Patents

Literature

145results about How to "Reduce the difficulty of hoisting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

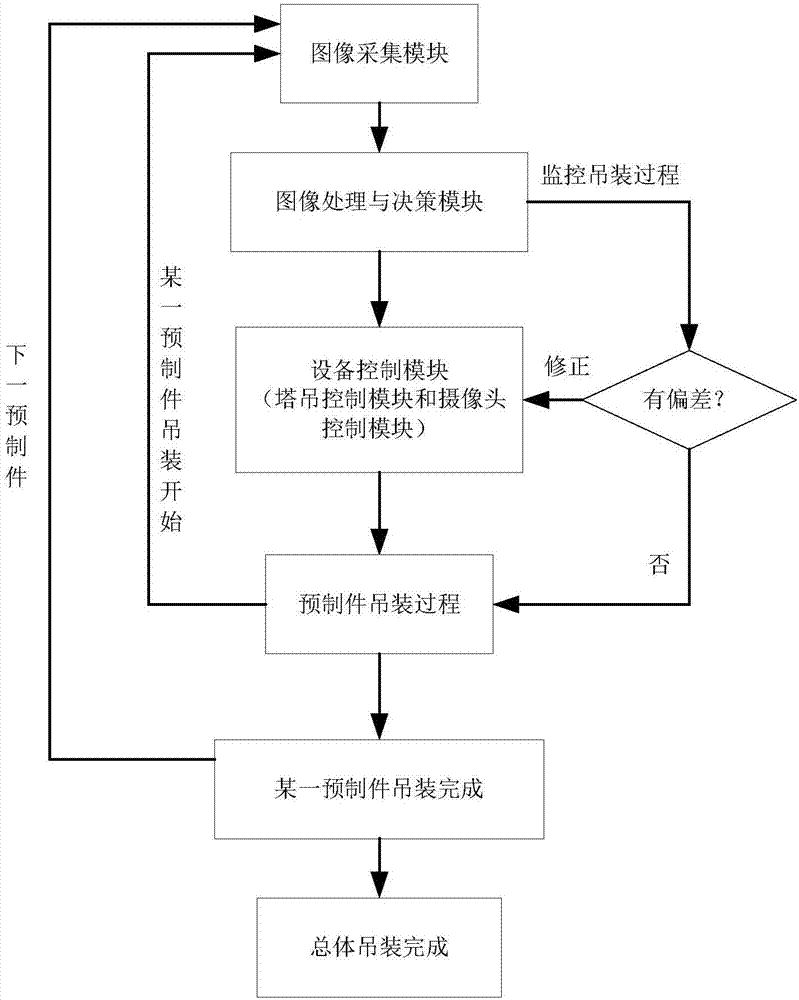

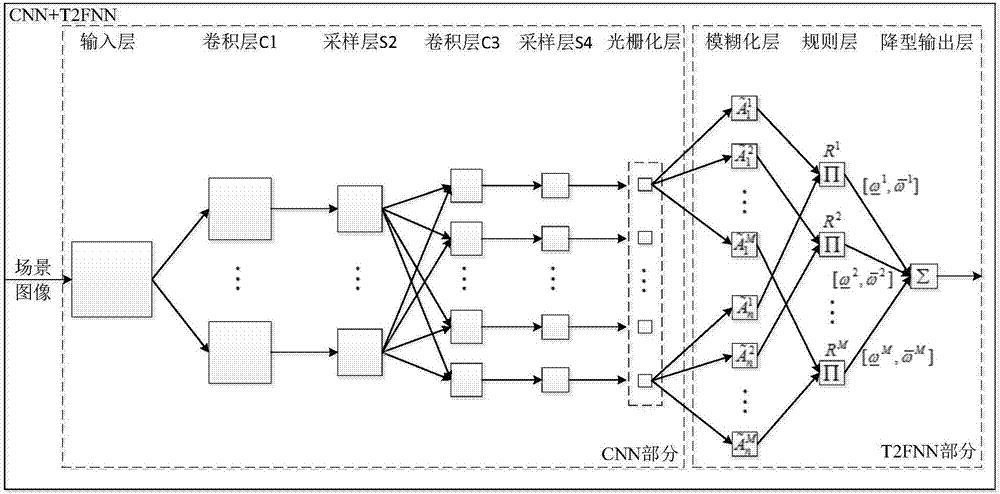

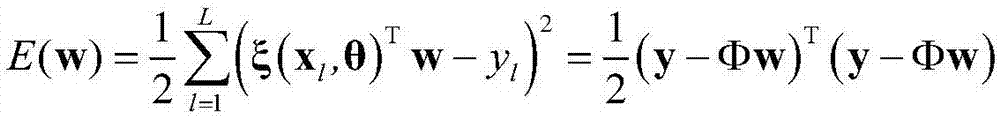

Fabricated type building intelligent hoisting method and system based on machine vision

ActiveCN106966298AImprove hoisting efficiencyImprove accuracyImage enhancementImage analysisIntelligent lightingMachine vision

The invention discloses a fabricated type building intelligent hoisting method and a system based on machine vision. The fabricated type building intelligent hoisting system based on the machine vision comprises an image gathering module, an image processing and decision module and a device control module, the image processing and decision module and the image gathering module are communicated, and the device control module and the image processing and decision module are communicated. According to the fabricated type building intelligent hoisting method and the system based on the machine vision, the machine vision replaces the reliance on human vision in the hoisting process of the fabricated type building. Obstacle recognition is conducted in a complex fabricated scene through a deep learning model of a convolutional neural network and a type-II fuzzy neural network by using the machine vision, prefabrication hoisting path planning is conducted by using ant colony algorithm, and consequently, the movement of equipment on the scene is controlled according to the decision result. The fabricated type building intelligent hoisting method and the system based on the machine vision analyze and obtain the best scheme from the complex scene by using the camera instead of the human eye, can better plan the prefabrication hoisting path, greatly improve the hoisting efficiency and accuracy of the fabricated type building, realize the intelligent hoisting of the fabricated type building, and improve the shortcomings of artificial hoisting.

Owner:日照安泰科技发展有限公司

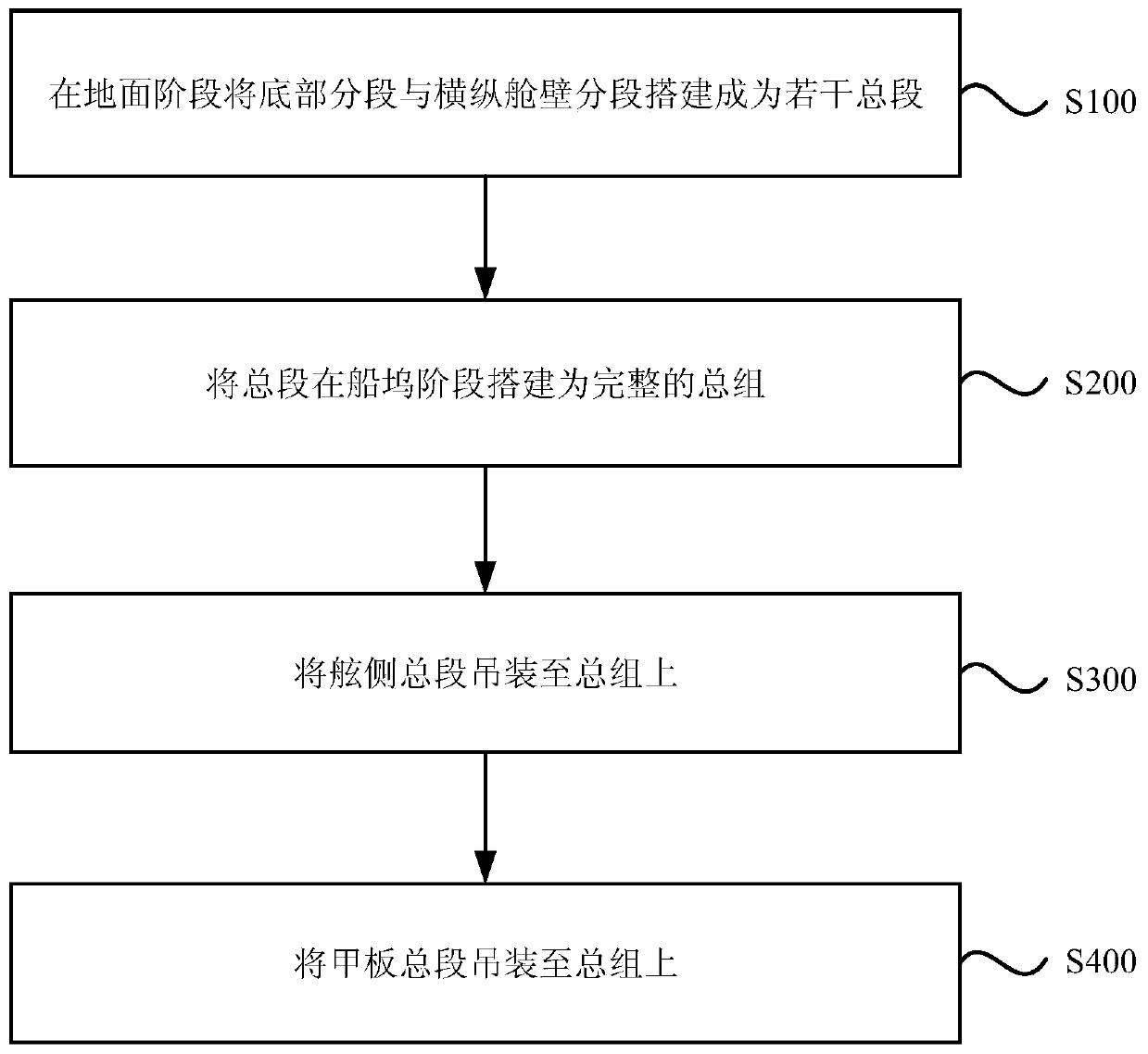

Ship total group erection method

ActiveCN109850066AReduce occupancyGuaranteed to workVessel partsMarine engineeringWorking environment

The invention discloses a ship total group erection method. A bottom part section and a transverse and longitudinal cabin wall of a ship are built into a plurality of blocks in the ground stage of theship; the blocks are built into a complete total group in the shipyard stage of the ship; and a broadside block and a deck block of the ship are built to the blocks in sequence to finish the erectionof the ship. By building the bottom part section and the transverse and longitudinal cabin wall of the ship into the plurality of blocks in the ground stage of the ship and hoisting the broadside block and the deck block of the ship to the blocks of the total group in sequence in the shipyard stage of the ship, the occupation of a shipyard can be effectively reduced; it can be guaranteed that thehoisting and welding of the broadside block can be finished in a relatively open environment; and the working environment of construction personnel can be effectively improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

