Patents

Literature

564results about How to "Avoid voids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy balancing wireless sensor network clustering method

ActiveCN102036308AEvenly distributedShorten the timePower managementEnergy efficient ICTEnergy balancingExtensibility

The invention relates to an energy balancing wireless sensor network clustering method, which comprises the following three steps of: selecting cluster heads, building a cluster and transmitting data, wherein in the process of selecting the cluster heads, the priorities of nodes to be selected as the cluster heads are set by parameters such as the energy of the nodes, the number of neighboring nodes and the like, so that the cluster heads are more uniformly distributed; in the process of building the cluster, an energy threshold is set as the rebuilding condition of the cluster, so that the aim of reducing the rebuilding frequency of the cluster is fulfilled; meanwhile, a single-hop and multi-hop combined data transmission model is adopted, so that hot problems in a network are solved. Bythe method, the energy can be effectively utilized, the stability of the network is improved, the energy consumption of the network can be balanced, the service life of the network is effectively prolonged, and the network has higher extensibility and safety.

Owner:JIANGSU HILLSUN INFORMATION IND

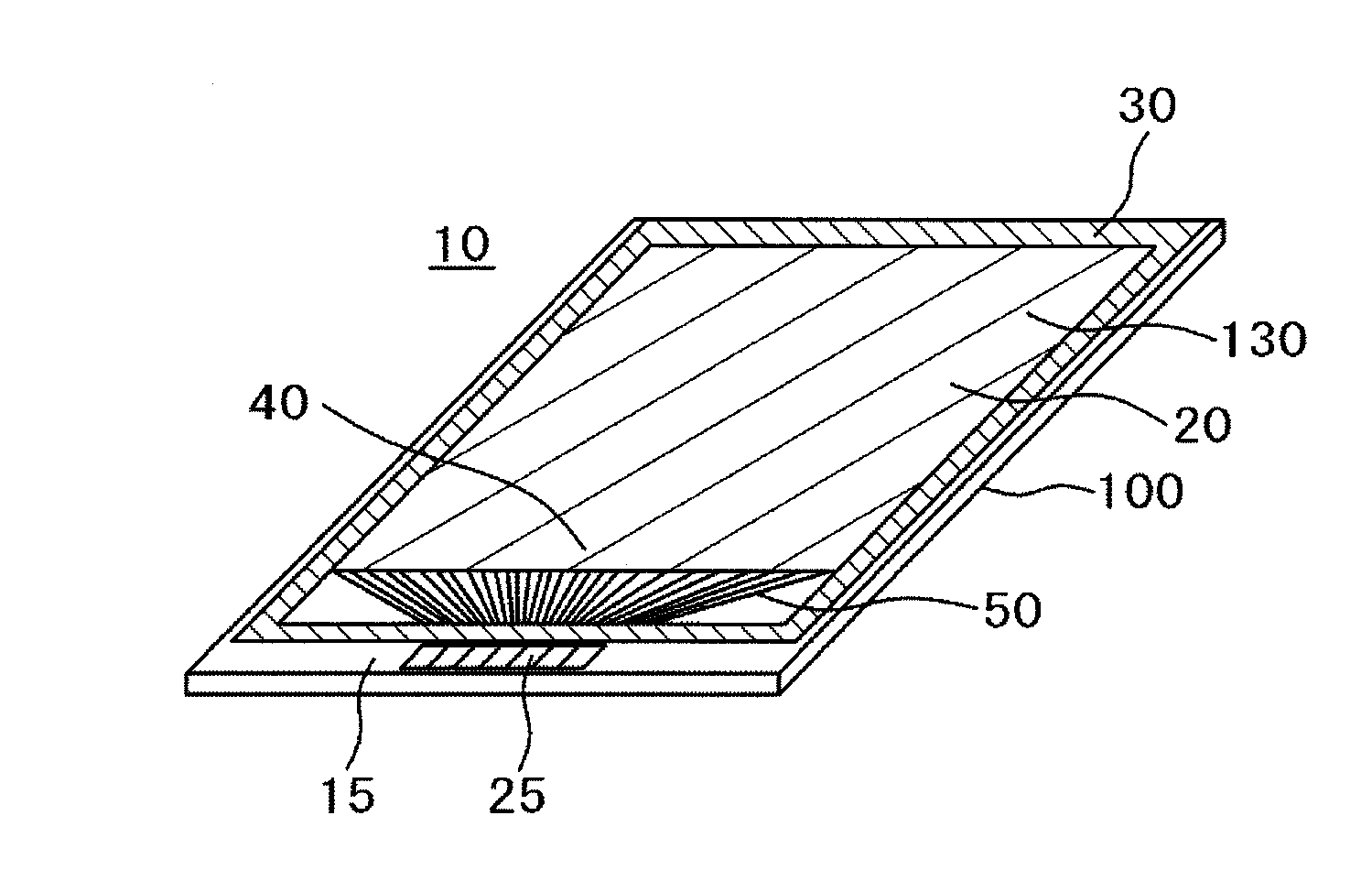

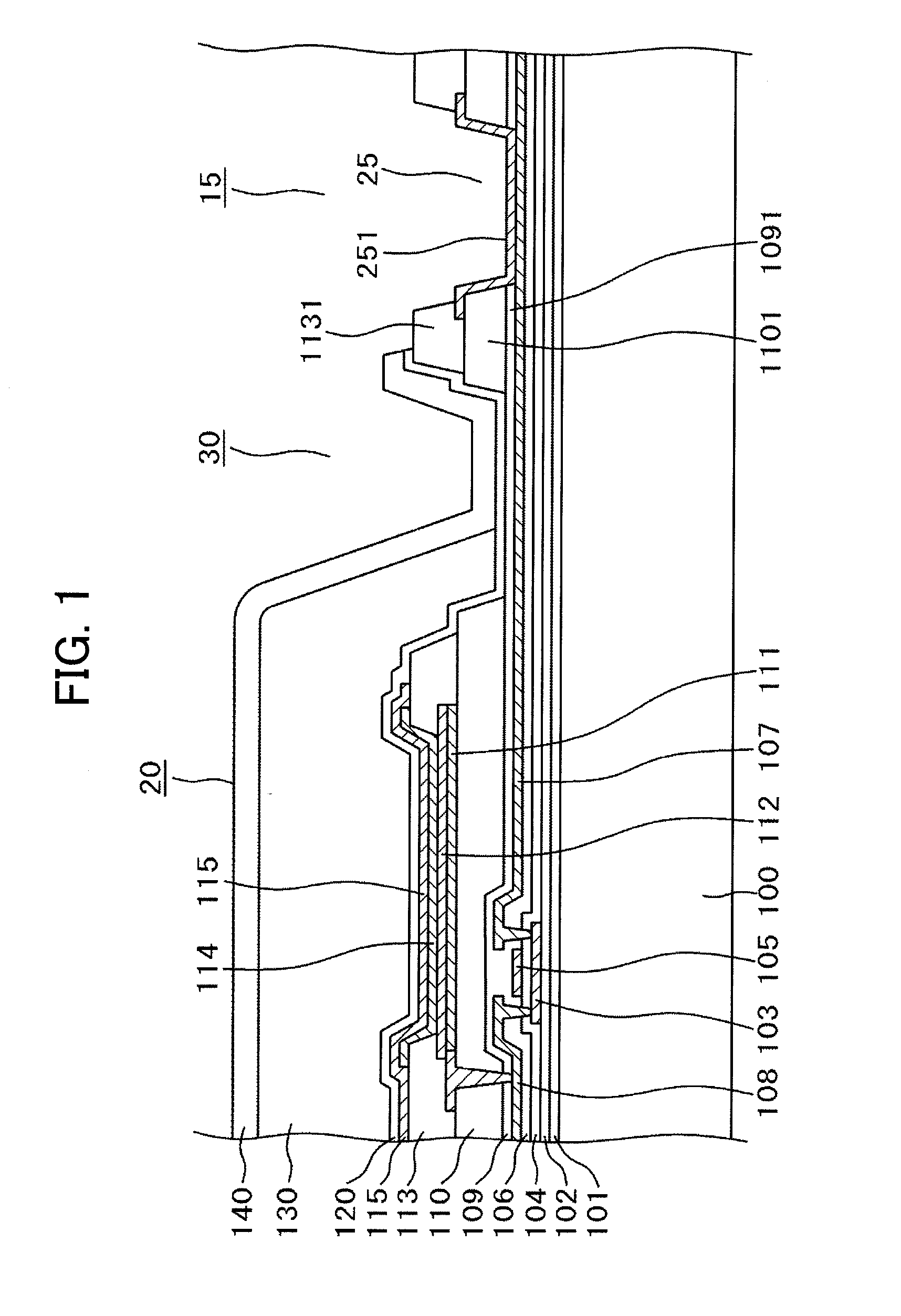

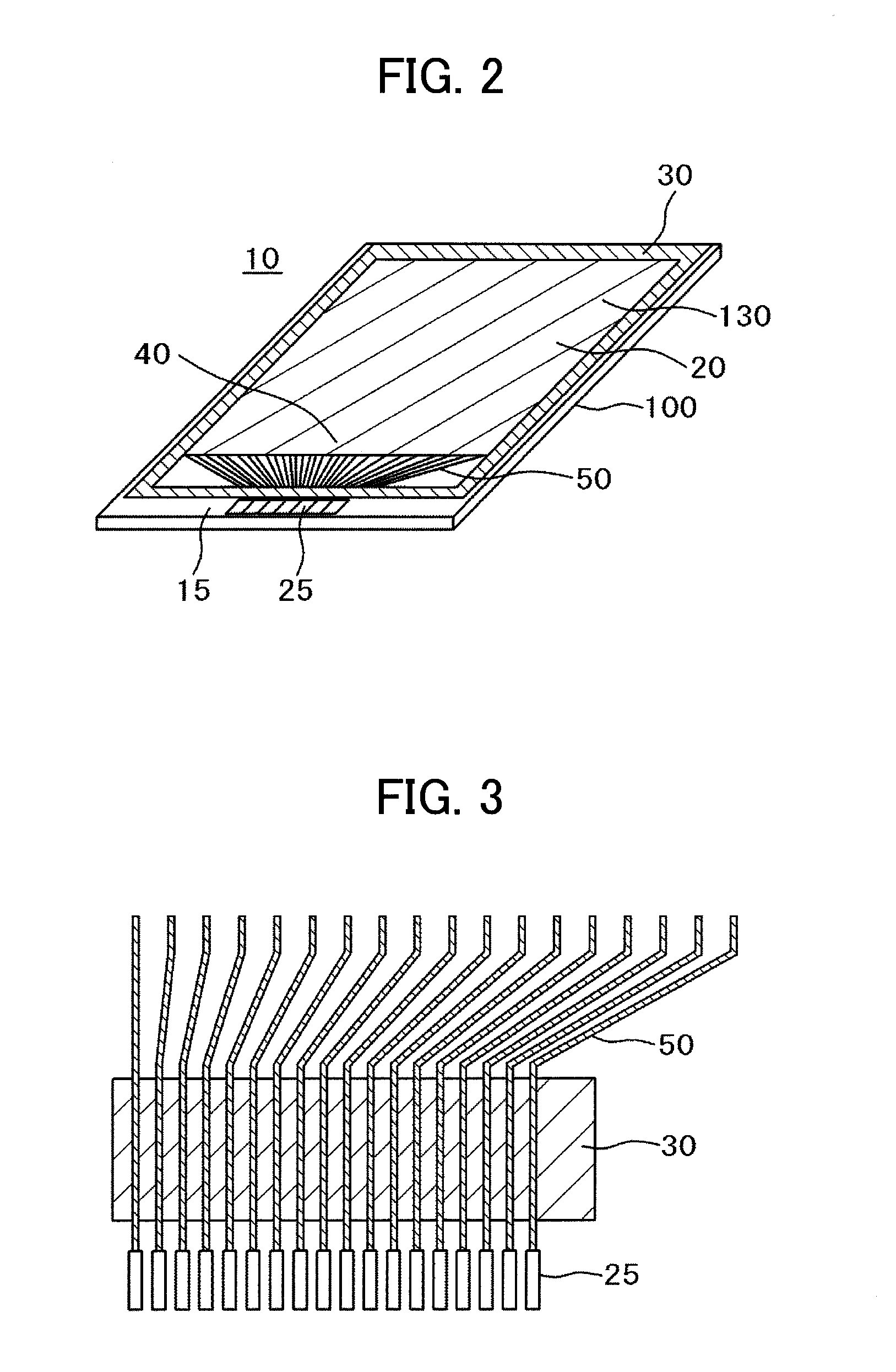

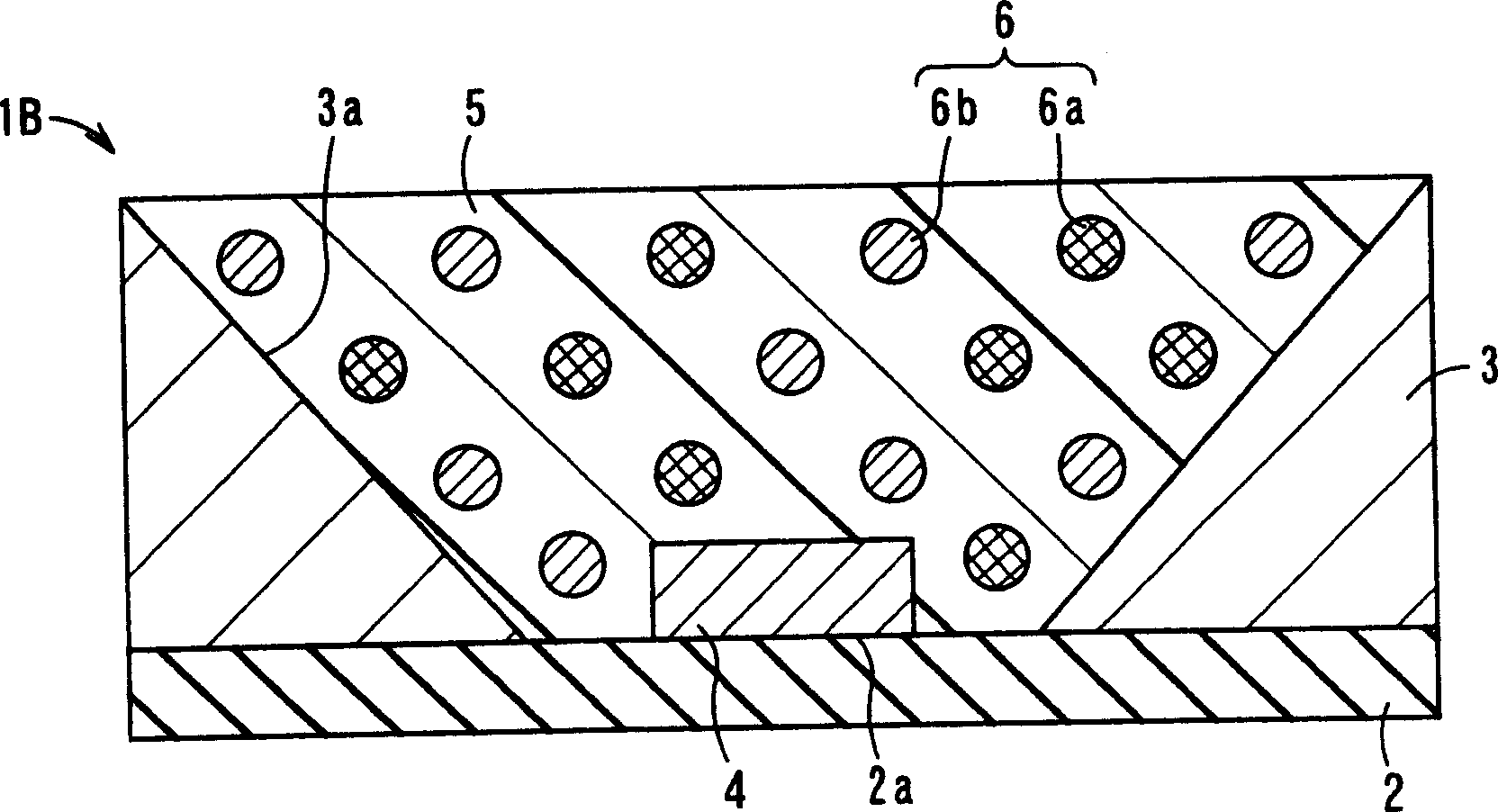

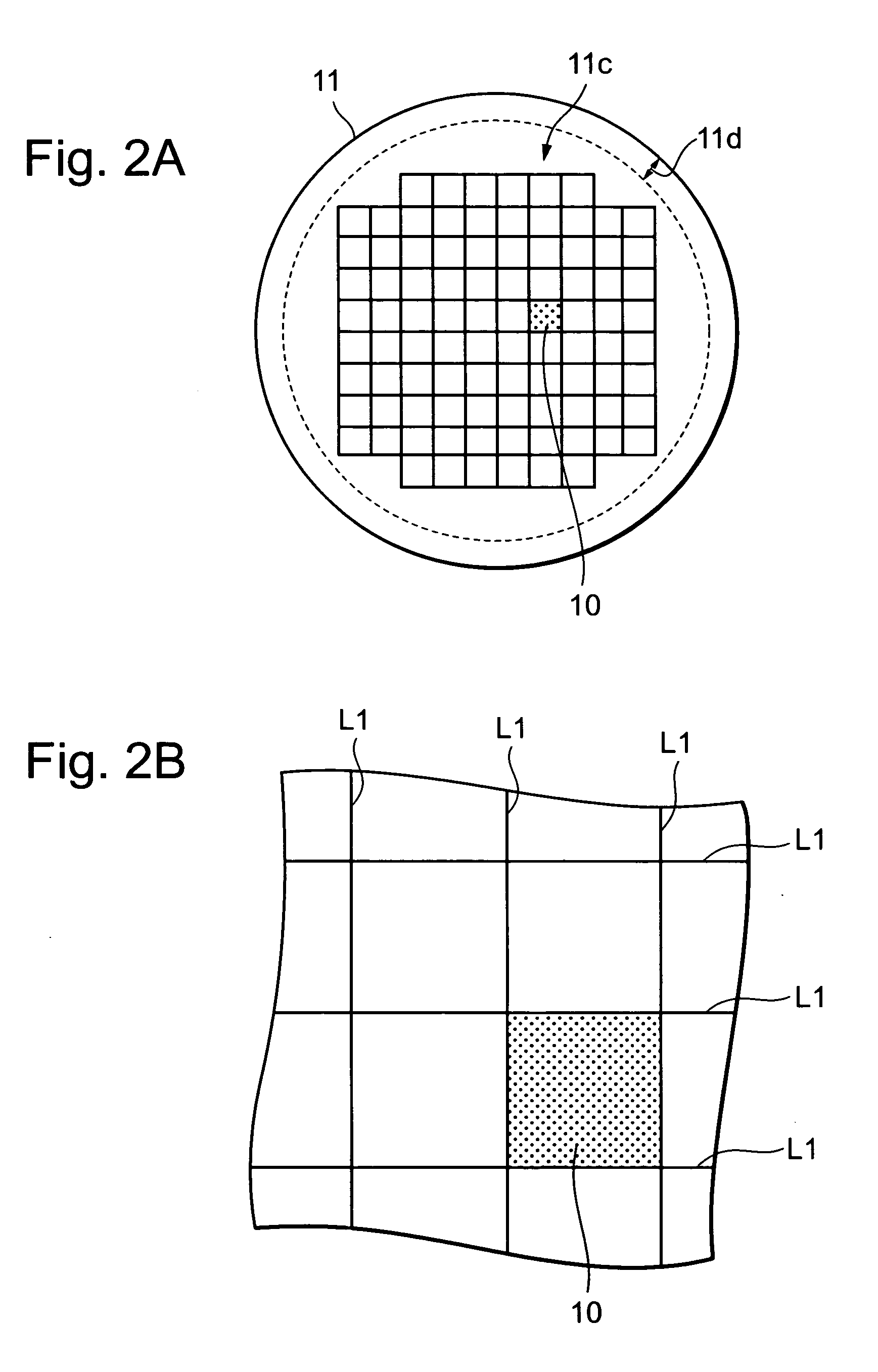

Organic el display device

InactiveUS20110006972A1Avoid voidsAvoid crackingStatic indicating devicesSolid-state devicesDisplay deviceEngineering

A solid-sealing type organic EL display device is provided that can prevent water permeation through a defect generated in a passivation film which covers an extraction line in a peripheral sealing region thereby making it possible to prevent deterioration of an organic EL layer. An extraction line that couples a wiring line in a display region with a terminal part passes a peripheral sealing region. The extraction line is covered with an inorganic passivation film in the peripheral sealing region. The extraction line has a first flexure part and a second flexure part in the peripheral sealing region thereby making it possible to prevent a void and a crack generated in the inorganic passivation film from penetrating the peripheral sealing region. Consequently it is possible to prevent water permeation from outside and to prevent the deterioration of the organic EL layer.

