Patents

Literature

2373results about "Tyre repairing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

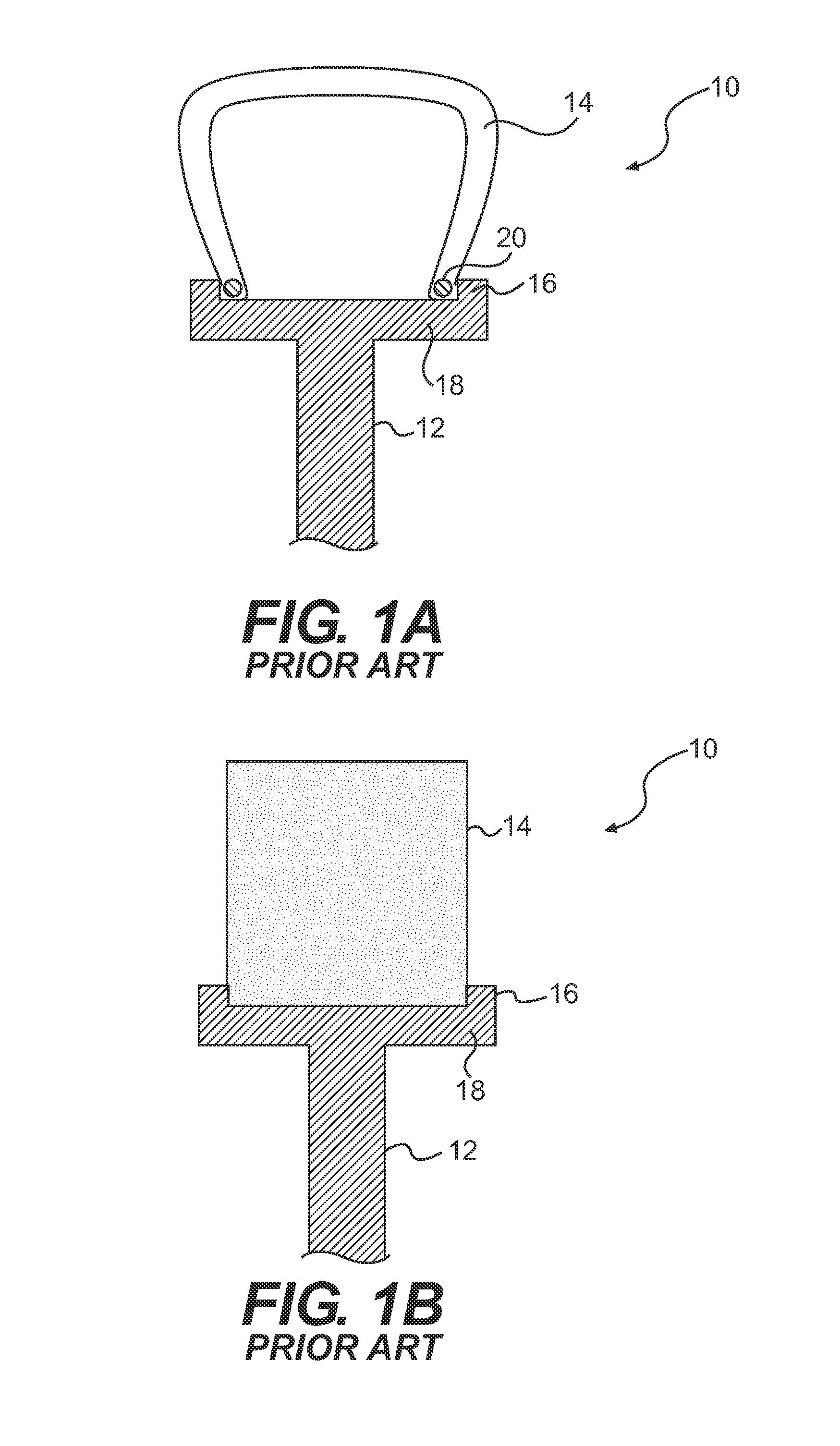

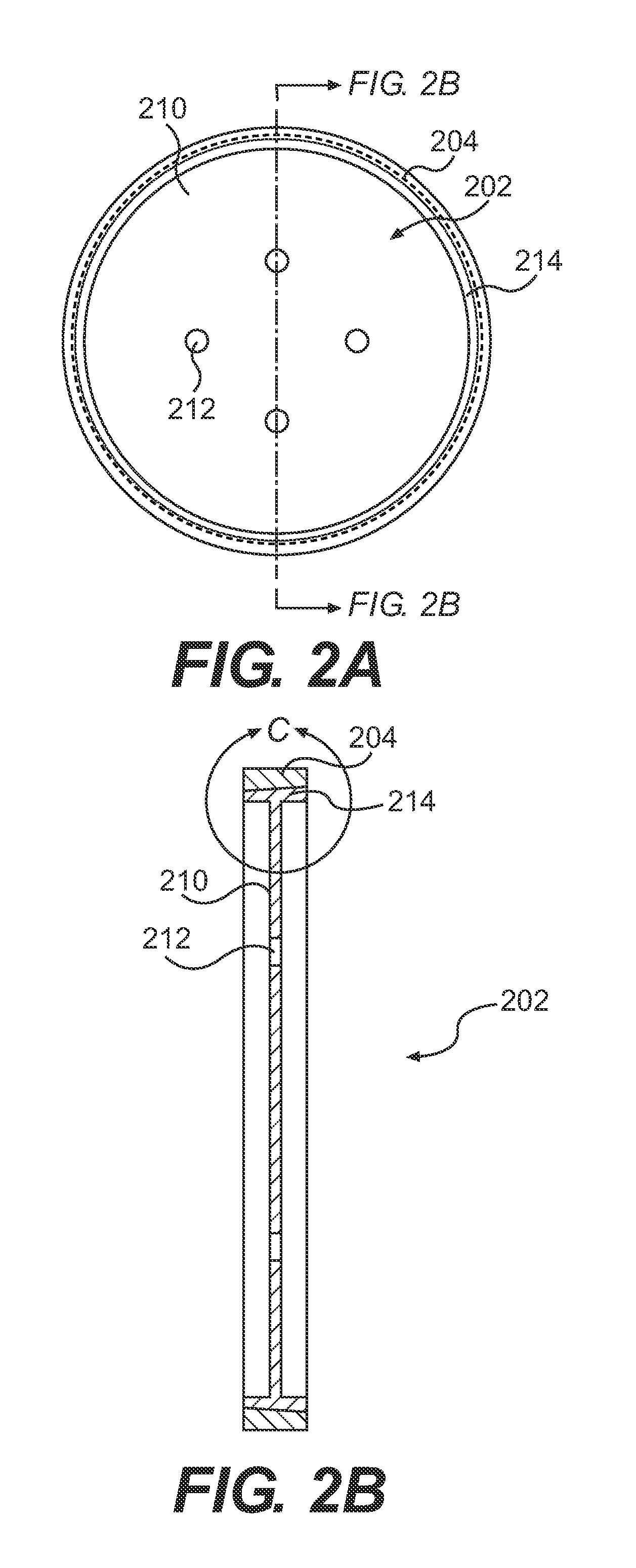

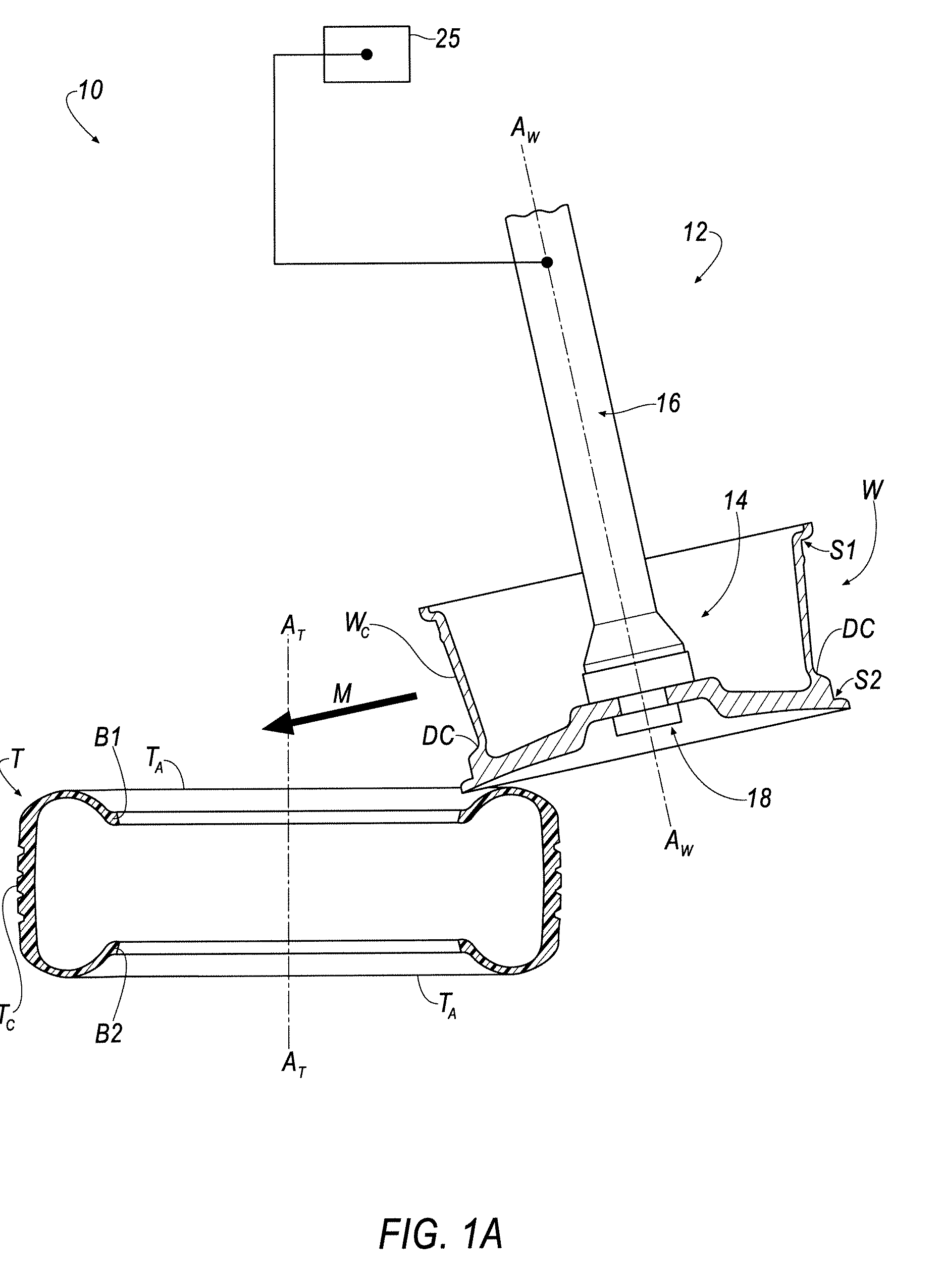

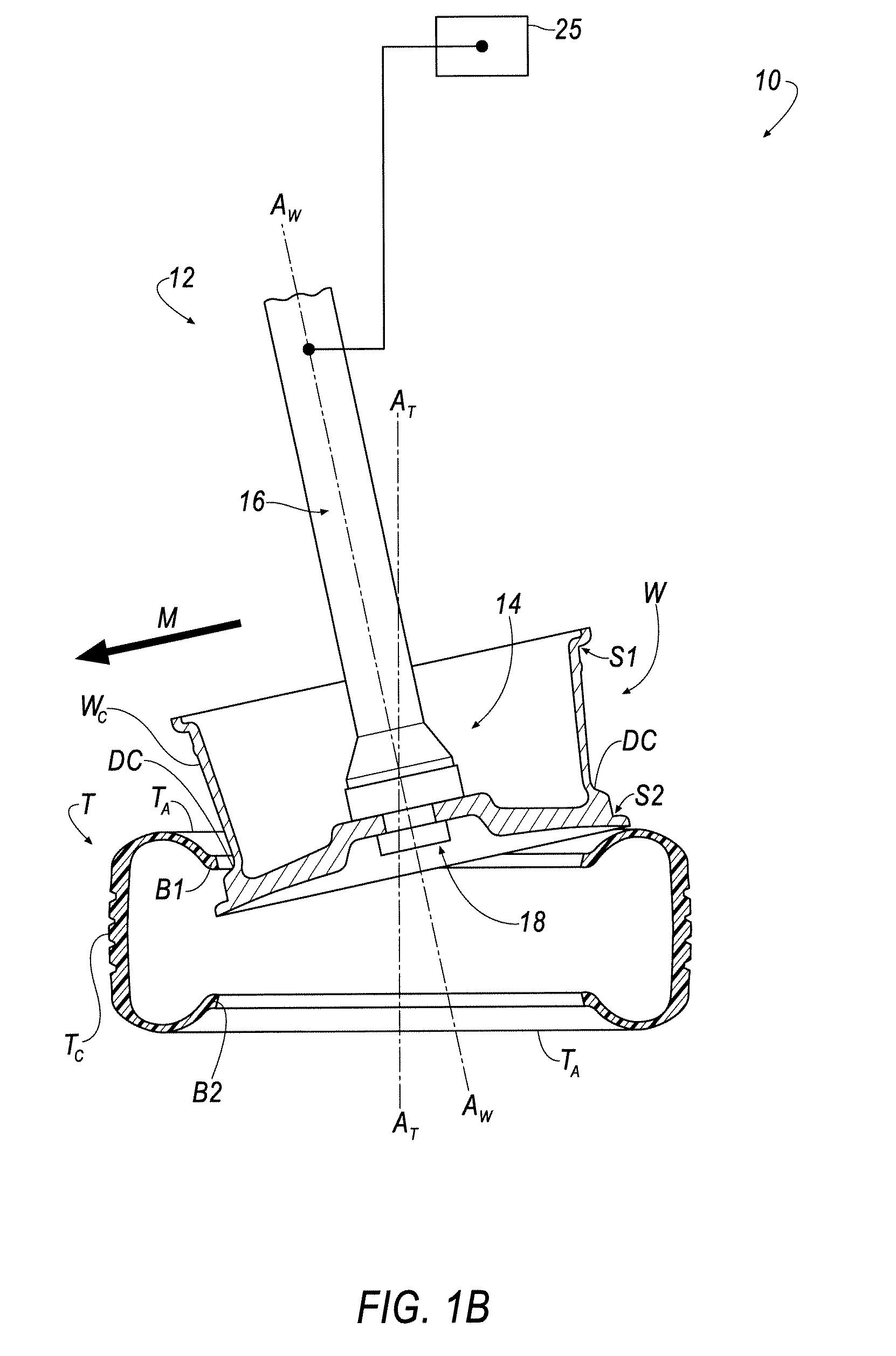

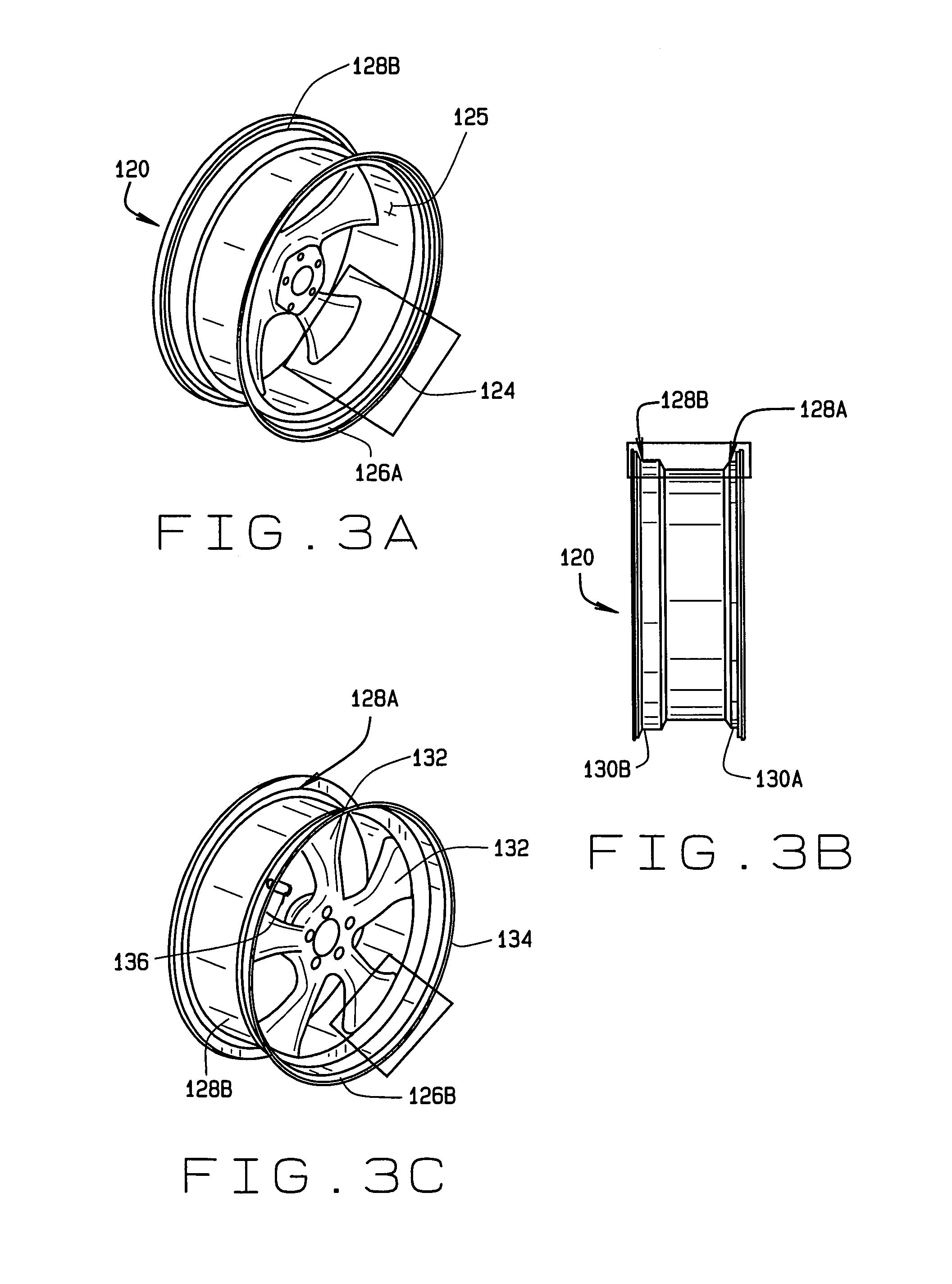

Self-inflating tire

ActiveUS8113254B2Great tractionTyre measurementsTyre-inflating valvesEngineeringMechanical engineering

