Patents

Literature

38results about How to "Reduce the risk of hoisting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

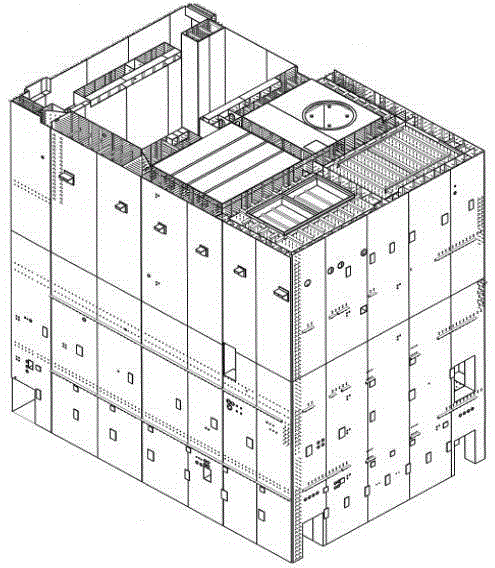

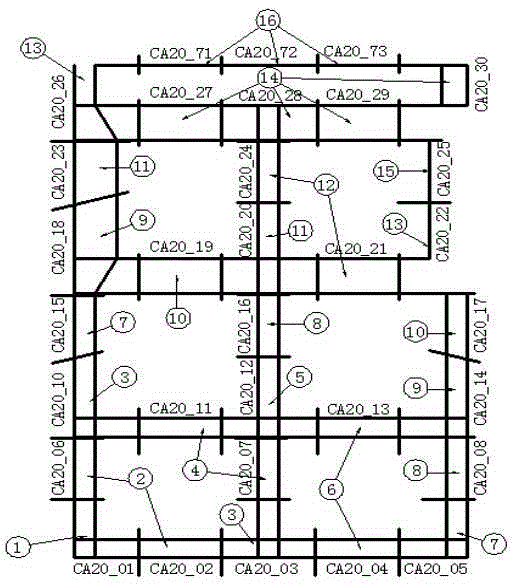

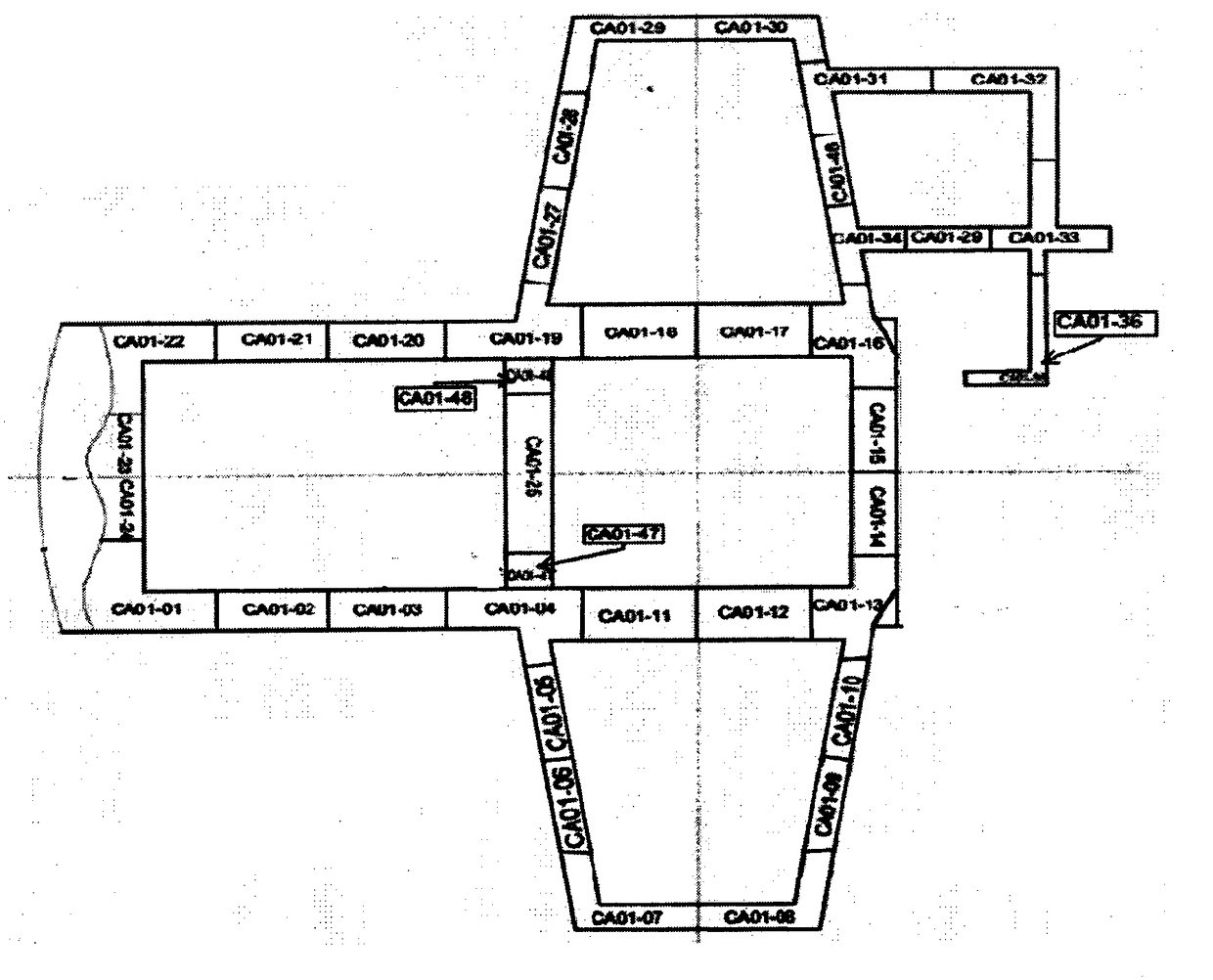

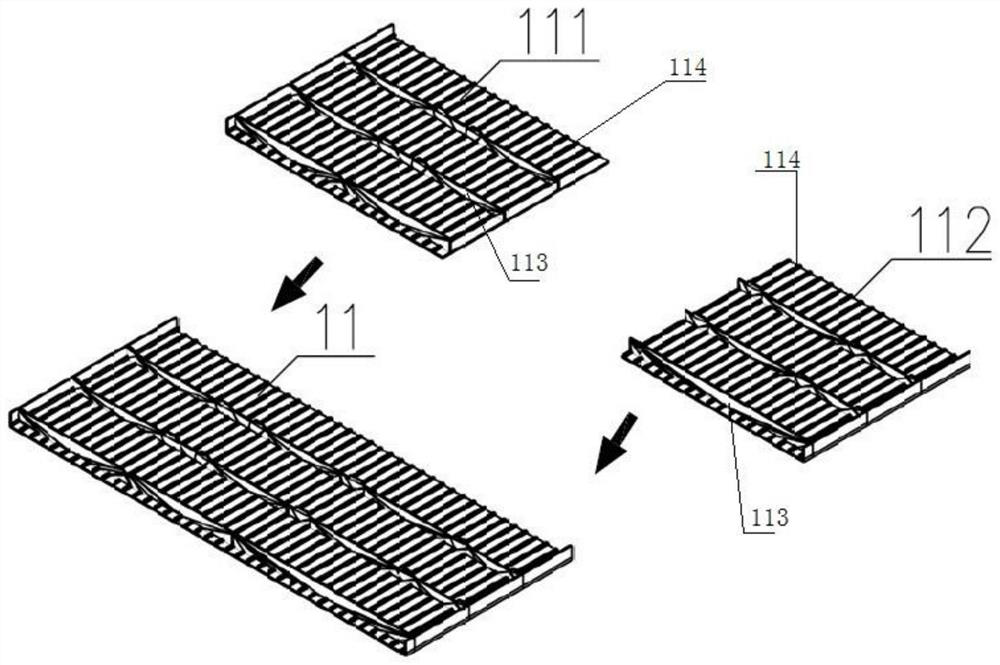

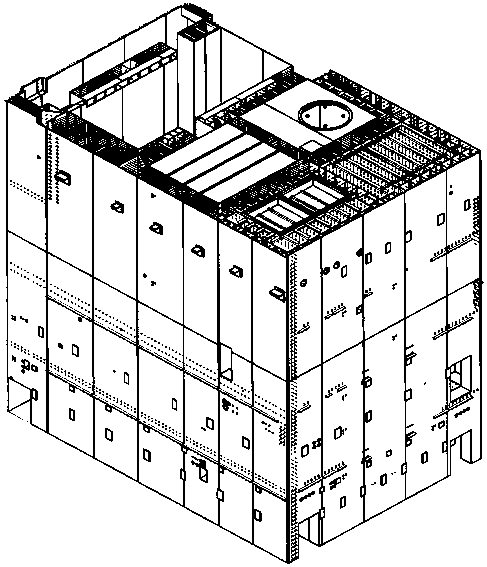

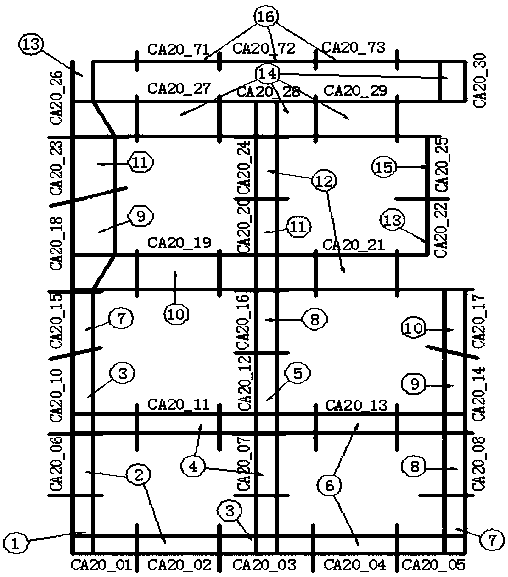

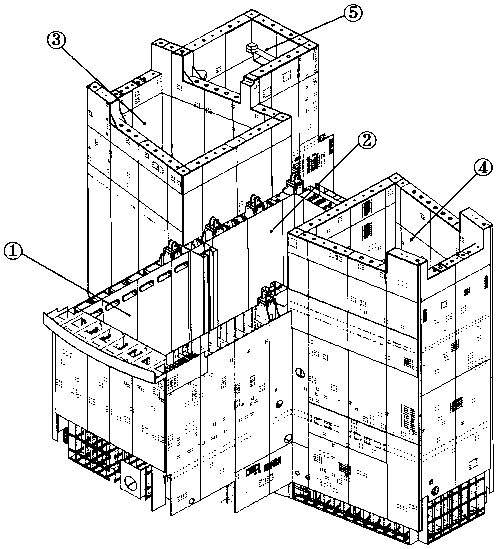

Assembling method of large steel structure module of nuclear power plant

ActiveCN105401732AGuaranteed accuracyLarge pair gapBuilding material handlingTotal stationEngineering

The invention discloses an assembling method of a large steel structure module of a nuclear power plant. The large steel structure module is divided into a plurality of module assembles according to areas. Each module assembly comprises a plurality of sub-modules. A coordinate system is established through the module assemblies, the point DP of one sub-module serves as the origin of coordinates, relative coordinates of the points DP of the rest of the sub-modules are obtained through conversion according to the design paper, the sub-modules are assembled according to the design paper, and three-dimensional coordinate monitoring is carried out on the points DP of the sub-modules through a total station in the assembling process so as to ensure the precision in the splicing process. The assembling method has the beneficial effects that procedures are simple, the splicing size can be controlled integrally, three-dimensional coordinate monitoring of the points DP is carried out through the total station, it is ensured that the points DP of the wall sub-modules are located on the same horizontal datum plane, and therefore the precision required by design is achieved.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

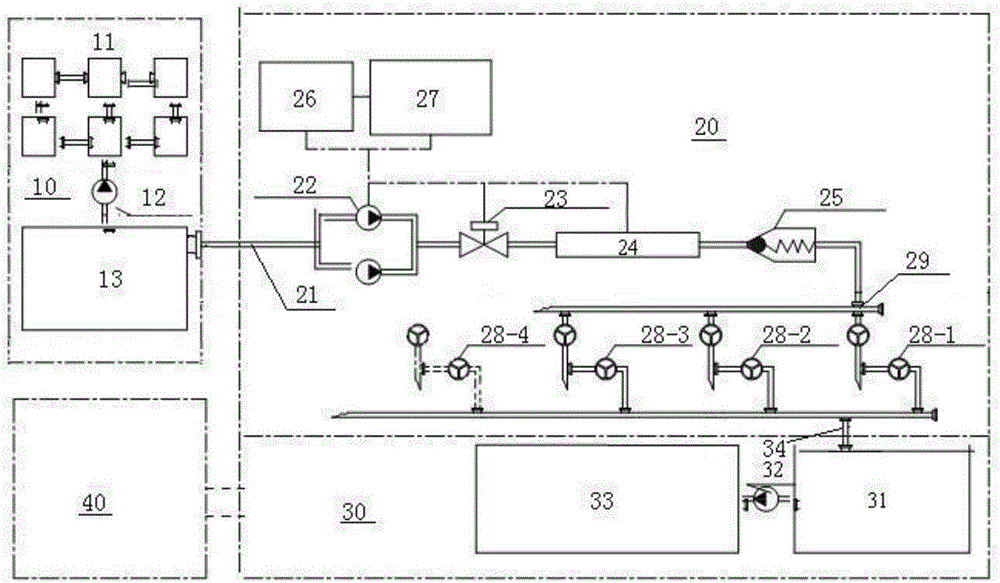

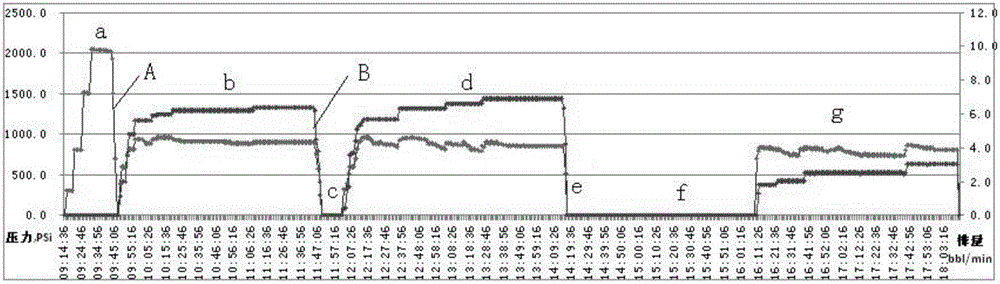

Industrial acidification system and method for offshore oil fields and oil-water wells

InactiveCN106050189AShorten working timeReduce the cost of relocation and the risk of relocation and hoistingCleaning apparatusWellheadChemistry

The invention discloses an industrial acidification system and method for offshore oil fields and oil-water wells. The industrial acidification system comprises an acid liquid preparation unit, an acidizing treatment unit and a residual liquid recycling unit which are adjacent to one another. The acid liquid preparation unit is connected with a wellhead of one oil-water well or wellheads of the multiple oil-water wells in the acidizing treatment unit through an acid injection pipeline. An acid injection adjusting subunit, a control subunit and a data analyzing subunit are arranged on the acid injection pipeline. Producing wells of the one or more oil-water wells are connected with the residual liquid recycling unit through a liquid return pipe. Flowback residual liquid is neutralized in the residual liquid recycling unit and returned. The industrial acidification method comprises the following steps that the industrial acidification system for the offshore oil fields and the oil-water wells is obtained by utilizing and connecting an offshore oil field production platform and anchoring arrangement; acidizing treatment preparation is conducted; industrial acidizing treatment is conducted on the oil-water wells through the industrial acidification system for the offshore oil fields and the oil-water wells; and acidification aftertreatment is conducted according to the types of the oil-water wells.

Owner:CHINA NAT OFFSHORE OIL CORP +2

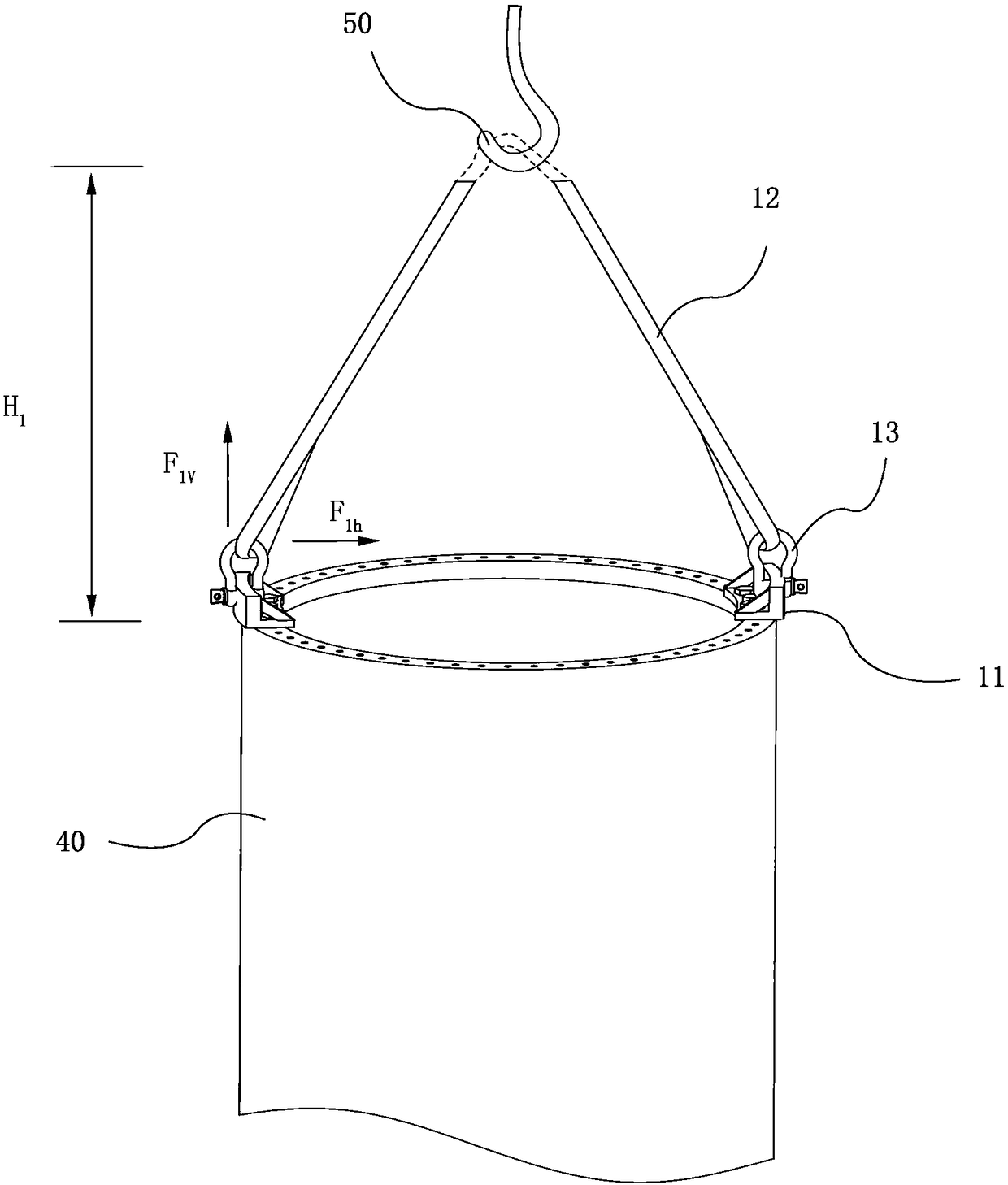

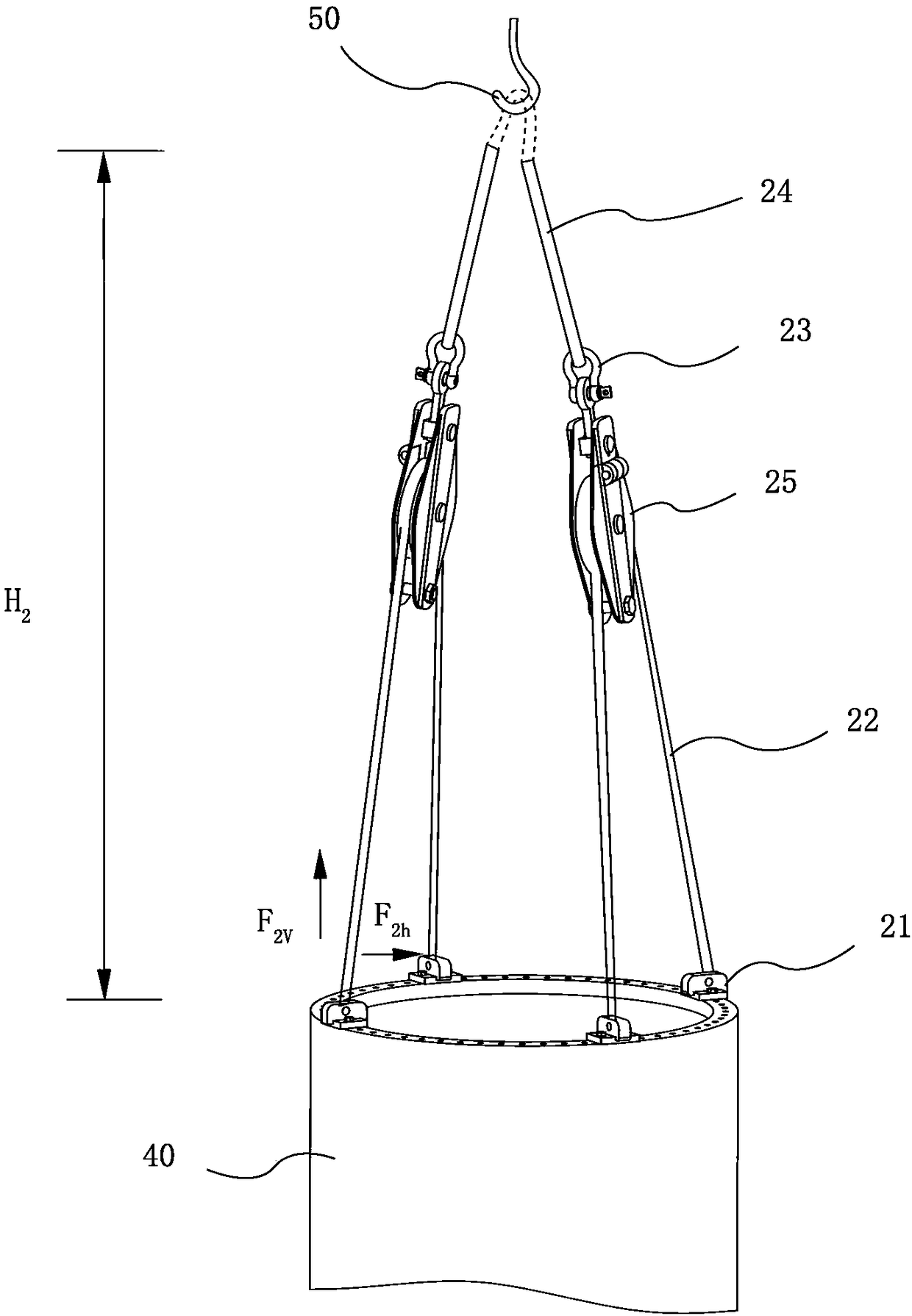

Lifting appliance

ActiveCN108358037AAffect assemblyReduce lifting heightLoad-engaging elementsTowerIndustrial engineering

The invention provides a lifting appliance. The lifting appliance comprises a lifting beam, lifting lugs, lifting rings and lifting belts, wherein the at least two lifting lugs are detachably installed on the lifting beam to connect a piece to be lifted; the lifting rings rotationally sleeve the lifting beam and are arranged in the accommodating spaces of the lifting lugs, and the lifting lugs canbe abutted against the lifting rings and prevent the lifting rings from moving in the length direction of the lifting beam; and the lifting belts are connected to the lifting rings. According to thelifting appliance provided by the invention, through the arrangement for the lifting beam, the flange of a tower barrel can be prevented from being deformed due to the effect of a radial component force in a lifting process to influence assembly for the tower barrel.

