Subway safety door capable of lifting vertically

A vertical lift, safety door technology, applied in door leaf, door/window accessories, window/door frame, etc., can solve the problems of limited horizontal installation position and large upper space of safety door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

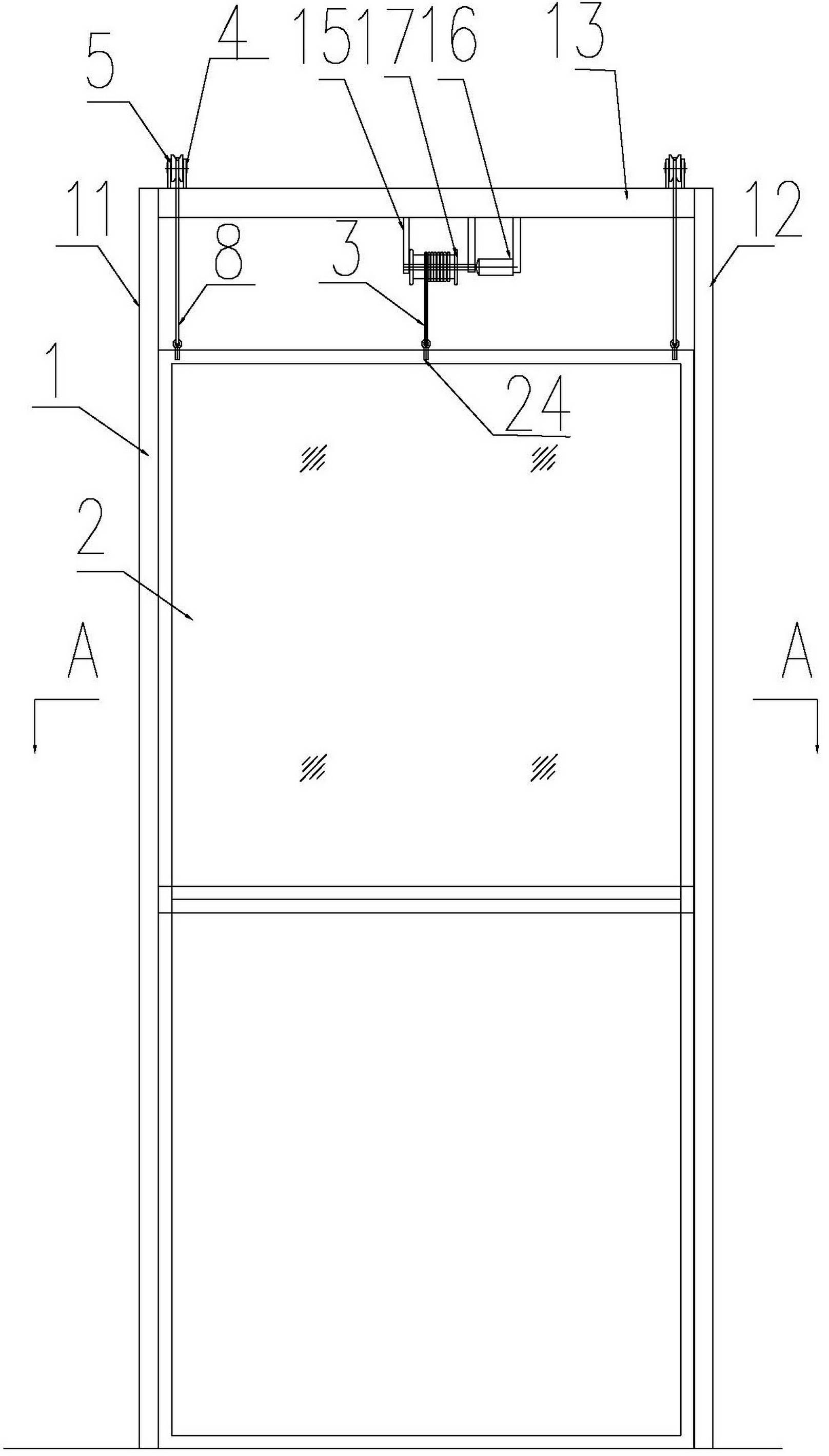

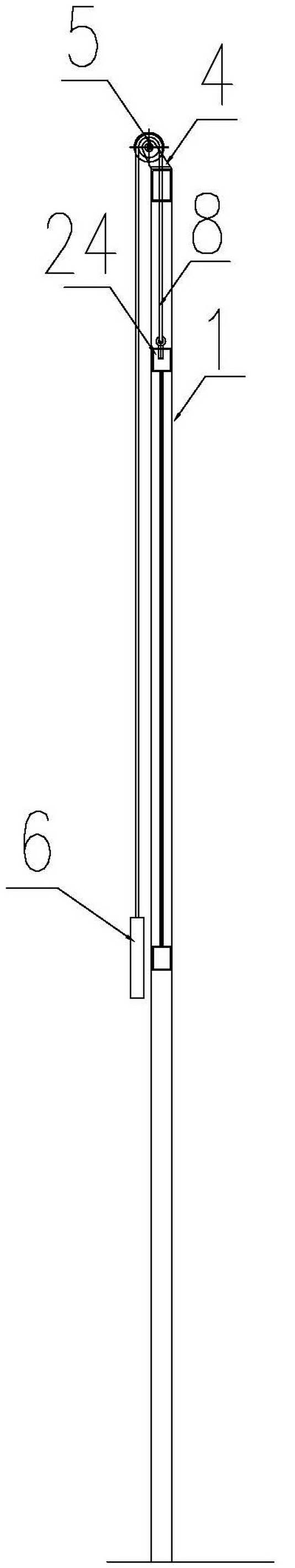

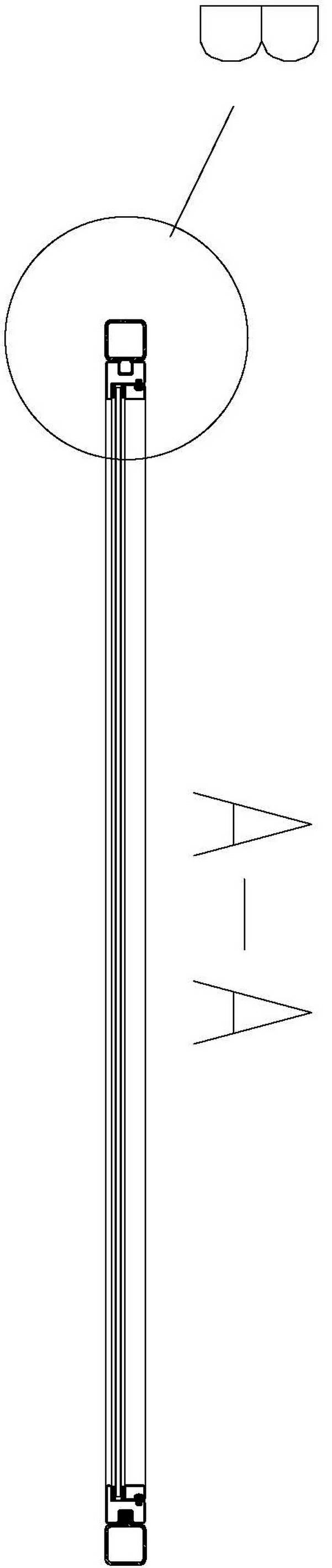

[0012] Such as figure 1 As shown, the vertically liftable subway safety door proposed by the present invention includes: a door frame 1 made up of a left column 11, a right column 12 and a crossbeam 13, the inside of the left and right columns is provided with a protruding guide rail 14, and the crossbeam is provided with A fixed bracket 15 protruding downwards, on which an electric drive device 16 and a reel device 17 driven by the electric drive device are installed; Groove 21, glass door body 22 and sealing device 23 are installed in the inner side; And lifting rope 3, one end is fixedly wound on the described reel device 17, and the other end is fixed on the middle part of moving door body horizontal frame.

[0013] The present invention also includes pulley brackets 4 respectively arranged at the two ends of the door frame beam 13, on which a pulley 5 is installed; hooks 24 arranged at both ends of the horizontal frame of the moving door body, and a counterweight rope 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com