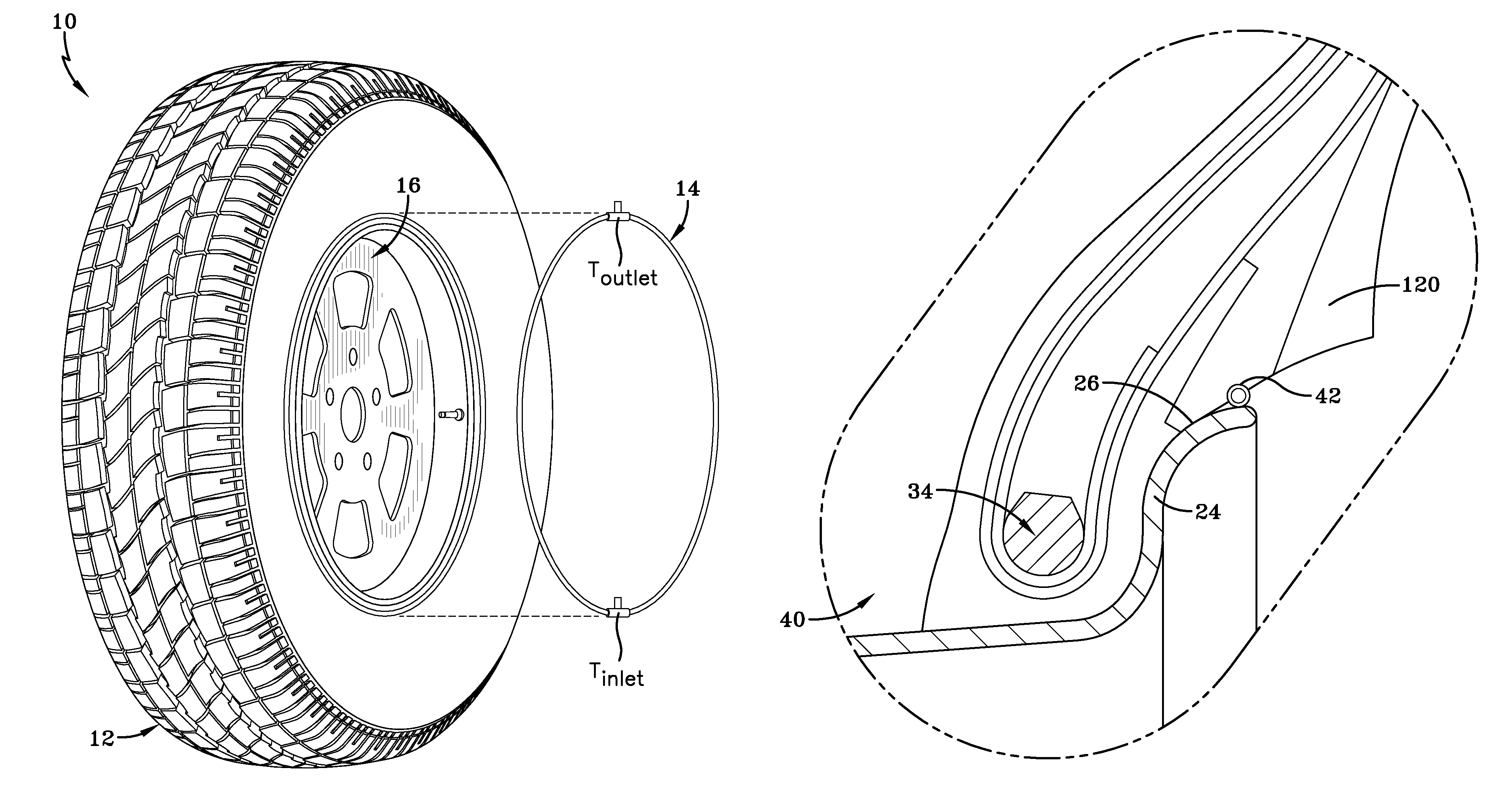

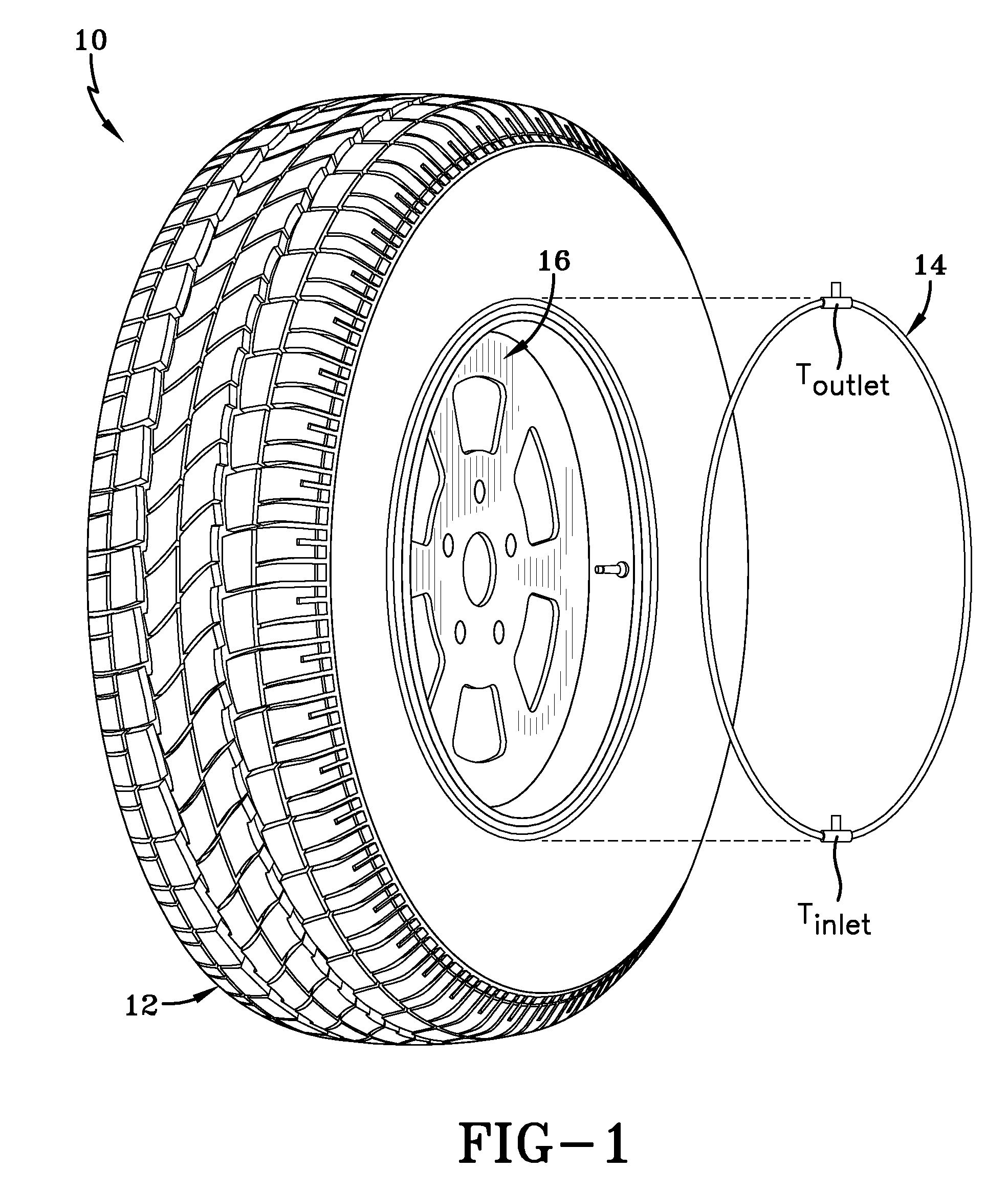

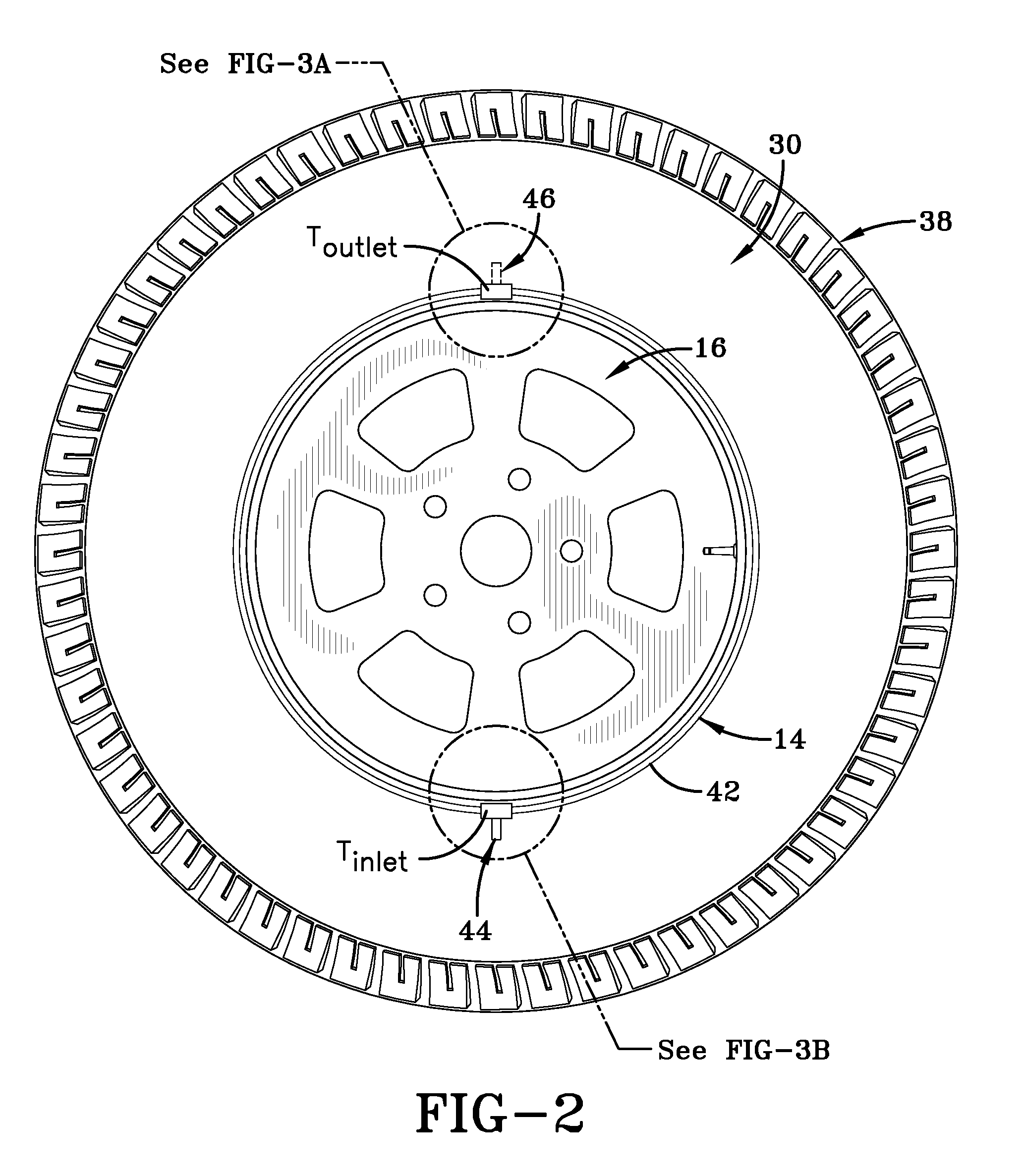

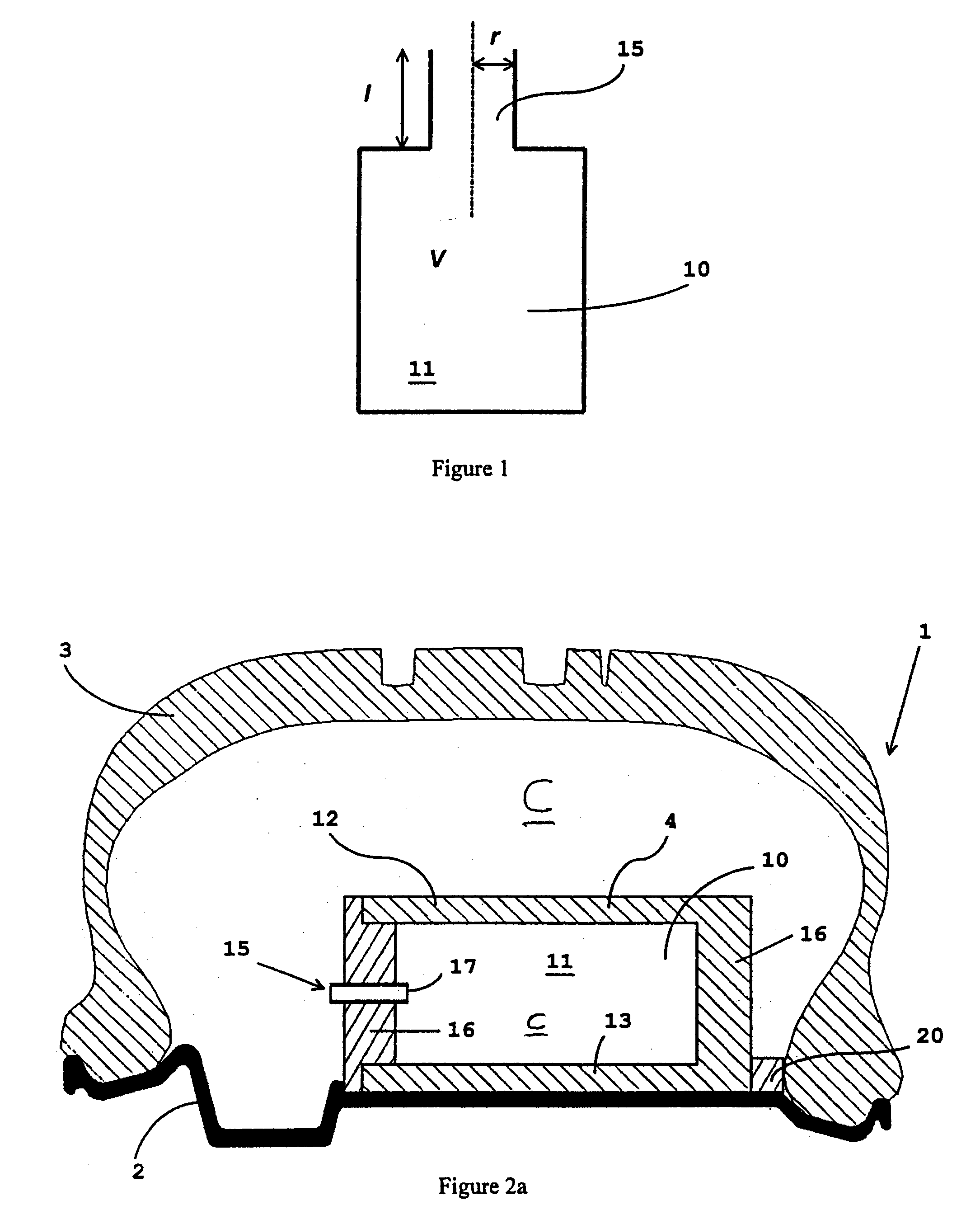

A self-inflating tire assembly includes an annular air tube connected to a tire and defining an annular air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to an inlet device for exhaust from the passageway or to an outlet device for direction into the tire cavity. The inlet device is positioned within the annular passageway 180 degrees opposite the outlet device such that sequential flattening of the air tube by the tire footprint effects pumping of air along the air passageway with the tire rotating in either a forward or reverse direction of rotation.

