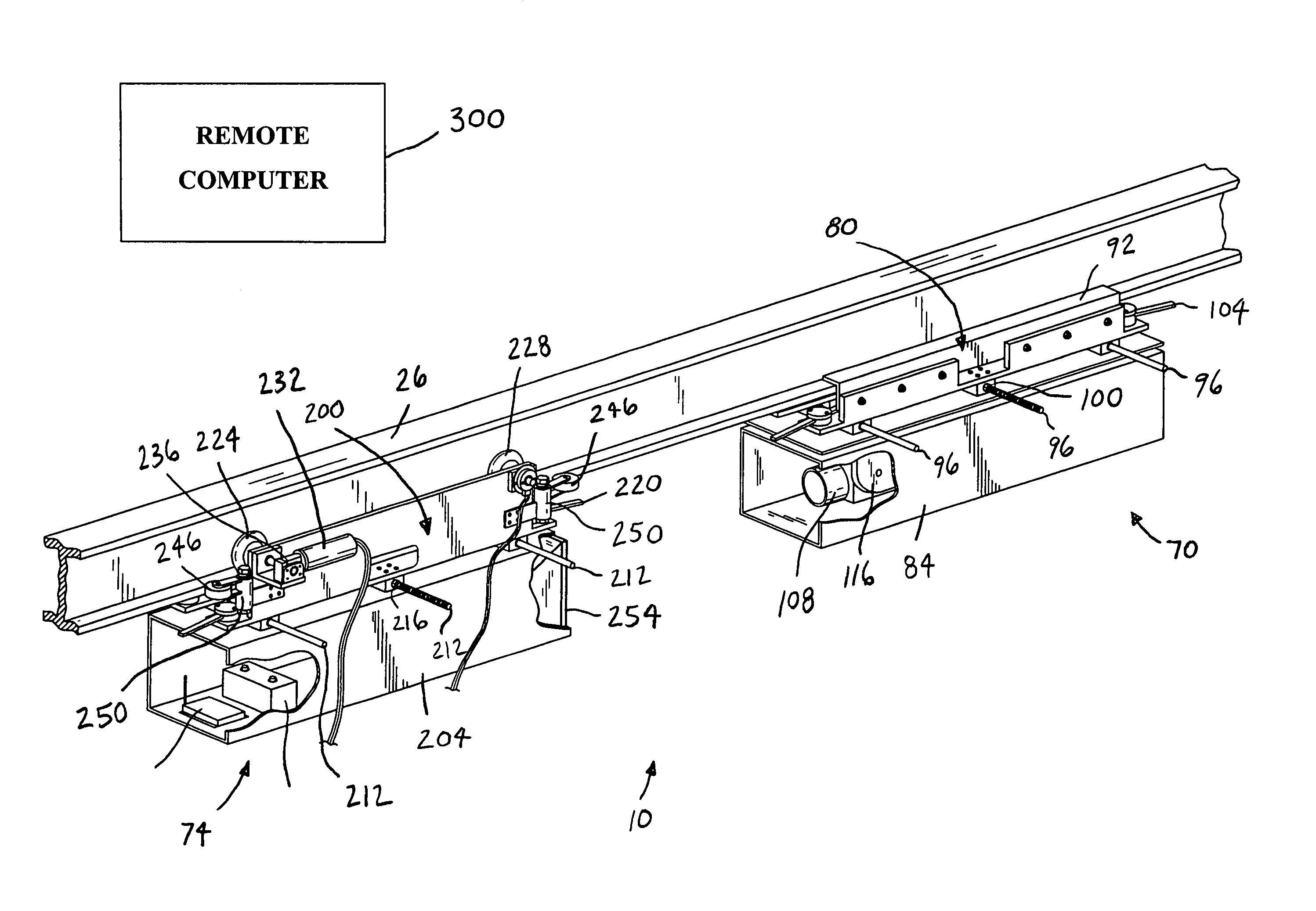

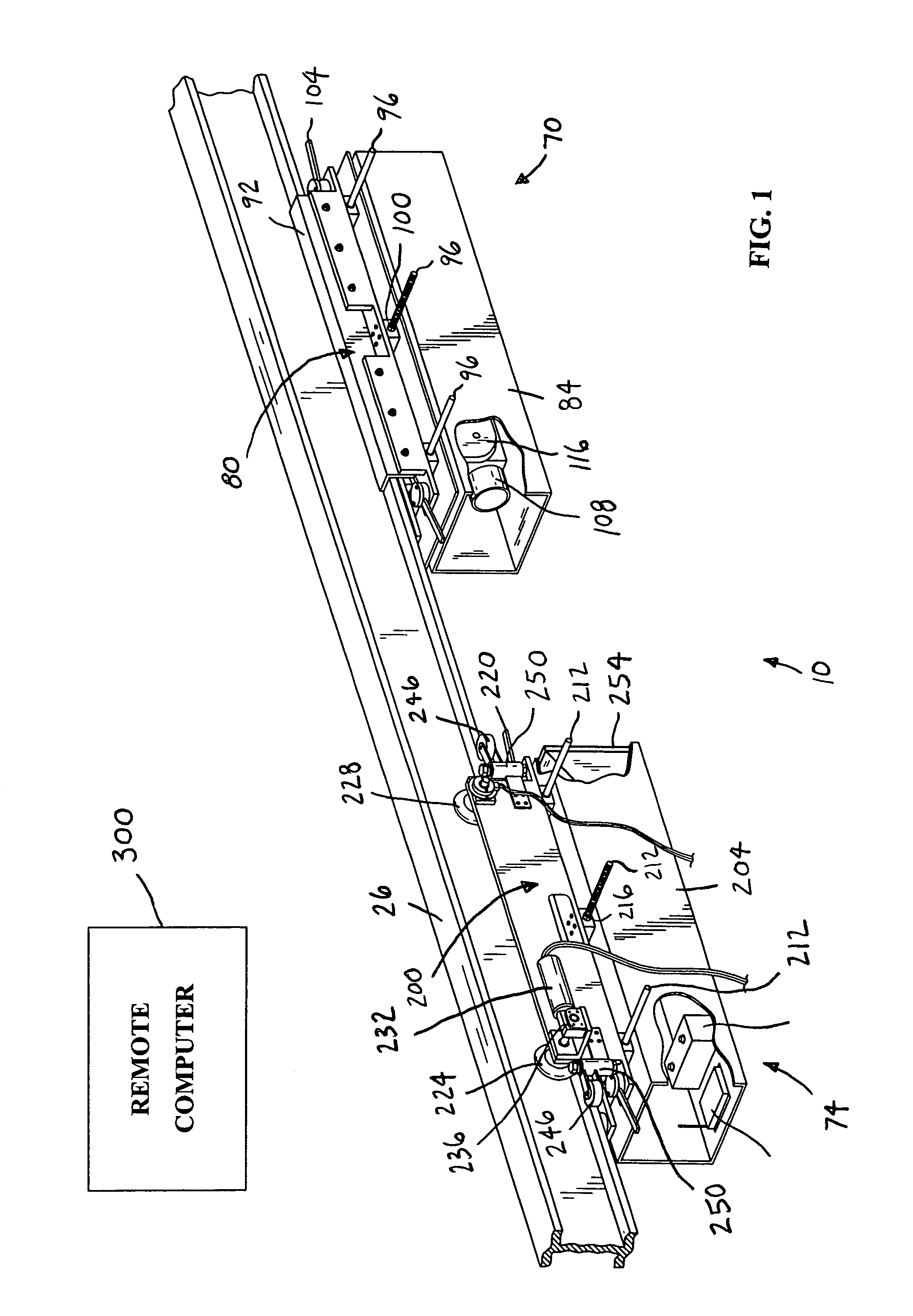

Laser survey device

InactiveUS20050111012A1The result is accurateUsing optical meansElevated railway with suspended vehicleMeasurement deviceEngineering

A remotely operated laser survey device for performing a runway survey on a rail system that supports a device such as an overhead crane. The survey device includes a laser assembly and a survey car. The laser assembly can include a self-leveling laser. The survey car includes an image acquisition device and can be self-propelled by a drive mechanism. Images obtained using the image acquisition device are transmitted to a remote computer for analysis. The analysis can include a centroidal analysis of the image. Deviation of the rails is compared to established standards and correction carried out if necessary. The image acquisition device can be triggered to obtain images based on movement of the survey car. The survey car can be centered on a rail of the rail system to ensure accurate results regardless of the condition of the rail.

Owner:U S BANK NAT ASSOC

Laser survey device

InactiveUS7499186B2The result is accurateUsing optical meansElevated railway with suspended vehicleAcquisition apparatusRemote computer

A remotely operated laser survey device for performing a runway survey on a rail system that supports a device such as an overhead crane. The survey device includes a laser assembly and a survey car. The laser assembly can include a self-leveling laser. The survey car includes an image acquisition device and can be self-propelled by a drive mechanism. Images obtained using the image acquisition device are transmitted to a remote computer for analysis. The analysis can include a centroidal analysis of the image. Deviation of the rails is compared to established standards and correction carried out if necessary. The image acquisition device can be triggered to obtain images based on movement of the survey car. The survey car can be centered on a rail of the rail system to ensure accurate results regardless of the condition of the rail.

