Control method of traction braking level of rail train

A technology for rail trains and control methods, applied in the directions of brakes, brake components, brake safety systems, etc., can solve the problem of the lack of redundant mechanism diagnosis mechanism and safety guidance mechanism for hard-line signal acquisition, the downgrade of train operation level, and the problem of train marking. Train operation order and other issues, to achieve the effect of reducing the probability of vehicles going offline, reducing train equipment, and strict control strategies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

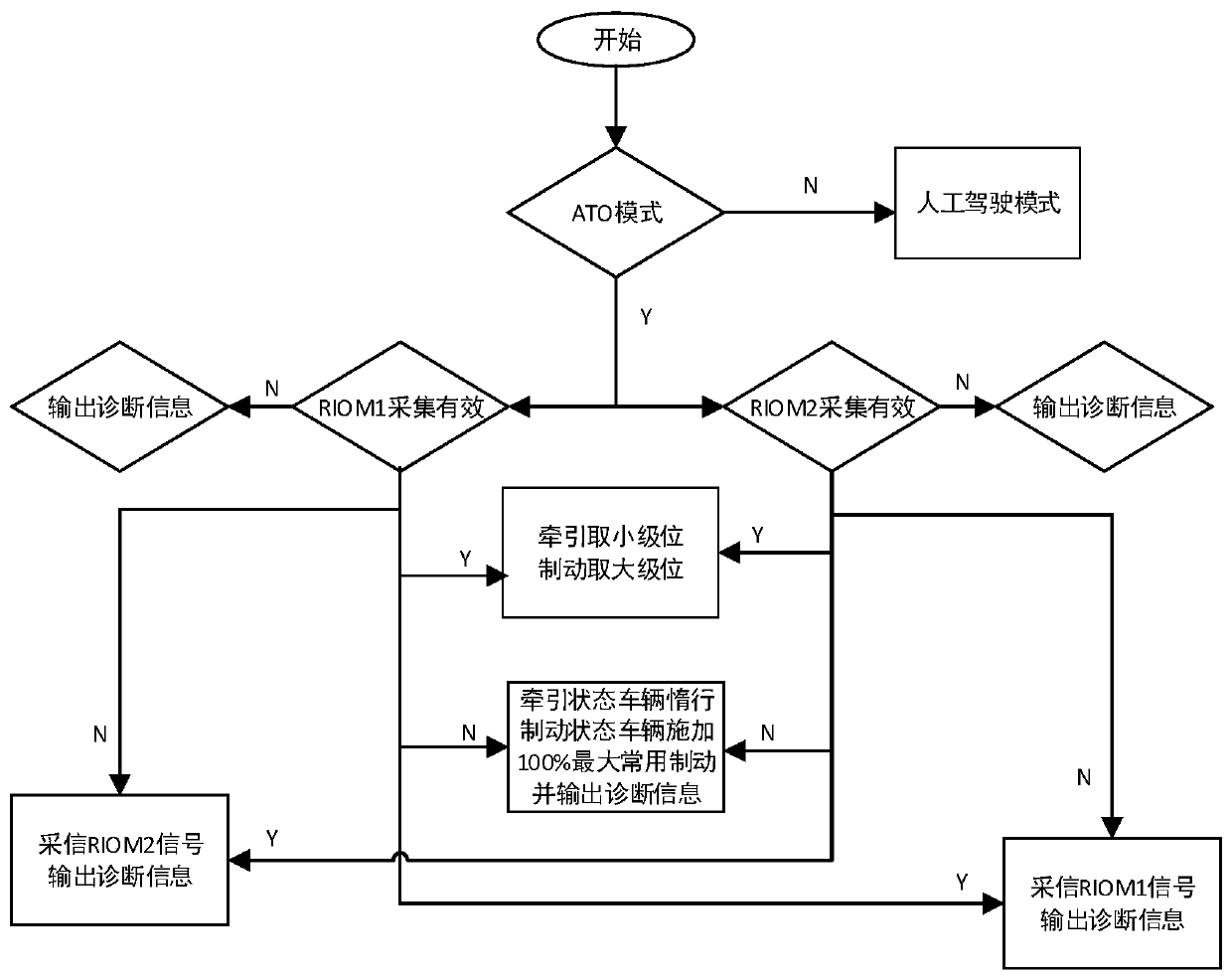

[0034] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

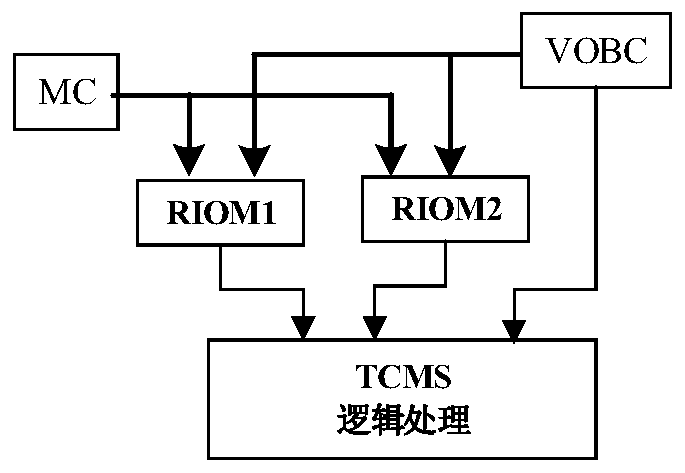

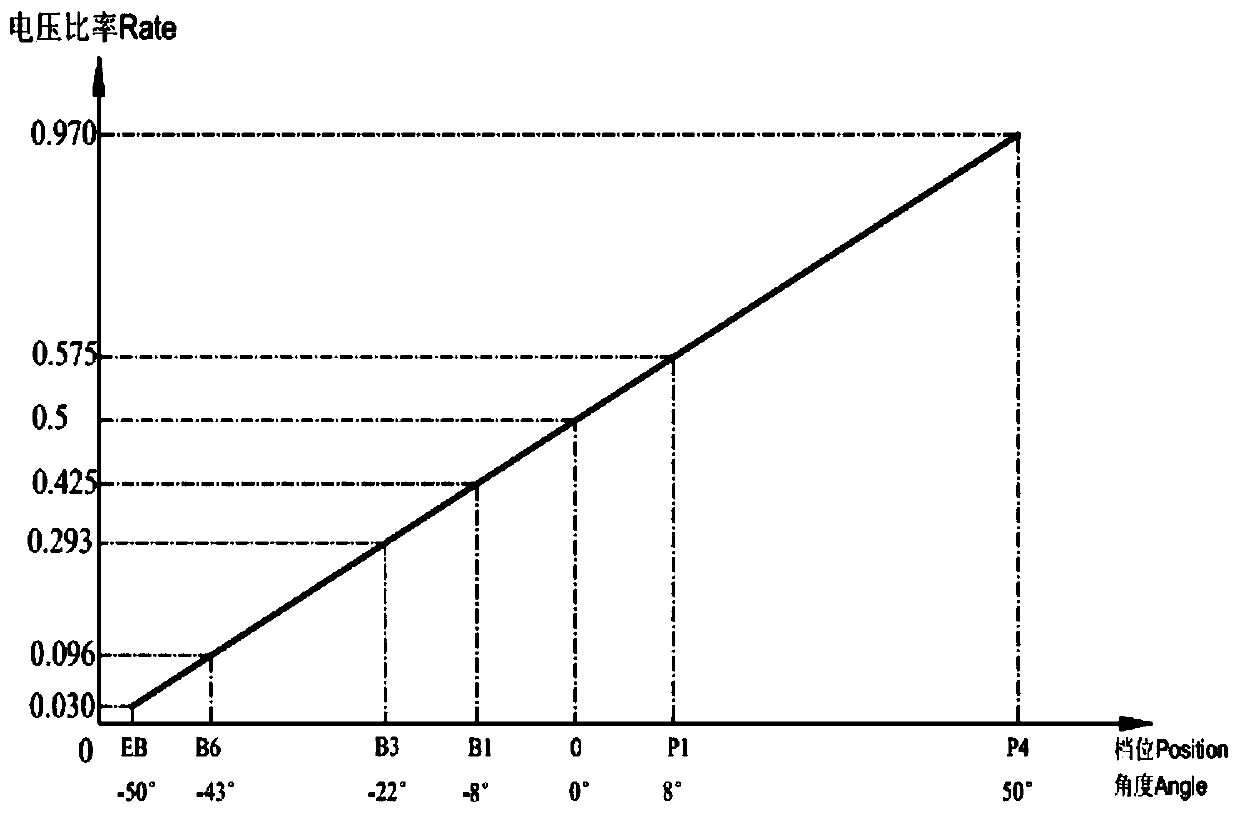

[0035] The traction braking level of rail trains is mainly derived from the signal system output (VOBC) of the automatic driving mode (ATO) and the controller (MC) output of the manual driving mode. The VOBC output in ATO mode is interfaced with the train network control system as a hard-wired signal, usually a 4-20mA current signal or a 0-10V voltage signal. 20mA current signal is mostly. The interface between the MC output in the manual driving mode and the TCMS is a hard-wire signal, usually a 0-10V voltage signal or a PWM signal. In recent years, the traction brake level signal output by the MC in the subway train project is mostly a 0-10V voltage signal. In this embodiment, taking the traction braking level control of a subway train as an example, a traction braking level control method is designed, including:

[0036] (1) Obtain the trai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com