Patents

Literature

124results about How to "Small modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

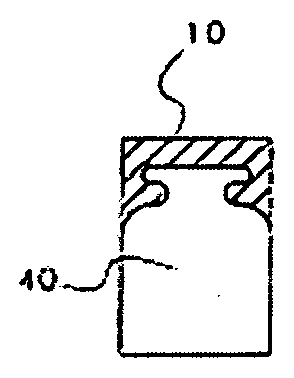

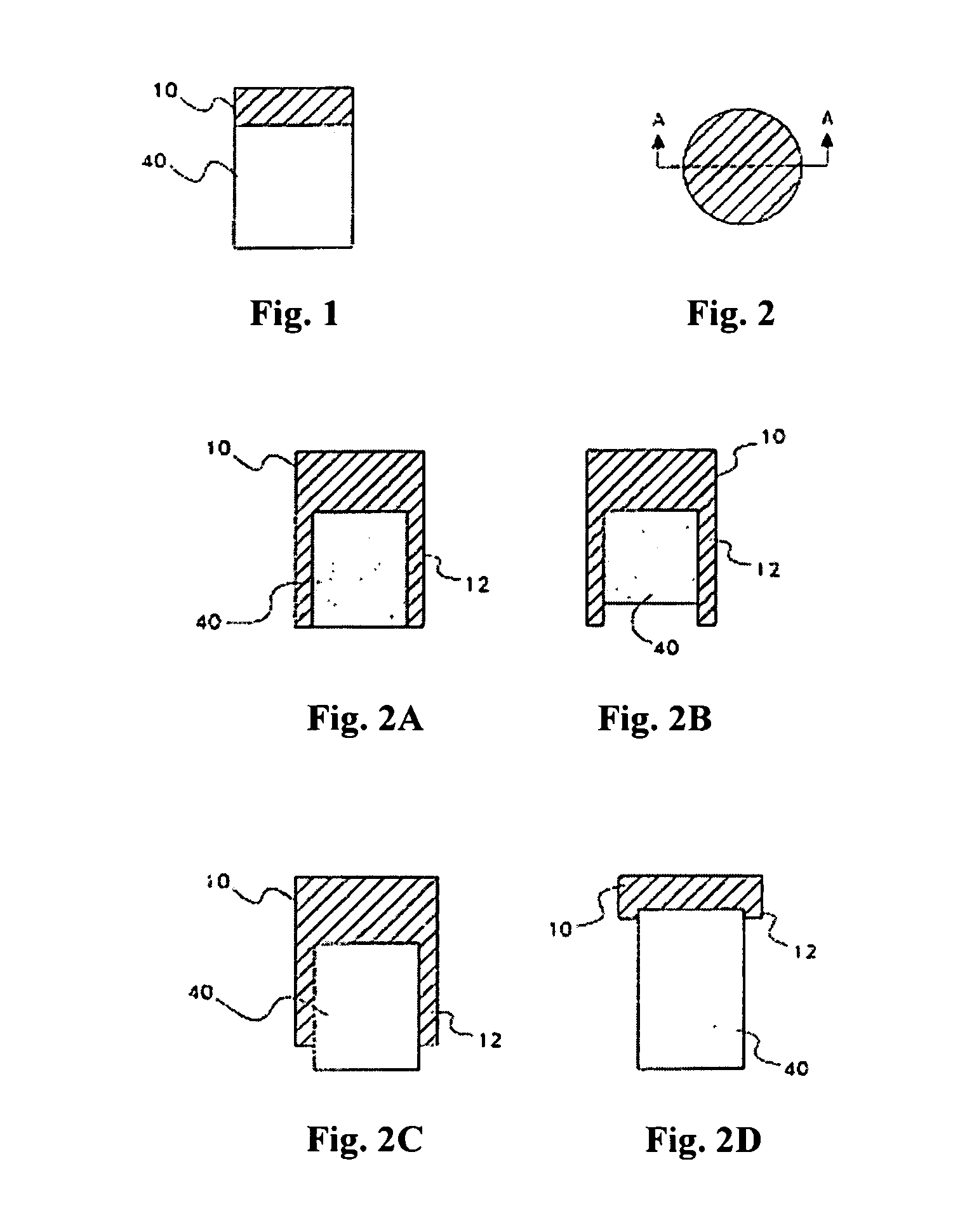

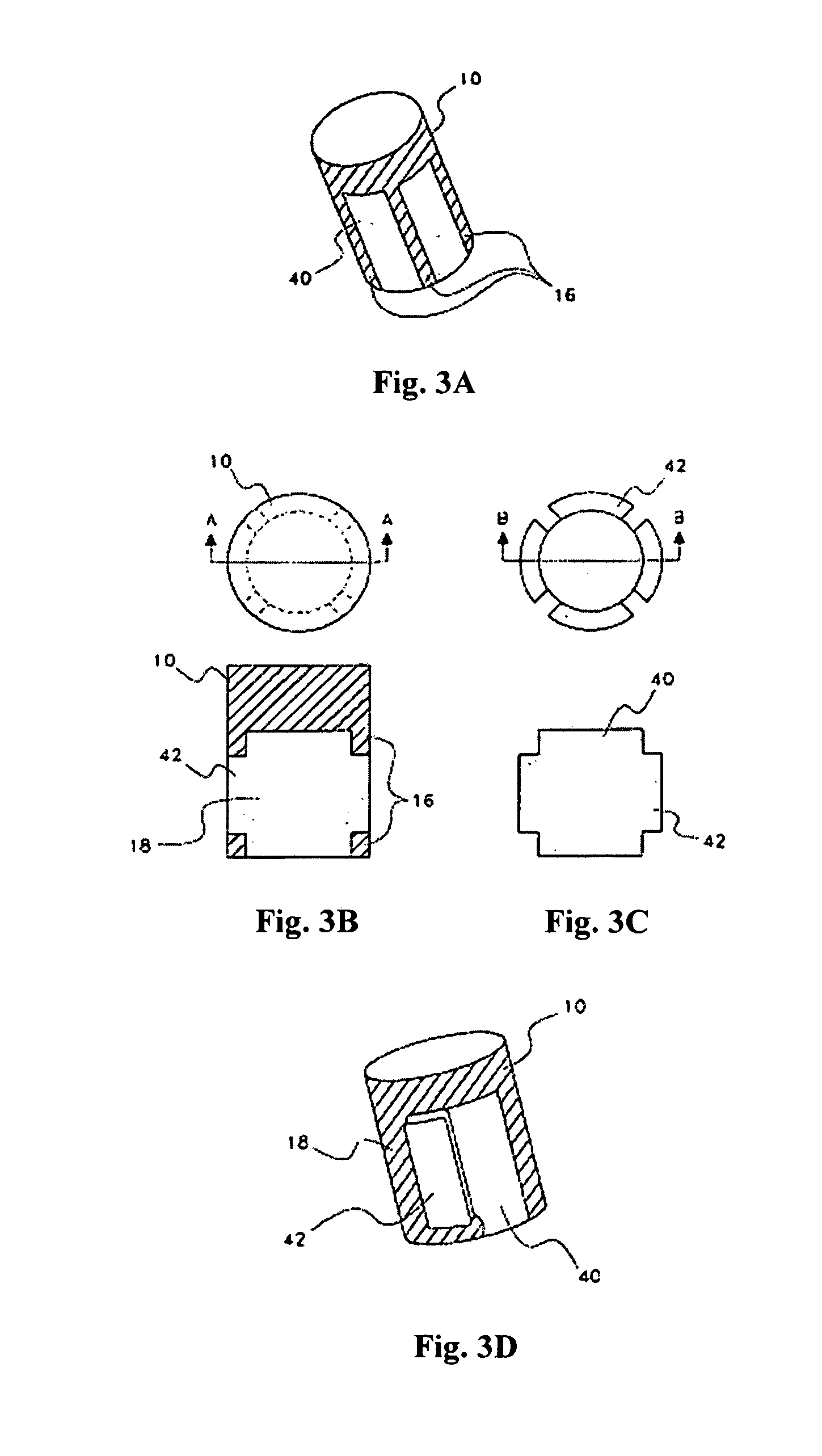

Multi-phase osteochondral implantable device

An osteochondral implantable device is provided, comprising an upper cap and at least one insert comprising a non-polymeric material in physical contact with the upper cap, said lower insert comprising at least one non-polymeric material, wherein the porosity of the upper cap is greater than the porosity of the insert and the Young's modulus of the upper cap is smaller than the Young's modulus of the insert.

Owner:WARSAW ORTHOPEDIC INC

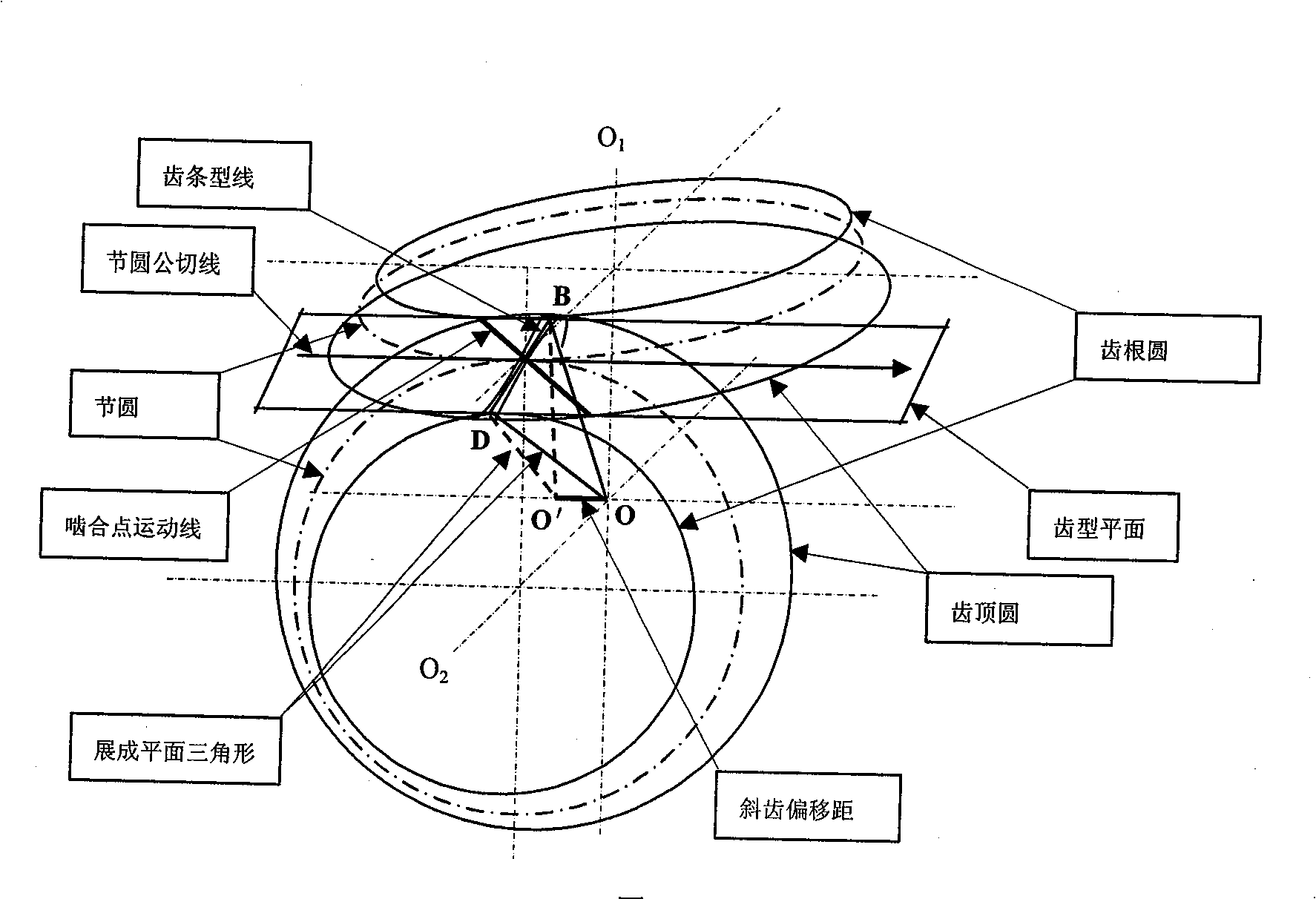

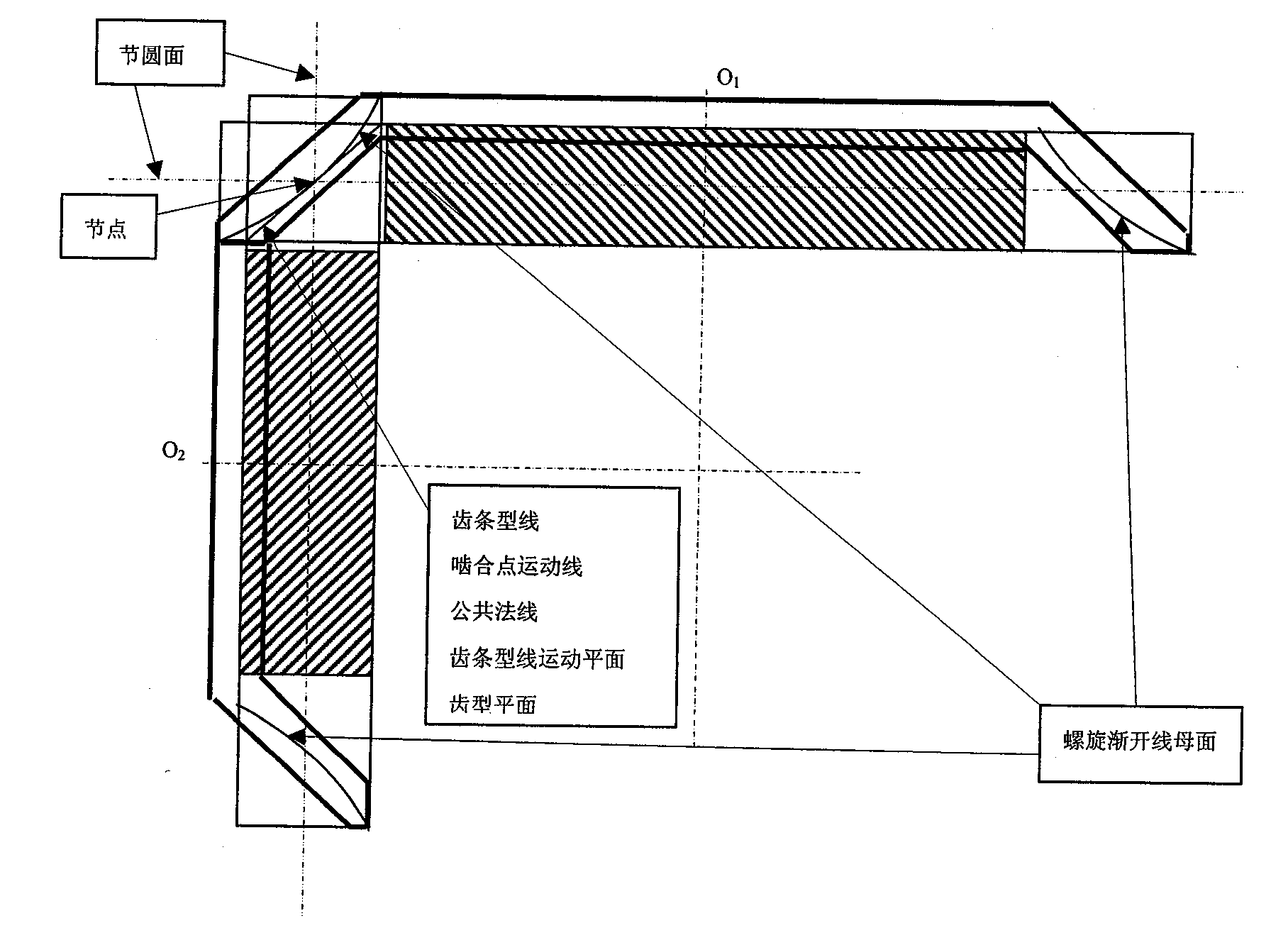

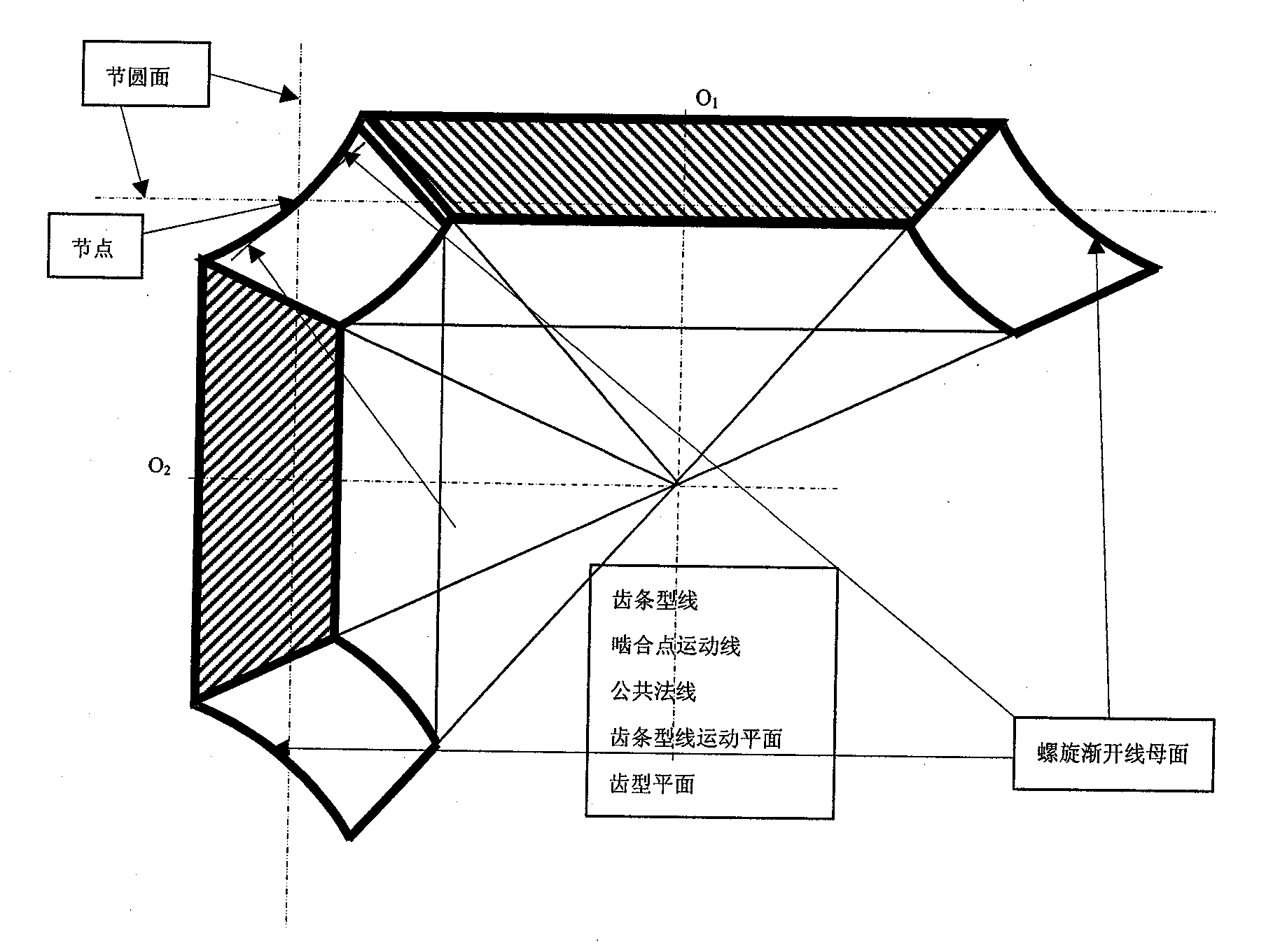

Helical involute gear and processing method thereof

InactiveCN101526129AEasy to processClear and easy to understand the transmission principlePortable liftingGear teethGear driveInvolute gear

The invention relates to a helical involute gear and a processing method thereof. The helical involute gear is characterized in that a tooth surface molded line is a helical involute which is a curve spread by a rack type line straightly moving along the pitch circle tangent line and pure-rolling with a gear pitch circle. The helical involute gear has clear and easy drive principle, can ensure the drive continuity and the drive uniformity, and can realize surface meshing with large meshing area so that the bearing capacity is strong; the helical involute gear has long meshing line and large superposition coefficient, especially, an inclined helical involute conical gear is easy to implement speed reduction at high speed ratio. The helical involute conical gear can realize the expansion processing, thereby having high processing accuracy, low processing cost and high processing tooth surface hardness, improving the motion stability of the gear and the bearing capacity, and prolonging the service life. Meanwhile, processing equipment required by the helical involute gear can be conveniently processed by utilizing the method, thereby solving the difficulties of large processing difficulty and high cost of a gear drive pair with intersecting axes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

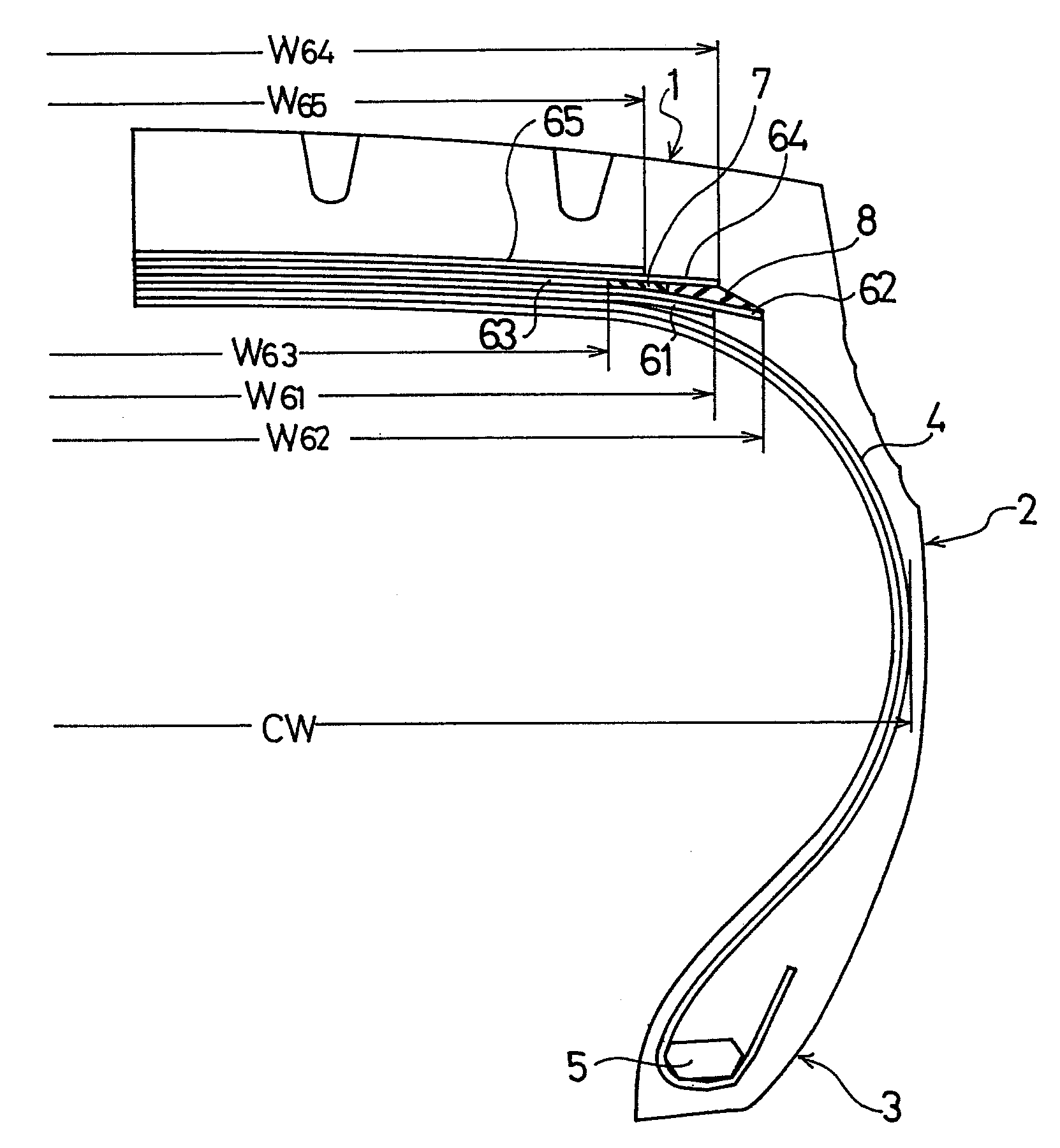

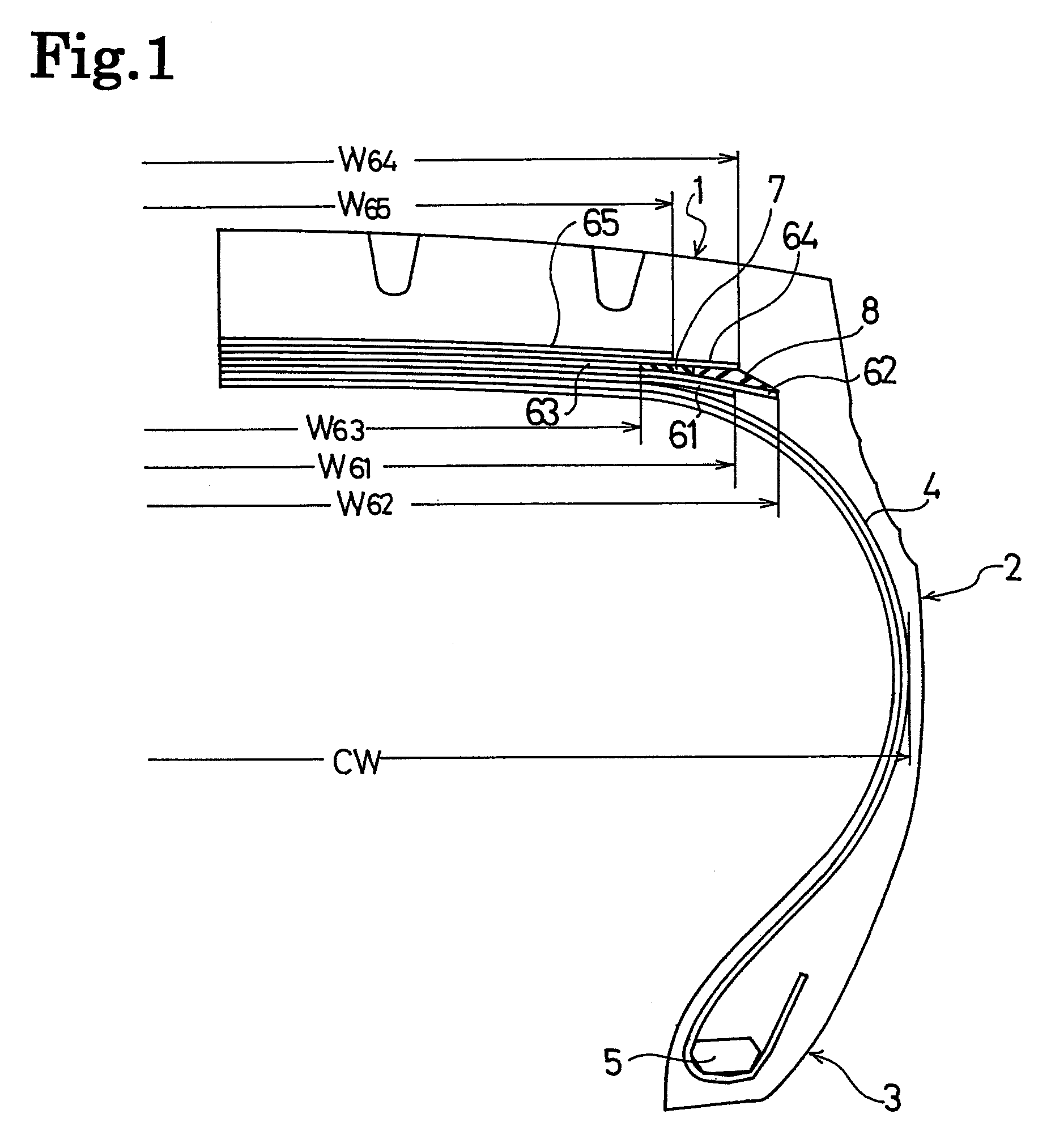

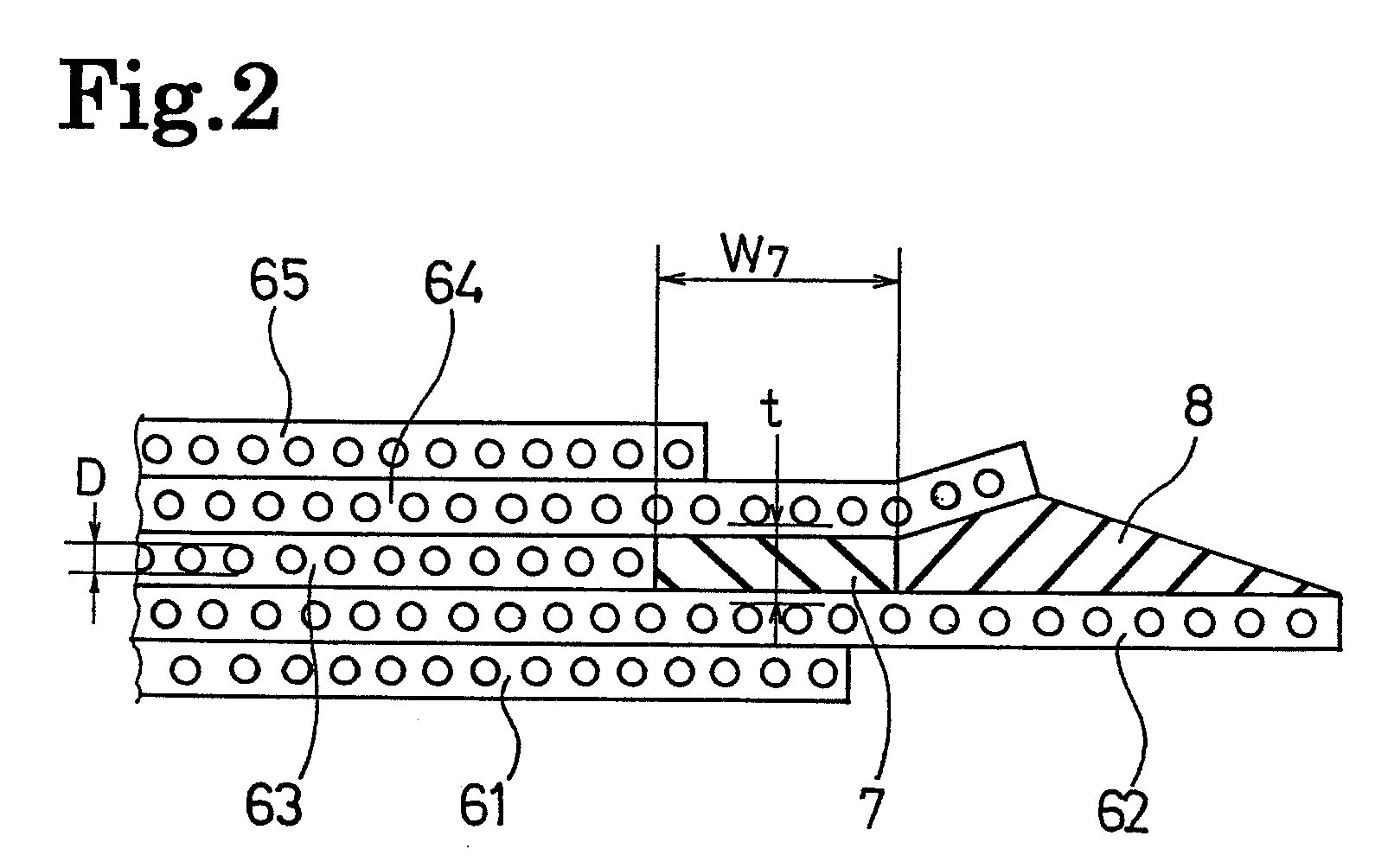

Pneumatic tire

ActiveUS20090277557A1Avoid fatigue fractureIncrease widthHeavy duty tyresHeavy duty vehicleEngineeringStress relaxation

The present invention provides a pneumatic tire that inhibits any fatigue rupture at an edge portion of a circumferential-direction reinforcing belt layer and also inhibits any separation at an edge portion of crossed belt layers. In the pneumatic tire, at least two crossed belt layers are disposed on the outer circumferential side of a carcass layer in a tread portion. At least one circumferential-direction reinforcing belt layer with a width smaller than those of the crossed belt layers is disposed between the crossed belt layers. Moreover, a stress relaxation layer of a rubber composition having a fixed thickness is disposed between the crossed belt layers while lying adjacent to an edge portion of and outside, in the width directions of, the circumferential-direction reinforcing belt layer.

