Construction method for mutually-buckled underground pipe gallery

A construction method and technology of underground pipe gallery, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of complex process, low efficiency, difficult prefabrication of prefabricated wall panels, etc., to simplify the process of assembly and construction, manufacturing Simple, easy connection and effect of the adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

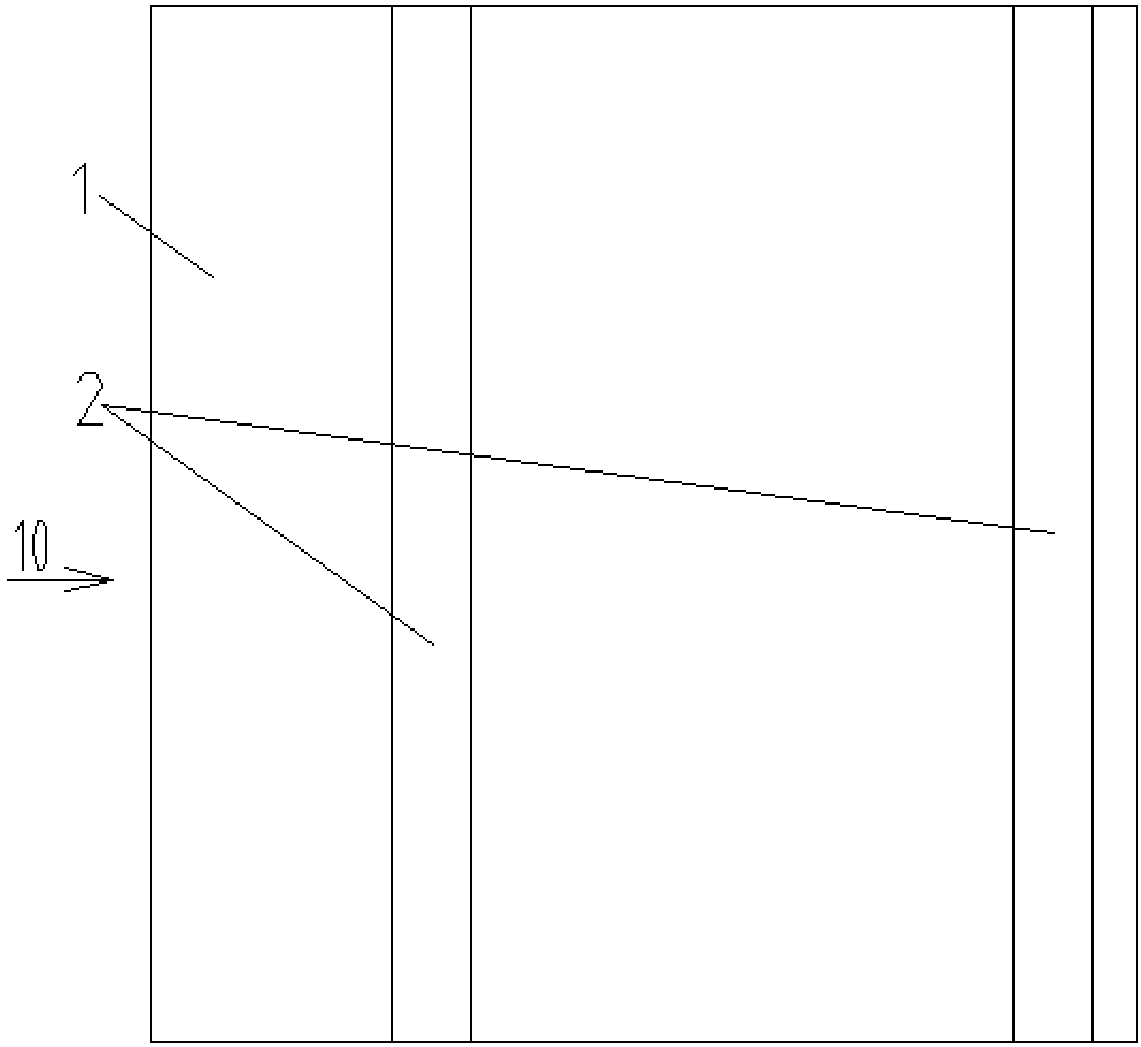

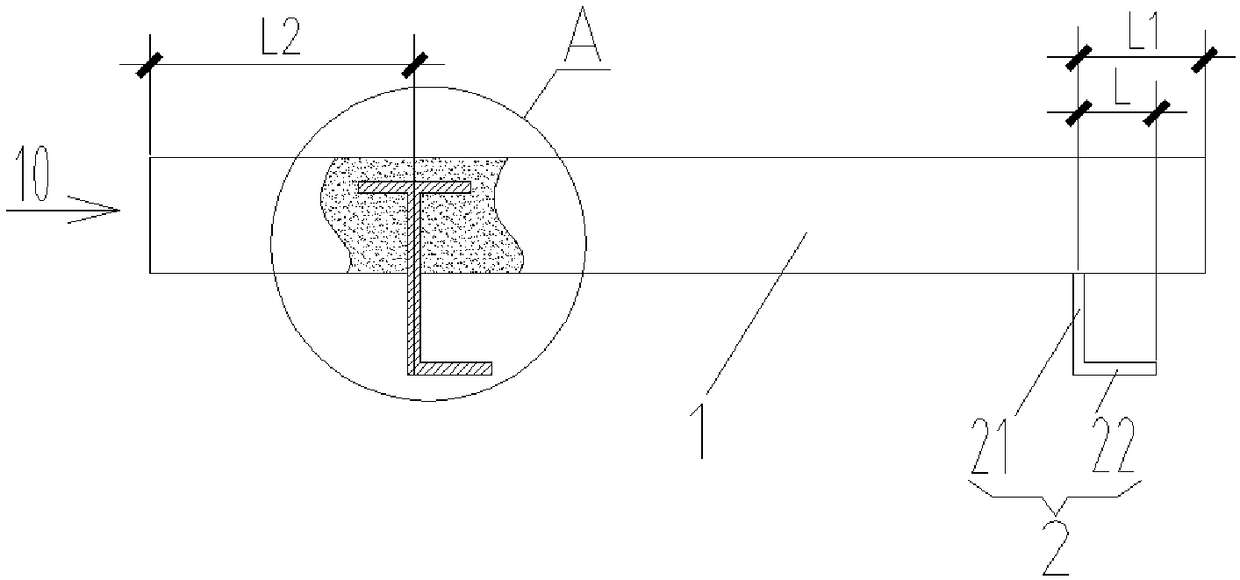

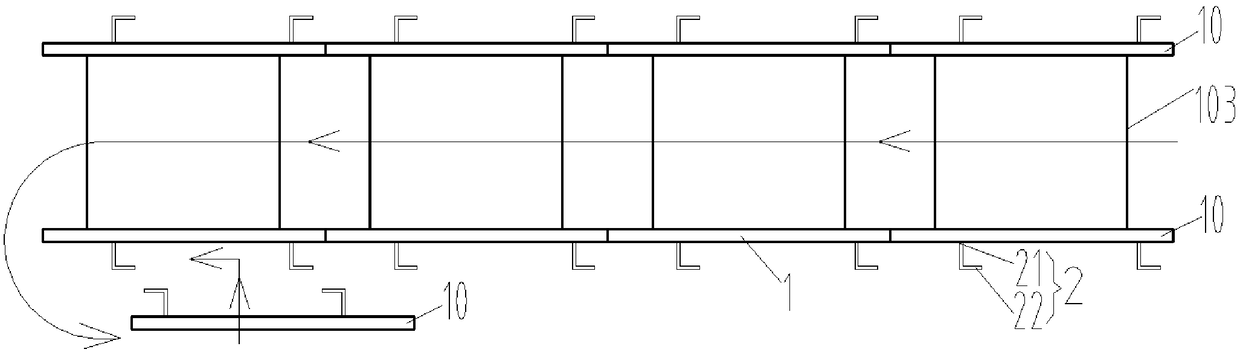

[0060] see figure 1 , figure 2 , the construction method of the interlocking type underground pipe gallery of the specific embodiment 1, including several interlocking type single-piece prefabricated wall panels 10 used in the construction process, and the interlocking type single-piece prefabricated wall panels 10 include vertical The wallboard 1, along the length direction of the wallboard 1, on one side of the wallboard 1, two buckle ribs 2 extending in the vertical direction and having an "L" shape in horizontal section, the buckle ribs The board 2 includes a vertical side 21 perpendicular to the wallboard 1 and fixedly connected to the wallboard 1 and a parallel side 22 connected to the free end of the vertical side 21 and parallel to the wallboard 1, and the two vertical sides 21 are flush up and down, The distances from the two parallel sides 22 to the wallboard 1 are the same and both face the same direction; the sum of the vertical distances from the two ends of the...

specific Embodiment 2

