Patents

Literature

250 results about "Bay window" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bay window is a window space projecting outward from the main walls of a building and forming a bay in a room.

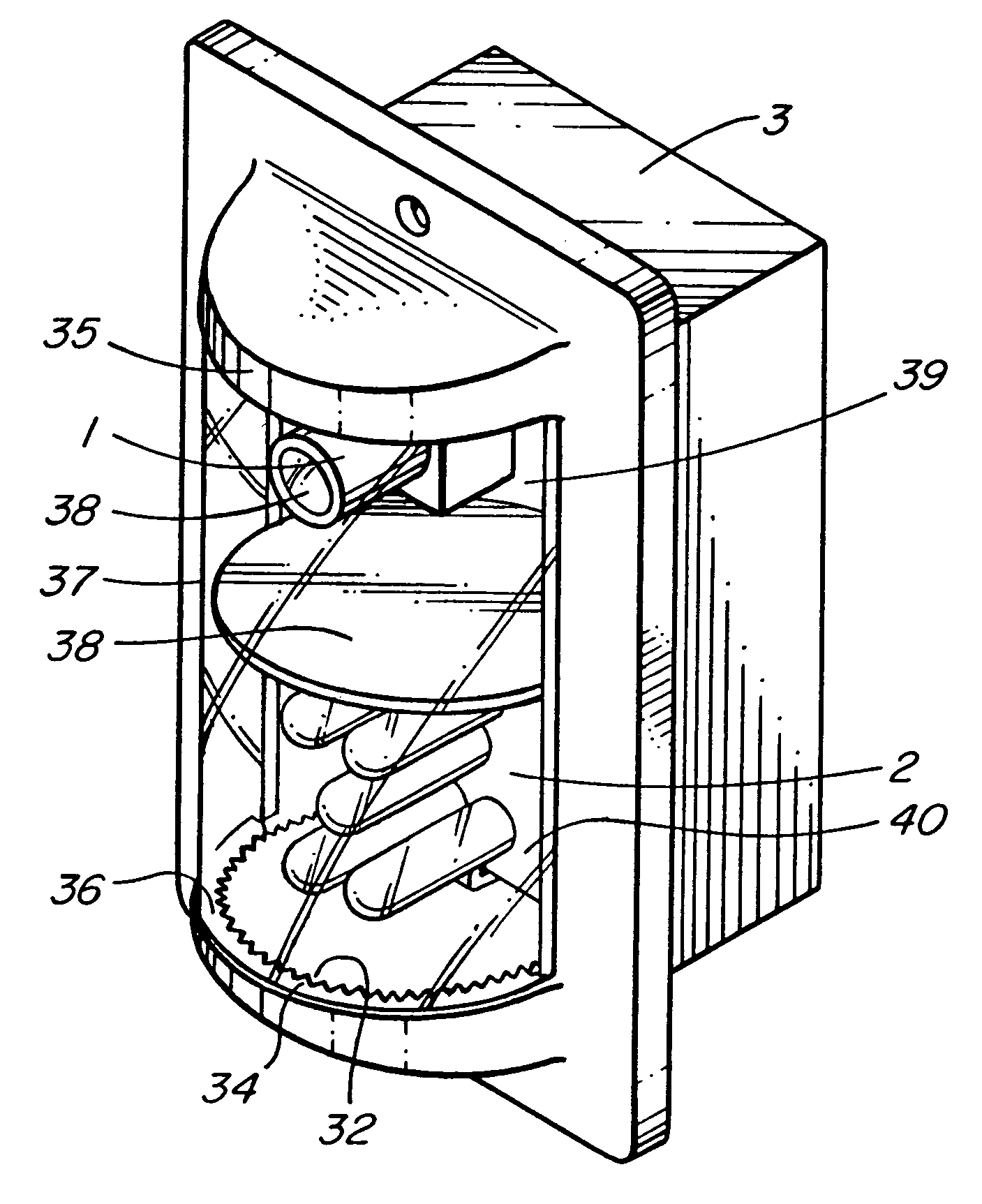

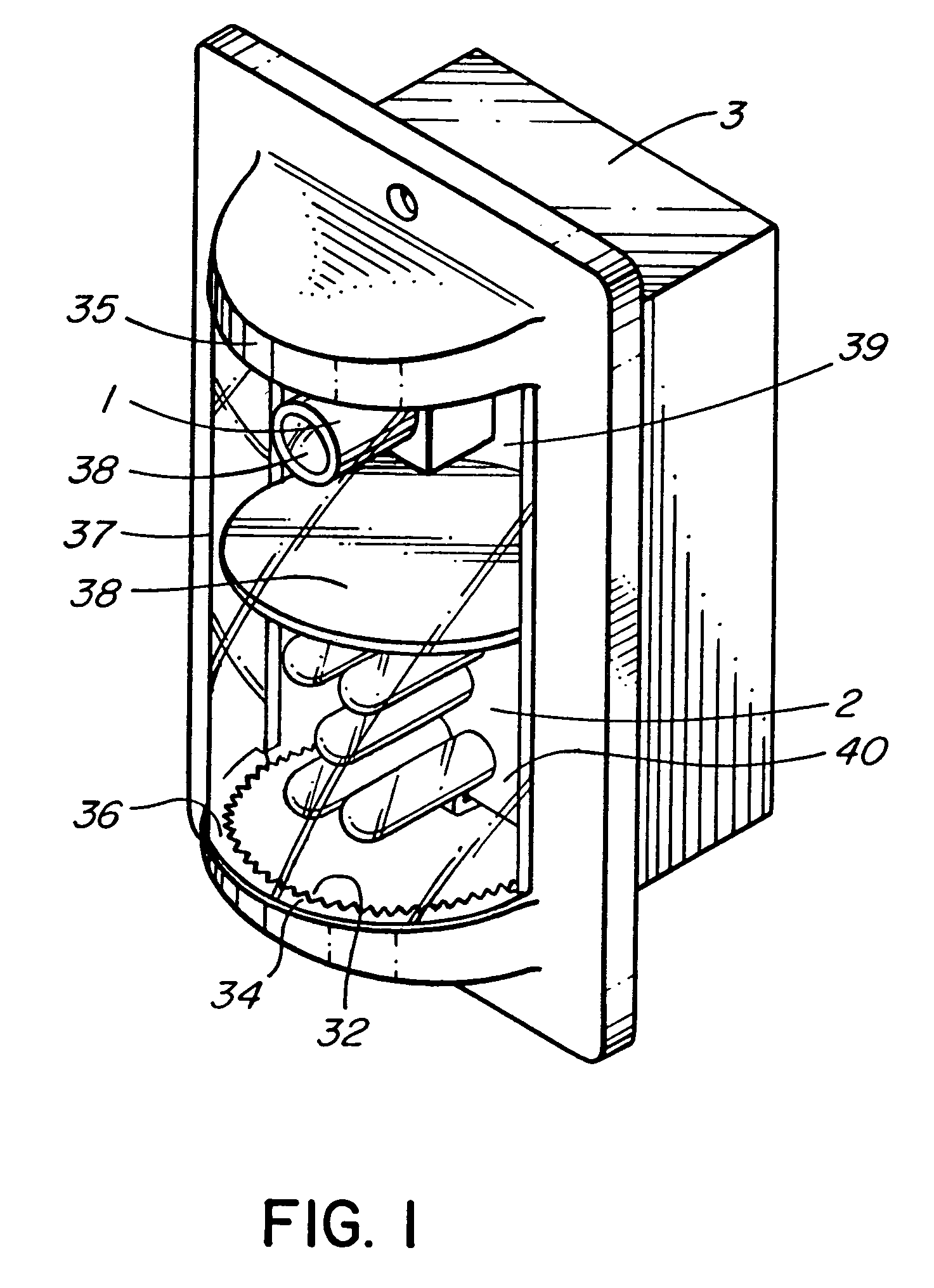

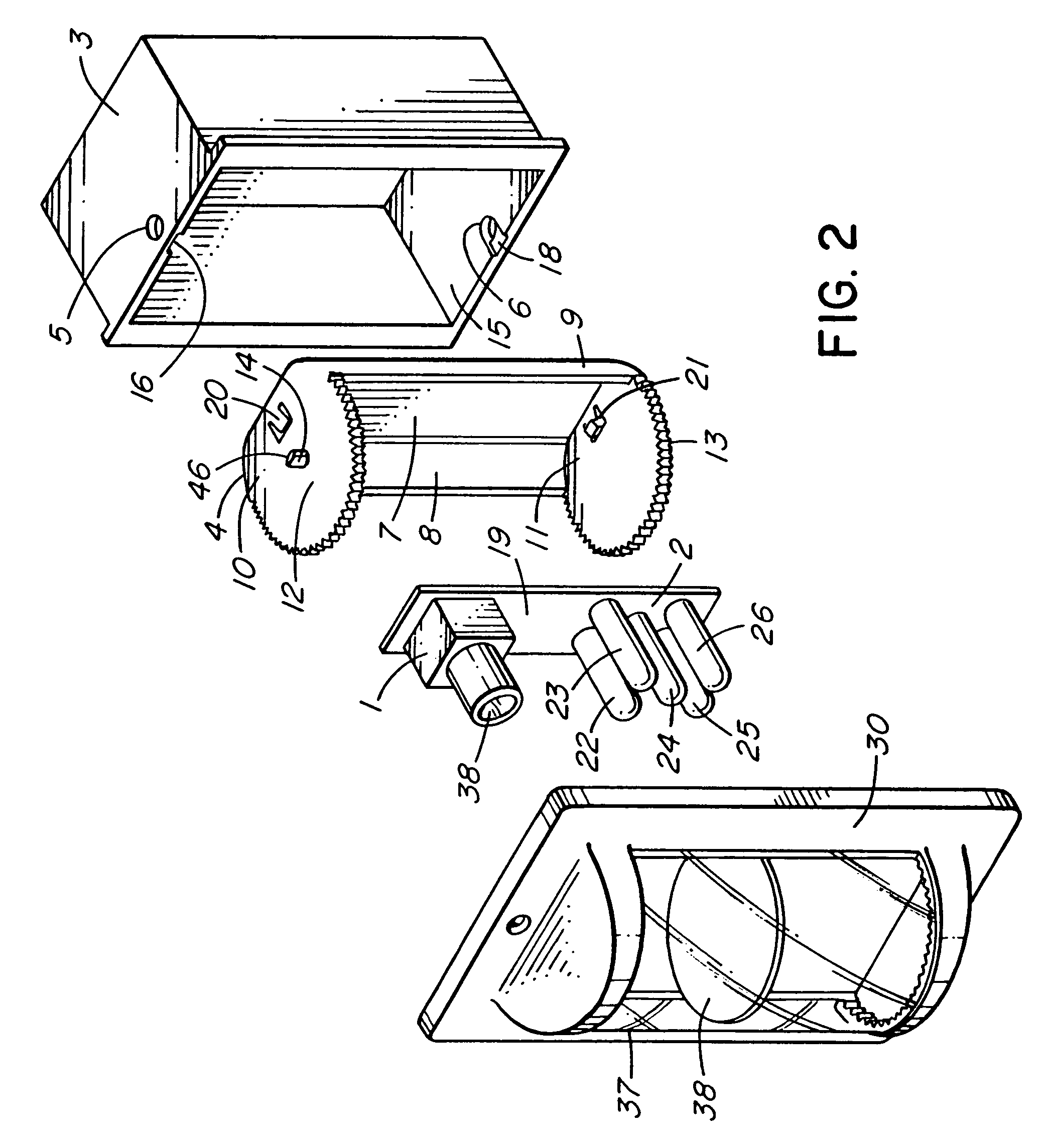

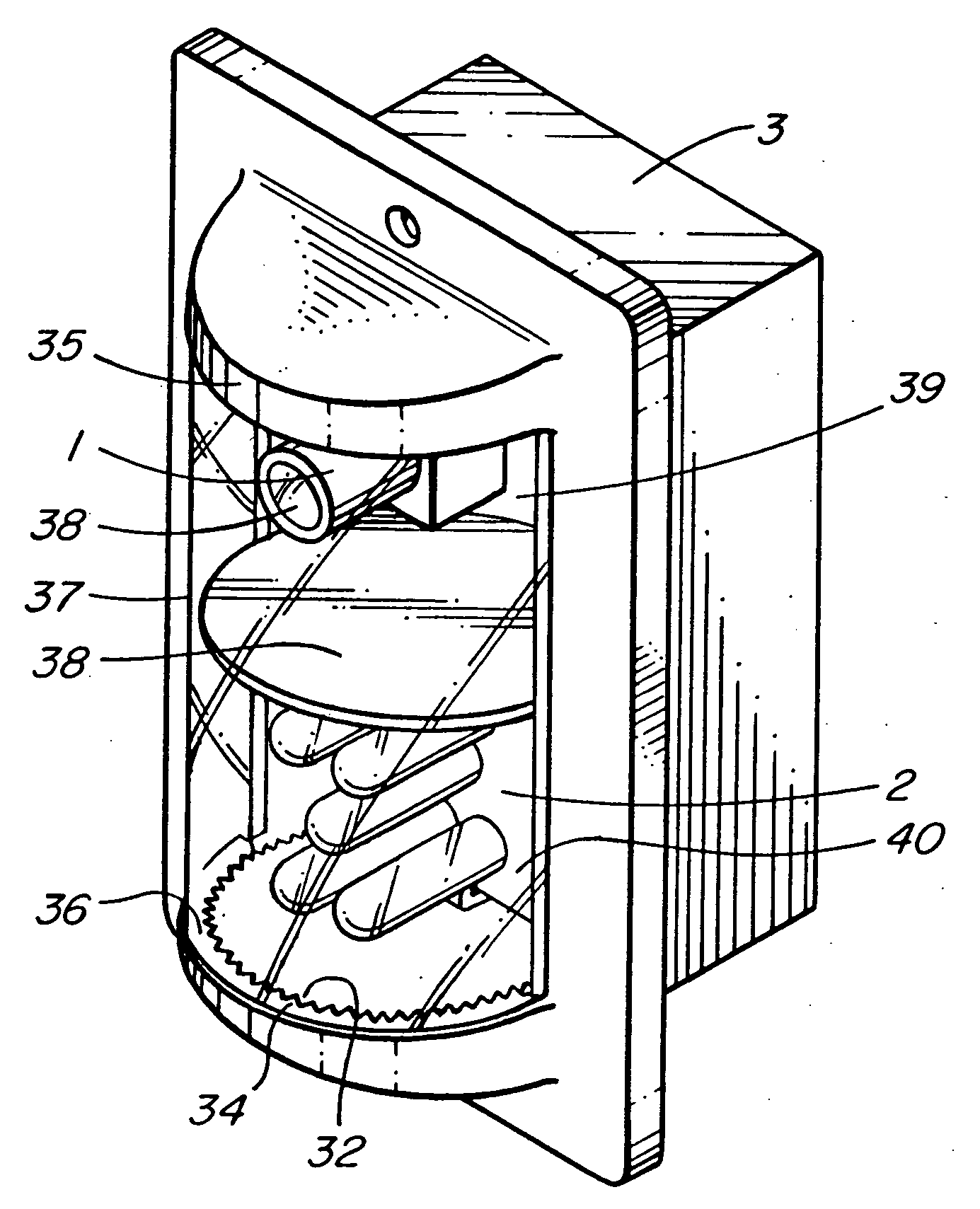

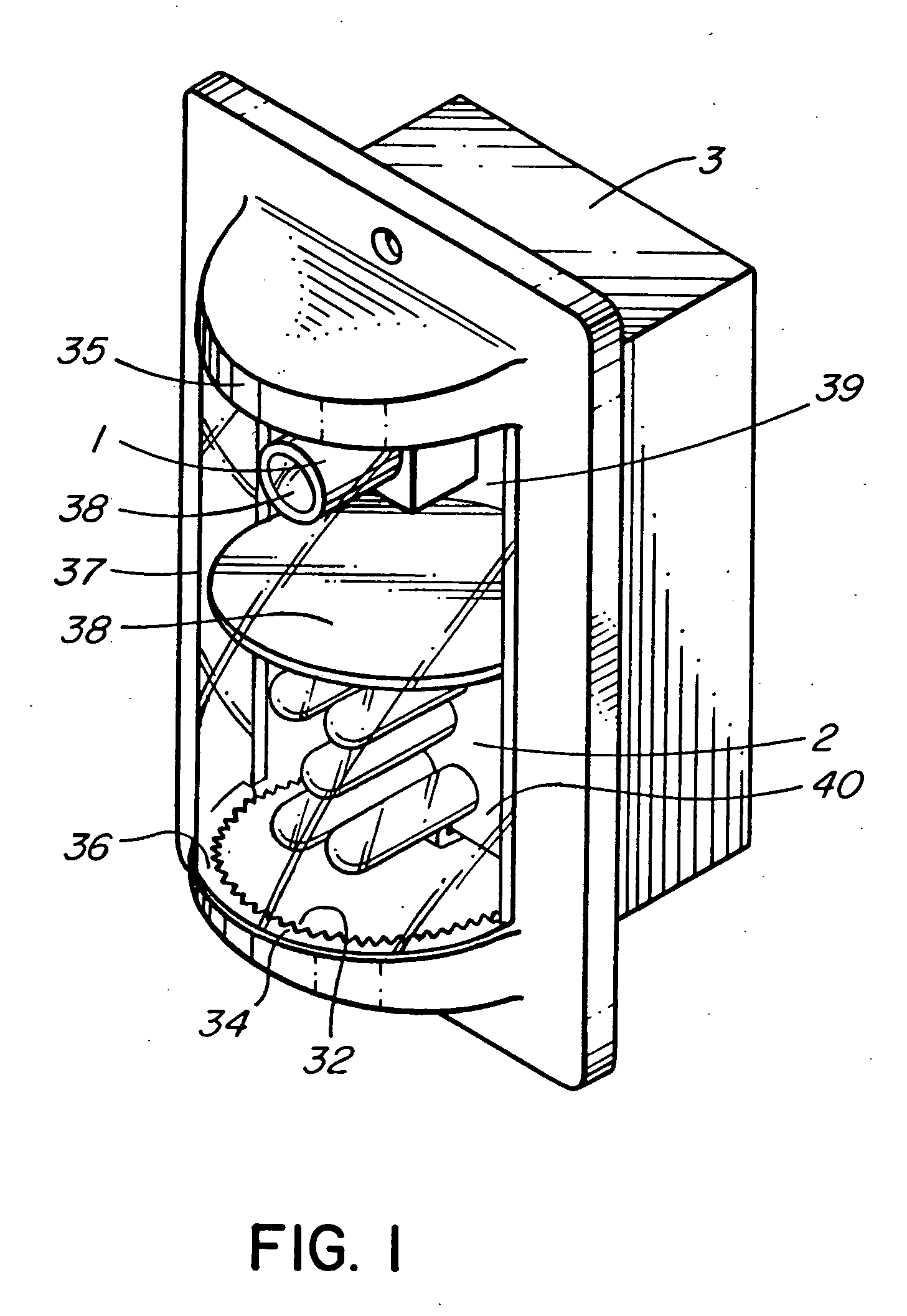

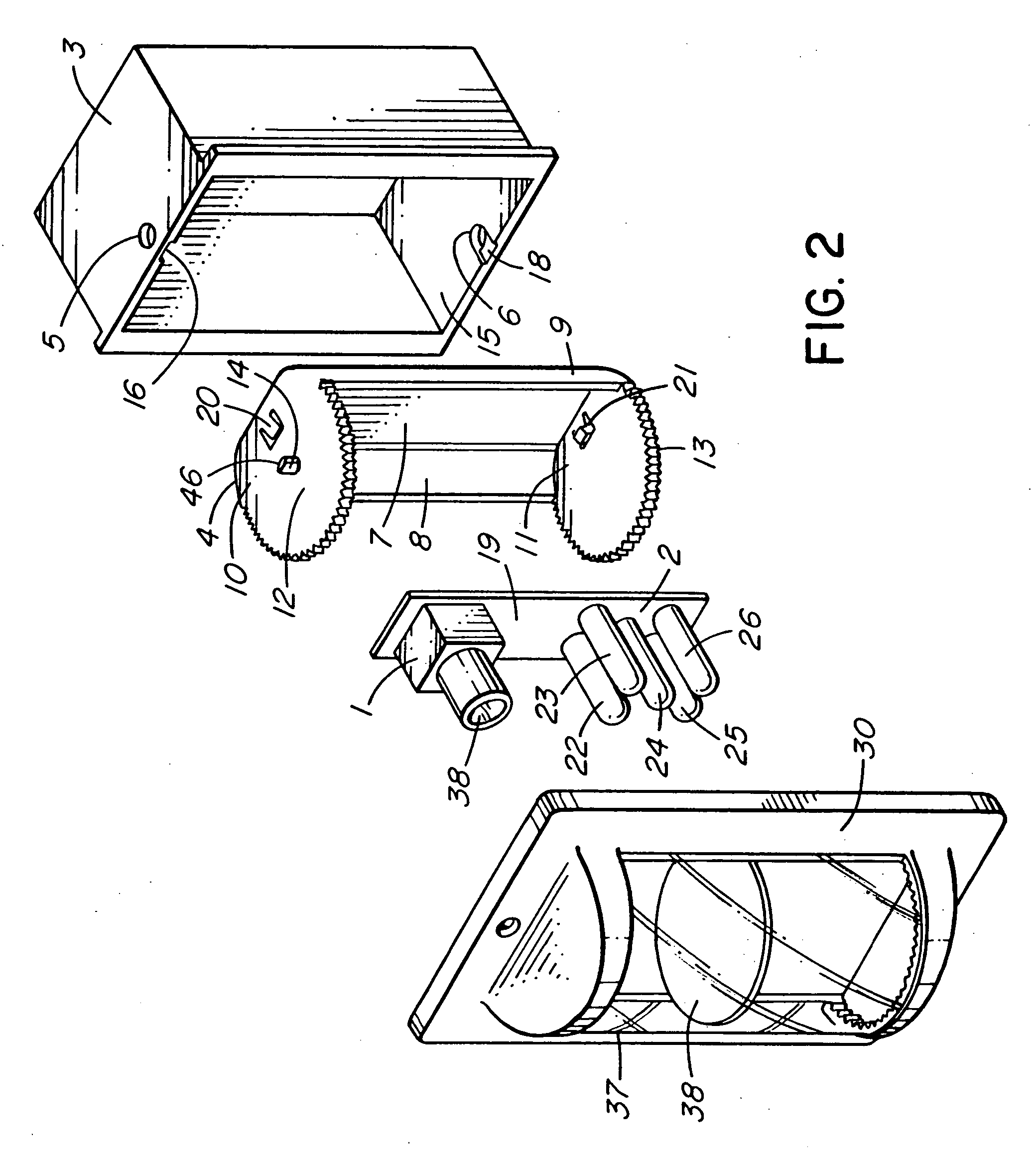

Rotatable bay window switch box surveillance camera and illuminator for facial recognition

InactiveUS7346196B2Television system detailsCharacter and pattern recognitionSwitch boxSurveillance camera

A surveillance camera and illuminator are covertly mounted in a partially rotatable bay window inner frame mounted within an electrical switch box. The bay window inner frame can thus be pivoted back and forth to orient the camera toward an entrance to a room in which the switch box is mounted. When the bay window inner frame is rotated to the desired position, a bay window switch box decor cover plate is mounted over the bay window inner frame, engaging it and locking it in the selected position by attachment of the cover plate to the switch box.

Owner:BOSCH SECURITY SYST INC

Quick construction method for high-rise buildings

InactiveCN102505845AFast constructionImprove construction qualityForms/shuttering/falseworksBuilding material handlingFloor slabRebar

The invention discloses a quick construction method for high-rise buildings, which includes: hoisting an integral lifting device; positioning all pneumatic pouring mould opening and closing devices; assembling single cradle units integrally to form an integrated mould cradle assembly while fixedly mounting the pneumatic pouring mould opening and closing devices below the integrated mould cradle assembly; starting all four-screw lifters to jack the integrated mould cradle assembly; hoisting reinforcement cages of walls and beams of a floor; falling the integrated mould cradle assembly, driving the pneumatic pouring mould opening and closing devices to close the moulds horizontally; pouring concrete and then opening the moulds after concrete is solidified; lifting the integrated mould cradle assembly upwards; hoisting floor slabs, prefabricated boards for superposed parts of balconies, prefabricated stairs and prefabricated bay windows; laying cast-in-situ reinforcing meshes of the superposed floor slabs and casting concrete on the superposed floor slabs; repeating the above steps until completing building of all floors; and finally removing the integrated mould cradle assembly and a lifting support. The quick construction method for the high-rise buildings has the advantages of quick construction, high construction quality, safety and reliability in construction and low construction cost.

Owner:DONGGUAN HUANAN JUNYE MACHINERY MFG CO LTD

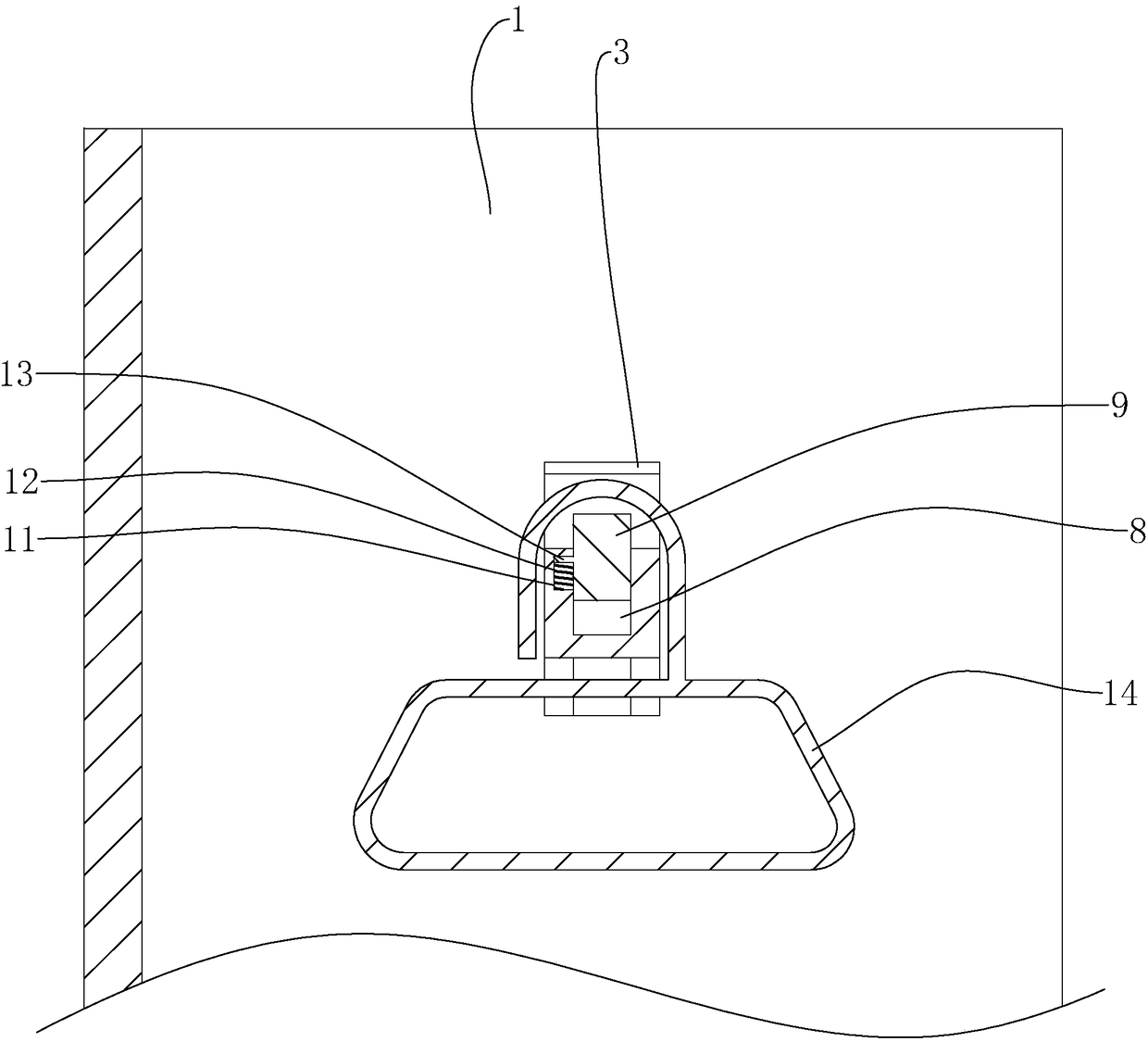

Rotatable bay window switch box surveillance camera and illuminator for facial recognition

InactiveUS20050025360A1Television system detailsCharacter and pattern recognitionSwitch boxSurveillance camera

A surveillance camera and illuminator are covertly mounted in a partially rotatable bay window inner frame mounted within an electrical switch box. The bay window inner frame can thus be pivoted back and forth to orient the camera toward an entrance to a room in which the switch box is mounted. When the bay window inner frame is rotated to the desired position, a bay window switch box decor cover plate is mounted over the bay window inner frame, engaging it and locking it in the selected position by attachment of the cover plate to the switch box.