Owner:HITACHI DISPLAYS +1

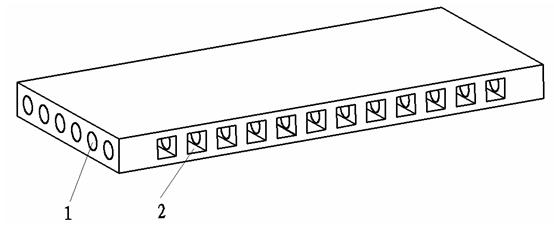

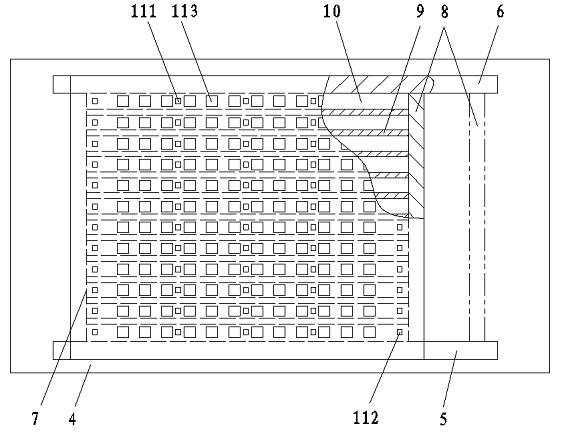

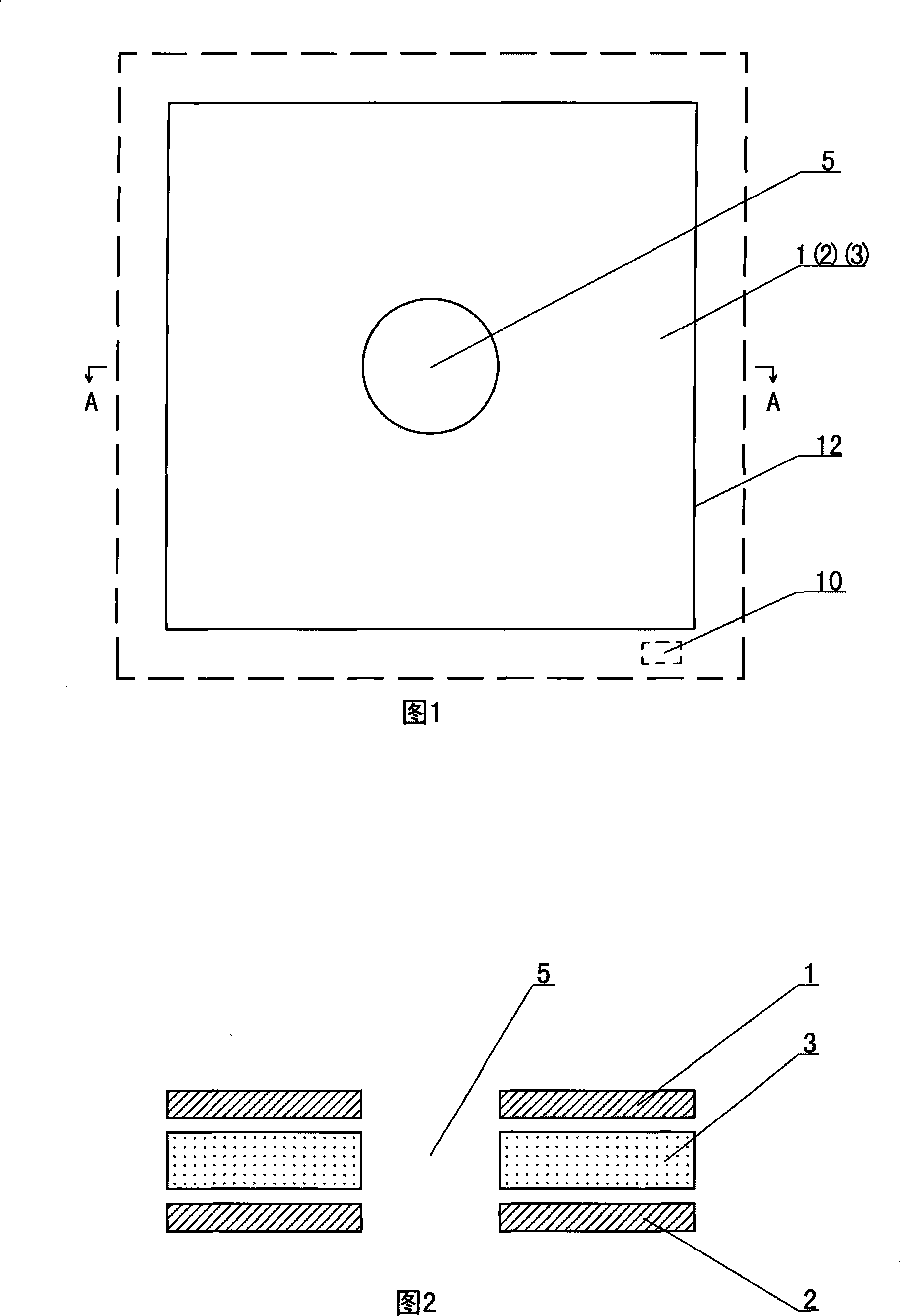

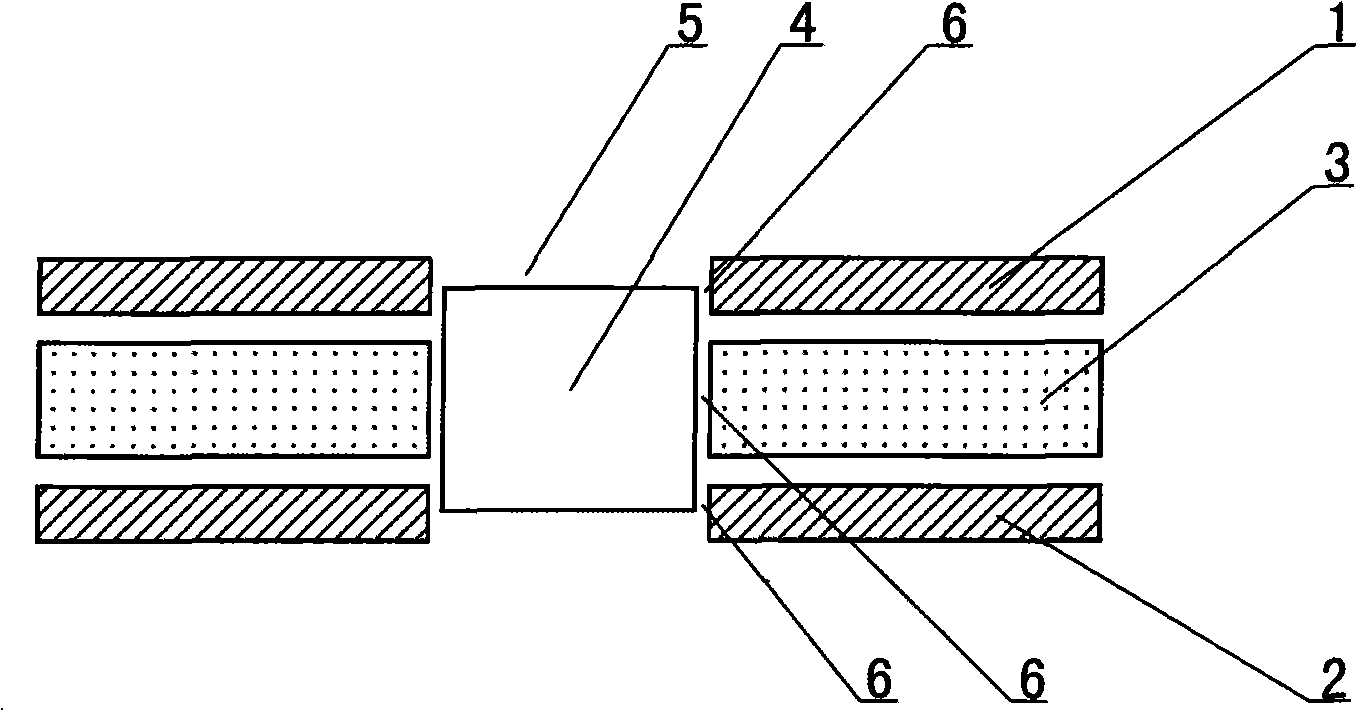

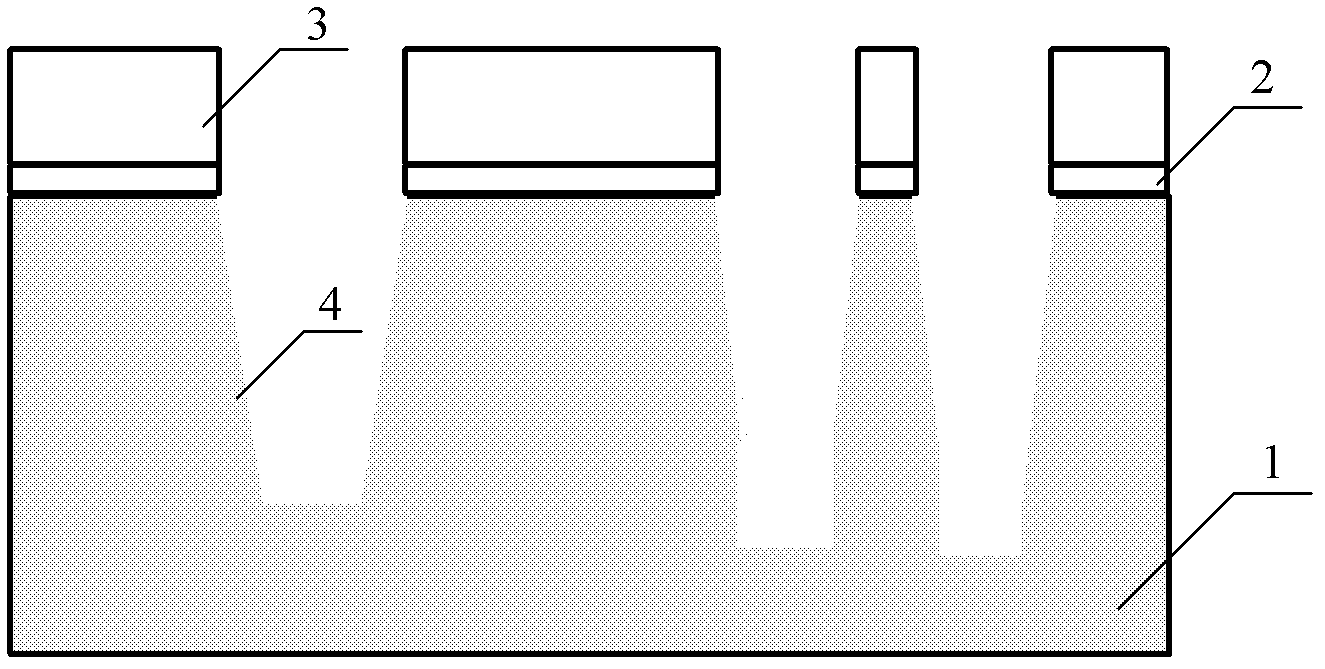

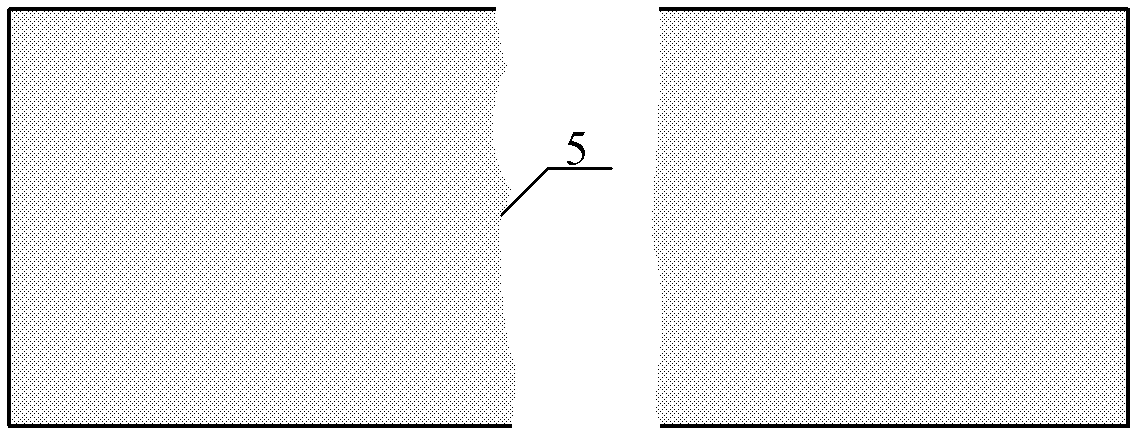

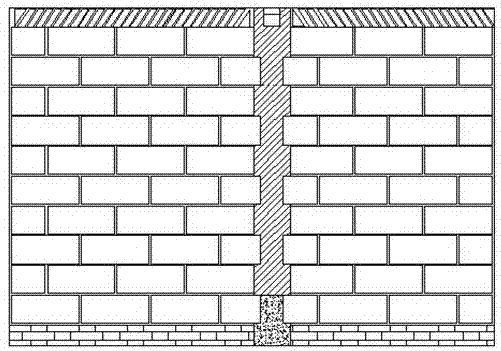

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

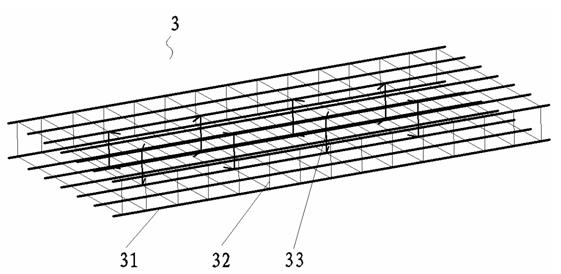

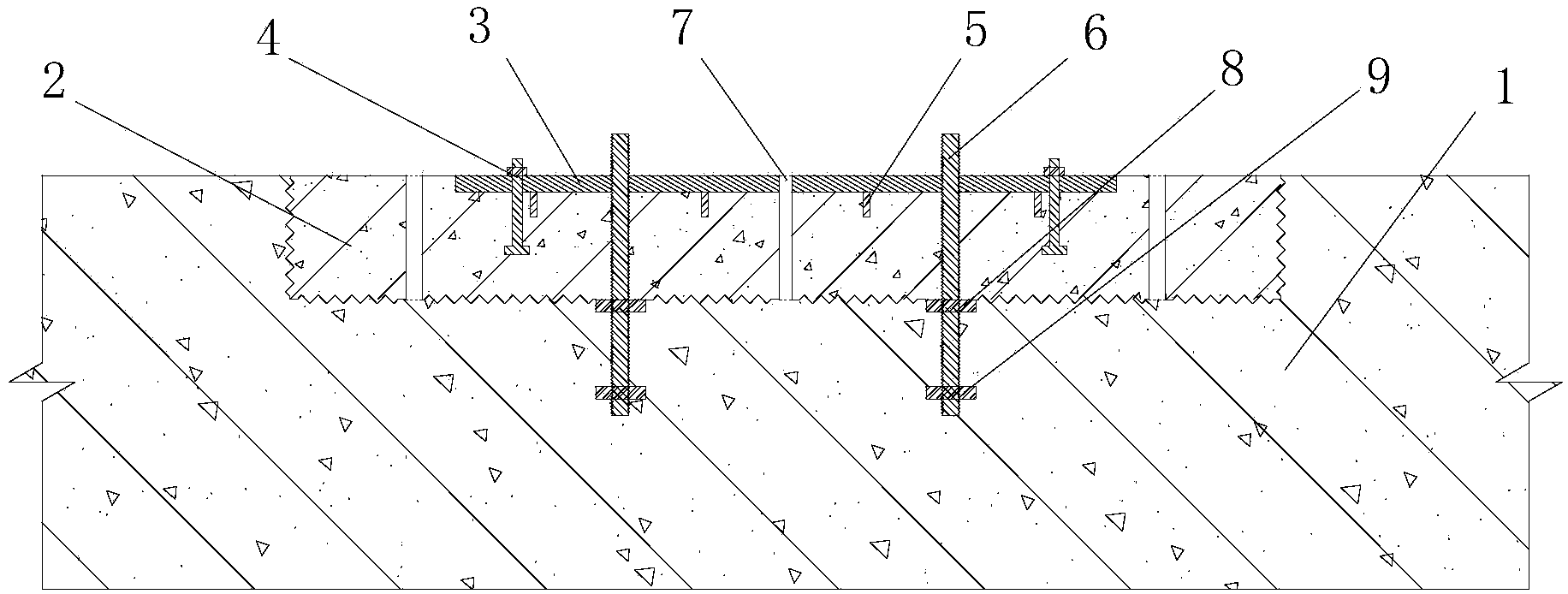

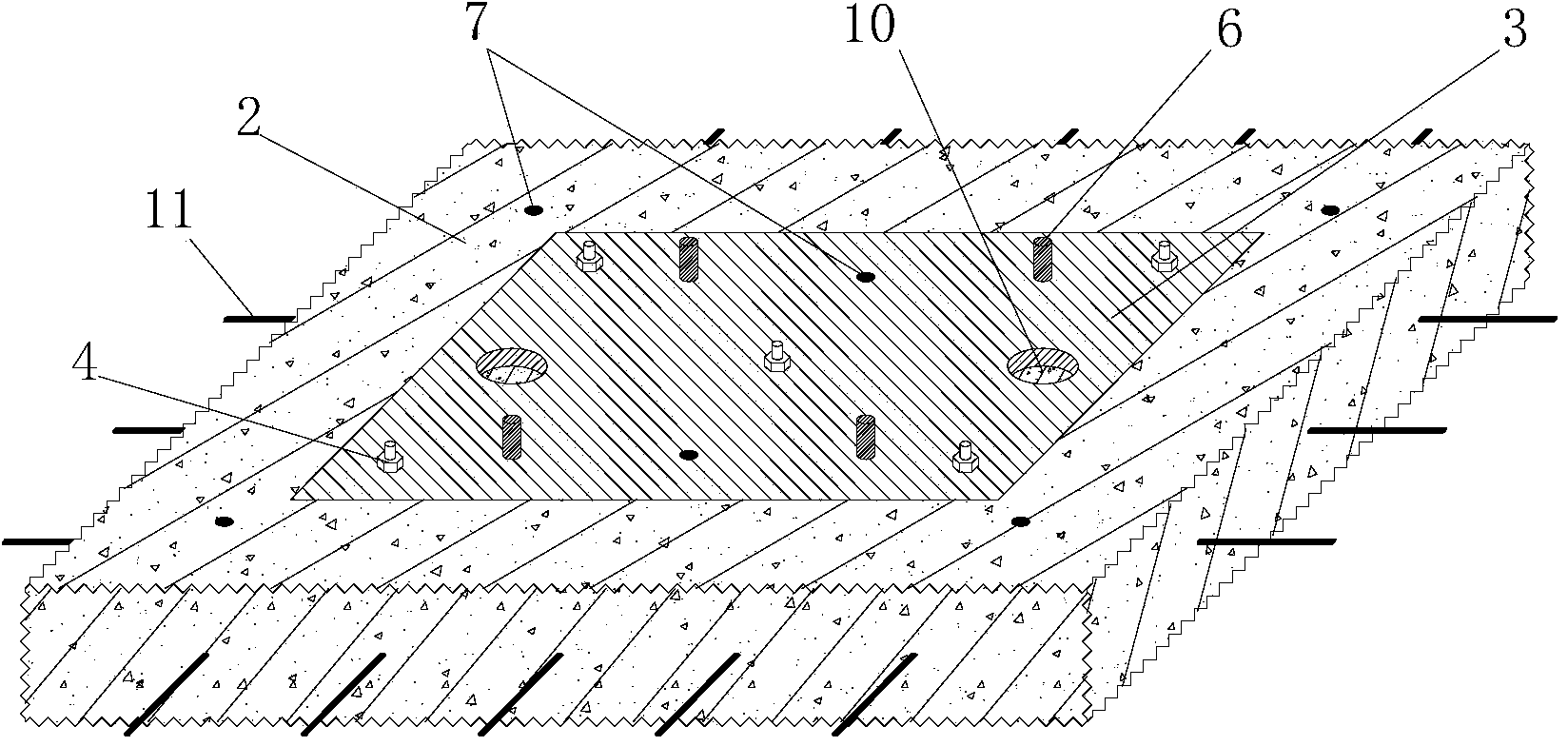

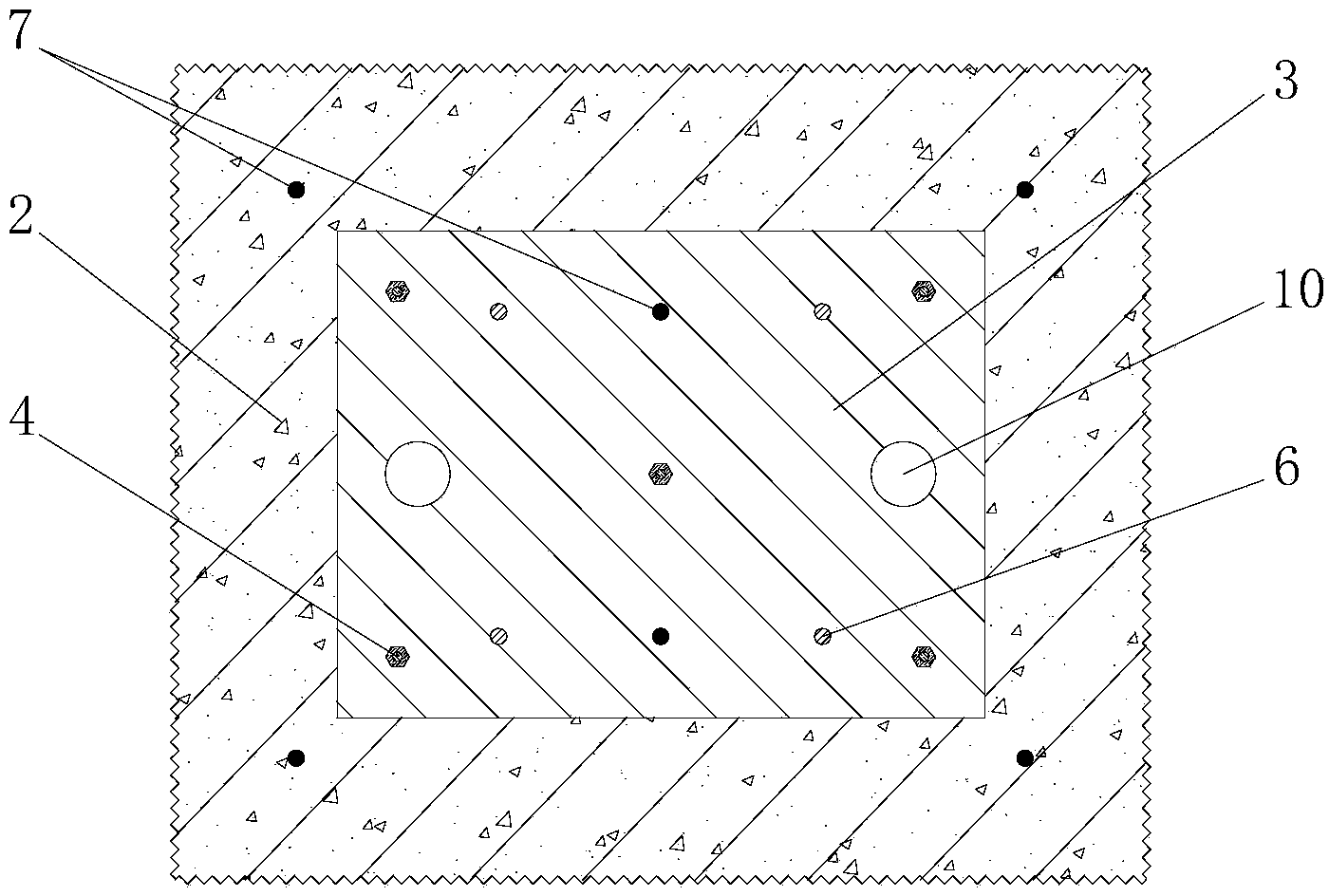

Steel structure and foundation pre-burying connection structure and construction method

ActiveCN104234070AImprove installation efficiencyHigh binding form strengthFoundation engineeringBuilding constructionsReinforced concreteArchitectural engineering

The invention relates to a steel structure and foundation pre-burying connection structure, which is characterized in that the pre-burying connection structure is integrally cast by a prefabricated component and a foundation bottom plate, the prefabricated component is a steel bar concrete connecting block with a connecting steel plate embedded in the upper surface, the periphery of the steel bar concrete connecting block is provided with reserved steel bars connected with steel bars arranged in a foundation, a plurality of steel structure connecting screw rods penetrating through the prefabricated component are arranged in a range of the connecting steel plate, and the lower parts of the connecting screw rods extend into the foundation. The connecting structure provided by the invention has the advantages that the connection intensity of the steel structure and the foundation can be effectively improved, the problems of bottom hollowing and the like due to non-compact casting of the bottom concrete of the traditional pre-burying component and nonuniform deformation of the steel plate and the concrete can be solved, and better technical and economic benefits are realized. The invention also discloses a construction method of the pre-burying connecting structure.

Owner:瑞洲建设集团有限公司

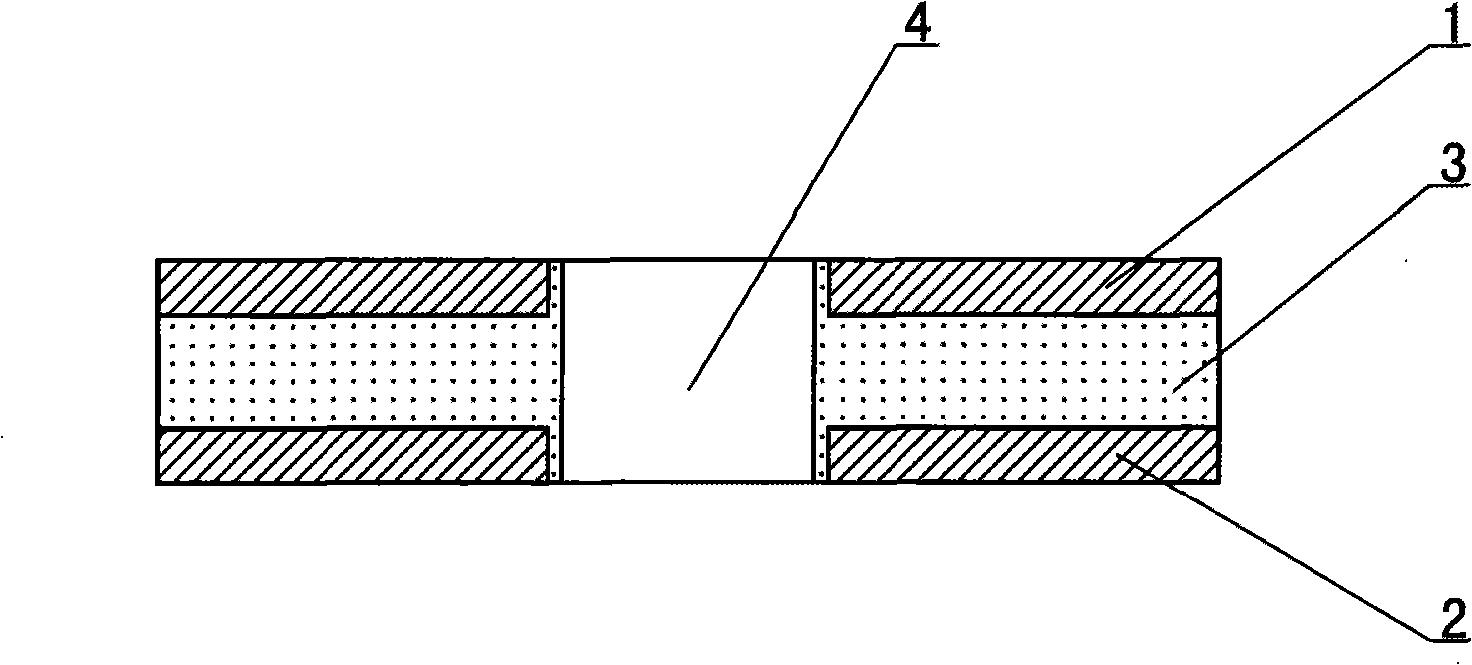

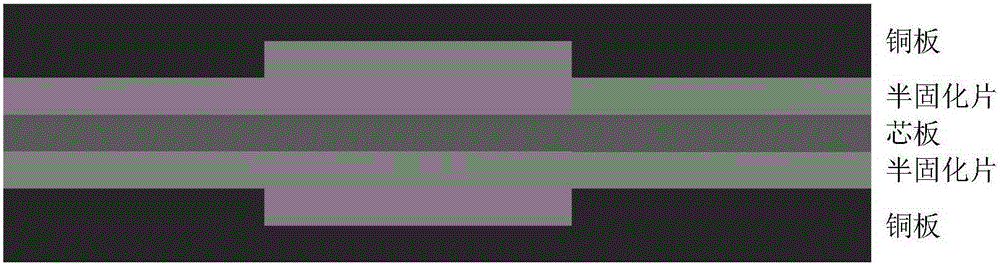

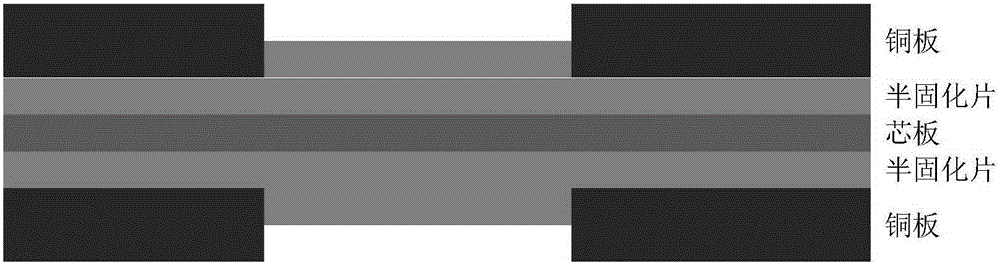

Manufacturing method for embedding heat radiating fin on printed circuit board

InactiveCN101257770AGood embedding effectSolve the problem of sagMultilayer circuit manufactureCooling/ventilation/heating modificationsHeat sinkPrinted circuit board

