Automatic welding machine for annular seam in specially shaped tank

An automatic welding machine and tank body technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of low production efficiency, large differences, and large differences in the appearance of welds, and achieve automatic and efficient welding. effect, quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

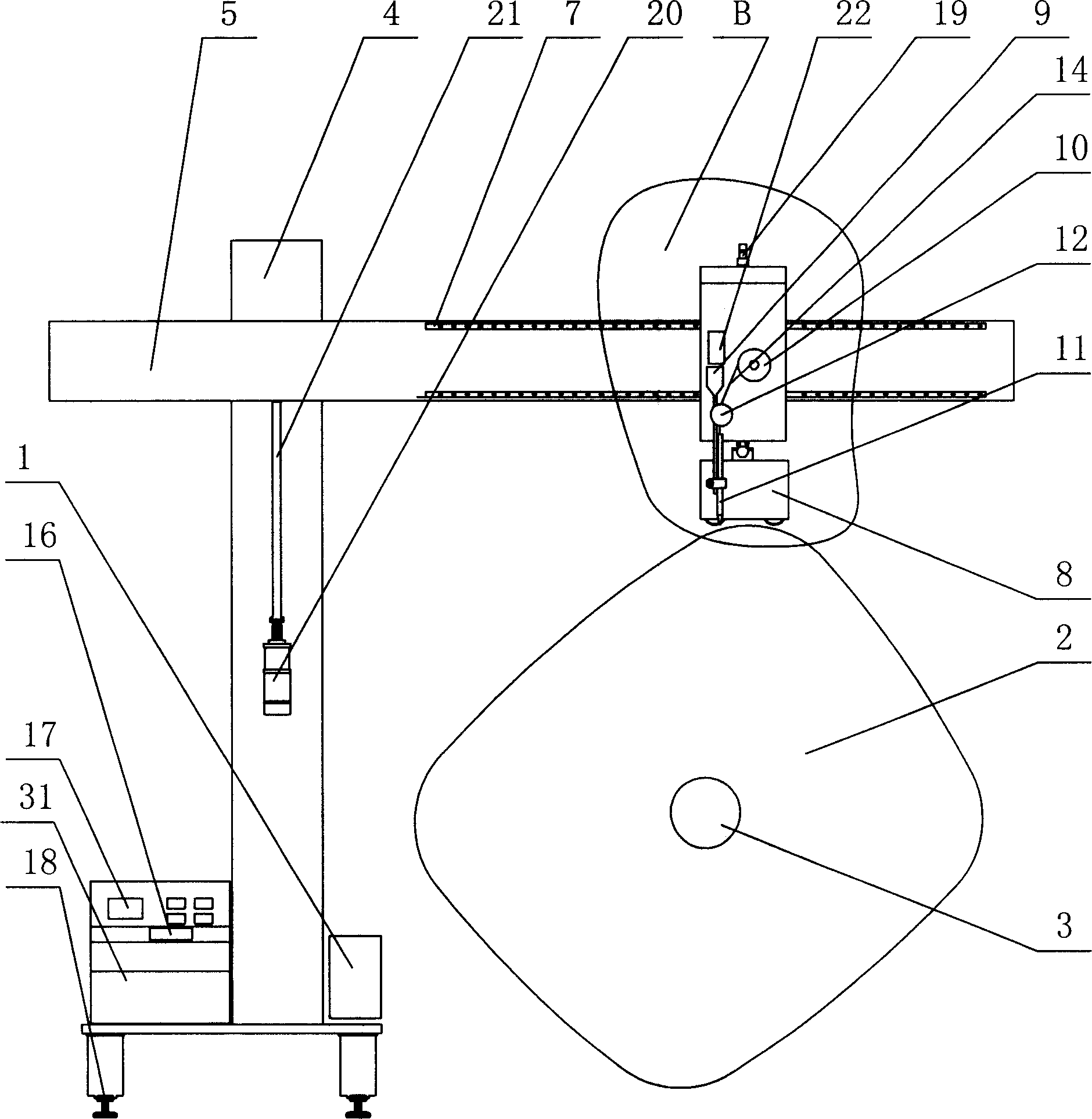

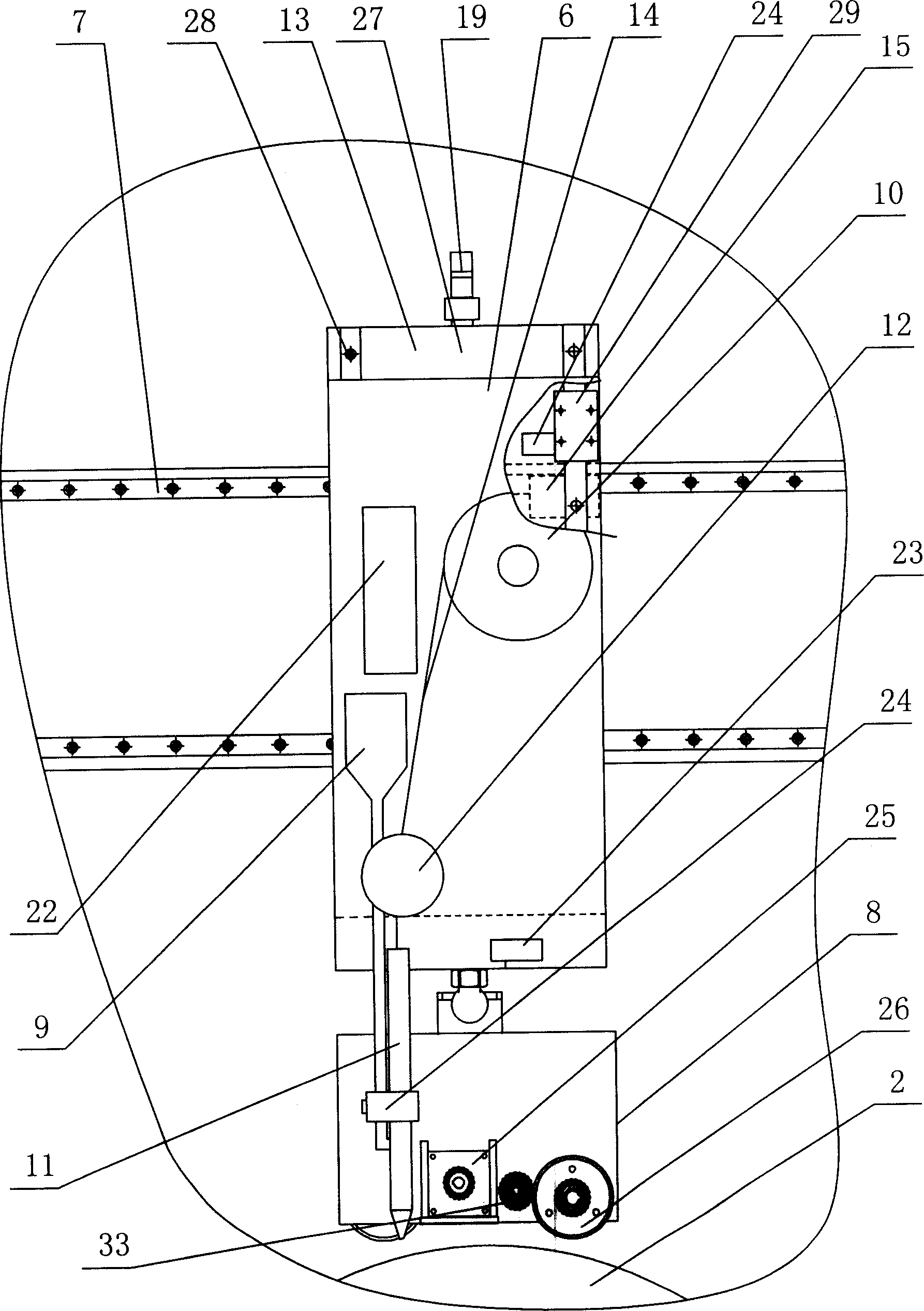

[0013] Embodiment one: the present invention comprises welding machine 1, special-shaped tank body 2, and rotating device 3 is installed on tank body 2, and a driving track 18 is arranged on one side of tank body 2, and support 4 is arranged on driving track 18, A crossbeam 5 is installed on the support 4, and it is characterized in that: a transverse guide rail 7 is fixedly installed on the crossbeam 5, and a transverse slide plate 13 is installed on the guide rail 7, and a slide block 15 is installed on one side of the slide plate 13, the slide plate 13 On the other side, a longitudinal guide rail 28 is fixedly installed, and a longitudinal slide plate 6 with a longitudinal slide block 29 is installed on the longitudinal guide rail 28. On the longitudinal slide plate 6, a welding wire reel 10, a welding wire conveying device 12 and a welding wire conveying device 12 for winding welding wire 14 are fixedly connected. The bucket 9 is fixedly connected with a trolley 8 at the bo...

