Sealing component and rotary kiln sealing component

A technology for sealing components and rotary kilns, which is applied to the sealing of engines, rotary drum furnaces, engine components, etc., and can solve the problems of poor sealing, inability to adapt to the deformation of rotating parts, and large air leakage gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

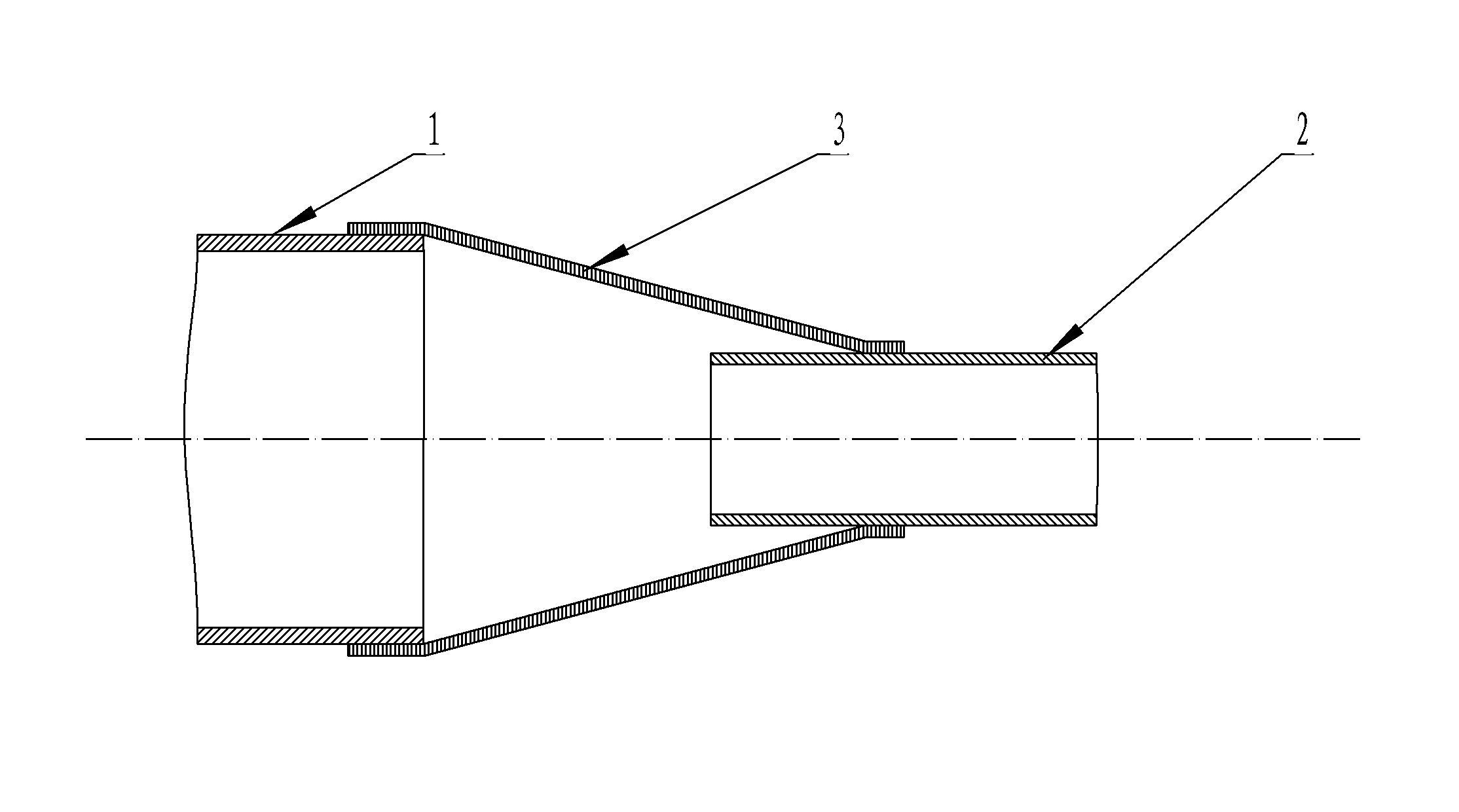

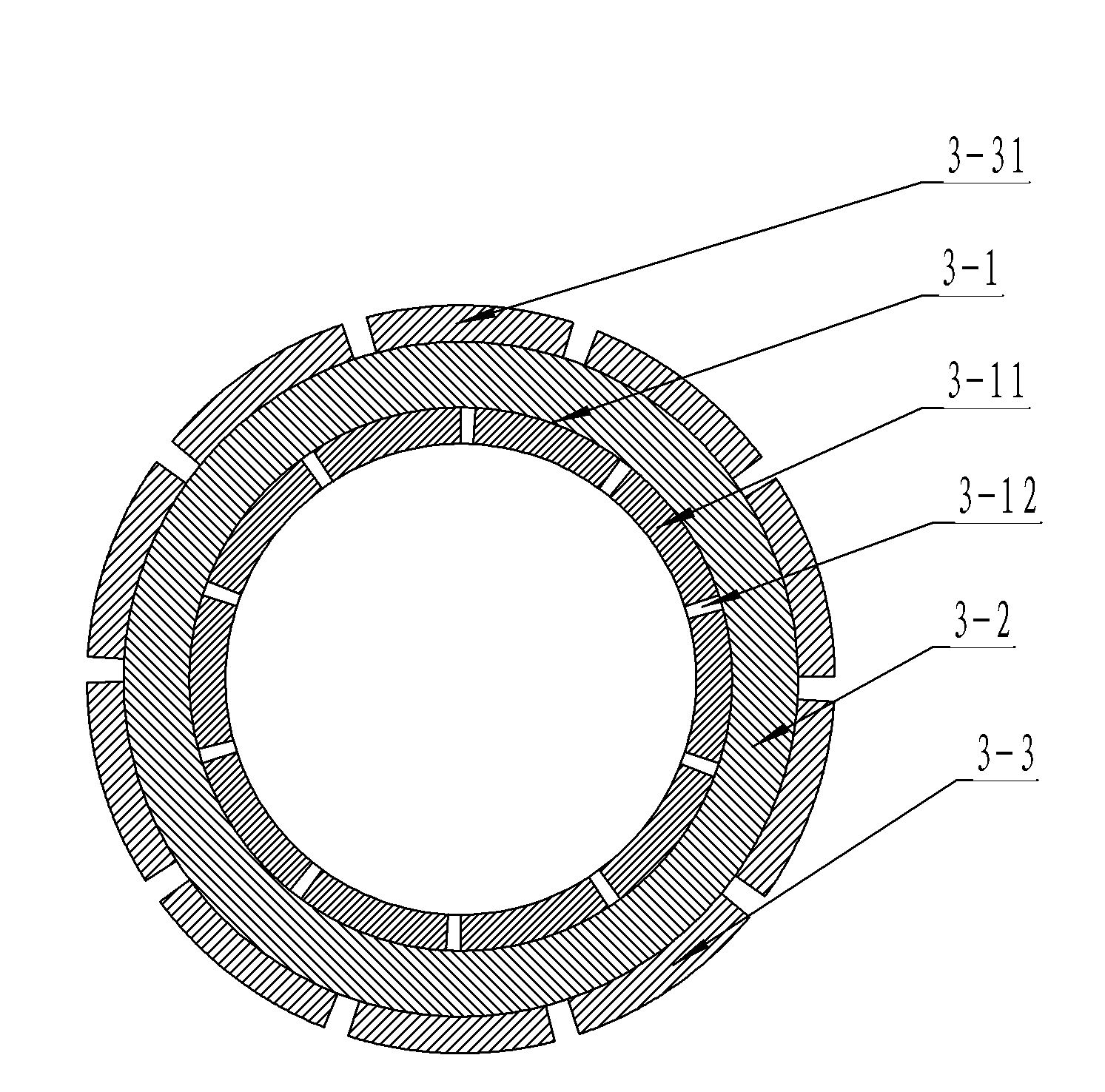

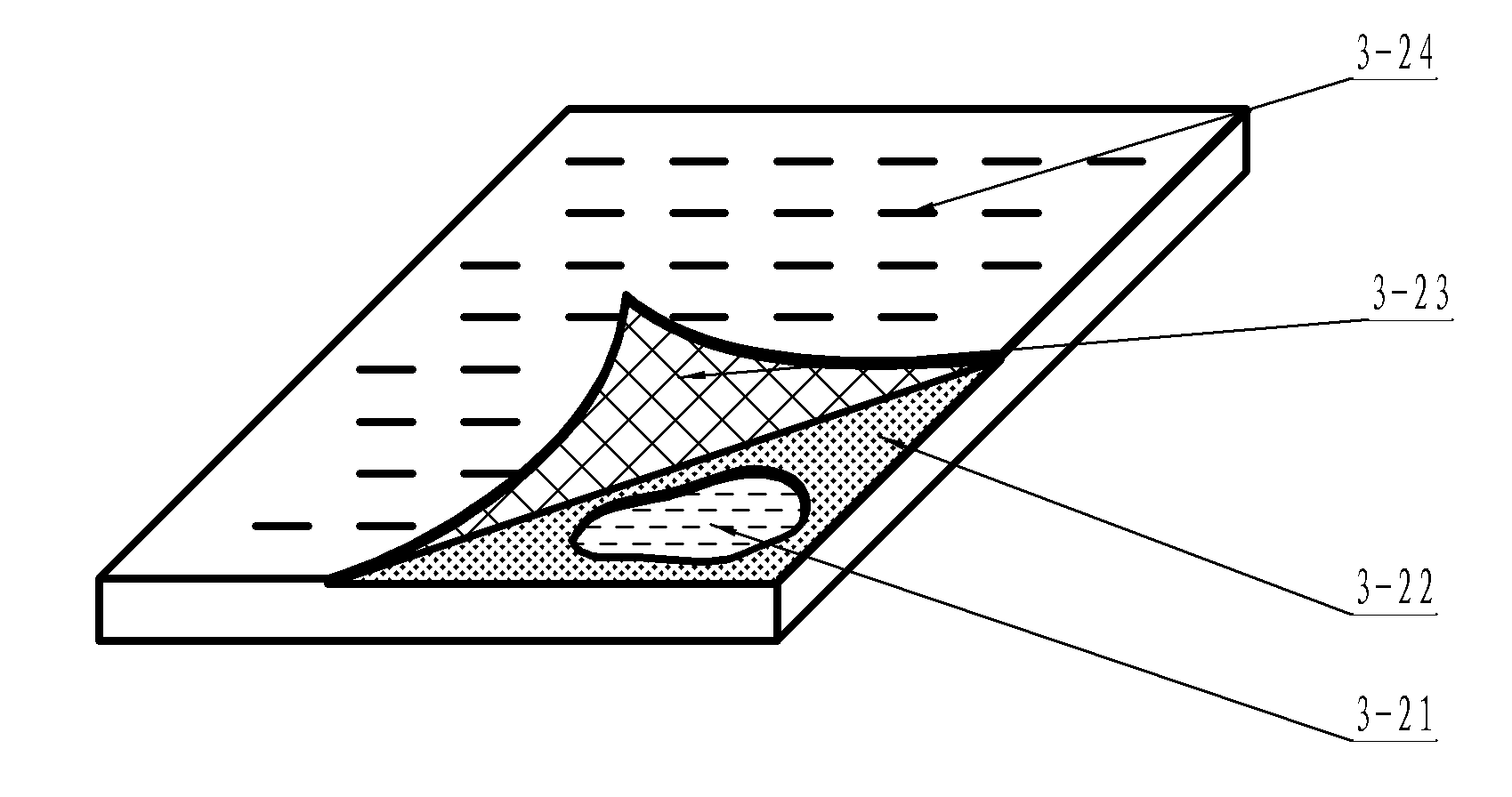

[0038] Such as figure 1 Shown is a schematic structural view of the first embodiment of the sealing assembly of the present invention. The figure shows the fixed part 1 and the cylindrical rotating part 2 of the hollow structure, and the sealing body 3 used for sealingly connecting the fixed part 1 and the rotating part 2 (the sealing assembly in this embodiment is the sealing body 3), wherein the sealing The front open end (large open end) of body 3 is fixed (preferably, sealed and fixed) on the rear open end of fixed part 1, makes sealing body 3 and the inner chamber of fixed part 1 communicate; (Small opening end) is set on the outer wall of the rotary part 2, that is, the