Owner:BOSCH SECURITY SYST INC

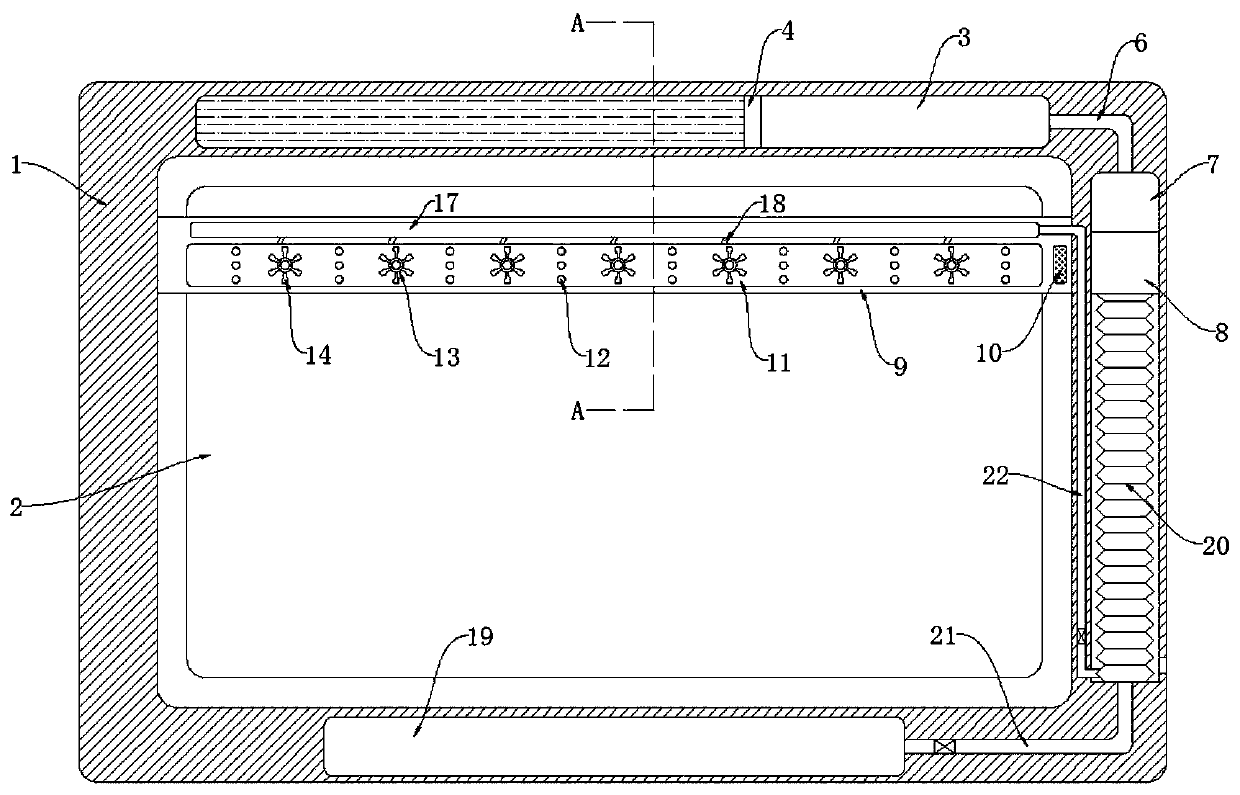

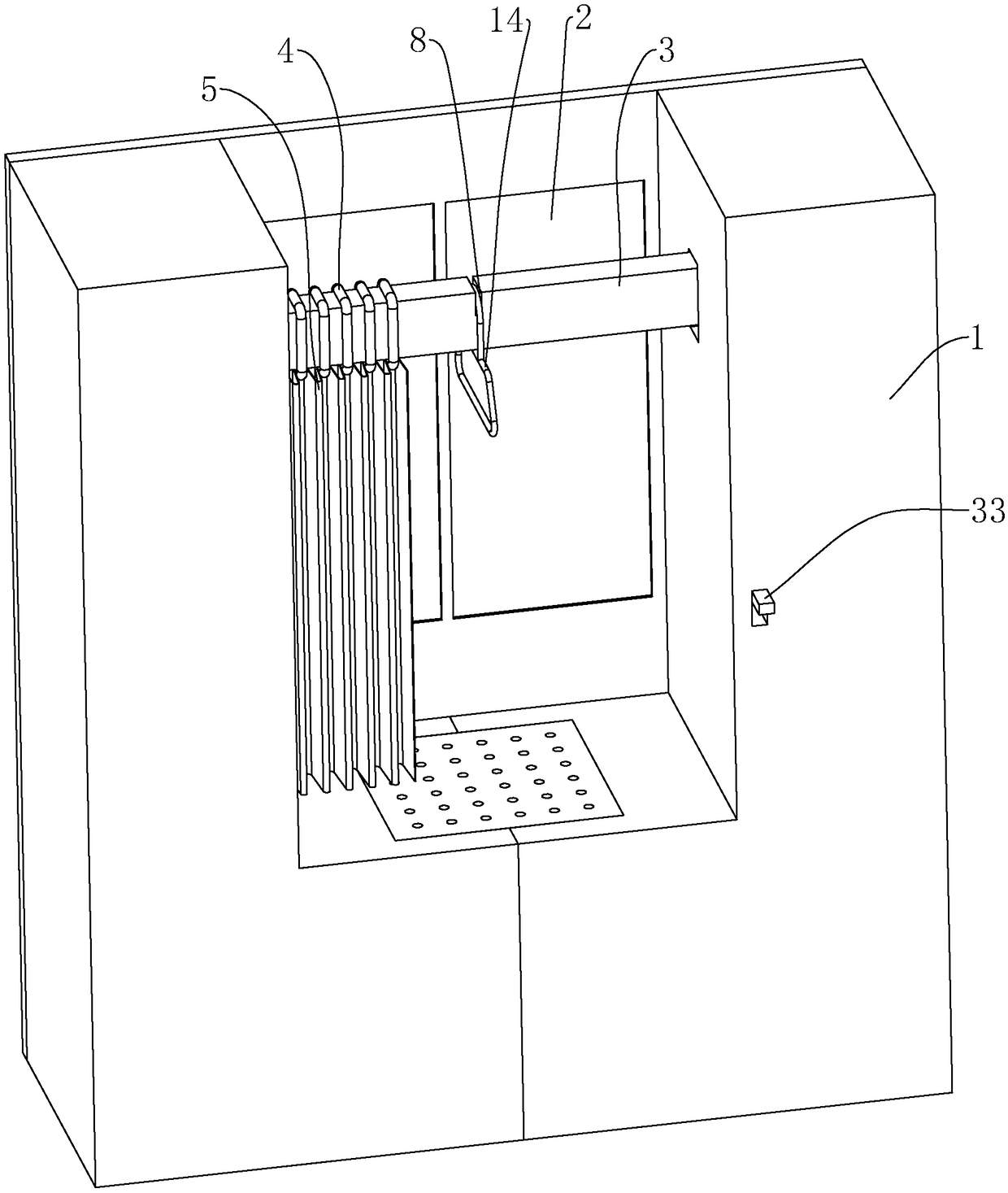

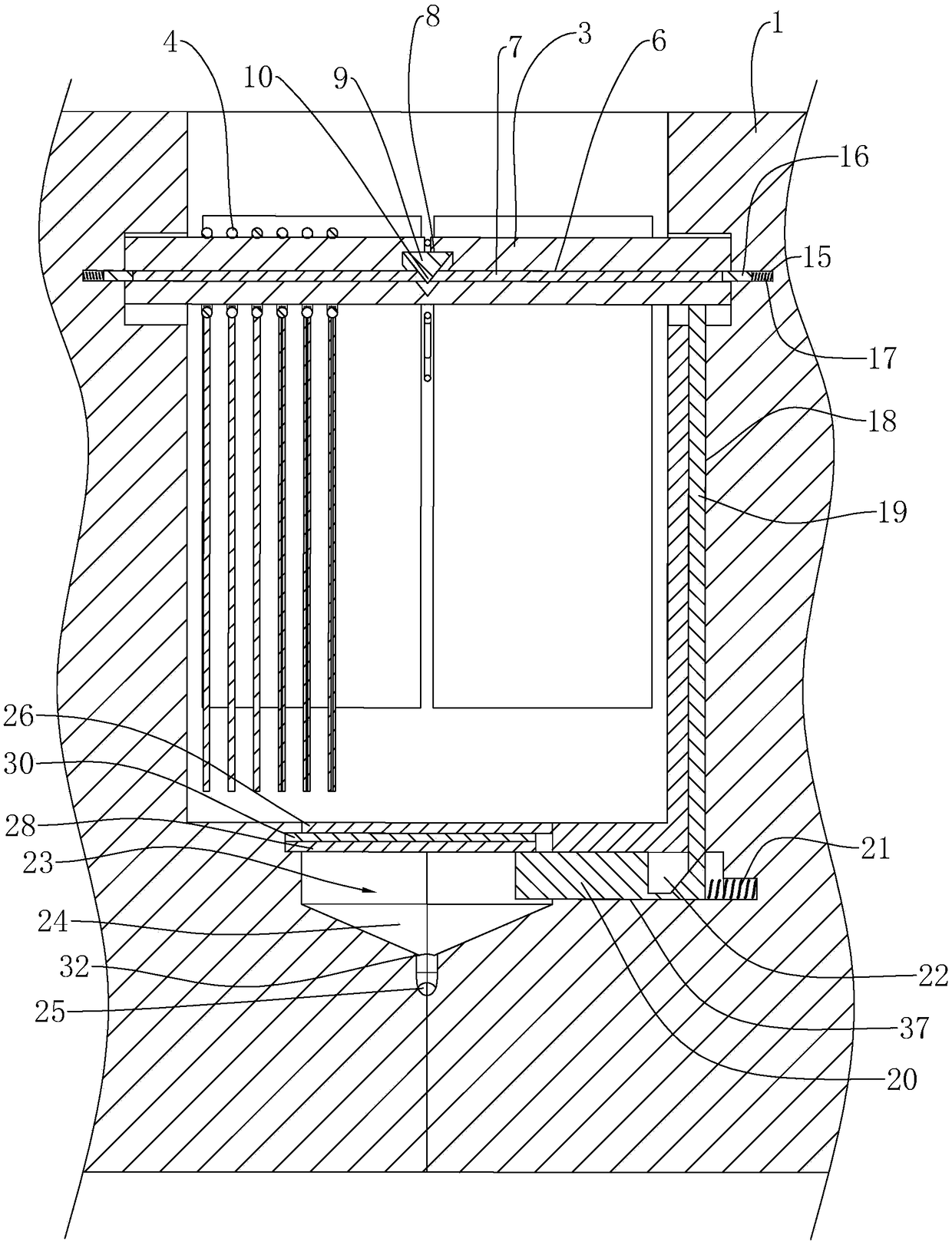

Self-cleaning device for smart home bay window

InactiveCN110840319AReduce difficultyNo need for manual cleaningWindow cleanersSpecial door/window arrangementsEngineeringMechanical engineering

The invention discloses a self-cleaning device for a smart home bay window. The self-cleaning device comprises a window frame, wherein glass is fixedly connected to the inner wall of the window frame;a sliding plug cavity is formed in the side wall of the window frame; a magnetic sliding plug is in sealing and sliding connection with the inner wall of the sliding plug cavity; a transverse plate is slidably connected to the inner wall of the window frame; a permanent magnet attracted to the magnetic sliding plug is embedded in the side wall of the transverse plate; a cavity is formed in the transverse plate; and a cleaning device for cleaning the glass surface is mounted on the transverse plate. By arranging a strip-shaped cavity, a low-boiling-point evaporation liquid, a sliding block, the magnetic sliding plug, the transverse plate, the permanent magnet and a cleaning strip, the magnetic sliding plug can drive the transverse plate to move up and down on the inner wall of the window frame through the permanent magnet in day time and at night, so that the cleaning strip on the side wall of the transverse plate carries out self-cleaning twice on the outer surface of the glass without manual intervention, and the cost of cleaning the outer surface of the glass is reduced.

Owner:操胜中

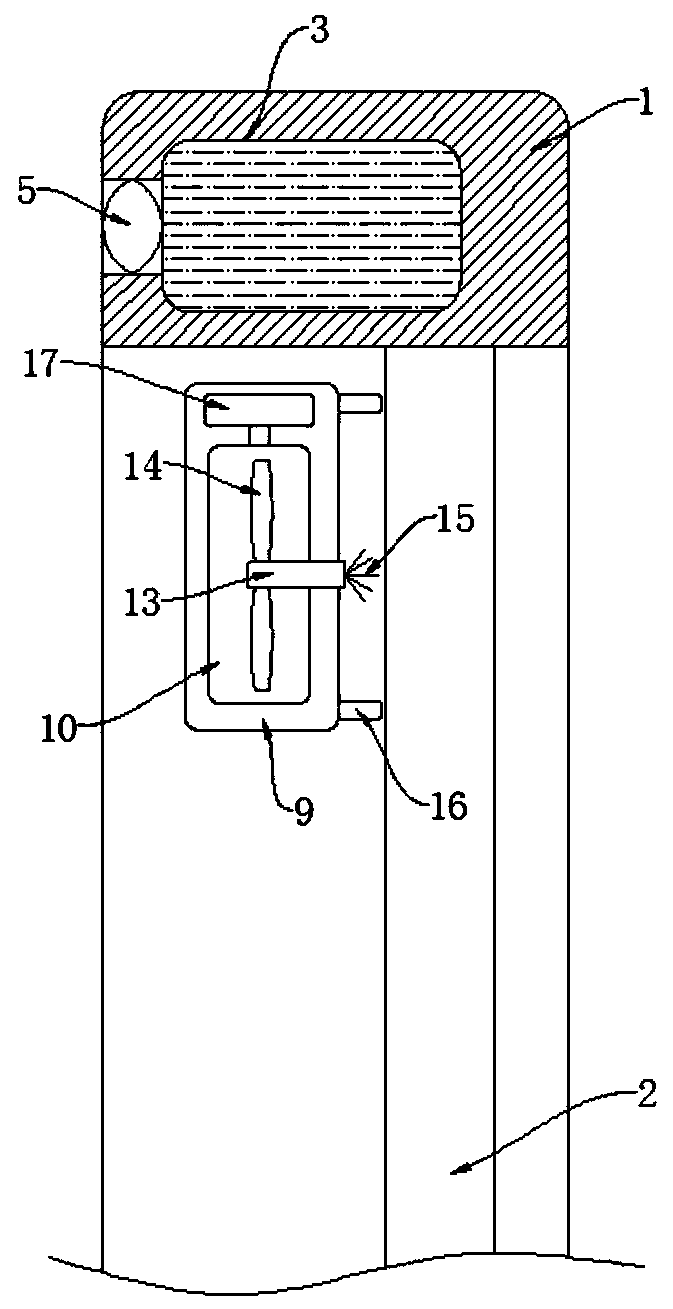

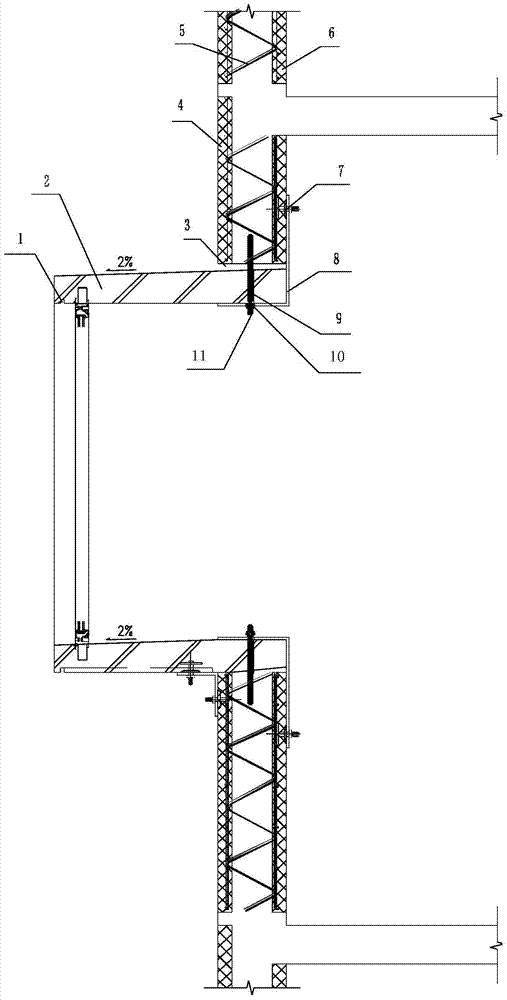

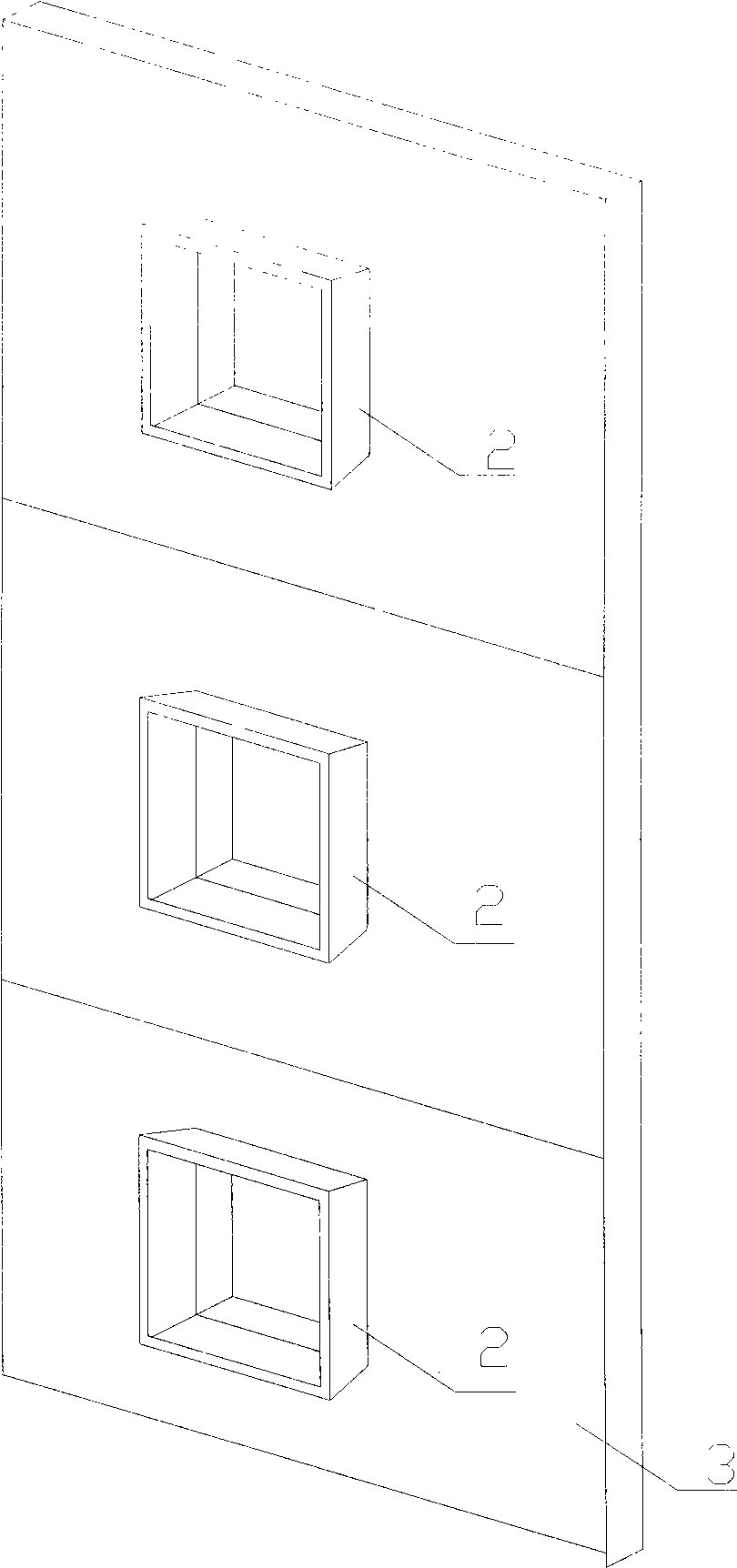

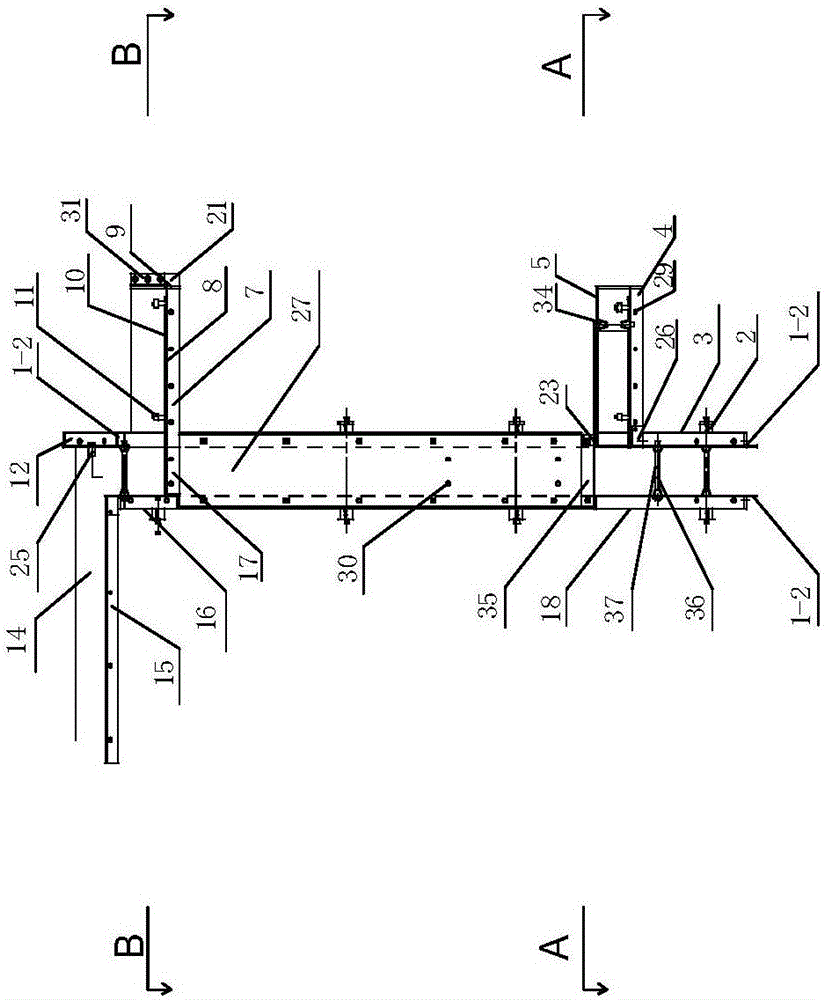

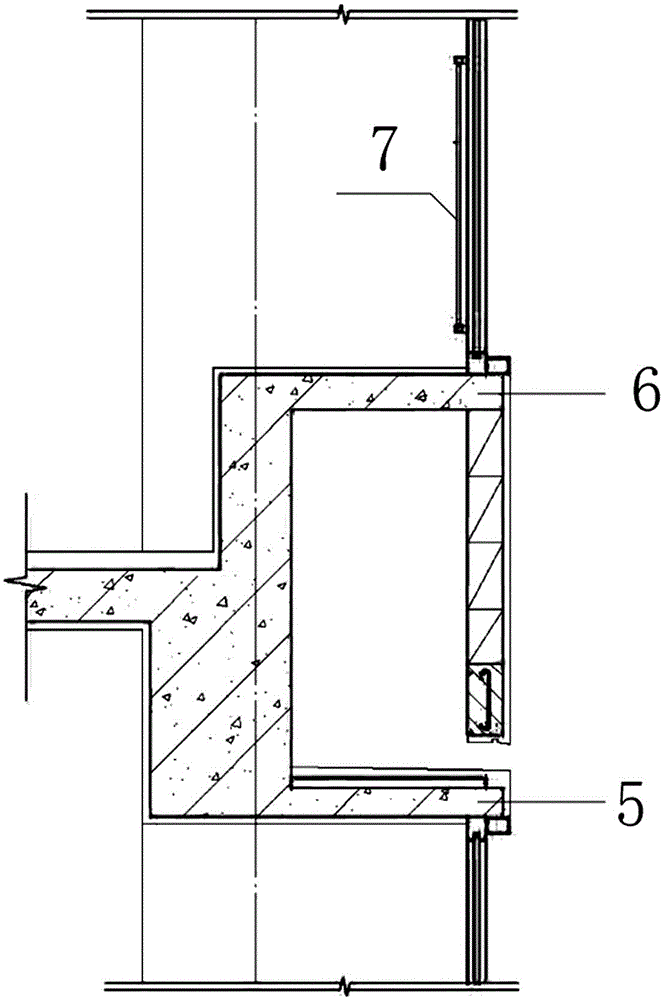

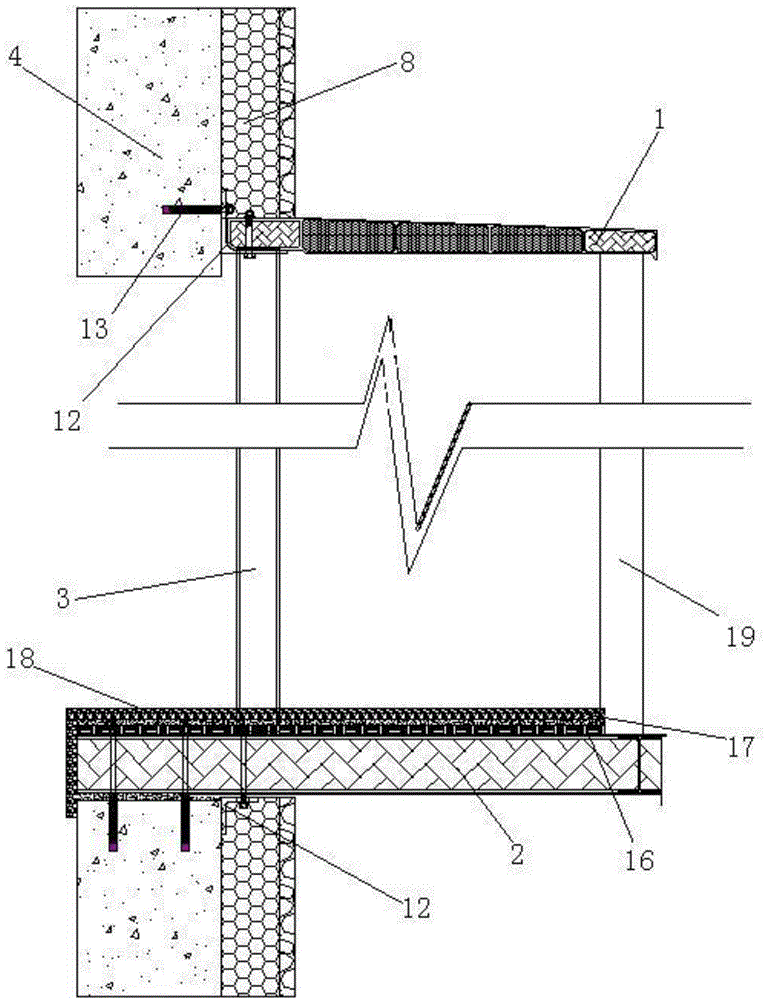

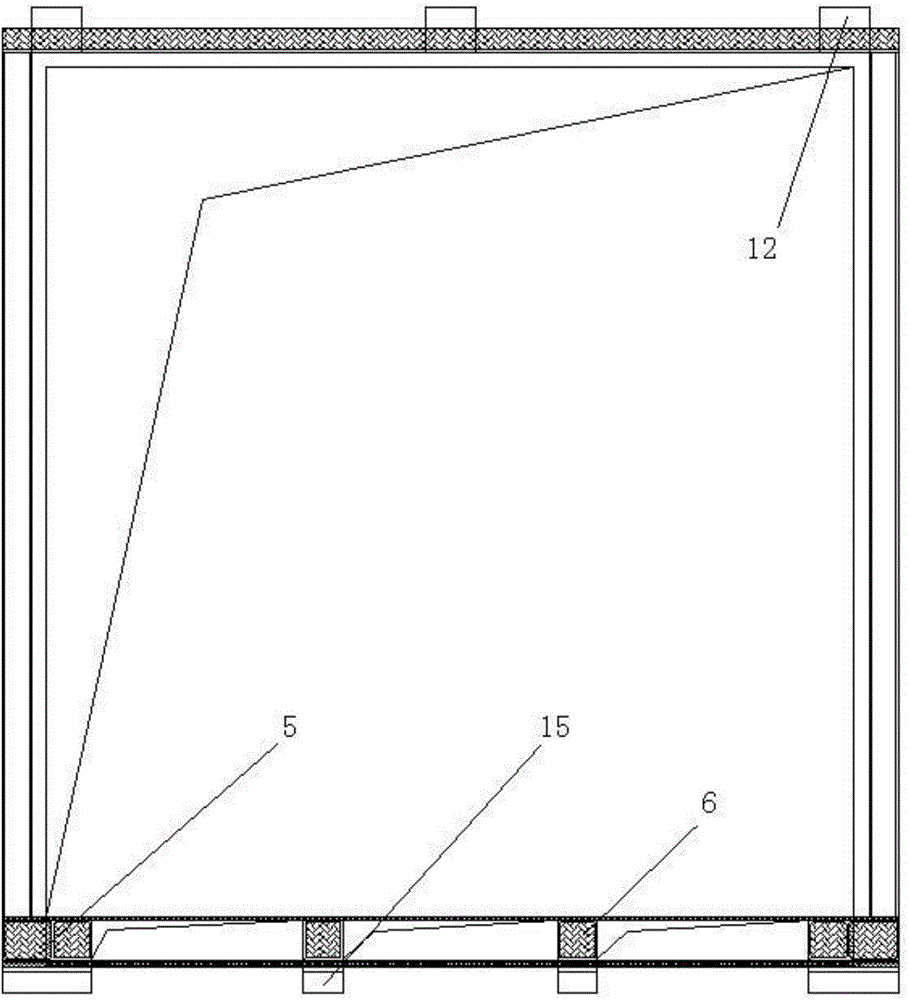

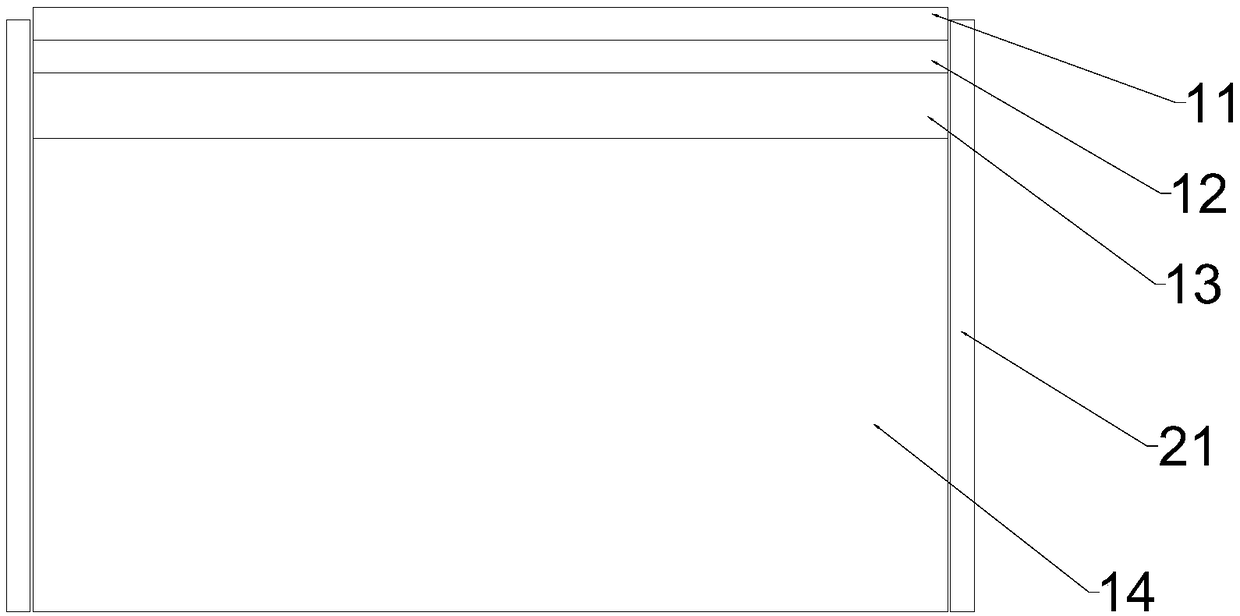

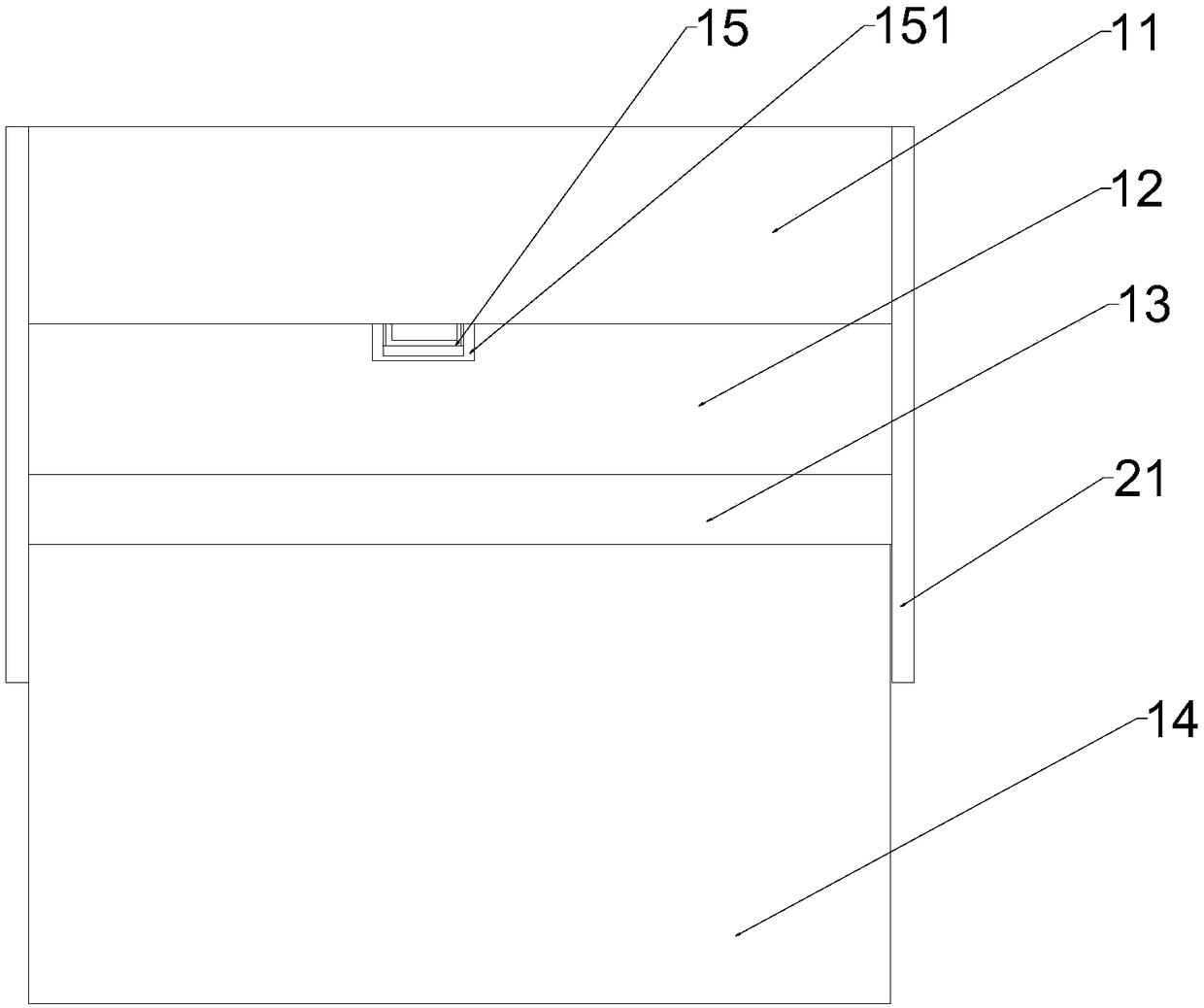

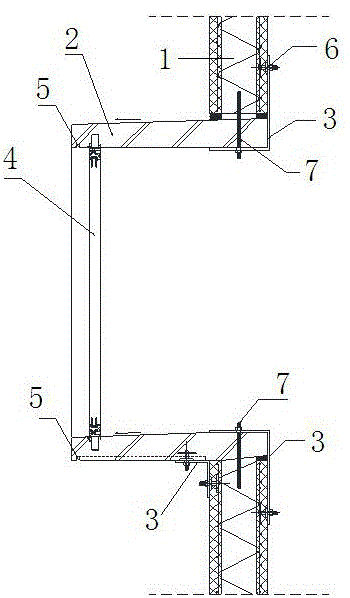

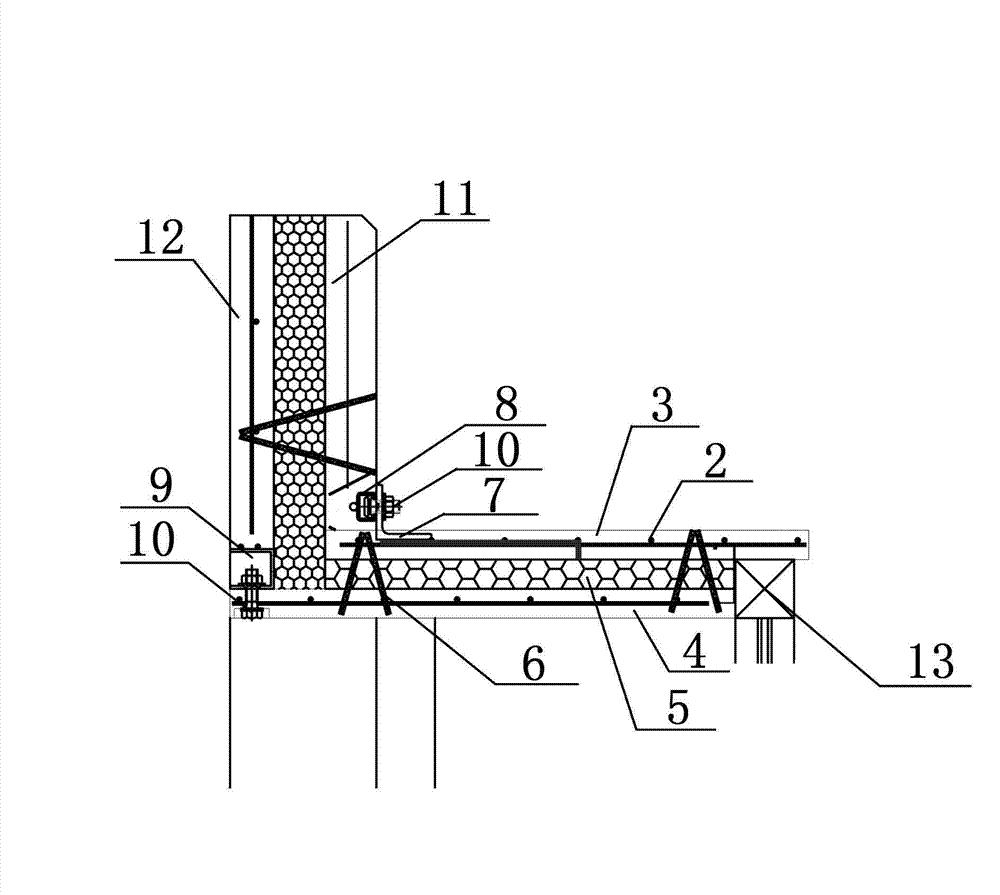

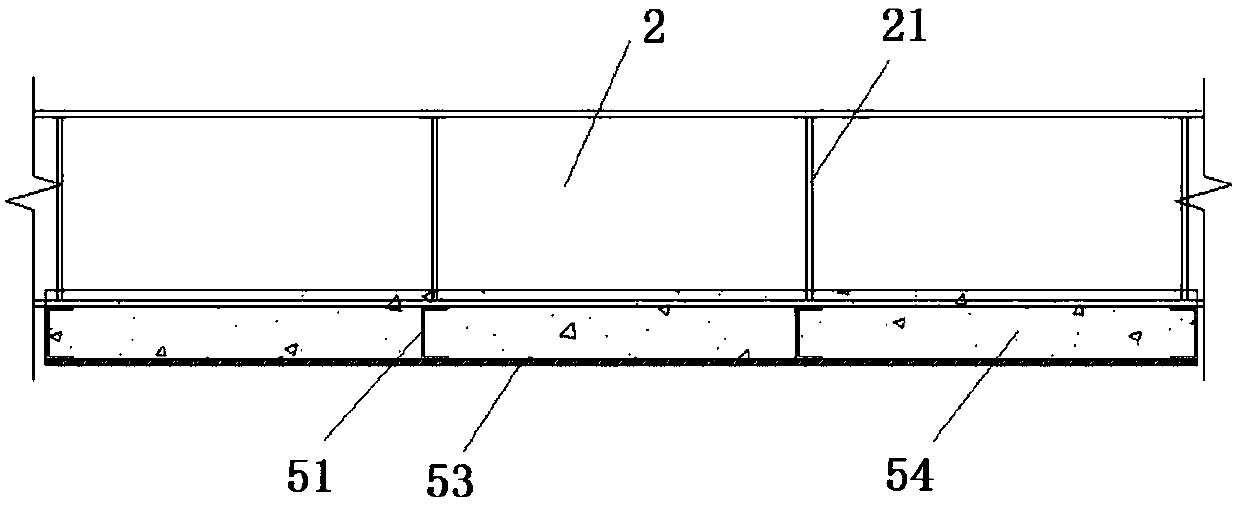

Prefabricated bay window structure installed on laminated wall board and installing method

