Installation device for centrifugal overload test of solid rocket engine

An overload test, solid rocket technology, applied in the direction of engine test, measurement device, machine/structural component test, etc., can solve the problem of inability to measure the axial thrust of the test piece, affecting the strength of the arm, poor versatility, etc., to achieve structural Simple, easy to operate, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

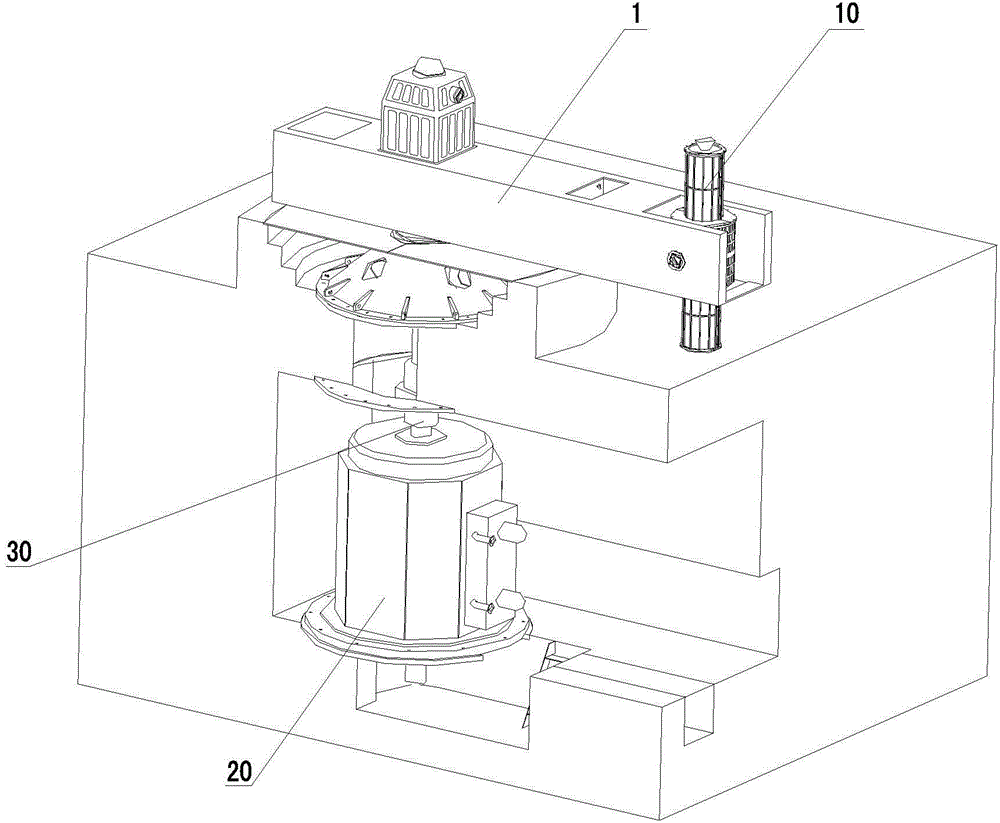

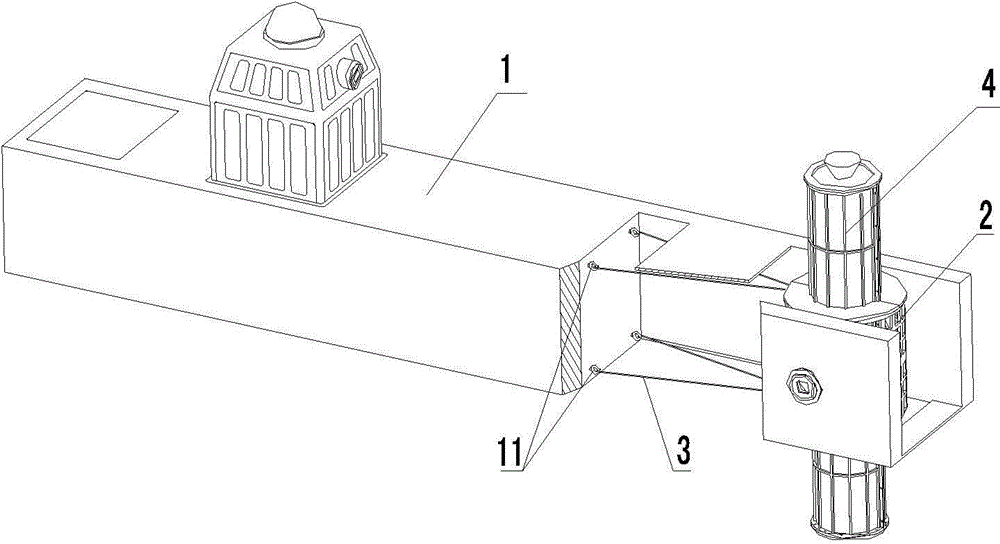

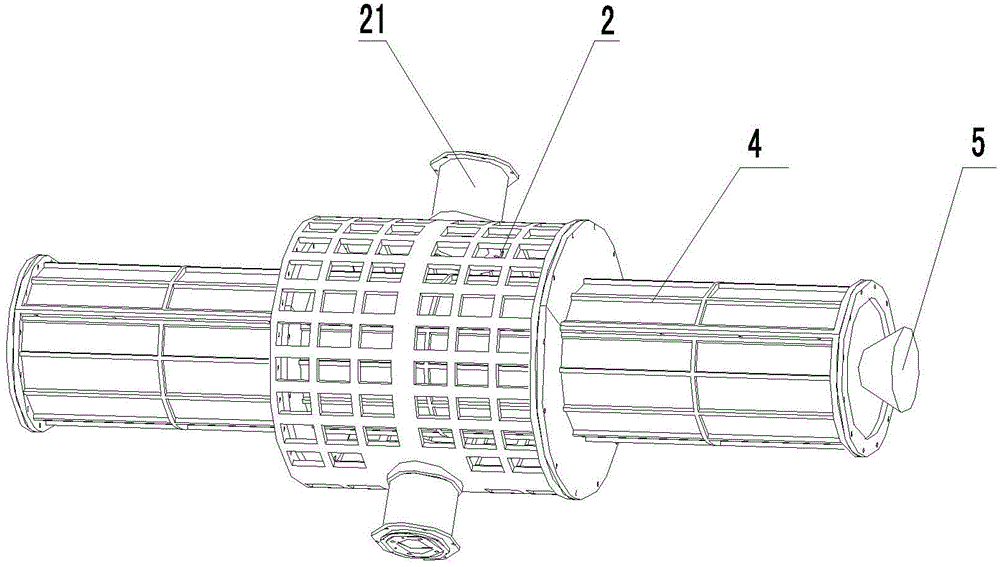

[0037] Such as figure 1 As shown, it is a solid rocket motor centrifugal overload test system in the present invention, and the system includes a motor 20, a coupling 30 and a rotating arm 1 from bottom to top, and the motor 20 drives the rotating arm 1 to rotate through the coupling 30, and the rotating arm The end of 1 is provided with an installation platform 10, through the rotation of the rotating arm 1, the test piece 5 in the installation platform 10 is provided with operating conditions such as acceleration, fast acceleration and lateral overload, and by controlling the ignition time of the test piece 5, the rocket engine can be reproduced. In the high overload environment under different attitudes during operation, real-time test data can be obtained by monitoring and controlling the test state, which provides a basis for the study of the flow field and thermal str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com