Owner:THE YOKOHAMA RUBBER CO LTD

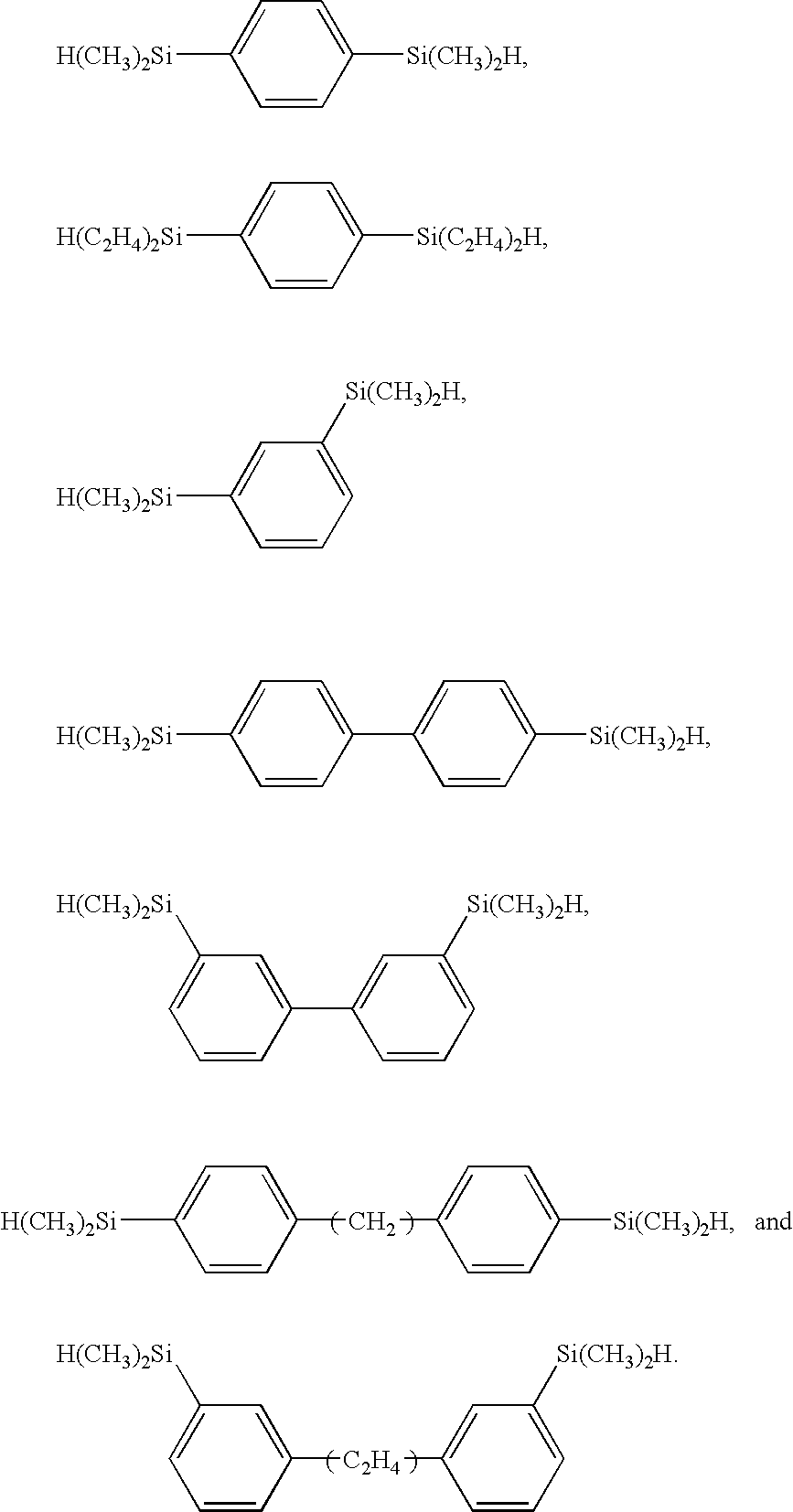

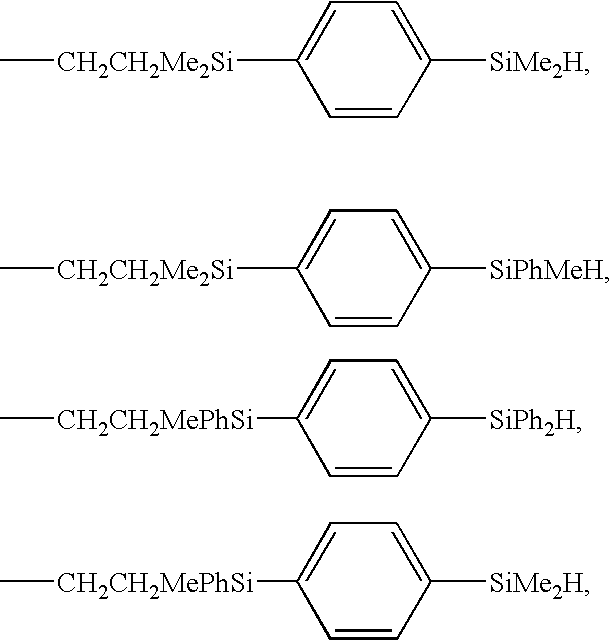

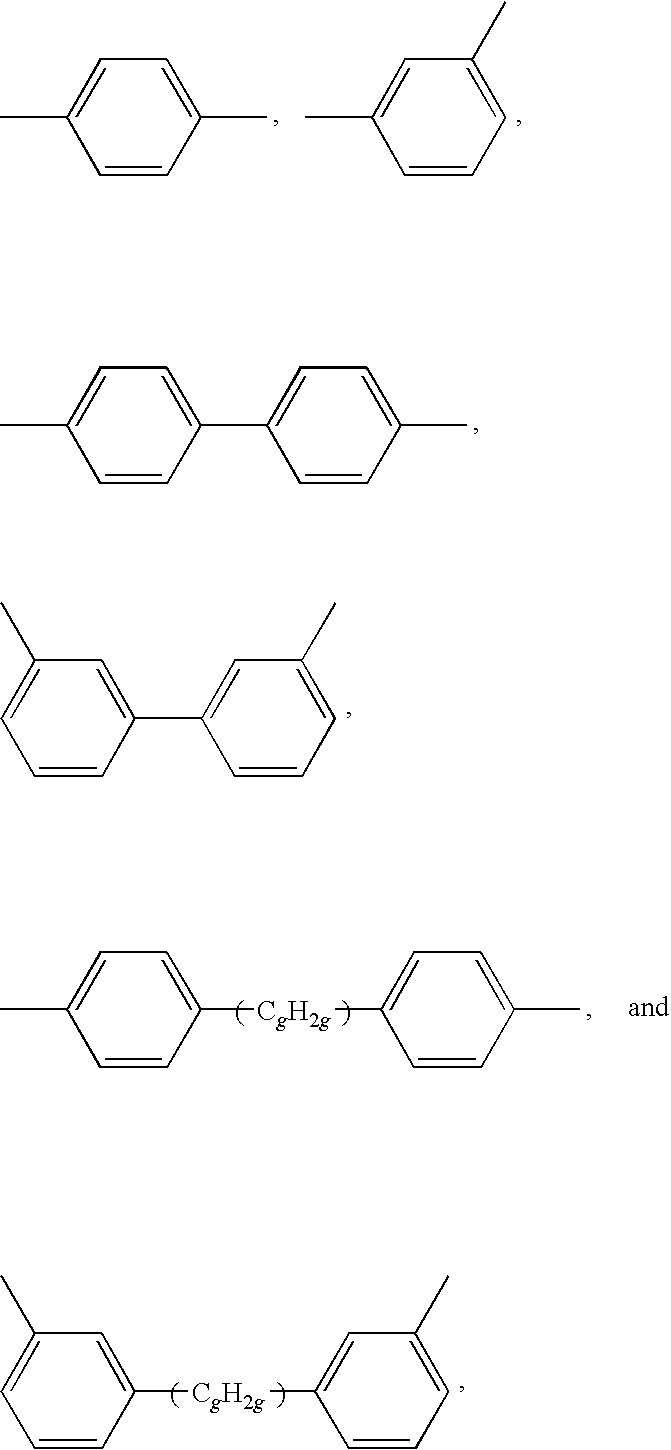

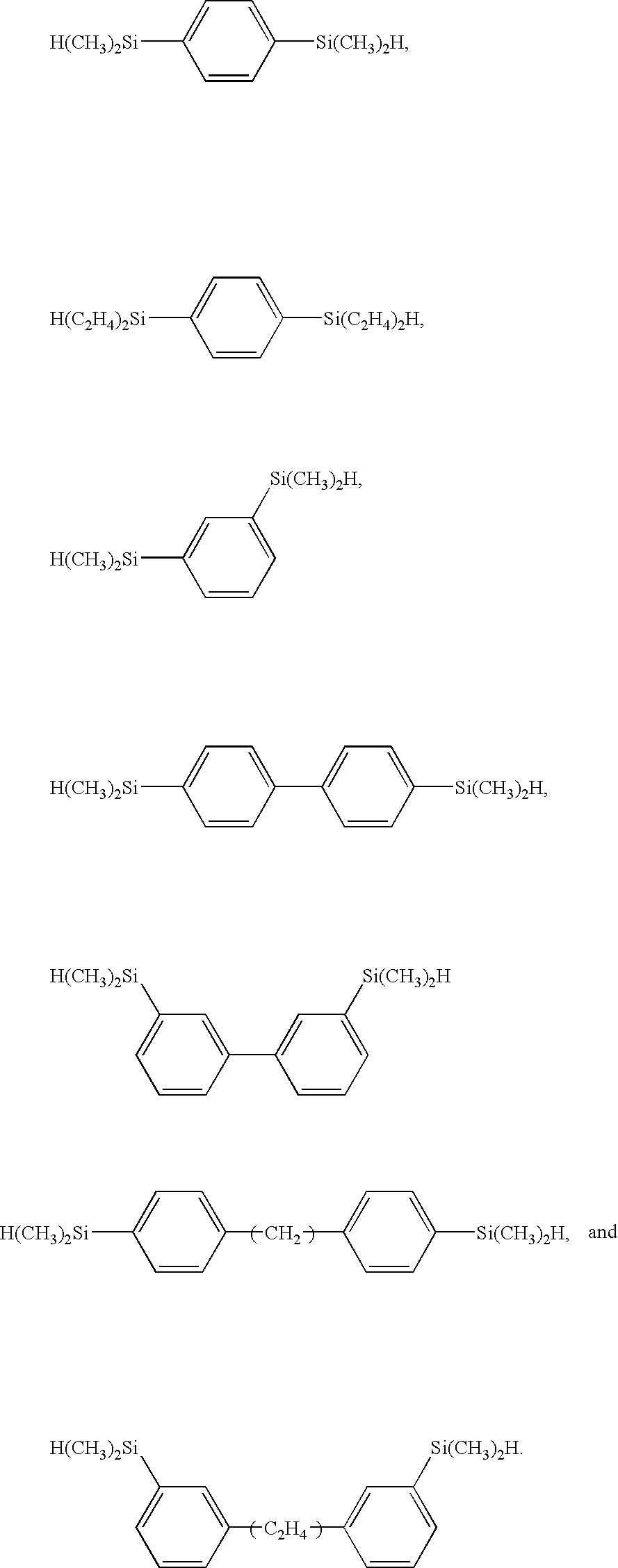

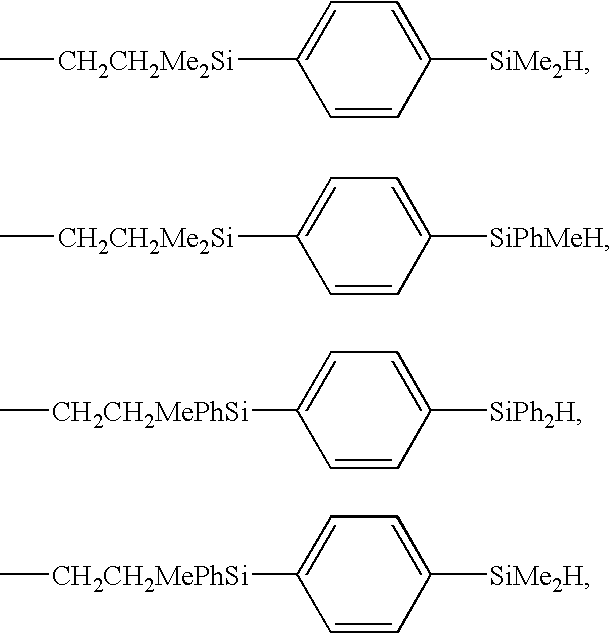

Fluorosilicone-Based Dielectric Elastomer and Method for its Production

InactiveUS20130236730A1Increased dielectric permittivityHigh modulusPiezoelectric/electrostrictive device manufacture/assemblyPlastic/resin/waxes insulatorsPolymer scienceThin membrane

A dielectric elastomer has a film that contains a fluorinated silicone elastomer and has two faces. A coating of a stretchable electrode material is applied to each one of the two faces. The fluorinated silicone elastomer has a modulus of elasticity of maximally 450 kPa. The fluorinated silicone elastomer is a three-dimensionally crosslinked, fluorinated, alkyl group-containing polysiloxane in combination with a fluorinated silicone oil. Alternatively, or in addition, the fluorinated silicone elastomer is a three-dimensional wide-mesh crosslinked, fluorinated, alkyl-group containing polysiloxane whose wide mesh property has been effected by a chain length extension by addition of a chain-shaped silicone molecule containing two Si—H groups to an alkenyl group-containing polysiloxane molecule.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