Owner:THE GOODYEAR TIRE & RUBBER CO

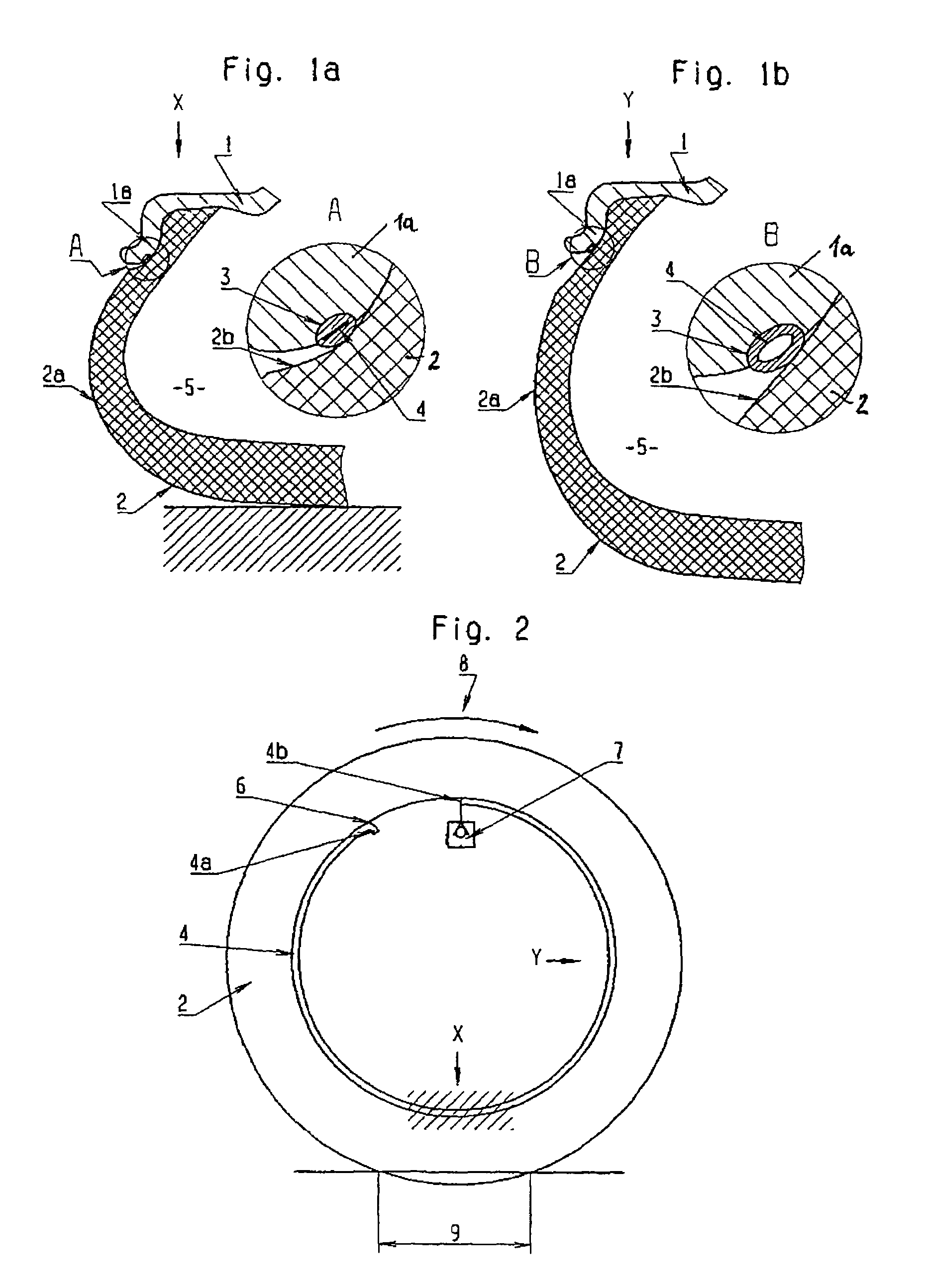

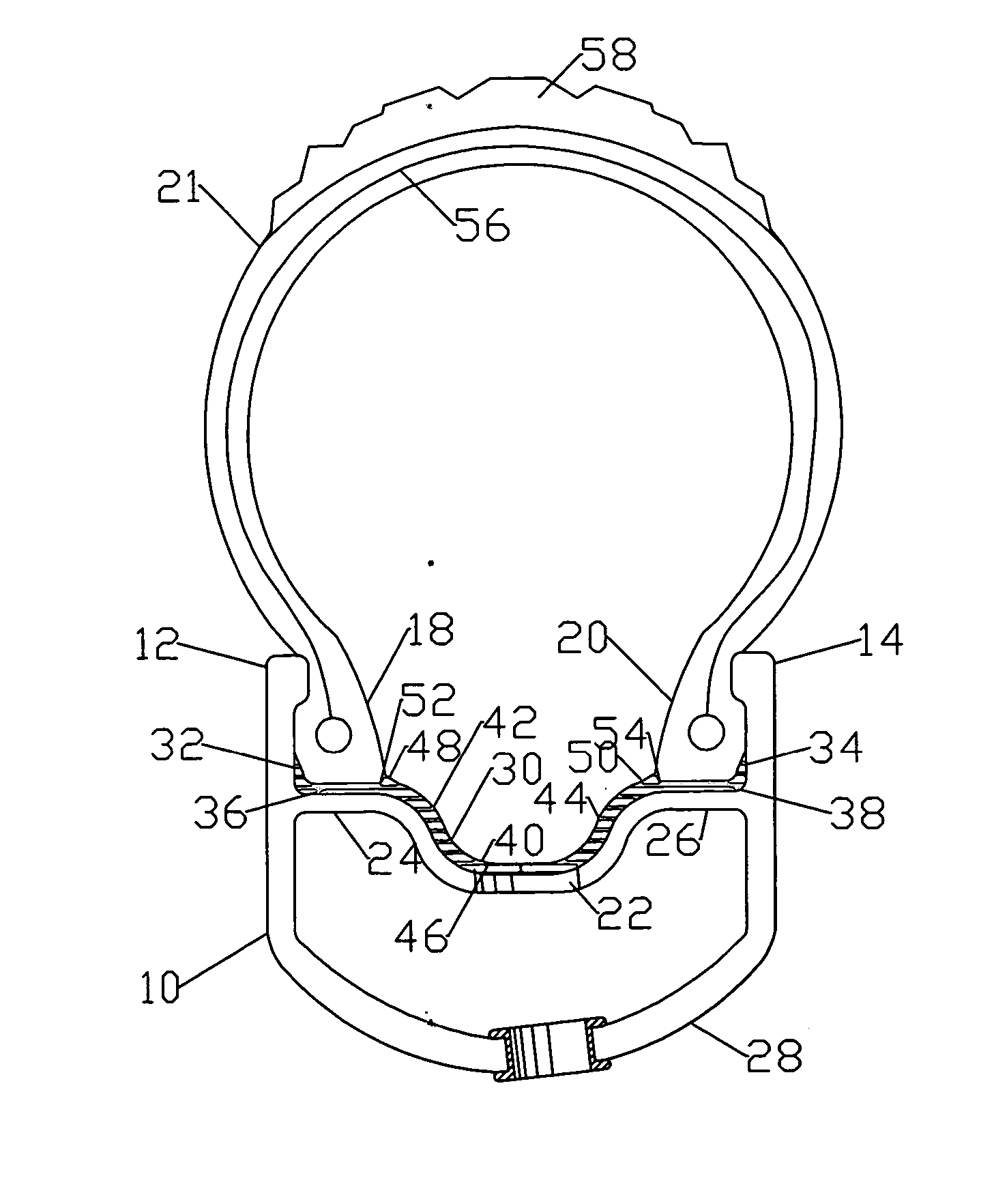

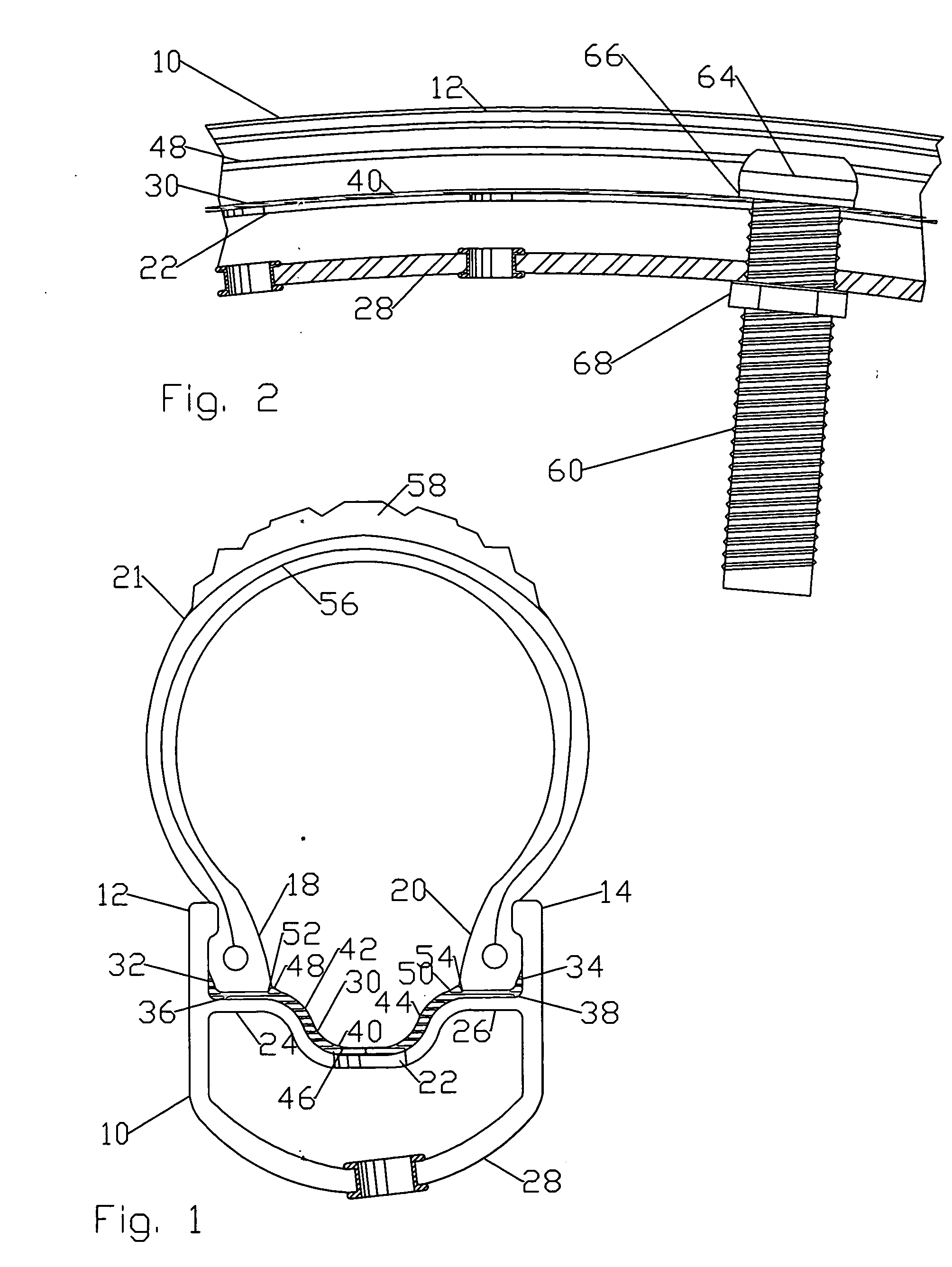

Arrangement for filling air into a rotating pneumatic tire

InactiveUS7225845B2Reduced strengthLose their sealing capabilityTyre measurementsTyre-inflating valvesFlangeTire pressure

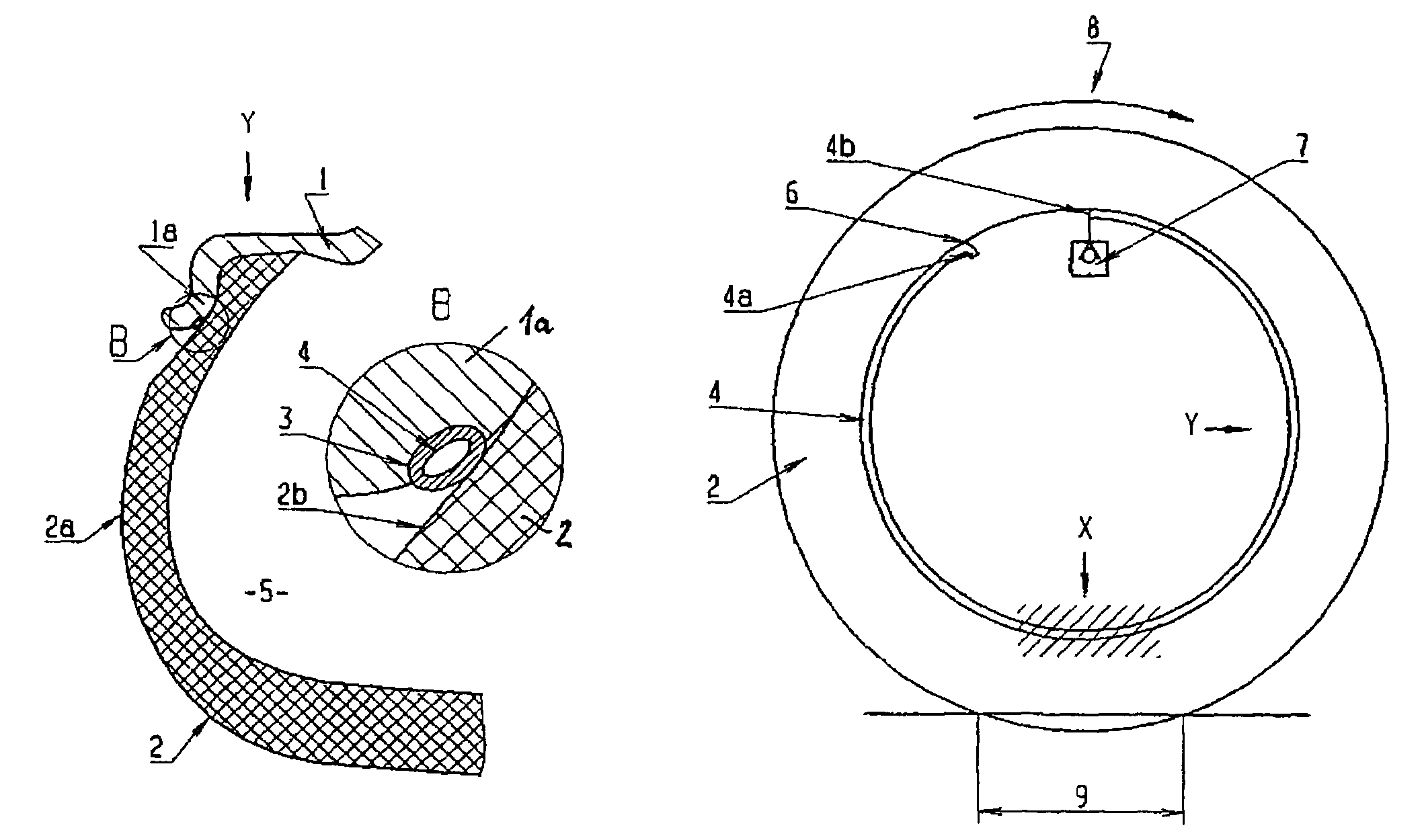

A hose-type structure is arranged essentially between the tire and the rim, which structure is connected at the end side with the environment and, by way of a valve, with the interior of the tire. The hose-type structure fills the tire during its rotating movement, and is locally squeezed from the environment side toward the tire interior, in which case the hose-type structure is provided in the area between the tire and the rim flange. A duct is provided in the rim flange or in the tire in the area of its bead chamfer, and at least partially receives the hose-type structure in the form of a hose. The geometry of the duct and of the hose-type structure is selected such that this air-conveying squeezing essentially takes place only as long as the internal tire pressure is below a desired value.