Owner:URUMQI GOLDWIND TIANYI WIND POWER CO LTD

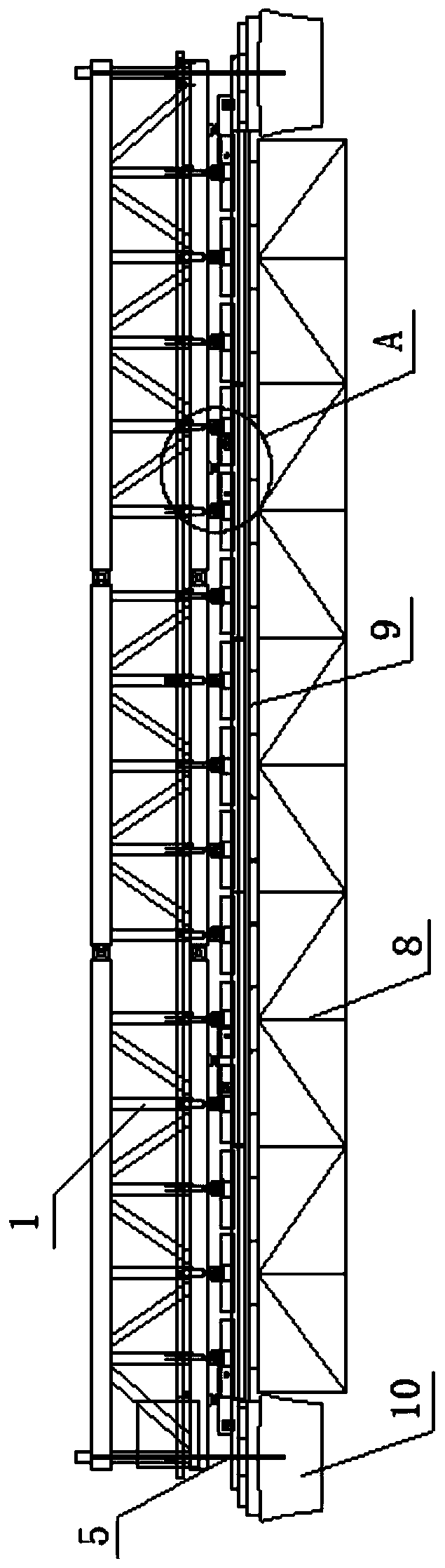

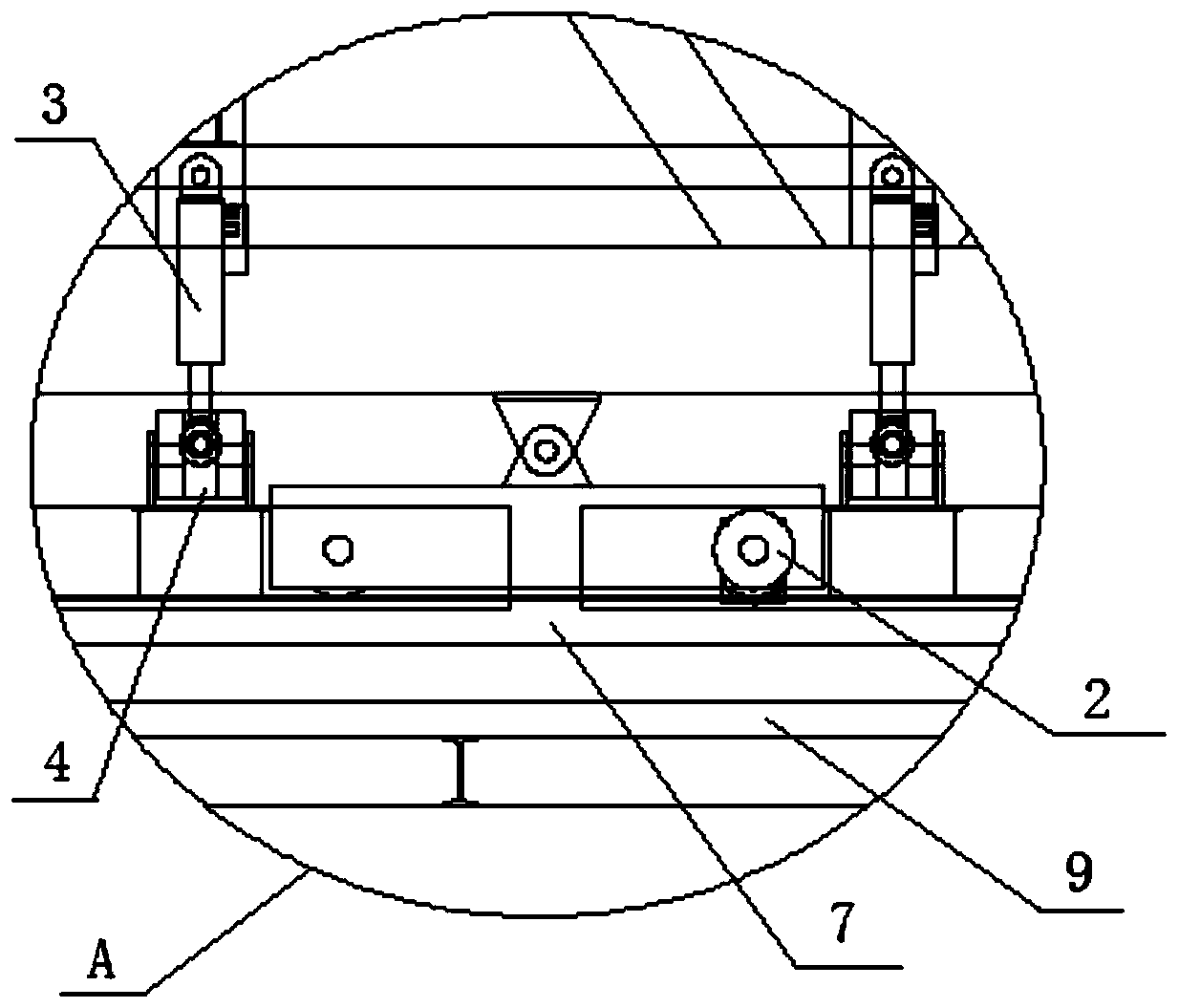

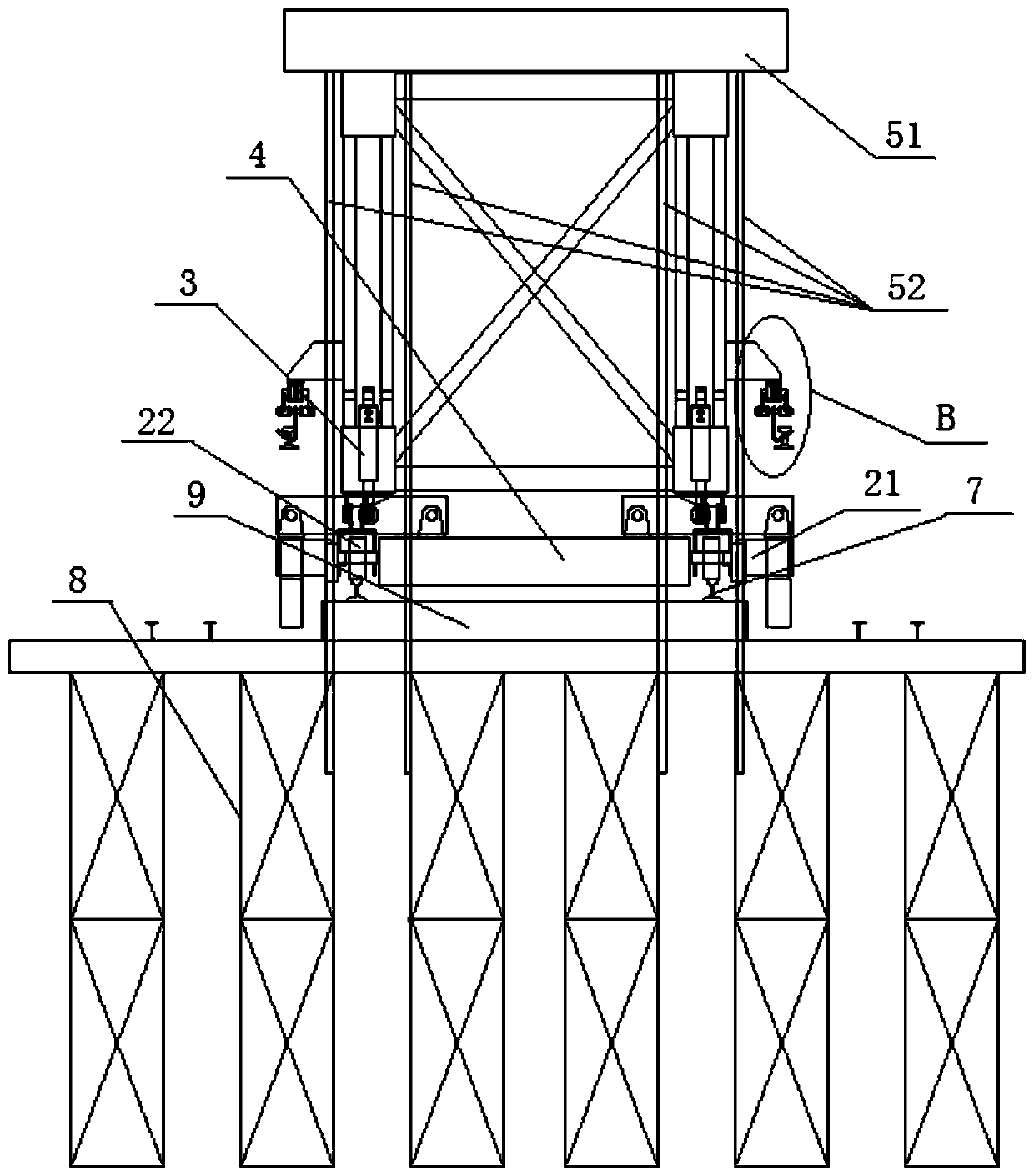

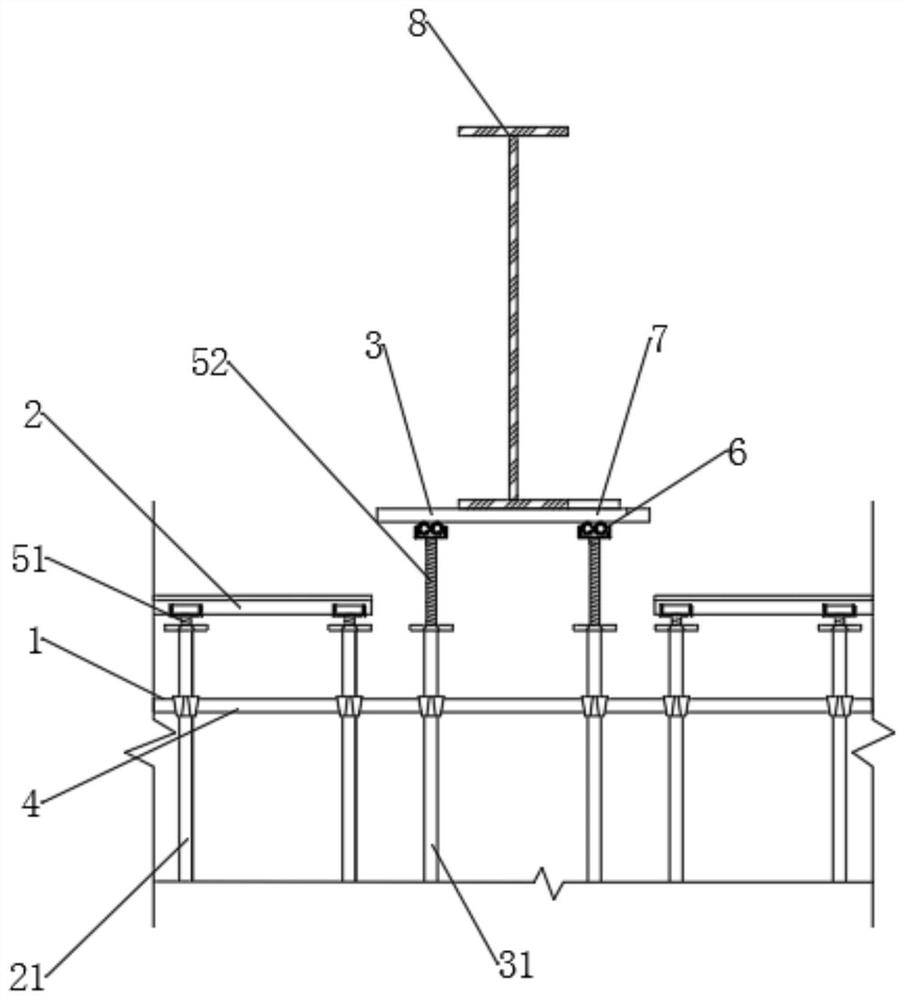

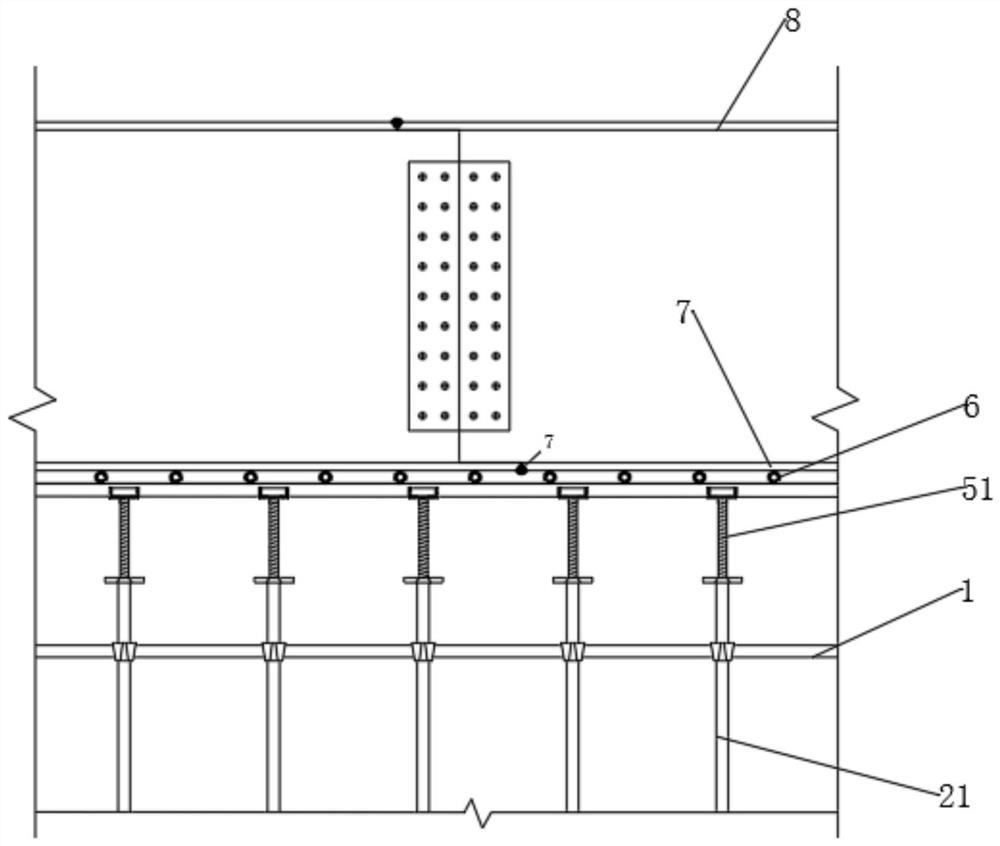

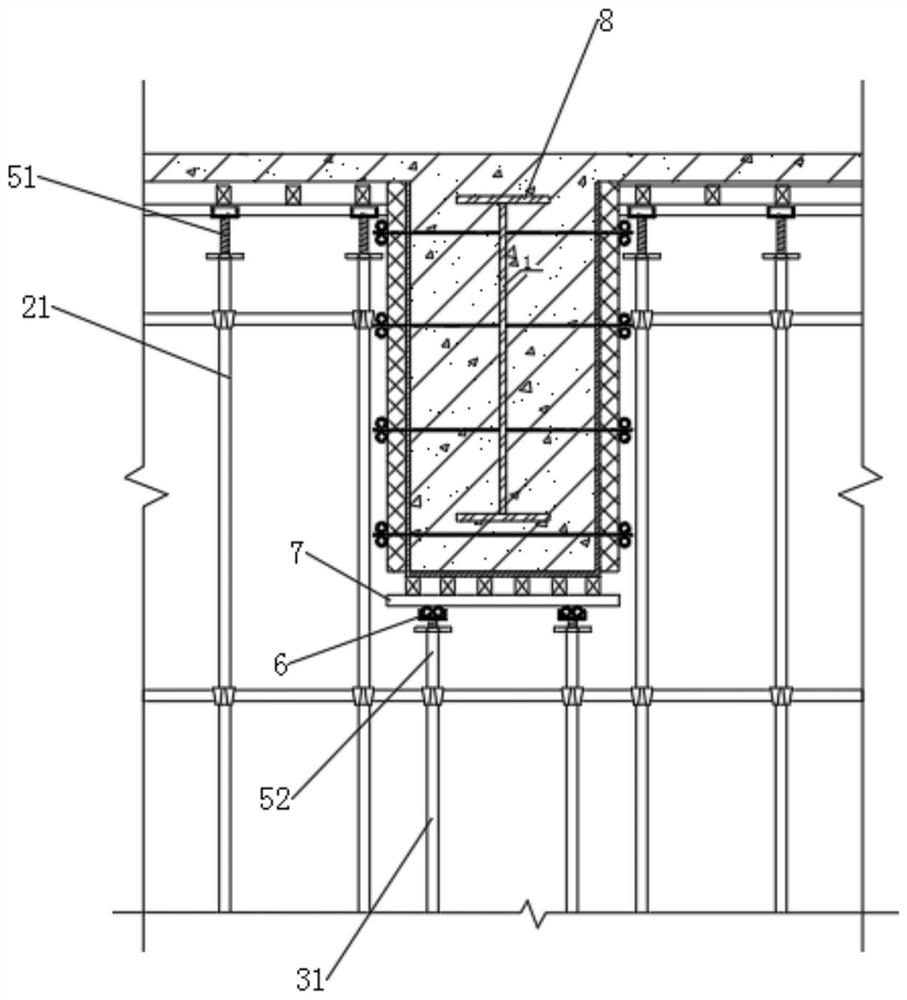

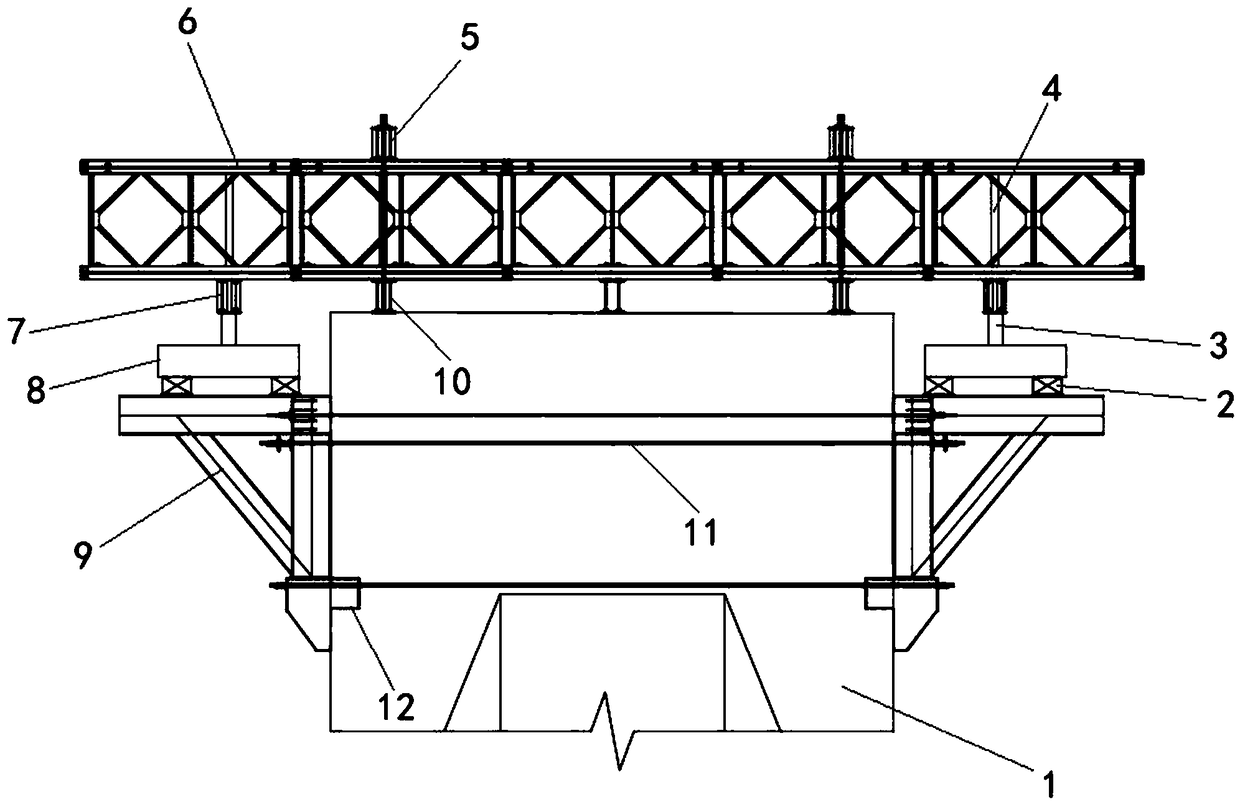

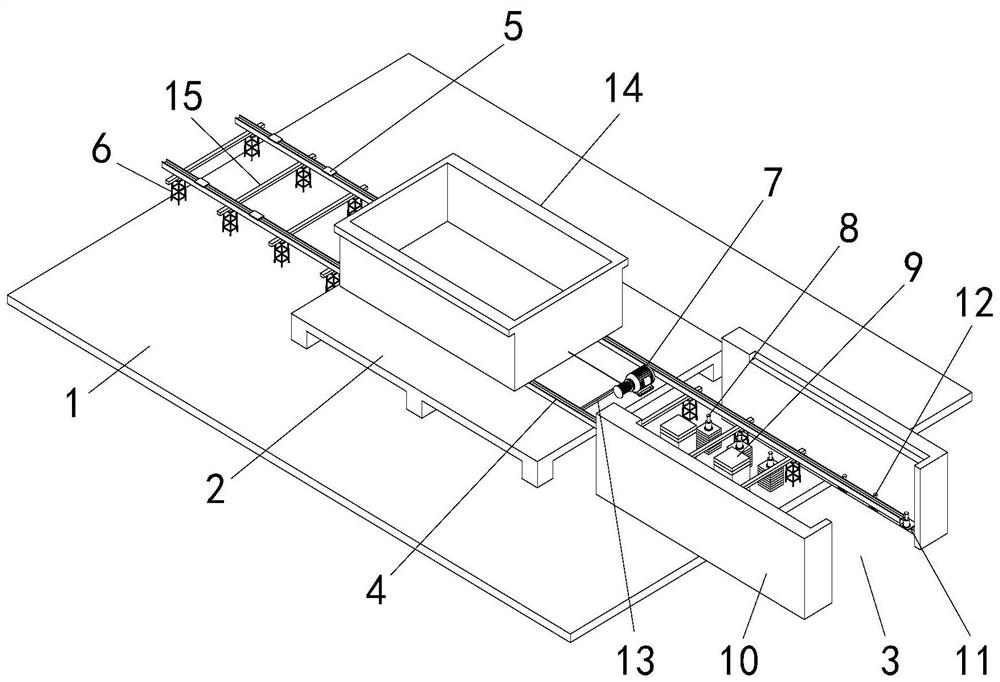

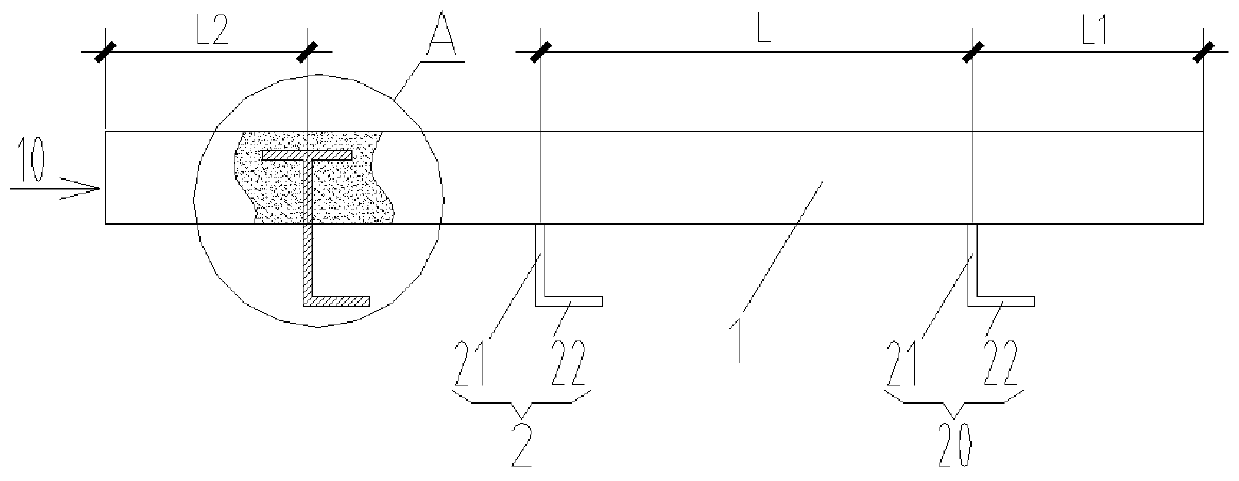

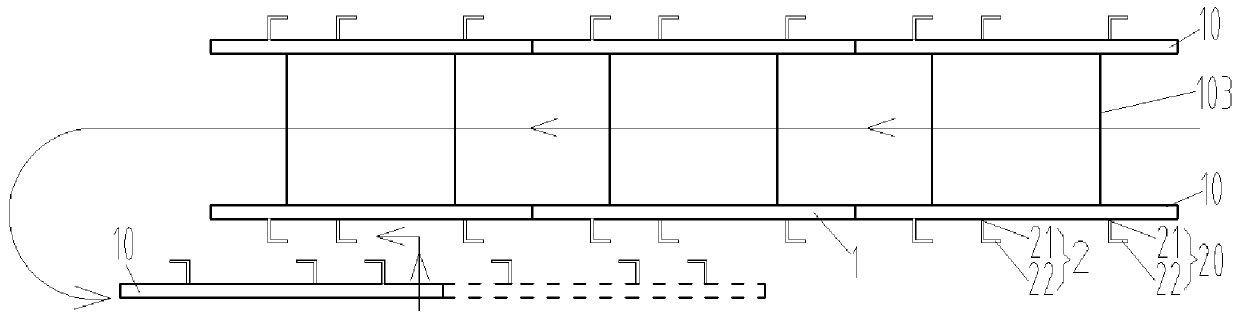

Self-walking prepressing device suitable for cast-in-place beam supports and prepressing method of self-walking prepressing device

