Patents

Literature

35results about How to "Depression depression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel corrosion-resistant alloy steel continuous casting powder and application thereof

The invention relates to novel corrosion-resistant alloy steel continuous casting powder and application thereof, and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises the following components in mass percentage: 17 to 25% of CaO, 23 to 31% of SiO2, 10 to 15% of Al2O3, 1 to 4% of MgO, 10 to 14% of (Na2O+Li2O), 1 to 8% of B2O3, 1 to 6% of TiO, 4 to 8% of BaO, and 10 to 13% of F<->. The casting powder has the characteristics that the melting point is small (865-988 DEG C), the viscosity is small (0.11-0.23Pa.s under 1,300 DEG C), the crystallizing rate is moderate (40-70%), etc. The casting powder can be applied well to the continuous casting of corrosion-resistant alloy steel (Fe-Cr-Ni system) containing 0 to 0.3% of Al and 0.8 to 1.1% of Ti in mass percentage.

Owner:CENT SOUTH UNIV

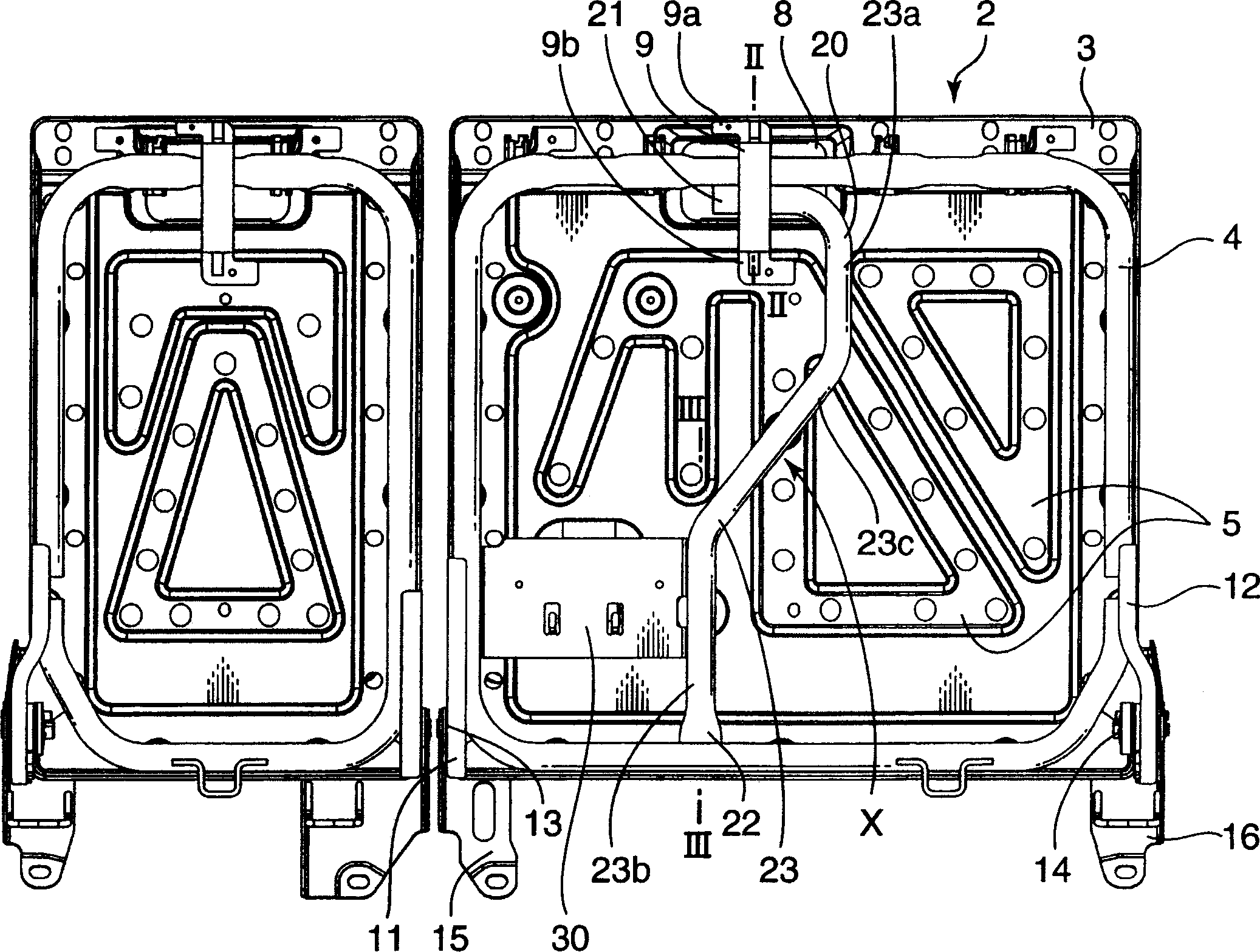

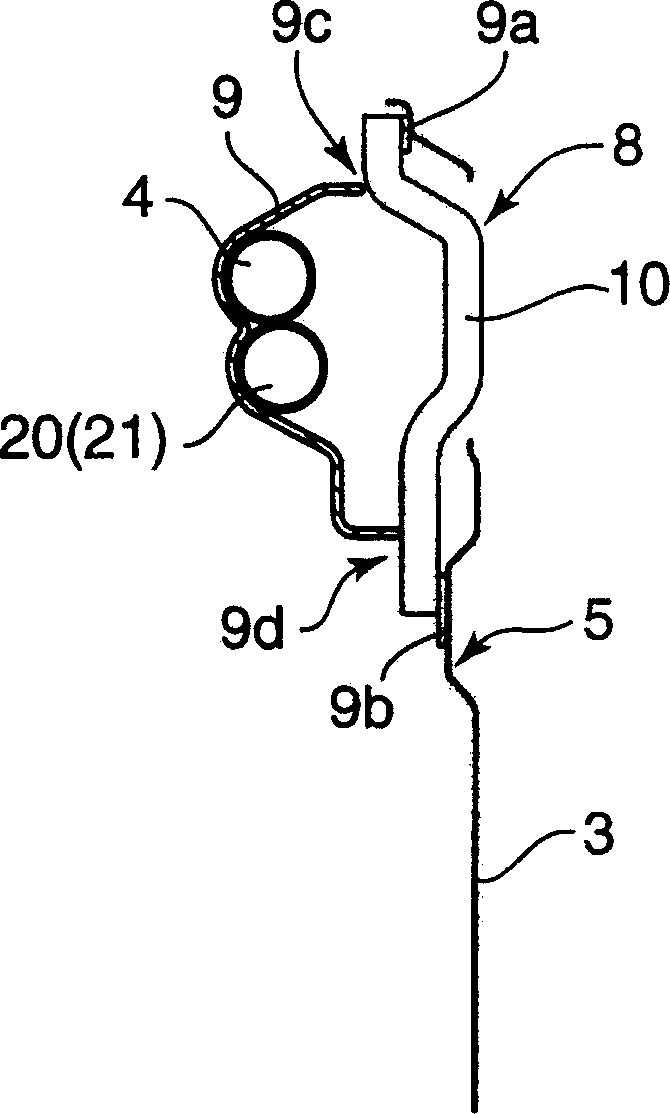

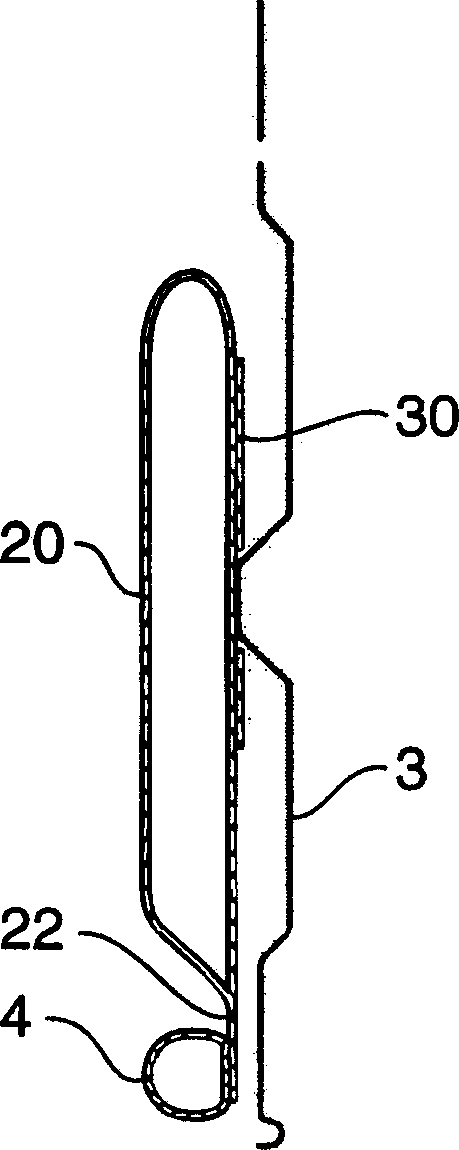

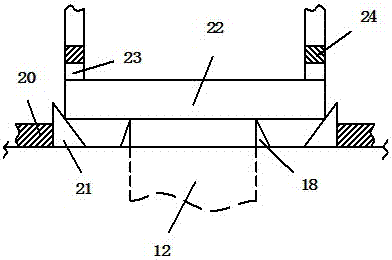

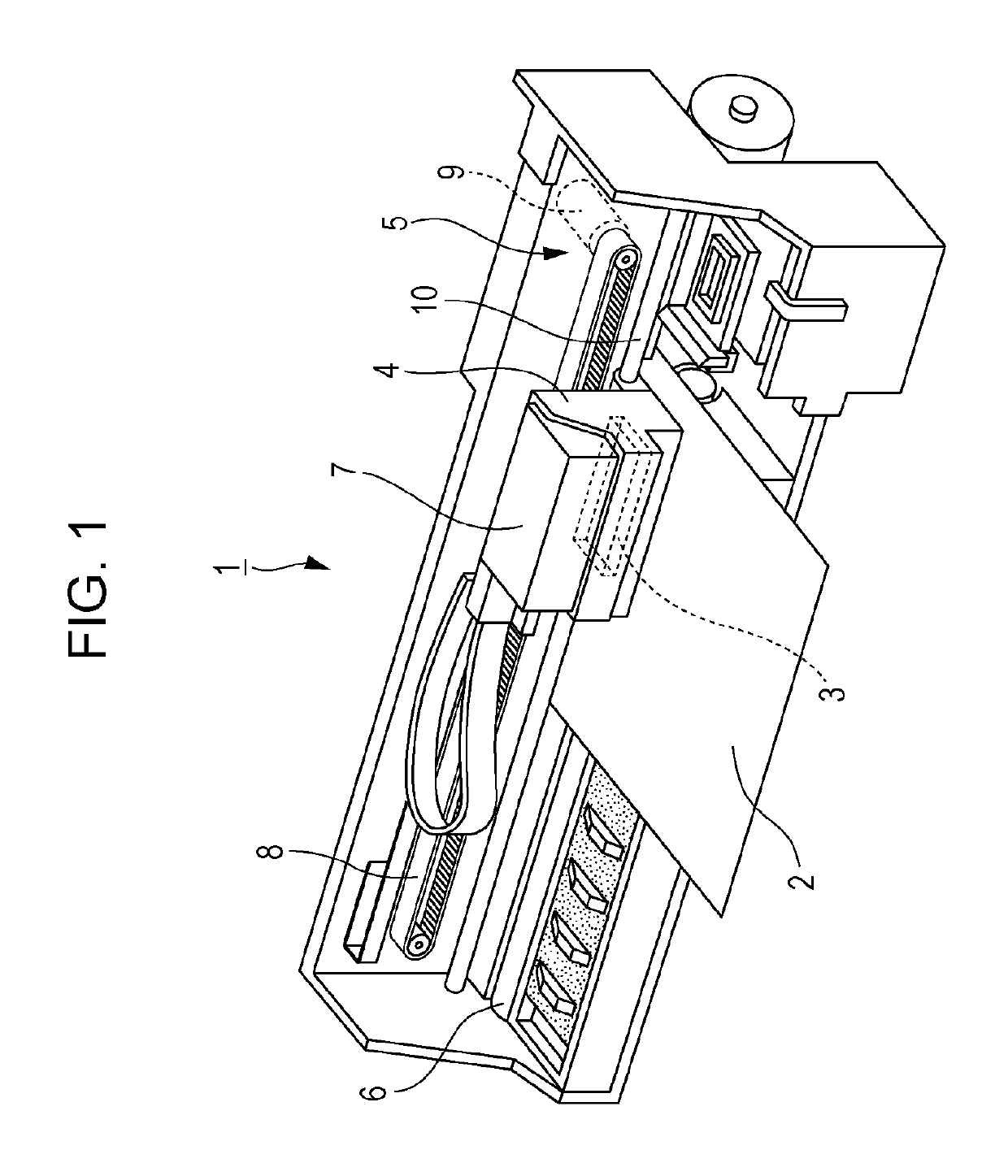

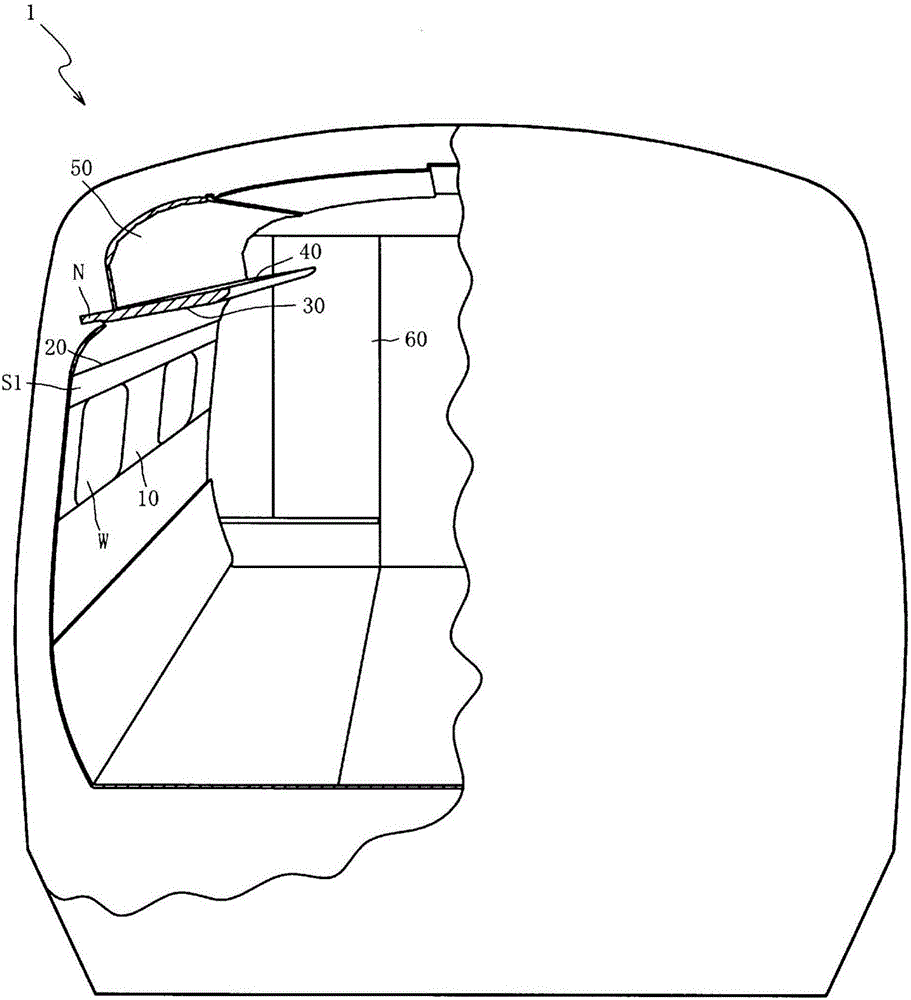

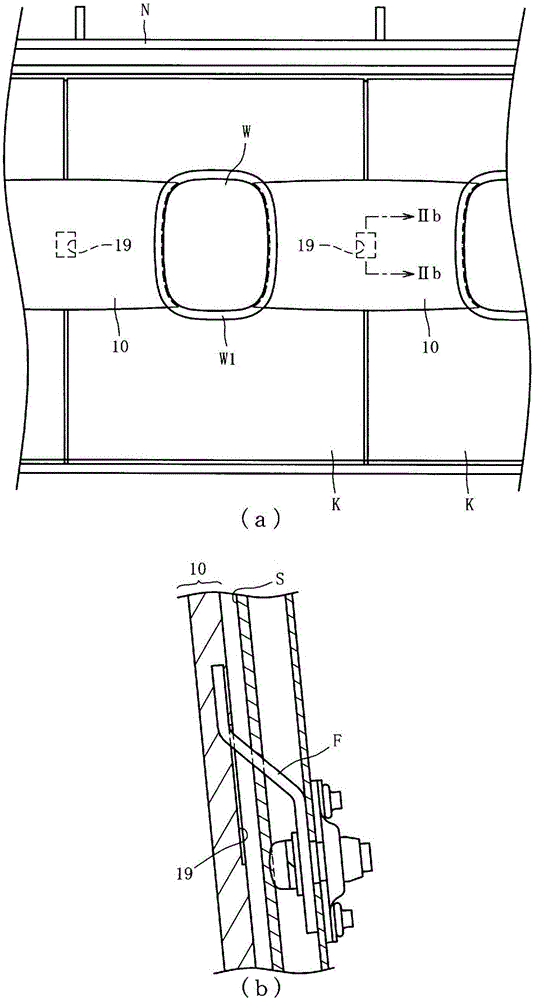

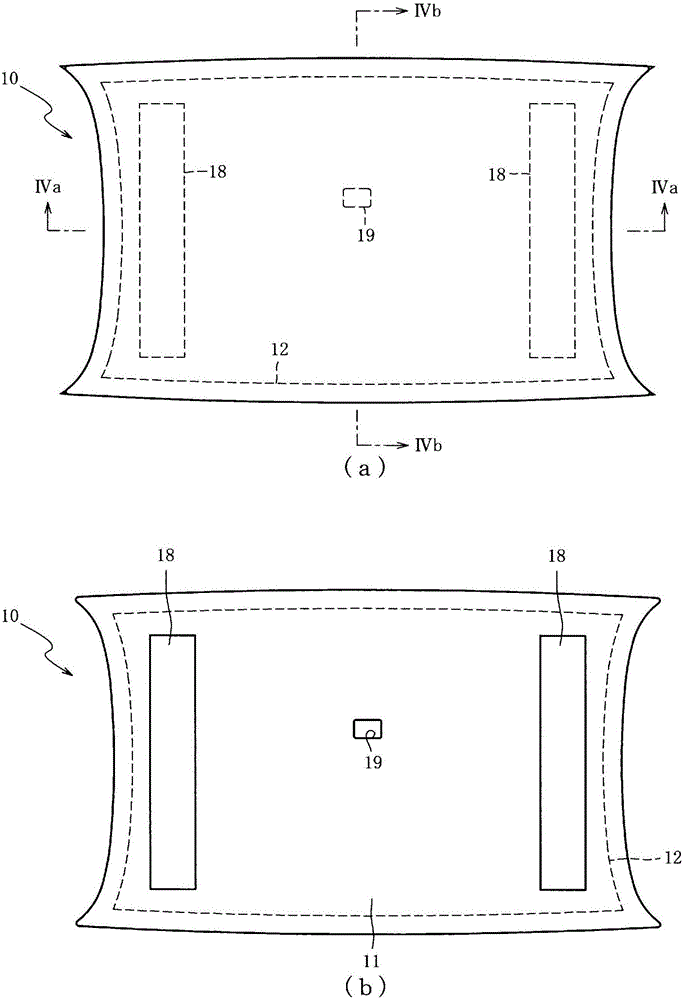

Seat backrest frame structure of vehicle and seat backrest

InactiveCN1439547ADepression depressionHigh strengthSeat framesStoolsEngineeringMechanical engineering

A seat back in a vehicle rear seat provided before a trunk includes a seat back frame structure in which a peripheral frame member is arranged along the periphery of a substantially rectangular panel frame member, and a reinforcing pipe frame member having opposite ends thereof coupled to an upper part and a lower part of the peripheral frame member and having an intermediate part formed to pass an external-force receiving portion of the panel frame member where an external force resulting from a possible movement of a luggage placed in the trunk is received. There can be provided a frame structure for the vehicle seat back having an improved strength against an external force exerted resulting from the movement of the luggage placed in the trunk.