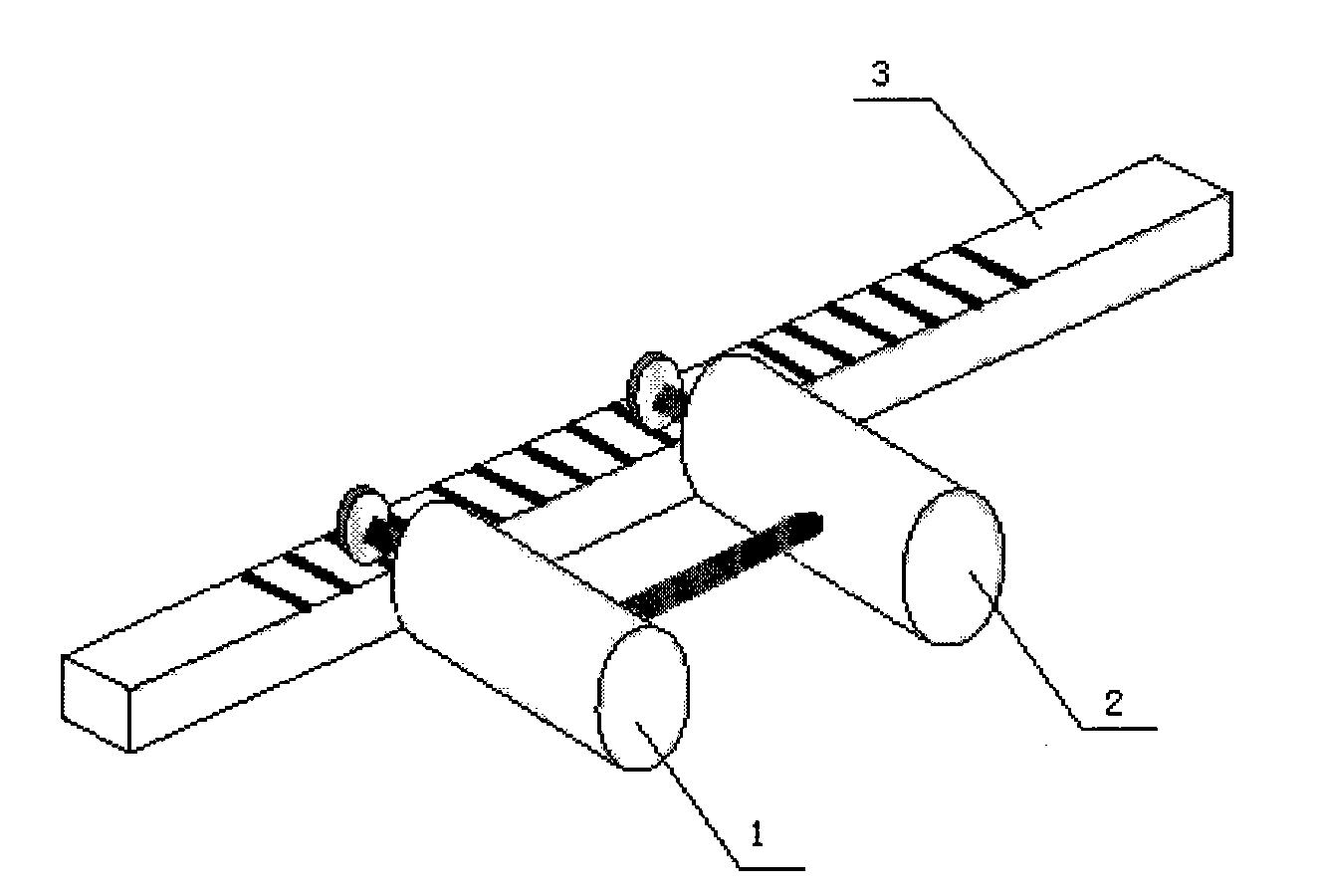

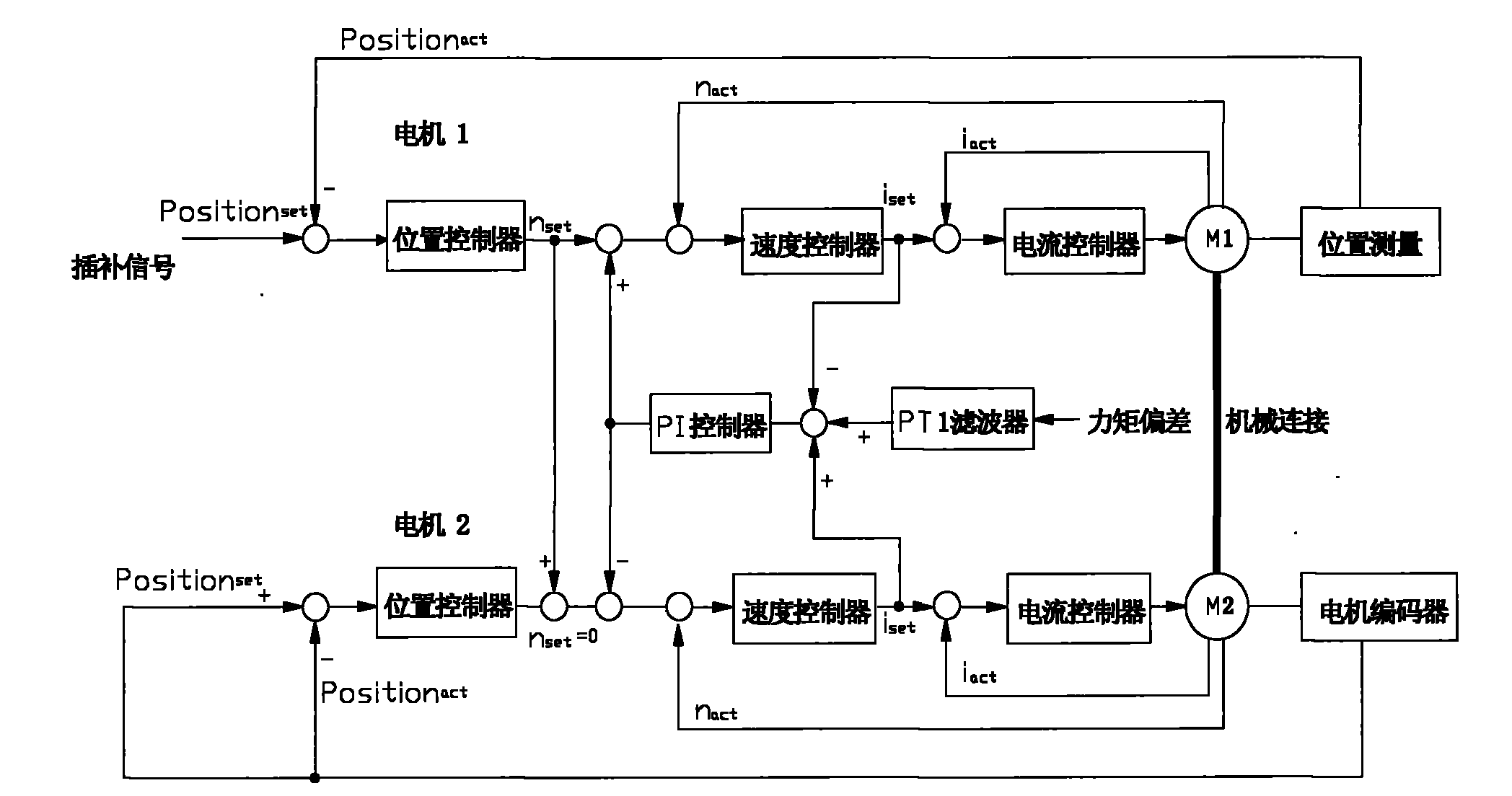

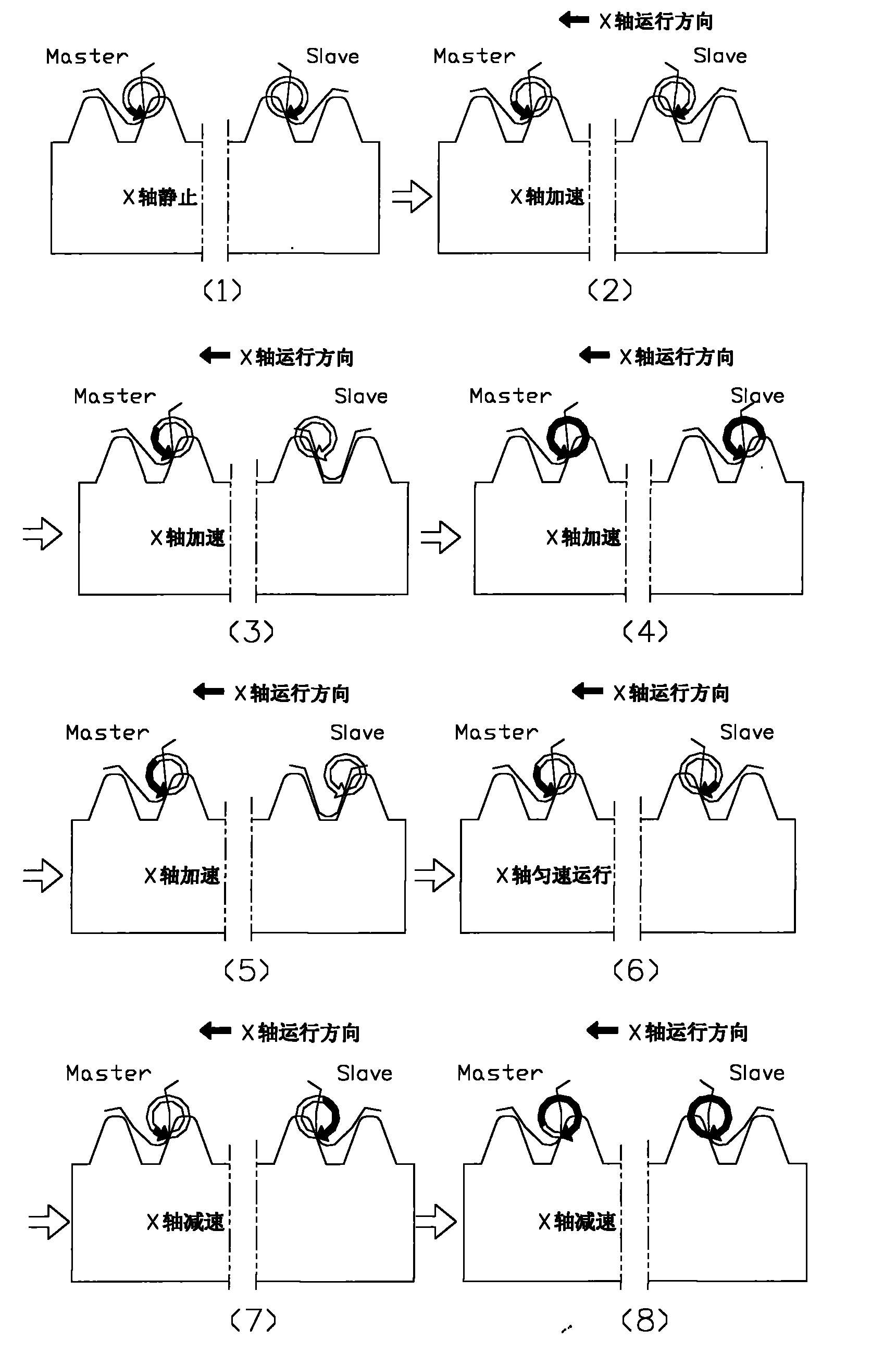

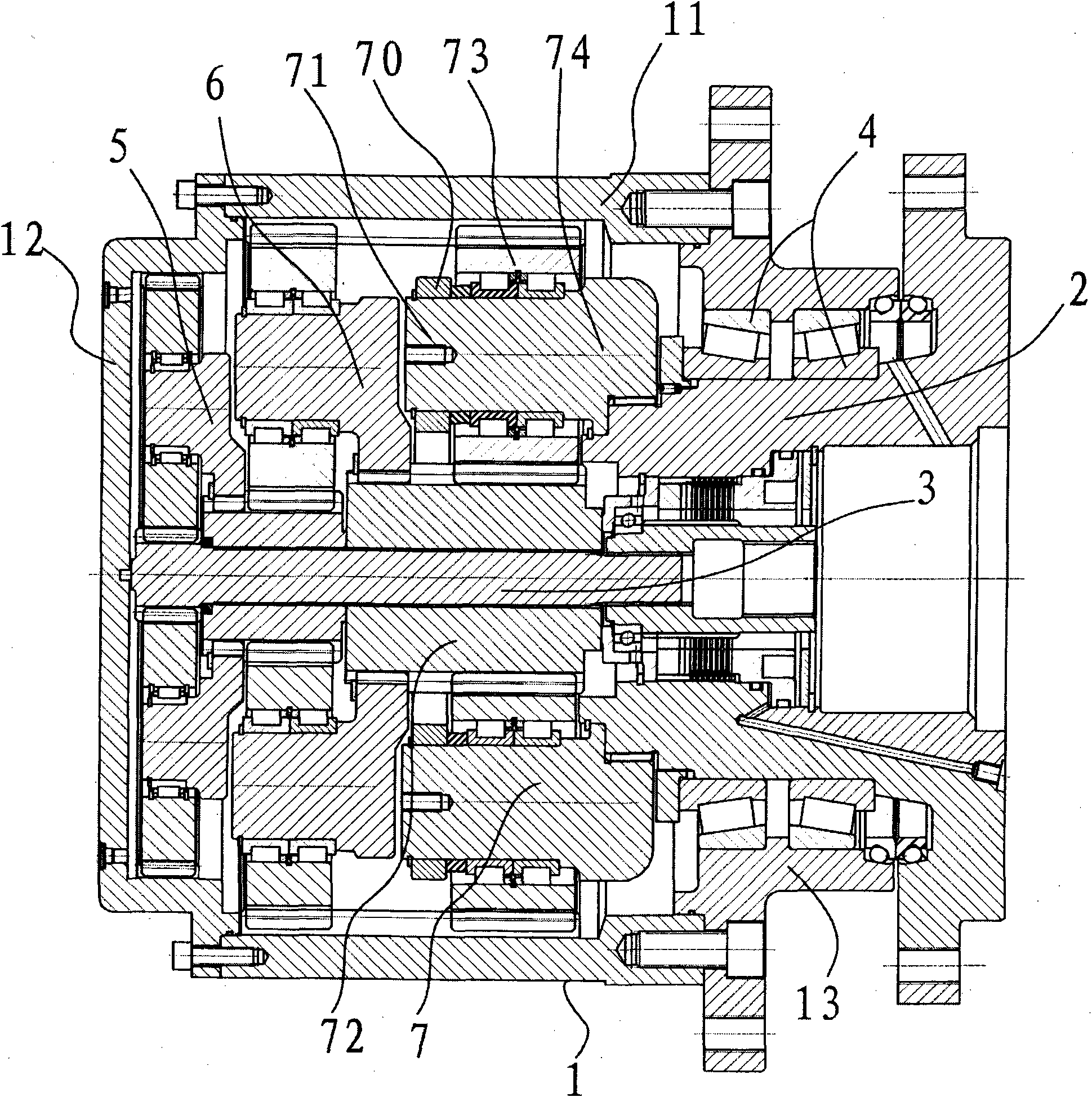

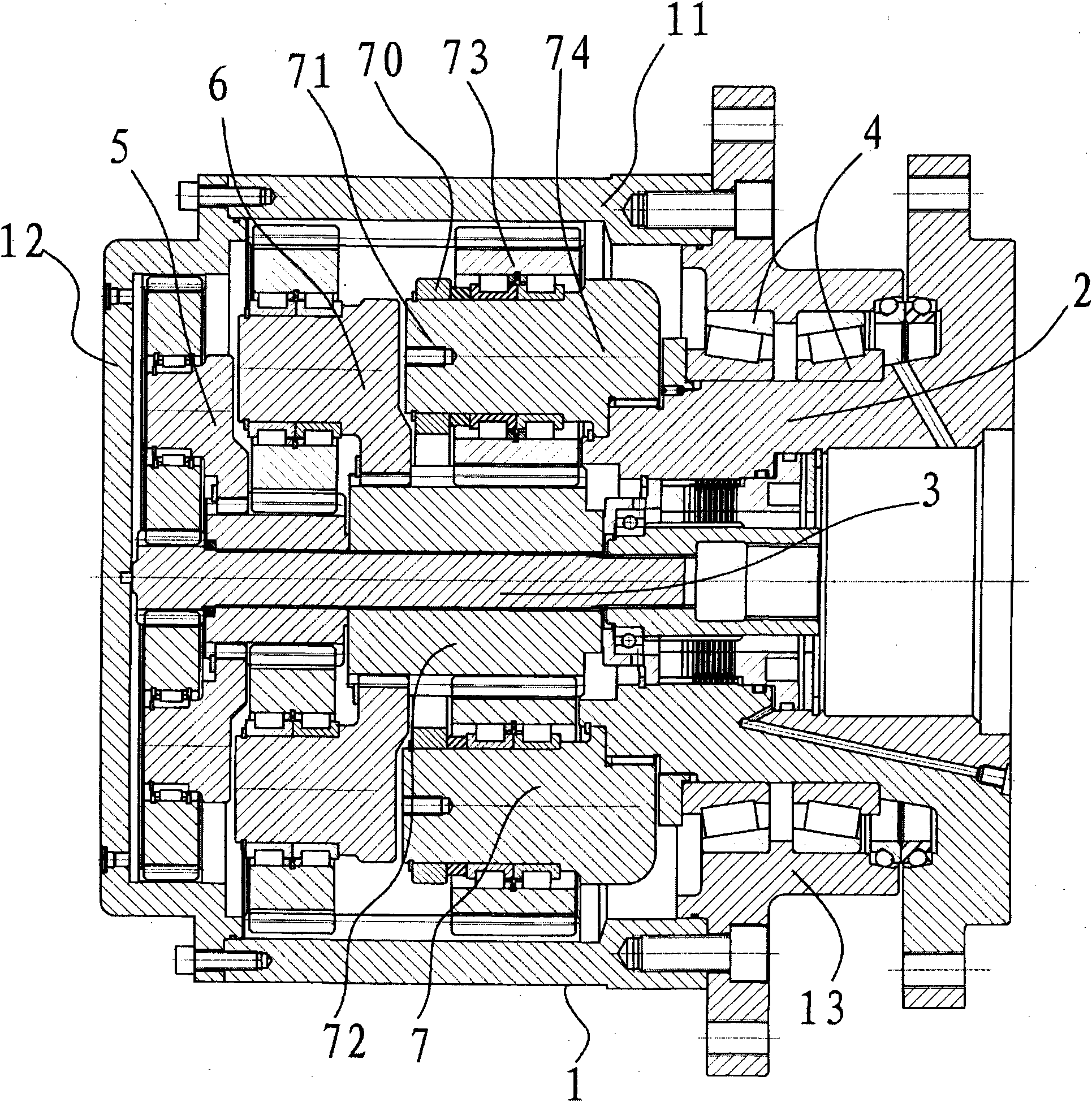

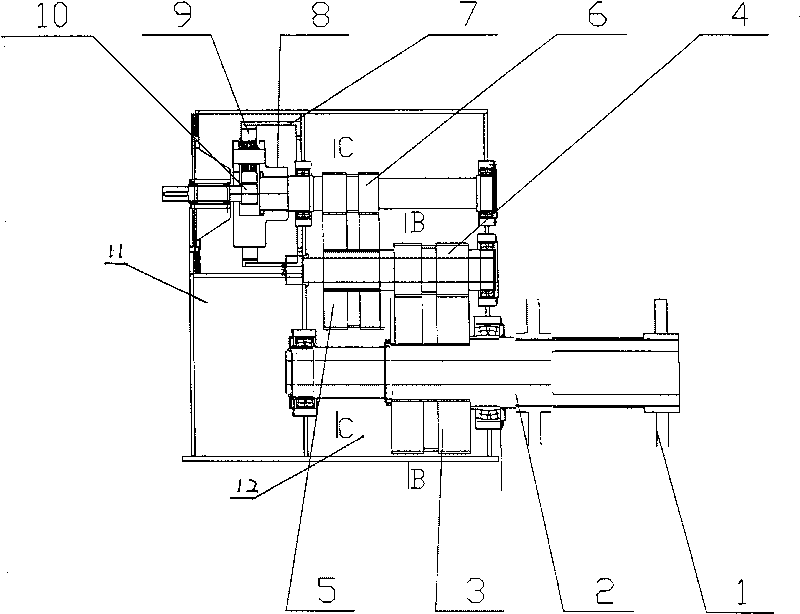

Double motor driven backlash eliminating device and backlash eliminating method

ActiveCN101841286AAccurate and stable controlThe control loop is stable and accurateMultiple dynamo-electric motors speed regulationDrive motorVelocity controller

The invention discloses a double motor driven backlash eliminating device, which comprises a rack fixed on a guide table, a drive motor fixed on a workbench and a motor control system which controls the drive motor. The double motor driven backlash eliminating device is characterized in that: the drive motor comprises a first motor and a second motor, and a first motor control system and a second motor control system both comprise a position measuring module which detects the position of the corresponding motor, a position controller which is connected with the output end of the position measuring module, a speed controller which is connected with the output end of the position controller and a current controller. A backlash eliminating method of the invention is characterized in that the difference between an output moment of the first motor and the output moment of the second motor is always kept at a constant value delta under the control action of the motor control system in the operation processes of the first and second motors. In the invention, backlash elimination is realized by arranging the two motors, so backlash vibration is removed, and modules of a gear and the rack are reduced.

Owner:JIER MACHINE TOOL GROUP

Silicone Resin Film, Method of Preparing Same, and Nanomaterial-Filled Silicone Composition

InactiveUS20090005499A1Increase flexibilityHigh mechanical strengthCoatingsHydrosilylationLength wave

A method of preparing a silicone resin film comprising coating a release liner with a nanomaterial-filled silicone composition comprising (i) a hydrosilylation-curable silicone composition comprising a silicone resin and a photoactivated hydrosilylation catalyst and (ii) a carbon nanomaterial, and exposing the coating to radiation having a wavelength of from 150 to 800 nm at a dosage sufficient to cure the silicone resin; a silicone resin film prepared according to the preceding method; and a nanomaterial-filled silicone composition.

Owner:FISHER MARK +1

Silicone Resin Film, Method of Preparing Same, and Nanomaterial-Filled Silicone Composition

InactiveUS20100068538A1Increase flexibilityHigh mechanical strengthMaterial nanotechnologySynthetic resin layered productsSilicone resinOrganosilicon

A method of preparing a silicone resin film, the method comprising coating a release liner with a nanomaterial-filled silicone composition comprising a hydrosilylation-curable silicone composition and a carbon nanomaterial, and heating the coated release liner at a temperature sufficient to cure the silicone resin; a silicone resin film prepared according to the preceding method; and a nanomaterial-tilled silicone composition.

Owner:DOW CORNING CORP

Silicone Resin Film, Method of Preparing Same, and Nanomaterial-Filled Silicone Composition

InactiveUS20100062247A1Increase flexibilityHigh mechanical strengthMaterial nanotechnologySynthetic resin layered productsPolymer scienceCarbon nanomaterials

A method of preparing a silicone resin film, the method comprising coating a release liner with a nanomaterial-filled silicone composition comprising a condensation-curable silicone composition and a carbon nanomaterial, and curing the silicone resin of the coated release liner; a silicone resin film prepared according to the preceding method, and a nanomaterial-filled silicone composition.

