Connector

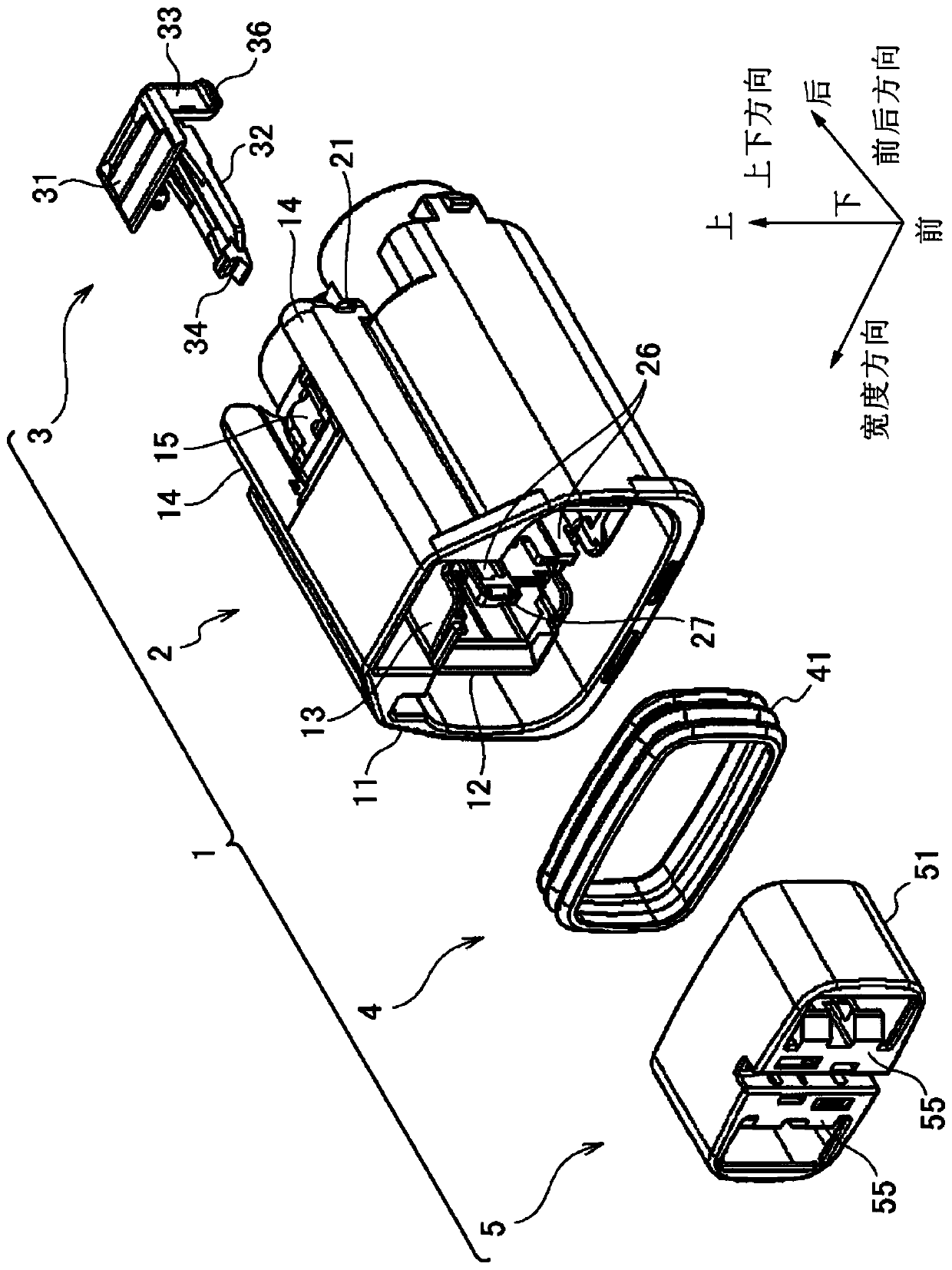

A technology of connectors and shells, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve the problems of front bracket depression and gap, shorten the locking arm, etc., to suppress extrusion, suppress depression and gap, increase Rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