Owner:U S BANK NAT ASSOC

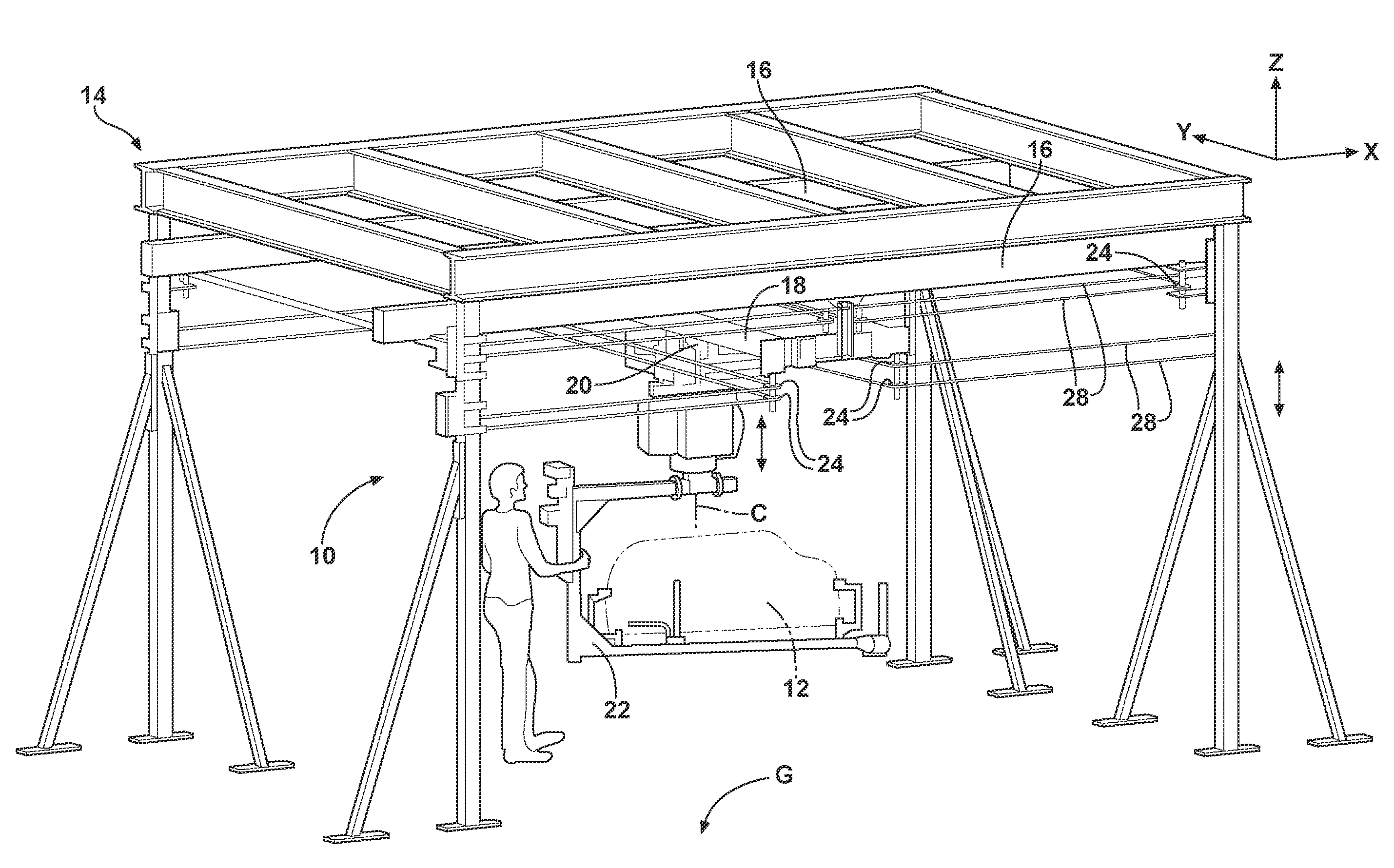

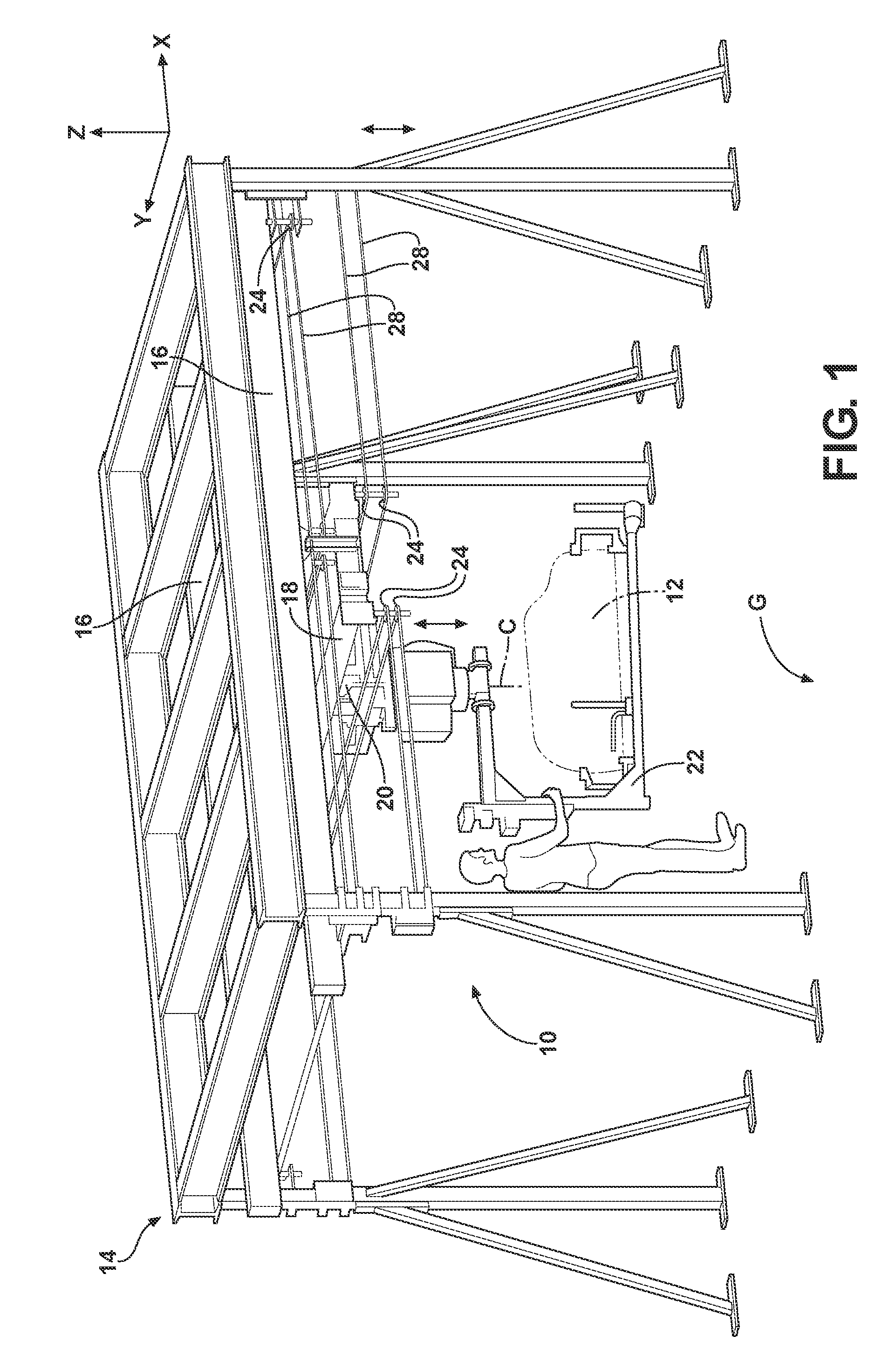

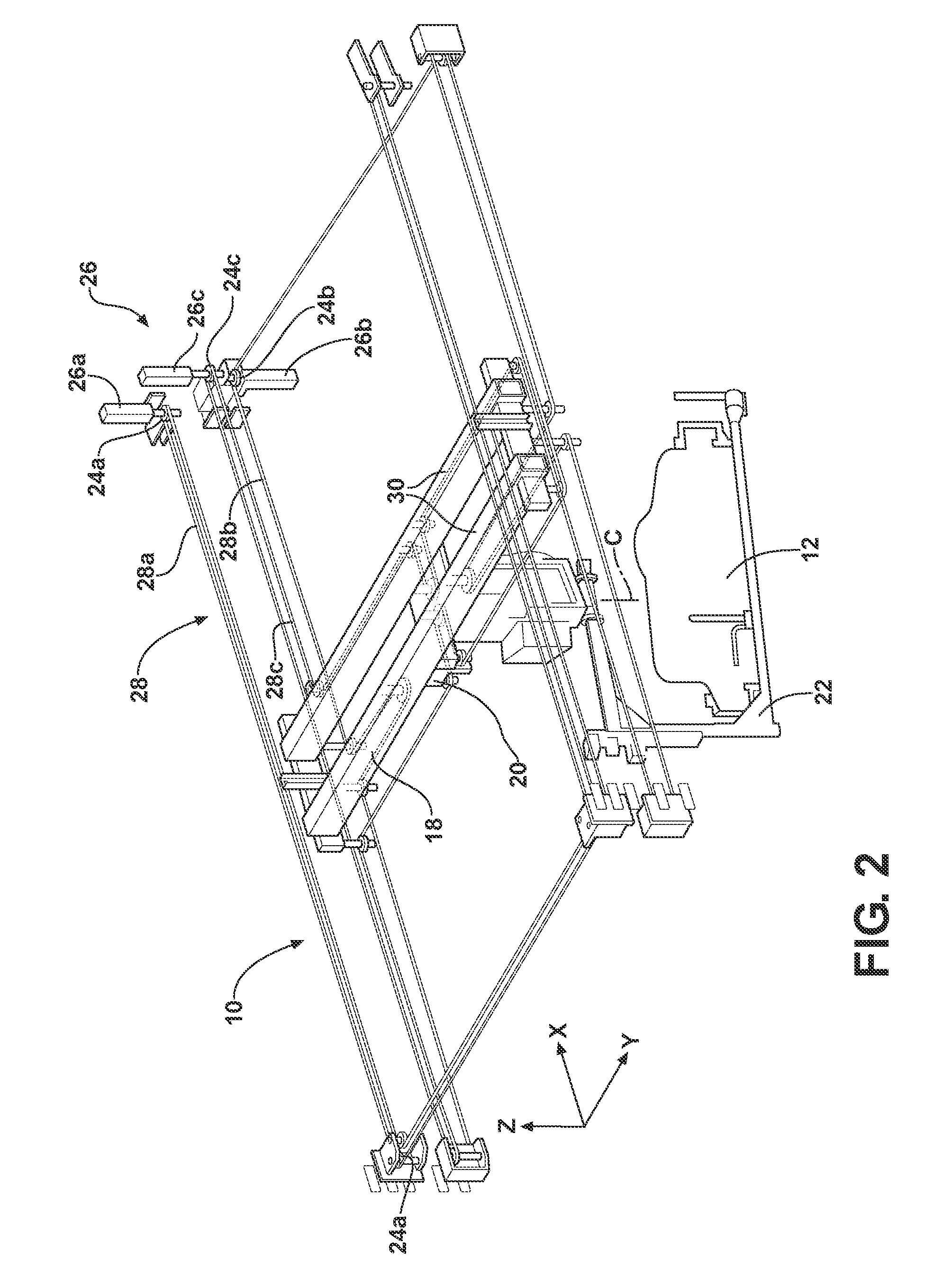

Actuation system configured for moving a payload

An actuation system includes a bridge crane, a trolley, and an end effector and is configured for moving a payload. A first actuator is operatively connected to the bridge crane. The bridge crane is configured for moving along an X axis in response to the first actuator being actuated. The trolley extends from the bridge crane. A second actuator is operatively connected to the trolley. The trolley is configured for moving along a Y axis in response to the second actuator being actuated. The end effector extends from the trolley and is configured for supporting a payload. A third actuator is operatively connected to the end effector. The end effector is configured for rotating about the Z axis in response to the third actuator being actuated to rotate the end effector. Each actuator is disposed in spaced relationship to the bridge crane, the trolley, and the end effector.