Owner:BAYERISCHE MOTOREN WERKE AG

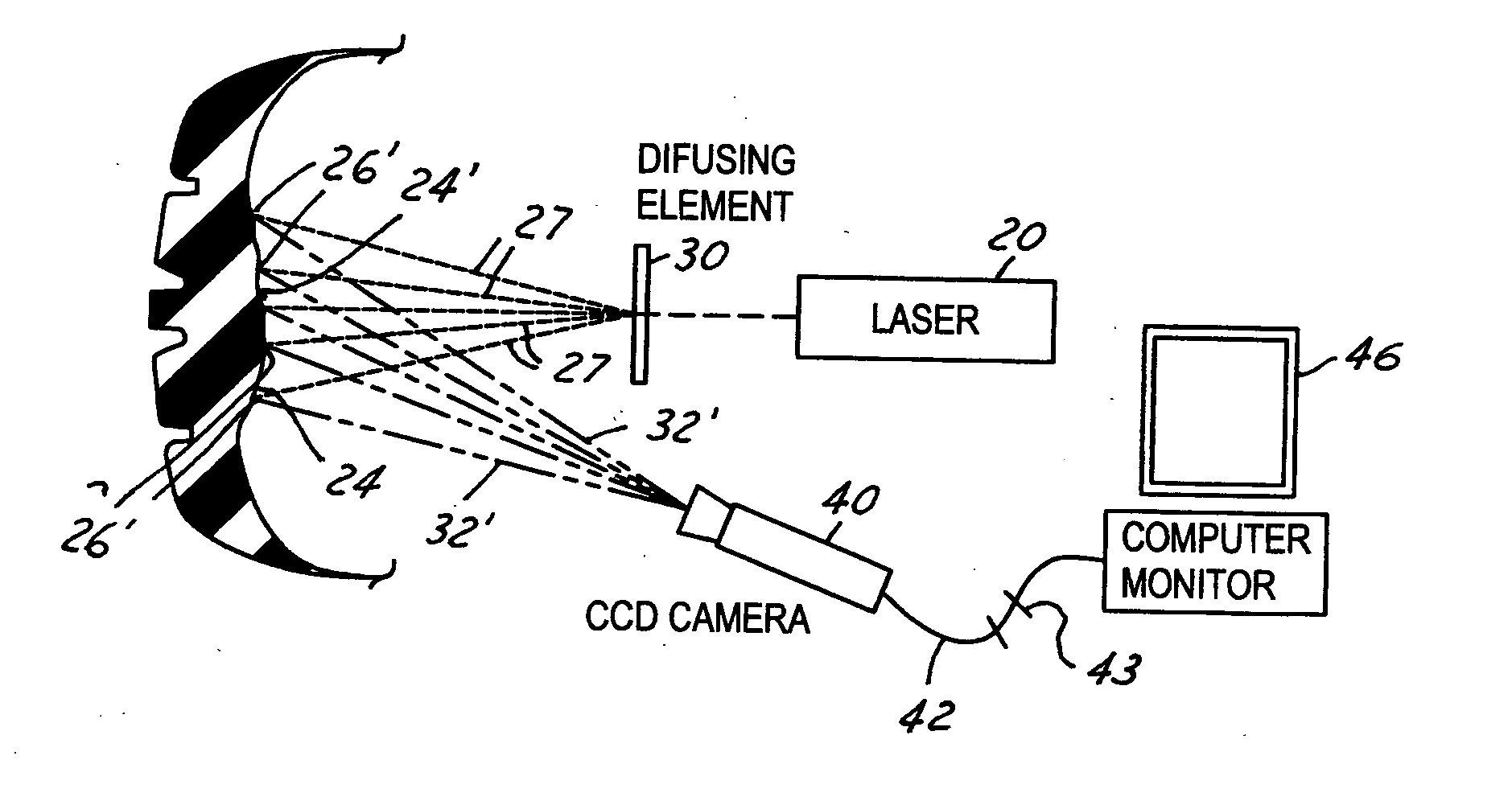

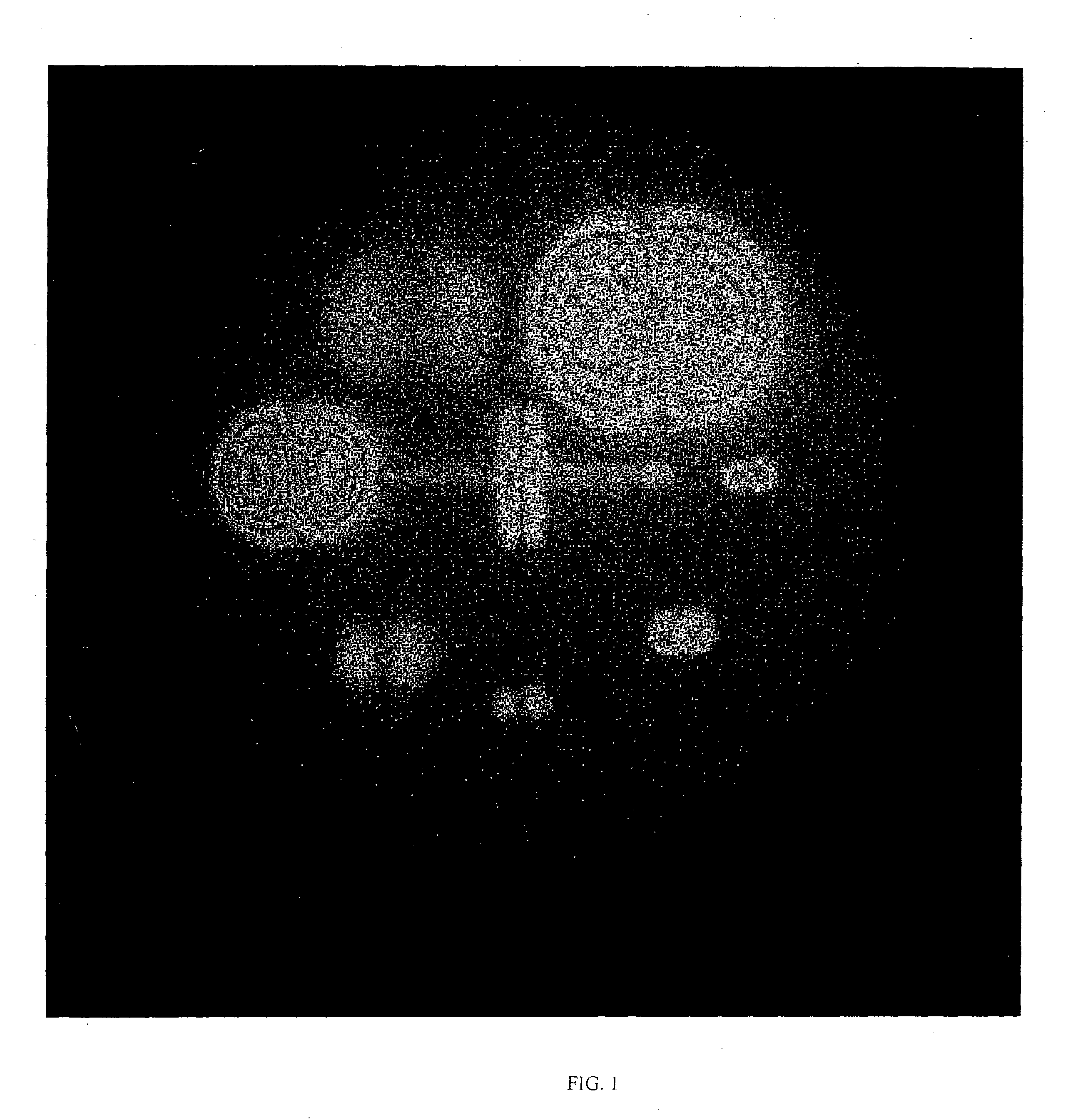

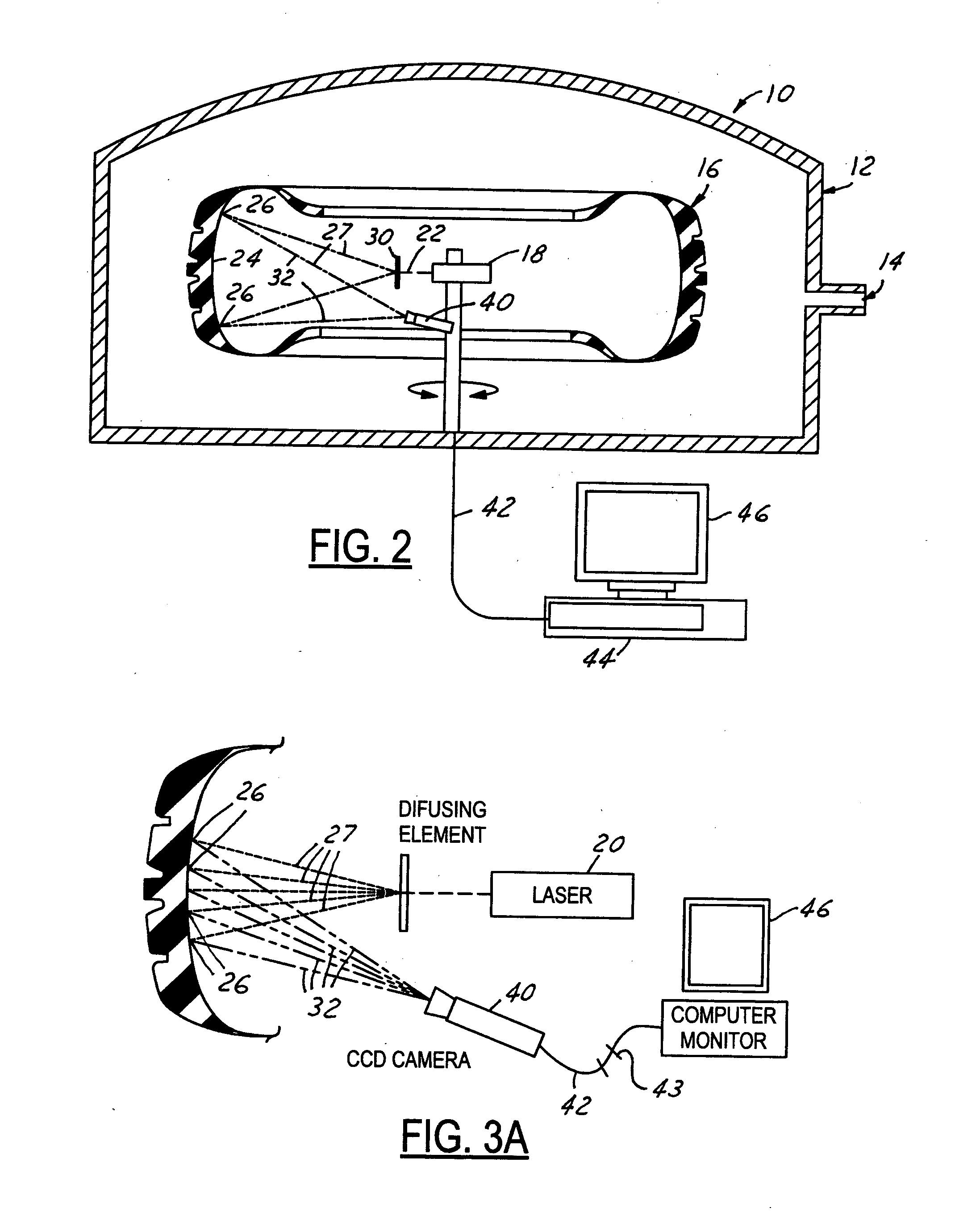

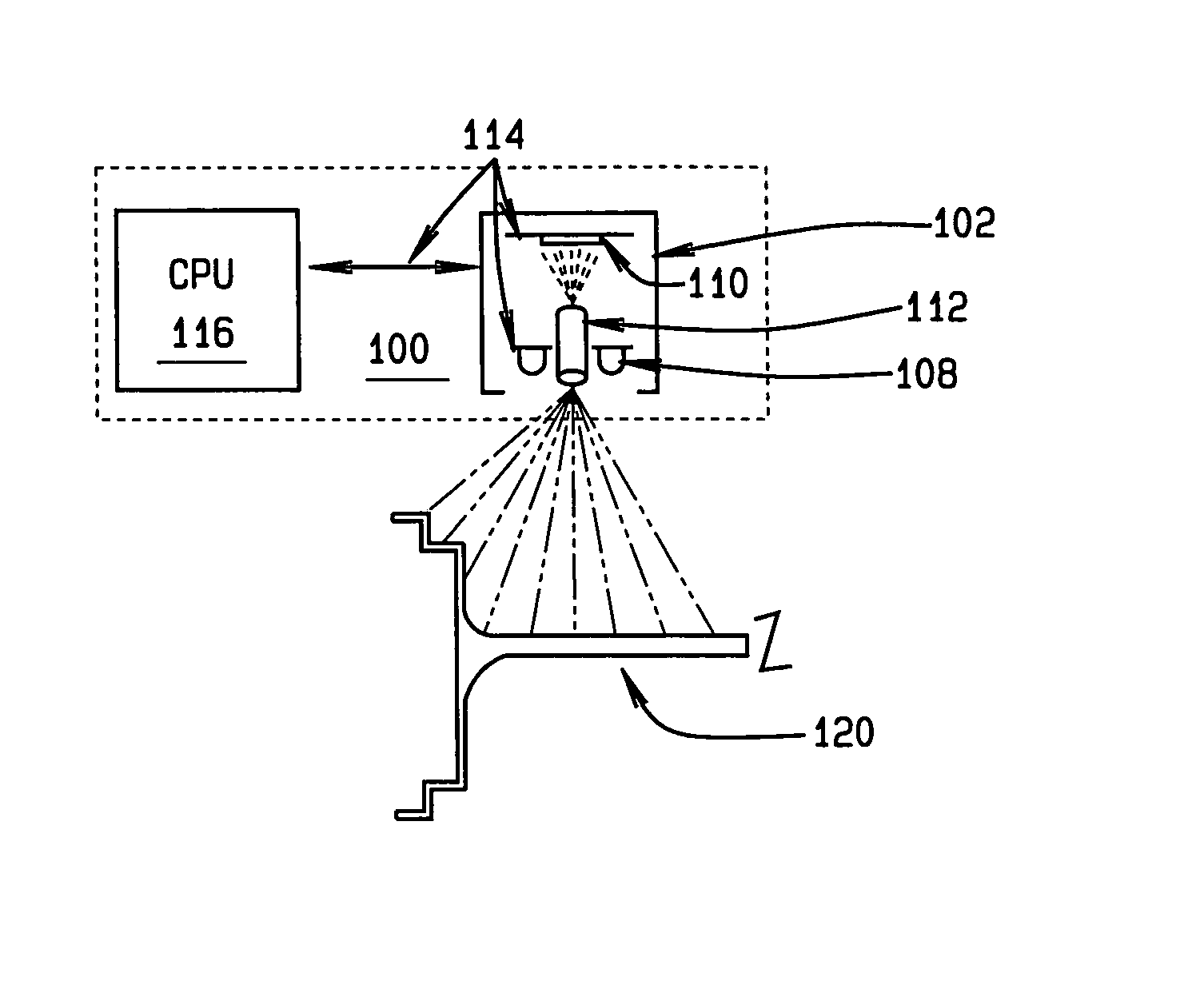

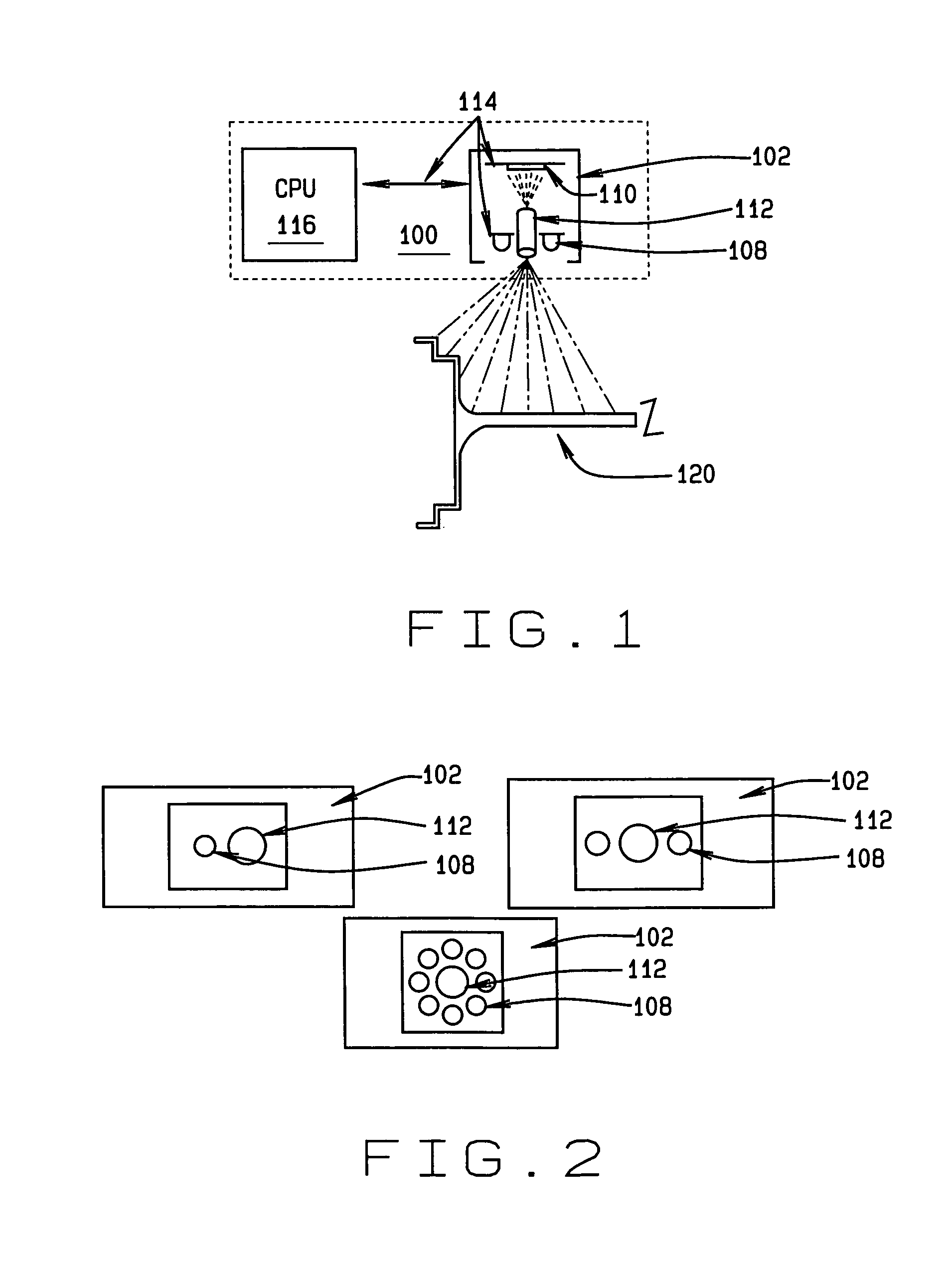

Tire inspection apparatus and method

InactiveUS20050052637A1Inflated body pressure measurementForce measurement by measuring optical property variationAnomaly detectionOptics

