Filled thermoplastic olefin composition

A thermoplastic olefin and composition technology, applied in the field of thermoplastic olefin composition, can solve the problems such as not getting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

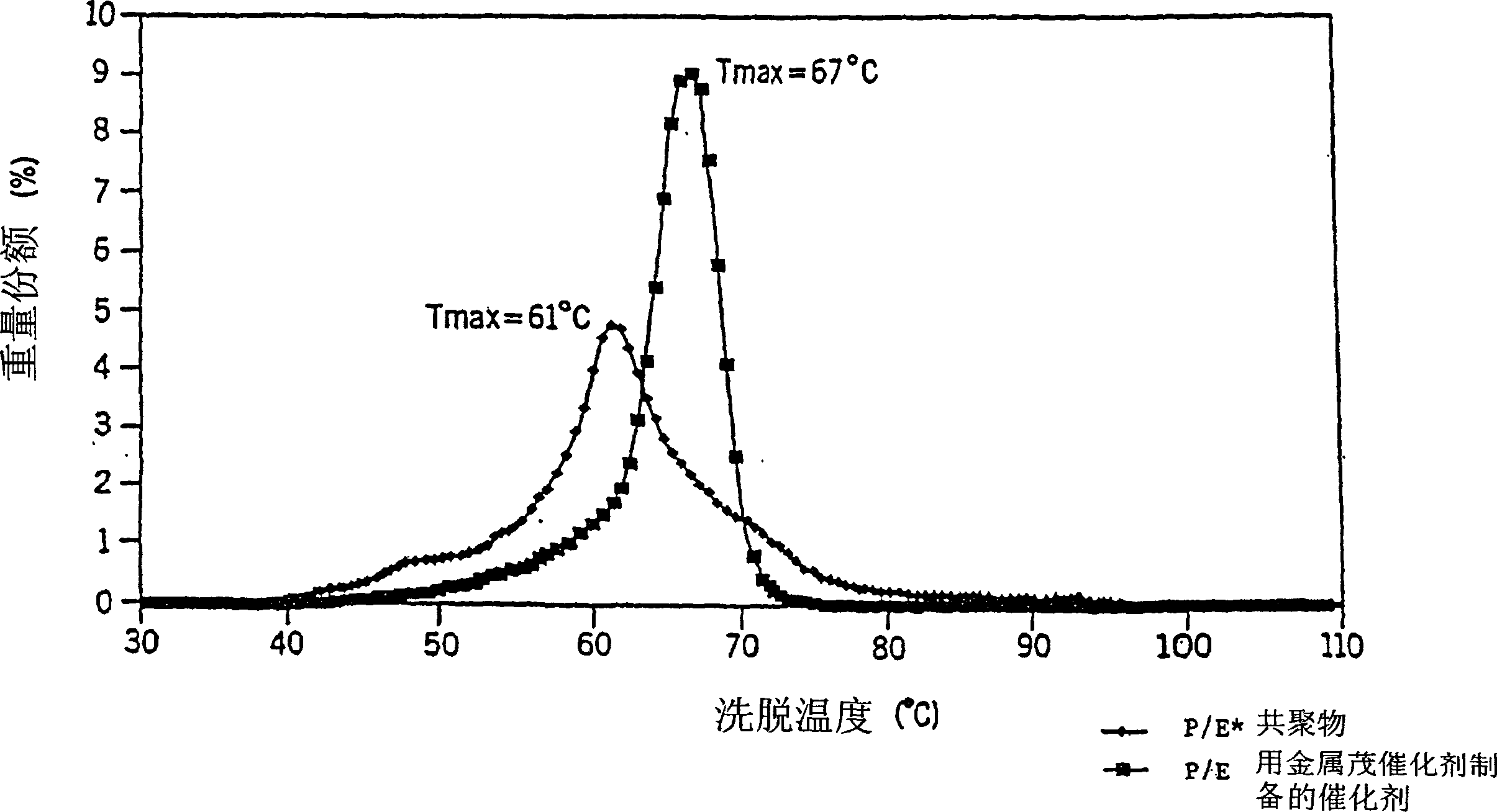

Image

Examples

Embodiment 1

[0130] Table 1 reports the results of the different tests carried out on the above polymers.

[0131] MicroWhite 100, 15 microns

[0132] MicroWhite 100, 15 microns

[0133] MicroWhite 100, 15 microns

[0134] The data in Table 1 show the improved properties of the compositions of the invention. In particular, the data indicate that the compositions of the present invention can incorporate greater than 30 volume percent filler, and in the largest instance greater than 55 volume percent filler, while still maintaining acceptable physical properties. Even with greater than 55% filler by volume, some compositions of the present invention have an ultimate tensile strength of at least 100 psi, while having an elongation at break of at least 500%, a Shore A of less than 90, and a Shore A of greater than 4000 psi. flexural modulus. In addition, the filled thermoplastic olefin composition of the present invention maintains ultimate elongation, ultimate...

Embodiment 2

[0136] The following compositions were prepared on a Brabender equipped with a 250ml mixing cup TM Prepared in a mixer. In each case, the temperature of the mixer was set to a mixing temperature of 150C, a mixing speed of 50 rpm, and mixed for 4 minutes, reducing the rpm if necessary to maintain the melt temperature below 175C. The composition was removed from the Brabender mixer and allowed to cool to room temperature before being granulated for use as described below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com