Owner:UNIV LAVAL +1

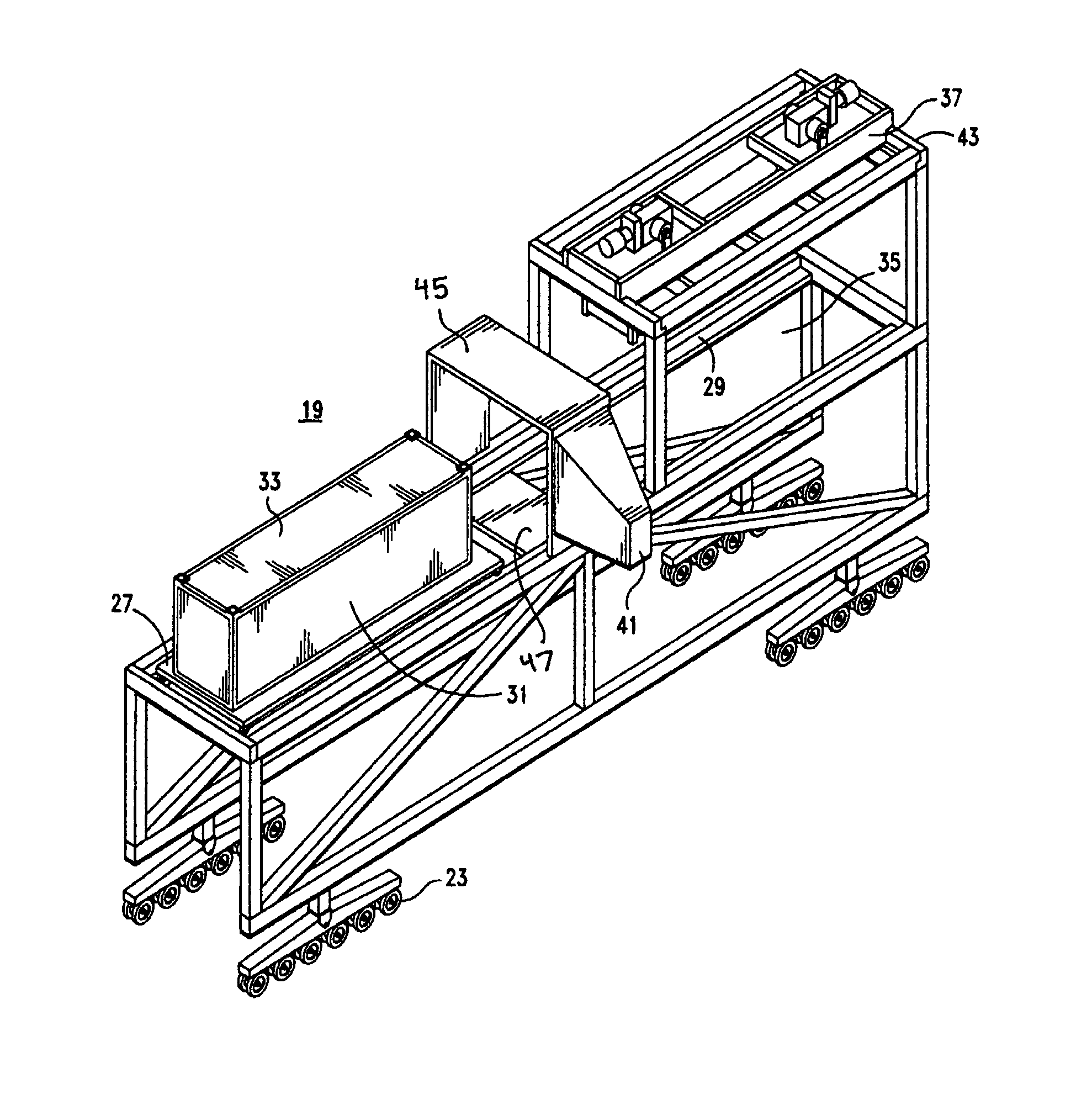

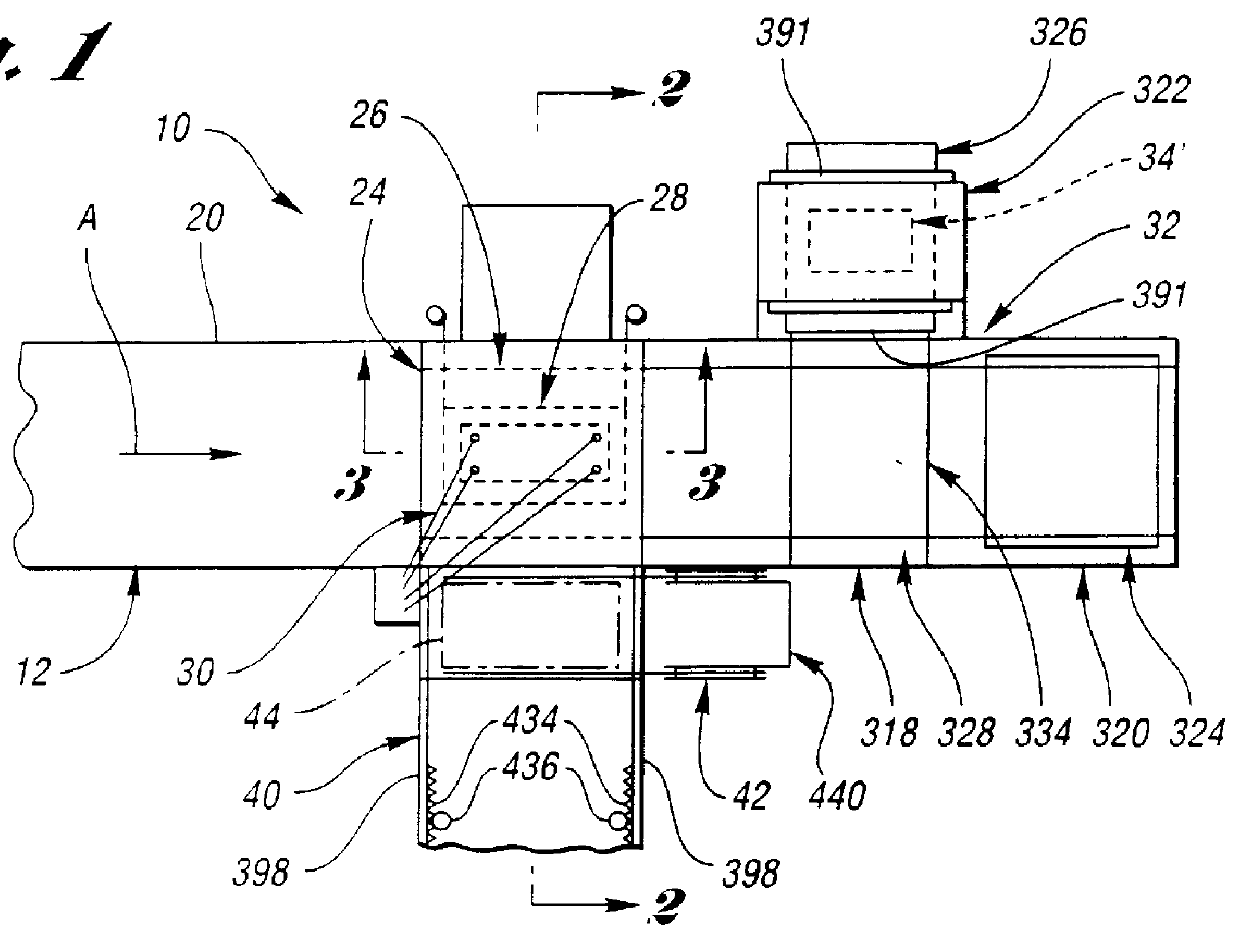

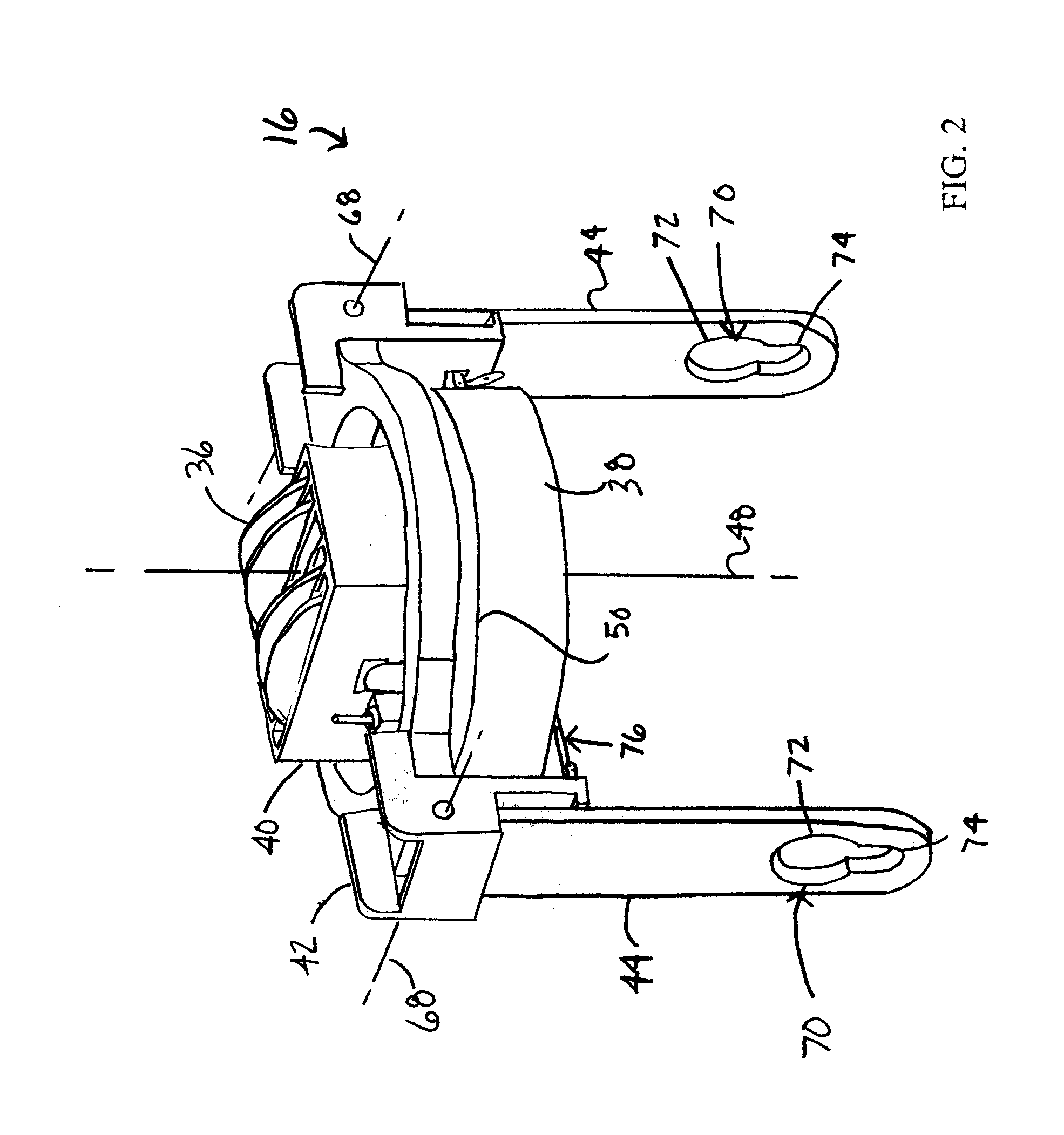

Method for installing glass sheet quench module set

A glass sheet quench station loader (42) and method for installing a quench module set (44) of lower and upper quench modules (46,48) includes a quench carriage (440) of a horizontally opening U shape that receives the quench modules for the loading. Mounts (446,454) mount the quench modules for movement to the quench station (40) and for subsequent movement from the quench station to permit installation of another quench module set for another production run. The quench loader (42) includes an overhead crane (447) and an overhead railway (448) along which the crane moves to move the quench carriage (440) and the quench modules mounted thereby to and from the quench station.