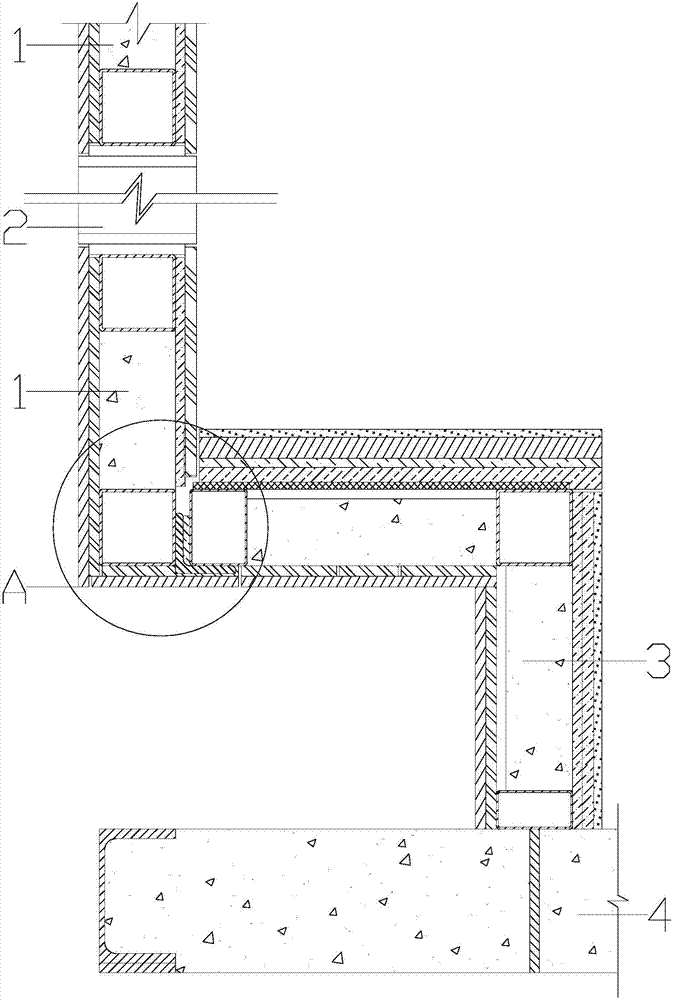

The invention relates to the window installing technology in the building field, in particular to a prefabricated bay window structure installed on a laminated wall board. A prefabricated bay window (2) is composed of an upper eave, a lower eave, a left vertical face and a right vertical face of the prefabricated cement board bay window, and embedded screw tubes (9) or nuts (7) are arranged at the corresponding joints of the periphery of the prefabricated bay window (2) and the laminated wall board. An installing method of the prefabricated bay window comprises the steps that firstly, a rectangular frame is formed; secondly, the nuts (7) are embedded; thirdly, the prefabricated bay window (2) is inserted and is flush with the inner wall of the laminated wall board; fourthly, a plurality of pieces of L-shaped angle iron (8) are prepared; fifthly, the inequilateral L-shaped angle iron (8) is arranged on the inner wall, and long screw rods (11) are screwed in the embedded screw tubes (9) through nuts; sixthly, the equilateral L-shaped angle iron (8) is arranged on the outer wall; seventhly, caulking is carried out through mortar (3) for blockage, and concrete is poured in a middle cast-in-place layer of the laminated wall board. The prefabricated bay window is not provided with an outer folded edge, the occupied space is small, manufacturing, storing and transporting are very easy and convenient, the prefabricated bay window structure is suitable for building window frame and laminated wall board factory-like line production, field assembling is easy, the construction speed is increased, the work period is shortened, the construction quality is high, and cost is saved.

Owner:BAOYE GROUP CO LTD +1

Construction method for construction floating window

InactiveCN101487290AMeet quality requirementsMeet the requirements of on-site civilized constructionBuilding constructionsResidencePre embedding

The invention relates to a bay window construction method, including the following steps: (1) iron parts are pre-embedded at the corresponding positions of a window of the main building; (2) the bay windows are collectively prefabricated according to the size and shape of the windows on the main building and the iron parts are also pre-embedded at the positions of the prefabricated bay windows which correspond to the pre-embedded iron parts on the main building; (3) the pre-embedded iron parts on the bay windows are connected with the corresponding pre-embedded iron parts on the window of the main building by welding. The invention carries out the collective prefabrication for the bay windows, thus saving the template and meeting the requirements of civil construction and the requirements of concrete quality. The method is especially suitable for the large-scale residence project.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

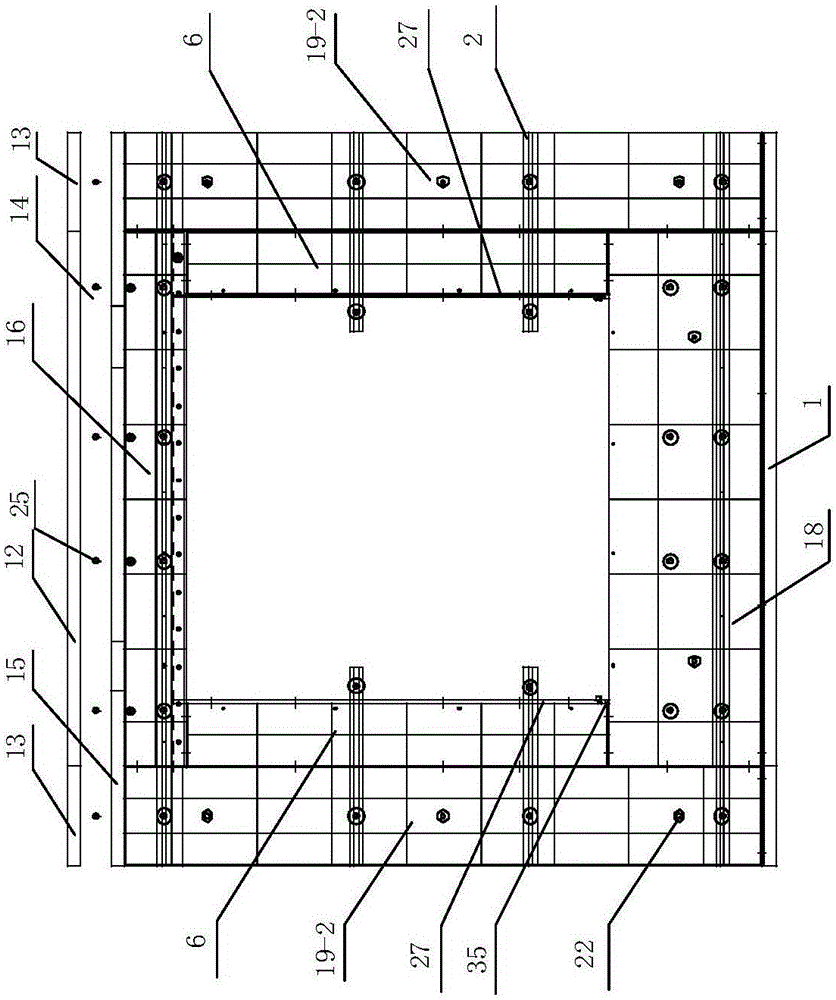

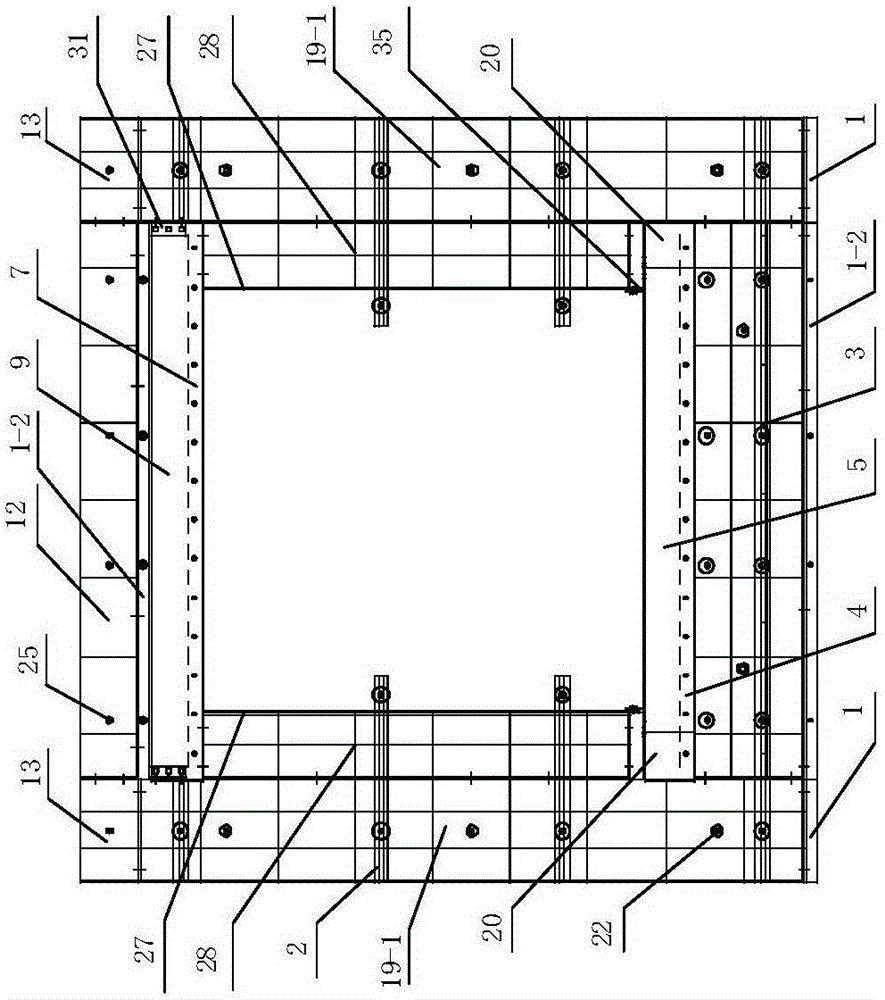

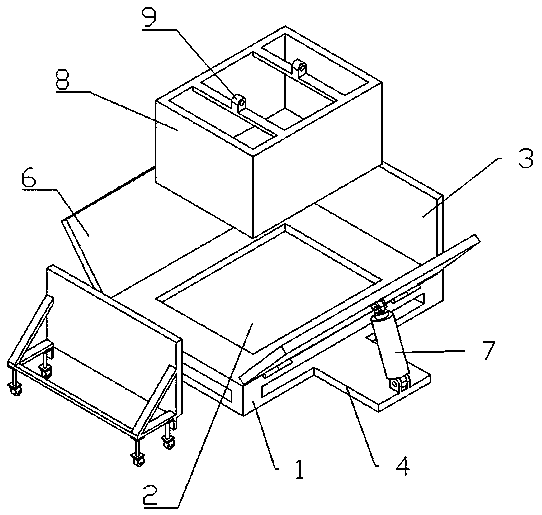

Bare concrete bay window steel formwork structural body device

InactiveCN105113789AFacilitate one-time pouring successEasy to assembleForms/shuttering/falseworksEngineeringBay window

The invention relates to a bare concrete bay window steel formwork structural body device. The bare concrete bay window steel formwork structural body device is characterized in that an under-window inner formwork and an under-window outer formwork are connected with main formworks commonly used for an inner wall and an outer wall through assembling holes, and a lower suspension bottom formwork and the under-window outer formwork can be directly assembled through corner connecting pieces; one side face of a window inner formwork and one side face of a window outer formwork are connected with the inner wall main formwork and the outer wall main formwork on the two sides of a window respectively; the bottom edges of two bay window aperture formworks are hung in the air to be at the same height as the lower side of the window inner formwork, and are connected with the other side face of the window inner formwork and the other side face of the window outer formwork respectively; an upper suspension bottom formwork, a window beam bottom formwork and window beam inner formworks are connected and assembled; the window beam inner formworks and window beam outer formworks are oppositely pulled to be fixed through screw rod sleeves; the window beam inner formworks, the window beam outer formworks, the window beam bottom formwork and the upper suspension bottom formwork are connected with the main formwork commonly used for the outer wall and a connection formwork on the upper portions of the bay window aperture formworks. The device has the advantages of being simple in structure, convenient to assemble and capable of reducing labor and cost; concrete can be successfully poured at a time to form a whole structural body, the anti-seismic effect is enhanced, and construction quality is improved; the steel formwork is high in university and capable of meeting various structural requirements.