Owner:DELTA KOGYO CO LTD

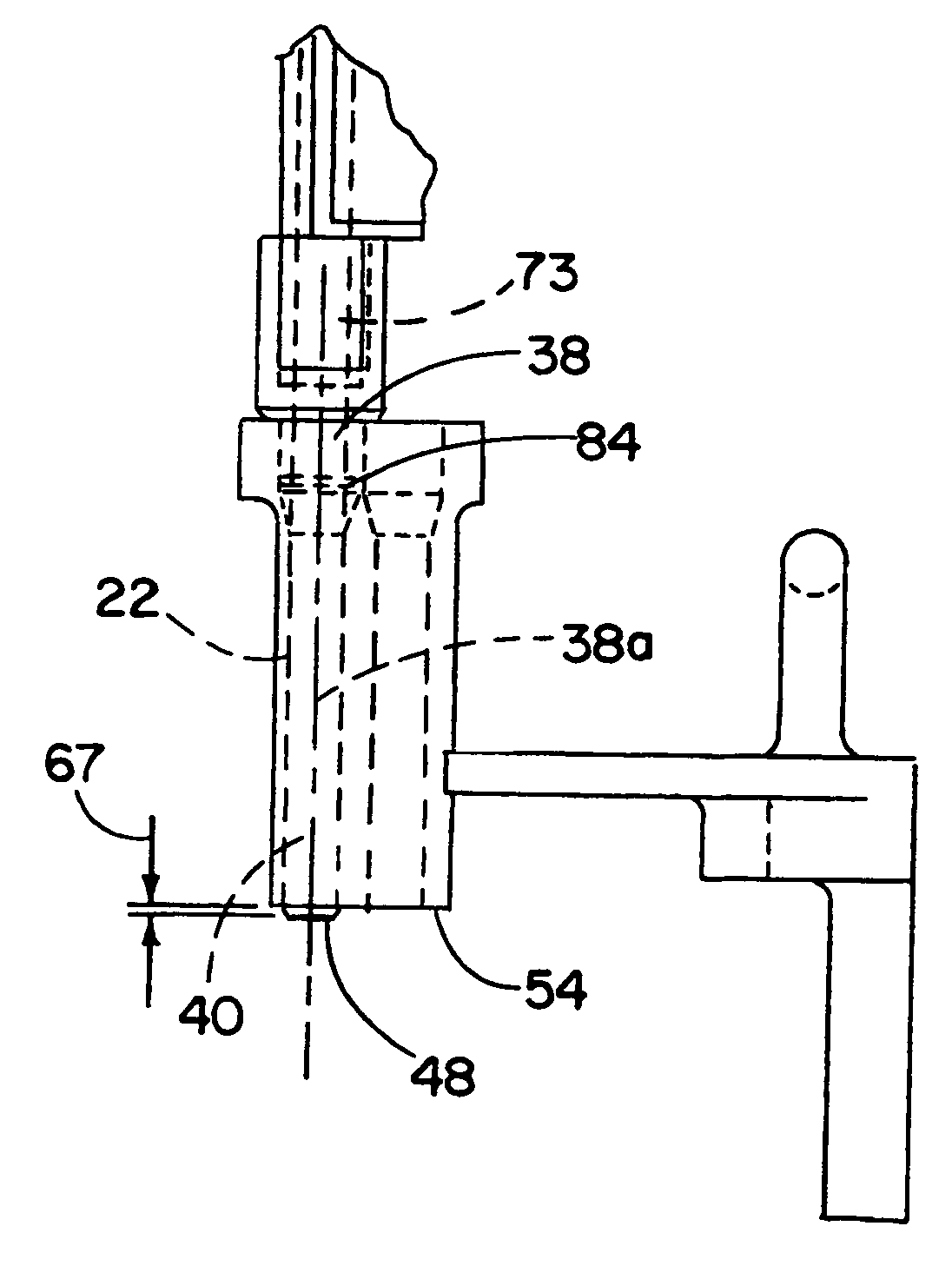

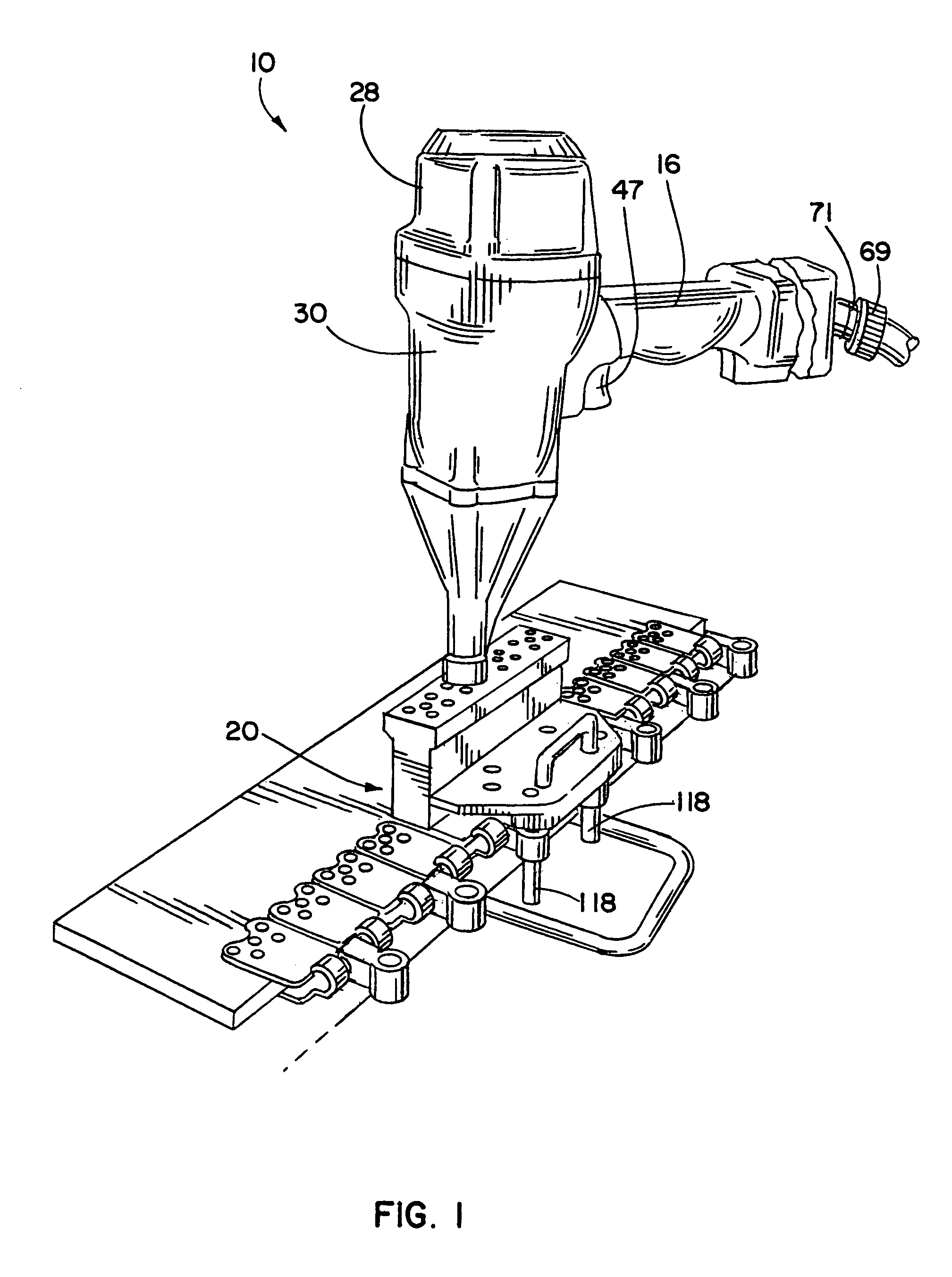

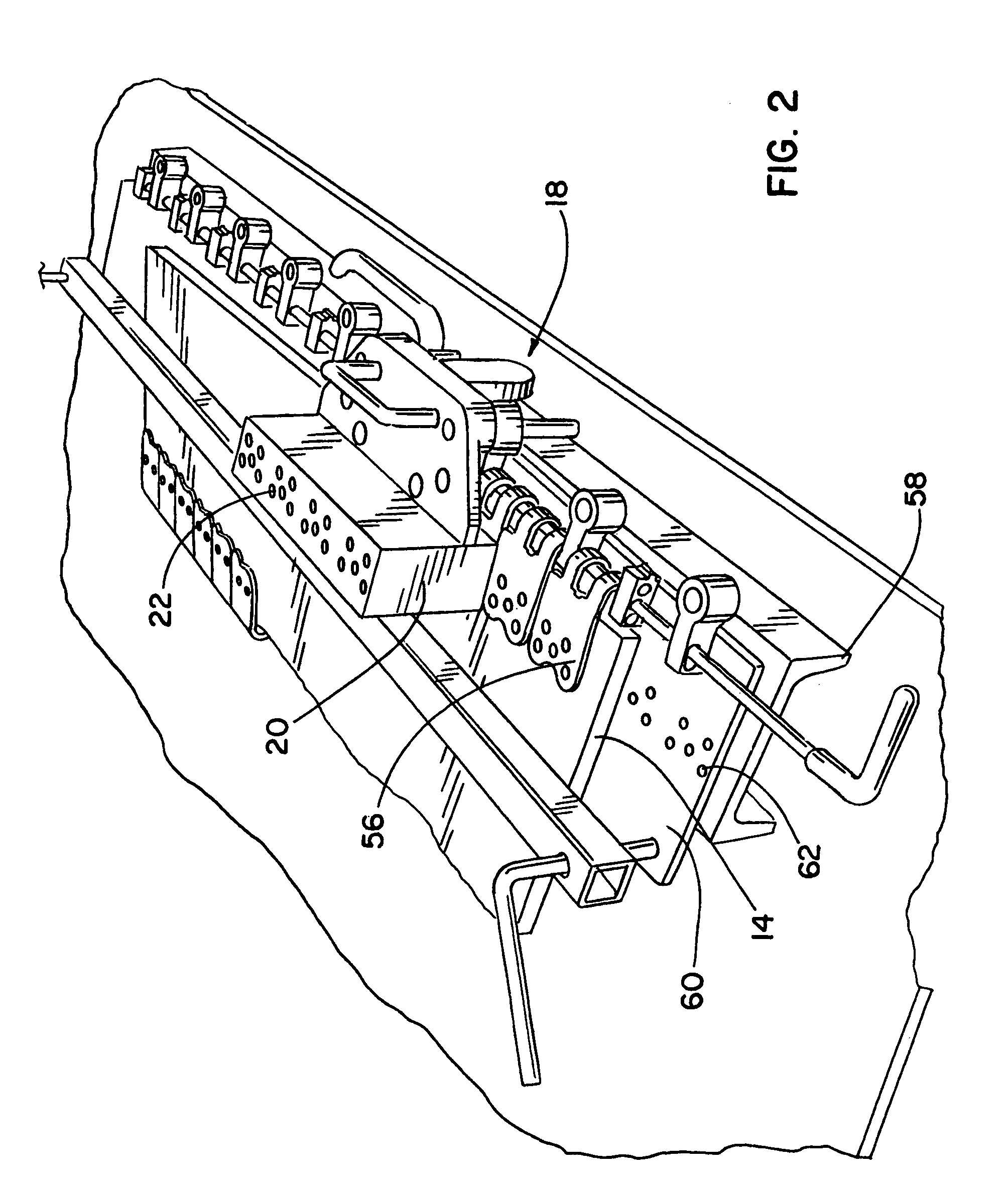

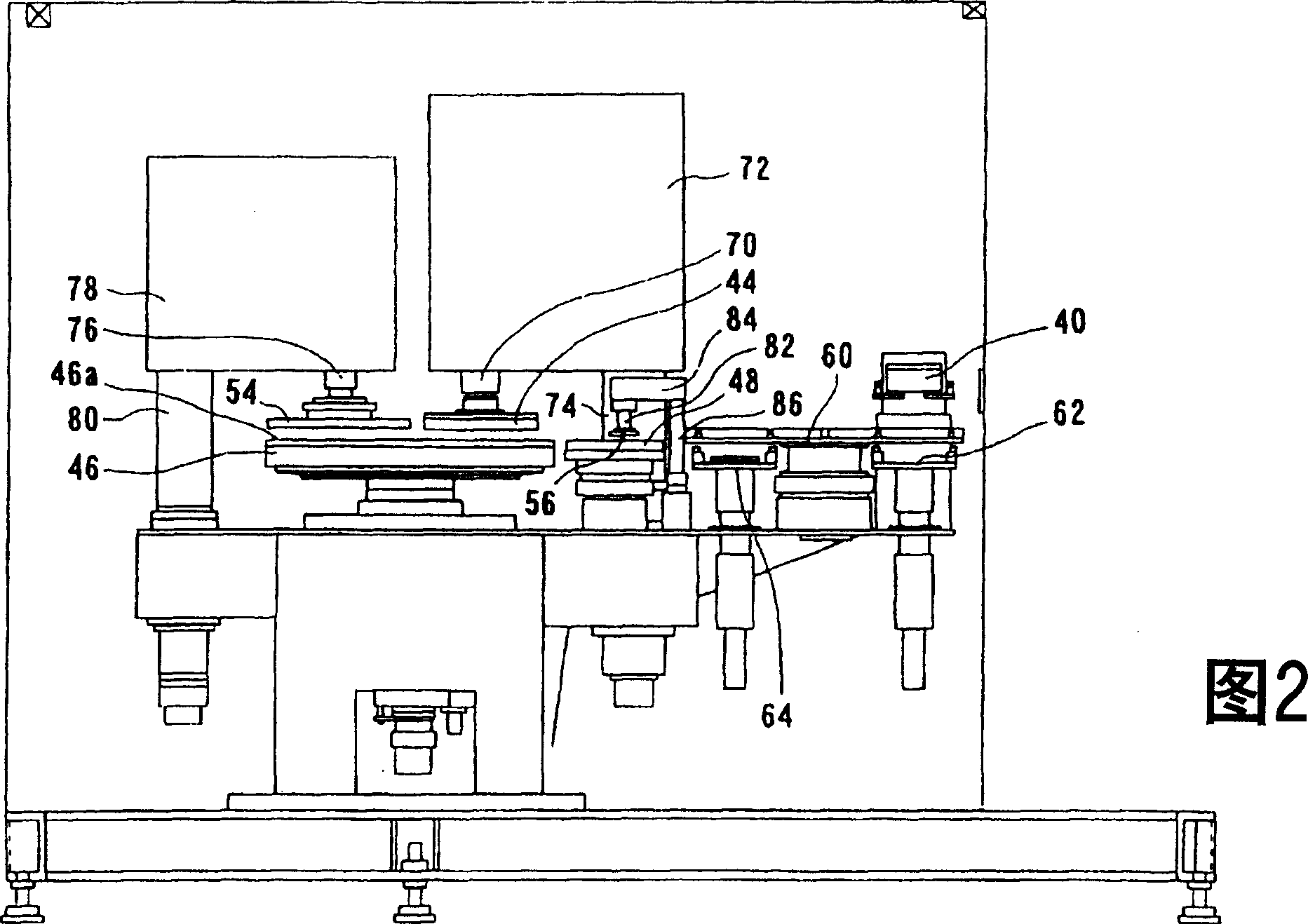

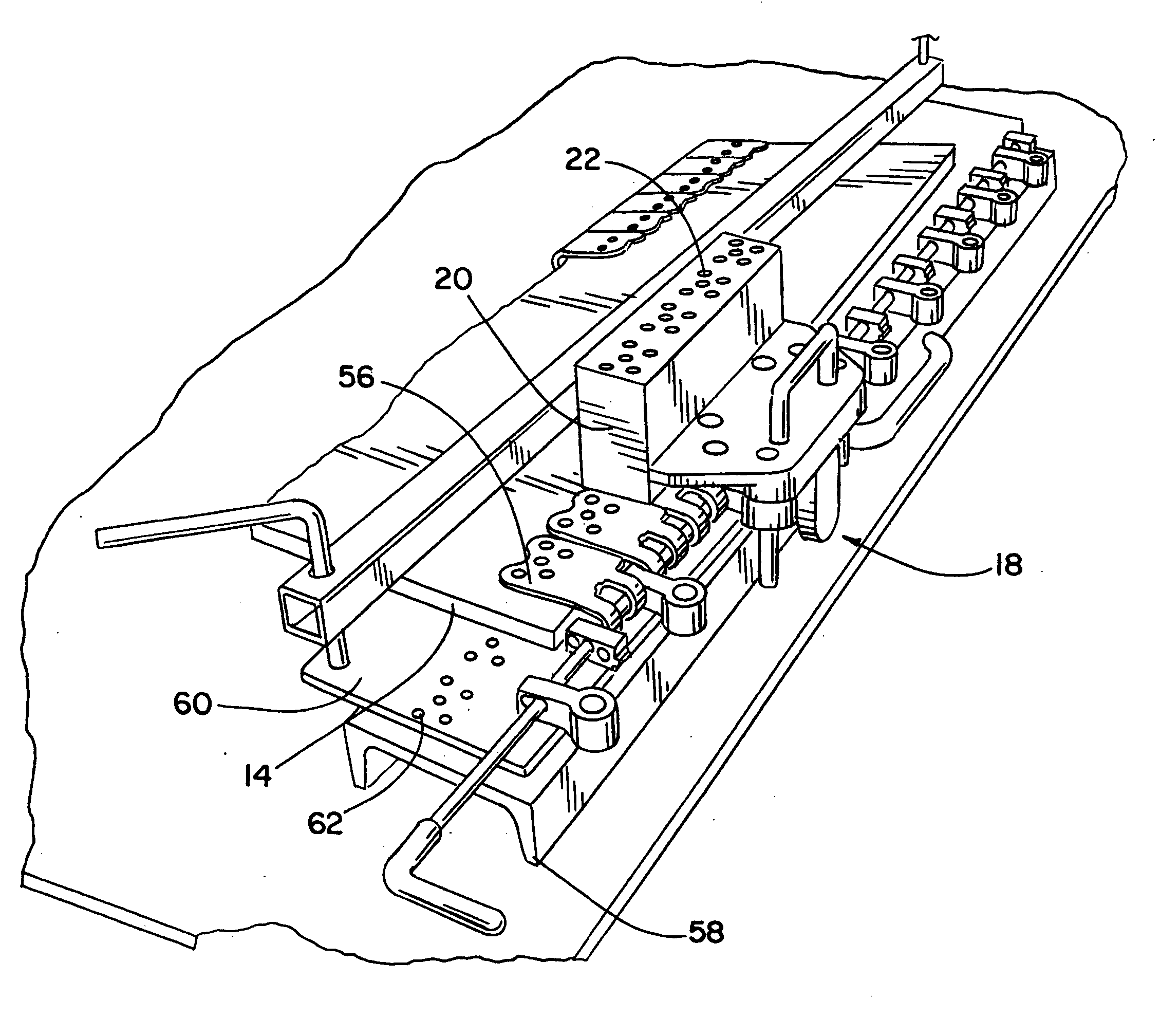

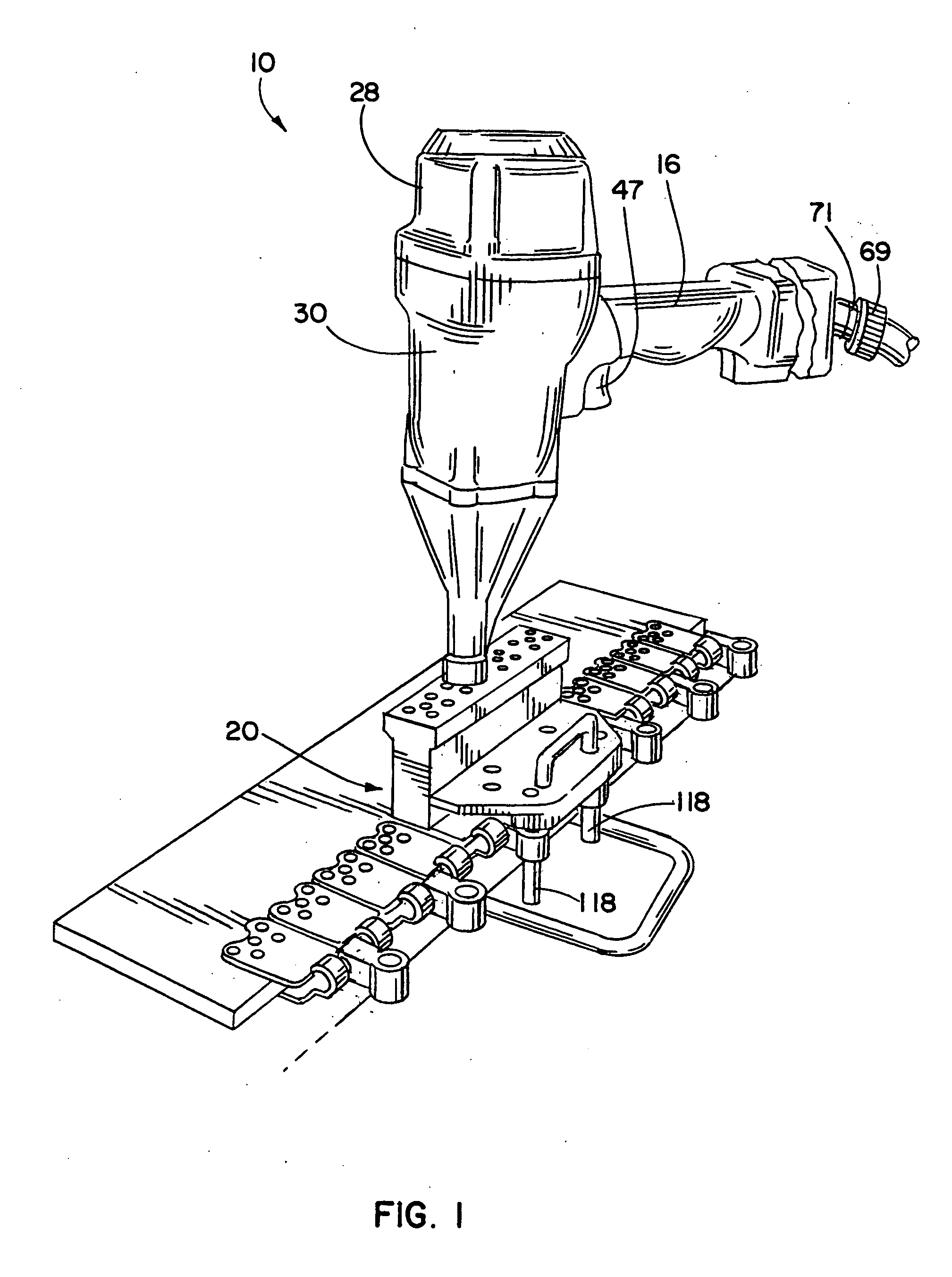

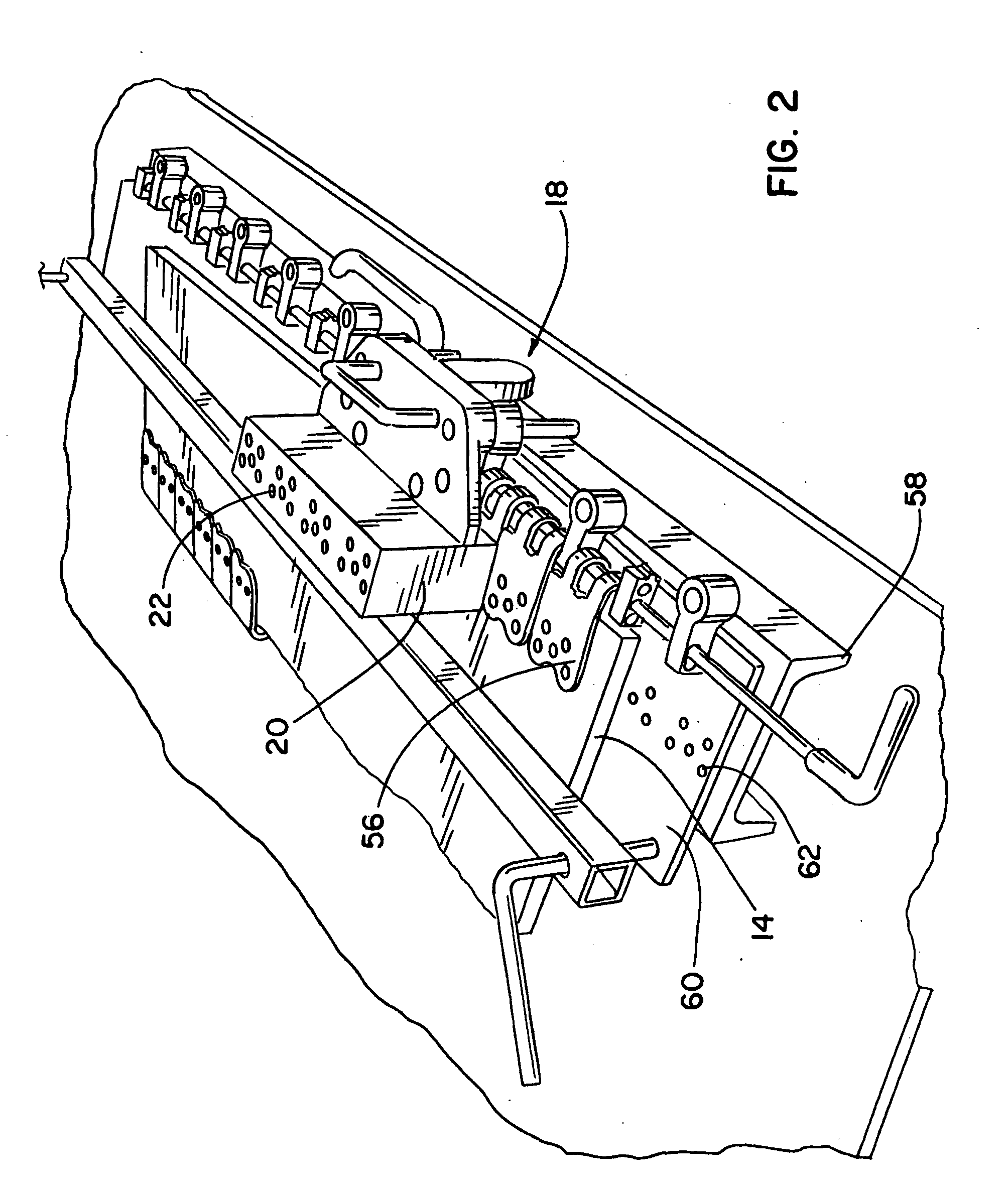

Power applicator system for conveyor belt fasteners

A system for applying belt fasteners to belt ends is disclosed. The system includes a power tool apparatus and a guiding apparatus. The guide apparatus includes a guide block having guide bores in which attachment members, e.g., rivets, are held in position relative to the belt fasteners so that a drive rod of the power tool impacts the rivets in the guide block bores. The guide block preferably is of a hard material, e.g. a machined steel or powder steel, for proper guiding of the drive rod and rivet during riveting operations.

Owner:FLEXIBLE STEEL LACING

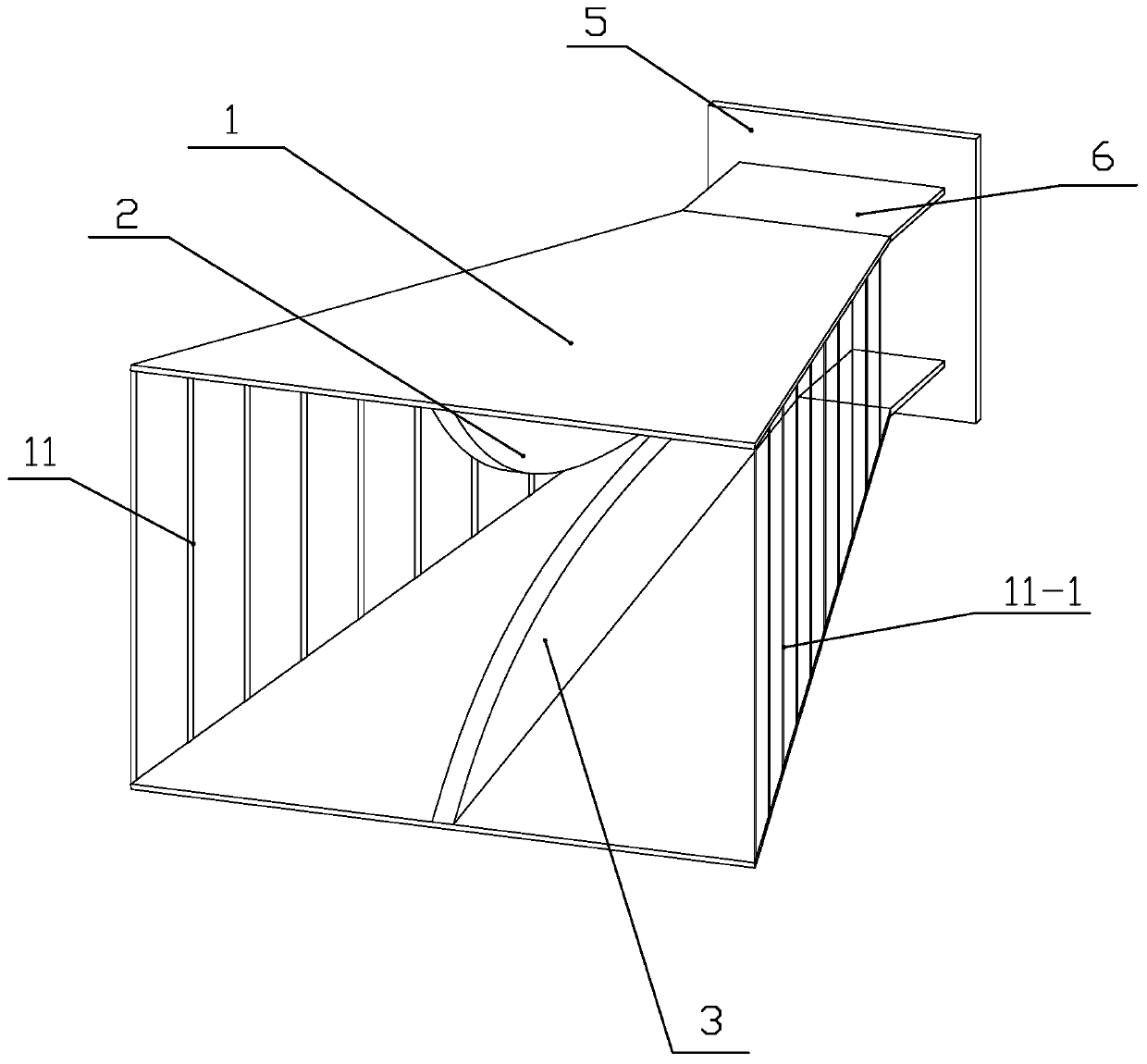

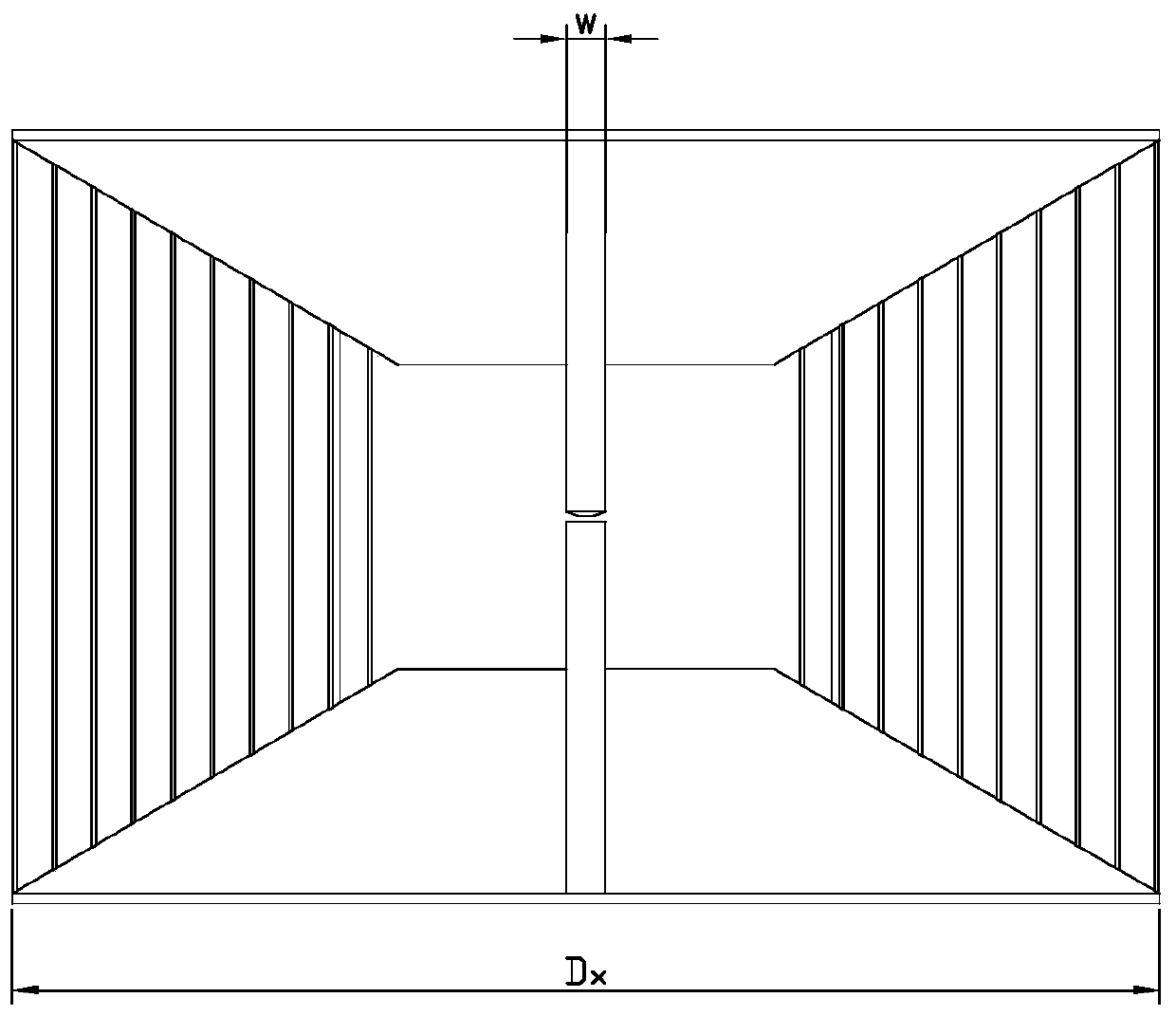

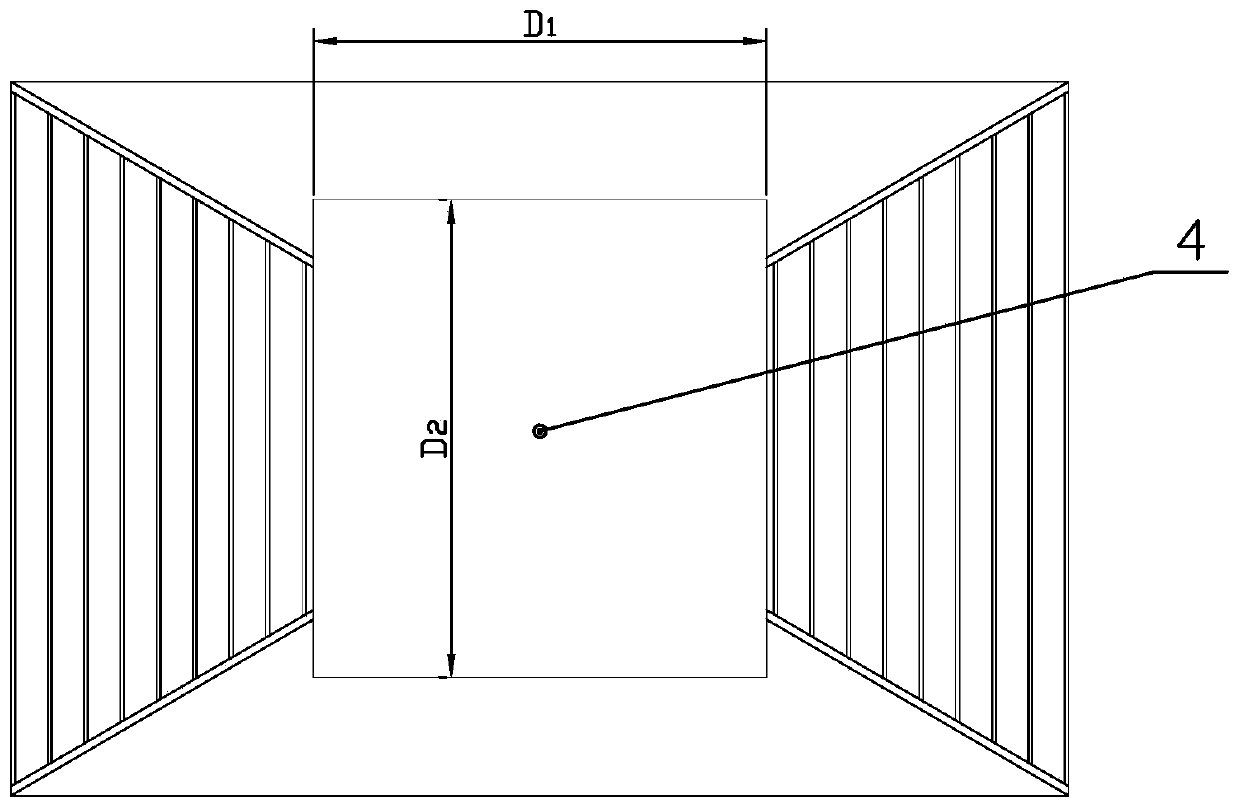

Ultra-wideband double-ridge horn antenna for 1-40GHz frequency band

InactiveCN110600877AImprove matchHigh bandwidthWaveguide hornsAntenna earthingsUltra-widebandLow frequency band

The invention discloses an ultra-wideband double-ridge horn antenna for a 1-40GHz frequency band, and belongs to the technical field of antennas. The problems are solved that an existing double-ridgehorn antenna is poor in low-frequency-band matching performance, high-frequency-band directional diagram main lobes are split, and gain is reduced. The antenna comprises a ridged horn and a feed structure, the ridged horn comprises a shell, an upper ridge and a lower ridge, the shell is a rectangular cone structure, metal grids are arranged on the left side wall and the right side wall of the shell, the upper ridge and the lower ridge are fixedly arranged on the inner sides of the upper side wall and the lower side wall of the shell respectively, and the ridge line of the upper ridge and the ridge line of the lower ridge are curves; the feed structure comprises a coaxial line, a metal floor and a waveguide section, the metal floor is vertically arranged, the coaxial line is horizontally arranged, and the coaxial line is connected with the ridged horn through the metal floor and the waveguide section.