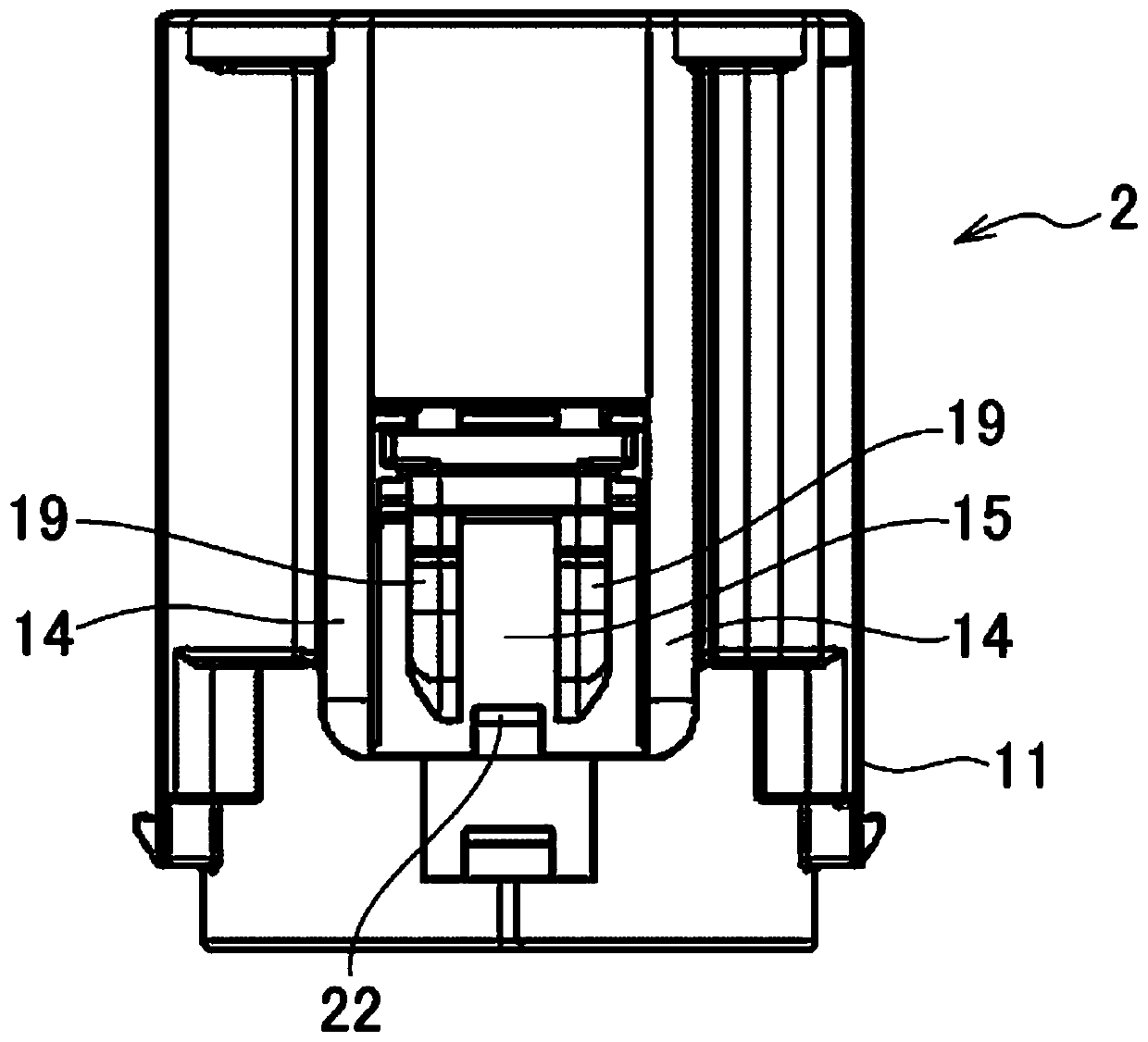

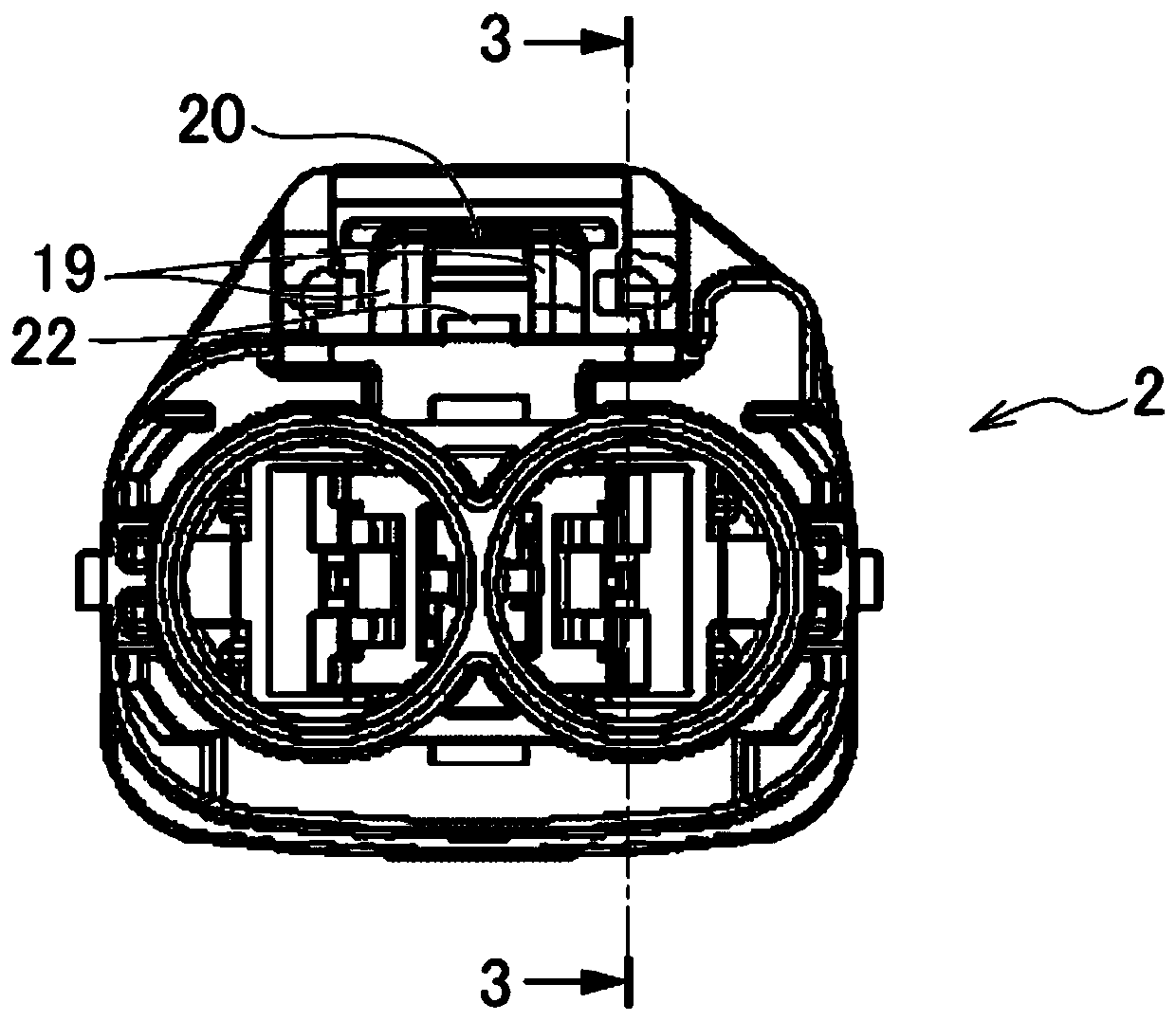

Examples

Embodiment approach

[0085] The present invention is not limited to the above-described embodiments, and various modifications can be employed within the scope of the present invention. For example, the present invention is not limited to the above-described embodiments, and may be appropriately modified, improved, and the like. In addition, the material, shape, size, quantity, arrangement position, etc. of the constituent components in the above-described embodiments are optional and not limited as long as the purpose of the present invention can be achieved.

[0086] In the above-described embodiment, the lock arm 54 of the front bracket 5 has a two-end support beam shape in which the root portion (rear end side) is supported by the base portion 53 and the tip portion (front end side) is supported by the extension portion 55 . In contrast, the lock arm 54 may have a cantilever shape in which it supports only one of the root portion (rear end side) and the front end portion (front end side).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com