Owner:刘其标

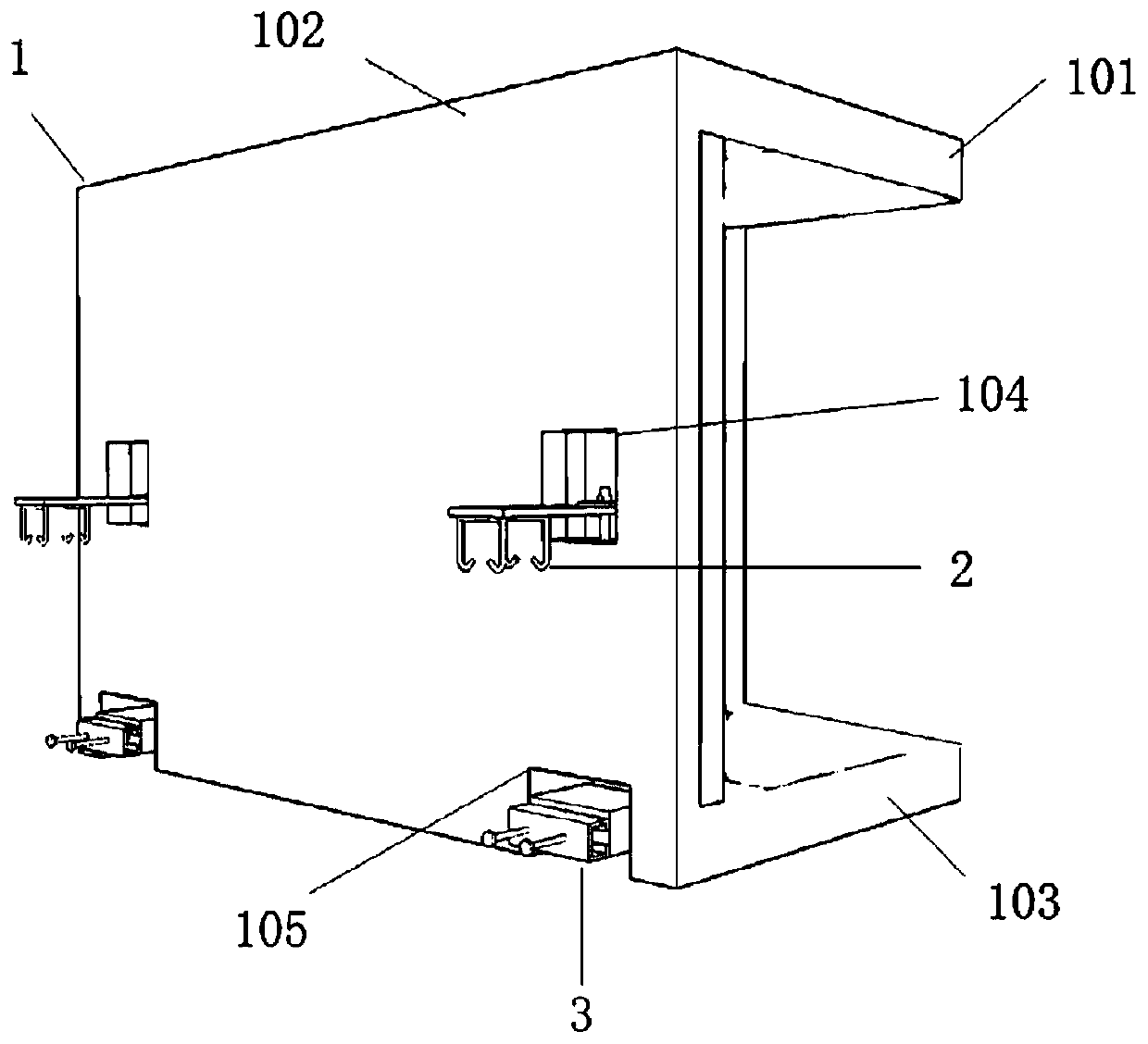

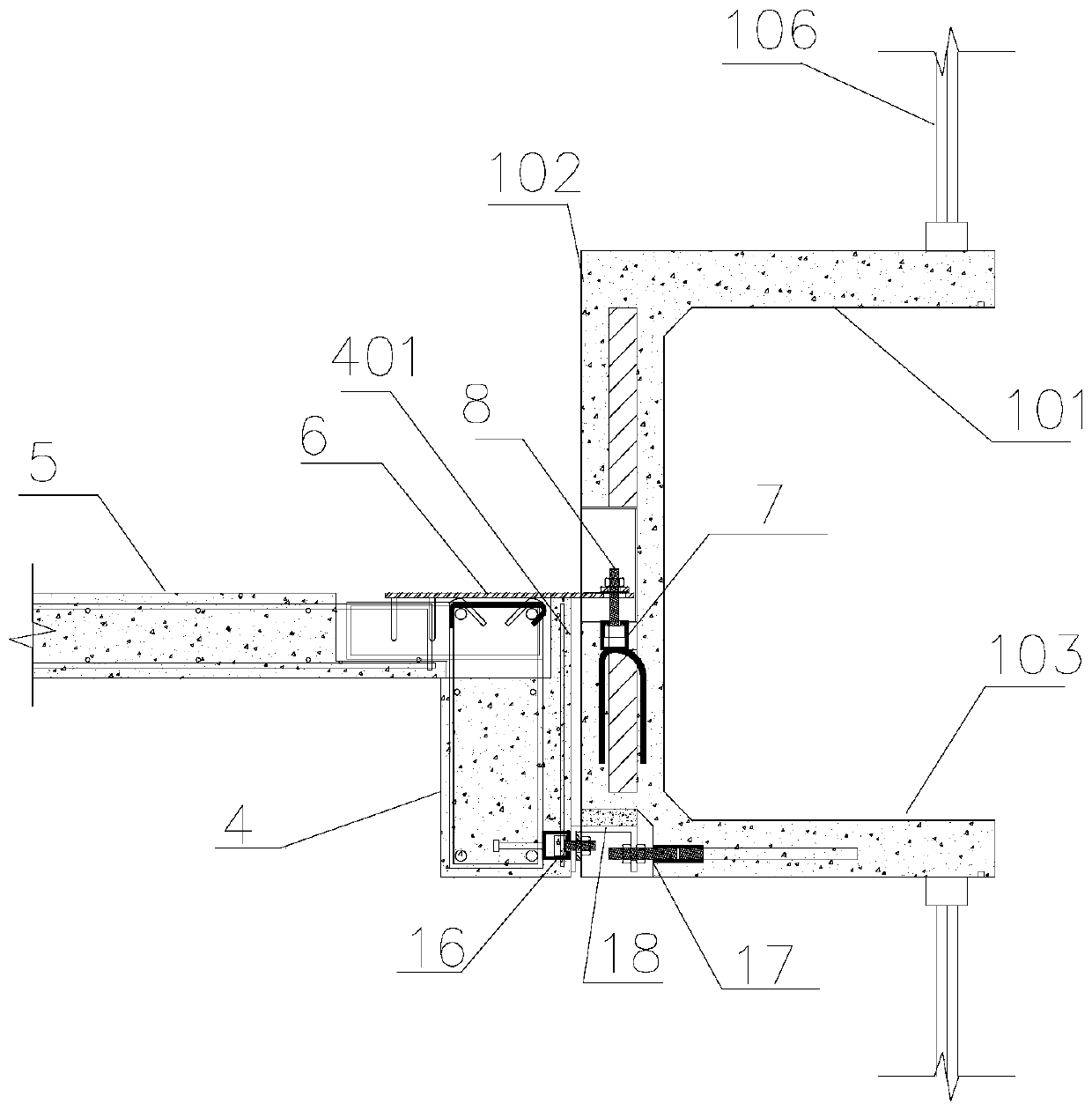

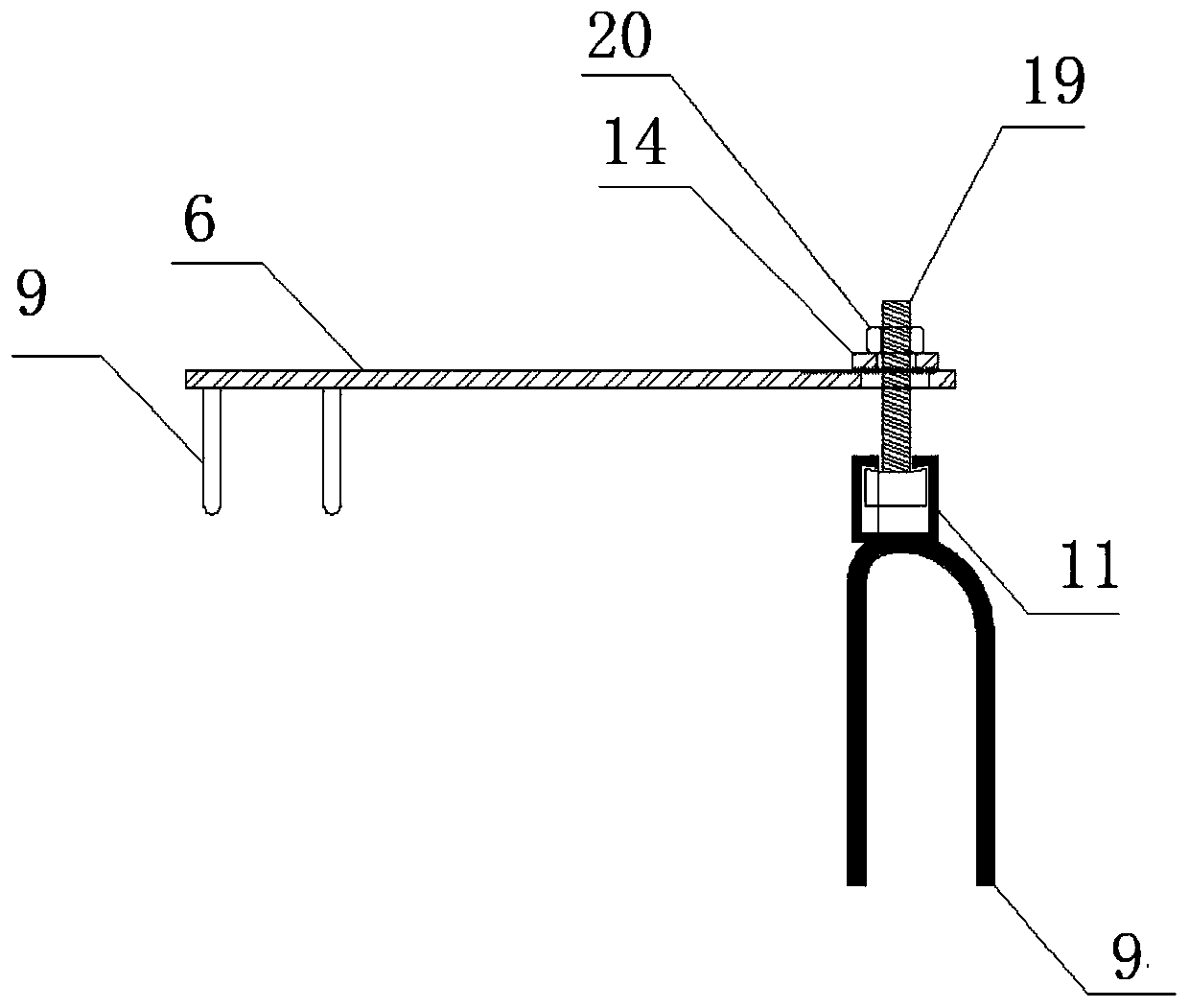

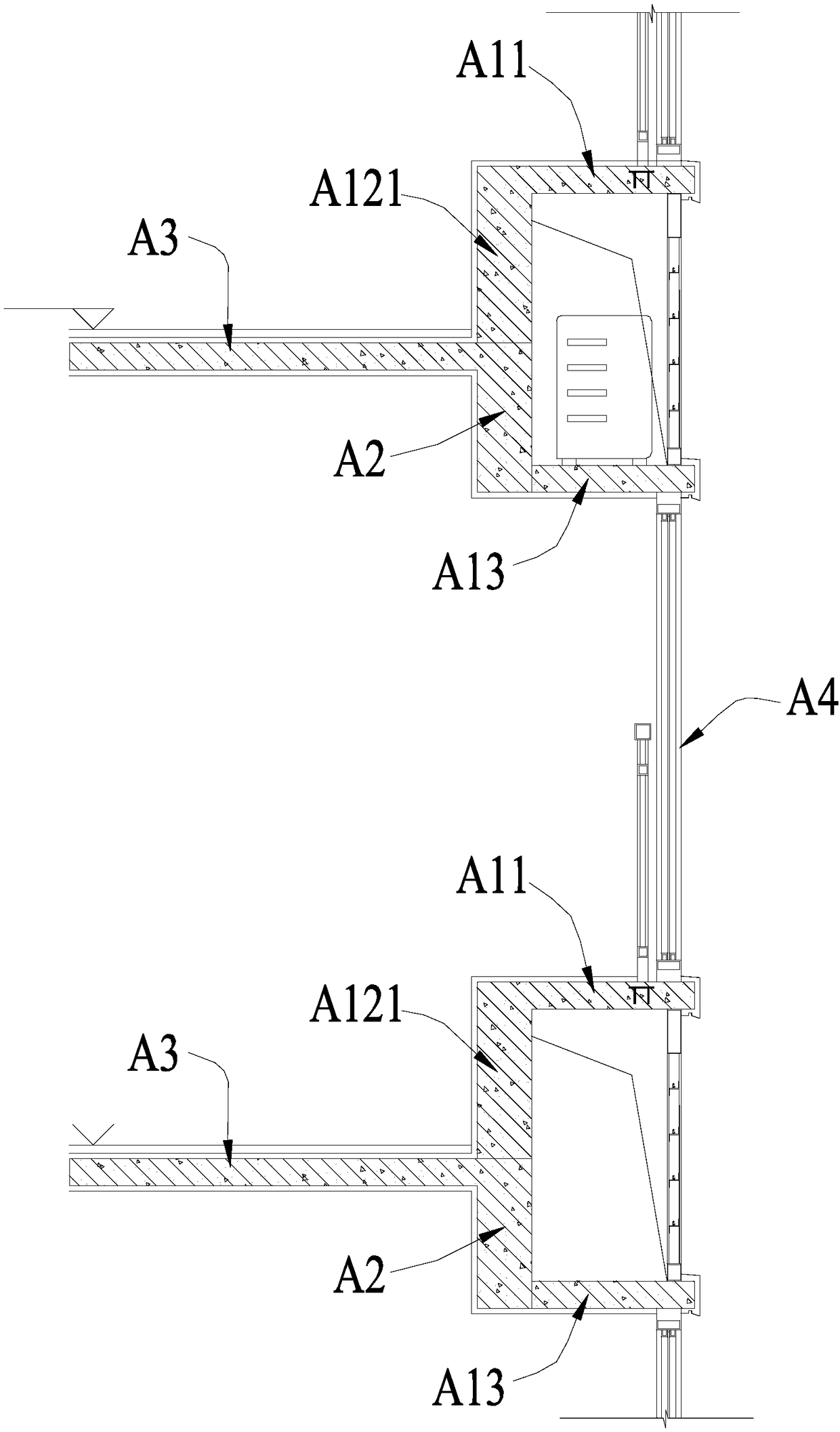

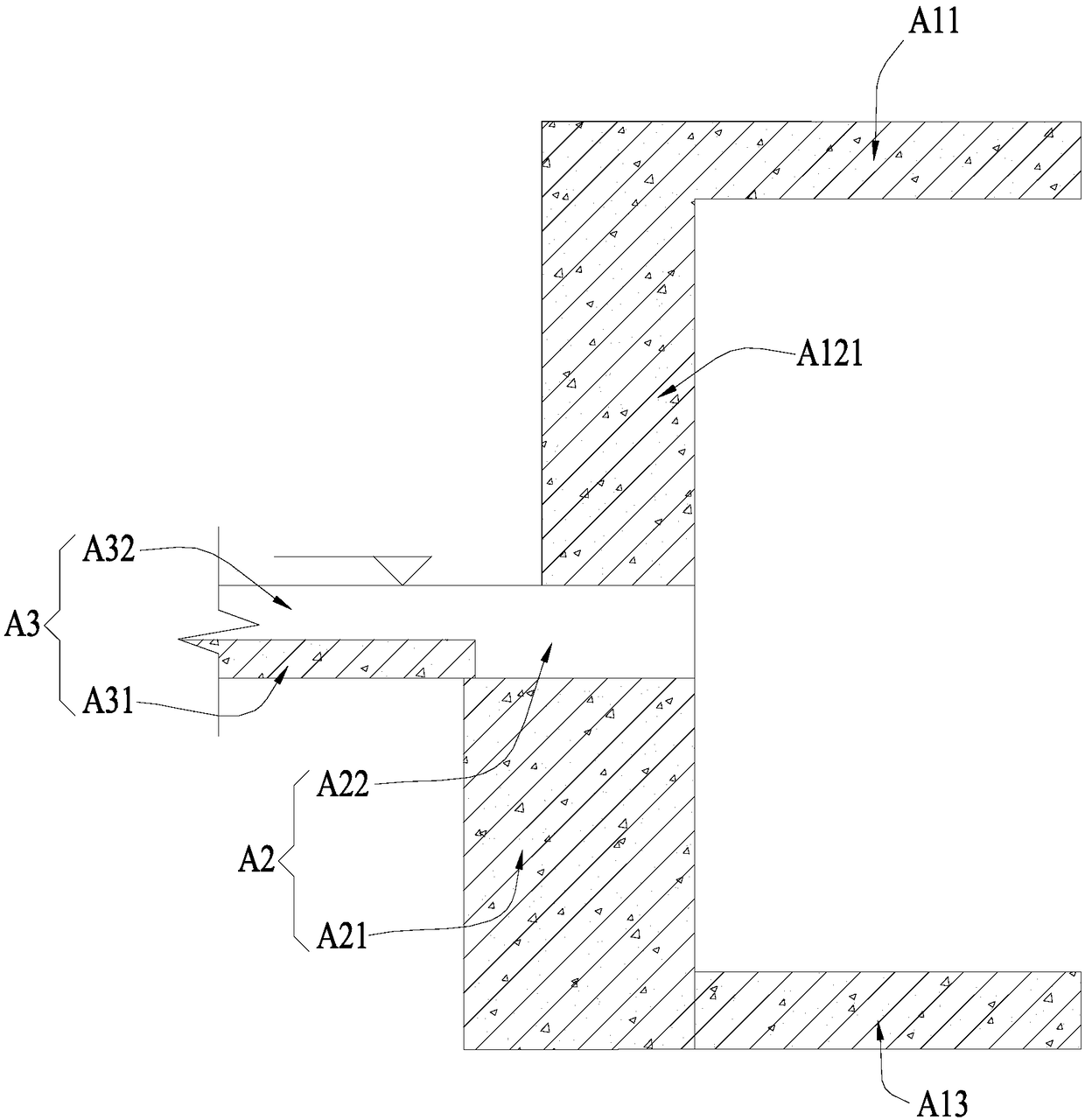

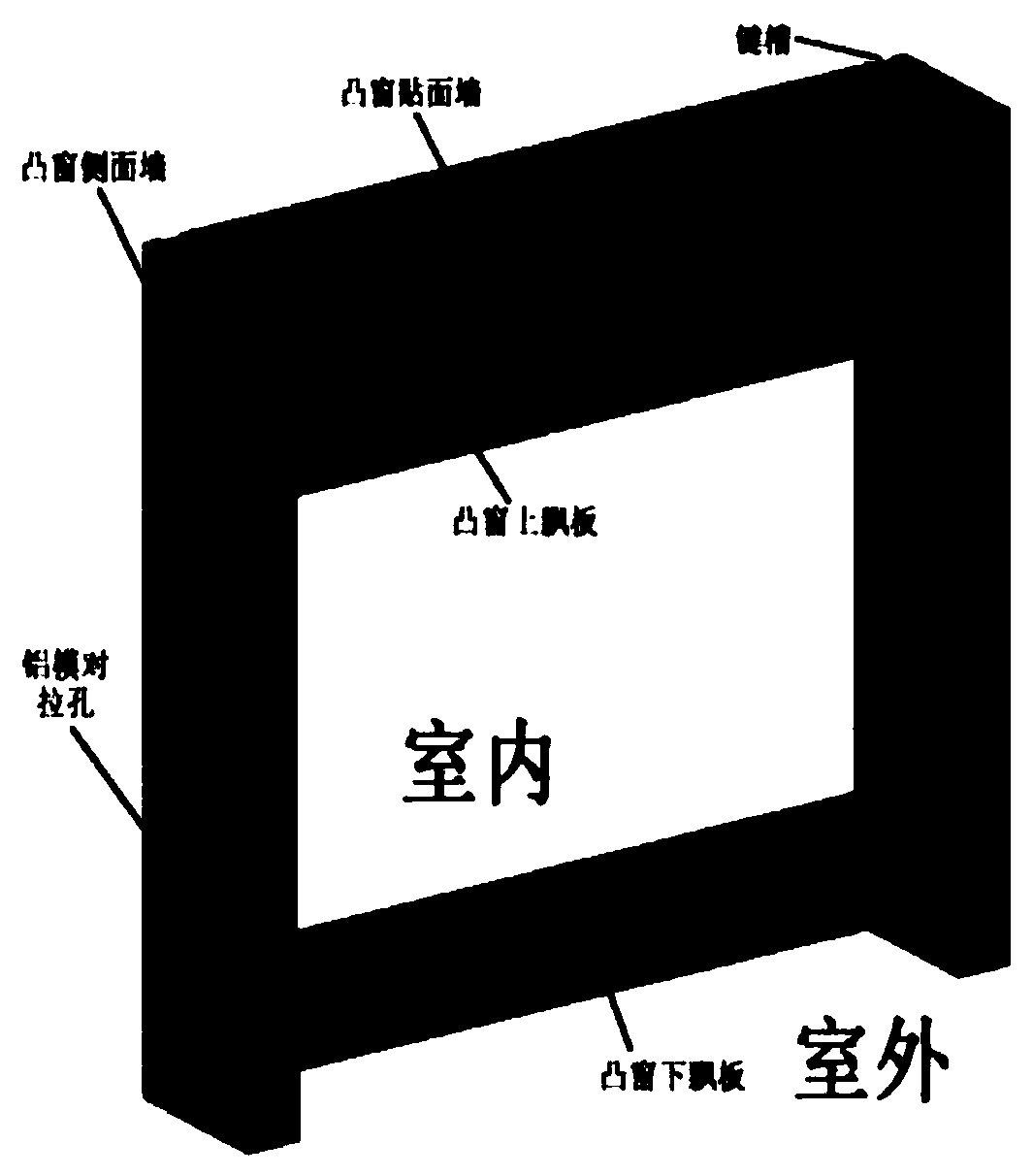

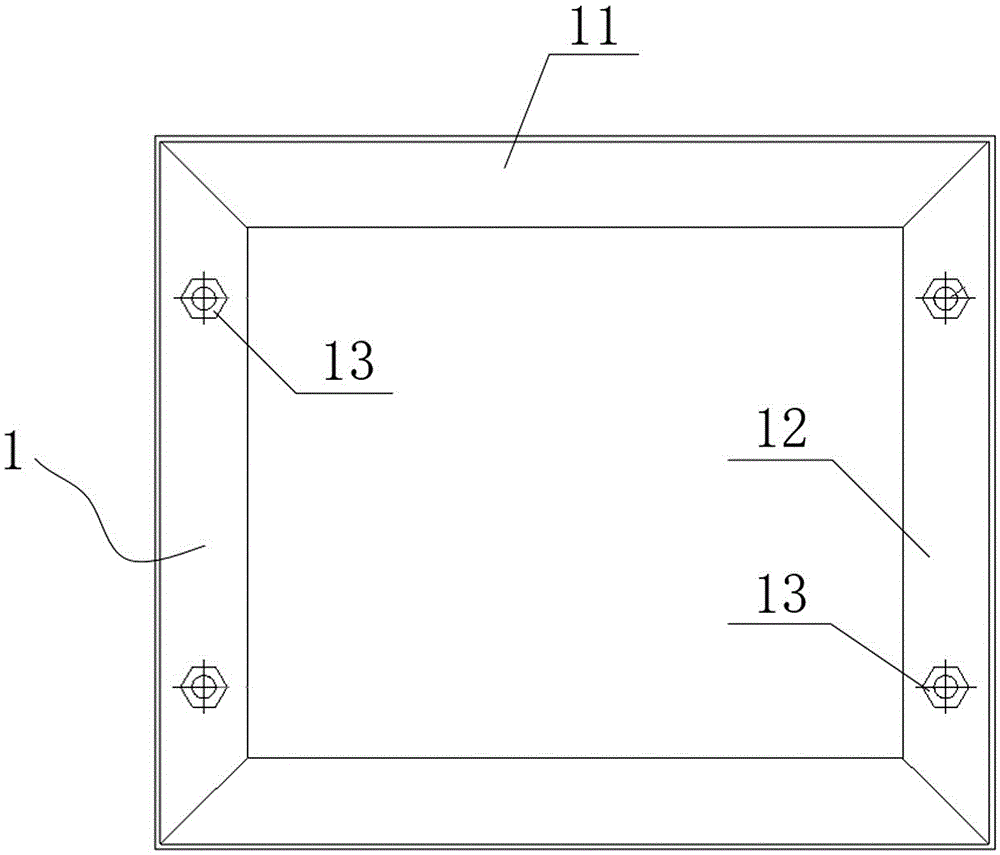

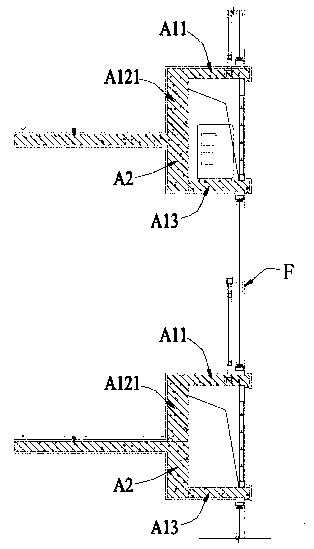

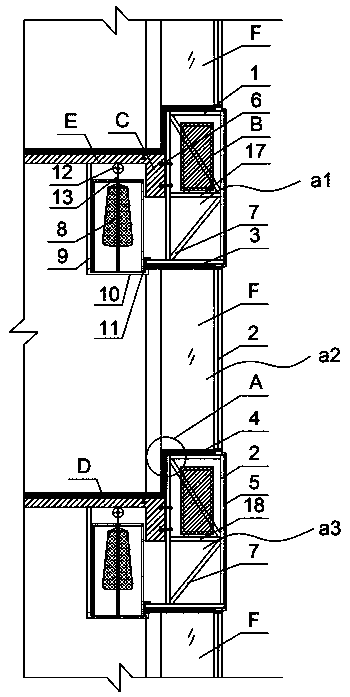

Connection structure for prefabricated integral bay window, and assembling method thereof

The invention provides a connection structure for a prefabricated integral bay window. The connection structure comprises a prefabricated integral bay window and a superposed beam and is characterizedin that the prefabricated integral bay window is integrally poured into a C-similar shape and comprises a top plate, a side wall and a bottom plate; the superposed beam comprises a prefabricated partand a cast-in-place part; the bottom surface of the bottom plate and the bottom surface of the prefabricated part are positioned on the same horizontal plane; the indoor side of the side wall is fixedly connected with the cast-in-place part through an upper connecting component; and the bottom plate is fixedly connected with the prefabricated part through a lower connecting component. When the connection structure for the prefabricated integral bay window in the scheme is produced and manufactured, no reinforcing steel bars extend out of the edge part of the prefabricated integral bay window,a production module is simple, demoulding efficiency is high, and a mould turnover frequency is improved. In a transportation stage, a loading rate can be improved; wet operations in an assembling field are few, form erection is avoided, field construction efficiency is improved, and construction cost is lowered; an error-tolerant rate of field assembling is high, the position of the prefabricated integral bay window can be regulated in field through ways, including gaskets, bolts, mortar, bed mortar and the like, and the connection structure disclosed by the invention is convenient for fieldinstallation and regulation.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

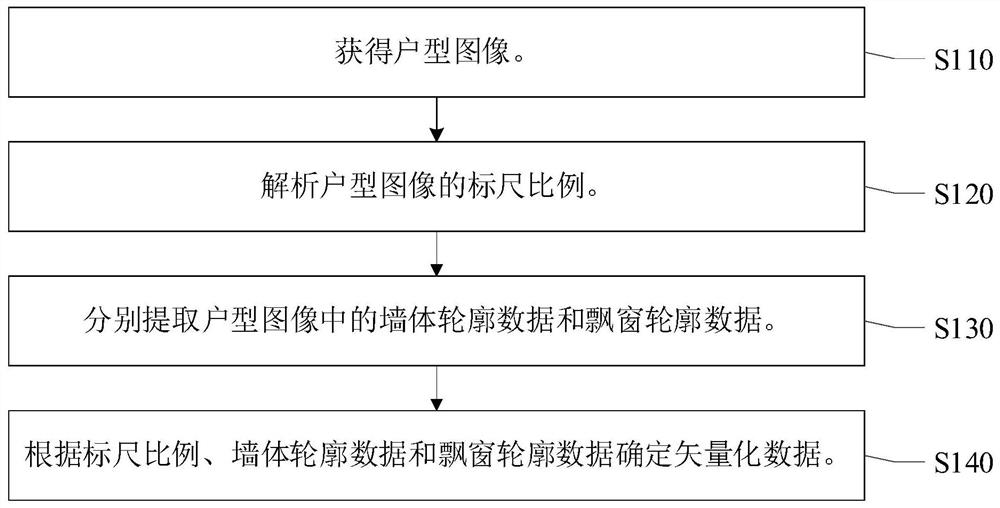

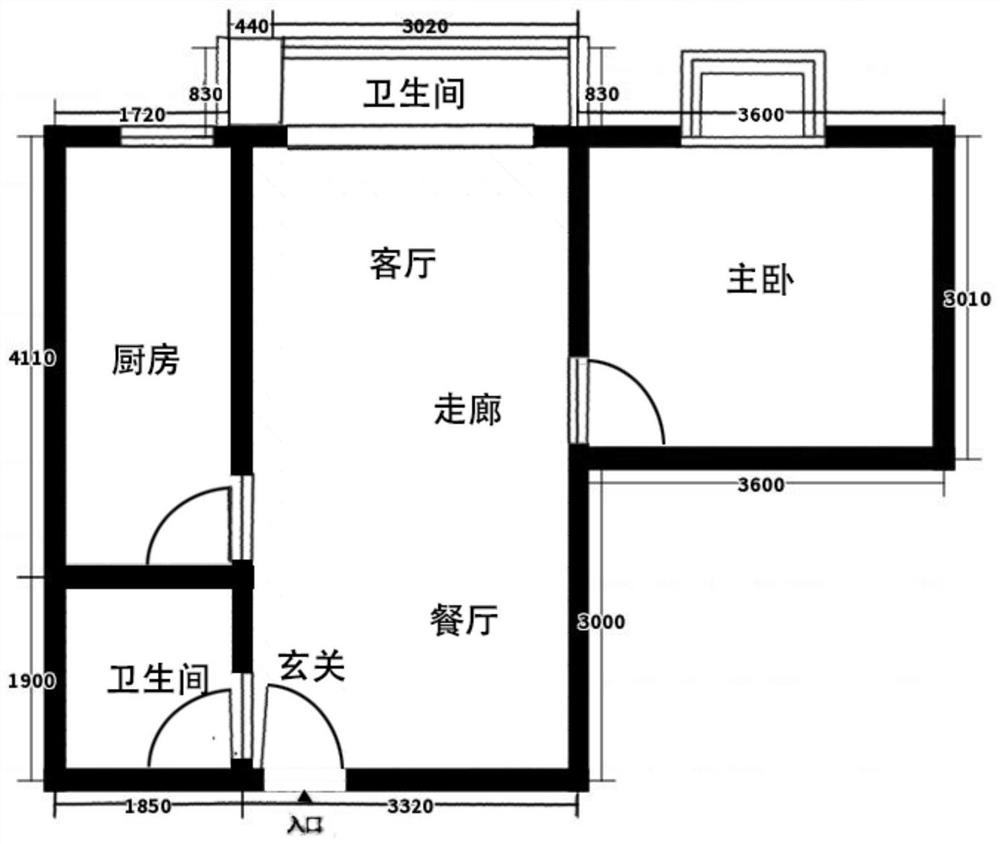

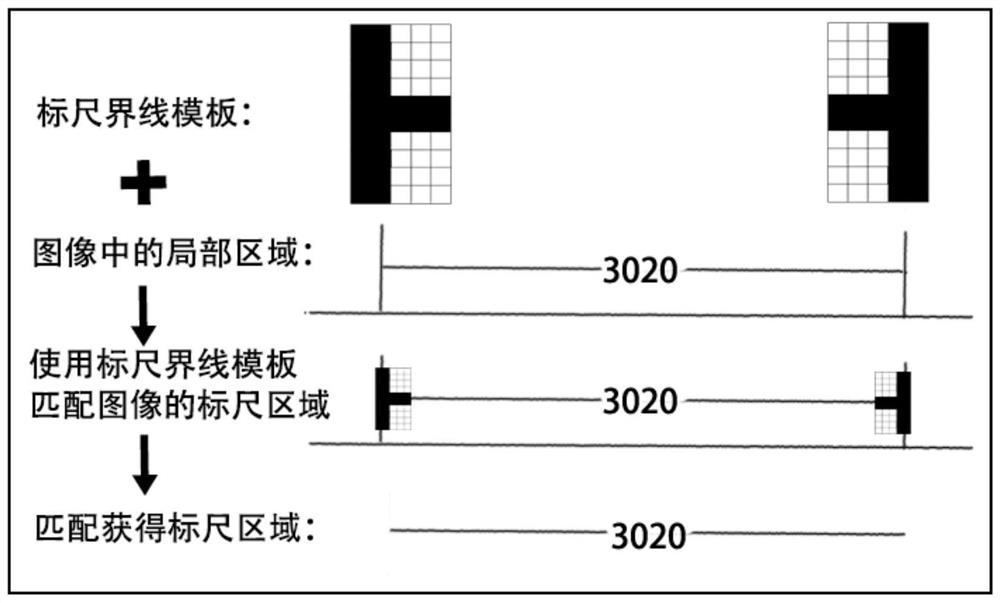

House type vectorized data obtaining method and device, electronic equipment and storage medium

The invention provides a house type vectorized data obtaining method and device, electronic equipment and a storage medium. The method comprises the steps of obtaining a house type image; analyzing the scale proportion of the house type image, wherein the scale proportion represents the proportion value of the house type size of the actual house and the house type size in the house type image; respectively extracting wall contour data and bay window contour data in the house type image; and determining vectorization data according to the scale proportion, the wall contour data and the bay window contour data. In the implementation process, the scale proportion of the house type image is analyzed through an electronic equipment executive program; wall contour data and bay window contour data are respectively extracted in the house type image; the vectorized data corresponding to the house type image is determined, and the vectorized data corresponding to the house type image is extracted by using the electronic equipment executive program, so that the error rate of manual extraction is reduced, and the efficiency of extracting the vectorized data from the house type image is effectively improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

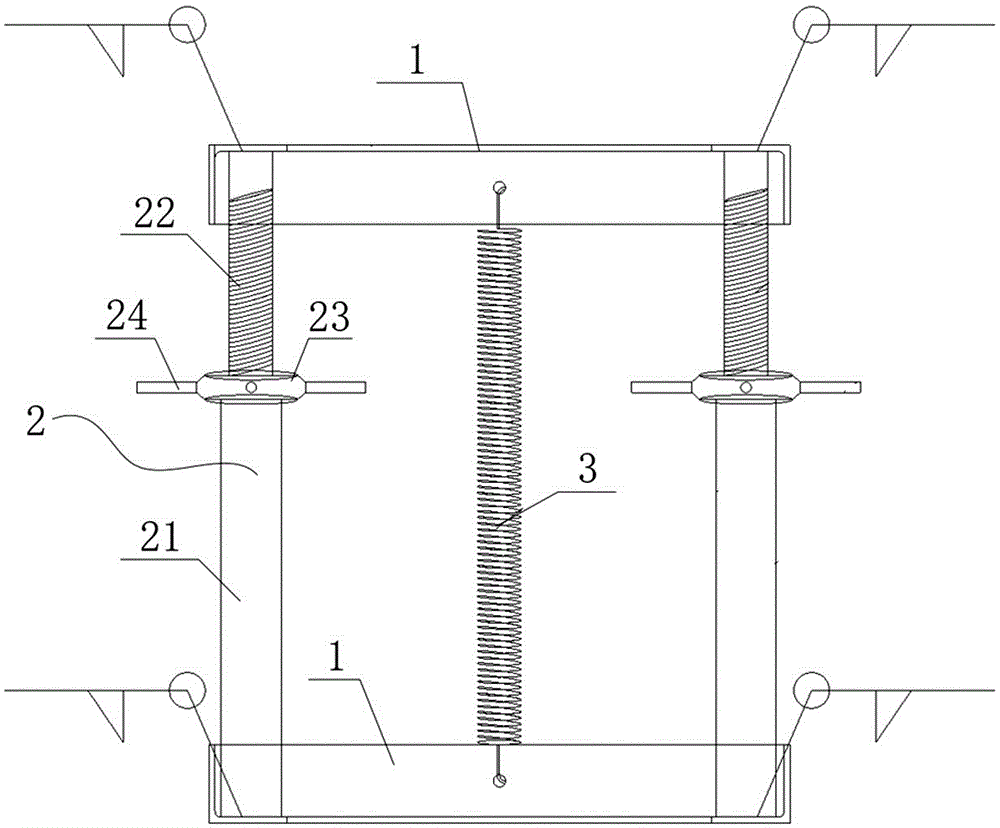

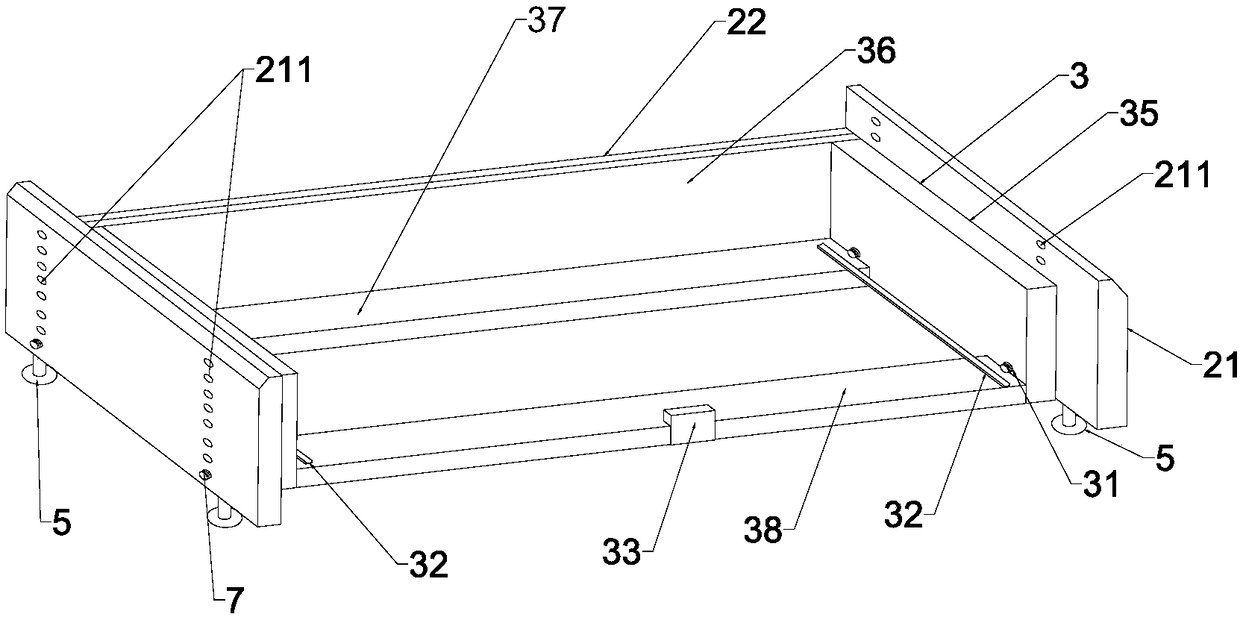

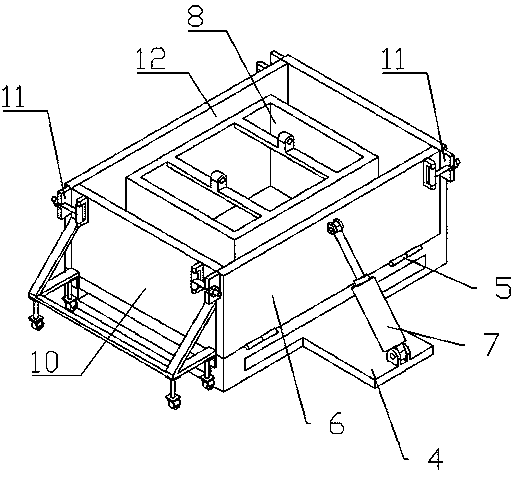

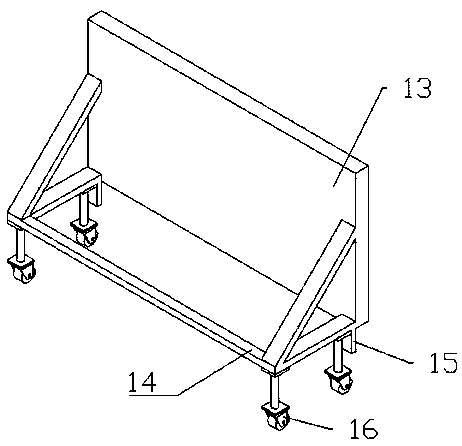

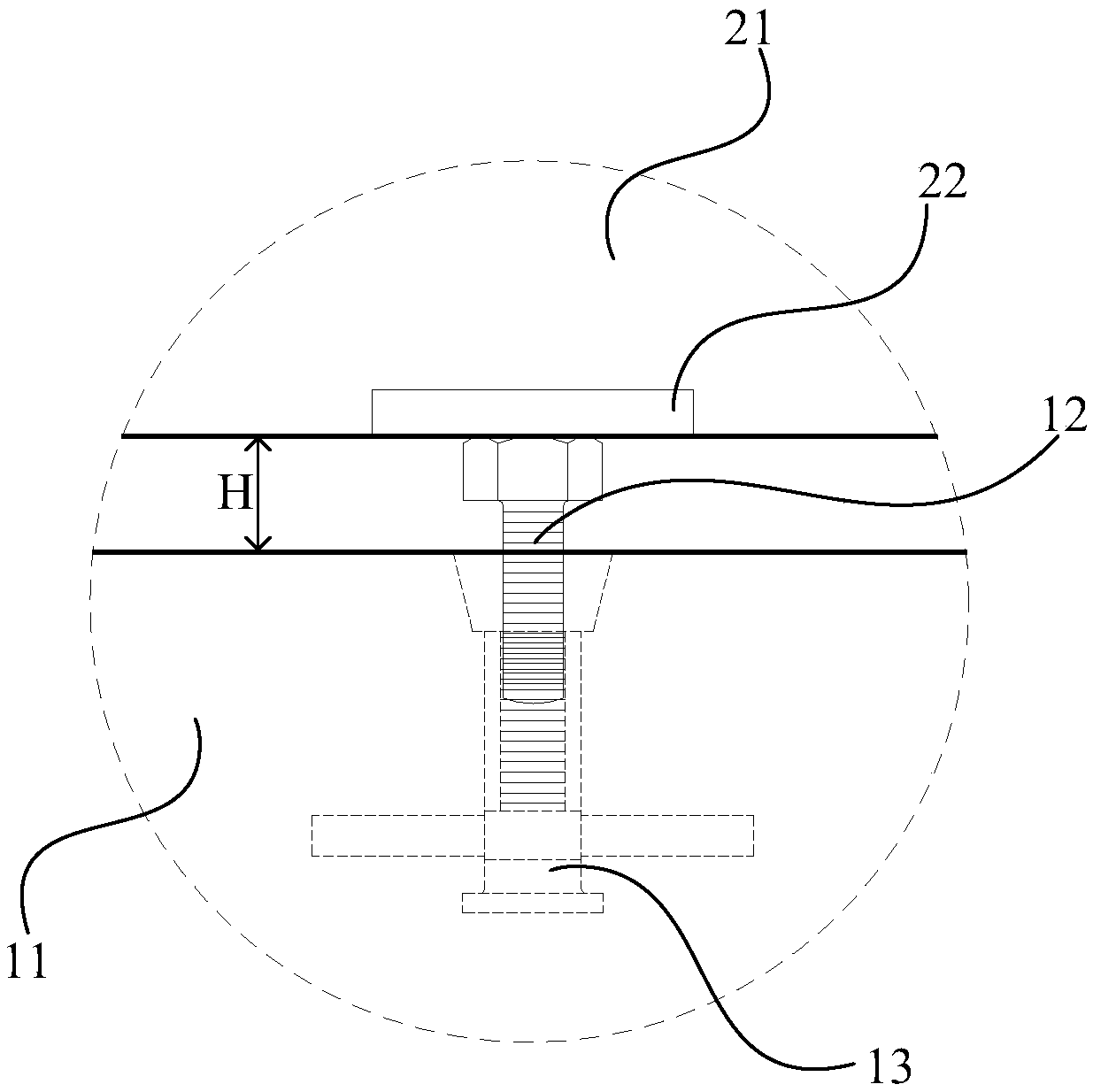

Elastic support platform for construction of bay window and bay window construction method

InactiveCN105040974AReduce in quantitySimplify construction stepsForms/shuttering/falseworksBuilding material handlingMarine engineeringBay window

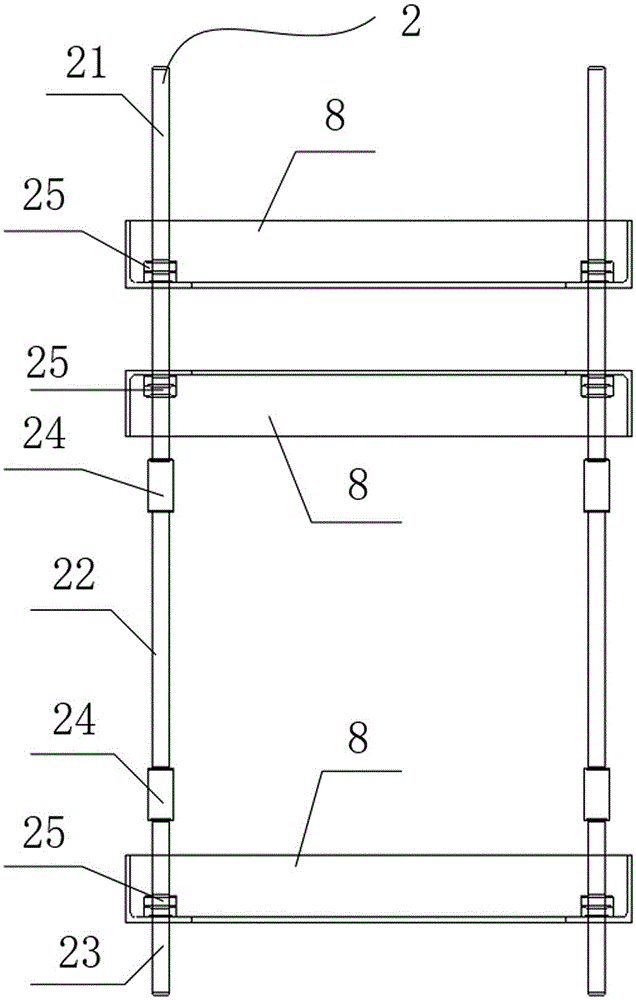

The invention discloses an elastic support platform for construction of a bay window and a bay window construction method, wherein the elastic support platform comprises a first support frame, lead screws, a second support frame, sleeves, adjusting locks and elastic pulling parts, the first support frame is provided with mounting holes, one end of the lead screws are fixed on four side corners of the first support frame, the second support frame is provided with mounting holes, one end of the sleeves are fixed on four side corners of the second support frame, the adjusting locks are arranged on the end heads of the sleeves, the lead screws pass through the sleeves, the depths of the lead screws going into the sleeves are adjusted through the adjusting locks, one end of the elastic pulling parts are connected into the mounting holes of the first support frame, and the other ends of the elastic pulling parts are connected into the mounting holes of the second support frame. The elastic support platform for construction of the bay window and the bay window construction method achieve to cast an upper and a lower bay plates of a bay window, are simple in construction step, reduce construction cost input, and prevent leakage hidden danger of outer walls. The elastic support platform for construction of the bay window and the bay window construction method enable first support parts to fall off under the action of elastic force when dismounting a template, and reduce difficulty and labor strength of artificial dismounting.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