Owner:GLASSTECH

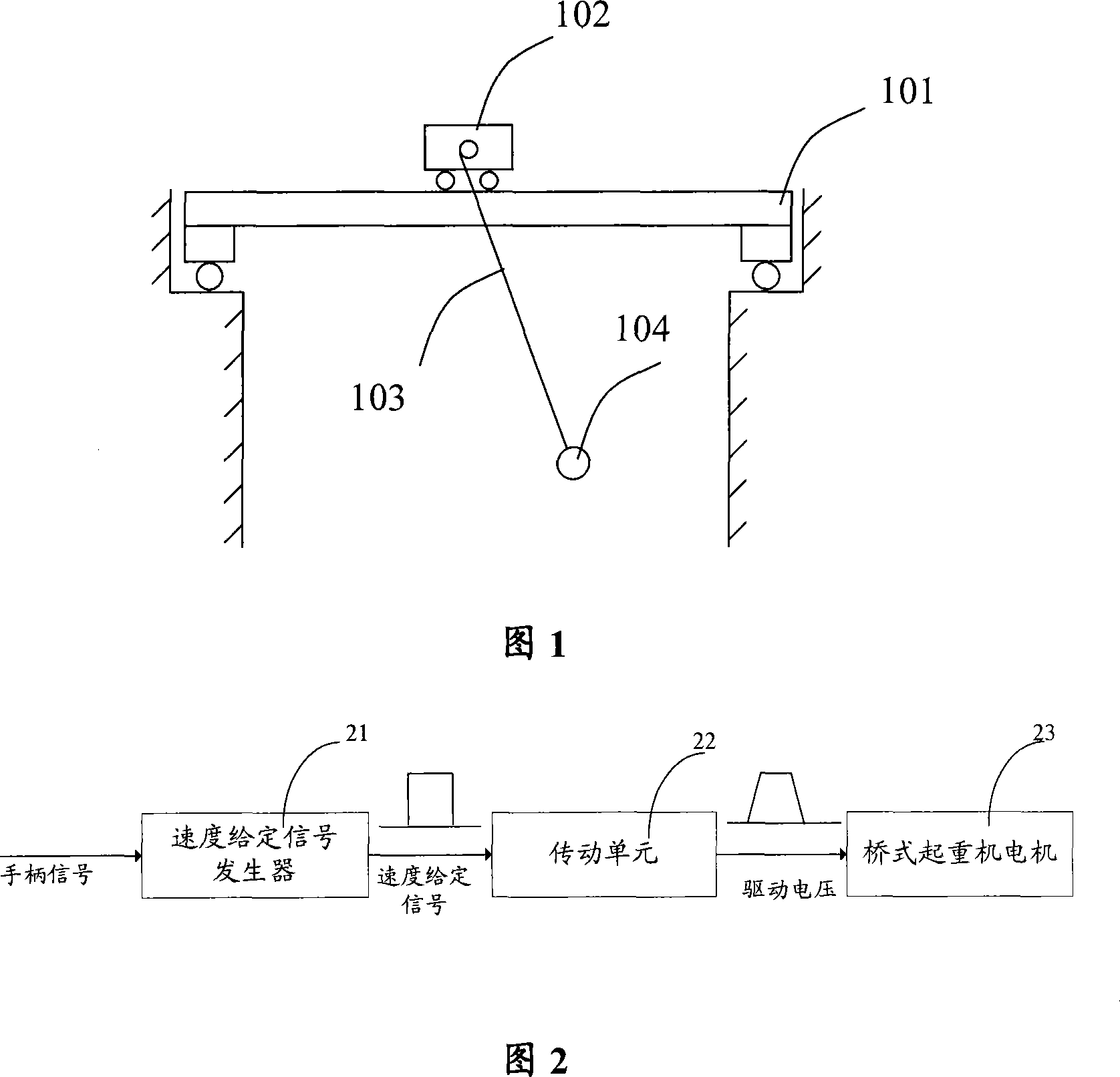

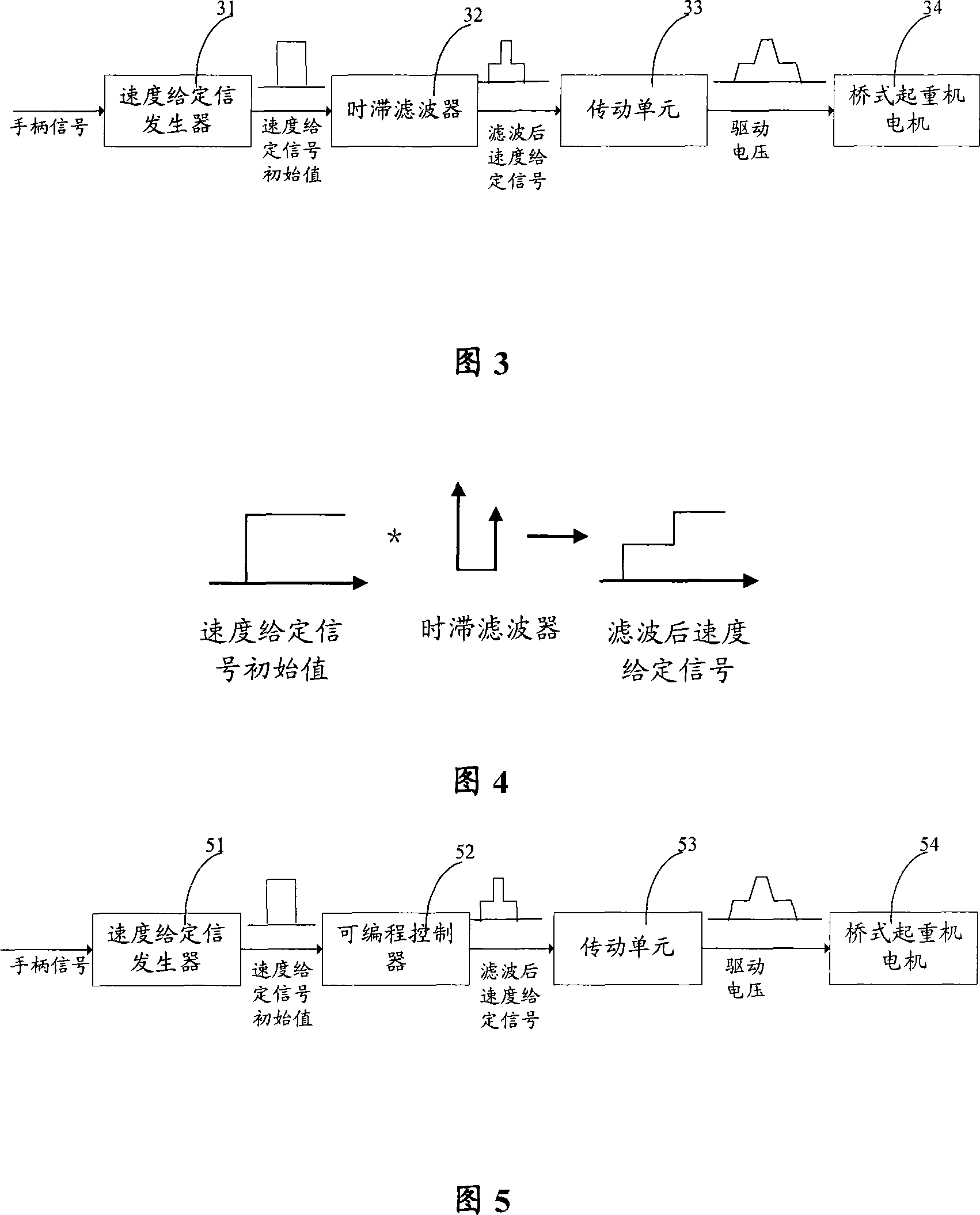

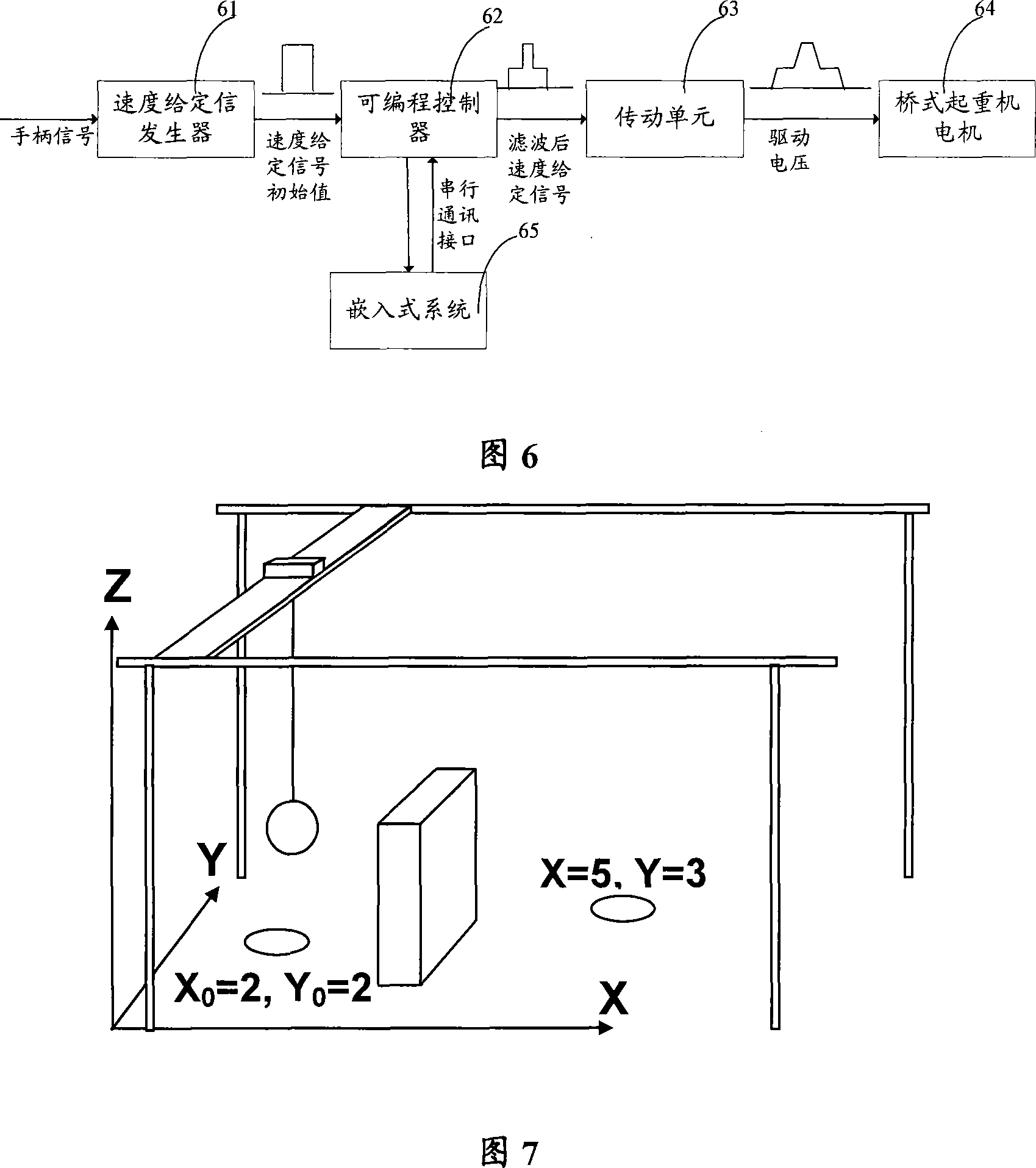

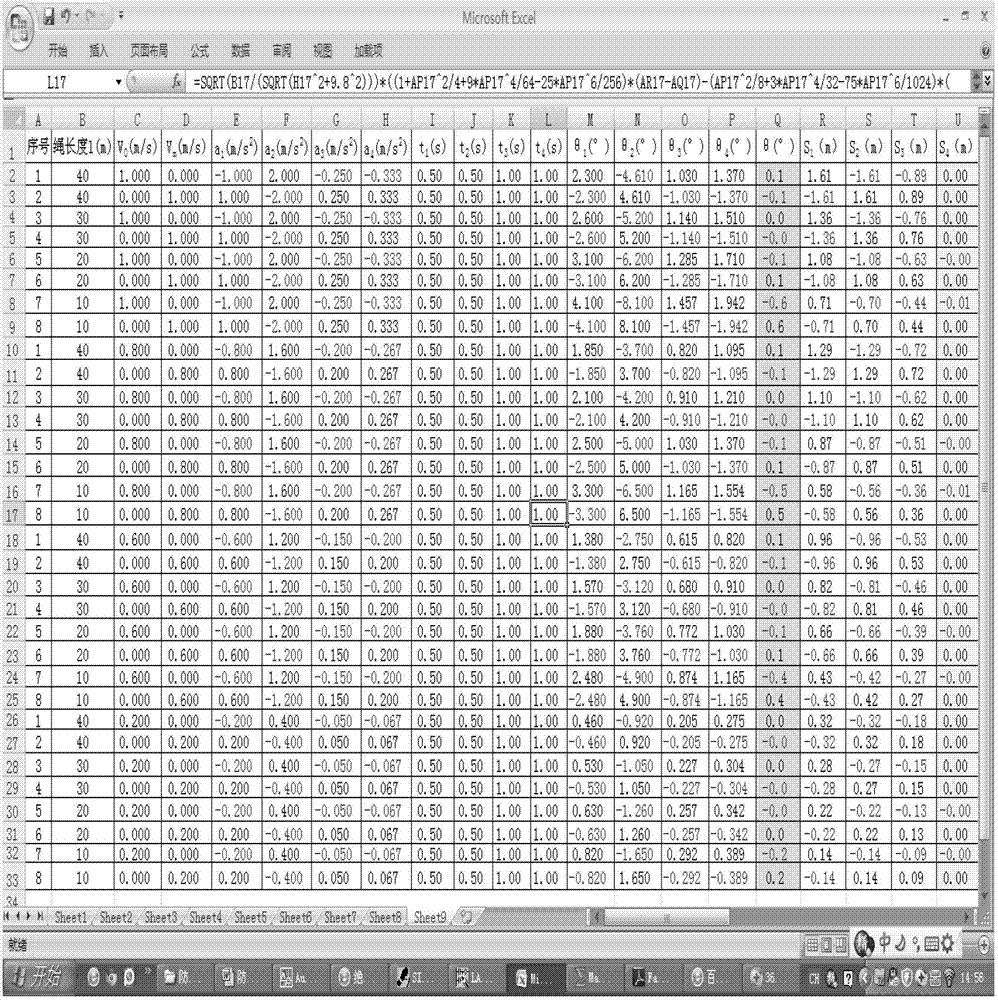

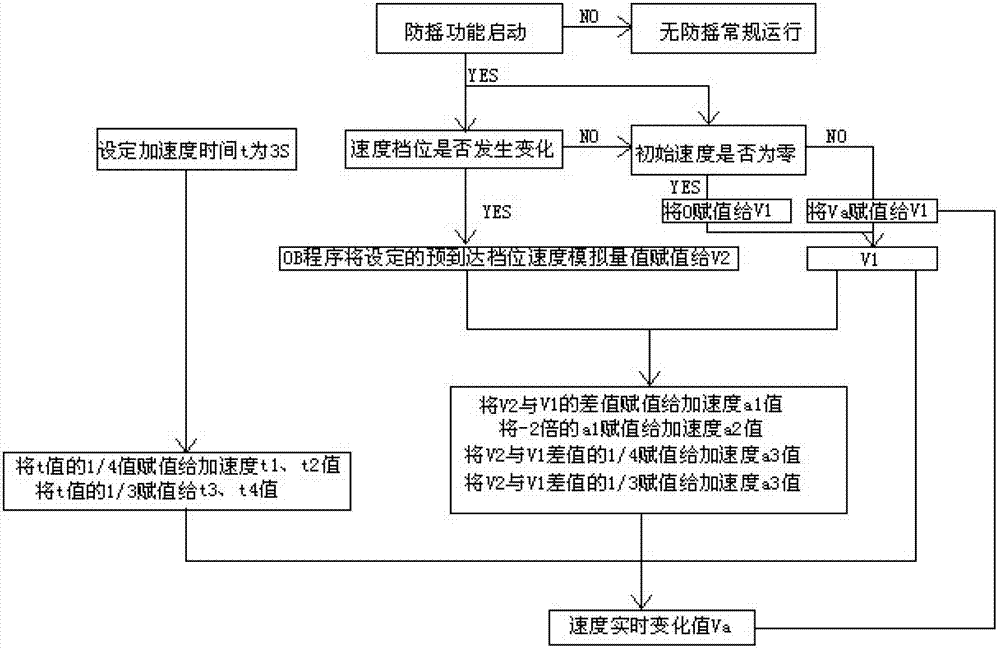

Bridge-type crane control apparatus with rocking-prevention function

ActiveCN101024471AWith anti-shake functionImprove the anti-shake effectLoad-engaging elementsTime lagBridge type

The invention discloses a bridge hoisting control device that has shaking-proof effect. It includes speed giving signal generator, speed adjusting unit and motor, time lag filter that receives the primary value of speed giving signal and transforms into filtered speed giving signal that has shaking-proof effect, and sends to speed adjusting unit. The invention realizes the shaking proof effect for bridge hoist.

Owner:ABB (CHINA) LTD

Garbage grab bucket crane and anti-swinging control method

ActiveCN102774750AGuaranteed uptimeOvercoming the problem of large swingsLoad-engaging elementsFrequency changerProgrammable logic controller

The invention discloses a garbage grab bucket crane, which comprises a PLC (programmable logic controller), a frequency converter and a motor, wherein an anti-swinging function module is arranged in the PLC, an output end interface of the anti-swinging function module is connected with the frequency converter, the anti-swinging function module carries out operation on the input speed analog quantity value and then transmits the data to the frequency converter, and the rotating speed of the motor is set by the frequency converter according to the data input from the anti-swinging function module for controlling the work of the motor. The anti-swinging function module is built in the PLC, only the speed analog quantity value of each gear needs to be set in the PLC, and the small-amplitude swinging or no swinging can be realized during the high-speed operation of the garbage grab bucket crane through the function block operation. Therefore, the problem of large-amplitude swinging often generated during the operation of the garbage grab bucket crane is solved, and the stable and reliable operation of the garbage grab bucket crane is ensured.

Owner:WUHAN KATTOR IND

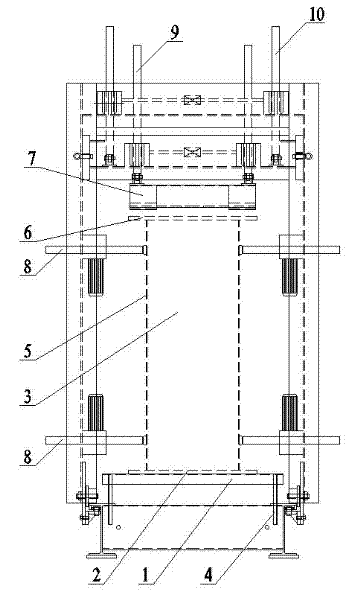

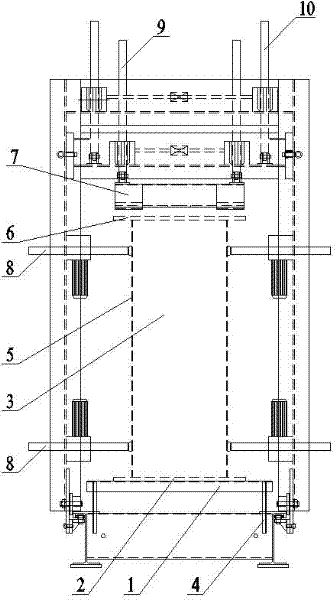

Method for forming and assembling four faces of bridge crane box type girder

InactiveCN102500979AControl twistEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOverhead crane

The invention provides a method for forming and assembling four faces of a bridge crane box type girder. A locating jig frame for adjusting camber by using a screw rod is arranged on the bottom surface of the girder, and corresponding push rods are arranged on the other three faces for locating and uses a worm mechanism so as to achieve back-and-forth telescoping. The method is suitable for multiple girder assembly. The running mode of a machine mechanism is simple, operation is convenient and reliable, assembly efficiency is high, and simultaneously torsion resistance and straightness of the girder and web plate verticality can be controlled well in the manufacturing process.