Owner:HARBIN INST OF TECH

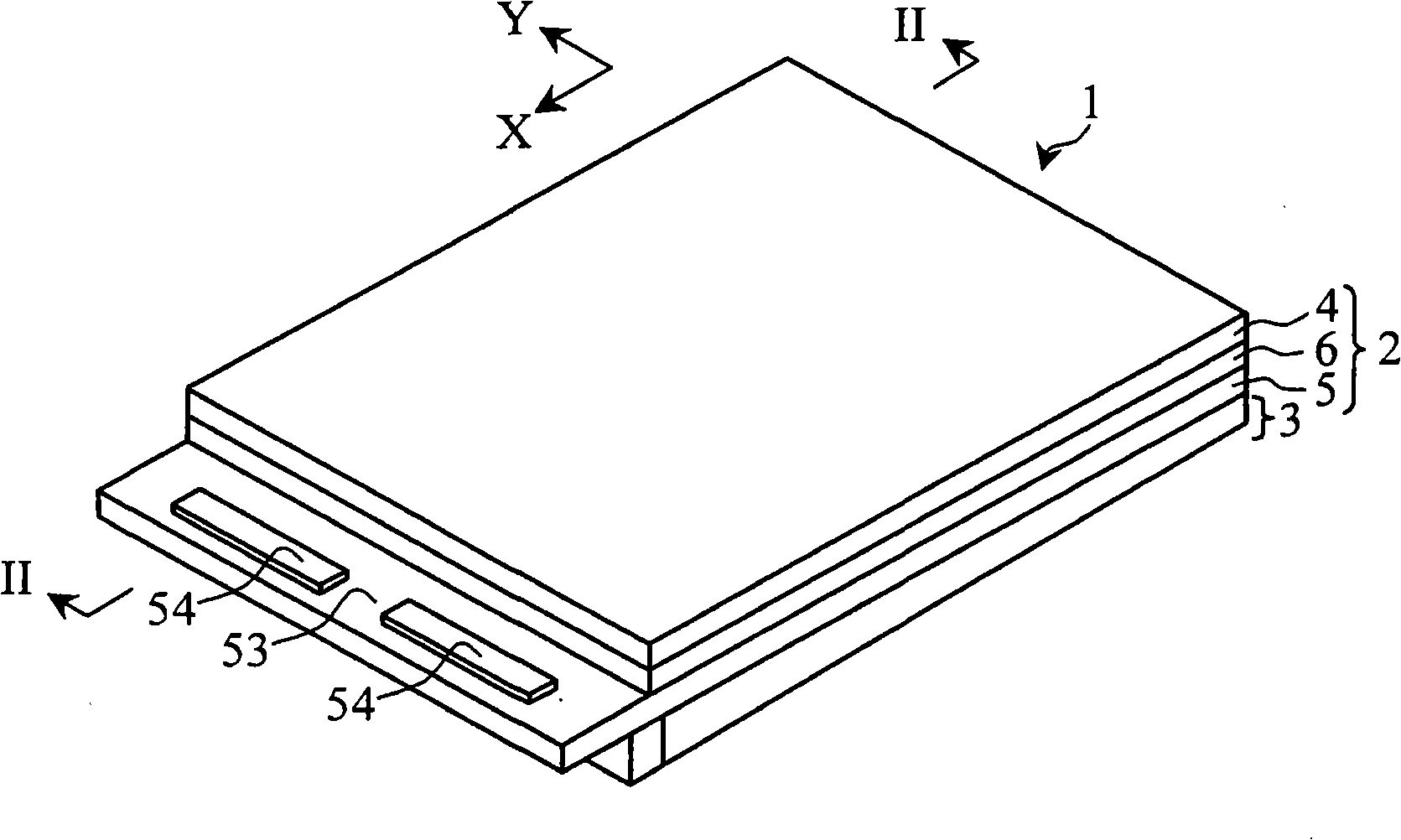

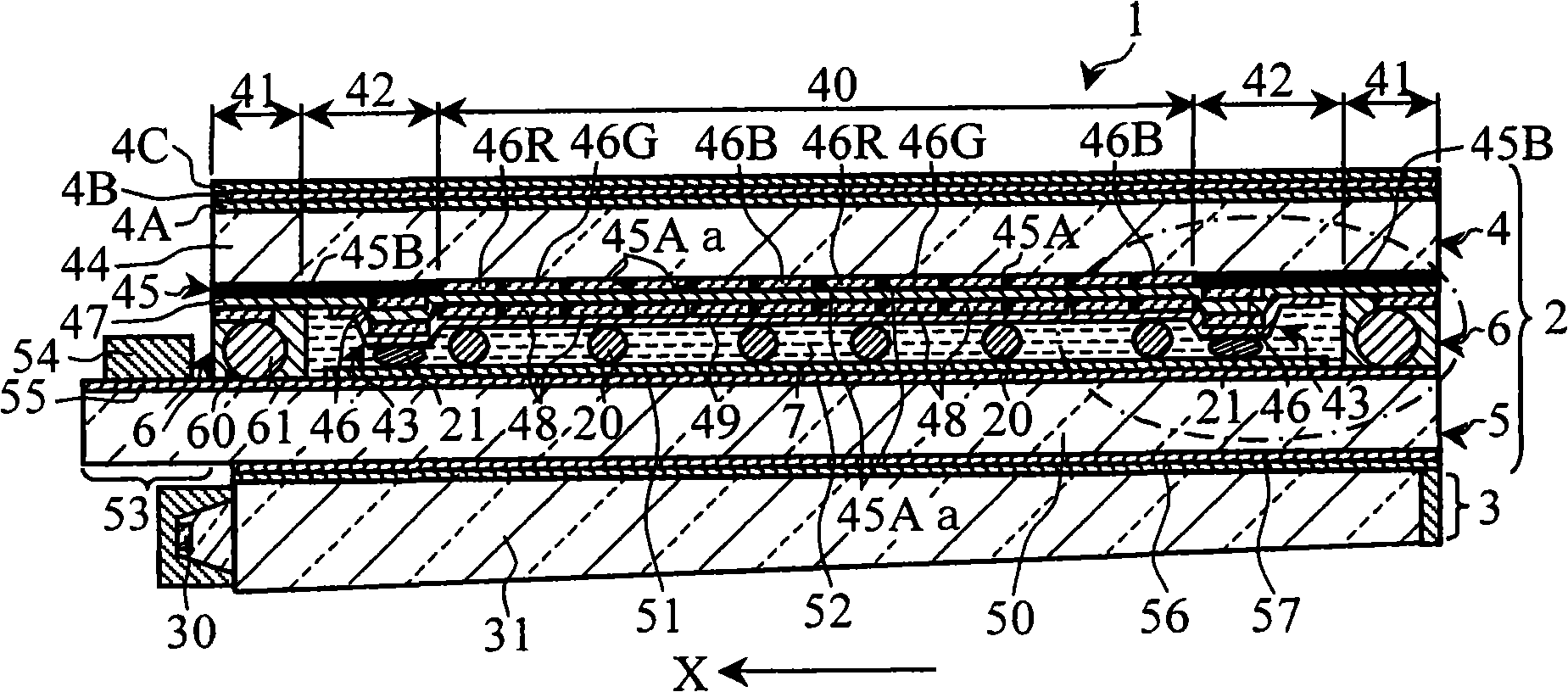

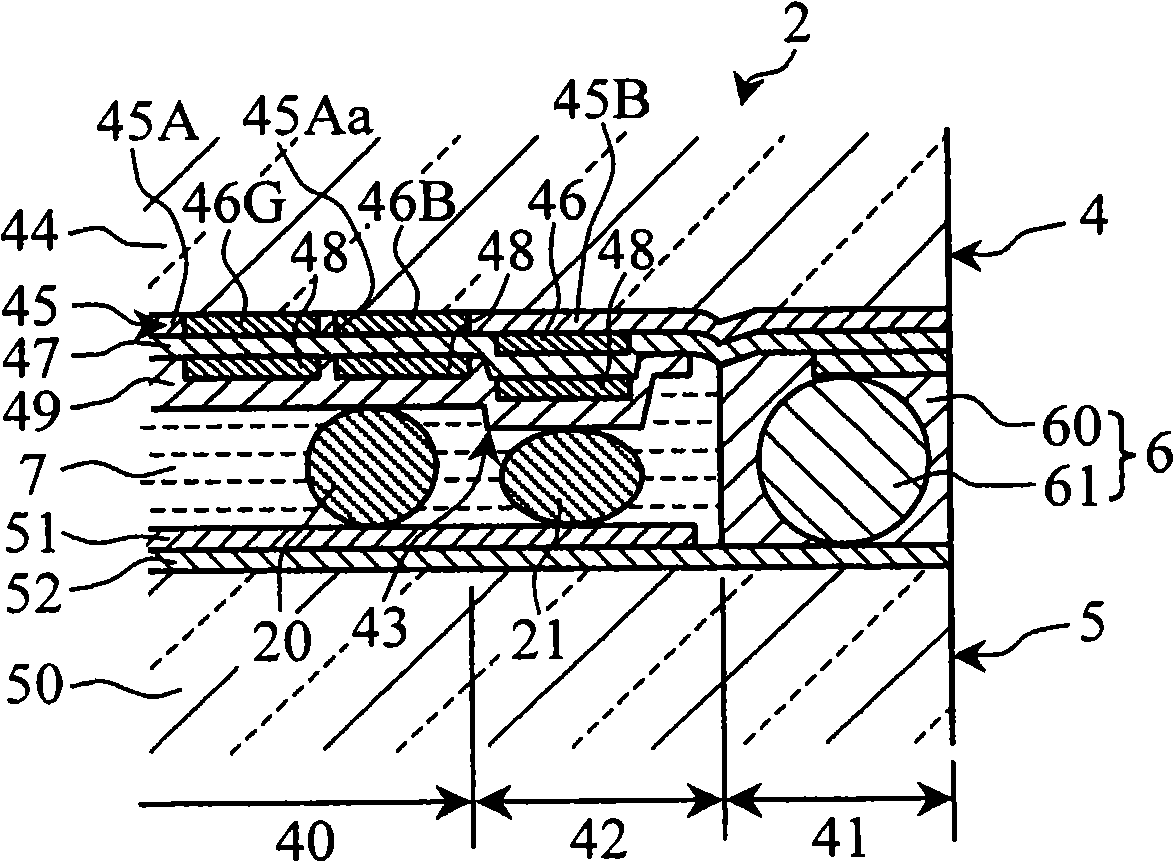

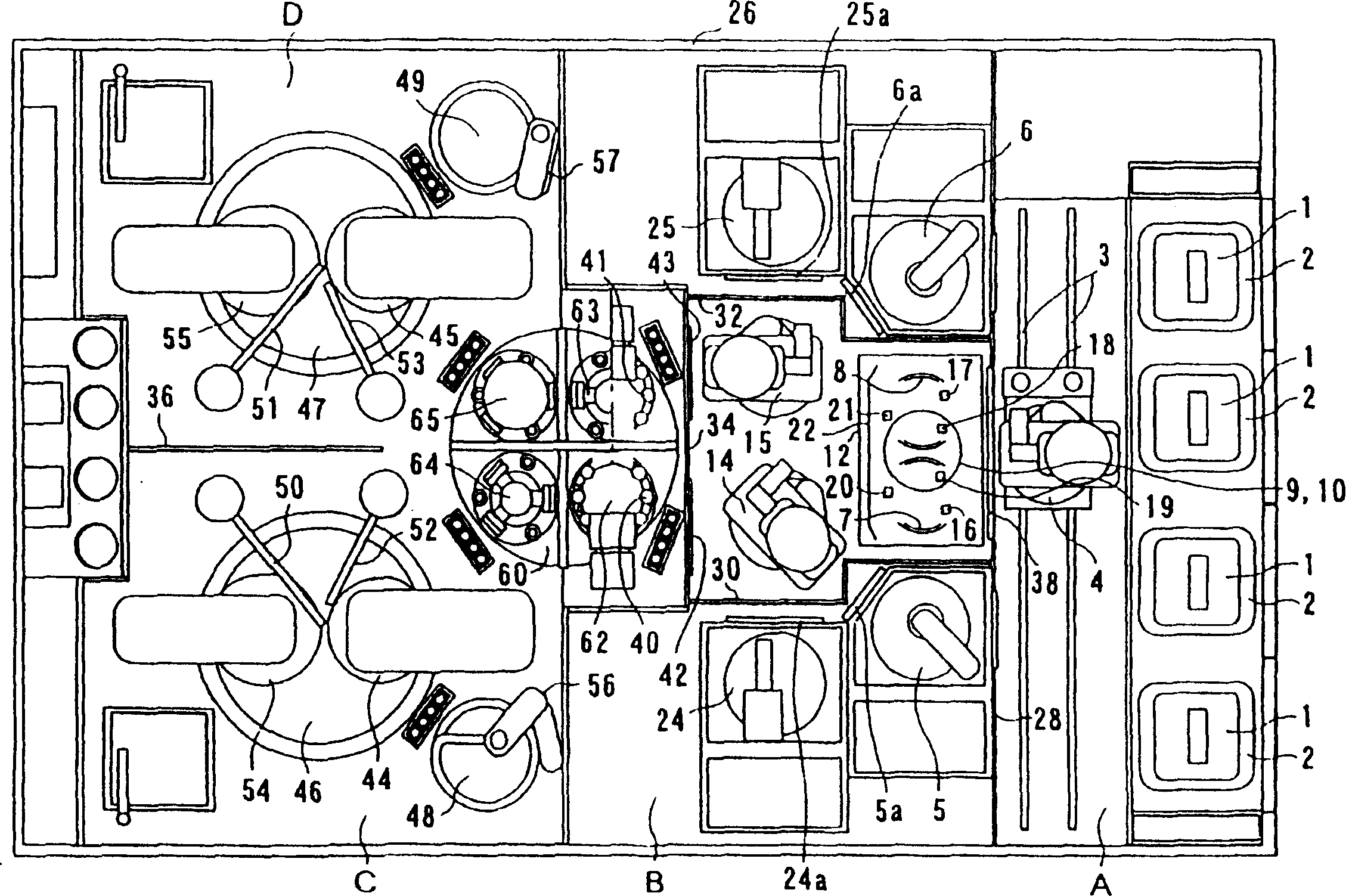

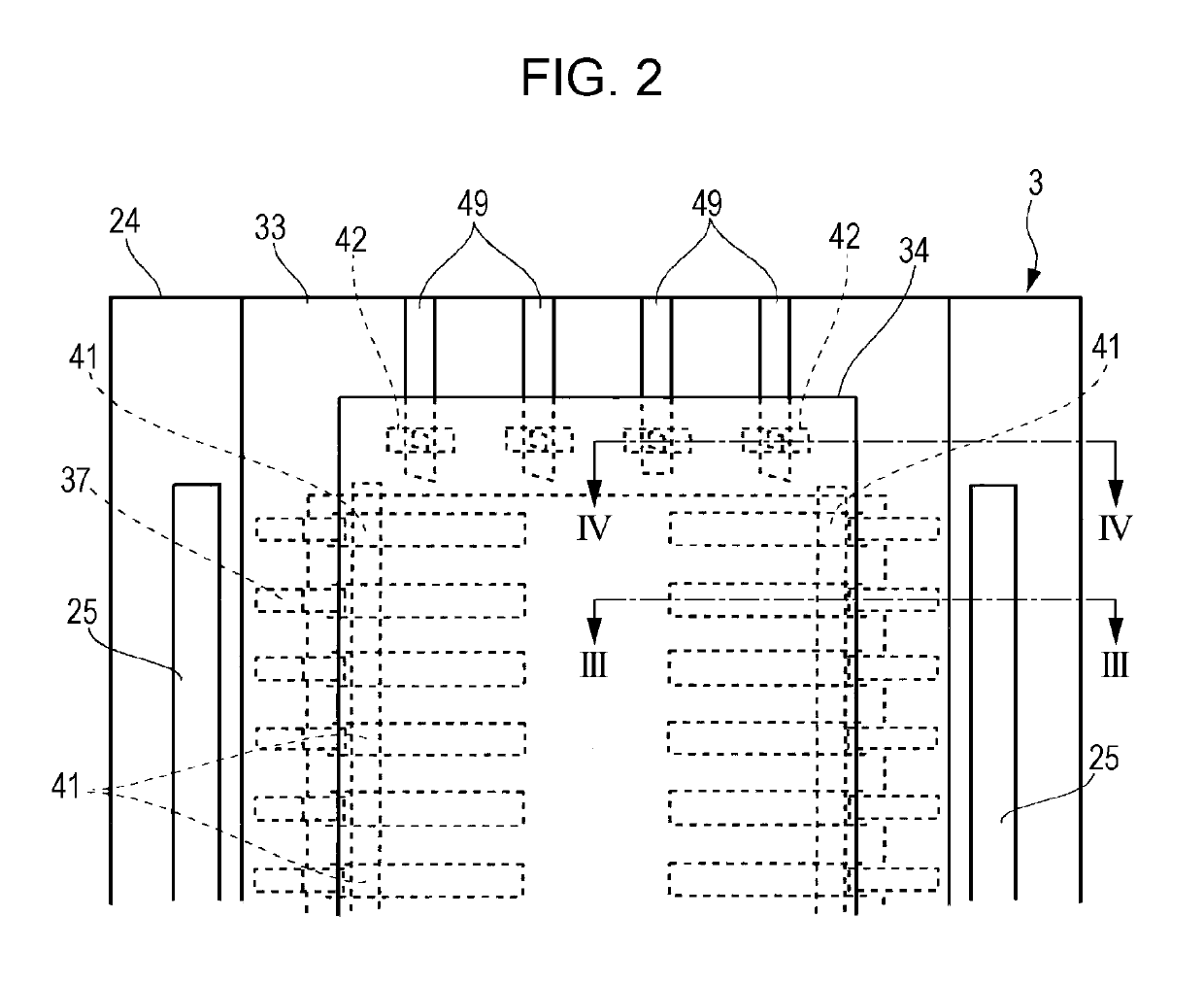

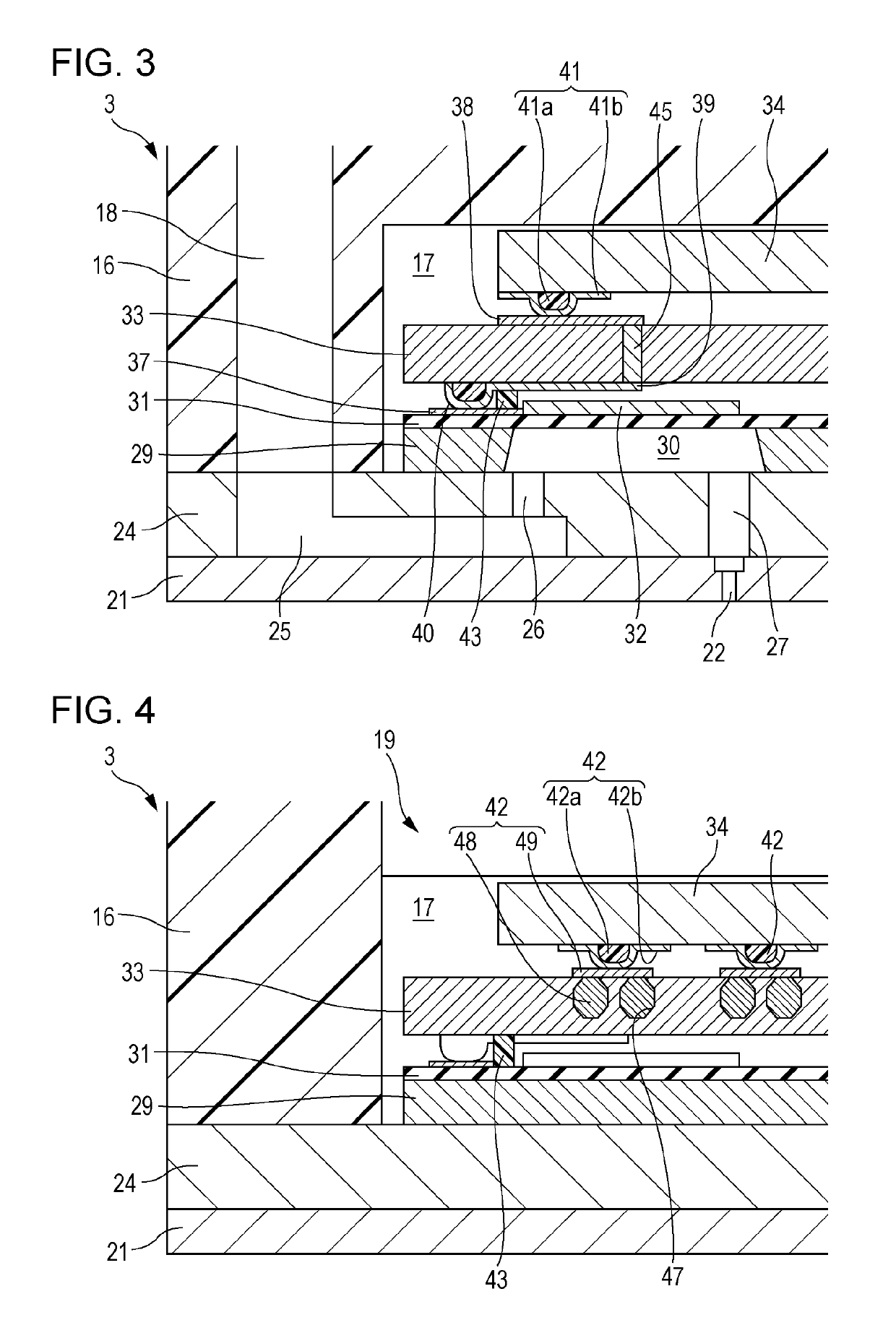

Liquid crystal display panel, liquid crystal display device provided with same, and bonding substrate for liquid crystal display panel

InactiveCN101278228AWill not be enlargedUniform thicknessNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display panel (2) is provided with a first substrate (4) having a light blocking film (45), a plurality of color filters (46R, 46G, 46B, 46) and a display electrode (48) formed on a first transparent substrate (44); a second substrate (5) having a display electrode (51) formed on a second transparent substrate (50); a plurality of spacers (20, 21) for maintaining a distance between the first substrate (4) and the second substrate (5); and a sealing member (6) for sealing a liquid crystal between the first substrate (4) and the second substrate (5). At least the first substrate (4) or the second substrate (5) is provided with a protruding section (43) formed to surround a display area (40) in a peripheral region (42) between a display area (40) including a plurality of display pixels and a sealing area (41) sealed by the sealing member (6). The spacers (20, 21) include the first spacer (20) positioned in the display area (40) and the second spacer (21) positioned at the protruding section.

Owner:KYOCERA CORP

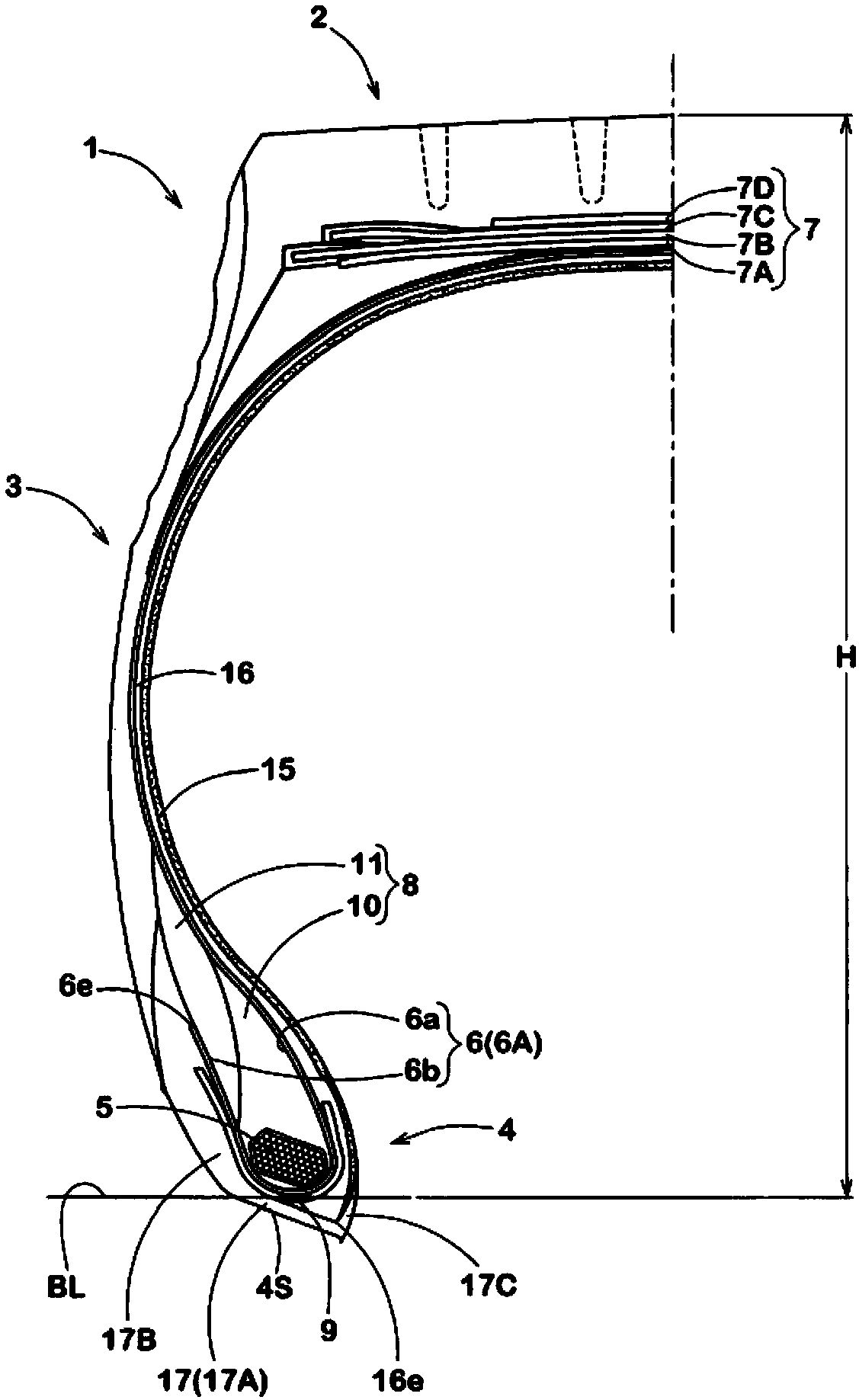

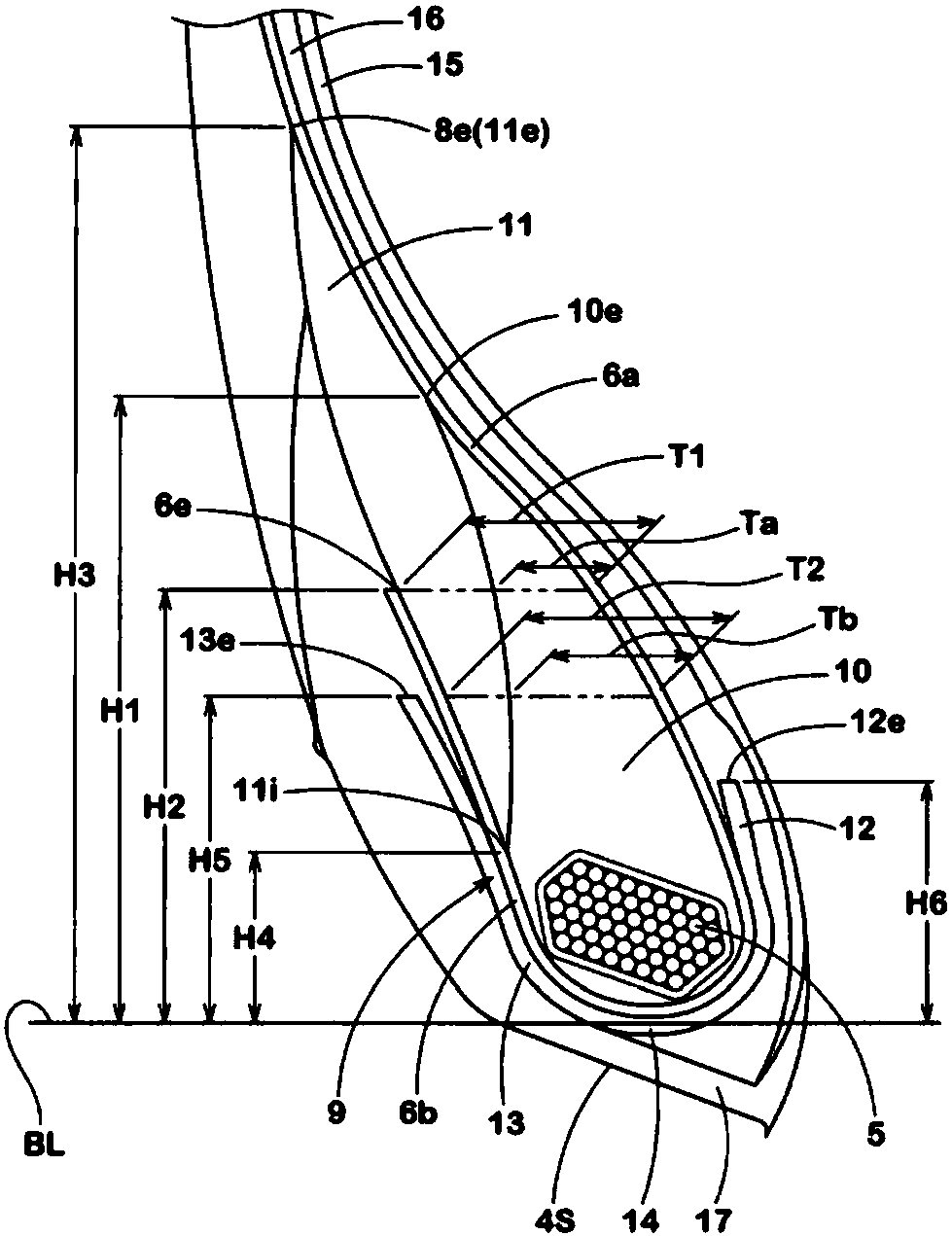

Pneumatic tire

ActiveCN108016215AIncreased durabilityFull bending rigidityHeavy duty tyresHeavy duty vehicleHardnessMechanical engineering

The present invention relates to a pneumatic tire which can improve the endurance performance. The pneumatic tire (1) comprises a carcass (6) comprising a carcass ply (6A) comprising a main body portion (6a) and turned up portions (6b), and bead apex rubbers (8). Each of the bead apex rubbers (8) comprises a first rubber portion (10) and a second rubber portion (11) provided on an outer side in atire axial direction of the first rubber portion and having smaller rubber hardness than the first rubber portion. A ratio H1 / H2 of a height (H1) of an outer end (10e) in a tire radial direction of the first rubber portion (10) from a bead base line (BL) and a height (H2) of an outer end in the tire radial direction of each of the turned up portions (6b) from the bead base line (BL) is in a rangeof from 1.4 to 1.7.