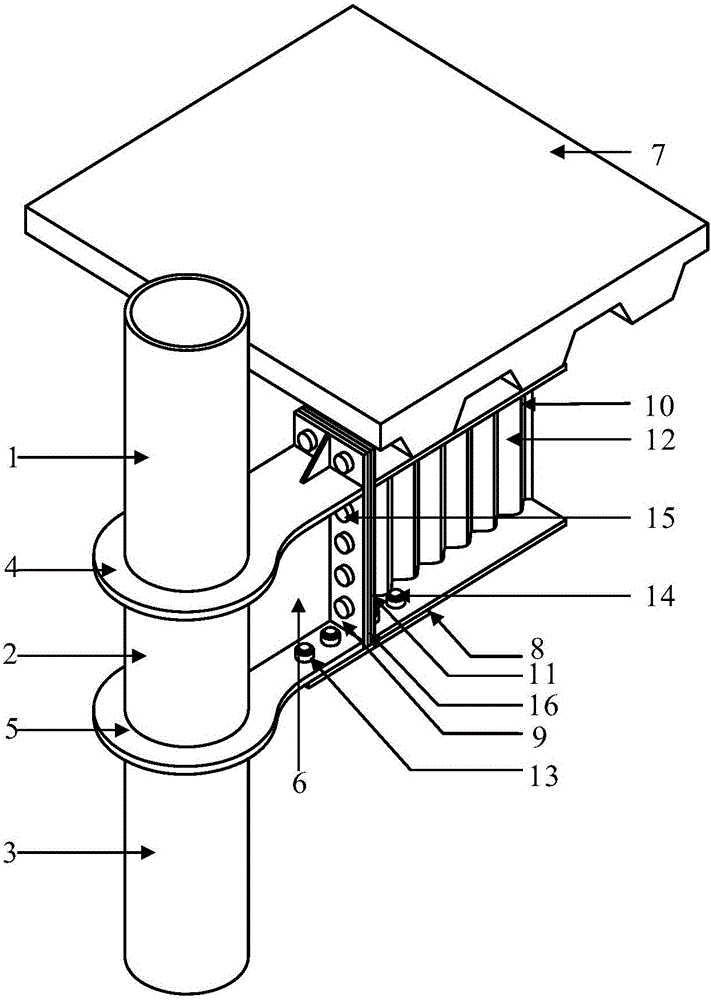

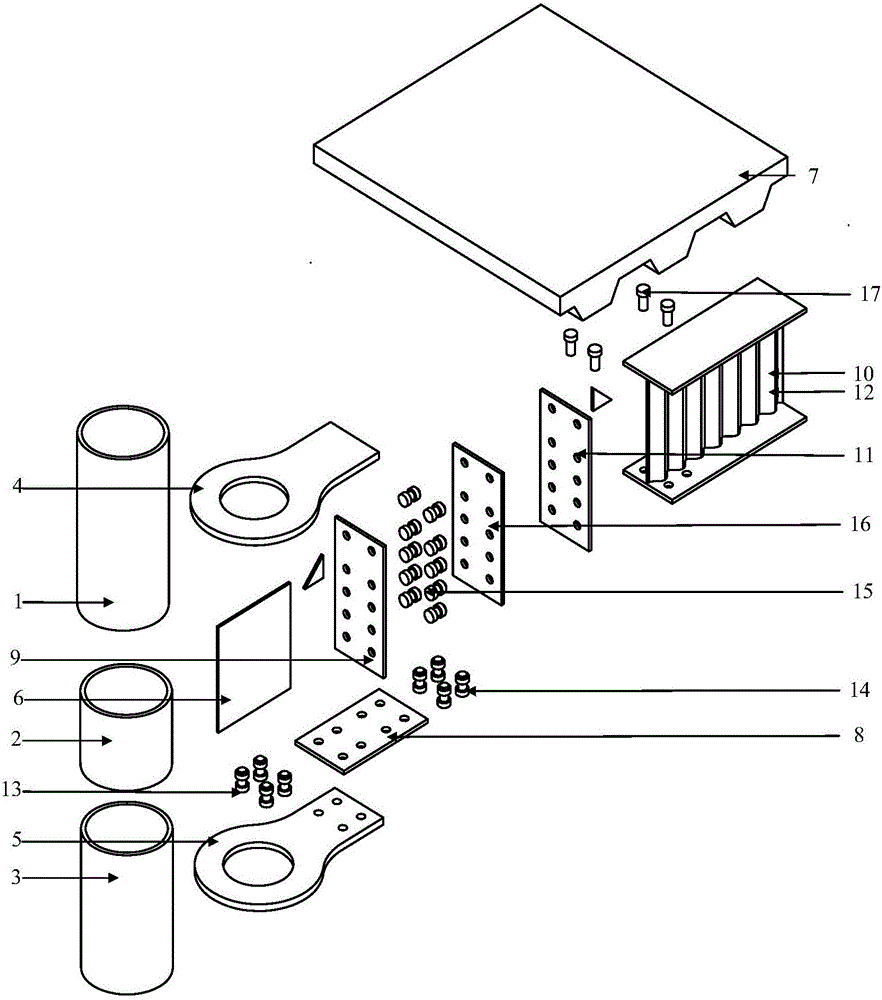

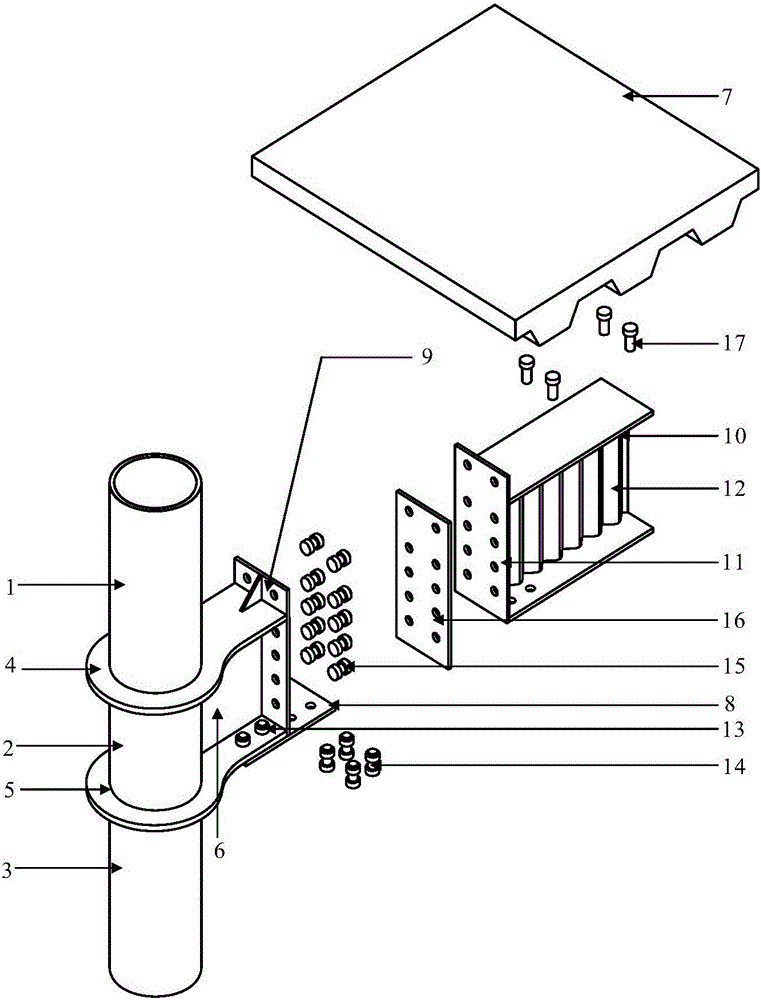

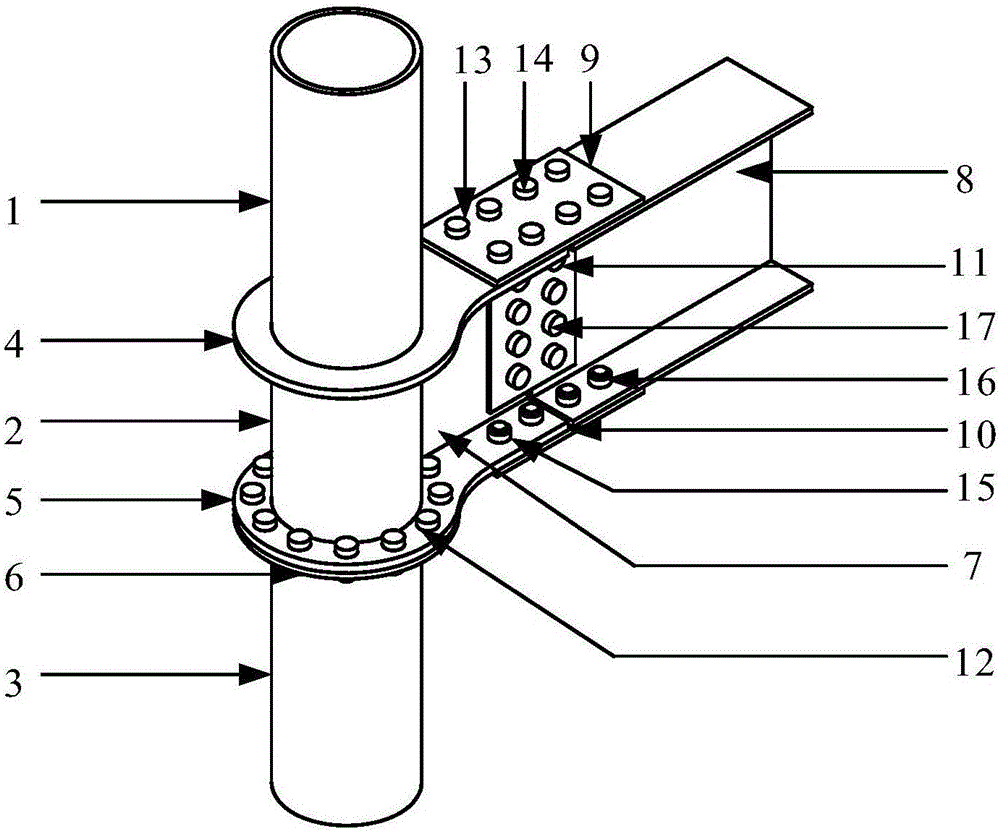

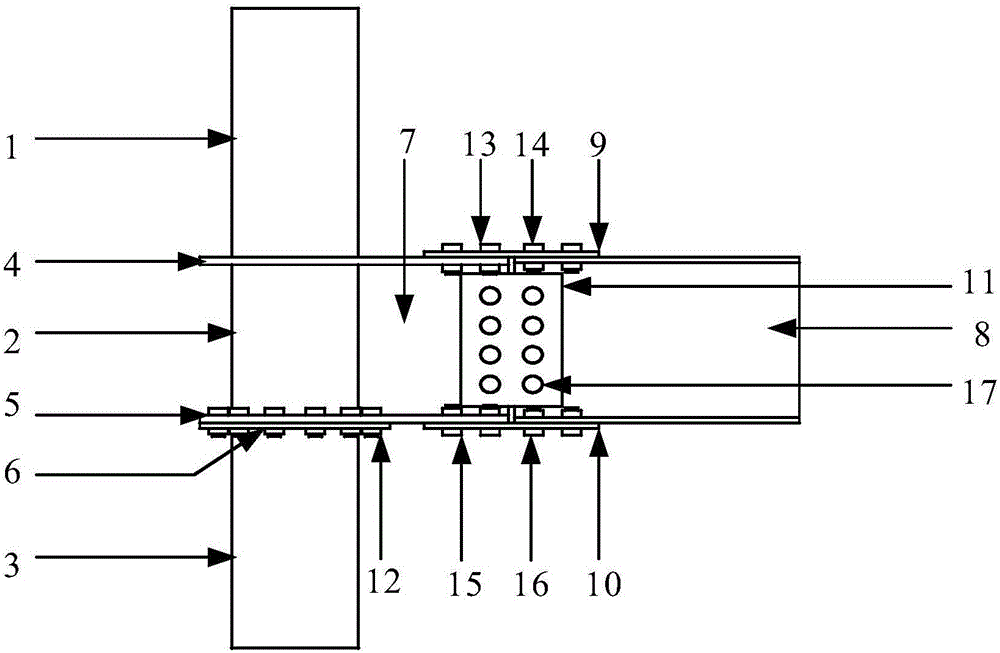

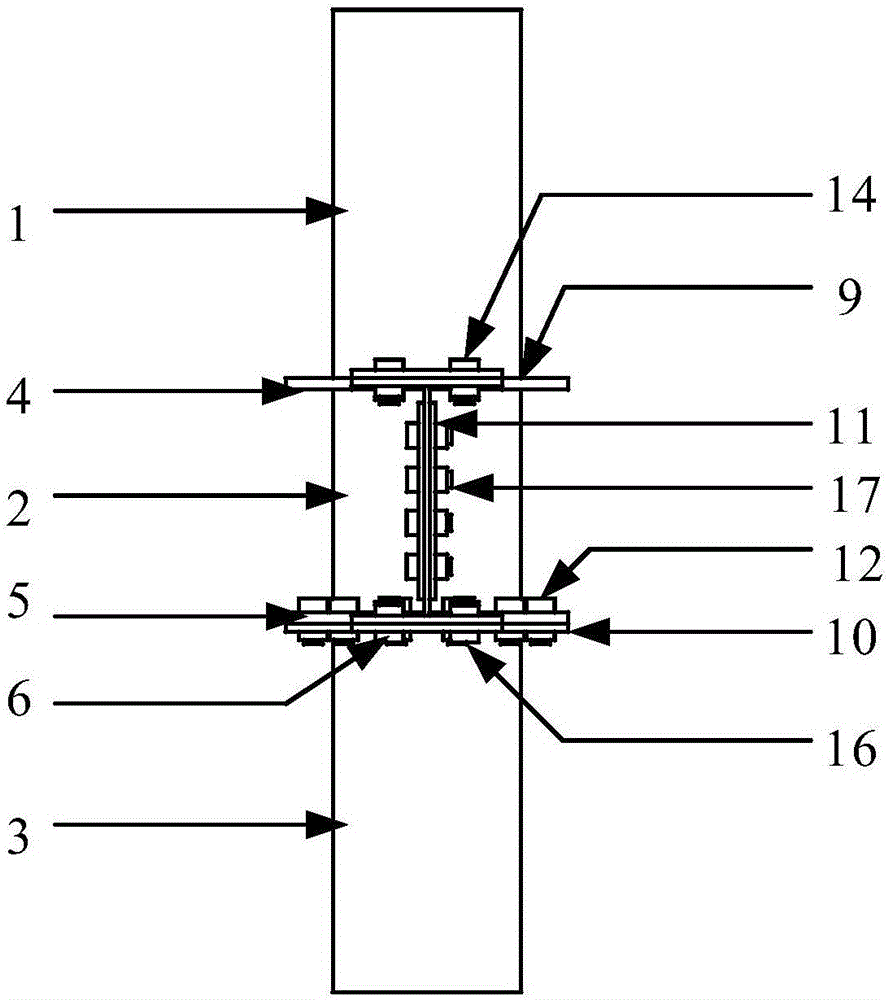

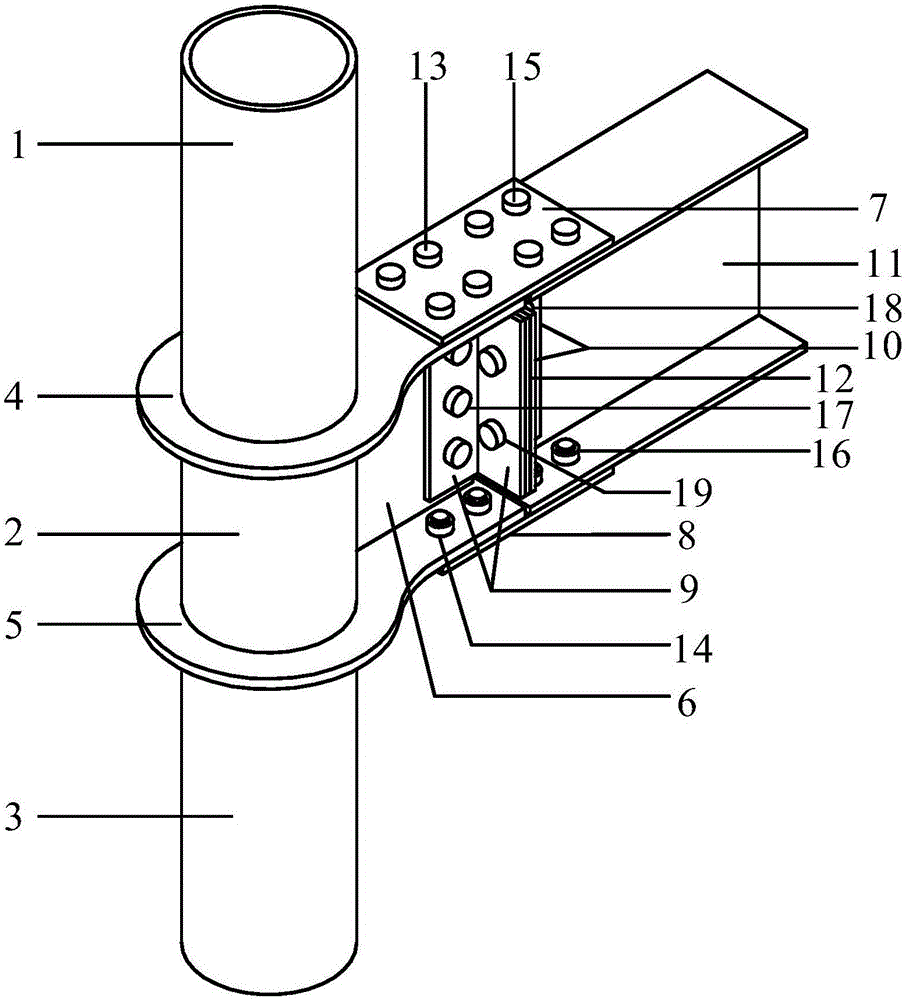

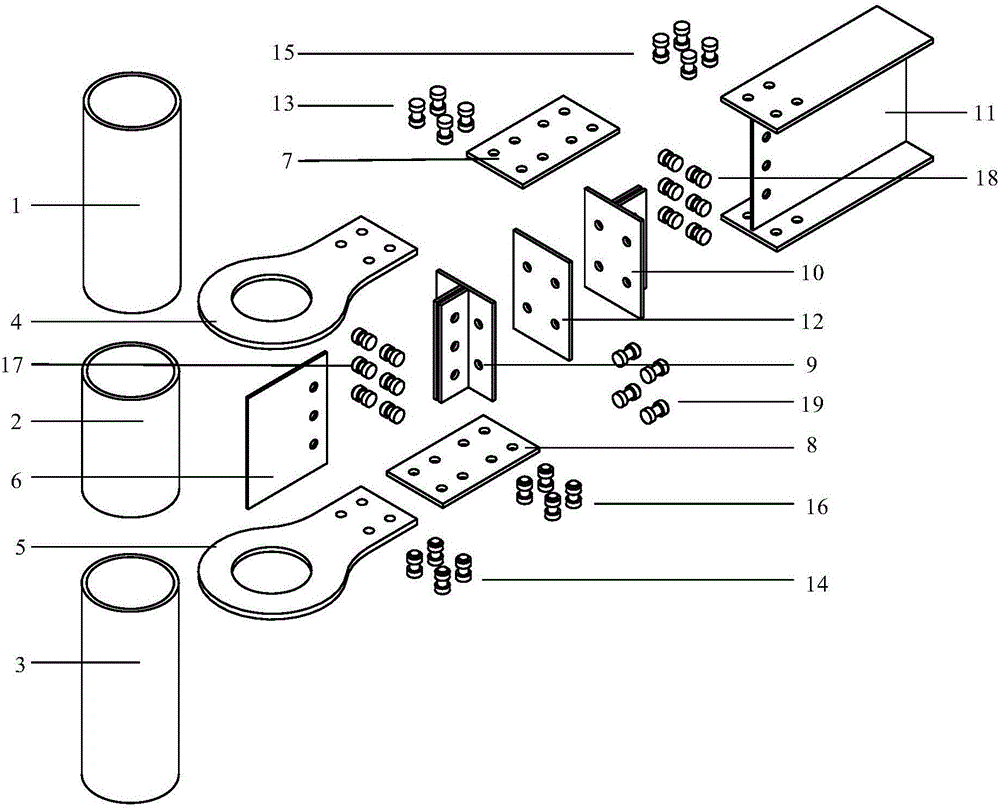

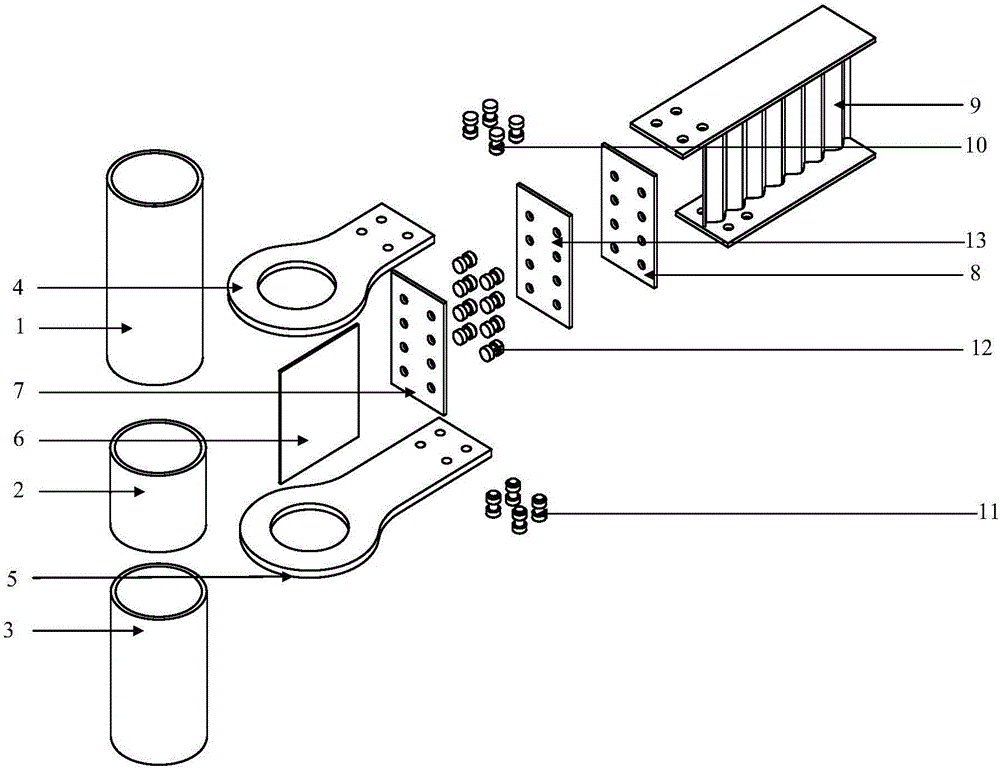

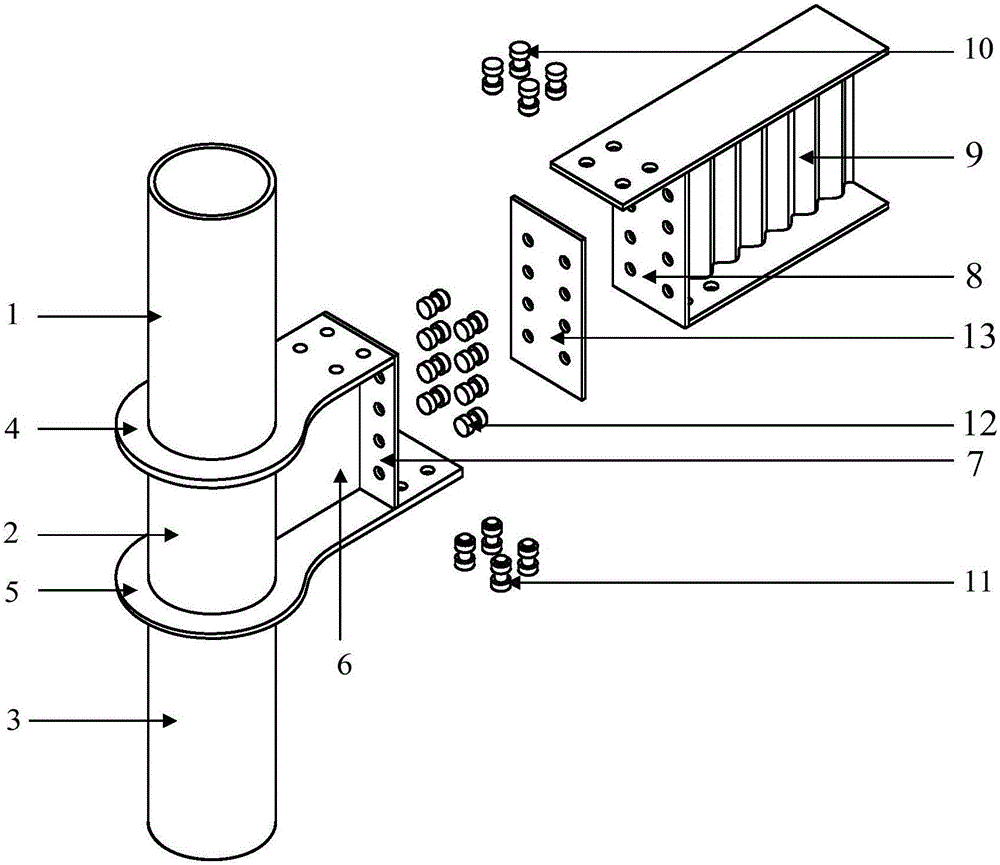

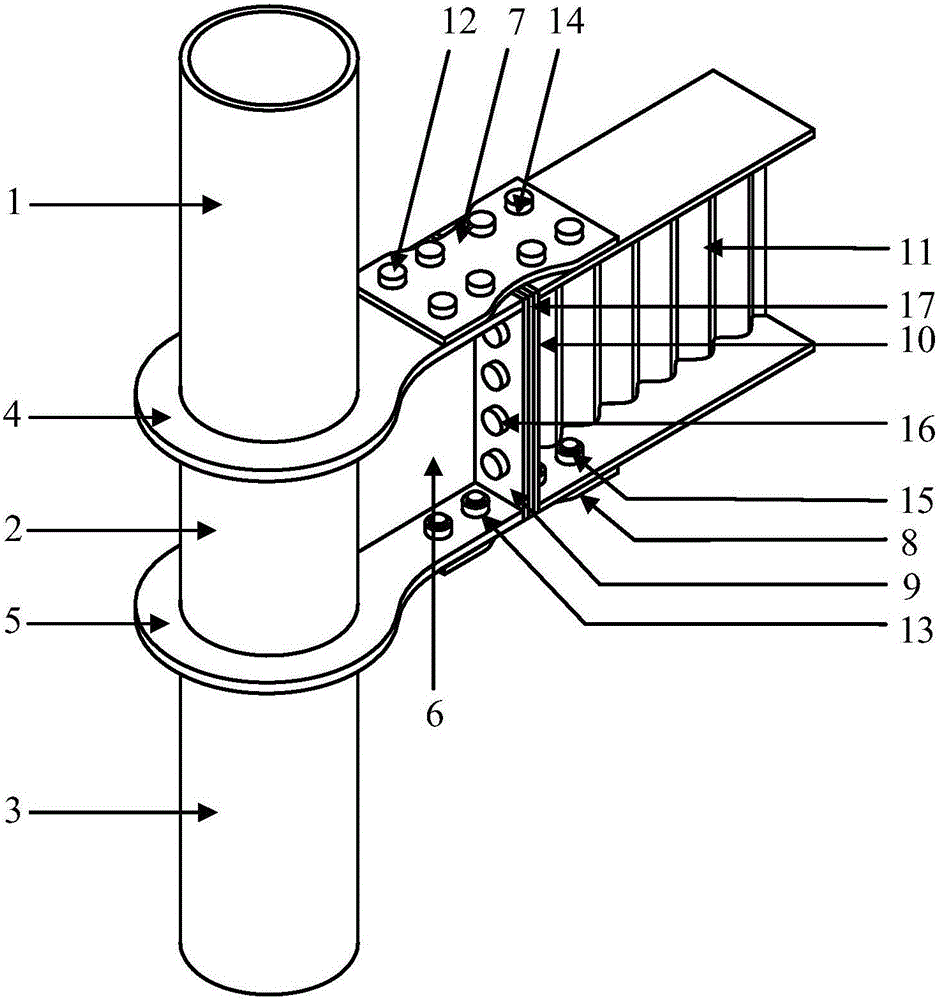

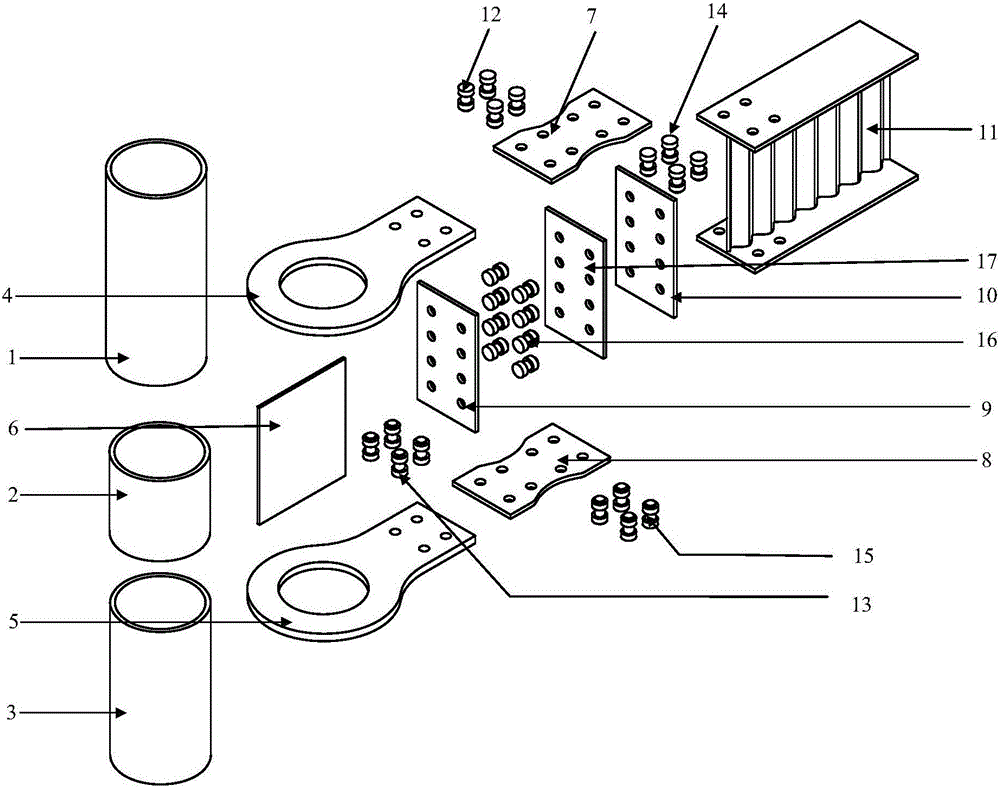

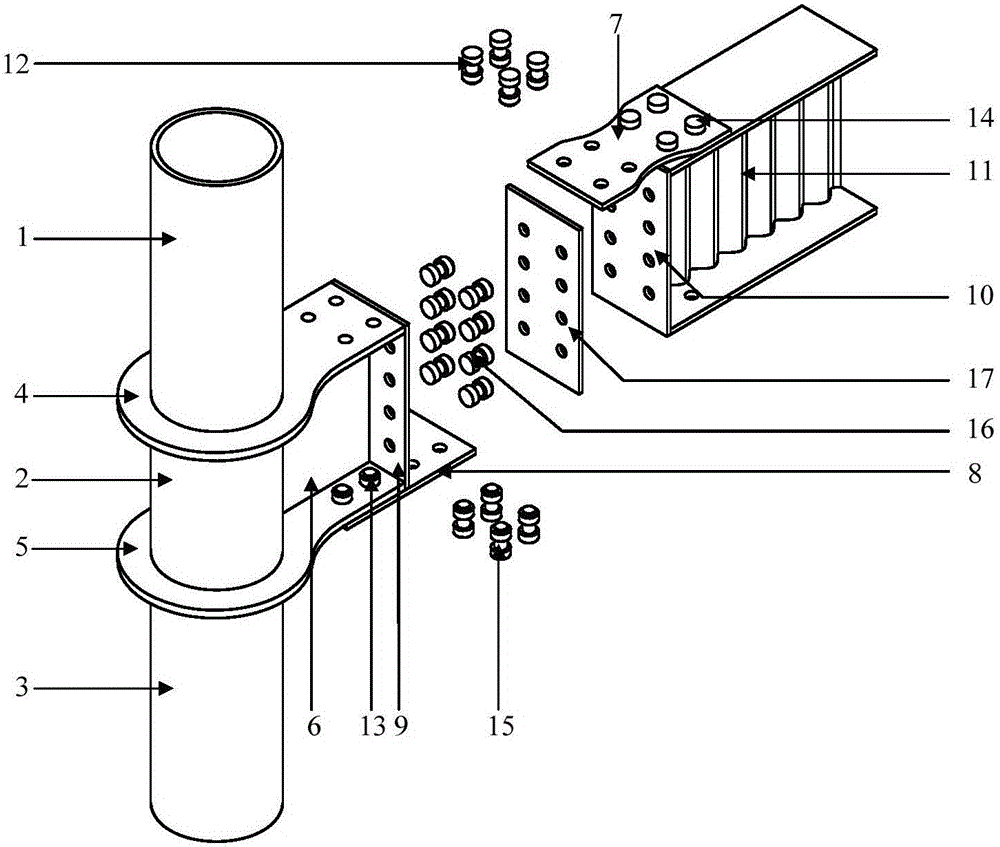

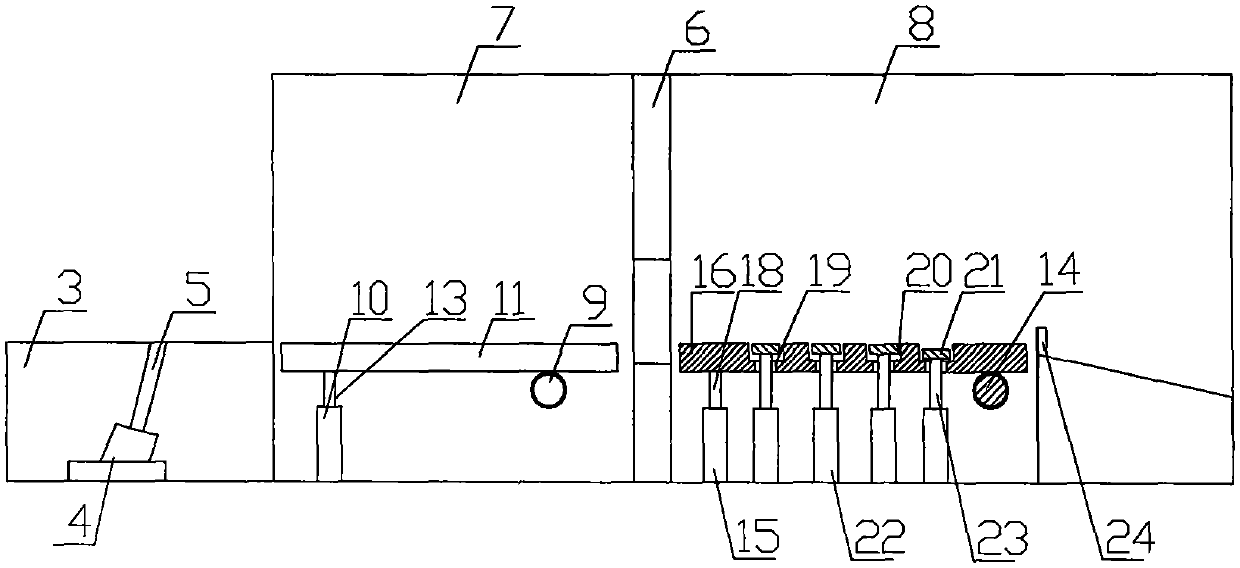

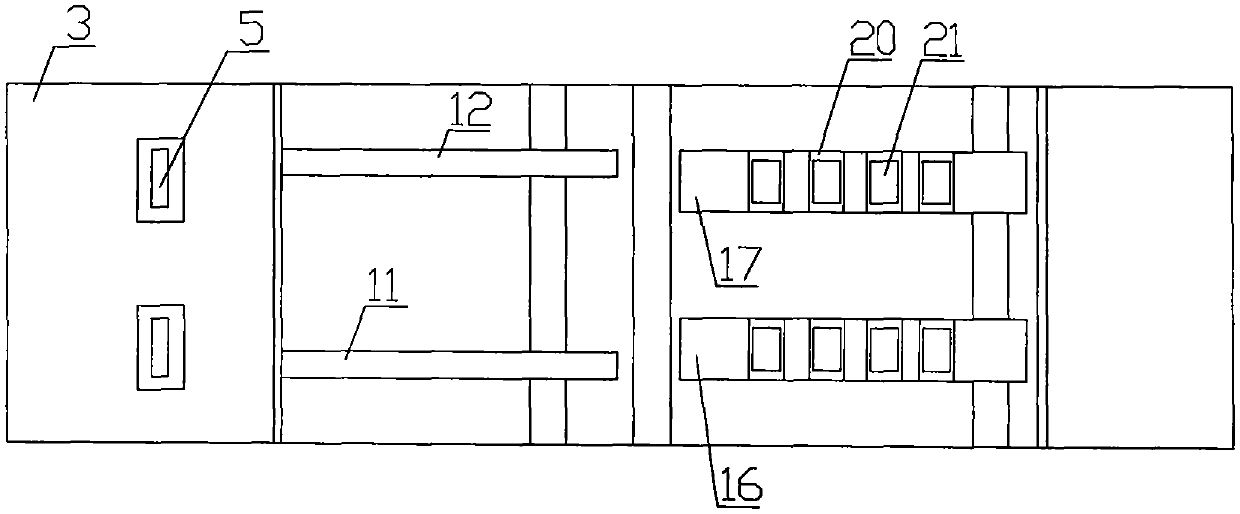

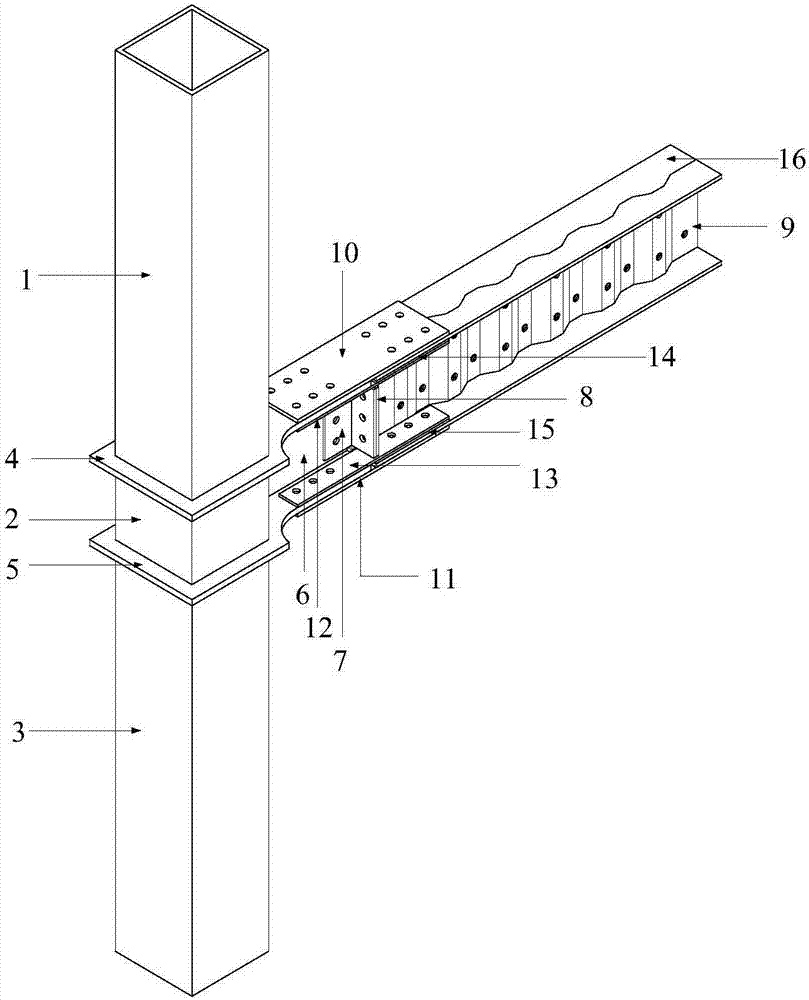

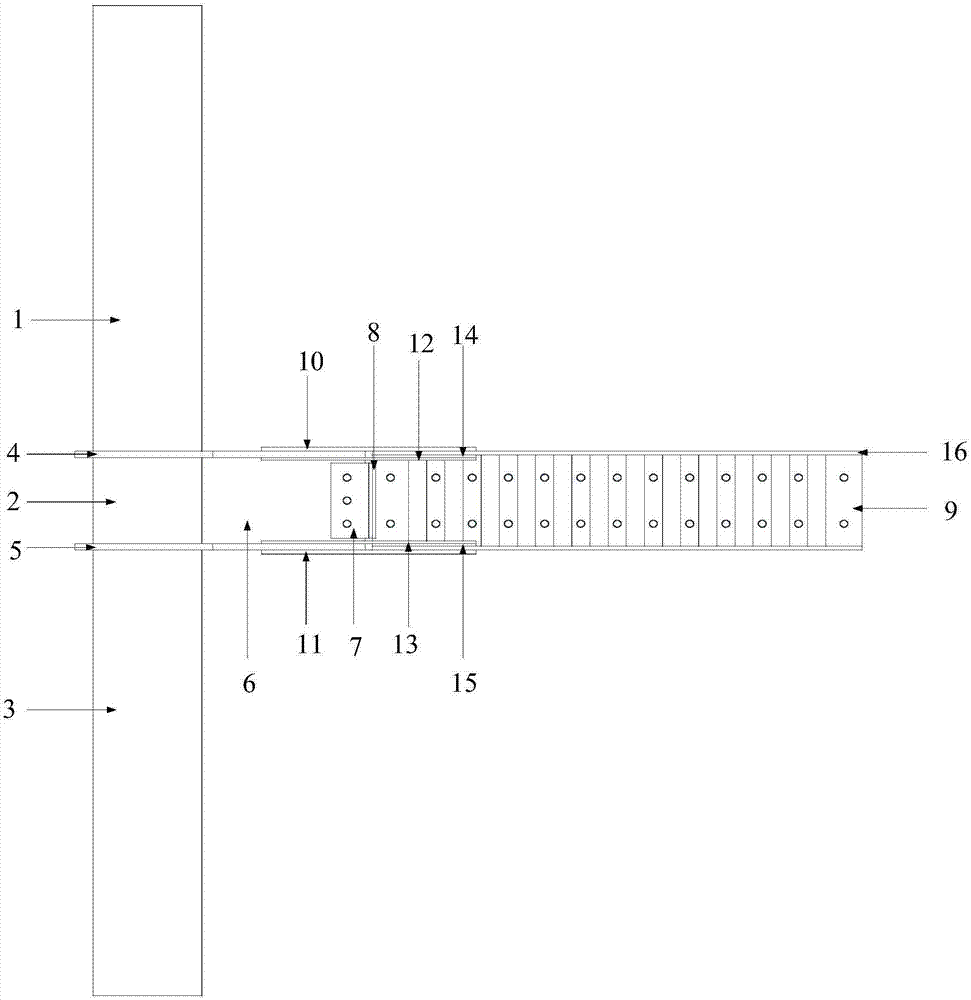

Function-restorable assembly type wave web beam-column composite joint connection device

ActiveCN105863050AReduce construction difficultyAvoid complex stress fieldsProtective buildings/sheltersShock proofingCantileverCivil/structural engineers

The invention relates to a function-restorable assembly type wave web beam-column composite joint connection device and belongs to the technical field of structural engineering. The function-restorable assembly type wave web beam-column composite joint connection device is composed of a round steel pipe column with a cantilever beam section, a wave web I-shaped composite beam section and a connecting device between the round steel pipe column with the cantilever beam section and the wave web I-shaped composite beam section. Welding of the joint connection device and assembly of the wave web I-shaped beam section and a composite floor are finished in a factory; weld seam and member qualities are easier to control; the round steel pipe column with the cantilever beam section and the wave web I-shaped composite beam section are assembled only through high-strength bolts and connection plates on site, so that the construction speed and quality are greatly improved; the wave web I-shaped composite beam section can be built on the lower flange connection plate of the round steel pipe column with the cantilever beam section, so that the hoisting difficulty is lowered and on-site assembly and positioning are easy; and through specific design, the structure destroyed positions can appear in the positions of energy dissipation members such as the easy-to-replace high-strength bolts and lower flange connection plate under the action of earthquake load, so that post-earthquake restoring is facilitated, and the function-restorable assembly type wave web beam-column composite joint connection device is adapted to development demands of a function-restorable assembly type steel structure.

Owner:BEIJING UNIV OF TECH

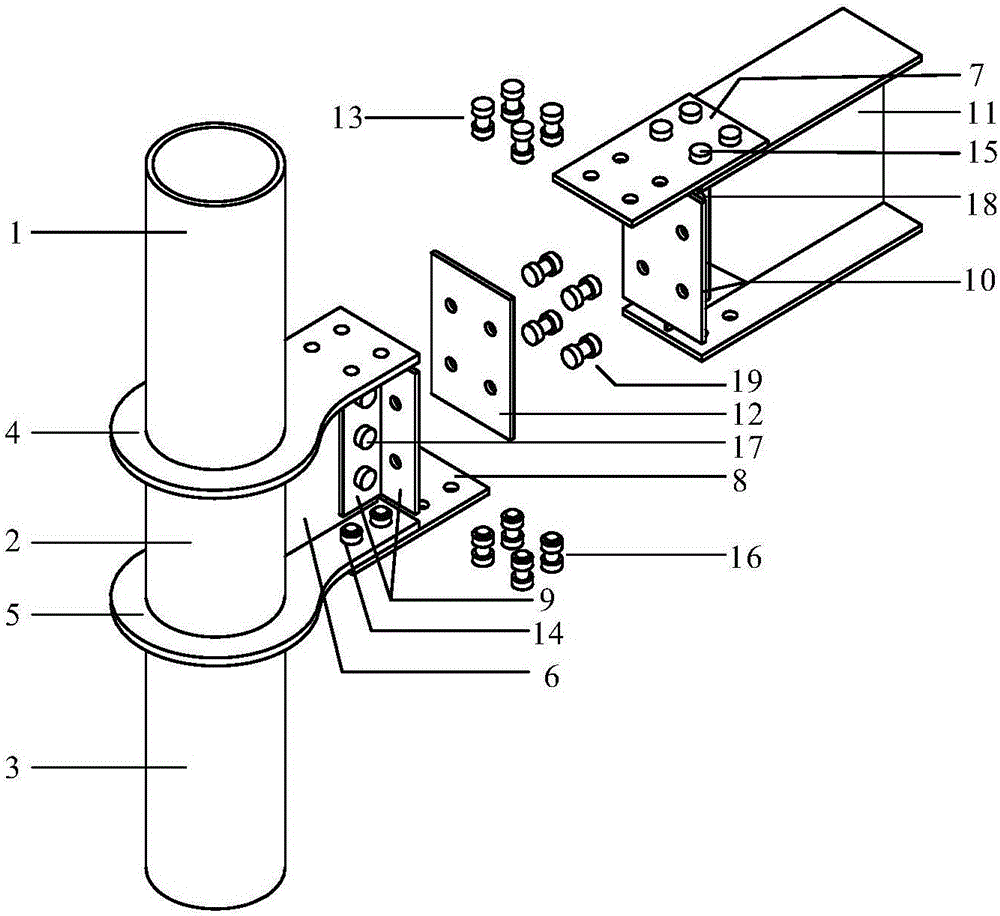

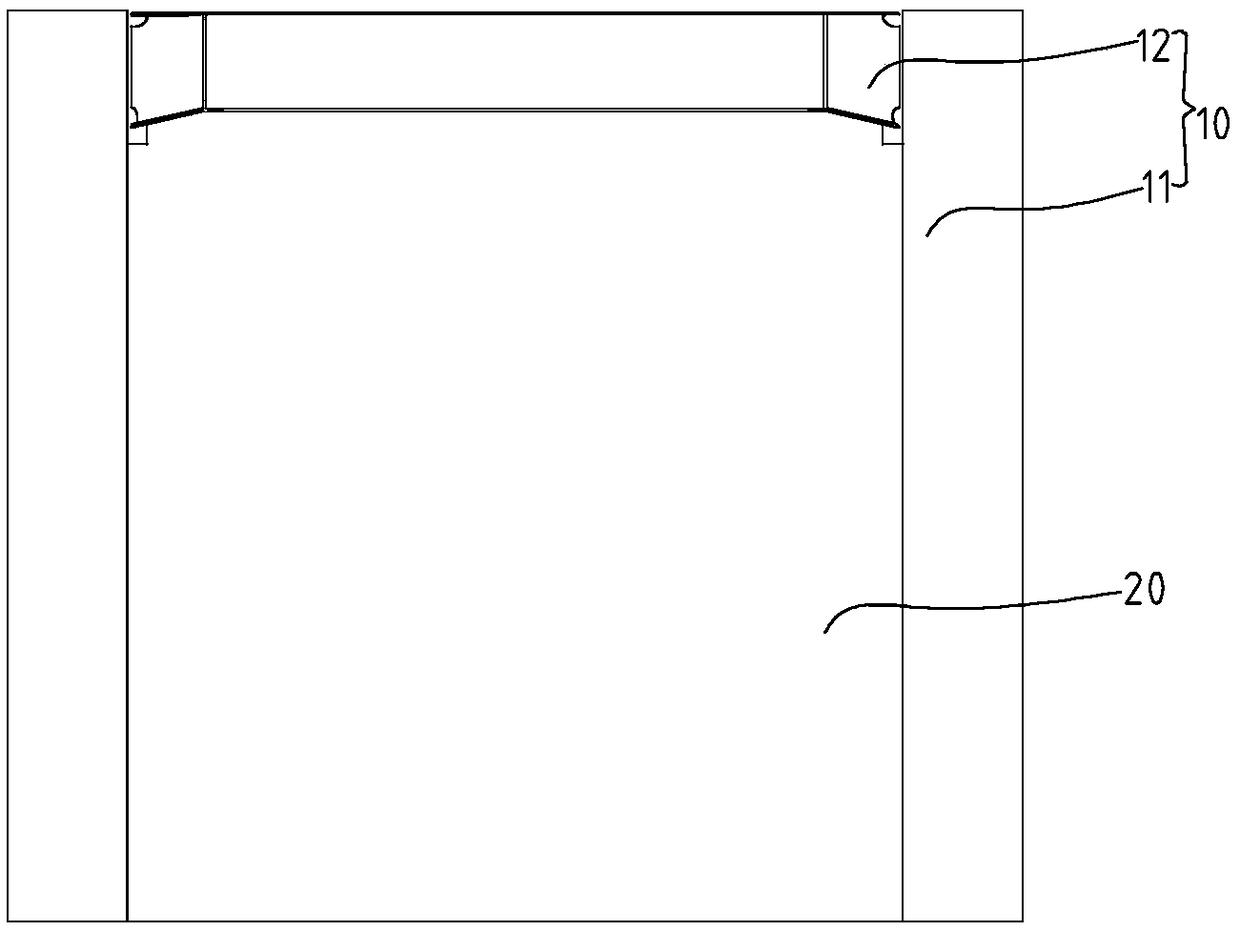

Function-restorable assembly type beam column-column flange connection joint device

ActiveCN105863052AImprove control accuracyQuality is easy to controlProtective buildings/sheltersShock proofingWeld seamCantilever

The invention relates to a function-restorable assembly type beam column-column flange connection joint device and belongs to the field of structural engineering. A function-restorable assembly type beam column-column flange connection joint is composed of a round steel pipe column with a cantilever beam section, a lower round steel pipe column section, a common beam section and a connecting device. Welded parts in the joint device are finished in a factory, and weld seam accuracy and quality are easier to control; the round steel pipe column with the cantilever beam section, the lower round steel pipe column section and the common beam section are assembled only through high-strength bolts and connecting plates on site; fastening work of the bolts is convenient and fast; and construction speed is greatly improved. Meanwhile, the common beam section can be built on the lower connecting plate of the cantilever beam section, so that the construction difficulty is lowered, and on-site assembly and positioning are easy. The joint of the joint device is a beam-end reinforcement and cover plate connecting weakening combined joint; through reasonable design, double energy dissipation of bolt friction slippage and plate plastic deformation can be achieved; fast restoring after an earthquake is easy; and the joint ductility is good, and the energy-dissipating capacity and bearing capacity are high.