A making method for embedding fins on a printed circuit board includes following steps: 1) opening a tool hole on the position to be embedded with fins in a circuit board and a prepreg forming region, and drilling a pre-positioning hole outside of the forming region; 2) arranging the prepreg between two adjacent circuit board, pre-positioning the circuit boards and the prepreg through the pre-positioning hole; 3) arranging fins in the tool hole in a stitching pre-lamination process; 4) stitching the circuit boards and the prepreg to fill the gap between the tool hole and fins by flowing latex, the prepreg cures automatically during stitching, combining the fins and the circuit boards; 5) mechanical brushing and grinding board elements, cleaning residual prepreg material on surfaces of circuit boards. The invention avoids the inanition phenomenon, solves depression or protrusion of circuit board surfaces, reduces abnormal wear of grinding brush wheels in following process, thereby the embedding effect of fins is good.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

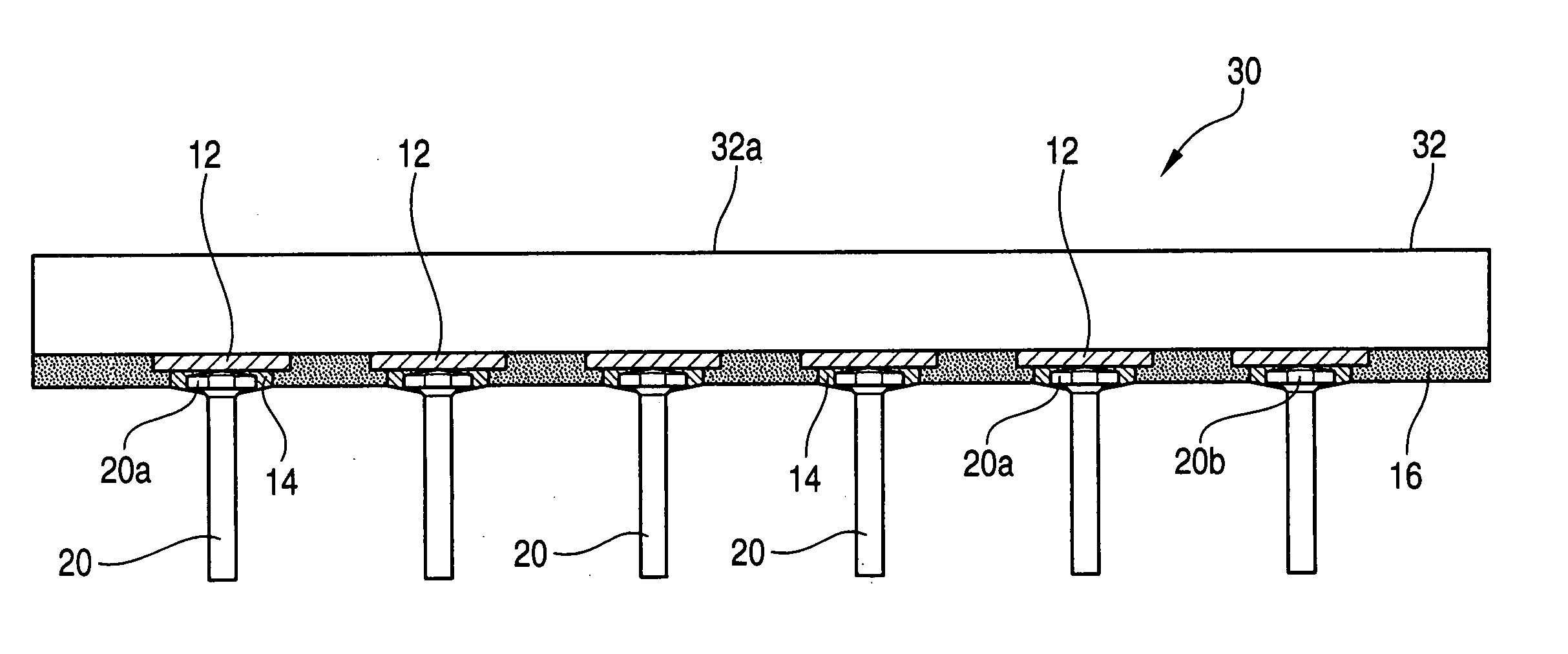

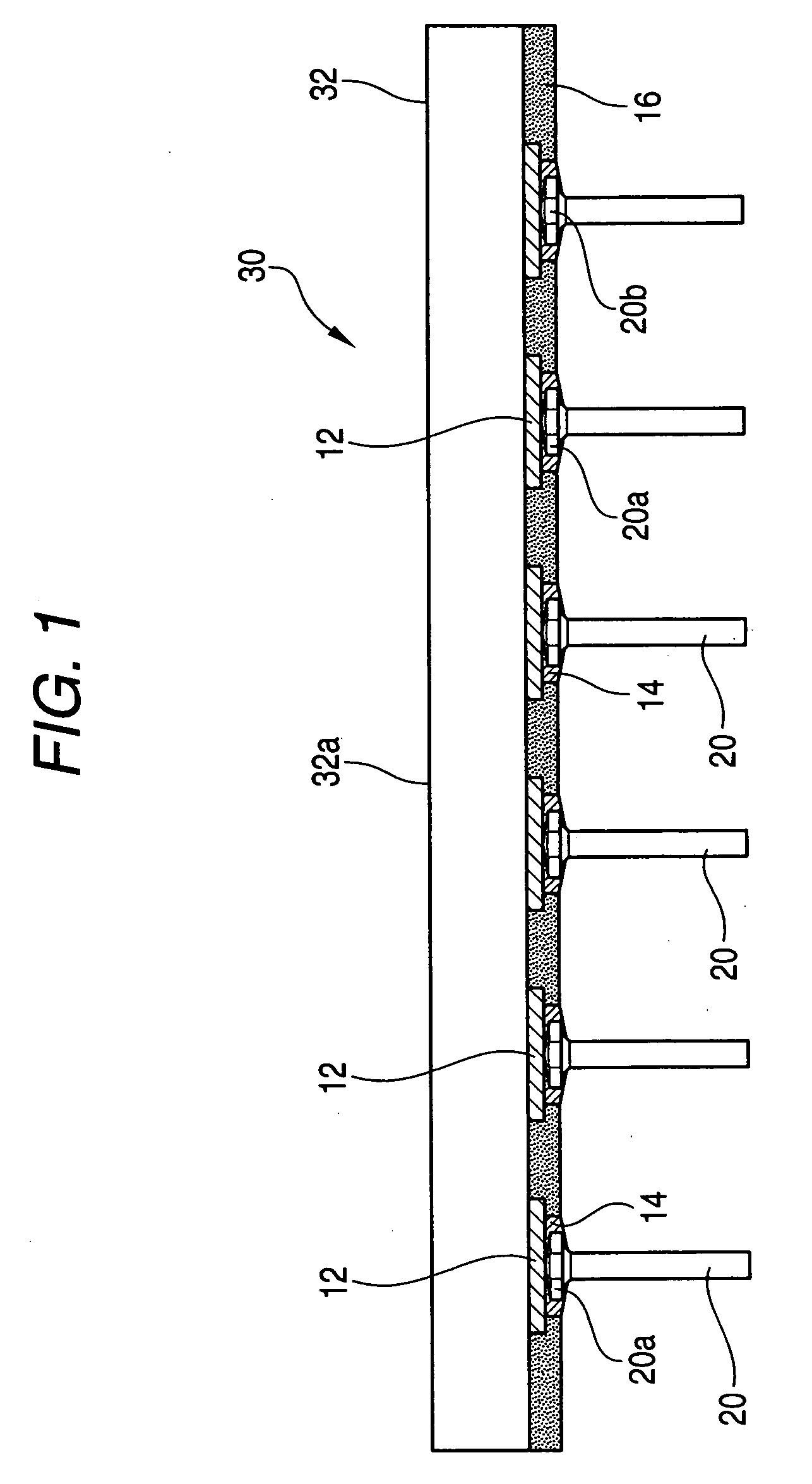

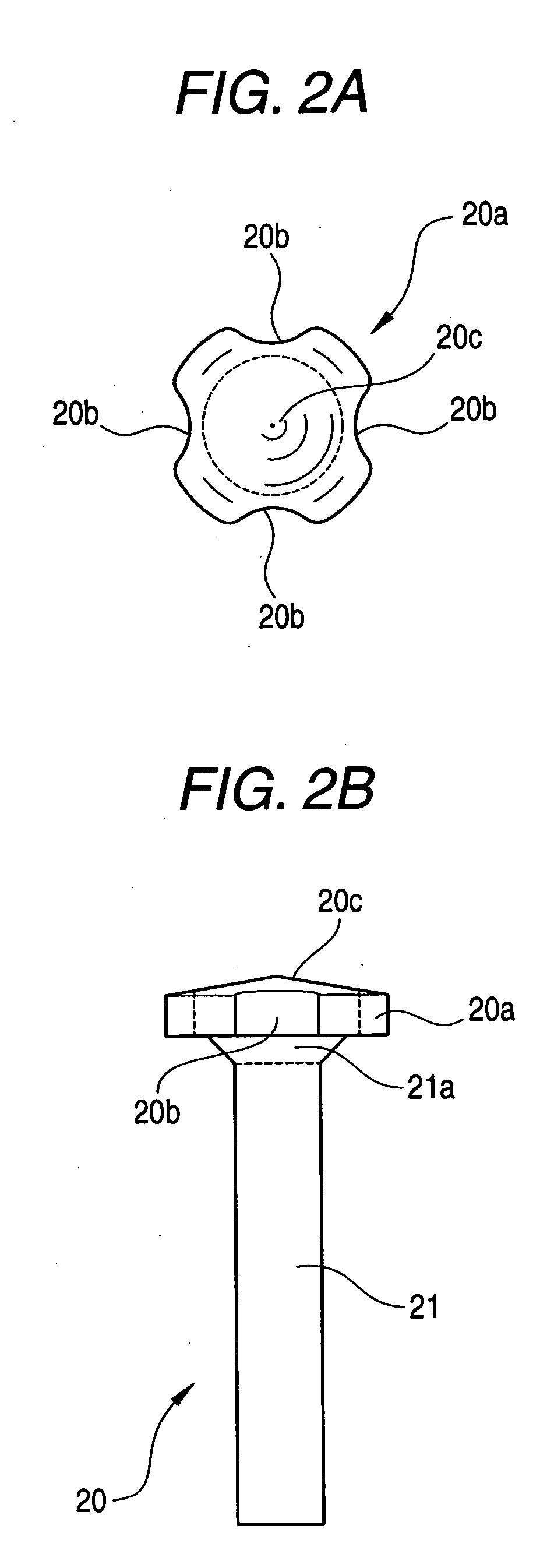

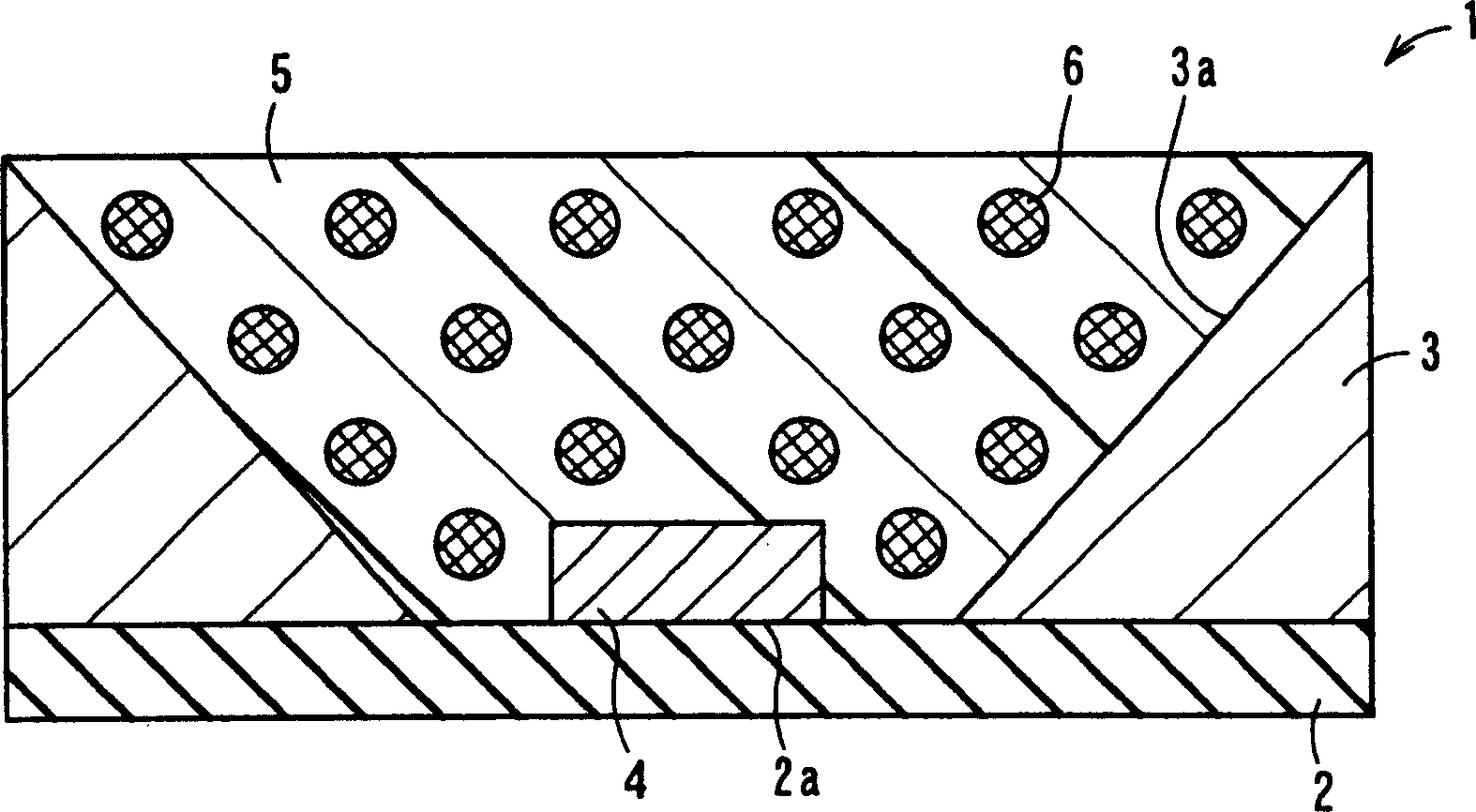

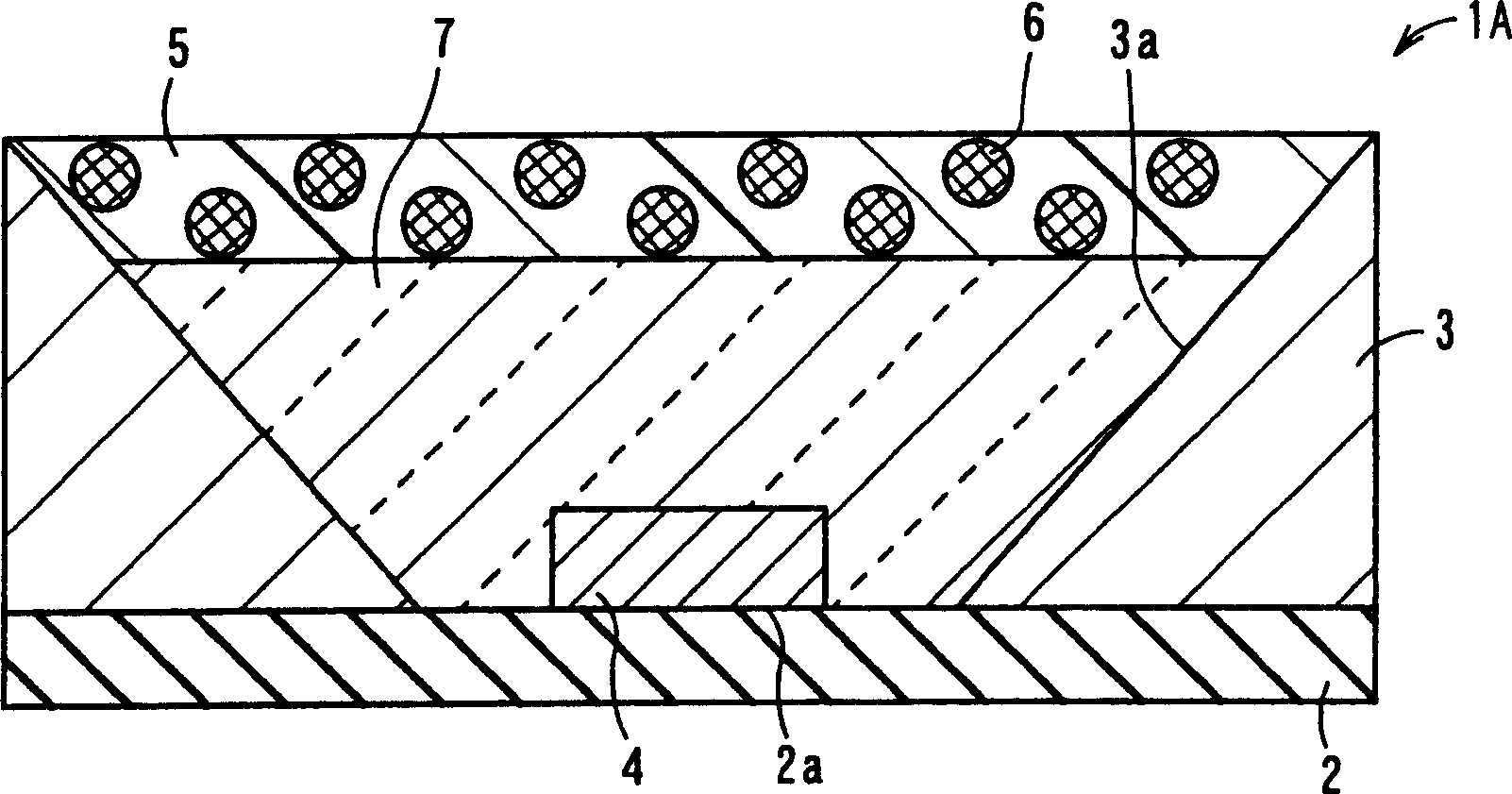

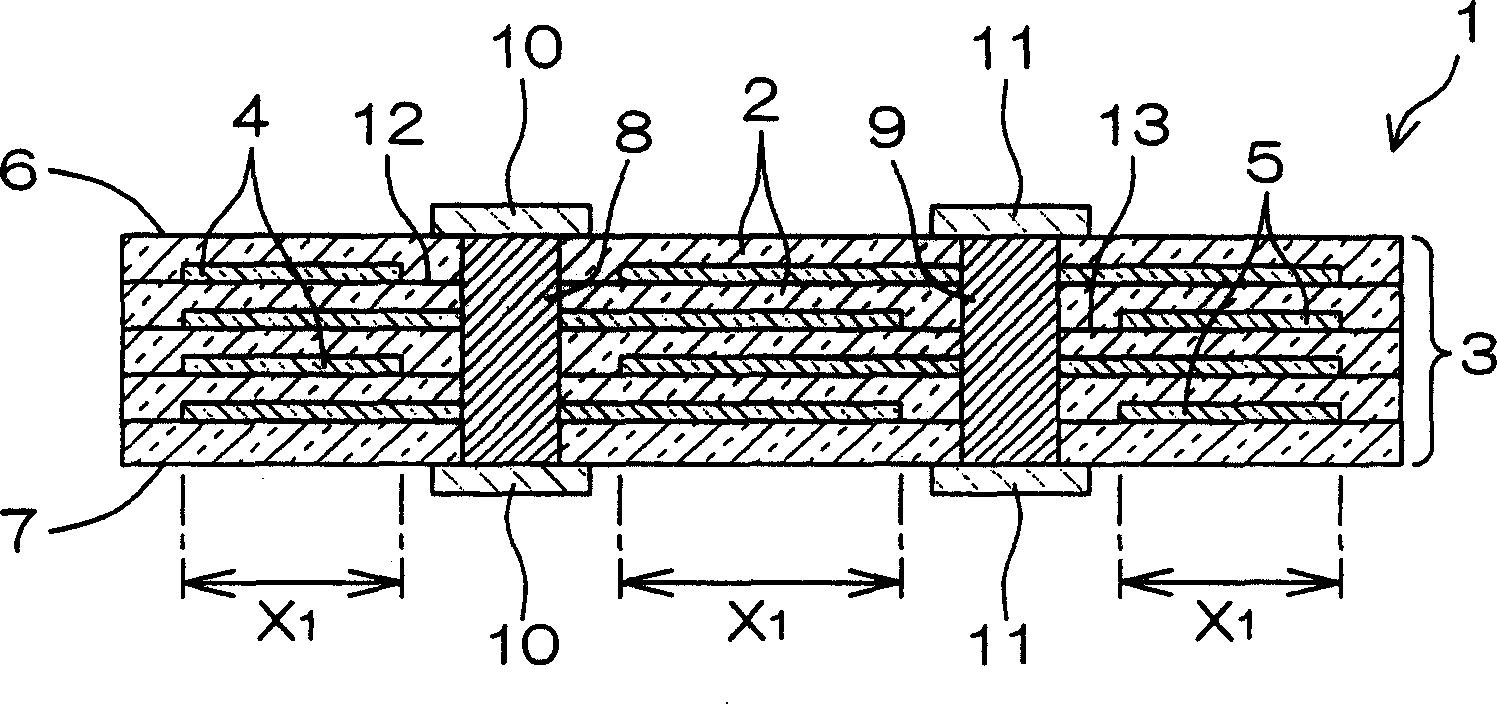

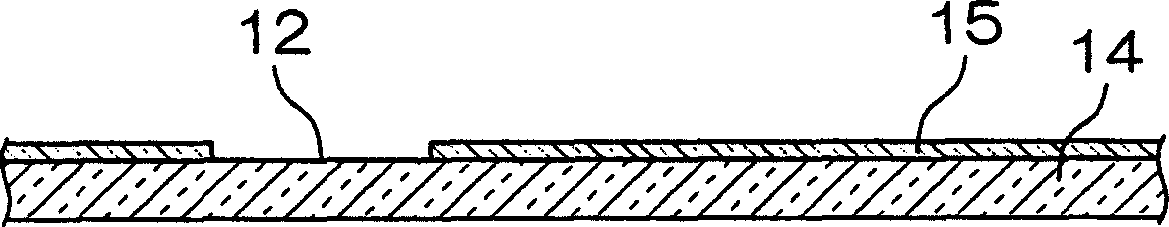

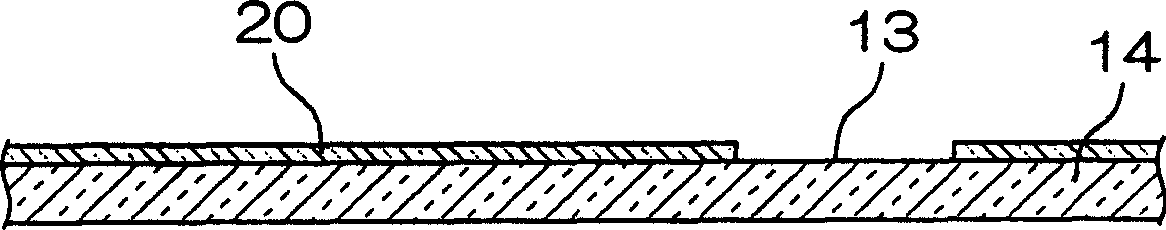

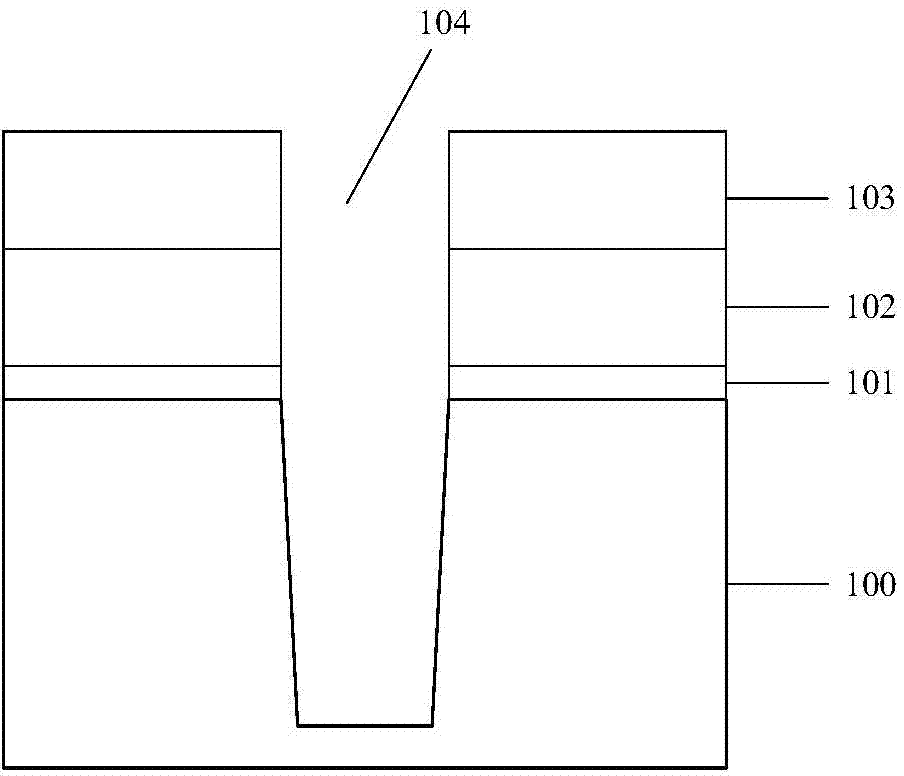

Wiring board with lead pins, and lead pin

ActiveUS20080009155A1High reliabilityAvoid voidsLine/current collector detailsFinal product manufactureBonding strengthNormal position

A wiring board with lead pins having high reliability is provided. When the lead pins are attached to electrode pads, the lead pins are attached to the electrode pads without leaving voids in a conductive agent, and bonding strength of the lead pins are improved. When the wiring board to which the lead pins are attached is reheated, the lead pins are prevented from being inclined or shifted from their normal positions. In the wiring board with lead pins formed by attaching head portions of the lead pins to the electrode pads formed on the wiring board through the conductive agent, the lead pin has notch portions are formed in cut-out shapes in peripheral edge portion of the disk shaped head portion.