Owner:EUROCRANE

Wind turbine erector

A wind tower erection device and method for erecting wind turbine towers which avoid the need for using expensive cranes. The device and method employs a stacker unit for anchoring to the wind turbine foundation, a plurality of intermediate modules, and a mechanical actuator for raising the intermediate modules vertically. The stacker unit has a receptacle allowing for lateral sliding of intermediate modules inside of the stacker unit. In one embodiment, the stacker unit has a receptacle for lateral sliding of intermediate modules inside of the stacker unit. The stacker unit and the intermediate modules each have at least one open side to for positioning of tower sections within the stacker unit and stacked intermediate modules. A bridge crane section is initially placed on top of the stacked intermediate modules. The bridge crane is raised vertically as additional intermediate modules are added at the bottom, thereby allowing wind tower sections to be winched into place using the crane, each being added on top of the other as the stacked intermediate modules increase to the necessary height.

Owner:VORHIES ROGER W

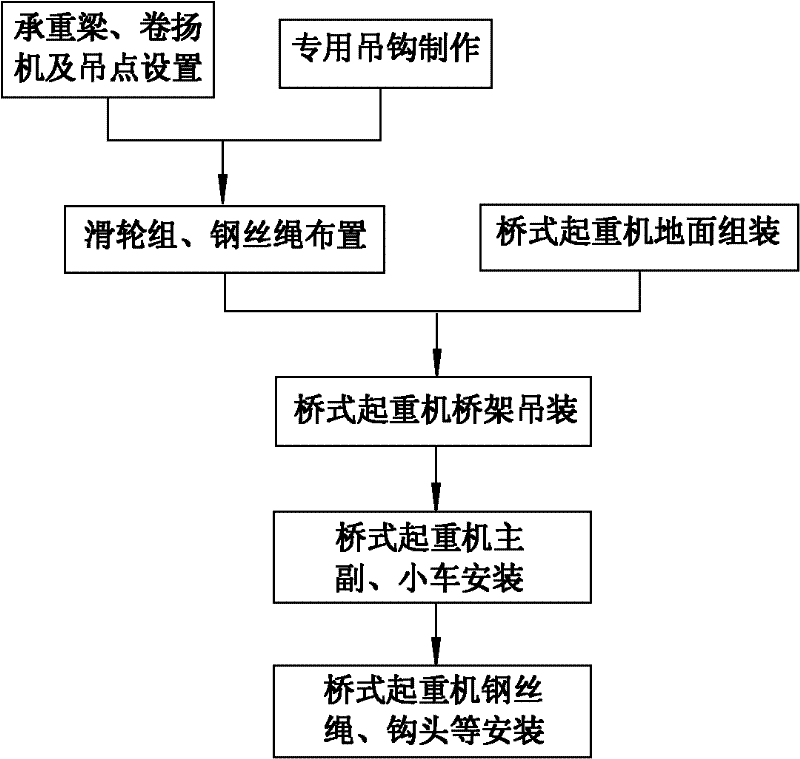

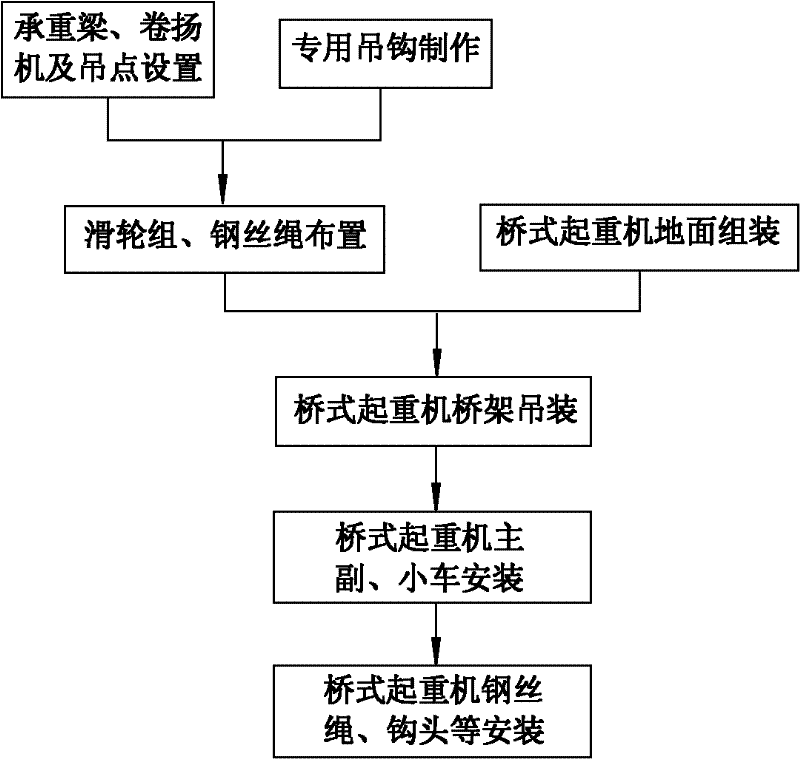

The method of installing the bridge crane by the beam hanging method and the use of this method

InactiveCN102267664ADoes not affect the installation progressReduce investmentTravelling cranesOverhead craneBeam bridge

The invention relates to a method for installing a bridge crane using load-supporting roof beams for hoisting and usage thereof. The invention is characterized in that: hoisting points are arranged on roof beams of a workshop, components of the bridge crane are assembled on the ground on site, and hoists and specified suspenders are used for hoisting the bridge crane; the method mainly comprises the steps of arranging of load-supporting beams for hoisting, hoists and hoisting points, fabrication of the specified suspenders, arranging of assembly pulleys and wire ropes, assembly of the bridge crane on the ground, hoisting of bridge stands of the bridge crane, hoisting of main and assistant trolleys of the bridge crane and installation of the wire ropes and the suspenders. According to the invention, site requirements are low, finished roofing of the workshop does not need to be dismounted, no giant crane is utilized, and facilities purchased and suspenders fabricated at a time can be used repeatedly, thereby saving cost; lifting and suspending with two cranes are avoided, thereby reducing safety risks; components are assembled in place on the ground and hoisted at a time, thereby improving working efficiency and abating risks in high altitude construction; time for actual hoisting is short and operationality is strong; the method is applicable to installation of large and medium-sized bridge cranes without being influenced by sites or hoisting height.