Owner:DOW CORNING CORP

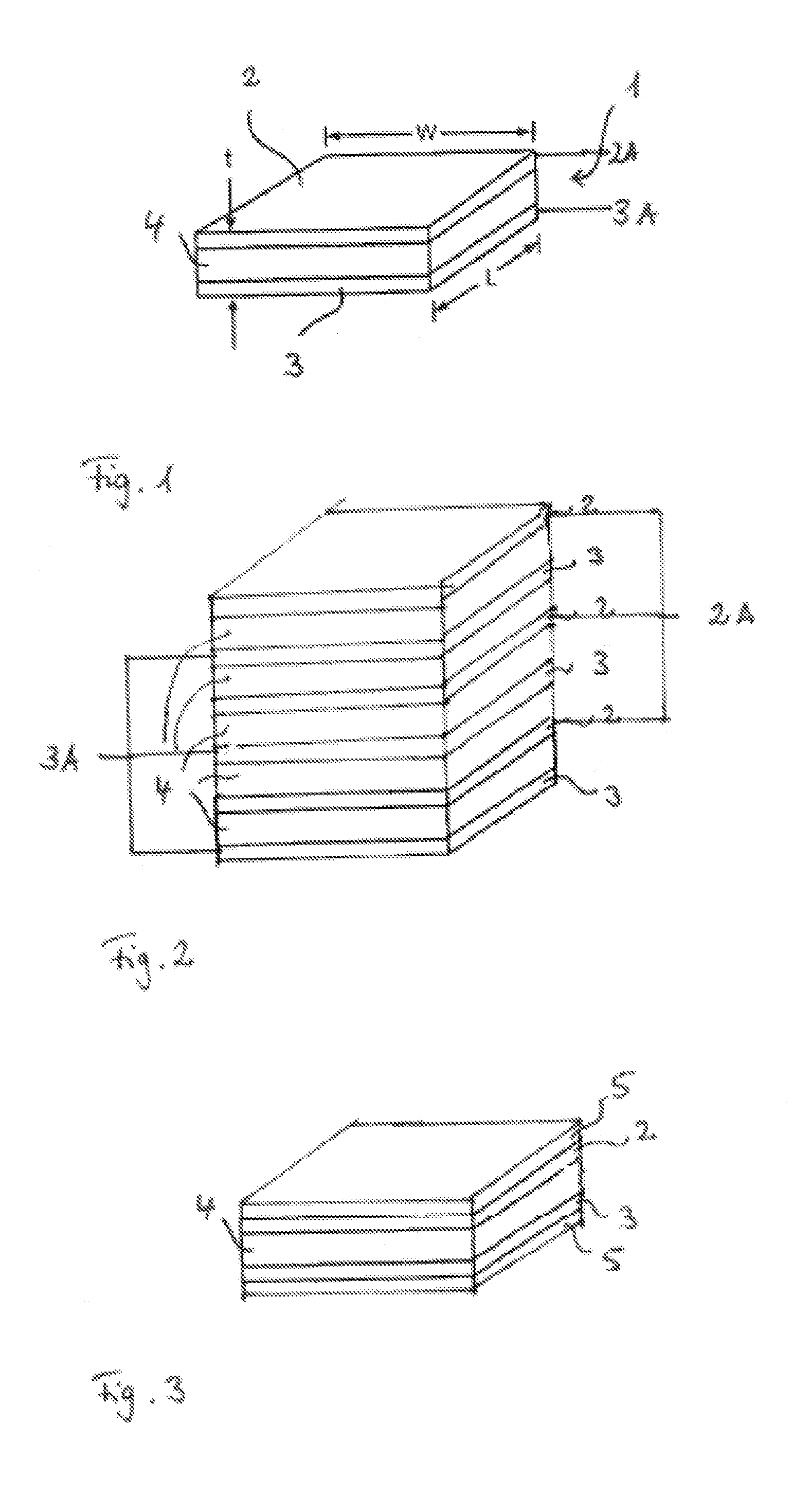

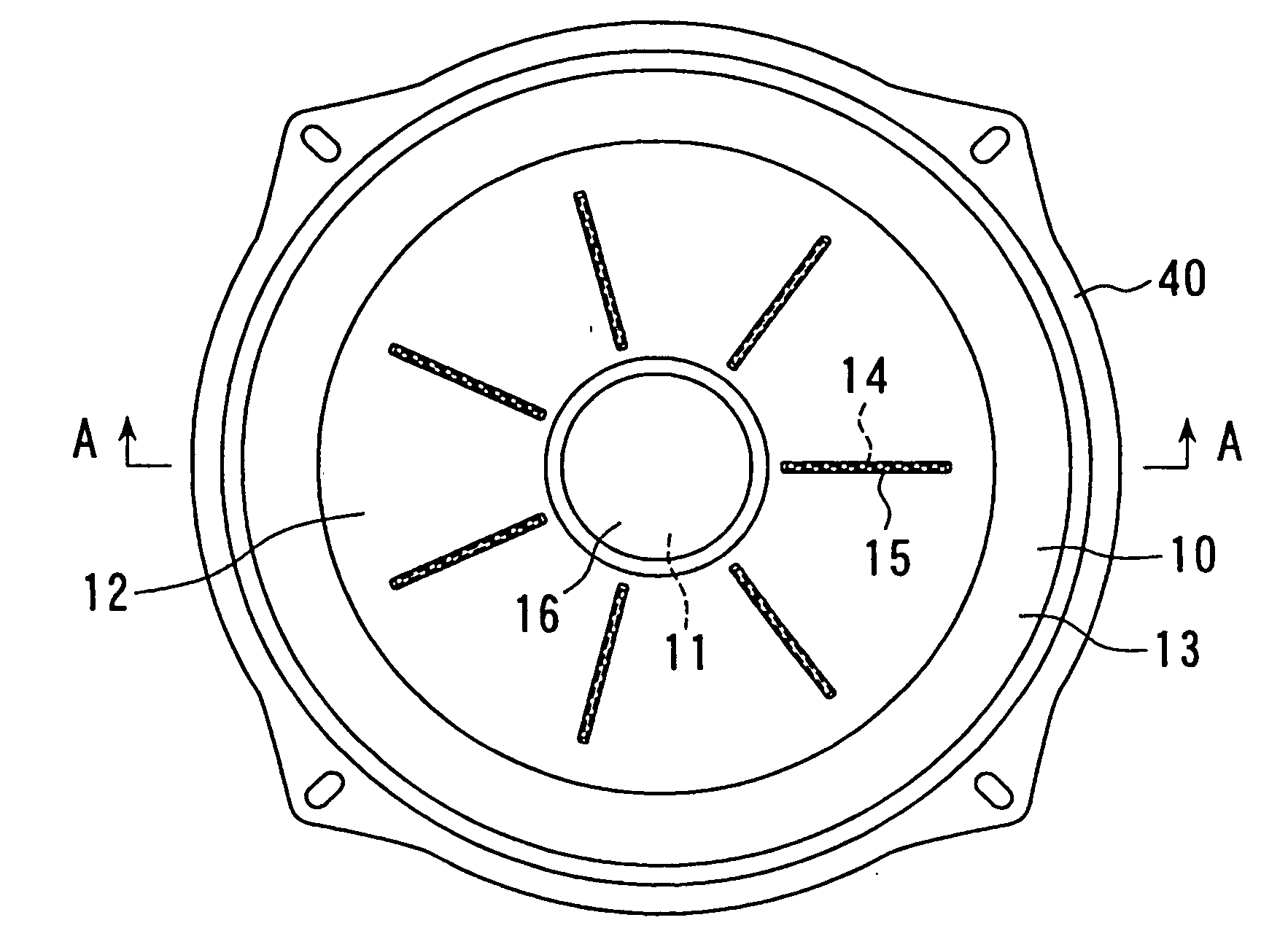

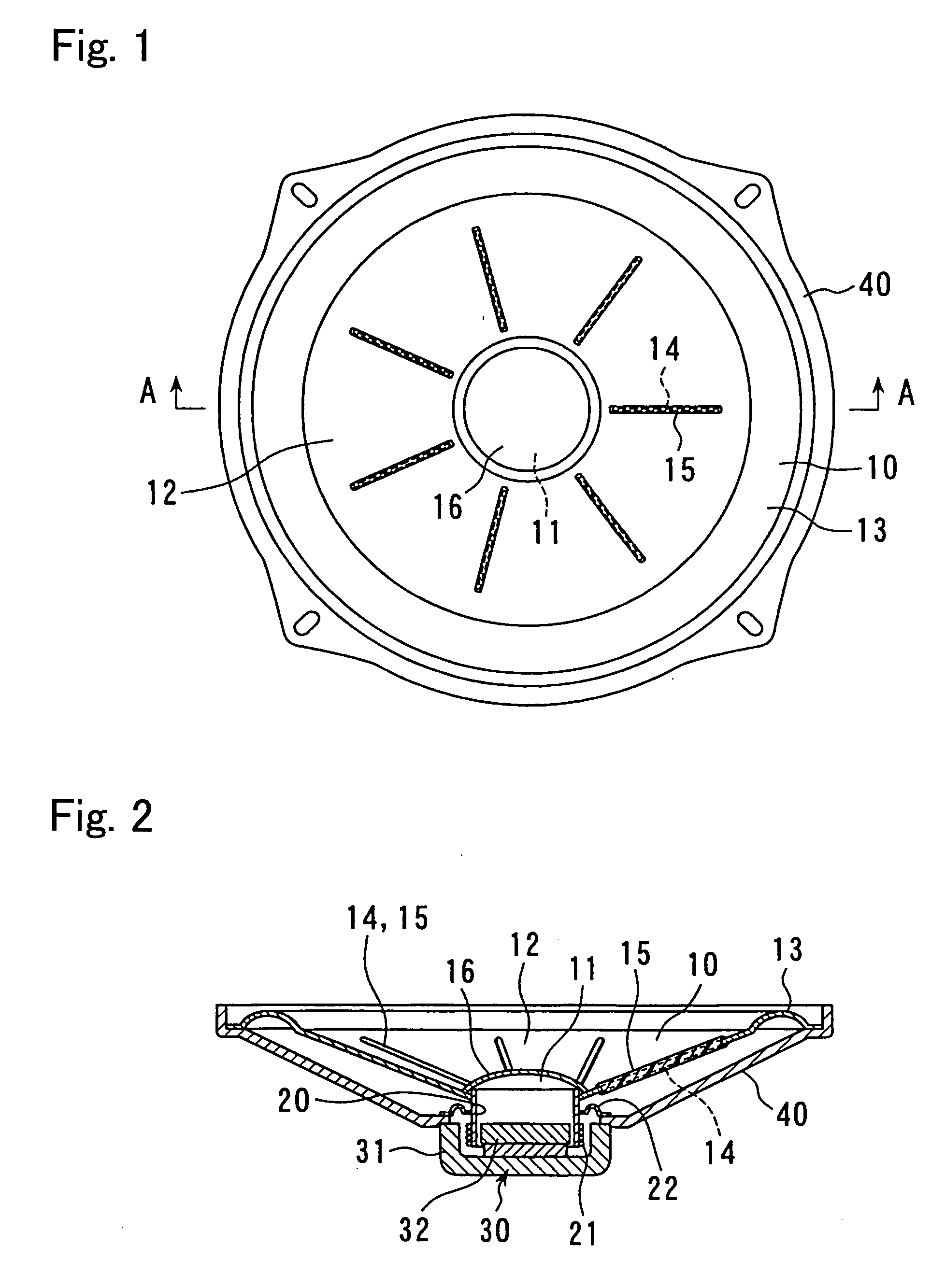

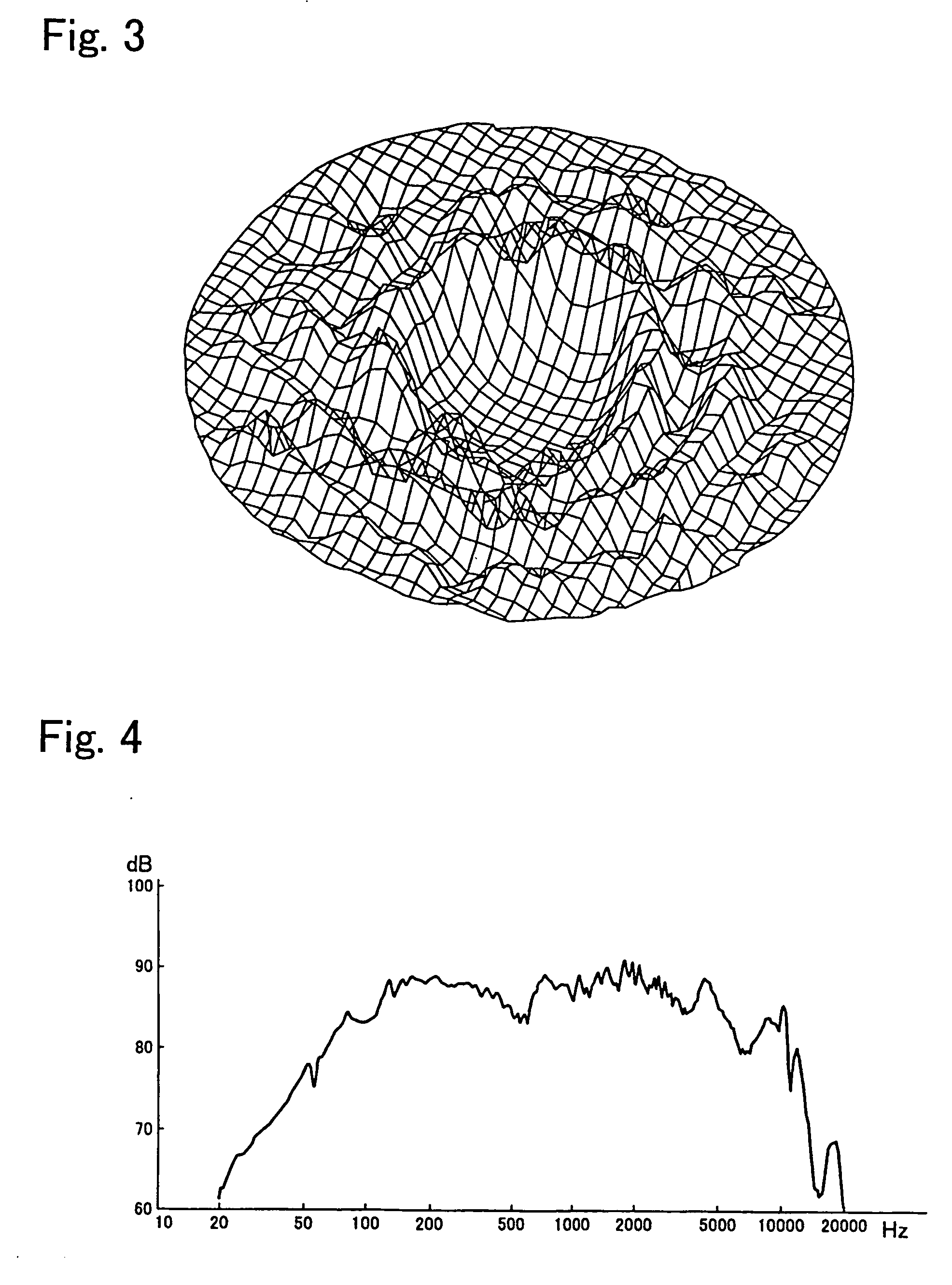

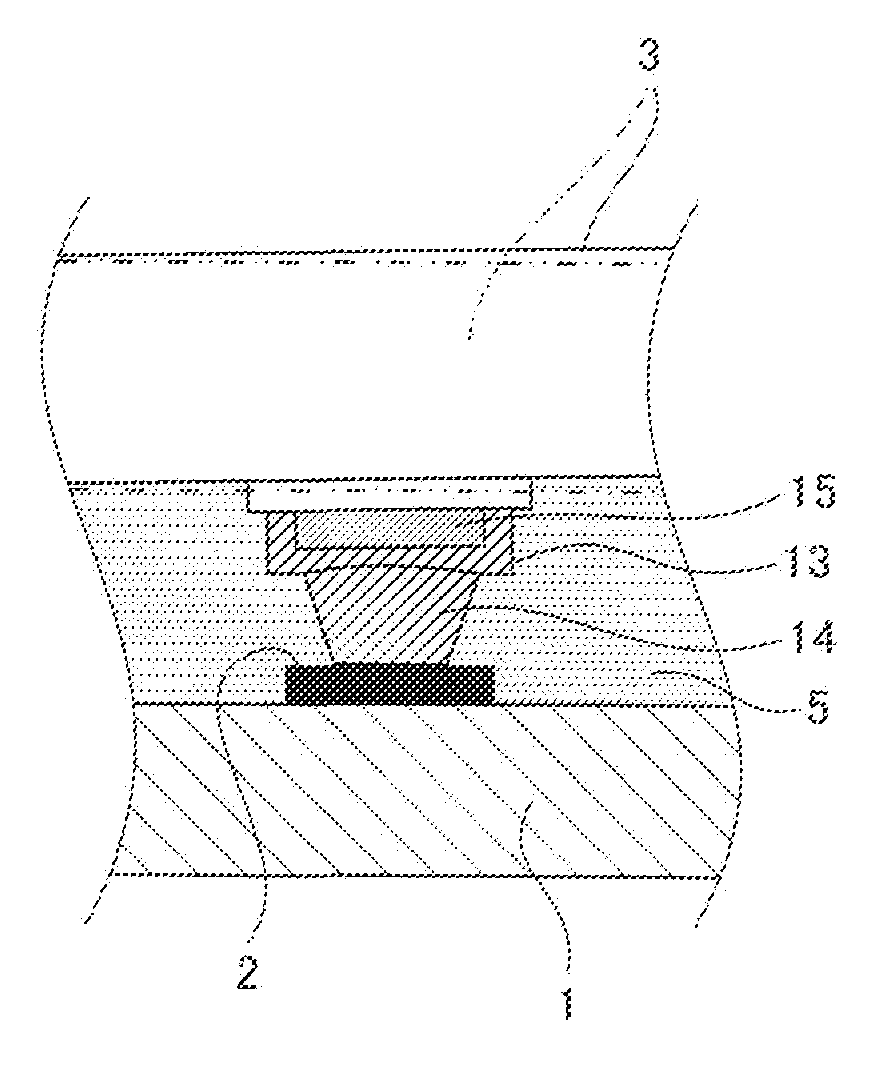

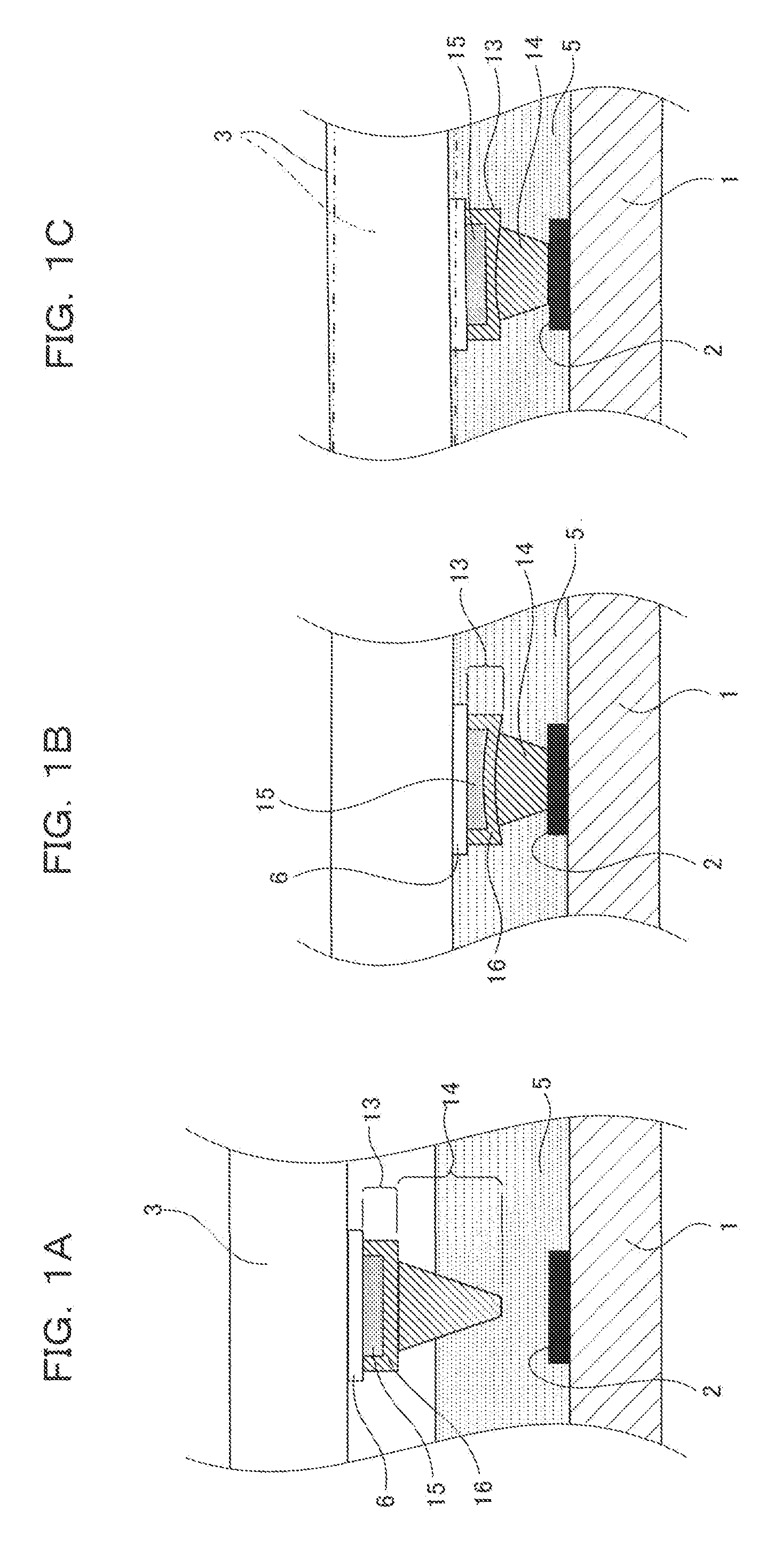

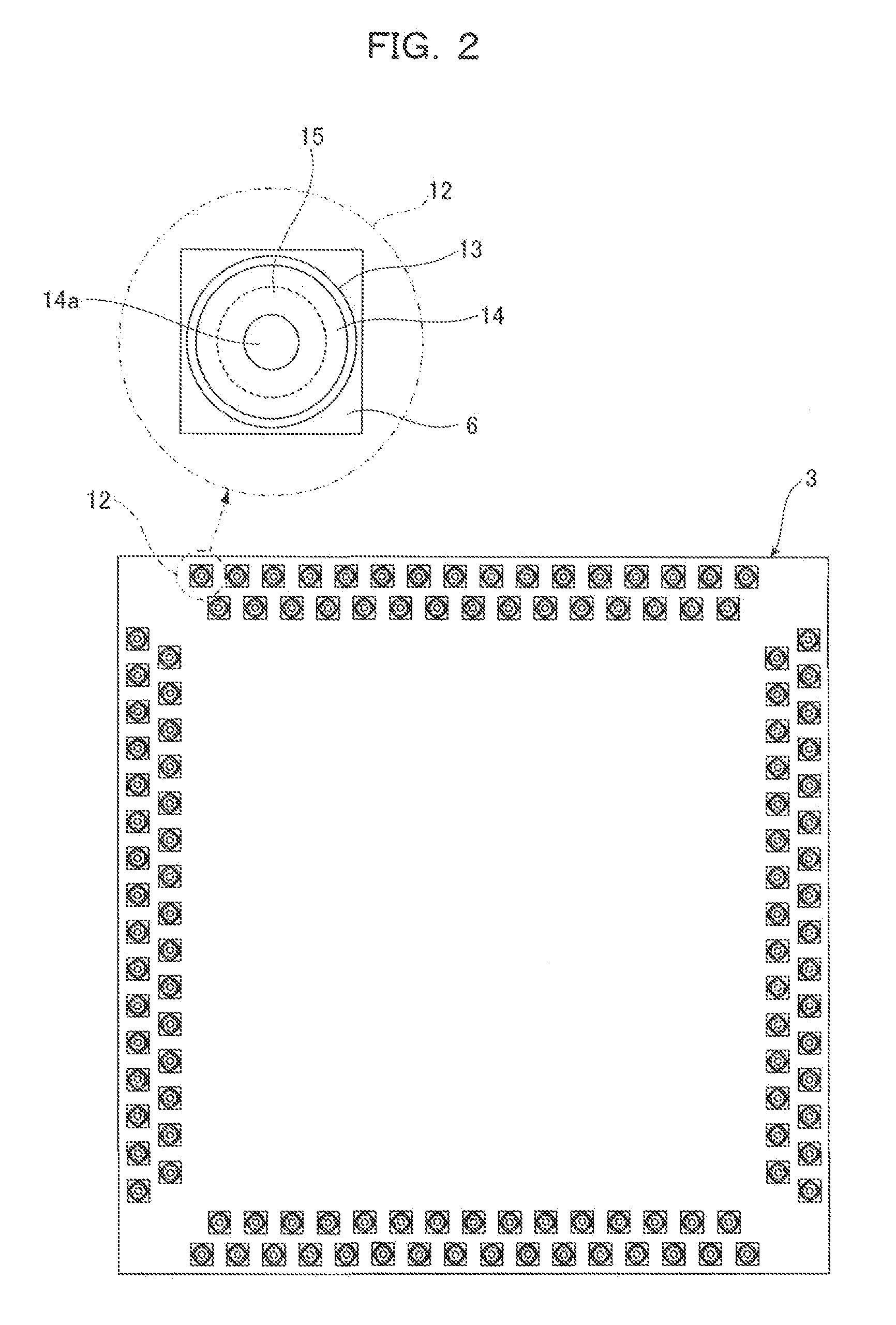

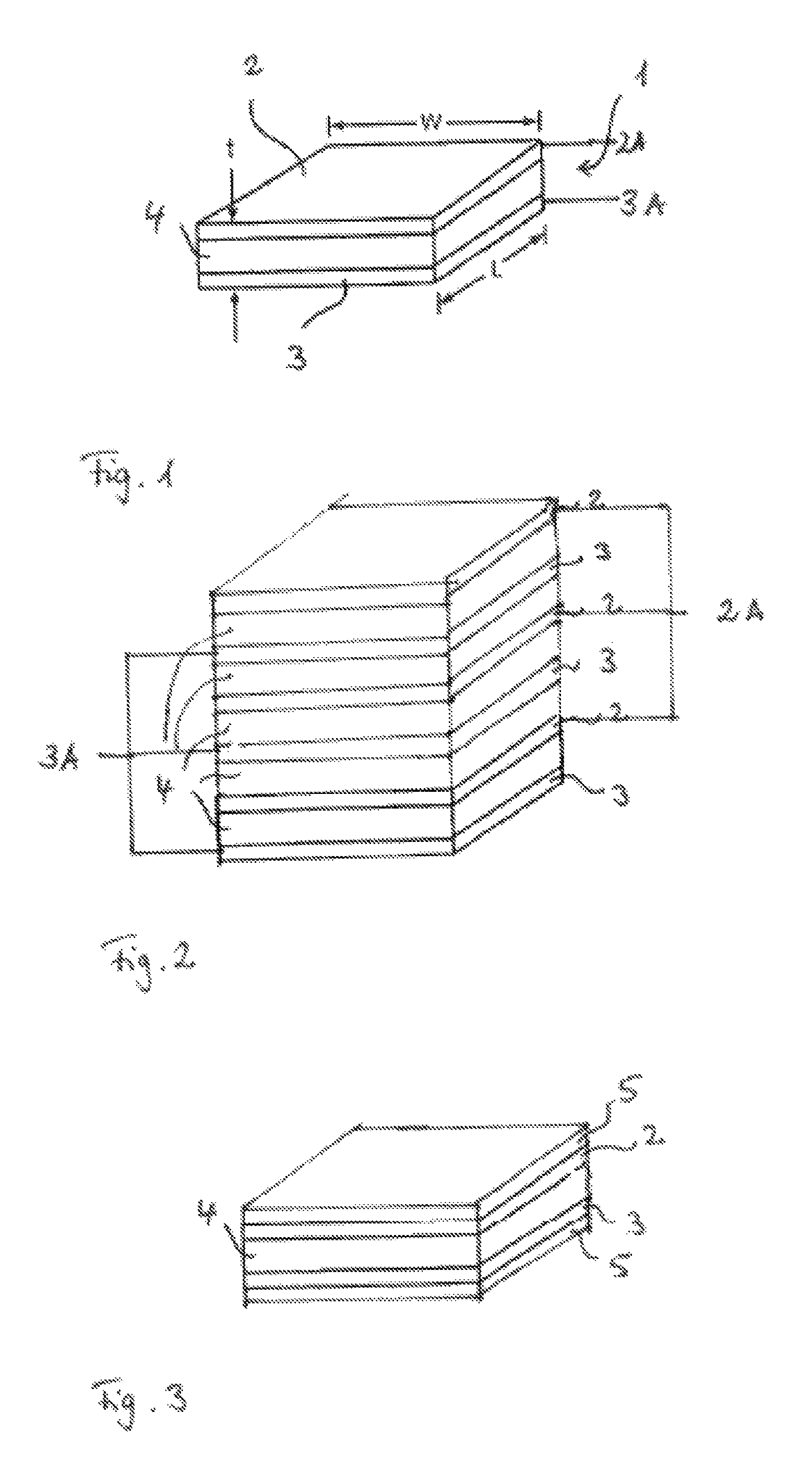

Diaphragm for loudspeaker and loudspeaker

InactiveUS20090028376A1Shorten production timeEasy to manufactureTransducer detailsNon-planar diaphragms/conesYoung's modulusLoudspeaker

A diaphragm body (12) is provided with a plurality of slits (14, 14a) extending from the central part thereof toward the outer circumference. The slits (14, 14a) are filled with a low-elasticity filling material composed of a material different from that of the diaphragm body (12). The slits (14, 14a) are extended rectilinearly or curvedly. The filling material (15) has a Young's modulus lower than that of the principal material of the diaphragm body (12) and / or an internal loss larger than of the principal material of the diaphragm body (12). Furthermore, the filling material (15) employs UV ray and / or visible ray curable resin or thermoplastic resin. Alternatively the filler (15) may be a porous material or a foamed material. The diaphragm body (12) produced by filling the slits (14, 14a) with the filling material (15) is employed for constituting a loudspeaker.

Owner:SAITO FUMIO +1

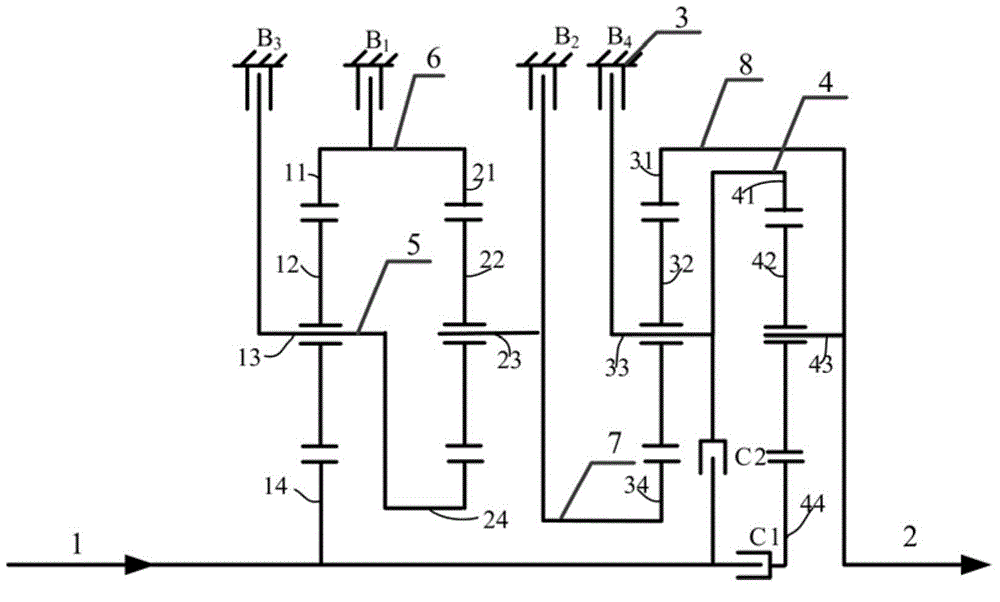

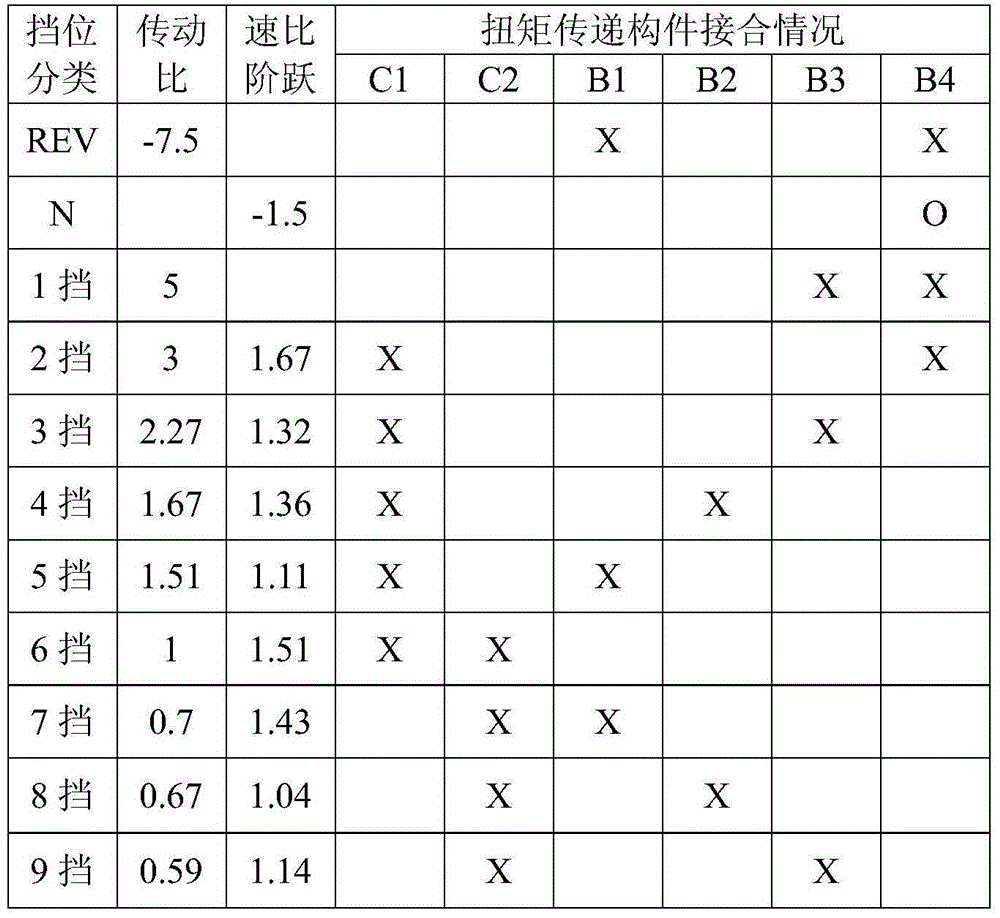

Nine-gear speed changer

InactiveCN105090394ASmall modulusCompact structureToothed gearingsTransmission elementsTorque transmissionGear train

The invention provides a nine-gear speed changer. The nine-gear speed changer mainly comprises an input shaft, an output shaft, planet gear rows, connecting members and torque transmission devices, which are all arranged in a speed changer housing, wherein each planet gear row comprises a sun gear, a planet carrier, a planet gear and a gear ring; the torque transmission devices include two clutches and four brakes; the two clutches and the four brakes are engaged selectively so as to rotate or fix the sun gears, the planet carriers, the gear rings or one of the five connecting members; the torque transmission devices can be engaged selectively in a combining form of at least two torque transmission devices so as to build the speed ratios of nine forward gears and the speed ratio of one reverse gear between the input shaft and the output shaft; and the nine forward gears include five deceleration gears, one direct gear and three overspeed gears. The speed changer provided by the invention is compact in structure, light in weight, small in size and easy to arrange on an automobile, and speed ratio steps between the transmission ratios of the gears of the speed changer meet the requirements of the speed changer.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

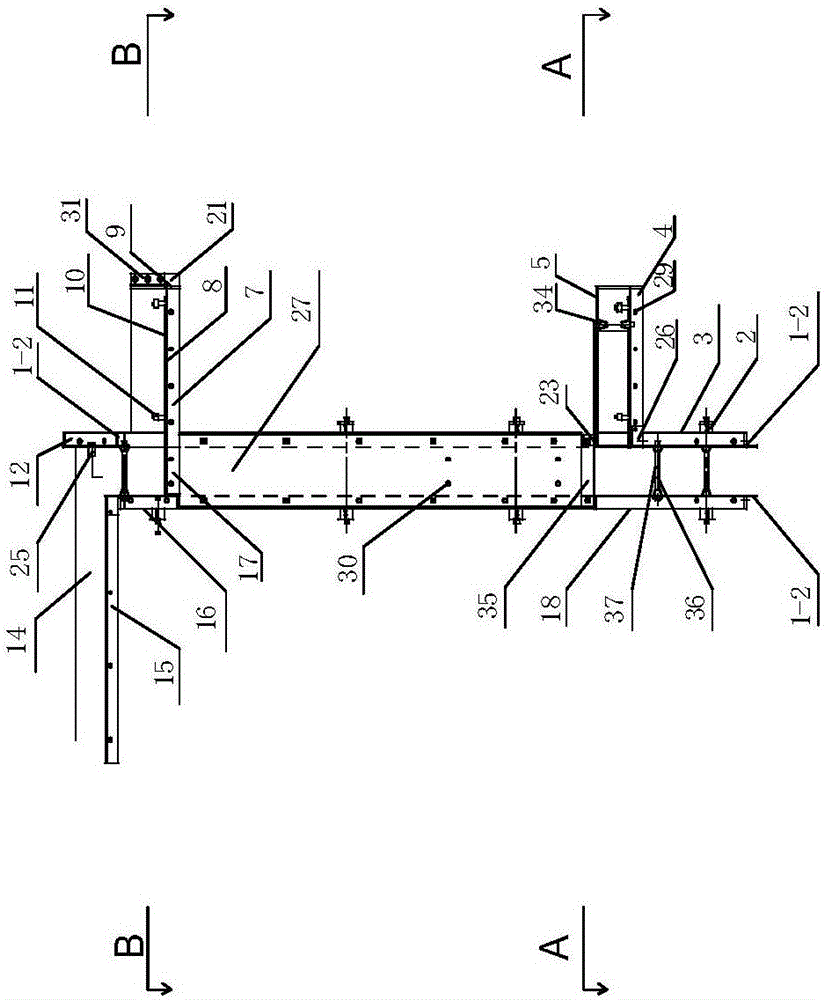

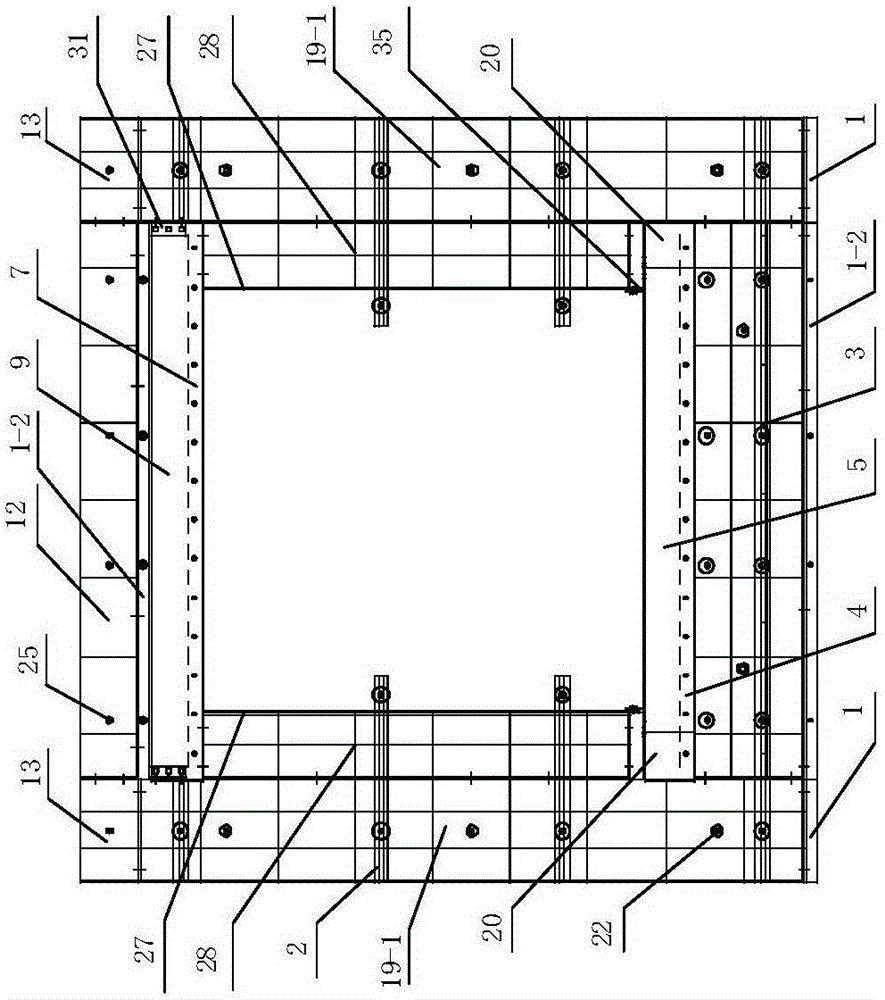

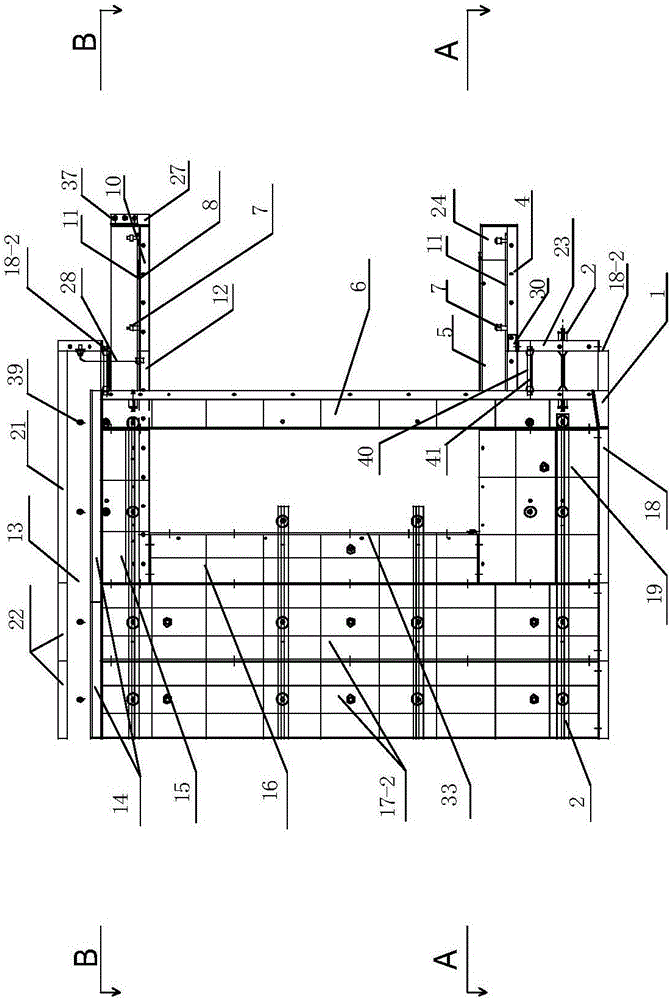

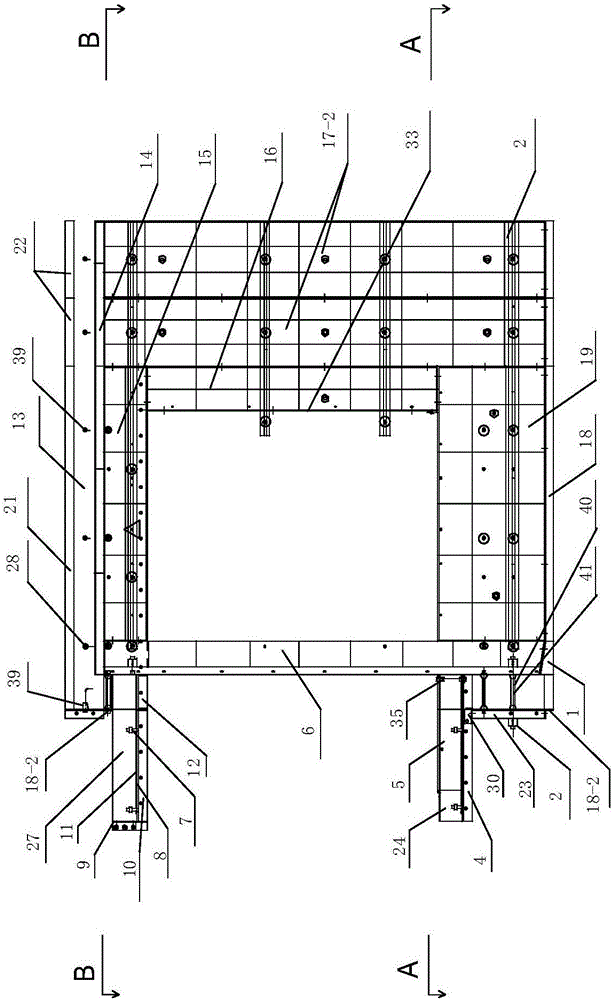

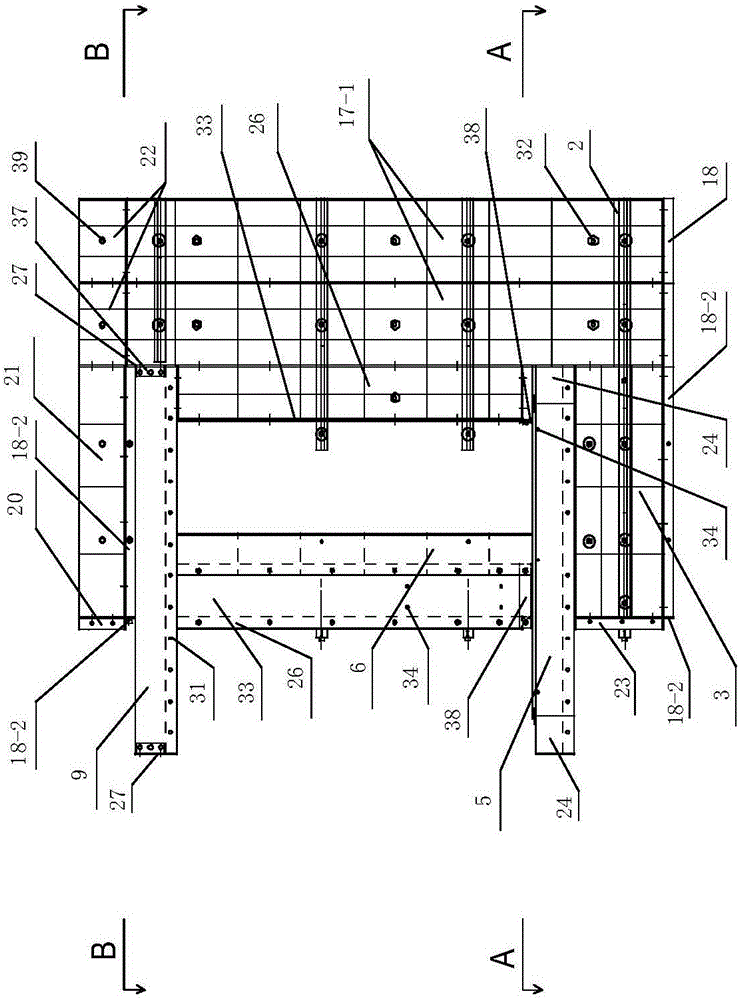

Bare concrete bay window steel formwork structural body device

InactiveCN105113789AFacilitate one-time pouring successEasy to assembleForms/shuttering/falseworksEngineeringBay window

The invention relates to a bare concrete bay window steel formwork structural body device. The bare concrete bay window steel formwork structural body device is characterized in that an under-window inner formwork and an under-window outer formwork are connected with main formworks commonly used for an inner wall and an outer wall through assembling holes, and a lower suspension bottom formwork and the under-window outer formwork can be directly assembled through corner connecting pieces; one side face of a window inner formwork and one side face of a window outer formwork are connected with the inner wall main formwork and the outer wall main formwork on the two sides of a window respectively; the bottom edges of two bay window aperture formworks are hung in the air to be at the same height as the lower side of the window inner formwork, and are connected with the other side face of the window inner formwork and the other side face of the window outer formwork respectively; an upper suspension bottom formwork, a window beam bottom formwork and window beam inner formworks are connected and assembled; the window beam inner formworks and window beam outer formworks are oppositely pulled to be fixed through screw rod sleeves; the window beam inner formworks, the window beam outer formworks, the window beam bottom formwork and the upper suspension bottom formwork are connected with the main formwork commonly used for the outer wall and a connection formwork on the upper portions of the bay window aperture formworks. The device has the advantages of being simple in structure, convenient to assemble and capable of reducing labor and cost; concrete can be successfully poured at a time to form a whole structural body, the anti-seismic effect is enhanced, and construction quality is improved; the steel formwork is high in university and capable of meeting various structural requirements.