PendingCN110714412AEasy to transportRealize graded preloadBridge erection/assemblyApparatus for force/torque/work measurementControl systemControl engineering

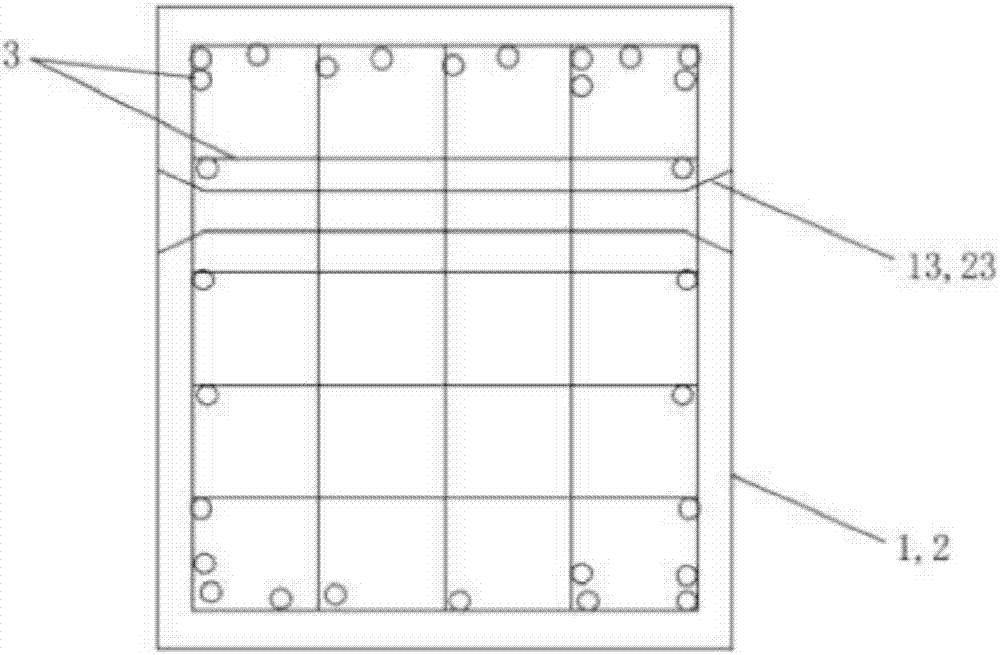

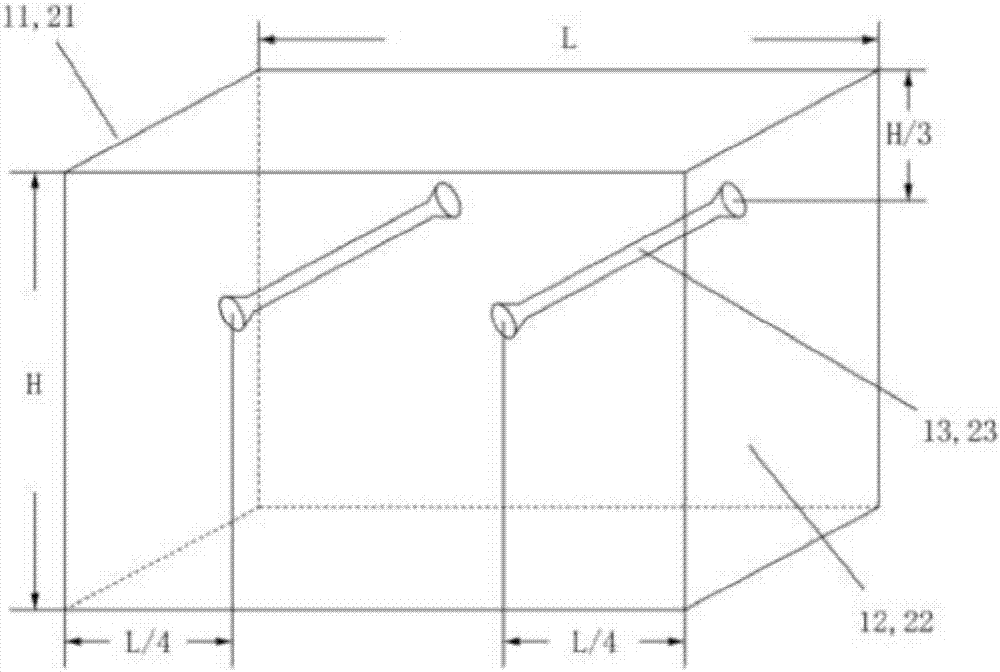

The invention discloses a self-walking prepressing device suitable for cast-in-place beam supports and a prepressing method of the self-walking prepressing device. The self-walking prepressing devicecomprises a counterforce beam support with a cuboid frame structure, a walking system, a pressure system, a load distributing system, a locking system and a control system. The walking system and thepressure system are fixedly connected to the bottom end of the counterforce beam support, the load distributing system is connected to the pressure system, the locking system is used for positioning the counterforce beam support, and the control system is used for controlling the walking system to walk and controlling the pressure system to drive the load distributing system to carry out prepressing at different load grades. The prepressing device for the cast-in-place beam supports can automatically walk, the cast-in-place supports can be automatically classified, loaded and prepressed, prepressing block or water bag prepressing is not needed, manpower and material resources can be greatly saved, and the construction efficiency is improved.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP +2

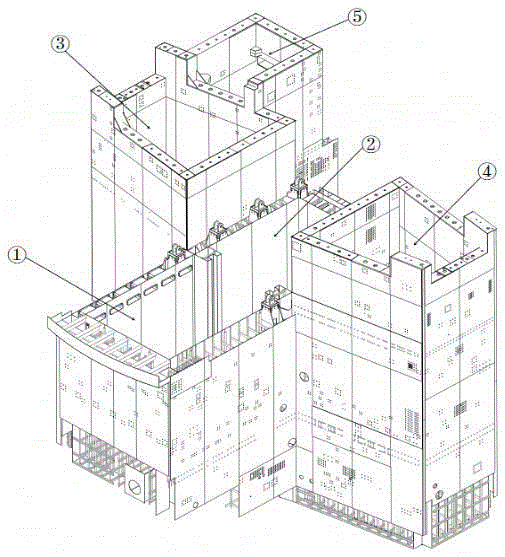

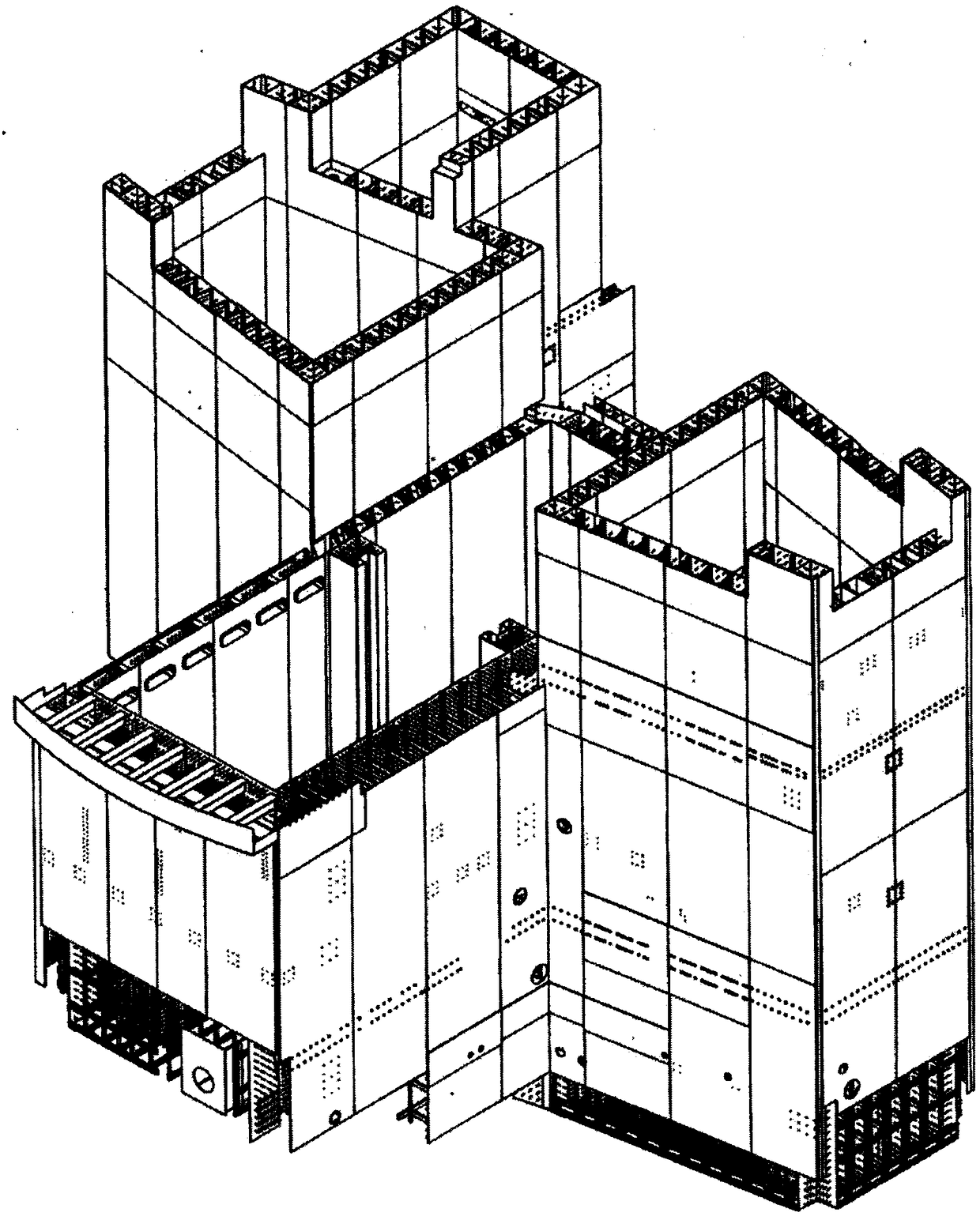

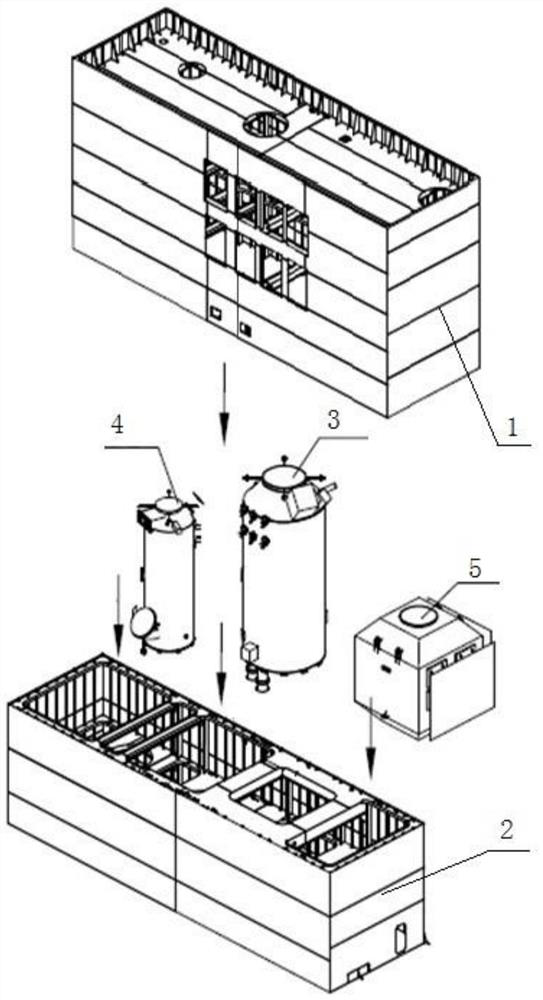

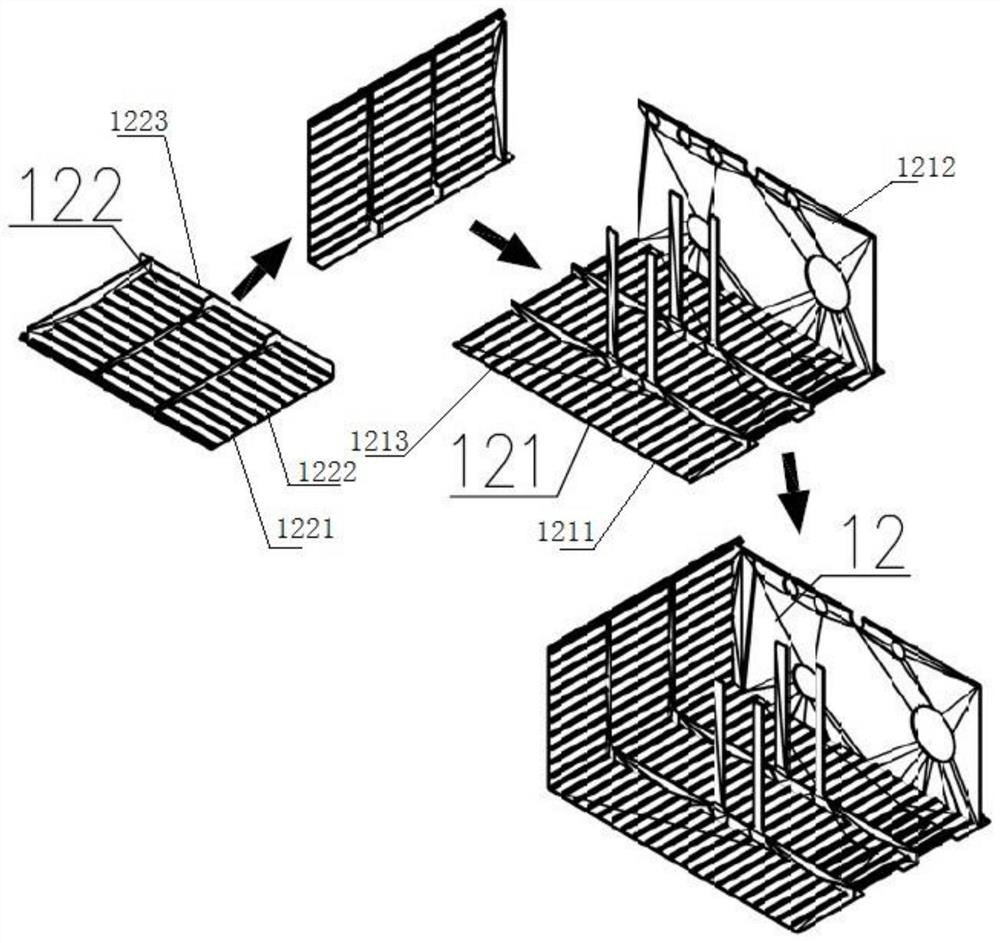

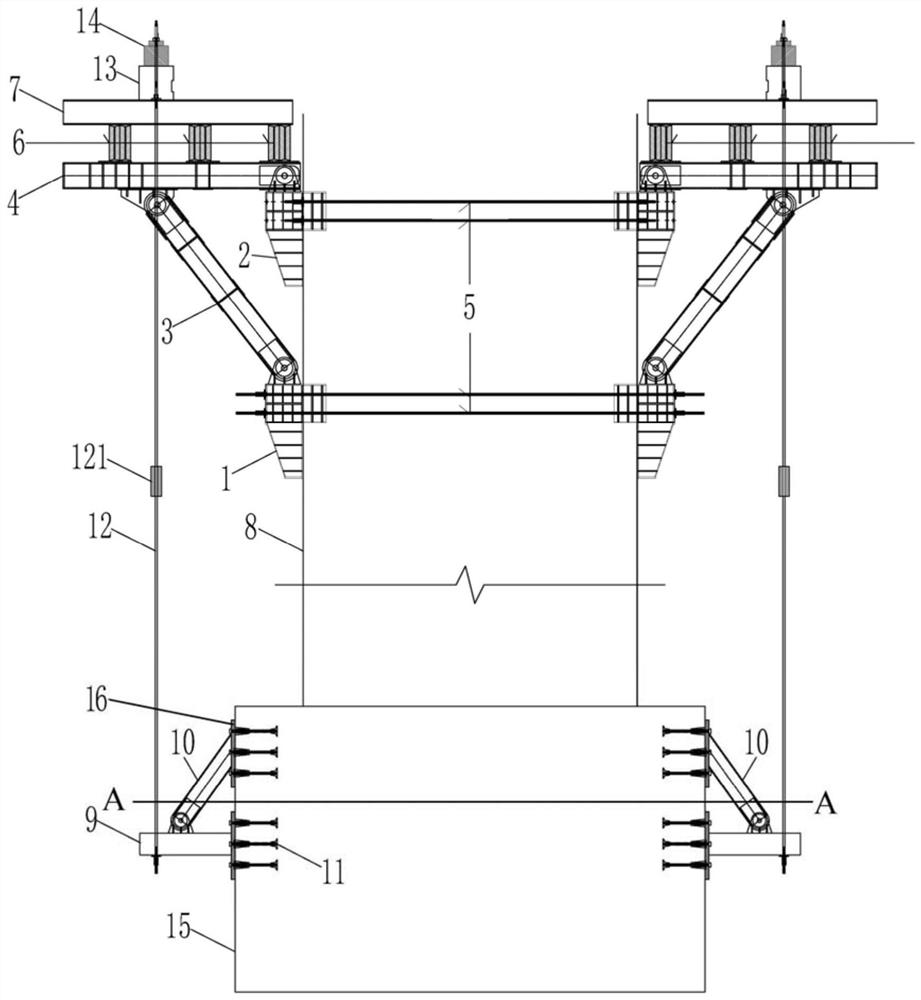

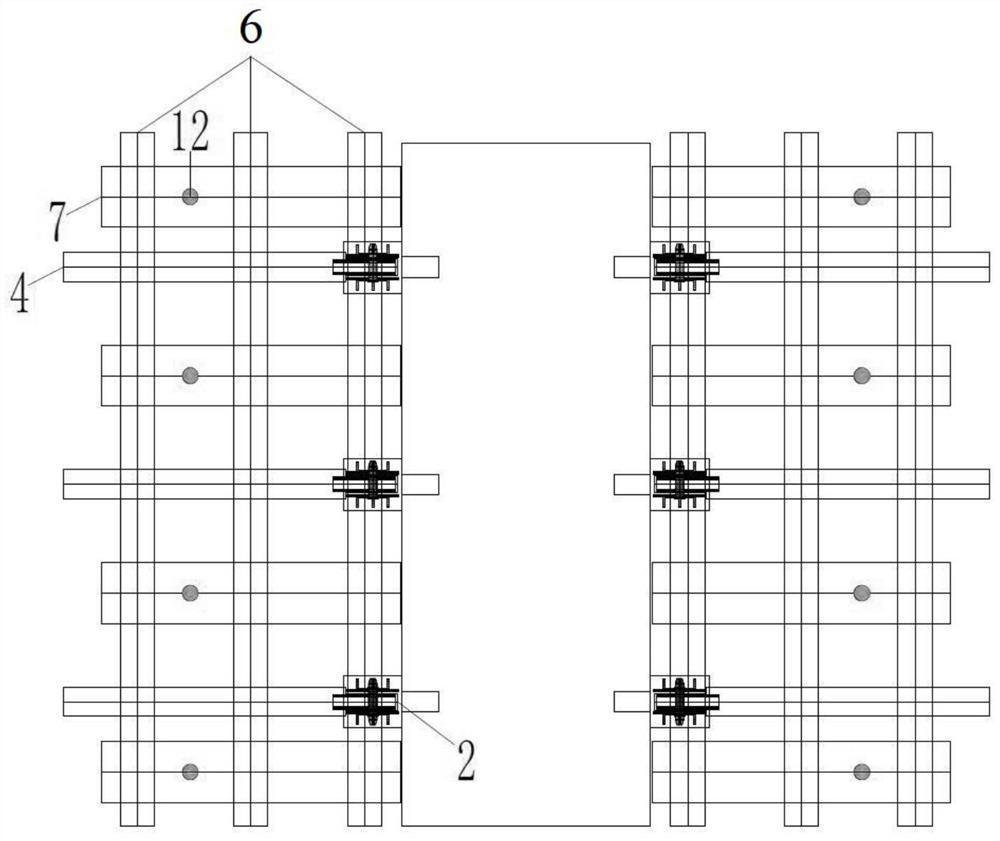

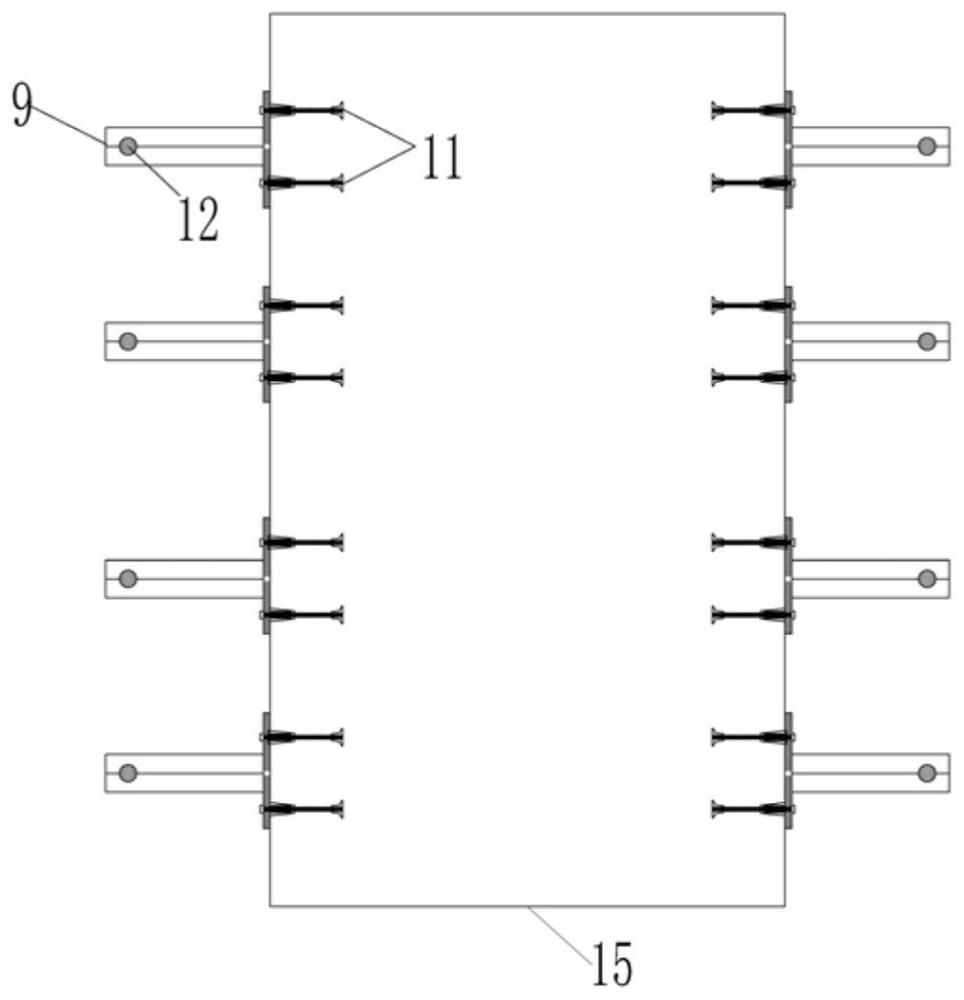

Vertical assembling method for structural modules of nuclear power plant

InactiveCN108442712AErrors do not accumulateImprove assembly accuracyBuilding material handlingNuclear powerComputer module