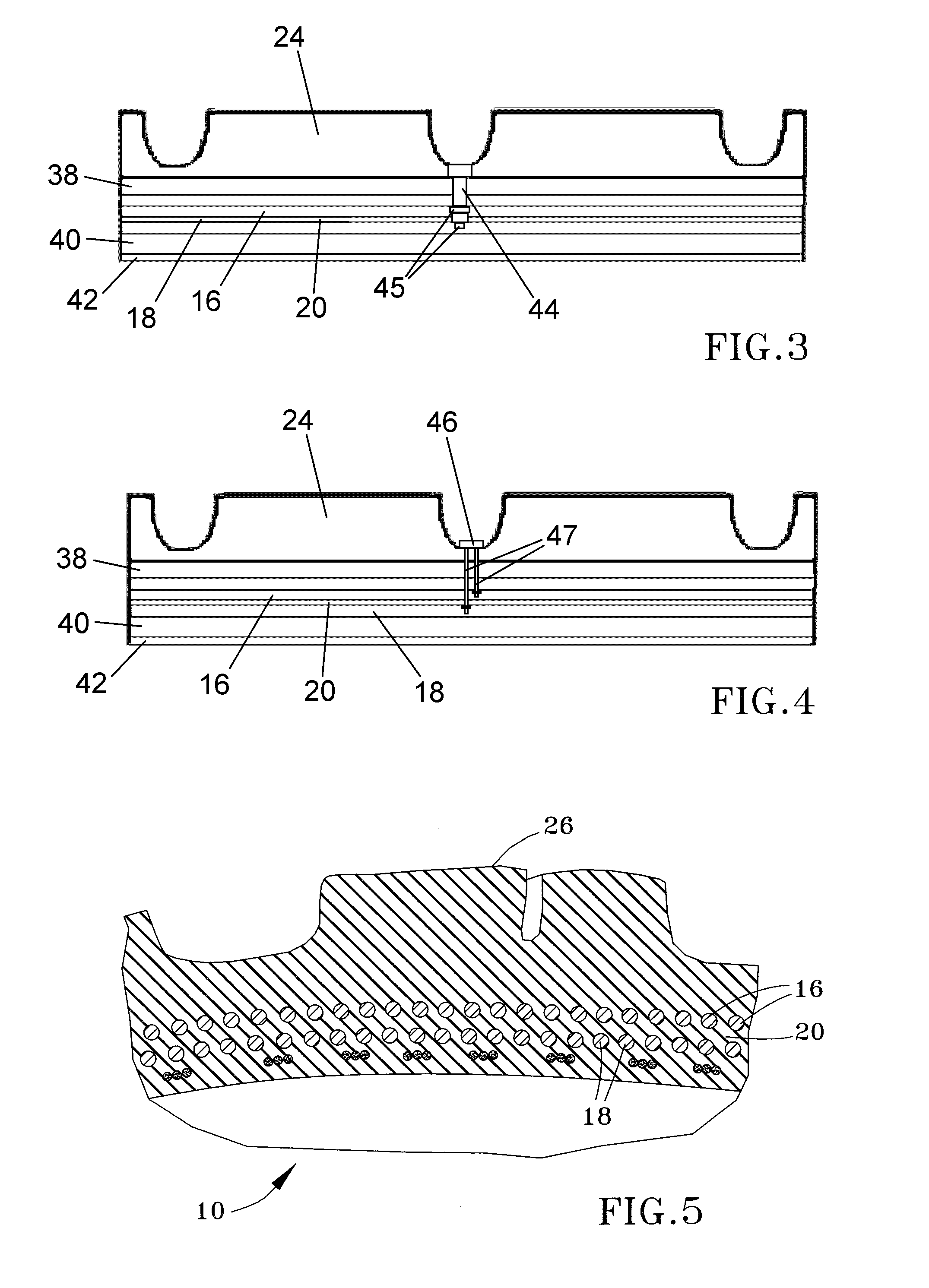

Described is an anomaly detector apparatus 10 for detecting an anomaly in a tire comprising: a source of coherent light 18 to shine the light 27 directly onto the tire surface 24 and the light being reflected 32 from the tire; a stressing apparatus 12 which can stress the tire; a reflected light receiving apparatus 40 for receiving the light 32 reflected directly from the tire surface 24 when the tire is in a stressed and unstressed condition; a processor 44 which compares images of reflected light from the reflected light receiving apparatus 40 when the tire is stressed and unstressed thereby ascertaining an anomaly in the tire and generates an output from the comparison; and a display apparatus 46 electronically connected to the processor for displaying the output from the processor.

Owner:RAVEN ENG

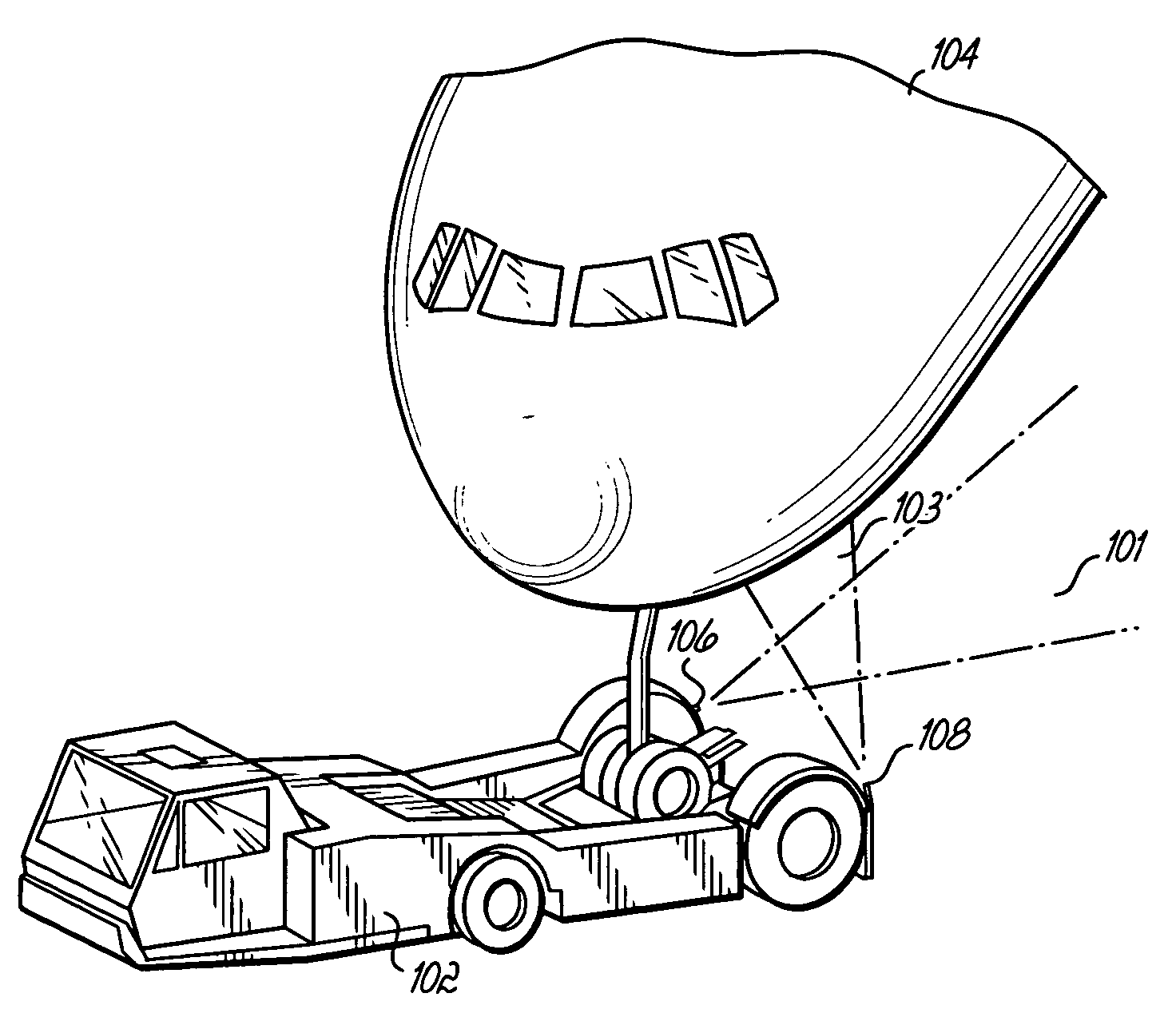

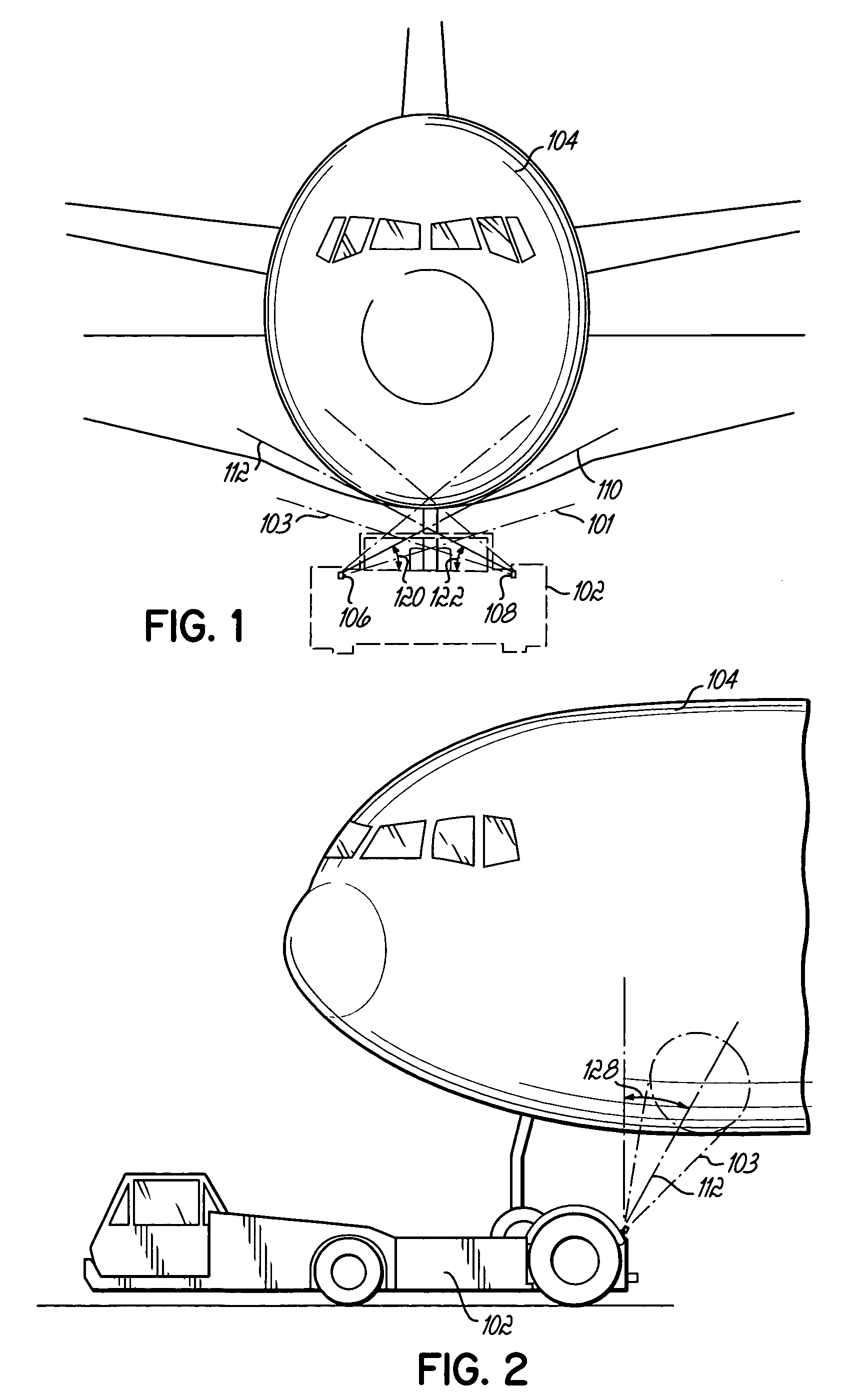

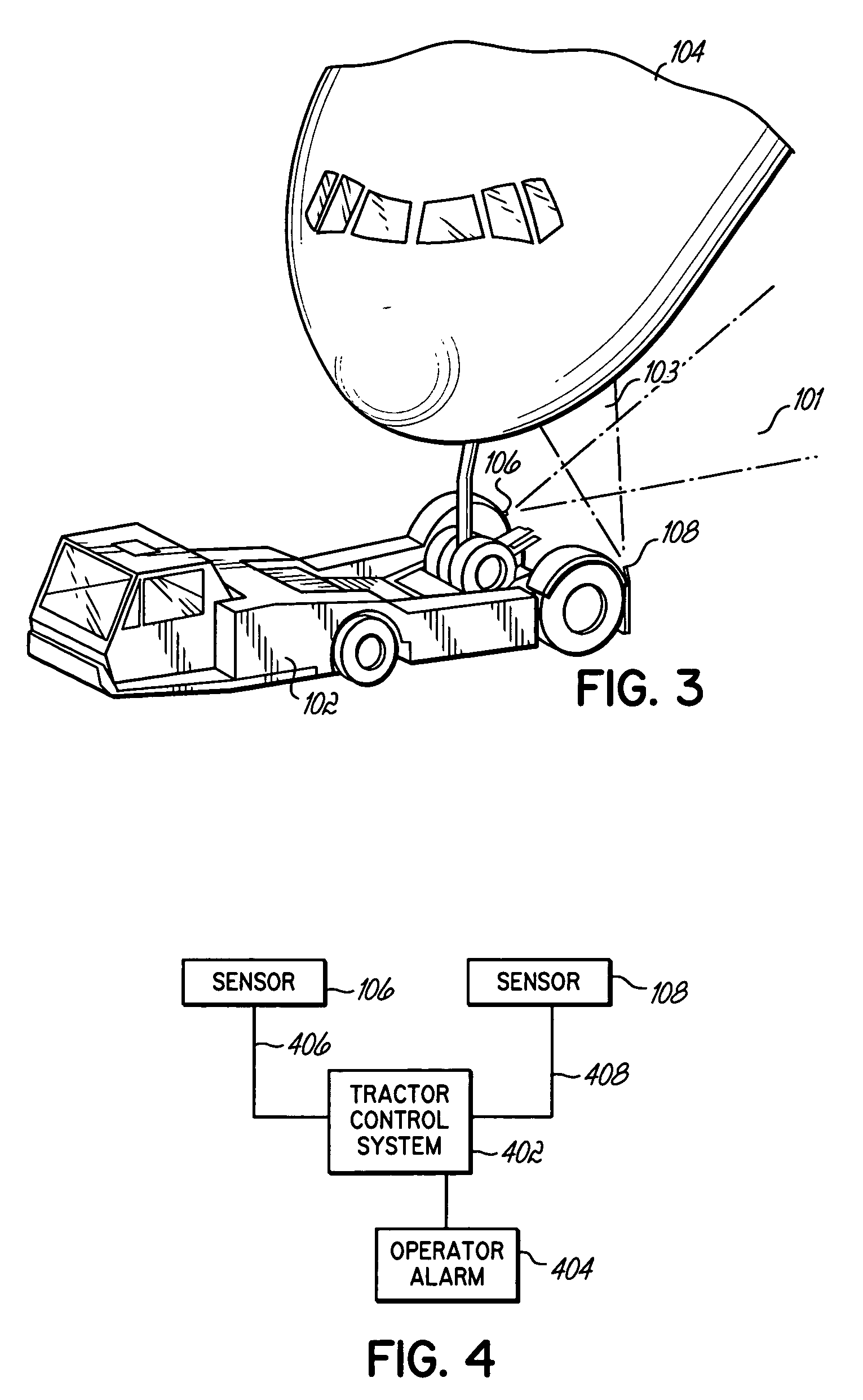

Method and system for over-steer avoidance

InactiveUS20050196256A1Minimize false positiveEasy to operateWheel mounting apparatusManual conveyance devicesEarly warning systemUltrasonic sensor

An early warning system for a tractor operator engaged in towing or pushing an aircraft includes two ultrasonic sensors that are used to create a detection area in which the aircraft should be present when the steering angle is well within a safe range. When one of the detectors fails to detect the presence of the aircraft, then the operator is alerted, before over steering can occur, in order that corrective action can be undertaken. Accordingly, complex distance-measuring algorithms can be avoided as can the requirement that an aircraft fuselage have a specially modified detection region.

