Large modulus gear and involute sawtooth wave clutch gearbox for lawn mower

A large-modulus, sawtooth wave technology is applied in the field of large-modulus gears and gear boxes with involute sawtooth wave clutches to prevent undercuts, improve transmission meshing parameters and geometric coefficients, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0177] Operate the walker to pull the self-propelled control handle, pull the cable pull arm 84 through the wire rope, and make the clutch block move in the axial direction to engage, that is, the bevel gear 82 with the clutch cone is engaged with the rear main shaft, and the power is transmitted through the first stage of the belt. , so that the small bevel gear 81 rotates, and the small bevel gear 81 is installed on the upper gear box cover 83 of the powder metallurgy bevel gear box through bearings, thereby driving the bevel gear 82 with the clutch cone for two-stage transmission , and then make the lawn mower self-propelled through the three-stage transmission.

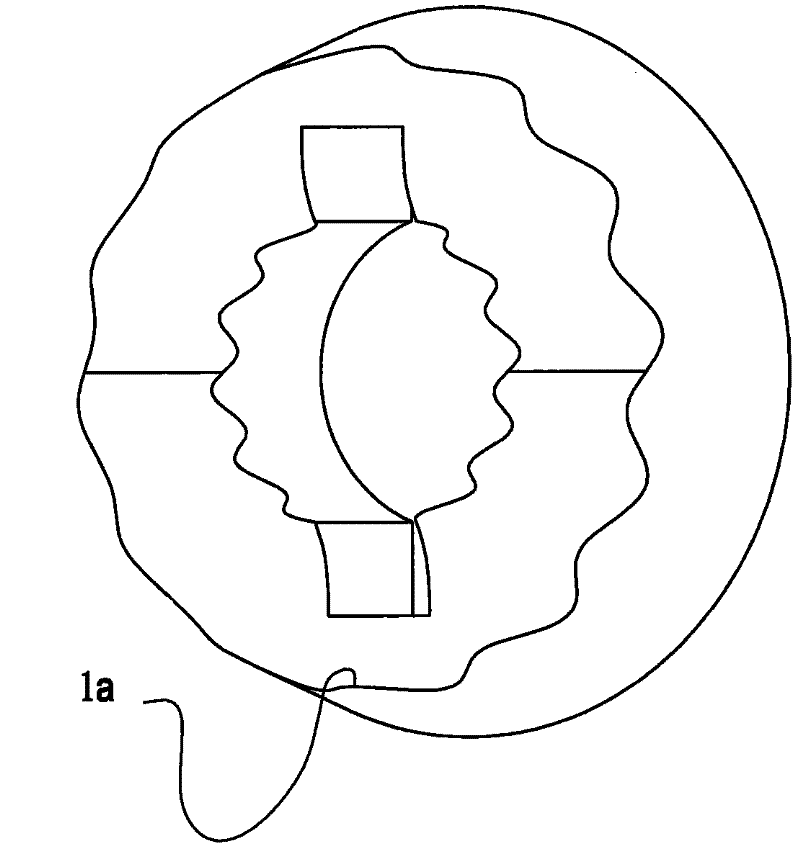

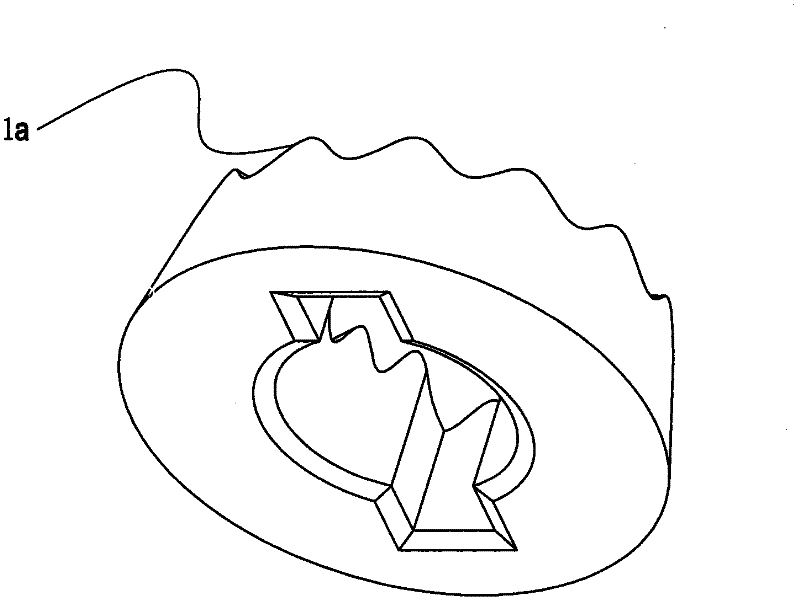

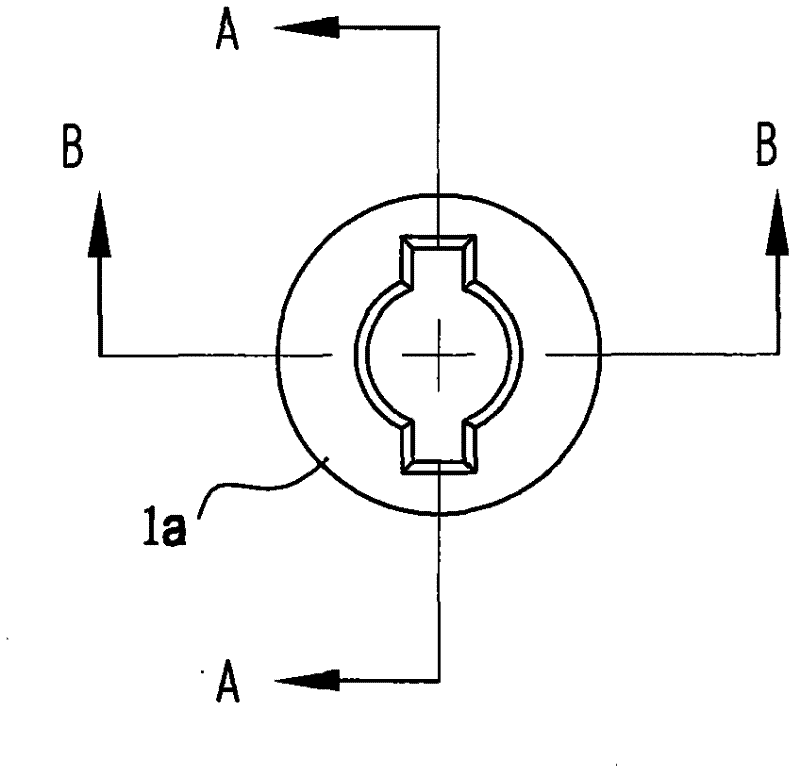

[0178] The clutch gear of the clutch device in the rear wheel drive gear reduction clutch of the self-propelled mechanism of the clutch is not only engaged by the cone on the inner surface of the clutch gear, or as an improvement, it uses a deformed waveform, especially a sine wave inner wall, and multiple small M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com