Recyclable group bundle post-tensioning unbonded prestress underground diaphragm wall and construction method

An underground diaphragm wall and construction method technology, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of rising, steel waste cost, etc., and achieve the effect of reducing consumption, reducing construction cost, and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

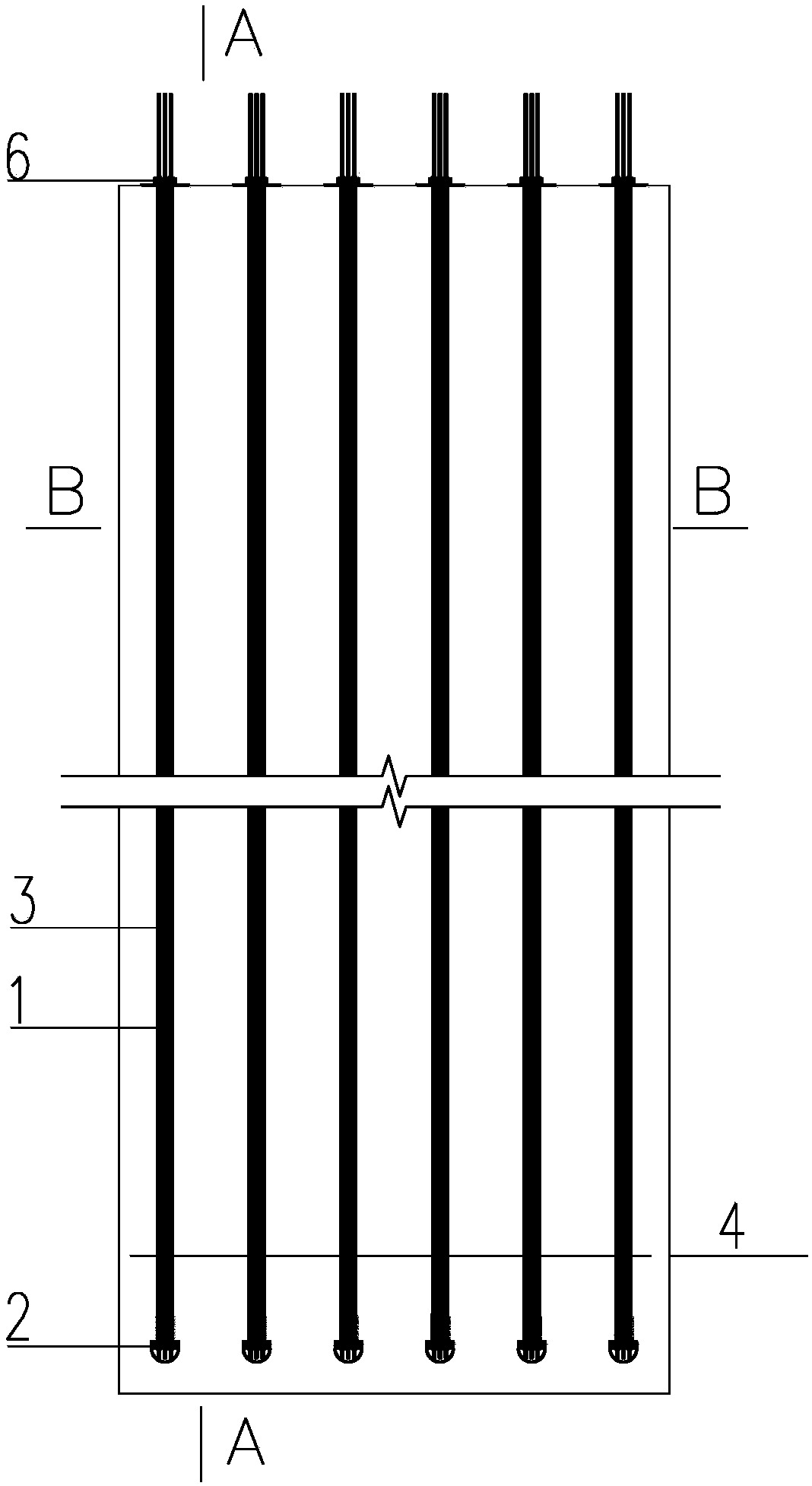

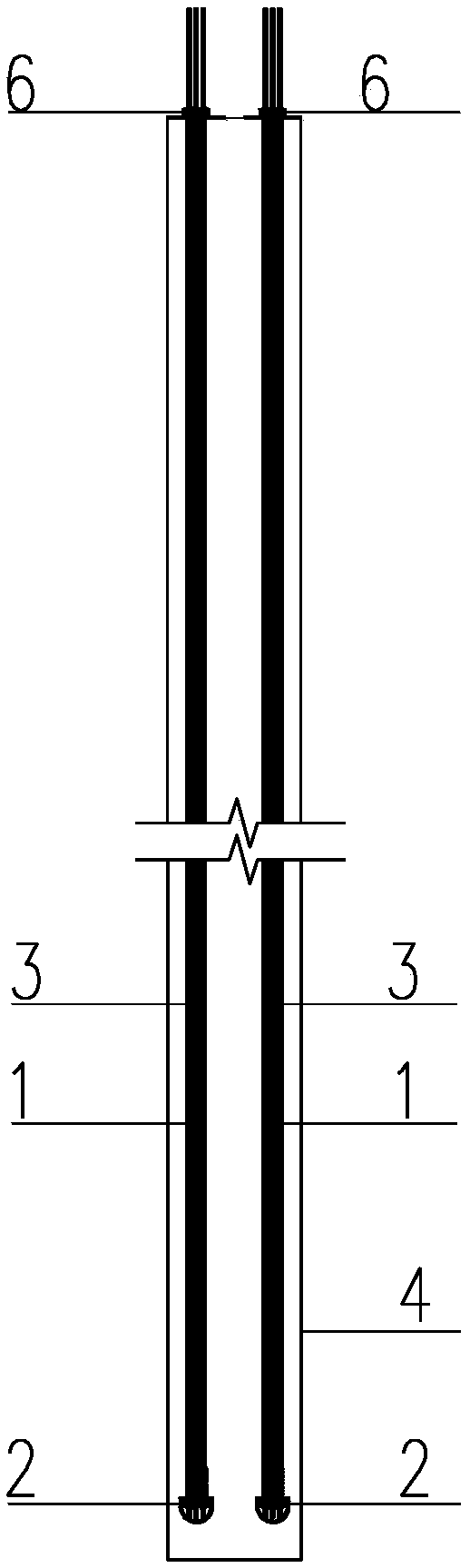

[0044] see Figure 1 to Figure 11 , the present embodiment provides a method for the construction of post-tensioned unbonded prestressed underground diaphragm walls with recoverable groups, including:

[0045] Assembling the prestressed bundle 1 and the porous fixed-end anchor 2 to form a prestressed bundle assembly, the lower end of the prestressed bundle 1 is installed in the porous fixed-end anchor 2, and each prestressed bundle 1 includes Several working cables 110 for applying prestress to the underground diaphragm wall and tool cables 120 for unanchoring the working cables 110, the working cables 110 are arranged around the outside of the tool cables 120, and the tool cables 120 and The working cables 110 are linear unbonded prestressed tendons, and the unbonded prestressed tendons include steel strands and sheath tubes set outside the steel strands, and the porous fixed end anchor 2 can anchor It can also release the steel strand 111 of the anchor working cable 110;