Owner:BEIJING UNIV OF TECH

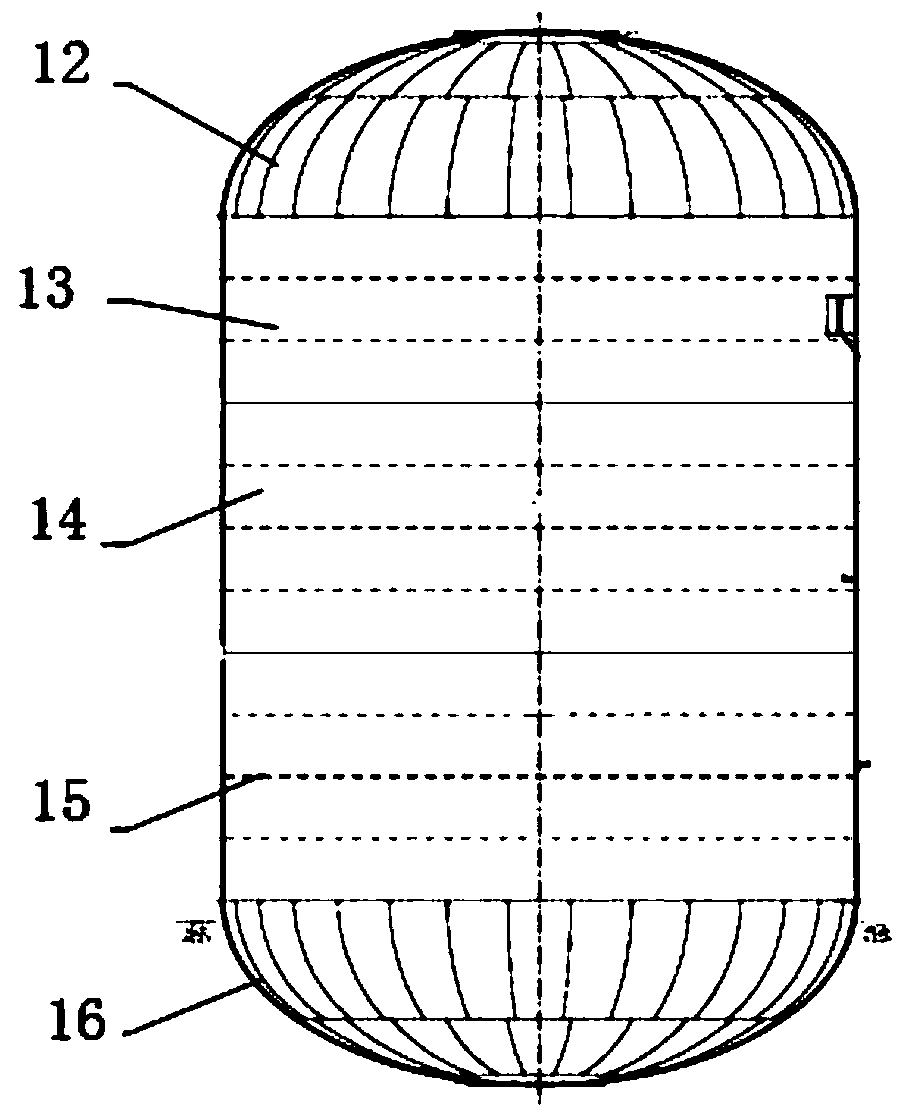

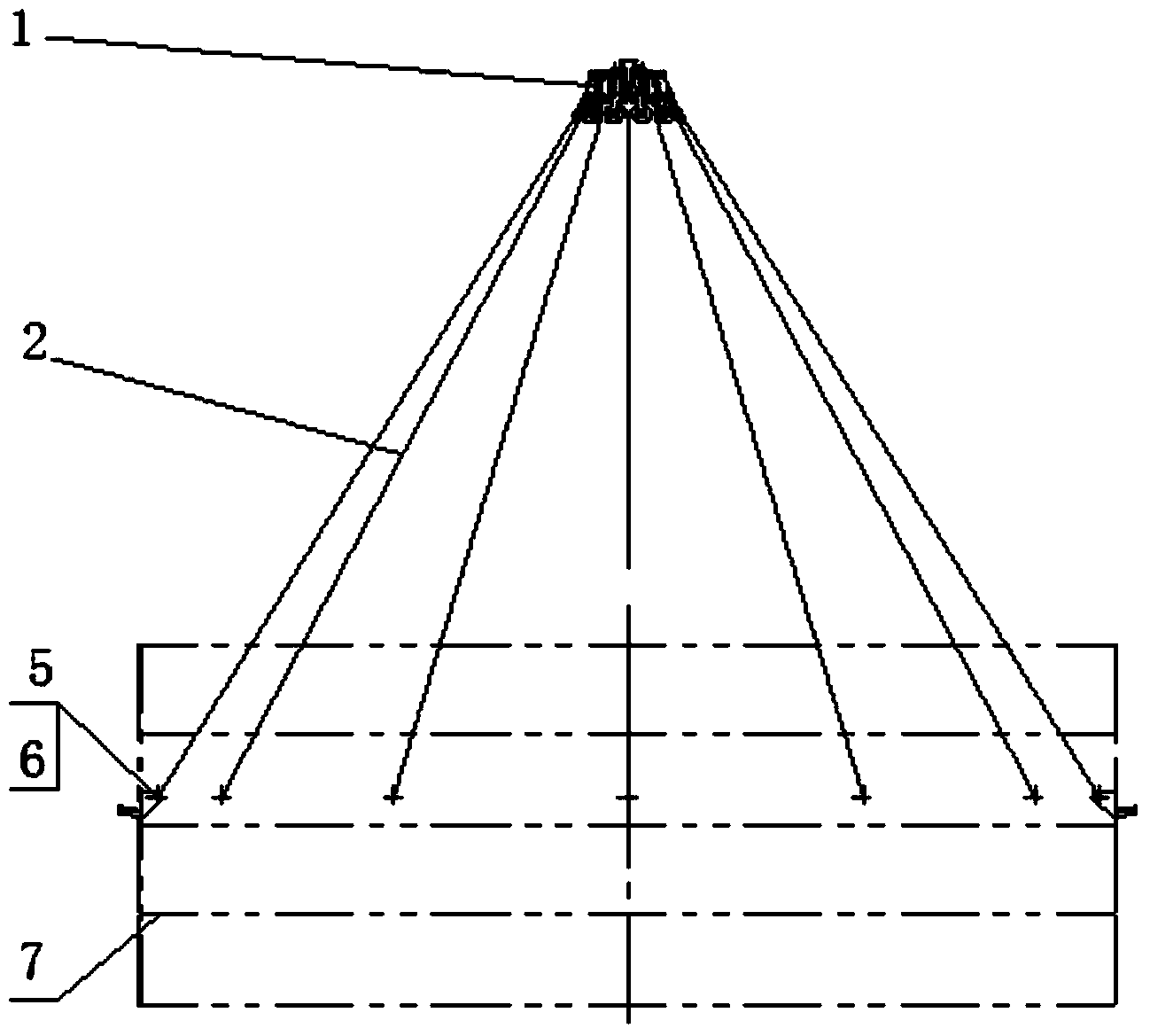

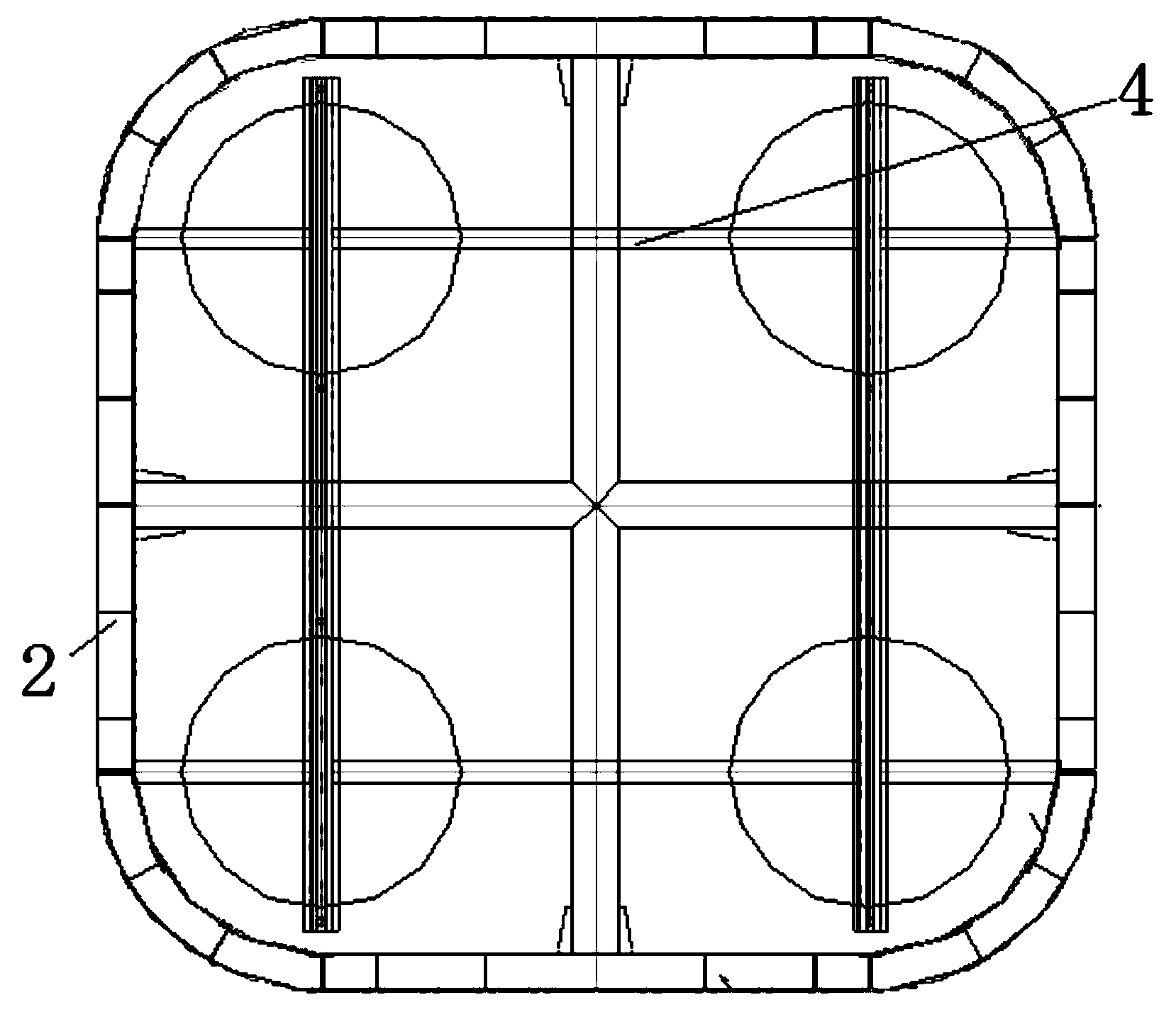

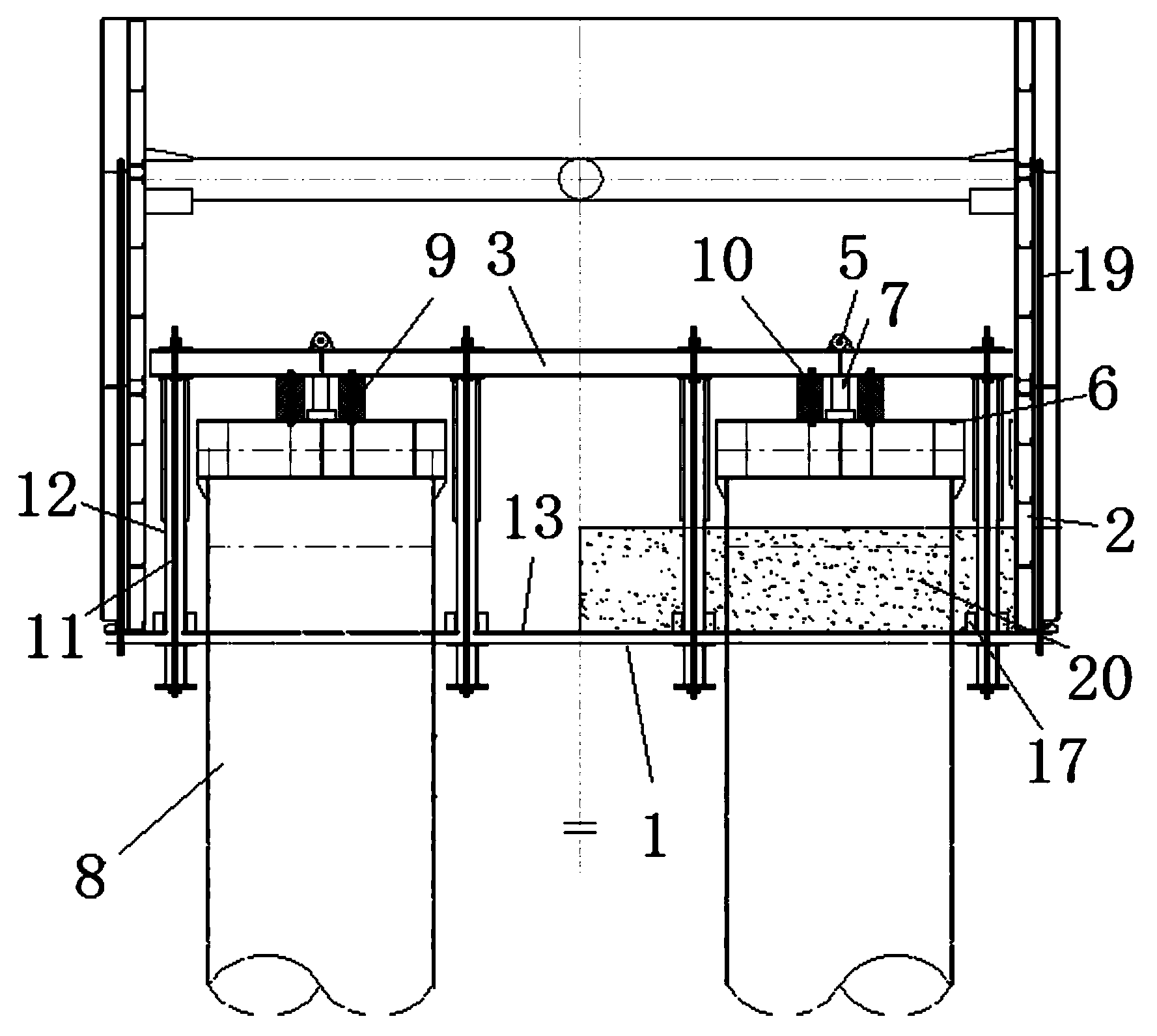

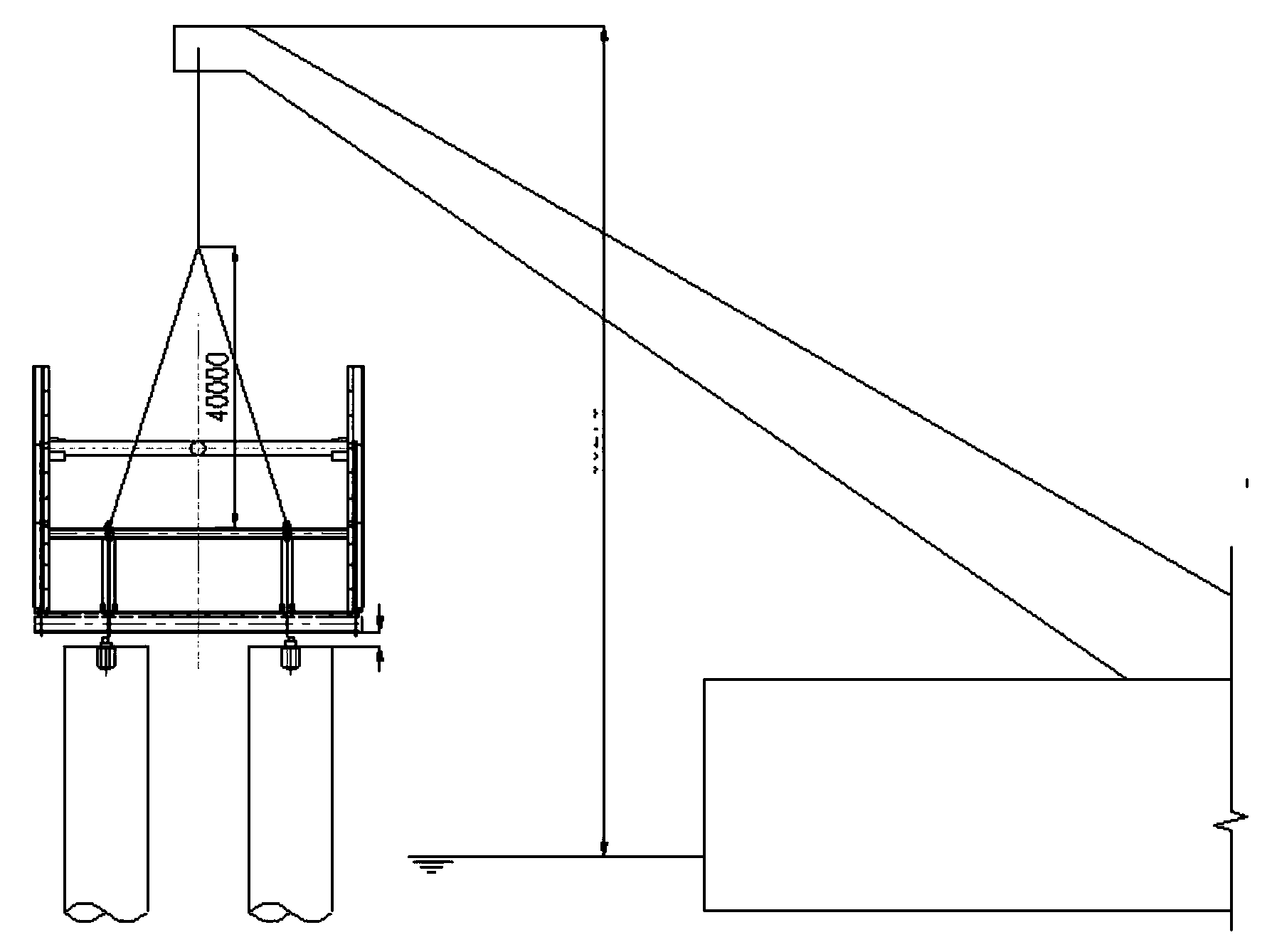

Self-balance type hoisting tool for steel containment module of nuclear power plant

ActiveCN103407872AAvoid the conditioning processReduce the difficulty of hoistingLoad-engaging elementsNuclear power plantWire rope

The invention provides a self-balance type hoisting tool for a steel containment module of a nuclear power plant. Three fixed hoisting points are arranged on the steel containment module; n pulley hoisting points are uniformly arranged on an arc line between two adjacent fixed hoisting points at intervals; a hoisting plate of a distributor is welded inside a cylinder; each of 3n+3 balance pulleys is fixed on the circumference of the cylinder through a branch beam and corresponds to one of the pulley hoisting points or one of the fixed hoisting points; a steel wire rope sequentially penetrates through the balance pulleys on the distributor, and pulleys at the pulley hoisting points corresponding to the balance pulleys or the fixed hoisting points on the steel containment module, so that the distributor is connected with the steel containment module. A hoisting beam is eliminated, so that the problems of storage, transportation and the like of the hoisting beam are solved; the dead weight of the hoisting tool is greatly reduced, and the hoisting capacity of a hoist is released; the stress balance of all hoisting points can be automatically realized, the hoisting difficulty can be greatly reduced, and the hoisting time can be greatly shortened.

Owner:上海核工程研究设计院股份有限公司

Light combined hanging box with recyclable baseplate steels and construction technology thereof

The invention discloses a light combined hanging box with recyclable baseplate steels. The light combined hanging box comprises a baseplate, four wall bodies, an outrigger, and lateral stable support beams which are connected between the outrigger and the wall bodies; wherein the four wall bodies are connected by a support frame; a lifting lug is arranged at the upper end face of outrigger; a jack placing beam is arranged under the outrigger; the outrigger is connected with the baseplate by a supporting column; a jack is arranged between the outrigger and the jack placing beam; the lower end of the jack placing beam is connected with the top end of a steel casing. The light combined hanging box has the following advantages: 1, the bearing abilities of bamboo plywood and bottom sealing concrete are fully used under a condition that a poor sea state of open seas is overcome, the turning of the baseplate steels is effectively realized, and the steel consumption is greatly reduced; 2, the structure is light; for the hanging box of the same specification, the lifting weight of the combined baseplate hanging box is similar to the self weight of a traditional steel baseplate hanging box, so that relative to the concrete prefabricated baseplate steel hanging box, the rated load weight and the lifting difficulty of a floating crane are effectively reduced.

Owner:CCCC SHEC FOURTH ENG +1

Function-restorable assembly type end plate connection joint connection device

ActiveCN105863051AEasy and fast fastening workImprove control accuracyProtective buildings/sheltersShock proofingWeld seamCantilever

The invention relates to a function-restorable assembly type end plate connection joint connection device and belongs to the field of structural engineering. The function-restorable assembly type end plate connection joint connection device is composed of a round steel pipe column with a cantilever beam section, a common beam section and a connecting device between the round steel pipe column with the cantilever beam section and the common beam section. Welded parts of the joint connection device are finished in a factory; weld seam accuracy and quality of the welded parts are easier to control; the round steel pipe column with the cantilever beam section and the common beam section are assembled only through high-strength bolts, connecting plates and Pi-shaped connecting members on site; and accordingly, the construction speed and construction quality are greatly improved. Meanwhile, the common beam section can be built on the lower connecting plate of the round steel pipe column with the cantilever beam section, so that the hoisting difficulty is lowered, and on-site assembly and positioning are easy. A joint of the joint connection device is a beam-end reinforcement and cover plate connecting weakening combined joint; through reasonable design, double energy dissipation of bolt friction slippage and connecting plate and bolt plastic deformation can be achieved, and fast restoring after an earthquake can be also achieved; and the joint ductility is good, and the energy-dissipating capacity and bearing capacity are high.

Owner:BEIJING UNIV OF TECH

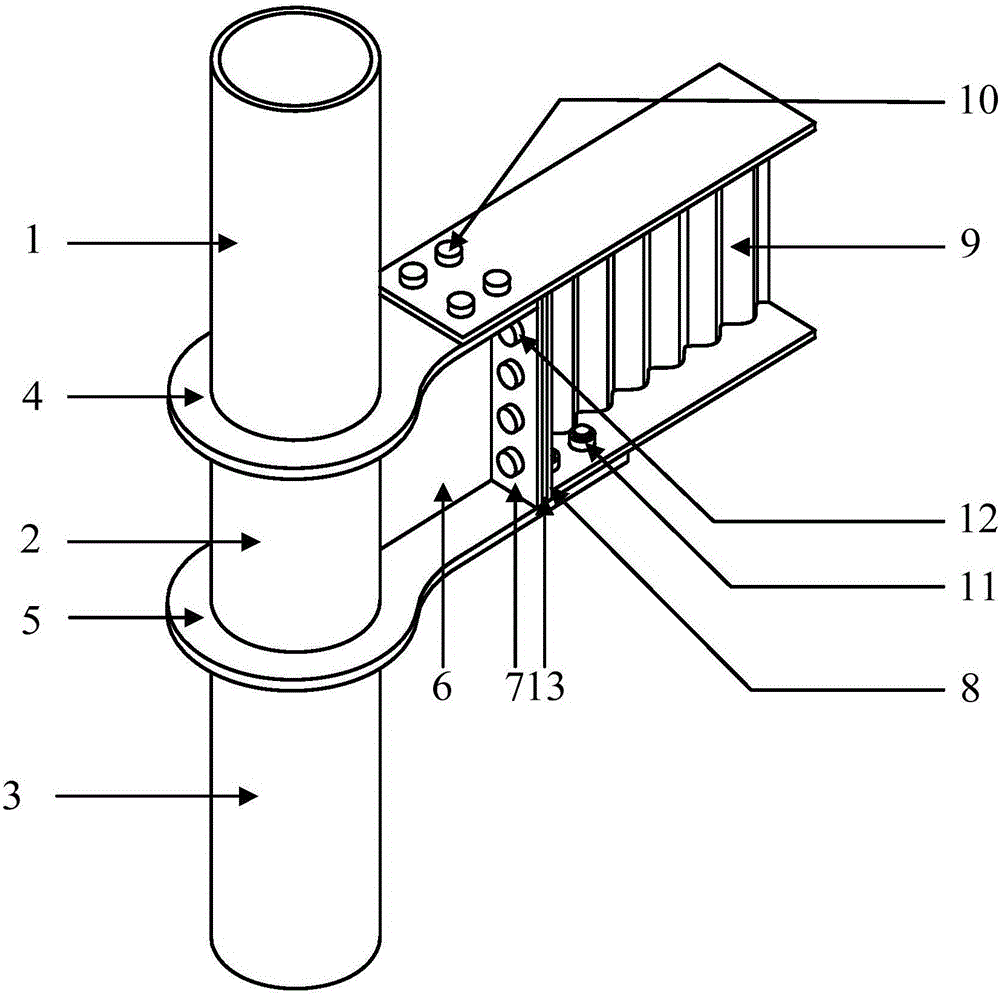

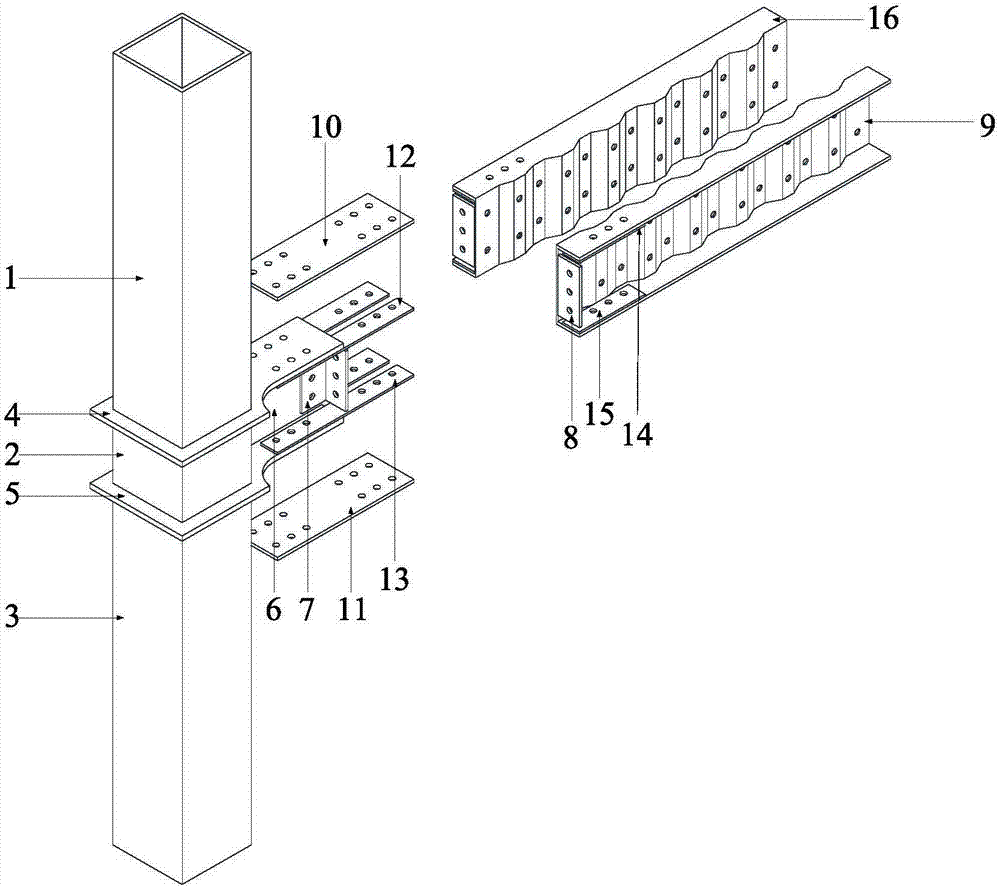

Assembly type wave web beam-column joint connection device

ActiveCN105863074AEasy and fast fastening workImprove control accuracyShock proofingShaped beamWeld seam

The invention relates to an assembly type wave web beam-column joint connection device and belongs to the field of structural engineering. The assembly type wave web beam-column joint connection device is composed of a round steel pipe column with a cantilever beam section, a wave web I-shaped beam section and a connecting device between the round steel pipe column with the cantilever beam section and the wave web I-shaped beam section. Welded parts of the joint connection device are all finished in a factory; the weld seam accuracy and quality of the welded parts are easier to control; the round steel pipe column with the cantilever beam section and the wave web I-shaped beam section are assembled only through high-strength bolts on site; the fastening work of the bolts is convenient and fast; the construction speed and construction quality are greatly improved; and accordingly, the joint connection device is adapted to development of an assembly type steel structure. Meanwhile, the wave web I-shaped beam section can be built on a lower annular partition board of the round steel pipe column with the cantilever beam section, thus the hoisting difficulty is lowered, the construction progress is accelerated, and moreover, on-site assembly and positioning are easy. The assembly type wave web beam-column joint connection device is good in joint ductility and high in energy-dissipating capacity and bearing capacity, advantages of material saving and high performance of a wave web member can be fully achieved, and application and popularization of the assembly type wave web beam-column joint connection device to the assembly type steel structure are facilitated.

Owner:BEIJING UNIV OF TECH

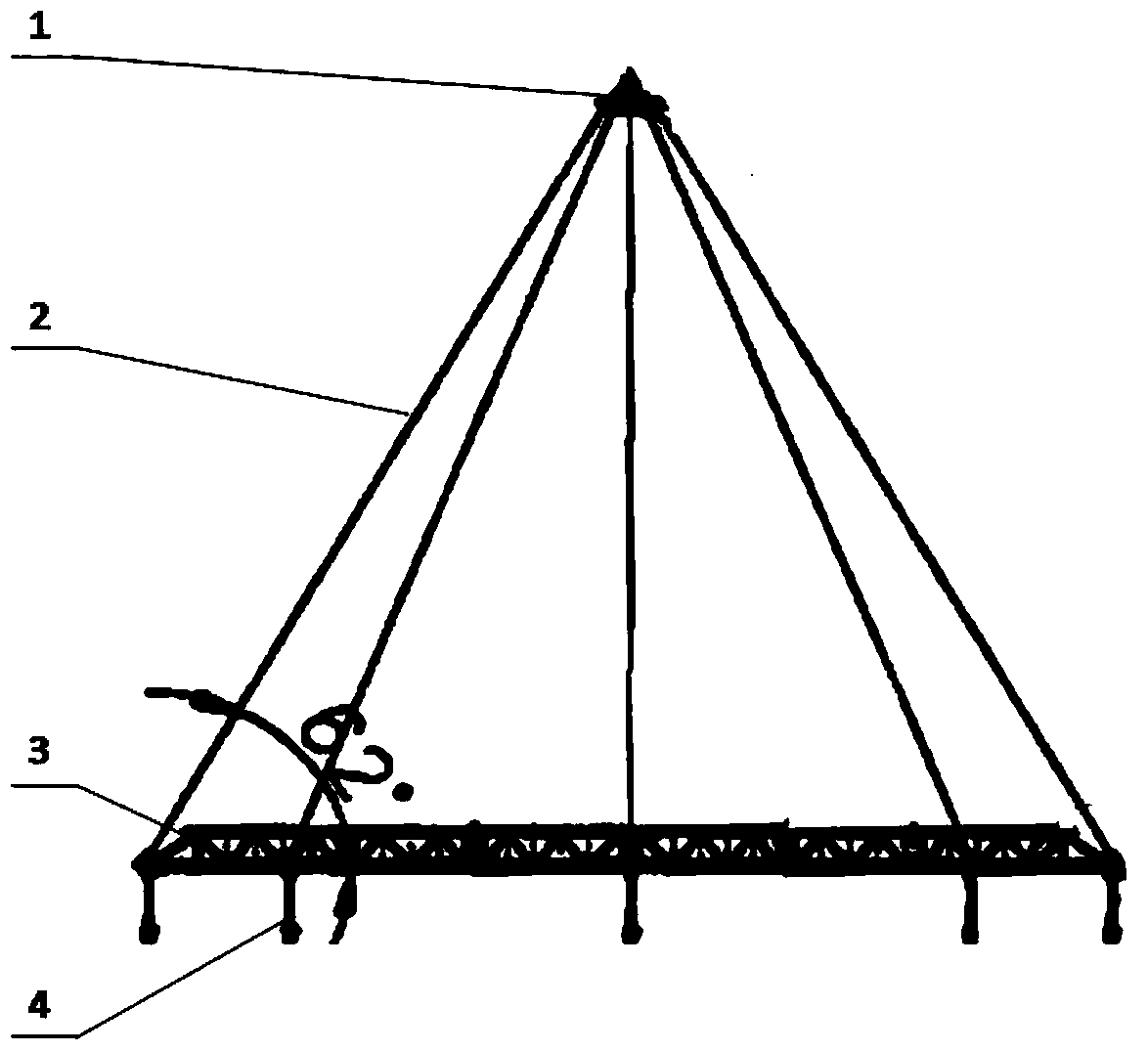

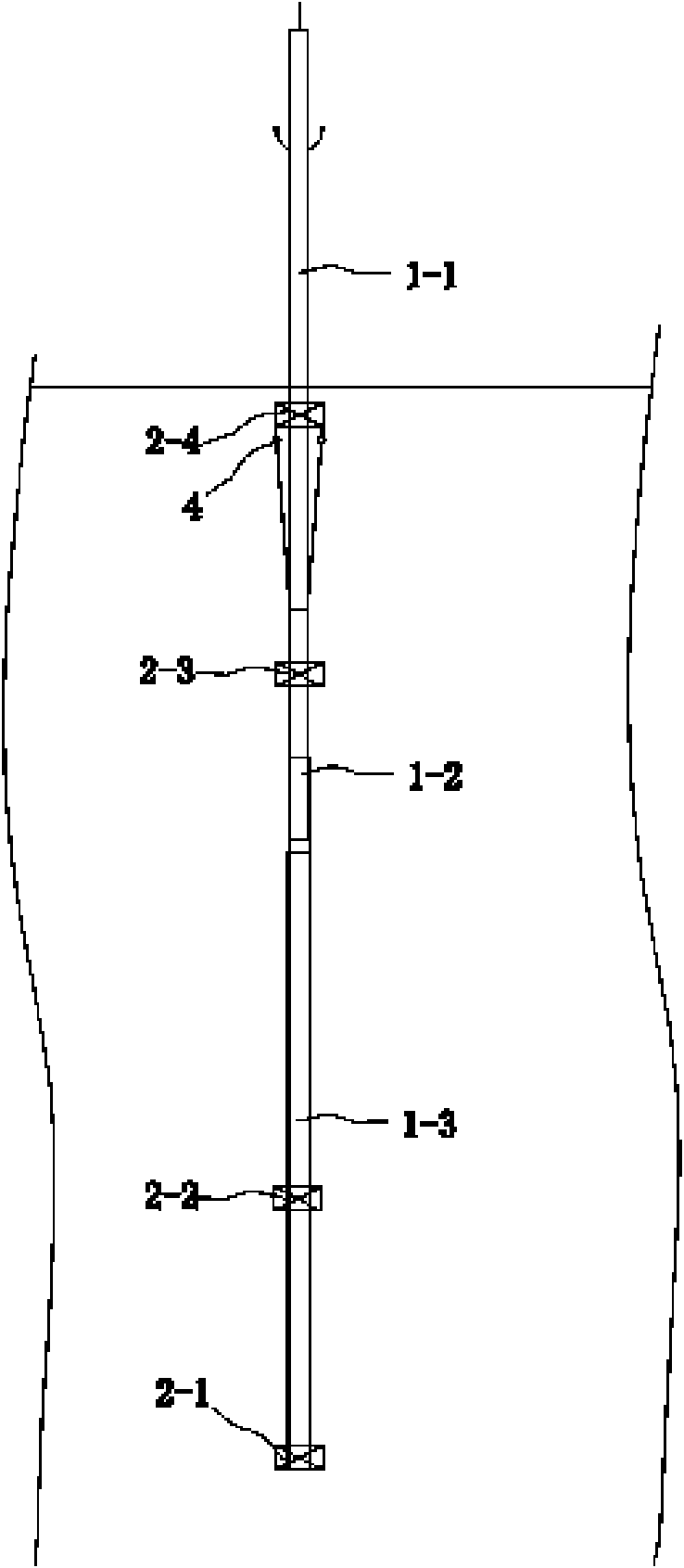

Installing method of roof mast

The invention relates to an installing method of a roof mast. The method comprises the following steps: firstly, lifting up a whole steel tube assembly by a windlass; and stopping the windlass when the bottom of the steel tube assembly reaches a base of the lowest place; secondly, connecting a pair of hand-drive block stringers to an outermost layer of steel tube and lifting up or down the steel tube assembly in an alternative working manner in order to fine adjusting the height of the steel tube assembly till the outermost layer of the steel tube is arranged at the base of the lowest place and a base of the lower place, and then keeping the position of the steel tube assembly and welding and fixing the steel tube assembly; connecting the hand-drive block stringers to an innermost layer ofsteel tube in the steel tube assembly, lifting up the innermost layer of the steel tube in an alternative working manner, and stopping the lifting when the length of the sleeved part of the lower endof the innermost layer steel tube and the upper end of an inner layer steel tube sleeved on the innermost layer steel tube is ranged from 0.3-2 m, and then welding and fixing the innermost layer of the steel tube with the inner layer of steel tube; and finally, repeatedly lifting up and welding each remained section of steel tubes sleeved in the outermost layer of the steel tube, and then finishing the installation of the roof mast.