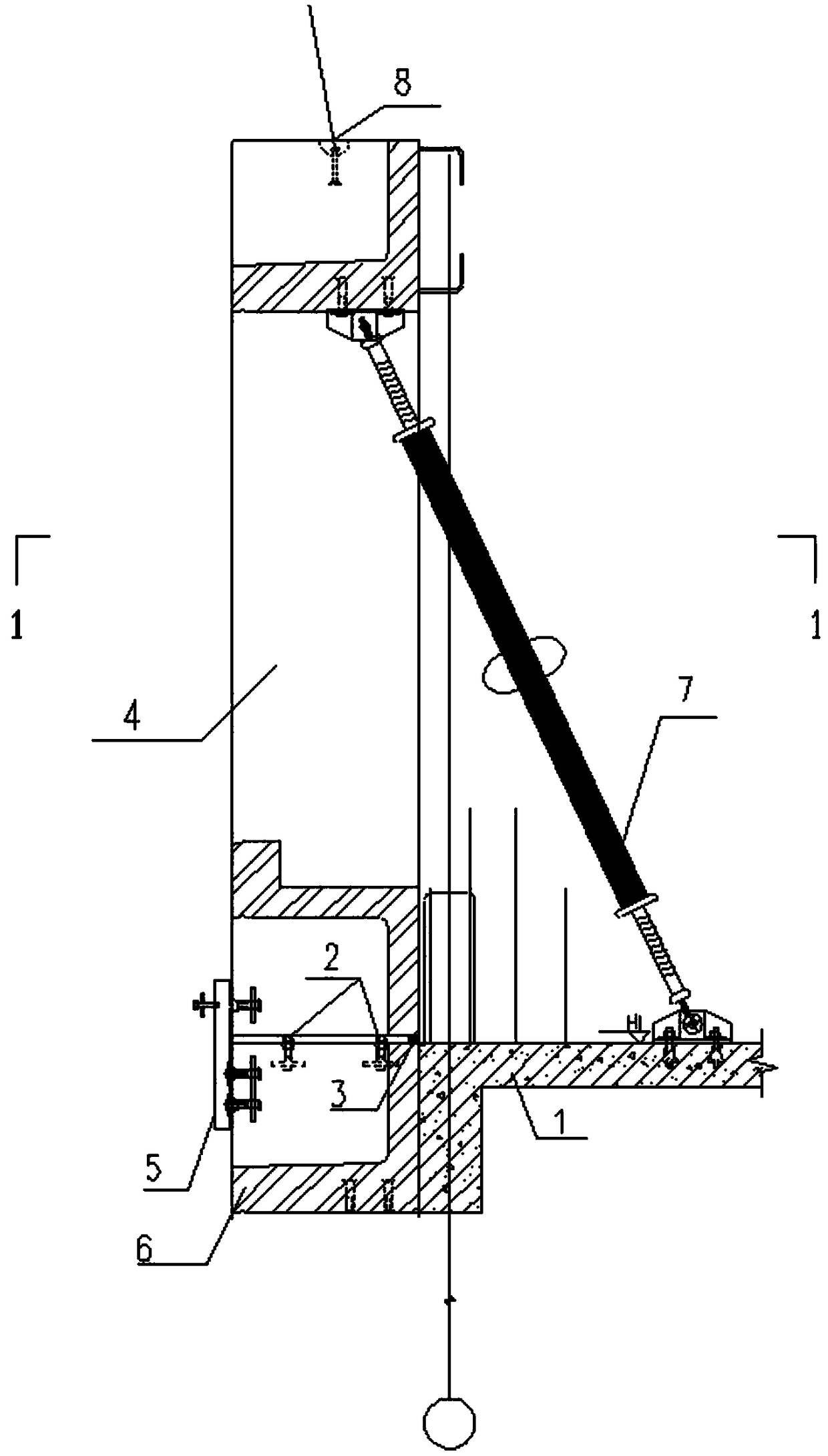

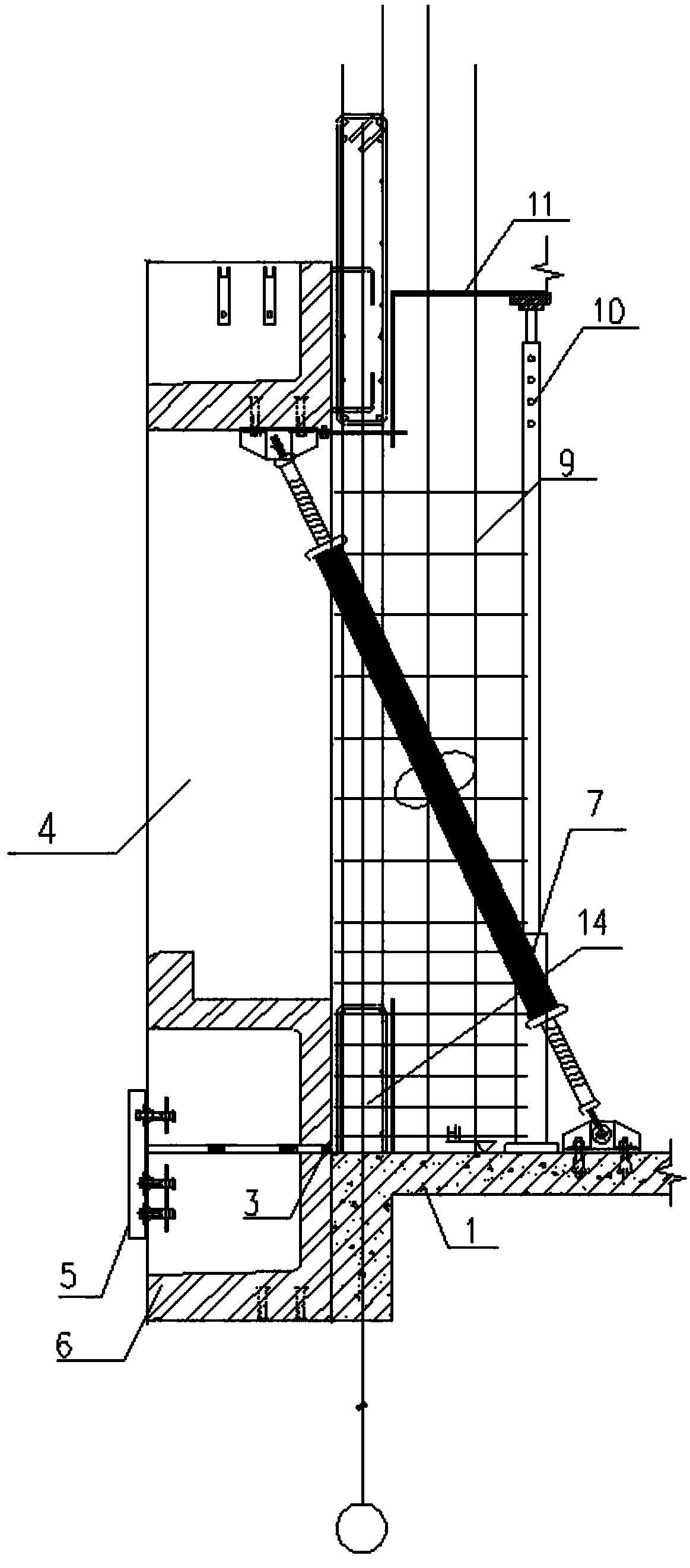

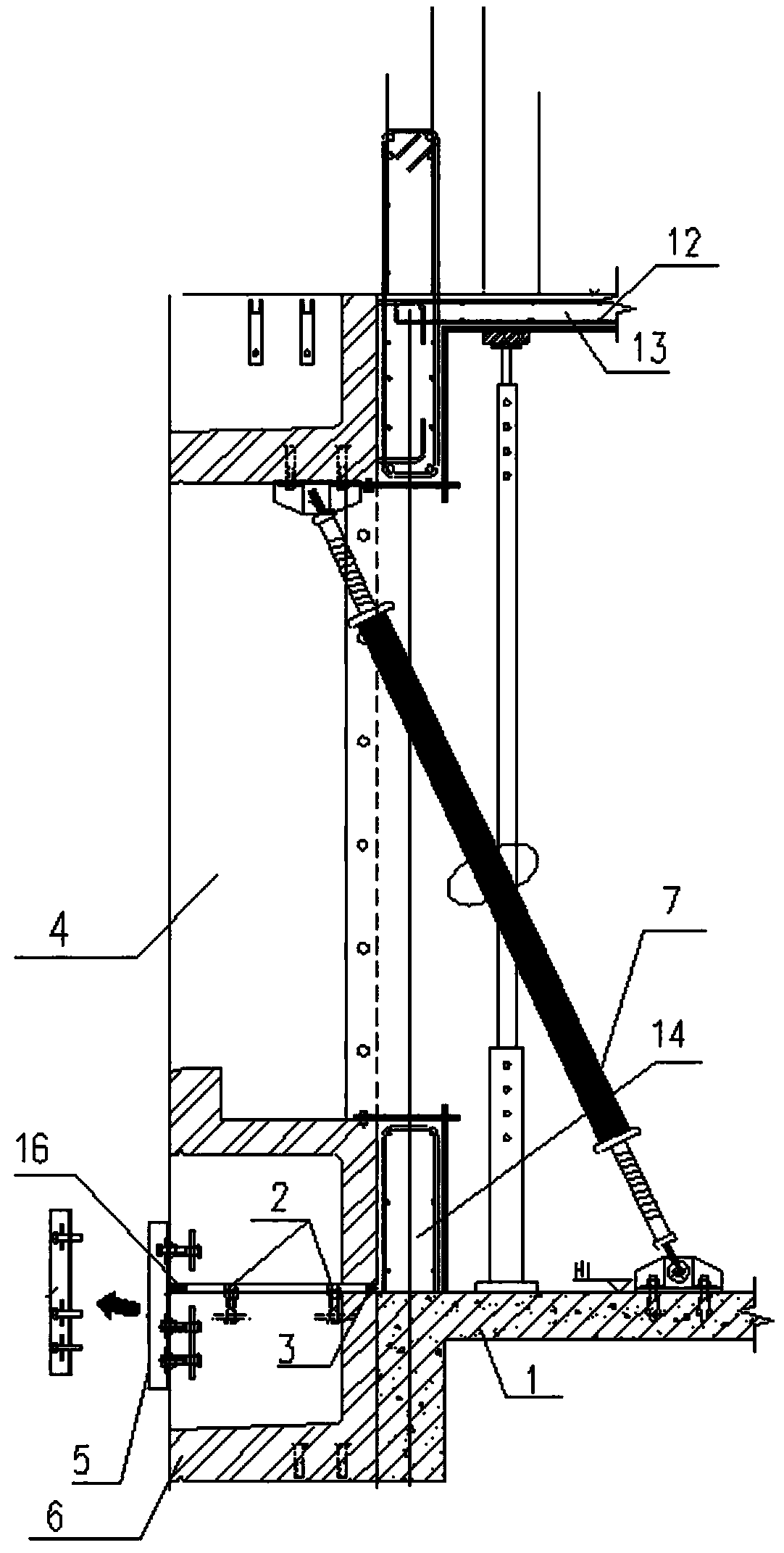

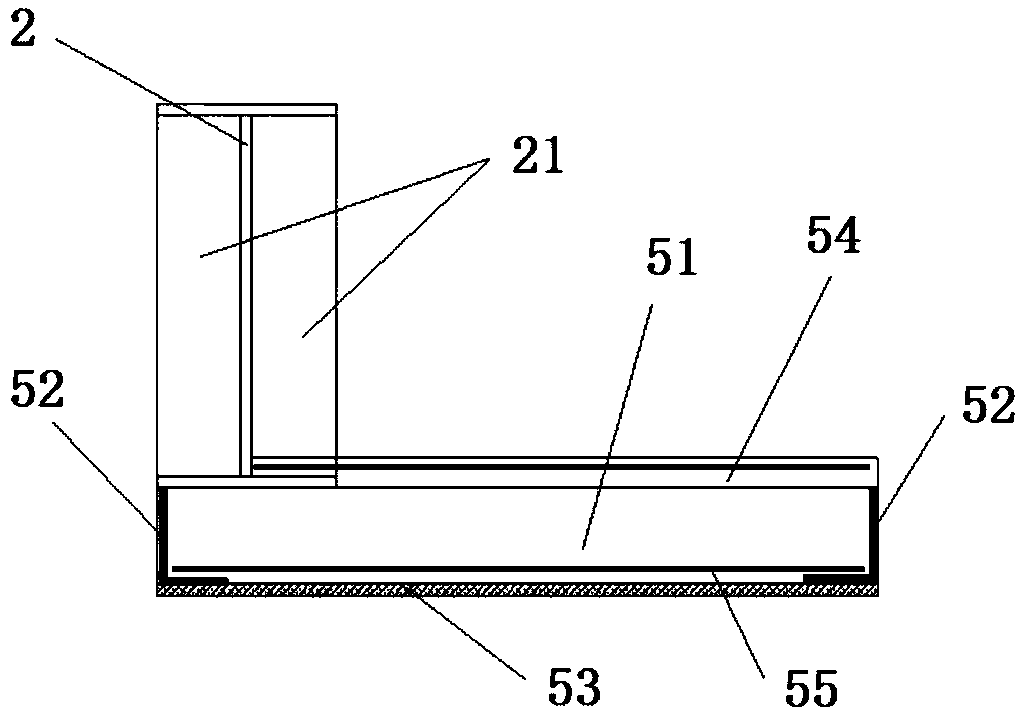

Residential building prefabricated bay-window construction structure and method

PendingCN108824632AImprove molding qualitySolve the problem of easy mold expansionForms/shuttering/falseworksArchitectural engineeringWater seepage

The invention provides a residential building prefabricated bay-window construction structure and method. The residential building prefabricated bay-window construction structure comprises a lower layer PC poured on the exterior side of a lower layer beam slab, a bolt is screwed into the upper end of the lower layer PC in the vertical direction, and the scale height of the top portion of the boltis Hi+0.020. An upper layer component is installed above the lower layer PC in an abutting joint mode, a PE stick is arranged on the interior side of a seam crossing between the lower layer PC and theupper layer component in a pressing mode, and the lower layer PC is fixedly connected with the exterior side of the upper layer component through a connecting piece. An inclined strut is installed between the upper layer component and the lower layer beam slab, the lower end of the inclined strut is fixed to the indoor lower layer beam slab, and the upper end of the inclined strut is fixed to theupper portion of the upper layer component. The problems that a traditional cast-in-place bay-window is prone to rising mould and leaking grout in the construction process, the molding quality is notsteady, and a post-installed window frame edge is subjected to water seepage are solved, and the invention belongs to the technical field of building main body construction.

Owner:CHINA CONSTR FOURTH ENG DIV +1

Prefabricated bay window component, assembly type bay window panel point construction and construction method thereof

PendingCN108316466AEnsure structural safetyFirmly connectedBuilding material handlingReinforced concreteArchitectural engineering

The invention discloses a prefabricated bay window component, an assembly type bay window panel point construction and a construction method thereof. The prefabricated bay window component is a reinforced concrete prefabricated component which is integrally cast and molded. The prefabricated bay window component comprises a first plate part, a second plate part and a third plate part, wherein a lug boss is formed in the upper part of the second part component relative to the lower part and is protruded toward the inner side of the second plate part; the first plate part and the third plate part are connected with the outer side of the second plate part; the first plate part is located above the third plate part; the second plate part is connected with an anchoring part used for connectinga building main body; the first plate part is used as a bay windowsill bottom plate; the upper part of the second plate part is used as a bay windowsill lower wall; the third plate part is used as a bay windowsill top plate. Through the prefabricated bay window component, the assembly type bay window panel pointconstruction and the construction method thereof, the occurrence of long-length specially-shaped prefabricated components in the bay window panel point construction is avoided under the precondition that the structure safety of the assembly type bay window panel point structure is ensured; the difficulties and the costs for producing, transporting and hoisting all the prefabricated components in the assembly type bay window panel point construction can be reduced.

Owner:广东省建工设计院有限公司

Open-web plate bay window

The invention discloses an open-web plate bay window, which solves the problems that the existing residential building bay windows are made of cement slabs, and the technical problems of long production period, high production cost and high work intensity are caused when the production mode is adopted. The open-web plate bay window has the following technical scheme that the open-web plate bay window comprises a bay window top plate, a bay window bottom plate and two upright posts, wherein the bay window top plate and the bay window bottom plate are arranged on a structure wall body; the height between the bay window top plate and the bay window bottom plate is the height of the bay window; and the two upright posts support positions between the bay window top plate and the bay window bottom plate and are fixed on the bay window top plate and the bay window bottom plate.

Owner:YIZHENG ZHONGZHI COMPOSITE MATERIAL PROD

Table

The invention provides a table, and relates to the technical field of furniture, and solves the technical problem of single function of existing tables. The table comprises a tabletop and a supportingdevice connected with the tabletop, the supporting device can be placed or fixed on a bay window platform to support the tabletop, the tabletop comprises at least two secondary panels which hinge with each other or detachably connected with each other, when the secondary panels are extended and assembled, the tabletop is at a using state, when the secondary panels are folded relative to each other, the tabletop is at an accommodation state, each secondary panel at least comprises mirror plate, the mirror plate is provided with at least one mirror, and the mirror plate can be in an upright state in which appearance checking of a user can be conveniently conducted. According to the table, multiple demands of people in daily life can be met under the situation that indoor bay window platformspace is fully utilized.

Owner:广东顺德创喜邦盛家居有限公司

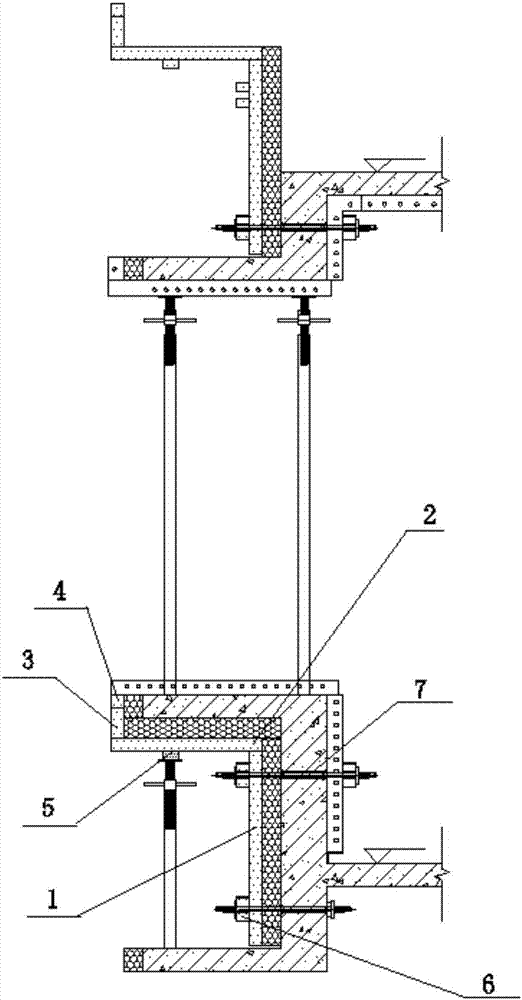

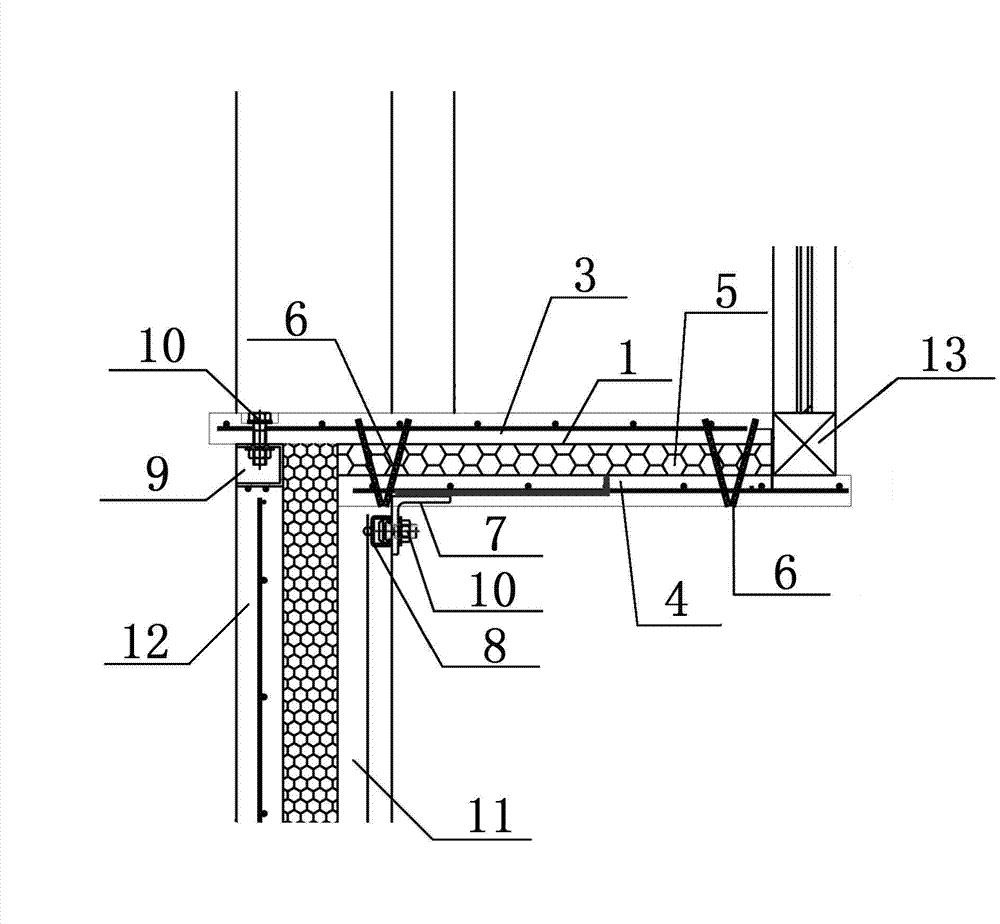

Template support installed at bay window through heat-preservation and template integrated plates and strengthening method thereof

InactiveCN107035143AGuaranteed stabilityNo shiftForms/shuttering/falseworksMarine engineeringSupport point

The invention belongs to the technical field of building construction and discloses a template support installed at a bay window through heat-preservation and template integrated plates and a strengthening method thereof. The template support comprises a plurality of under-window wall body vertical support bodies, outer bay window plate bottom mold horizontal supporting bodies, bay window plate outer side face vertical supporting bodies, top connecting square tubes, upright supporting point connecting square tubes and four opposite-pull screw pull node connecting square tubes. The top ends of the window lower wall body vertical support bodies are perpendicularly connected with one ends of the outer bay window plate bottom mold horizontal supporting bodies, and the other ends of the outer bay window plate bottom mold horizontal supporting bodies are perpendicularly connected with the bottom ends of the bay window plate outer side face vertical supporting bodies; and the top connecting square tubes are fixed to the top ends of the bay window plate outer side face vertical supporting bodies, the upright supporting point connecting square tubes are fixed below the outer bay window plate bottom mold horizontal supporting bodies and located in front of the bay window plate outer side face vertical supporting bodies, and the four opposite-pull screw pull node connecting square tubes are correspondingly fixed to the side faces of the window lower wall body vertical support bodies in pairs. The template support has the advantages of being firm and not out of the position, high in construction speed, not prone to falling off and the like.

Owner:SHANXI CONSTR ENG CO LTD +2

Novel house building bay window cabinet

ActiveCN108552797AAchieve drainageCurtain suspension devicesFurniture partsArchitectural engineeringHouse building

The invention discloses a novel house building bay window cabinet, and relates to the technical field of house building structures. The novel house building bay window cabinet is characterized by comprising a cabinet body, a curtain rod is slidably arranged on the cabinet body, and first stopping assemblies for limiting movement of the curtain rod are arranged in the cabinet body; a downward moving part of which the bottom is a first tip is slidably arranged on the curtain rod, first sliding rods are slidably arranged in the curtain rod, one end of each first sliding rod is in contact with thetip of the downward moving part, and the other end of each first sliding rod is in contact with the corresponding first stopping assembly; when the first sliding rods move towards the first stoppingassemblies, the first stopping assemblies move and do not apply resistance to the curtain rod; the lower end of the curtain rod is fixedly provided with a vertical rod, a second sliding rod is slidably arranged in the cabinet body, a slant groove is formed in the second sliding rod, the lower end of the vertical rod abuts against the slant groove, and a drainage area is arranged on the cabinet body. According to the novel house building bay window cabinet, the curtain rod used for hanging curtain cloth serves as a supporting rod for airing clothes, and the novel house building bay window cabinet has the effect of conveniently airing the clothes.

Owner:温州正城建设有限公司

Detachable assembled bay window mold

The invention discloses a detachable assembled bay window mold, which comprises a mold base, a clamping slot, a fixed plate, hydraulic cylinder blocks, hinges, side plates, hydraulic cylinders, a window mold, a lifting seat, a moving plate, a plate buckle, and a pouring cavity, wherein the rectangular clamping slot is formed in the middle of the mold base, the vertical fixed plate is arranged at the right end of the mold base, the hydraulic cylinder blocks are fixed to the front and the rear of the mold base, and the two side plates are hinged to the front and the rear of the mold base throughthe hinges; the two ends of the hydraulic cylinders are respectively connected to the hydraulic cylinder blocks and the side plates, the window mold is a rectangular body, the window mold is slidablyconnected to the clamping slot, the top of the window mold is provided with the lifting seat, the lifting seat is connected to a lifting device, and the left side of the mold base is provided with the moving plate. The moving plate of the invention is convenient to move, and the side plates can be rotated to facilitate the lifting of the bay window by the lifting device.

Owner:山东连云山建筑科技有限公司

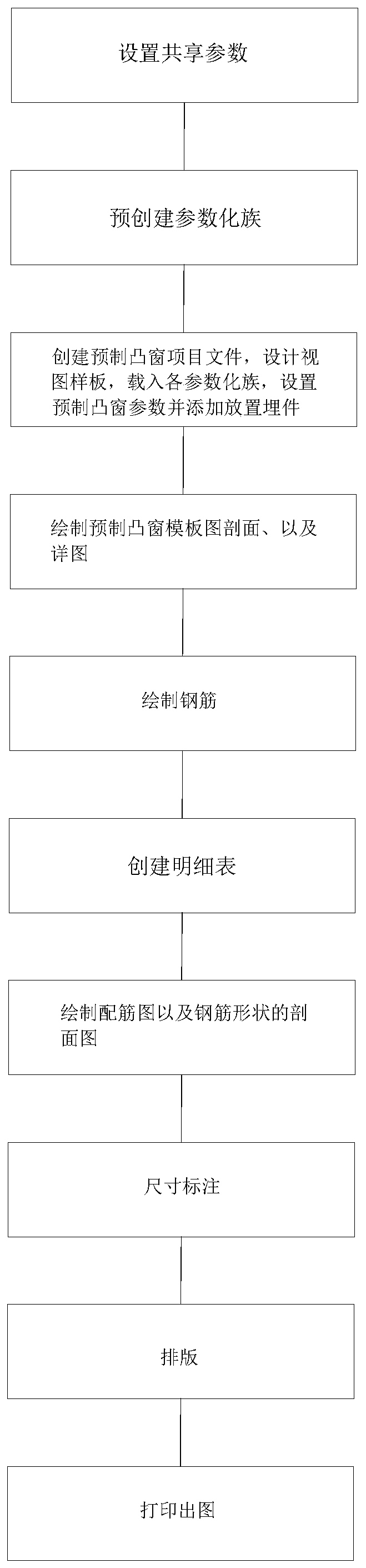

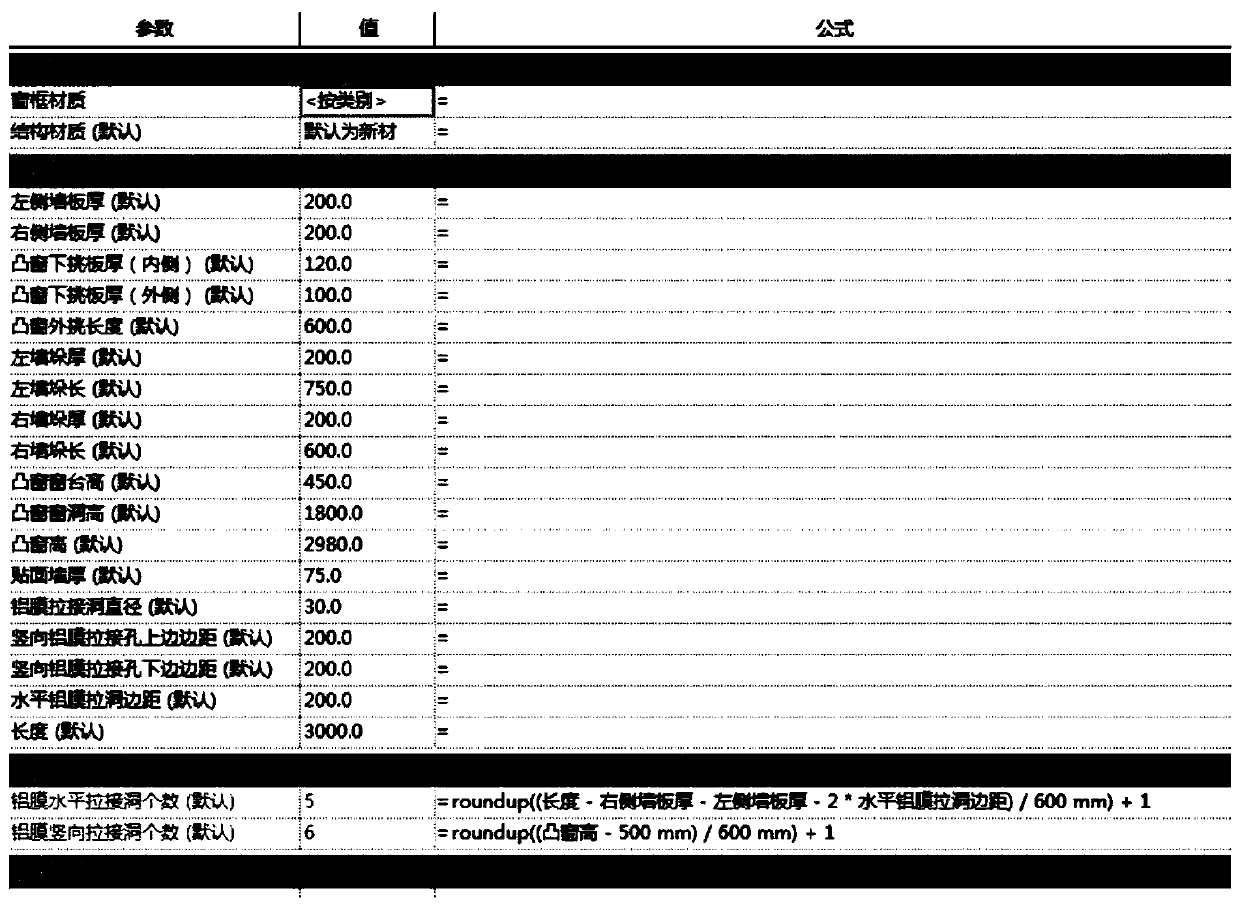

Rapid drawing method for prefabricating bay window detail drawing based on Revit software

InactiveCN110716701AReduce error rateReduce omissionsGeometric CADData processing applicationsProfile diagramFile design

The invention discloses a rapid drawing method for prefabricating a bay window detail drawing based on Revit software. The method sequentially comprises the following steps: S1, setting shared parameters; S2, pre-creating a parameterized family; S3, creating a prefabricated bay window project file, designing a view template, loading each parameterized family, setting prefabricated bay window parameters, and adding placement embedded parts; S4, drawing a prefabricated bay window template drawing section and a detail drawing; S5, drawing reinforcing steel bars; s6, creating a detail list; S7, drawing a reinforcement diagram and a profile diagram of the shape of the steel bar; S8, performing size marking; S9, performing typesetting; S10, printing a drawing. According to the rapid drawing method for prefabricating a bay window detail drawing based on Revit software, modification is linked immediately, information extraction is simple and convenient, data statistics is efficient, and the drawing speed is high.

Owner:周发喜

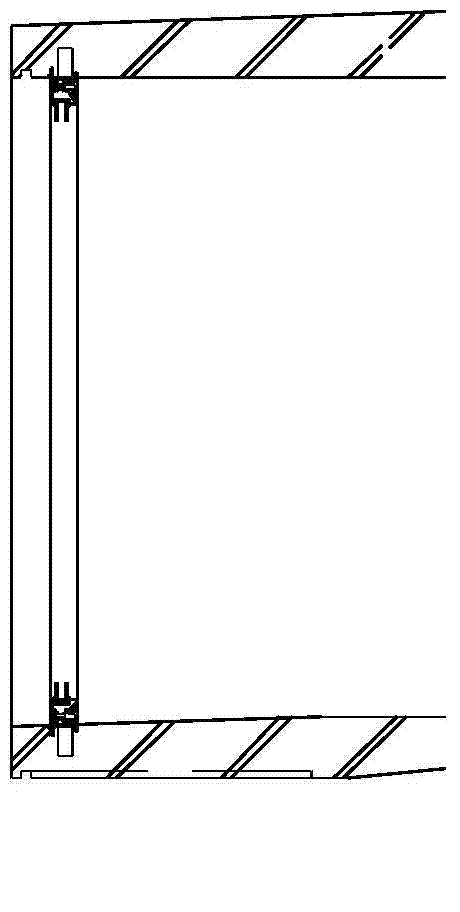

Prefabricated bay window and installation method

InactiveCN106193902ASimple structural designImprove applicabilityFrame fasteningWindow/door framesEavesBay window

The invention discloses a prefabricated bay window. The prefabricated bay window comprises a window body and a window frame. The window frame is arranged at the outer end of the interior of the window body. Slopes extending towards the outer end from the inner end of the window body are arranged on the upper surfaces of the upper eave and the lower eave of the window body. According to the prefabricated bay window, through the simple slope design, the prefabricated window body can be conveniently demoulded, rainwater can conveniently flow down along the slopes, and the waterproof performance is improved with the combination of a waterproof trough; besides, the joint of the window body and a wall can be conveniently filled with caulking mortar, and compactness and heat preservation are achieved; through the simple structural design, the construction installation technology is simplified, the construction difficulty is lowered, the construction time is shortened, the construction efficiency is improved, and the construction safety is ensured; furthermore, materials consumed in the prefabricating and installing processes of the window body are greatly reduced, and the prefabricated bay window is extremely high in applicability.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