Owner:SHINKO ELECTRIC IND CO LTD

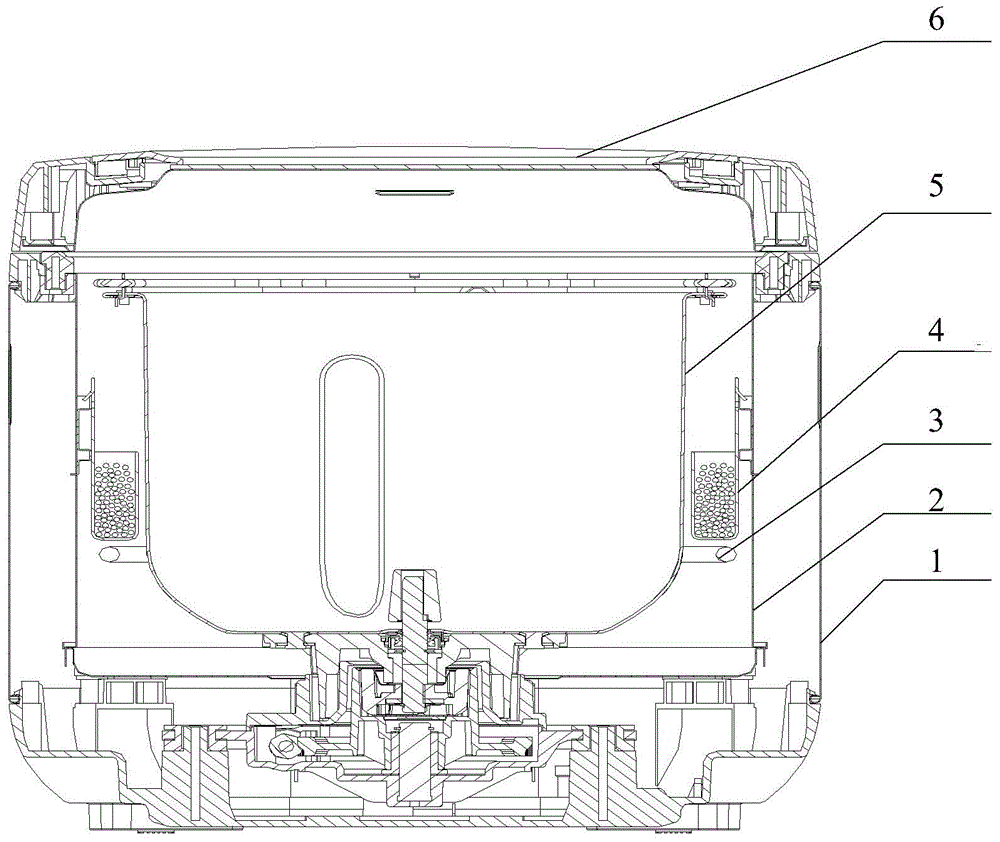

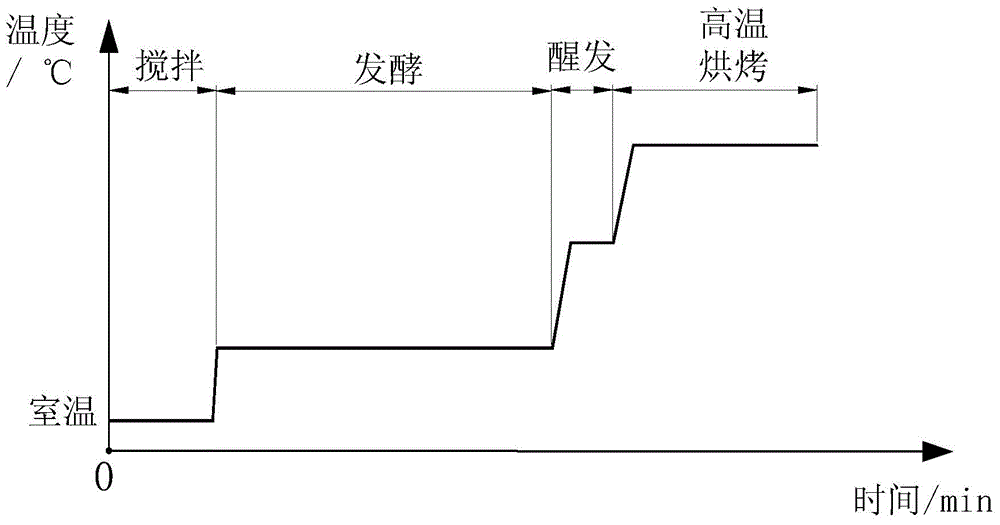

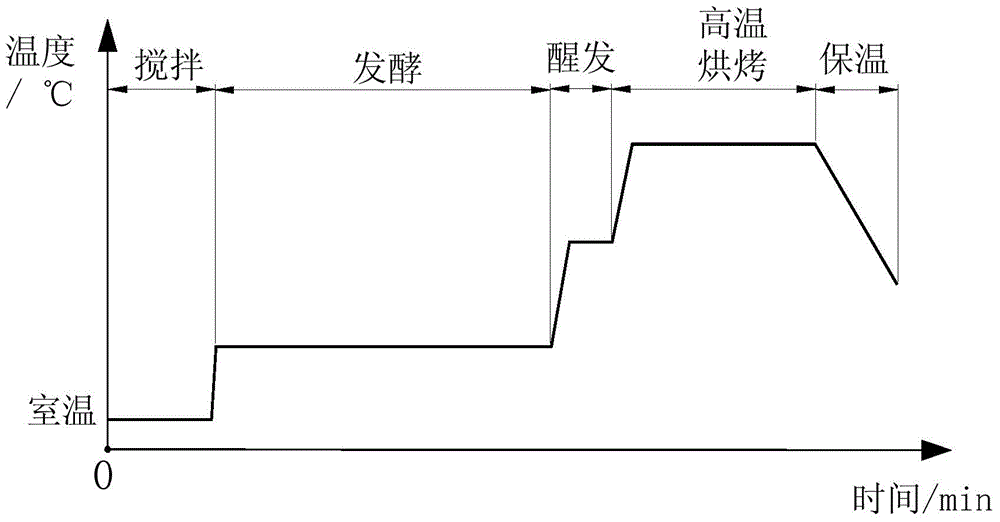

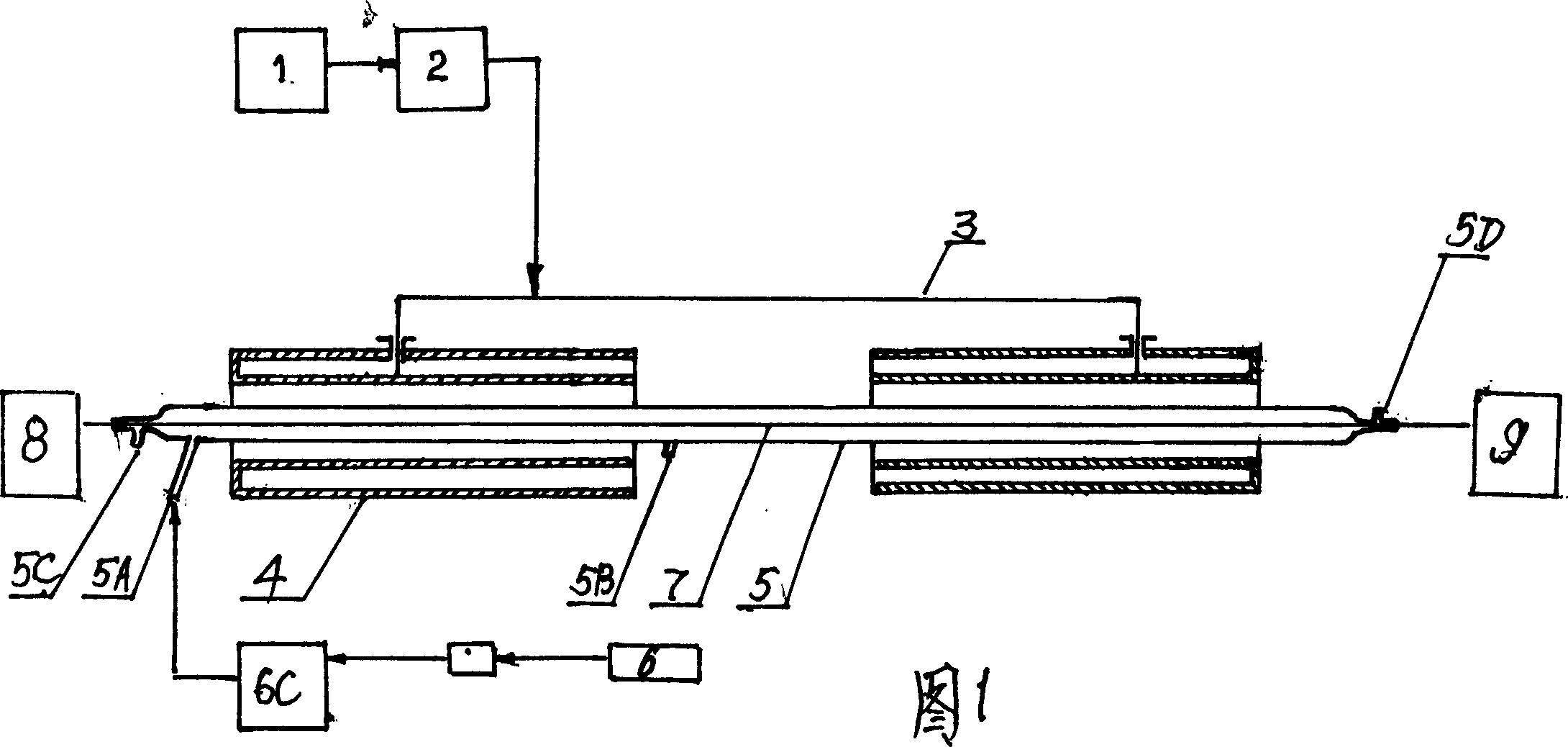

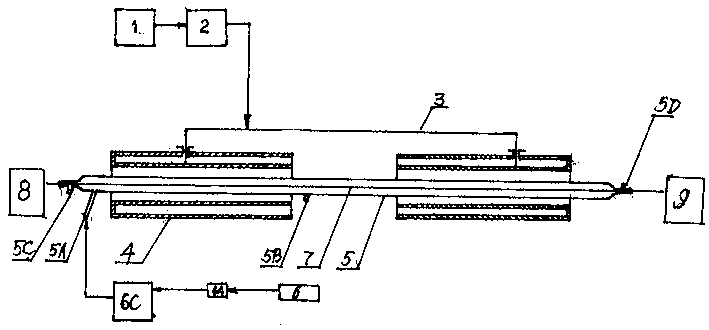

Bread making method

The invention provides a bread making method. A bread machine is used for making bread, the bread machine consists of a bread bucket and an oven bucket, a steam device is arranged between the bread bucket and the oven bucket, and the steam device is used for generating steam under the heating action of a heating element arranged on the inner side wall of the oven bucket. The making method comprises the following steps: firstly, putting bread raw materials in the bread bucket, and forming a bread dough under the stirring action of a stirring piece, wherein the stirring time is 20 to 40 min; secondly, controlling the temperature inside the bread machine to be 28 to 35 DEG C, and fermenting the bread blanks for 50 to 90 min; thirdly, controlling the temperature inside the bread machine to be 50 to 80 DEG C and the relative humidity to be 80% to 90%, and finally fermenting the fermented bread dough for 20 to 30 min; fourthly, controlling the temperature inside the bread machine to be 110 to 140 DEG C, and carrying out high-temperature baking on the bread dough after final fermentation to make the bread. The bread making method provided by the invention solves the technical problem that bread skins of the bread made by an existing bread making method are relatively thick as well as brown and crisp.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Repairing method of carbon fiber surface defect

InactiveCN1461829AImprove mechanical propertiesAvoid voidsArtificial filament chemical after-treatmentFiberCarbon fibers

A process for reparing the surface defects on the surface of carbon fibre by gas-phase deposition method includes such steps as preparing an acetylene reaction environment, putting the defective carbon fibres in it, heating by focused electromagnetic field to crack the acetylene into H2 and carbon atoms, and depositing the carbon atoms on the surface of carbon fibres.

Owner:陈新谋

Ultra-thick copper circuit board and manufacturing method thereof

ActiveCN105188269AGuaranteed stabilityAvoid over erosionPrinted circuit aspectsConductive material chemical/electrolytical removalPrinting inkCopper

The invention relates to an ultra-thick copper circuit board and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) etching partial thickness of a non-circuit-pattern area copper plate on one side of the copper plate by adopting an etching process to form a groove, and carrying out the lamination step on the side by virtue of a binding layer; (2) drilling, metalizing the hole, etching the rest thickness of the non-circuit-pattern area copper plate on the other side of the copper plate by adopting the etching process to obtain a circuit pattern; (3) carrying out the printing resistance soldering steps: printing resin onto the non-circuit-pattern area, drying, and then printing ink onto the entire circuit board; and (4) carrying out the subsequent procedures. By adopting the method, the copper plate of 80Z or more is realized, and the blank that a multilayer ultra-thick copper circuit board cannot be manufactured in the industry is filled; moreover, the manufacturing method is simple, the manufacturing method can be realized by adopting a circuit board conventional device, and the manufactured ultra-thick copper circuit board is good in yield and reliable in performance.

Owner:GCI SCI & TECH

Light-emitting apparatus and illuminating apparatus

InactiveCN1674317AIncrease the intensity of radiant lightReduced light extraction efficiencyOther plywood/veneer working apparatusMechanical surface treatmentPhosphorLight emitting device

There is provided a light-emitting apparatus with favorable radiation light intensity, which is excellent in light extraction efficiency, color temperature and color rendering property. The light-emitting apparatus includes a light-emitting element, a base body having, on its top surface, a placement portion for emplacing thereon the light-emitting element, a frame body attached to the top surface of the base body so as to surround the placement portion, a light transmitting member disposed inside the frame body so as to cover the light-emitting element, and phosphors contained in the light transmitting member, which performs wavelength conversion on the light emitted from the light-emitting element. The light transmitting member has a pre-cured viscosity ranging from 0.4 to 50 Pa.s.

Owner:KYOCERA CORP

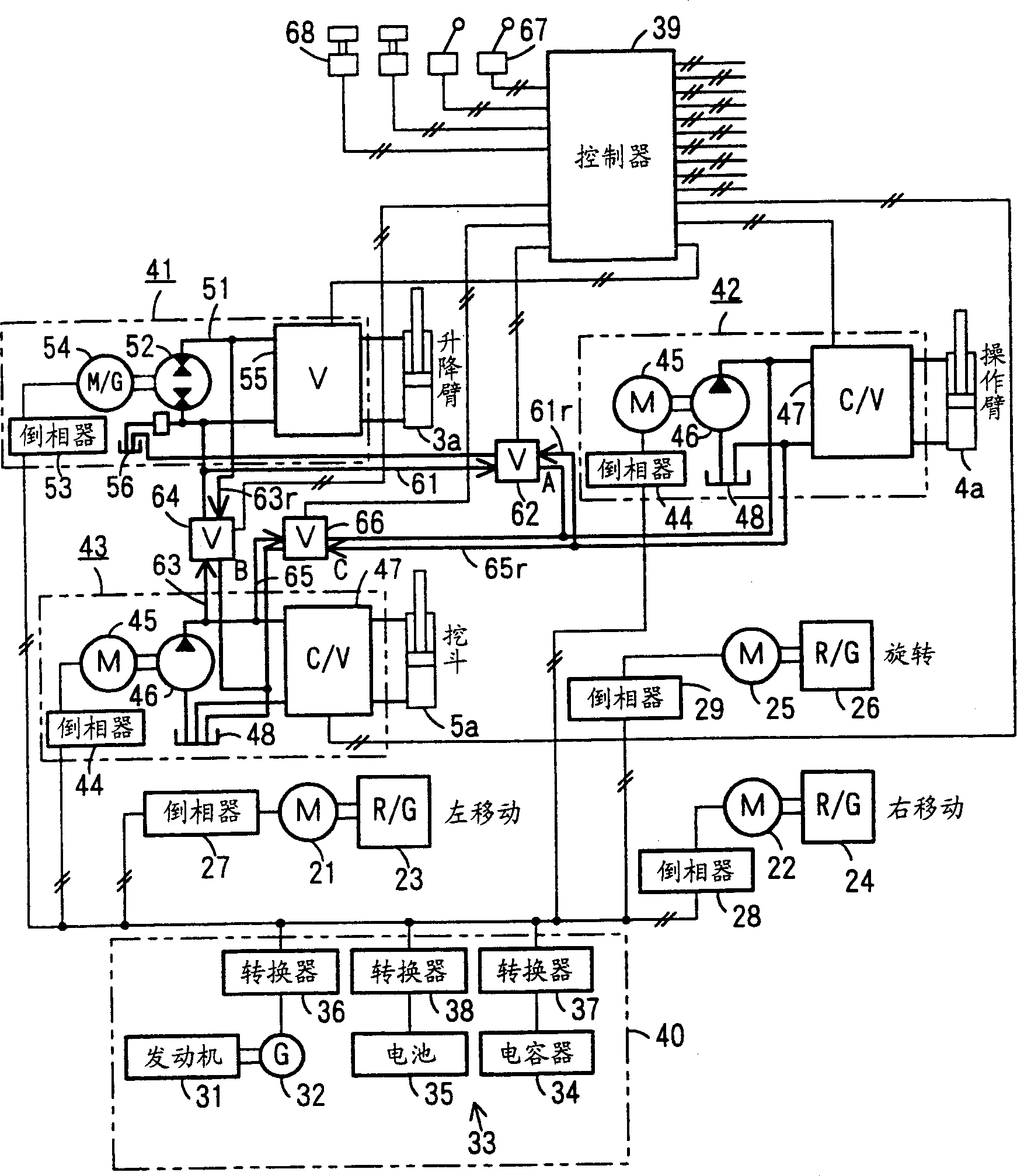

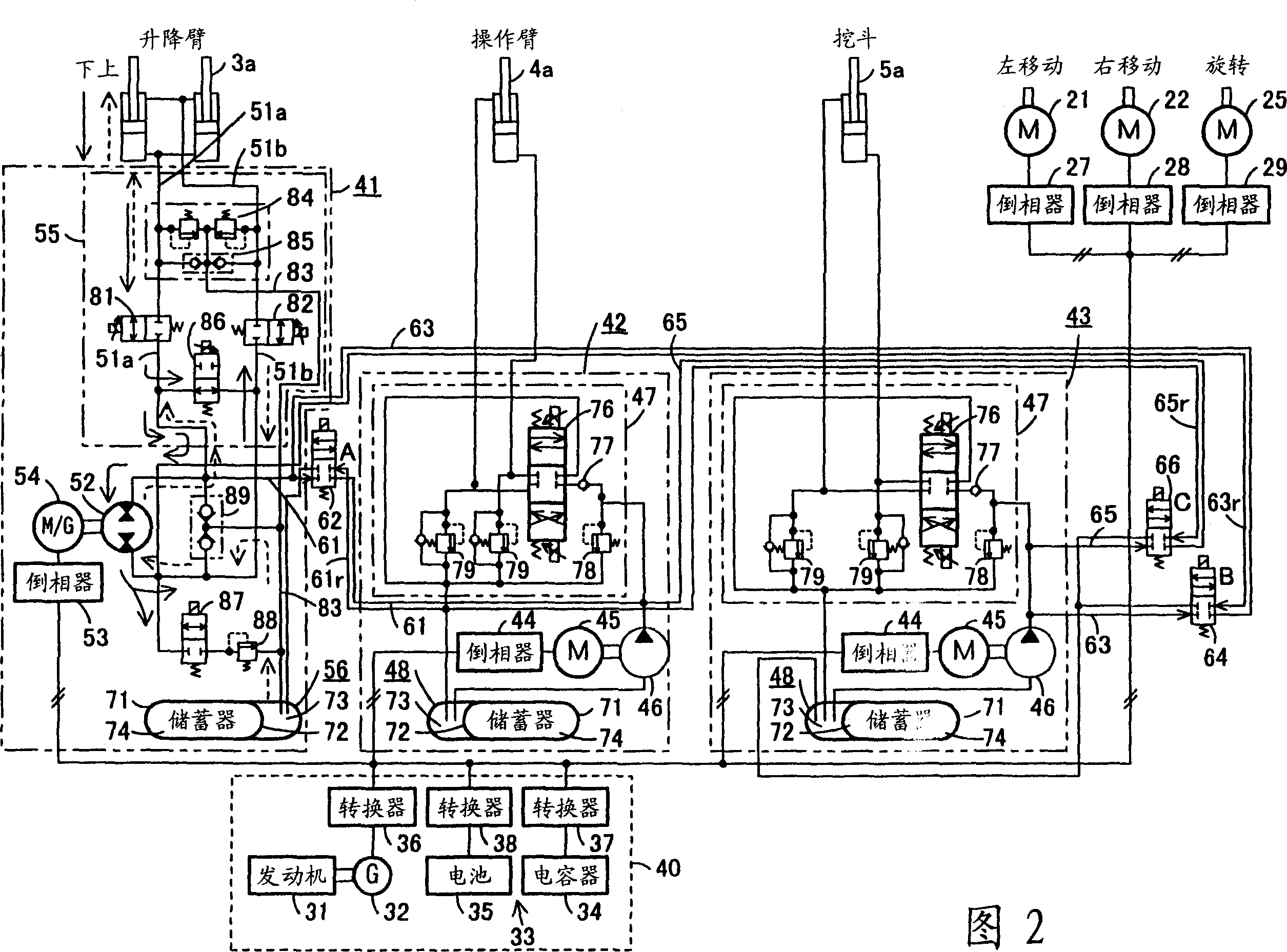

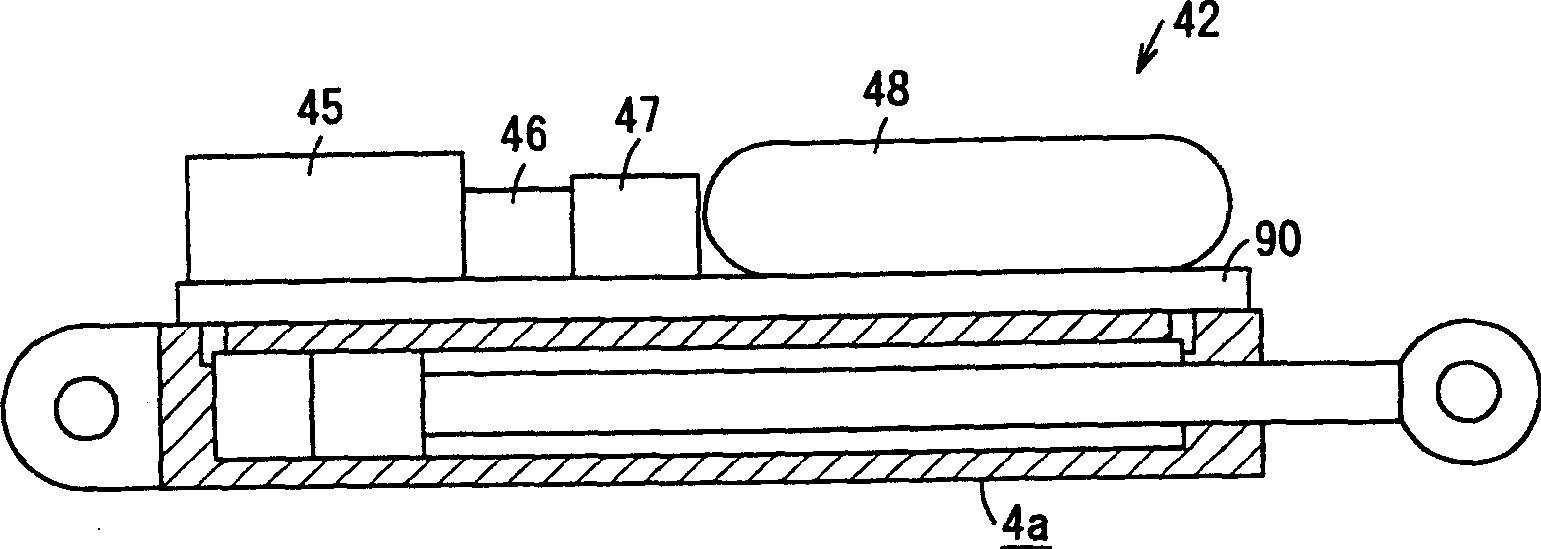

Working machine driving unit

InactiveCN1685161AReduce the numberLow costServomotorsServometer circuitsElectric power systemEngineering

A driving device of a work machine includes a power generator adapted to be driven by an engine, and a power storage device for storing the electric power generated by the power generator. Electric motors and a motor generator, both adapted to be operated by electric power supplied from either one or both of the power generator and the power storage device respectively drive pumps and a pump motor. Supporting circuits for feeding supporting hydraulic oil are provided between a plurality of driving circuits that drive a plurality of hydraulic actuators of a working unit by oil hydraulics generated by the pumps and the pump motor. By enabling the plurality of driving circuits to effectively share excess energy, the invention makes possible a compact construction of a driving device of a work machine.