Owner:SUMITOMO RUBBER IND LTD

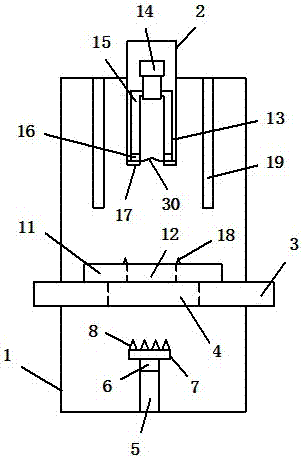

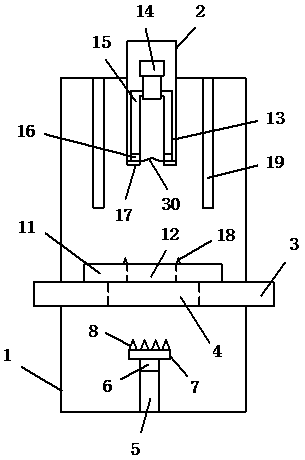

Aluminum profile punching device and punching method thereof

ActiveCN107081374AReduce the stress areaIncrease shear forcePerforating toolsArchitectural engineeringPunching

The invention discloses an aluminum profile punching device. The aluminum profile punching device comprises a rack. A hydraulic punch is mounted at the top of the rack. A base plate is fixedly connected to the rack and located below the hydraulic punch. A first cylinder is vertically mounted at the bottom of the rack. The top of the first cylinder is fixedly connected with a first motor, a first annular tool apron is fixed to an output shaft of the first motor, and a plurality of first tool bits are annularly arranged on the first annular tool apron and hinged to the first annular tool apron. A template is slidably connected to the top surface of the base plate, a template hole is formed in the template, and an annular blade is arranged on the edge of the template hole. An annular cavity is formed in the hydraulic punch, a second motor is mounted at the top of the annular cavity and connected with a second annular tool apron through a connecting rod, the connecting rod is located in the annular cavity, and a plurality of second tool bits are fixedly connected to the bottom of the second annular tool apron. By adoption of the aluminum profile punching device, defects of the prior art can be overcome, and the machining quality of aluminum profile punching is improved.

Owner:肇庆市美联达有色金属制品有限公司

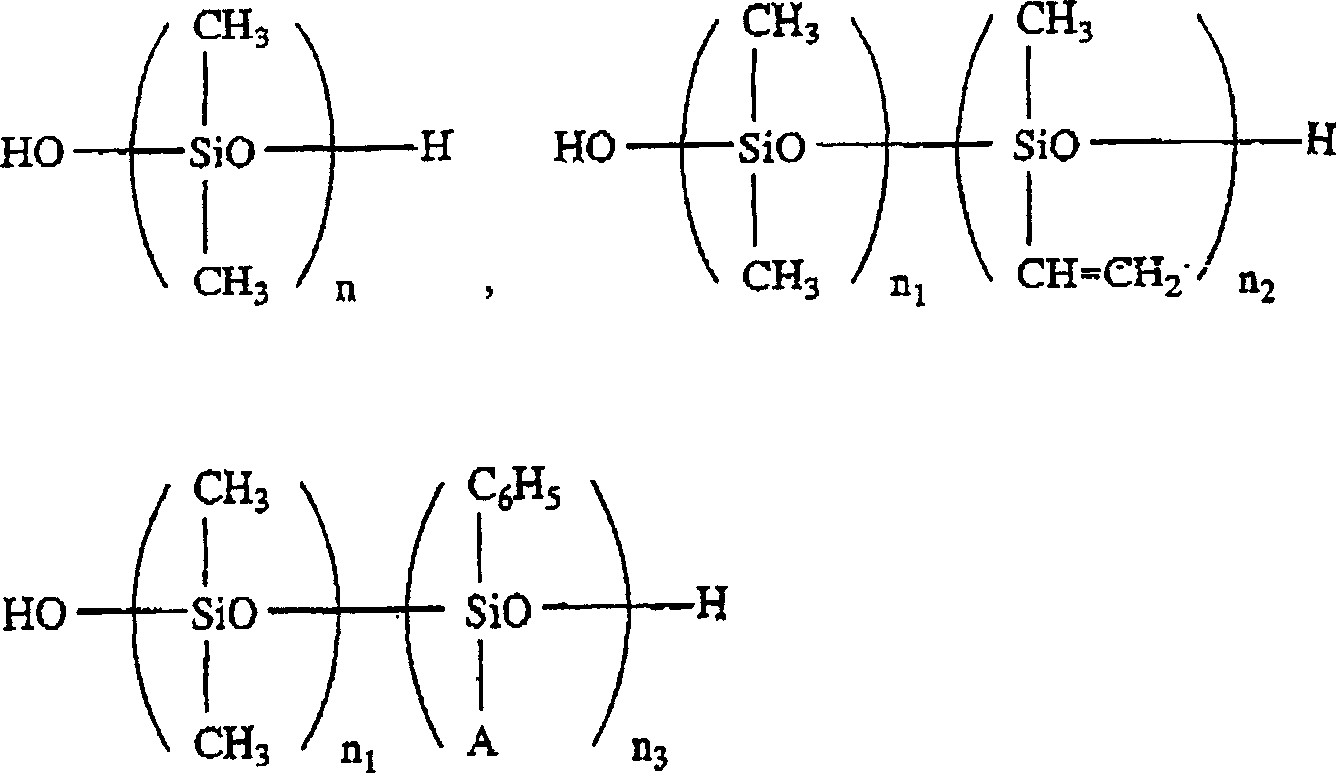

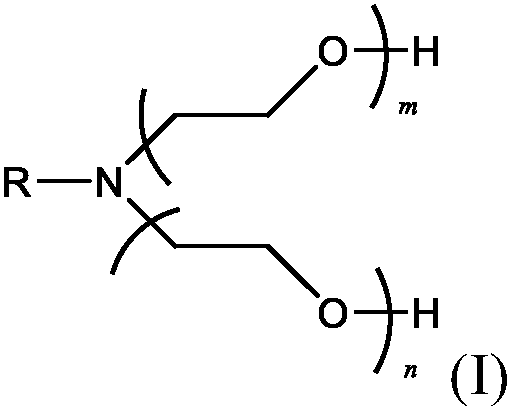

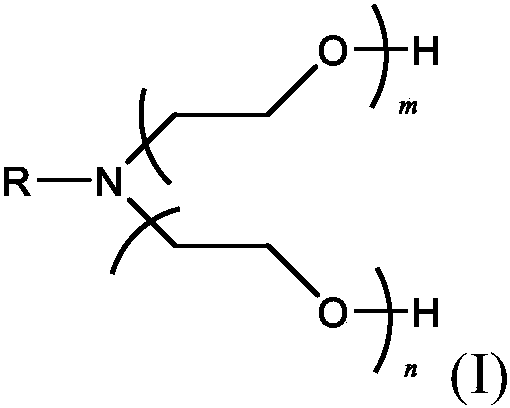

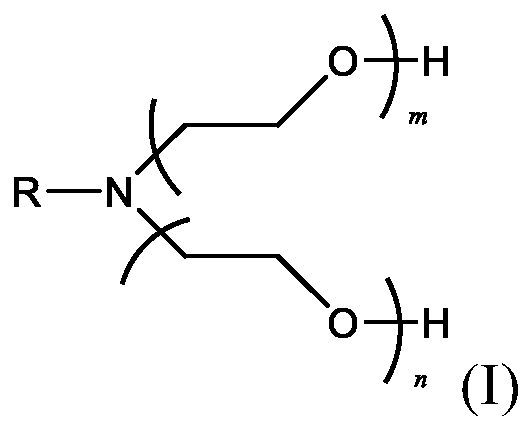

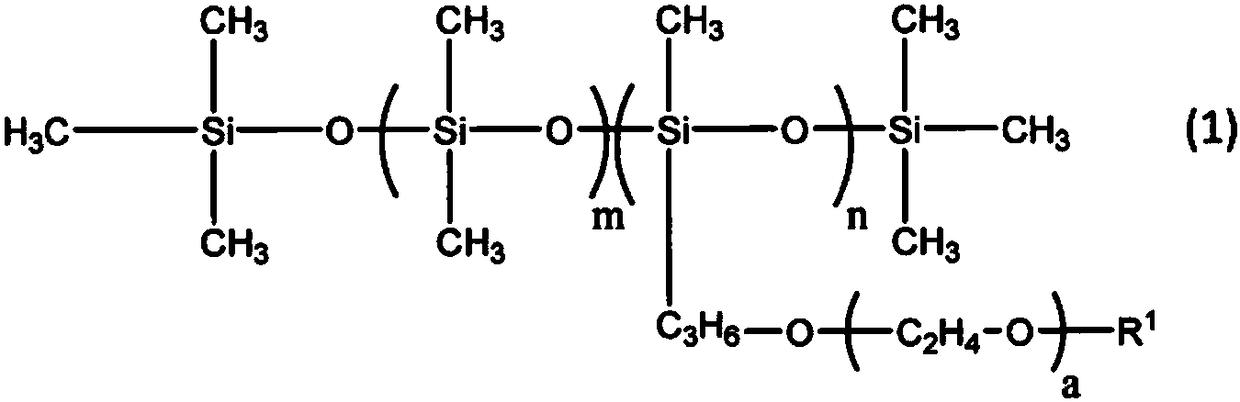

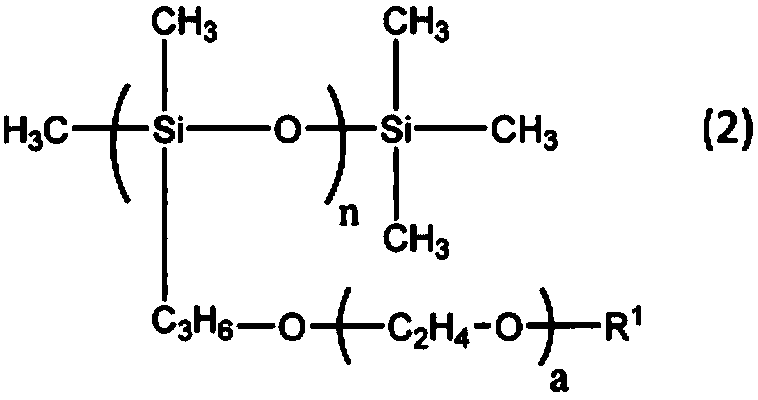

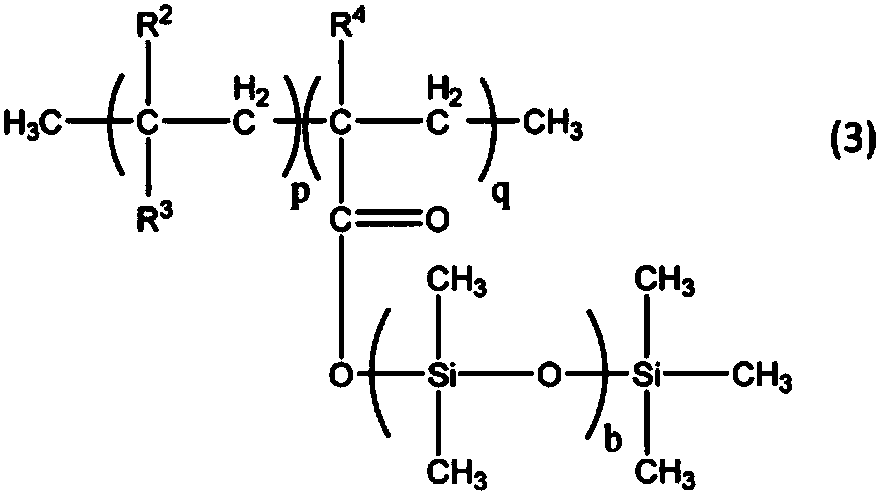

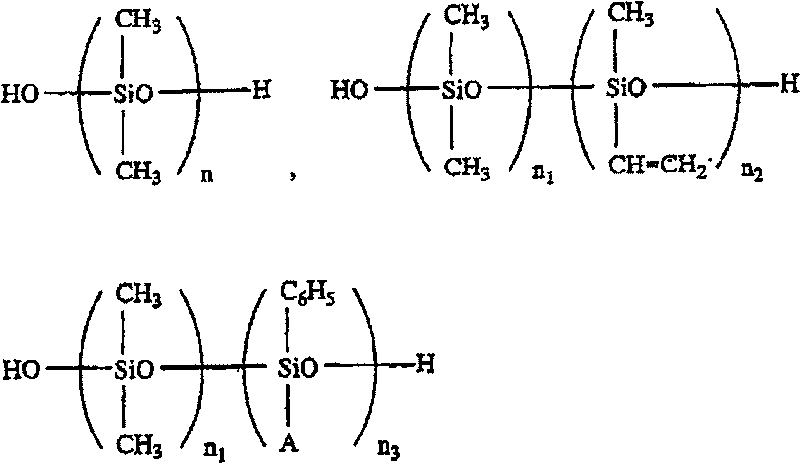

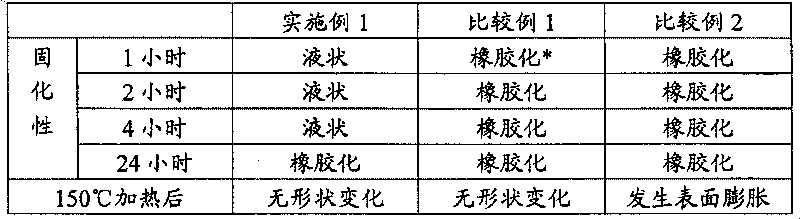

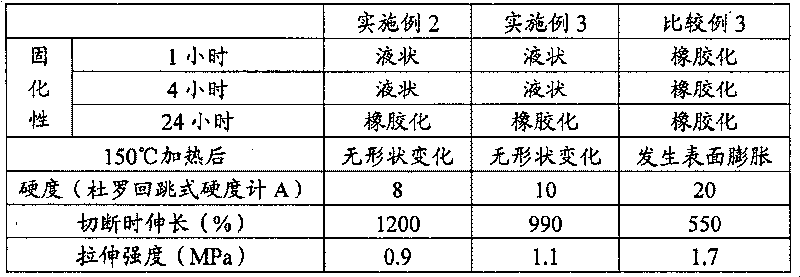

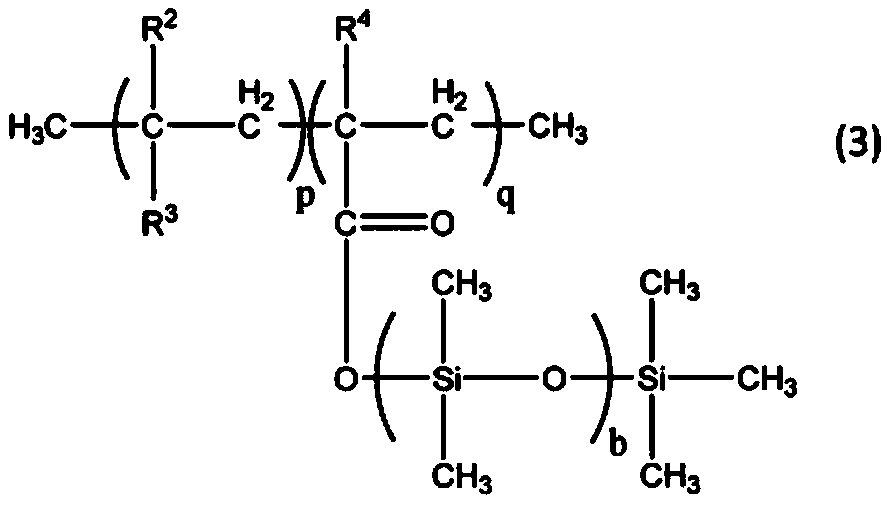

Normal temperature cured organic polysiloxane composition

The invention provides an organopolysiloxane compound used as sealing substance, bonding agent, coating agent and embedding agent and characterized by long operational time, no happen of unsuitable condition caused by volatile silane. The compound is characterized in that: it comprises (A) 100 units (by weight) of organopolysiloxane with hydroxyl group sealing the two ends; (B) organopolysiloxane 1-100 units by weight, R1 is alkyl with same or different carbon number of 1-6,or alkoxy with 2-10carbon number; R2 is same or different substituted or unsubstituted hydrocarbon radical; m is integral number between 1-3; k is integral number 10 or that larger than 10); (C) tin catalyst 0.01-10 units by weight.

Owner:SHIN ETSU CHEM IND CO LTD

Polishing method and grinding fluid

InactiveCN1533595AReduce grinding speedGet in-plane uniformityOther chemical processesSemiconductor/solid-state device manufacturingSurface-active agentsSliding contact

Owner:EBARA CORP +1

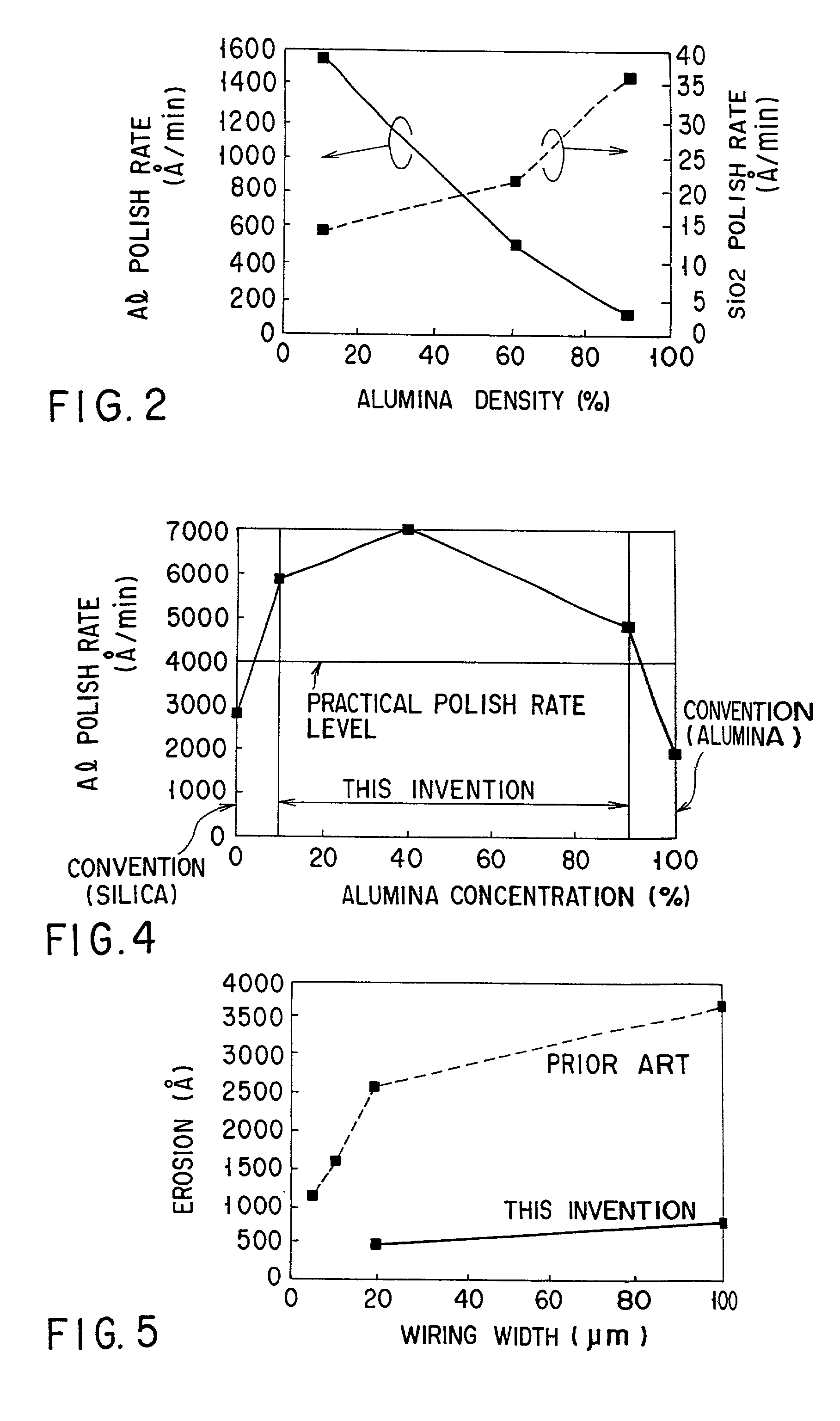

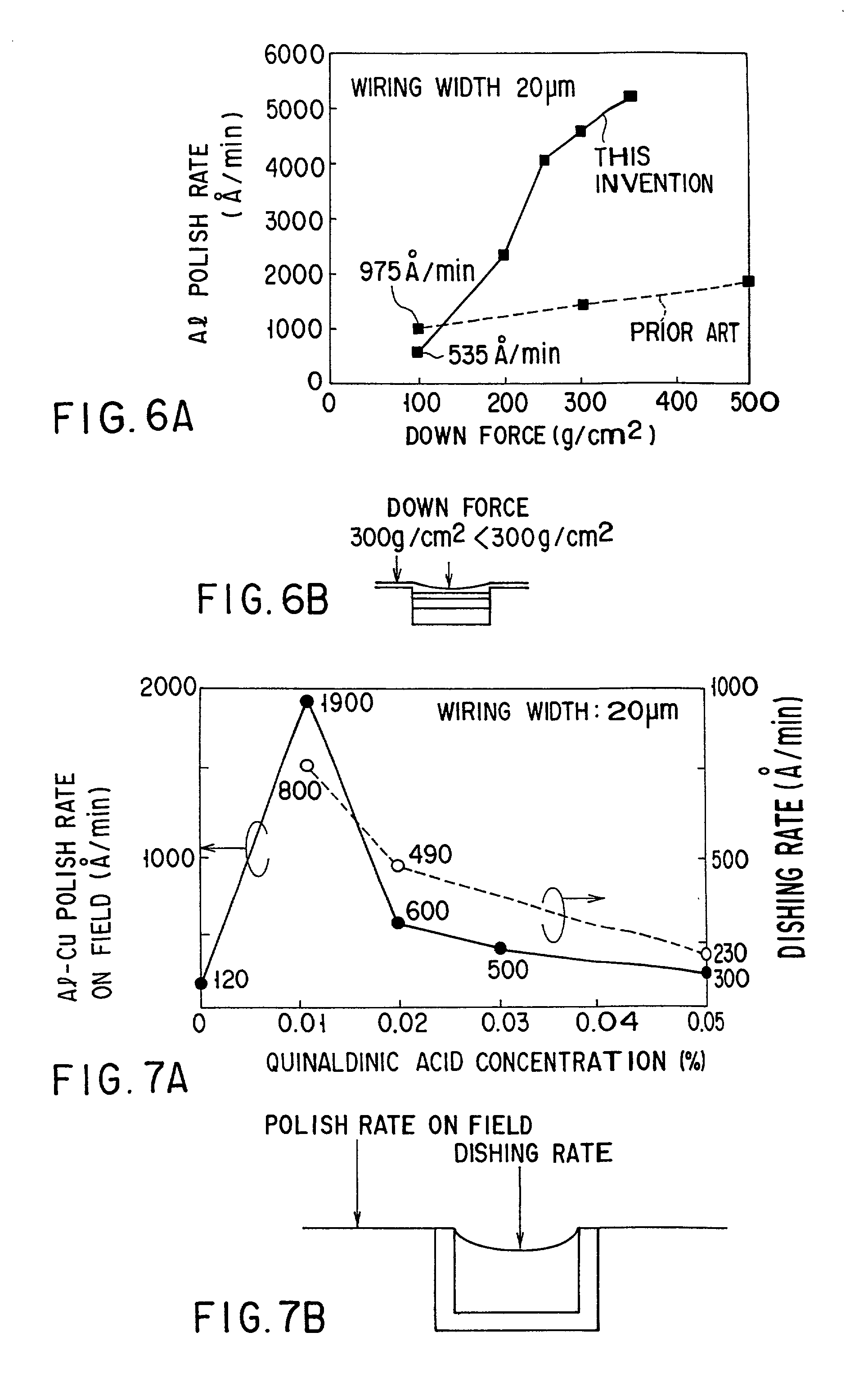

Slurry for CMP and CMP method

InactiveUS7364667B2Stable polishing characteristicHigh selectivityPigmenting treatmentOther chemical processesSlurrySilicon dioxide

A CMP slurry comprising polishing abrasives containing mixture abrasives of silica and alumina is used. In CMP using the slurry comprising mixture abrasives of silica and alumina as polishing abrasives, a down force-dependency of a polishing rate is high and an increase in dishing can be effectively suppressed.