Owner:刘其标

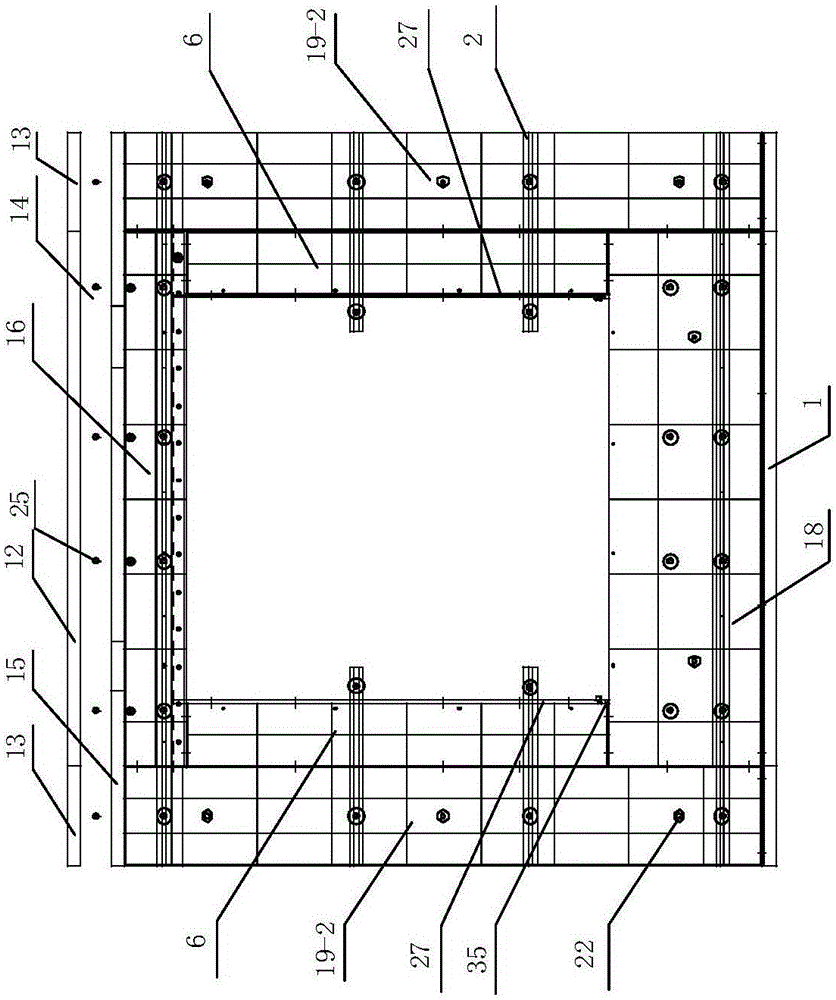

Bare-concrete corner floating window steel formwork structure body device

InactiveCN105113790AEasy to pour at one timeEasy to assembleForms/shuttering/falseworksStructural engineeringLower face

The invention relates to a bare-concrete corner floating window steel formwork structure body device. The device is characterized in that an internal corner formwork stretching to the top is arranged at the corner, and on the lower portion of the internal corner formwork, an under-window inner formwork, an under-window outer formwork and lower floating bottom formworks are assembled to be connected with an inner-wall universal main formwork and an outer-wall universal main formwork through the internal corner formwork; one side faces of two window inner formworks and one side faces of two window outer formworks are connected with the inner-wall main formwork and the outer-wall main formwork arranged on the two sides of a window respectively; the bottom edges of two floating window hole formworks suspend at the height same as that of the lower faces of the window inner formworks and connected with the other side faces of the window inner formworks and the window outer formworks; on the upper portion of the internal corner formwork, a window beam inner formwork, a window beam outer formwork, a window beam bottom formwork and upper floating bottom formworks are assembled to be connected with the inner-wall universal main formwork and the outer-wall universal main formwork through the internal corner formwork. Due to the fact that the device adopts the internal corner formwork stretching to the top, assembly of a corner floating window steel formwork is facilitated; according to the device, concrete can be successfully poured into an integral structure body for once, and therefore the anti-shock effect is enhanced; the steel formwork is high in universality and comprehensive in function and can meet requirements of various structures.

Owner:刘其标

Conductive composition and electronic parts using the same

ActiveUS20170243849A1Small modulusMaintain bonding strengthNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsSolventBonding strength

A conductive composition, which can form bonded portions and is capable of maintaining a thickness of the bonded portions and bonding strength, and which includes: (A) silver fine particles having a number average particle diameter of primary particles of 40 nm to 400 nm, (B) a solvent, and (C) thermoplastic resin particles having a maximal value of an endothermic peak in a DSC chart, determined by a measurement using a differential scanning calorimeter, within a range of 80° C. to 170° C.

Owner:NAMICS CORPORATION

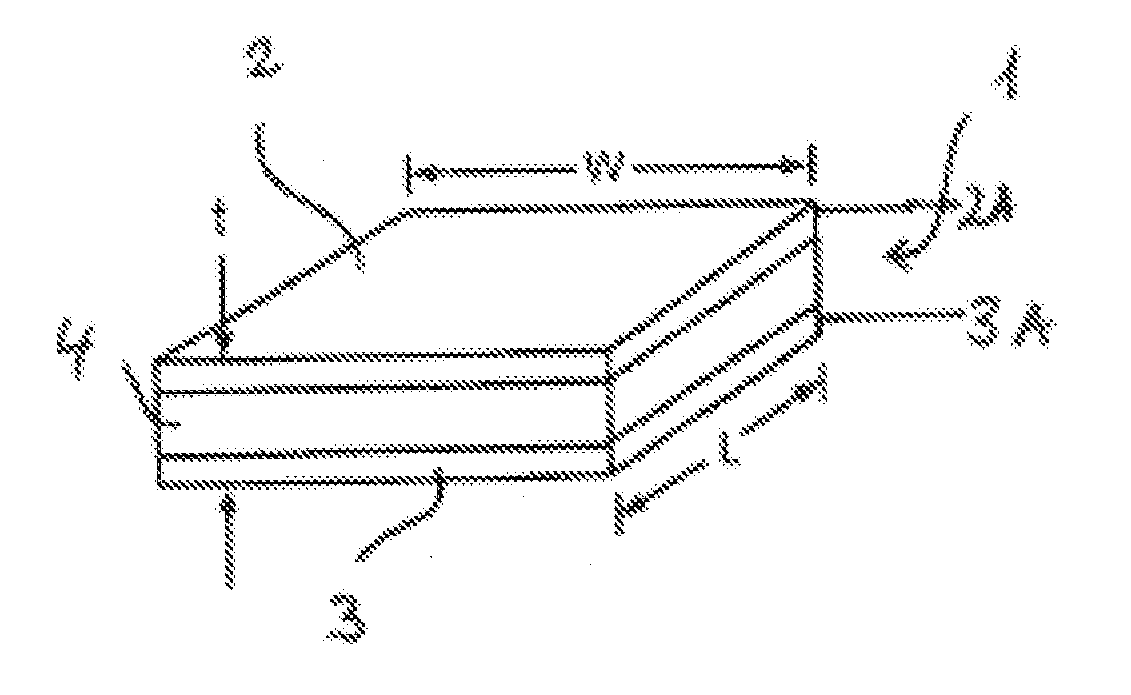

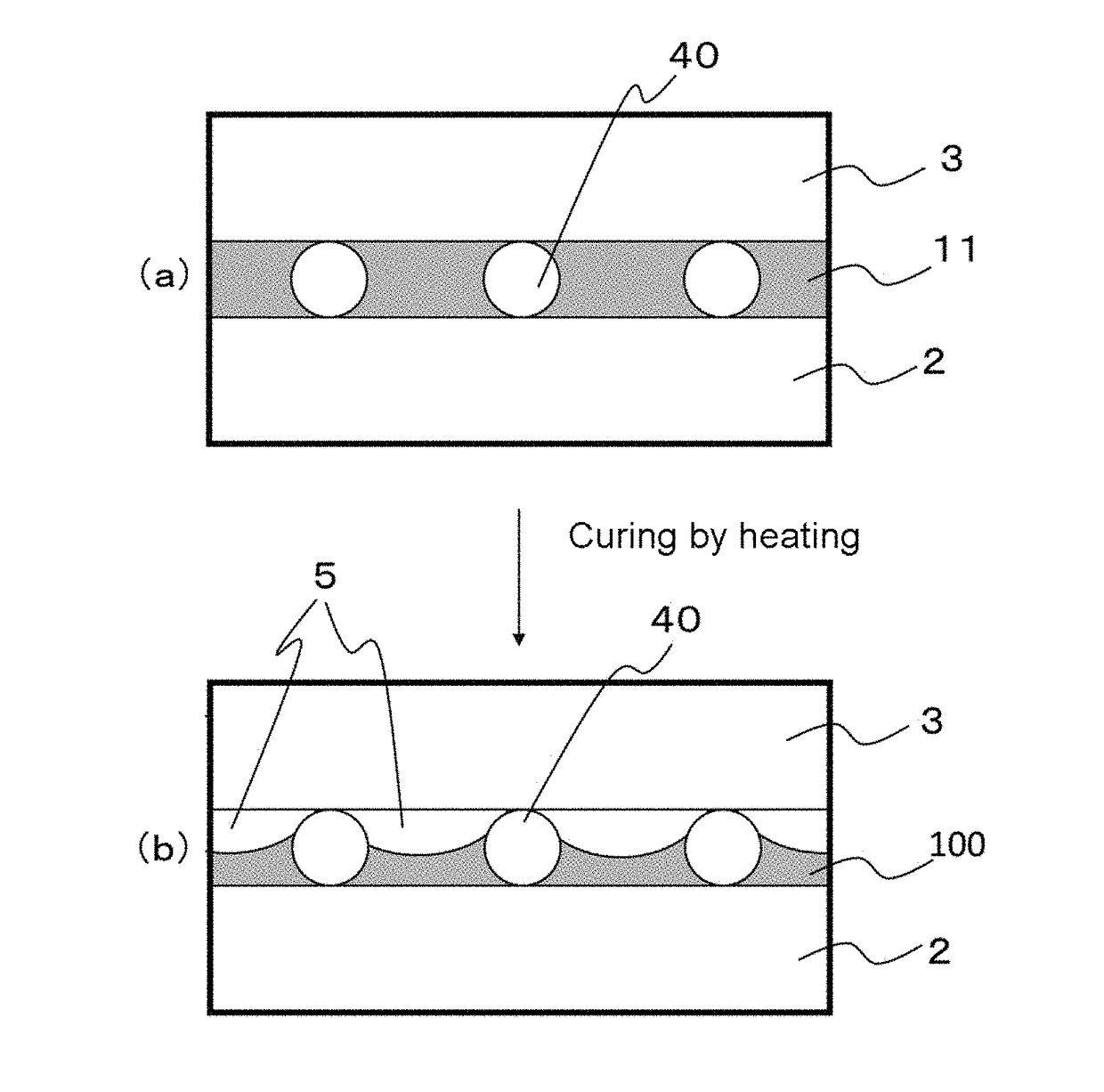

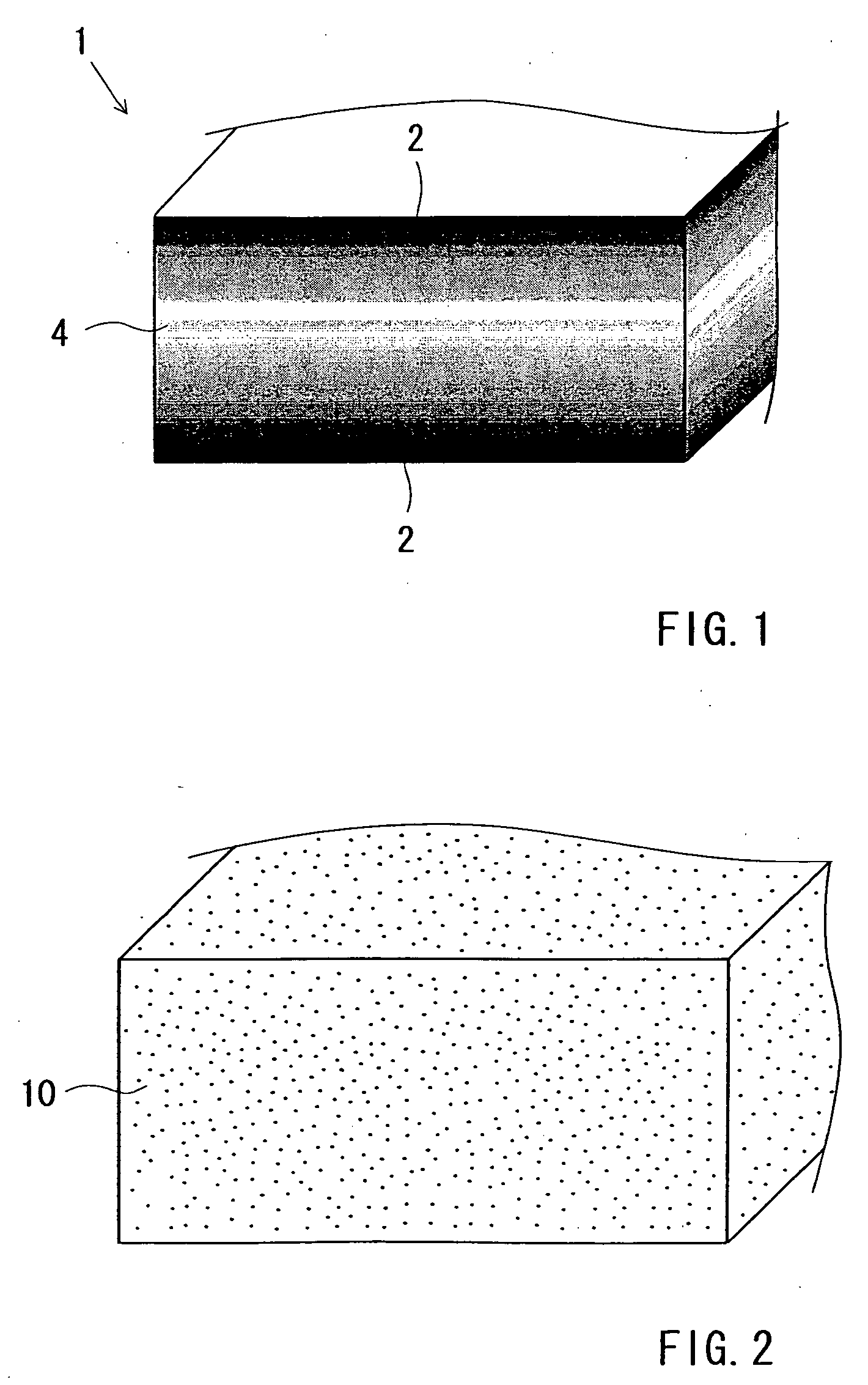

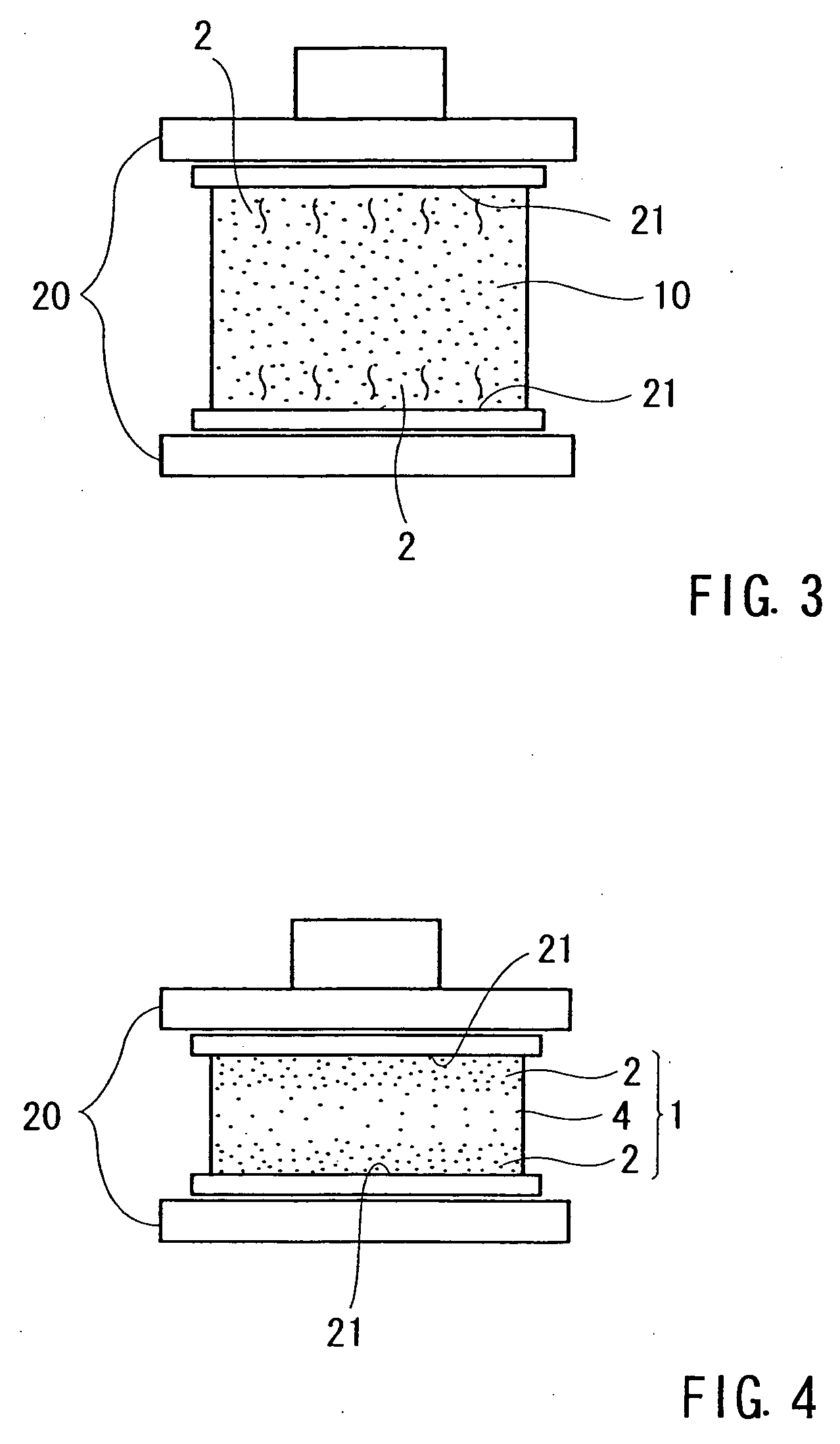

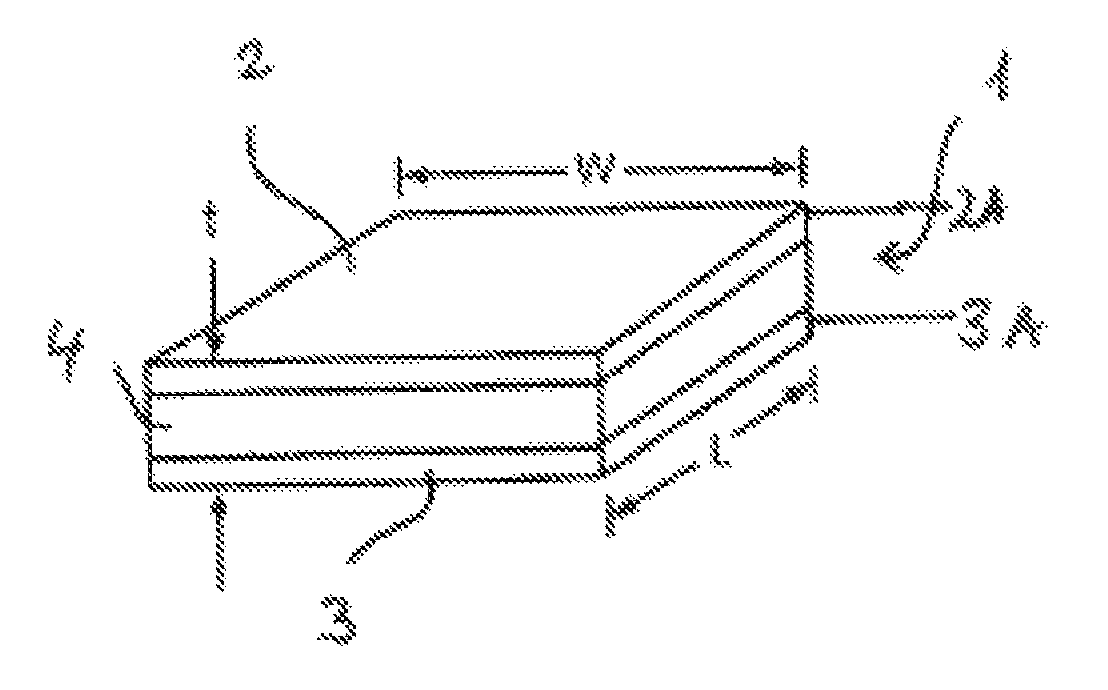

Method of manufacturing woody formed body and woody formed body

InactiveUS20050127567A1Satisfactory bending strengthEasy to manufactureWood working apparatusFlat articlesHigh densityVolumetric Mass Density

A method of manufacturing a molded woody product 1 includes the steps of: softening a surface portion 2 of a primary molding body containing a woody material and a thermosetting binder; and compressing the primary molding body as a whole; and hardening the primary molding body as a whole in a state in which the primary molding body is compressed by the compressing step. In this manufacturing method, the primary molding body is compressed after softening the surface portion 2 thereof, thereby making it possible to selectively compress the surface portion 2. Then, by hardening the primary molding body as a whole in this state, it is possible to obtain a woody molded product whose surface portion 2 is of relatively high density and hardened, and whose inner portion 4 is of relatively low density.

Owner:ARACO CORP

Silicone Resin Film, Method Of Preparing Same, And Nanomaterial-Filled Silicone Composition

InactiveUS20100233379A1Increase flexibilityHigh mechanical strengthPigmenting treatmentNanotechPolymer scienceCarbon nanomaterials

A method of preparing a silicone resin film comprising coating a release liner with a nanomaterial-filled silicone composition comprising (i) a free radical-curable silicone composition comprising a silicone resin and (ii) a carbon nanomaterial, and curing the silicone resin of the coated release liner; a silicone resin film prepared according to the preceding method; and a nanomaterial-filled silicone composition.

Owner:DOW CORNING CORP

Method for solving problem of burnt-on sand of thick-wall steel casting

InactiveCN102794426ASmall modulusUnique process methodFoundry mouldsFoundry coresWater basedIsolation layer

The invention relates to a method for solving the problem of burnt-on sand of a casting, in particular to a method for solving the problem of burnt-on sand of a thick-wall steel casting. The method comprises the following steps of: preparing the materials Q235 steel and Phi 80 sand-isolation chiller; uniformly distributing and welding the sand-isolation chiller on an arbor, and placing the arbor in a core box, wherein the thickness of the sand-isolation layer of the sand-isolation chiller is controlled at 30-50mm; enabling a layer of 50mm-thick chrome ore to flow on the inner surface in the core box; reinforcing and compacting the key corner parts; enabling silica sand to flow; and opening the box and coating the whole box with water-based paint for three times. The method provided by the invention is unique and can solve the problem of burnt-on sand of the thick-wall casting.

Owner:NINGXIA KOCEL GRP CO LTD +1

Silicone resin film, method of preparing same, and nanomaterial-filled silicone composition

InactiveUS8084097B2Reduction factorHigh tensile strengthPigmenting treatmentNanotechCarbon nanomaterialsPolymer chemistry

A method of preparing a silicone resin film comprising coating a release liner with a nanomaterial-filled silicone composition comprising (i) a free radical-curable silicone composition comprising a silicone resin and (ii) a carbon nanomaterial, and curing the silicone resin of the coated release liner; a silicone resin film prepared according to the preceding method; and a nanomaterial-filled silicone composition.

Owner:DOW CORNING CORP

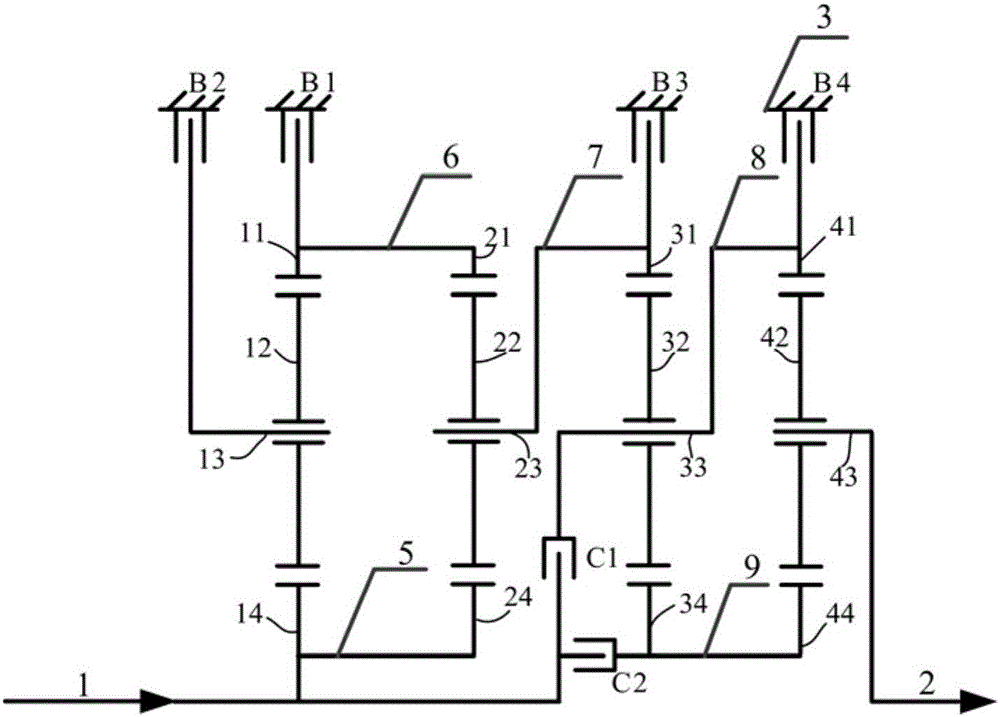

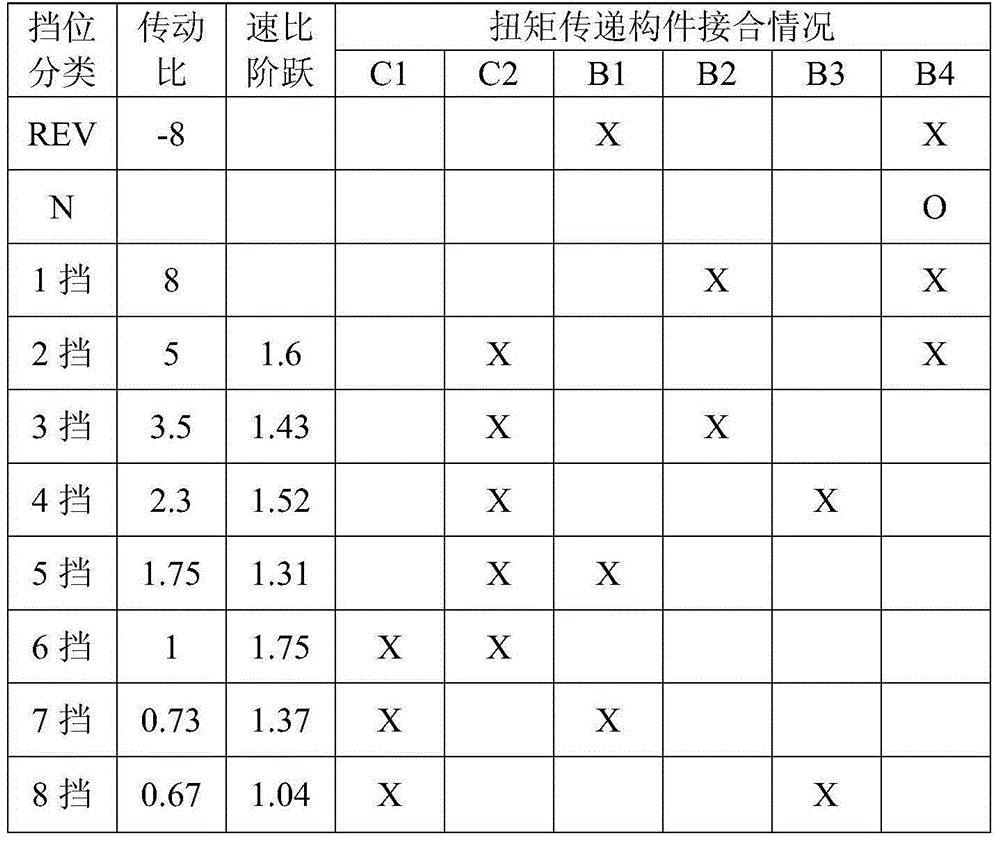

Improved eight-gear transmission

InactiveCN105003633ASmall modulusCompact structureToothed gearingsTransmission elementsGear transmissionVariator

The invention provides an improved eight-gear transmission which mainly comprises an input shaft, an output shaft, planet gear rows, connecting components and torque transmission devices. The input shaft, the output shaft, the planet gear rows, the connecting components and the torque transmission devices are arranged in a transmission shell. Each planet gear row comprises a sun gear, a planet carrier, a planet wheel and a gear ring. Each torque transmission device comprises two clutches and four brakes, wherein the two clutches and the four brakes are connected selectively so that the sun wheels, the planet carriers, the gear rings and one of the five connecting components can rotate or can be fixed. In addition, at least two torque transmission devices can be connected selectively in a combined mode so that eight forward gear speed ratios and one reverse gear ratio can be established between the input shaft and the output component; the forward gears are five deceleration gears, one direct gear and two overspeed gears. The transmission is compact in structure, low in weight, small in size and easy to arrange on an automobile, and the speed ratio step among the gears of the transmission meets the requirement of the transmission.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method of joining members having different thermal expansion coefficients

InactiveUS7686205B2Increased durabilityReduce stiffnessWelding/cutting media/materialsSoldering mediaWaxPowder mixture

Provided is a method of joining members having different thermal expansion coefficients, capable of joining them at a temperature lower than the melting point of Ag to obtain a joining layer having excellent durability to a thermal cycle. First Ag particles 3 having an average particle diameter of 50 nm or less and an Ag foil 4 or metal foil 4 having a smaller modulus of longitudinal elasticity than that of Ag are placed between two types of members 1 and 2 at least one of which has a lower thermal expansion coefficient than that of Ag, heated to join the members 1 and 2. A wax material 3, which is a powder mixture containing first Ag particles having an average particle diameter of 50 nm or less and second Ag particles or particles of a metal (having a modulus of longitudinal elasticity than that of Ag) having an average particle diameter of 20 μm or more and being contained in a volume fraction of 10 to 40% relative to a total volume of the powder mixture, is placed between the two types of members 1 and 2, heated to join the members 1 and 2. The metal foil 4 and the particles of a metal have an Ag coating layer on a surface thereof. The first member 1 is formed of one type of material selected from the group consisting of Si, SiC, Al2O3, AlN and Si3N4 and the second member is formed of Al or Cu.

