Convenient-to-repair fabricated steel structure beam-column joint connection structure and fabricating method thereof

A beam-column joint and connection structure technology, applied in building construction, construction, etc., to achieve the effect of easy control of precision and quality, simple structure, and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

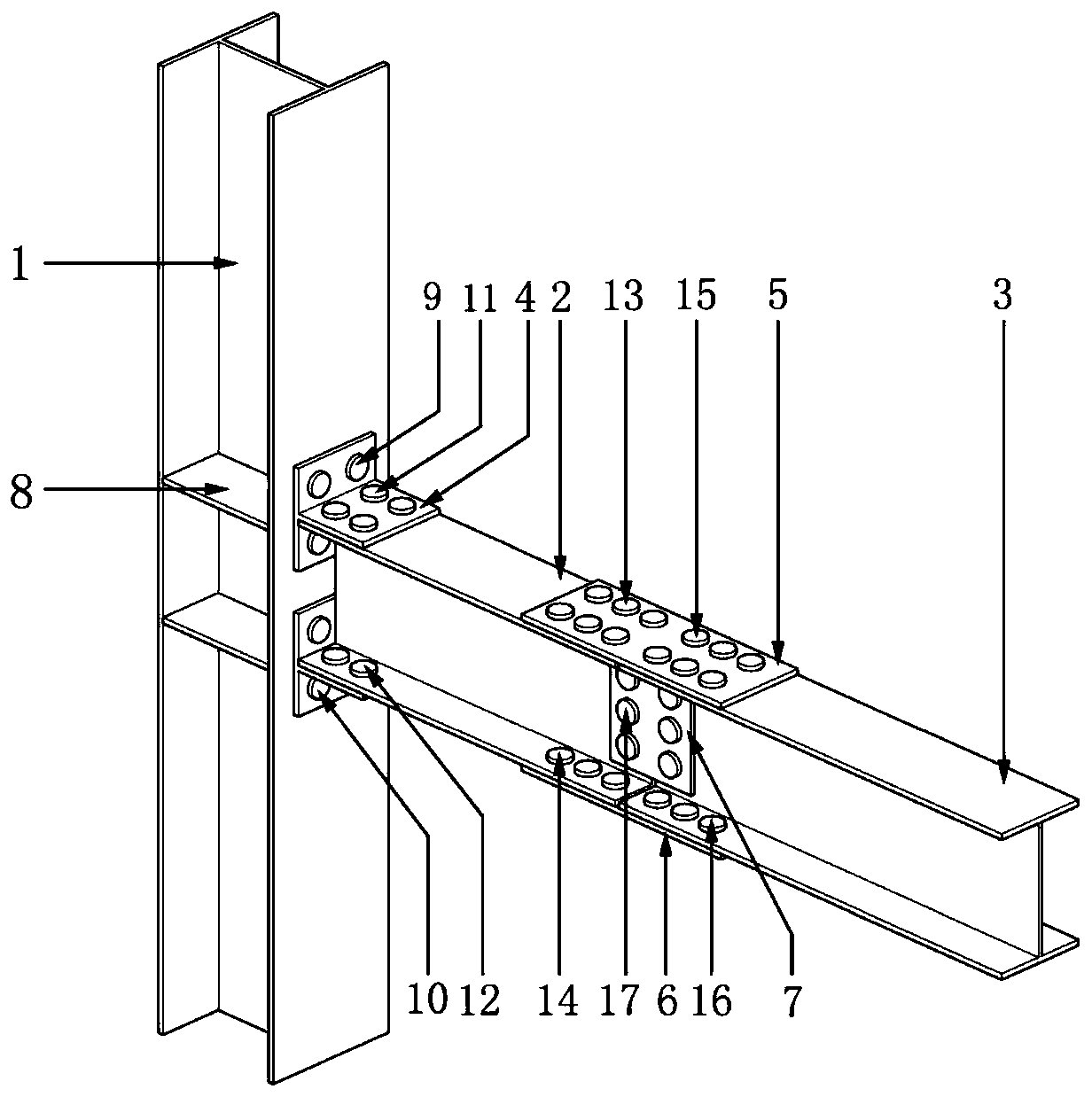

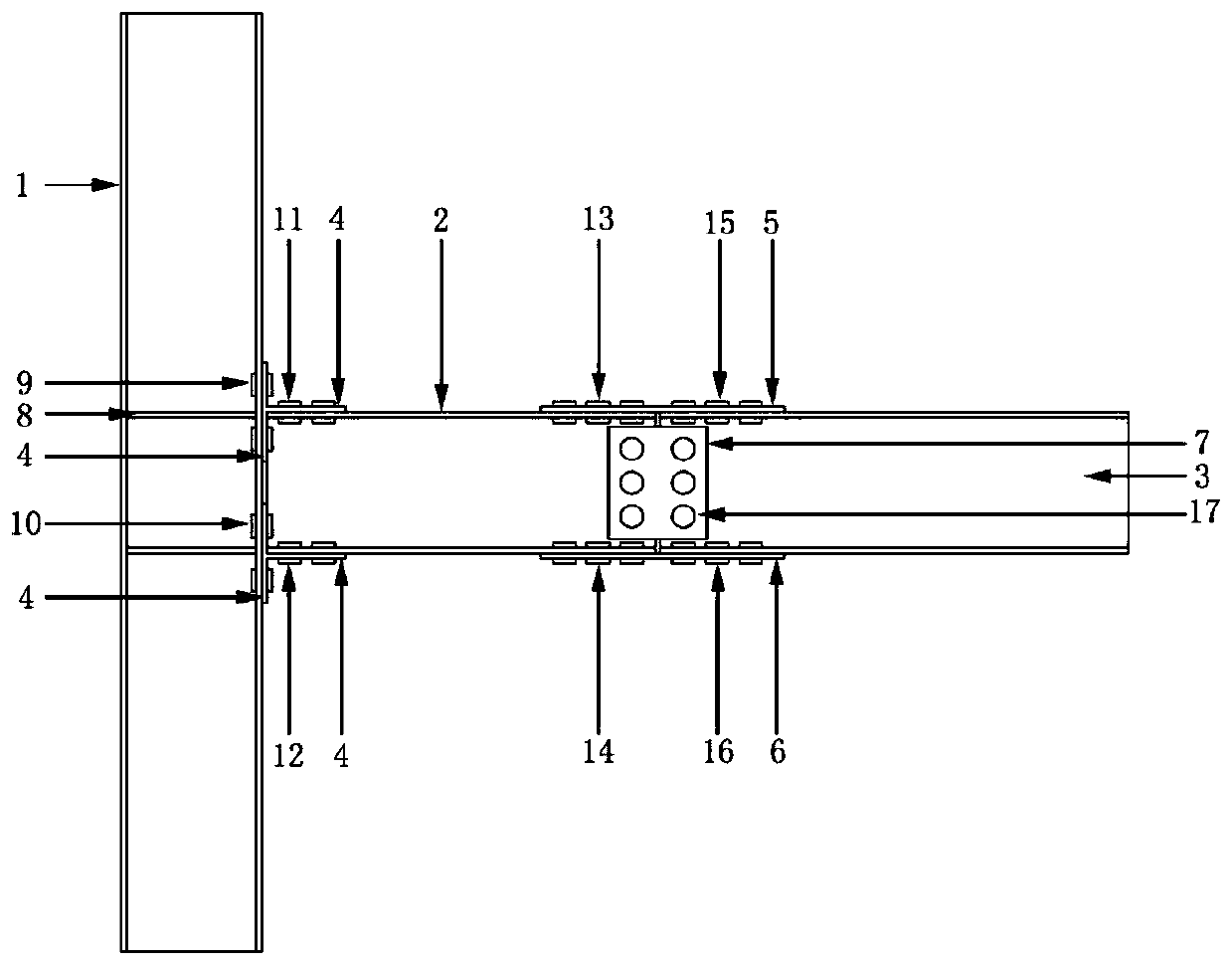

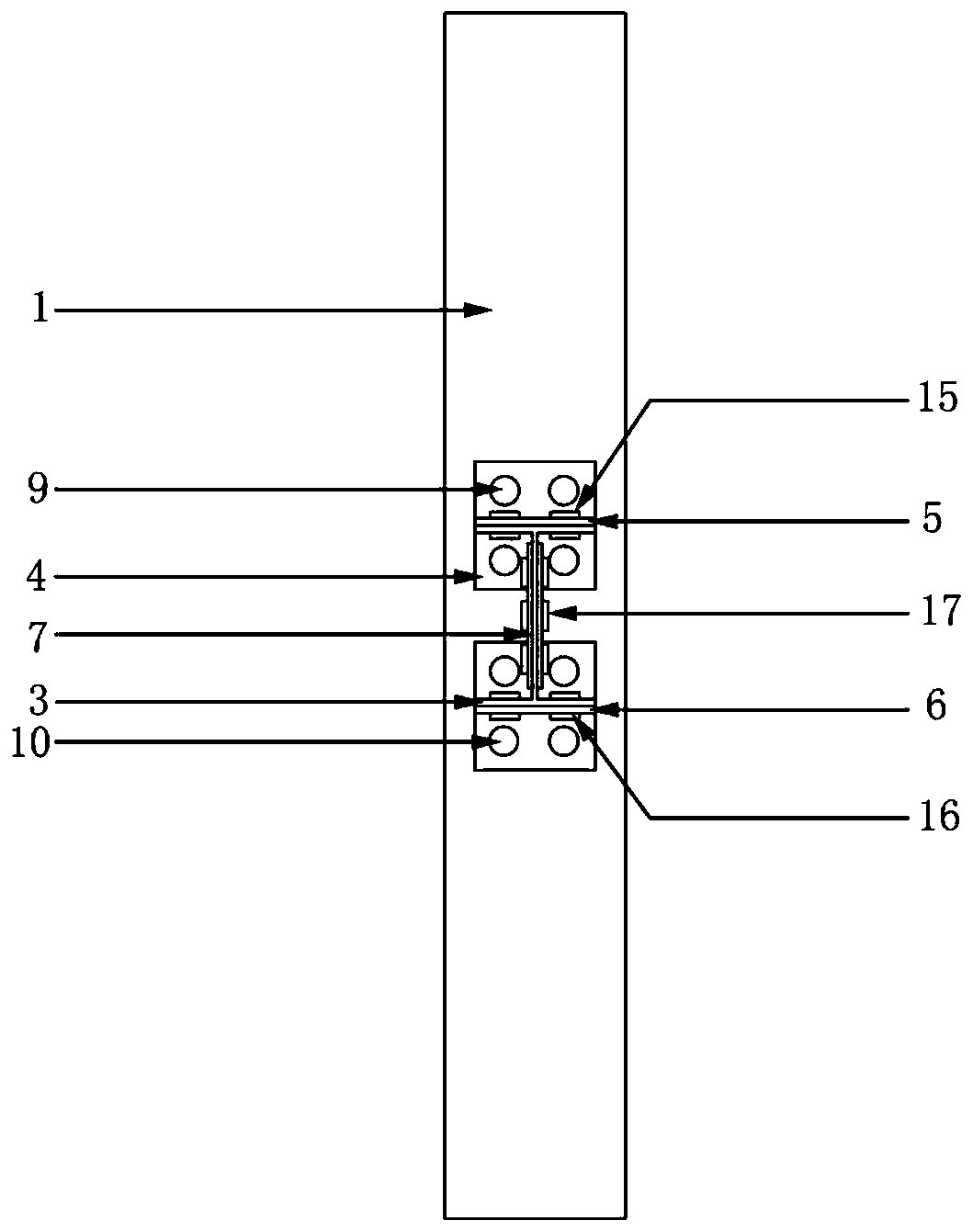

[0040] refer to Figure 1 to Figure 6, a prefabricated steel structure beam-column joint connection structure that is easy to repair, consists of H-shaped steel columns with stiffeners, H-shaped steel energy-dissipating beam sections 2, H-shaped steel ordinary beam sections 3, and connecting devices for the three. Both the H-shaped steel energy-dissipating