Owner:CATEPILLAR SARL

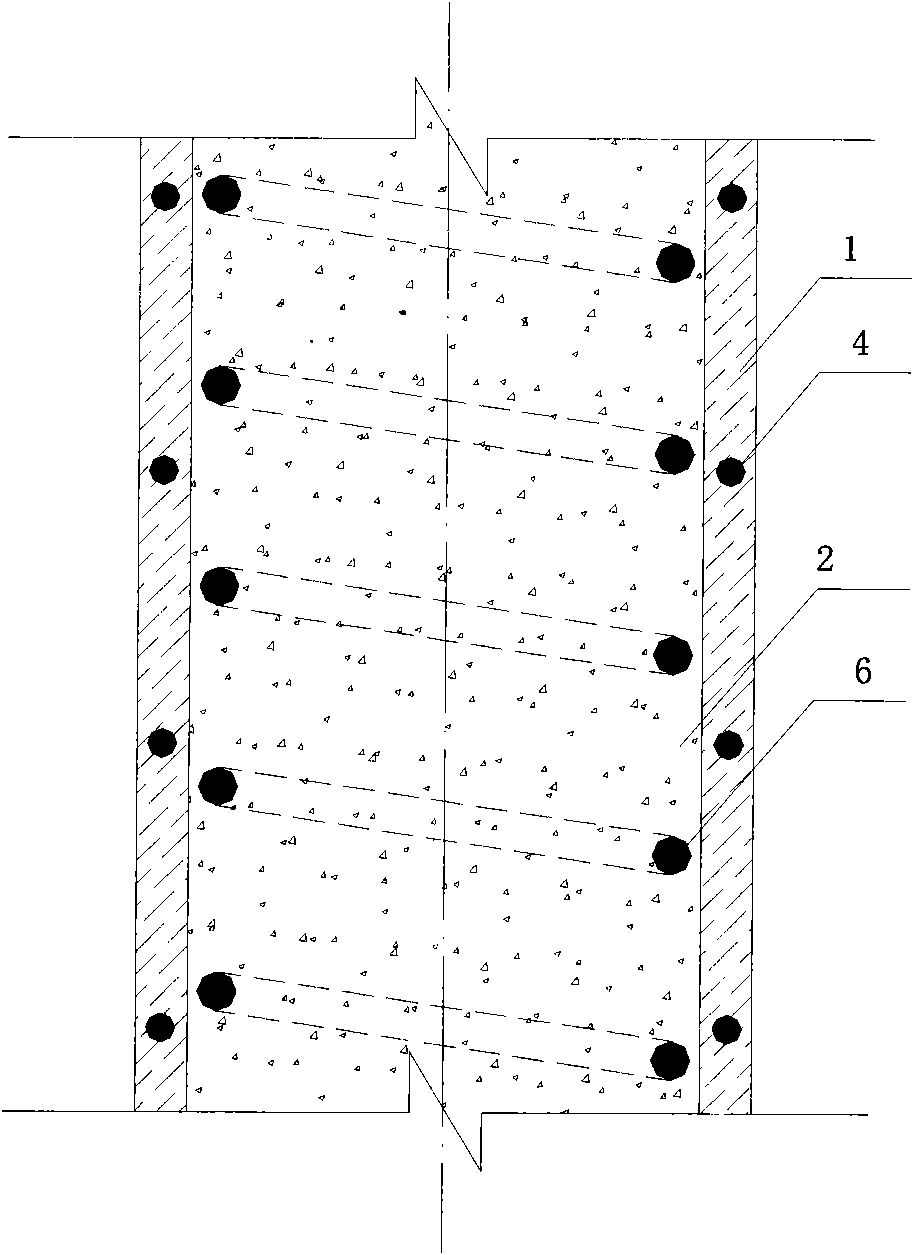

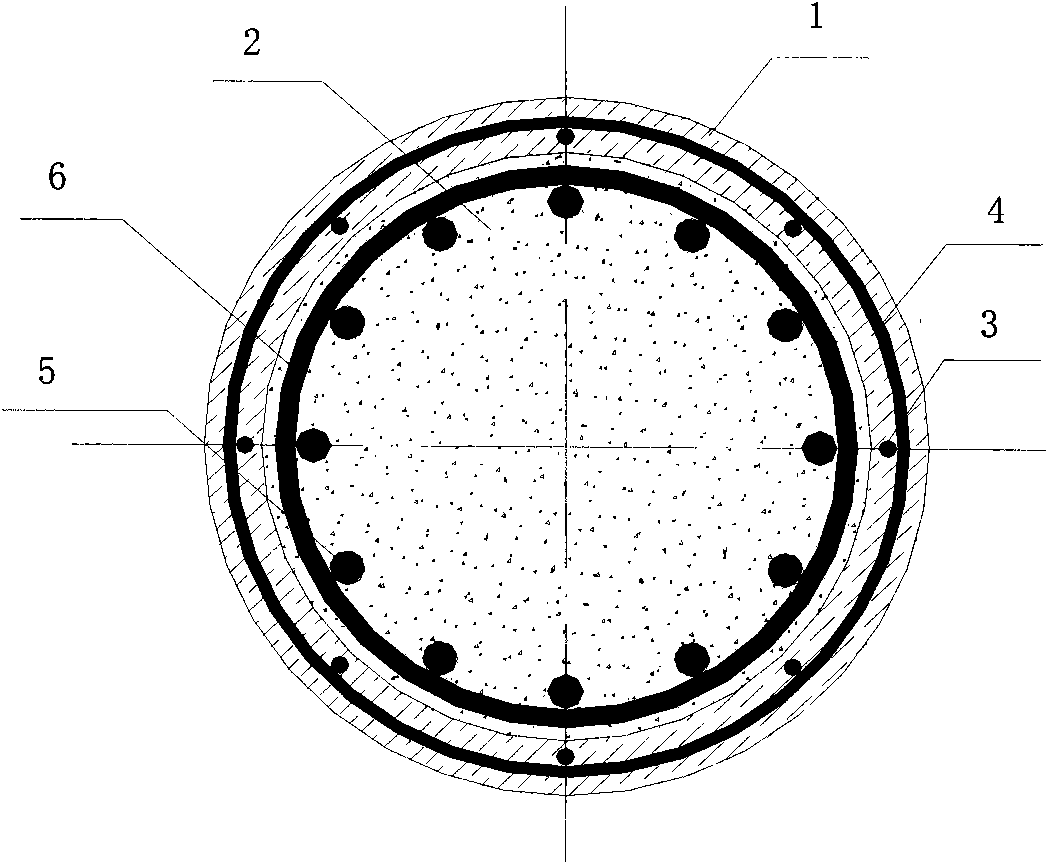

Sleeve reinforced concrete column

InactiveCN102102423AGive full play to the material performanceEasy constructionStrutsPillarsReinforced concrete columnShock resistance

The invention discloses a sleeve reinforced concrete column. The sleeve reinforced concrete column is characterized in that: a sleeve (1) of a reinforced concrete column (2) is a prefabricated active powder concrete sleeve. The sleeve reinforced concrete column has the advantages of convenience for construction, low cost, high axial bearing capacity, good shock resistance, predominant fireproof performance, excellent durability and the like, meanwhile, saves more resources and energy, and accords with the requirements of sustainable development.