Owner:HONDA MOTOR CO LTD

Double-motor input wheel-side speed reducer for electric bus

InactiveCN102529710AGuaranteed uptimeExtended service lifeMotor depositionControl devicesGear wheelReduction drive

The invention relates to a double-motor input wheel-side speed reducer for an electric bus. The double-motor input wheel-side speed reducer comprises a planetary gear speed reducer arranged in a wheel, wherein a wheel shaft is arranged in the planetary gear speed reducer; a driven bevel gear is arranged on the wheel shaft; two driving bevel gears are arranged on the outer side of the driven bevel gear and meshed with the driven bevel gear; meshed points between the two driving bevel gears and the driven bevel gear averagely divide the circumference of the driven bevel gear; and each driving bevel gear is driven by a driving motor. The double-motor input wheel-side speed reducer provided by the invention is suitable for electric buses.

Owner:SUZHOU LECE E BUS ENG TECH

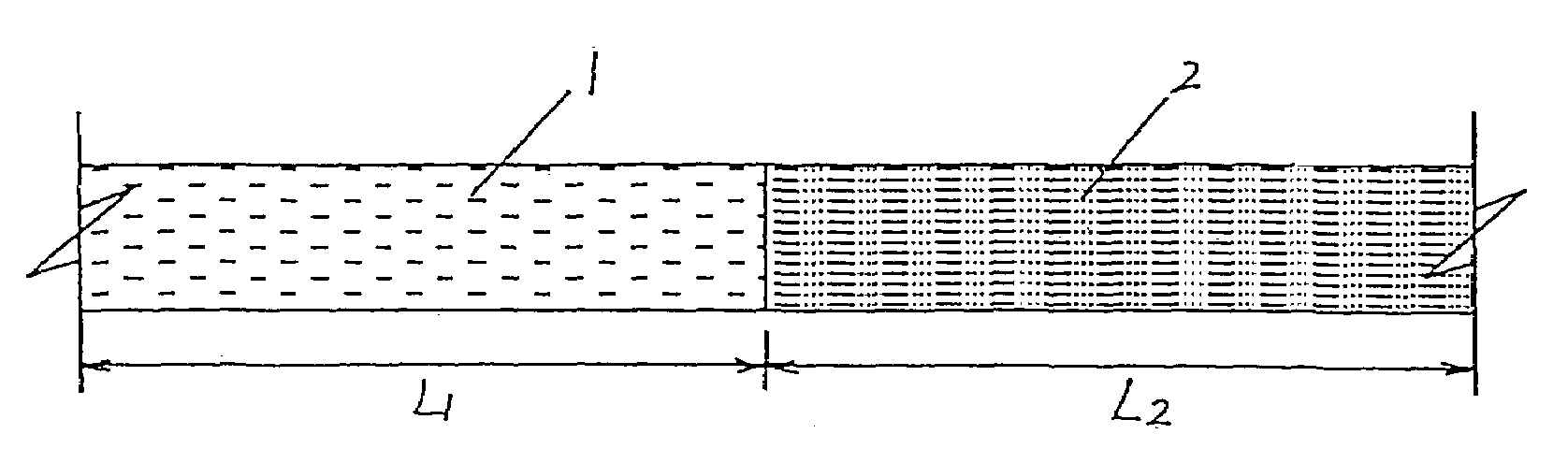

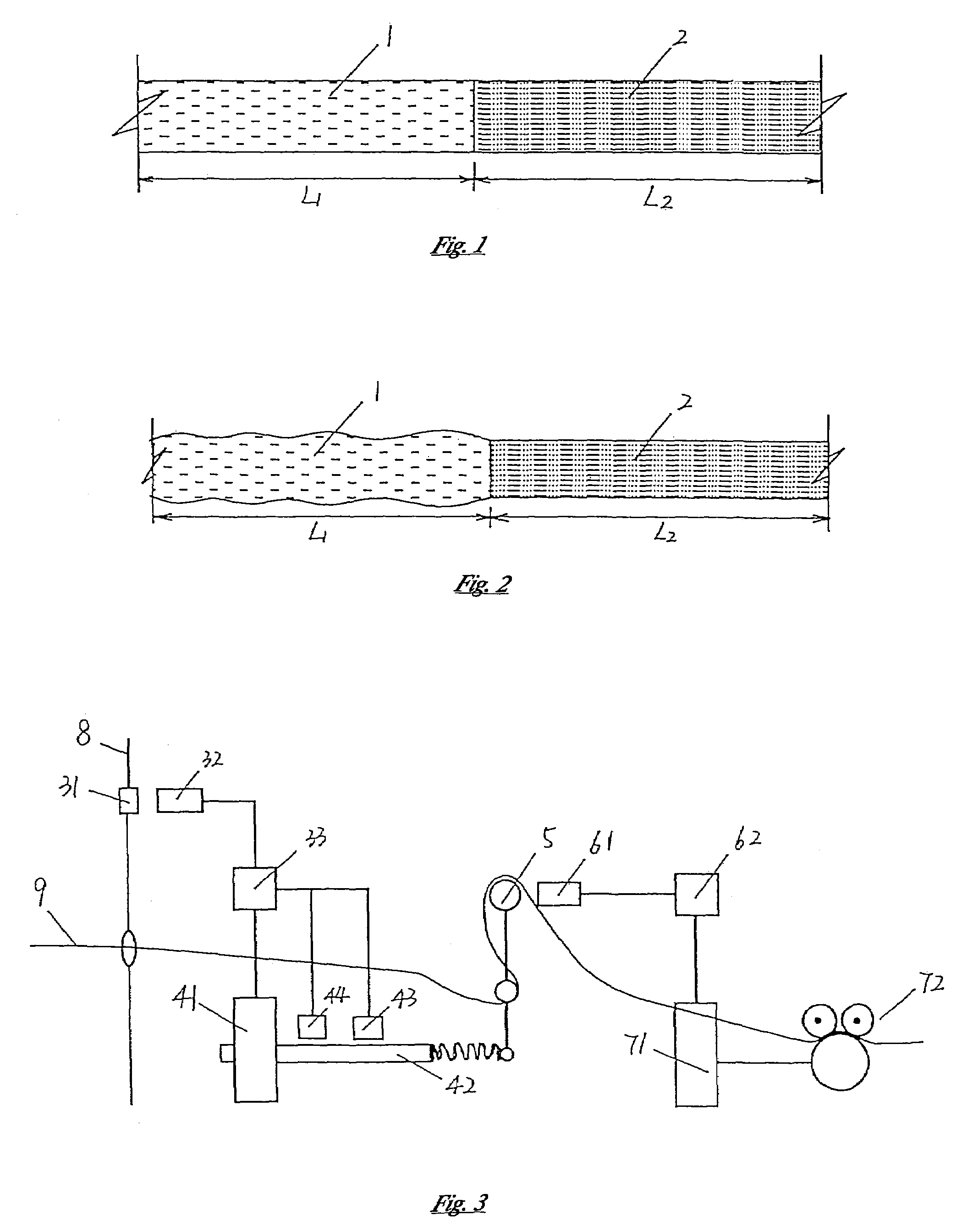

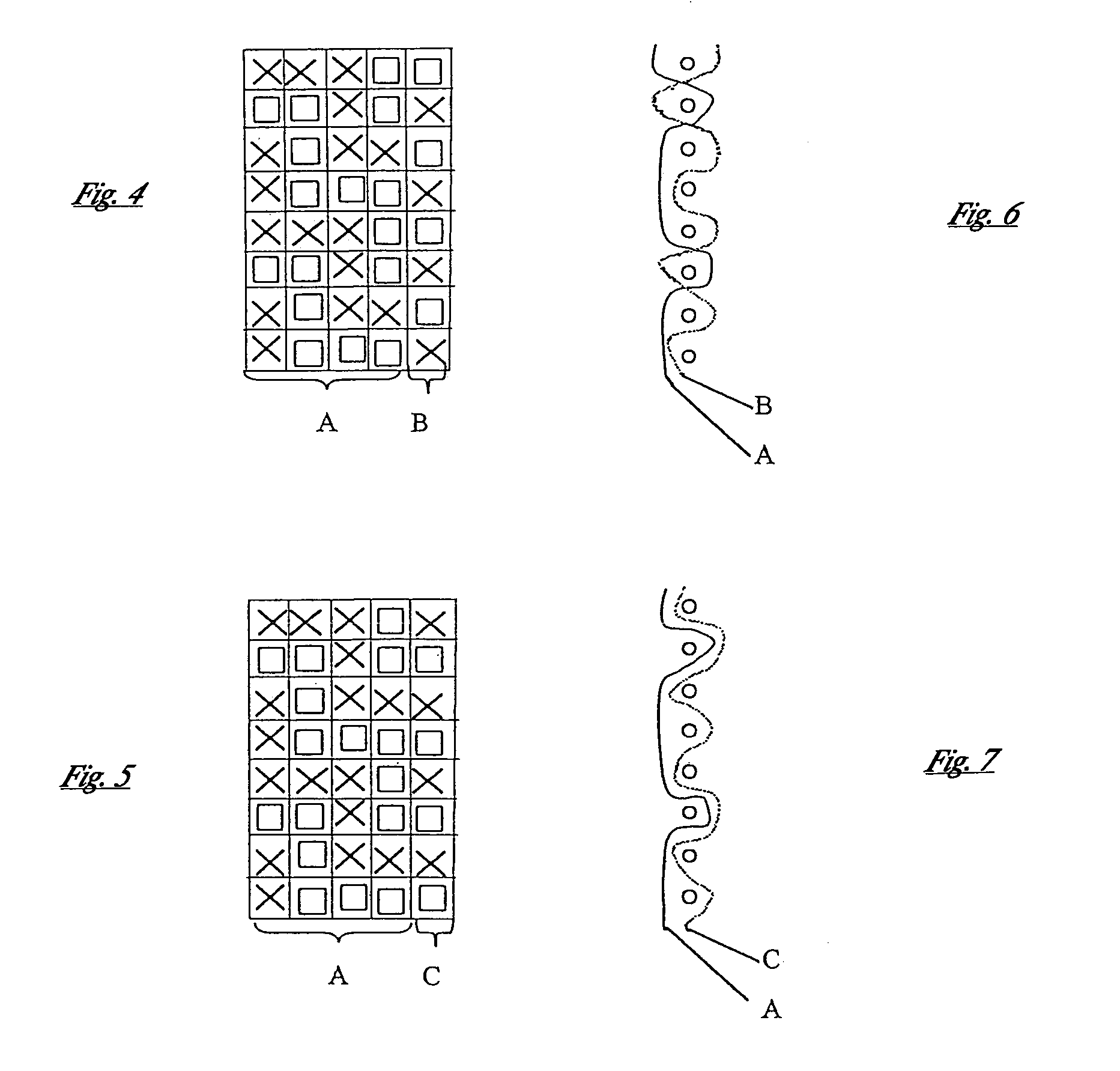

Elastic woven tape and a method of forming same

ActiveUS7117900B2Guaranteed aestheticsLarge elongationLayered productsShoulder strapContinuous integrationEngineering

An elastic woven tape is disclosed as being composed of at least two kinds of tape sections, each of which having a respectively different elongation and / or modulus, and formed by alternating and continuous integration of these two kinds of tape sections by weaving. The weaving method of the said elastic woven tape includes controlling the changes in the degrees of elasticity provided by elastic threads for the woven tape in mechanized weaving through the control of the feeding speeds of the elastic threads. The advantageous effects of this invention lie in the production of a woven tape composed of tape sections respectively with larger elongation but smaller modulus and with smaller elongation but larger modulus by means of their alternating and continuous integration by weaving, which simplifies the post-weaving operation and improves production efficiency. The resultant woven tape has no connections or joints, which assures the overall beauty of the apparel with the woven tape and the comfort of the apparel in wearing.