Owner:CHANGZHOU NO 1 CONSTR GRP

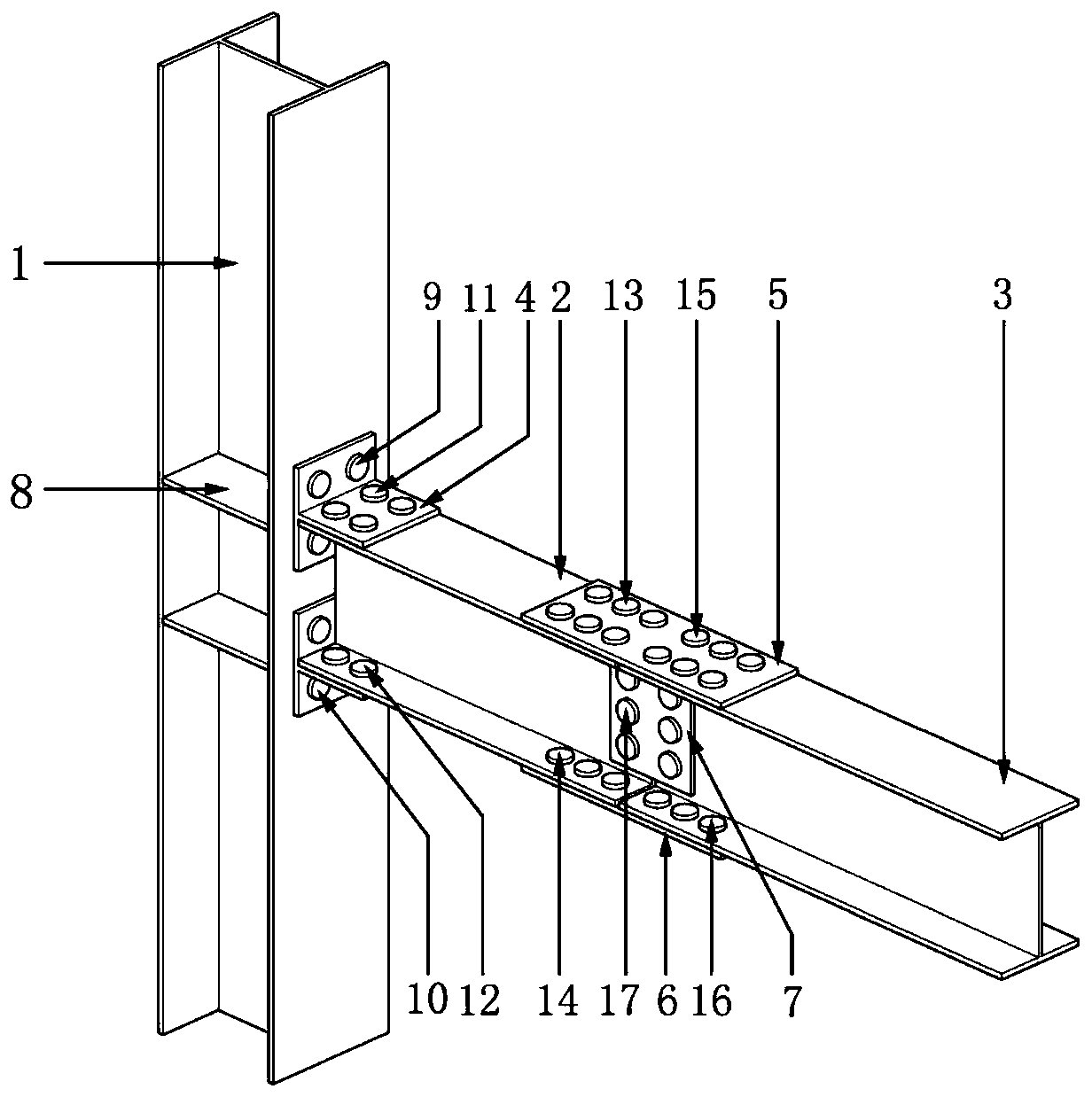

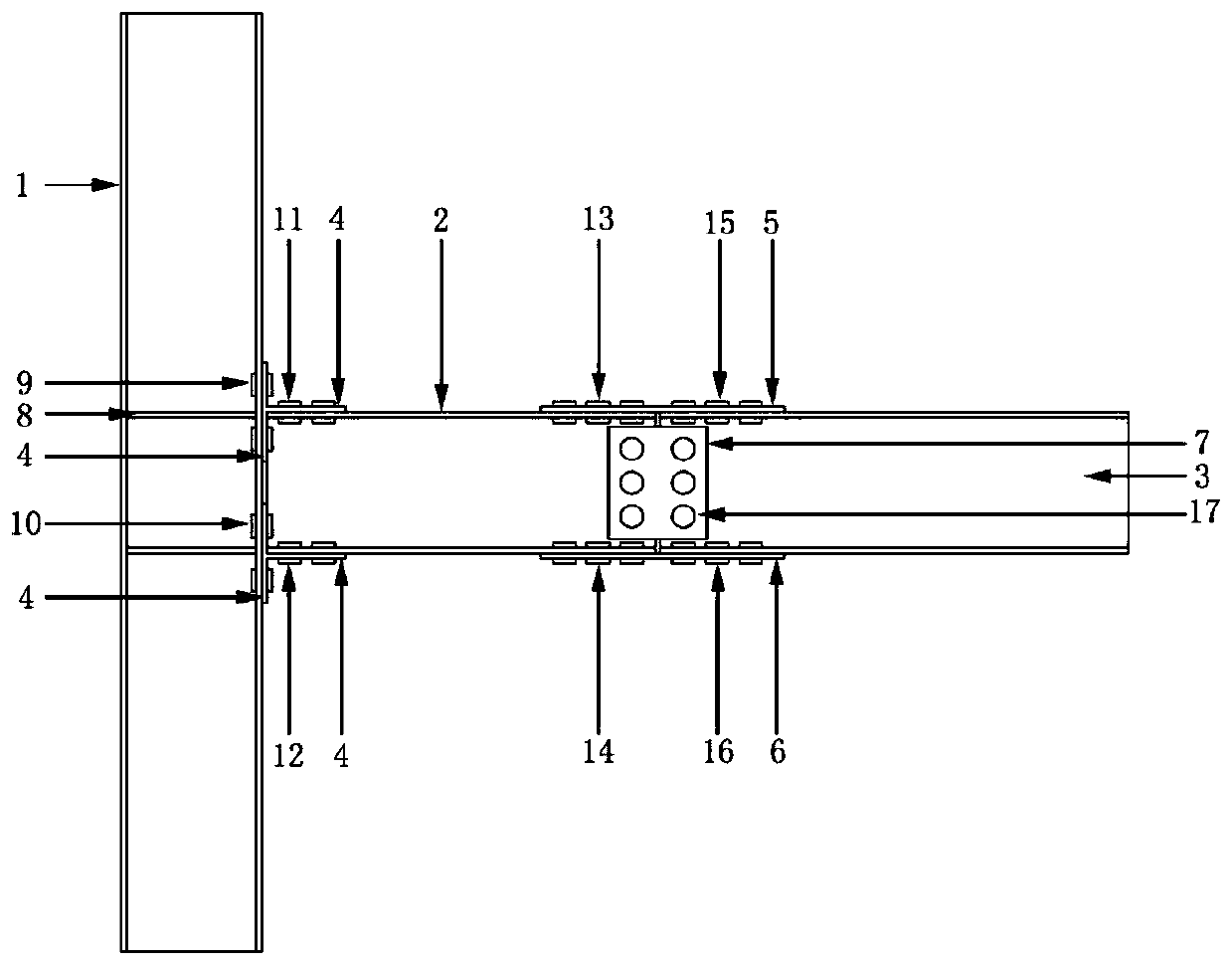

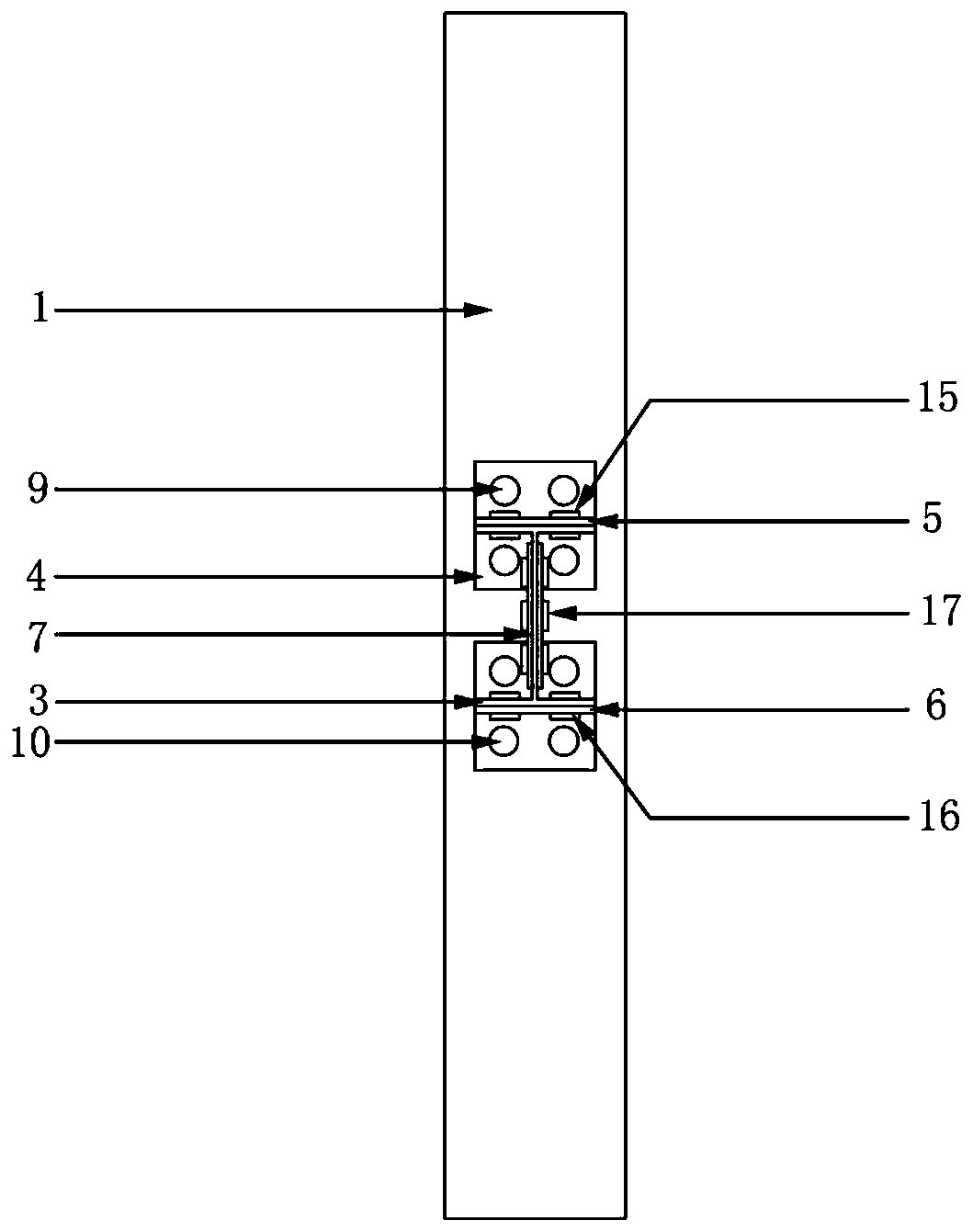

Convenient-to-repair fabricated steel structure beam-column joint connection structure and fabricating method thereof

InactiveCN110499825AImprove control accuracyQuality is easy to controlBuilding constructionsSteel columnsToughness

The invention discloses a convenient-to-repair fabricated steel structure beam-column joint connection structure and a fabricating method thereof. The convenient-to-repair fabricated steel structure beam-column joint connection structure comprises an H-shaped steel column, an H-shaped steel energy-consuming beam segment and an H-shaped steel ordinary beam segment, the H-shaped steel column is fixedly connected with the H-shaped steel energy-consuming beam segment through a T-shaped connecting part, an upper flange of the H-shaped steel energy-consuming beam segment and an upper flange of the H-shaped steel ordinary beam segment are fixedly connected through an upper flange connecting plate, a lower flange of the H-shaped steel energy-consuming beam segment and a lower flange of the H-shaped steel ordinary beam segment are fixedly connected through a lower flange connecting plate, and a web of the H-shaped steel energy-consuming beam segment and a web of the H-shaped steel ordinary beamsegment are fixedly connected through a web connecting plate. Destroying possibly occurring in a column or joint area is transferred and limited in the locally replaceable H-shaped steel energy-consuming beam segment, by utilizing plastic deformation energy consumption of the H-shaped steel energy-consuming beam segment, the purpose of protecting the column and a joint can be achieved, and afteran earthquake, the anti-seismic toughness and the use function of the structure can be quickly restored only by replacing the locally damaged beam segment.

Owner:CHANGAN UNIV

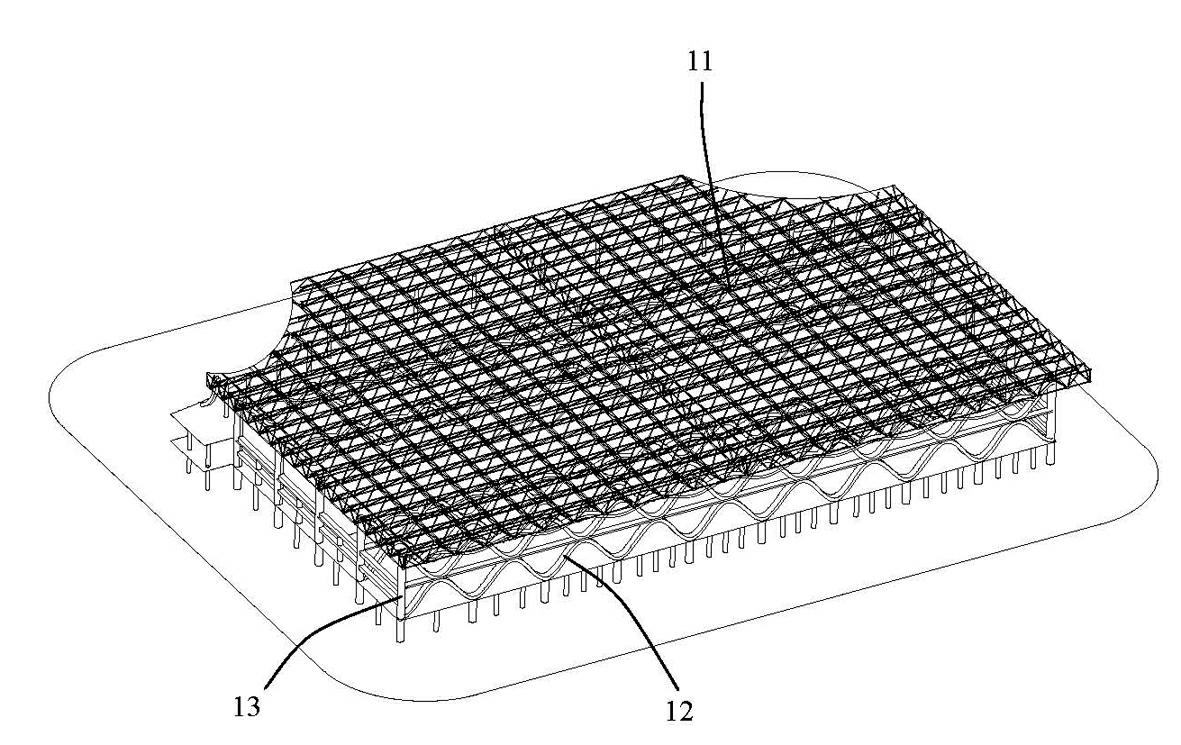

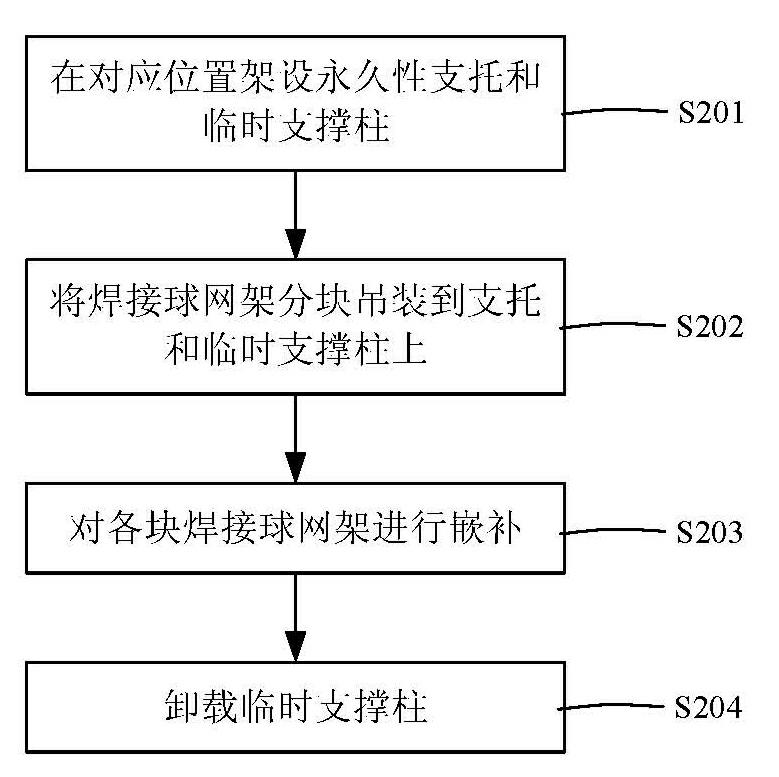

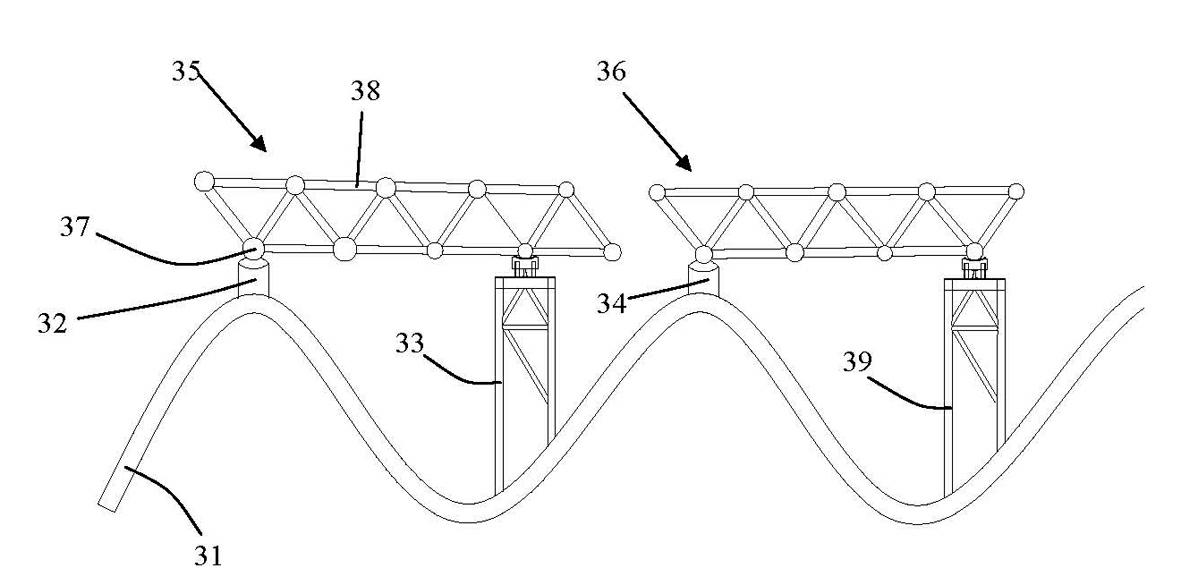

Partition direct hoisting construction method for hyperboloidal welded ball net rack

InactiveCN102168490AReduce the difficulty of hoistingReduce construction costsBuilding material handlingArchitectural engineeringStructural engineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

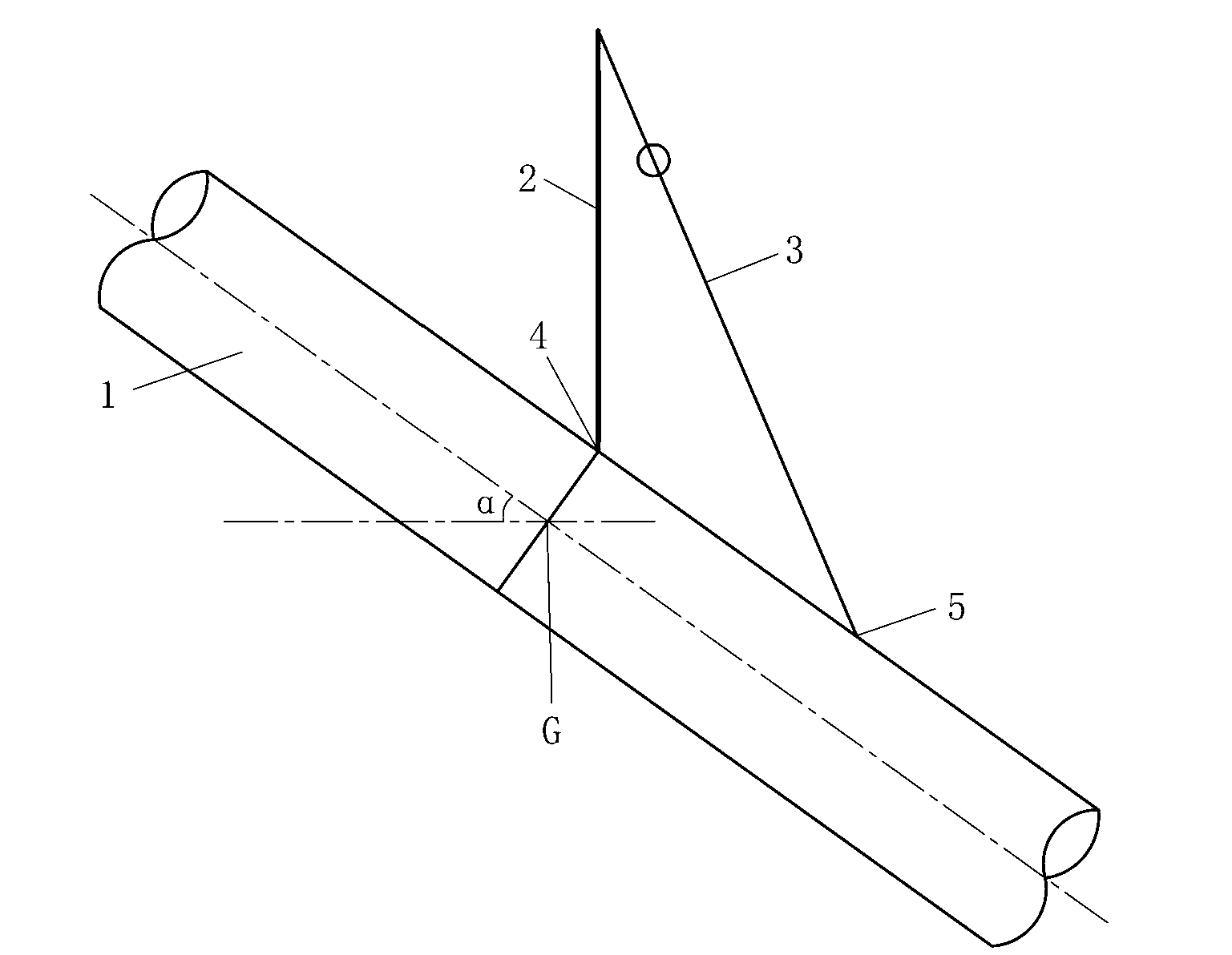

Method for lifting downcomer of blast furnace

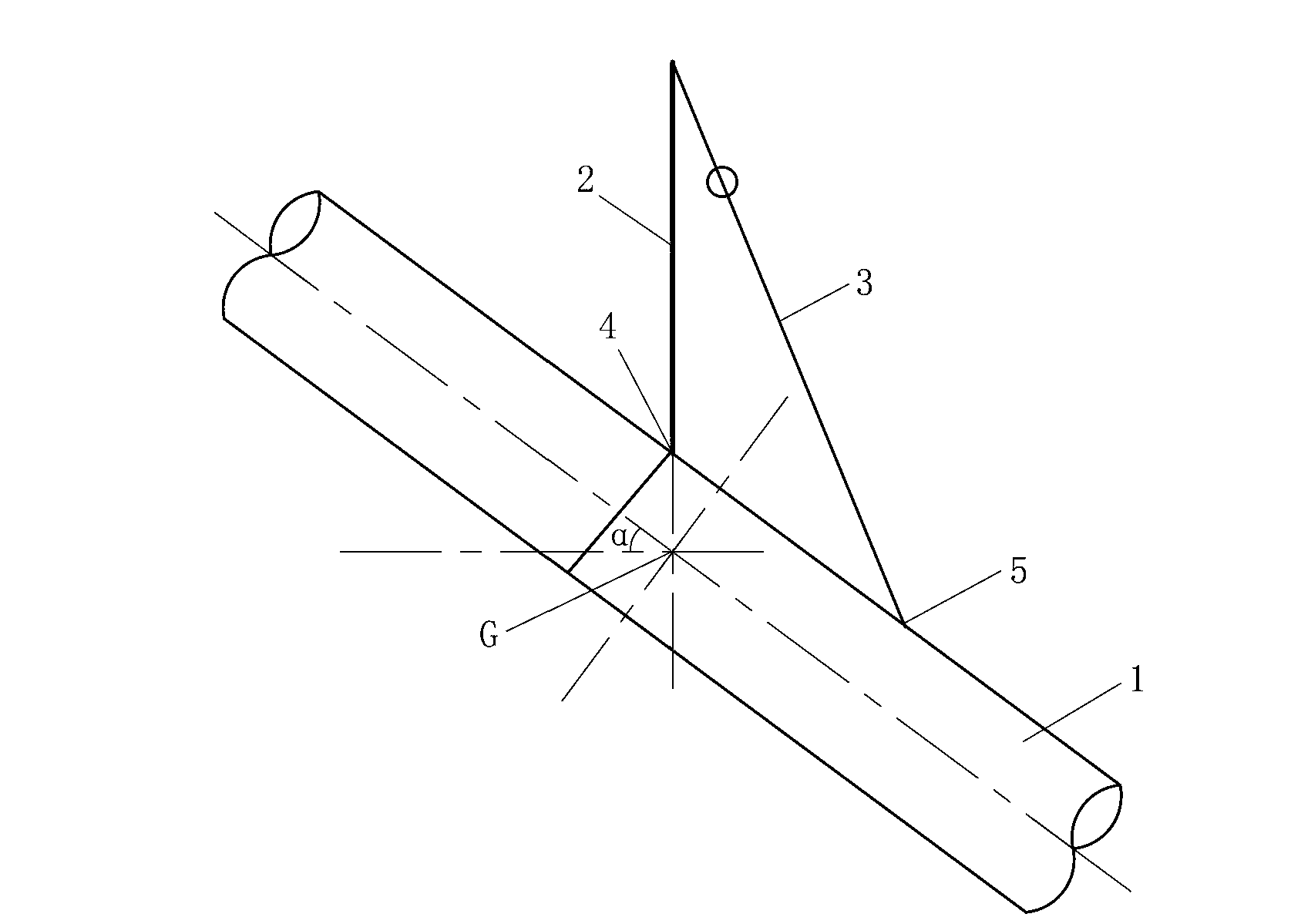

ActiveCN103233087ASmall forceAdjust the tilt angleBlast furnace componentsBlast furnace detailsGravity centerEngineering

The invention discloses a method for lifting a downcomer. The method comprises the following steps that: A, a gravity center position of the downcomer is confirmed; B, positions of a main lifting point and an auxiliary lifting point are confirmed according to the gravity center position, and a cross section in which the main lifting point is located is allowed to pass through the gravity center or to shift upward slightly relative to the gravity center; C, a first lifting rope and a second lifting rope are fixedly connected with the main lifting point and the auxiliary lifting point of the downcomer respectively; and D, under the condition that an inclination angle of the downcomer is equal to a preset lifting angle all the time, the downcomer is lifted to the preset height, and is butted between upper and lower end connectors of the downcomer. The method simplifies a lifting technique, improves the lifting reliability, lowers the lifting cost and shortens the lifting time.

Owner:PANGANG GRP ENG TECH

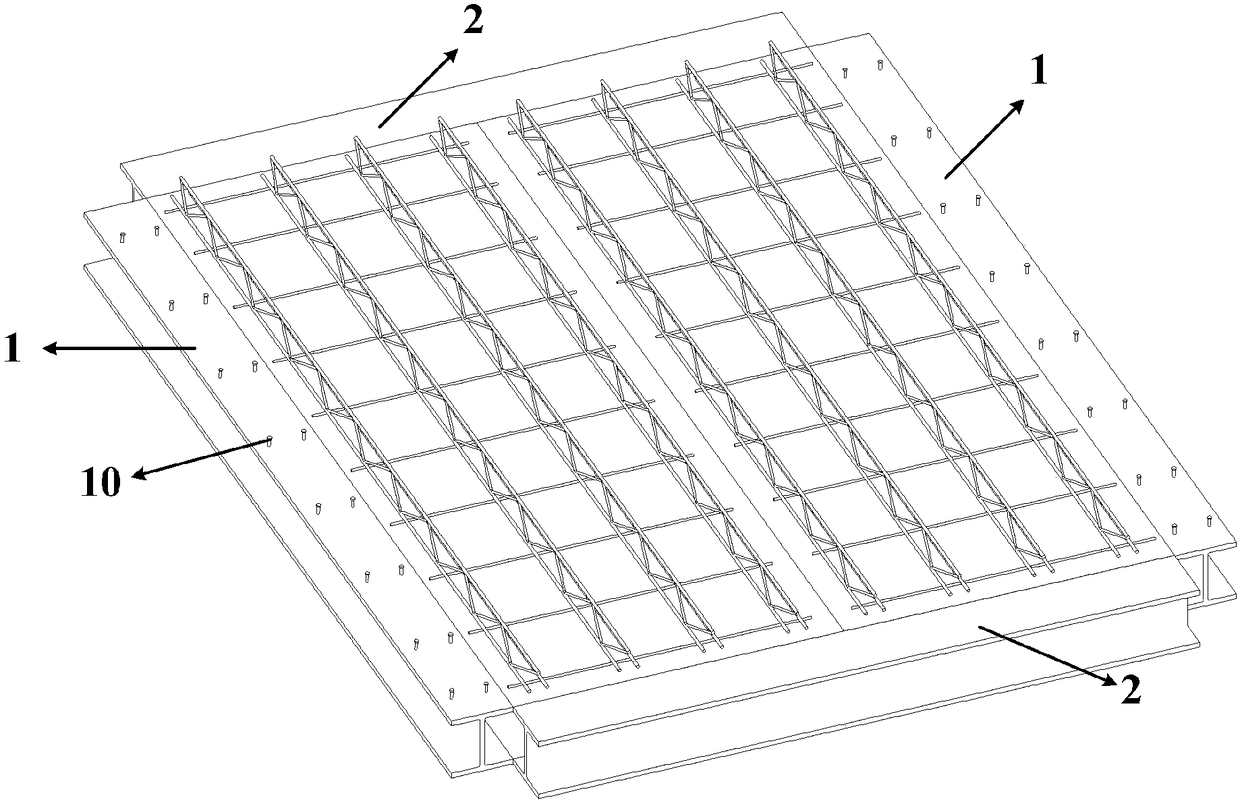

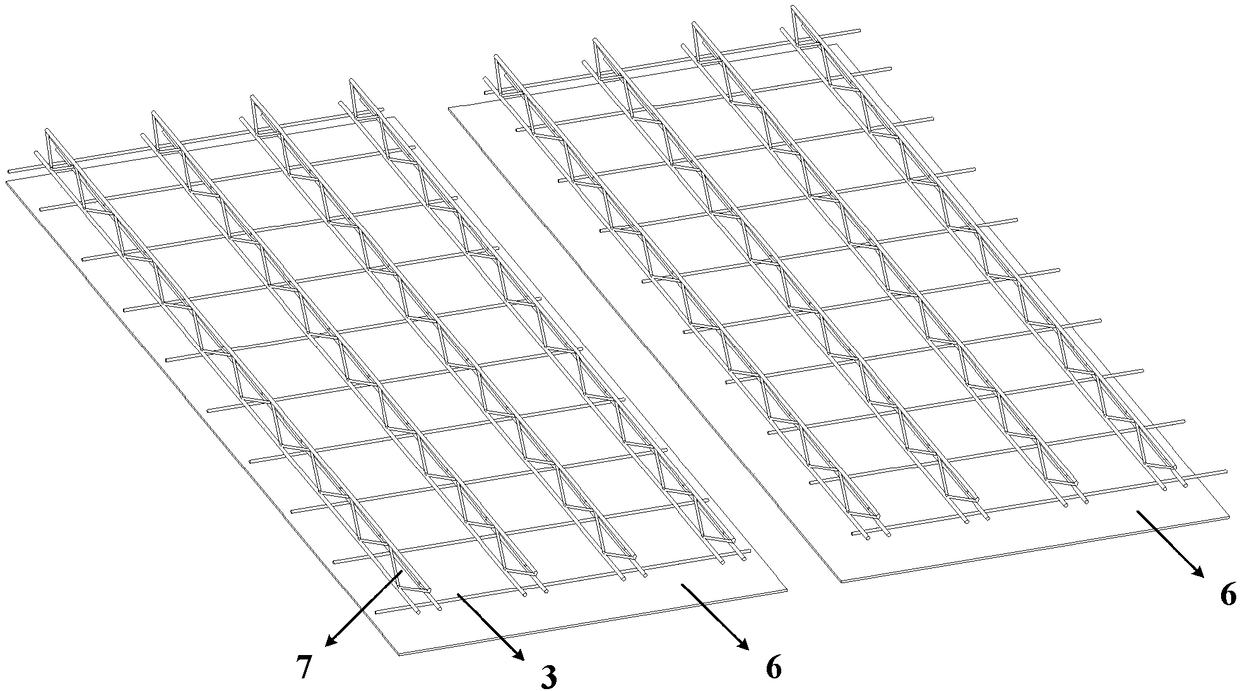

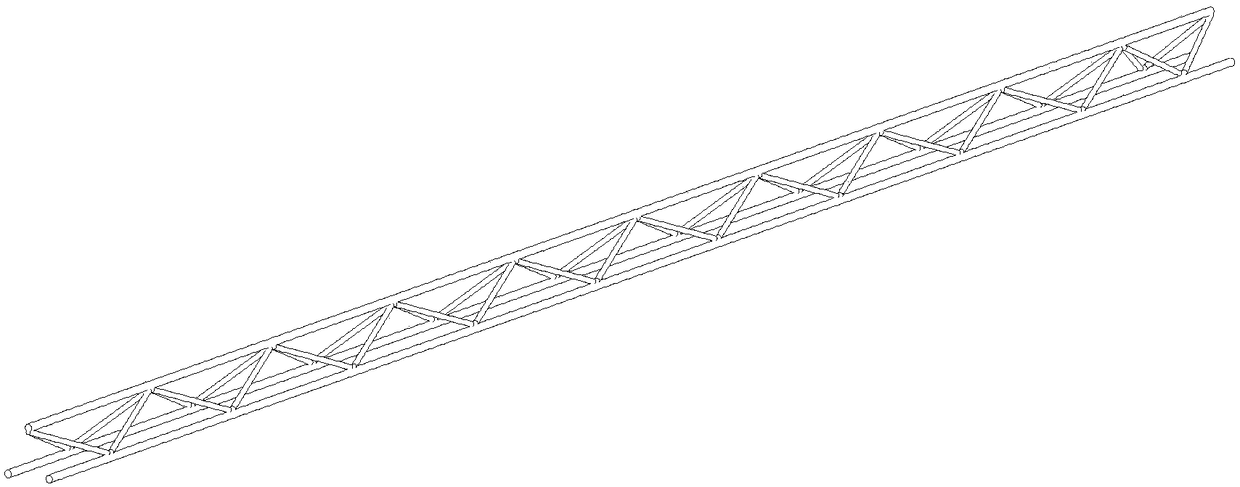

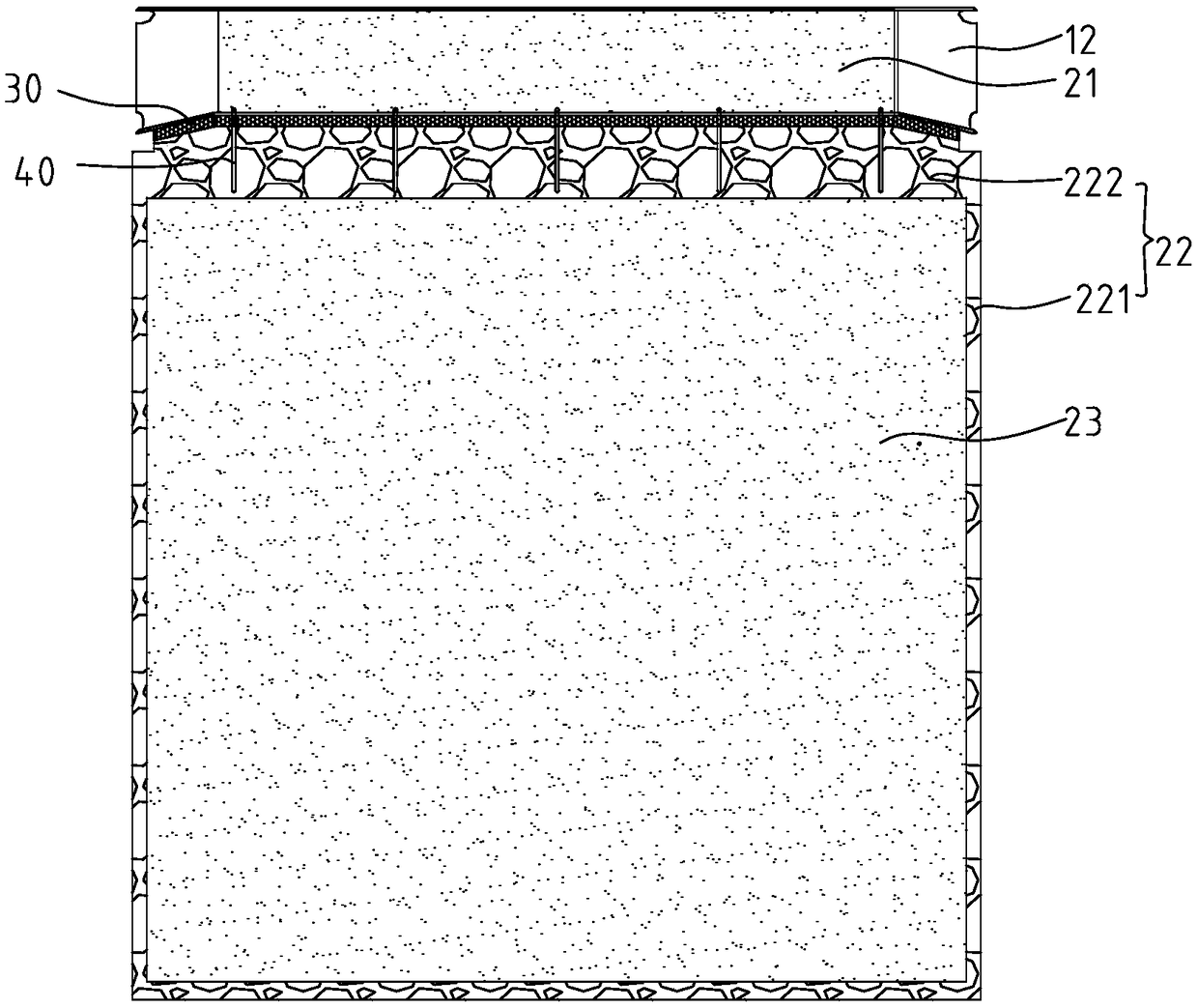

Prefabricated concrete ultra-thin type two-way stress fabricated steel bar truss composite floor slab

