Tapered roller bearing with high strength and low friction torque

A tapered roller bearing, low-friction technology, applied in the direction of roller bearings, rolling contact bearings, bearings, etc., can solve problems such as bearing damage, large rib rupture of the inner ring of the bearing, reduce bearing friction torque, etc., to prevent cracking , Improve lubrication conditions, improve the effect of bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

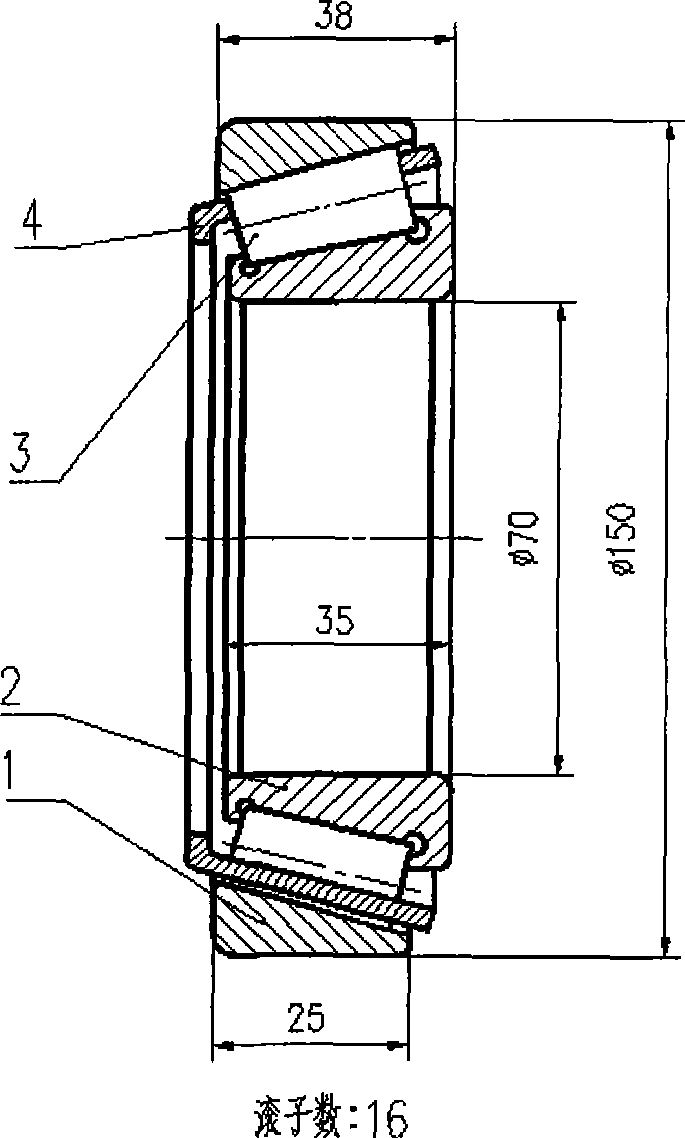

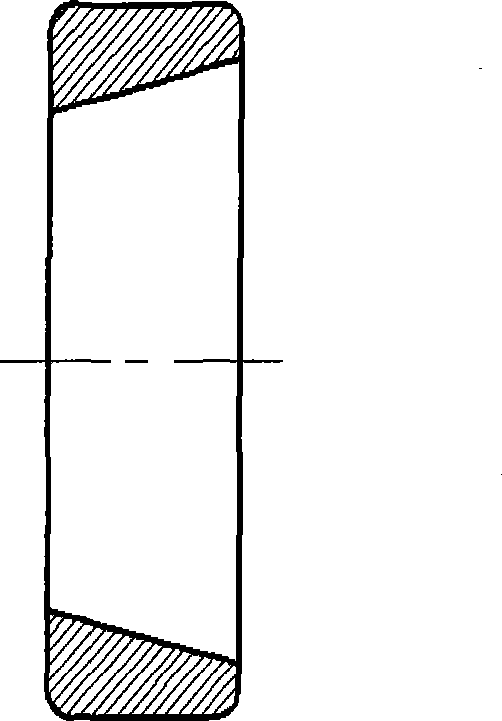

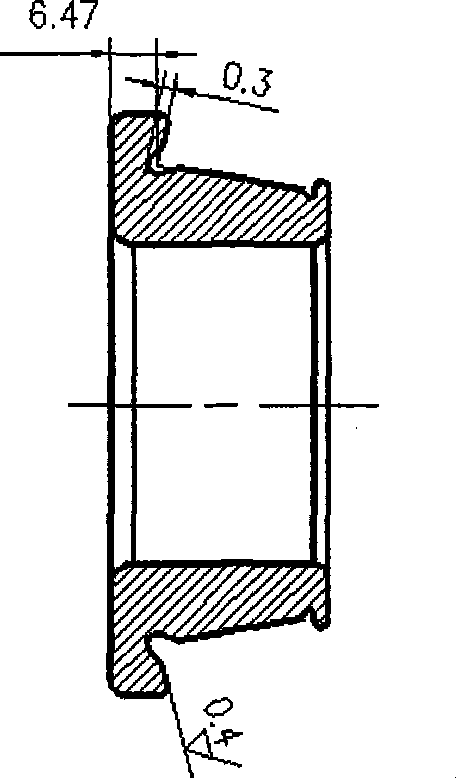

[0016] Such as Figure 5 ~ Figure 8 The present invention shown includes an outer ring, an inner ring, a plurality of rollers sandwiched between them to support and realize relative rotation, and a cage that separates and guides the movement of the rollers, corresponding to the corresponding parts of the prior art Compared, in the present invention: the large rib of the inner ring is an outward convex curve rib; the width of the root of the large rib of the inner ring is greater than 6.47mm, and the axial depth of the oil groove is less than 0.5mm; the inner and outer raceway generatrix and the roller The bus bar is a logarithmic curve convex shape; the number of rollers is less than 16, the length of the rollers is less than 24mm, and the radius of the convex surface of the raceway is reduced; the radius of the base surface of the roller ball is less than 136mm, and the diameter of the roller is greater than 21.671mm. The roughness value of the large rib is less than 0.4 μm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com