Owner:PIONEER ELASTIC FABRIC

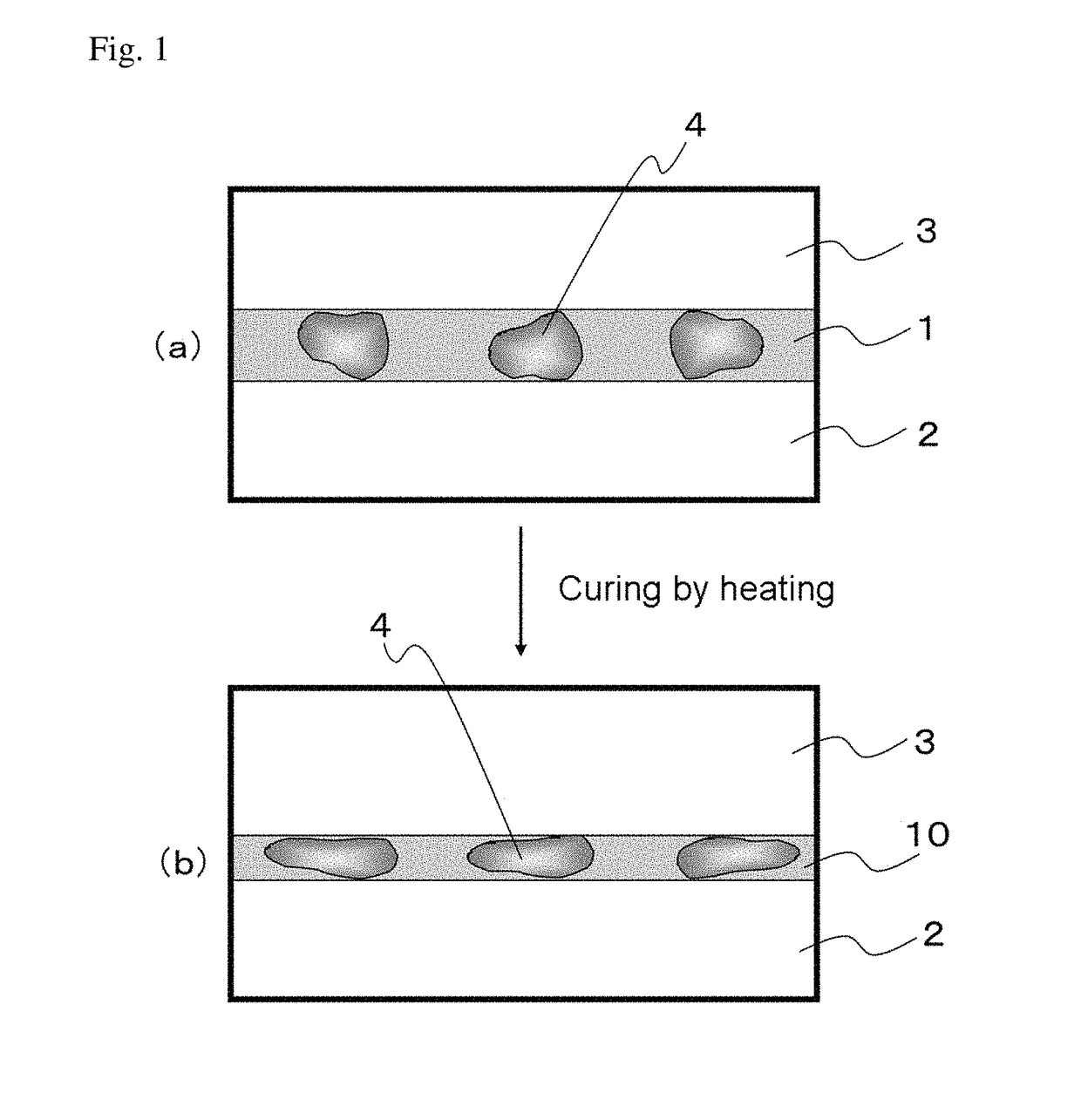

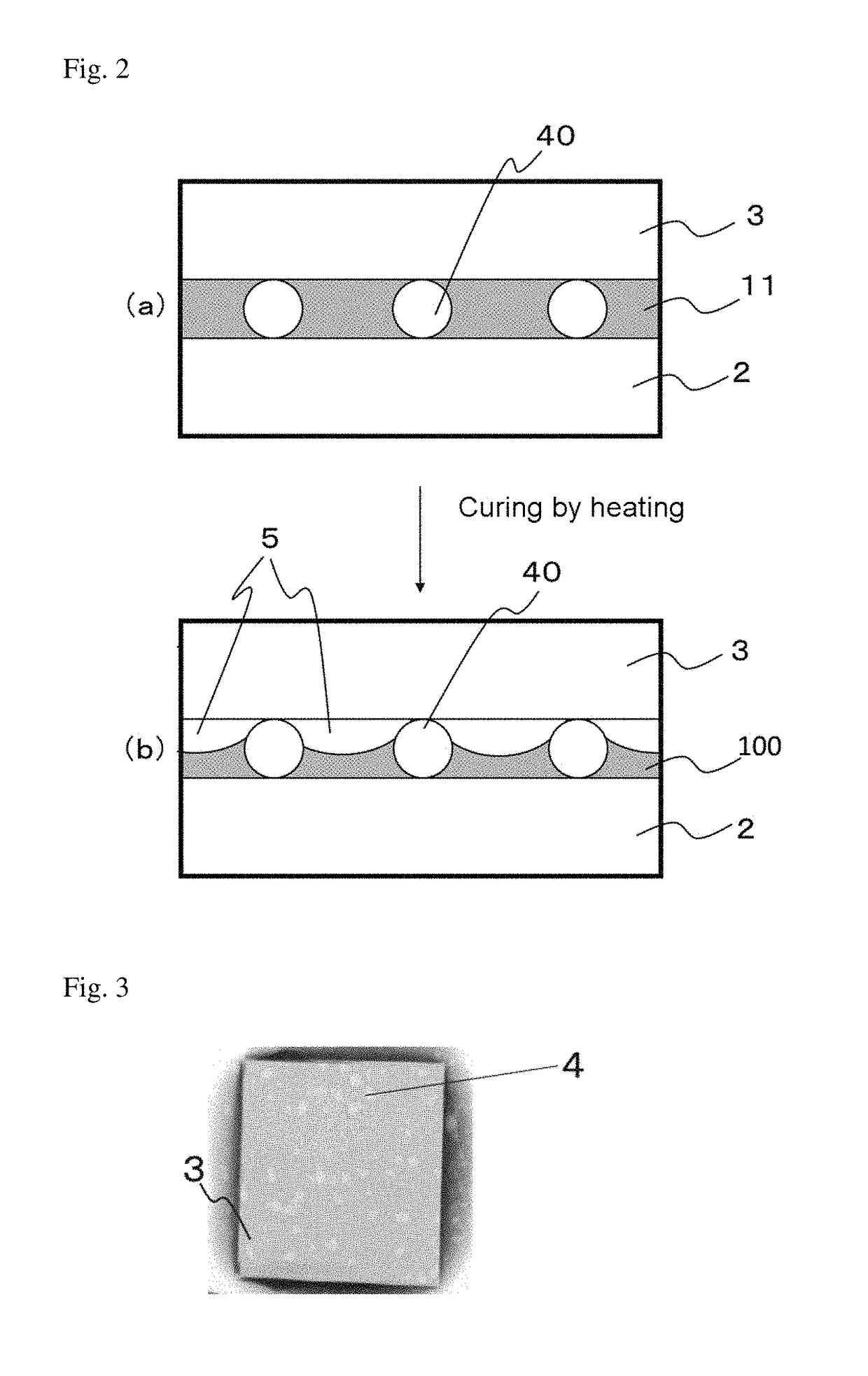

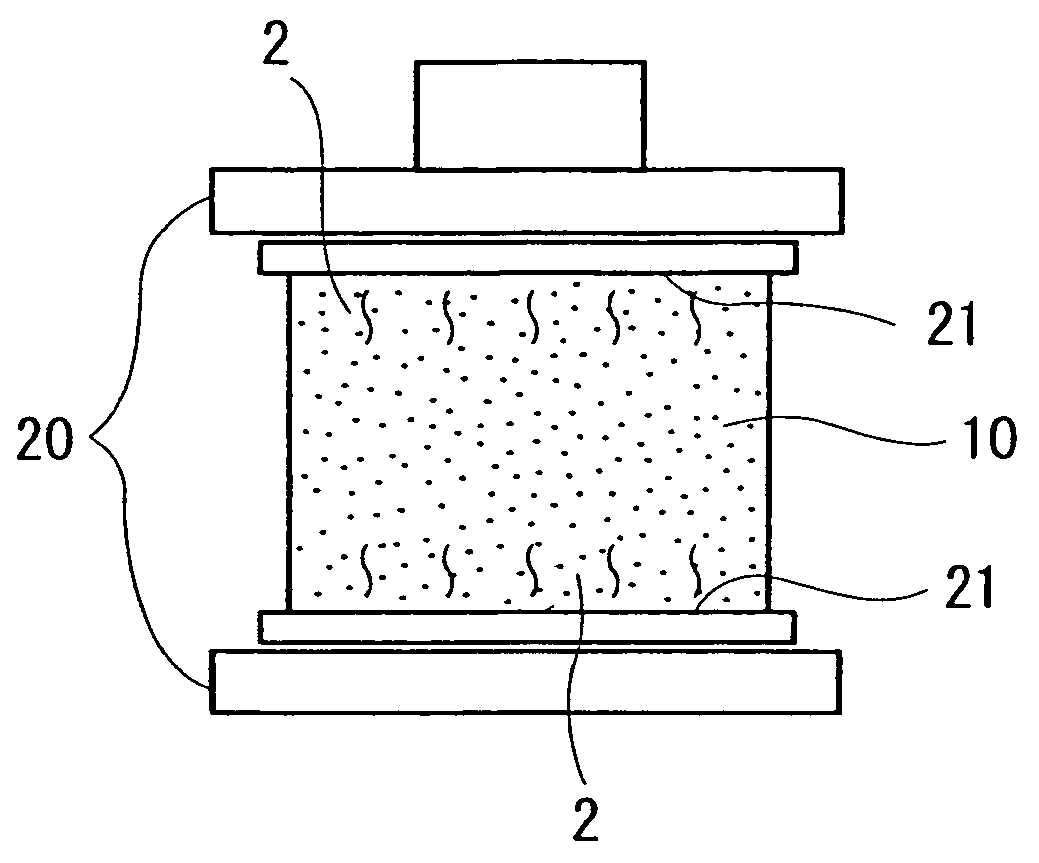

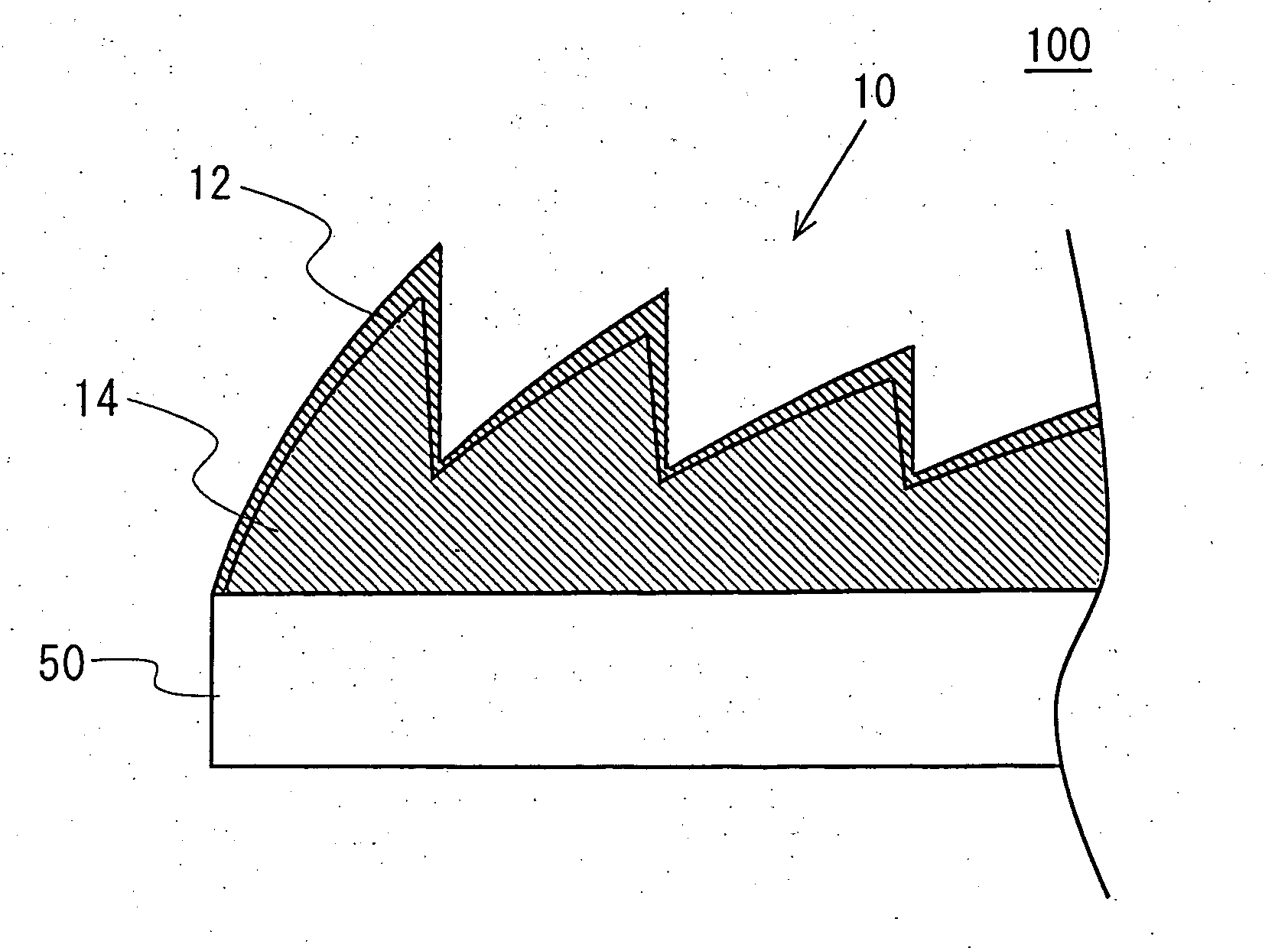

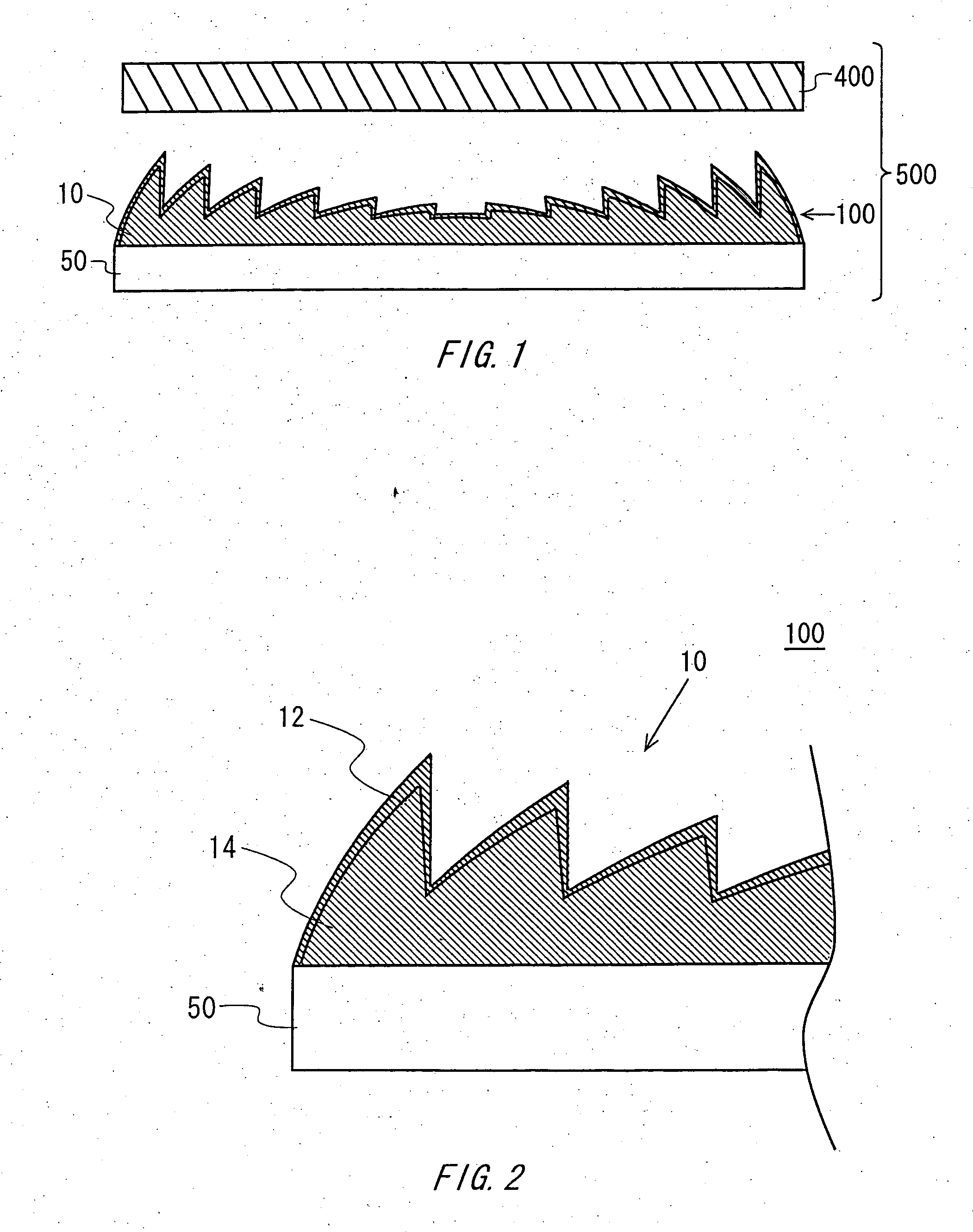

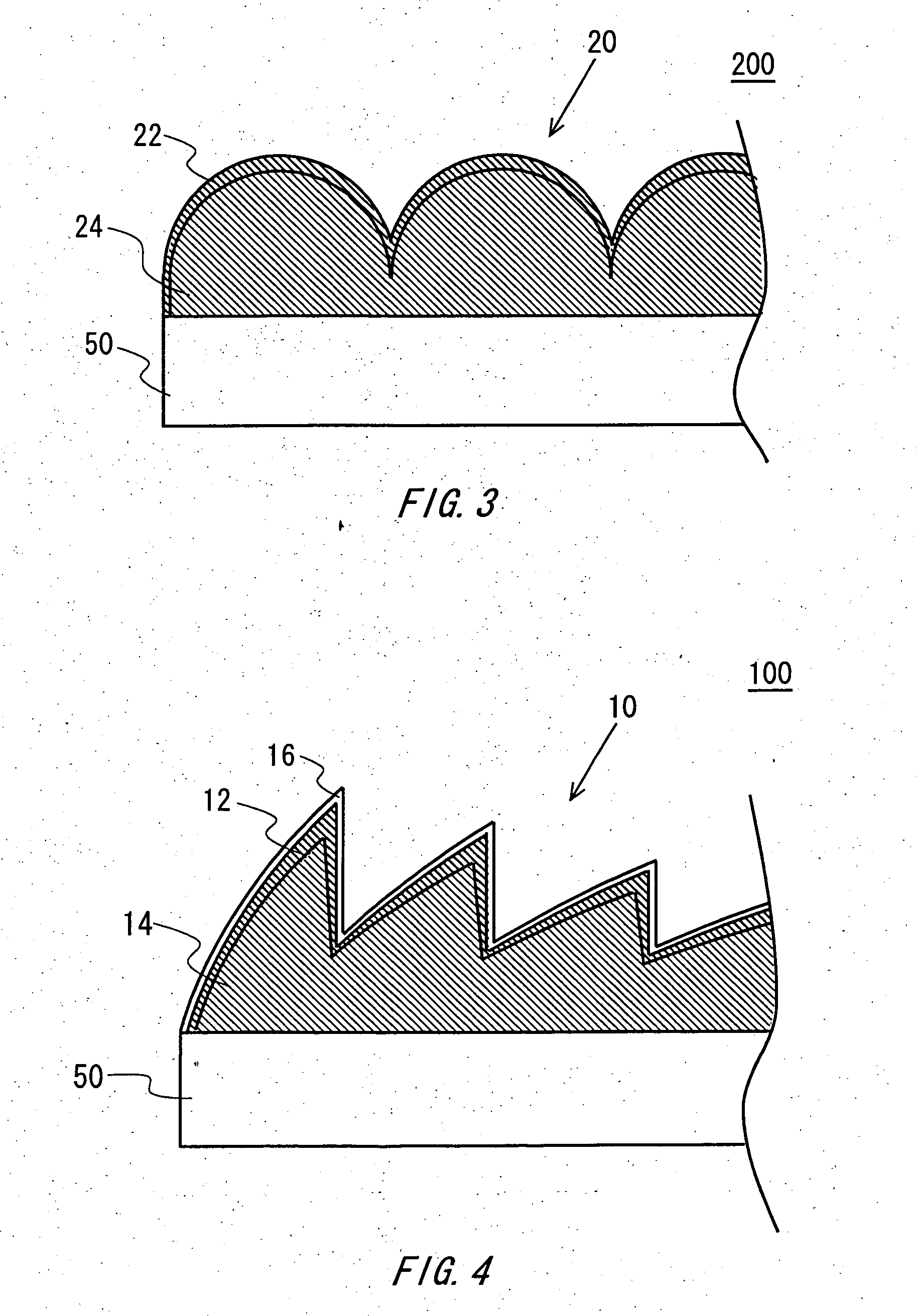

Lens, transmission screen, and method for manufacturing the lens

A lens which has a plurality of protrusions and cavities includes a core layer having a cross sectional shape smaller than and similar to a cross sectional shape of the lens; and a skin layer, which covers the core layer, having a smaller storage modulus of elasticity than that of said core layer. The lens may further include a substrate for fixing the core layer on a surface thereof, the substrate having tabular shape being made of a light-transmitting material.

Owner:ARISAWA MFG CO LTD

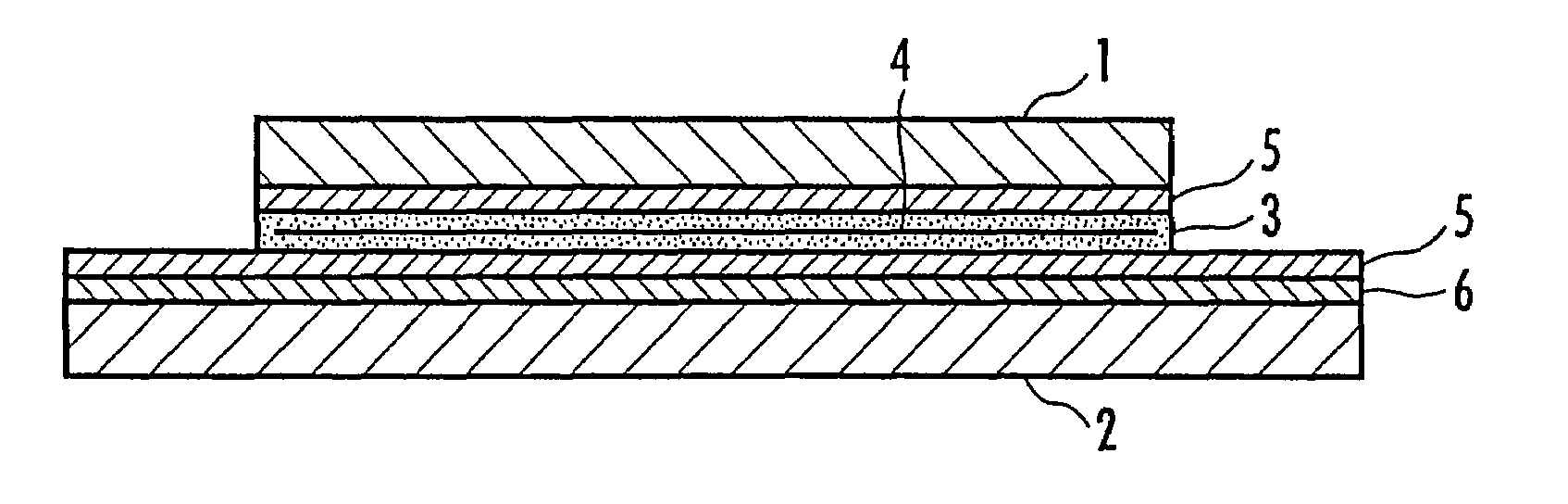

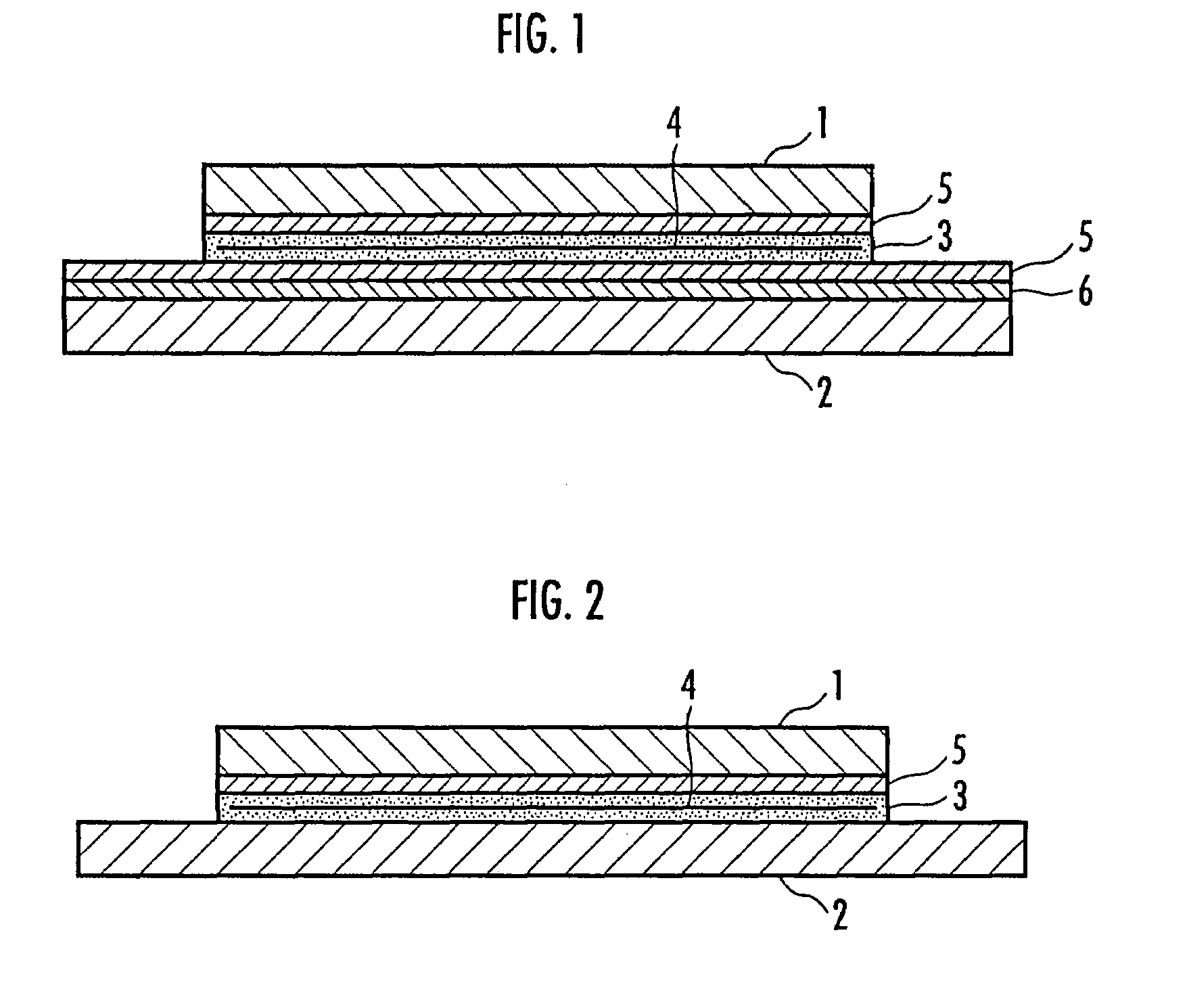

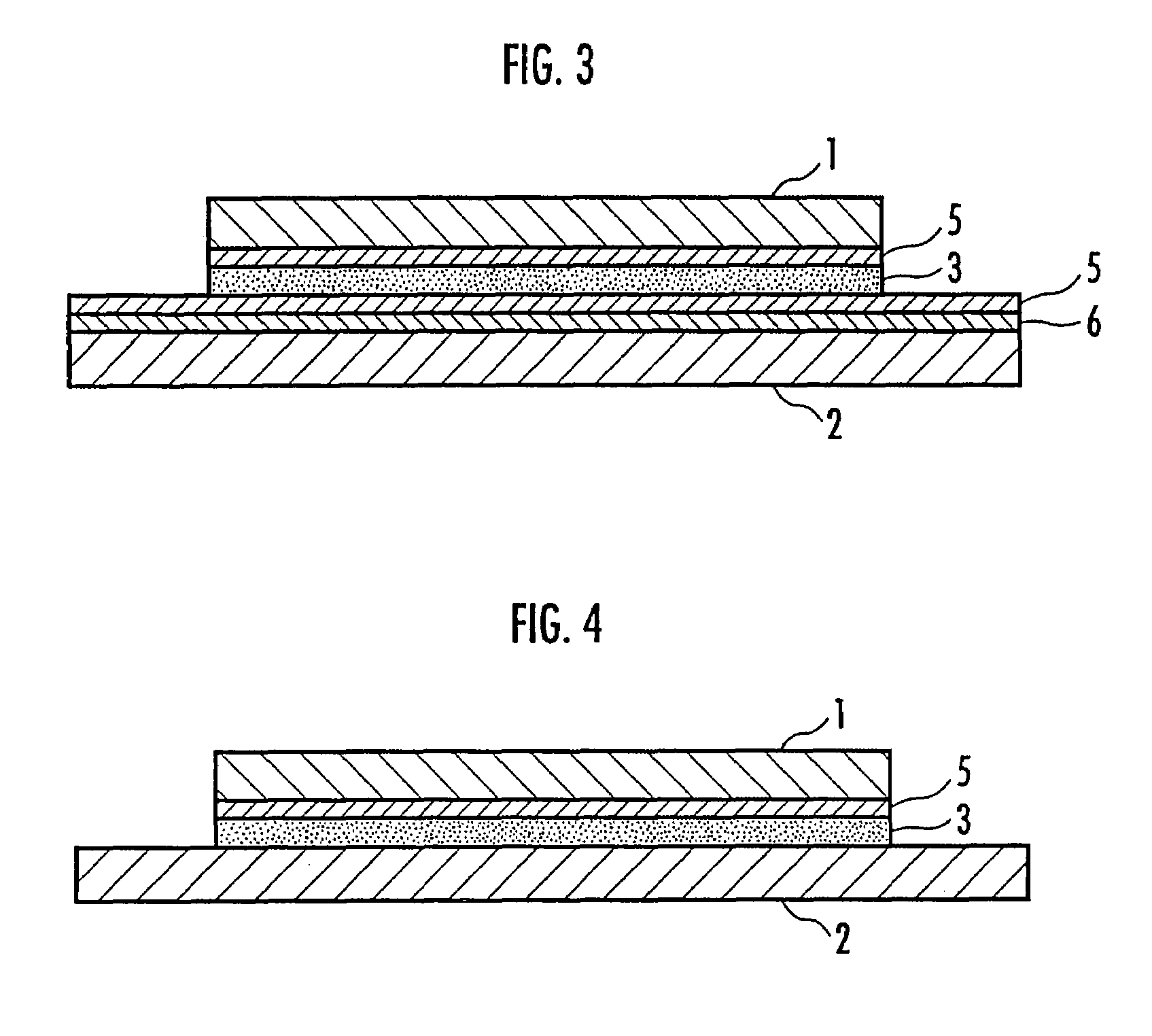

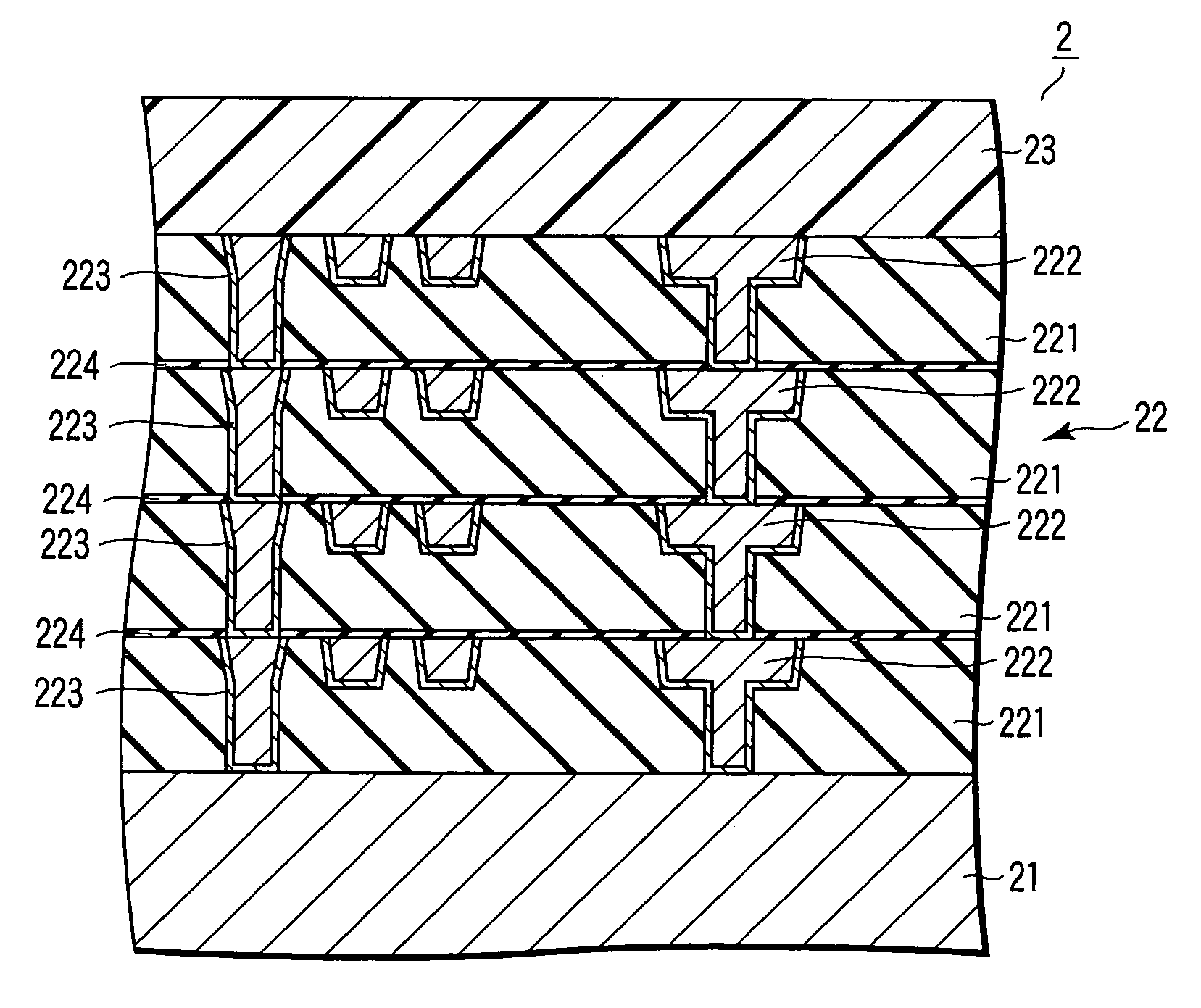

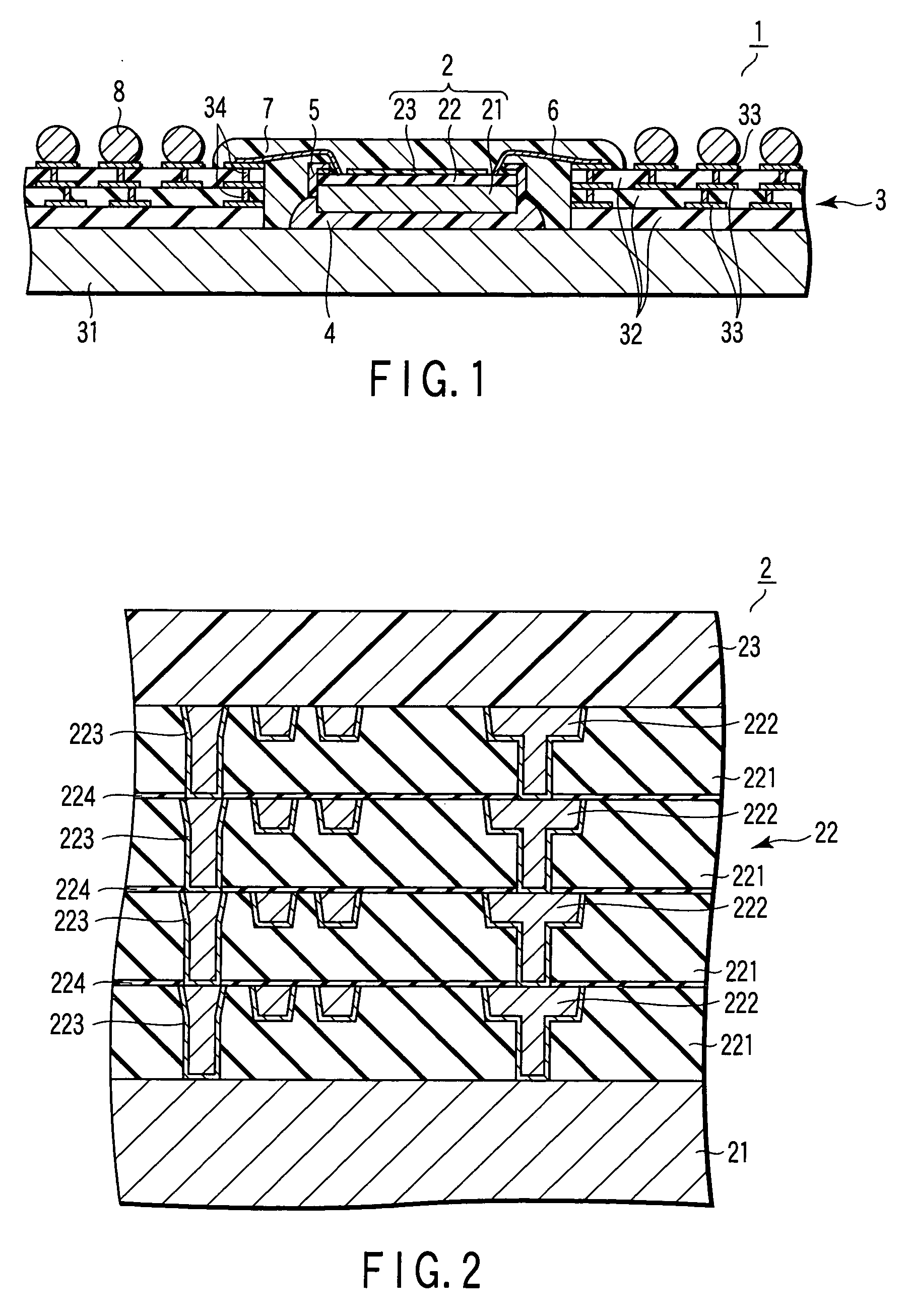

Semiconductor device

ActiveUS20050200022A1Small dielectric constantSmall modulusSemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor chip

There is provided a semiconductor device including a semiconductor chip which includes a semiconductor substrate and a multilayer interconnection structure formed thereon, the multilayer interconnection structure including an interlayer insulating film smaller in relative dielectric constant than an SiO2 film, an encapsulating resin layer which covers a major surface of the semiconductor chip on a side of the multilayer interconnection structure and covers a side surface of the semiconductor chip, and a stress relaxing resin layer which is interposed between the semiconductor chip and the encapsulating resin layer, covers at least a part of an edge of the semiconductor chip on the side of the multilayer interconnection structure, and is smaller in Young's modulus than the encapsulating resin layer.

Owner:KIOXIA CORP

Planetary gear speed reducer

The invention discloses a planetary gear speed reducer which comprises output torque shell, a bracket flange, a spline housing, a primary planetary gear train, a secondary planetary gear train and a tertiary planetary gear train, wherein the bracket flange and the shell are assembled together through a bearings; the spline housing is utilized as the high-speed input shaft of the speed reducer; the primary planetary gear train, the secondary planetary gear train and the tertiary planetary gear train transfer an input torque to the shell through a gear in the shell; a tertiary planetary frame of the tertiary planetary gear train is provided with a tertiary planetary frame side plate and five cantilever beam cylinders which are cast together with a planetary frame body; and the bearings at the joint of the shell and the bracket flange are two single-row tapered roller bearings. According to the invention, by utilizing one planetary side plate, the intensity of the planetary frame is increased, and the service life is improved; through the two single-row tapered roller bearings which are installed together correspondingly at an adjustable interval, the loading supporting points of the bearings can be enlarged, and the static loading of the whole planetary gear speed reducer can be improved; and through changing gear materials, a heat processing technology and a manufacturing process, the gear module can be reduced while the gear intensity is improved.

Owner:NINGBO XINHONG HYDRAULIC

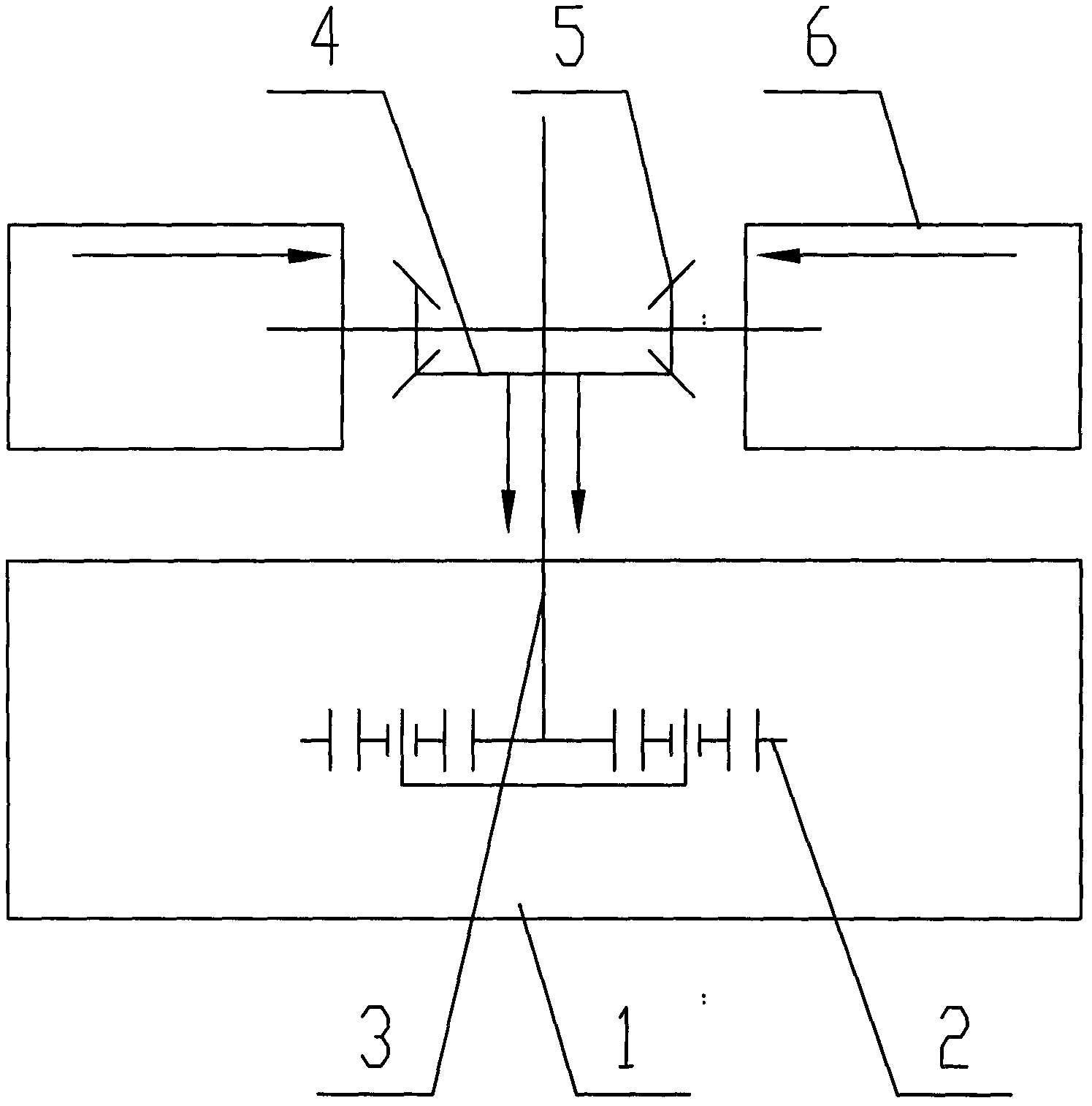

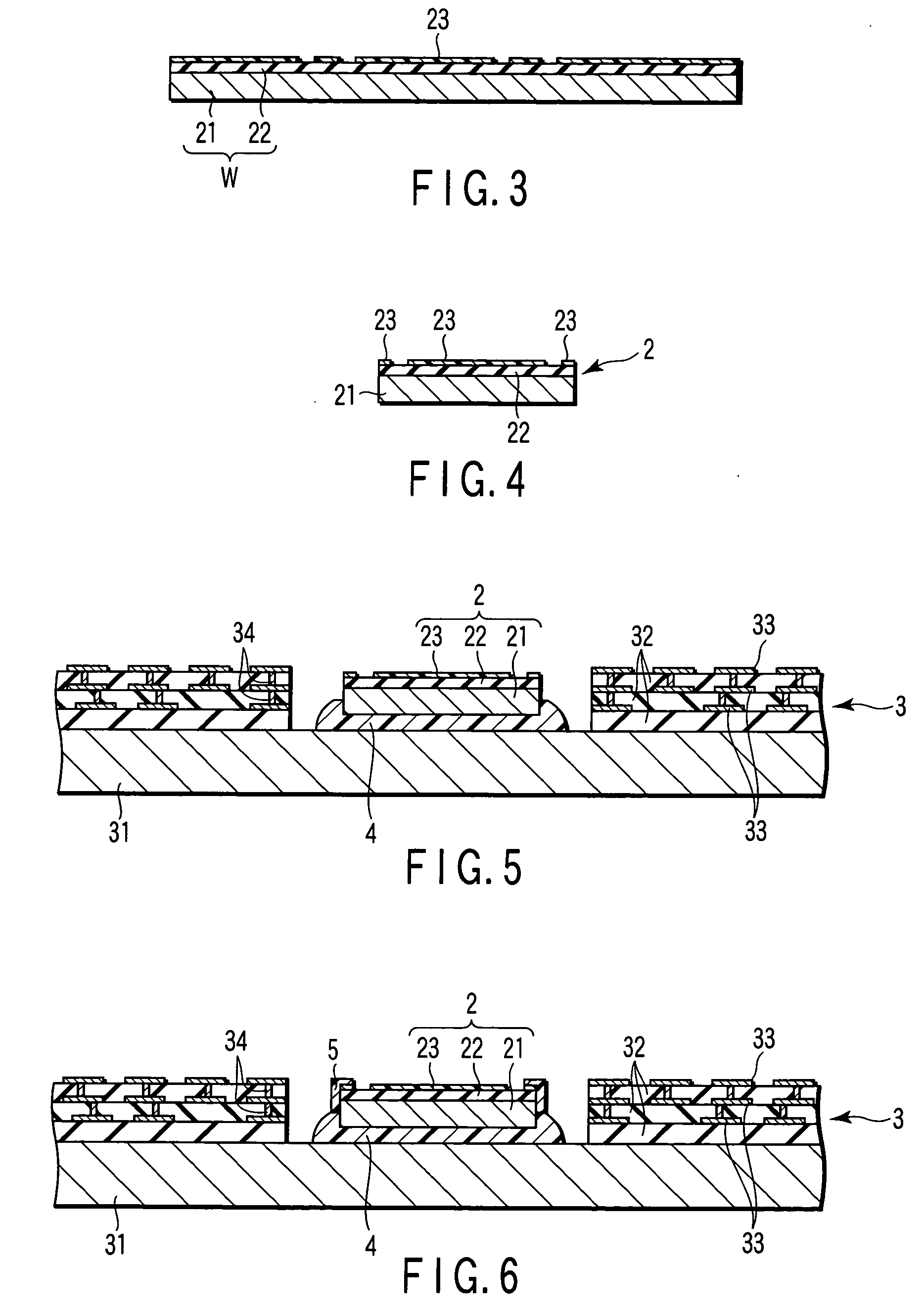

Semiconductor chip and semiconductor device

InactiveUS20100032832A1Large modulusSmall modulusSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipYoung's modulus

In this semiconductor chip 3, a table electrode 13 is interposed between a bump electrode 14 and an electrode pad 6. The table electrode 13 is formed by forming a plurality of cores 15 having a smaller Young's modulus than the bump electrode 14, on the electrode pad 6, and then covering the surfaces of the cores 15 with a conductive electrode 16. When the semiconductor chip 3 is flip-chip mounted, the bump electrode 14 is plastically deformed and the table electrode 13 is elastically deformed appropriately, thereby obtaining a good conductive state.