[0080] The difference between specific embodiment two and specific embodiment one is: see Figure 8 , Figure 9 , the interlocking single-piece prefabricated wall panel 10 used in the construction method of the interlocking underground pipe gallery in the second embodiment is provided with four walls at intervals on one side of the wall panel 1 along the length direction of the wall panel 1. One buckle rib panel 2 extending in the vertical direction, the vertical sides 21 of the four buckle rib panels 2 are arranged symmetrically with the median planes 211 of the two vertical sides 21 closest to the two ends of the wallboard 1 to ensure two identical structures All the parallel sides 22 of the interlocking type monolithic prefabricated wall panels 10 can be interlocked in pairs, and the distances from the parallel sides 22 of the four buckle rib panels 2 to the wall panels 1 are consistent and all face the same direction; The vertical distance from the end face of the upper p...

specific Embodiment 3

[0083] The difference between specific embodiment three and specific embodiment one is: see Figure 12 , Figure 13 , the interlocking single-piece prefabricated wall panel 10 used in the construction method of the interlocking underground pipe gallery in the third embodiment is provided with five intervals along the length direction of the wall panel 1 on one side of the wall panel 1. One buckle rib plate 2 extending in the vertical direction, the vertical sides 21 of the five buckle rib plate 2 are set in a symmetrical form with the median planes 211 of the two vertical sides 21 closest to the two ends of the wallboard 1 to ensure two identical structures All the parallel sides 22 of the interlocking type monolithic prefabricated wall panels 10 can be interlocked in pairs. Since the number of the interlocking ribs 2 is an odd number, the middlemost one of the buckling ribs 2 is located on the median plane. 211, the distance between the parallel side 22 of the five-way clasp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com