The method of installing the bridge crane by the beam hanging method and the use of this method

A bridge crane and hoisting technology, which is applied in the direction of walking bridge cranes, cranes, transportation and packaging, etc., can solve the problems of increasing the number of hoisting and high-altitude work time, dispatching a large amount of investment in equipment roofing, and affecting the progress of plant structure installation. , to achieve the effect of reducing the risk of high-altitude operation, reducing the risk of high-altitude operation, and reducing the risk of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

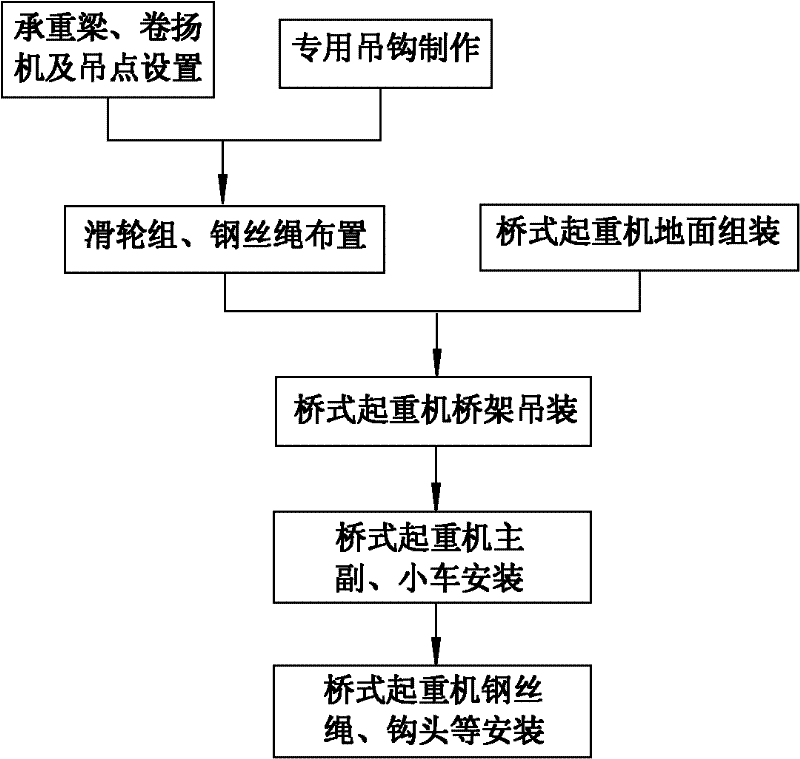

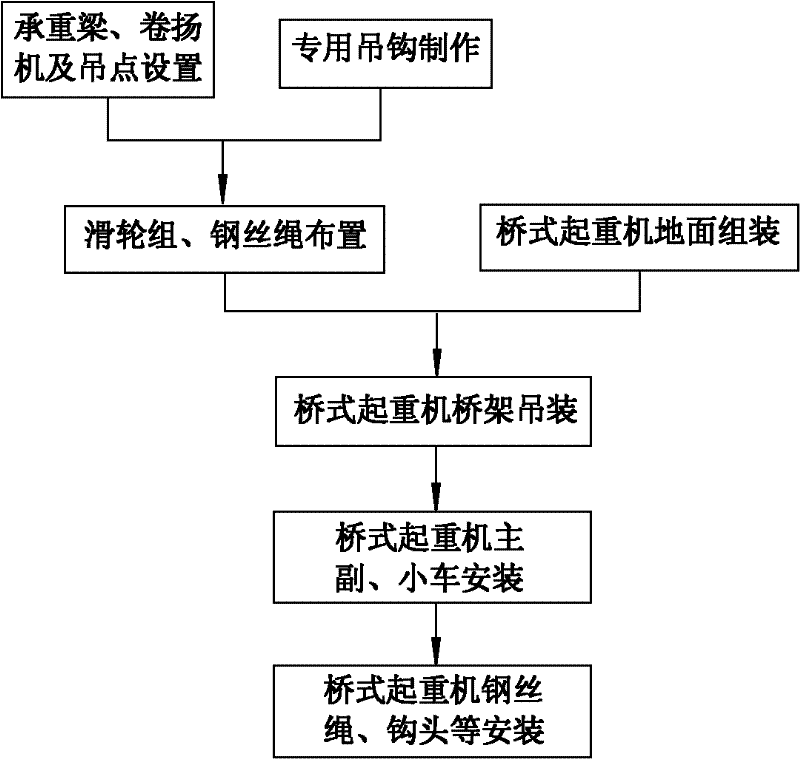

[0048] as attached figure 1 As shown, the beam crane method provided by the present invention is a method for installing a bridge crane, which is a method for setting a load-bearing beam and utilizing a winch to install a bridge crane. The steps include lifting the load-bearing beam, winches, and setting of lifting points; Production; arrangement of pulley blocks and wire ropes; ground assembly of bridge cranes; hoisting of bridge crane bridges; hoisting of main and auxiliary trolleys of bridge cranes; installation of wire ropes and hooks of bridge cranes. Specifically, follow the steps below:

[0049] Step 1. Setting of load-bearing beam, winch and lifting point:

[0050] (1) The load-bearing beams for hoisting use roof beams. If the factory roof is designed in the form of trusses, before installing the roof, select a truss connected to the factory building columns to be changed to a load-bearing beam design. The load-bearing beam meets the requirements of 120t lifting cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com