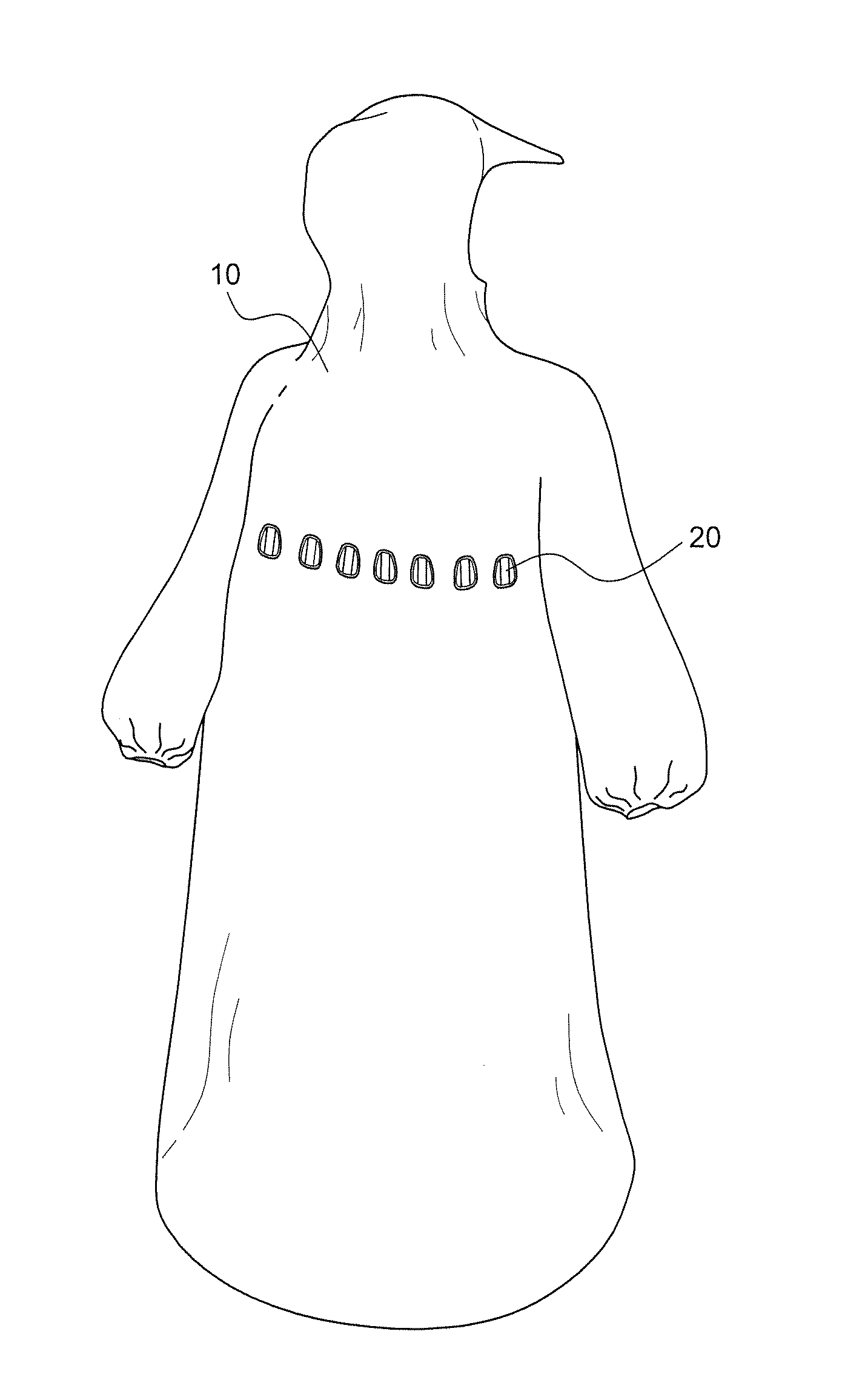

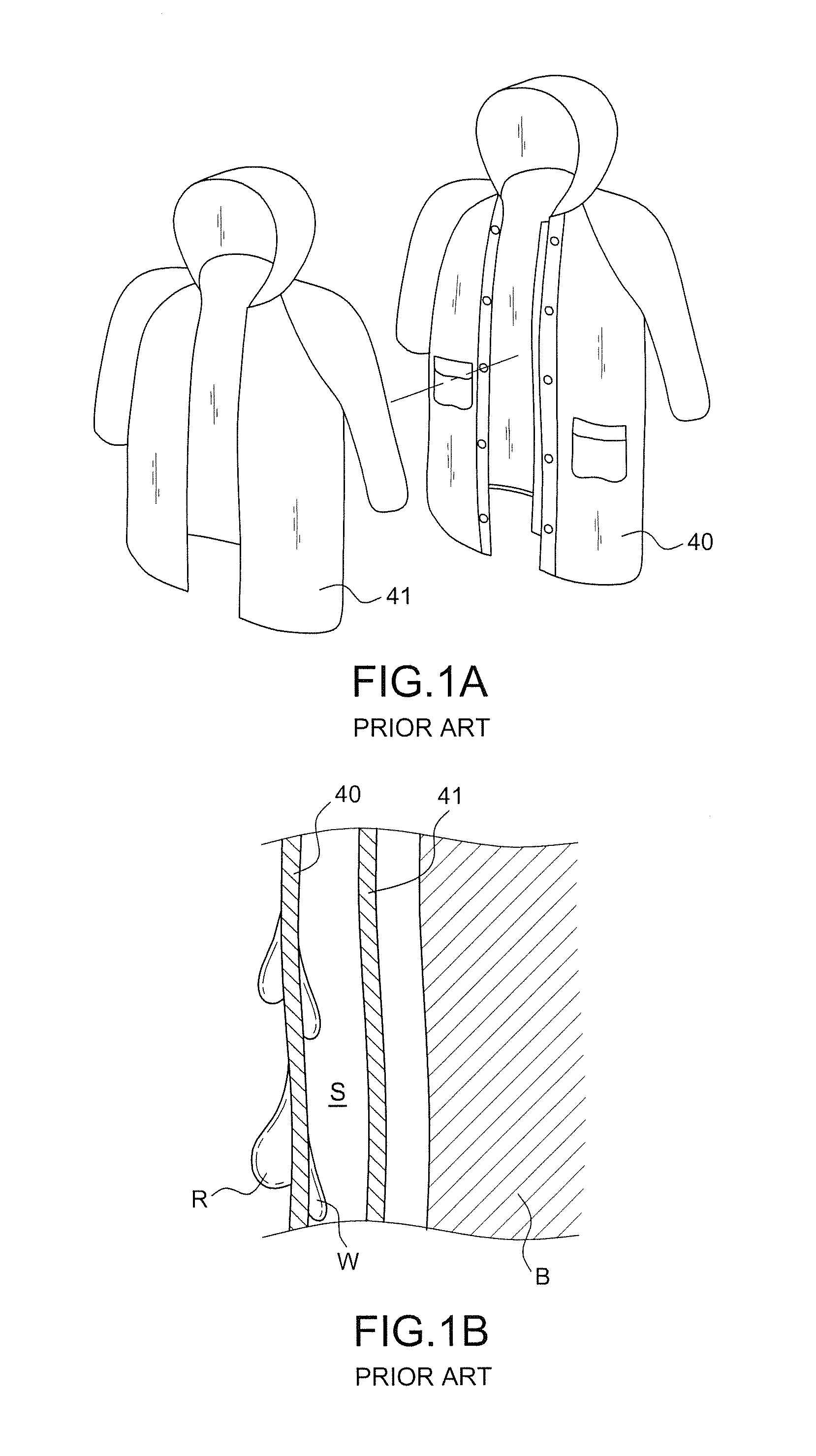

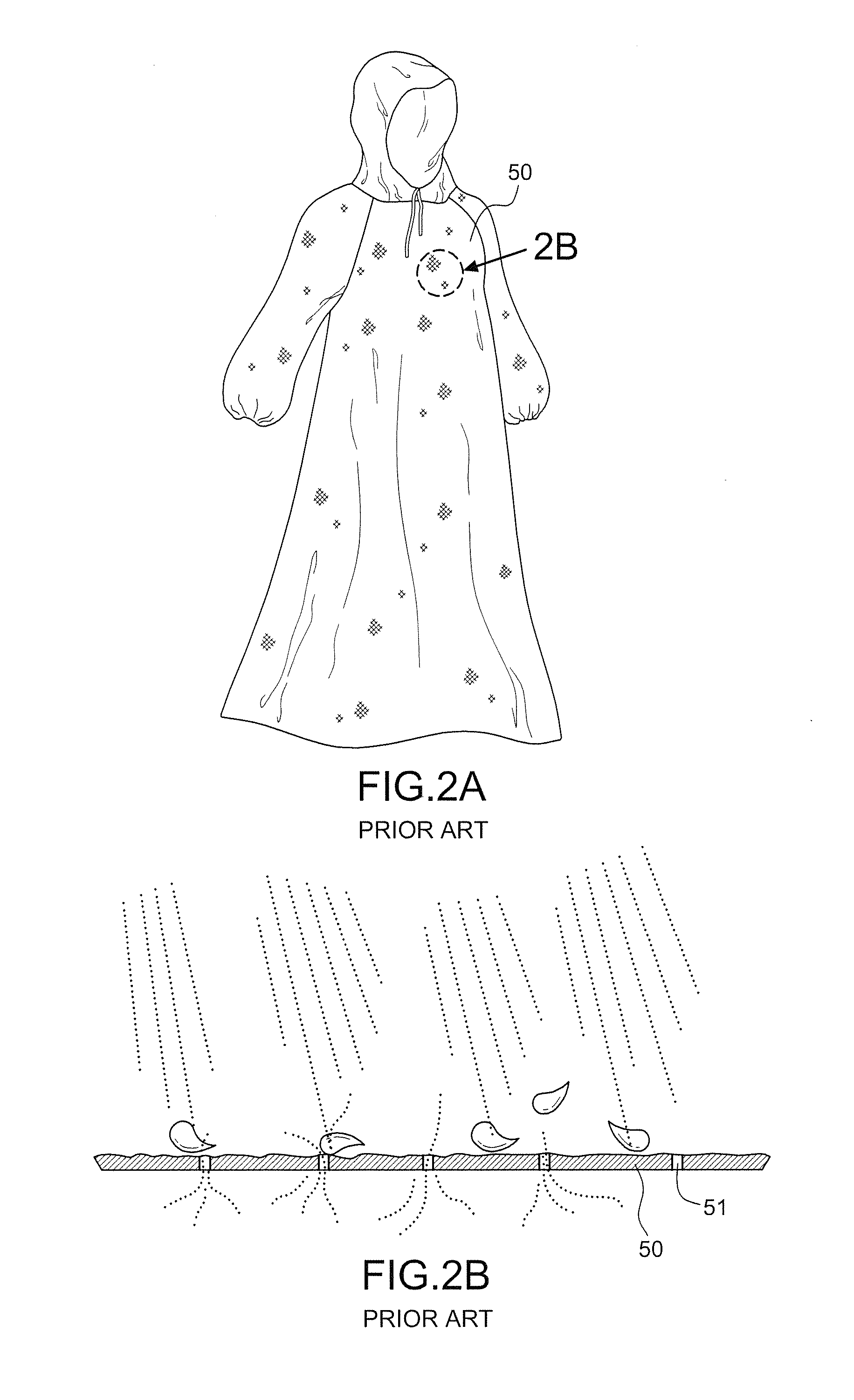

Ventilating raincoat with bay windows

InactiveUS20140020150A1High strengthSolve the lack of flexibilityOvergarmentsEngineeringUltimate tensile strength

A ventilating raincoat with bay windows, comprising: a raincoat having a plurality of vent units arranged at a predetermined position thereof; and a plurality of bay windows arranged at an external surface of each vent unit, and having a top edge, two side edges extended downward from both sides of the top edge and a cover surface arranged between the top edge and the two side edges to form a hollow cover body with a downward opening between the raincoat and the bay window. Moreover, the top edge and the two side edges of the bay window form an inverted U-shaped structure made of a flexible and elastic material for the cover surface to have a support strength; such that the cover surface does not deform, remaining a ventilating path between an inner edge of the hollow cover body and the surface of the raincoat.

Owner:YANG CHI CHIH

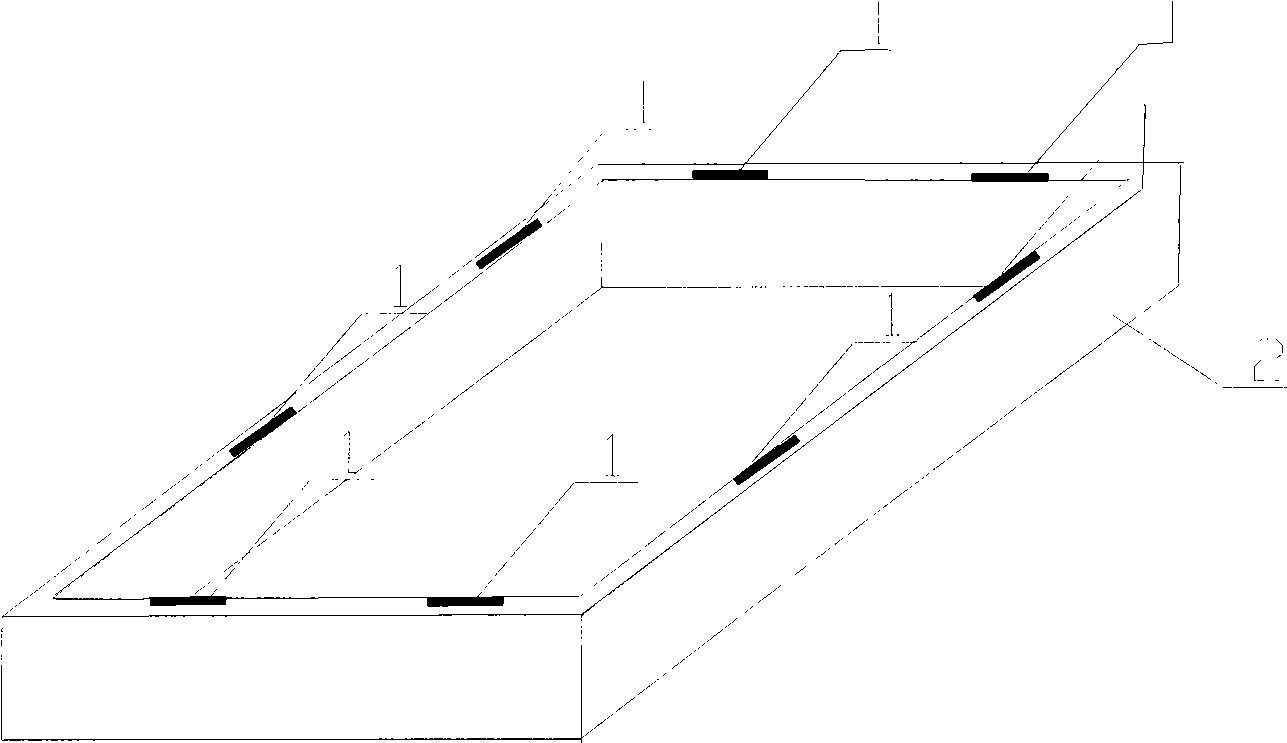

Support platform utilizing bay window to construct and construction method of bay window

InactiveCN105040975AEasy to adjustReduce in quantityForms/shuttering/falseworksBuilding material handlingArchitectural engineeringSupport plane

The invention discloses a support platform utilizing a bay window to construct and a construction method of the bay window. The support platform utilizing the bay window to construct comprises a support frame and support rods, wherein the support frame is of a rectangle, comprises two long rods and two short rods which are connected, and is provided with mounting holes, the support rods comprise first rod segments, middle rod segments and second rod segments, the first, the middle and the second rod segments are screw rods, the first rod segments and the middle rod segments are connected through sleeves, the second rod segments and the middle rod segments are connected through the sleeves, and the numbers of the support rods and the mounting holes are equal. The middle rod segments are penetrated into the mounting holes of the support frame when being used, and the support rods and the support frame are fixed through nuts. The support platform utilizing the bay window to construct and the construction method of the bay window achieve to cast bay window upper bay plates and lower bay plates at one time, are less in dosage of required templates during the construction process and simple in construction steps, and reduce cost input of secondary and multiple casting construction of bay windows. Furthermore, the support platform utilizing the bay window to construct and the construction method of the bay window prevent the hidden danger that concrete interfaces which are casted for many times are easy to cause external structure surfaces to leak and cause outer walls to leak.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

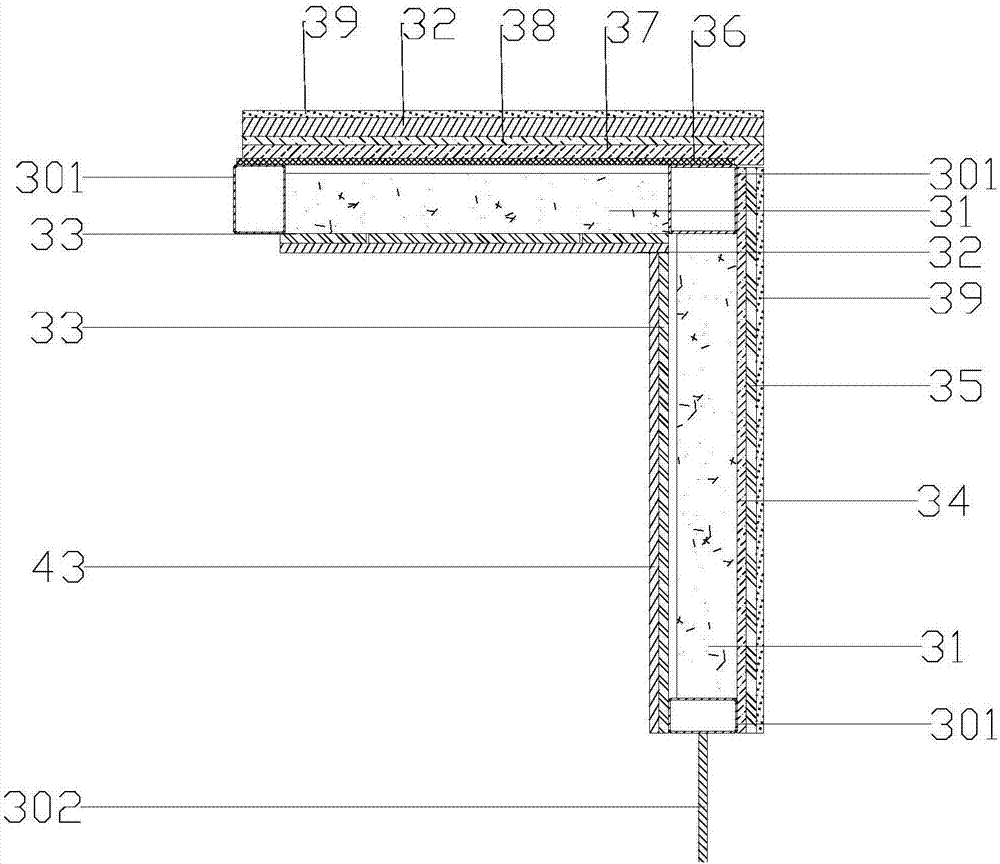

Embedded bay window

ActiveCN106869679AWith sound absorption and shockproofWaterproofSills/thresholdWater leakageVertical plane

The invention discloses an embedded bay window. The embedded bay window comprises a wall body and a window body. The window body is embedded in the wall body. The embedded bay window further comprises window sill connected with the lower end of the wall body. The section, in the length direction, of the window sill is in a right-angled shape. The horizontal plane of the window sill is connected with the lower end of the wall body, and the vertical plane of the window sill is connected with the floor. The window sill comprises a steel frame, and the section of the steel frame is in a right-angled shape. A lightweight concrete layer is arranged inside the steel frame. A cement pressure plate is arranged over the horizontal plane of the steel frame. A cement pressure batten and a cement pressure plate are sequentially arranged under the horizontal plane of the steel frame from inside to outside. A magnesium oxide board and a gypsum board are sequentially arranged on the side, facing indoors, of the vertical plane of the steel frame form inside to outside. A cement pressure batten and a cement pressure plate are sequentially arranged on the side, facing outdoors, of the vertical plane of the steel frame from inside to outside. The embedded bay window has the advantages that since the bay window is concave indoors, water leakage of the bay window can be effectively prevented; and since the main body structure of the window sill is the steel frame filled with the lightweight concrete layer, manufacturing is easy, and cost is low.

Owner:BIOMEDY LIMITED

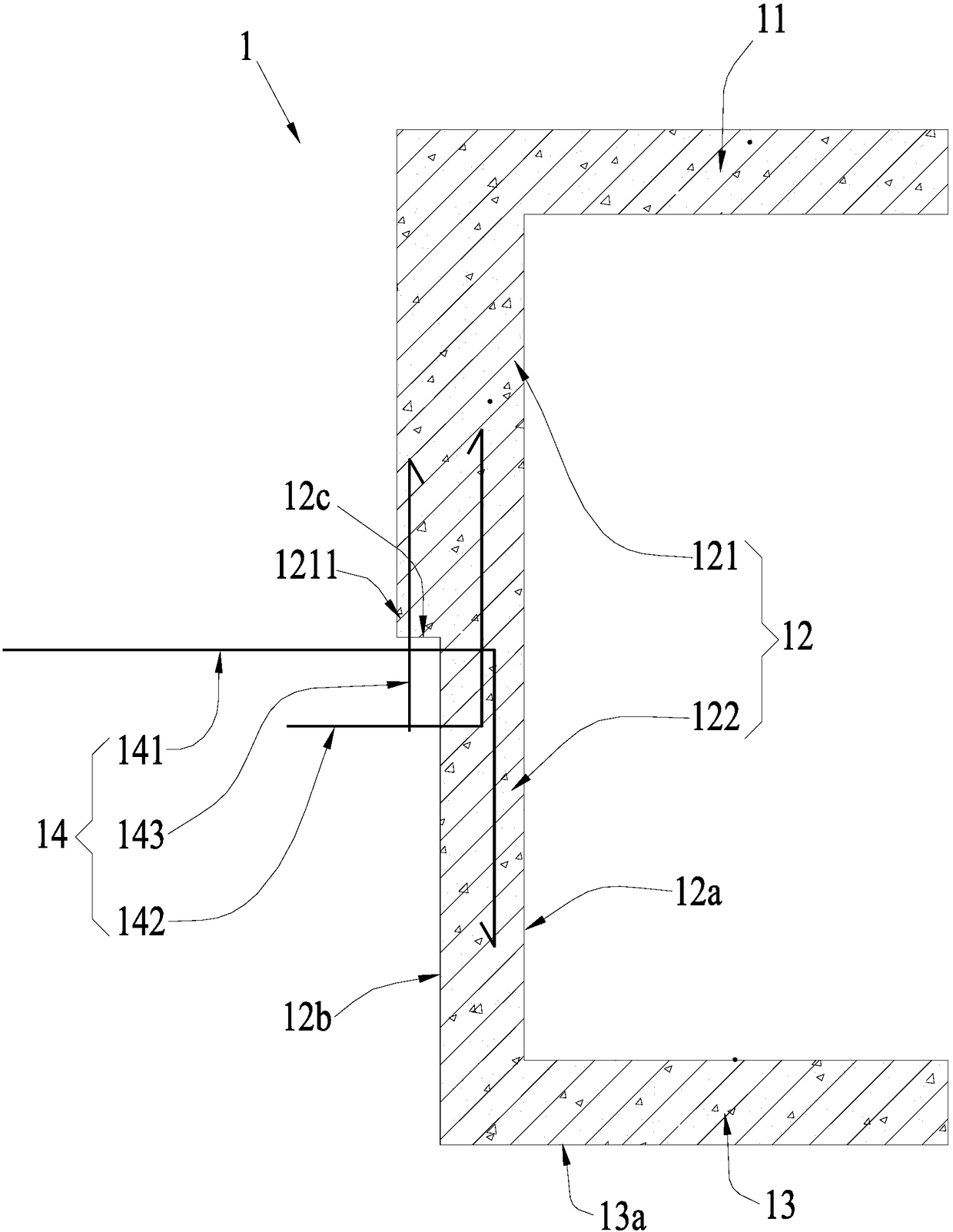

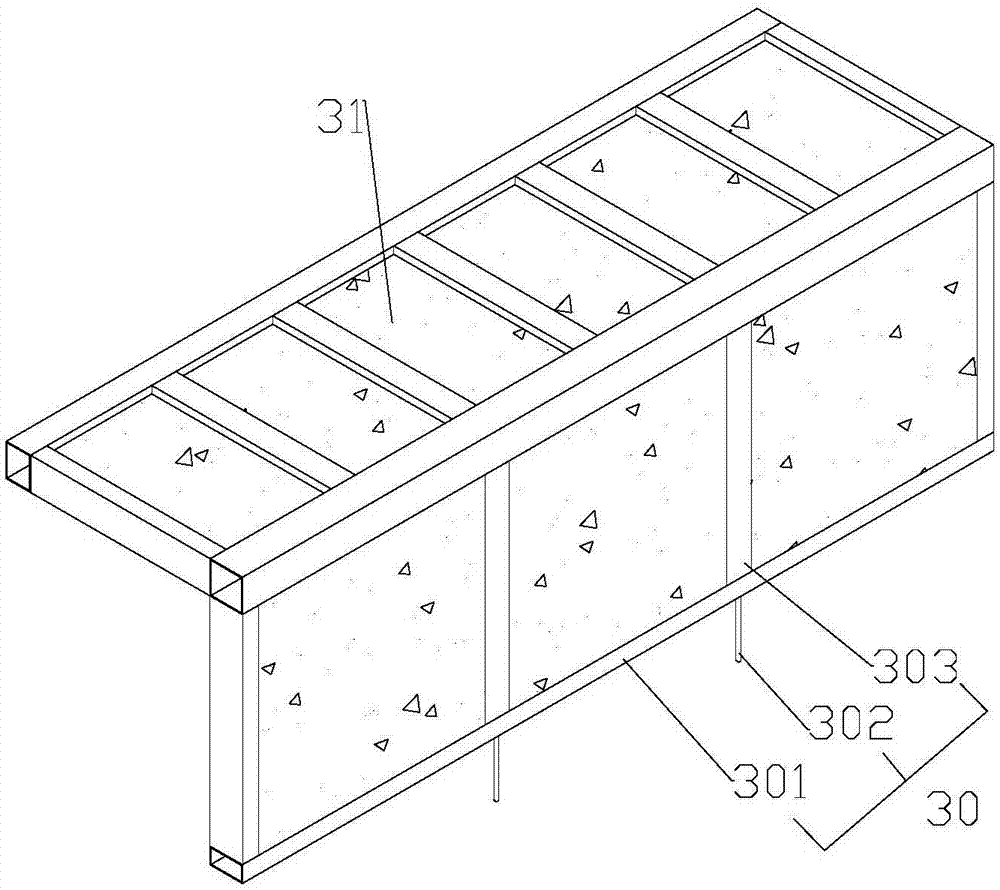

Integrally-prefabricated U-shaped bay window component and fabricated bay window joint structure and construction method thereof

PendingCN108708452AGuaranteed anchoringEnsure structural safetyFloorsBalconiesPre embeddingUpper floor

The invention discloses an integrally-prefabricated U-shaped bay window component and a fabricated bay window joint structure and a construction method thereof. The integrally-prefabricated U-shaped bay window component is formed by first, second and third plates, the upper portion of the second plate forms a boss relative to the lower portion, the boss projects towards the inner side of the second plate, a plurality of grouting sleeves are pre-embedded into the boss, an operating notch is reserved corresponding to each group of the grouting sleeves, and the lower ends of each group of the grouting sleeves extends downwards from the lower end face of the boss. The first plate serves as a bay window bottom plate of an upper floor of two adjacent floors; the upper portion of the second plateserves as a bay window lower wall of the upper floor of the two adjacent floors; the third plate serves as a bay window top plate of the lower floor of the two adjacent floors. On the premise that structure safety of the fabricated bay window joint structure is guaranteed, long special-shaped prefabricated components of bay window joints are avoided, and accordingly production, transporting and hoisting difficulty and cost of each prefabricated part in the fabricated bay window joint structure can be reduced.