The invention provides a vertical assembling method for structural modules of a nuclear power plant. The vertical assembling method comprises the following steps that firstly, an assembly piece is disassembled with sub-modules as basic units, and the sub-modules are recombined and optimized, and the assembly sequence is determined; then, the placement position around an assembly platform of each sub-module in a site is determined according to the performance of a crane; the first two sub-modules are hoisted to the corresponding positions of the assembly platform; a scaffold is erected outsidethe sub-modules in place; the sub-modules in place are accurately measured and adjusted, the sub-modules are adjusted to the most ideal positions, and then assembling and welding-line welding are carried out; and similarly, the processes of hoisting of the next sub-module, erecting of a scaffold, accurate measuring and adjusting, assembling and welding-line welding are carried out, each follow-upsub-module is completed in sequence according to the assembly sequence, and the assembly advance route can generally be carried out symmetrically on both sides at the same time until all the sub-modules are assembled. The vertical assembling method greatly improves the assembling precision and quality of the structural modules of the nuclear power plant, the use of a large crane is avoid, and theeconomic performance is good.

Owner:STATE NUCLEAR POWER ENG

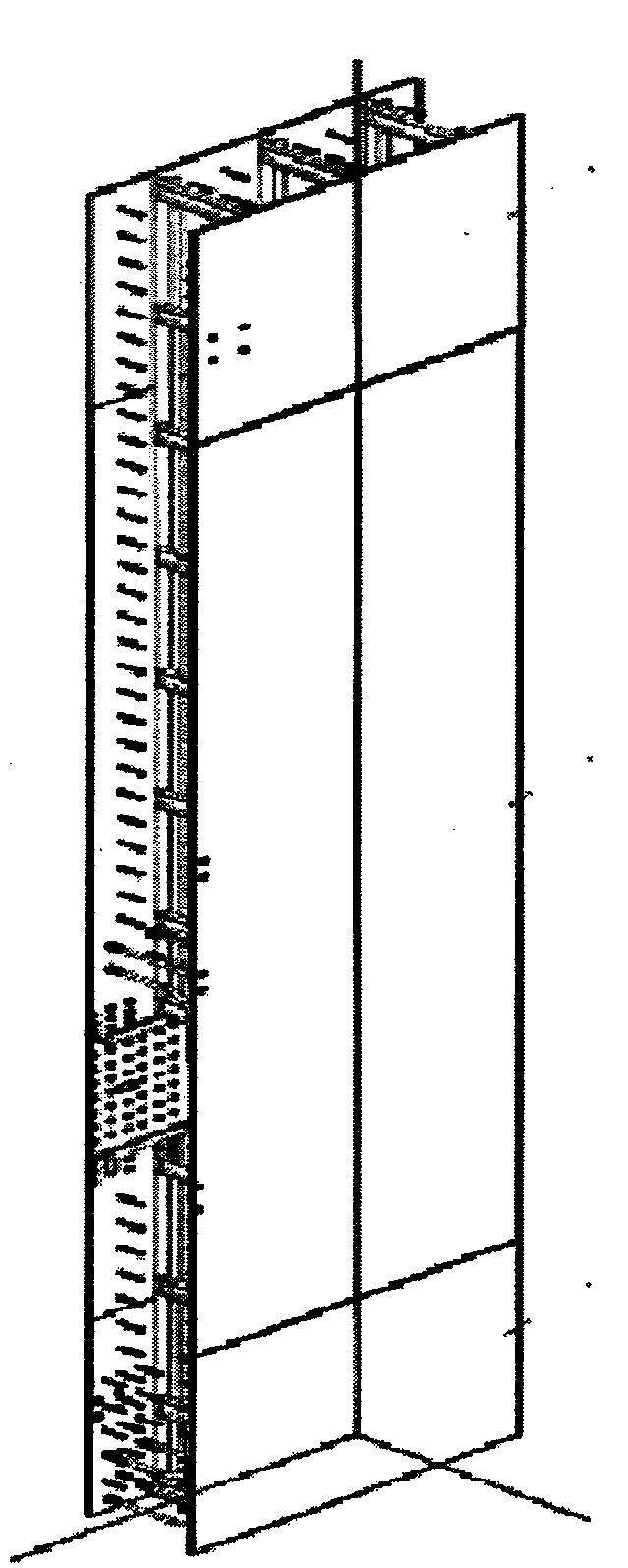

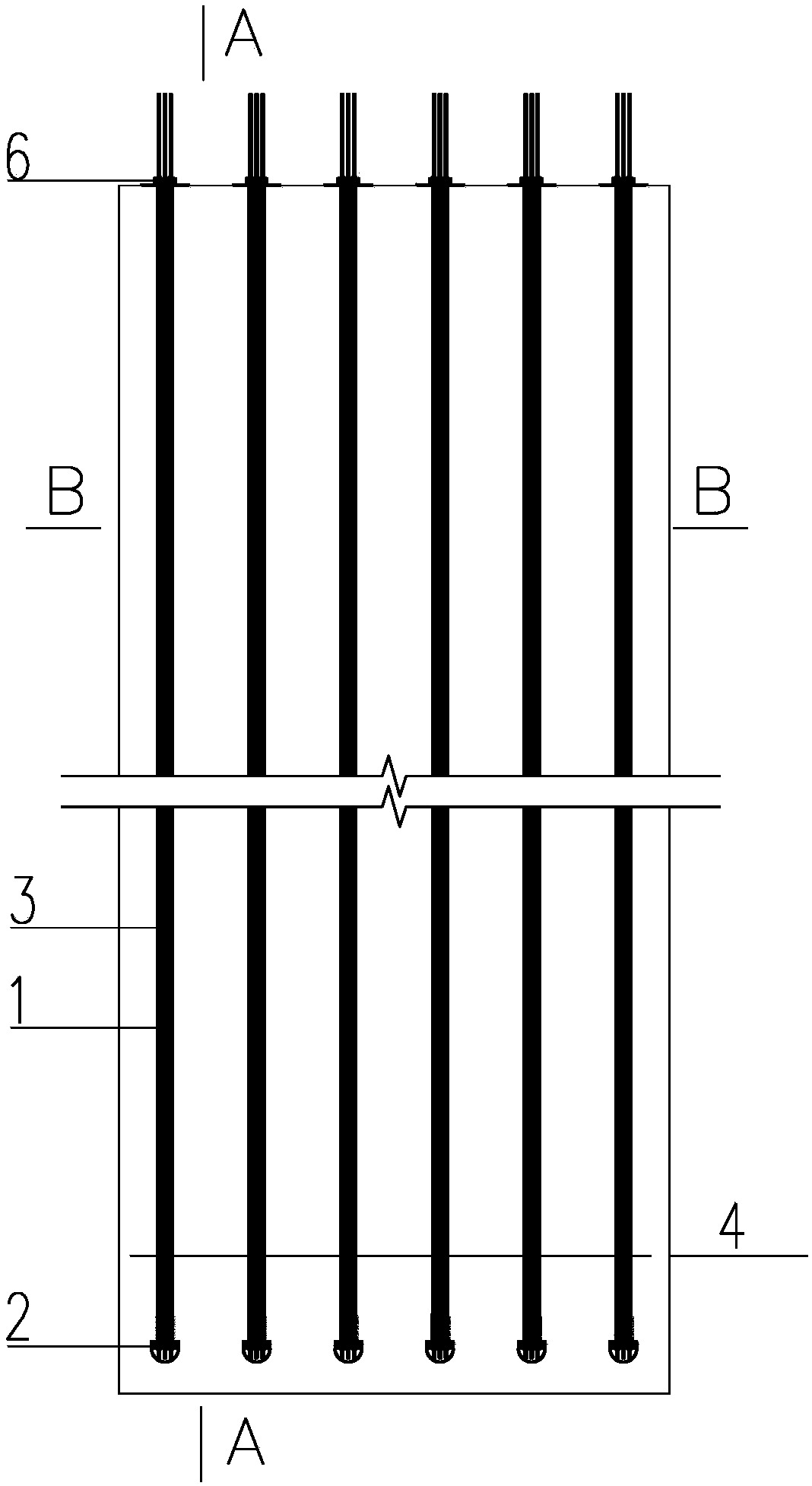

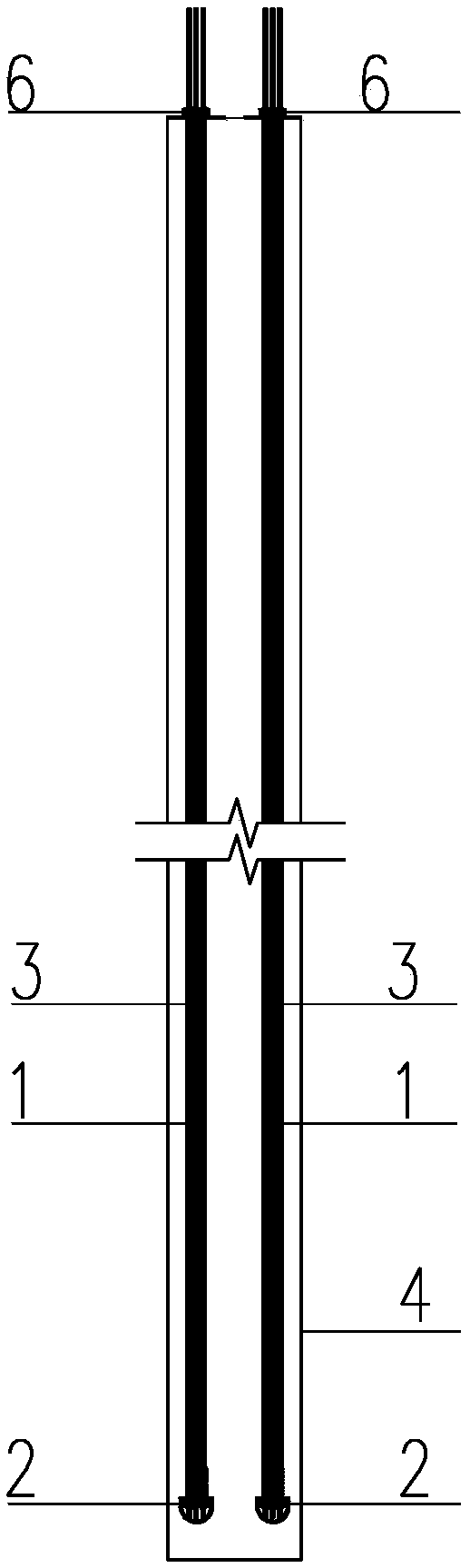

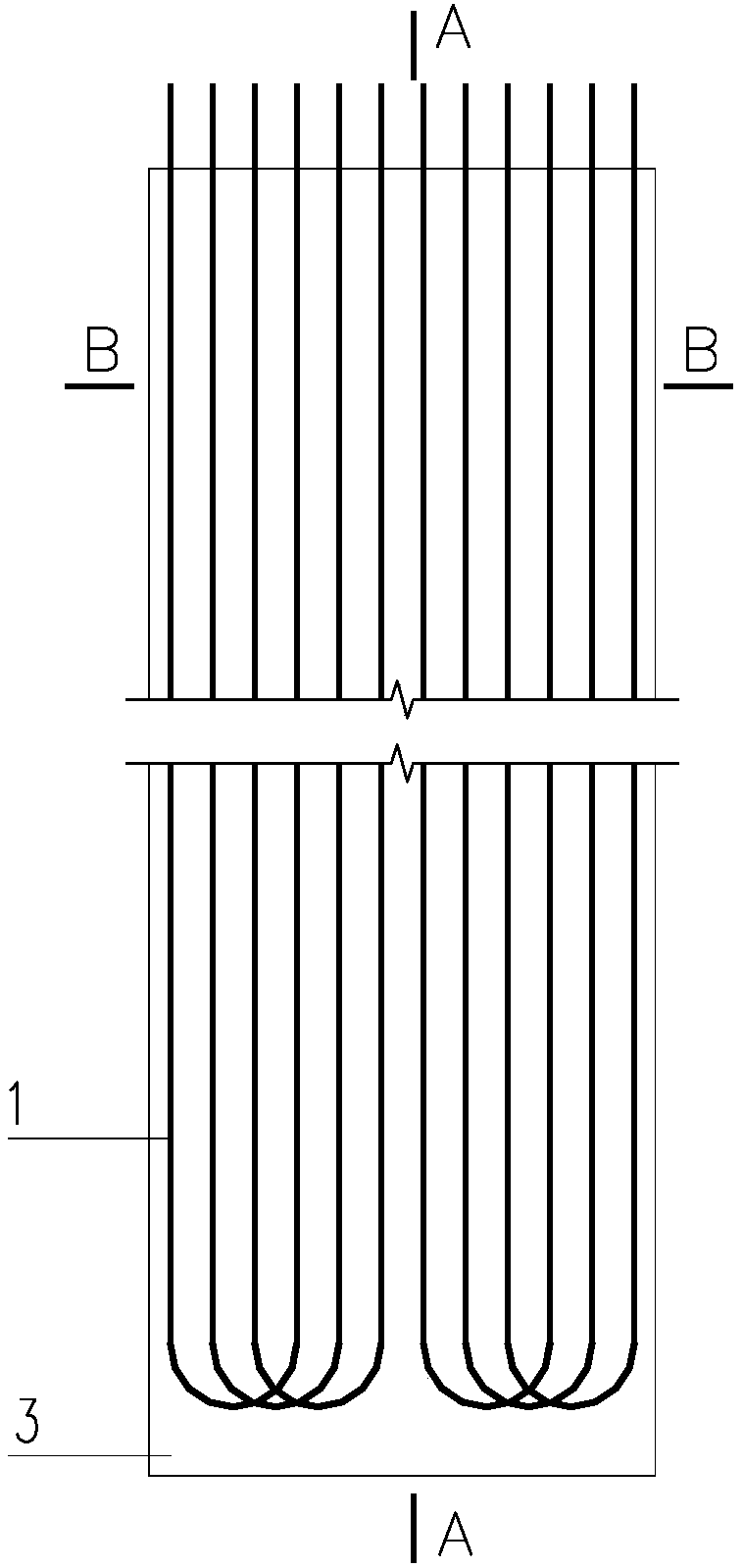

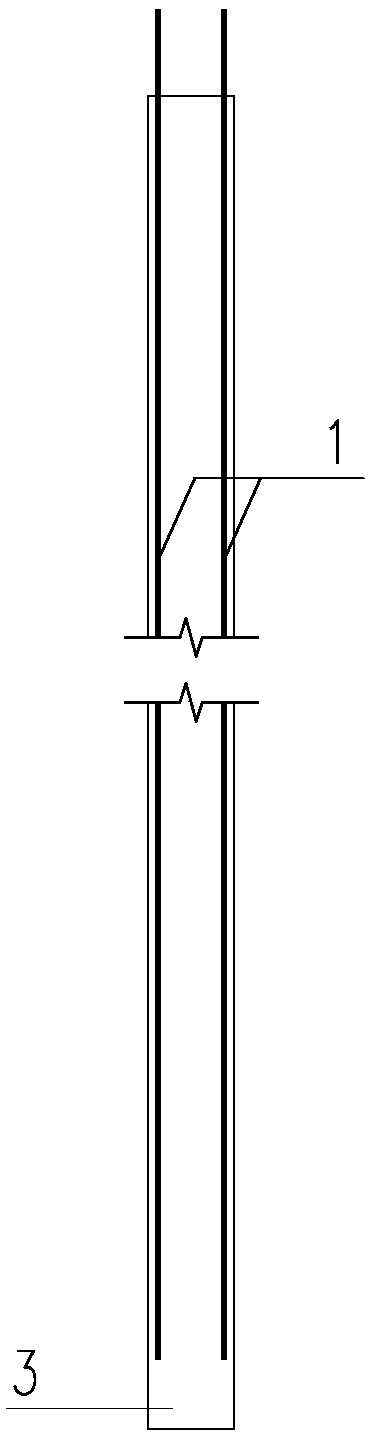

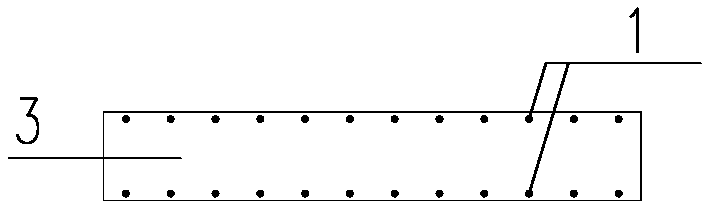

Recyclable group bundle post-tensioning unbonded prestress underground diaphragm wall and construction method

The invention provides a recyclable group bundle post-tensioning unbonded prestress underground diaphragm wall and a construction method. A prestress group bundle is arranged in a reinforcement cage,wherein the prestress group bundle is used for bearing the load in the construction process of an underground structure. The lower end of the prestress group bundle is provided with a multi-hole fixing end anchor device which can anchor and disanchor a steel strand of a working cable. The upper end of the prestress group bundle extends out of the top face of an underground diaphragm wall segment and is sequentially provided with an anchor backing plate and a stretching and drawing end anchor device. After pouring of the underground diaphragm wall segment is completed and before the undergroundstructure is constructed, the steel strand of the working cable in the prestress group bundle is stretched and drawn; the crack resistance degree of the underground diaphragm wall is raised; the surface fracture of the underground diaphragm wall is reduced; consumption of common rebars is reduced; the weight of the underground diaphragm wall reinforcement cage is reduced; and the reinforcement cage hoisting difficulty and risk are lowered. After construction of the underground structure is completed, the steel strand of the tool cable is withdrawn; so that the steel strand of the working cable is disanchored through the multi-hole fixing end anchor device, and thus recycling and reuse of the steel strand of the working cable are achieved; and the construction cost is lowered.