Owner:PANASONIC CORP

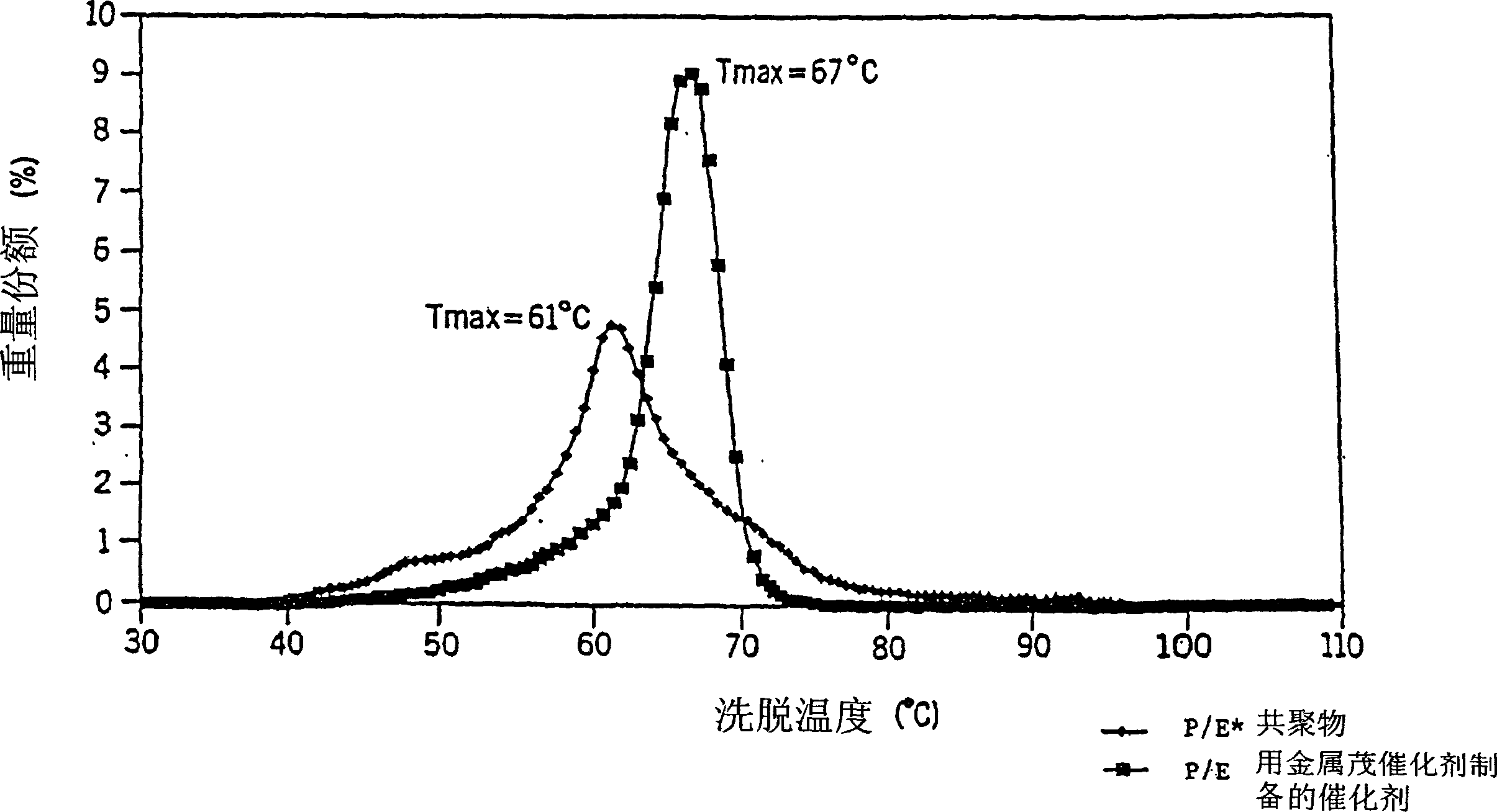

Filled thermoplastic olefin composition

The present invention relates to filled thermoplastic olefin compositions comprising (a) a first polypropylene comprising (i) substantially isotactic propylene sequences, (ii) a narrow molecular weight distribution , (iii) a broad composition distribution, and (b) at least about 20 volume percent filler, based on the total volume of the composition. Optionally, the composition may comprise a second polypropylene different from the first polypropylene, both polypropylenes being preferably propylene / α-olefin copolymers. The fillers can be organic or inorganic and, among other applications, the present compositions can be used as protective coatings for wires and cables.

Owner:DOW GLOBAL TECH LLC

Large modulus gear and involute sawtooth wave clutch gearbox for lawn mower

InactiveCN102282974AMeet the installation requirementsAvoid undercutHarvestersPortable liftingPlastic injection moldingHigh volume manufacturing

There are a variety of solutions available on several models. In order to further reduce costs, plastic molding methods, especially injection molding, are recommended to mass-produce gears and gearboxes for lawn mowers. The ninth solution is to use less expensive non-machine Processing, especially the large modulus gears for injection-molded lawn mowers and the reduction boxes for involute saw-tooth wave clutches. A large number of injection molded parts are used. Let the injection molded gears be able to work with larger torques and clutch tasks, increase the modulus, reduce the number of teeth, and change the friction cone to an involute sawtooth wave clutch. It is characterized in that: the large modulus gear (88) with involute sawtooth wave clutch is provided with large modulus teeth (88a), connecting wall (88b), sawtooth (88c), involute sawtooth wave (88d), Main rear axle clearance slot (88e). The number of teeth of the pinion (89) is single teeth, or double teeth, or 3 teeth, or more, preferably 3 teeth.

Owner:NINGBO DAYE GARDEN EQUIP

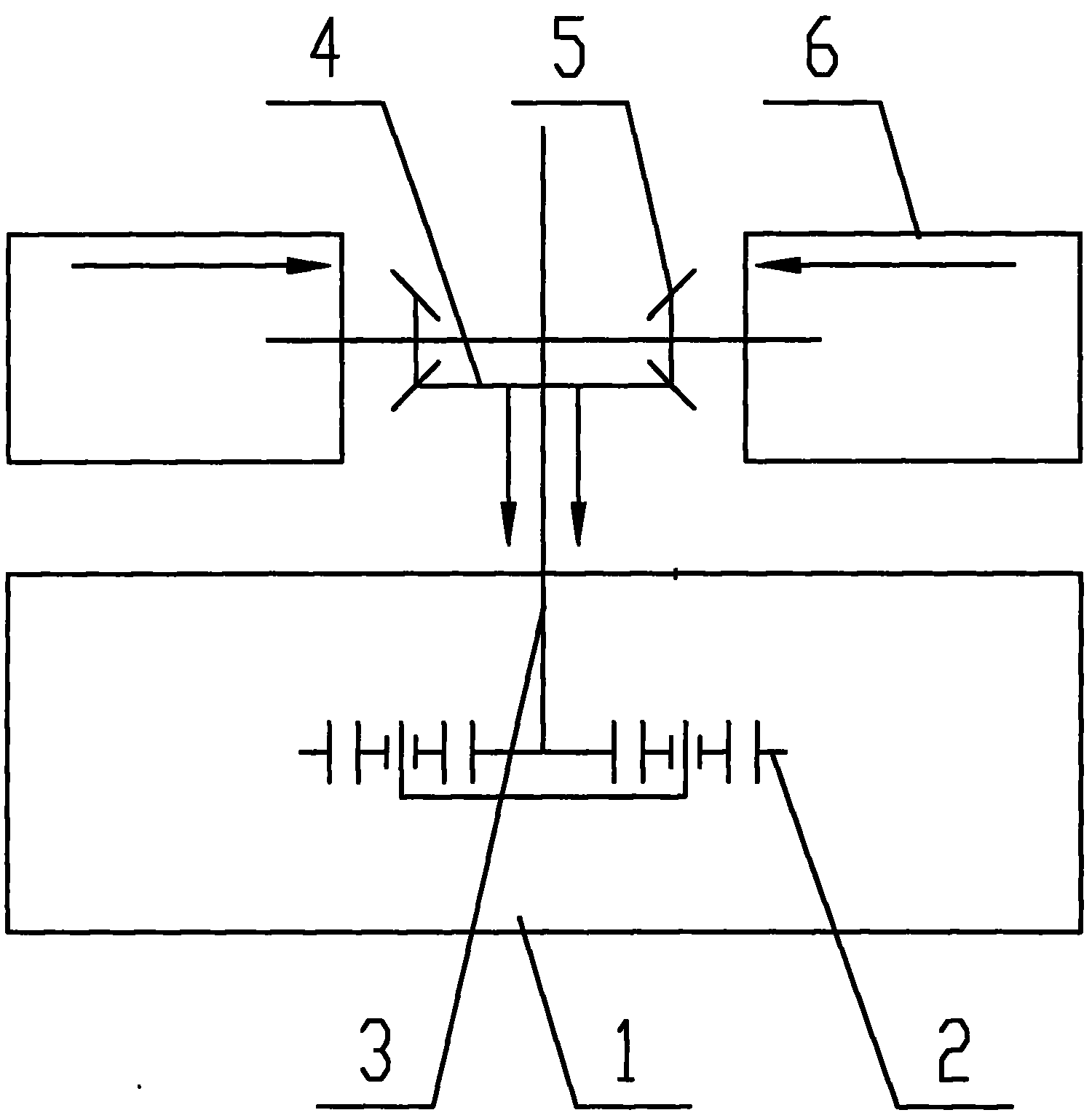

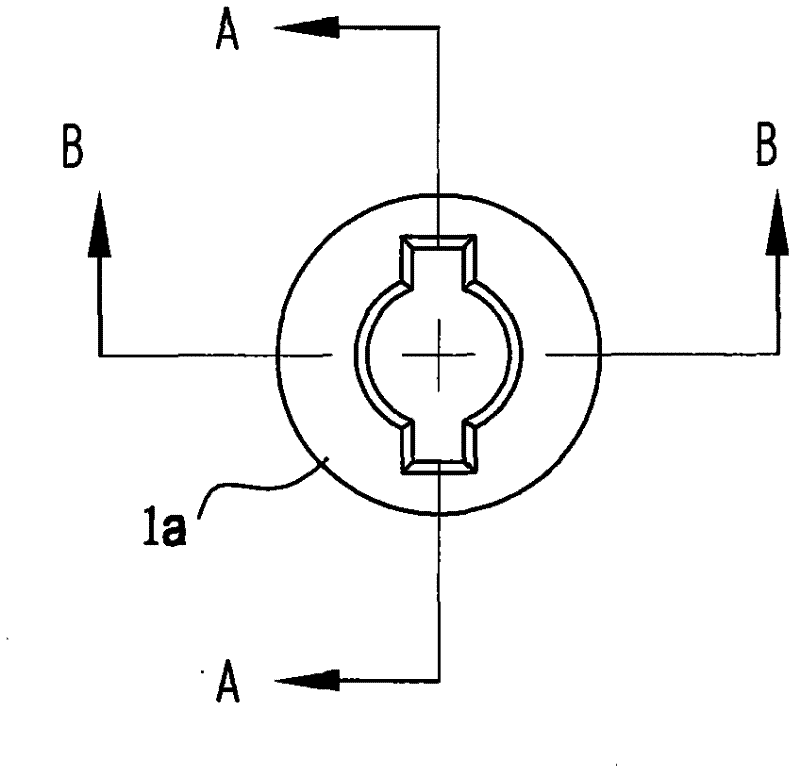

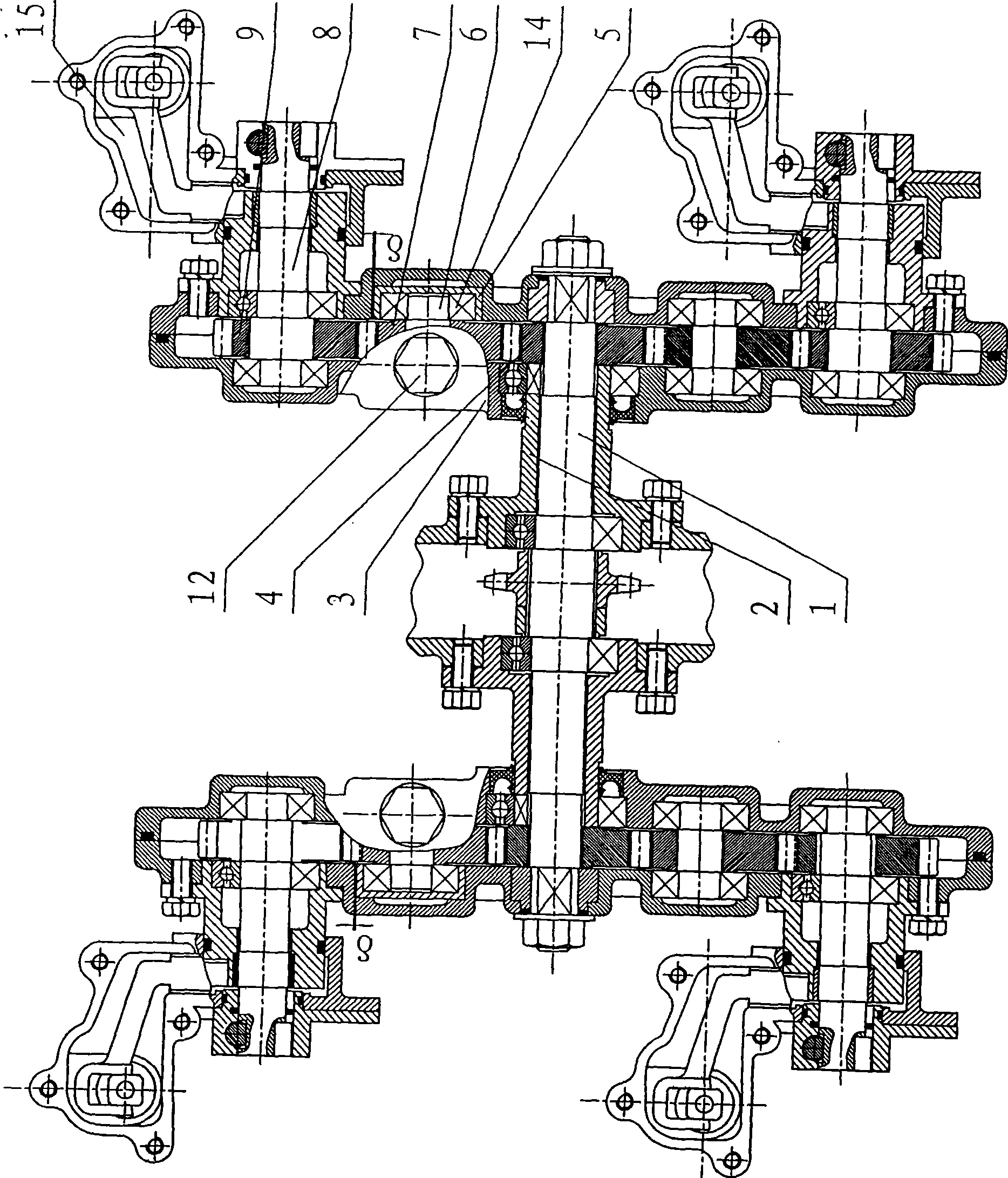

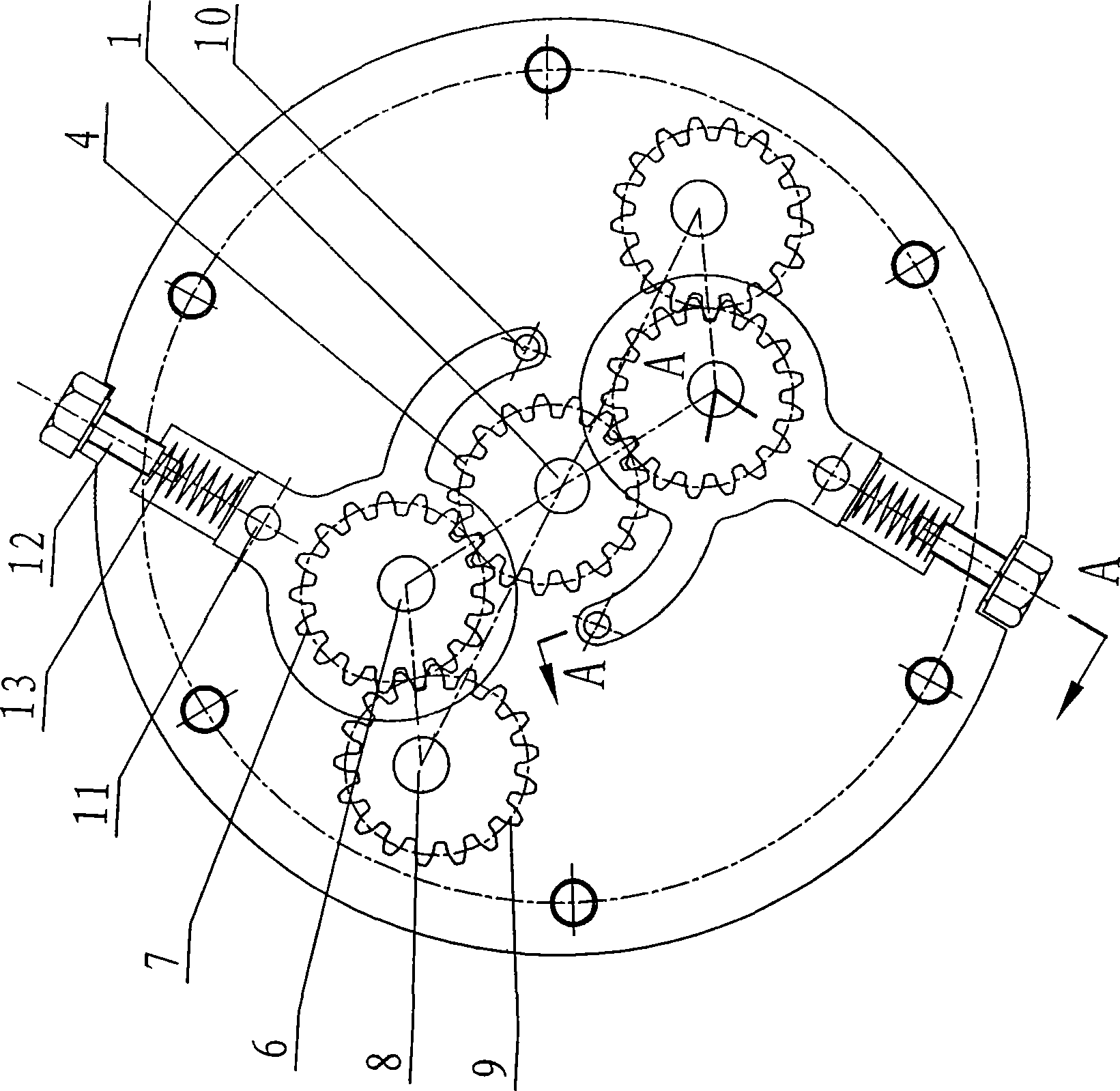

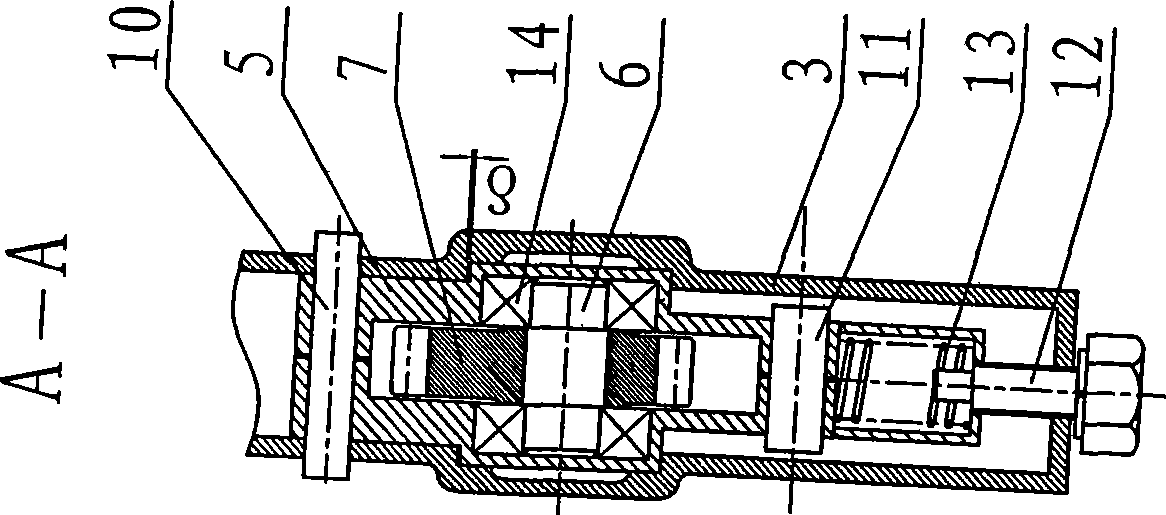

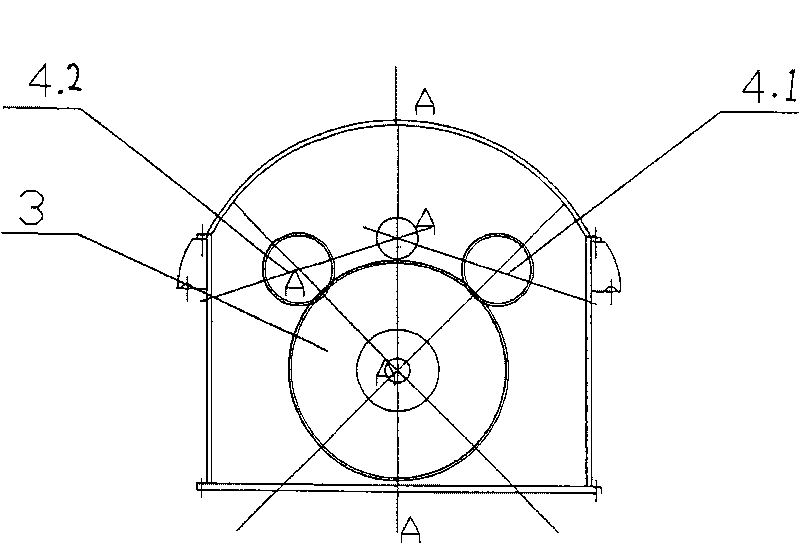

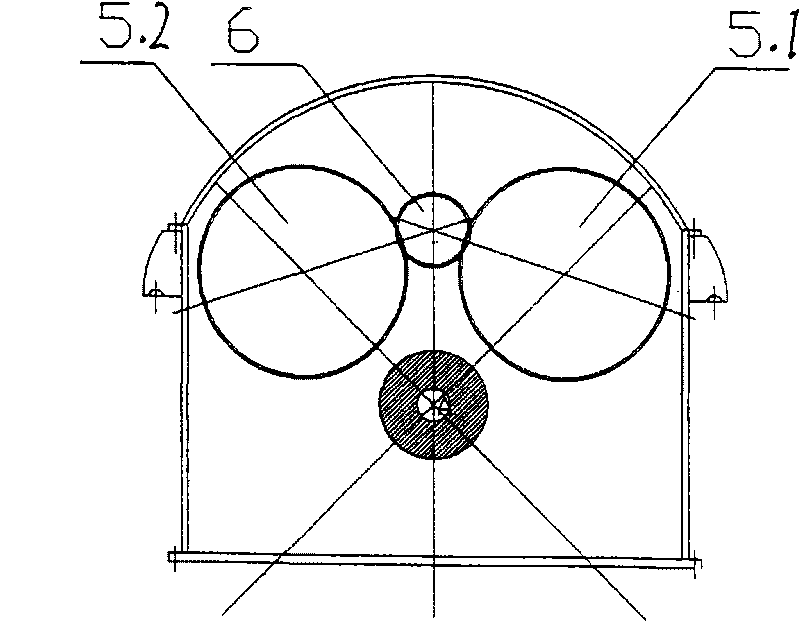

Noncircular gear drive system transplanting mechanism capable of eliminating pitch play

The present invention discloses a non- cylindrical gear transmission system separating insertion mechanism which can eliminate the tooth space. Two ends of central shaft are respectively installed with a left transmission box body and a right transmission box body which have same structure. A central non- cylindrical gear which is freely sleeved on two ends of central shaft is fixedly connected with a frame through a jaw flange. The two sides, the upper part and lower part of the central non- cylindrical gear are equally symmetrically installed with an intermediate non- cylindrical gear and a planet non- cylindrical gear sequentially. One end of planet shaft is fixed with a planting arm. The shaft center of five shafts are arranged with two congruence triangles which are opposite through the intermediate shaft when seen from the side surface. Two ends of intermediate shaft are movably supported in the base hole of transmission box body through the shaft hub of adjusting sleeve. A clearance delta is provided between the shaft hub and the base hole of adjusting sleeve, or a spring piece is installed in the shaft hole of intermediate shaft of transmission box body for eliminating the tooth side clearance among the central gear, the intermediate gear and the planet gear. The non- cylindrical gear transmission system separating insertion mechanism of the invention structurally has the advantages of large gear module and small box body, etc. The non- cylindrical gear transmission system separating insertion mechanism also has the advantages of adjustable tooth space, smooth transmission, small seedling insertion cavity and good erection property of seedling. The non- cylindrical gear transmission system separating insertion mechanism is especially suitable for the operation requirement of high-speed seedling transplanter.

Owner:ZHEJIANG SCI-TECH UNIV

Fluorosilicone-based dielectric elastomer and method for its production

InactiveUS9478727B2Improved propertyIncrease forcePiezoelectric/electrostrictive device manufacture/assemblyPlastic/resin/waxes insulatorsChain lengthSilicone Elastomers

A dielectric elastomer has a film that contains a fluorinated silicone elastomer and has two faces. A coating of a stretchable electrode material is applied to each one of the two faces. The fluorinated silicone elastomer has a modulus of elasticity of maximally 450 kPa. The fluorinated silicone elastomer is a three-dimensionally crosslinked, fluorinated, alkyl group-containing polysiloxane in combination with a fluorinated silicone oil. Alternatively, or in addition, the fluorinated silicone elastomer is a three-dimensional wide-mesh crosslinked, fluorinated, alkyl-group containing polysiloxane whose wide mesh property has been effected by a chain length extension by addition of a chain-shaped silicone molecule containing two Si—H groups to an alkenyl group-containing polysiloxane molecule.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Speed-increasing gearbox of wind driven generator

InactiveCN101699065ASolution to short lifeImprove transmission efficiencyToothed gearingsMachines/enginesWind drivenLow speed

The invention relates to the improvement of a speed-increasing gearbox of a wind driven generator, which is characterized in that: a gear transmission has 3 to 4 stages, wherein the last stage is a planetary gear transmission; the former stages are all double-circular-arc cylinder herringbone spiral gear transmissions. Compared with the conventional generally-used speed-increasing gearbox which mainly uses the planetary gear transmission, because the low-speed stages (1 to 3 stages) adopt double-circular-arc cylinder herringbone spiral gears with high transmission efficiency and a subsequent stage adopts the planetary gear transmission, the advantages of the double-circular-arc cylinder herringbone spiral gear transmission and the planetary gear transmission are combined together, thus the effective one-off life is long, the transmission efficiency is high and the volume is small; and moreover, the double-circular-arc cylinder herringbone spiral gear is used for the speed-increasing gearbox of the wind driven generator for the first time.

Owner:YIXING HUATAI INT GRP IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com