Owner:CHINA FIRST METALLURGICAL GROUP

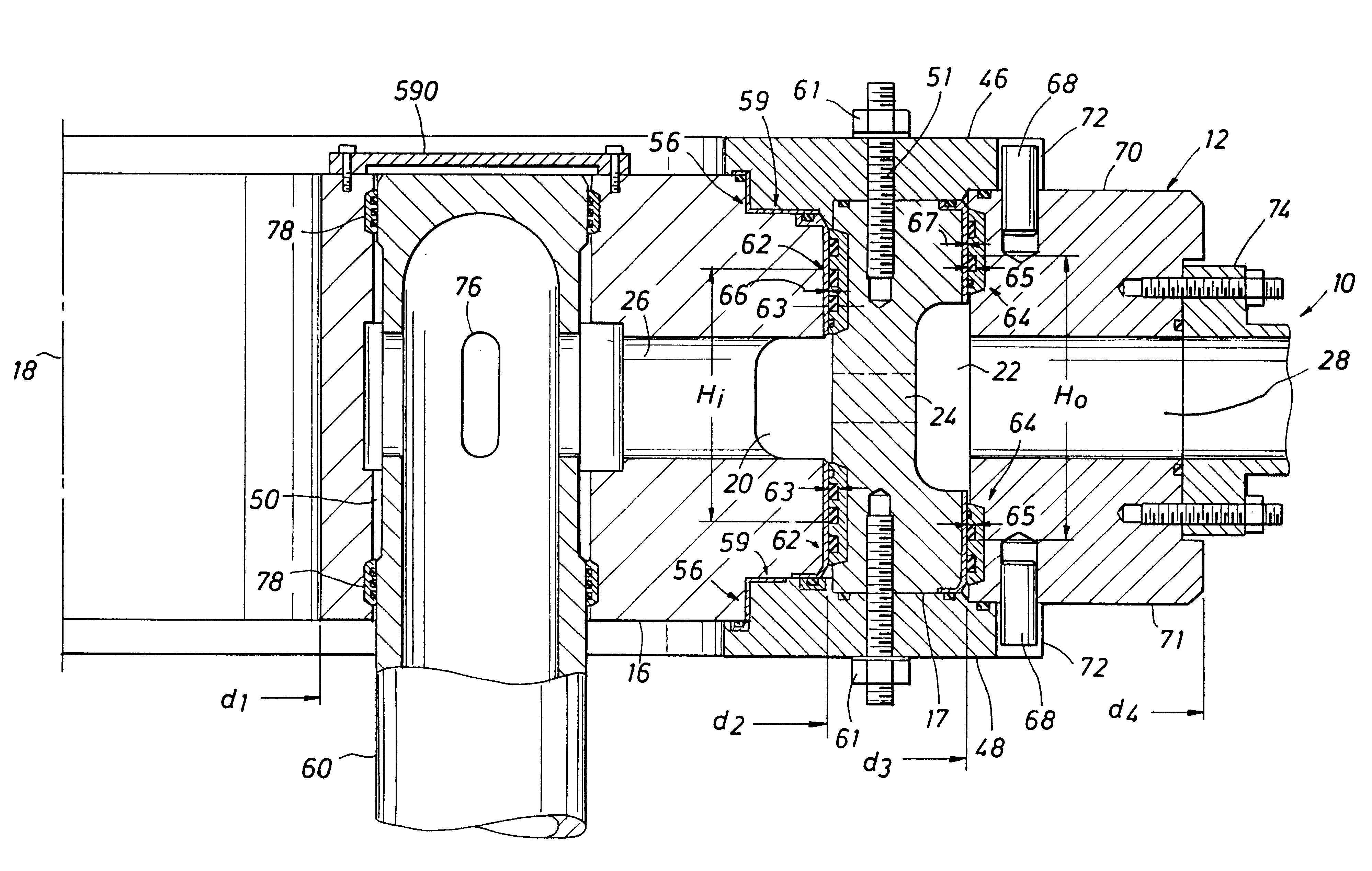

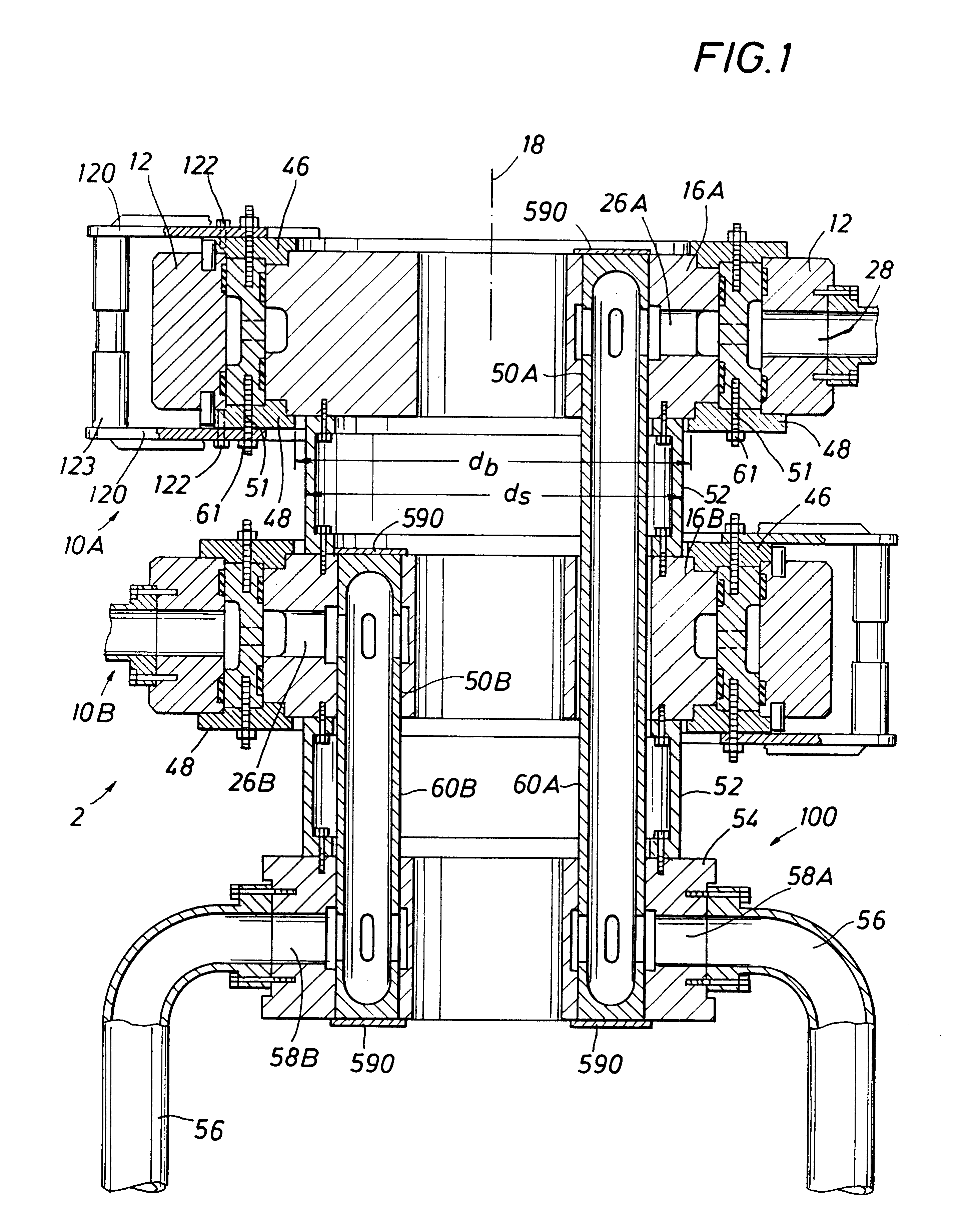

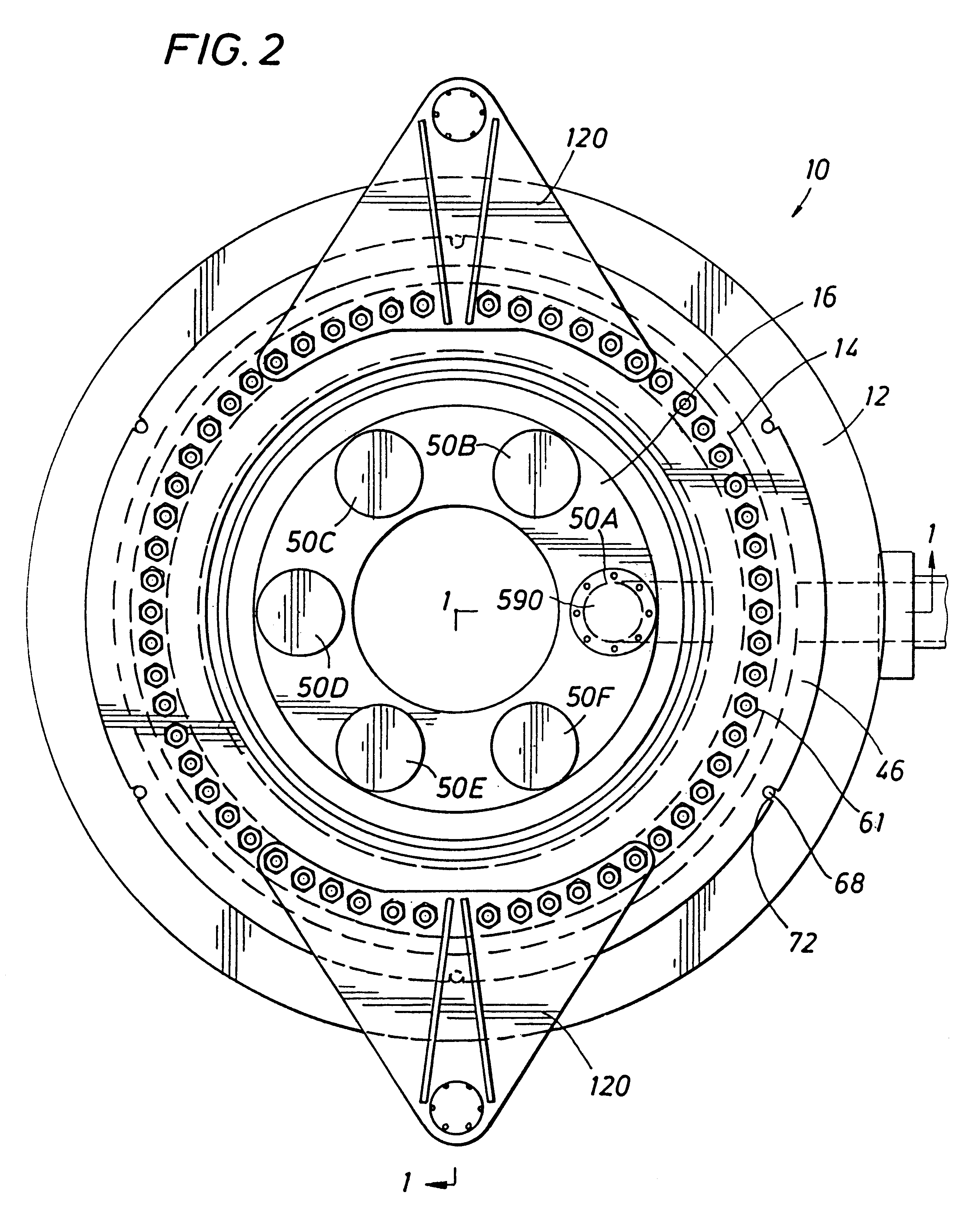

High pressure product swivel

InactiveUS6450546B1Big gapGap minimizationFluid pressure sealed jointsAdjustable jointsOverhead craneEngineering

A production swivel with passive control of dynamic seal gap width using internal swivel pressure. The swivel includes inner and outer housings with a middle housing which transfers, component deformation due to fluid pressure from the dynamic sealing interface to the static sealing interface. The outer housing and inner housing rotate together, but the outer housing is free to expand radially outward from the middle housing with increasing fluid pressure. A floating riser spool is pressure balanced at the connection to the inner housing and to a fixed swivel stack base. Swivels are stacked with a swivel connector / spool and upper and lower mounting rings cooperatively dimensioned so that access to seals can be obtained while the swivels remained stacked without the use of overhead cranes or other lifting points than the swivel being serviced.

