Bare concrete bay window steel formwork structural body device

A technology of fair-faced concrete and steel formwork, applied in formwork/formwork/work frame, building structure, on-site preparation of building components, etc. Complex construction and other problems, meet the standard specifications, enhance the seismic effect, and facilitate the construction and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

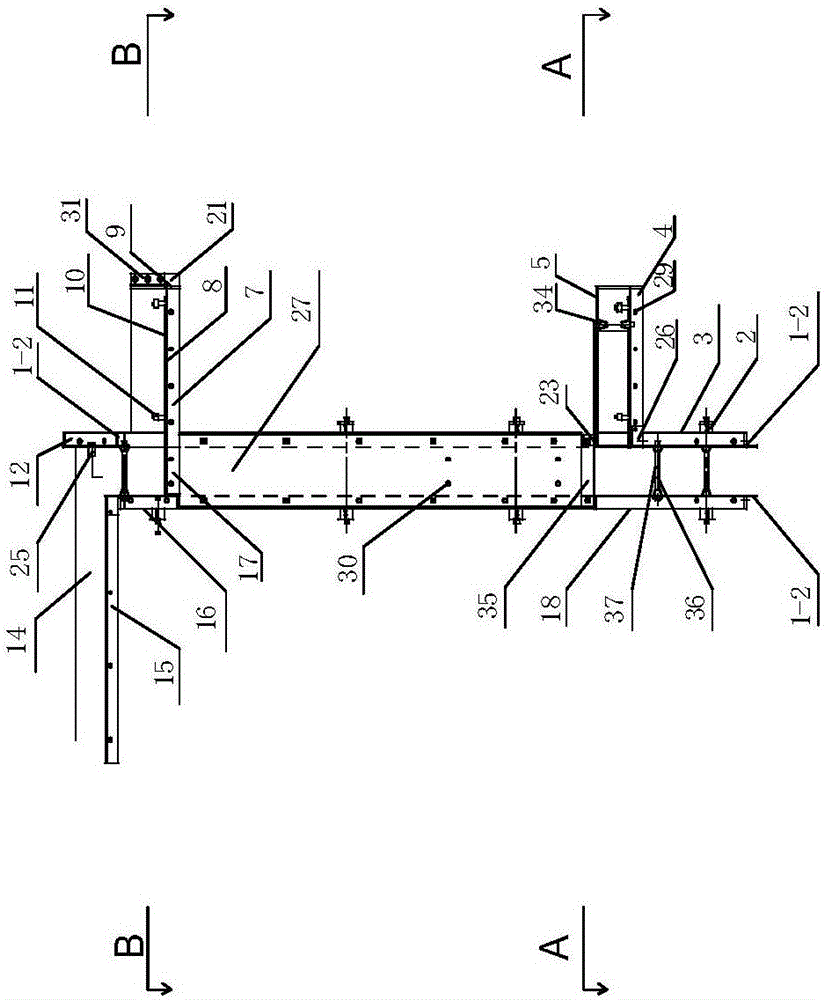

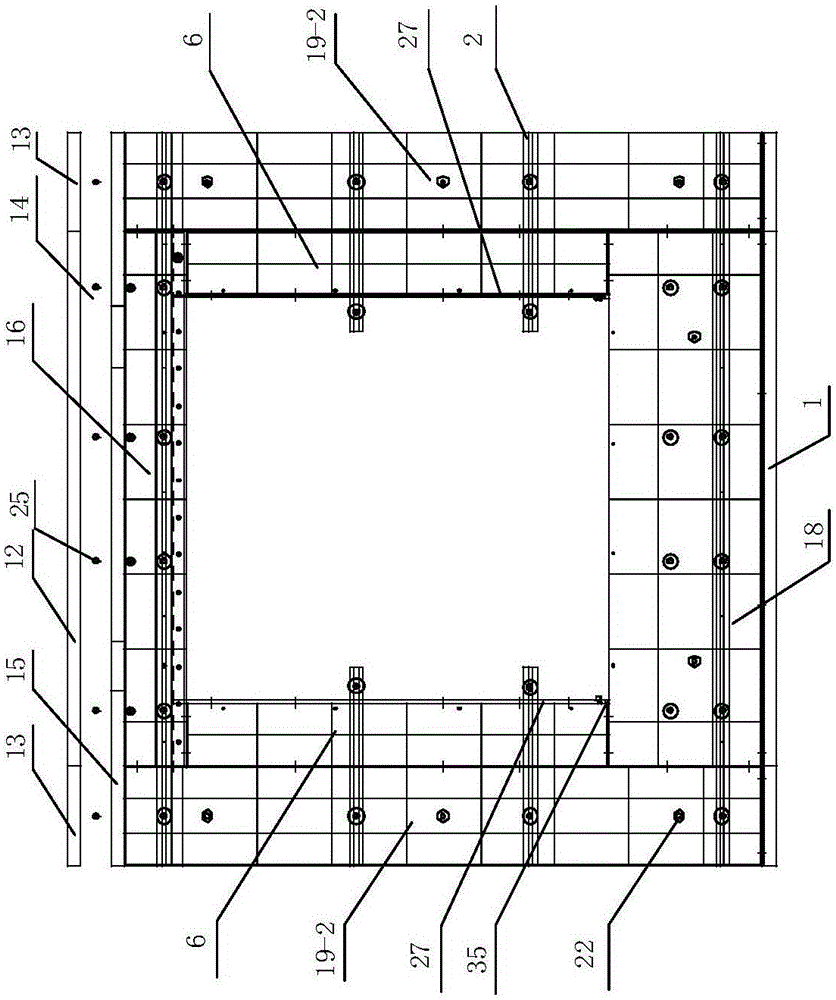

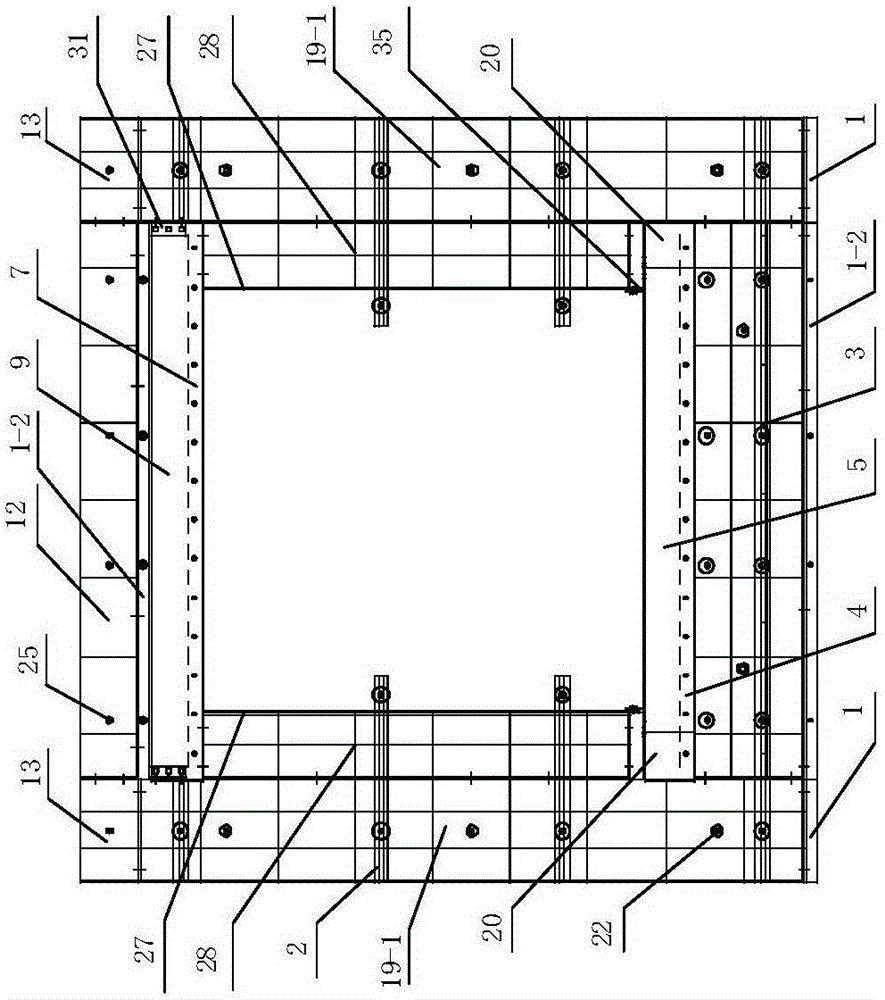

[0043] In order to further illustrate the above-mentioned purpose, technical scheme and effect of the present invention, the present invention will be described below in conjunction with the accompanying drawings and relevant known technical knowledge through the embodiments:

[0044] Such as Figure 1-13 As shown, this kind of fair-faced concrete bay window steel formwork structure includes an inner wall main formwork 19-2, an outer wall main formwork 19-1, an outer wall joint formwork 13, and a floor steel formwork 15; this structure also includes a window inner formwork 6. Window outer mold 28, lower window inner mold 18, lower window outer mold 3, lower floating bottom mold 4, upper floating bottom mold 7, window beam bottom mold 17, window beam inner mold 16, window beam outer mold 12, bay window hole mold 27. Upper floating enclosure mold 9, upper floating top head circumference mold 21, lower floating enclosure mold 5, lower floating top head circumference mold 33, lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com