A flexible crawler pantograph bow suitable for electric traction locomotives

An electric traction and pantograph technology, applied in electric vehicles, current collectors, vehicle parts, etc., can solve the problems of wear of pantograph carbon slides, high off-line rate of rigid carbon slides, shortened life of carbon slides, etc. The effect of large area, reduction of pantograph offline rate, and high stability of current receiving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

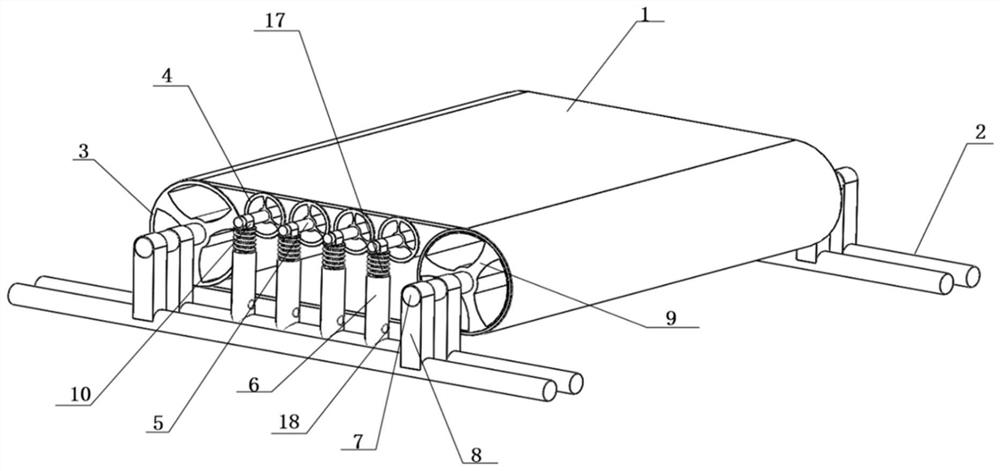

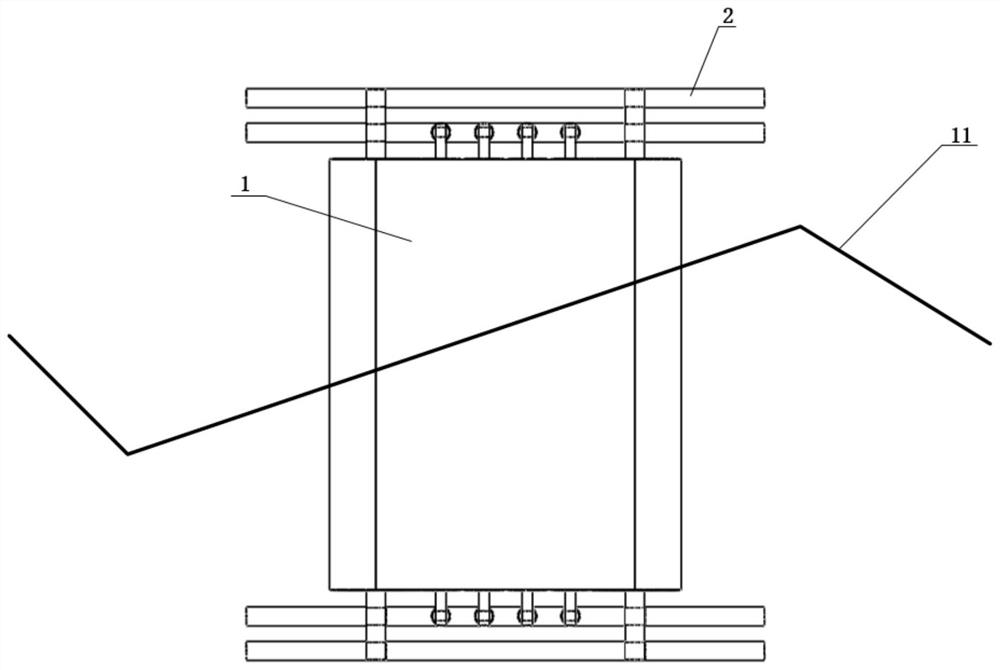

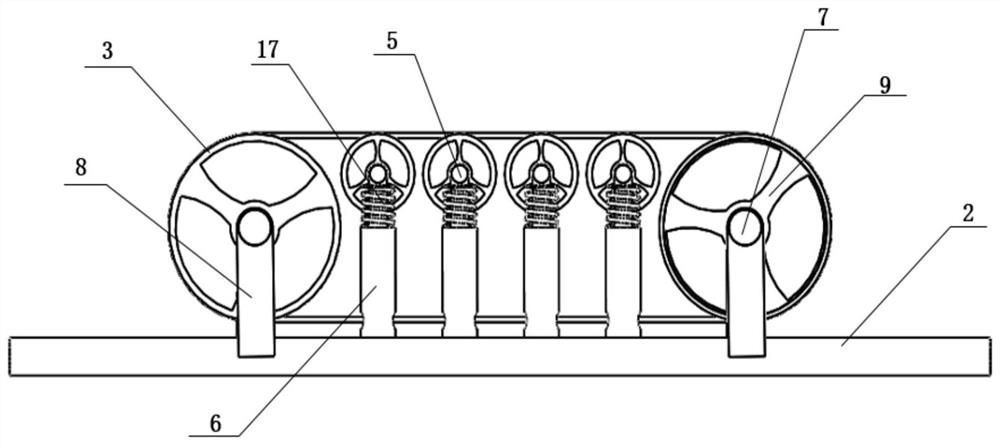

[0027] figure 1 -4 shows a flexible crawler-type pantograph head suitable for electric traction locomotives, used as a pantograph bracket 2 arranged horizontally on the roof of the electric traction locomotive and provided with two metal rollers 3 : The drum shaft 7 of each metal drum 3 is made of insulating material, the drum shaft 7 is fixed on two drum brackets 8, and the two drum brackets are vertically fixed on the pantograph bracket 2, and the metal drum 3 is insulated by two The bearing 12 is rotatably installed on the drum shaft, and a metal spring 16 is arranged in at least one through hole perpendicular to the axial direction on the drum shaft, and a current receiving carbon brush 13 is respectively fixed on the two ends of the metal spring protruding from the through hole , the outer end surface of the current-receiving carbon brush is in contact with the inner wall of the metal drum to receive current, and the current-receiving carbon brush outputs the current to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com