Owner:SOFEC

Multi-component lifting assembly for a container

InactiveUS6338513B1Reduce in quantityThe method is simple and convenientClosuresLarge containersOverhead craneEngineering

A multi-component lifting assembly is provided for a container which carries cargo. The container includes a floor, opposite side walls extending upwardly from the floor, and a roof sheet attached to upper ends of the side walls. The lifting assembly is attached to the walls and to the roof sheet such that four-point lifting stability is provided when the container is lifted by an overhead crane. The lifting assembly includes a stacking header which spans the width of the container, an inner cap which is provided on an interior of the container, and an outer cap which is provided on the exterior of the container. The roof sheet is sandwiched between the outer cap and the stacking header. The side wall is sandwiched between the outer cap and the inner cap. Aligned apertures are provided through the outer cap, the roof sheet, the stacking header and the inner cap such that a bayonet can be inserted therein and the container can be lifted. Aligned apertures are provided through the outer cap, the side wall, and the inner cap such that a side lifting pin can be inserted therein and the container can be lifted.

Owner:WABASH NAT SERVICES +1

Erection method of stiffening girder of suspension bridge and device thereof

ActiveCN101446066AConstruction safetyLow costSuspension bridgeBridge erection/assemblyTraction systemOverhead crane

The invention discloses an erection method of a stiffening girder of a suspension bridge and a device thereof. The method comprises the following steps: 1) a track cable is erected below the position of a main cable of the suspension bridge; 2) a sling suspended on the main cable is taken as a middle suspension center of the track cable; 3) the middle suspension center is connected with the track cable by a saddle; 4) two ends of the track cable are arranged on anchorage systems at two banks; 5) a stiffening girder section is suspended by an overhead crane system supported on the track cable, and a traction system or a pushing system draws or pushes the overhead crane system to carry the stiffening girder section to a required position; and 6) the stiffening girder segment carried to the position is vertically lifted by a lifting device to be connected with the sling for achieving system transform. The method and the device have the obvious advantages of safe construction, cost saving, flexible and convenient operation, wide application range and the like, and help solve the problems of inconvenient transportation under a bridge in a mountainous area and hard stiffening girder erection of a super major suspension bridge in an area with extremely high vertical lifting height.

Owner:HUNAN ROAD & BRIDGE CONSTR GROUP

Bottom block assembly with pivoting trunnion paddles

ActiveUS20080085177A1Nuclear engineering problemsNuclear engineering solutionsHorizontal axisEngineering

A bottom block assembly for an overhead crane includes a main bottom block, an outer frame carried by the main bottom block and rotatable relative to the main bottom block about a vertical axis of rotation, and a pair of paddles carried by the outer frame and downwardly extending from the outer frame on opposed sides of the main bottom block. Upper ends of the paddles are pivotably secured to the outer frame about horizontal axes so that lower ends of the paddles pivot toward and away from each other. The paddles are pivotable between a closed position wherein each of the paddles is substantially vertical and an open position wherein the lower end of each of the paddles is outwardly pivoted away from a vertical central axis. Each of the paddles has a keyhole-shaped closed-section opening near its lower end.

Owner:MHE TECH

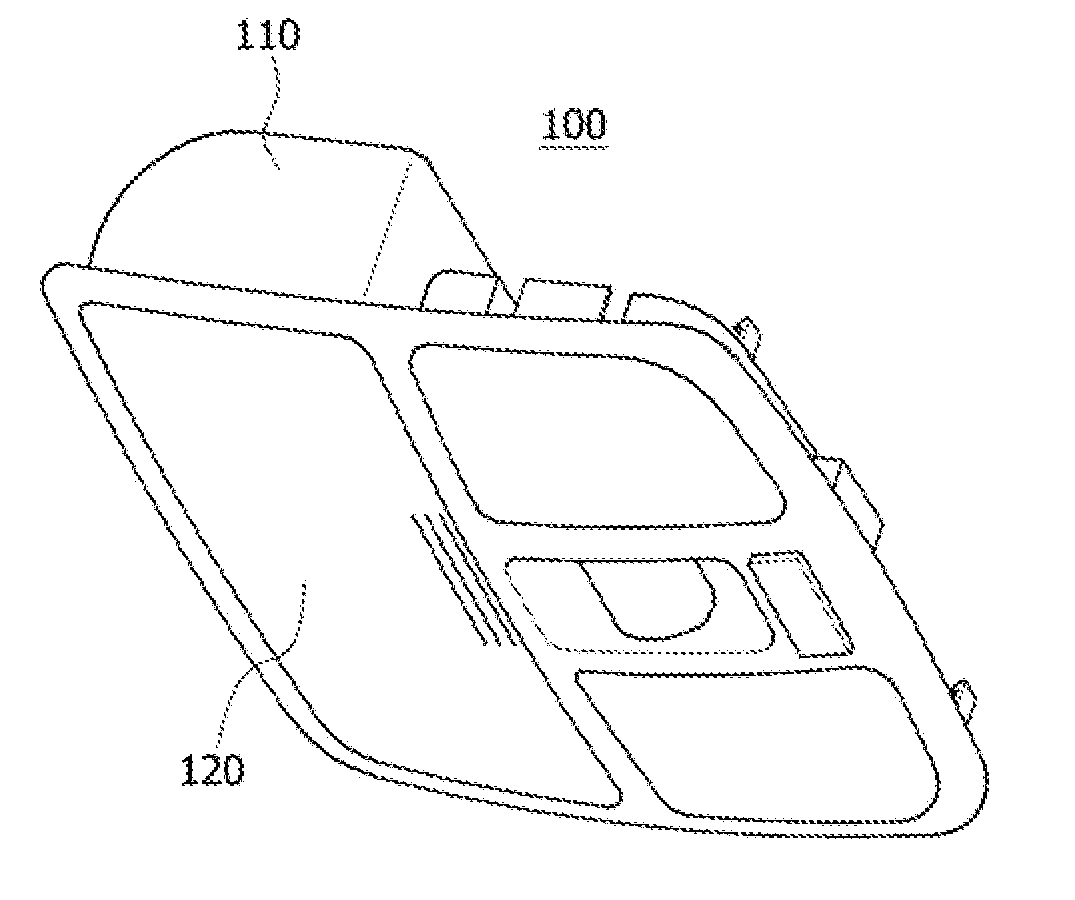

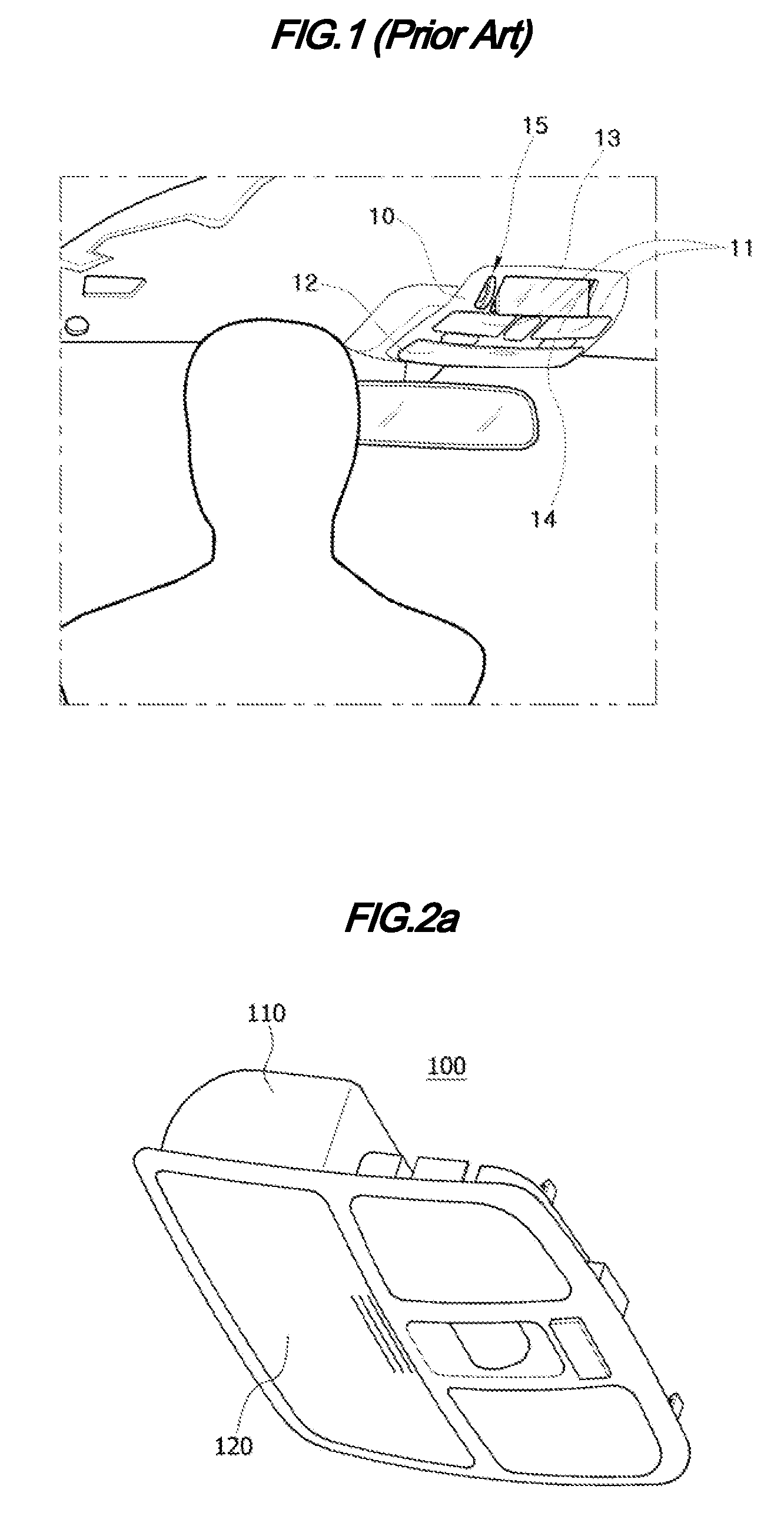

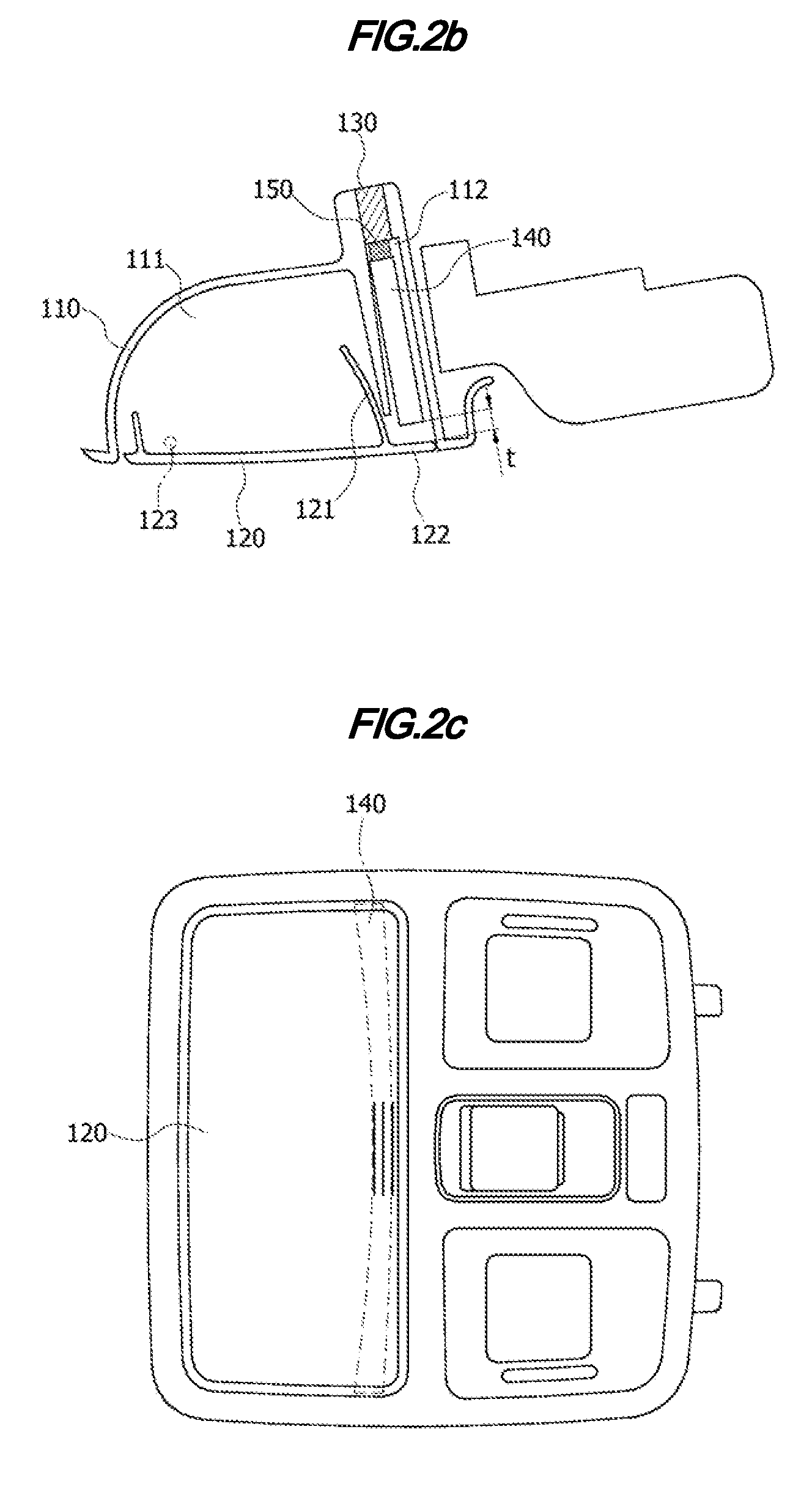

Overhead console

ActiveUS20100301625A1Easy to applyBeautiful appearancePassenger spaceMirrorsOverhead craneMechanical engineering