Owner:KK TOSHIBA

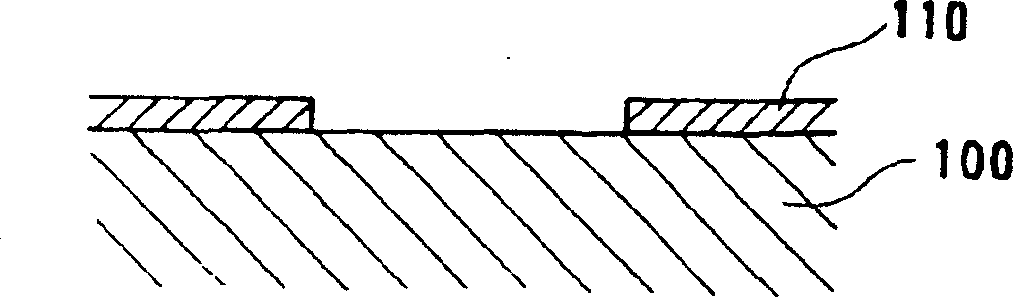

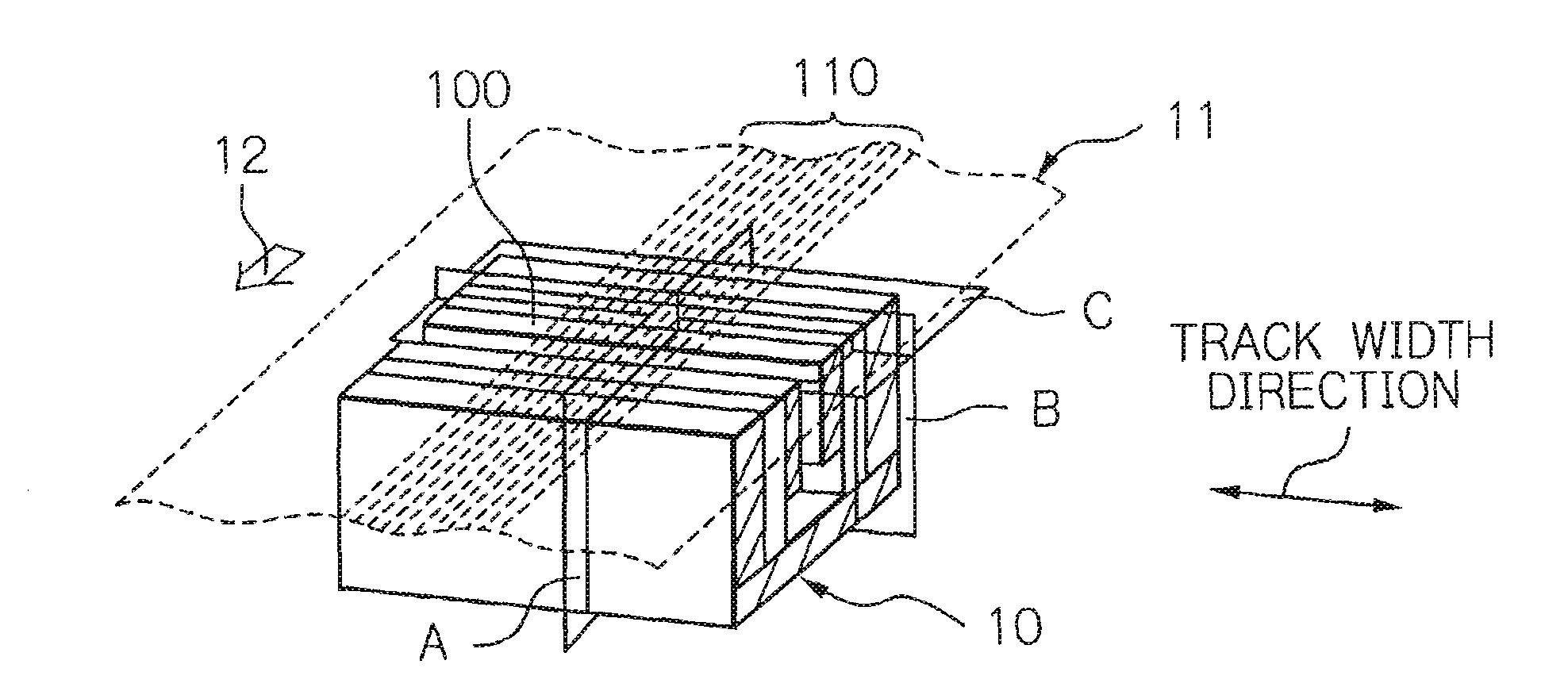

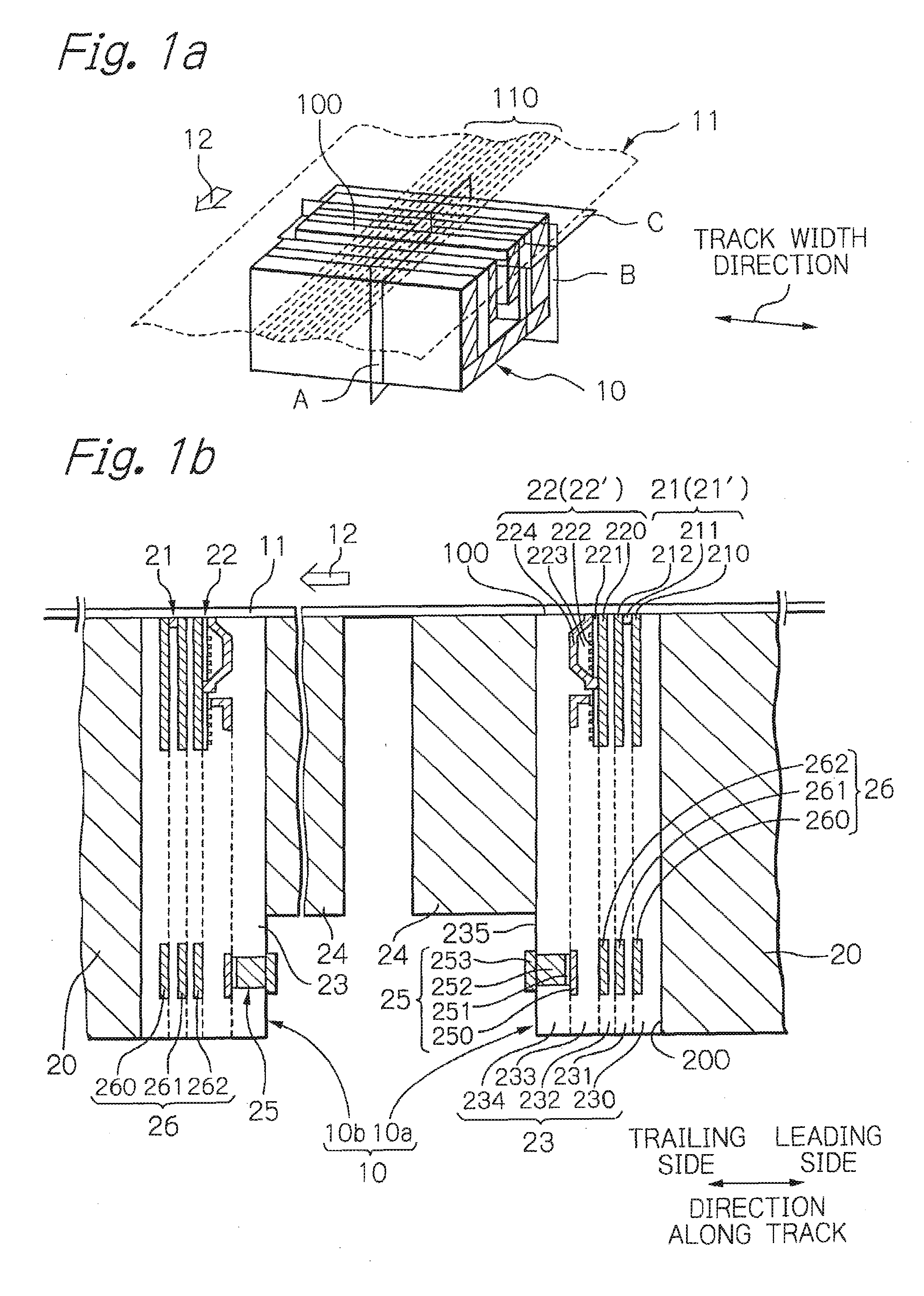

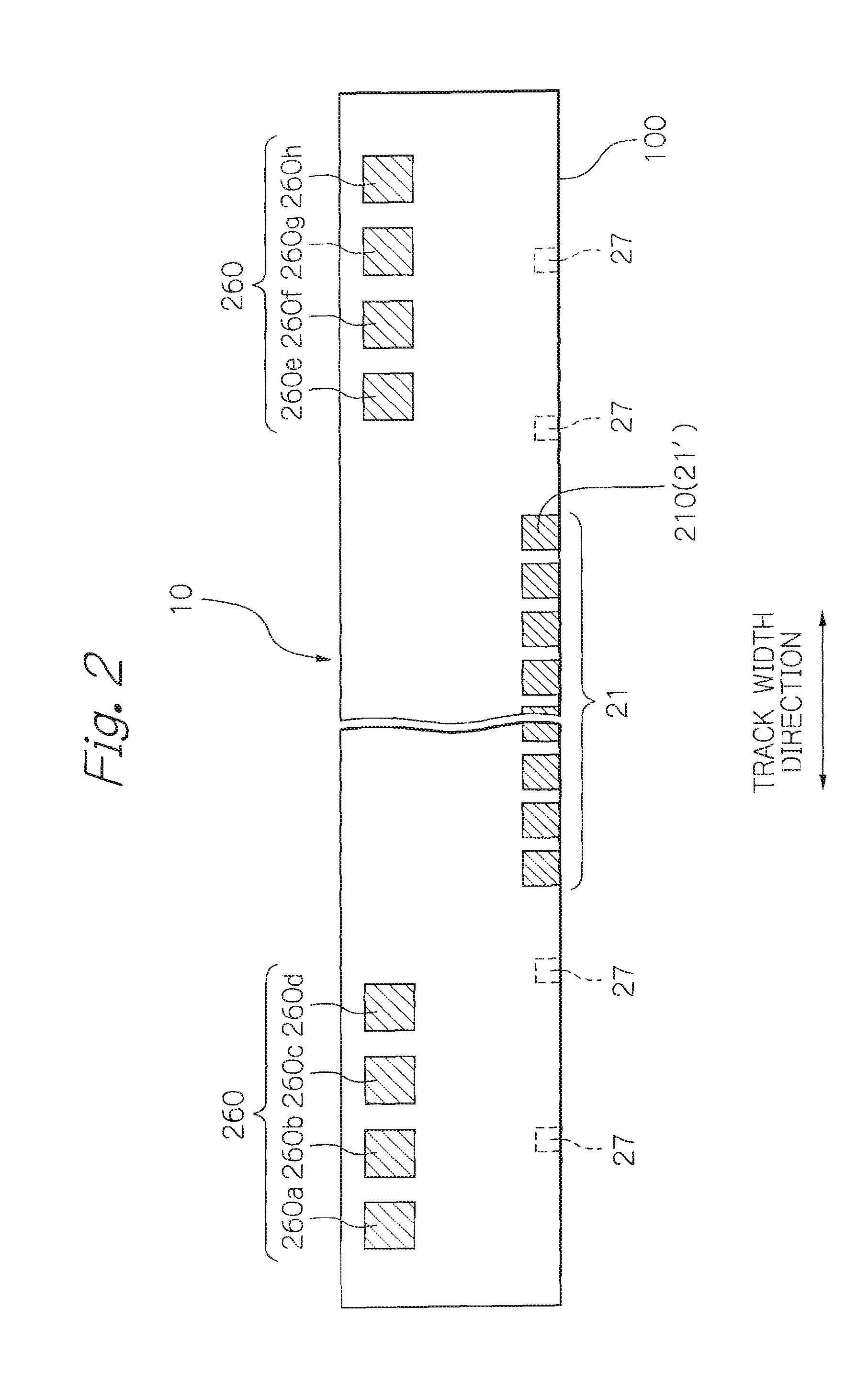

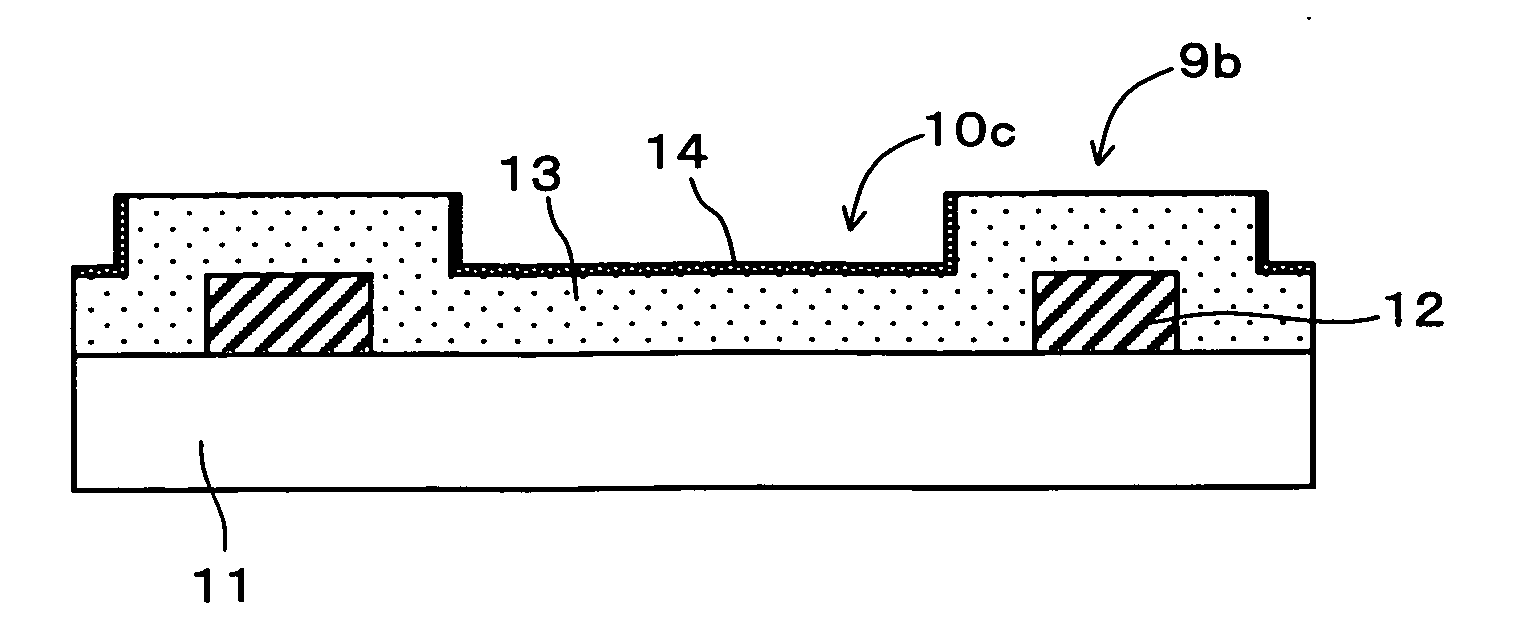

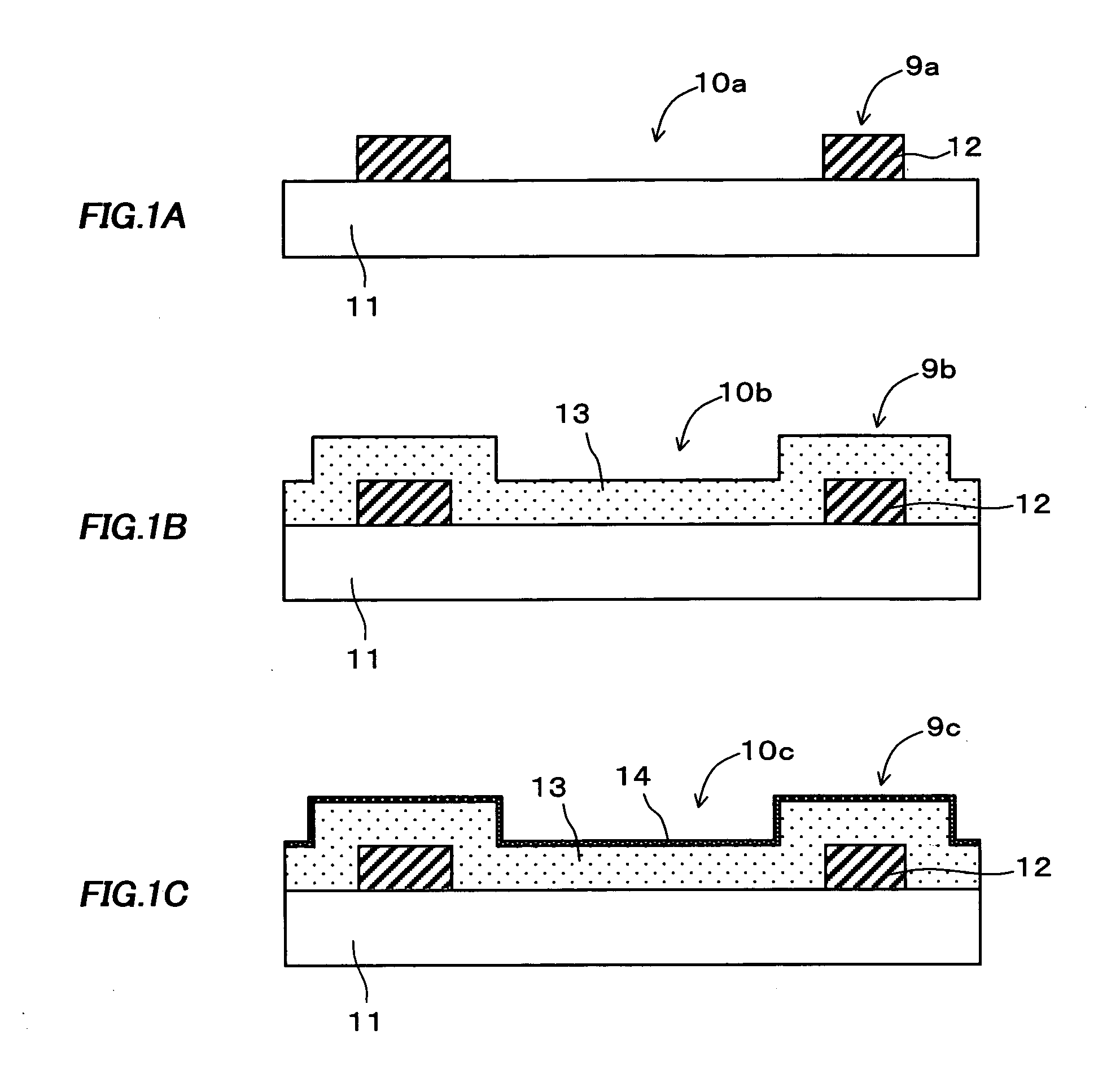

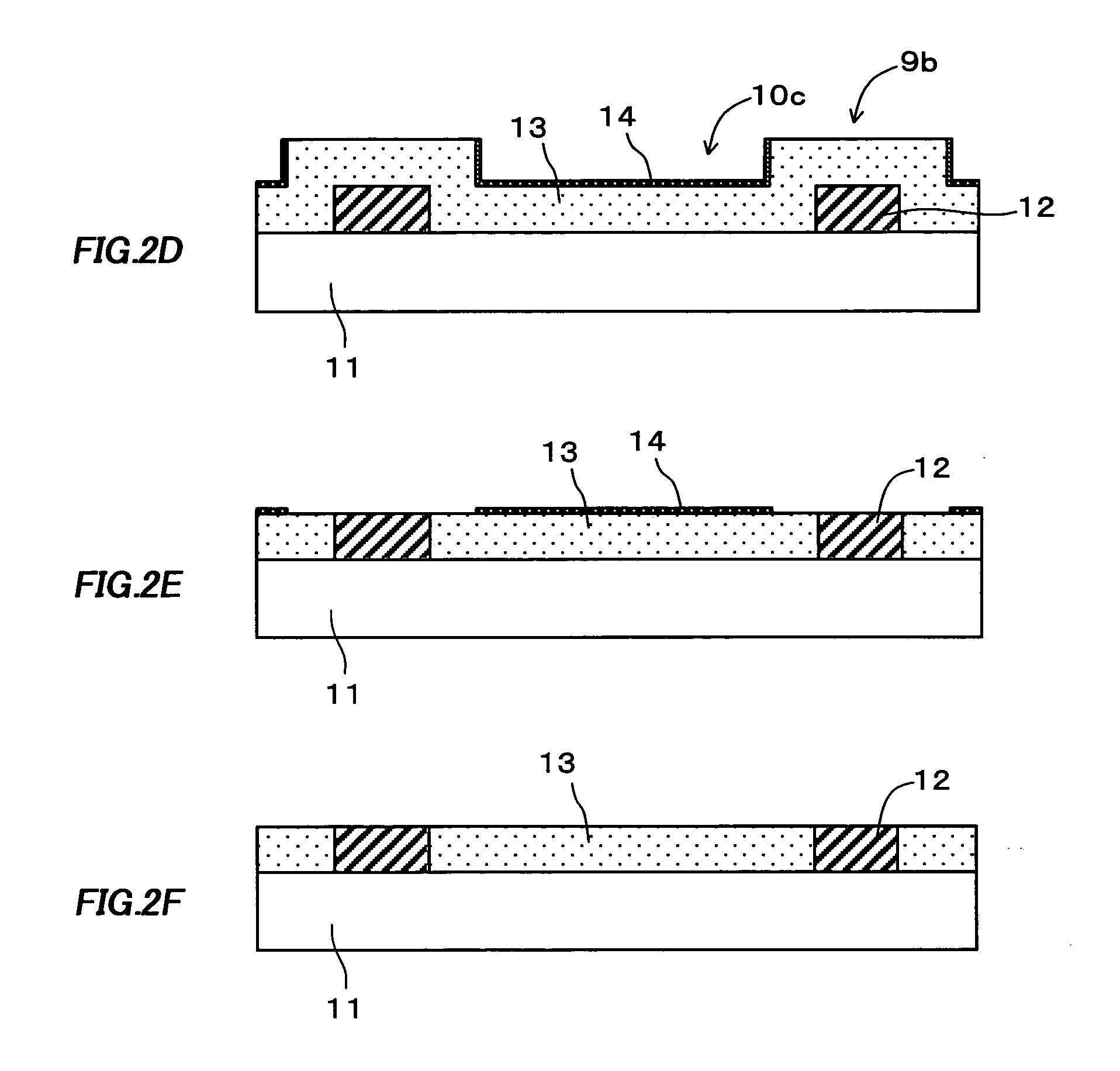

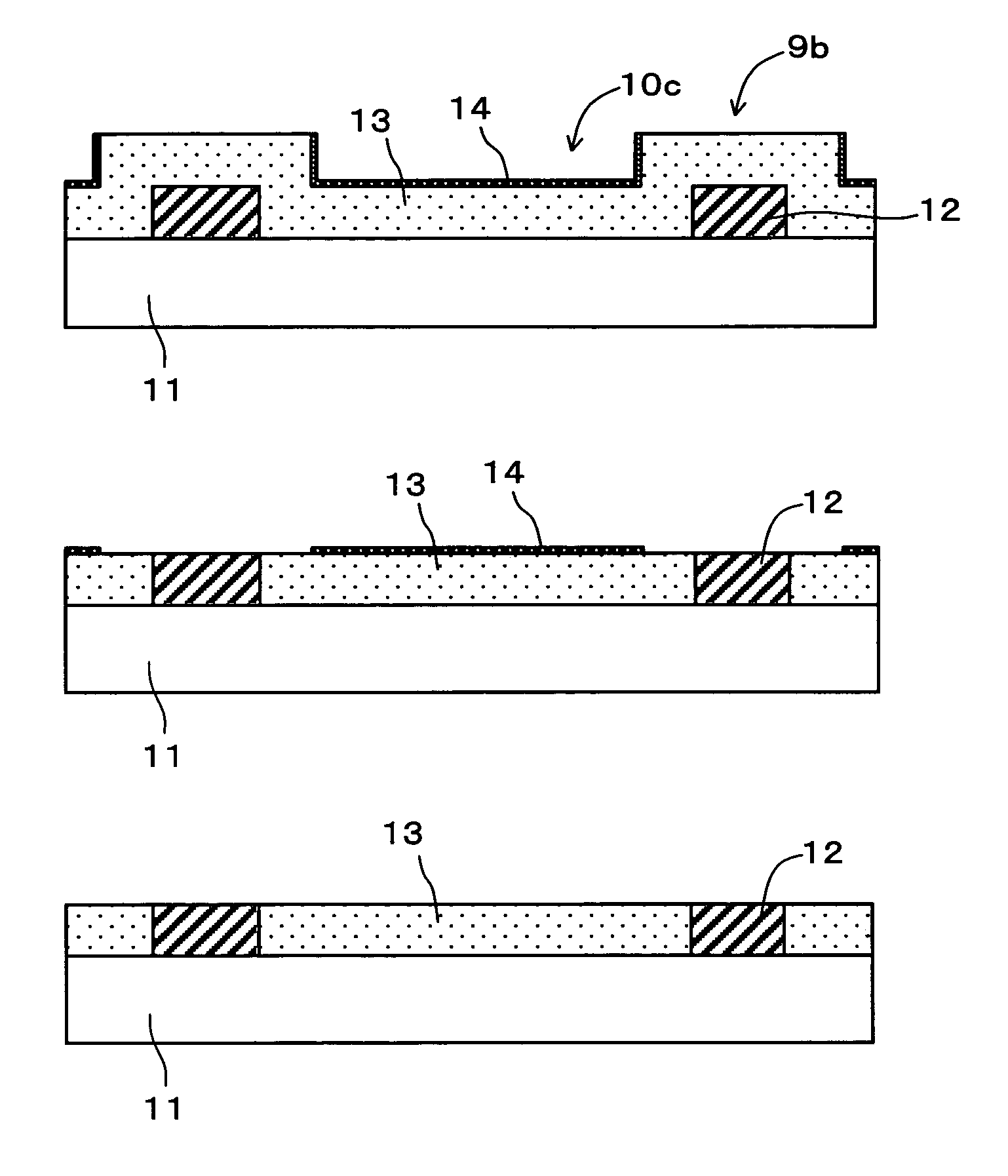

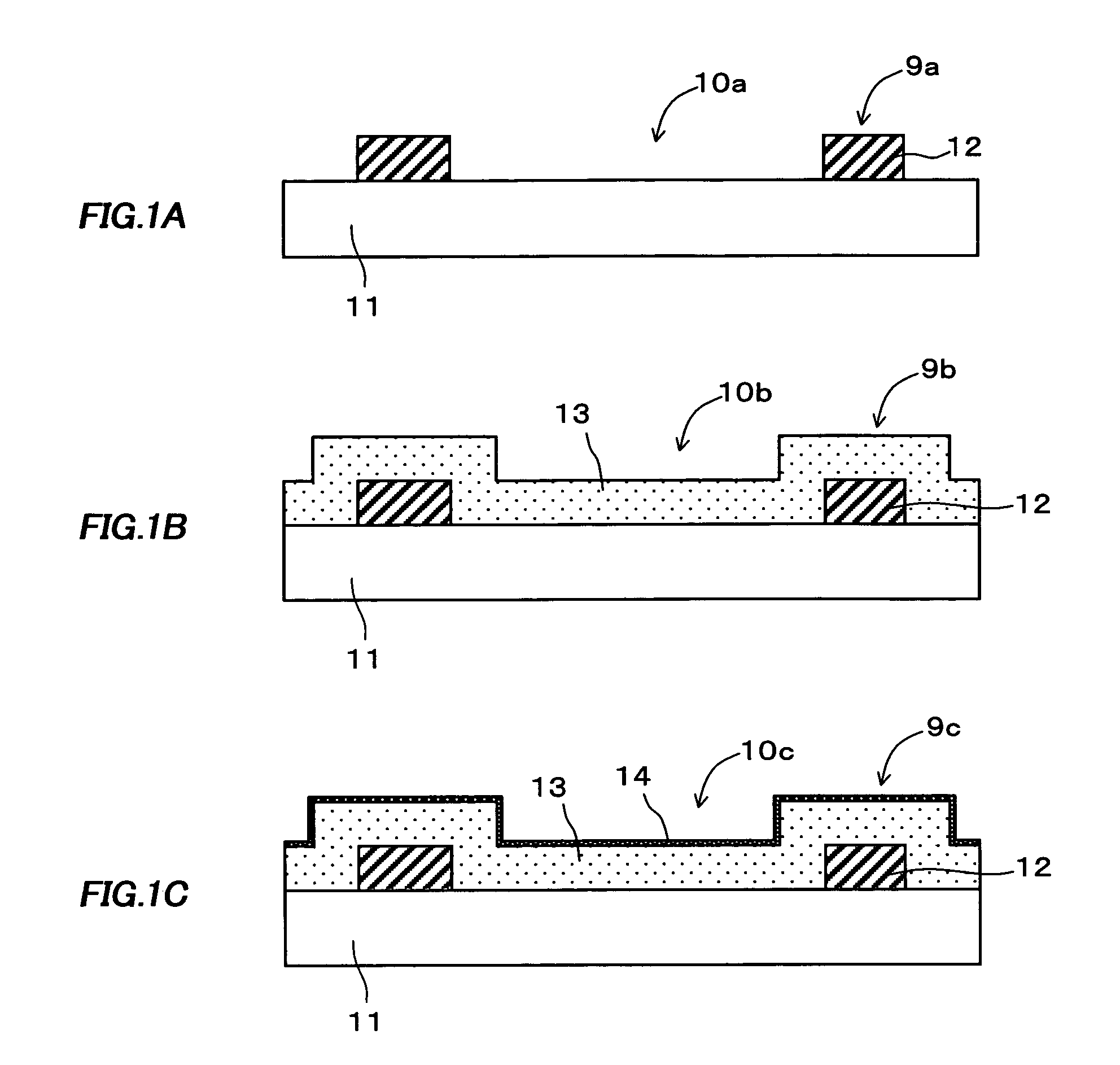

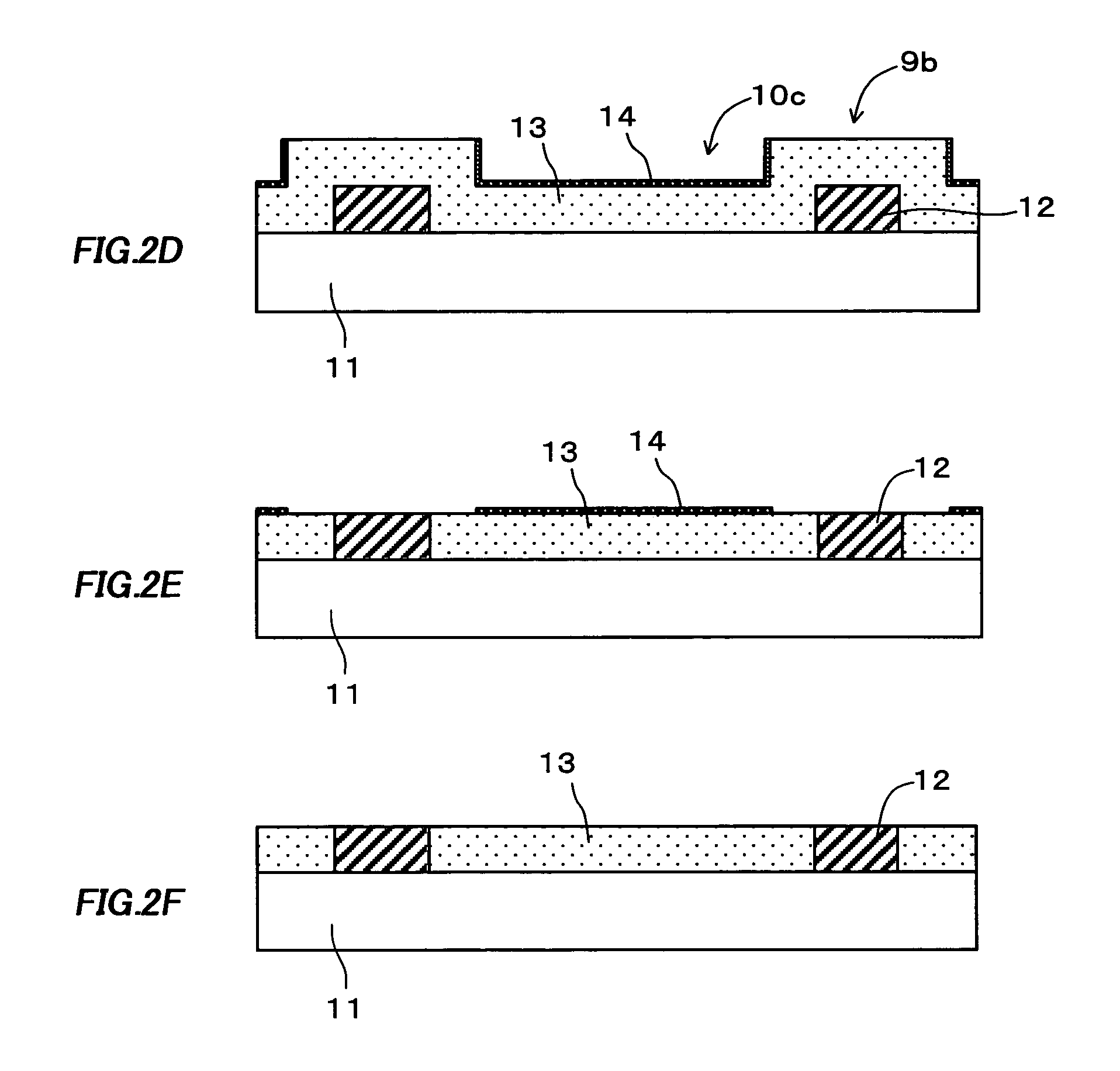

Manufacturing method of thin-film magnetic head with dishing suppressed during polishing

InactiveUS20090086381A1Smooth and reliable contactStable and reliableRecord information storageManufacture of flux-sensitive headsMagnetic polesEngineering

A manufacturing method of a thin-film magnetic head with a dishing suppressed in the case of planarizing a magnetic shield which a read head portion has or a magnetic pole which a write head portion has is provided. A manufacturing method of a thin-film magnetic head comprising a read head portion for data reading which has at least two magnetic layers functioning as a magnetic shield and a write head portion for data writing which has two magnetic layers functioning as a magnetic pole is provided, in a process forming at least the lowest magnetic layer in at least the two magnetic layers functioning as the magnetic shield and the two magnetic layers functioning as the magnetic pole in the case of forming a plurality of thin-film magnetic head patterns on an element formation surface of the wafer substrate, which comprises steps of: forming this magnetic layer so as to reach a position which becomes a medium opposed surface at a middle portion to a trick width direction in each thin-film magnetic head pattern, and forming a dishing prevention portion at a position farther than this magnetic layer from the position which becomes the medium opposed surface in both sides or either side along the track width direction of this magnetic layer; forming a nonmagnetic insulating layer so as to cover the magnetic layer and the dishing prevention portion; and planarizing and polishing the magnetic layer, the dishing prevention portion, and the nonmagnetic insulating layer thereafter.

Owner:TDK CORPARATION

Power applicator system for conveyor belt fasteners

A system for applying belt fasteners to belt ends is disclosed. The system includes a power tool apparatus and a guiding apparatus. The guide apparatus includes a guide block having guide bores in which attachment members, e.g., rivets, are held in position relative to the belt fasteners so that a drive rod of the power tool impacts the rivets in the guide block bores. The guide block preferably is of a hard material, e.g. a machined steel or powder steel, for proper guiding of the drive rod and rivet during riveting operations.