Owner:广东省建工设计院有限公司

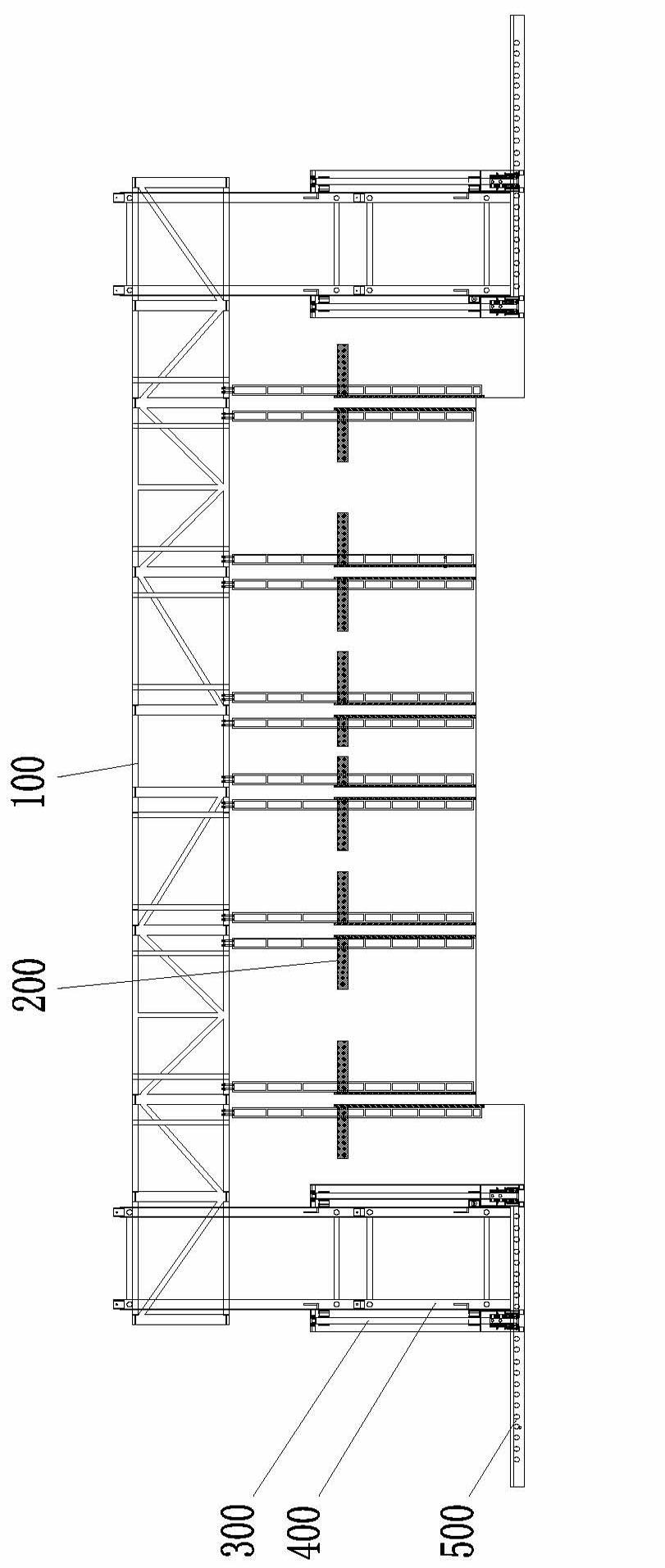

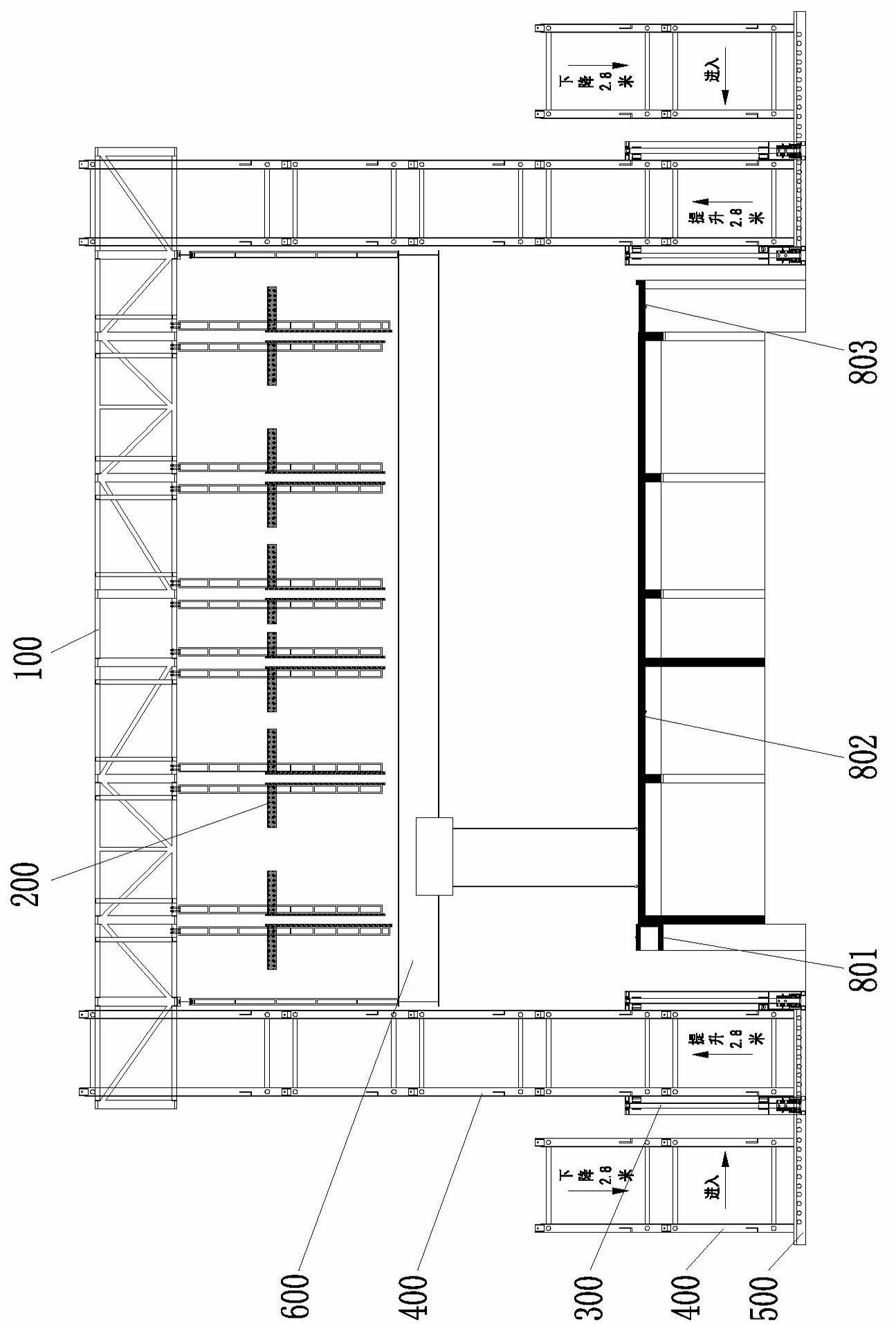

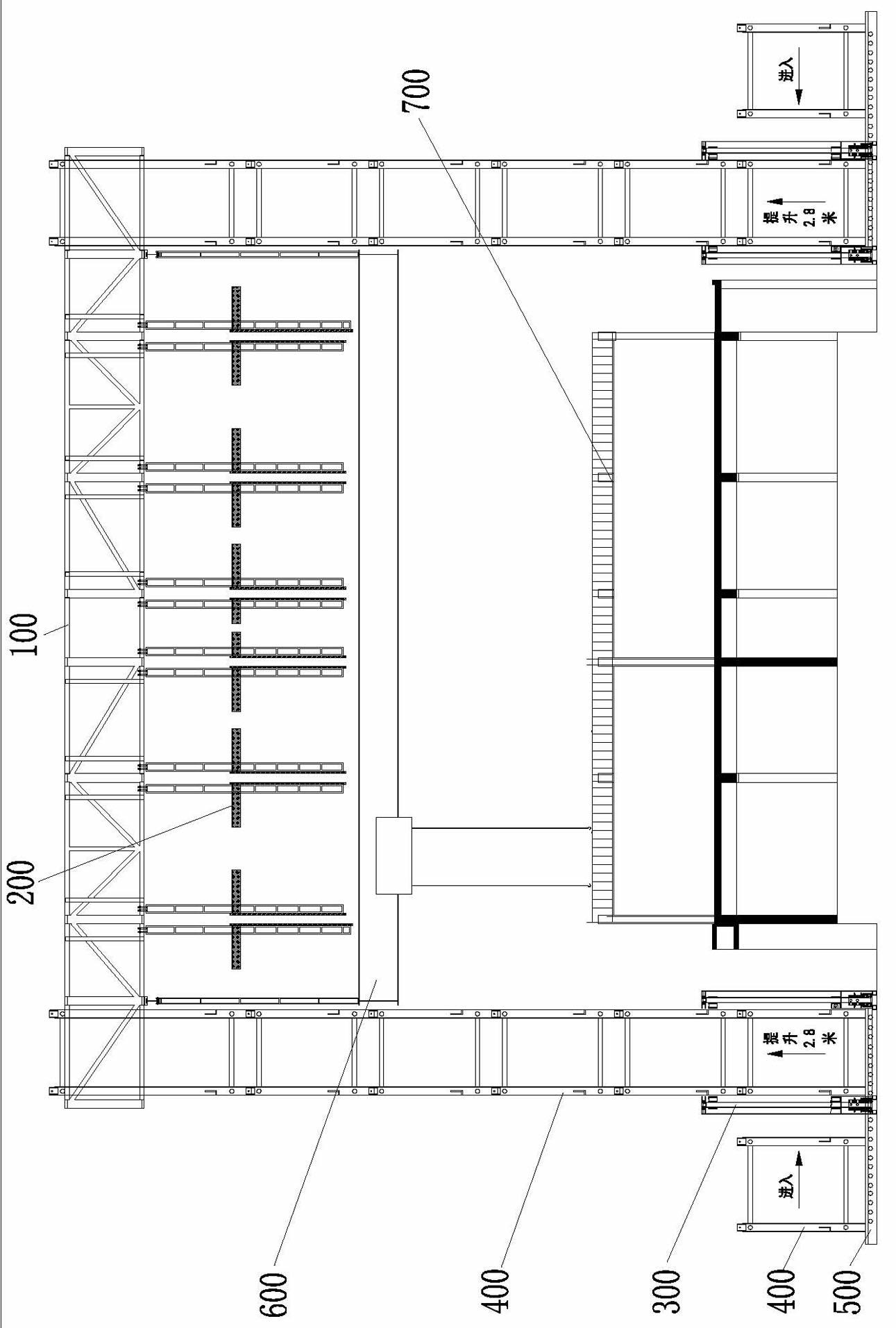

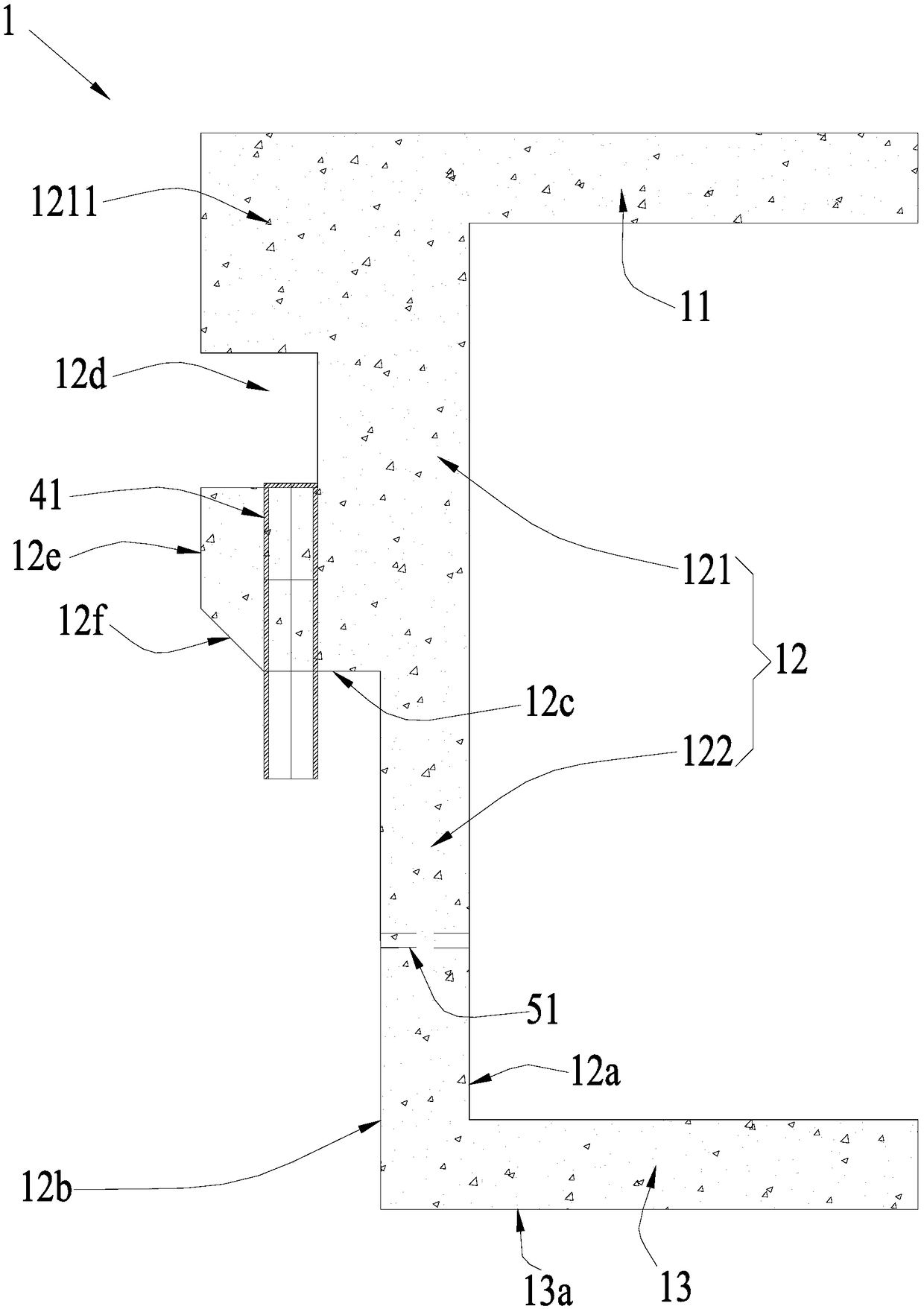

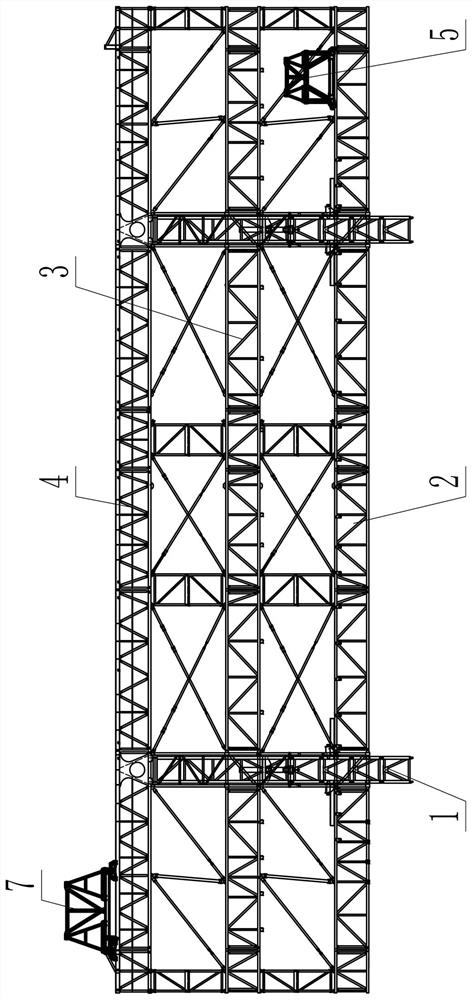

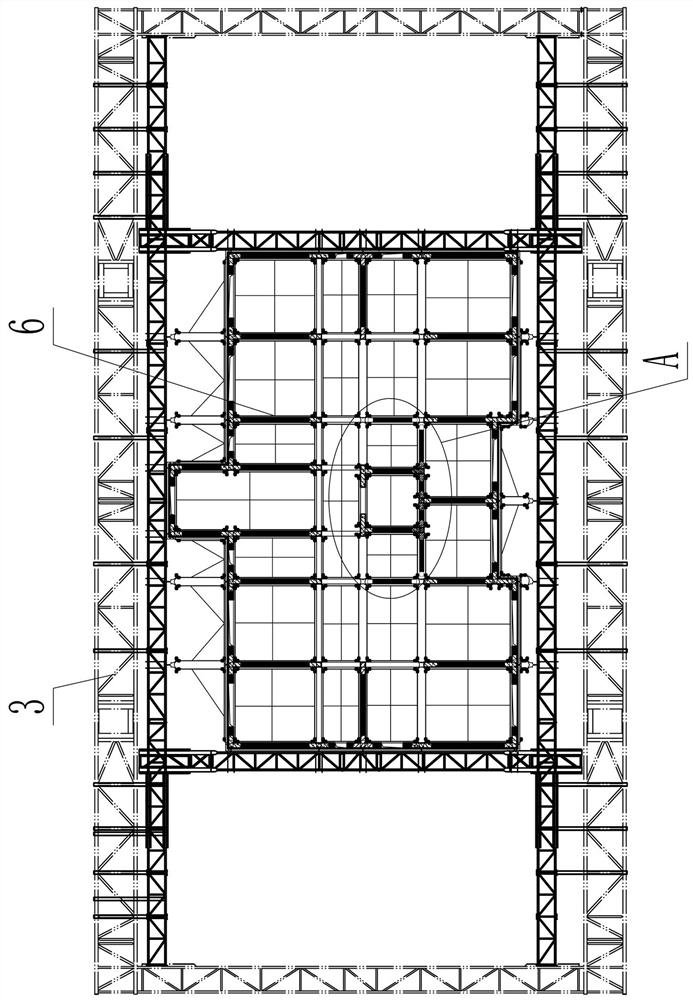

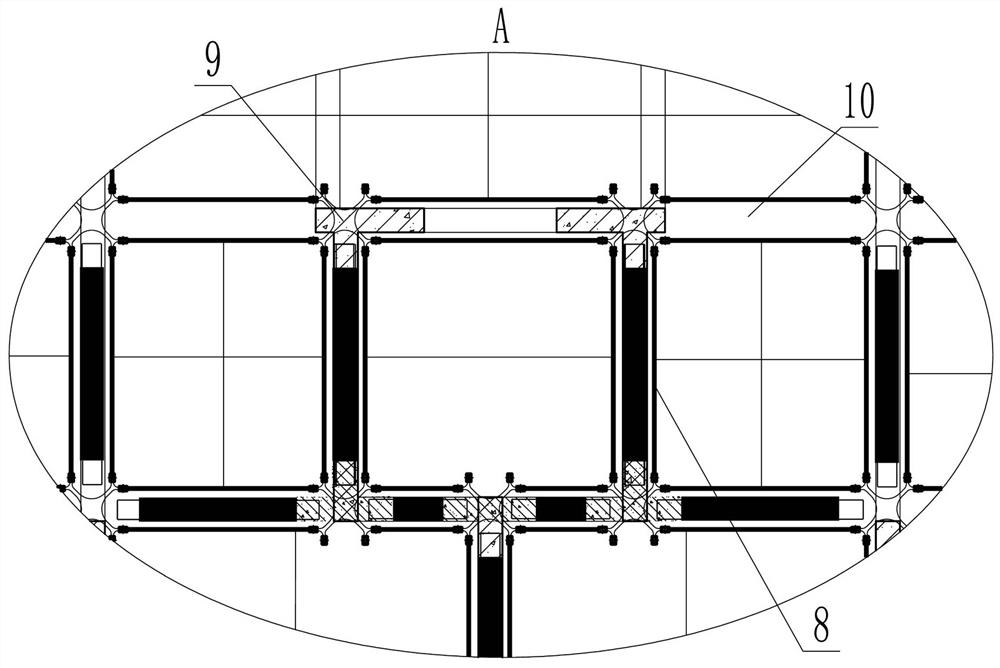

Fabricated building component hoisting comprehensive equipment and construction method thereof

ActiveCN112267692APrecise liftingPrecise positioningBuilding material handlingCranesFloor slabTrackway

The invention relates to fabricated building component hoisting comprehensive equipment and a construction method thereof. The problems that in the fabricated building construction process, the construction efficiency is low, and the in-place difficulty is large are effectively solved. According to the technical scheme, the equipment comprises a special hoisting platform with a steel structure, the special hoisting platform comprises a a first track layer, a second track layer and a third track layer which are arranged from bottom to top, a horizontal prefabricated part hoisting device is arranged on the first track layer and used for hoisting horizontal prefabricated floors, balconies, air conditioner plates and the like, a vertical prefabricated part temporary positioning support systemis arranged on the second track layer and used for temporarily clamping a vertical prefabricated part and temporarily positioning and adjusting the vertical prefabricated part, and a vertical prefabricated part and stair hoisting device is arranged on the third track layer and used for hoisting vertical prefabricated parts such as wallboards and bay windows and stairs. According to the equipment,the hoisting, mounting and positioning of the vertical components are accurate, and the working efficiency and safety are greatly improved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

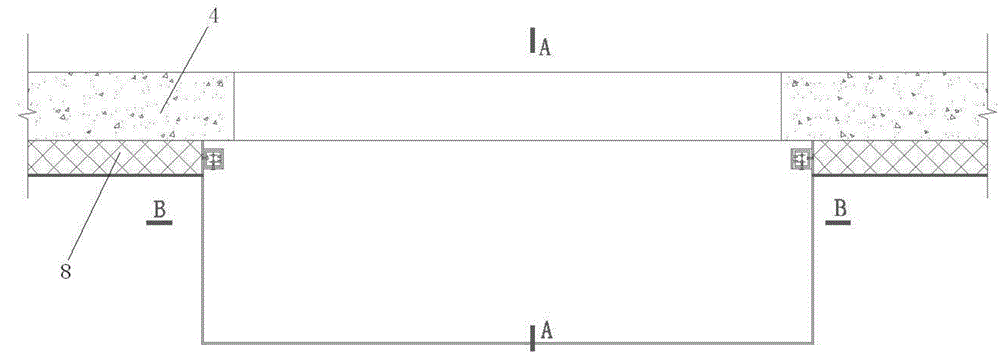

Assembling type bay window structure

PendingCN110195560AThere will be no problem of not being able to install the glass windowShorten the construction periodVentilation arrangementSills/thresholdIndustrial technologyGlass window

The invention discloses an assembling type bay window structure and relates to the technical field of the building industry. The assembling type bay window structure comprises a bay window frame formed by connecting transverse rods and vertical rods which are crossed longitudinally and transversely; an upper table plate and a lower table plate are installed on the bay window frame, and are horizontally arranged, and an upper area, a middle area and a lower area are divided in the bay window frame; an air conditioner outdoor unit can be placed in the upper area and the lower area, and the outersides of the upper area and the lower area are each provided with a blind window; a glass window is installed on the outer side of the middle area; the bay window frame is provided with a connectionstructure used for anchoring the bay window frame onto a room beam; after the bay window frame is anchored to the room beam, the upper table plate is lower than a ceiling of a room, and the lower table plate is at least higher than a floor of the room by 0.35 m. The bay window structure is very easy and fast to install, and the construction period can be shortened easily.

Owner:衡阳市金铭环境科技有限公司

Heat-bridge-insulation bay window

ActiveCN103089113AImprove transportation efficiencyPrevent intrusionSills/thresholdHeat proofingHeat transmissionEmbedded system

A heat-bridge-insulation bay window comprises a bay-window upper window board and a bay-window lower window board. The bay-window upper window board and the bay-window lower window board are laminboards with thermal insulated materials. Inner boards and outer boards of the laminboards are obliquely connected in a bidirectional mode by nonmetal complex fiber reinforcement. Angle steel connectors are embedded in the bay-window upper window boards and the bay-window lower window boards. Connecting grooves and embedded steel boxes are respectively embedded in an outer sandwiched heat-insulation wall panel and an inner sandwiched heat-insulation wall panel. The bay-window upper window boards and the bay-window lower window boards are respectively fixedly connected with the embedded connecting grooves of the outer sandwiched heat-insulation wall panel and the embedded steel boxes of the inner sandwiched heat-insulation wall panel through ultra-strong connecting bolts. The heat-bridge-insulation bay window can effectively insulate heat transmission from outside to achieve heat preservation in an energy-saving way, factory-like mass manufacturing and field assembly can be realized, construction is convenient, and manufacturing efficiency is high.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

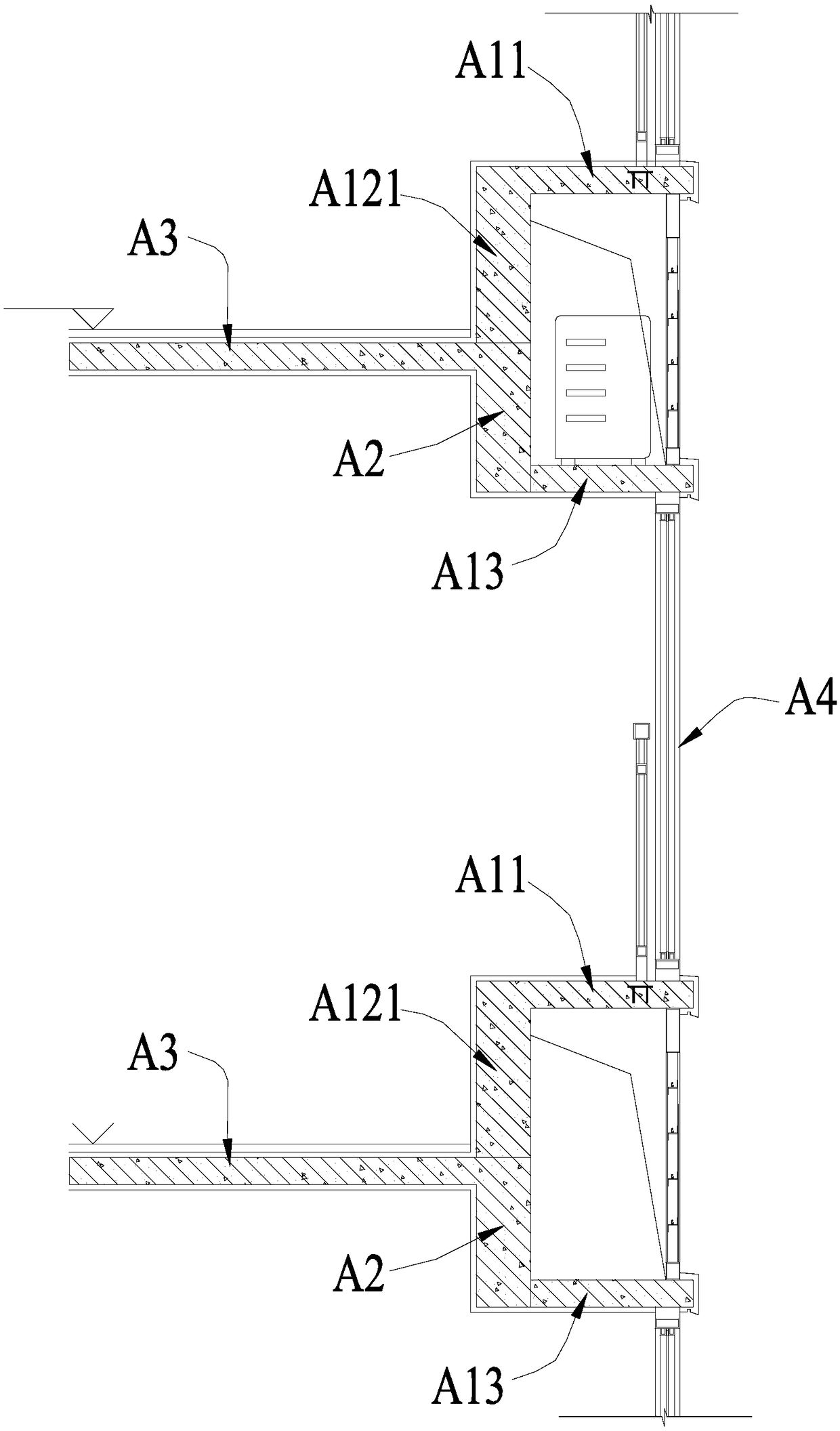

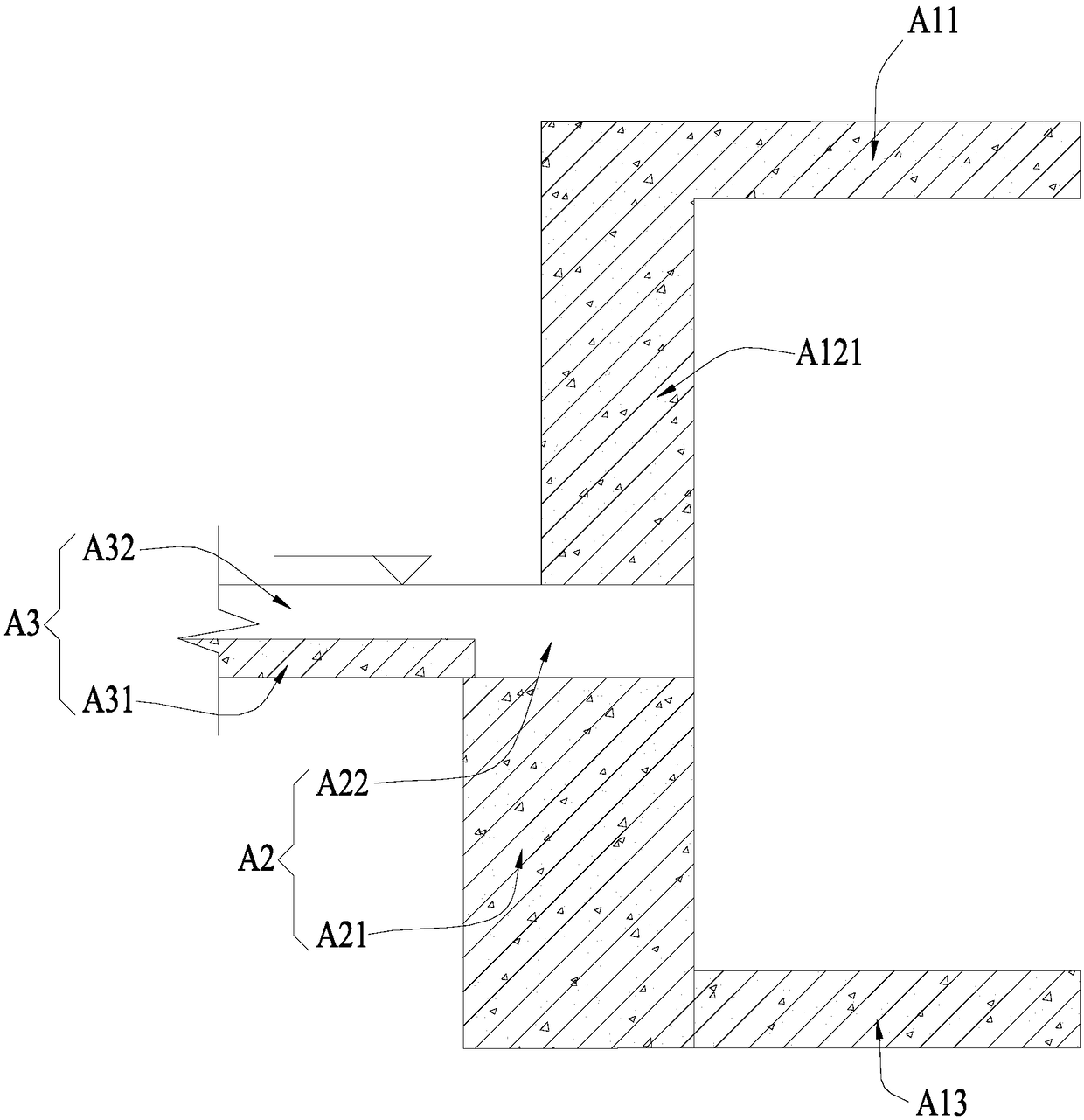

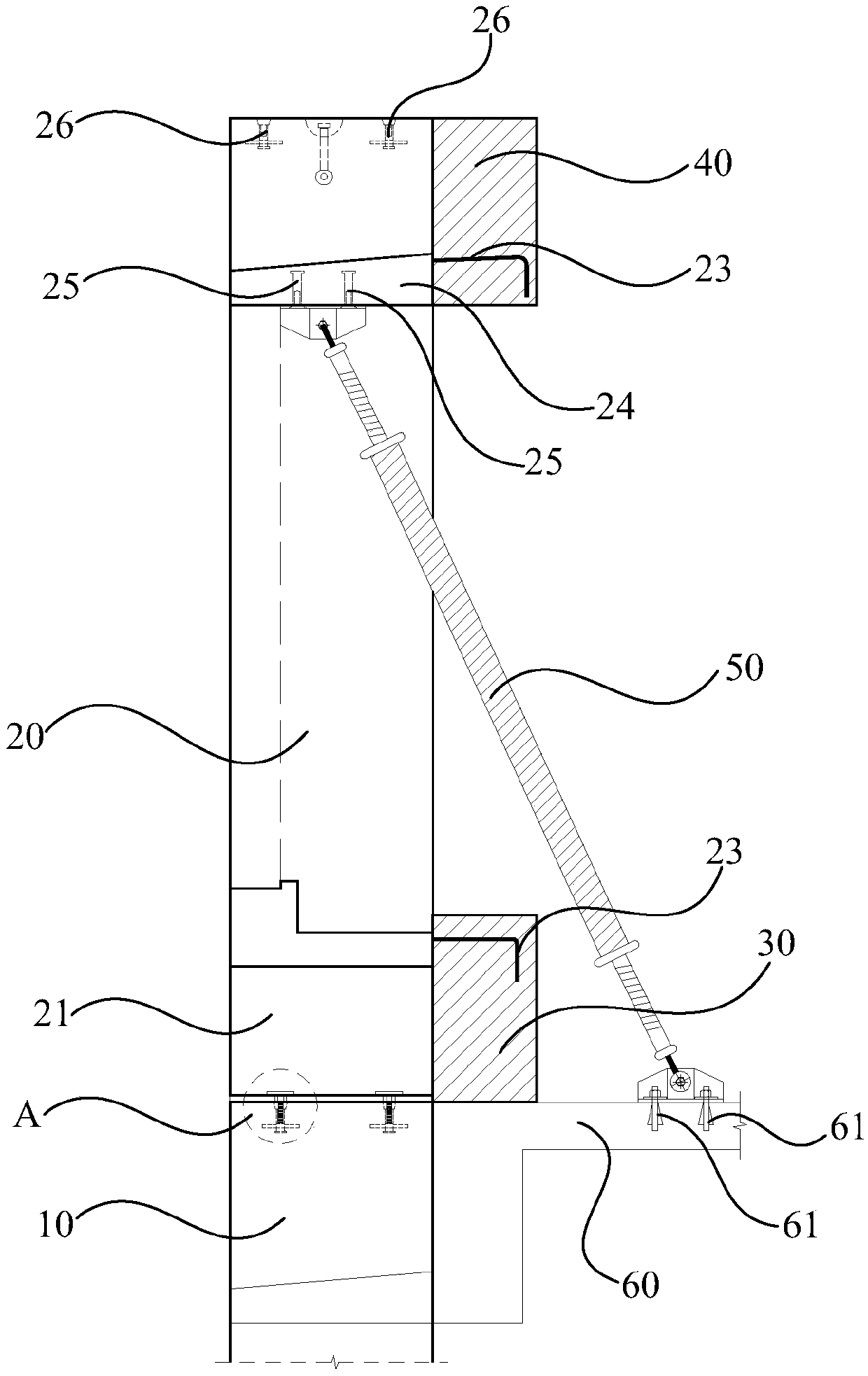

Installation method of prefabricated bay window, prefabricated bay window and house building

The invention relates to an installation method of a prefabricated bay window, the prefabricated bay window and a house building. The installation method comprises the following steps that after a lower prefabricated bay window body is installed, two side plates of a current-layer prefabricated bay window body are aligned and installed to two side plates of the lower prefabricated bay window bodyrespectively; a supporting device supports and fixes the current-layer prefabricated bay window body; connecting reinforcing steel bars reserved at the bottom of the current-layer prefabricated bay window body and current-layer reverse beam reinforcing steel bars are bound and poured with concrete to form a reverse beam; connecting reinforcing steel bars reserved at the top of the current-layer prefabricated bay window body and current-layer beam reinforcing steel bars are bound and poured with concrete to form a beam; after the beam and the reverse beam are poured and formed, the supporting device is disassembled. By means of the installation method of the prefabricated bay window, supporting pieces abut against and support the lower portions of the plate surfaces of pre-embedded rigid plates, the pre-embedded rigid plates and the supporting pieces cannot be deformed, and therefore the high installation flatness of the prefabricated bay window can be ensured.