Embodiment 2

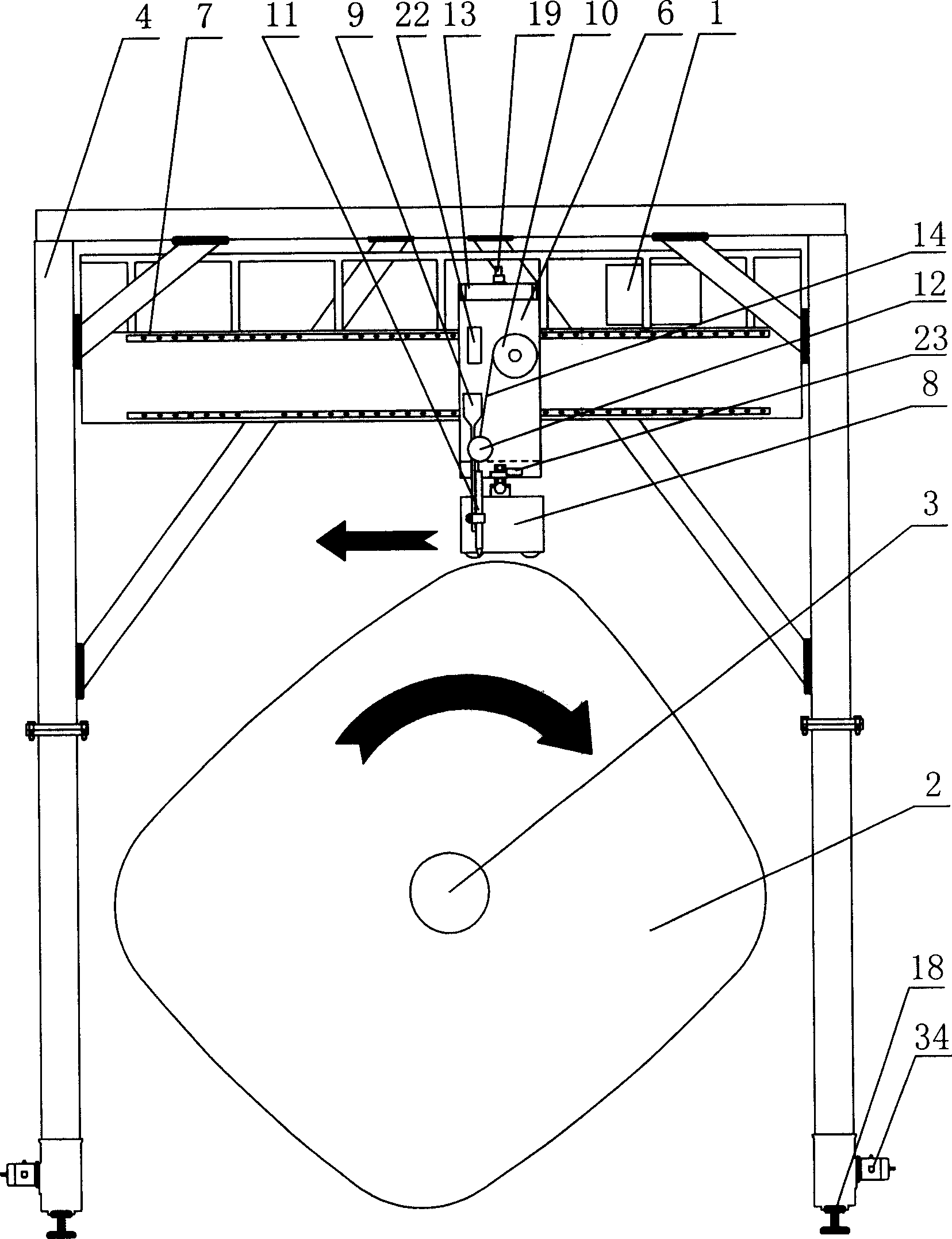

[0015] Embodiment two: if image 3 , Figure 4 As shown, the difference from Embodiment 1 mainly includes the following points: the form of the support 4 is changed from a single operation frame type on one side of the tank body 2 to a gantry type across both sides of the tank body 2, and on the brackets 4 on both sides, respectively A driving motor 34 is provided to realize that the support 4 automatically walks along the track 18 . The single beam 5 in the first embodiment is changed to a welding platform 30, and the welding machine 1 is installed on the welding platform 30; the platform lifting motor 20 is changed from one to two on both sides. Other structures are the same as in Embodiment 1.

[0016] Compared with Embodiment 1, although the cost of this method is higher, it can greatly increase the stability and automaticity of the whole system, further ensuring the efficiency and quality of welding.

[0017] The welding form can adopt submerged arc welding or MIG / MAG ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com