Owner:SHANGHAI CONSTRUCTION GROUP

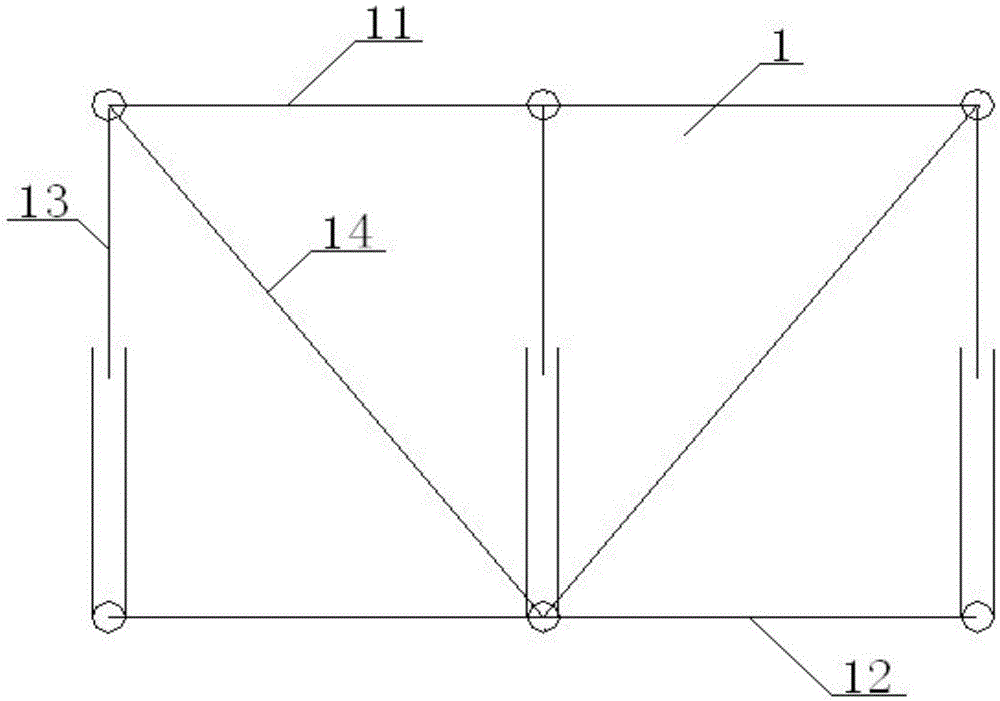

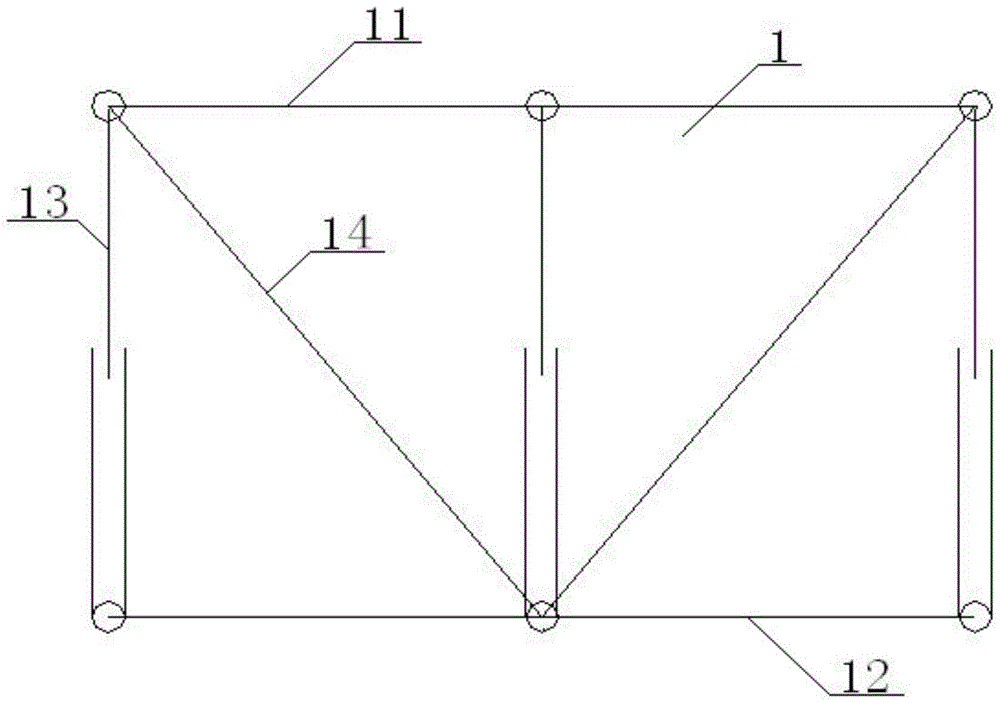

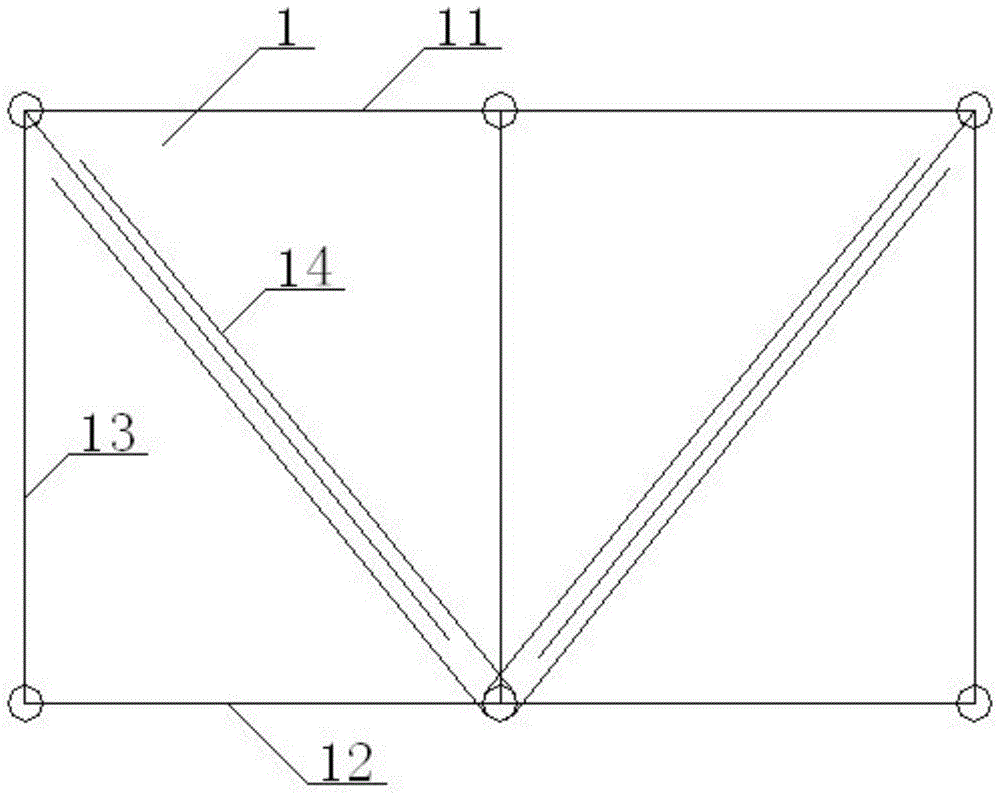

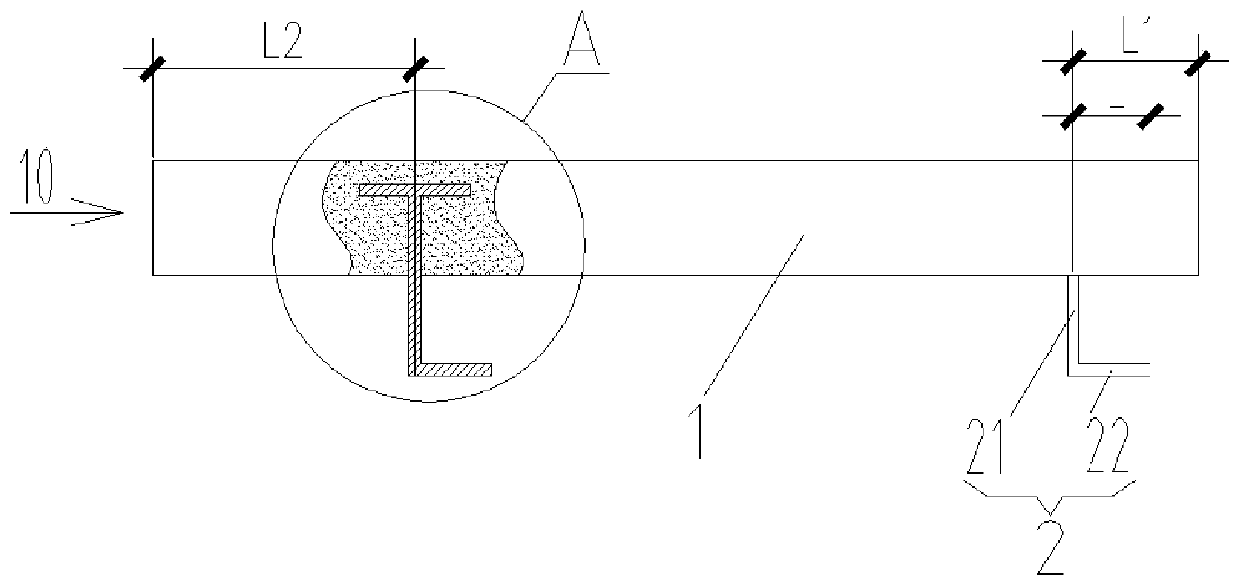

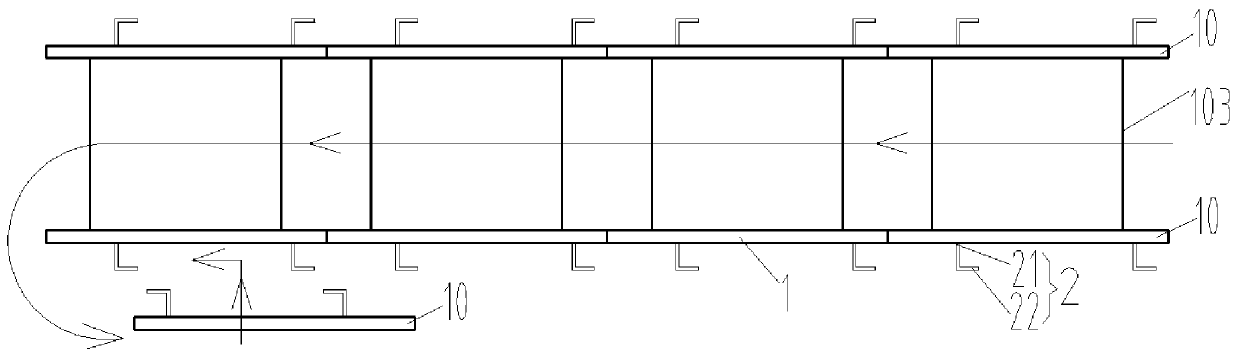

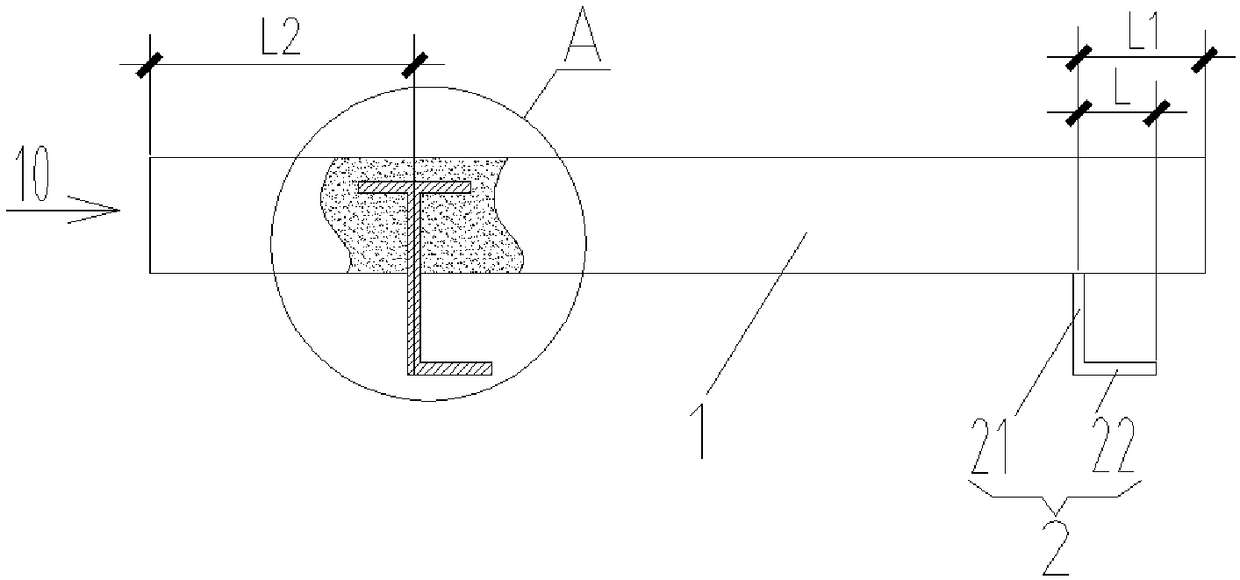

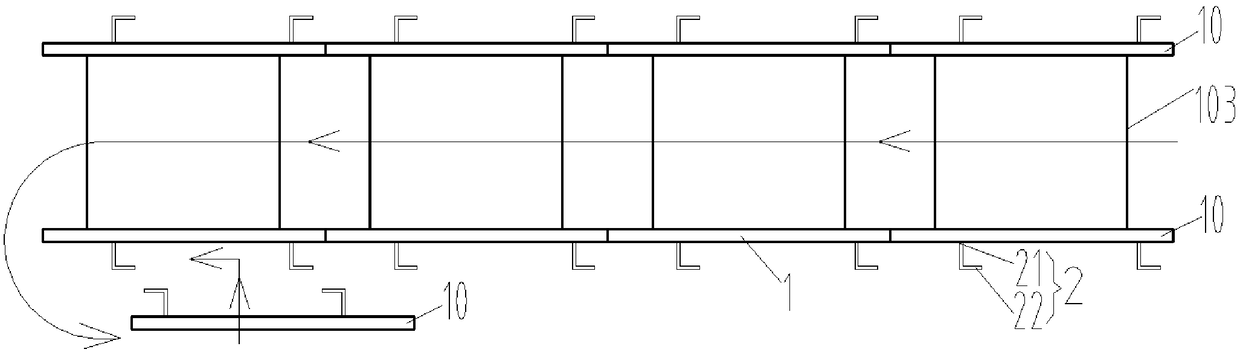

Longitudinal foldable plane truss and application method thereof

ActiveCN105464007ASimple structureThe unfolding and collapsing process is fastBridge erection/assemblyBridge strengtheningSurface plateStructural engineering

A longitudinal foldable plane truss comprises an upper chord member and a lower chord member which are parallel to each other, wherein a vertical web member and a diagonal web member are connected between the upper chord member and the lower chord member; the upper end of the vertical web member is hinged with the end part of the upper chord member; the lower end of the vertical web member is hinged with the end part of the lower chord member; the upper end of the diagonal web member is hinged with a part at the connected part of the upper chord member and the vertical web member; the lower end of the diagonal web member is hinged with a part at the connected part of the lower chord member and the vertical web member; and the vertical web member is a stretchable member or the diagonal web member is a stretchable member. In application, the plurality of plane trusses are assembled through member pieces and panels to obtain a plane truss system; as a working platform or a bridge, the plane truss system can realize longitudinal unfolding or folding function of the working platform or the bridge through controlling the lengths of the stretchable members. The design is advantaged in that the longitudinal foldable plane truss can be longitudinally folded, the longitudinal foldable plane truss is simply structured and simple and convenient to operate, and the longitudinal foldable plane truss applicable to structure overhauling and emergency works.

Owner:WUDA JUCHENG STRUCTURE CO LTD

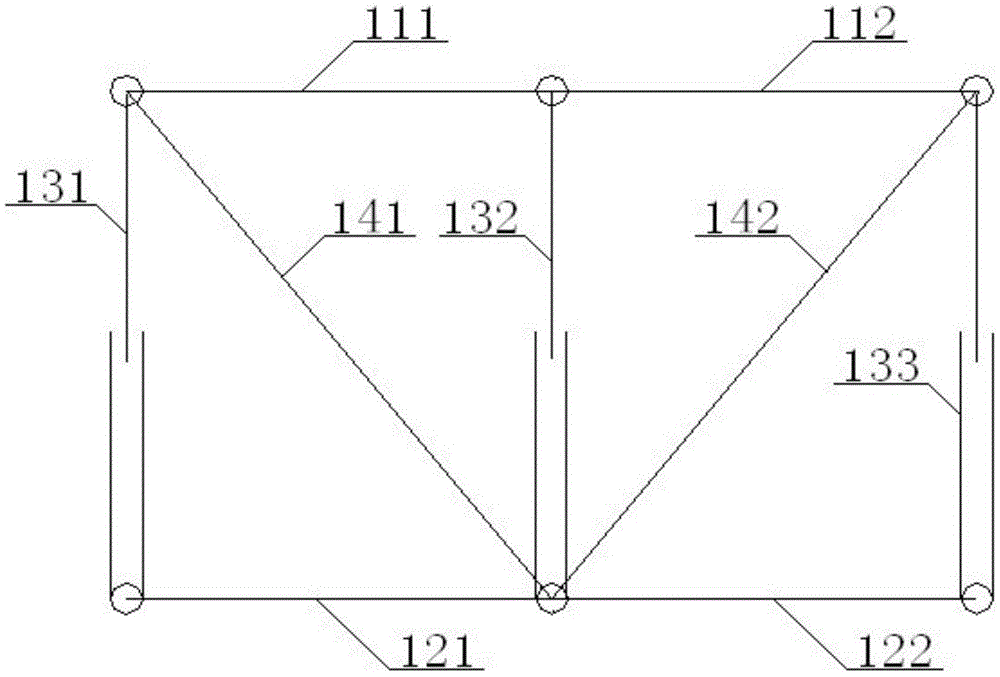

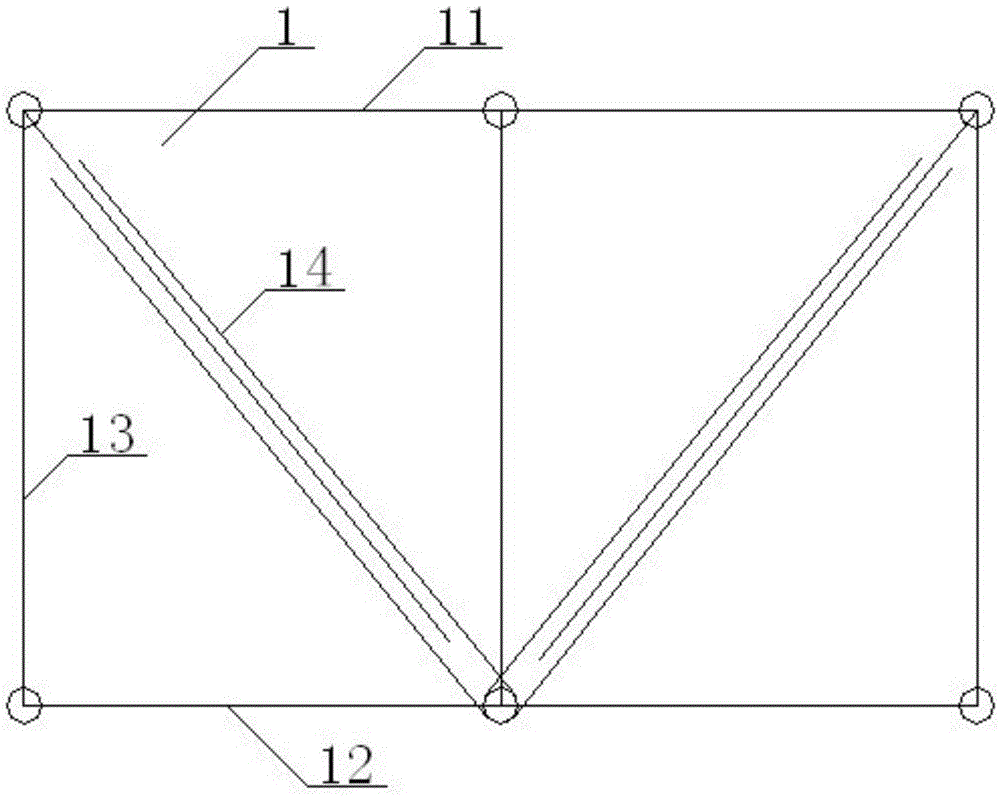

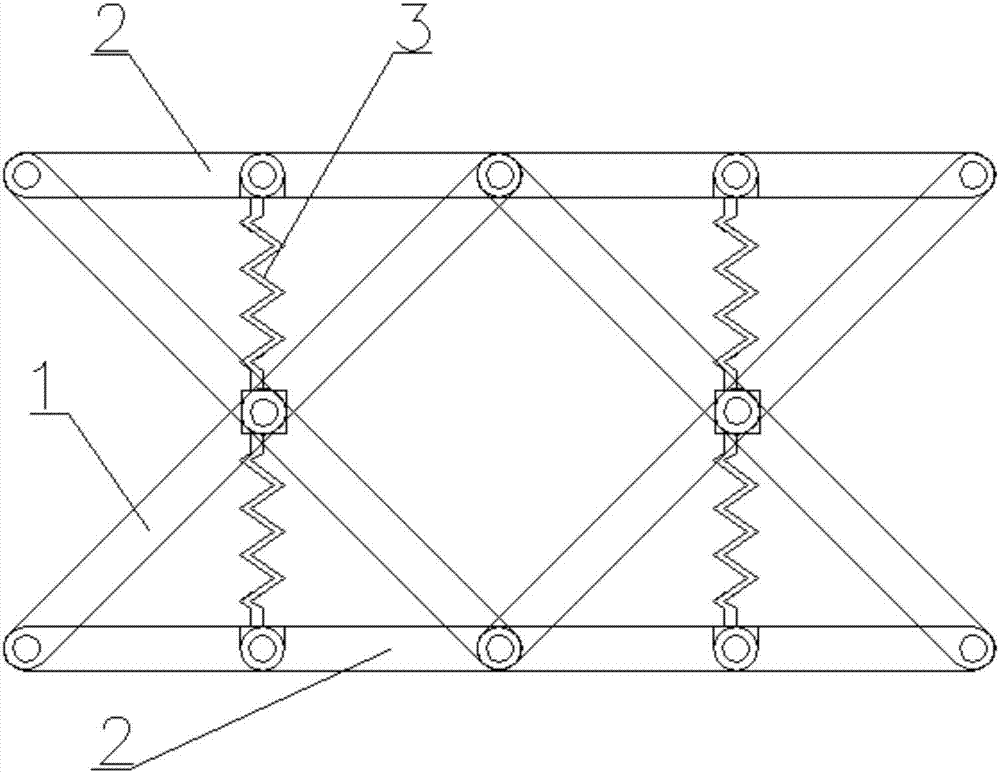

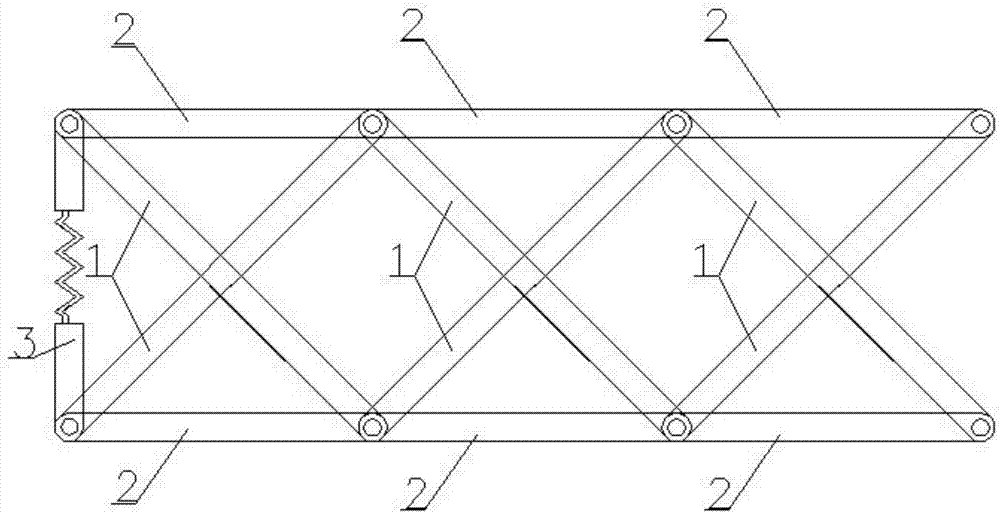

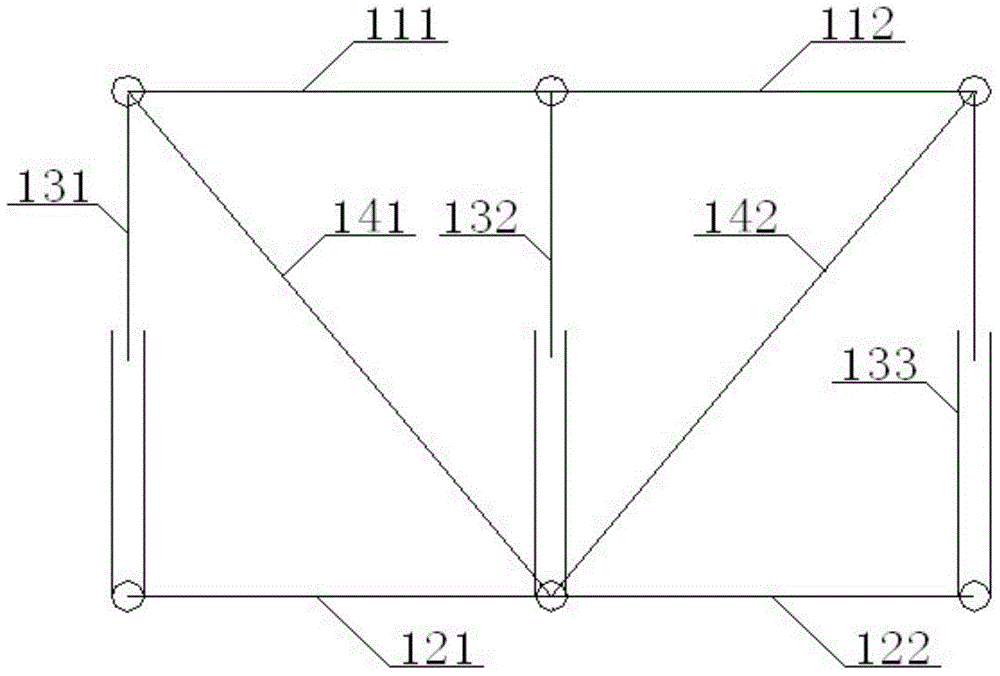

Scissor type folding truss

InactiveCN106948281AMorph SynchronizationControllable shapeBridge structural detailsBridge erection/assemblyEngineering

The invention provides a scissor type folding truss. The scissor type folding truss comprises diagonal web members, chord members and vertical web members. The diagonal web members and the chord members are fixed in length. The middle positions of the two diagonal web members are trepanned and are hinged with each other in a scissor type mode. The ends of the two diagonal web members are trepanned and are hinged with one end of one chord member. The other ends of the two chord members of the corresponding positions are trepanned and are hinged with each other. The vertical web members are telescopic. One end of each vertical web member is fixed to the position that the two chord members are hinged with each other in a hinged mode and the other end of each vertical web member is fixed to the position that the two diagonal web members are hinged with each other in a hinged mode. According to the scissor type folding truss, the chord members and the vertical web members are added to a scissor type folding extension device, the length of the vertical web members can be telescopically changed, a scissor type folding mechanism composed of the chord members, the vertical web members and the diagonal web members are hinged at nodes, and the longitudinal folding or unfolding function of a truss system is realized by controlling the length of the vertical web members, and synchronous deformation between sections of the truss is ensured.