The invention discloses a prefabricated concrete ultra-thin type two-way stress fabricated steel bar truss composite floor slab, and belongs to the technical field of structural engineering. The basiccomposition of a composite beam-slab structure comprises shape steel beams, three-dimensional truss temporary supports, connecting plates, triangular reinforcing steel bar trusses, prefabricated short bars and prefabricated concrete slabs, wherein the shape steel beams are welded to the connecting plates, and the prefabricated short bars, the reinforcing steel bar trusses and the prefabricated floor slab are poured into a whole. The beams, the temporary supports and precast concrete floor slabs are hoisted in place and connected by bolts, reinforcing steel bars are paved in a penetrating mode, and the beams, the temporary supports and precast concrete floor slabs are poured with remaining concrete. The prefabricated concrete ultra-thin type two-way stress fabricated steel bar truss composite floor slab with temporary supports is used, the problem of integrity of the floor slab is solved, the reliability of the floor slab in the construction stage is guaranteed, a post-pouring strip ofthe fabricated floor slab is avoided, the field work efficiency is improved, the thickness of the prefabricated concrete slab is reduced, the weight of the hoisting is reduced, and the fabricated accuracy is improved.

Owner:BEIJING UNIV OF TECH

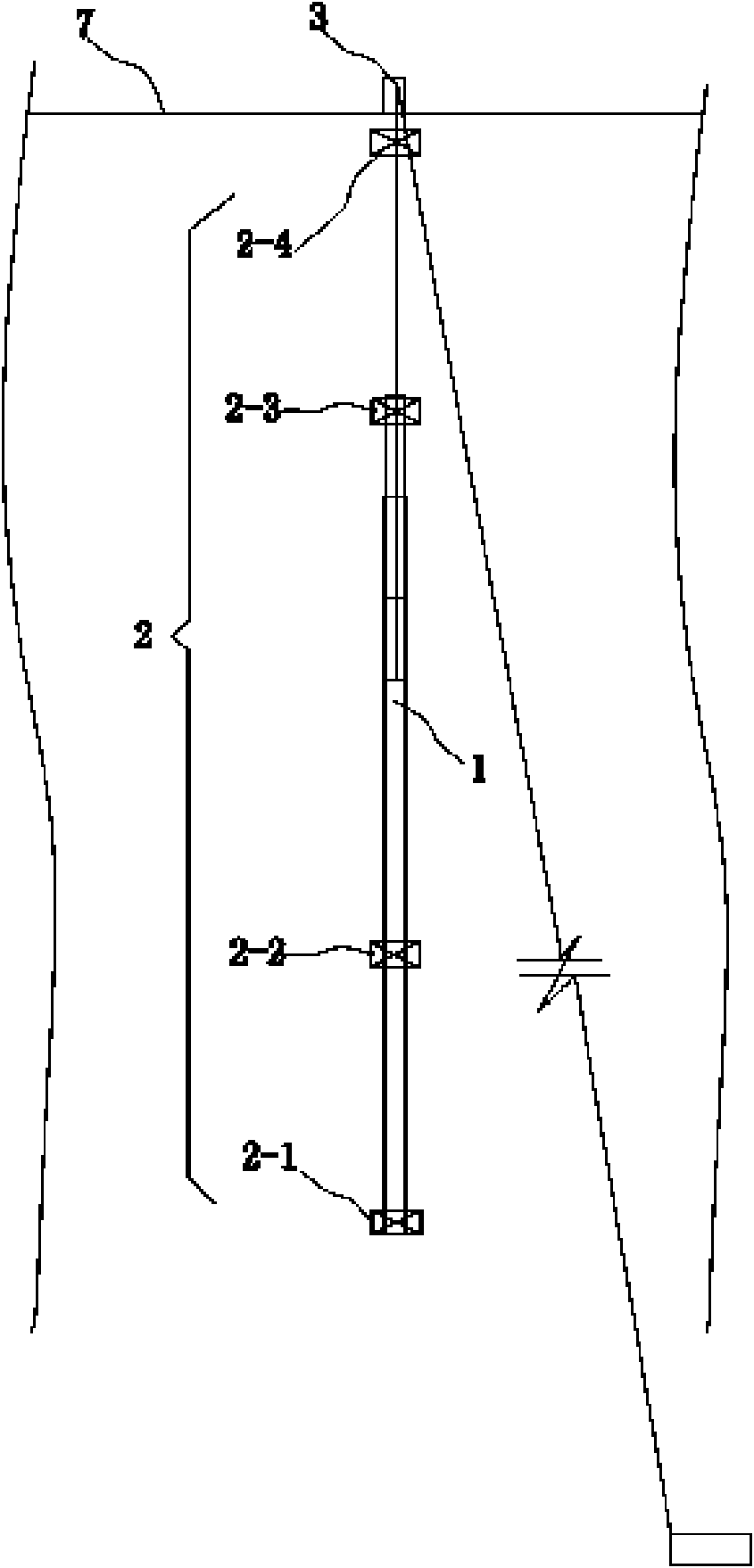

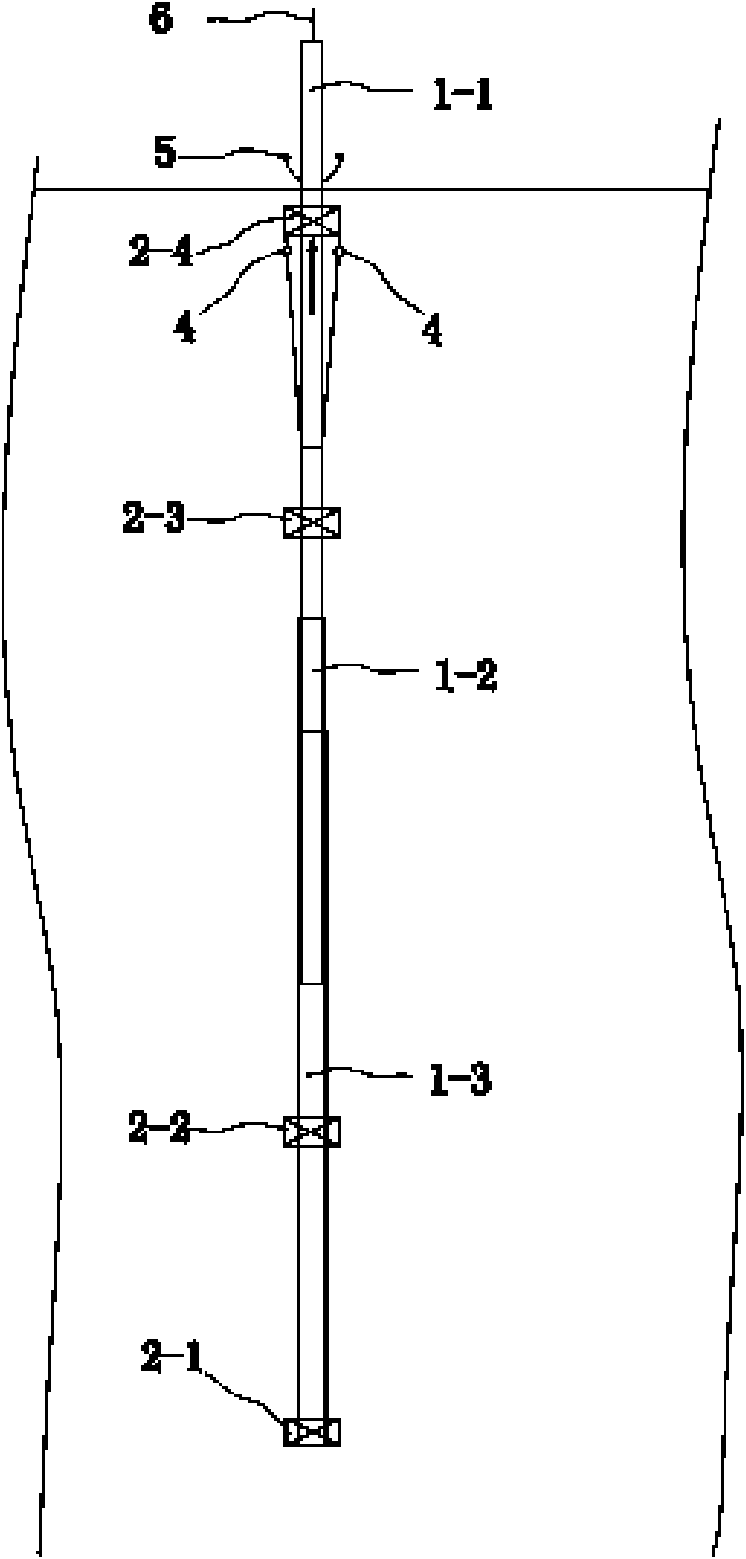

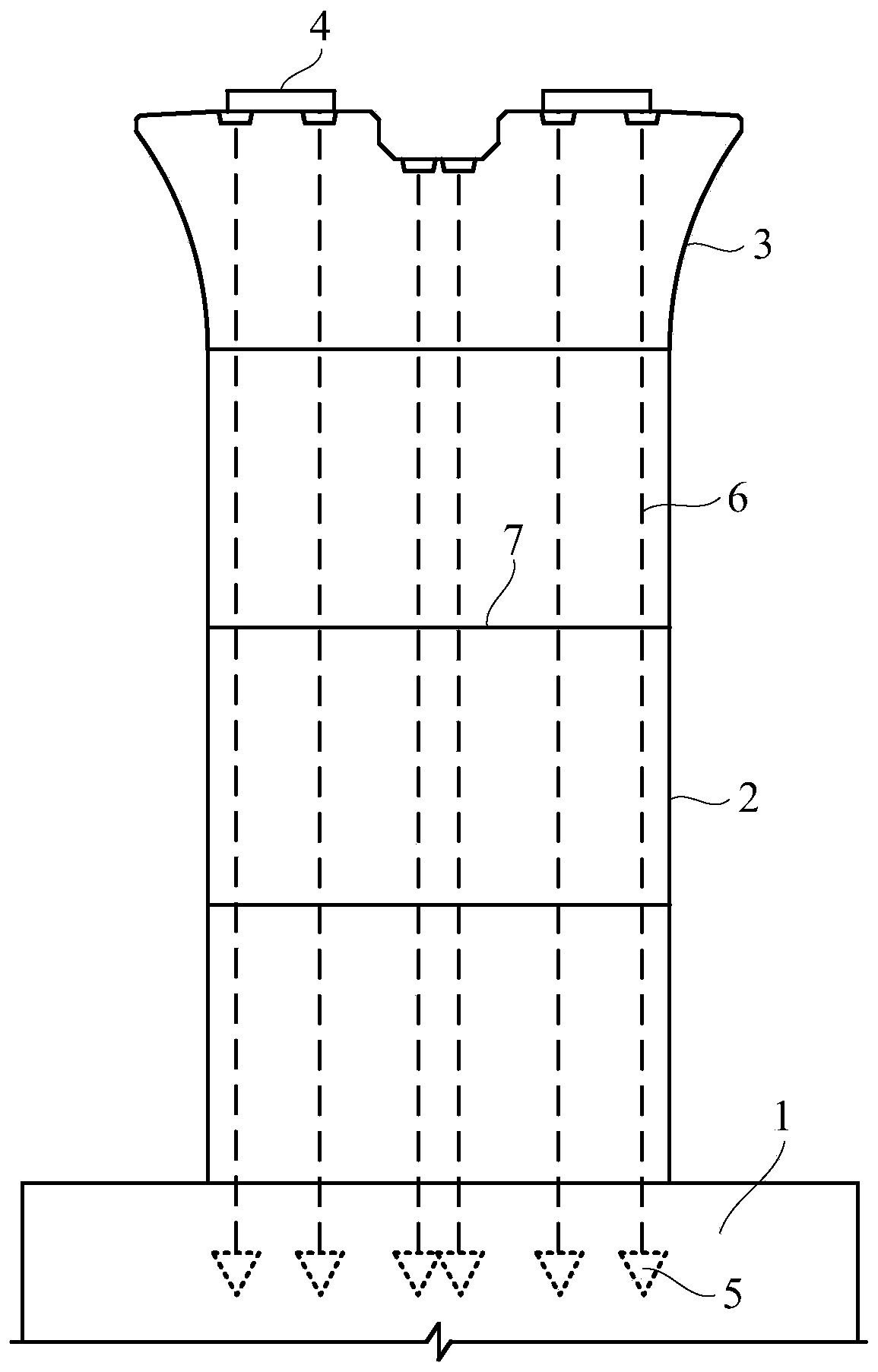

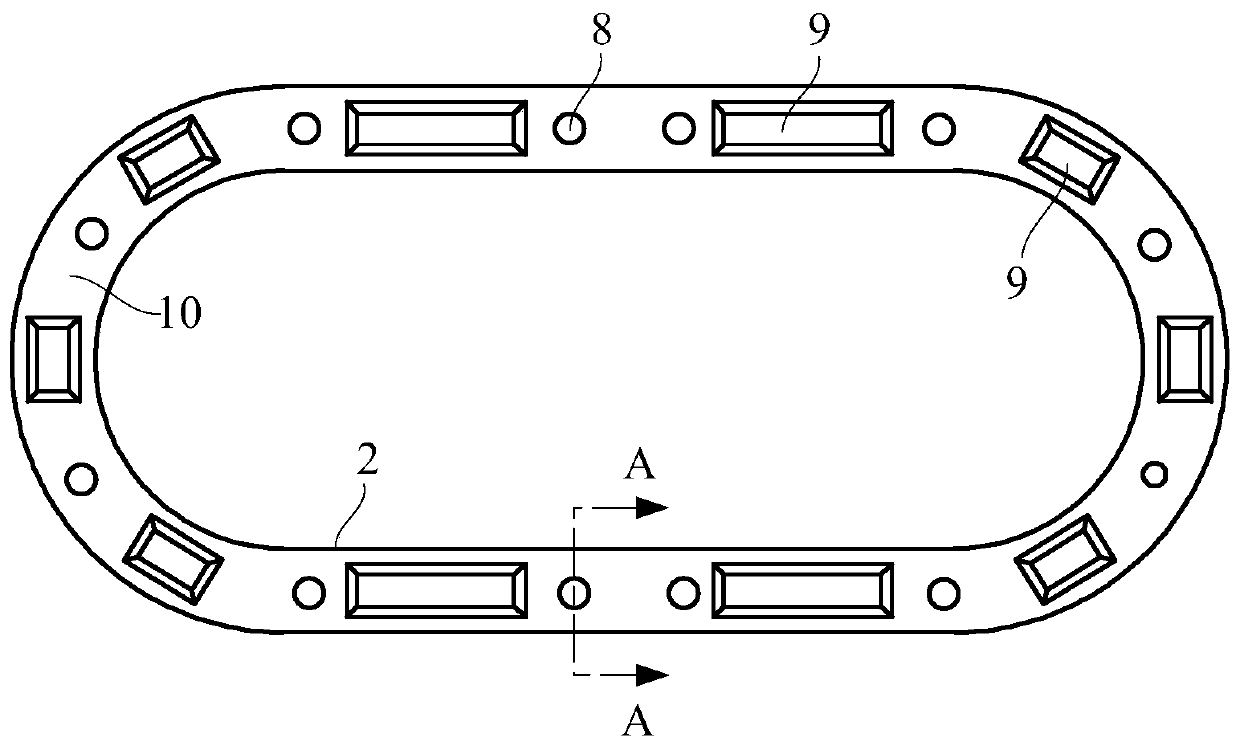

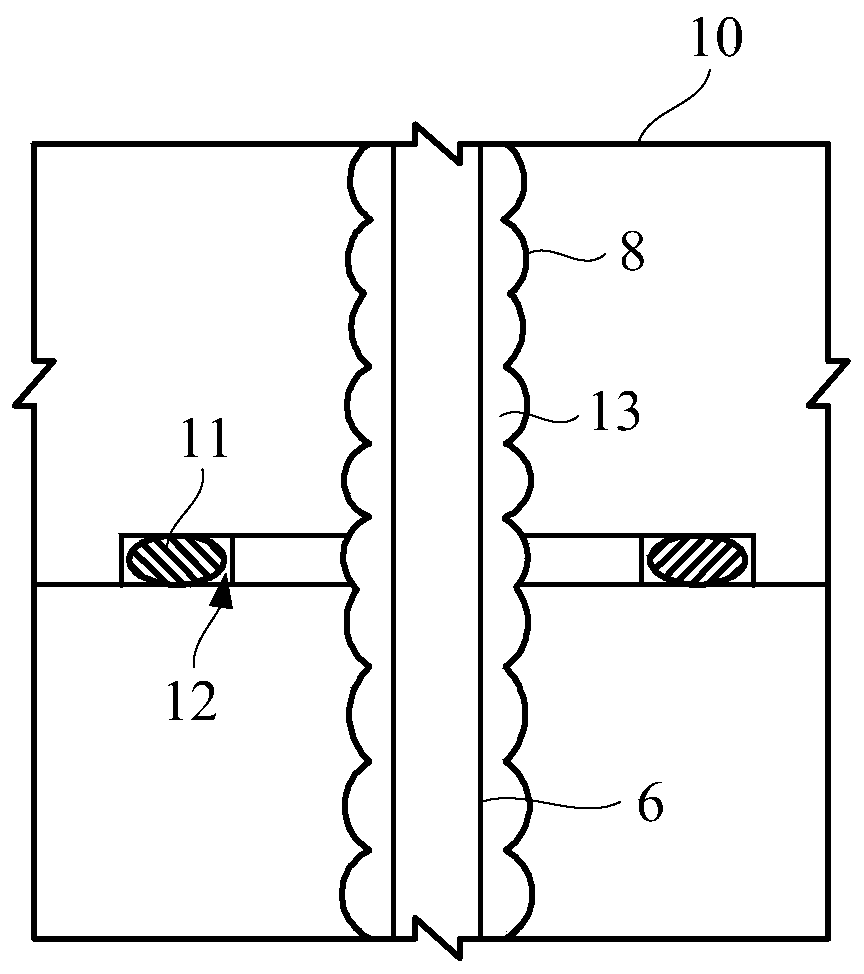

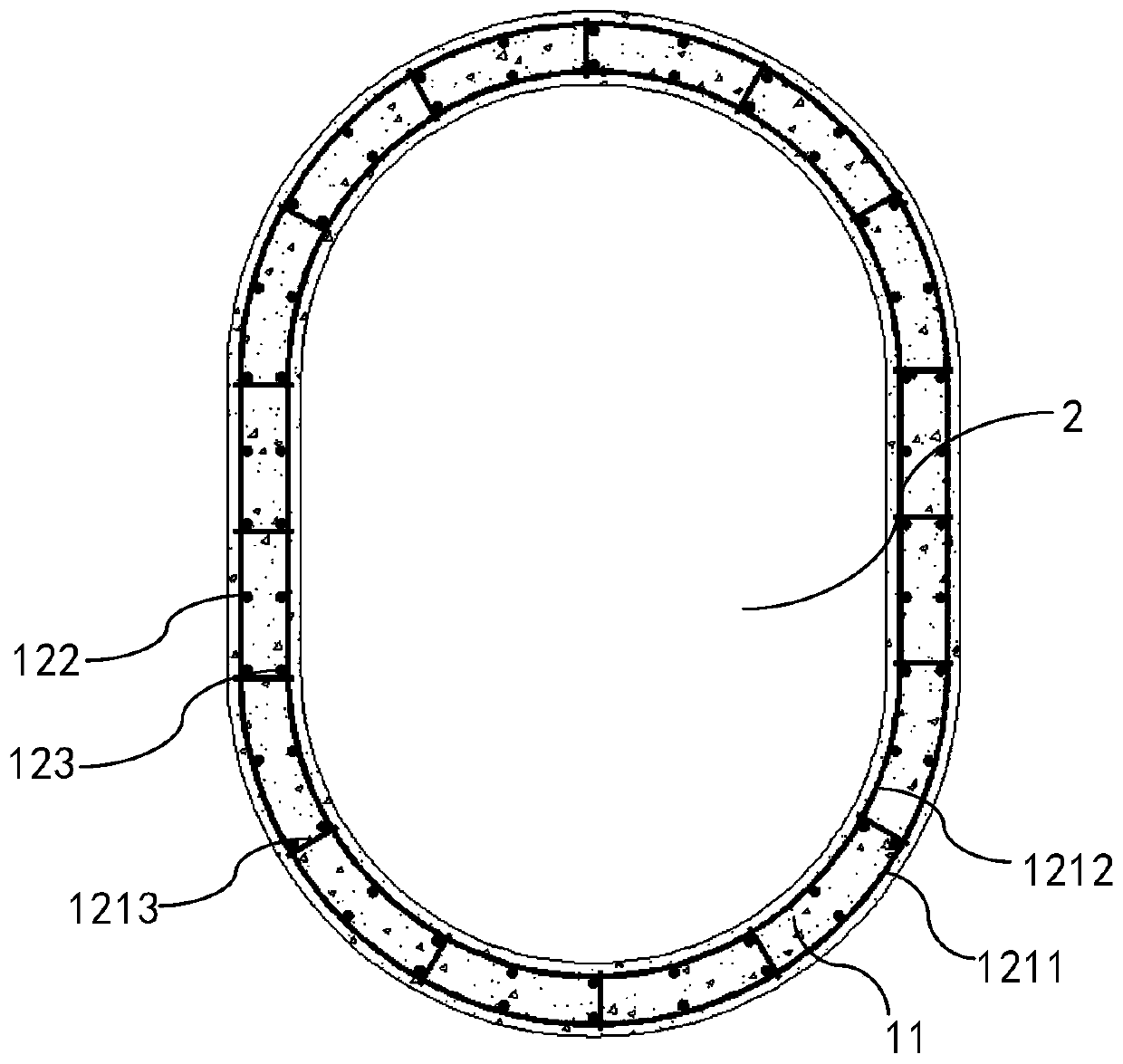

Railway assembled hollow pier and construction method thereof

InactiveCN111335155ASimple designReasonable designBridge structural detailsBridge erection/assemblyButt jointPre stress

The embodiment of the invention relates to the technical field of railway pier construction, and especially relates to a railway assembled hollow pier and a construction method thereof. The railway assembled hollow pier comprises a bearing platform, standard pier stud sections, pier top pier stud sections and padstones; the bearing platform and the padstones are both manufactured by in-situ casting; the pier top pier stud sections and the standard pier stud sections are all prefabricated parts; the standard pier stud sections are of hollow tubular structures; a self-locking anchorage device fixing end, a steel strand corrugated pipe and an embedded steel bar are embedded in the bearing platform; the bearing platform, the standard pier stud sections and the pier top pier stud sections are assembled and positioned through a plurality of concave-convex shear keys; and the top ends of the prestress steel strands are tensioned on the tops of the pier top pier stud sections, and the guide heads at the bottom ends of the prestress steel strands are fixedly connected with the self-locking anchorage device fixing ends in a self-locking mode. The railway assembled hollow pier can meet the rigidity design requirement of a railway bridge, the light design concept is achieved, all components are in precise butt joint, the assembling reliability is achieved, and the construction period is shortened.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

Cover plate weakening type assembly type wave web beam-column joint connection device

ActiveCN105863075AEasy and fast fastening workImprove control accuracyShock proofingShaped beamArchitectural engineering

The invention relates to a cover plate weakening type assembly type wave web beam-column joint connection device and belongs to the field of structural engineering. The assembly type wave web beam-column joint connection device is composed of a round steel pipe column with a cantilever beam section, a wave web I-shaped beam section and a connecting device between the round steel pipe column with the cantilever beam section and the wave web I-shaped beam section. Welded parts of the joint connection device are finished in a factory; weld seam accuracy and quality of the welded parts are easier to control; the round steel pipe column with the cantilever beam section and the wave web I-shaped beam section are assembled only through high-strength bolts and connecting plates on site; the fastening work of the bolts is convenient and fast; and the construction speed and construction quality are greatly improved. Meanwhile, the wave web I-shaped beam section can be built on the lower connecting plate of the round steel pipe column with the cantilever beam section, so that the construction difficulty is lowered, and on-site assembly and positioning are easy. A joint of the joint connection device is a beam-end reinforcement and dog-bone weakening combined joint; through reasonable design, double energy dissipation of bolt friction slippage and connecting plate and bolt plastic deformation can be achieved; and the joint ductility is good, and the energy-dissipating capacity and bearing capacity are high.

Owner:BEIJING UNIV OF TECH

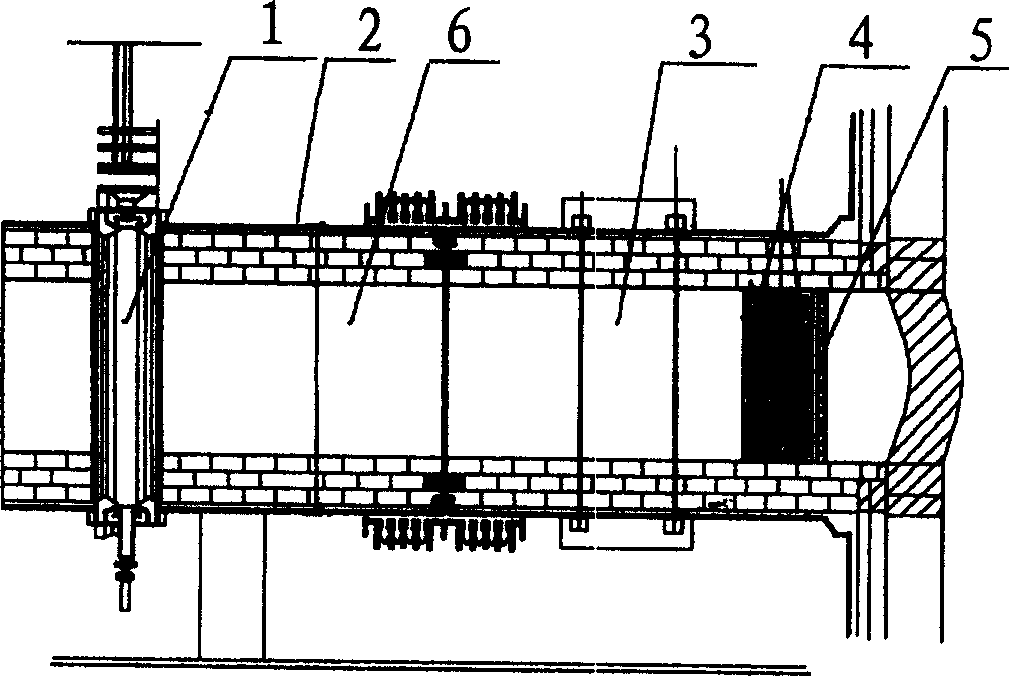

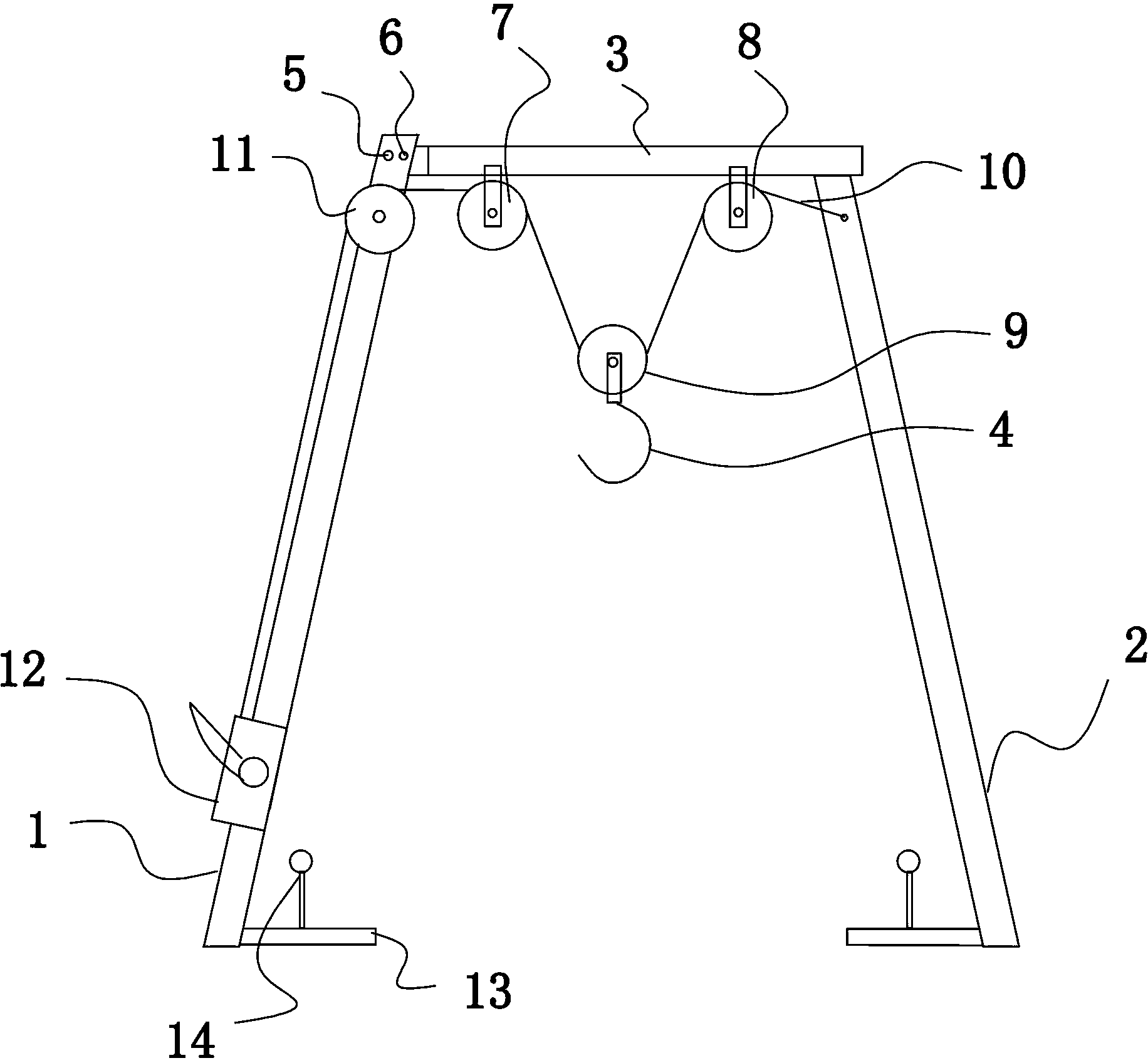

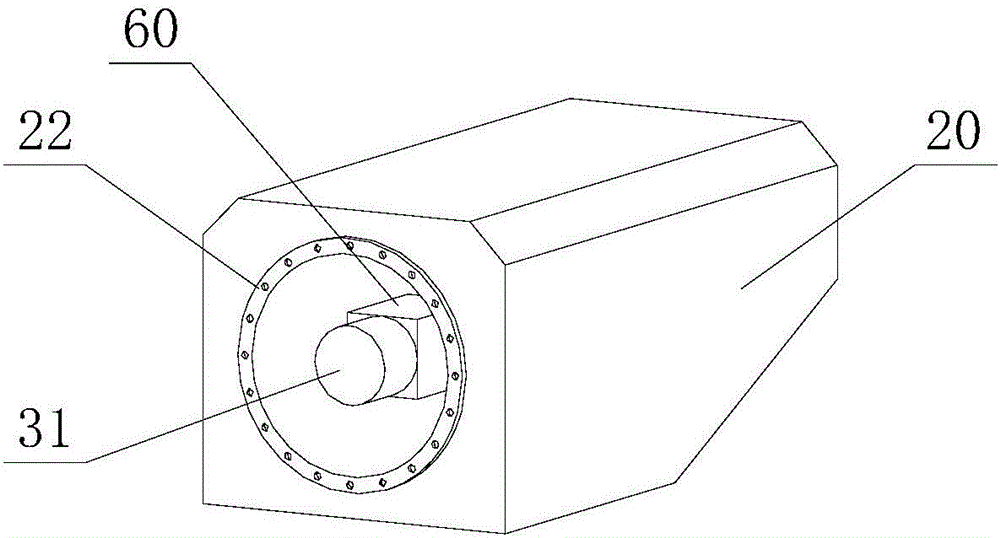

Steam curing system for building elements

ActiveCN105500510AImprove quality and efficiencyImprove work efficiencyCeramic shaping apparatusHydraulic cylinderEngineering

The invention relates to the technical field of building steam curing, and discloses a steam curing system for building elements. The steam curing system comprises a steam chamber, the left side and the right side of the steam chamber are provided with a feeding port and a discharging port respectively, and the feeding port and the discharging port are provided with doors which can open and close the feeding port and the discharging port; the left side of the steam chamber is provided with a feeding frame, the bottom of the fixing frame is fixedly provided with a first hydraulic cylinder which is inclined, a piston rod of the first hydraulic cylinder can stretch to the position over the top of the feeding frame, and a partition wall is arranged in the steam chamber and divides the steam chamber into a first steam chamber body and a second steam chamber body. According to the steam curing system for the building elements, the structure is reasonable, use is convenient, a crane is not needed to hoist the elements to be cured into the steam chamber and then hoist the cured elements out of the steam chamber, therefore, the hoisting difficulty is greatly lowered, the steam loss is greatly reduced, and the curing cost is lowered; the curing quality can be further improved by dividing the steam chamber into the two steam chamber bodies; the curing quality and working efficiency can be further improved by arranging pit grooves.