Owner:HUNAN UNIV

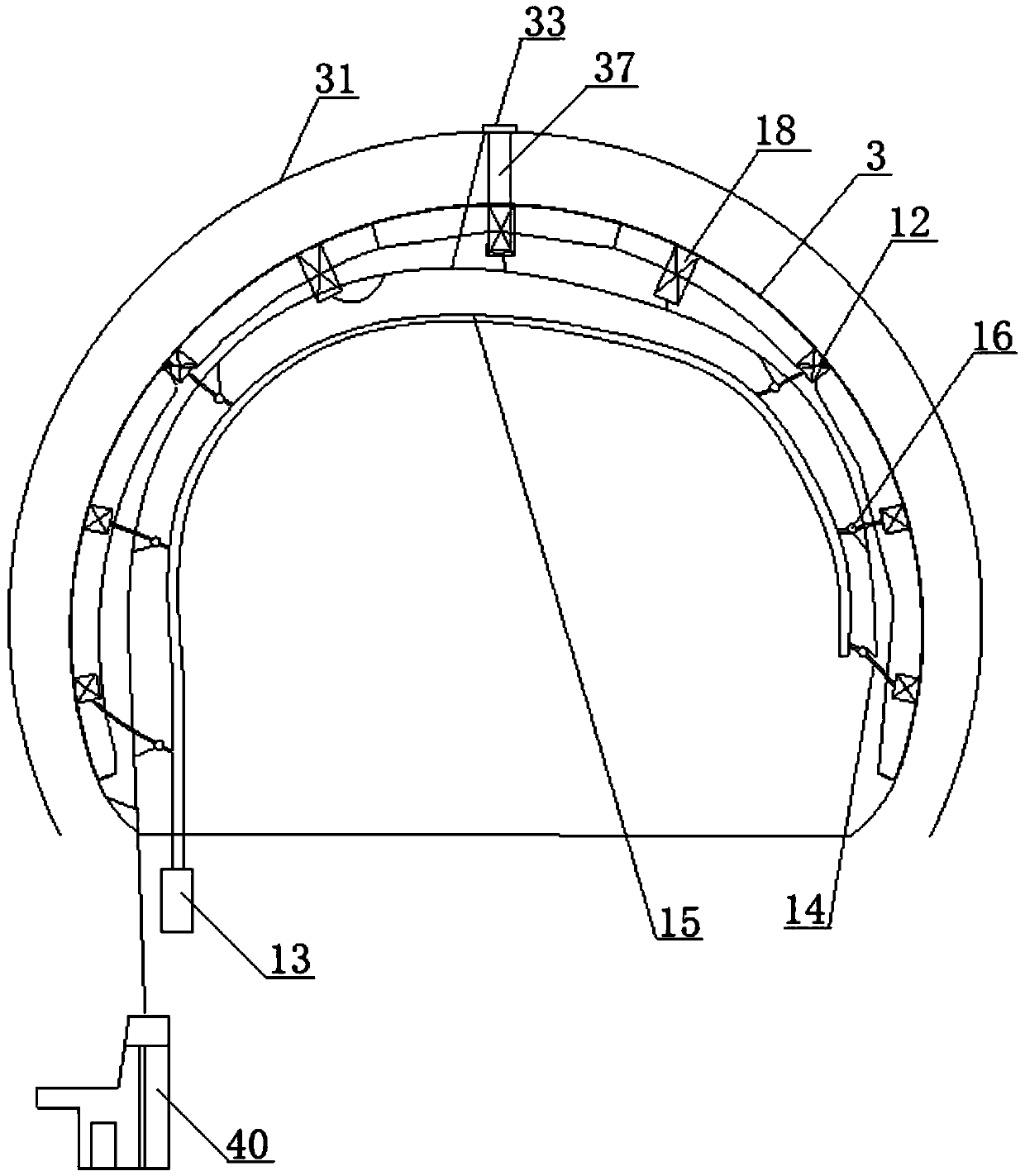

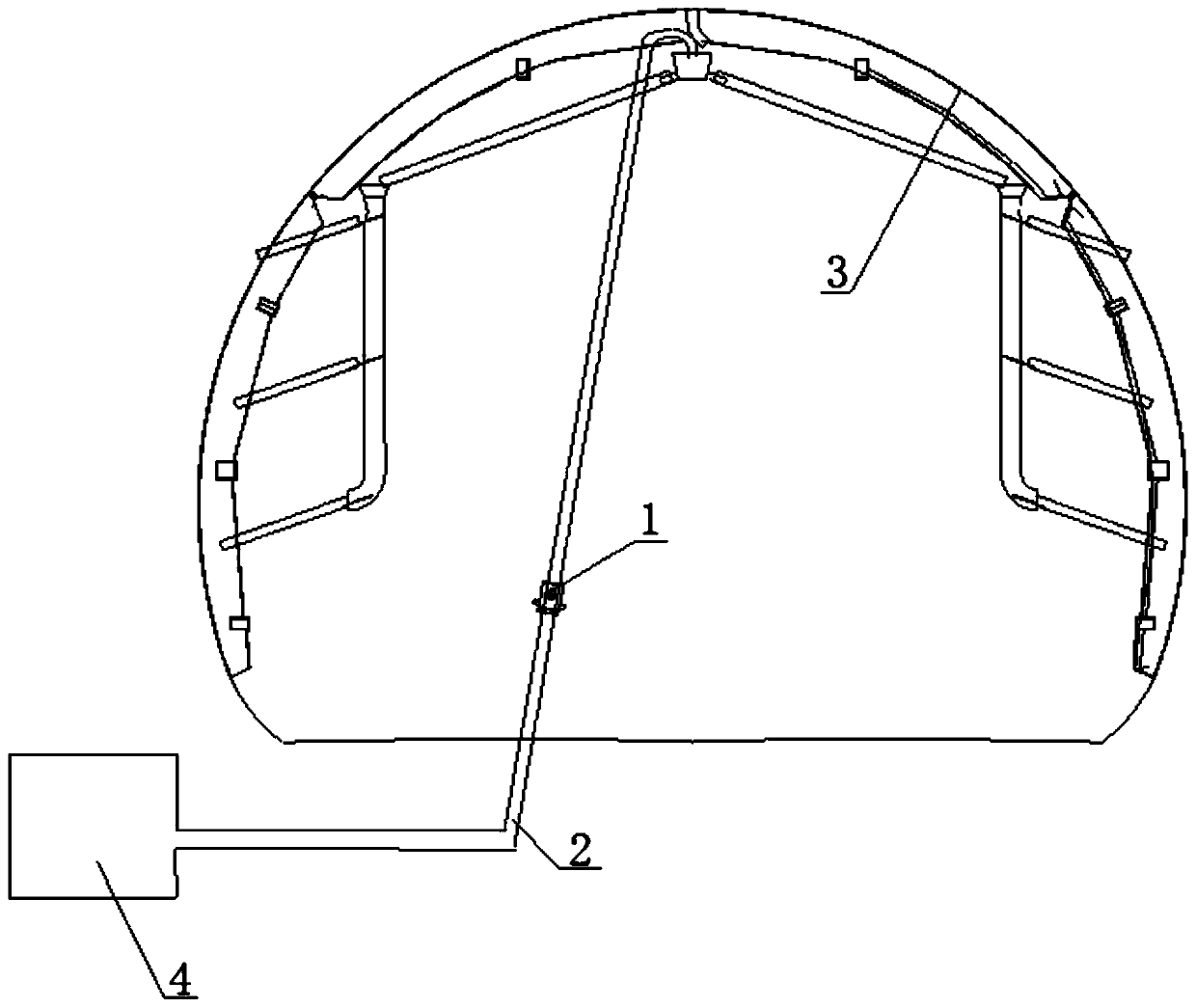

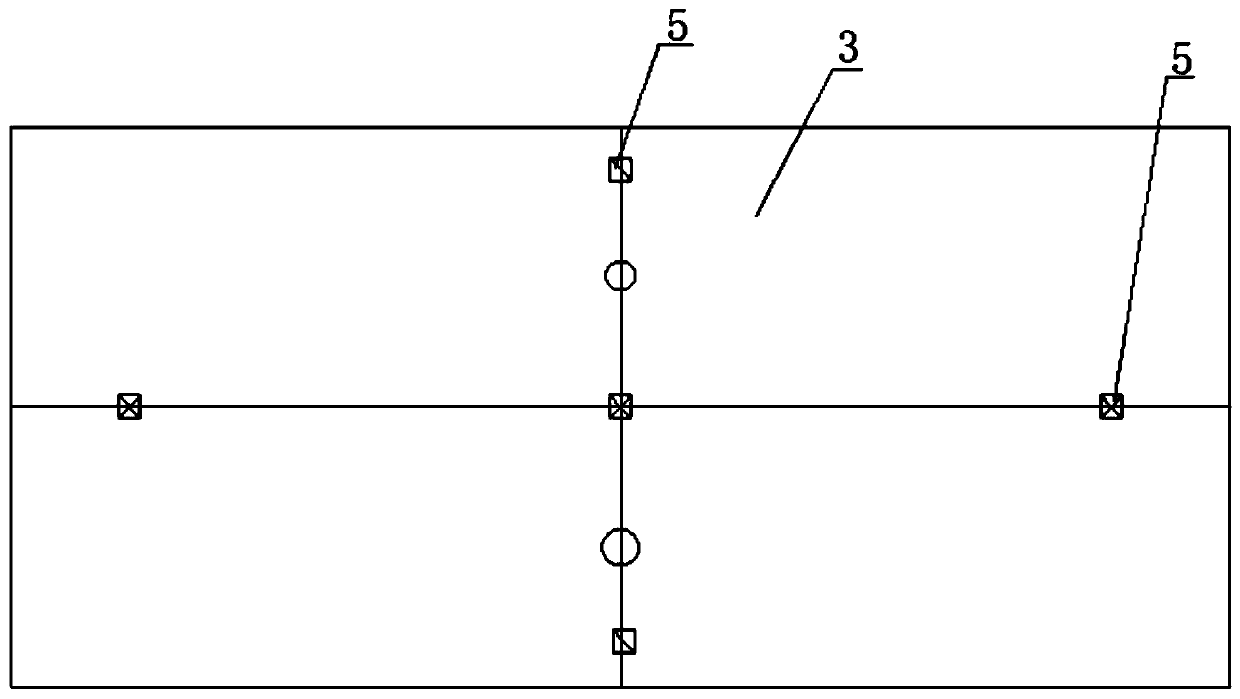

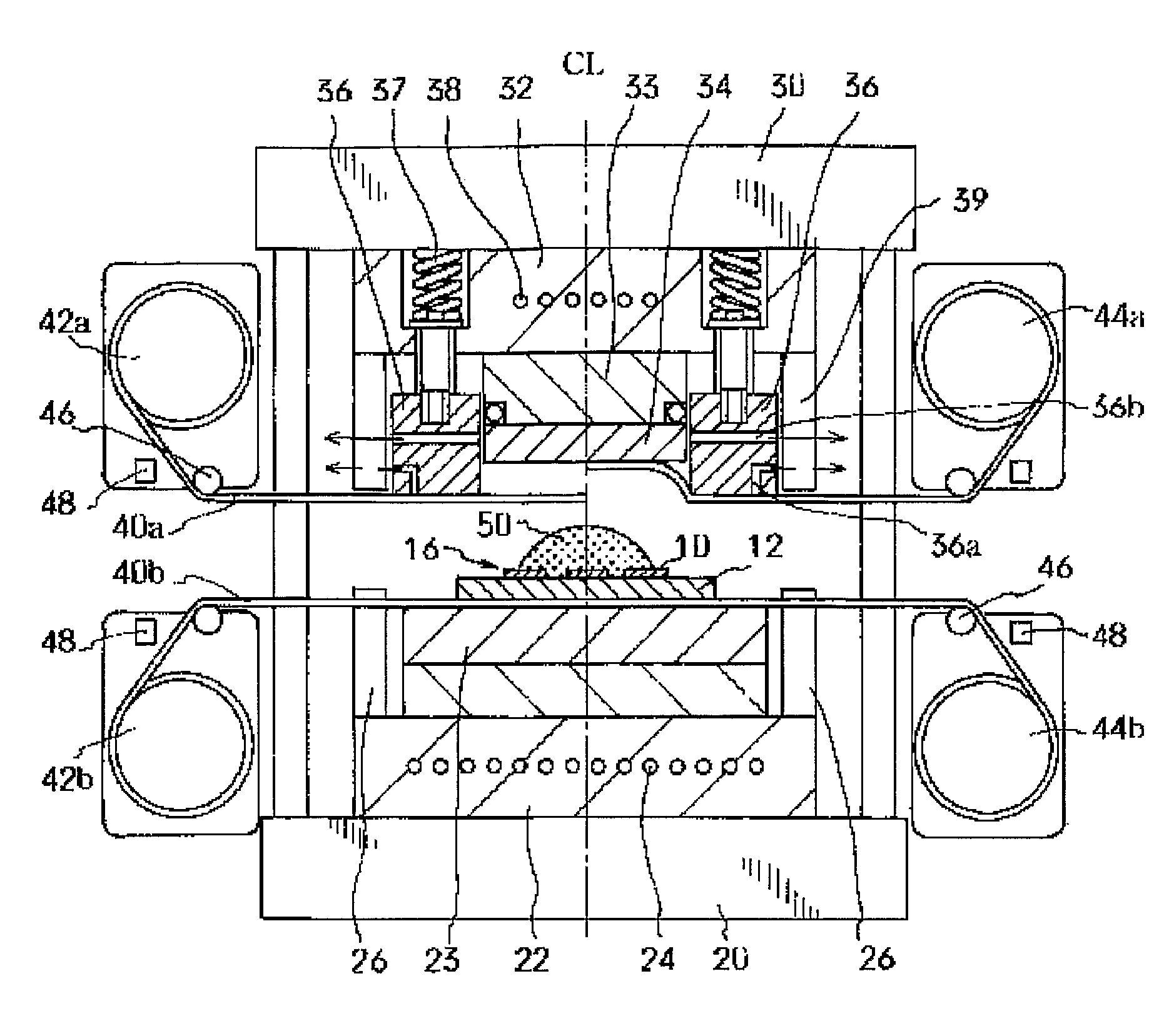

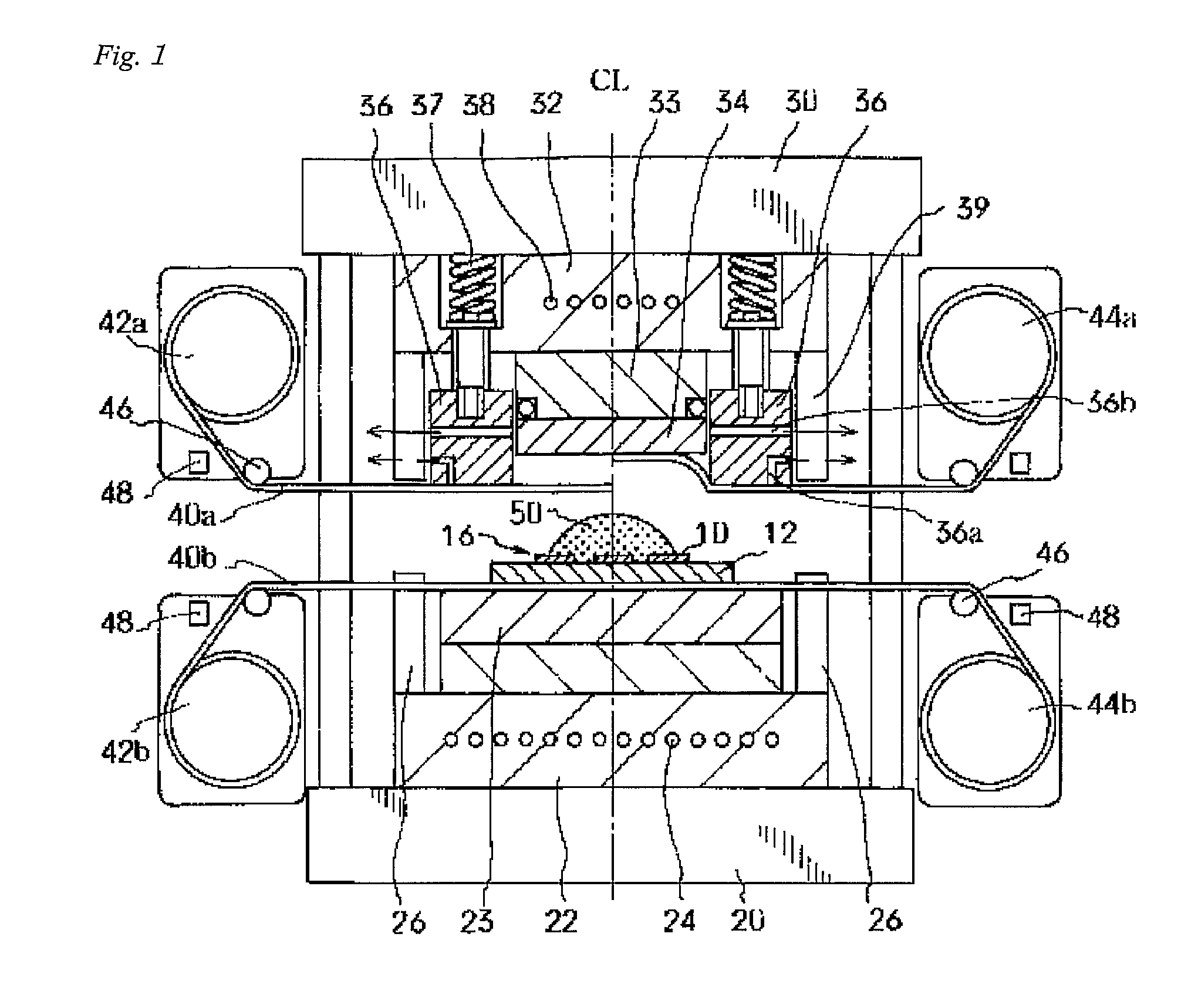

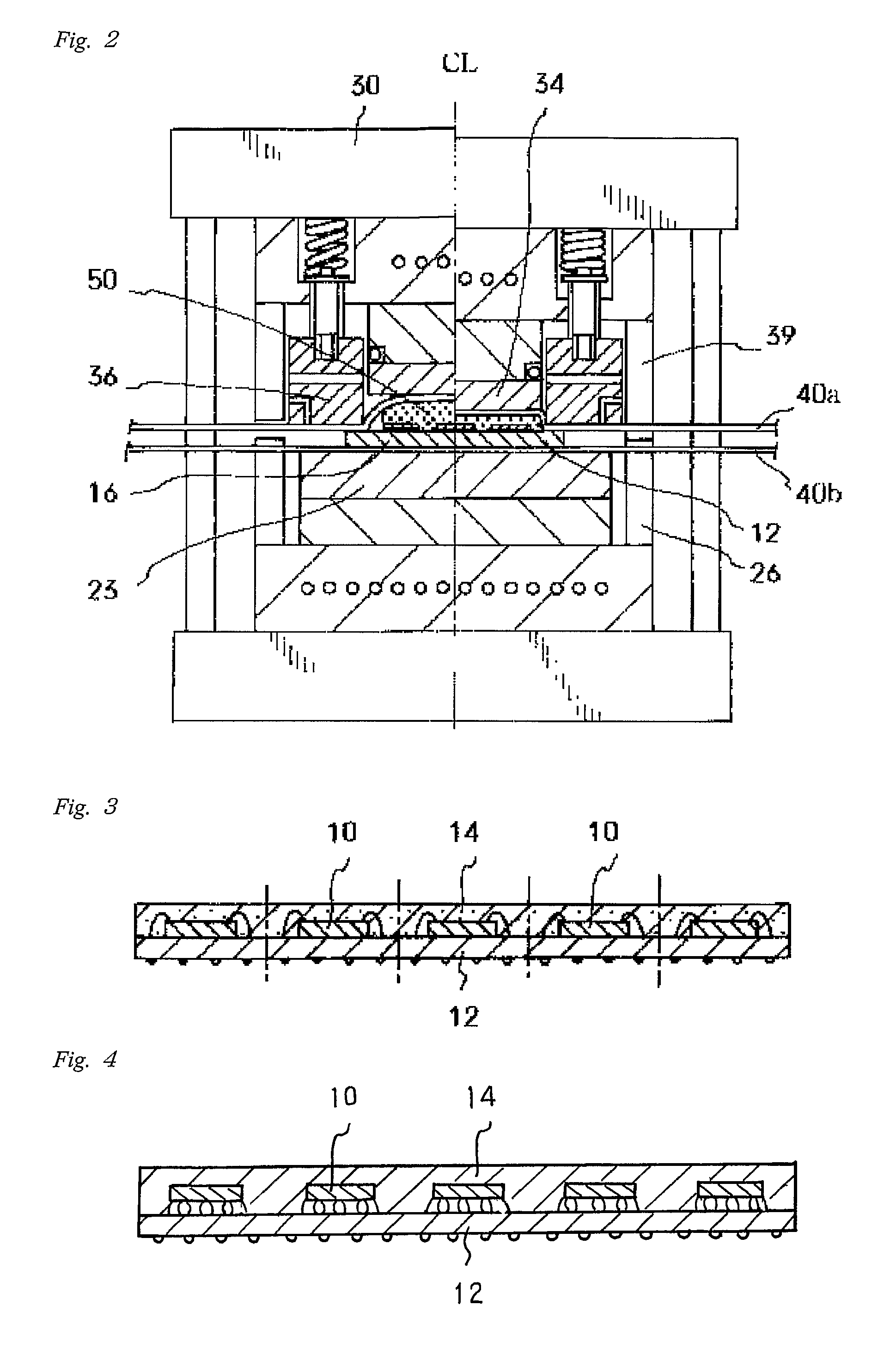

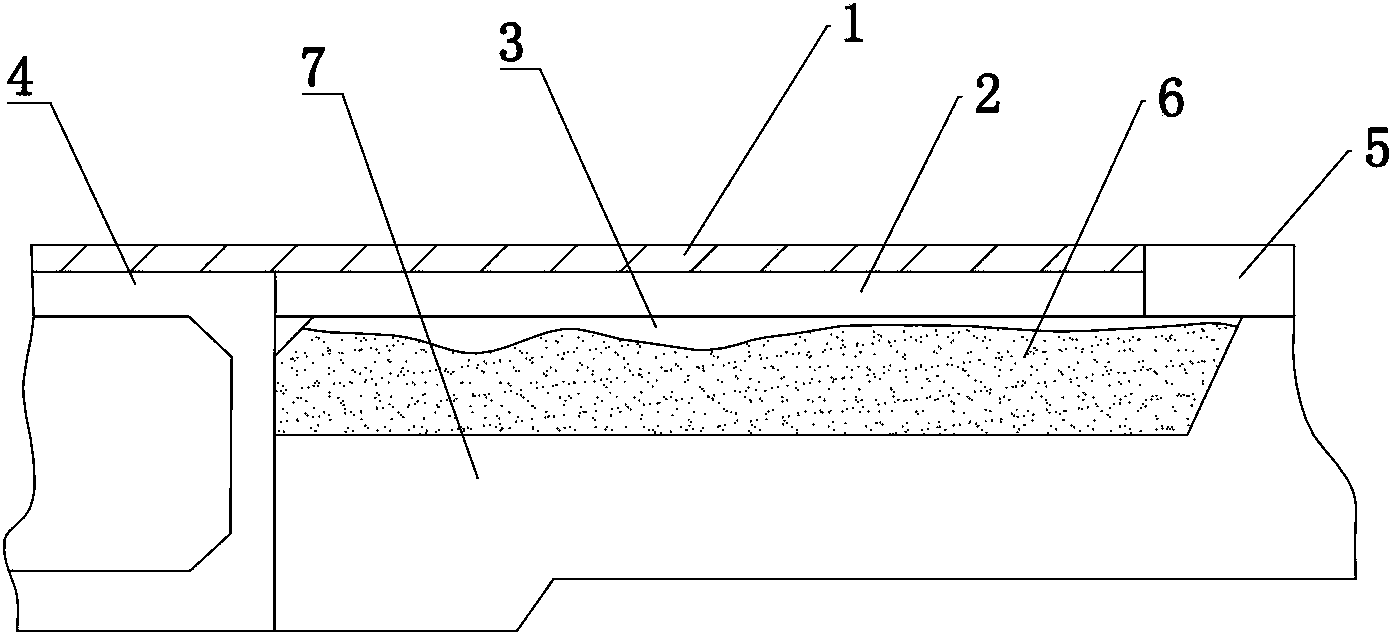

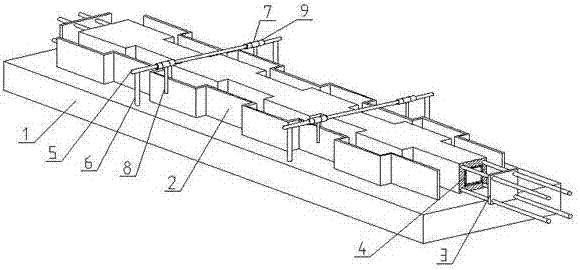

Construction method of tunnel two-lining concrete pouring system

ActiveCN109826649AWon't crackQuality assuranceUnderground chambersApparatus for force/torque/work measurementPressure senseEngineering

The invention relates to a construction method of a tunnel two-lining concrete pouring system, which comprises the following steps of: carrying out full-coverage scanning on a primary cross section byusing a three-dimensional laser scanner, calculating an estimated pouring two-liner concrete square quantity, and transmitting the estimated pouring two-liner concrete square quantity to an electriccabinet (40); installing a strip-shaped pressure sensing gasket (33) and a transparent pipe (30); installing a pressure sensing chip (9), a pressure sensing piece (32) and a temperature sensor (5); arranging a high-frequency pneumatic vibrator (12) and an automatic insertion type vibrator (18), and installing a flow sensor (1); stopping jacking when the pressure sensing value of the pressure sensing chip (9) is greater than the pressure resistance value of the upper plate two-lining concrete, installing a comprehensive pipe (3); pressing air, monitoring the square quantity of the concrete; carrying out pneumatic vibrating; carrying out insertion vibrating; judging that the concrete is full, and finishing pouring the concrete. The automation of the pouring of the two-lining concrete is achieved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

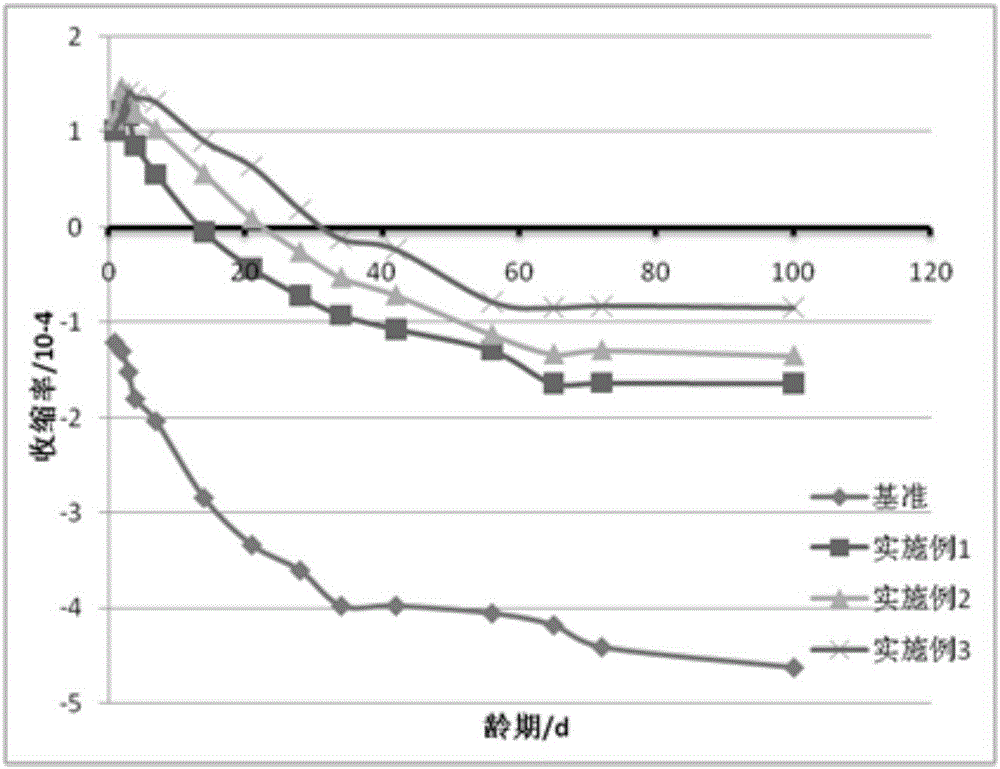

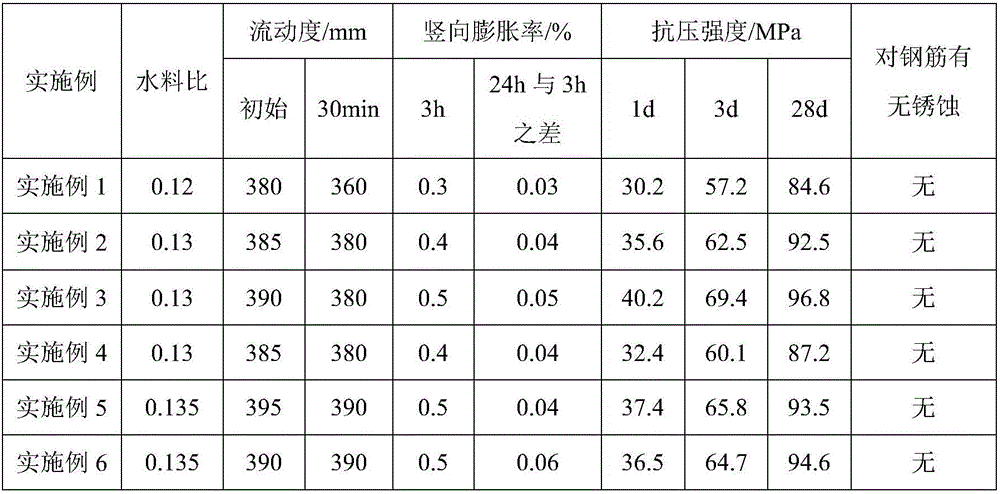

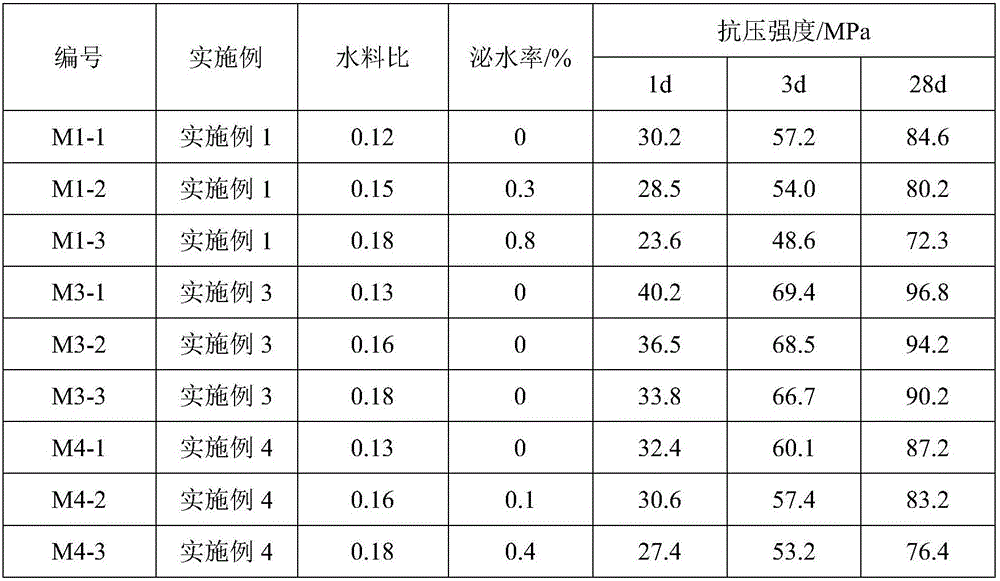

High-flow-state and high-strength non-shrinkage grouting material and preparation method thereof

ActiveCN106747128AImprove liquidityHigh mechanical strengthSolid waste managementMoisture distributionSuperplasticizer

The invention belongs to the field of buildings, and particularly relates to a high-flow-state and high-strength non-shrinkage grouting material and a preparation method thereof. The grouting material is prepared from the following components in percentage by mass: 30-45% of cement, 5-20% of a mineral admixture, 3-10% of dolomite composite powder, 2-8% of a composite expansion agent, 40-55% of aggregates, 0.2-1.0% of a polycarboxylate superplasticizer and 0.2-1.5% of a synergistic additive. Through a powder system and a close packing technology of the aggregates, the fluidity and the strength are improved; through introduction of the synergistic additive, moisture distribution is adjusted through thickening of a composite anti-segregation agent and water absorption and water release effects, so that the problems of high-flow-state grouting material segregation and bleeding and sensitive water consumption are solved; and adjustment of the expansion properties at different stages is carried out through introducing a plastic expansion agent and the composite expansion agent, so that the problems of shrinkage and sedimentation of the grouting material are solved.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Transistor forming method

ActiveCN105513965AReduce leakage currentSmall sizeSemiconductor/solid-state device manufacturingEtchingDielectric layer

The invention provides a transistor forming method. The transistor forming method is characterized in that a substrate can be provided; dummy grid layers can be formed on the surface of the substrate, and the surfaces of the side walls of the dummy grid layers are provided with side walls; first dielectric layers are formed on the substrate and the surfaces of the side walls, and the surfaces of the first dielectric layers are lower than the surfaces of the dummy grid layers; the side walls higher than the surfaces of the first dielectric layers can be removed, and the parts of the surfaces of the side walls of the dummy grid layers can be exposed, and first openings can be formed in the first dielectric layers between adjacent dummy grid layers and the surfaces of the side walls; second dielectric layers are formed in the first openings, and the surfaces of the second dielectric layers are aligned with the surfaces of the dummy grid layers, and the densities of the materials of the second dielectric layers are higher than the densities of the materials of the first dielectric layers; the dummy grid layers can be removed, and second openings can be formed in the second dielectric layers and the first dielectric layers; the etching of the side walls of the second dielectric layers of the second openings can be carried out, and then the sizes of the top parts of the second openings can be enlarged; grid layers can be formed in the second openings after the etching of the side walls of the second dielectric layers of the second openings. The performance of the formed transistors is stable, and the reliability can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Ceramic electronic component and method for manufacturing the same

InactiveCN1747087AFixed tightlyIncrease the amount addedStacked capacitorsPrinted circuit aspectsInorganic particleElectrical conductor

The present invention relates to a ceramic electronic component wherein via conductors that are embedded in through holes of dielectric layers formed from a sintered body of ceramic particles are made by firing a electrically conductive paste for via conductor that contains inorganic particles made of the same material as the ceramic particles that constitute the dielectric layer and having an average particle diameter smaller than that of the ceramic particles, and a method for manufacturing the same. According to the present invention, such a ceramic electronic component can be provided that the via conductors and the internal electrodes are electrically connected with each other satisfactorily without voids generated therein.

Owner:KYOCERA CORP

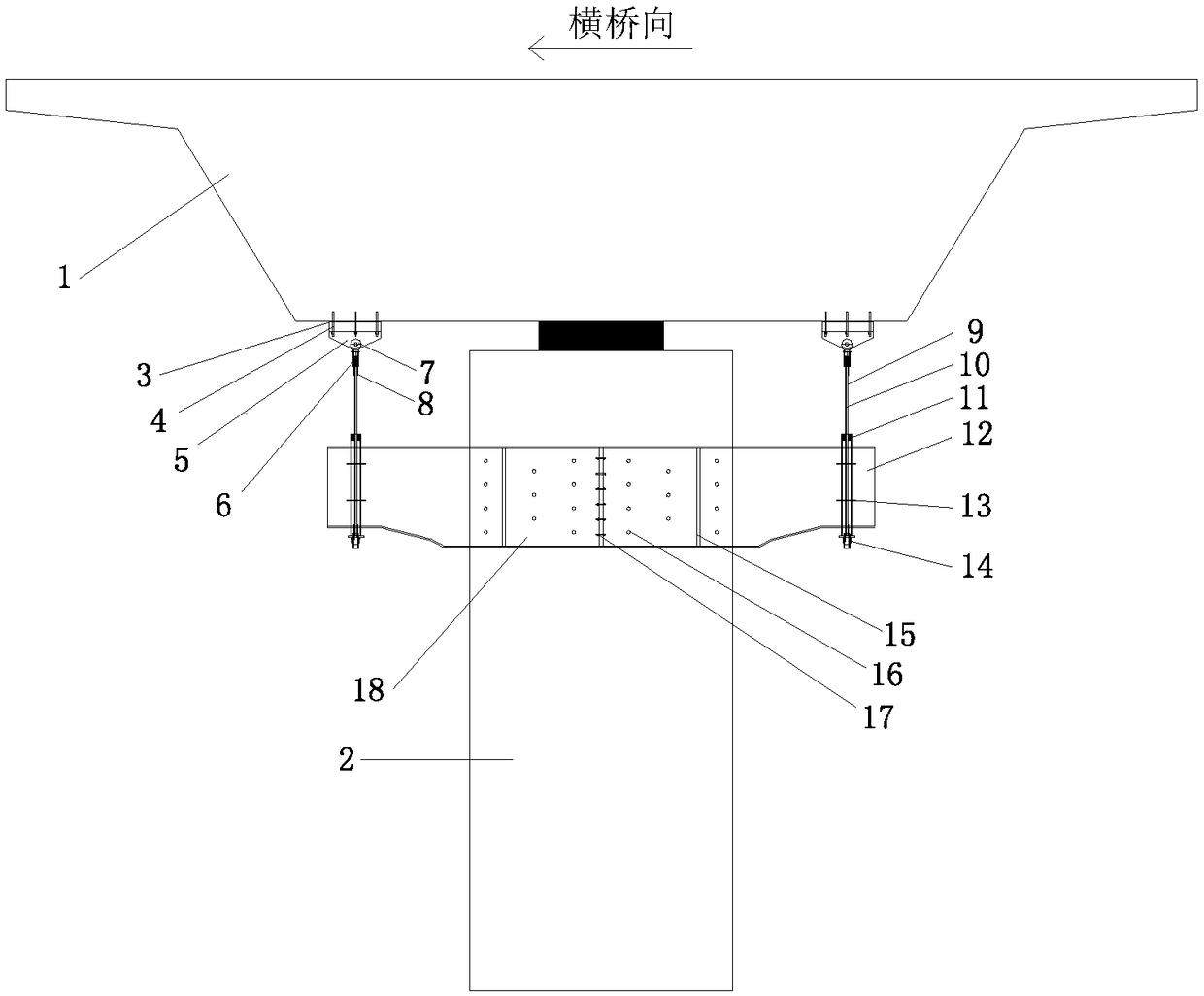

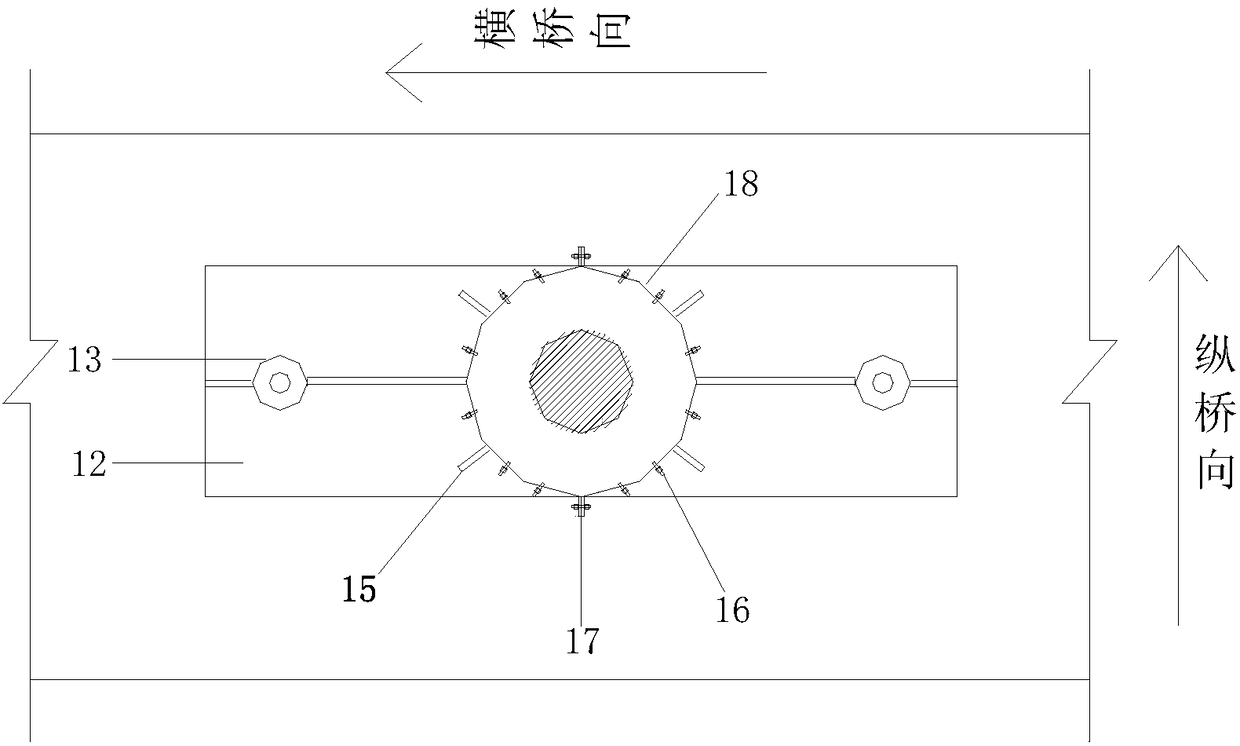

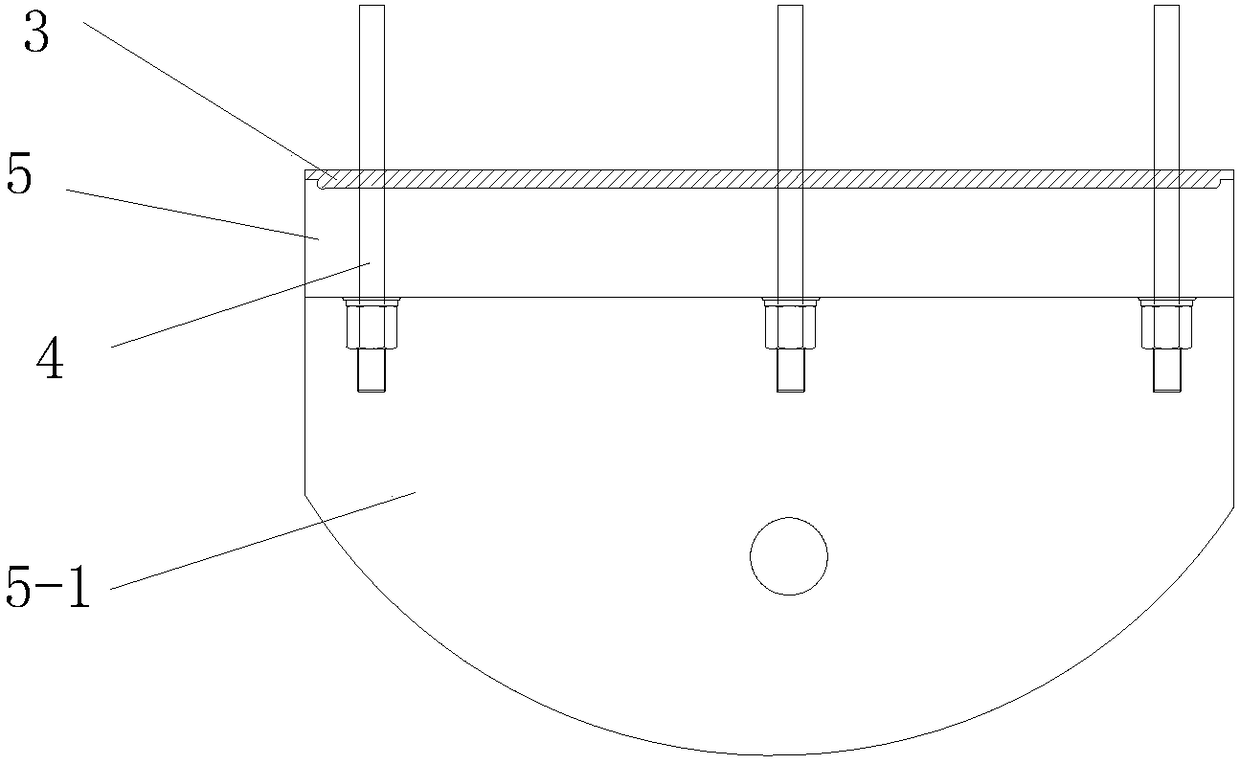

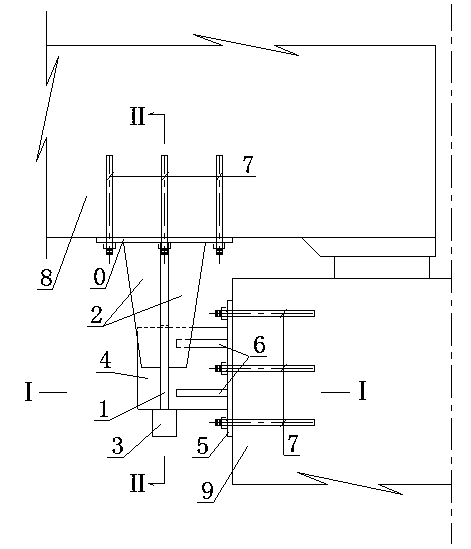

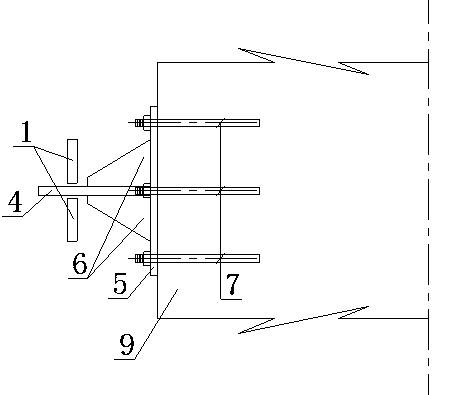

Anti-overturning reinforcement system for single-column pier bridges and mounting method

