Method for mounting ship three-main-engine three-airscrew main frame shafting

A technology for propellers and main shafts, applied to shaft frames, hulls, ship parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

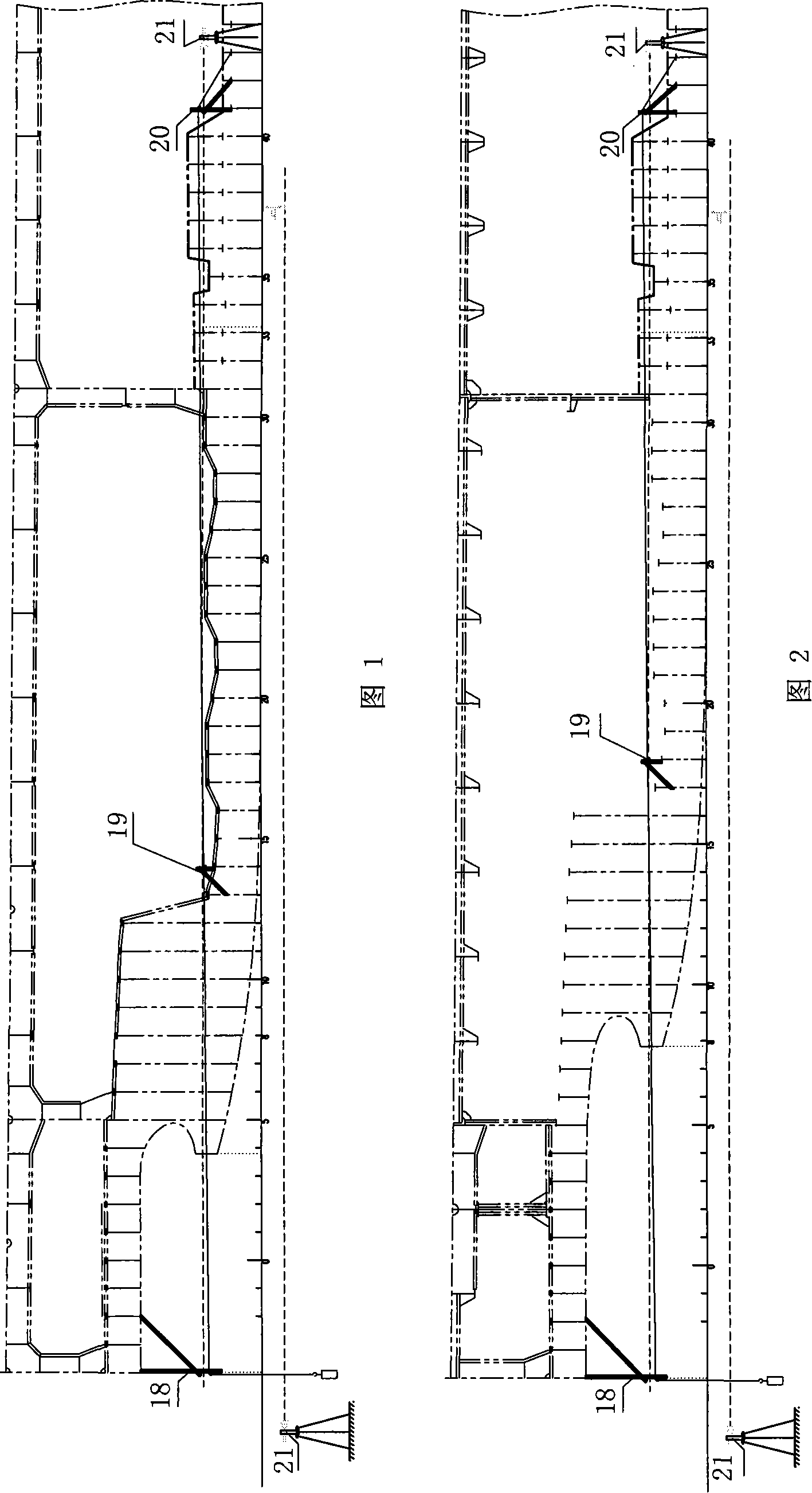

[0019] 1 Measurement of centerline of ship shafting.

[0020] 1.1 Overview

[0021] The ship has 3 shaft systems, namely the left and right side shaft systems and the midship shaft system. The left and right side side shafts are respectively 5785mm away from the midship, the tail of the side axis is 970mm above the baseline at #8-100 (3900mm towards the bow of #0), and the height of the bow is 970mm above the baseline at #33+100 (16600mm towards the bow of #0) 1100mm, the inclination angle between the axis and the baseline is about 0.7574°; the central axis is located in the midship, the longitudinal axis coincides with the midship, the tail of the central axis is 970mm above the baseline at #4 100 (1900mm from #0 to the bow), and the bow is at #33(# 0 to the bow (16600mm) is 1100mm above the baseline, and the inclination angle between the axis and the baseline is about 0.5961°.

[0022] 1.2 Basic requirements for centerline of ship shafting

[0023] 1.2.1. The deviation be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com