Owner:郑州暖树实业有限公司

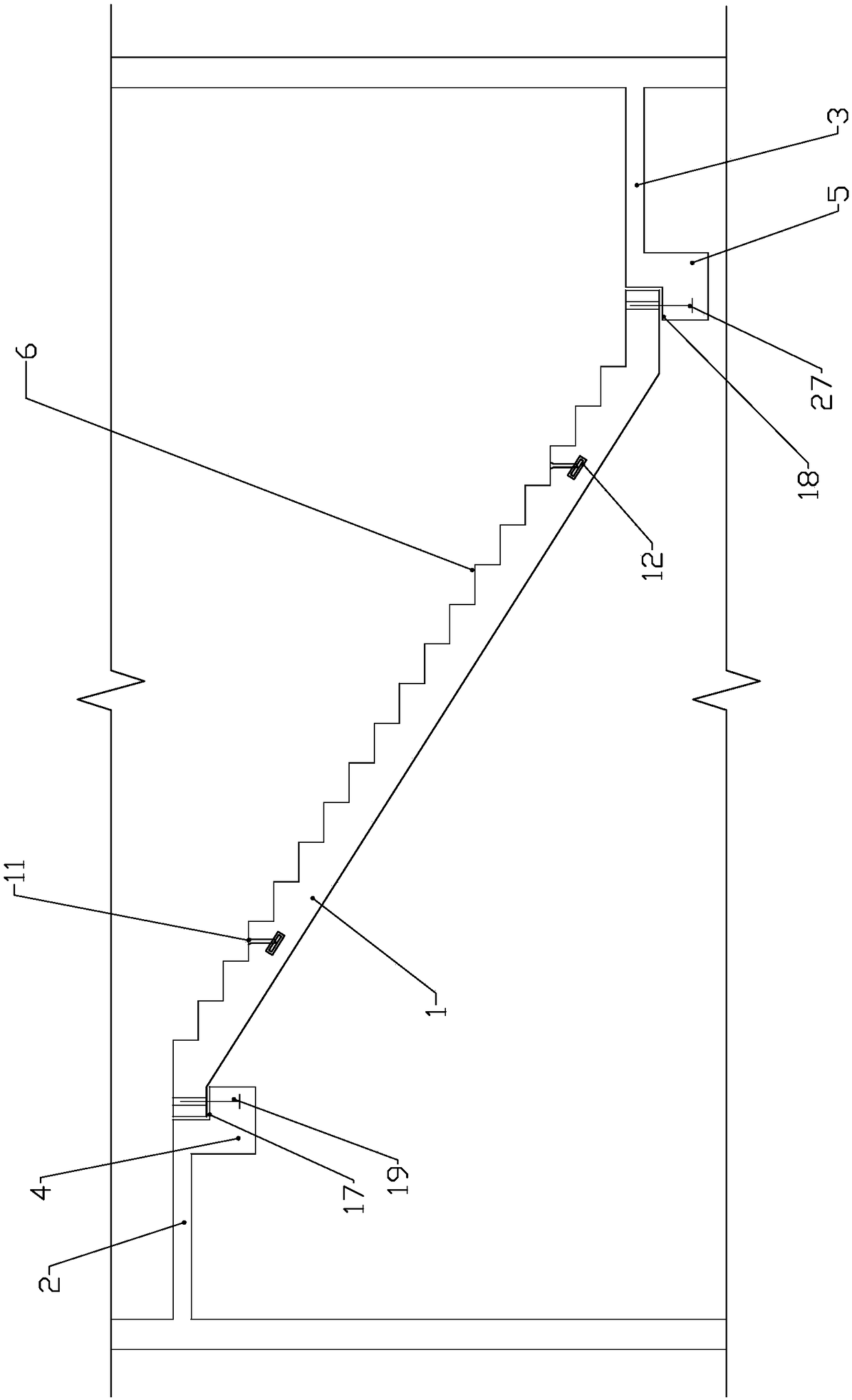

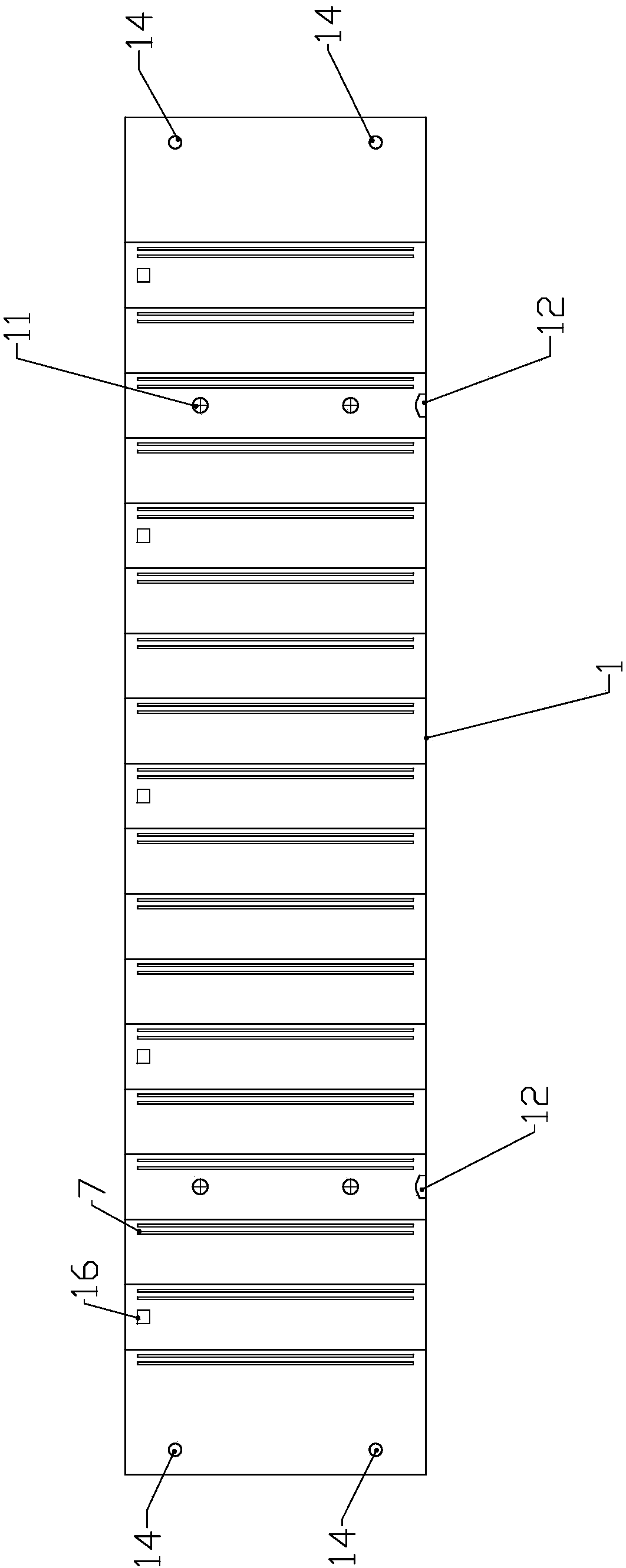

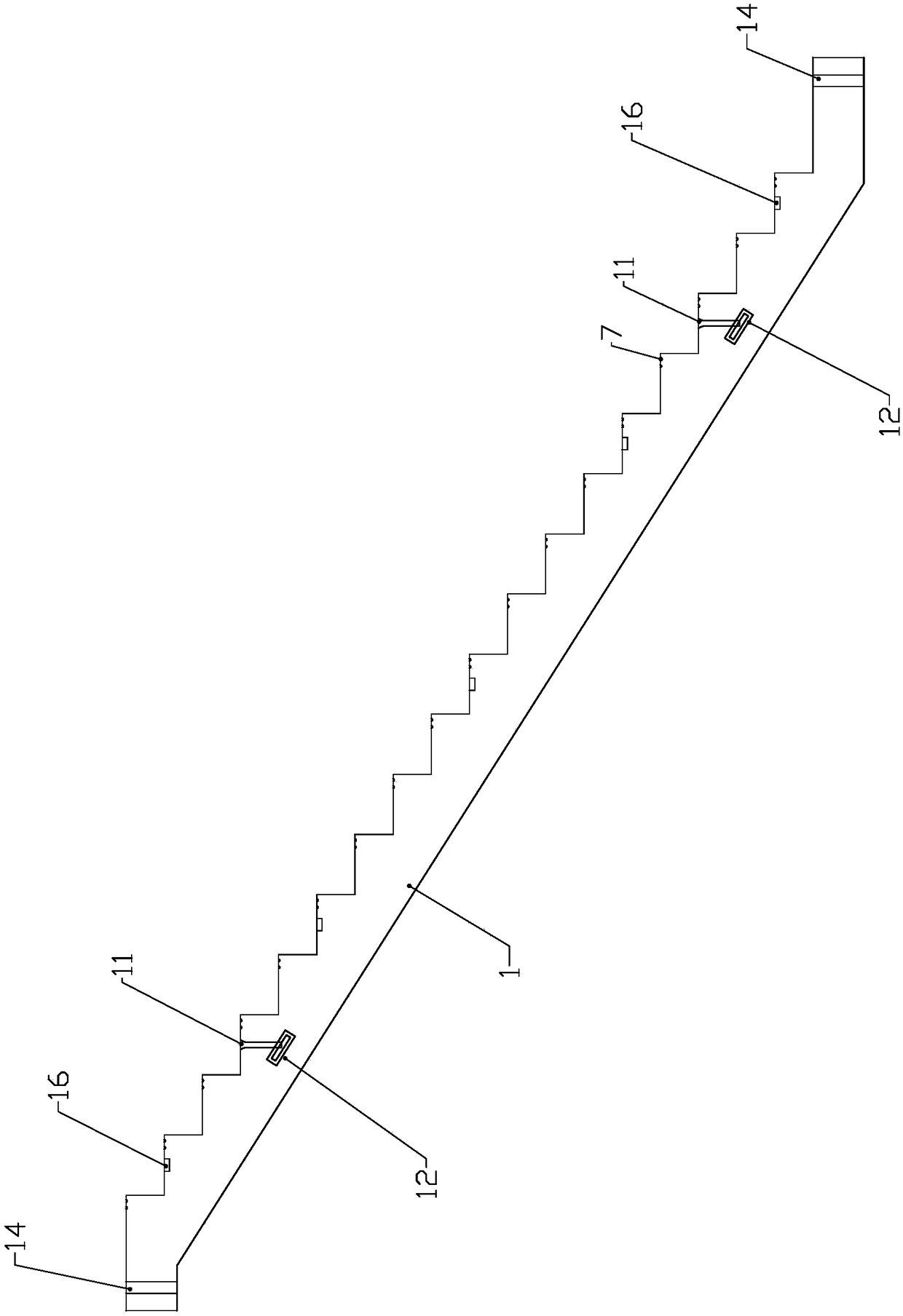

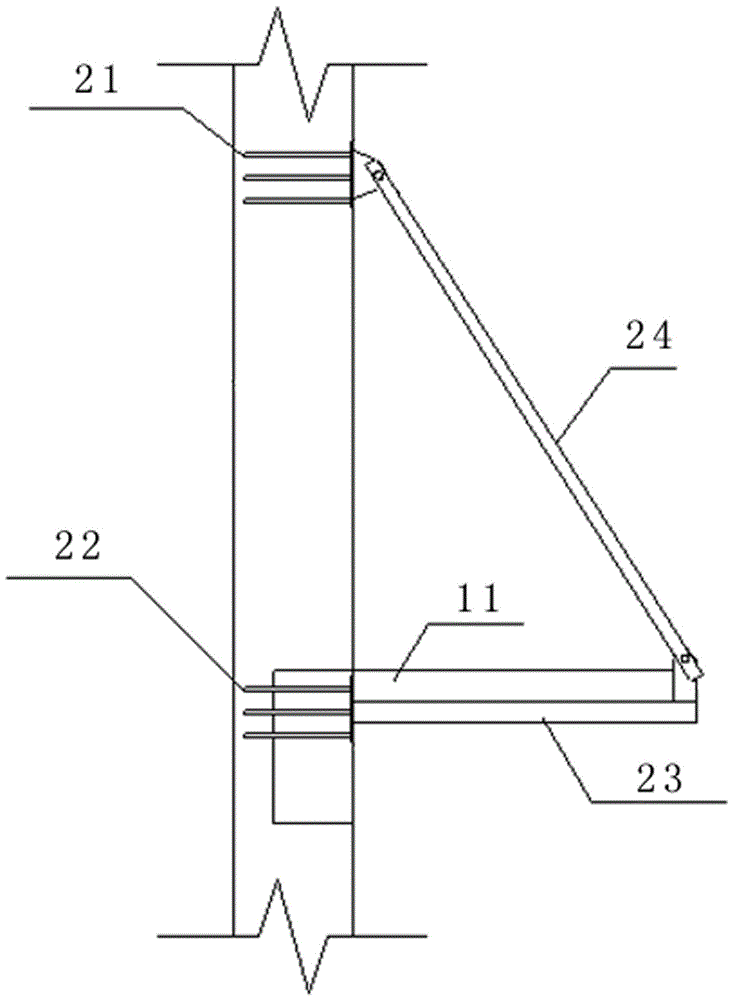

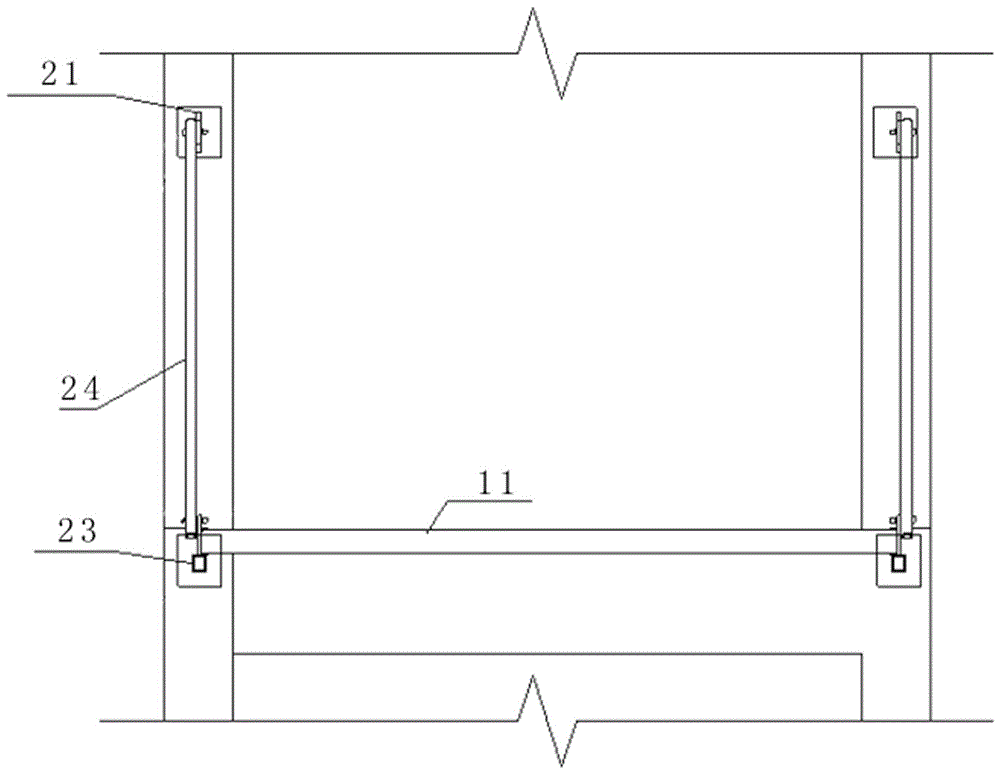

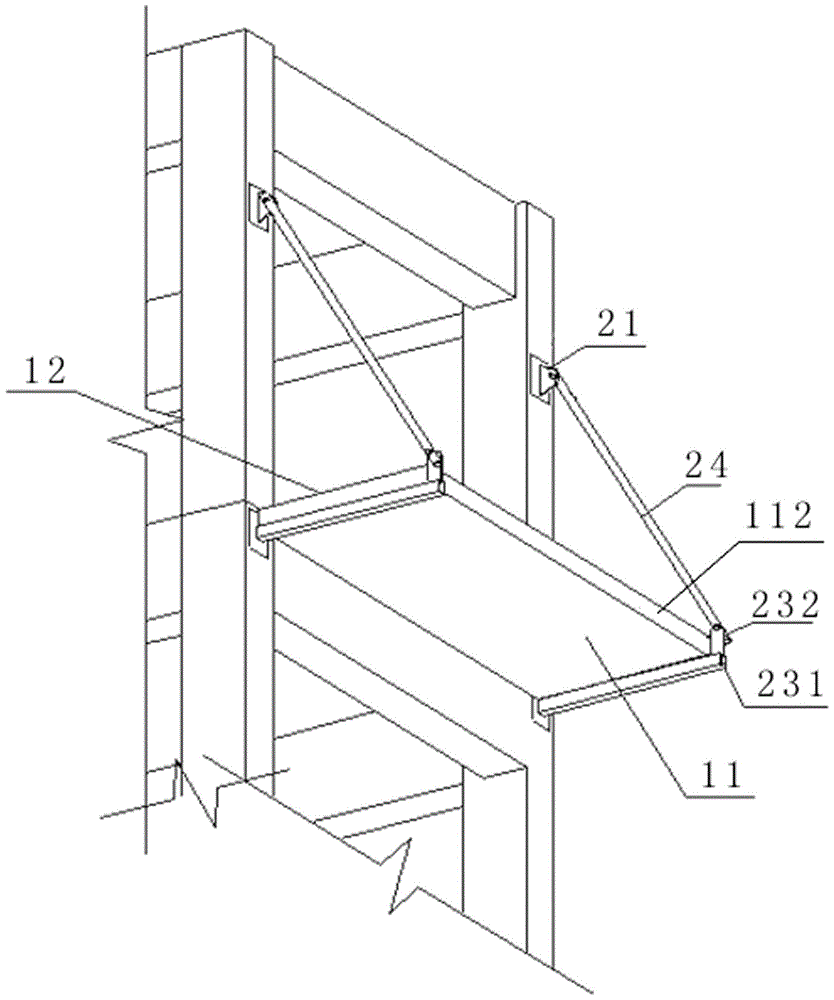

Precast prestressed-concrete slab-type stair and making construction method

PendingCN108166690AReduce transportationReduce the difficulty of hoistingTreadsEarthquake resistanceCrack resistance

The invention discloses a precast prestressed-concrete slab-type stair and a making construction method, and belongs to the technical field of constructional engineering. The precast prestressed-concrete slab-type stair structurally comprises a slab-type stair body aslant arranged, an upper stair platform, a lower stair platform, an upper stair beam and a lower stair beam; the upper stair platformis connected with the upper stair beam, the lower stair platform is connected with the lower stair beam, and the two ends of the slab-type stair body are connected with the upper stair beam and the lower stair beam respectively; ladder-shaped steps are arranged on the slab-type stair body; a prestresed reinforcing steel bar is arranged at the lower portion in the slab-type stair body in the length direction, an upper common reinforcing steel bar is arranged at the upper portion in the slab-type stair body in the length direction, and annular distribution reinforcing steel bars are arranged inthe middle in the slab-type stair body in the length direction at equal intervals, and are located between the prestresed reinforcing steel bar at the lower portion and the upper common reinforcing steel bar at the upper portion. The precast prestressed-concrete slab-type stair and the making construction method have the advantages of being large in application span, good in crack resistance, light in self weight, convenient to hoist and transport, excellent in earthquake resistance and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

Exchange technology of hot air furnace hot air short pipe

InactiveCN1618991AEasy to determine the sizeQuality assuranceBlast furnace detailsHeating stovesEngineeringMechanical engineering

A technology for exchanging the short hot air tube of blast heater includes holding the temp of the blast heater, closing hot air valve, slightly opening flue valve to generate negative pressure, masoning firewall at the side of blast heater, detaching the damaged shot hot air tube, installing new one consisting of fixed short tube and detachable short tube, detaching the detachable short tube, masoning the linear, detaching firewall, and installing the detachable short tube.

Owner:MAANSHAN IRON & STEEL CO LTD

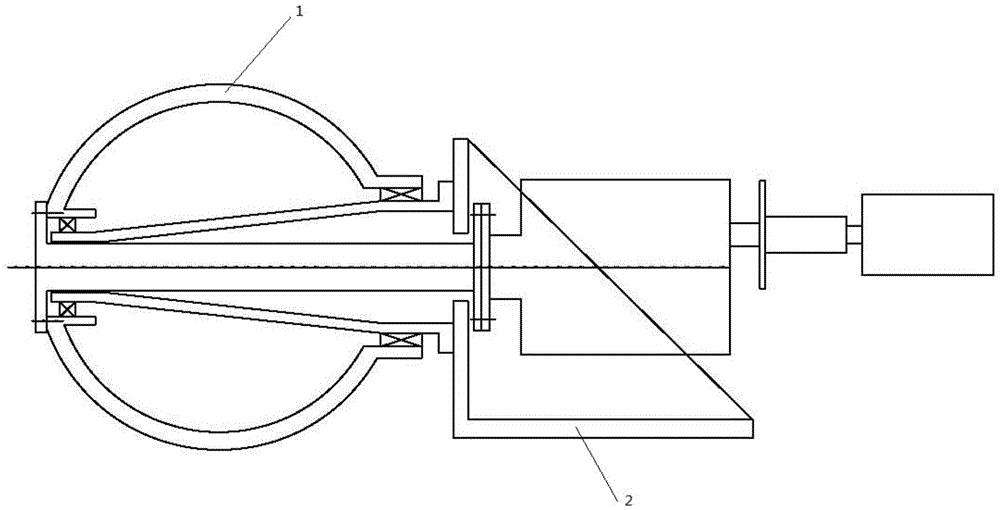

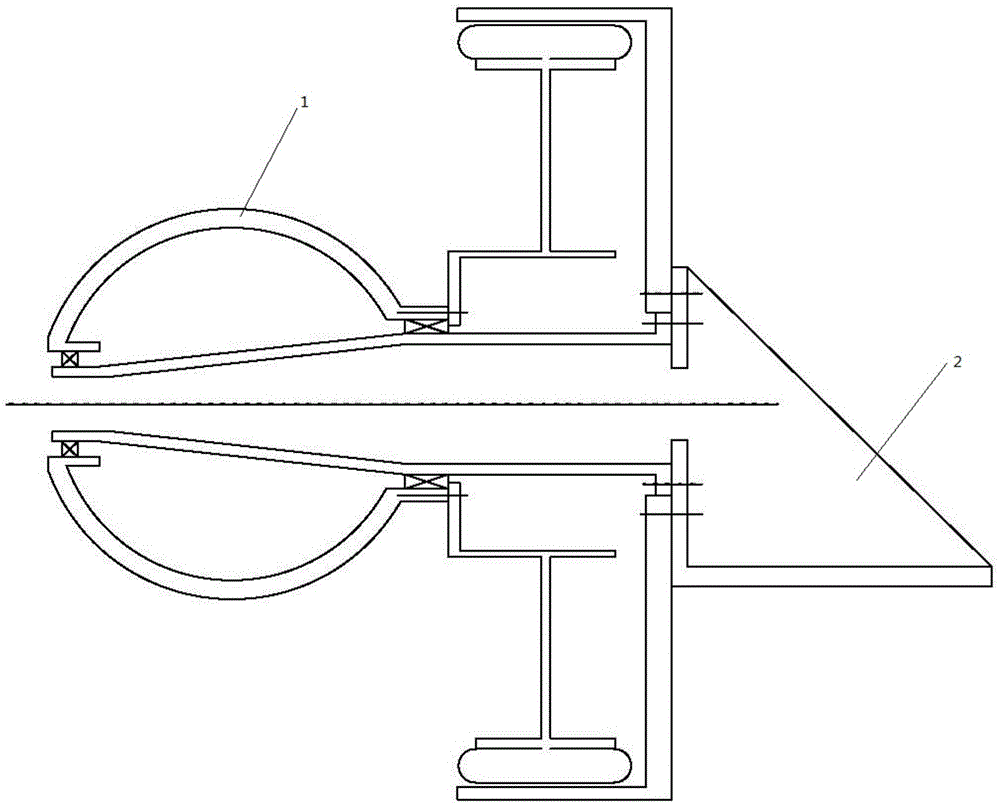

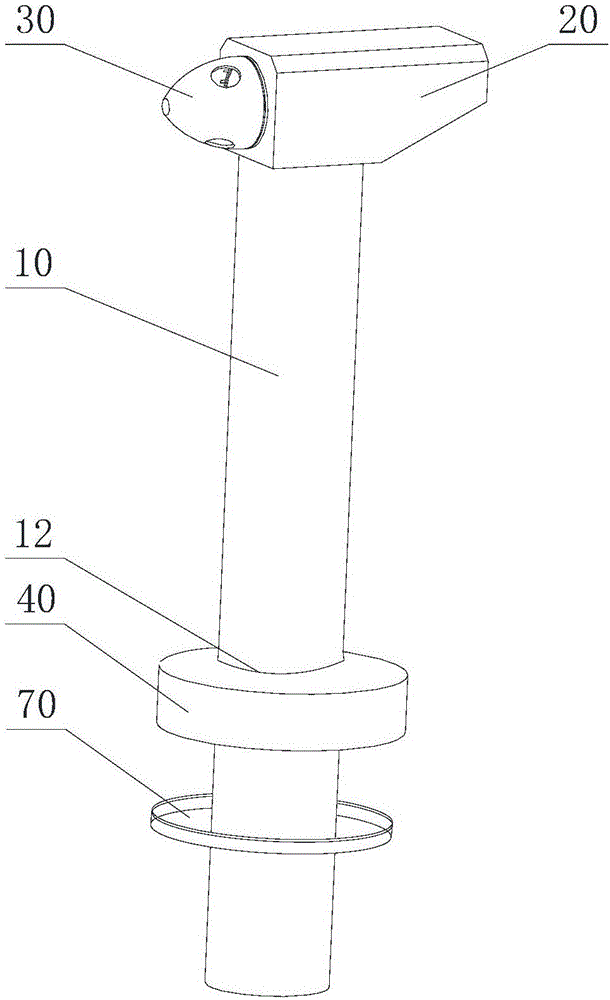

Wind driven generator, wind driven generator set and installation method thereof

ActiveCN105649885AReduce the difficulty and cost of hoistingAchieve connectionWind motor assemblyWind motor supports/mountsWind drivenAutomotive engineering

The invention provides a wind driven generator, a wind driven generator set and an installation method thereof. The wind driven generator comprises a stator and a rotor coating the stator, and further comprises a driving part connected with the rotor and driving the rotor to axially move. The wind driven generator can reduce the lifting difficulty.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

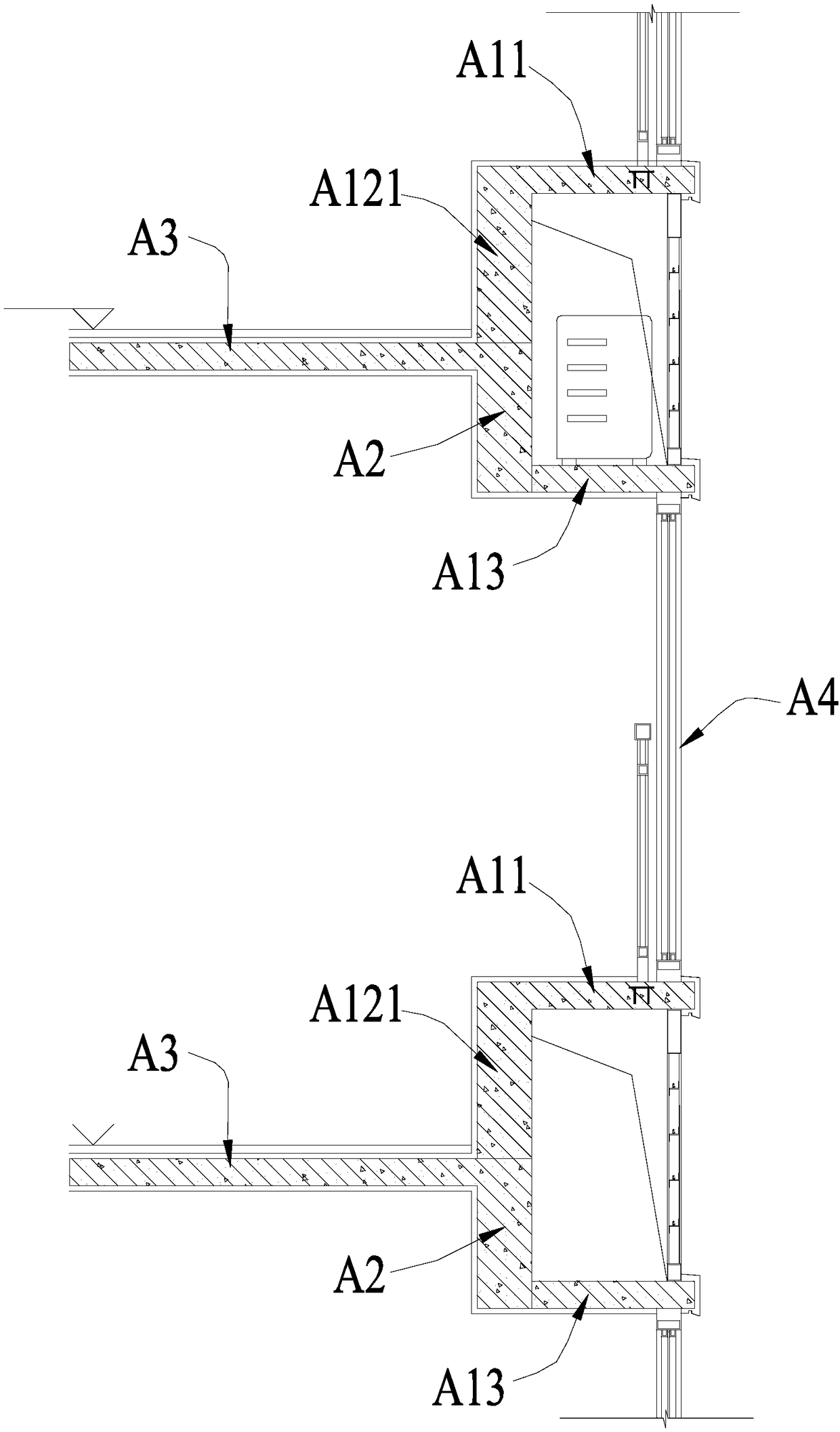

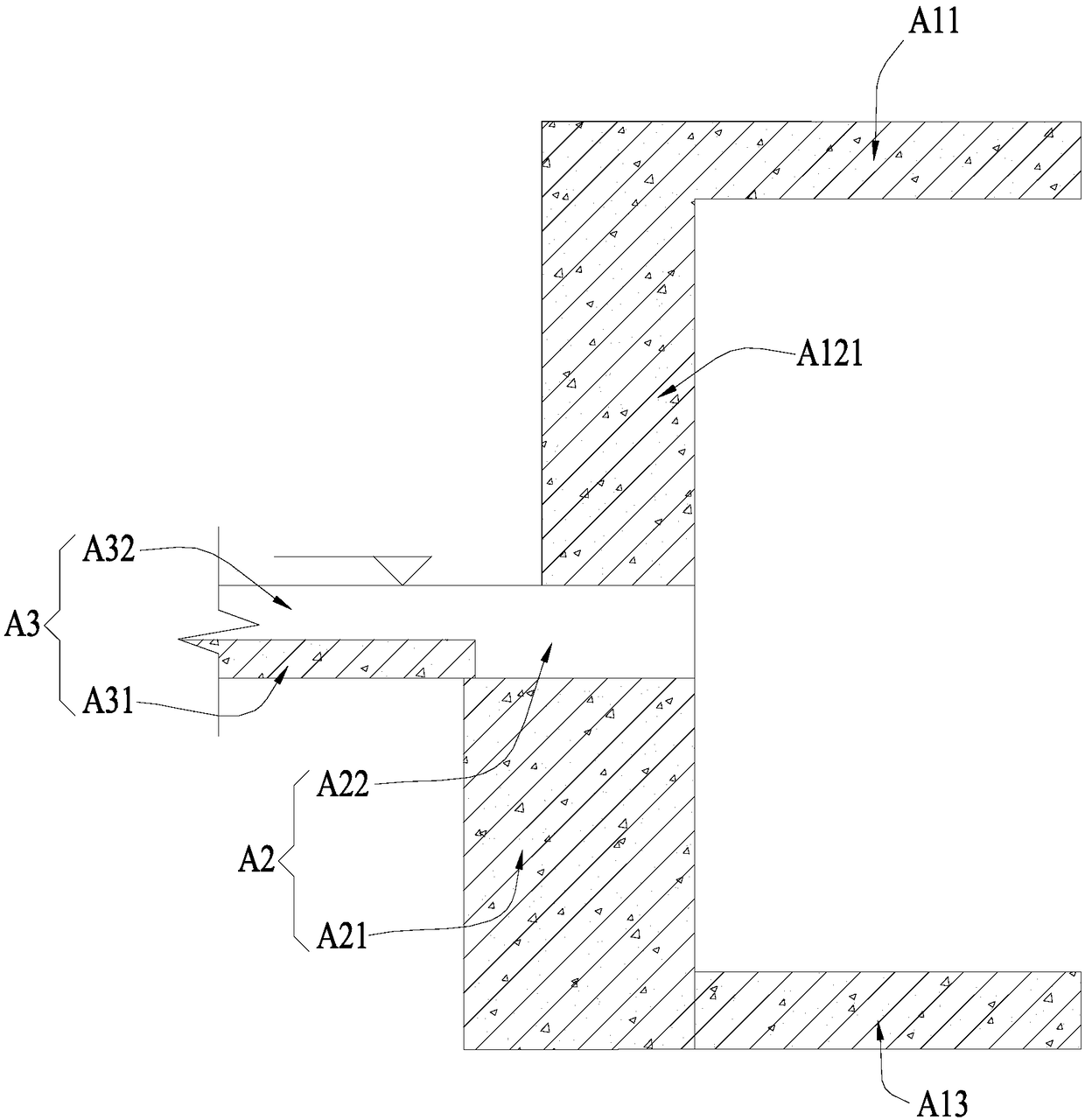

Prefabricated bay window component, assembly type bay window panel point construction and construction method thereof

PendingCN108316466AEnsure structural safetyFirmly connectedBuilding material handlingReinforced concreteArchitectural engineering

The invention discloses a prefabricated bay window component, an assembly type bay window panel point construction and a construction method thereof. The prefabricated bay window component is a reinforced concrete prefabricated component which is integrally cast and molded. The prefabricated bay window component comprises a first plate part, a second plate part and a third plate part, wherein a lug boss is formed in the upper part of the second part component relative to the lower part and is protruded toward the inner side of the second plate part; the first plate part and the third plate part are connected with the outer side of the second plate part; the first plate part is located above the third plate part; the second plate part is connected with an anchoring part used for connectinga building main body; the first plate part is used as a bay windowsill bottom plate; the upper part of the second plate part is used as a bay windowsill lower wall; the third plate part is used as a bay windowsill top plate. Through the prefabricated bay window component, the assembly type bay window panel pointconstruction and the construction method thereof, the occurrence of long-length specially-shaped prefabricated components in the bay window panel point construction is avoided under the precondition that the structure safety of the assembly type bay window panel point structure is ensured; the difficulties and the costs for producing, transporting and hoisting all the prefabricated components in the assembly type bay window panel point construction can be reduced.