Owner:FMC TECH INC

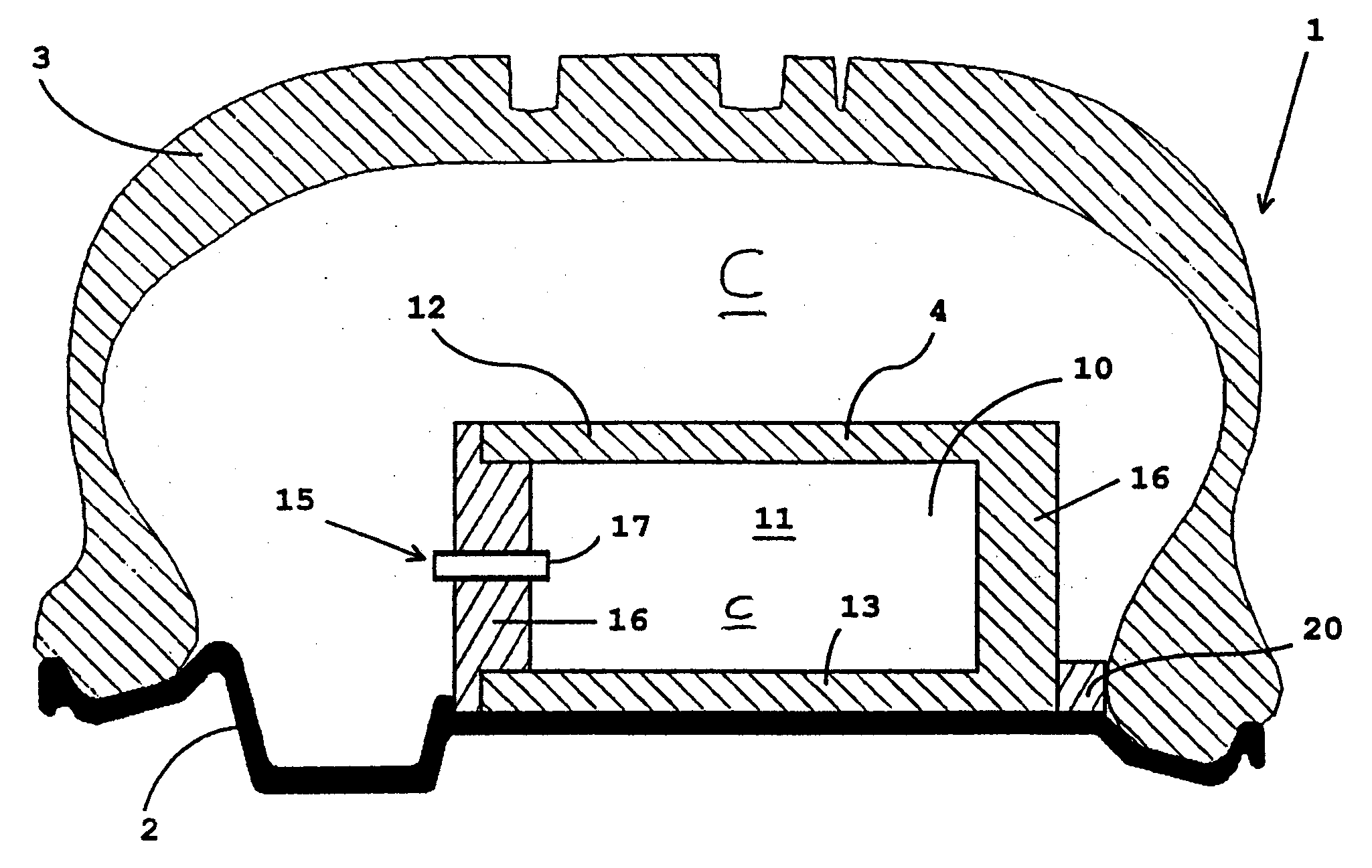

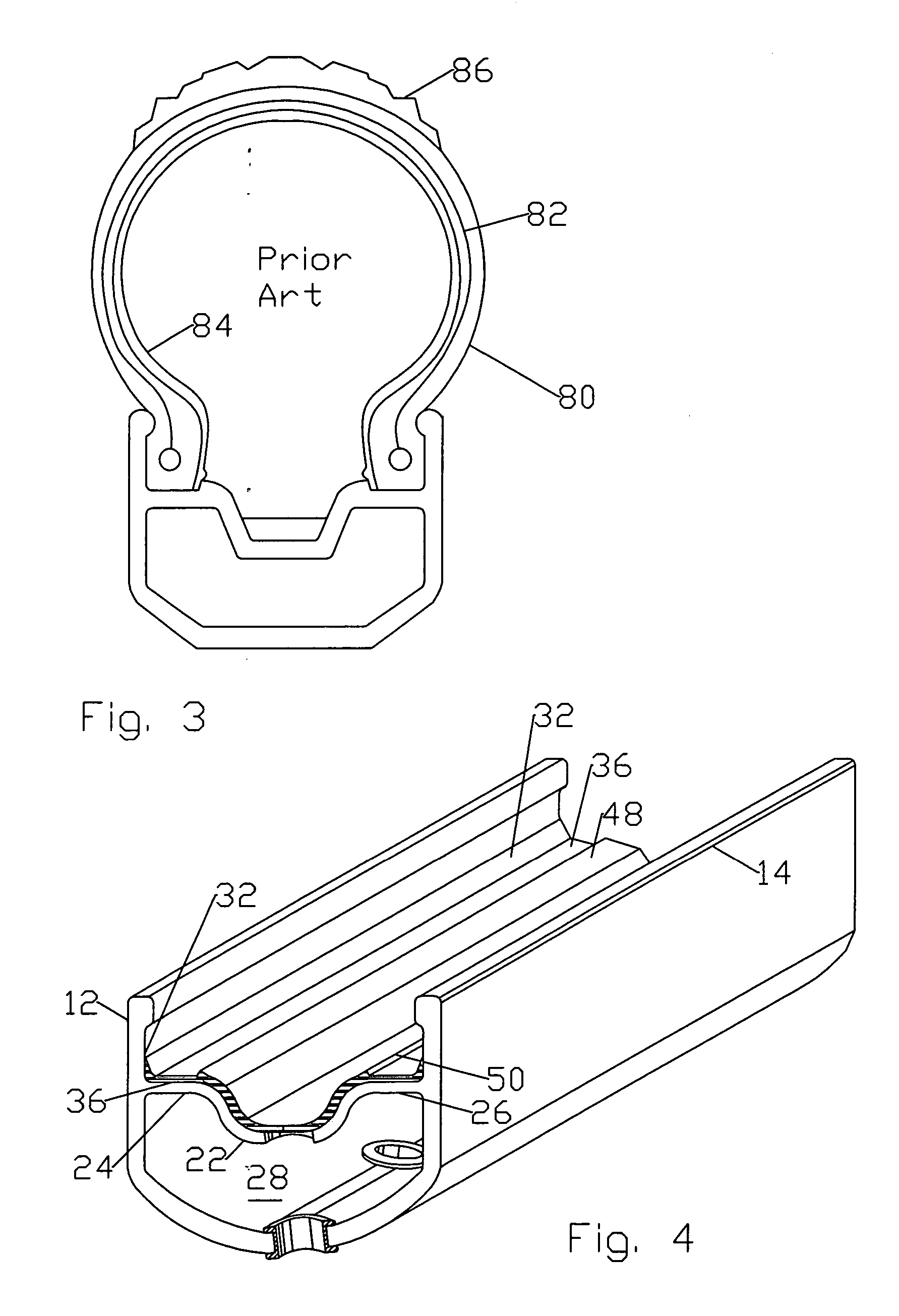

Safety support with a noise attenuator for a vehicle wheel

InactiveUS6516849B2Permit dissipation of vibrational energyMinimize eliminate transferWithout separate inflatable insertsRimsTreadResonator

Owner:MICHELIN RECH & TECH SA

Method and apparatus for gripping and transferring pieces of luggage

ActiveUS8473094B2Increase suction pressureIncrease contact pressureDigital data processing detailsGripping headsEngineeringGrippers

A method and an apparatus for automatically removing pieces of luggage that have different surface properties and dimensions and getting the pieces of luggage ready for further transport by means of a gripper that is hingedly connected to a robot arm is described. The method includes: a) moving the gripper and the container that is to be emptied close together; b) determining the first piece of luggage to be removed; (c) gripping the piece of luggage using a horizontal suction elements (3) and withdrawing the luggage horizontally; d) if the vertical suction elements (4) are not yet able to sufficiently grip the luggage, the vertical suction elements (4) are repositioned and turned off, the vertical suction elements (5) are repositioned, and then turned on to re-grip the piece of luggage.

