Ship ultrahigh stand column hoisting tool and hoisting method thereof

A hoisting method and ultra-high technology, applied in the field of shipbuilding, can solve the problems of increasing the risk and cost of column hoisting, laborious and time-consuming execution process, and difficult unhooking operation, so as to reduce hoisting risks and expenses, and improve the efficiency of unhooking operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the description of the present invention, it should be understood that the orientations or positional relationships indicated by the terms "front", "rear", "upper", "lower", "left", "right" etc. are based on the Orientation or positional relationship is only for the convenience of describing the present invention and simplifying the description, and does not indicate or imply that the referred device or element must have a specific orientation, be constructed and operated in a specific orientation, and thus should not be construed as a limitation of the present invention.

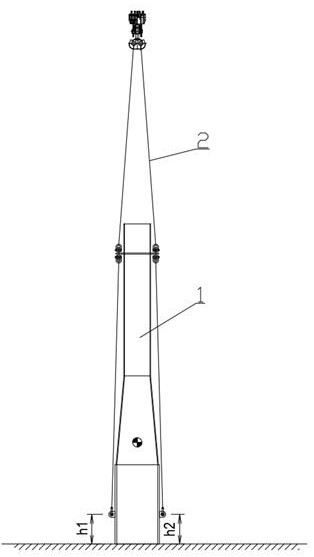

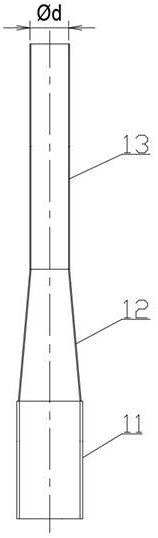

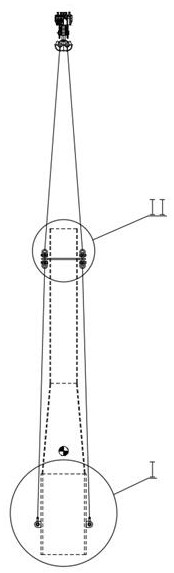

[0044] In order to make it easier for those skilled in the art to fully understand the technical solution disclosed in the present invention, here, a brief description of the project intention and structure of the super-high column of the pre-hoisted ship is required: the European shipowner company undertaken by COSCO SHIPPING The 3200T self-elevating wind power installation vessel is specially desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com