Owner:HUBEI WUDA LUOJIA INSPECTION & CONSULTATION OF ENG STRUCTURE

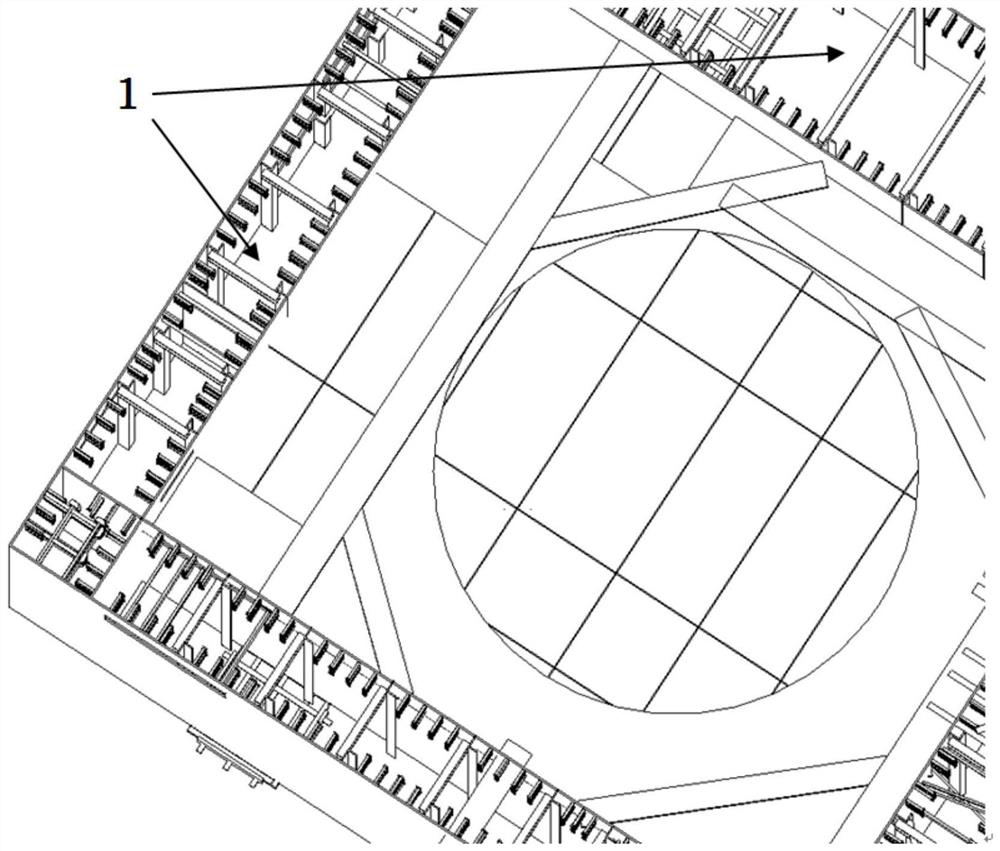

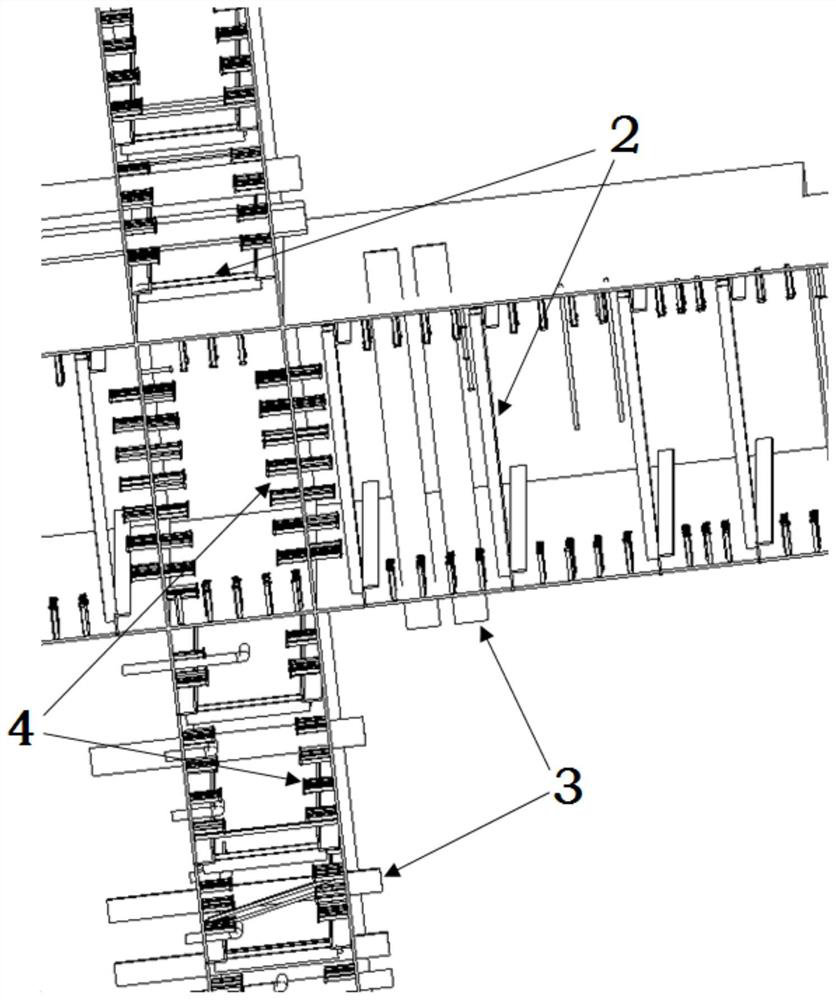

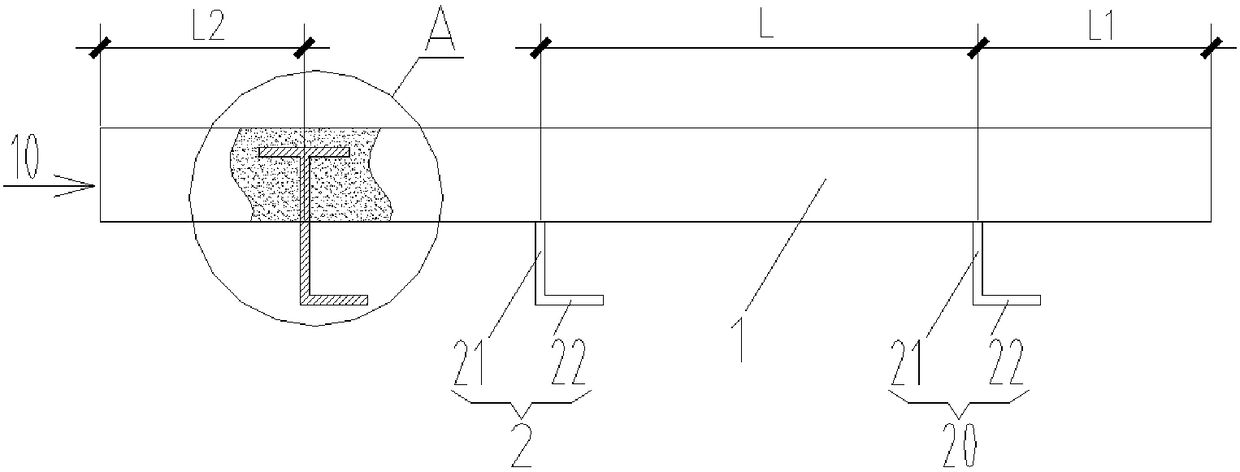

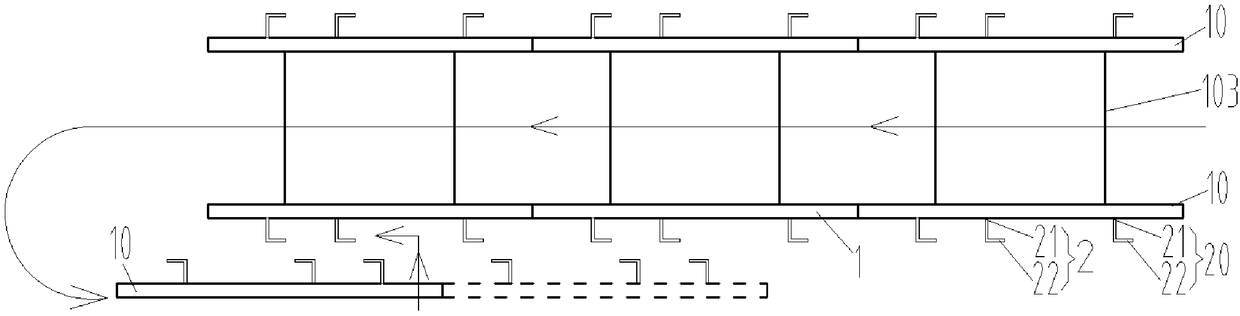

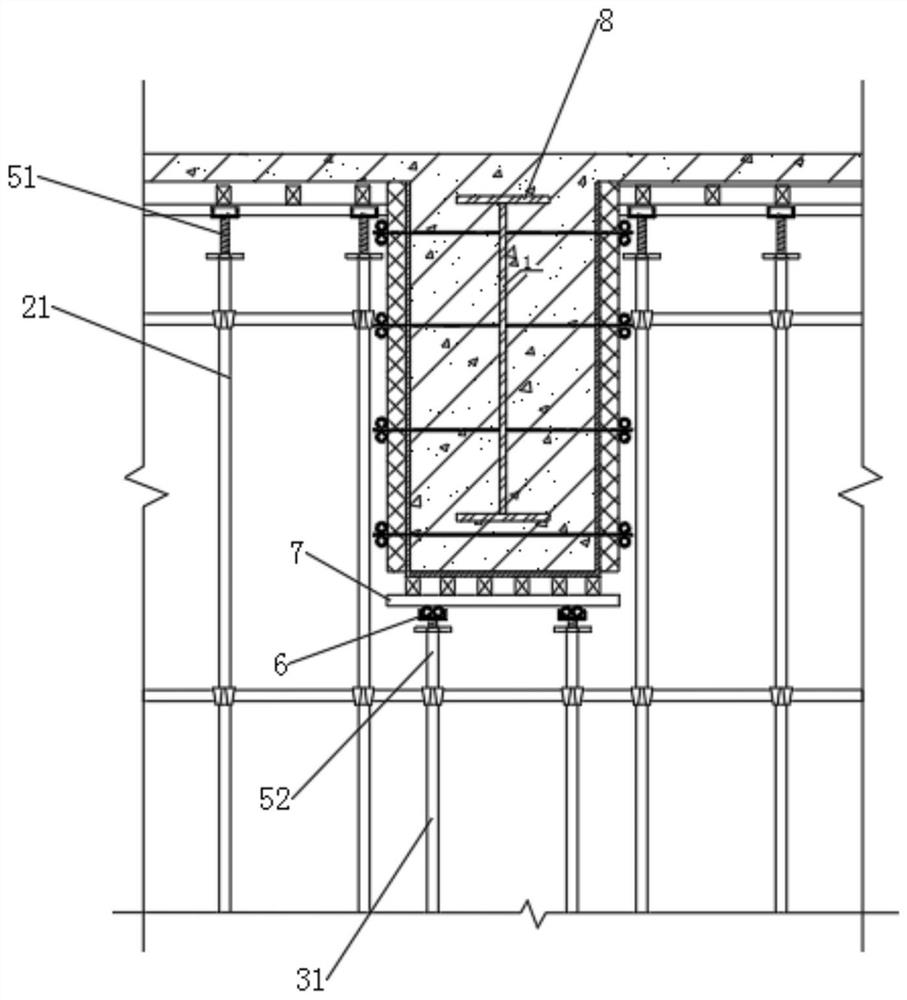

Dual-purpose large-span stiff beam construction structure and construction method thereof

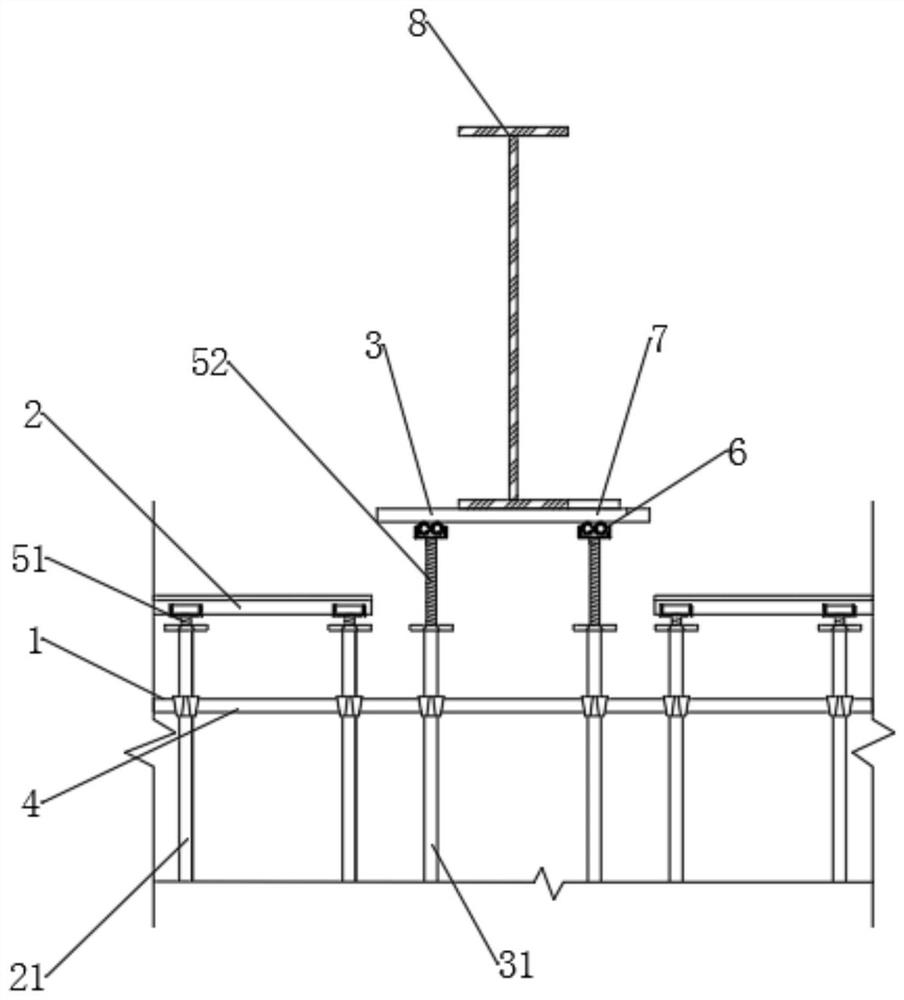

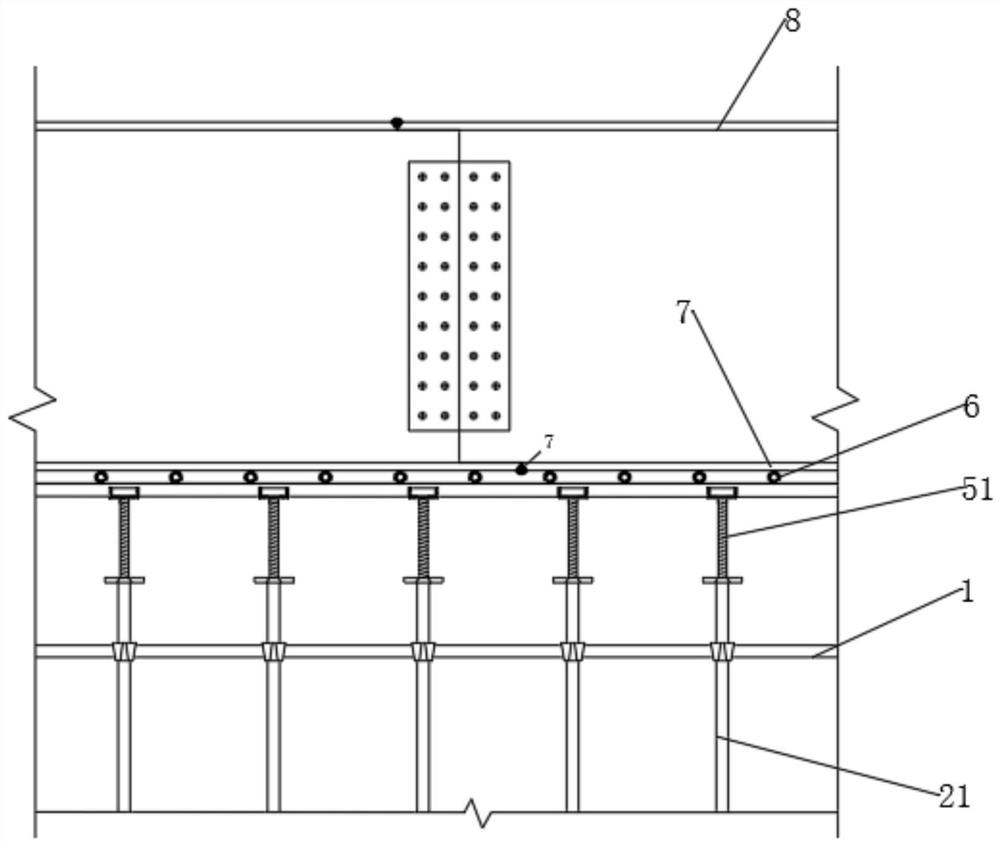

ActiveCN112324131AReduce lifting weightReduce the risk of hoistingForms/shuttering/falseworksSteel tubePipe support

The invention discloses a dual-purpose large-span stiff beam construction structure and a construction method thereof, and belongs to the technical field of stiff beam construction. The dual-purpose large-span stiff beam construction structure comprises a support system, wherein the support system comprises a plurality of sets of first support assemblies which are arranged at equal intervals and asecond support assembly, each first support assembly comprises a set of first tool type steel pipes which are arranged at equal intervals, the second support assembly comprises a set of second tool type steel pipes which are arranged at equal intervals, and the adjacent first tool type steel pipes and second tool type steel pipes, the two adjacent first tool type steel pipes and the two adjacentsecond tool type steel pipes are connected through a plurality of cross rods. According to the dual-purpose large-span stiff beam construction structure, sectional steel beams are hoisted in sections,so that the hoisting risk is reduced, the structure and components are protected conveniently, and the safety is higher; tool type steel pipe supports are erected, and the purpose that one support has two purposes is achieved through an adjustable jacking; andthe construction method is simple, easy to operate and good in integrity, shortens the construction period and reduces the cost.

Owner:杭州二建建设集团有限公司

Recyclable single-bundle post-tensioning non-bonding prestress underground diaphragm wall and construction method

The invention provides a recyclable single-bundle post-tensioning non-bonding prestress underground diaphragm wall and a construction method. Prestressed ribs are arranged in a reinforcement cage, andafter concrete pouring to the underground diaphragm wall section is finished and the designed strength is reached, tensioning of the prestressed ribs is conducted, the crack resistance degree of theunderground diaphragm wall is improved, the fracture surface of the underground diaphragm wall is reduced, the usage amount of ordinary steel bars is reduced, the weight of the reinforcement cage of the underground diaphragm wall is reduced, and the reinforcement cage hoisting difficulty and risks are reduced. In addition, due to the fact that each prestressed rib is a non-bonding prestressed rib,each non-bonding prestressed rib comprises an outer casing pipe and a steel strand arranged in the outer casing pipe, the prestressed ribs are arranged on the reinforcement cage in a U shape manner,the two ends of each prestressed rib stretch out of the top face of the underground diaphragm wall section planned to be built, and after underground structure construction is finished, the steel strands of the prestressed ribs are unloaded and recycled, the steel strands can be repeatedly utilized, and the construction cost is reduced.

Owner:SHANGHAI CONSTRUCTION GROUP +1

Tooling suitable for high pier and large span continuous rigid frame extra heavy 0 # bracket preloading

PendingCN109235275AImprove construction efficiencyGuarantee the construction qualityBridge erection/assemblyPre compressionJackscrew

The invention discloses a tooling suitable for high pier and large span continuous rigid frame extra heavy 0 # bracket preloading. By using the strong bending resistance of single or double-spelled Bailey beams, Bailey beam are anchored on that pier top by a beam body pre-embedded fine tie screw bar, I-steel is used as temporary support pad at the bottom, a jack is installed at the top of the bracket (the low part of the Bailey beam), and a downward force is generated on the bracket by the jack jacking to achieve the purpose of pre-compression, the inelastic deformation of the bracket is eliminated equivalently, and the purpose of elastic deformation of the bracket is obtained. The invention can greatly improve the construction efficiency of loading and unloading in the preloading processof the bracket, save the construction time and reduce the construction investment. At the same time, it can also ensure the construction quality of bracket preloading and reduce the risk of hoisting in high-altitude operation.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Synchronous folding truss

InactiveCN106948261ARealize folding and collapsingAchieve expansionBridge structural detailsEngineeringDegrees of freedom

The invention provides a synchronous folding truss. The synchronous folding truss comprises diagonal web members trepanned in two ends, chord members and vertical web members. The diagonal web members and the chord members are fixed in length. The top ends of two equilong diagonal web members are hinged at both ends of one chord member. The bottom ends of two equilong diagonal web members are hinged at both ends of the other chord member. The two diagonal web members are arranged in an intersecting mode. The top end of one diagonal web member and the bottom end of the other diagonal web member are hinged at both ends of the vertical web members correspondingly. The truss is composed of adding vertical web members, based on a plane mechanism with only one degree of freedom inside formed through chord members and crossed diagonal web members. The length of the vertical web members can be telescopically changed, the diagonal web members, the chord members and the vertical web members are hinged at nodes, the vertical web can be arranged in one or can be arranged in multiple according to needs, and the longitudinal folding or unfolding function of a truss system is realized by controlling the length of the vertical web members, and synchronous deformation between sections of the truss is ensured.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Mounting method and device for super high-rise air suspension acrylic swimming pool

InactiveCN113279615AReduce difficultyReduce the risk of hoistingGymnasiumBuilding material handlingMarine engineeringStructural engineering

The invention discloses a mounting method and a device for a super high-rise air suspension acrylic swimming pool. The method comprises the following steps that the acrylic swimming pool is decomposed into a plurality of components, then block transportation and block hoisting are carried out, after swimming pool layers are assembled into the acrylic swimming pool with an integral structure, then the acrylic swimming pool is horizontally moved to a swimming pool mounting notch through a bearing tank on a rail, and then the acrylic swimming pool is integrally lifted through alternate operation of a set of jacking jacks and jacking base plates, after the rail is dismounted, the acrylic swimming pool is supported on the set of in-place jacks through alternate operation of the set of jacking jacks and the set of jacking base plates, then the jacking jacks and the jacking base plates are dismounted, and finally the acrylic swimming pool is integrally mounted in the swimming pool mounting notch through synchronous slow descending of the set of in-place jacks. The integral mounting difficulty of the acrylic swimming pool can be greatly reduced, the safety can be improved, and the hoisting risk of components is reduced.

