Automatic control method of mold temperature in rotational molding process

A technology of mold temperature and rotomolding mold, which is applied in the direction of coating, etc., can solve the problems of low temperature control accuracy and reaction lag, and achieve the effects of strong real-time performance, simple control and improved synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so as to better understand the substantive content of the present invention.

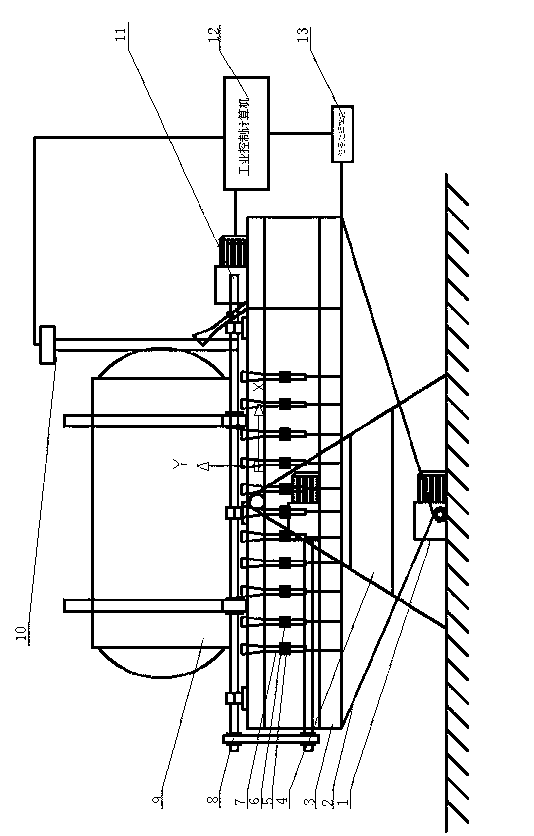

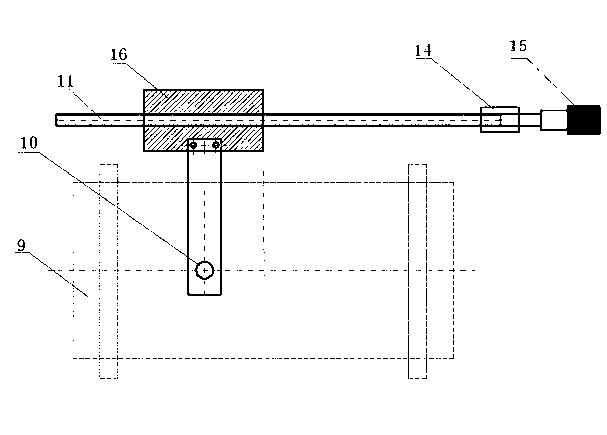

[0042] refer to figure 1 , figure 2 The polyethylene tank shown has a volume of . The method of monitoring and controlling the temperature of the mold surface is as follows:

[0043] (1) Open the main gas valve, heat the surface of the rotomolding mold 9, and turn on the motor 1 to make the rotomolding mold 9 rotate, and preheat for about 10 minutes (the positive and negative error is controlled within 1 minute, and the preheating can be 9-11 minutes , both too long and too short will affect the control accuracy);

[0044] (2) Close the main gas valve and motor 1, add polyethylene particles with a pre-calculated quality into the rotomolding mold, close the mold after adding the material, start the motor 1, rotate the rotomolding mold 9, and open the main gas valve, Feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com