Garbage grab bucket crane and anti-swinging control method

An anti-sway and crane technology, applied in the field of anti-sway, to achieve the effect of stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

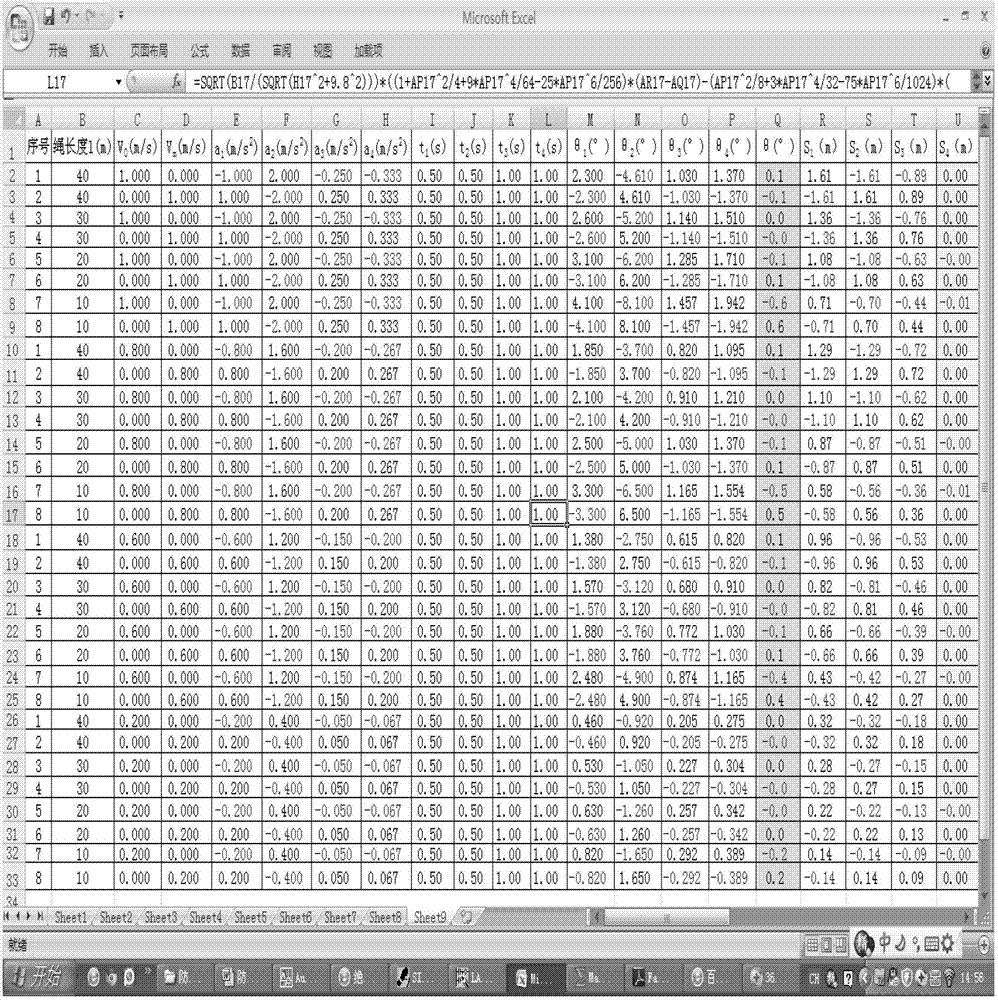

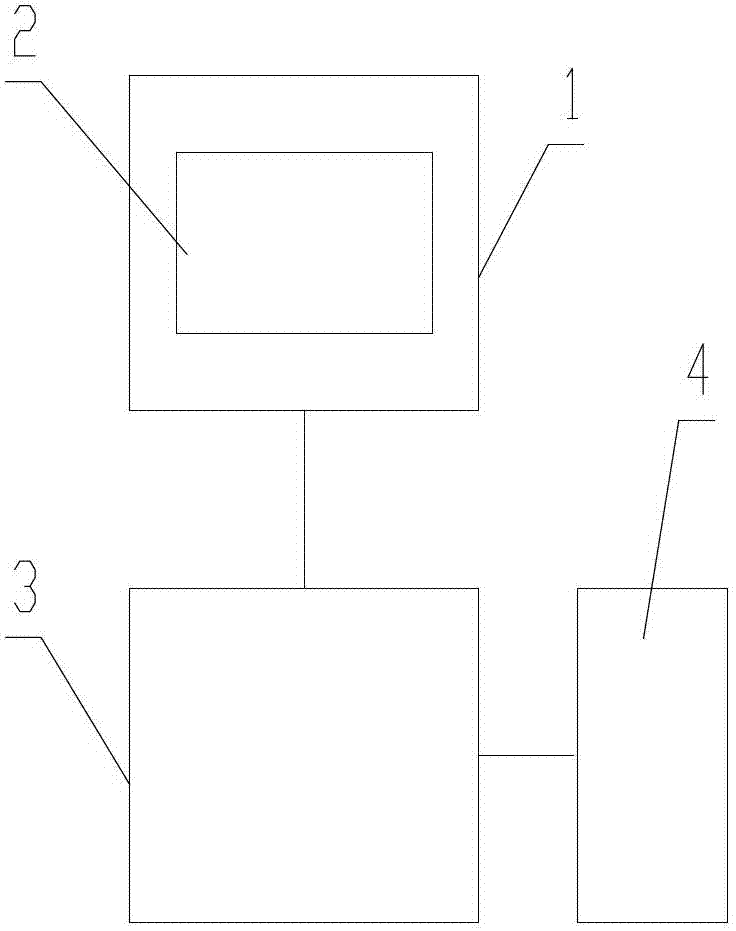

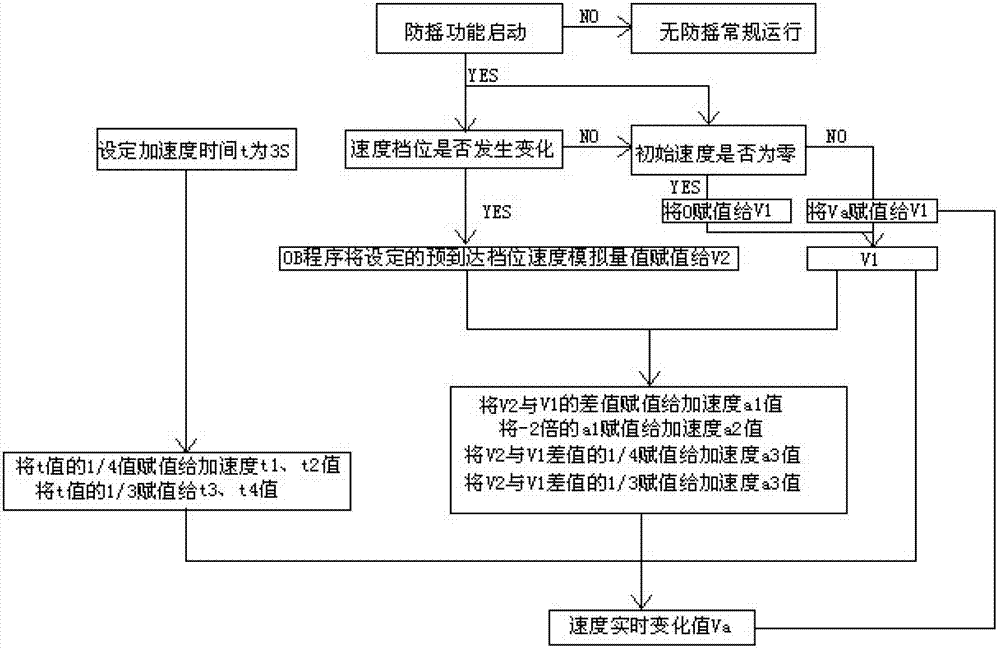

[0018] Among them, such as figure 1 As shown, the anti-swing structure of the garbage grab crane includes a PLC1, a frequency converter 3 and a motor 4. The PLC has a built-in anti-swing function module 2, and the PLC input port of the anti-sway function module inputs the speed analog value of each gear of the crane. value, the PLC output interface of the anti-swing function module is connected to the frequency converter, the frequency converter is connected to the motor and the parameter "acceleration" on the frequency converter is set to "0", and the anti-sway function module performs calculation on the input speed analog value Finally, the data is transmitted to the frequency converter, and the frequency converter sets the speed of the motor according to the data input from the anti-swing function module to control the motor to work. The PLC output interface of the anti-swing function module is connected to the frequency converter with a shielded wire, or a wireless communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com