Ceramic electronic component and method for manufacturing the same

A technology of electronic components and manufacturing methods, applied in the direction of printed circuit manufacturing, electrical components, circuits, etc., can solve problems such as difficult to prevent, insufficient effect, and increased conduction resistance of via-hole conductors, so as to prevent voids and improve adhesion , The effect of stabilizing electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

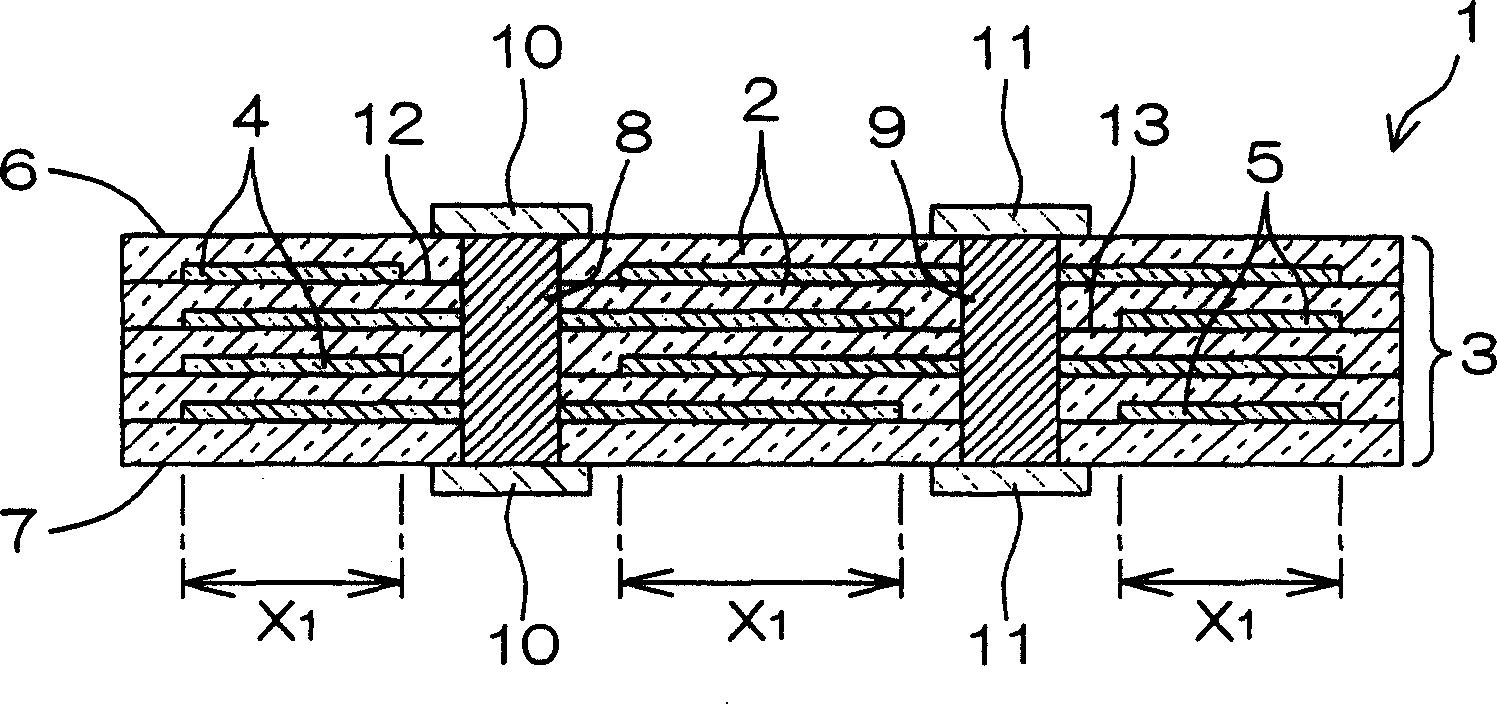

[0035] figure 1 It is a cross-sectional view showing a multilayer ceramic capacitor 1 as an example of the ceramic electronic component of the present invention. refer to figure 1 , The multilayer ceramic capacitor 1 of this example includes a dielectric block 3 in which a plurality of dielectric layers 2 formed of ceramics are stacked.

[0036] Between the layers of the respective dielectric layers 2 forming the dielectric block 3 , internal electrodes 4 and 5 serving as conductor wiring are alternately arranged for each of the plurality of layers. In addition, the dielectric block 3 is formed with via conductors 8, 9 extending from the upper surface 6 shown in the drawing to the lower surface 7 of the dielectric block 3 through its stacking direction, and the upper surface 6 and the lower surface 7 of the dielectric block 3 are , external electrodes 10 electrically connected to via-hole conductors 8 and external electrodes 11 electrically connected to via-hole conductors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com