Owner:广东省建工设计院有限公司

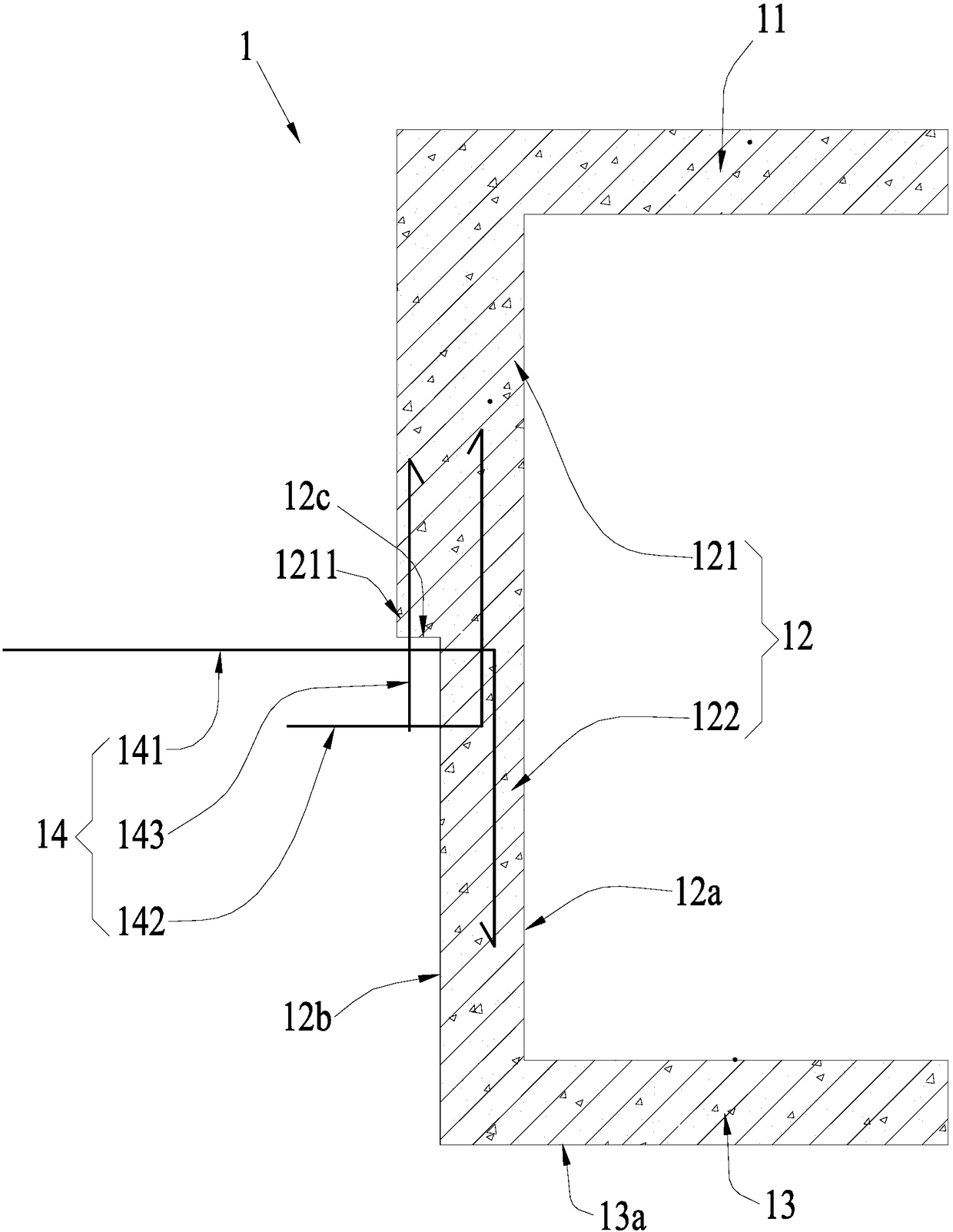

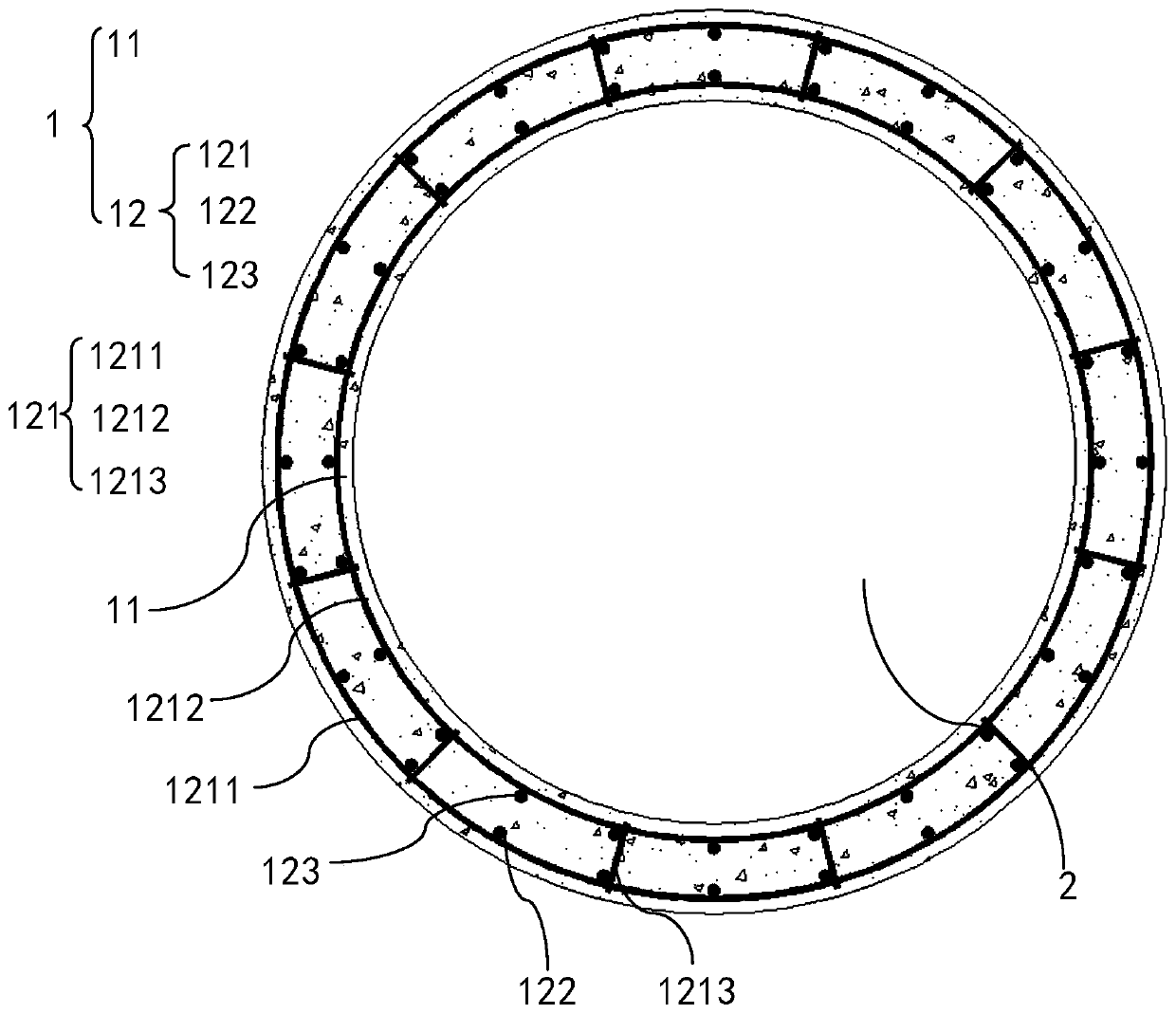

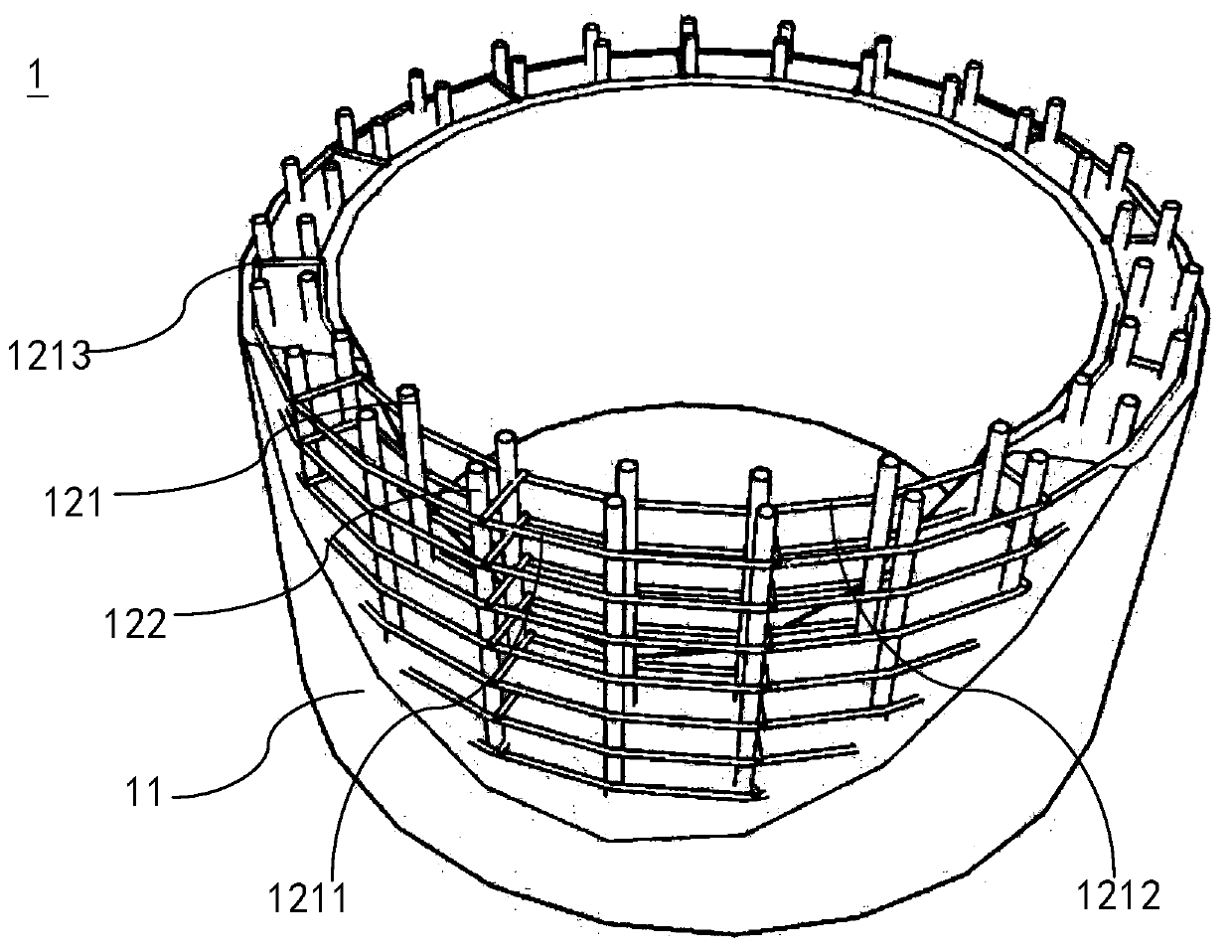

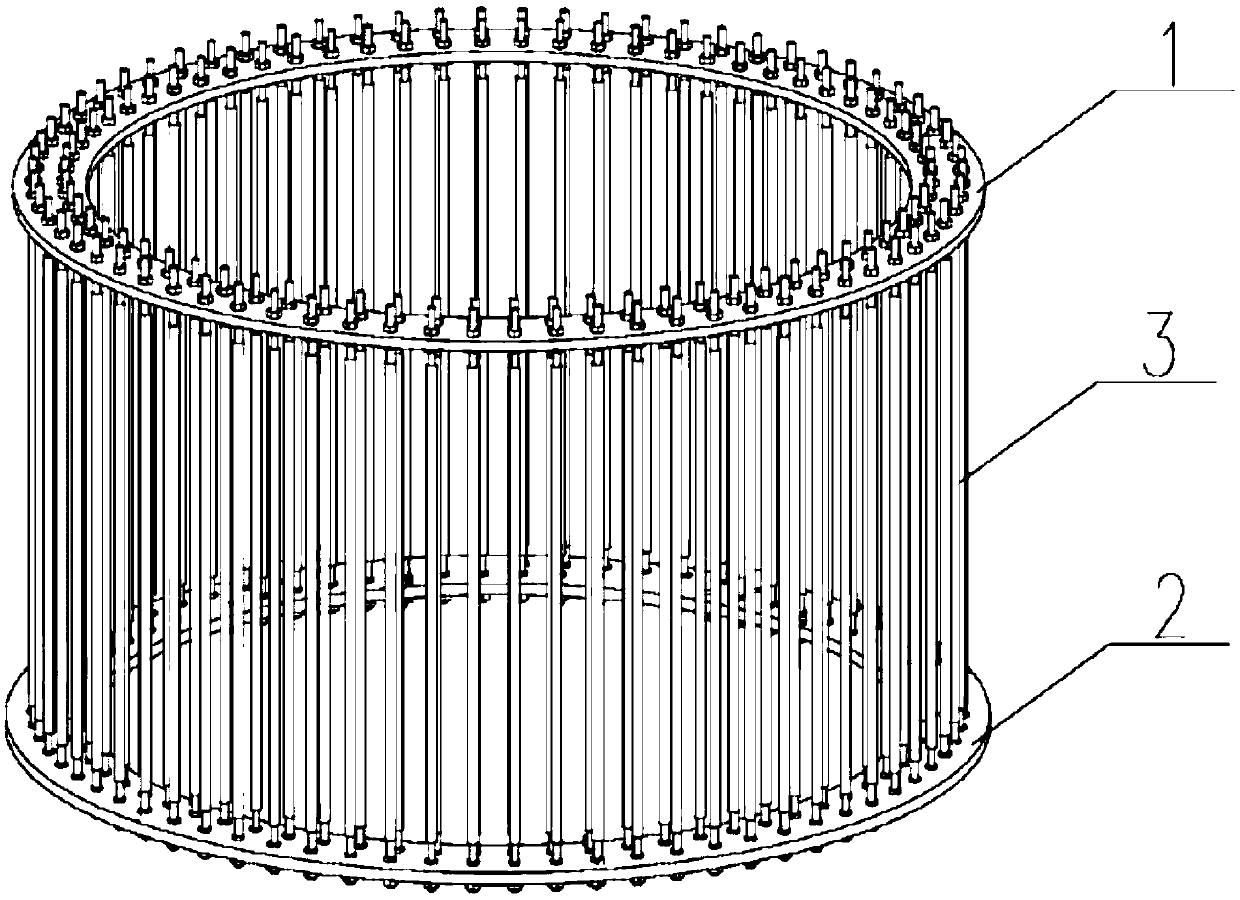

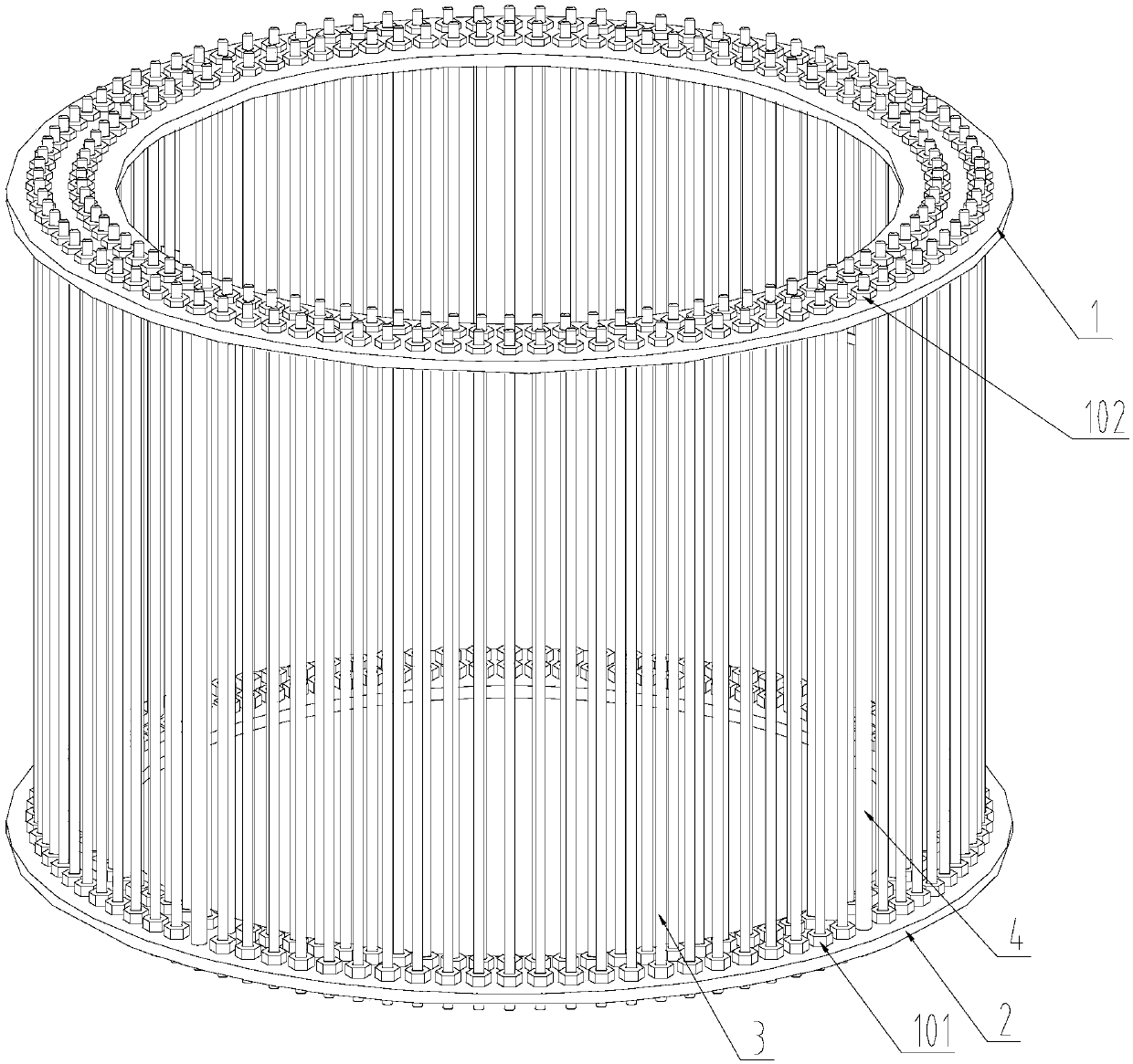

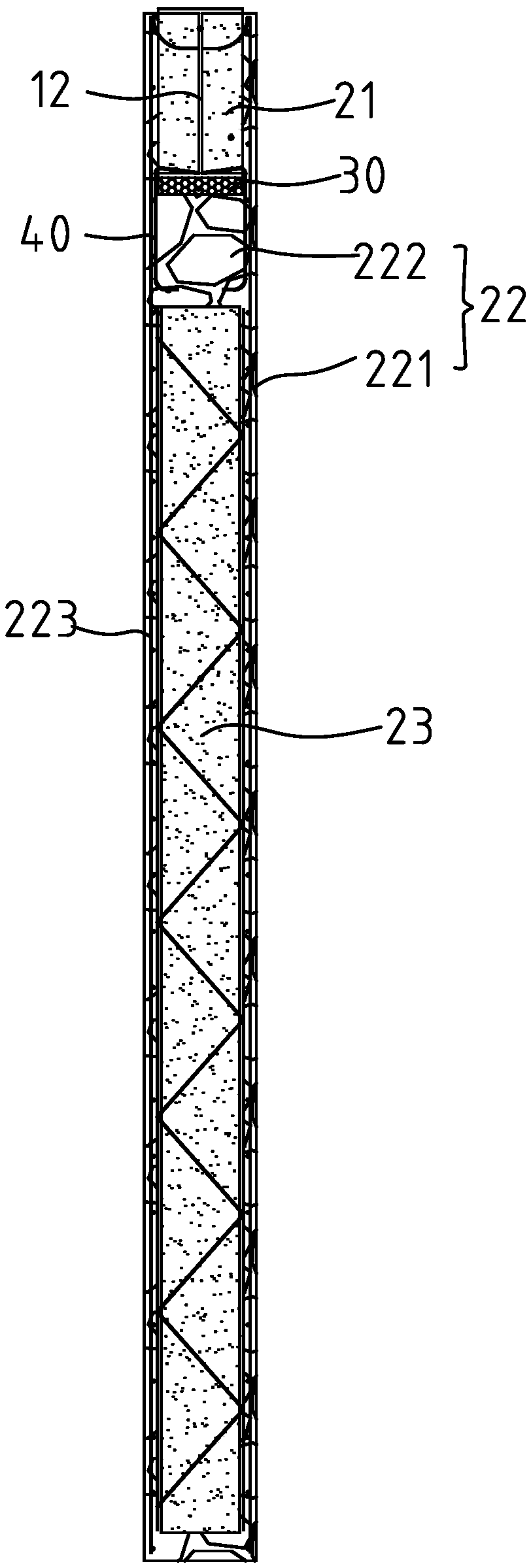

Fabricated reinforced concrete bridge pier and construction method thereof

PendingCN110130212AReduce weightReduce workloadBridge structural detailsBridge erection/assemblyReinforced concreteRebar

The invention provides a fabricated reinforced concrete bridge pier. The fabricated reinforced concrete bridge pier comprises a hollow bridge pier shell and cast-in-place core concrete arranged in thebridge pier shell, the bridge pier shell comprises a concrete layer and a reinforcement cage, and the reinforcement cage is arranged in the concrete layer; and the reinforcement cage comprises a plurality of circumferential stirrup meshes and a plurality of vertical steel bars, the multiple circumferential stirrup meshes are equidistantly arranged at intervals in the vertical direction, and the multiple vertical steel bars are equidistantly arranged at intervals along the circumferential stirrup meshes. The invention provides a construction method of the fabricated reinforced concrete bridgepier, the reinforcement cage and formworks are manufactured, then concrete is poured into spaces between the formworks and congealed into a whole so as to form the integrated bridge pier shell, the bridge pier shell is transported to a construction site, and the cast-in-place core concrete is poured into a hollow hole of the bridge pier shell. According to the fabricated reinforced concrete bridgepier and the construction method thereof, the weight is small, the construction period is short, transporting and hoisting difficulty is greatly reduced, multiple construction ways are provided, andoverall performance after the structure is formed is good.