Owner:CCFED THE FIRST CONSTR & ENG

Container ship washing tower subsection dividing and installing method

PendingCN112339931AReduce the risk of hoistingImprove integrityWaterborne vesselsMarine engineeringMechanical engineering

The invention relates to a container ship washing tower subsection dividing and installing method which comprises the steps of dividing a washing tower subsection into an upper subsection and a lowersubsection according to a deck platform, a subsection breaking joint is formed between the upper subsection and the lower subsection, the upper subsection and the lower subsection are built on a planejig frame, and then the lower subsection is placed in a normal state; hoisting washing tower equipment on the lower section, and normally carrying the upper section on the lower section after the washing tower equipment is mounted and fixed. By means of the dividing and installing method, washing tower equipment in the washing tower subsections can be normally installed in the installation stage,the hoisting risk is greatly reduced, the subsection construction efficiency can be improved, and the subsection turnover risk is reduced; when the upper part section and the lower part section are normally folded, high-altitude scaffold erection is not needed, a constructor can complete assembling and welding work by standing on an internal platform, and safety and reliability are achieved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

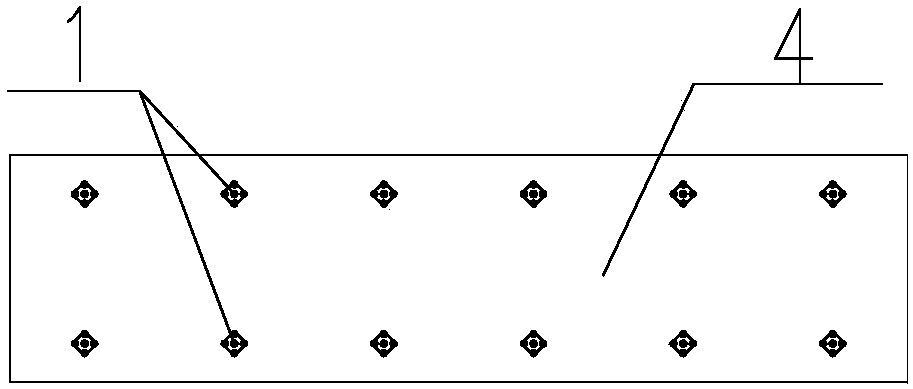

Deep foundation pit concrete supporting structure with hoisting holes being pre-formed and construction method thereof

The invention discloses a deep foundation pit concrete supporting structure with hoisting holes being pre-formed and a construction method thereof. The concrete supporting structure comprises a concrete waist beam and concrete supports which are mutually connected; the concrete waist beam is provided with a plurality of waist beam pre-cutting surfaces; the multiple waist beam pre-cutting surfaces divide the concrete waist beam into a plurality of waist beam pre-cutting sections; and a waist beam hoisting hole pipe is arranged in each waist beam pre-cutting section in a penetrating and pre-buried mode. The concrete supporting structure can guarantee hoisting safety of concrete supporting blocks. The construction method of the concrete supporting structure comprises the steps that structural steel bars of the concrete waist beam and the concrete supports are bound; the waist beam hoisting hole pipes and supporting hoisting hole pipes are arranged in the concrete waist beam and the concrete supports correspondingly, and the waist beam hoisting hole pipes and the supporting hoisting hole pipes are bound on the structural steel bars through binding wires; and a formwork is erected, the concrete waist beam and the concrete supports are poured, and the formwork is removed after pouring The construction method is simple and feasible, and the situation that in concrete pouring, the waist beam hoisting hole pipes and the supporting hoisting hole pipes are dislocated can be avoided.

Owner:SINOHYDRO BUREAU 8 CO LTD

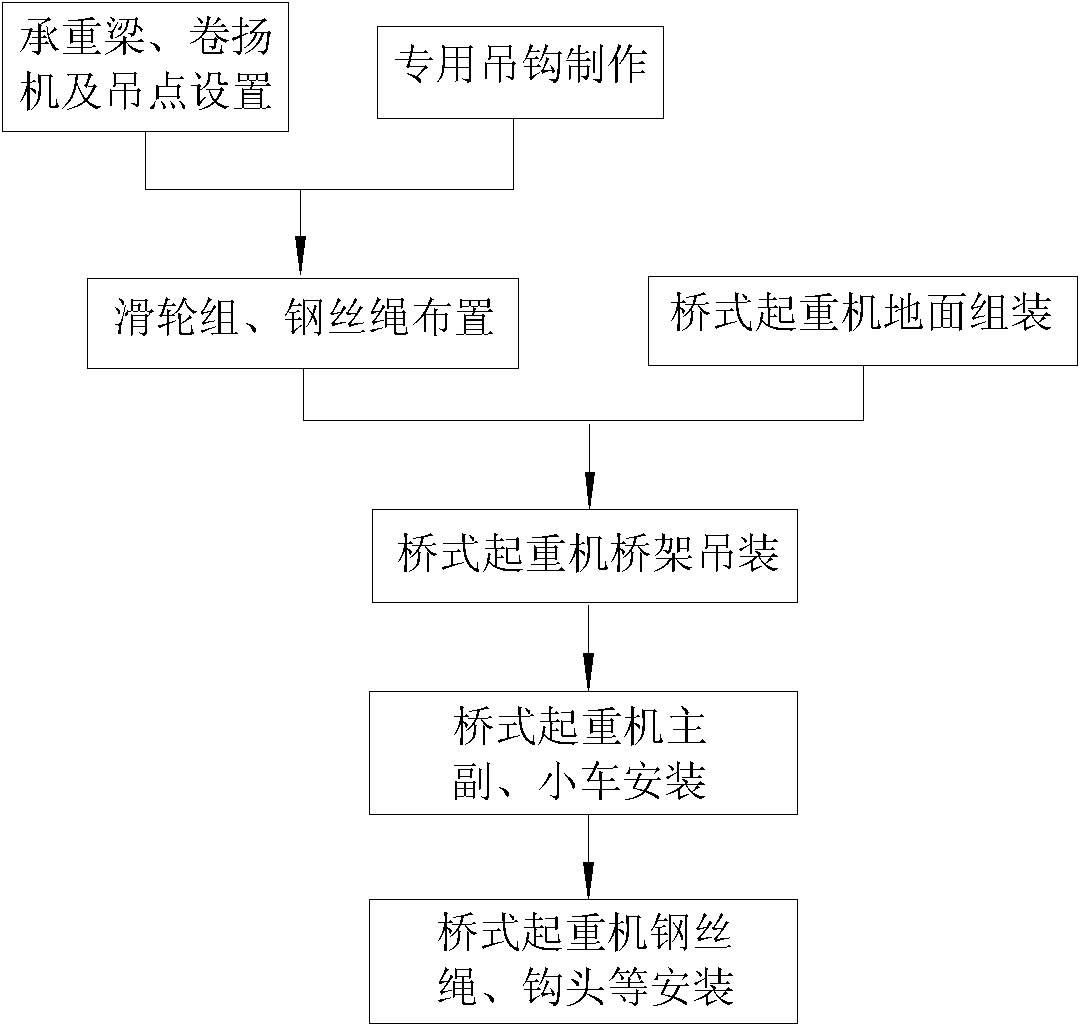

Method for installing bridge crane using load-supporting roof beam for hoisting and usage thereof

InactiveCN102267664BDoes not affect the installation progressReduce investmentTravelling cranesArchitectural engineeringBlock and tackle

The invention relates to a method for installing a bridge crane using load-supporting roof beams for hoisting and usage thereof. The invention is characterized in that: hoisting points are arranged on roof beams of a workshop, components of the bridge crane are assembled on the ground on site, and hoists and specified suspenders are used for hoisting the bridge crane; the method mainly comprises the steps of arranging of load-supporting beams for hoisting, hoists and hoisting points, fabrication of the specified suspenders, arranging of assembly pulleys and wire ropes, assembly of the bridge crane on the ground, hoisting of bridge stands of the bridge crane, hoisting of main and assistant trolleys of the bridge crane and installation of the wire ropes and the suspenders. According to the invention, site requirements are low, finished roofing of the workshop does not need to be dismounted, no giant crane is utilized, and facilities purchased and suspenders fabricated at a time can be used repeatedly, thereby saving cost; lifting and suspending with two cranes are avoided, thereby reducing safety risks; components are assembled in place on the ground and hoisted at a time, thereby improving working efficiency and abating risks in high altitude construction; time for actual hoisting is short and operationality is strong; the method is applicable to installation of large and medium-sized bridge cranes without being influenced by sites or hoisting height.

Owner:CHINA FIRST METALLURGICAL GROUP

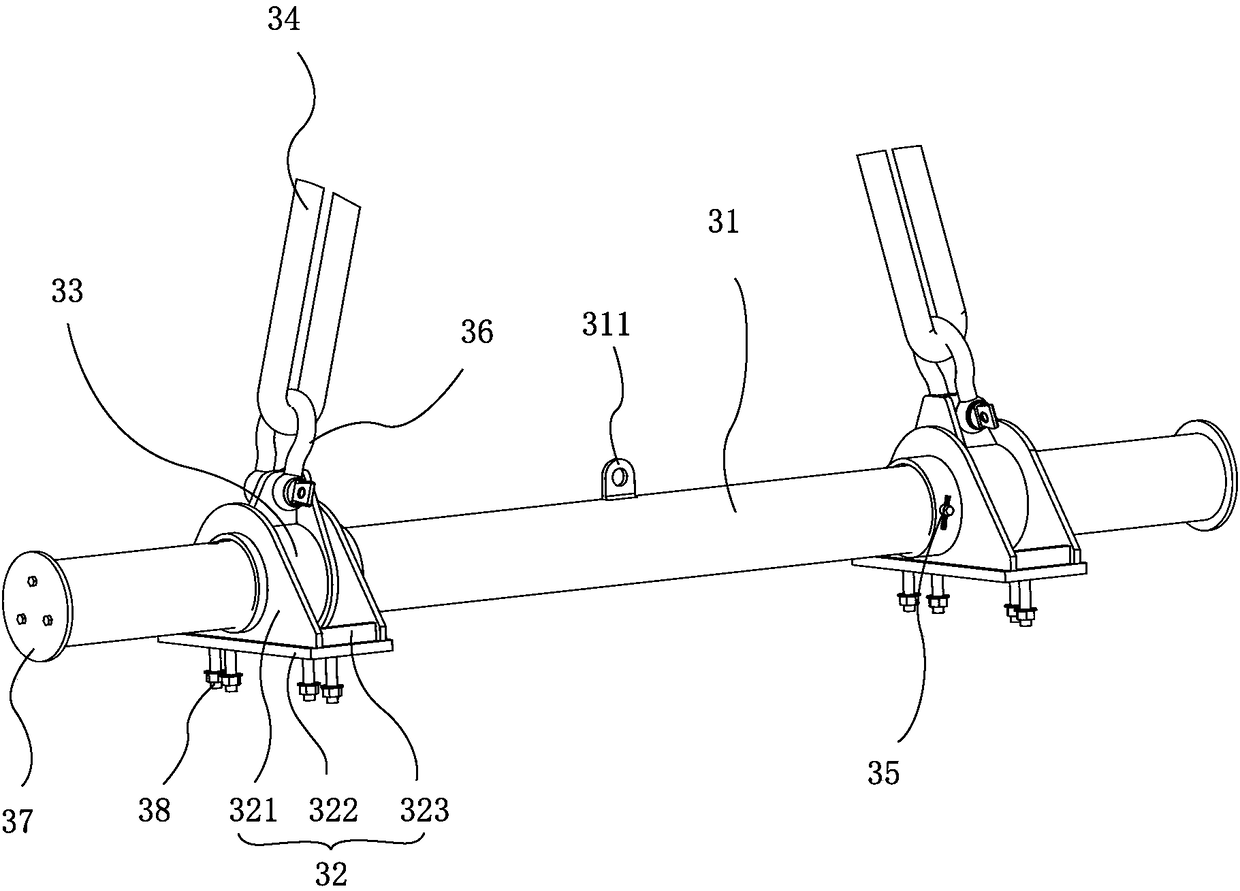

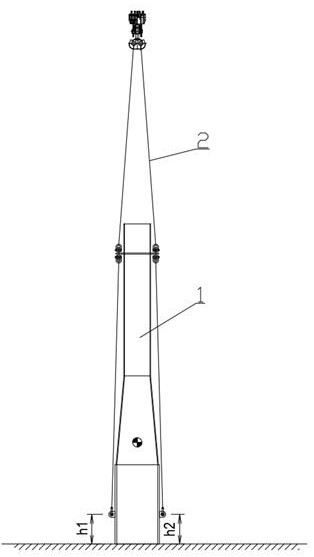

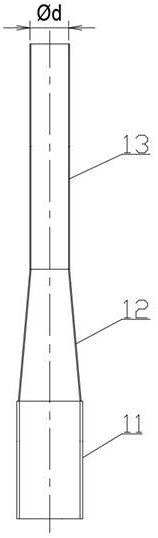

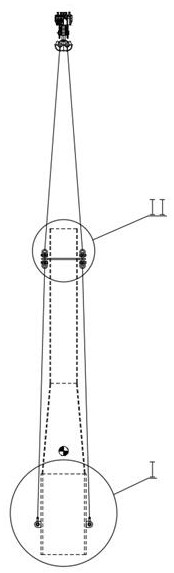

Ship ultrahigh stand column hoisting tool and hoisting method thereof

PendingCN114455447AImprove the efficiency of dehook operationReduce hoisting risks and expensesLoad-engaging elementsWire ropeMarine engineering

The invention relates to a ship ultrahigh stand column hoisting tool. The ship ultrahigh stand column hoisting tool is composed of a lower hoisting unit, an upper hoisting unit, a force transmission unit and a pulling unit. The lower hoisting unit is composed of a left lifting lug and a right lifting lug which are welded to the large-diameter section of the lower portion of the ultrahigh vertical column of the ship. The upper hoisting unit is composed of a hoisting frame, a left hoisting lug plate and a right hoisting lug plate, wherein the left hoisting lug plate and the right hoisting lug plate are welded to the hoisting frame. And in a formal hoisting state, the hoisting frame is sleeved on the periphery of the small-diameter section at the upper part of the ship ultrahigh stand column. The force transmission unit is composed of a left force transmission steel wire rope connected between the left lifting lug and the left lifting lug plate and a right force transmission steel wire rope connected between the right lifting lug and the right lifting lug plate. And the lifting hook is assisted by the pulling unit to realize the traction of the upper hoisting unit. In this way, the design concept that high-altitude unhooking operation is converted into low-altitude unhooking operation is ingeniously achieved, and the problem that high-altitude unhooking of the ultrahigh vertical column of the ship is difficult is solved. In addition, the invention further relates to a ship ultrahigh stand column hoisting method.

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD +1

A method for assembling a large steel structure module of a nuclear power plant

ActiveCN105401732BGuaranteed accuracyLarge pair gapBuilding material handlingNuclear powerComputer module

The invention discloses an assembling method of a large steel structure module of a nuclear power plant. The large steel structure module is divided into a plurality of module assembles according to areas. Each module assembly comprises a plurality of sub-modules. A coordinate system is established through the module assemblies, the point DP of one sub-module serves as the origin of coordinates, relative coordinates of the points DP of the rest of the sub-modules are obtained through conversion according to the design paper, the sub-modules are assembled according to the design paper, and three-dimensional coordinate monitoring is carried out on the points DP of the sub-modules through a total station in the assembling process so as to ensure the precision in the splicing process. The assembling method has the beneficial effects that procedures are simple, the splicing size can be controlled integrally, three-dimensional coordinate monitoring of the points DP is carried out through the total station, it is ensured that the points DP of the wall sub-modules are located on the same horizontal datum plane, and therefore the precision required by design is achieved.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

A longitudinally foldable planar truss and its application method

ActiveCN105464007BRealize vertical foldingSimple structureBridge erection/assemblyBridge strengtheningStructural engineering

Owner:WUDA JUCHENG STRUCTURE CO LTD

High pier zero block counter-force pre-pressing method based on combined bracket

InactiveCN113186840ASimple processReduce the risk of hoistingBridge erection/assemblyStringerMechanical engineering

The invention provides a high pier zero block counter-force pre-pressing method based on a combined bracket. The method comprises the following steps of installing an embedded climbing cone and reserving a finish rolling thread steel hole channel, installing an upper shear key and a lower shear key, installing a bracket straight support and a bracket inclined support, laying a distribution longitudinal beam, laying a distribution cross beam, installing a tensioning unit, installing a reaction frame, installing a vertical opposite-pull rod and obtaining prepressing deformation data. The construction problem that the universality is not achieved when the bearing platform is used as a supporting point for counter-force prepressing is solved, and meanwhile the device has the advantages of being easy to install, convenient to disassemble, economical, efficient, high in universality, wide in application range and capable of improving the construction efficiency.

Owner:NO 1 ENG CO LTD OF CR11BG +1

Construction method of cross-button underground pipe gallery

ActiveCN108560584BAvoid the problem of prefabricating separatelyReduce the difficulty of prefabricationArtificial islandsUnderwater structuresClassical mechanicsEngineering

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Large-scale structure and equipment installation method combined with laser scanning technology

PendingCN114577187AEliminate the effects ofBig amount of dataNuclear energy generationActive open surveying meansFault tolerancePoint cloud

The invention belongs to large-scale equipment, and particularly relates to a large-scale structure and equipment installation method combined with a laser scanning technology. A large-scale structure and equipment installation method combined with a laser scanning technology comprises the following steps that firstly, key points are combed and checked; 2, formulating a scanning scheme; 3, collecting and combining data; 4, modeling is carried out; and 5, formulating a field treatment measure scheme. The method provided by the invention has the remarkable effects that the automation degree is high, the influence of manual operation on the result is small, the influence of field conditions is eliminated to a great extent by virtue of the non-contact data acquisition advantage of the laser scanning technology, and the model structure or the equipment body and the mounting area thereof can be subjected to live-action restoration; the point cloud data of all required parts can be obtained by 100% basically, the amount of point cloud data obtained through scanning is huge, and the fault tolerance is good.

Owner:CHINA NUCLEAR IND 23 CONSTR

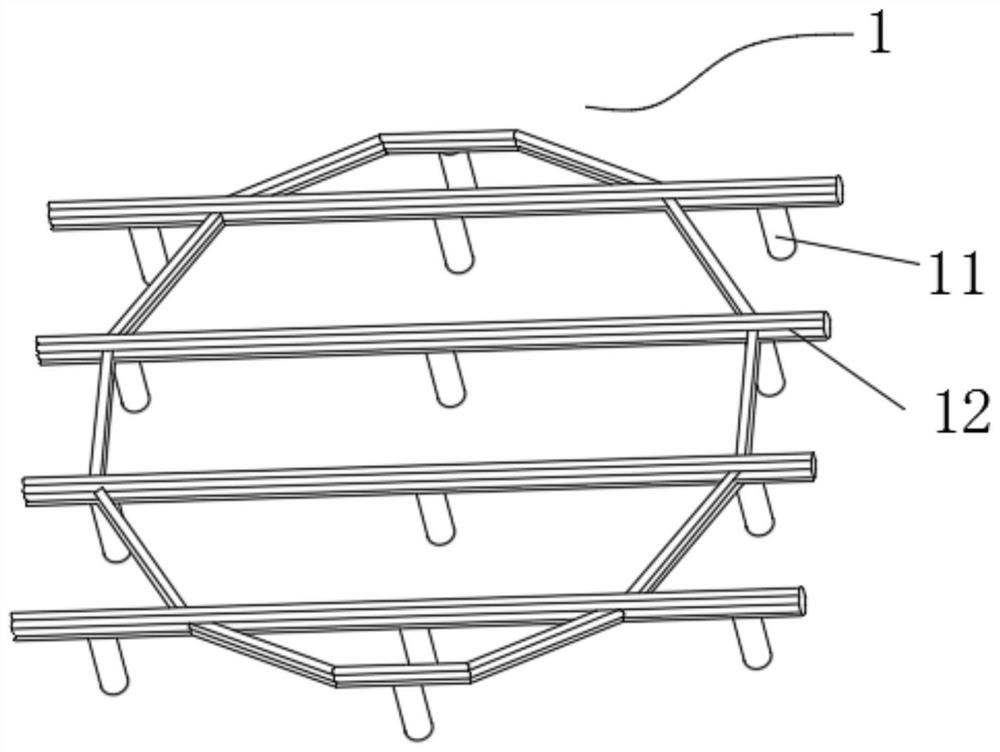

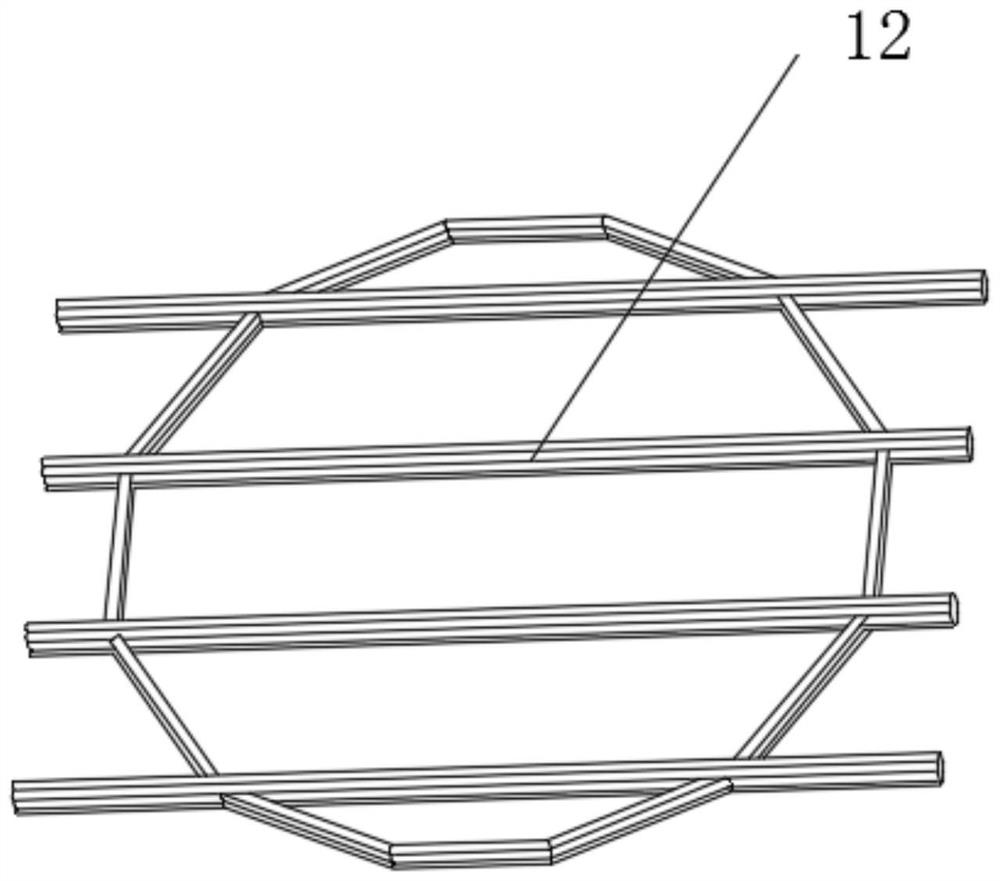

Base suitable for construction and transportation of suction anchor

PendingCN113830251AEven by forceReduce operating costsWaterborne vesselsSuction forceArchitectural engineering

The invention belongs to the technical field of ocean engineering, and particularly relates to a base suitable for construction and transportation of a suction anchor. The base and a self-propelled hydraulic flat car are included, the base comprises fourteen groups of parallel cushion piers and an upper frame, the suction anchor is placed on the base and comprises a suction anchor barrel section, the tops of the parallel cushion piers abut against the lower surface of the upper frame, and the self-propelled hydraulic flat car is arranged under the upper frame and does not make contact with the parallel cushion piers. By arranging the base, the parallel cushion piers, the upper frame and the self-propelled hydraulic flat car, the upper frame is specifically formed by splicing I-shaped steel, is integrally in an eight-diagram shape and is easily attached to the periphery of the suction anchor, it is guaranteed that stress on the base is more uniform in the construction process, and the problem that the hoisting capacity is insufficient can be solved; the hoisting risk can be reduced, the risk of delivery and loading is reduced, safety and reliability are achieved, operation is convenient, and the operation cost of a company is reduced.