Owner:FLEXIBLE STEEL LACING

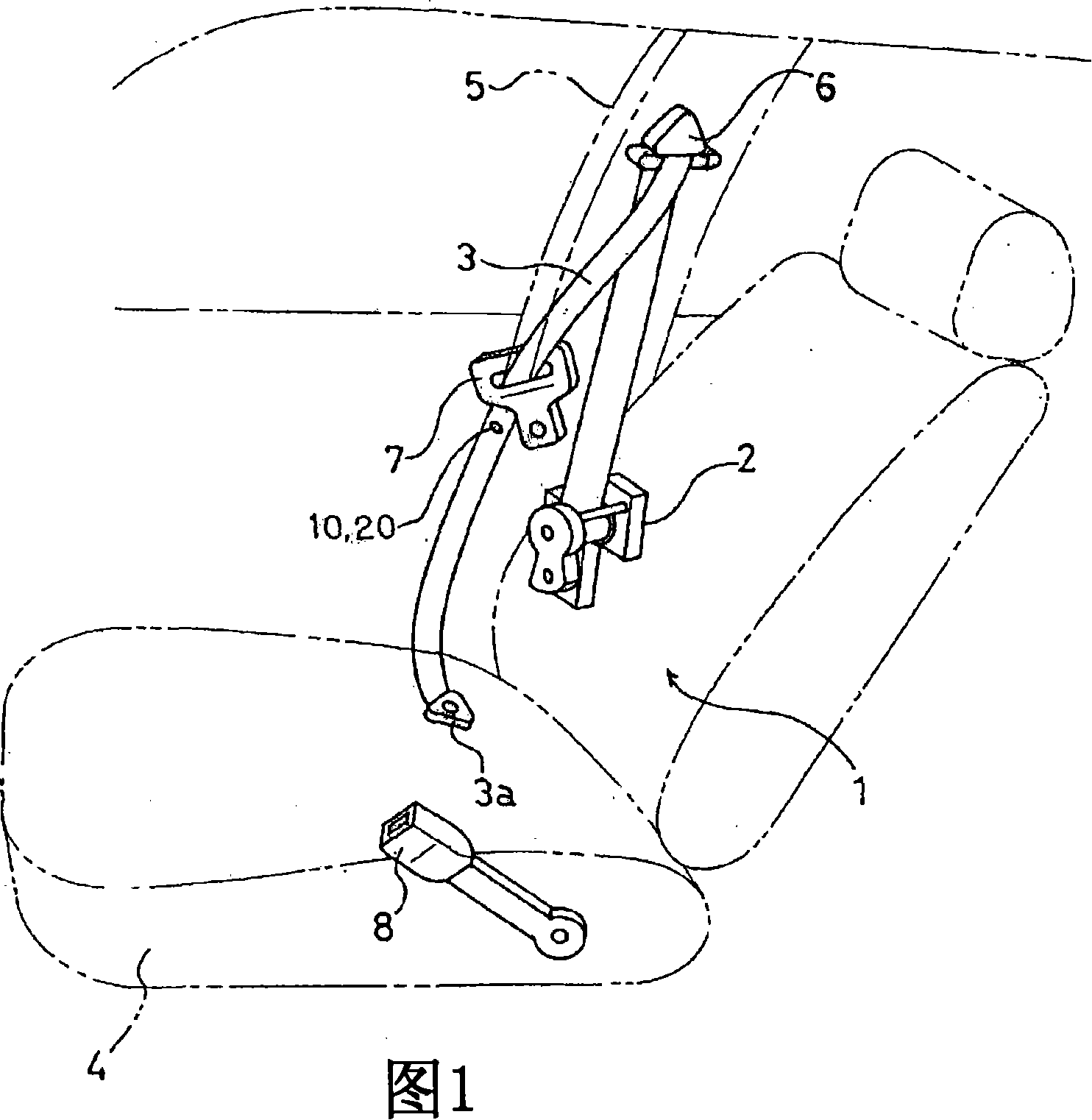

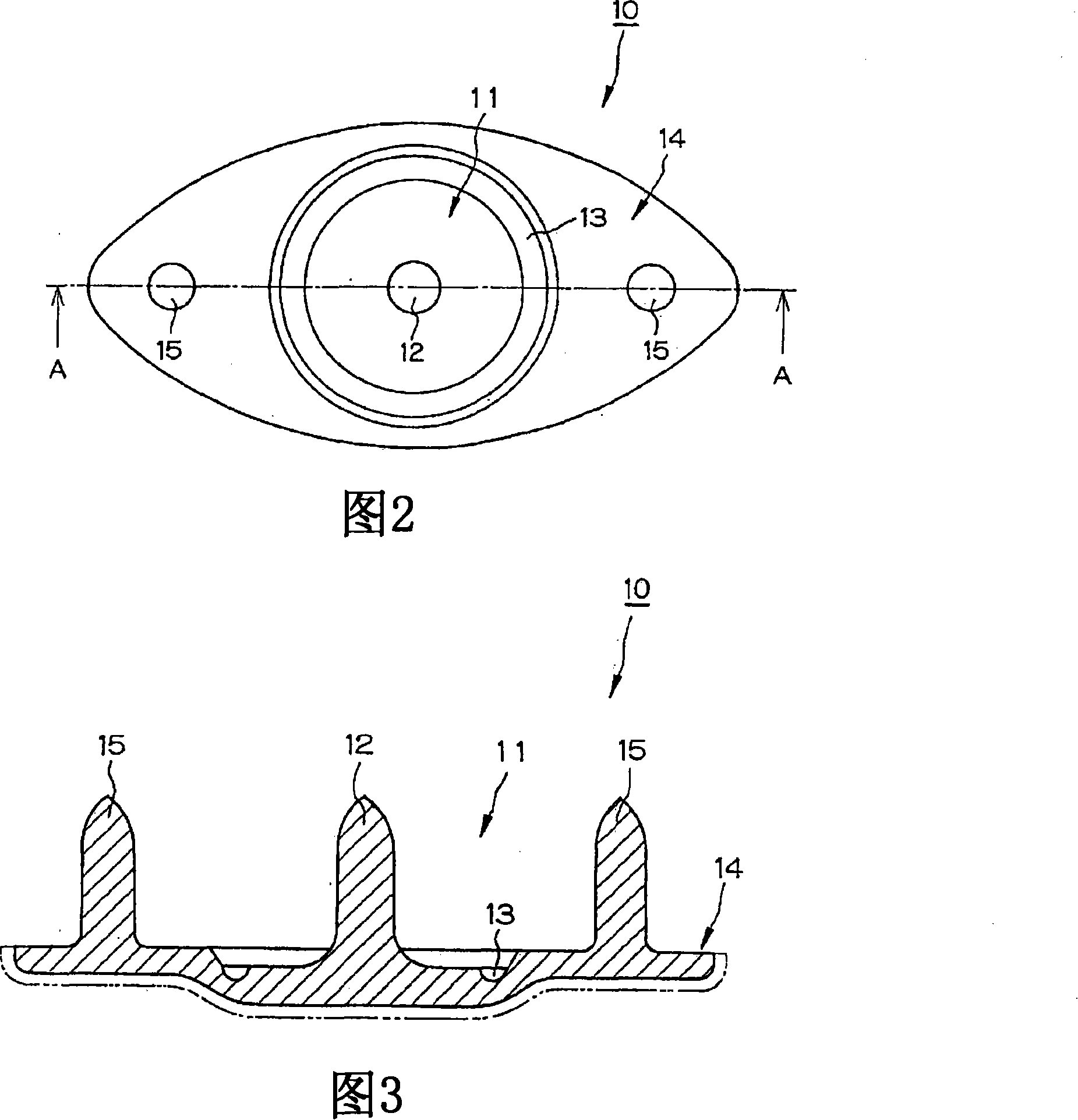

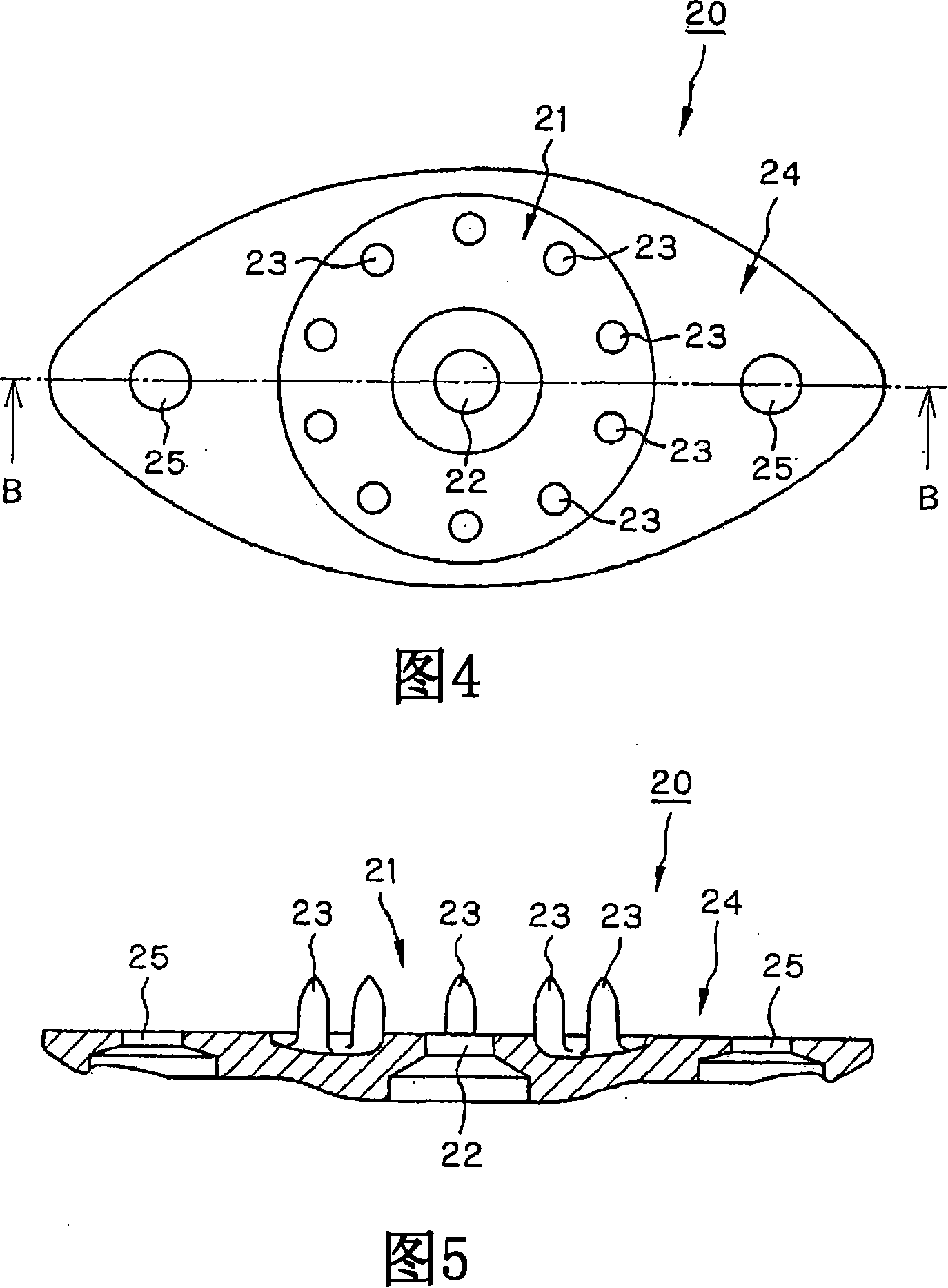

Tongue plate stopper and safety belt device using the same

InactiveCN101213119AReduce distortionFine-tune the quantityHaberdasheryBelt/harness contructionBelt safetyBiomedical engineering

A tongue plate stopper having a first member (10) with pins (12, 15) that penetrate a seatbelt webbing (30) and also having a second member (20) with holes (22, 25) through which the pins (12, 15) that penetrated the seatbelt webbing (30) penetrate. The pins (12, 15) penetrate through the respective corresponding holes (22, 25), and the seatbelt webbing (30) is held from both sides by the first member (10) and the second member (20).

Owner:TAKATA CORPORATION

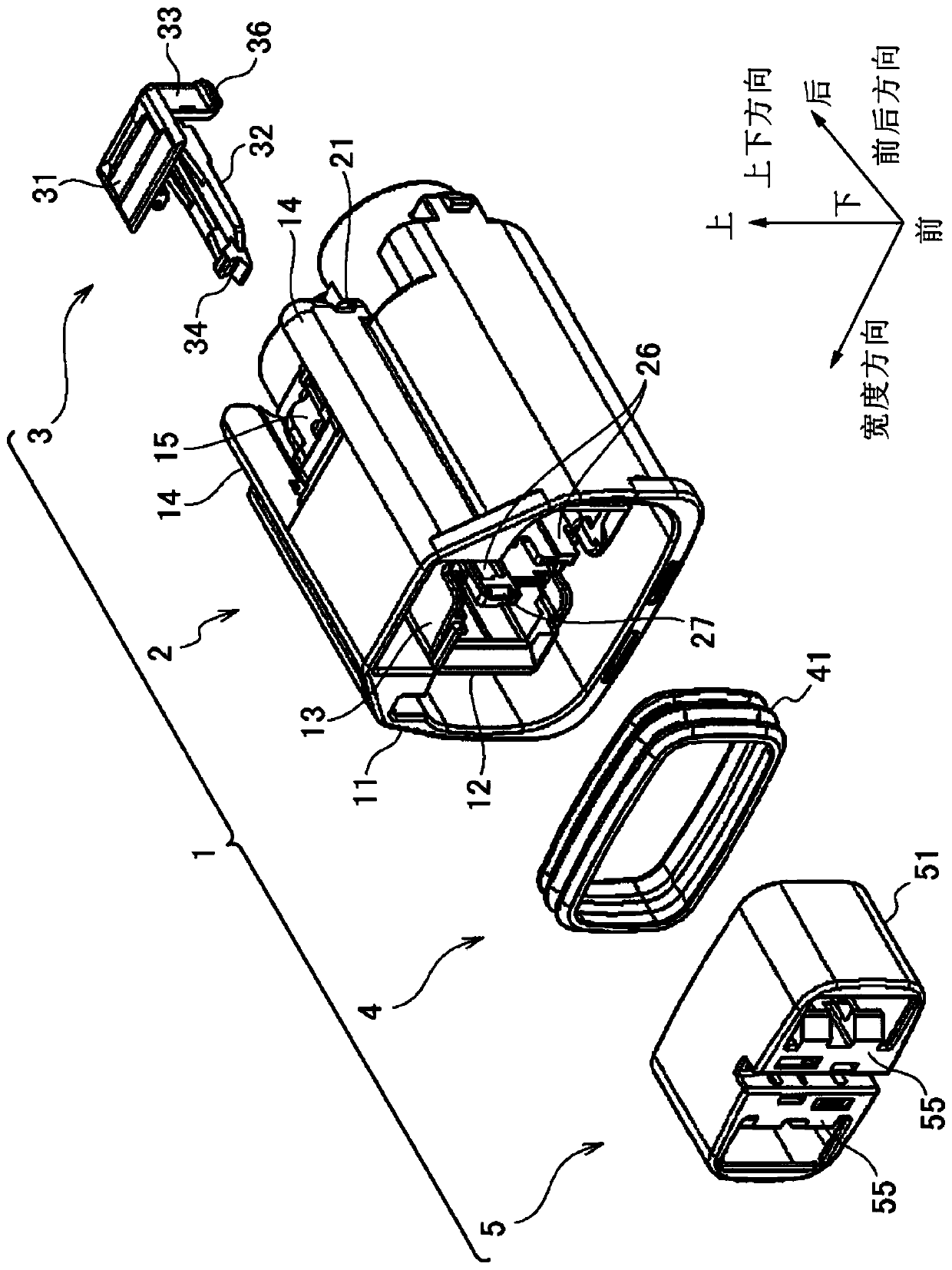

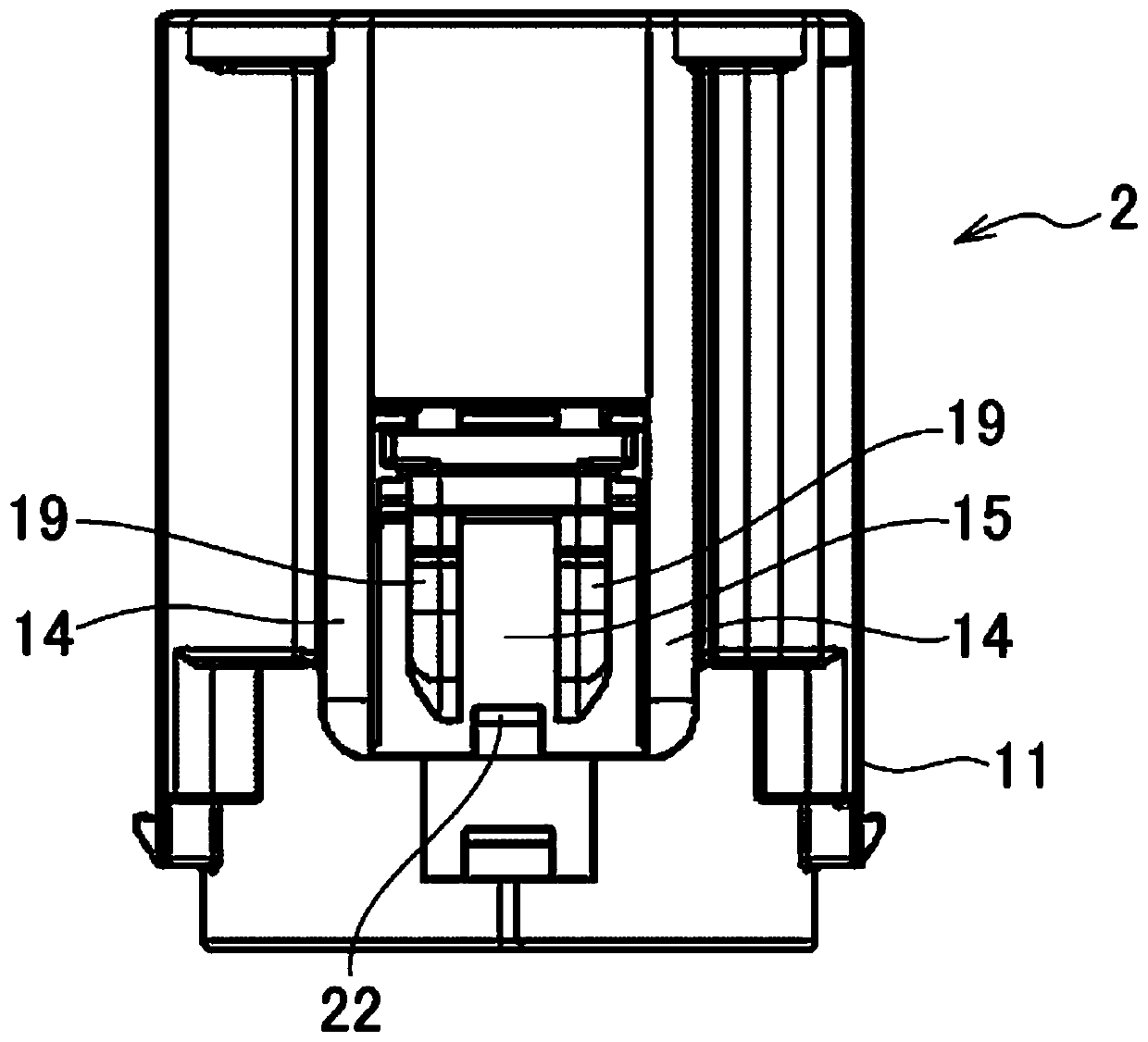

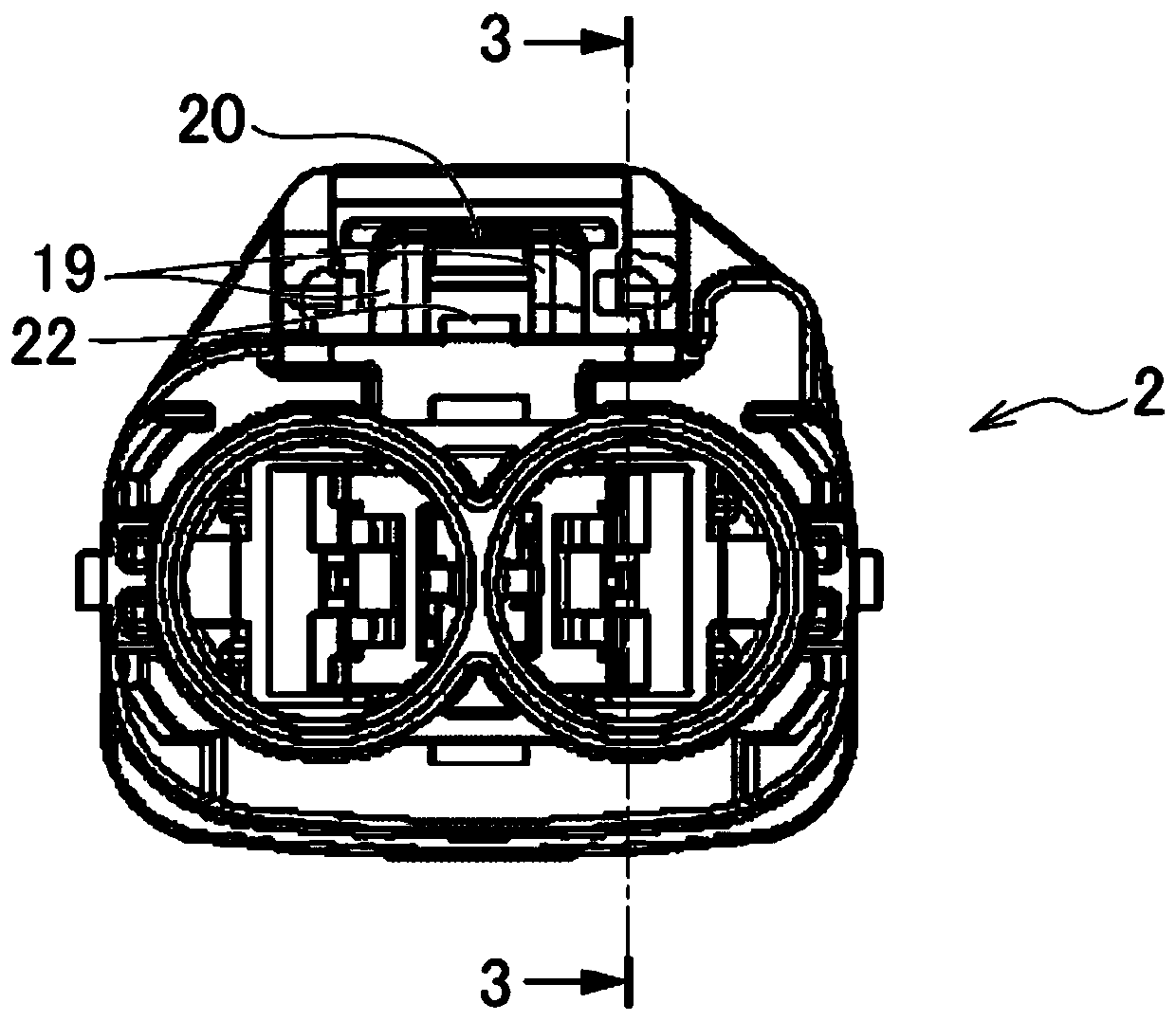

Connector

ActiveCN110875539ASuppression squeezeImprove rigidityCoupling device detailsStructural engineeringHOLDING CHAMBER

A connector includes a housing and a holder. The housing includes a terminal housing chamber housing terminals and a support portion in which a first locking portion for locking the holder in the temporary locking position is formed. The holder is mounted on the housing so as to be movable in a fitting direction of the housing and a mating housing between a temporary locking position and a main locking position. The holder is configured to be immovable from the temporary locking position to the main locking position when the terminal inserted into the terminal housing chamber is in a halfway insertion position and is configured to be movable from the temporary locking position to the main locking position when the terminal is in a normal insertion position.

Owner:YAZAKI CORP

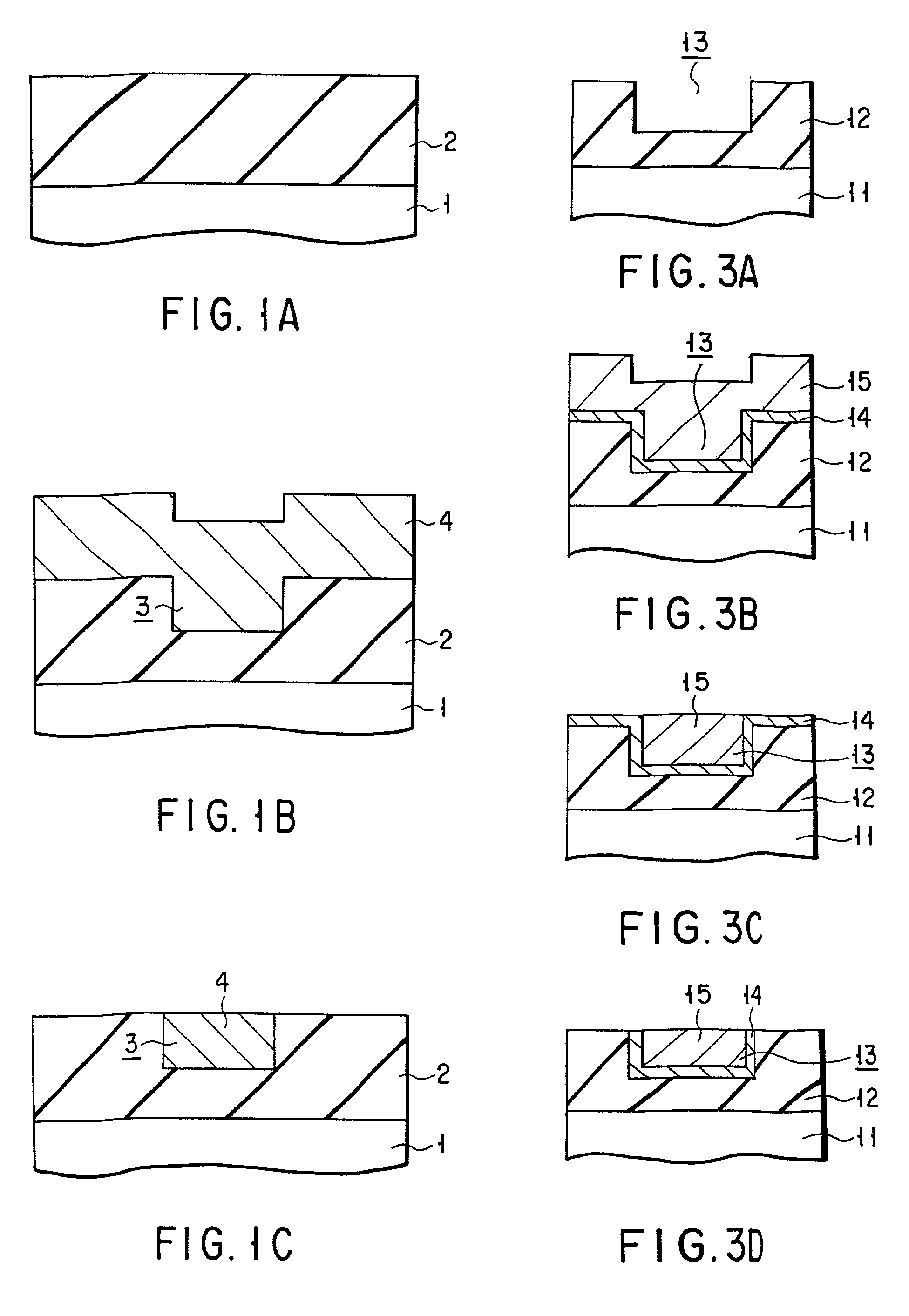

Semiconductor device fabrication method

ActiveUS20050282389A1Avoid it happening againAvoid dentsSemiconductor/solid-state device manufacturingSlurrySilicon

A semiconductor device fabrication method according to the invention comprises the steps of: (1) exposing a silicon layer by removing a portion of an insulating layer above a projected part of the silicon layer, the insulating layer covering the silicon layer; and (2) chemically and mechanically polishing the exposed silicon layer with a polishing slurry for the silicon layer while protecting the silicon layer with the remaining of the insulating layer.