Owner:RBS PARTNERS S&T CO LTD

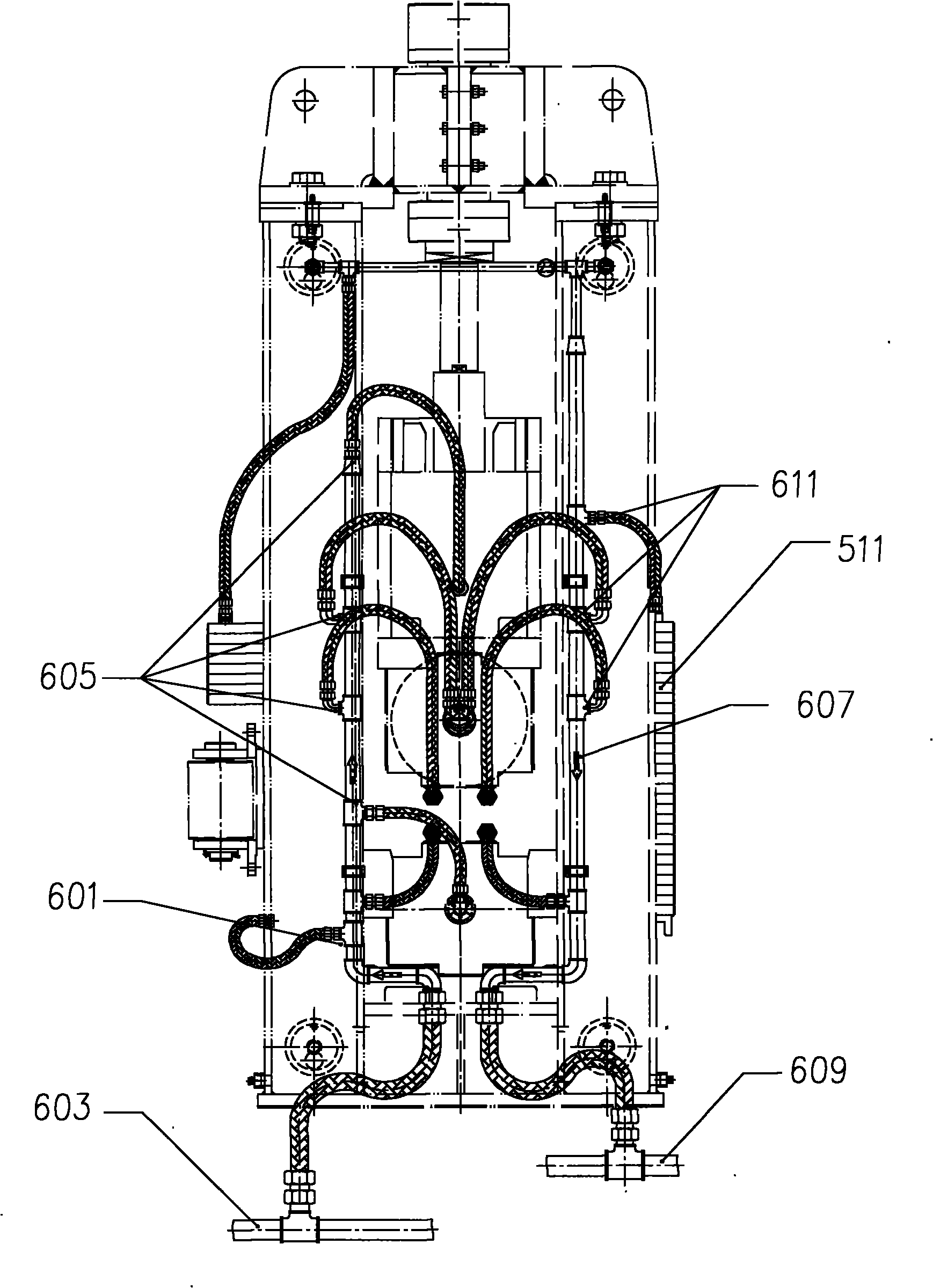

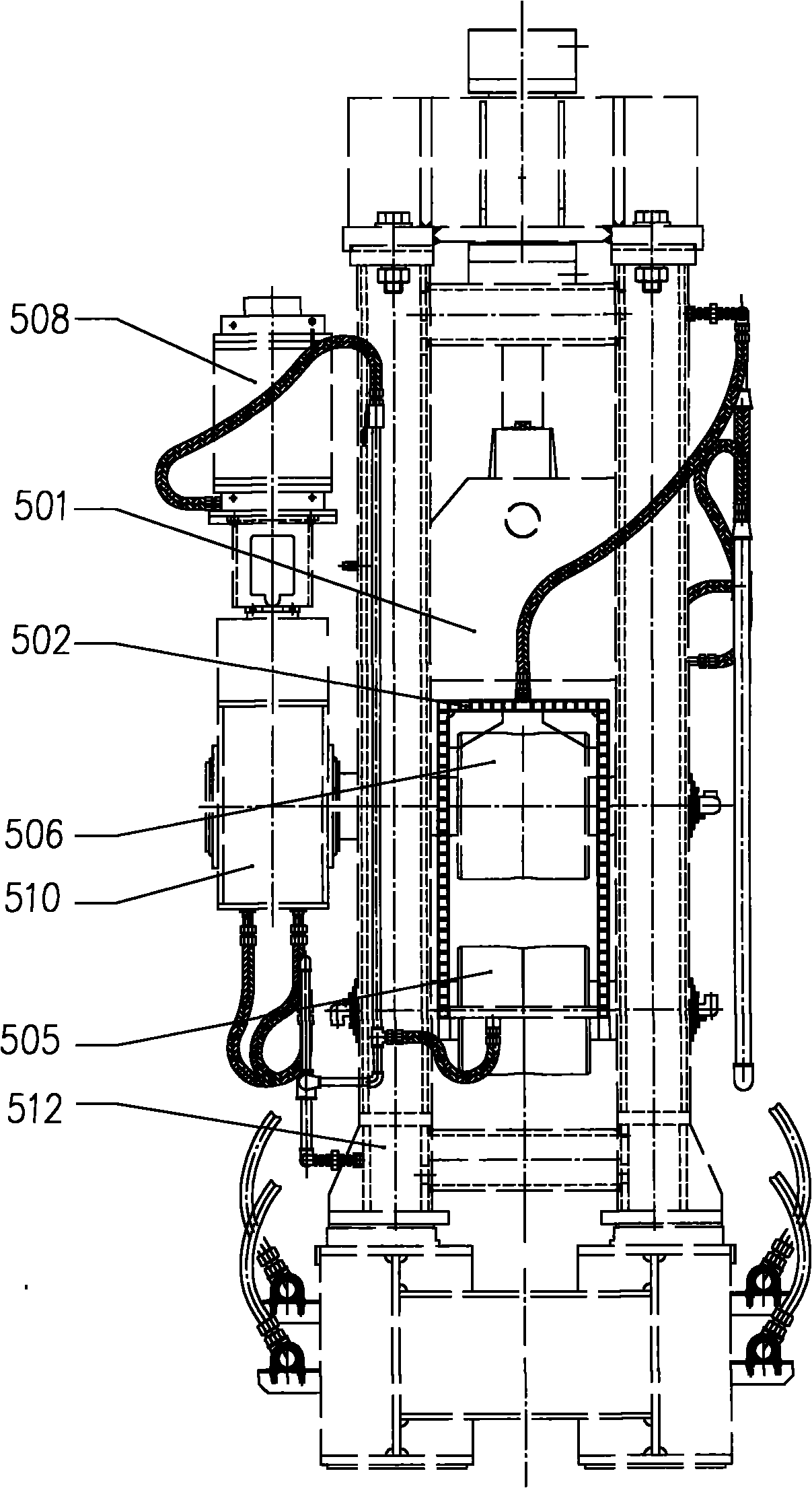

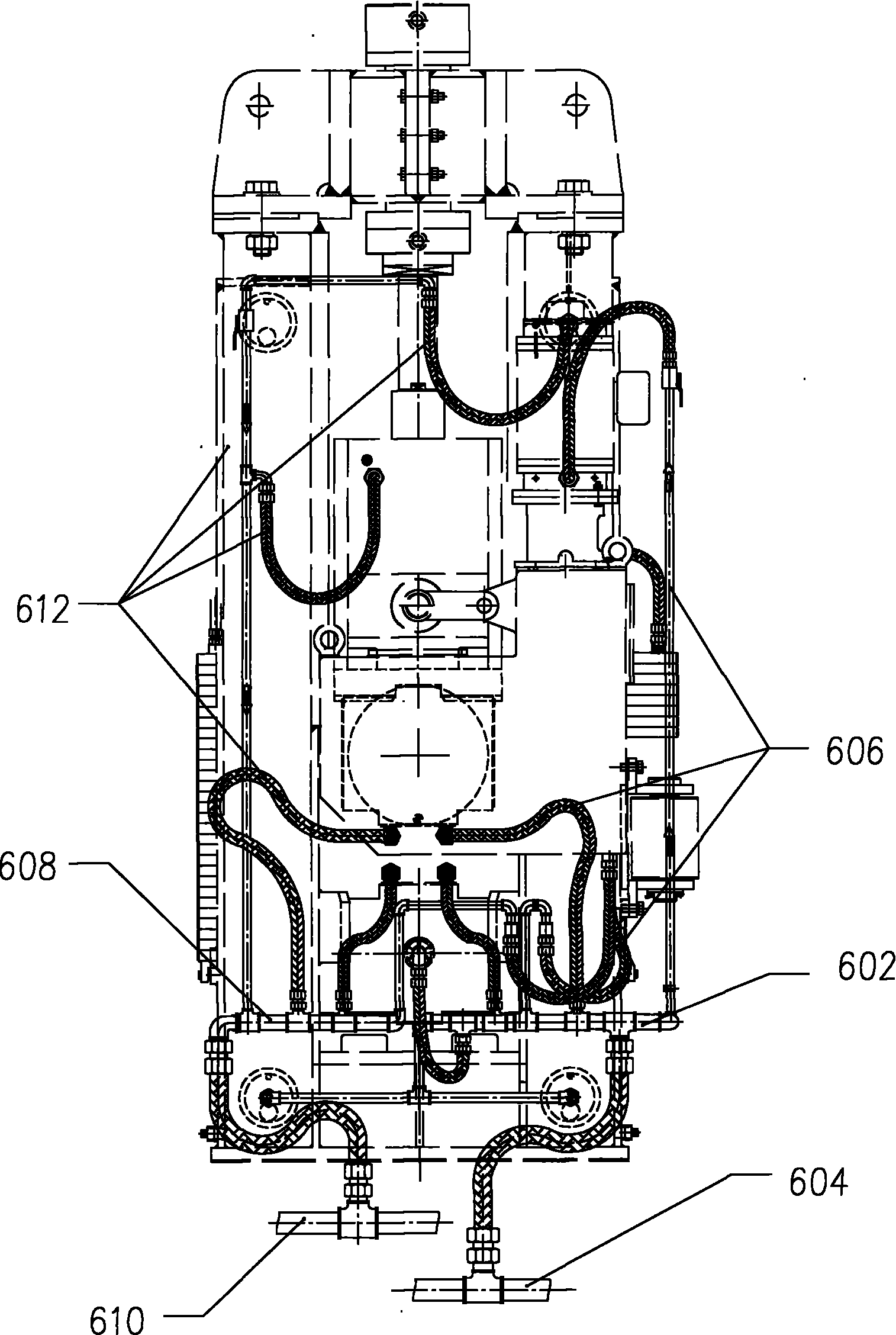

Tension leveler for continuous caster

The embodiment of the invention discloses a tension leveler for a continuous caster, which comprises a first upright post, a second upright post, a third upright post, a fourth upright post and functional components. The functional components are arranged in a rectangular space enclosed by four upright posts; communicating pipes are arranged in the four upright posts respectively and communicated with one another; the first upright post is provided with a main water inlet; the third upright post is provided with a main water return port; the first upright post and the second upright post are provided with a plurality of water intakes; the third upright post and the fourth upright post are provided with a plurality of water outlets; and the water intakes and the water outlets are communicated with the components through water pipes. The water inlet and the water return port are directly arranged on a water inlet upright post and a water return upright post, so water inlet and water return drift diameters are increased, cooling water flow rate is increased, and the mobility of cooling water is accelerated. The functional components are directly connected with the water inlet upright post and the water return upright post through the water pipes, so the flow rates of water flowing through the function components are ensured, the problem of non-uniform cooling caused by the lowered back end water pressure is solved, and a fault point is easy to check when the device fails.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

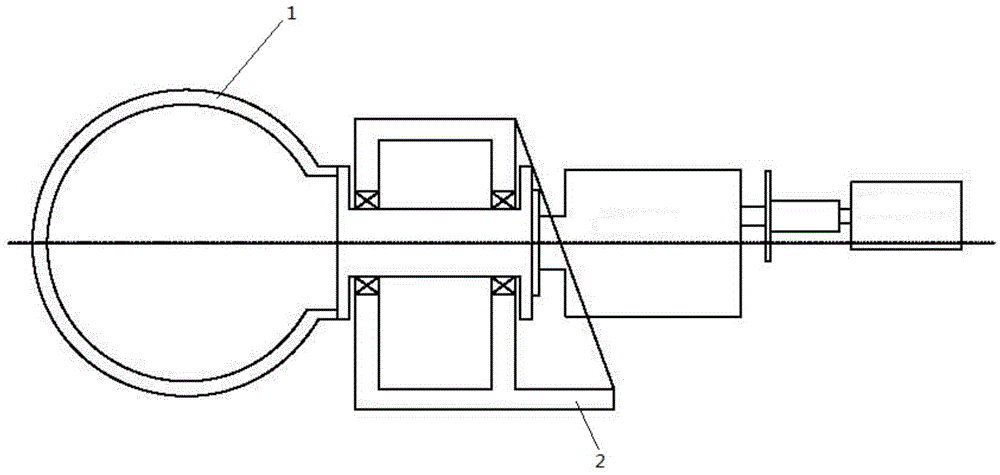

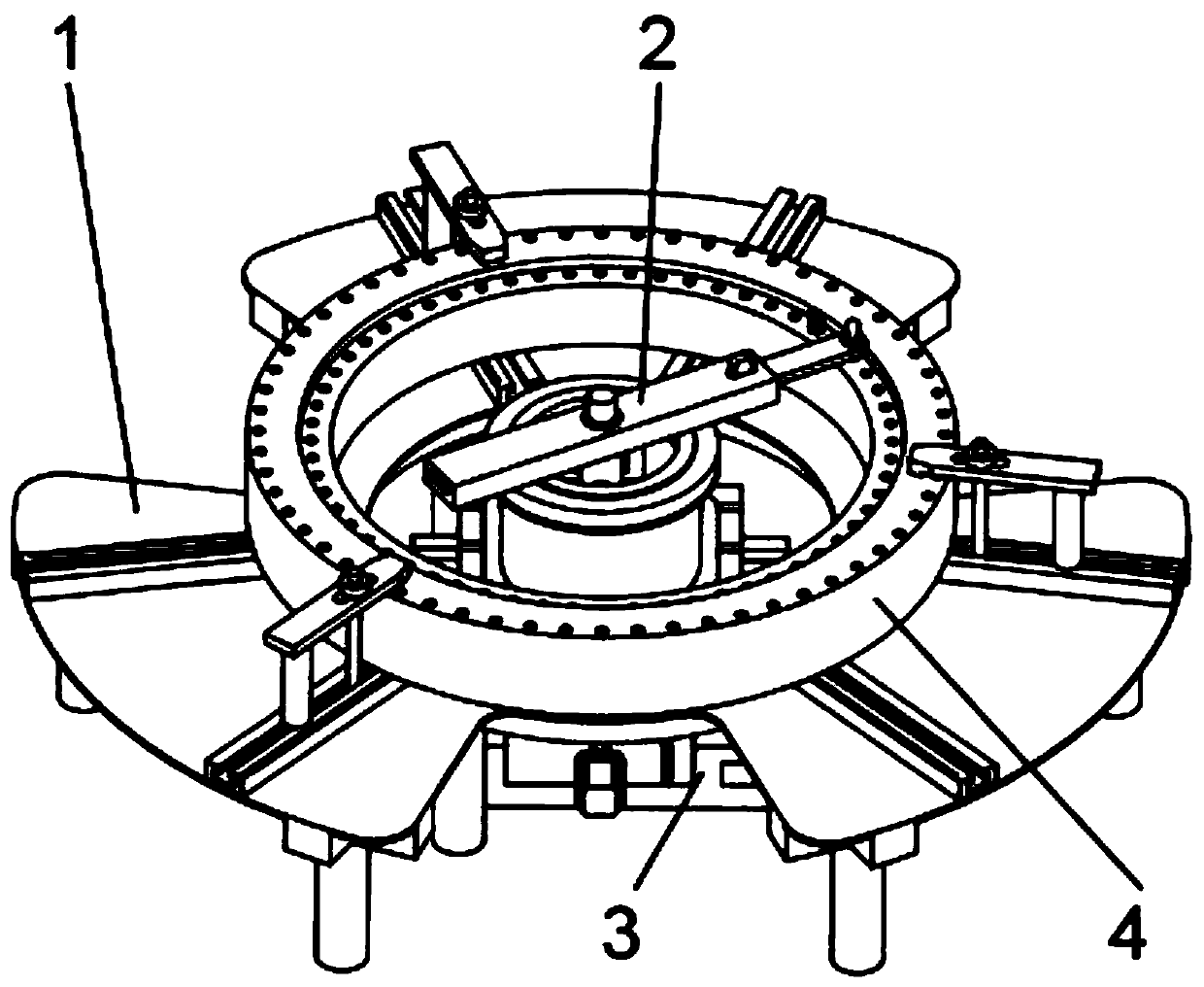

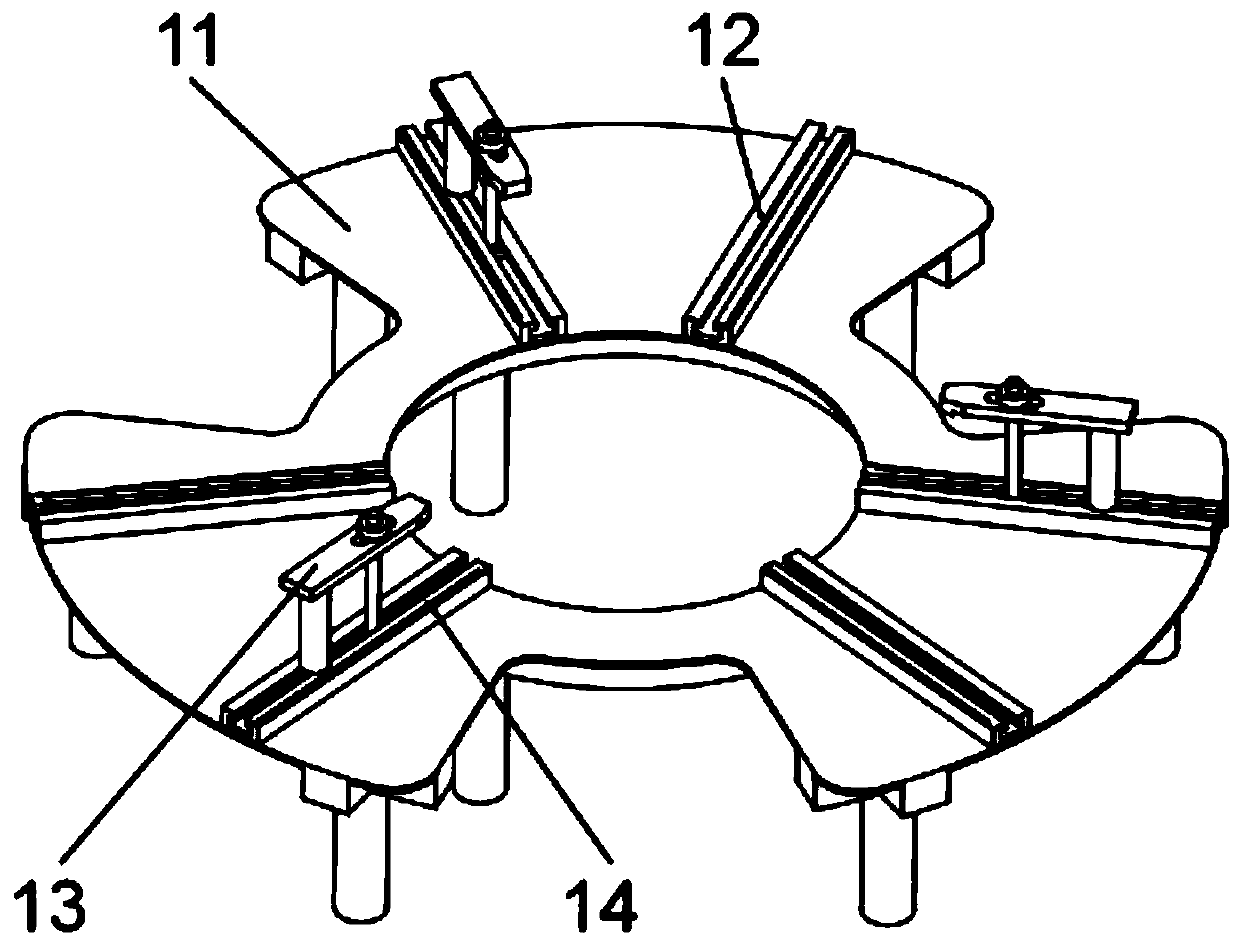

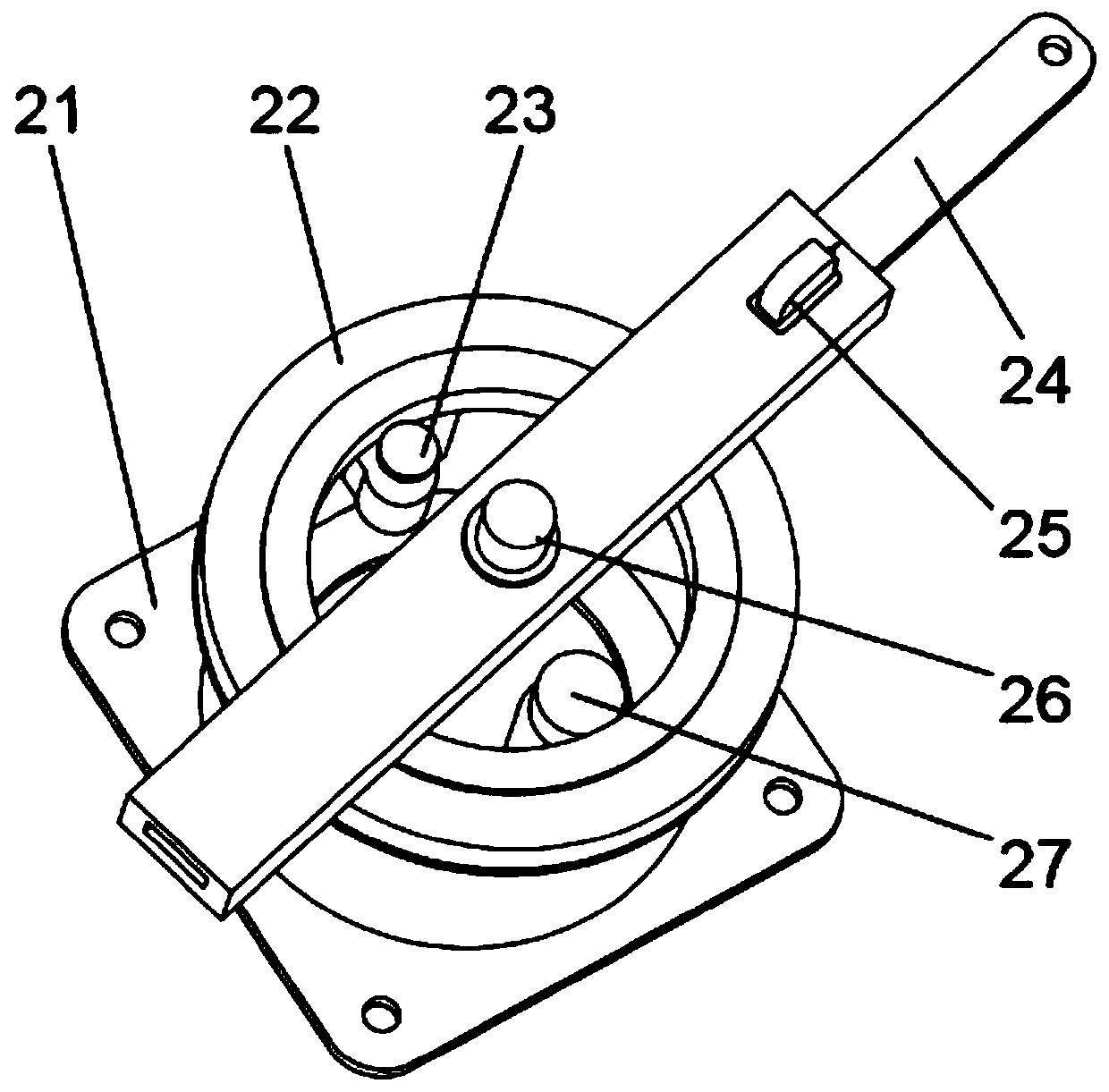

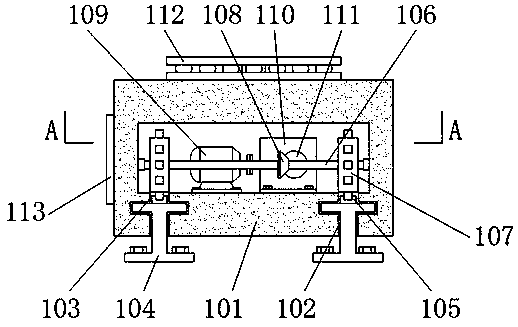

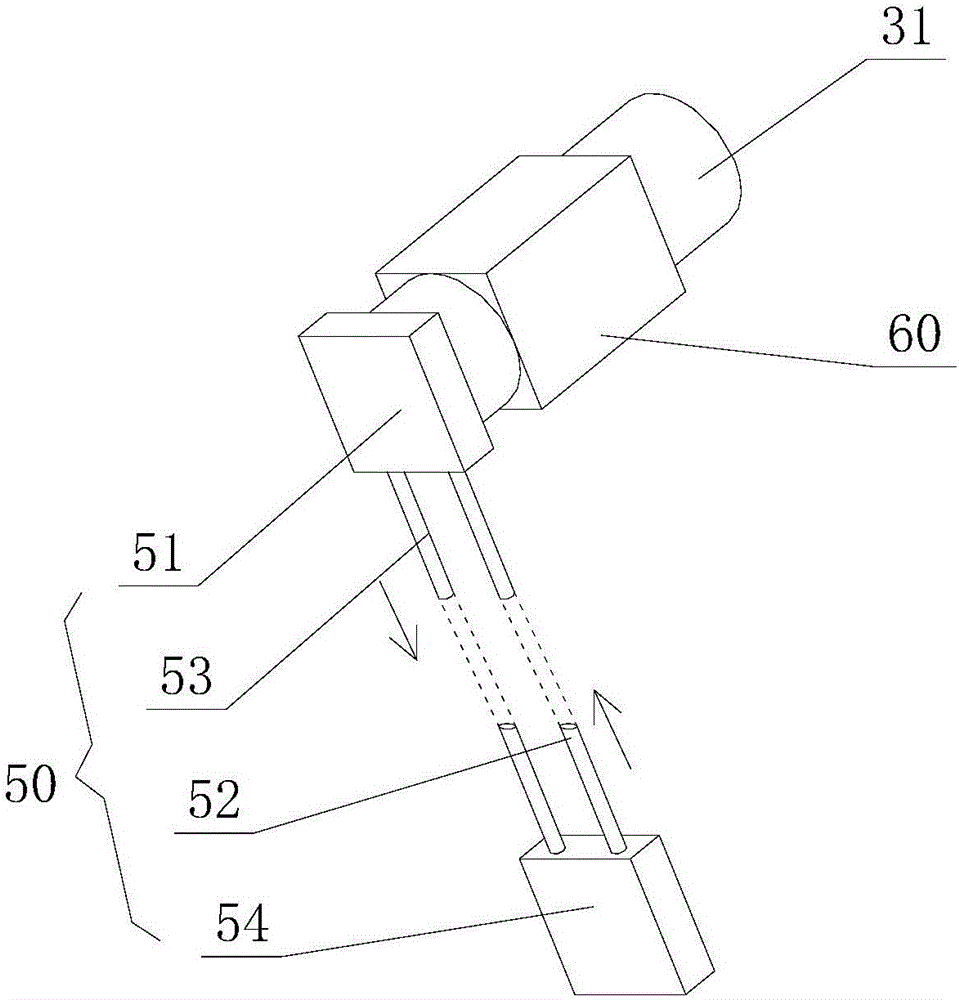

Slewing bearing performance testing device

PendingCN111413094AReduce the difficulty of hoistingImprove work efficiencyMachine bearings testingSlewing bearingMechanical engineering

The invention discloses a slewing bearing performance testing device. The slewing bearing performance testing device comprises a supporting rack, a slewing driving unit and a planar moving sliding table, wherein the supporting rack is used for bearing the slewing bearing, the slewing driving unit is used for driving an inner ring and an outer ring of the slewing bearing to rotate relatively, and the slewing driving unit is fixed on the plane moving sliding table. During testing, after the slewing bearing is placed on the supporting rack, if the slewing center of the slewing bearing and the slewing center of the slewing driving unit are not coaxial, the plane moving sliding table is started at the moment, and the slewing driving unit is controlled to move in a plane until the central axis of the slewing driving unit coincides with the central axis of the slewing bearing, so that the hoisting difficulty can be reduced, and the working efficiency can be improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Assembly type prefabricated truss balcony and installation method therefor

InactiveCN105756186AQuick connect installationQuick installationBalconiesPulp and paper industryBuilding construction

The invention discloses an assembly type prefabricated truss balcony and an installation method therefor. The assembly type prefabricated truss balcony comprises a balcony slab, two first embedded parts, two second embedded parts, two first connecting pieces and two second connecting pieces, wherein the balcony slab is fixedly mounted between the two first connecting pieces; one end of any first embedded part and one end of any second embedded part are both embedded in a main body structure; and one end of the corresponding first connecting piece is fixedly connected with the second embedded part, and the other end of the corresponding first connecting piece is fixedly connected with the first embedded part through the corresponding second connecting piece. The prefabricated truss balcony disclosed by the invention is convenient and quick to mount; no form erecting and concrete pouring are required on site; the number of temporary supports is greatly reduced; and the purpose of improving the installation efficiency and construction quality is achieved.

Owner:SICHUAN PROVINCIAL ARCHITECTURAL DESIGN & RES INST

Auxiliary hoisting device for ultra-high-rise climbing formwork

The invention discloses an auxiliary hoisting device for an ultra-high-rise climbing formwork. The device comprises a traveling mechanism, and a support is arranged on the top surface of the travelingmechanism. A balance device is limited through the cooperation of the support, an energy storage device and a transmission device, so that the balance device is more stable in the lifting process, the swing amplitude of the balance device under the action of external force is effectively reduced, the hoisting difficulty is reduced, the balance device is pulled through the gravity of parts, the balance device can trigger a limit device, the limit device drives a buffer device to move upwards, and the buffer device can enter a preset position. Through the cooperation of a ratchet gear and the buffer device, the hoisting device can automatically lock the balance device which moves fast downwards, so that the problem that safety accidents are caused by falling of the parts under accidents such as steel wire rope breakage and winding machine failure is avoided, and the safety and practicability of the hoisting device are improved.

Owner:安徽朗辰建筑工程有限公司

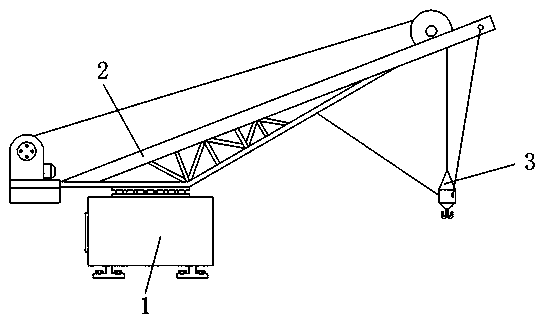

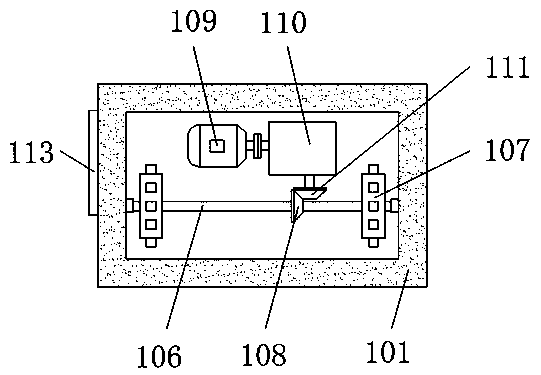

Movable suspension bracket for power installation

InactiveCN103407893ASave spaceEasy to transportBase supporting structuresBraking devices for hoisting equipmentsBlock and tackleEngineering

The invention provides a movable suspension bracket for power installation. The suspension bracket comprises a first supporting leg, a second supporting leg, a cross beam, a pulley block at the bottom of the cross beam and a lifting hook arranged at the pulley block, wherein a hinge joint groove is formed in the top part of the first supporting leg; a hinge joint tenon is arranged at one end of the cross beam, is inserted into the hinge joint groove and is in hinge joint with the hinge joint groove through a pin shaft; a positioning pin is arranged at the top of the first supporting leg and used for fixing the cross beam; a blind hole is formed in the lower surface of the other end of the cross beam and is in splicing fit with the top of the second supporting leg. When transshipment is required, as long as the positioning pin is pulled out, the second supporting leg is pulled out of the blind hole and the cross beam and the first supporting leg are combined together, so that the space is saved, and the transshipment is convenient; when articles are hoisted, as long as the beam is overturned, the positioning pin is adopted for positioning, and the second supporting leg is inserted into the blind hole.

Owner:STATE GRID CORP OF CHINA +1

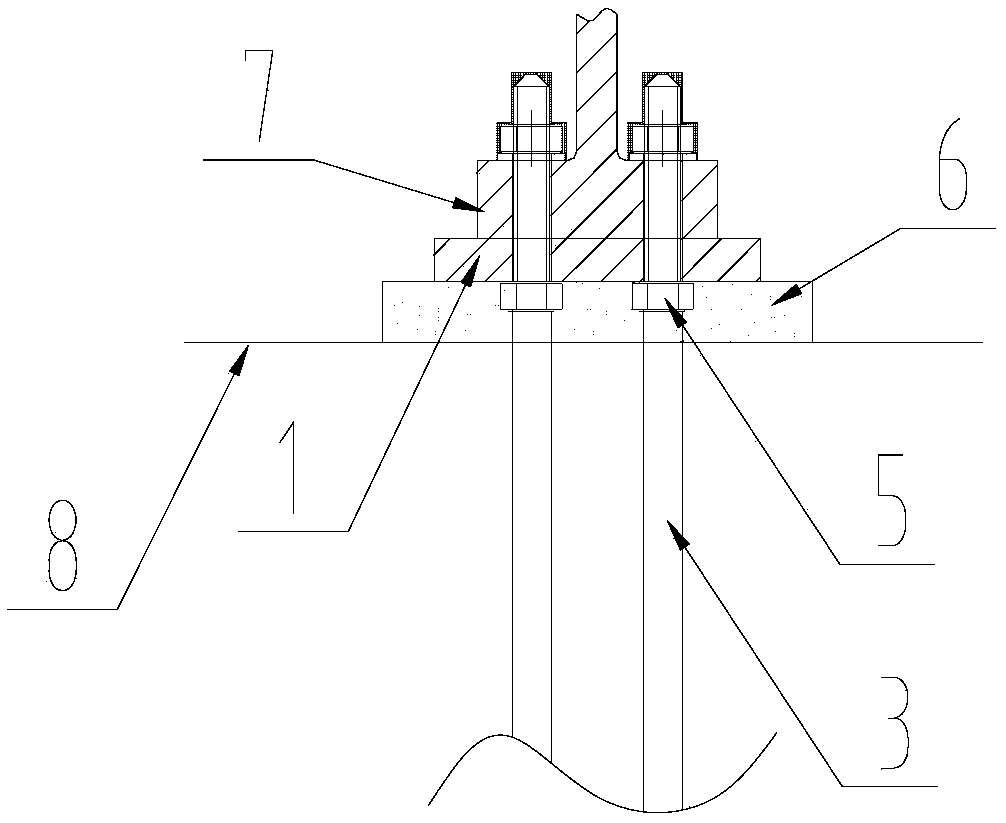

Wind generating set foundation anchor bolt assembly and construction method of connecting tower cylinder thereof

ActiveCN109595126AHigh precisionQuality improvementWind motor supports/mountsWind energy generationTowerWind force

The invention relates to a wind generating set foundation anchor bolt assembly and a construction method of a connecting tower cylinder thereof. The wind generating set foundation anchor bolt assemblycomprises an upper anchor plate, a lower anchor plate, multiple anchor bolts, a supporting casing pipe set and a protecting casing pipe; the anchor bolts are connected with the upper anchor plate andthe lower anchor plate, the supporting casing pipe set comprises a first supporting pipe, a second supporting pipe and a connecting pipe fixedly connected with the first supporting pipe and the second supporting pipe, two adjacent anchor bolts are sleeved with the first supporting pipe and the second supporting pipe correspondingly, the upper anchor plate is supported by the first supporting pipeand the second supporting pipe, the protecting casing pipe is arranged on remaining anchor bolts in a sleeving manner, two adjacent anchor bolts are sleeved with the integrated supporting casing pipeset, deviation of the anchor bolts in the horizontal direction after the anchor bolts are arranged on the upper anchor plate and the lower anchor plate can be limited, whole torsion deforming of theanchor bolts around a vertical shaft of the foundation anchor bolt assembly is avoided, whole precision of the wind generating set foundation anchor bolt assembly is improved, the quality of the windgenerating set foundation anchor bolt assembly is improved, and the tower cylinder lifting difficulty is reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Wind power generation set

InactiveCN106593775ALower installation heightReduce loadMachines/enginesWind motor combinationsLow speedTransmitted power

The invention discloses a wind power generation set. The wind power generation set comprises a tower, a cabin, a wheel hub, a speed increasing gear, a power generator and a transmission device. The cabin is fixedly mounted at the top end of the tower, and the speed increasing gear is arranged inside the cabin. The wheel hub is connected with a main shaft of the cabin. The speed increasing gear is arranged in the cabin, and the low-speed end of the speed increasing gear is connected with a main shaft of the wheel hub. The power generator is mounted on the tower. One end of the transmission device is connected with the high-speed end of the speed increasing gear, and the other end of the transmission device is connected with the power generator. The transmission device transmits power along the interior of the tower. According to the wind power generation set, the power generator is mounted on the tower, so that the mounting height of the power generator is reduced; and in addition, the power generator can be combined with the tower organically, hoisting difficulty can be reduced, cost can be lowered, and loading of the set can be reduced.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

End plate assembly type corrugated web grip beam-column joint connection device with recoverable function

InactiveCN107268787AAvoid complex stress fieldsReduce construction difficultyBuilding constructionsCantilevered beamFloor slab

The invention relates to an end plate assembly type corrugated web grip beam-column joint connection device with a recoverable function, and belongs to the field of structure engineering. The joint connection device is composed of square steel pipe columns, corrugated web channel steel beam sections and a connection device body. The welding parts of the joint connection device are finished in a factory and assembled on site, and the construction speed and the construction quality are greatly improved. A corrugated web grip beam and a floor can be assembled into a modular assembly unit in a factory, assembly units are assembled and connected through the corrugated web grip beam and the square steel pipe columns with cantilever beam sections on a construction site, and the advantages of material saving and high performance of corrugated web components can be fully played. The joint is a beam end reinforcing and cover board connection weakening combined type joint, bolt friction slippage and the triple energy dissipation of plastic deformation of a cover board, a connection board and bolts can be achieved, plastic hinges are transferred onto the cover board and the connection board, and only the connection board and an L-shaped part need to be replaced to achieve the function recovering of the structure after an earthquake.

Owner:BEIJING UNIV OF TECH

Connection structure of steel structure and precast concrete slab

The invention relates to the field of prefabricated houses, in particular to a connecting structure of a steel structure and a precast concrete plank. The steel structure comprises stand columns and beams, wherein the end faces of the beams are fixed to the stand columns, and beam body parts of the beams are placed in the precast concrete plank. The precast concrete plank comprises a foam concrete layer and a reinforced concrete layer, wherein the foam concrete layer is filled around the beams, the reinforced concrete layer wraps the foam concrete layer and the beams, and an elastic transition layer is arranged between the beams and the reinforced concrete layer below the beams. In this way, it can be effectively ensured that the deformation of the steel beams under the effects of working loads is not restrained by a wall body at the lower portions of the steel beams, and meanwhile cracks between the beams and the precast concrete plank are prevented. The beams and the precast concrete plank are of an integrated structure and can be hoisted at a time during splicing, so hoisting difficulty is reduced and work efficiency is improved.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com