Measuring system of high-intensity focusing ultrasonic sound field

A technology of focused ultrasound and measurement systems, applied in the direction of measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of unable to quickly scan the sound field, unable to weaken the influence of ultrasonic reflection, and unable to perform measurements, etc., to achieve and three-dimensional graphics Ultrasonic sound field measurement, controllable step accuracy and scanning range, and the effect of intelligent ultrasonic sound field measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical solutions of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings and embodiments. The technical parameters used in the examples do not limit the present invention.

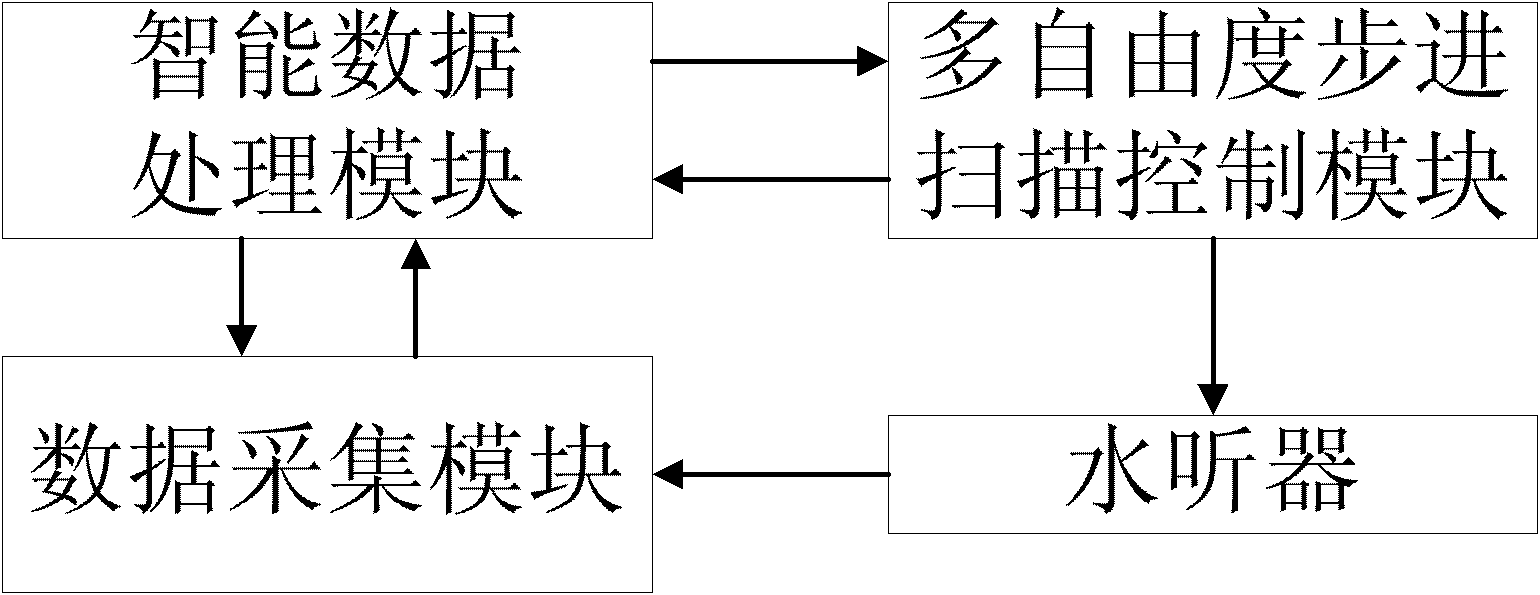