Owner:SHARP KK

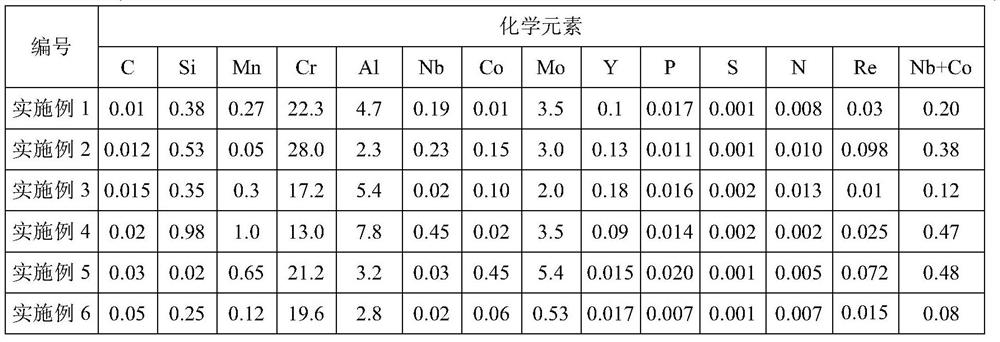

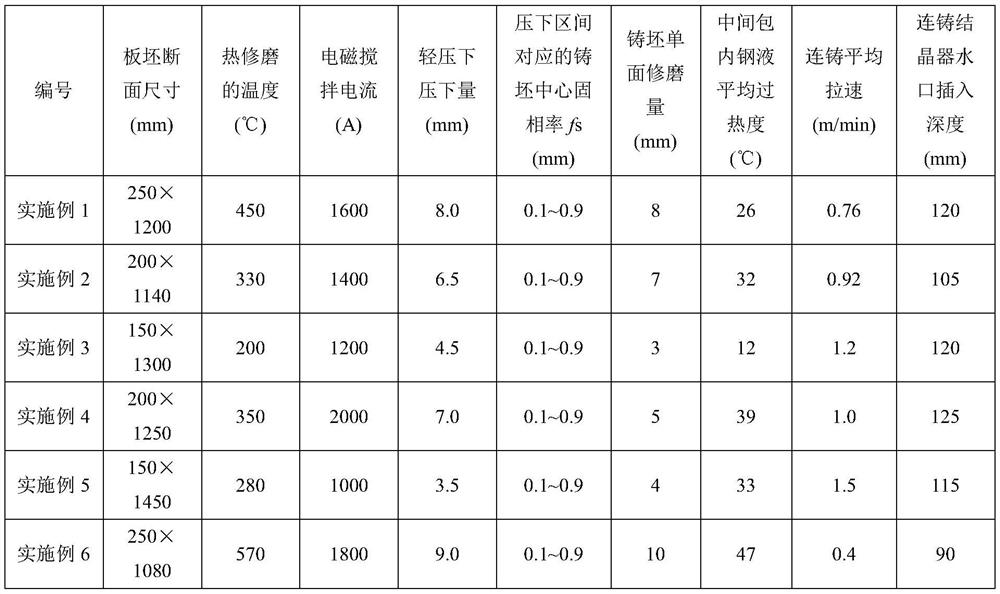

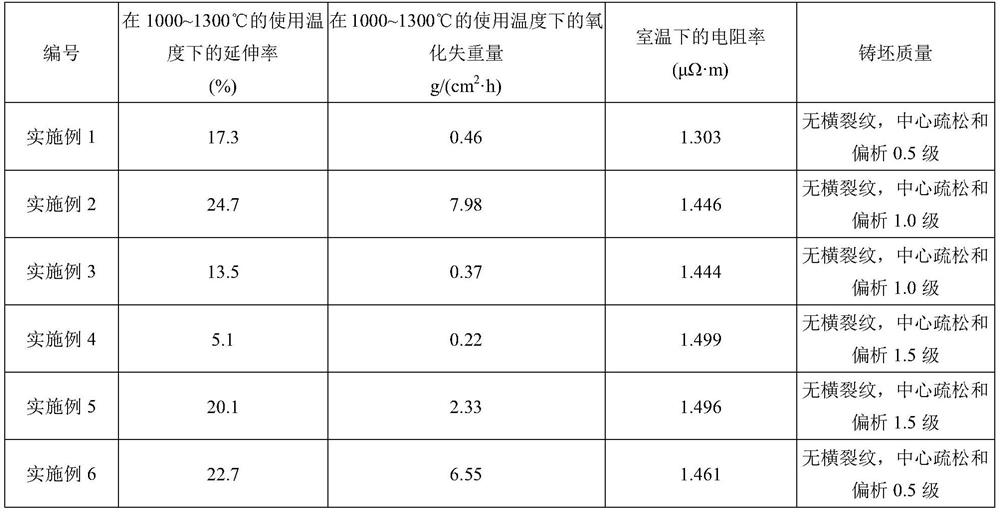

Rare earth-containing heat-resistant alloy steel and slab continuous casting process thereof

The invention discloses rare earth-containing heat-resistant alloy steel. The rare earth-containing heat-resistant alloy steel comprises the following chemical elements in percentage by mass: larger than 0 and smaller than or equal to 0.05% of C, larger than 0 and smaller than or equal to 1.0% of Si, larger than 0 and smaller than or equal to 1.0% of Mn, 13%-28% of Cr, 2%-8% of Al, larger than 0 and smaller than or equal to 0.50% of Nb, larger than 0 and smaller than or equal to 0.50% of Co, 0.5%-6% of Mo, 0.01%-0.2% of Y and 0.01%-0.1% of at least one of 57-71 rare earth elements in the periodic table of chemical elements. In addition, the invention further discloses a slab continuous casting production process of the rare earth-containing heat-resistant alloy steel, and in the continuous casting process, the specific water flow of secondary cooling water is controlled to be 1.02 + / -0.10 L / kg. The rare earth-containing heat-resistant alloy steel adopts reasonable chemical components and process design, has excellent quality and performance, can tolerate the use temperature of 1,000-1,300 DEG C, has the elongation of 5%-25% at the use temperature of 1,000-1,300 DEG C, has the oxidation weight loss of 0.2-8.0 g / (cm<2>.h) at the use temperature of 1,000-1,300 DEG C, and has the resistivity of 1.3-1.5 mu omega.m at room temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

Semiconductor device fabrication method

ActiveUS7030019B2Depression depressionStable flatnessSemiconductor/solid-state device manufacturingSlurrySilicon

A semiconductor device fabrication method according to the invention comprises the steps of: (1) exposing a silicon layer by removing a portion of an insulating layer above a projected part of the silicon layer, the insulating layer covering the silicon layer; and (2) chemically and mechanically polishing the exposed silicon layer with a polishing slurry for the silicon layer while protecting the silicon layer with the remaining of the insulating layer.

Owner:SHARP KK

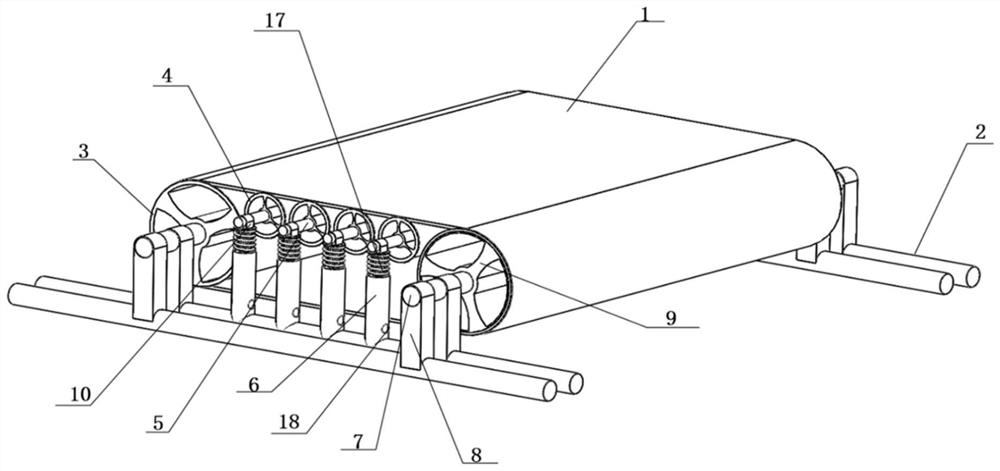

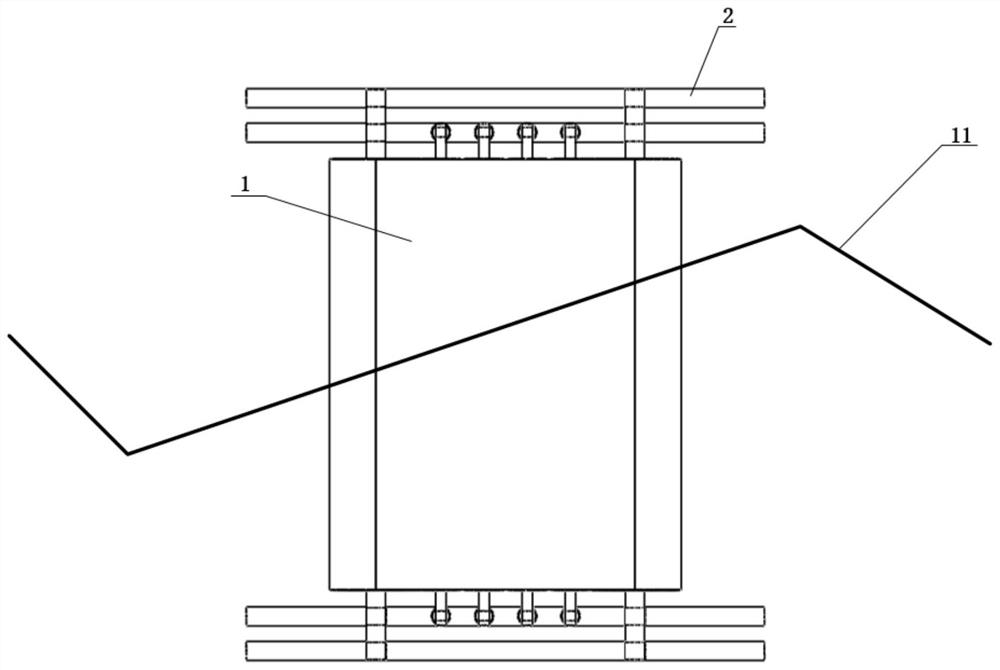

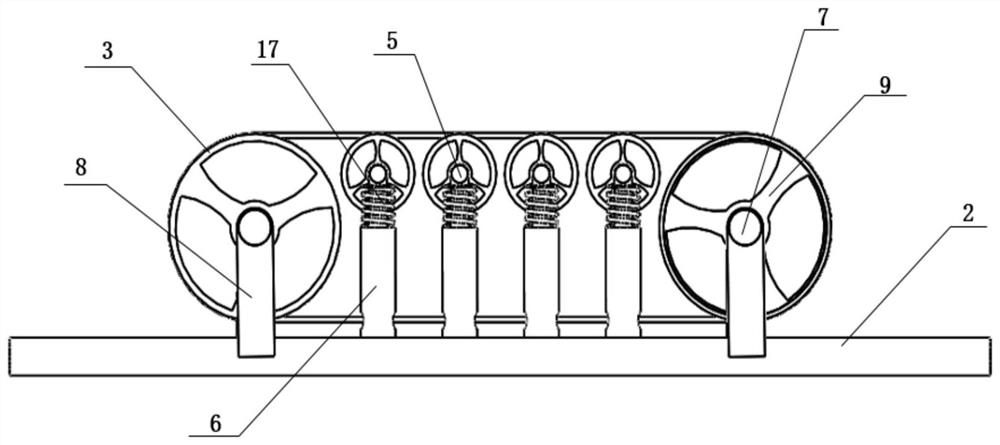

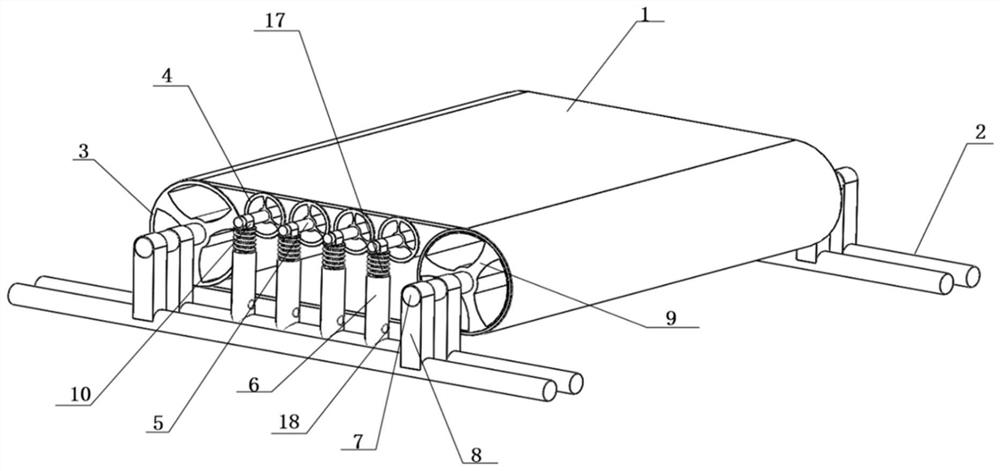

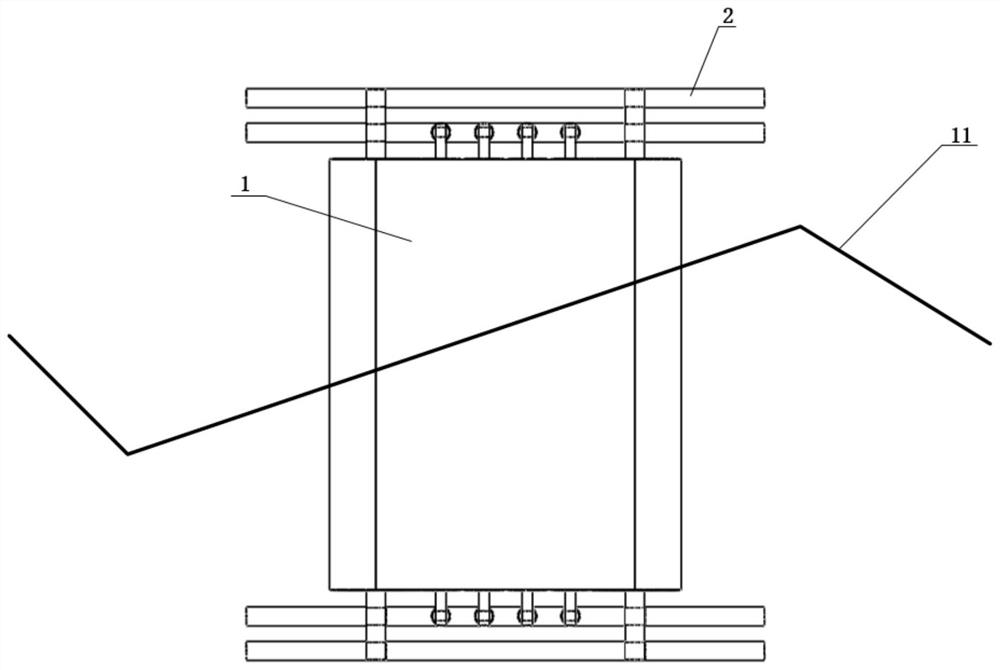

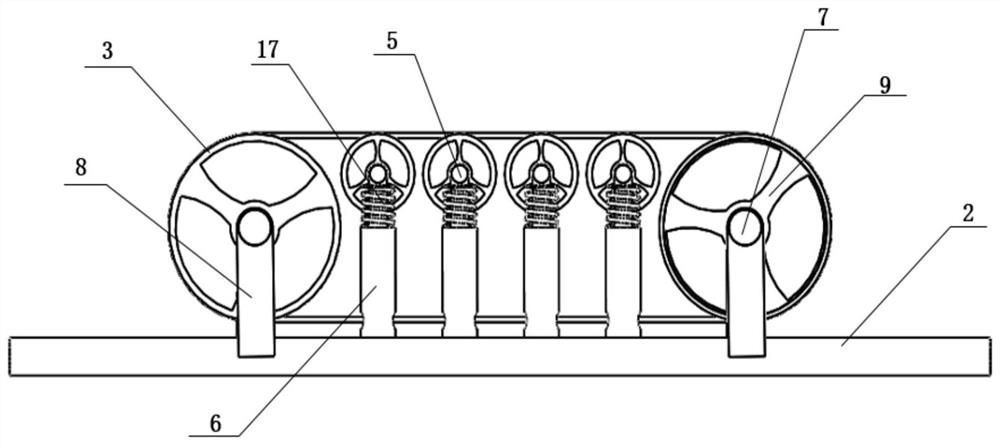

Flexible crawler-type pantograph head suitable for electric traction locomotive

ActiveCN112498113AImprove impact resistanceImprove impact performancePower current collectorsSlide plateBrush

The invention discloses a flexible crawler-type pantograph head suitable for an electric traction locomotive. The flexible crawler-type pantograph head is characterized in that two metal rollers are arranged on a pantograph support, an insulating roller shaft is fixed on two roller supports, the two roller supports are fixed on the pantograph support, and the metal rollers are mounted on a rollershaft through two insulating bearings; a metal spring is arranged in at least one through hole in the roller shaft; a current collection carbon brush is fixed at each of the two ends, extending out ofthe through hole, of the metal spring; a flexible crawler belt is sleeved on the two metal rollers, more than one insulating supporting cylinder is arranged below the crawler belt, and the insulatingsupporting cylinder is structurally characterized in that a piston is fixed at the upper end of a movable supporting column and at the lower end of a supporting cylinder shaft and extends into an inner cavity of a supporting cylinder support to form an air cylinder, the supporting cylinder support is provided with a vent hole, and a limit spring is sleeved on the movable supporting column. The movable supporting column is arranged on the supporting cylinder support through a linear bearing. The flexible crawler-type pantograph head has the characteristics of good impact resistance, high current collection stability, large contact current collection area, low pantograph-catenary offline rate and the like.

Owner:SOUTHWEST JIAOTONG UNIV

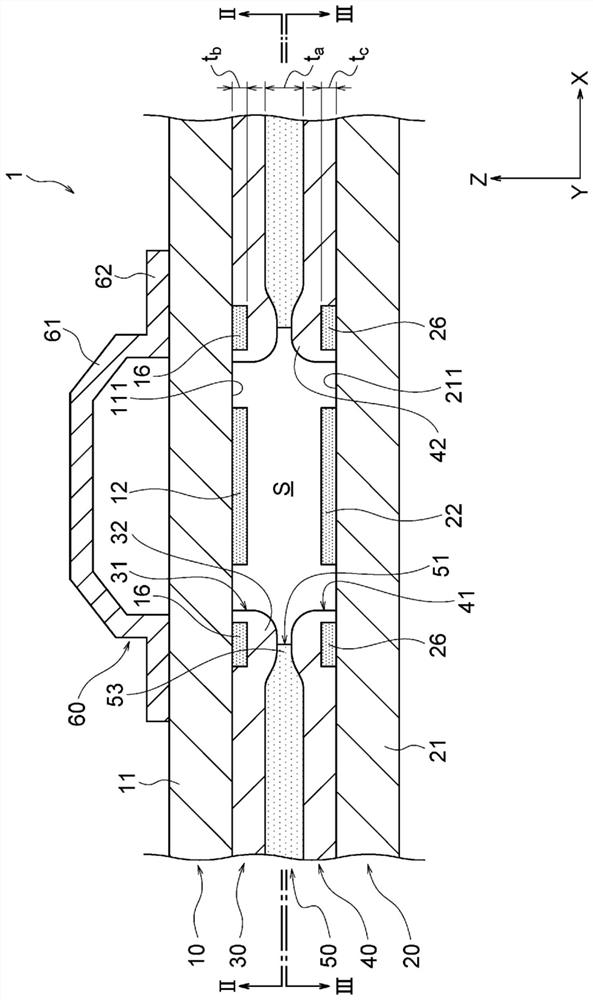

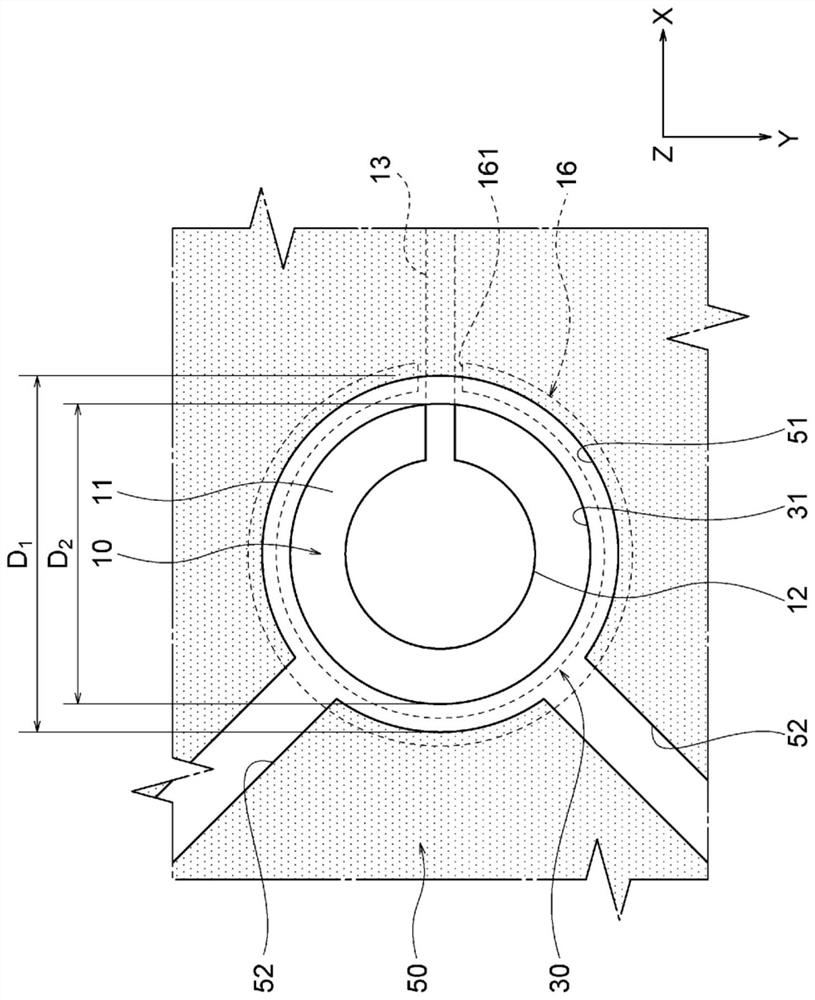

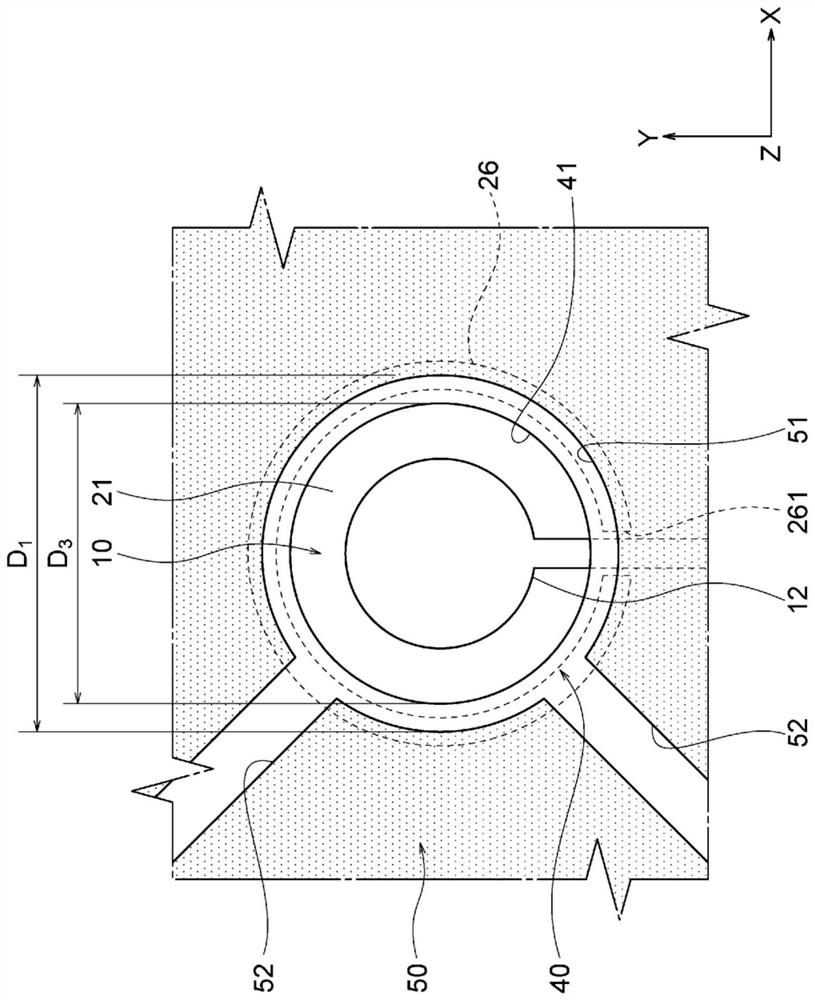

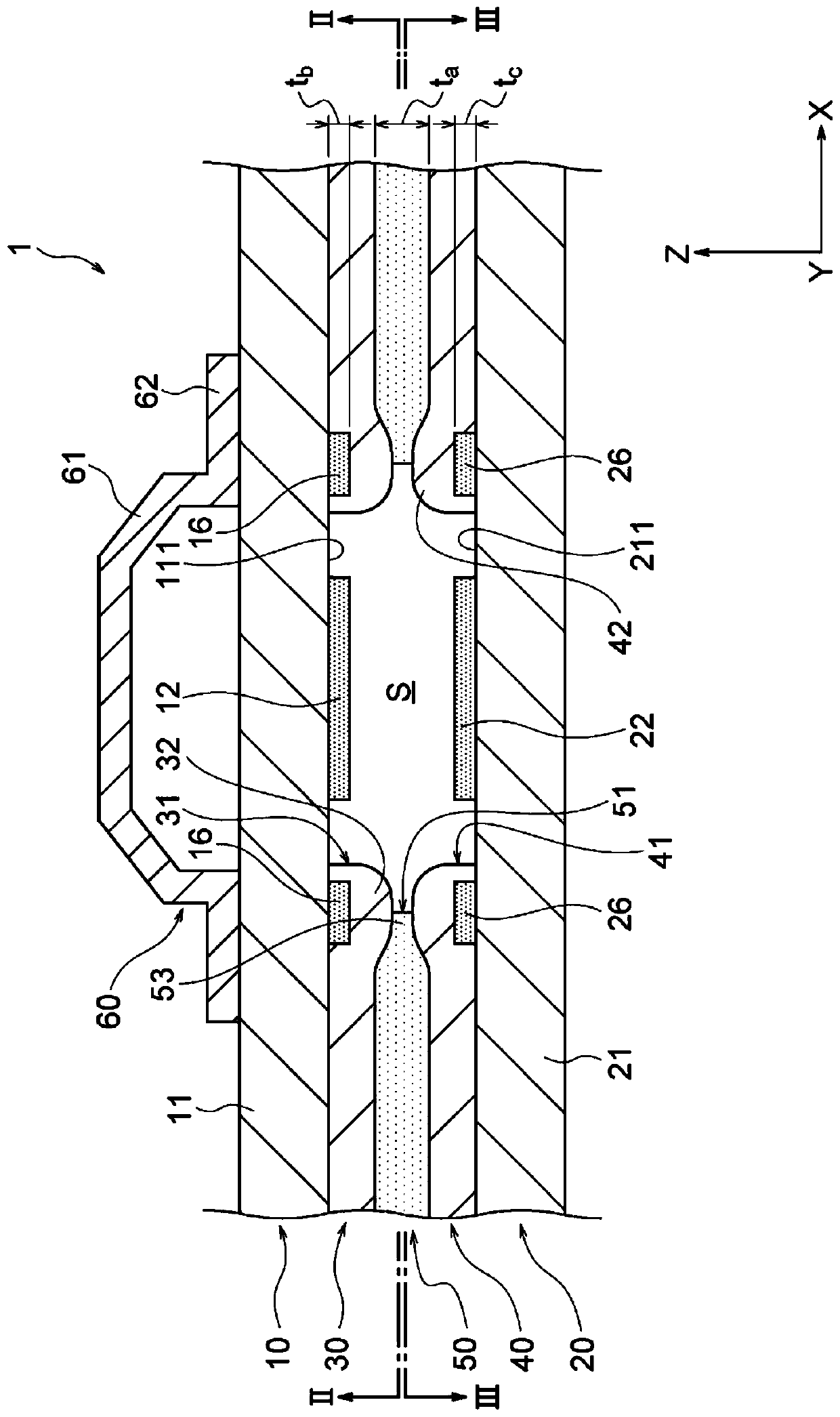

MEMS device, liquid ejecting head, liquid ejecting apparatus, and MEMS device manufacturing method

ActiveUS10377134B2Depression depressionInking apparatusElectrical and Electronics engineeringElectrode

A MEMS device includes a wire that is formed of a conductive portion embedded into a recess opened in a first face of a substrate and a bump electrode that is electrically connected to the wire. A total width, in a second direction intersecting a first direction along which the wire extends on the first face, of an opening of the recess in a connection region where the wire and the bump electrode are electrically connected to each other is narrower than a width, in the second direction, of an opening of the recess in a region outside the connection region.

Owner:SEIKO EPSON CORP

Polishing slurry composition for sti process

InactiveCN113195658AFast polishingExcellent polishing inhibition performanceOther chemical processesAqueous dispersionsMetallurgySlurry

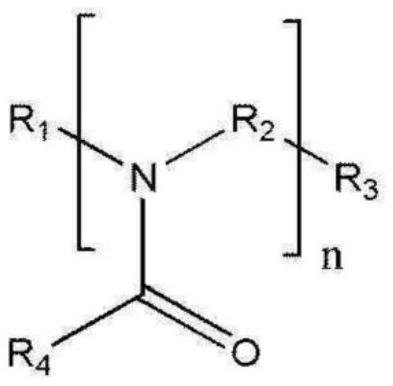

The present invention relates to a polishing slurry composition for an STI process and, more specifically, to a polishing slurry composition for an STI process, the polishing slurry composition comprising: a polishing solution including polishing particles; and an additive solution containing a polymer having an amide bond, and a polysilicon film polishing barrier inclusive of a monomer having three or more chains linked to one or more atoms.

Owner:K C TECH

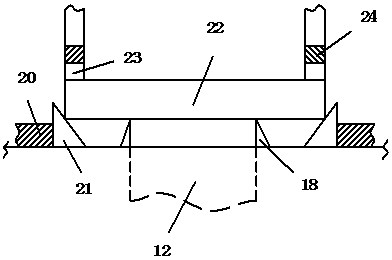

Sound-absorbing panels

InactiveCN104837709BCurb bendingImprove sound absorptionAxle-box lubricationSound producing devicesAdhesiveHeat resistance

The present invention provides a sound-absorbing panel capable of satisfying heat resistance and melt-dripping resistance required for the interior of a railway vehicle. The sound-absorbing panel (10) between windows is laminated with five sheets of first to fifth glass cloths (13-17) on an aluminum substrate (11). In addition, the fifth glass cloth (17) is pasted on the back side of the substrate (11) by an adhesive edge, and the first to fourth glass cloths (13, 14, 15, 16) are fixed by the needles of the stapler. That is, the first glass cloth (13) and the substrate (11) are fixed by an adhesive, and the adhesive is prevented from melting by five sheets, that is, the first to fifth glass cloths (13-17). The fifth glass cloth (13 to 17) and the substrate (11) prevent the adhesive that fixes the edge of the fifth glass cloth (17) to the other side of the substrate (11) from melting.

Owner:CENTRAL JAPAN RAILWAY COMPANY +1

An aluminum profile punching device and punching method thereof

ActiveCN107081374BReduce the stress areaReduce rigid deformationPerforating toolsPunchingArchitectural engineering

The invention discloses an aluminum profile punching device. The aluminum profile punching device comprises a rack. A hydraulic punch is mounted at the top of the rack. A base plate is fixedly connected to the rack and located below the hydraulic punch. A first cylinder is vertically mounted at the bottom of the rack. The top of the first cylinder is fixedly connected with a first motor, a first annular tool apron is fixed to an output shaft of the first motor, and a plurality of first tool bits are annularly arranged on the first annular tool apron and hinged to the first annular tool apron. A template is slidably connected to the top surface of the base plate, a template hole is formed in the template, and an annular blade is arranged on the edge of the template hole. An annular cavity is formed in the hydraulic punch, a second motor is mounted at the top of the annular cavity and connected with a second annular tool apron through a connecting rod, the connecting rod is located in the annular cavity, and a plurality of second tool bits are fixedly connected to the bottom of the second annular tool apron. By adoption of the aluminum profile punching device, defects of the prior art can be overcome, and the machining quality of aluminum profile punching is improved.