inner side of the rear open end of the sealing body 3 is connected with the outer wall of the rotary part 2, so that the sealing body 3 and the inner cavity of the rotary part 2 are connected, when the rotary part 2 When rotating, the inner side of the rear opening end of the sealing body 3 and the outer...

Embodiment 2

[0043] Figure 4 As shown, it is another embodiment of the sealing assembly. The difference between this embodiment and Embodiment 1 is:

[0044] The diameter of the rear end surface of the fixed part 1 in Embodiment 1 is greater than the diameter of the front end surface of the rotary part 2, while the diameter of the rear end surface of the fixed part 1 in this embodiment is smaller than the diameter of the front end surface of the rotary part 2. At this time, the diameter of the rear open end is adopted. The sealing body 3 whose diameter is greater than the diameter of the front opening end (the sealing assembly of the present embodiment is the sealing body 3), so that the rear opening end of the sealing body 3 is compatible with the front opening end of the rotary part 2 and the front opening end of the sealing body It is suitable for the rear open end of the fixed part 1.

[0045] Preferably, in the case of this embodiment, in order to make the rear open end of the seali...

Embodiment 3

[0047] Figure 5 It is a structural schematic diagram of the third embodiment of the seal assembly used between the fixed part and the rotating part. The difference between this embodiment and embodiment 1 is:

[0048] The sealing assembly in this embodiment (see Figure 5 ) also includes a hollow revolving body structure of the tapered support 4, the tapered support 4 is fixedly connected (also can adopt the sealing and fixed connection mode of welding) on the fixed part 1, the tapered support 4 can also be connected with the fixed part 1 Integral structure, the tapered support 4 plays the role of connecting the fixed part 1 and the sealing body 3, through the transition connection of the tapered support 4, the setting of the sealing body 3 is more flexible, and the support 4 of different structures can be used To change the relative relationship between the sealing body 3 and the rotating part 2. For example: when the diameter of the end face of the fixed part 1 is small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com