ActiveCN108532474AAvoid voidsPrevent overturning damageBridge erection/assemblyBridge strengtheningCantileverBolted joint

The invention provides an anti-overturning reinforcement system for single-column pier bridges, which comprises a steel structure support, a steel connecting base, and rigid tie rods; the steel structure support comprises two semicircular hoops with cantilevers, and the surface, which is in contact with a pier, of each semicircular hoop is provided with reserved holes for the mounting of anchor bolts at intervals; the external surfaces of the semicircular hoops are provided with axial reinforcing ribs; the two semicircular hoops are connected through first high-strength bolts to hoop both sides of the pier, and the semicircular hoops and the cantilevers are of an integrated structure; one end, which is far from the hoop, of each cantilever is provided with a vertically through mounting through hole; the steel connecting base is fixed on the bottom of a bridge, the center of the steel connecting base and the center of the through hole are on the same vertical line, and both ends of eachrigid tie rod are respectively fixedly connected to the steel structure support and the steel connecting base. The invention can effectively enhance the anti-overturning performance of a single-column pier bridge, the structure is simple, stress is clear, construction is convenient, the anti-overturning reinforcement system has relatively good economical efficiency and appearance, and the invention is suitable for popularization and application in the field of bridge reinforcement.

Owner:HUATIAN ENG & TECH CORP MCC

Bridge sliding clamping plate hook lock type box girder overturning prevention mechanism

InactiveCN103510460ASolve the hidden dangers of overturning accidentsSolve the problem of lateral overturning stabilityBridge structural detailsBridge erection/assemblySocial benefitsEconomic benefits

The invention discloses a bridge sliding clamping plate hook lock type box girder overturning prevention mechanism and a construction method thereof. The bridge sliding clamping plate hook lock type box girder overturning prevention mechanism comprises a box girder and a capping beam. The box girder is characterized in that a U-shaped box girder sliding clamping plate hook lock assembly is arranged on the bottom face of the box girder in an anchoring mode. The capping beam is characterized in that a capping beam sliding clamping plate hook lock assembly is anchored on the side face of the capping beam. The two assemblies are locked in a sliding mode, and additional stress generated by the box girder and a bridge pier due to stretching of the box girder is removed. When the box girder has an overturning trend, the two assemblies are assembled together in a hook lock mode, and thus the box girder can be prevented from overturning. After the mechanism is mounted on a continuous box girder bridge, the overturning problem of the box girder can be solved. The bridge sliding clamping plate hook lock type box girder overturning prevention mechanism has the advantages that the structure is simple and reasonable, main beam stretching is released, a support can be replaced conveniently, the usability is good, and manufacturing cost is low. The mechanism can be machined (welding or casting) in a factory in a concentrated mode, and the construction period is shortened. Huge investment is saved for China, remarkable economic benefits are obtained, meanwhile, huge social benefits are achieved, and the negative effect of bridge overturning on the society is removed.

Owner:孙超

Semiconductor device and method of manufacturing thereof

ActiveUS7651958B2Efficient preparationAvoid voidsSemiconductor/solid-state device detailsSolid-state devicesCompression moldingPlatinum

A method of manufacturing a semiconductor device sealed in a cured silicone body by placing a semiconductor device into a mold and subjecting a curable silicone composition that fills the spaces between said mold and said semiconductor device to compression molding, wherein the curable silicone composition comprises the following components: (A) an organopolysiloxane having at least two alkenyl groups per molecule; (B) an organopolysiloxane having at least two silicon-bonded hydrogen atoms per molecule; (C) a platinum-type catalyst; and (D) a filler, wherein either at least one of components (A) and (B) contains a T-unit siloxane and / or Q-unit siloxane. By the utilization this method, a sealed semiconductor device is free of voids in the sealing material, and a thickness of the cured silicone body can be controlled.

Owner:DOW TORAY CO LTD

LED photocured inkjet ink suitable for high-speed ink jetting

InactiveCN104845451AImprove anti-aging propertiesImprove adsorption fastnessInksUltraviolet lightsEngineering

The invention discloses and provides LED photocured inkjet ink suitable for high-speed ink jetting, which does not evaporate a solvent, can reduce energy consumption, can reduce environmental pollution and is suitable for cold light source LEDs. The inkjet ink comprises the following components in parts by weight: 1-10 parts of a nanoscale pigment, 2-5 parts of an ultraviolet light absorber, 1-10 parts of a super dispersion agent, 2-10 parts of a quick initiator, 2-20 parts of a macromolecular prepolymer, 0.1-2 parts of a wetting and leveling agent, 0.1-1 part of a defoaming agent, 0.1-10 parts of an adhesion promoter, 5-10 parts of a combined monomer and 30-70 parts of a UV active diluent. According to the formula of the ink, the viscosity of the ink can be reduced, a spray head of a printer cannot be blocked, ultraviolet lights can be absorbed, curing energy can reach 130 mj / cm<2>, the curing speed of the ink can be increased, the curing time can be controlled within 5-20 seconds, and meanwhile, the transfer rate of printing pattern is improved; the LED photocured inkjet ink has long-acting antioxidative and anti-yellowing performances, high luster sensation and marresistance.

Owner:珠海欣威科技有限公司

Manufacturing method for JANS plate type thick film resistor

ActiveCN101593589AGood adhesionAvoid voidsResistors adapted for applying terminalsEngineeringElectroplating

The invention discloses a manufacturing method for a JANS plate type thick film resistor, which belongs to a manufacturing method for a plate type resistor. The invention aims to provide the manufacturing method for the JANS plate type thick film resistor. The manufacturing method comprises the manufacture of a gauge, a back electrode and a resistor body, encapsulating, trimming, splintering, sintering, end coating and electroplating; and the concrete steps comprise substrate cleaning, printing for the gauge and the back electrode, electrode sintering, stirring and defoaming for resistance paste and secondary glass paste, resistor body printing, resistor body sintering, primary glass printing, primary glass sintering, laser trimming, resistor body cleaning, secondary glass printing, primary splintering, end coating for the electrode, end electrode sintering, secondary splintering, nickel plating and tinlead plating. The products manufactured by the manufacturing method have the advantages of low resistance value, low TCR, high precision, high power, high reliability and the like, and completely meet the requirements of JANS products.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

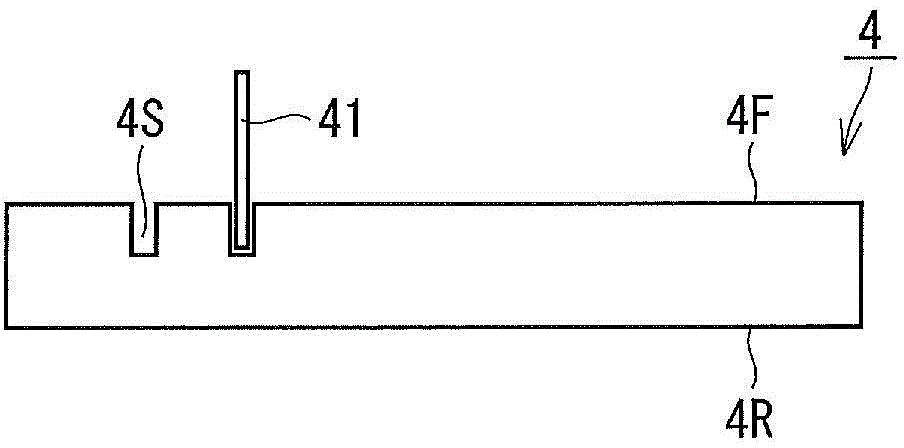

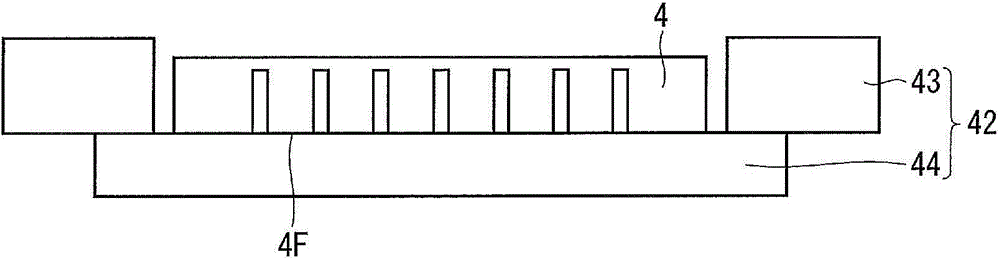

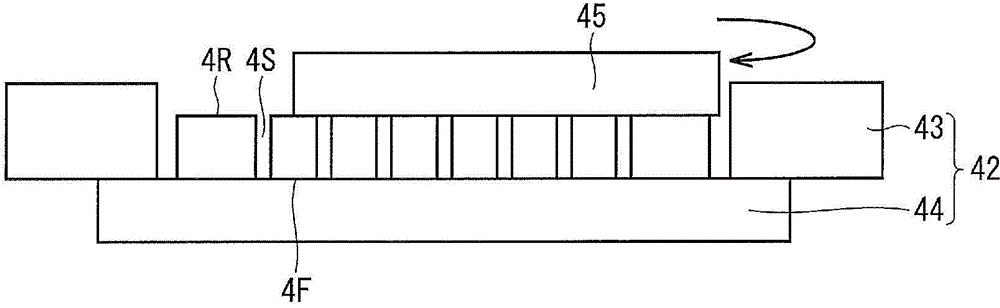

Semiconductor device manufacturing method, and adhesive film used in semiconductor device manufacturing method

ActiveCN104040697AInhibition of attachmentImprove cut-off reliabilityNon-macromolecular adhesive additivesSolid-state devicesEngineeringLength wave

The purpose of the present invention is to provide a semiconductor device manufacturing method, whereby cutting reliability of an adhesive film can be improved and debris contamination due to the adhesive film can be suppressed. Provided is a semiconductor device manufacturing method which is provided with: a step wherein, after forming a groove (4S) on the front surface of a semiconductor wafer (4), a protective adhesive film (44) is adhered, the rear surface of the semiconductor wafer is ground, and the groove is exposed from the rear surface; a step wherein, after adhering the adhesive film on the rear surface of the semiconductor wafer, the protective adhesive film is peeled; and a step wherein a laser beam having a wavelength of 355 nm is radiated along the groove exposed from the adhesive film, and the adhesive film is cut. The adhesive film has (a) a light absorption coefficient of 40 cm-1 or more at a wavelength of 355 nm, (b) a tensile storage elastic modulus of 0.5-20 MPa at 50 DEG C, and (c) a tensile storage elastic modulus of 0.3-7 MPa at 120 DEG C, or a melt viscosity of 2,000 Pa.s or more at 120 DEG C.

Owner:NITTO DENKO CORP

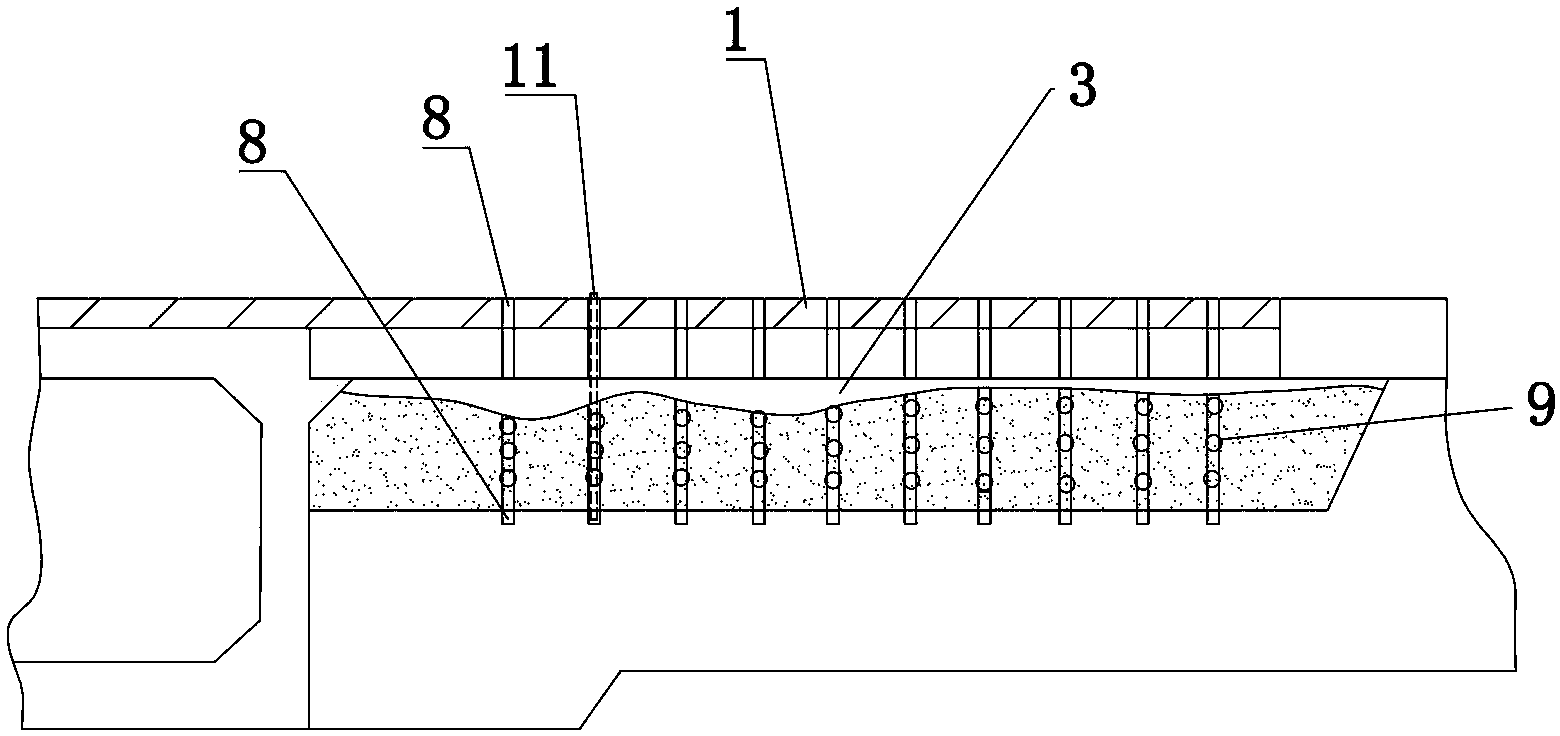

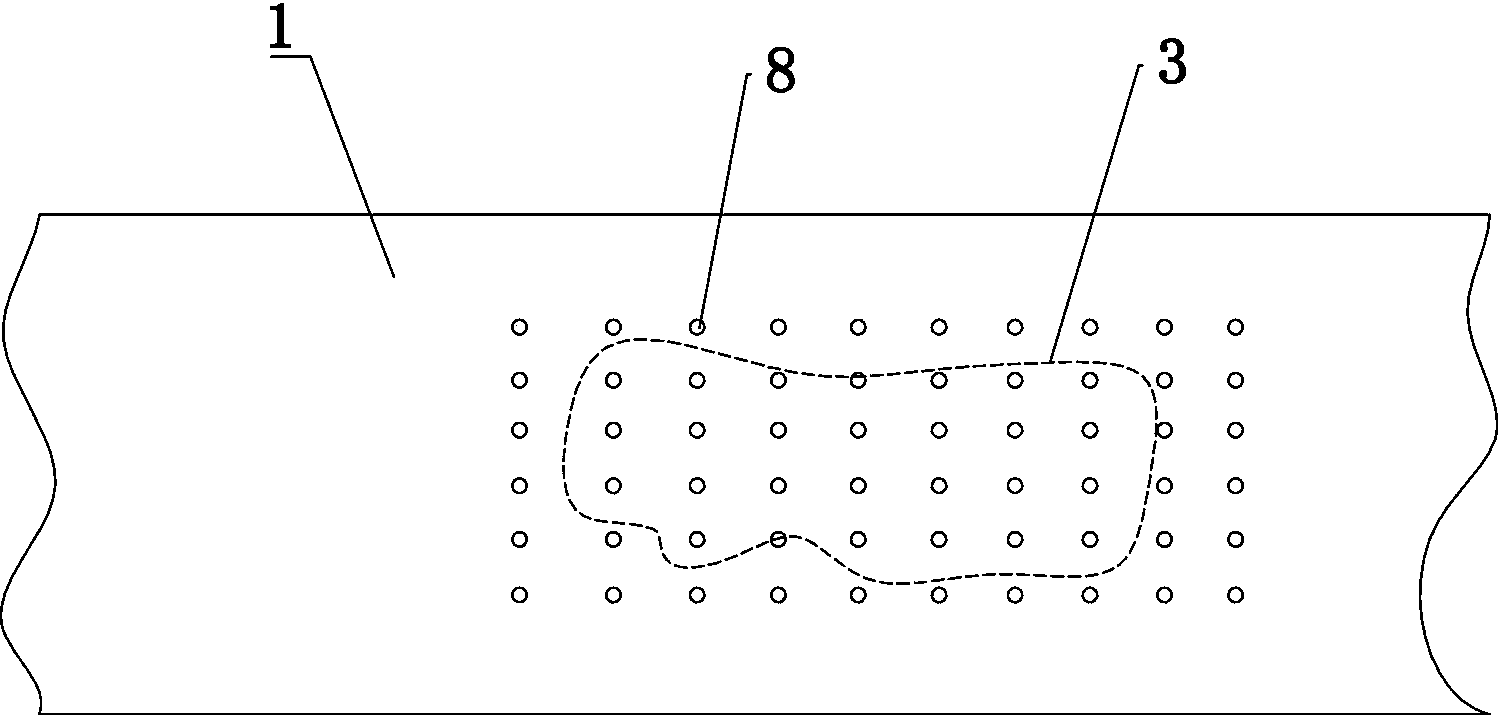

Repair method of vehicle bump pavement of bridgehead

ActiveCN104047236APrevent jumpingSame settling velocityBridge structural detailsBridge erection/assemblySoft layerRadar

The invention relates to a repair method of the vehicle bump pavement of a bridgehead. The repair method comprises the following steps: detecting a disengaging position in an approach slab of a damaged bridge by a detection radar, marking the positions of grouting holes I on the surface of the approach slab and drilling, wherein the grouting holes I reach the hard layer and are distributed in an array manner, the center distance between the adjacent grouting holes I is 10-20 cm, and the disengaging position is enabled to fall into the array range; enabling grouting holes II to penetrate the soft layer and to be crossed with the grouting holes I, and arranging one-way valves for exhausting at two ends of the grouting holes II; grouting the grouting holes I and detecting the slurry filling conditions of the disengaging position, the grouting holes I and the grouting holes II in time by a three-dimensional detection radar, and stopping the grouting when the disengaging position, the grouting holes I and the grouting holes II are filled with slurry; detecting and rechecking the filled part by the detection radar after grouting stopping, and drilling and grouting parts which are not filled with slurry again. The method solves the problem of the difference between settling velocities of the hard layer and the soft layer.