Owner:肇庆市美联达有色金属制品有限公司

switch

Owner:FUJIKURA LTD

Chemical mechanical polishing composition and method for tungsten

ActiveCN111074281AAvoid corrosionDepression depressionEdge grinding machinesRevolution surface grinding machinesColloidal silicaFatty amine

A composition and method for chemical mechanical polishing a substrate containing tungsten to at least inhibit corrosion of the tungsten. The composition includes, as initial components: water; an oxidizing agent; selected fatty amine ethoxylate; a dicarboxylic acid, a source of iron ions; a colloidal silica abrasive; and, optionally, a pH adjusting agent; and, optionally, a biocide. The chemicalmechanical polishing method includes providing a chemical mechanical polishing pad, having a polishing surface; creating dynamic contact at an interface between the polishing pad and the substrate; and dispensing the polishing composition onto the polishing surface at or near the interface between the polishing pad and the substrate; wherein some of the tungsten is polished away from the substrateand corrosion of the tungsten is inhibited.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

A flexible crawler pantograph bow suitable for electric traction locomotives

ActiveCN112498113BImprove impact resistanceImprove impact performancePower current collectorsSlide plateElectric traction

A flexible tracked pantograph head suitable for electric traction locomotives, two metal rollers are set on the pantograph bracket, the insulating roller shaft is fixed on the two roller brackets, and the two roller brackets are fixed on the pantograph bracket , the metal drum is installed on the drum shaft through two insulating bearings, and a metal spring is arranged in at least one through hole on the drum shaft, and a current receiving carbon brush is respectively fixed on the two ends of the metal spring extending out of the through hole; On the metal drum, more than one insulating support cylinder is set under the track. The structure of the insulating support cylinder is: the upper end of the movable support is fixed to the support cylinder shaft and the lower end is fixed to the piston. The piston extends into the inner cavity of the support cylinder to form a cylinder. There is a vent hole, the limit spring coil is set on the movable support, and the movable support is arranged on the supporting tube bracket through the linear bearing. The invention has the characteristics of good impact resistance of the carbon slide plate, high flow receiving stability, large contact and flow receiving area, low pantograph-catenary off-line rate and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Coloring resin composition

ActiveCN108431648AGood lookingDepression depressionOptical filtersPhotosensitive materials for photomechanical apparatusPolymer scienceOrganic solvent

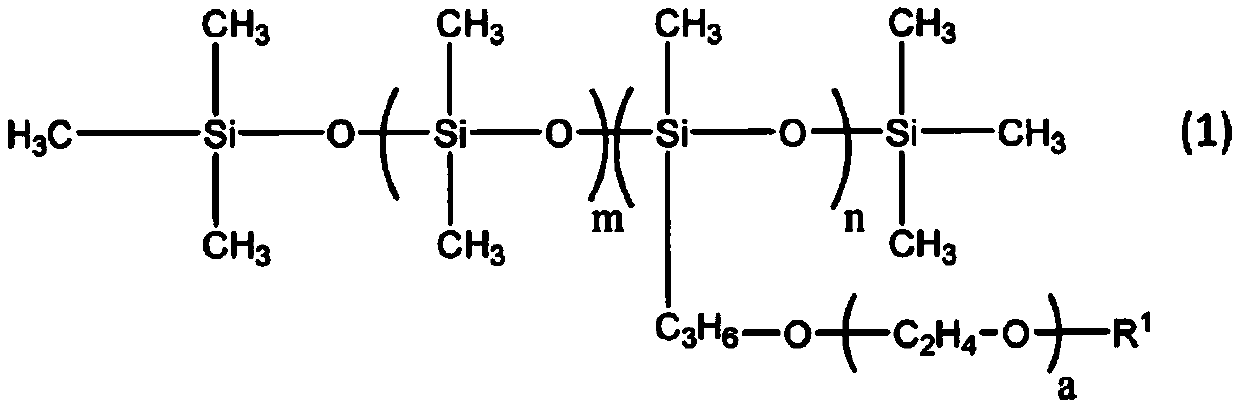

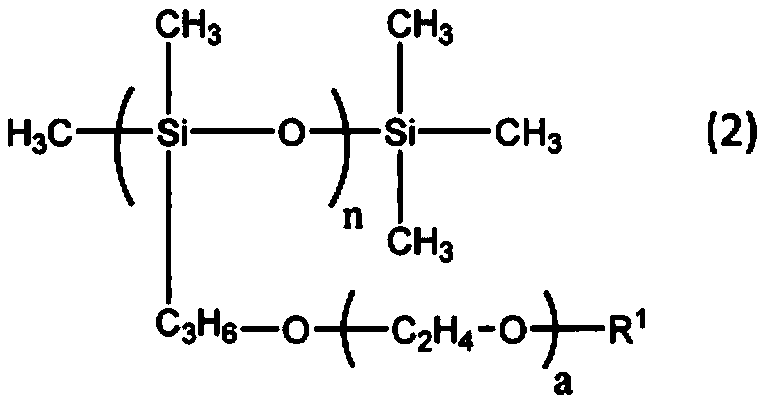

The objective of the present invention is to provide a coloring resin composition which is capable of forming a colored coating film having good appearance by suppressing cissing or unevenness even incases where coating is carried out by means of spray or inkjet. The present invention is a coloring resin composition which contains at least (A) a coloring material, (B) a binder resin, (C) an organic solvent and (D) two or more surfactants, and wherein: (D1) a polyether-modified siloxane-based surfactant and (D2) a silicon-modified acrylic surfactant are contained as the surfactants; and the total content of the surfactants (D1) and (D2) is from 200 ppm to 1,500 ppm (inclusive) in the coloring resin composition.

Owner:TORAY IND INC

Normal temperature cured organic polysiloxane composition

Owner:SHIN ETSU CHEM CO LTD

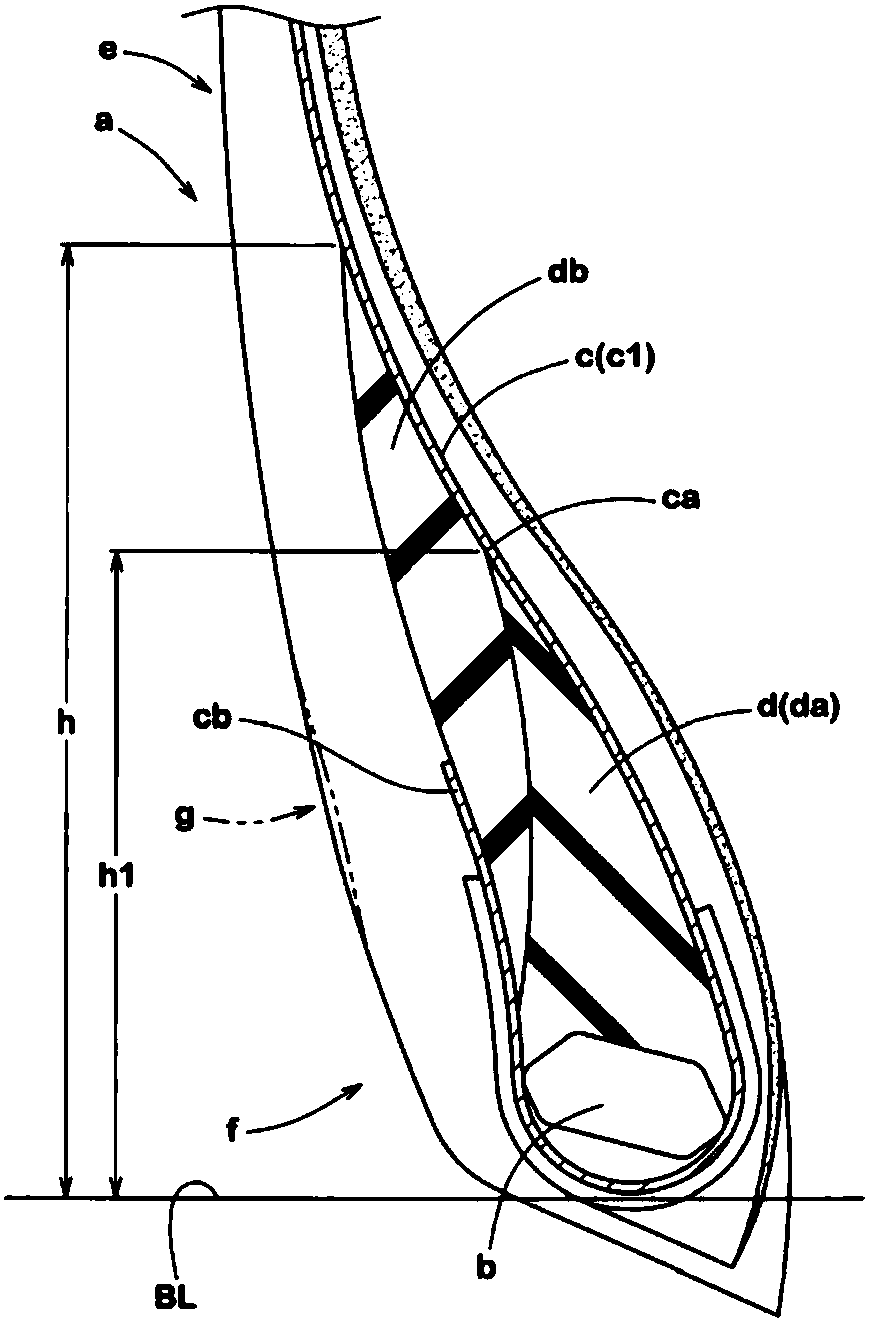

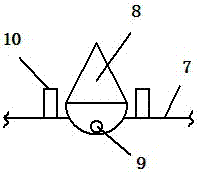

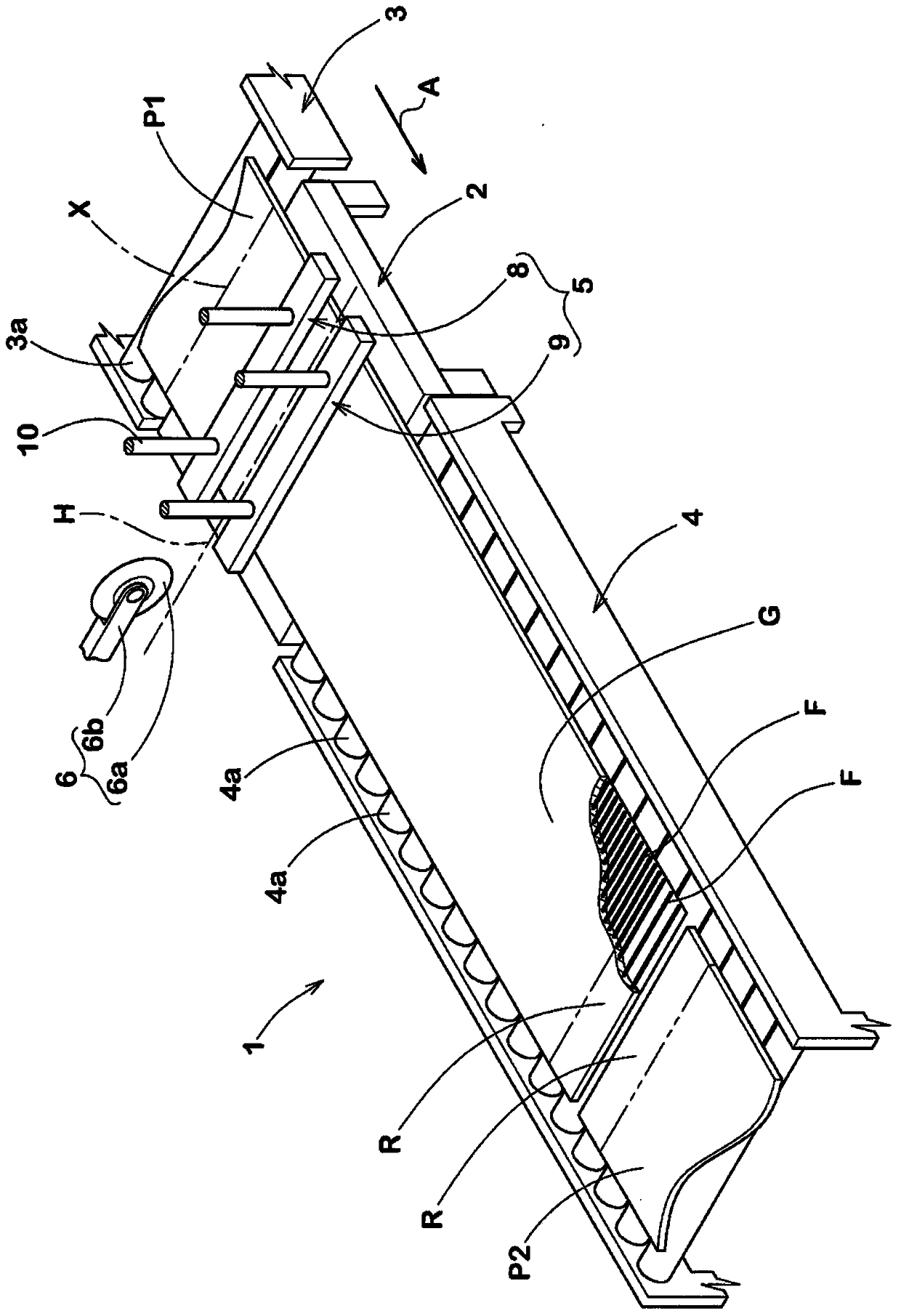

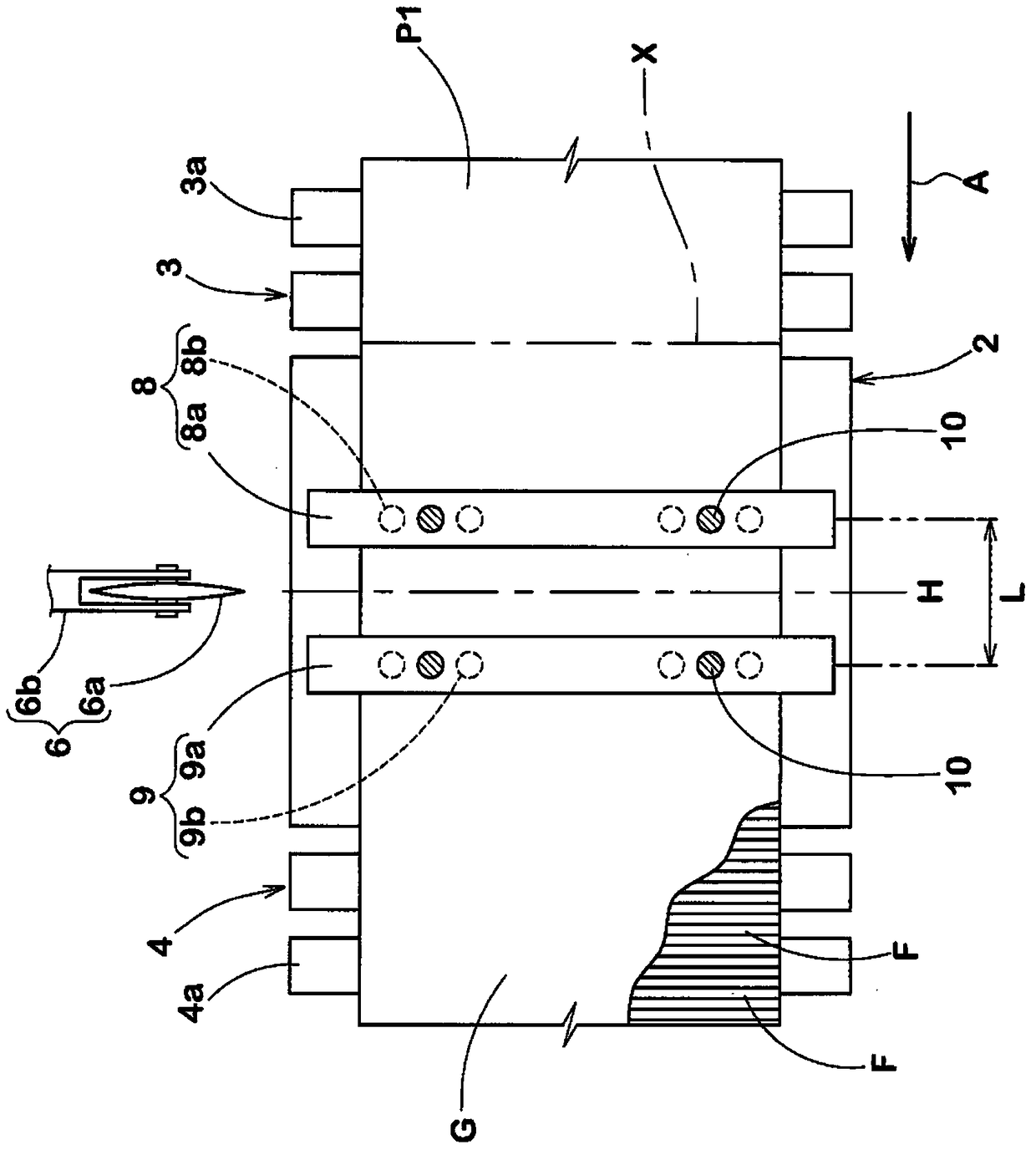

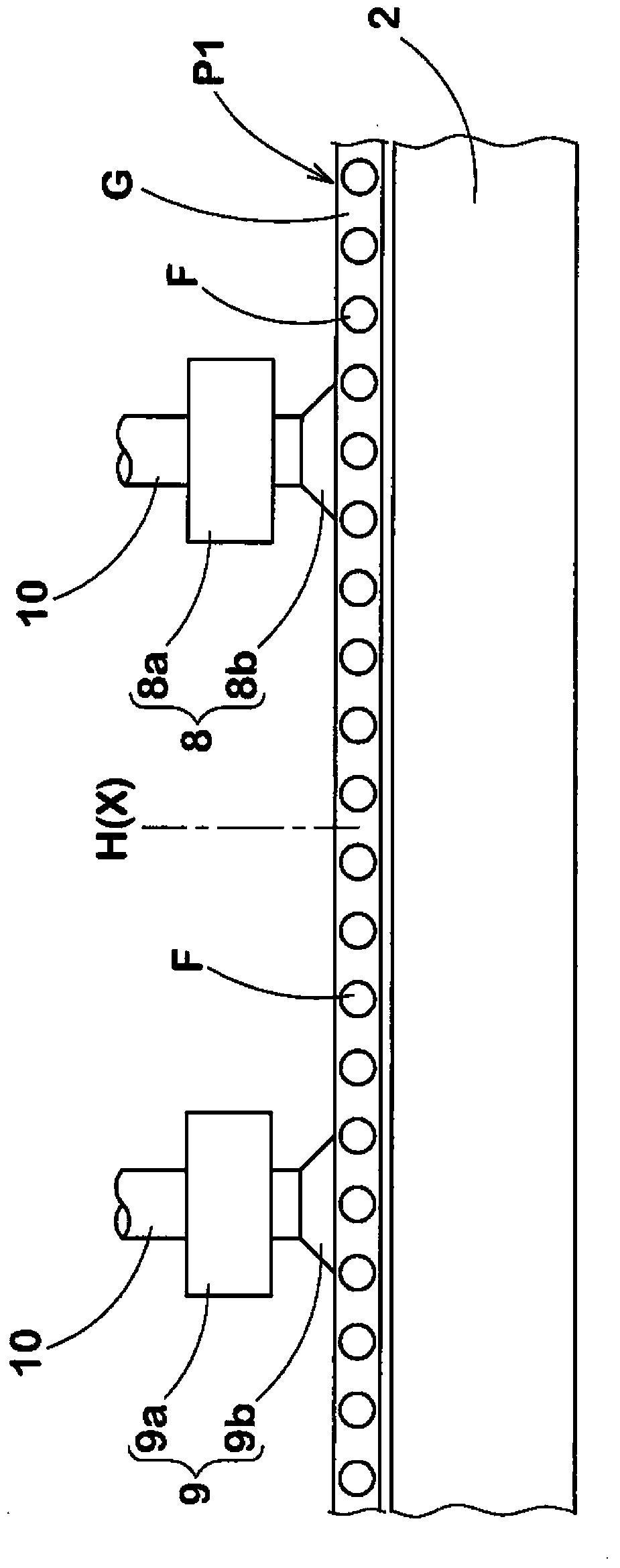

Carcass ply manufacturing method and pneumatic tire manufacturing method

The small cylindrical carcass ply rigid difference was easily molded to provide a method capable of producing an excellent pneumatic tire appearance without impairing the productivity. A manufacturing method of a pneumatic tire a first step of obtaining the carcass ply P2 by cutting the carcass ply material P1, mosquitoes; and a second step of forming a cylindrical carcass ply P3 by overlapping both end portions of the Kasupurai P2, the first step, in the first holding means 8 and the second holding means 9, step holding for holding the carcass ply material P1, if Shin a first holding means 8 pull the carcass ply material P1 by the second holding means 9 is separated from each other; and, stretching the step of forming the extended portion R on both sides of the cut position X, and, after the stretching process, including. (select the cutting process to obtain the carcass ply P2 by cutting the carcass ply material P1 in the cutting position X Figure).

Owner:SUMITOMO RUBBER IND LTD

Switch

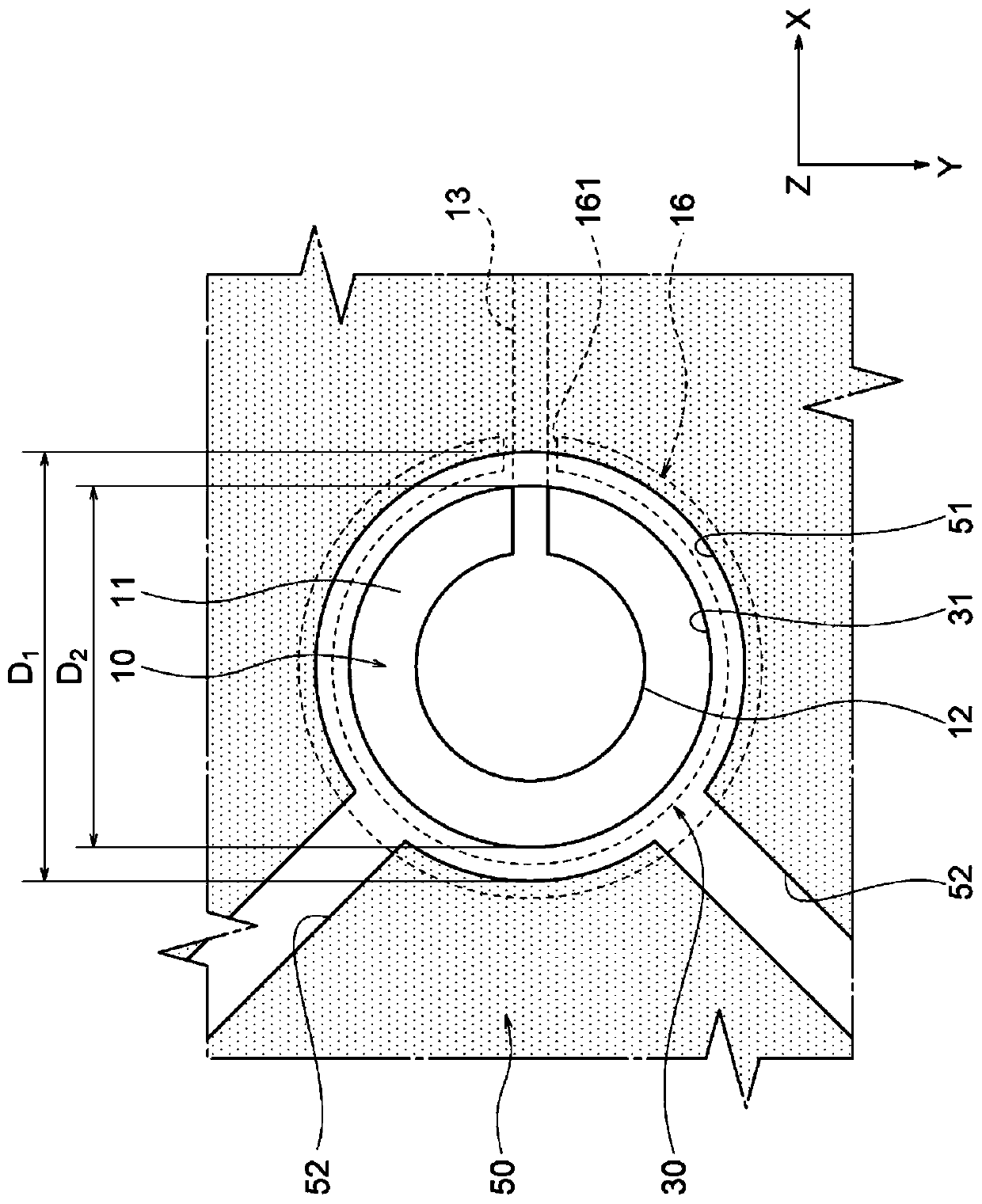

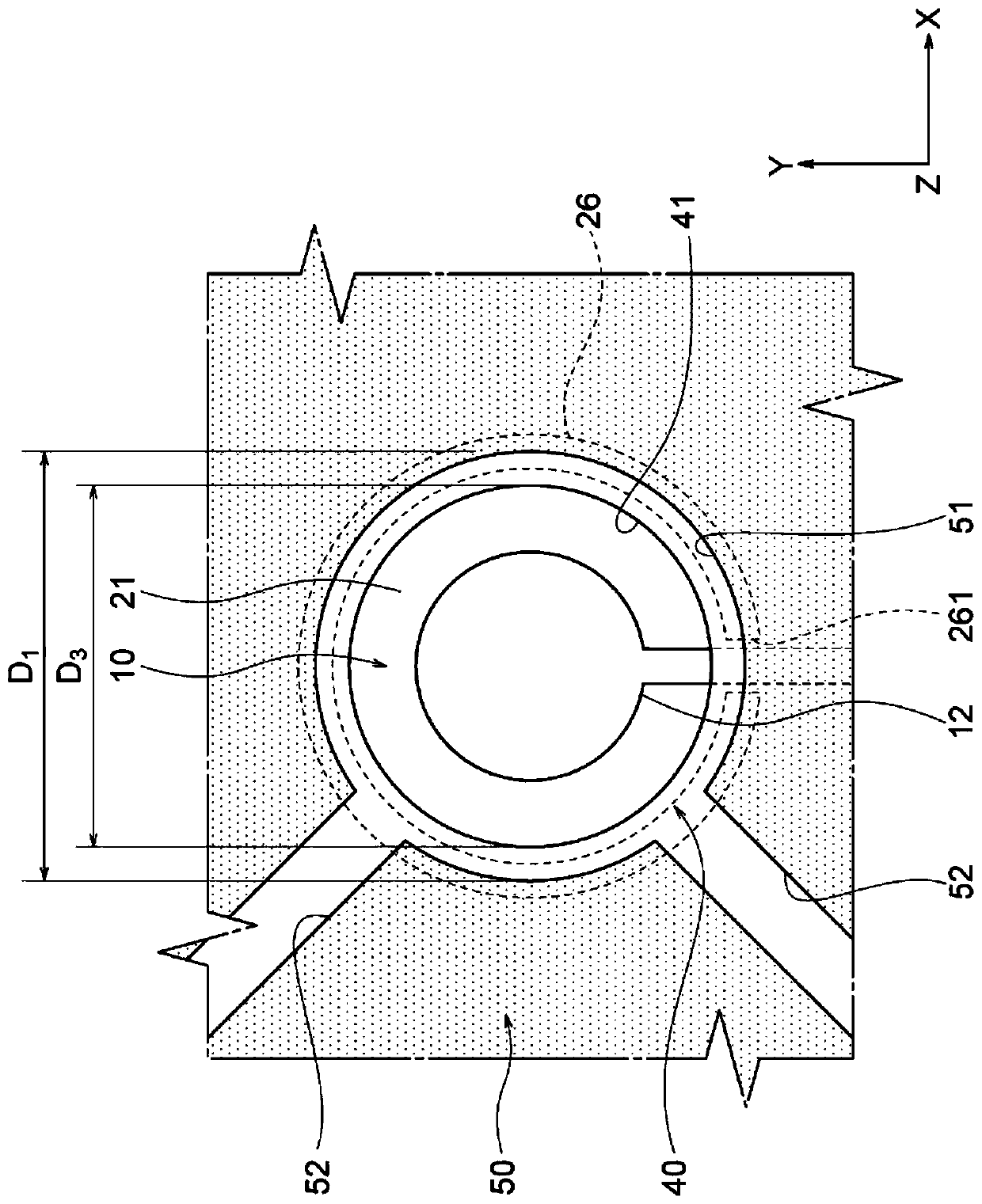

This switch 1 is provided with: an upper electrode sheet 10 which comprises an upper electrode 12; a lower electrode sheet 20 which faces the upper electrode sheet and comprises a lower electrode 22;and an adhesive layer 50 which has an opening 51 where the electrodes face each other, and which bonds the electrode sheets with each other. The upper electrode sheet comprises: an upper substrate 11on which the upper electrode is formed; an upper insulating layer 30 which is provided between the upper substrate and the lower electrode sheet, while having an opening 31 at a position correspondingto the upper electrode, and which is bonded to the lower electrode sheet by means of the adhesive layer; and an upper base part 16 which is provided between the upper substrate and the upper insulating layer, and which is arranged so as to overlap an edge 53 of the opening of the adhesive layer. The upper insulating layer bulges toward the lower electrode sheet by means of the upper base part ina portion corresponding to the upper base part.

Owner:THE FUJIKURA CABLE WORKS LTD

Colored resin composition

ActiveCN108431648BGood lookingDepression depressionOptical filtersPhotosensitive materials for photomechanical apparatusPolymer scienceOrganic solvent

The object of the present invention is to provide a colored resin composition capable of suppressing sinking and unevenness and forming a colored film having a good appearance even when it is applied by spraying or inkjet. The present invention is a colored resin composition comprising at least: (A) a coloring material, (B) a binder resin, (C) an organic solvent, and two or more kinds of (D) surfactants, as the above-mentioned surfactants, Containing (D1) polyether-modified siloxane-based surfactant and (D2) silicon-modified acrylic-based surfactant, the total content of the above-mentioned surfactants (D1) and (D2) in the colored resin composition is 200ppm Above 1500ppm below.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com