Owner:HYUNDAI MOTOR CO LTD

Compound-arm manipulator

ActiveUS8317453B2Large range of motionReduced footprintProgramme-controlled manipulatorJointsTransport systemRange of motion

In a first aspect, the invention is directed to a manipulator that is relatively compact and has a relatively large range of motion. The manipulator includes a linkage that folds back on itself, which reduces the footprint of the linkage. In a particular embodiment, the manipulator includes a linkage and a load balancing device. The linkage includes a first link, a second link, a third link and a fourth link. The first link and second links are rotatably connected to a base about first and second connection axes. The third and fourth links are connected to the first and second links respectively about third and fourth connection axes respectively. The third and fourth links are rotatably connected to a lift arm about fifth and sixth connection axes respectively, wherein the fifth and sixth connection axes are horizontally displaced from the third and fourth connection axes in the direction of the first and second connection axes. The load balancing device is configured to support the linkage in a selected position against a load and configured to permit the load to be moved upwards or downwards with a selected amount of force on the lift arm. The manipulator may be provided as part of a load maneuvering system that further includes a transport system that may be similar to that used on an overhead crane.

Owner:GIVENS RAY

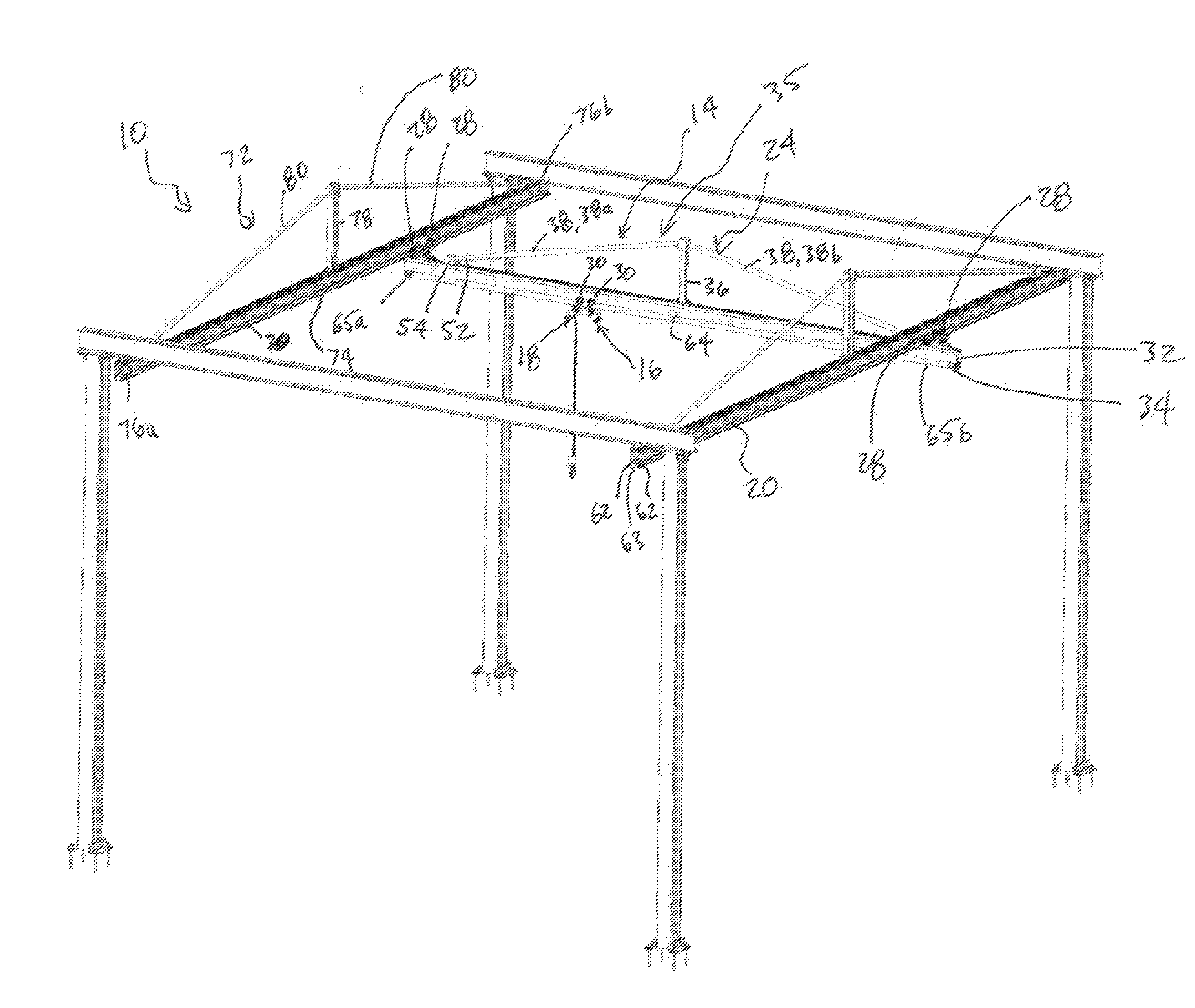

Slant-truss crane rail

ActiveUS20110180507A1Reduce the total massPromote sportsBase supporting structuresBraking devices for hoisting equipmentsMomentumDrive motor

In one aspect, the invention is directed to an overhead crane with one or more bridge rails, that incorporates a reinforcement truss into its one or more bridge rails so as to reduce the overall mass of the one or more bridge rails. This facilitates movement of a load carried by the bridge by an operator to a destination point, particularly in embodiments wherein the one or more bridge rails do not have any bridge drive motors thereon. Reducing the mass of the bridge can increase the amount of lifted load that can comfortably be maneuvered by an operator, particularly when the bridge is manually moved along the runway. Additionally, reducing the mass of the bridge reduces the momentum associated with the bridge, which can increase the amount of control that the operator has when it is desired to stop the bridge when the load has been maneuvered to its desired destination point. The second reinforcement members may have first and second ends that are inserted into receiving apertures in the first reinforcement member and in a bracket that mounts to the bridge rail respectively. In embodiments wherein the bridge includes two rails and is capable of supporting a load in such a way as to generate a downward force that is offset from the bridge axis, the second reinforcement members may be connected to the first reinforcement member and to brackets in such a way as to prevent the withdrawal of the second reinforcement members from the receiving apertures.

Owner:GIVENS RAY

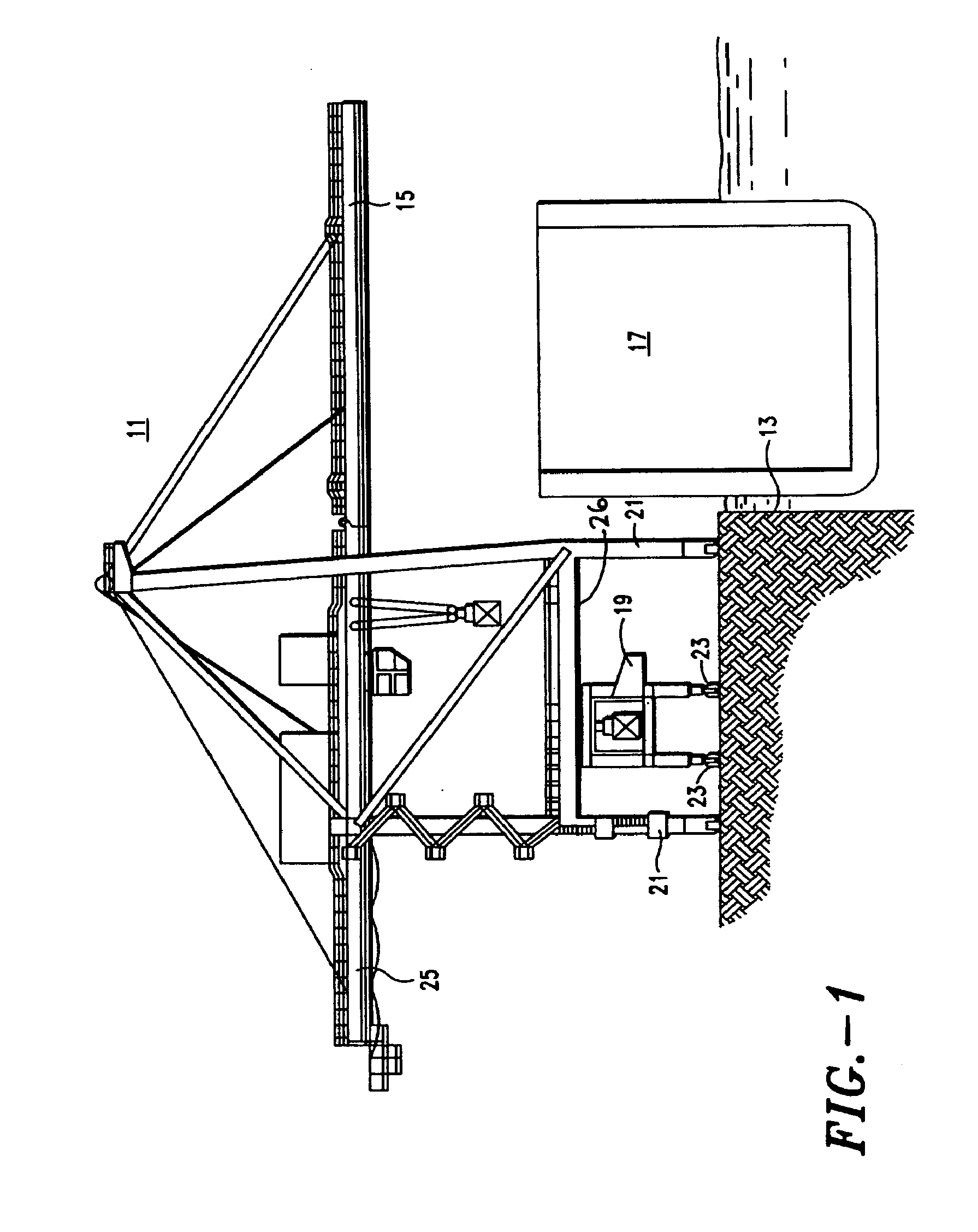

Mobile cargo container scanning crane

InactiveUS20050036854A1Maintain port efficiencyCargo handling apparatusBase supporting structuresEngineeringOverhead crane

A mobile cargo container handling buffer crane having a bridge crane mounted thereon for transferring cargo containers between a ship and land transportation with an intermediate transfer position at which a suspended container can be noninvasively inspected by a longitudinally reciprocating container traversing nonintrusive inspection apparatus.

Owner:PACECO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com