Owner:GRENZEBACH MASCHINENBAU GMBH

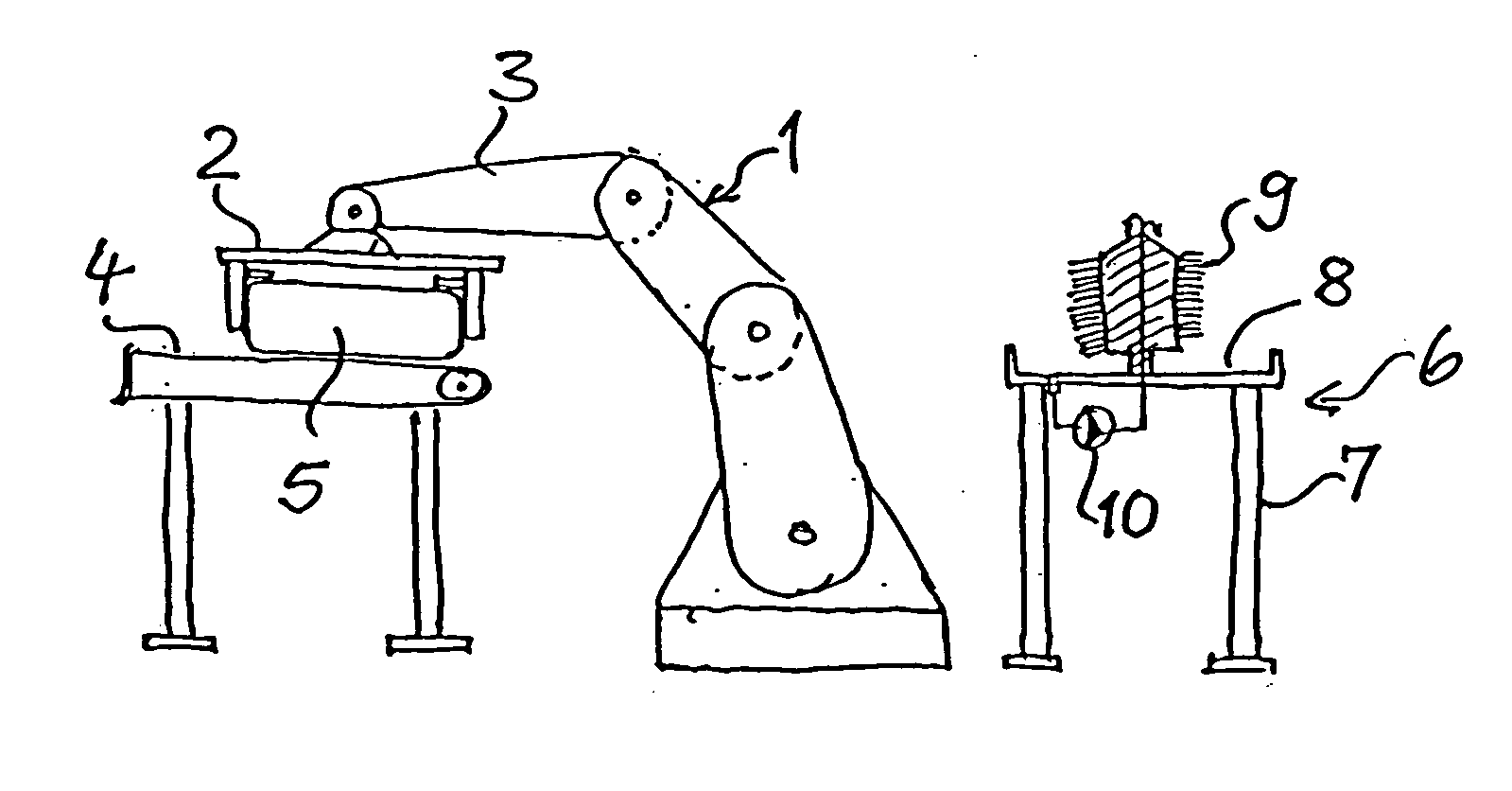

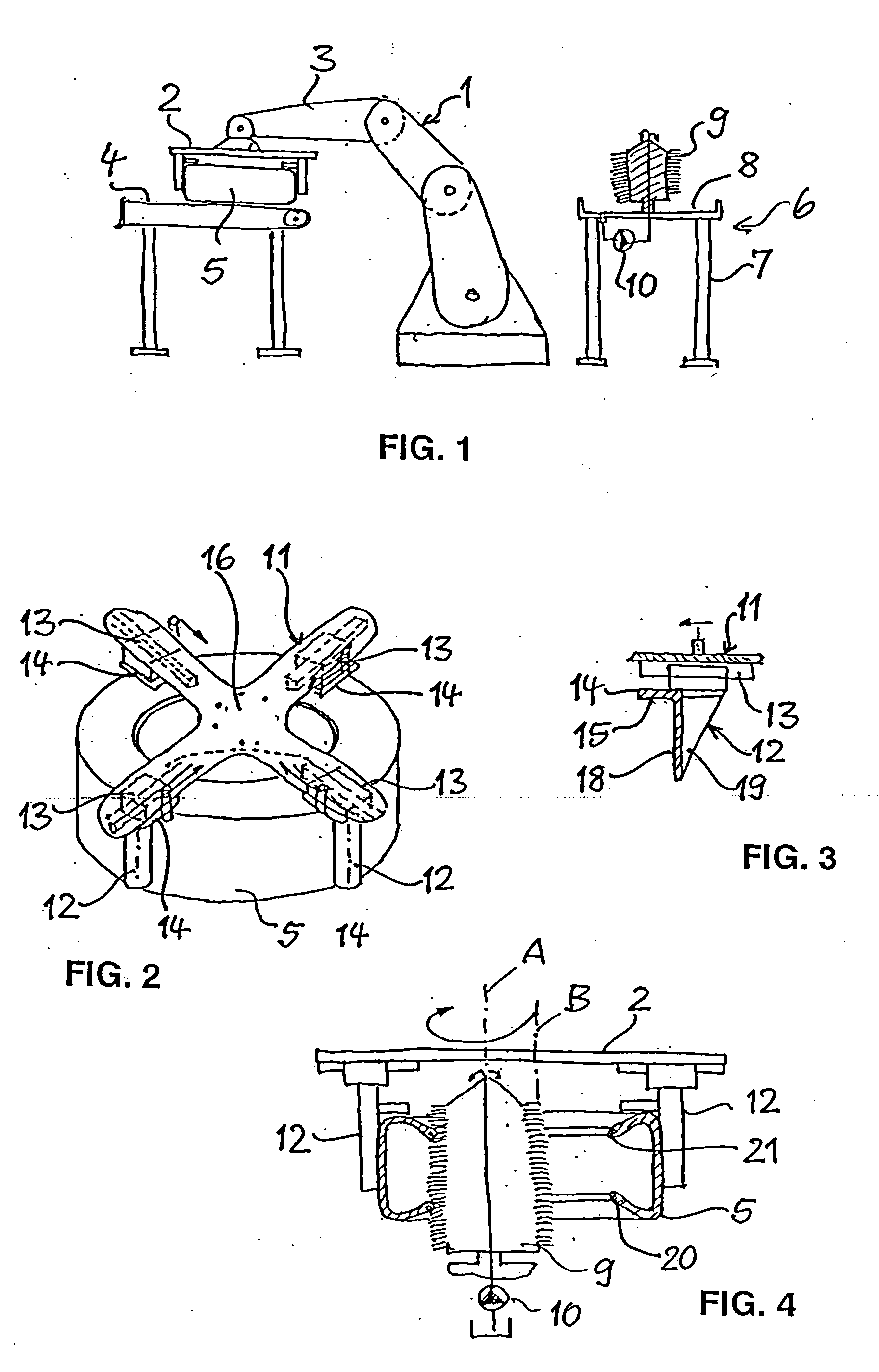

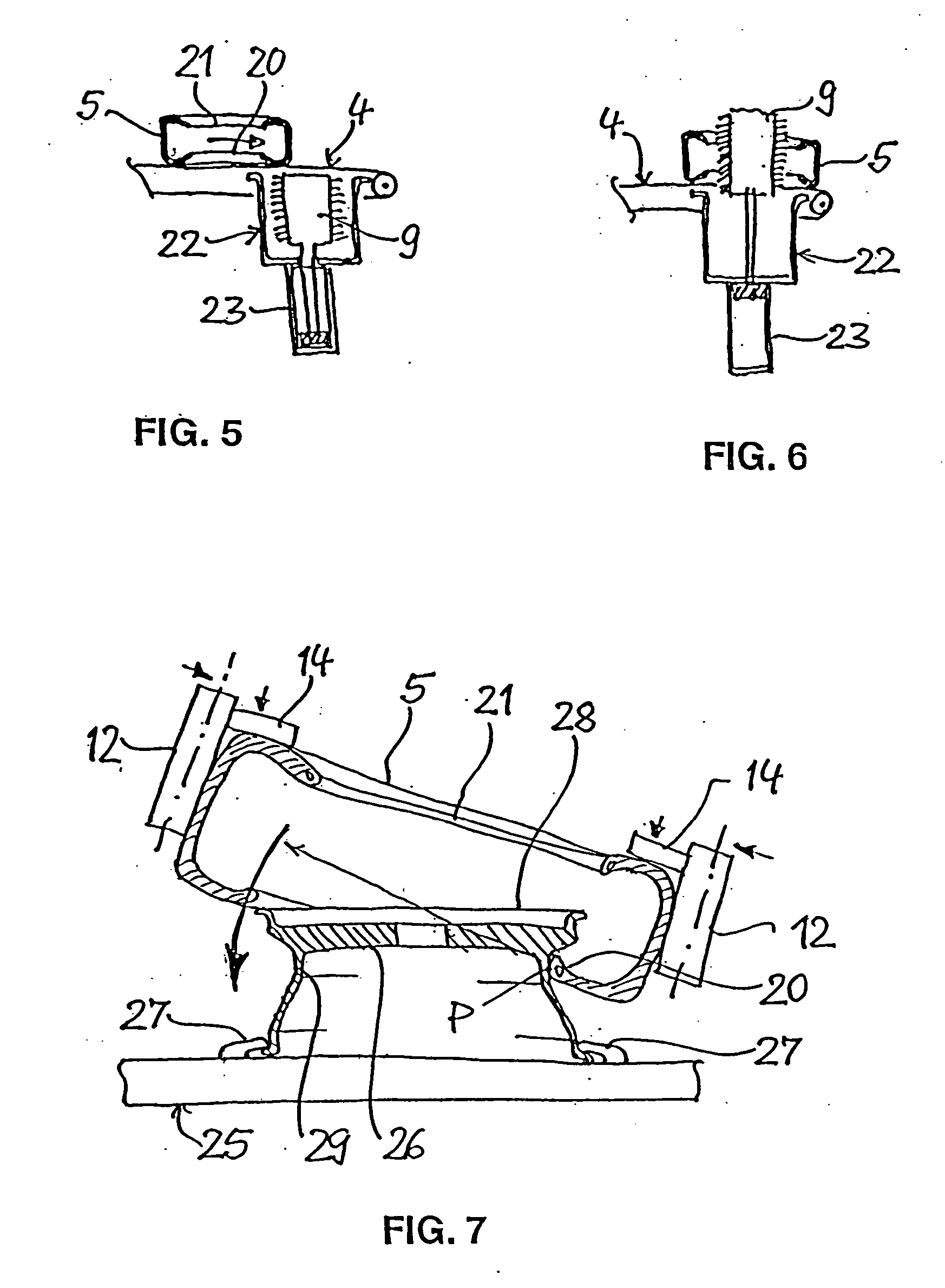

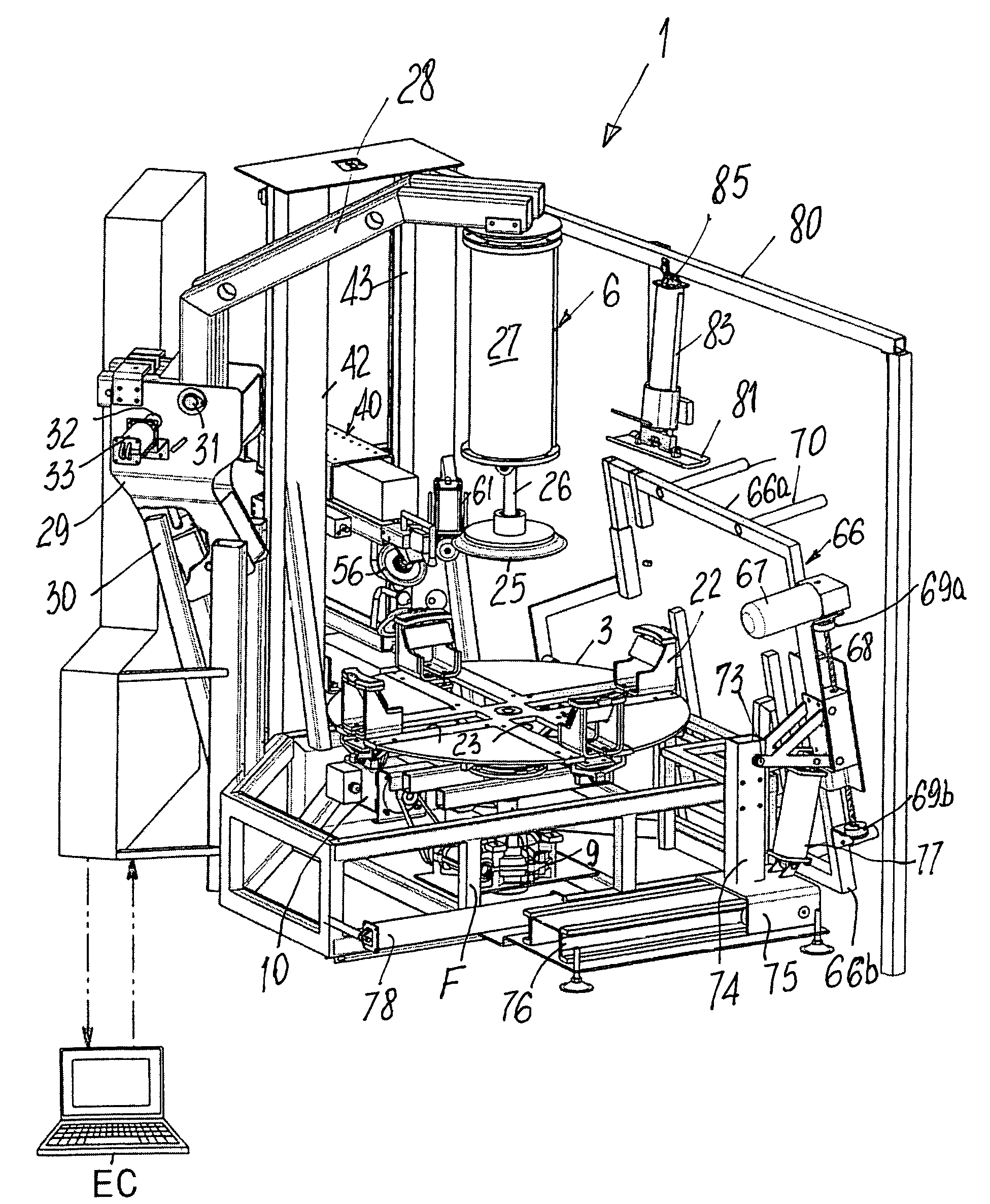

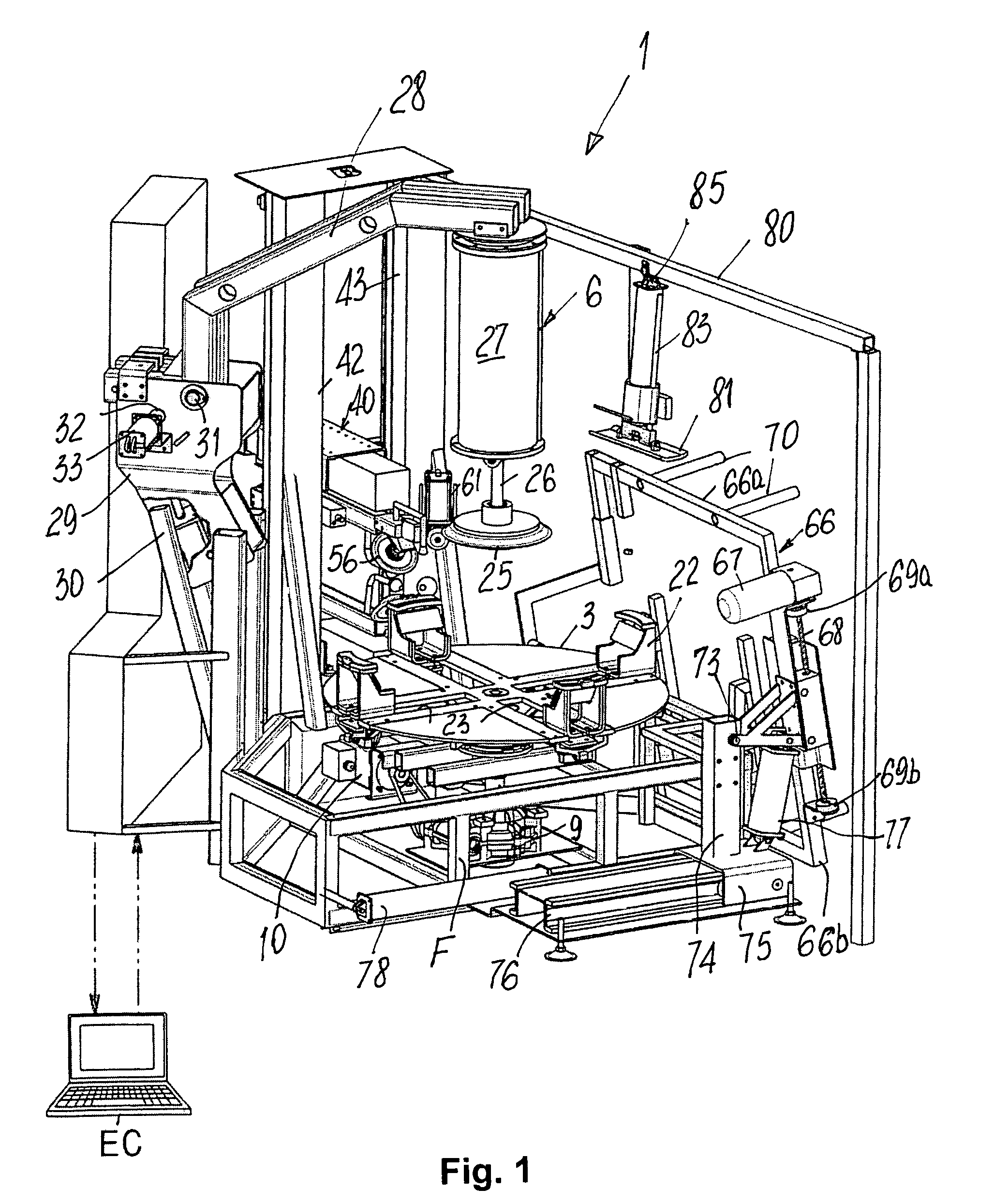