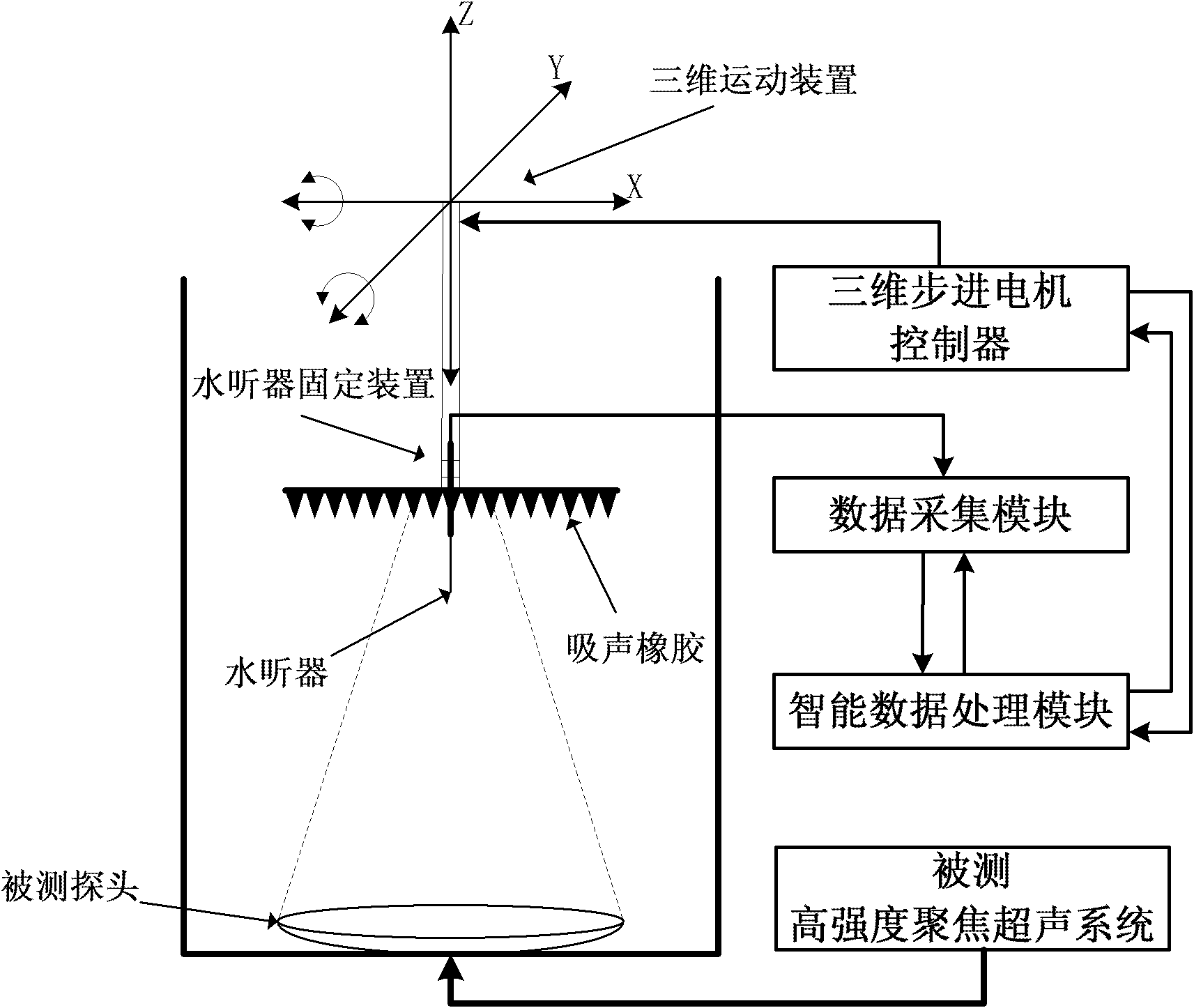

[0022] figure 1 It is a structural block diagram of the high-intensity focused ultrasound sound field measurement system of the present invention. like figure 1 As shown, the present invention is composed of an intelligent data processing module, a multi-degree-of-freedom step-scan control module, a data acquisition module and a hydrophone. The intelligent data processing module is connected with the multi-degree-of-freedom step-scan control module, and sends instructions to the multi-degree-of-freedom step-scan control module to perform intelligent sound field scanning. The multi-degree-of-freedom step-scan control module is connected with the hydrophone. The data acquisition module is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com