Owner:JIANGSU DINGTAI ENG MATERIAL

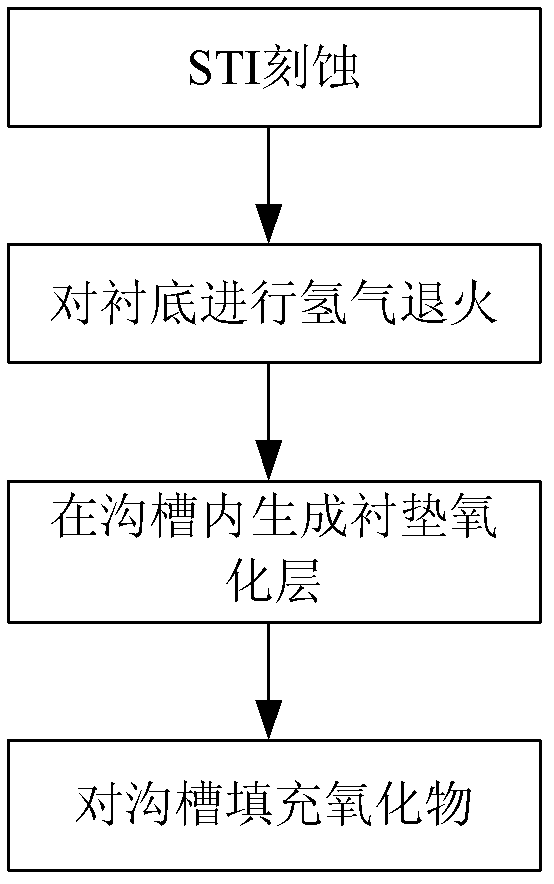

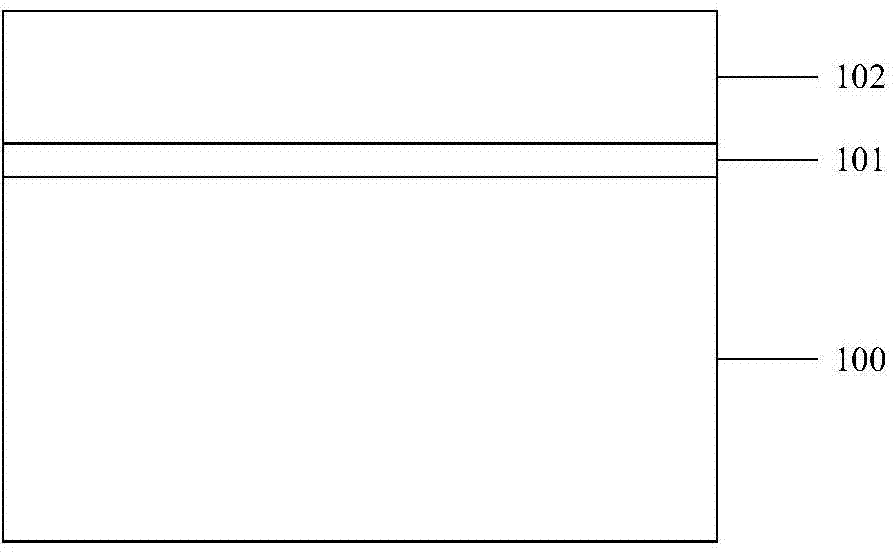

Method for manufacturing shallow trench isolation

InactiveCN102867774AReduce roughnessEffective migrationSemiconductor/solid-state device manufacturingHydrogen atmosphereEngineering

The invention provides a method for manufacturing shallow trench isolation. After being etched to form a shallow trench, a substrate is subject to an annealing process under a certain condition of hydrogen atmosphere, so that element atoms of the substrate are promoted to make thermal motion migration under a high temperature, side walls of the rough shallow trench and square corners of the shallow trench become smooth, the leakage current of a semiconductor device employing the shallow trench isolation is reduced, and the performances of the semiconductor device and an integrated circuit are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

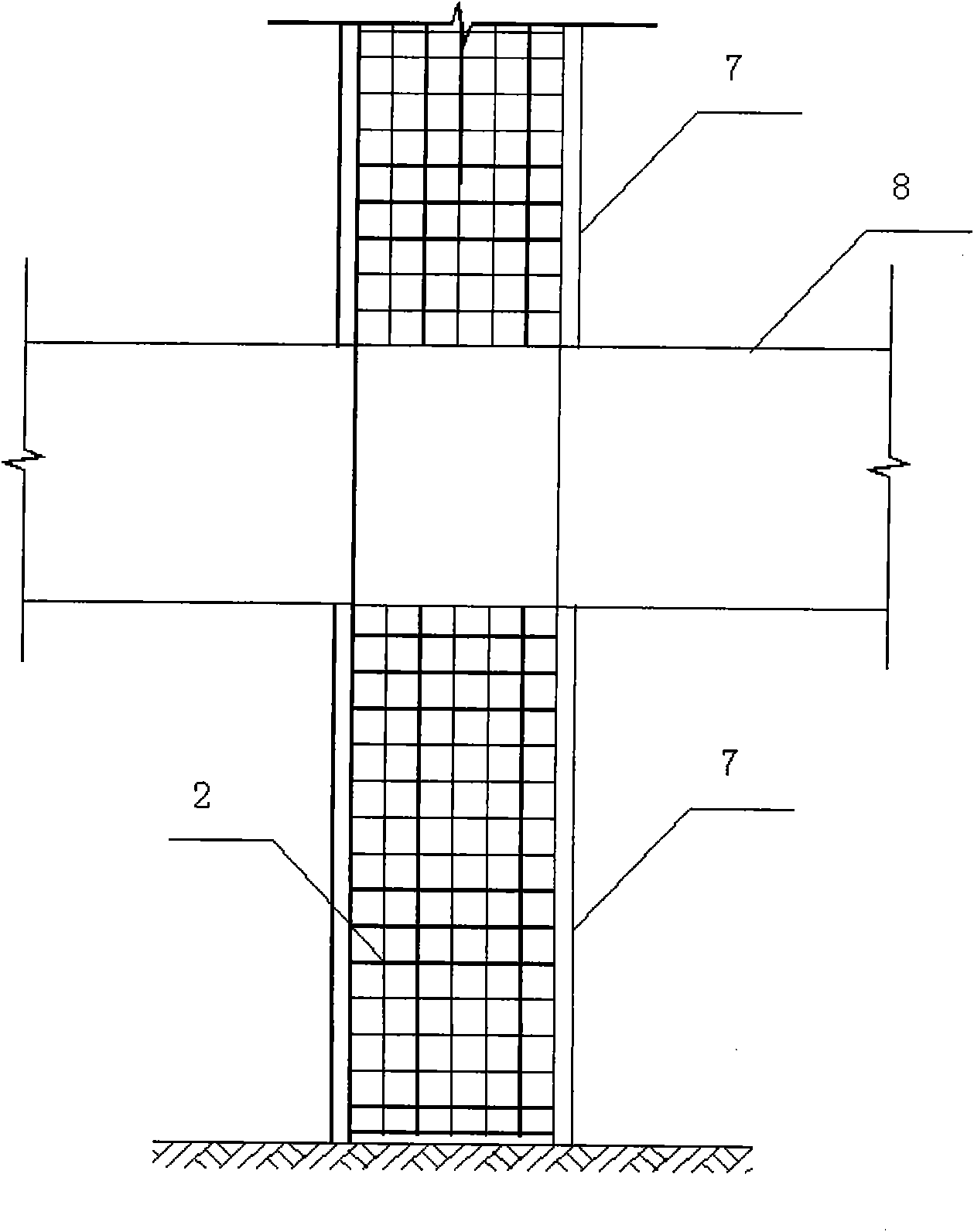

Manufacturing method of prefabricated structural column formwork

The invention discloses a manufacturing method of a prefabricated structural column formwork. According to the manufacturing method of the prefabricated structural column formwork, a prefabricated structural column formwork manufacturing device is used, the two ends of a structural column steel bar penetrate through through holes in sealing cover plates at the two ends correspondingly so that the structural column steel bar can be positioned, then concrete is poured into a structural column concrete pouring trough directly, a vibration platform is started at the same time, the concrete can evenly fill all portions in the structural column concrete pouring trough, cavitation can be avoided, and a corresponding formwork is removed after the concrete is solidified. The prefabricated structural column formwork is manufactured easily and conveniently, and the forming quality is high.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

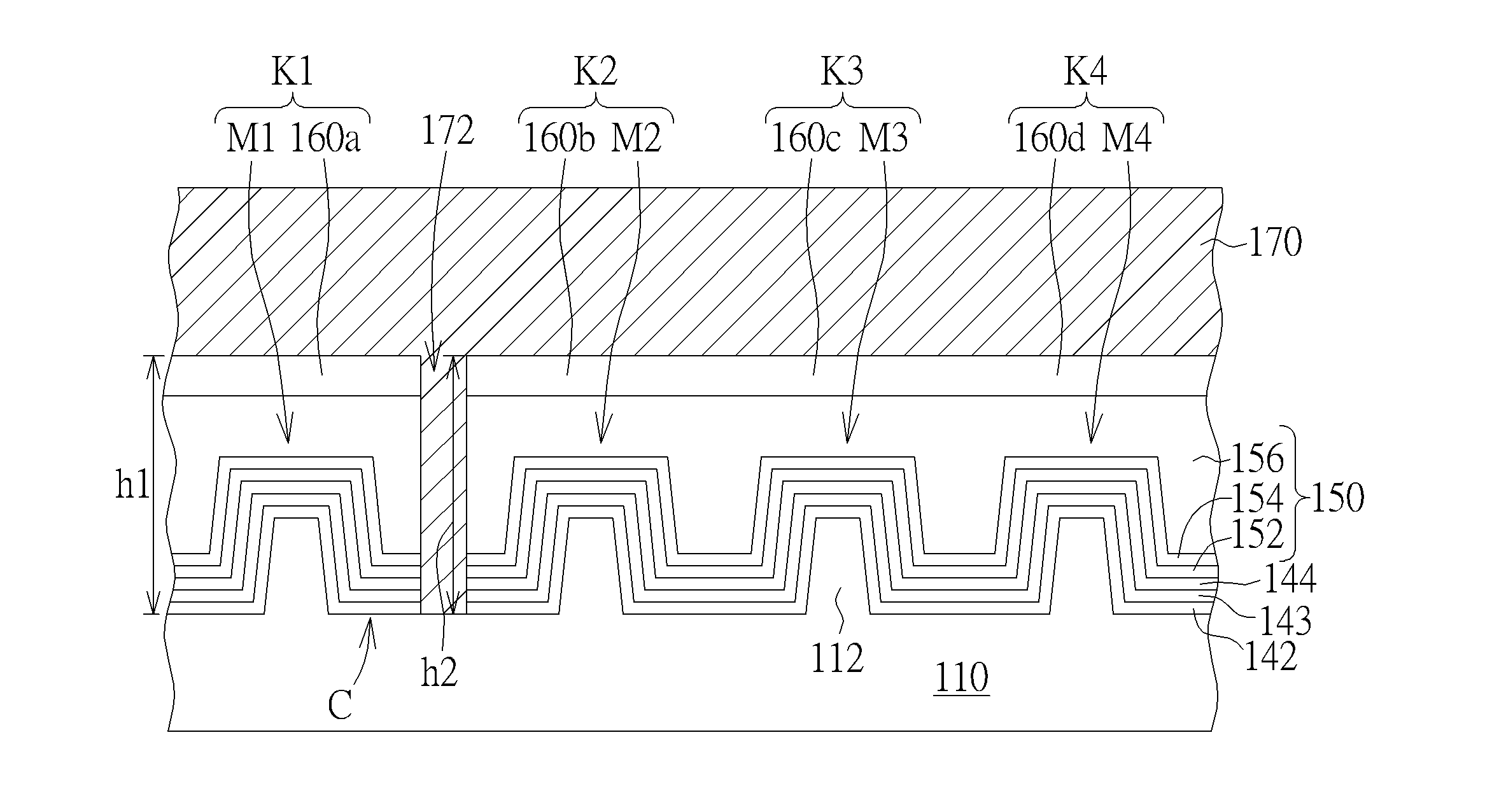

Semiconductor structure and process thereof

ActiveUS20160300755A1Short heightProcessing problemSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

A semiconductor process includes the following step. A metal gate strip and a cap layer are sequentially formed in a trench of a dielectric layer. The cap layer and the metal gate strip are cut off to form a plurality of caps on a plurality of metal gates, and a gap isolates adjacent caps and adjacent metal gates. An isolation material fills in the gap. The present invention also provides semiconductor structures formed by said semiconductor process. For example, the semiconductor structure includes a plurality of stacked structures in a trench of a dielectric layer, where each of the stacked structures includes a metal gate and a cap on the metal gate, where an isolation slot isolates and contacts adjacent stacked structures at end to end, and the isolation slot has same level as the stacked structures.

Owner:MARLIN SEMICON LTD

Preliminary dip material for vacuum forming massive article

The invention relates to a high polymer material field, in particular to a prepreg compound used in a vacuum forming massive article, which comprises reinforcing fiber, matrix resin and fiber base-material and is characterized in that the reinforcing fiber is retted by the matrix resin to form the reinforcing fiber at one side which is completely soaked by the matrix resin and the prepreg compound at the other side which is not completely soaked by the matrix resin; wherein for one side of the reinforcing fiber which is not completely by the matrix resin, the soakage rate of the matrix resin is more than or equal to 20% and is less than or equal to 95%.

Owner:WEIHAI GUANGWEI COMPOSITES

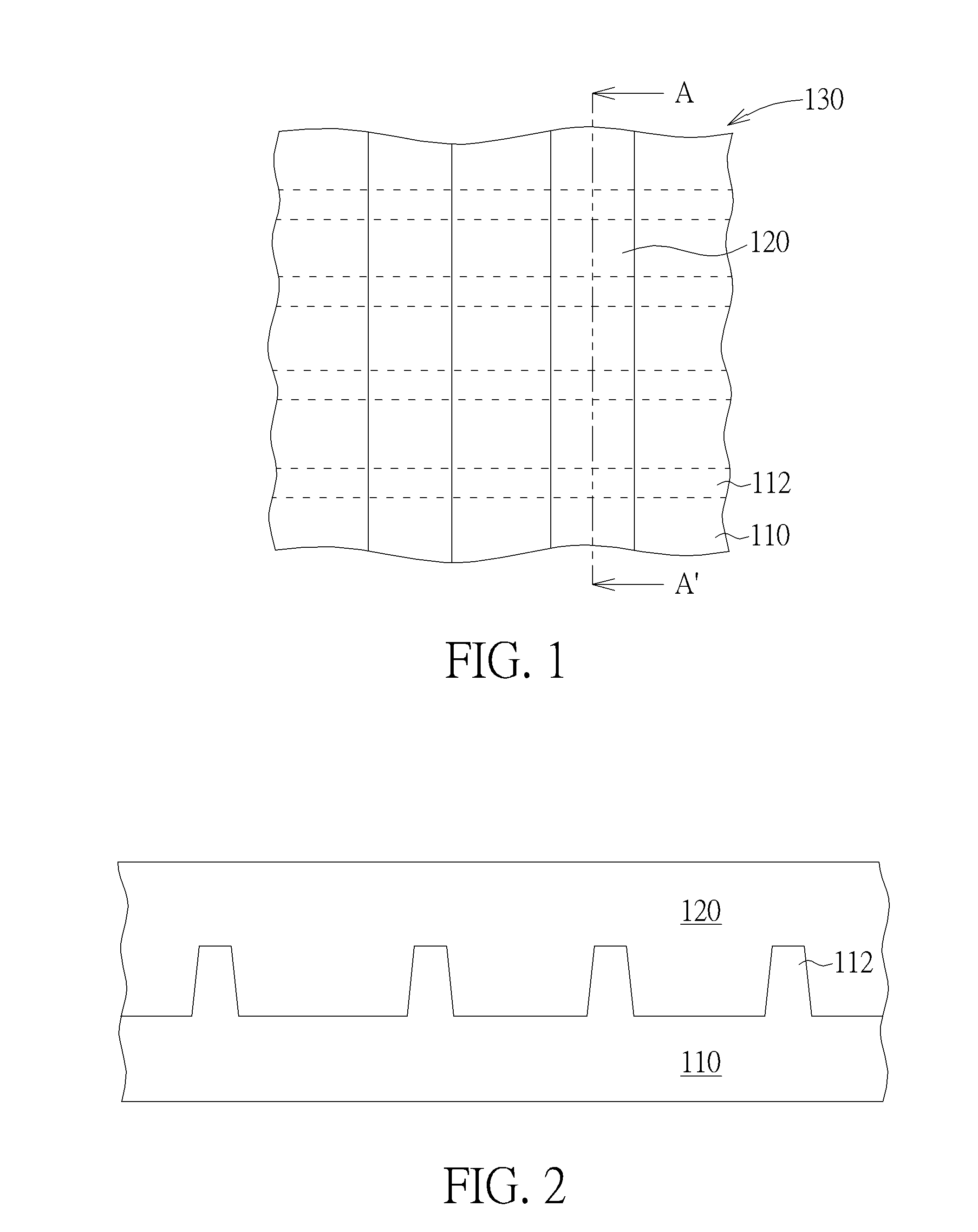

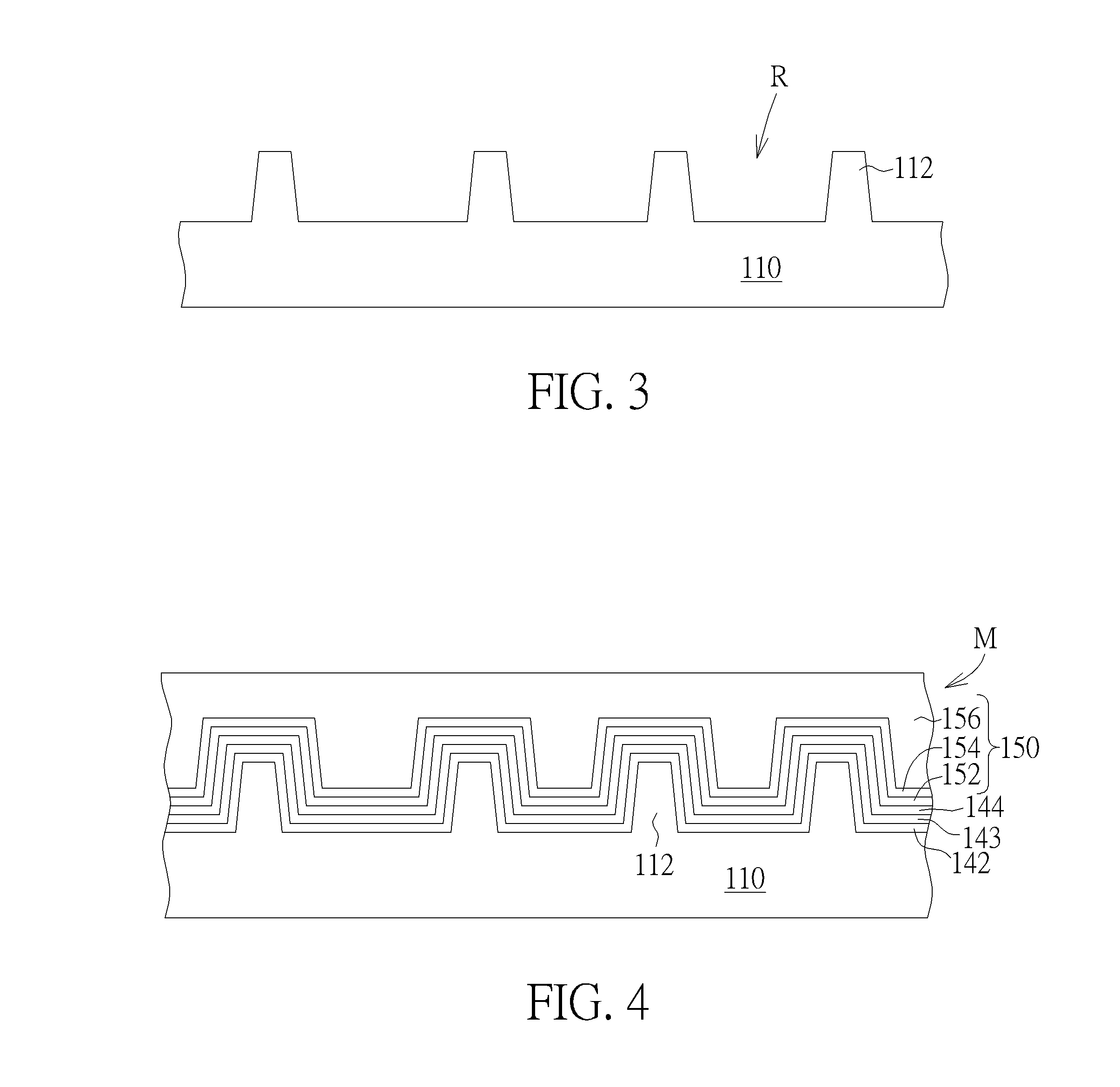

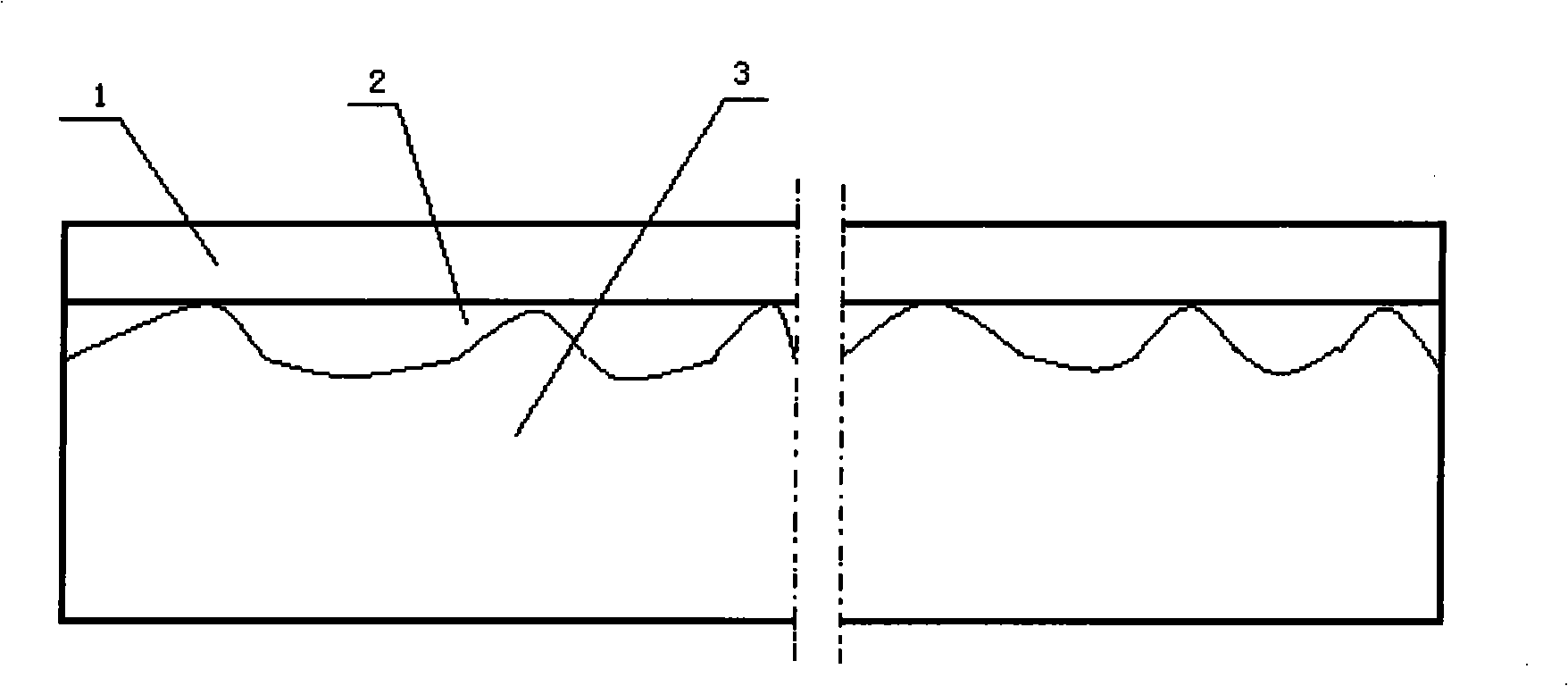

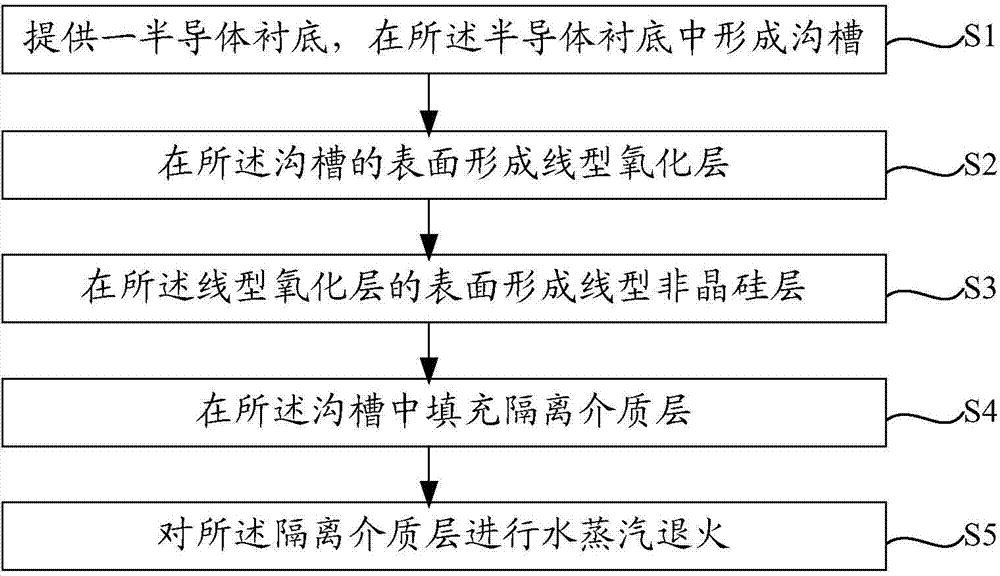

Preparation method of shallow trench isolation structure

InactiveCN104779195APrevent oxidationAvoid consumptionSemiconductor/solid-state device manufacturingAmorphous siliconMaterial consumption

The invention provides a preparation method of a shallow trench isolation structure. After a linear oxidation layer is formed in a trench, a linear amorphous silicon layer is introduced to consume H2O and other oxygen-containing groups generated in a subsequent water steam annealing step for an isolation medium layer, and diffusion of the formed H2O and the other oxygen-containing groups to a semiconductor substrate is further stopped; during water steam annealing of the linear amorphous silicon layer, the semiconductor substrate on the side wall of the trench is replaced, and the H2O and the other oxygen-containing groups are consumed and completely converted into SiO2 to be part of the isolation medium layer in the trench, so that oxidation of a boundary of an active area of the side wall of the trench in the water steam annealing process can be avoided, the material consumption of the semiconductor substrate on the side wall of the trench is reduced, the decrease of the critical dimensions (AA CD) of the active area is reduced, and meanwhile, the defect of forming of a cavity or a gap inside an isolation medium filled in the trench is avoided.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method of manufacturing semiconductor device

ActiveUS20050026418A1Reduce gapReduce capacitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A method of manufacturing a semiconductor device includes preparing a semiconductor wafer including a first main surface having a semiconductor device forming region and a peripheral region, and a second main surface; preparing first and second dies defining a cavity; holding the semiconductor wafer by the first die so that the first main surface is exposed; placing a film member on the second die; supplying a predetermined amount of resin to a predetermined region on a resin layout region of the film member; heating the first die and the second die; bringing the first die and the second die into contact with each other through the film member to form the cavity, thereby the first main surface and the resin are placed in the cavity; and pressure-reducing the interior of the cavity and reducing the capacity of the cavity to cause the molten resin obtained by melting the resin to contact the first main surface, thereby forming an encapsulating portion on the first main surface.

Owner:LAPIS SEMICON CO LTD

Resin hole-plugging method for large-aperture back-drilled hole

ActiveCN110831336AAvoid voidsSolve the problem of plug holePrinted circuit manufactureGrindingDrill hole

The invention discloses a resin hole-plugging method for a large-aperture back-drilled hole, and the method comprises the following steps: drilling a through hole on a production plate, wherein one surface of the production plate is a back-drilled surface, and the other surface is a non-back-drilled surface; metalizing the through hole through copper deposition and full-board electroplating in sequence; performing back drilling at the position, corresponding to the metallized through hole, in the back-drilled surface through a depth-controlled drilling method, and forming a stepped back-drilled hole, wherein the hole diameter of the back-drilled part is larger than that of the through hole; filling resin in the back-drilled hole in a vertical vacuum hole-plugging manner and performing curing; filling resin into the back-drilled hole for the second time in a horizontal vacuum hole-plugging manner and curing; and removing the resin protruding out of the plate surface through an abrasivebelt grinding plate. According to the method, the quality problems that a conventional resin hole-plugging process cannot be used for manufacturing or hole plugging cavities, holes are not full, and hole openings are sunken are solved, full resin hole plugging is ensured, and hole opening sunken parts are less than 30 microns.

Owner:珠海崇达电路技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com