beam section 2 and the H-shaped steel ordinary beam section 3 are composed of H-shaped steel. The H-shaped steel column with stiffeners is welded by the H-shaped steel column 1 and two stiffeners 8, the thickness of the stiffeners 8 is not less than the thickness of the flange of the H-shaped steel energy-dissipating beam section 2, and the width of the stiffeners 8 is greater than that of the H-shaped steel consumption The width of the flange of the energy-dissipating beam section 2, and the two stiffeners 8 are respectively located on the same level as the two flanges of the H-shaped steel energy-dissipating beam section 2...

Embodiment 2

[0052] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that: the flange of the H-shaped steel energy-dissipating beam section 2 is provided with a dog-bone weakening area 18 .

Embodiment 3

[0054] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 lies in that: the web of the H-shaped energy-dissipating beam section 2 is provided with a web hole weakening area 19 .

[0055] A large number of studies have shown that weakening the section of the beam member can form a weak zone on the beam member, so that a plastic ratio can be formed in the weakened zone, which can improve the rotation capacity and energy dissipation capacity of the node. The common weakening section method is in the flange Set a dog bone weakening area or open a hole at the web. Therefore, the node proposed by the present invention can be provided with a dog-bone weakened area at the flange of the H-shaped steel energy-dissipating beam section or with an opening area at the web according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com