A method for assembling a large steel structure module of a nuclear power plant

A technology of structural modules and assembly methods, which is applied in building construction, processing of building materials, construction, etc., can solve the problems of unguaranteed assembly accuracy, high risk of hoisting, and heavy weight of components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

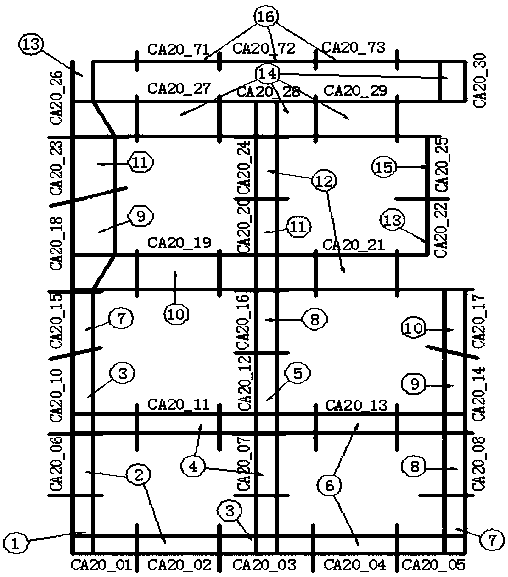

[0070] Taking the assembly method of the three modules CA01, CA20, and CA03 in the AP1000 pressurized water reactor as an example, the specific implementation is described.

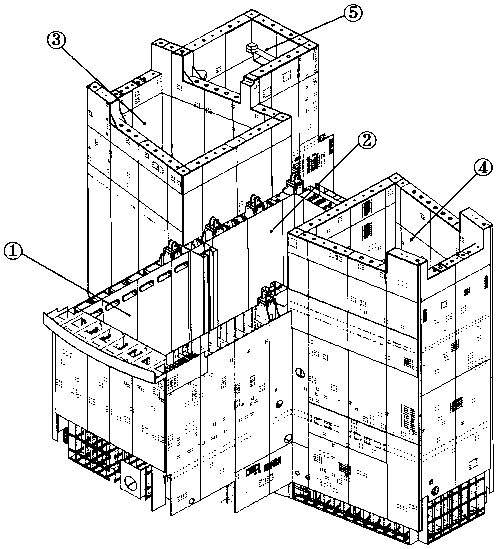

[0071] CA01 module assembly: such as image 3 as shown,

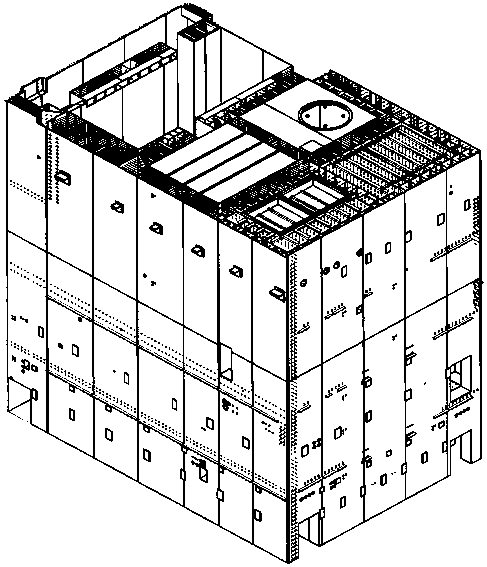

[0072] The CA01 module is a complex structure. The module is in the shape of "pin", with the longest dimension of 26.74 meters, the widest width of 28.96 meters, the highest top of 22.86 meters, and the lowest top of 15.92 meters. It is composed of 47 sub-modules.

[0073] Module assembly is carried out from low to high, and the modules are divided into 5 areas, in the order of area 1 (①) → area 2 (②) → area 3 (③) → area 4 (④) → area 5 (⑤). The assembly sequence number of each area is shown in Table 1.

[0074] Table 1 Assembly sequence numbers for each area

[0075]

[0076]

[0077]

[0078] Installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com