...

Embodiment 2

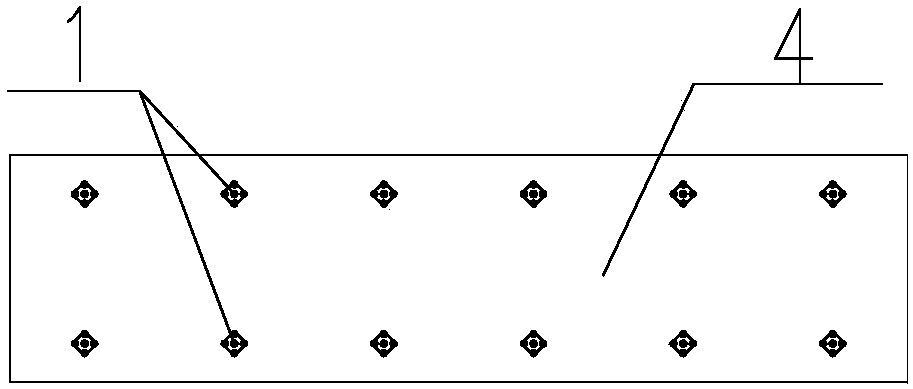

[0066] read on Figure 1 to Figure 11 , the present embodiment discloses a recoverable post-tensioned unbonded prestressed underground diaphragm wall, comprising several underground diaphragm wall sections 4, adjacent underground diaphragm wall sections 4 are connected by joints, and the underground diaphragm wall sections 4 include Reinforcement cage (not shown) and several prestressed cluster components, the prestressed cluster components are formed by assembling the prestressed cluster 1 and the porous fixed end anchorage 2, and the upper end of the prestressed cluster 1 protrudes from the underground diaphragm wall The top surface of the section 4, the lower end of the prestressed bundle 1 is installed in the porous fixed end anchorage 2, each prestressed bundle 1 includes a number of working cables 110 for applying prestress to the underground continuous wall and A tool cable 120 for unanchoring the working cable 110, the working cable 110 is arranged around the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com