Owner:GUANGDONG LIANCHENG RESIDENTIAL EQUIP INFORMATION TECH CO LTD

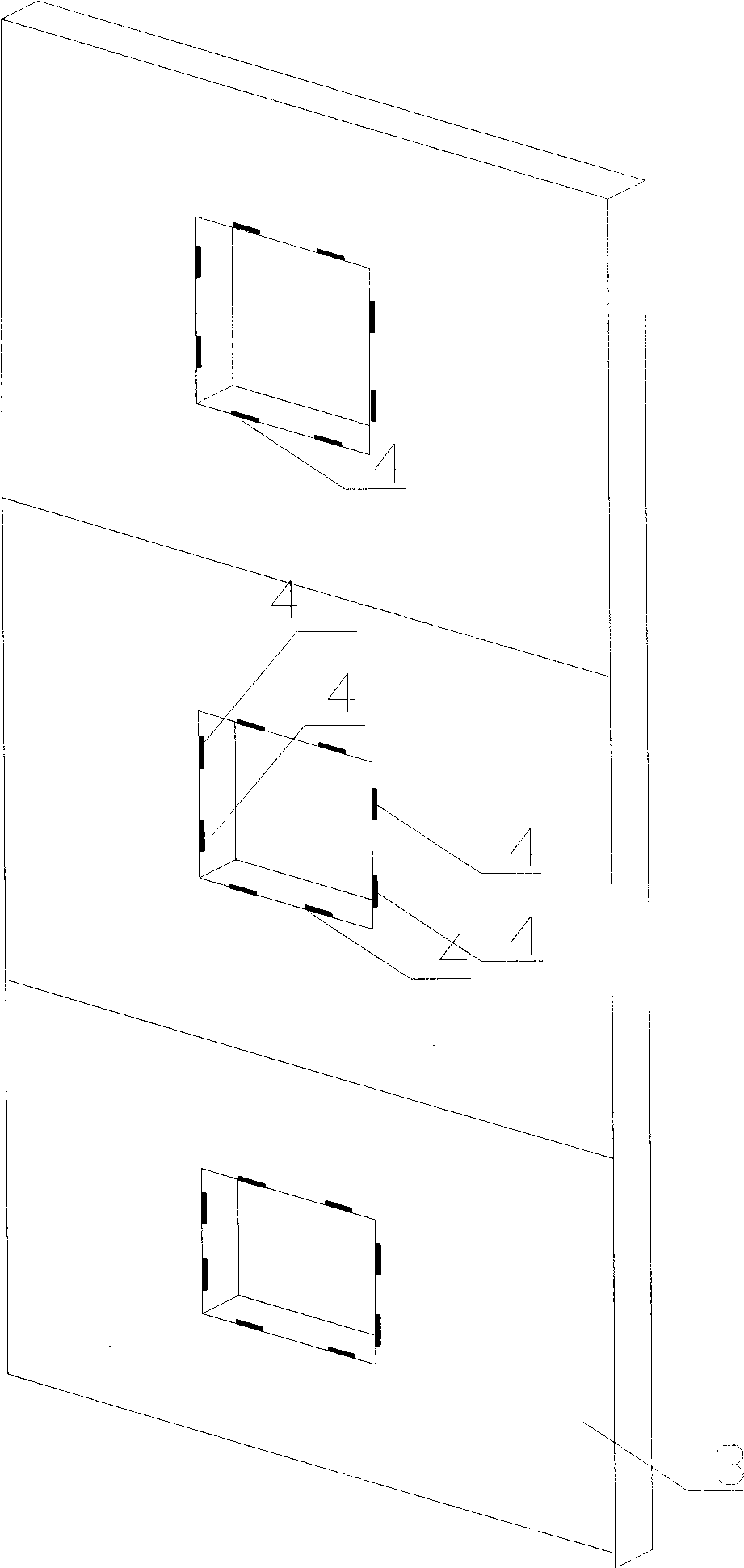

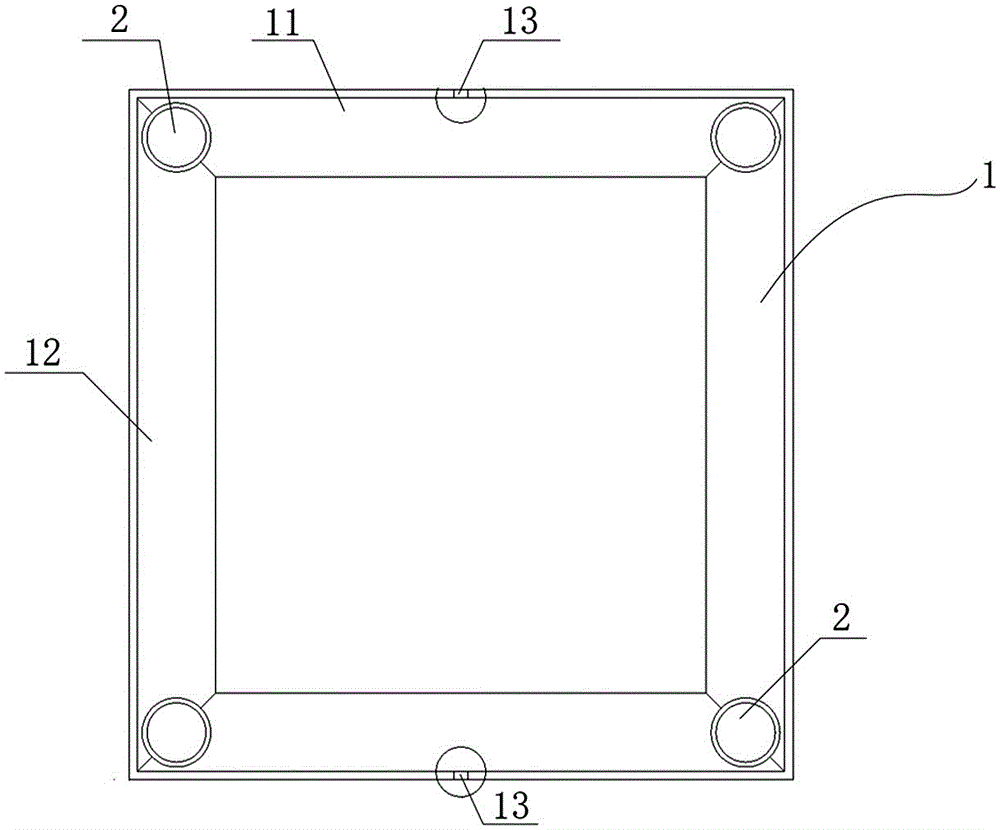

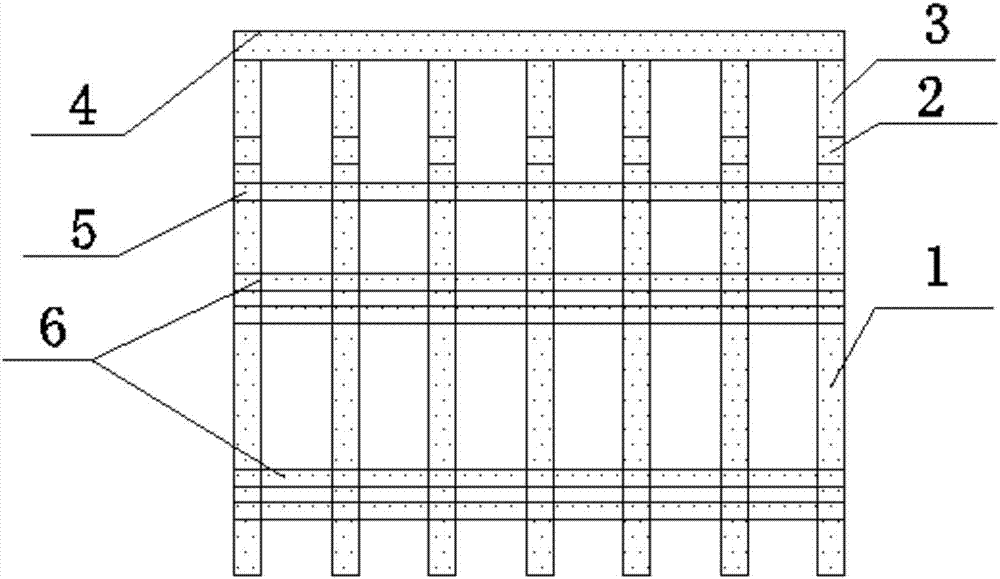

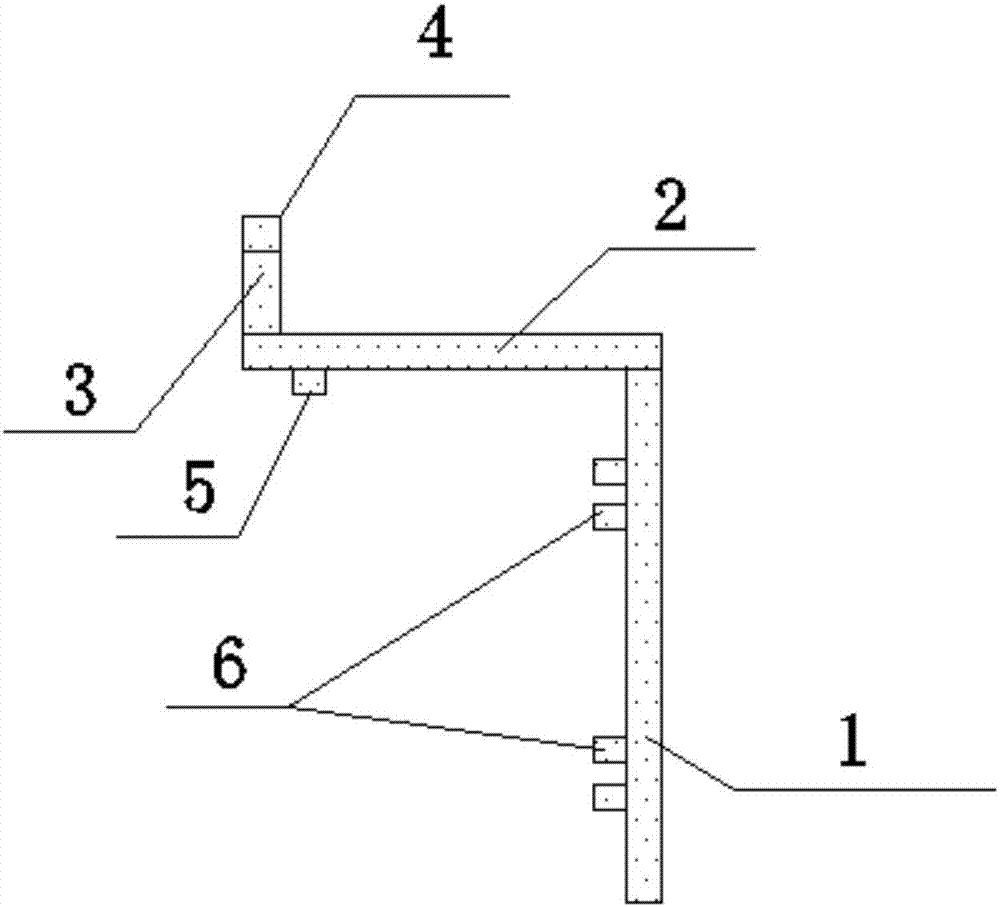

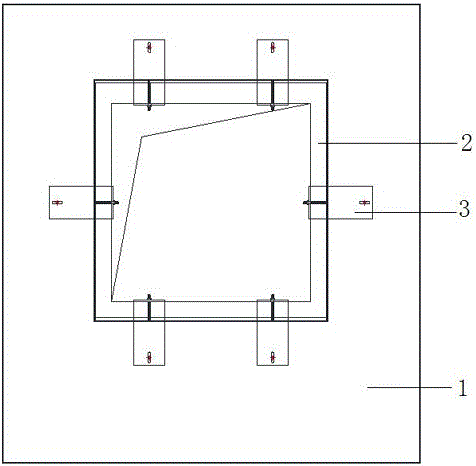

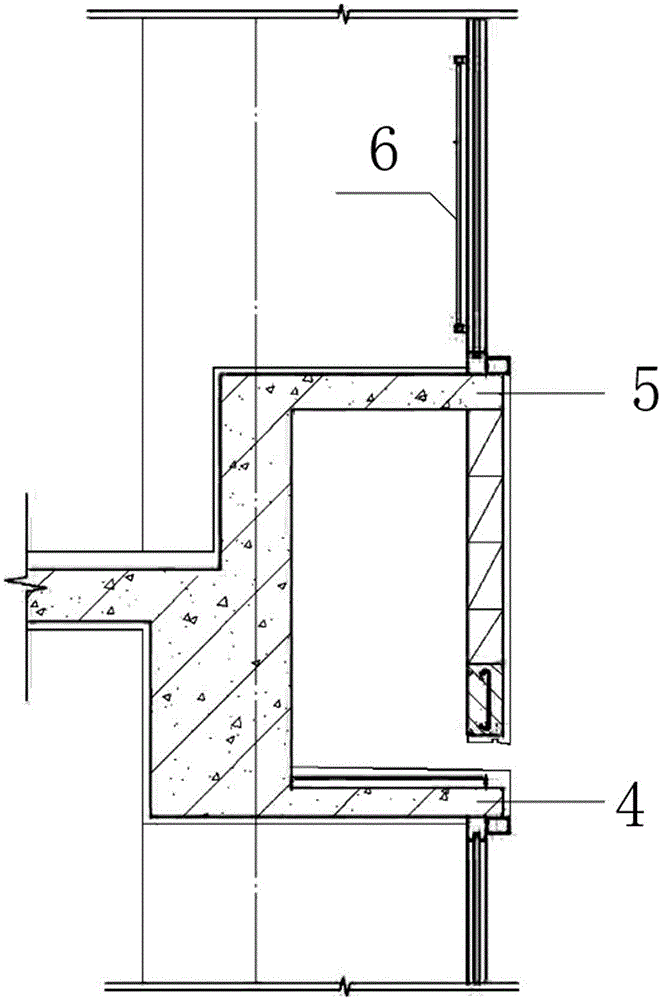

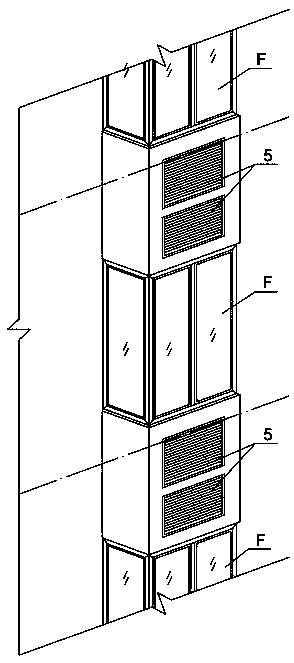

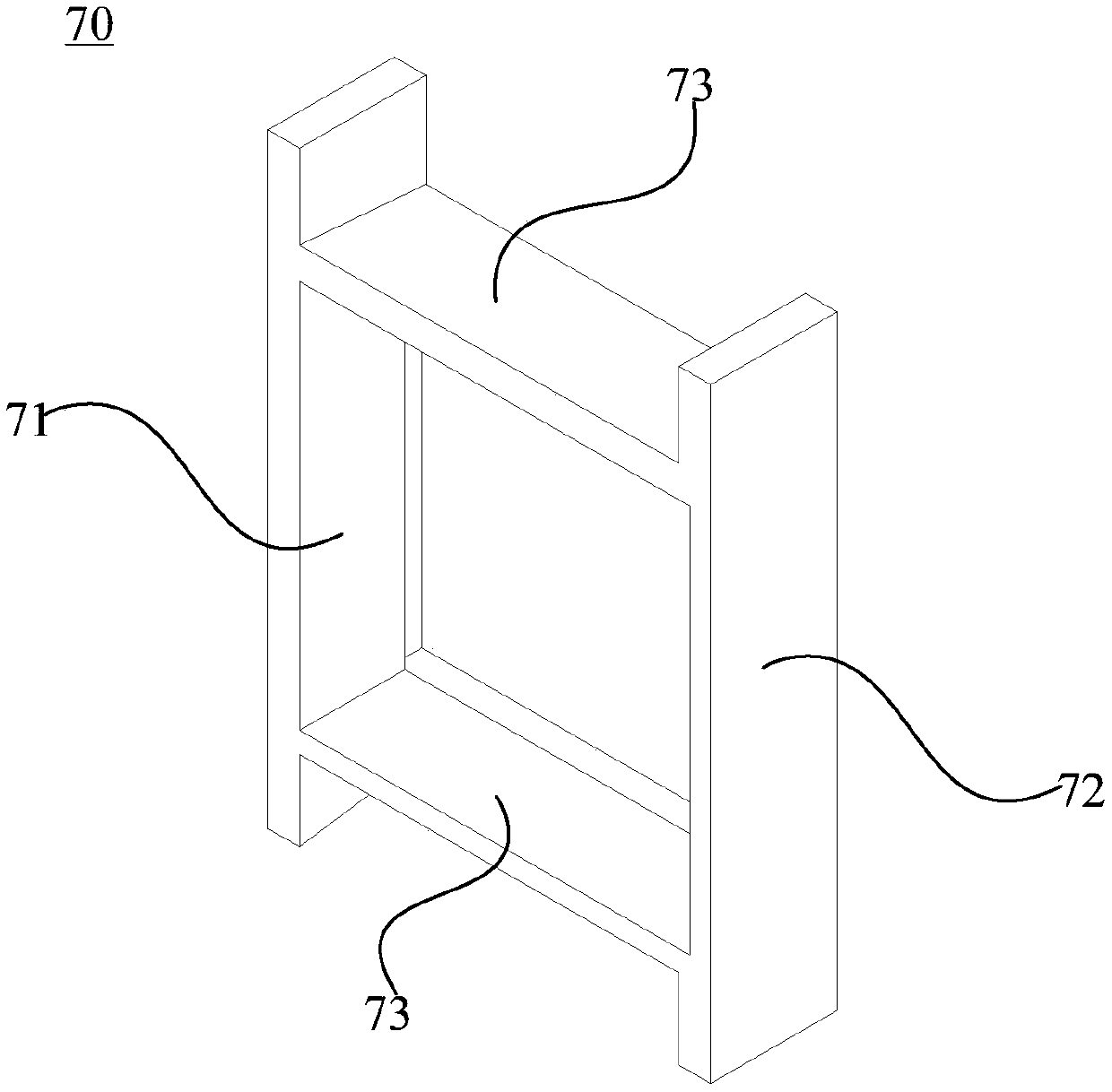

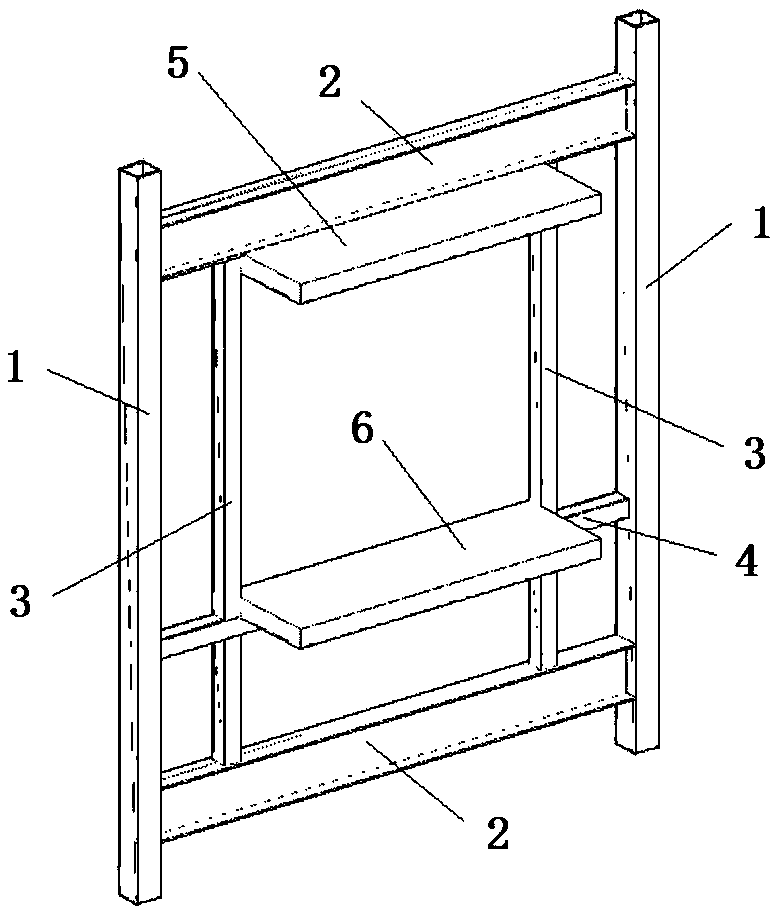

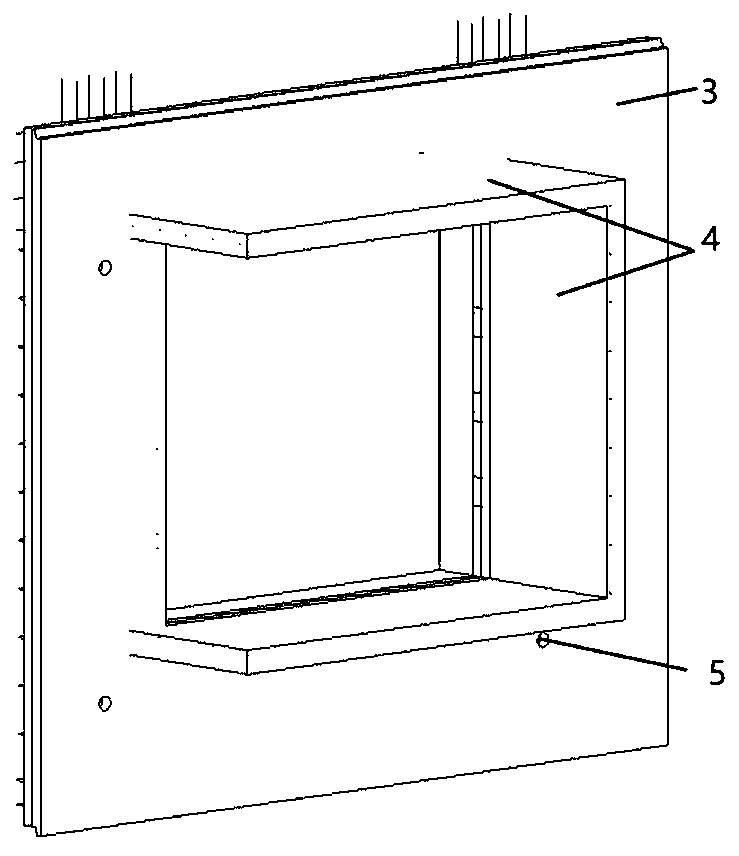

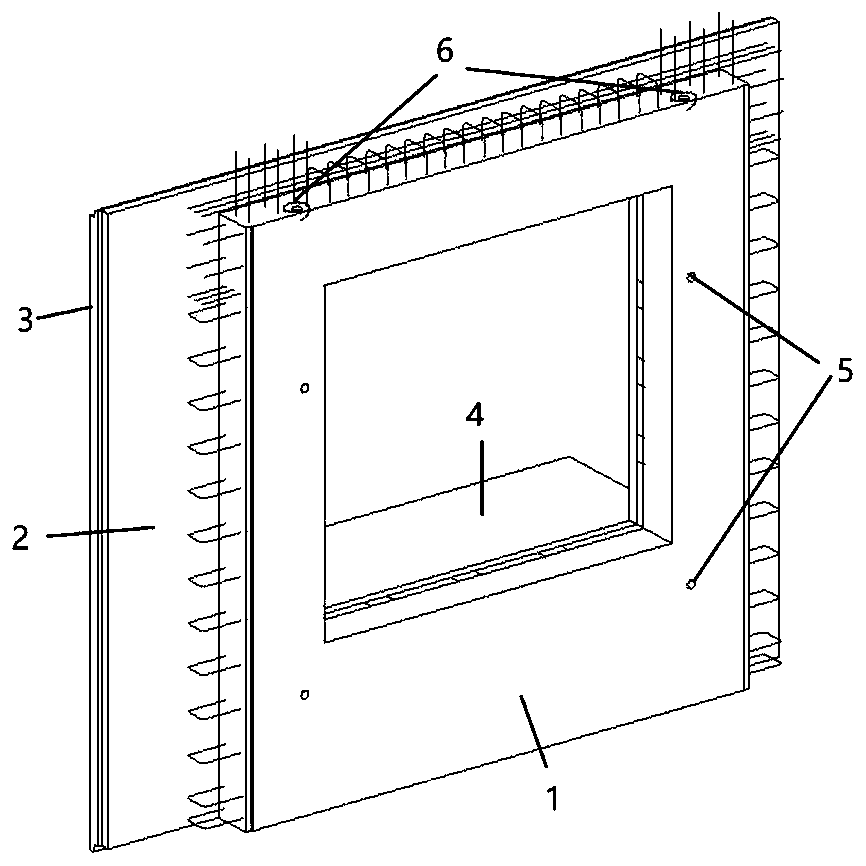

Bay window applied in assembled steel-structure building

The invention discloses a bay window applied in an assembled steel-structure building. The bay window includes a square frame comprising left and right frame columns (1) and upper and lower frame beams (2); the bay window further includes two bay-window constructional columns (3) and a bay-window constructional beam (4), wherein the two bay-window constructional columns (3) are arranged at the inner sides of the two frame columns (1) respectively, and the upper and lower ends of each bay-window constructional column are welded to the upper and lower frame beams (2) respectively; the bay-windowconstructional beam (4) is arranged on the lower middle part and is welded to the frame columns (1) and the bay-window constructional columns (3) separately; an upper bay platform (5) is arranged under the upper frame beam (2) and between the two bay-window constructional columns (3); a lower bay platform (6) is arranged on the bay-window constructional beam (4) and between the two bay-window constructional columns (3). A manufacturing method of the bay window is simple and feasible, and the blank of bay-window application in the assembled steel-structure building is filled; the bay window applied in the assembled steel-structure building is simple in structure and convenient to construct, and can meet requirements of inhabitants.

Owner:CHINA CONSTR SCI & IND CORP LTD

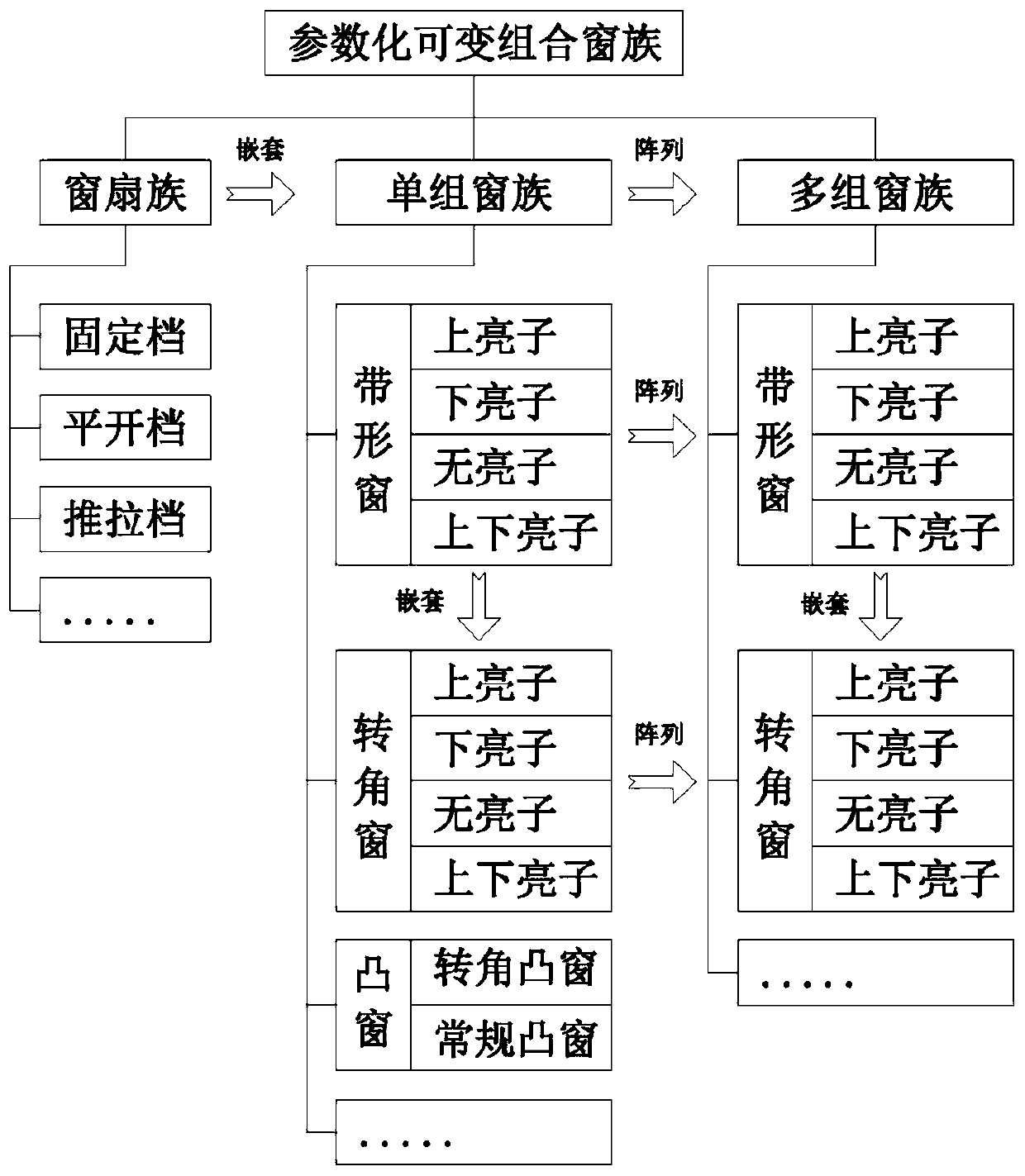

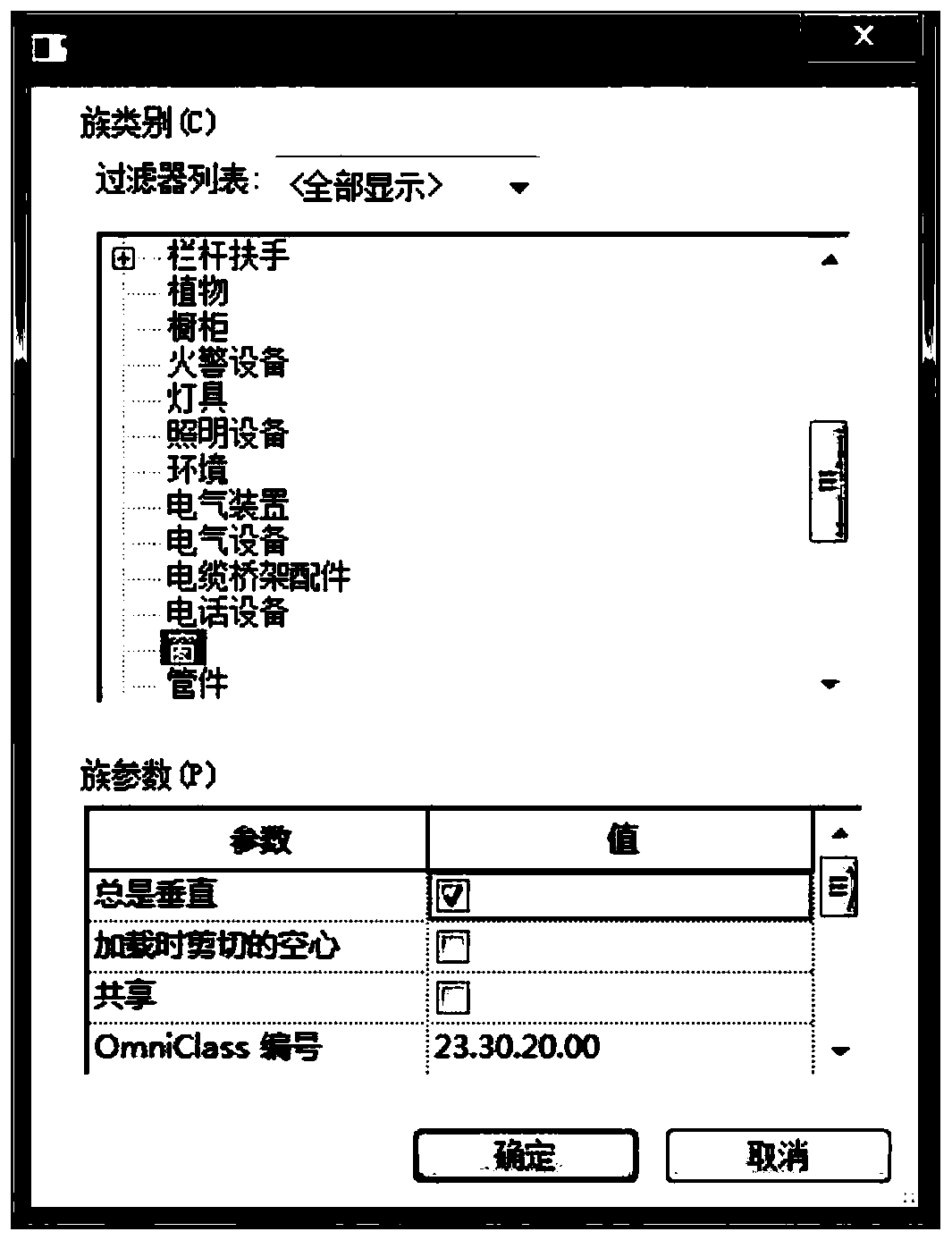

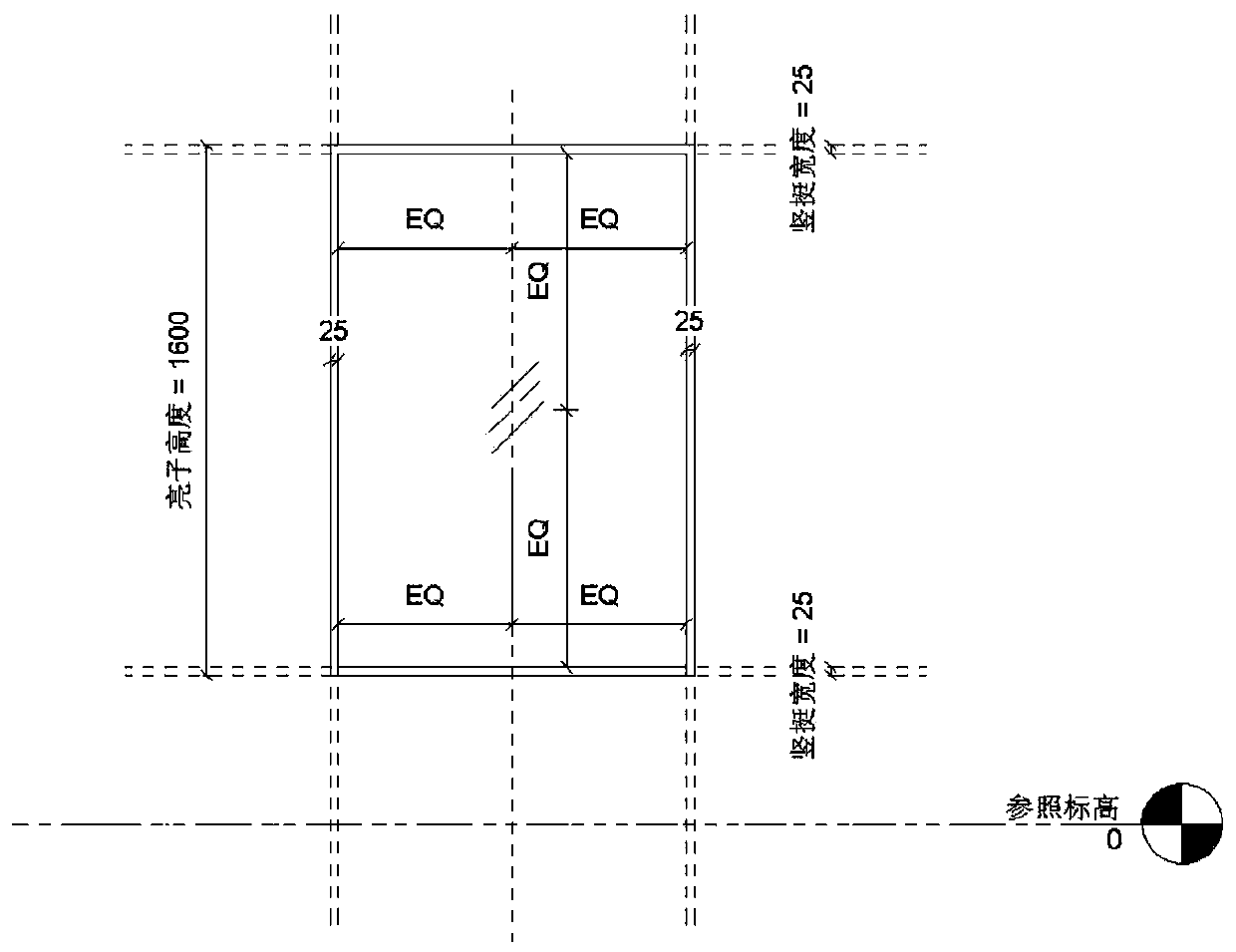

Construction method of REVIT parameterized variable combination window group

The invention discloses a construction method of an REVIT parameterized variable combination window group, and the method comprises the following steps: creating a basic part window sash group of a combination window, wherein the window sash group comprises a fixed stop, a side-hung stop, and a push-pull stop; creating a single window group by utilizing the window sash group; creating a pluralityof window groups by utilizing the single window group, wherein the plurality of window groups are divided into strip-shaped windows and corner windows; manufacturing a plurality of strip-shaped windowgroups by using the single window group; creating a plurality of corner window groups by using the plurality of strip-shaped window groups; creating a bay window family by using the single set of window families. According to the invention, the window group is constructed through hierarchical systematization, the construction method is simple and unified, and the efficiency is high. Through the variable window group number and the variable corner angle, the universality of the window group is good, the reuse rate is high, and the window group is convenient to find. The vertical stiles, the side stiles and the cross beams of the combined window are directly formed by splicing the frames of the window sash group, so that the modeling workload and unnecessary parameters are reduced. Nestedtechnology is adopted, so that window group modification and information management are facilitated.

Owner:广东工业大学建筑规划设计院有限公司

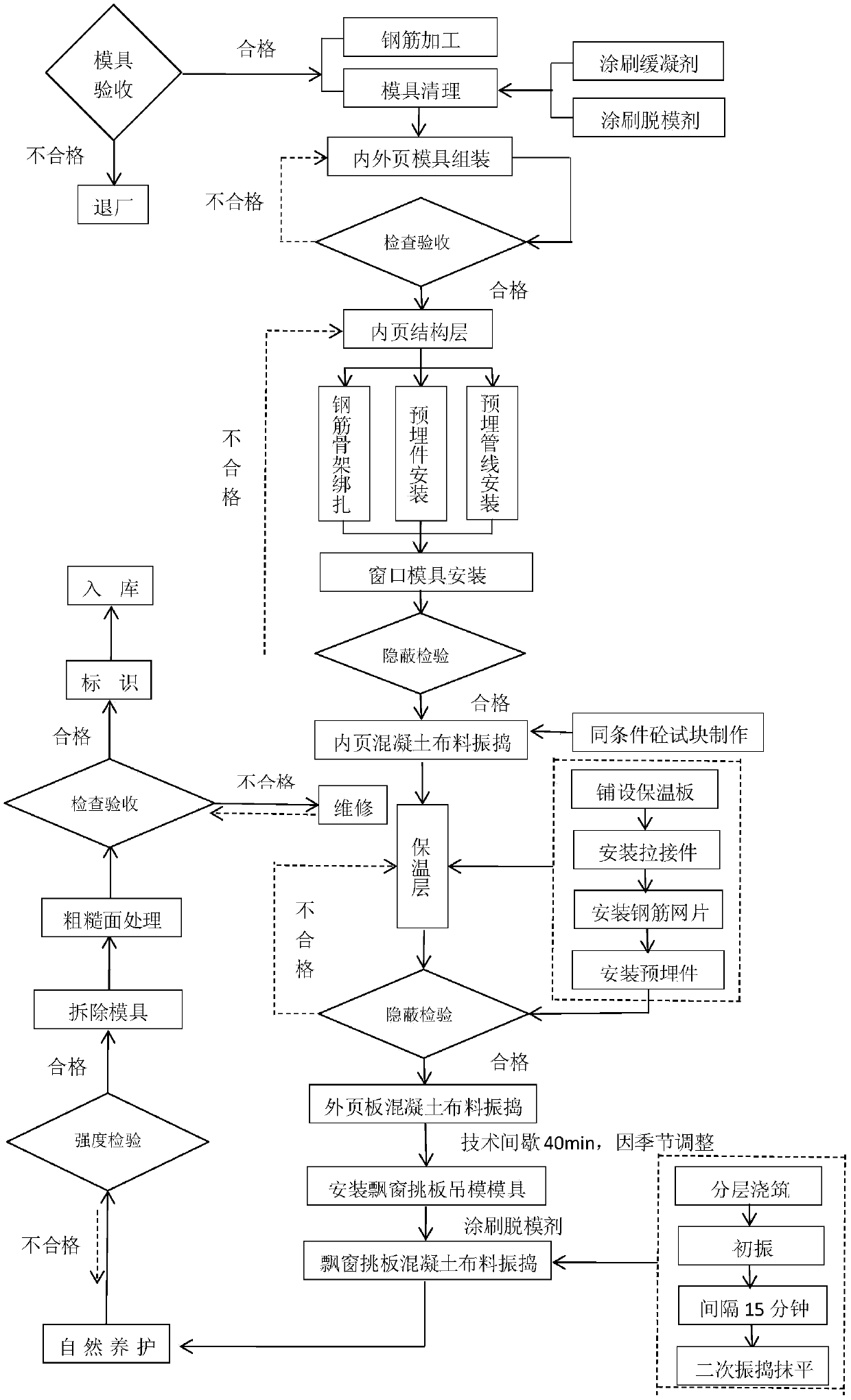

Prefabricated sandwich thermal insulation bay window shear wall board and manufacturing method thereof

PendingCN111411734AImprove appearance qualityReduce weightClimate change adaptationCeramic shaping apparatusInsulation layerThermal insulation

The invention relates to the technical field of fabricated building wall boards, in particular to a prefabricated sandwich thermal insulation bay window shear wall board and a manufacturing method thereof. An existing bay window is messy at the root and has excessive bubbles on the surface. The prefabricated sandwich thermal insulation bay window shear wall board comprises a structure layer and anouter leaf layer, a thermal insulation layer is arranged between the structure layer and the outer leaf layer, bay window boards are arranged on the side wall of the outer leaf layer, a window hole is reserved in the middles of the structure layer, the thermal insulation layer and the outer leaf layer, the bay window boards in a U shape are arranged on three sides of the window hole, a pluralityof threaded sleeves are reserved in the thickness direction of the outer leaf layer, and two hanging nails extending in the vertical direction are reserved in the top of the structure layer. The technological operation is simple, the problems that the appearance quality of components is poor, and the bay window is messy at root and has excessive bubbles on the surface are solved at low cost, and good development prospects are achieved in the technical field of fabricated building wall boards.

Owner:河南清水建设科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com