Owner:OFFSHORE OIL ENG CO LTD

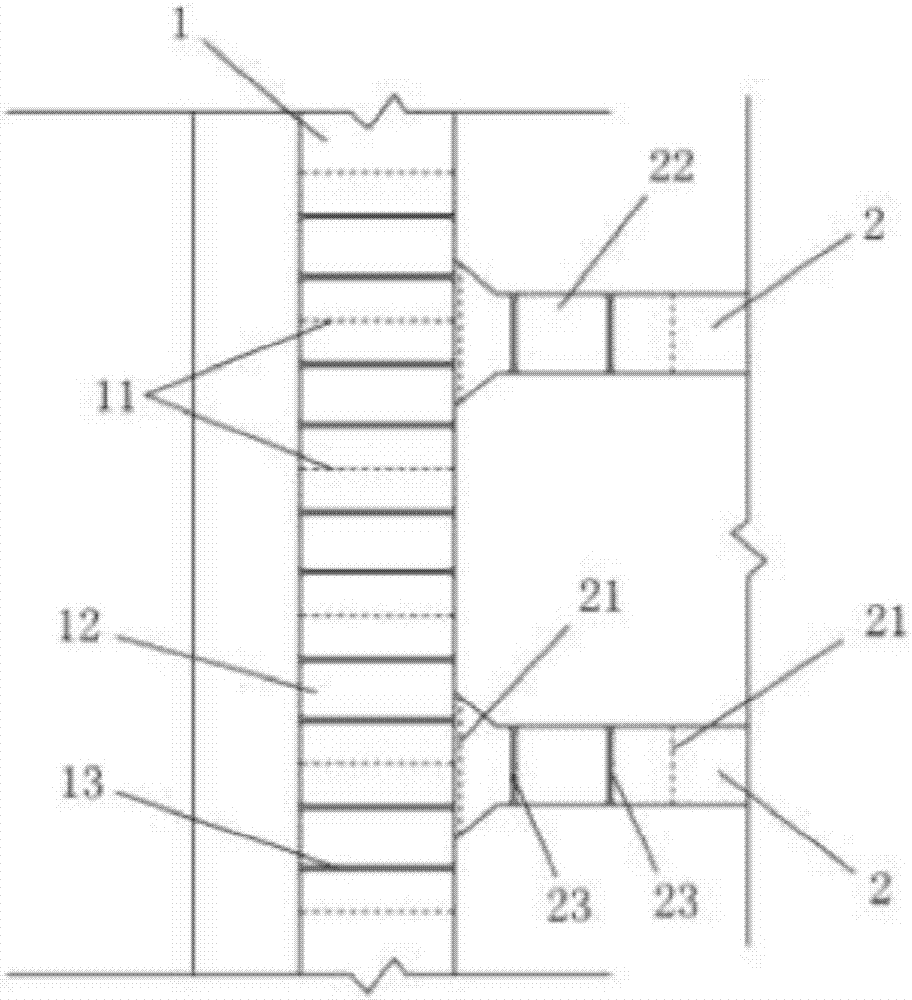

Staggered buckled type construction method for underground pipe gallery

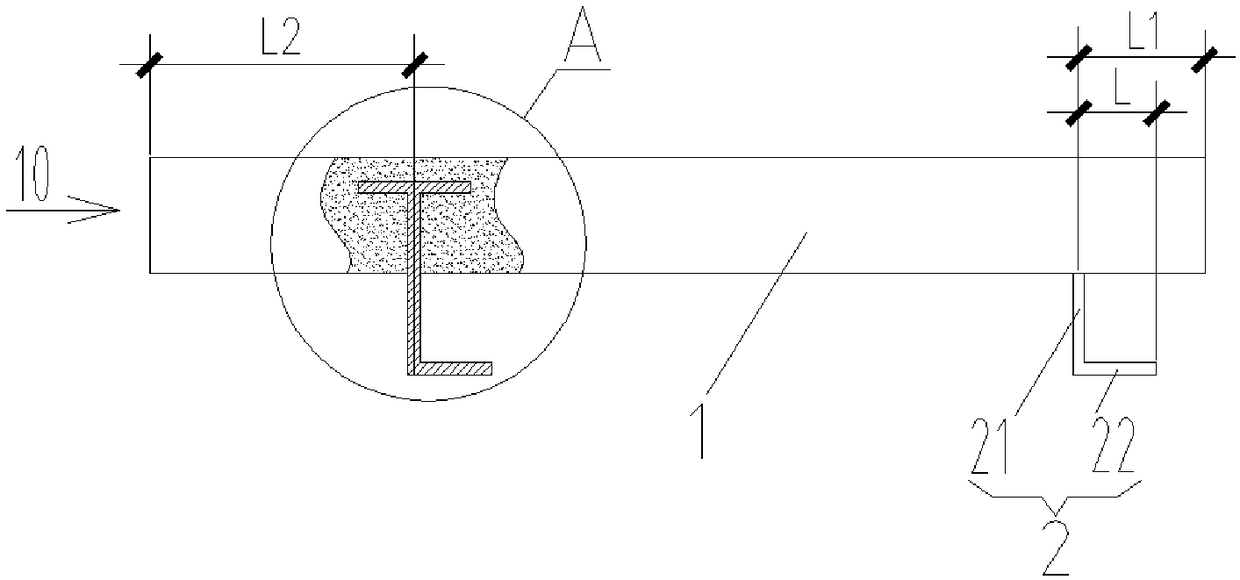

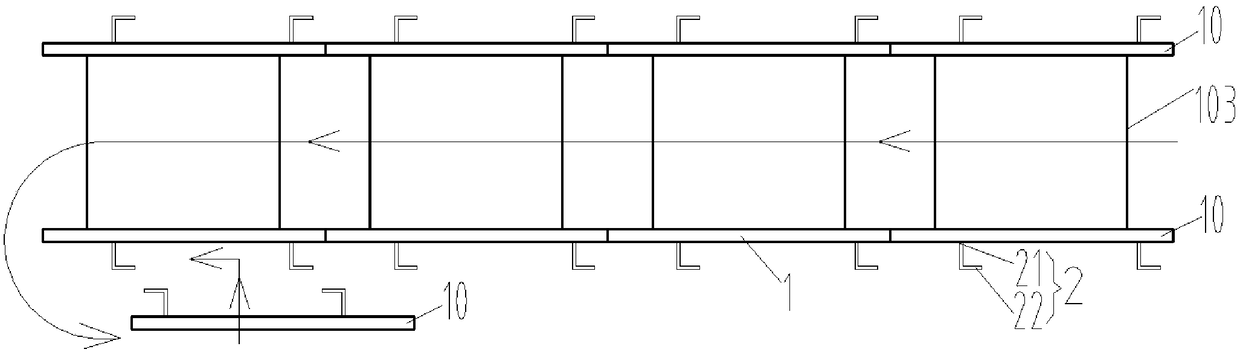

ActiveCN108560584AAvoid the problem of prefabricating separatelyReduce the difficulty of prefabricationArtificial islandsUnderwater structuresWall plateBuilding construction

The invention relates to a staggered buckled type construction method for an underground pipe gallery. Staggered buckled type single-piece prefabricated wall plates are included, the staggered buckledtype single-piece prefabricated wall plates comprise vertical wall plate bodies, and one side face of each wall plate body in the length direction of the corresponding wall plate body is provided with a group of mutually-connected buckled rib plates and a staggered-connected buckled rib plate. The construction method comprises the steps that (1), the two staggered buckled type single-piece prefabricated wall plates are oppositely arranged in parallel, the side faces provided with the buckled rib plates all face outwards, a supporting device is arranged between every two staggered buckled typesingle-piece prefabricated wall plates in an erected manner, and each supporting device and the corresponding staggered buckled type single-piece prefabricated wall plates form an assembling assembly; (2), a plurality of the assembling assemblies are built in the length direction of the pipe gallery and prop against one another, and all the parallel edges located on the same side face the same direction; (3), the outer sides of all the staggered buckled type single-piece prefabricated wall plates are correspondingly connected with the staggered buckled type single-piece prefabricated wall plates again in a buckled manner. According to the staggered buckled type construction method for the underground pipe gallery, only the staggered buckled type single-piece prefabricated wall plates of one structural form are needed, the fabrication difficulty of the fabricated wall plates is lowered, the process that the staggered buckled type single-piece prefabricated wall plates are buckled and connected with one another to be assembled into a stacked wall body is quite simple, the pipe gallery construction process is effectively simplified, and efficiency is improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Construction method of interlocking type comprehensive pipe gallery

ActiveCN108360565AEasy to manufactureReduce the difficulty of prefabricationArtificial islandsUnderwater structuresWall plateBuilding construction

The invention relates to a construction method of an interlocking type comprehensive pipe gallery. The interlocking type comprehensive pipe gallery comprises interlocking type single prefabricated wall boards. Each interlocking type single prefabricated wall board comprises a vertical wall board body, wherein in the length direction of the wall board body, at least two interlocking rib plates arearranged on one side face of the wall board in a spaced manner and extend in the vertical direction, wherein the horizontal section of each interlocking rib plate is in an L shape. The construction method comprises the steps that (1) two interlocking type single prefabricated wall boards are oppositely arranged in parallel, the side faces with the interlocking rib plates are outward, a supportingdevice is erected between the two interlocking type single prefabricated wall boards, and an assembling component is formed; (2) a plurality of assembling components are erected in the length direction of the pipe gallery, the two interlocking type single prefabricated wall boards of each assembling component are located on the two vertical faces correspondingly, and all the parallel edges on thesame side face the same direction; (3) the outer side of each the interlocking type single prefabricated wall board is correspondingly connected with one interlocking type single prefabricated wall board. By the adoption of the construction method of the interlocking type comprehensive pipe gallery, just one structural manner of interlocking type single prefabricated wall boards are needed, and the whole pipe gallery construction process is simplified.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Construction structure and construction method of a double-purpose long-span stiff beam

ActiveCN112324131BReduce lifting weightLower the altitudeForms/shuttering/falseworksDual purposeSteel tube

A dual-purpose large-span stiff beam construction structure and its construction method belong to the technical field of stiff beam construction. It includes a support system, the support system includes several groups of first support components and second support components arranged at equal intervals, the first support components include a group of first tool steel pipes arranged at equal intervals, and the second support components include A group of second tool-type steel pipes arranged at equal intervals, between the adjacent first tool-type steel pipes and the second tool-type steel pipes, between two adjacent first tool-type steel pipes and between two adjacent second tool-type steel pipes The steel pipes are connected by several cross bars. In the present invention, the shaped steel beam is hoisted in sections, which reduces the risk of hoisting, facilitates the protection of structures and components, and is safer; and uses the erection of tool-type steel pipe brackets, and realizes the purpose of one frame for dual purposes through adjustable jacking; the construction method is simple The operation is easy, the integrity is good, the construction period is saved, and the cost is reduced.

Owner:杭州二建建设集团有限公司

Construction method of interlocking comprehensive pipe gallery

ActiveCN108360565BAvoid the problem of prefabricating separatelyReduce the difficulty of prefabricationArtificial islandsUnderwater structuresArchitectural engineeringWall plate

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Construction method for mutually-buckled underground pipe gallery

ActiveCN108487313AEasy to manufactureReduce the difficulty of prefabricationArtificial islandsUnderwater structuresBuilding construction

The invention relates to a construction method for a mutually-buckled underground pipe gallery. The mutually-buckled underground pipe gallery comprises mutually-buckled single-sheet prefabricated wallboards, each mutually-buckled single-sheet prefabricated wallboard comprises a vertical wallboard, and at least two buckling rib plates which extend in the vertical direction and have the L-shaped horizontal sections are arranged on one side face of each wallboard in the length direction of the wallboard at intervals. The construction method comprises the steps that (1), a first layer of steel barmeshes and trapezoidal bearing platforms are laid; (2), a second layer of steel bar meshes are laid; (3), the two mutually-buckled single-sheet prefabricated wallboards are oppositely arranged in parallel, the faces which are provided with the buckling rib plates are outward, a supporting device is arranged between the two wallboards, and a group of assembling assemblies are formed; (4), a plurality groups of assembling assemblies are erected in the length direction of the pipe gallery, the two wallboards of all the assembling assemblies are located on the two corresponding vertical faces, and all the parallel edges located on the same side face the same side; and (5), the outer sides of all the mutually-buckled single-sheet prefabricated wallboards are correspondingly connected with a mutually-buckled single-sheet prefabricated wallboard in a buckling mode. According to the construction method for the mutually-buckled underground pipe gallery, only the mutually-buckled single-sheet prefabricated wallboards with one structural form are needed, and the overall pipe gallery construction process is simplified.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

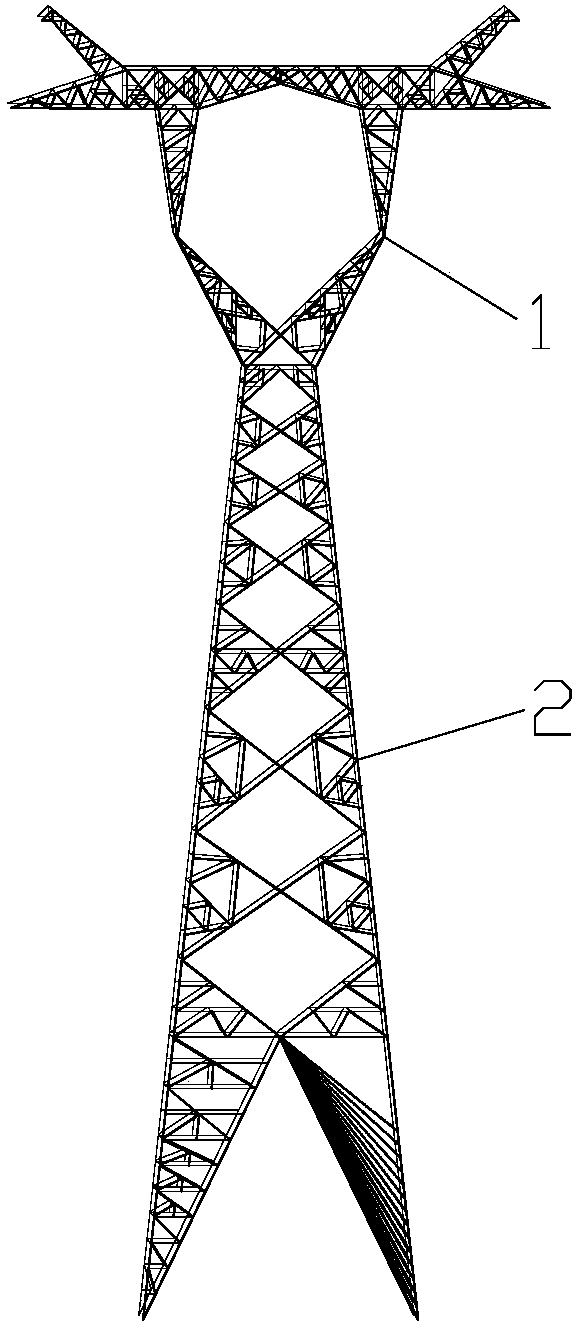

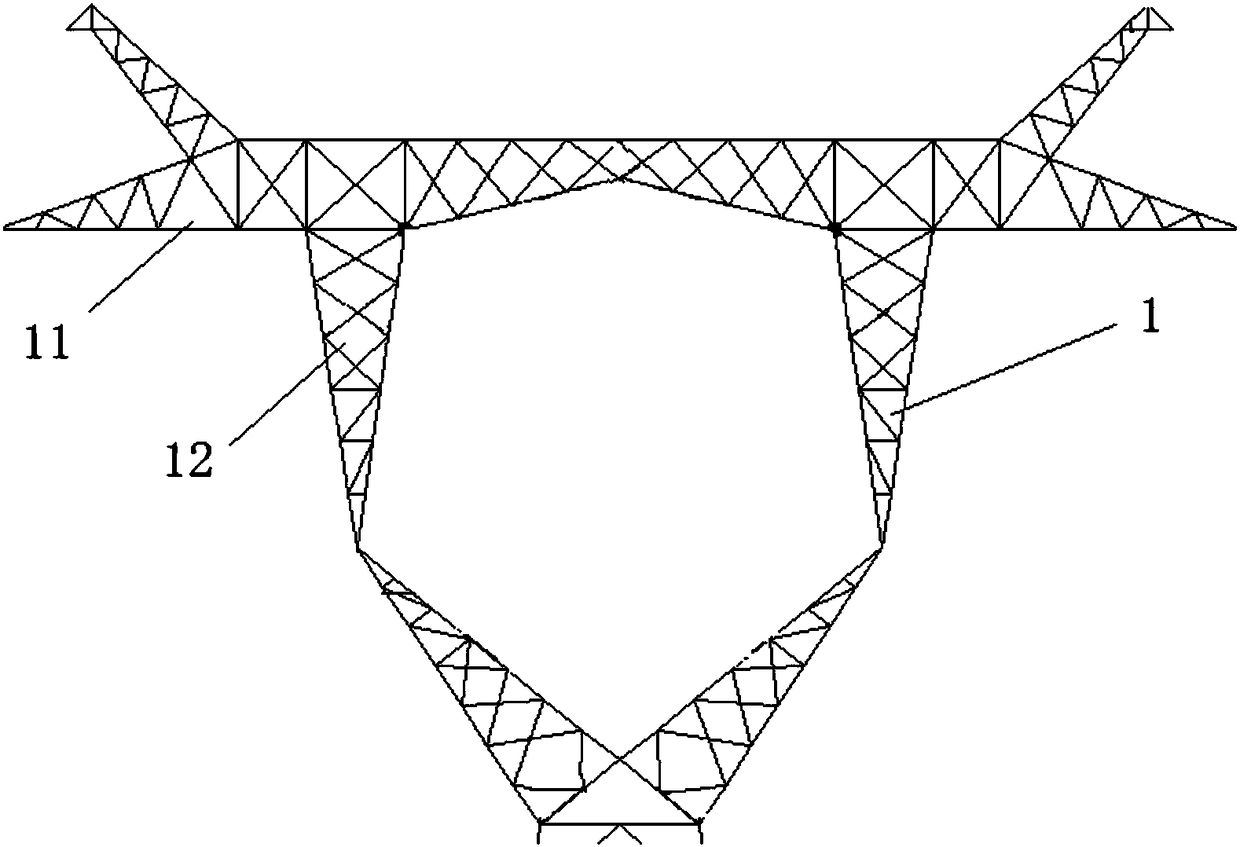

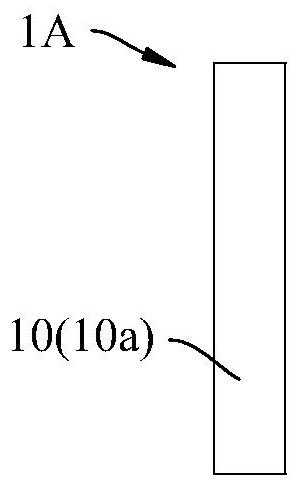

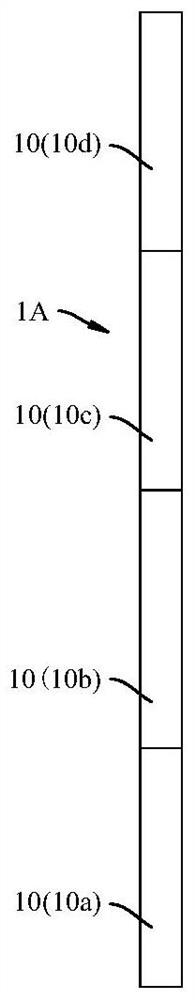

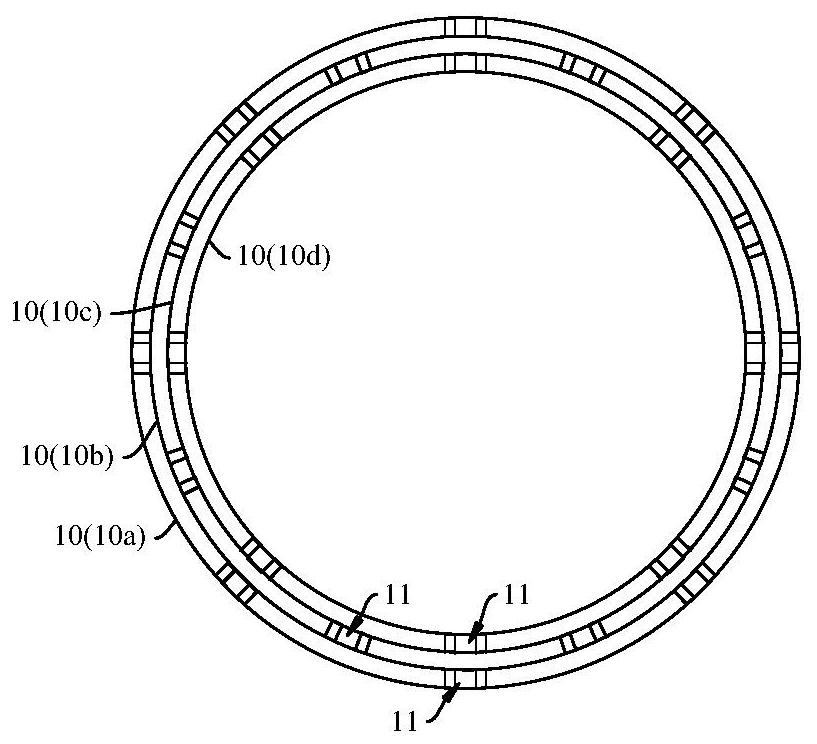

500kv Single-loop Wine Cup Type Linear Tower with Large Span Length Used in High Altitude Area

The invention relates to a 500kv single-loop wine cup type linear tower with large span length used in high altitude area, which includes a tower head and a tower body, wherein the tower head is arranged on the top of the tower body; the tower head includes a cross arm and a tower head connecting part, the tower head connecting part adopts two, and the two tower head connecting parts are arrangedat the lower part of the cross arm and are arranged in parallel; the top of the tower body adopts a V-shaped structure and is connected with the two tower head connecting parts. According to the invention, the height of the tower head can be reduced, the weight of the iron tower can be reduced, the comprehensive cost of the iron tower is reduced, the operation reliability is improved, and meanwhile, the hoisting and construction risk of the tower head rod material of the iron tower is reduced; it can be applied in the condition of high altitude area (altitude of 4000-50000m) and span length of1600m-1800m.

Owner:STATE GRID CORP OF CHINA +5

Wind power tower drum, wind turbine and construction method of wind turbine

PendingCN112796955AImprove installation accuracyReduce usageWind motor assemblyWind motor supports/mountsMarine engineeringWind power

The invention discloses a wind power tower drum, a wind turbine and a construction method of the wind turbine. The wind power tower drum comprises a plurality of tower drum units and a plurality of jacking mechanisms. The tower drum units are sequentially arranged in a sleeved mode from inside to outside, and every two adjacent tower drum units can relatively slide in the axis direction of the wind power tower drum. Each jacking mechanism is arranged between the two corresponding adjacent tower drum units and used for jacking one of the two adjacent tower drum units. According to the technical scheme, the problems of high difficulty and high construction cost of construction of the wind turbine in the prior art can be solved.

Owner:中国电建集团重庆工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com