Steel structure and foundation pre-burying connection structure and construction method

A technology for connecting structures and steel structures, which is applied in basic structure engineering, building construction, construction, etc., can solve problems such as voids at the bottom of pre-embedded steel plates, affecting structural force transmission, silting, etc., to speed up construction progress and ensure connection strength , The effect of high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, the concrete mix ratio, technical requirements for pouring construction, technical requirements for steel cutting and welding construction, and technical requirements for steel bar binding and formwork support will not be repeated, and the embodiments of the present invention will be focused on.

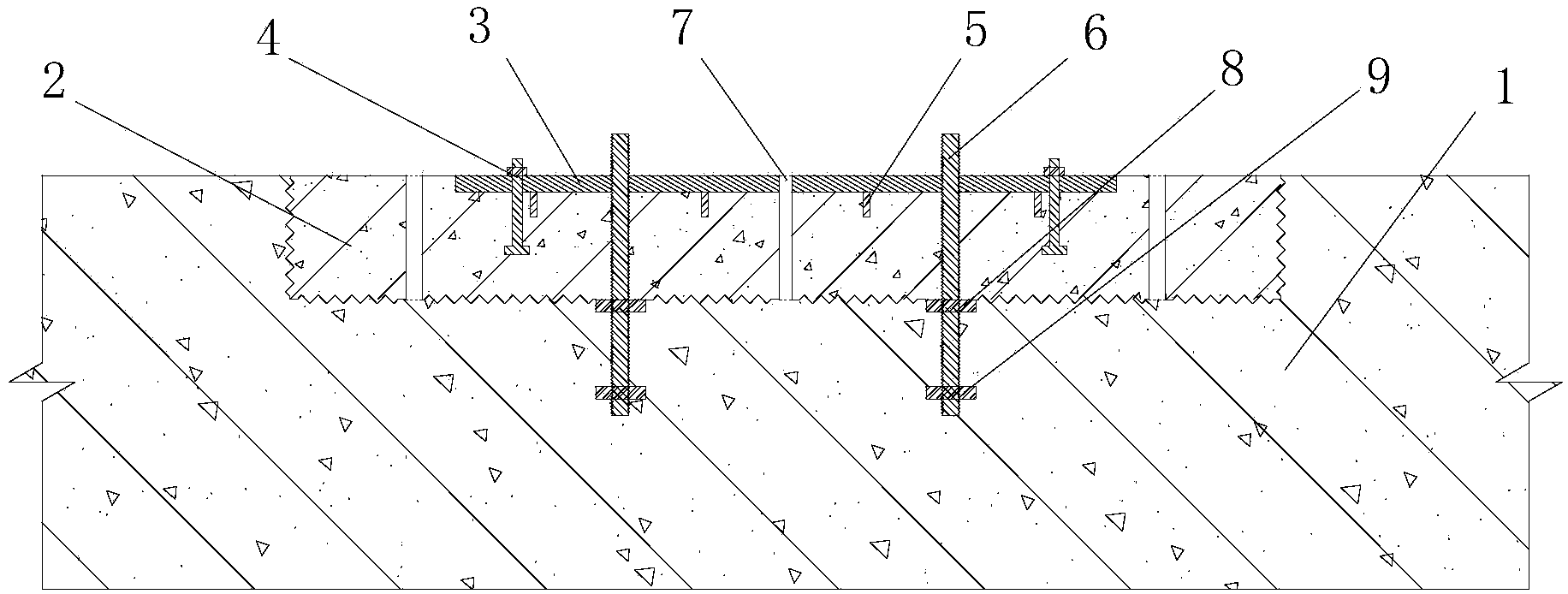

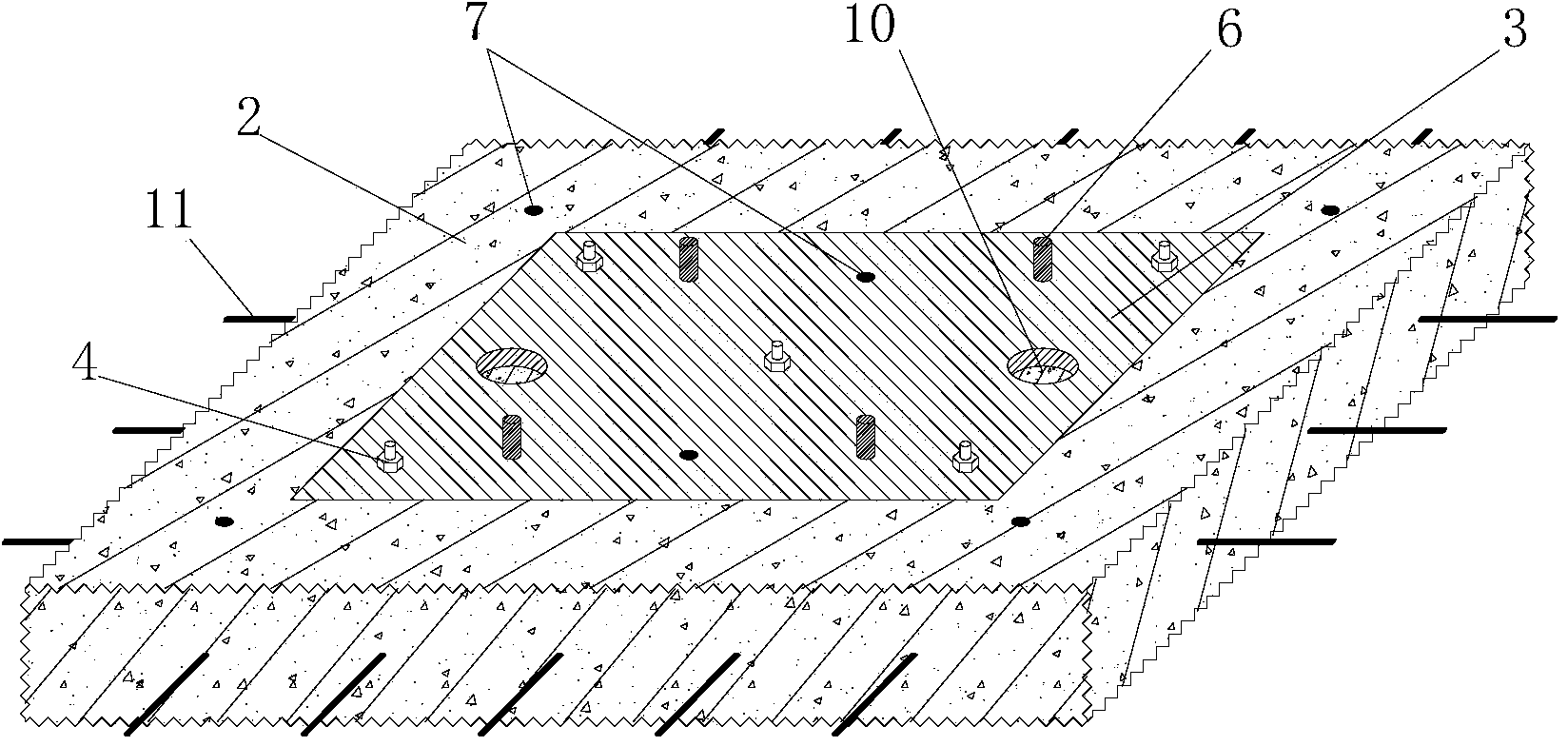

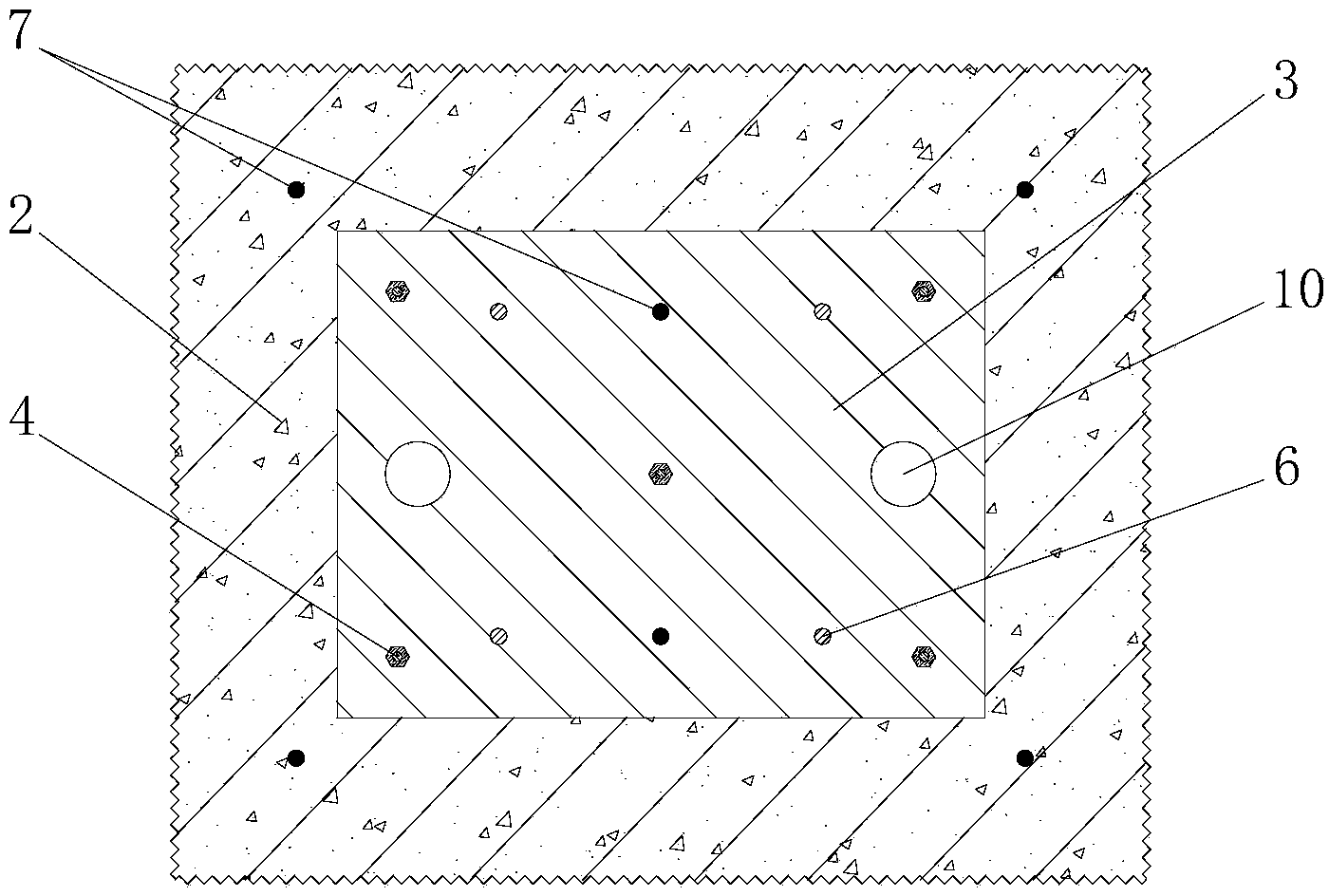

[0037] figure 1 It is a schematic diagram of a steel structure and foundation pre-embedded connection structure of the present invention; figure 2 It is a structural schematic diagram of the prefabricated component of the present invention; image 3 It is a schematic diagram of the upper surface of the prefabricated component of the present invention. refer to Figure 1~3 As shown, a pre-embedded connection structure between steel structure and foundation mainly includes: foundation 1, reinforced concrete connection block 2, connection steel plate 3, prestressed bolt 4, connection short bar 5, connection screw 6 and reserved steel bar 11, etc.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com