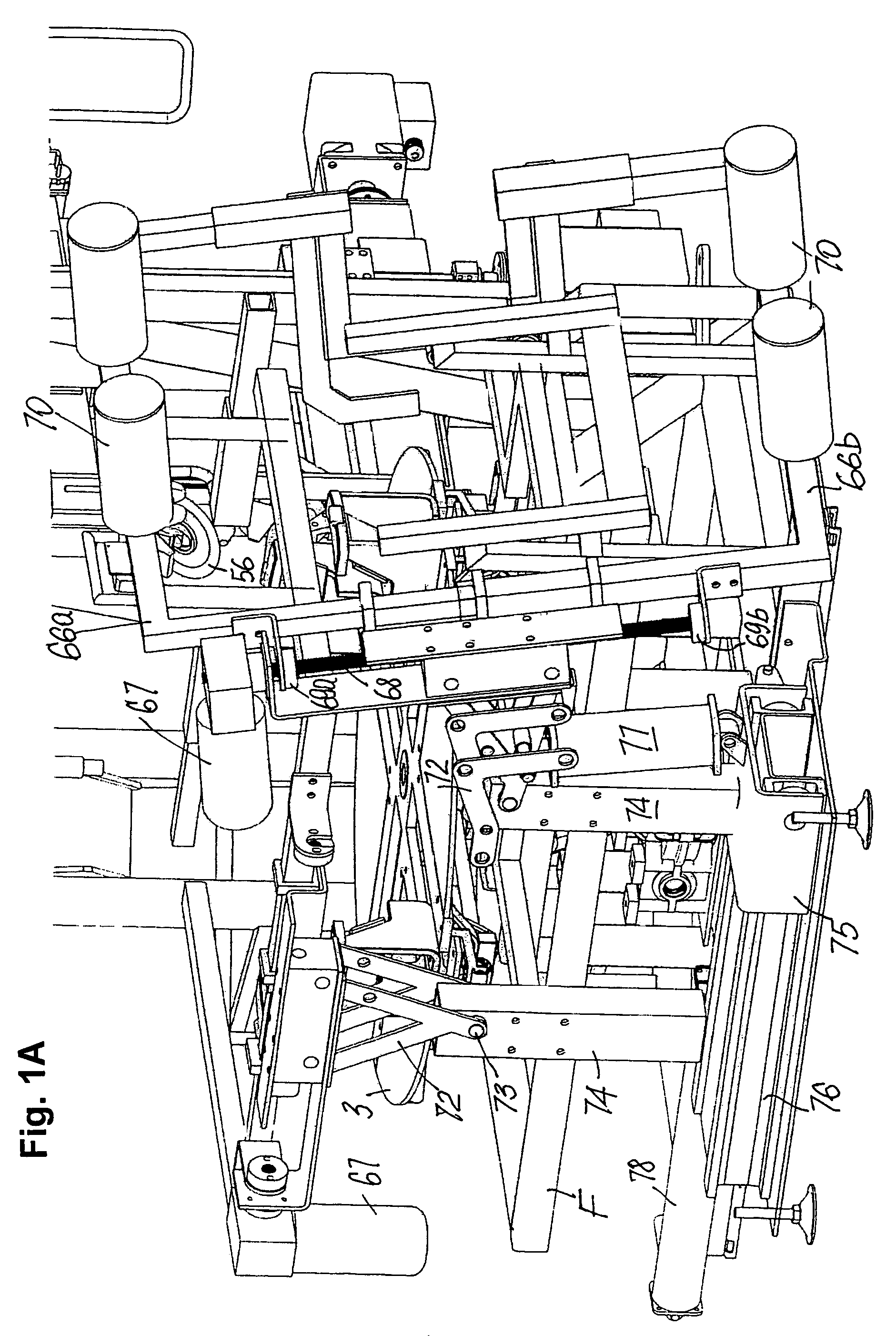

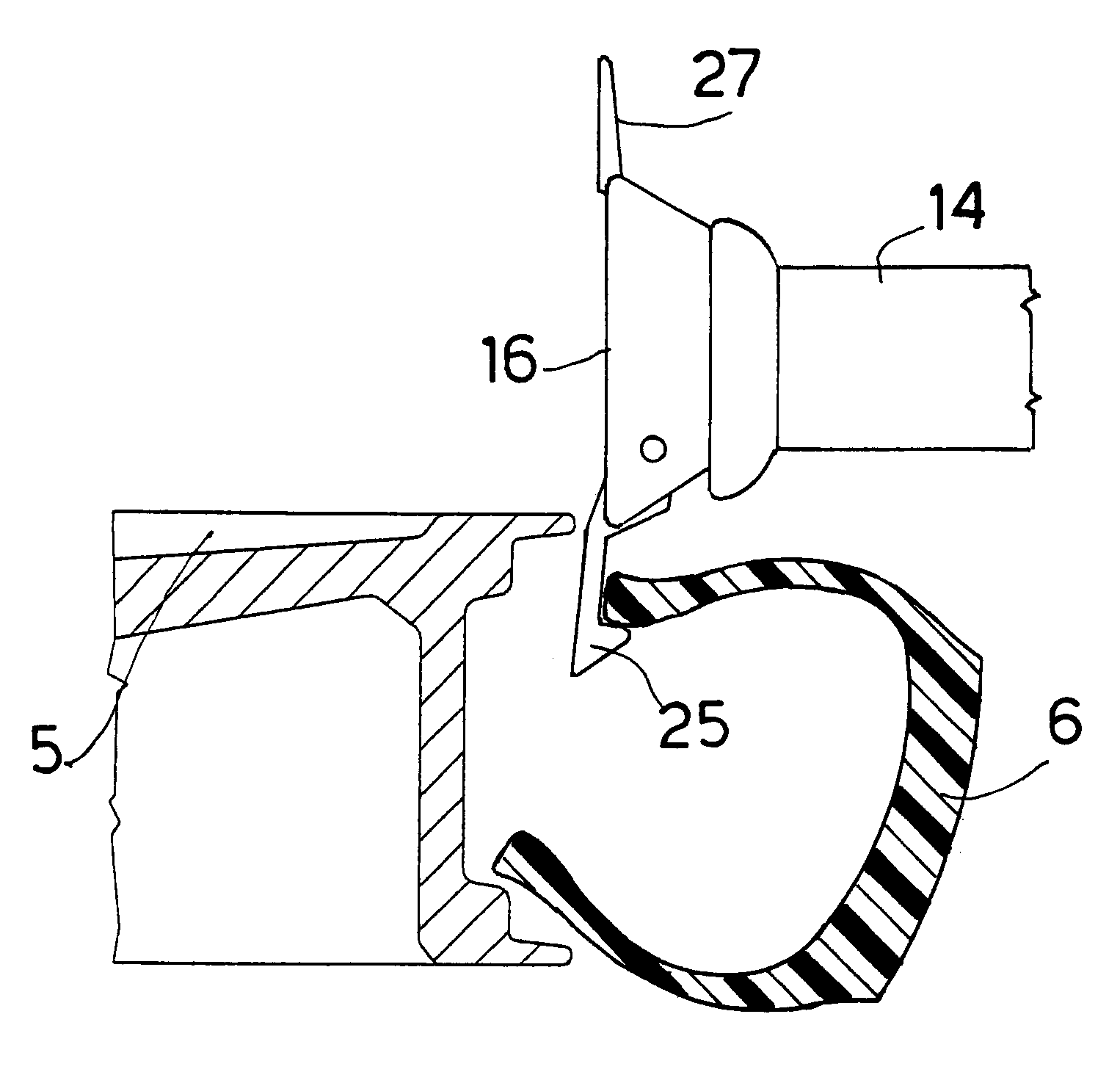

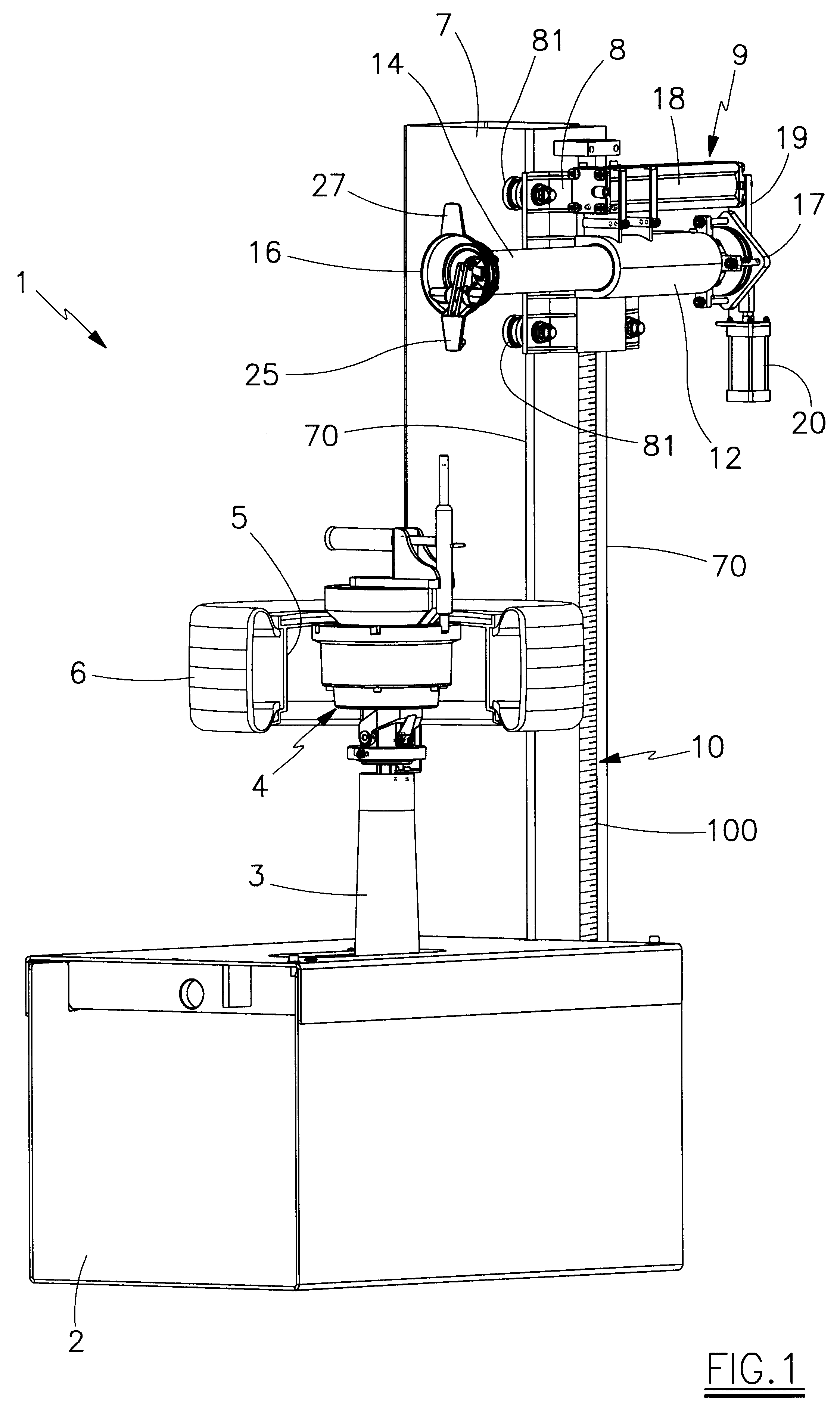

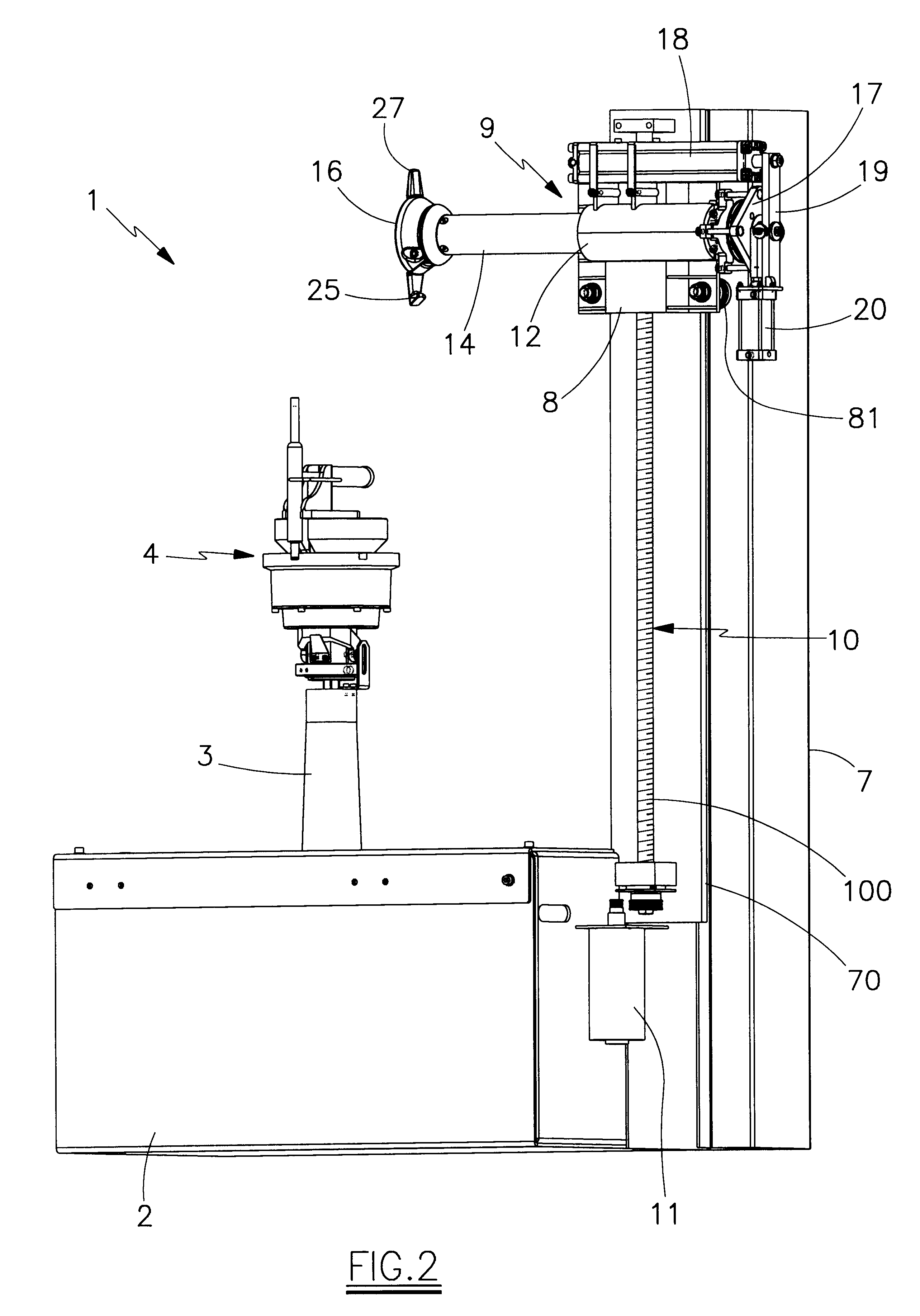

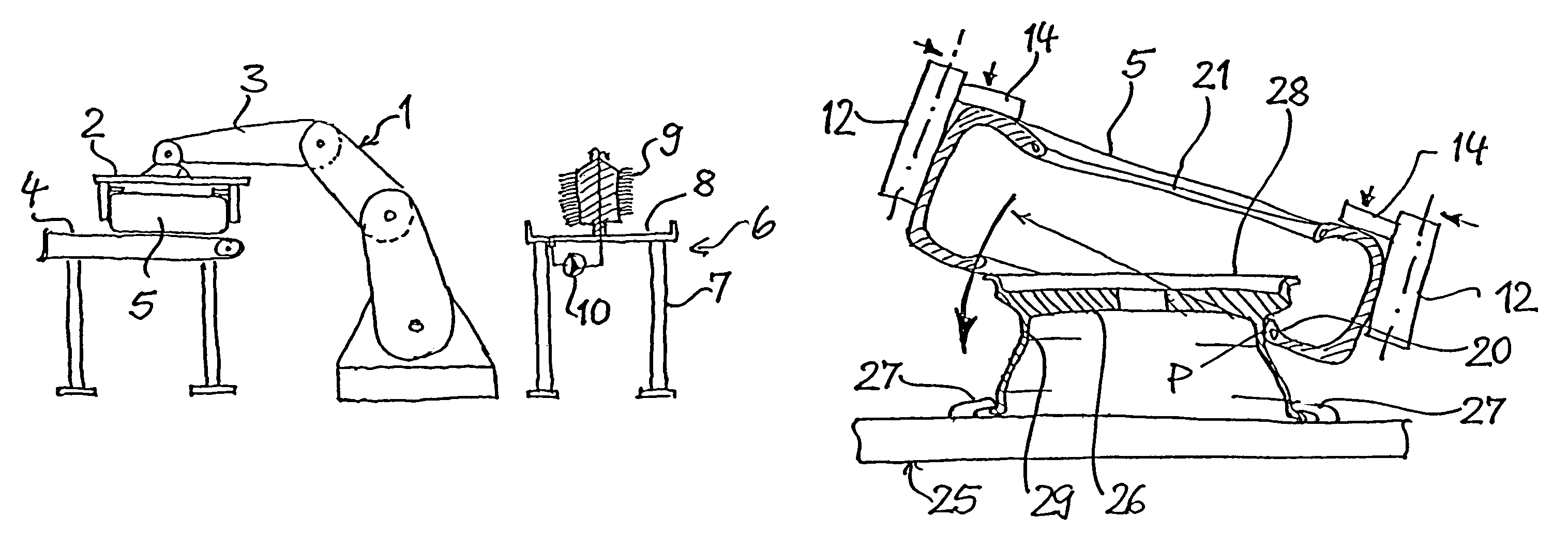

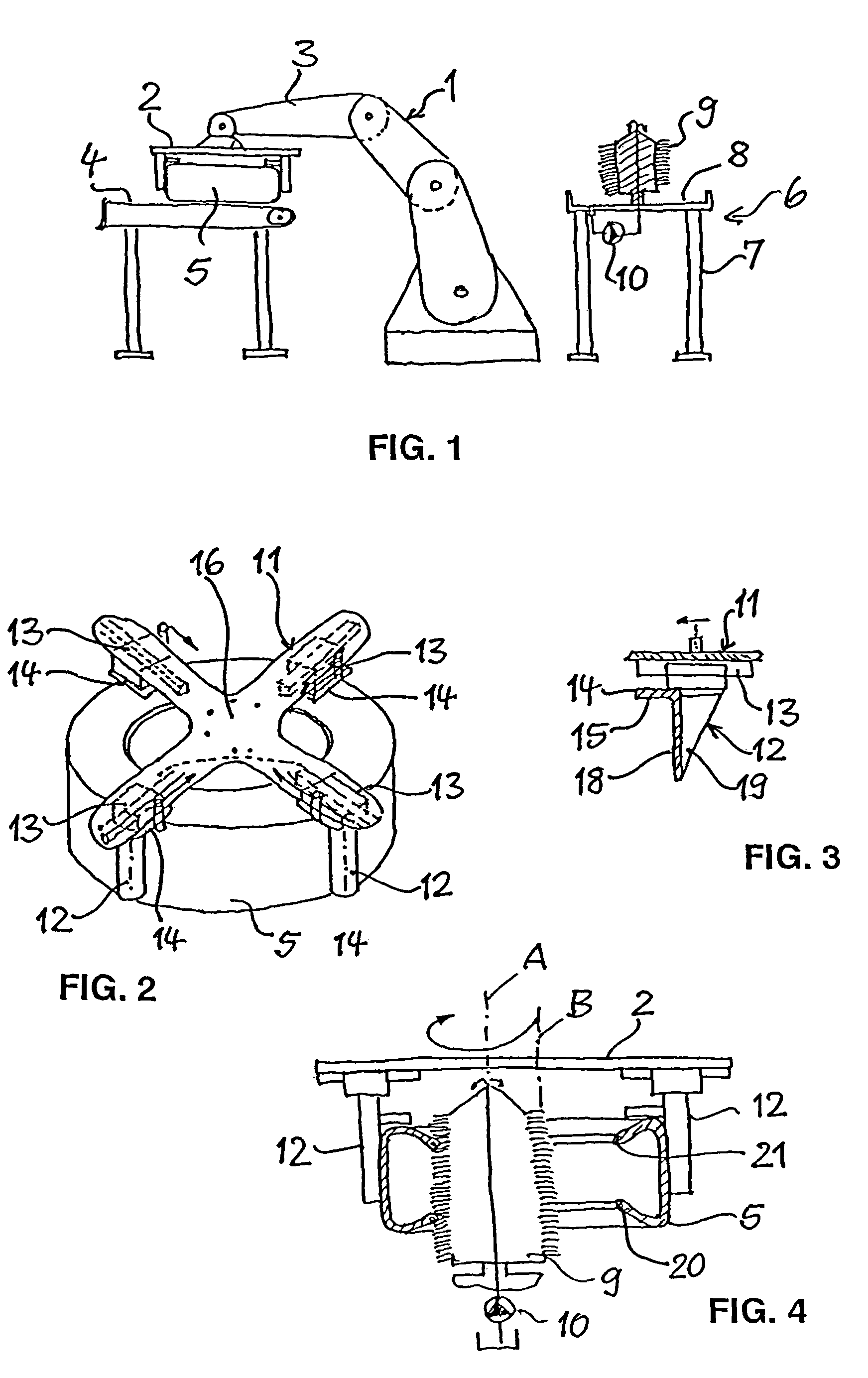

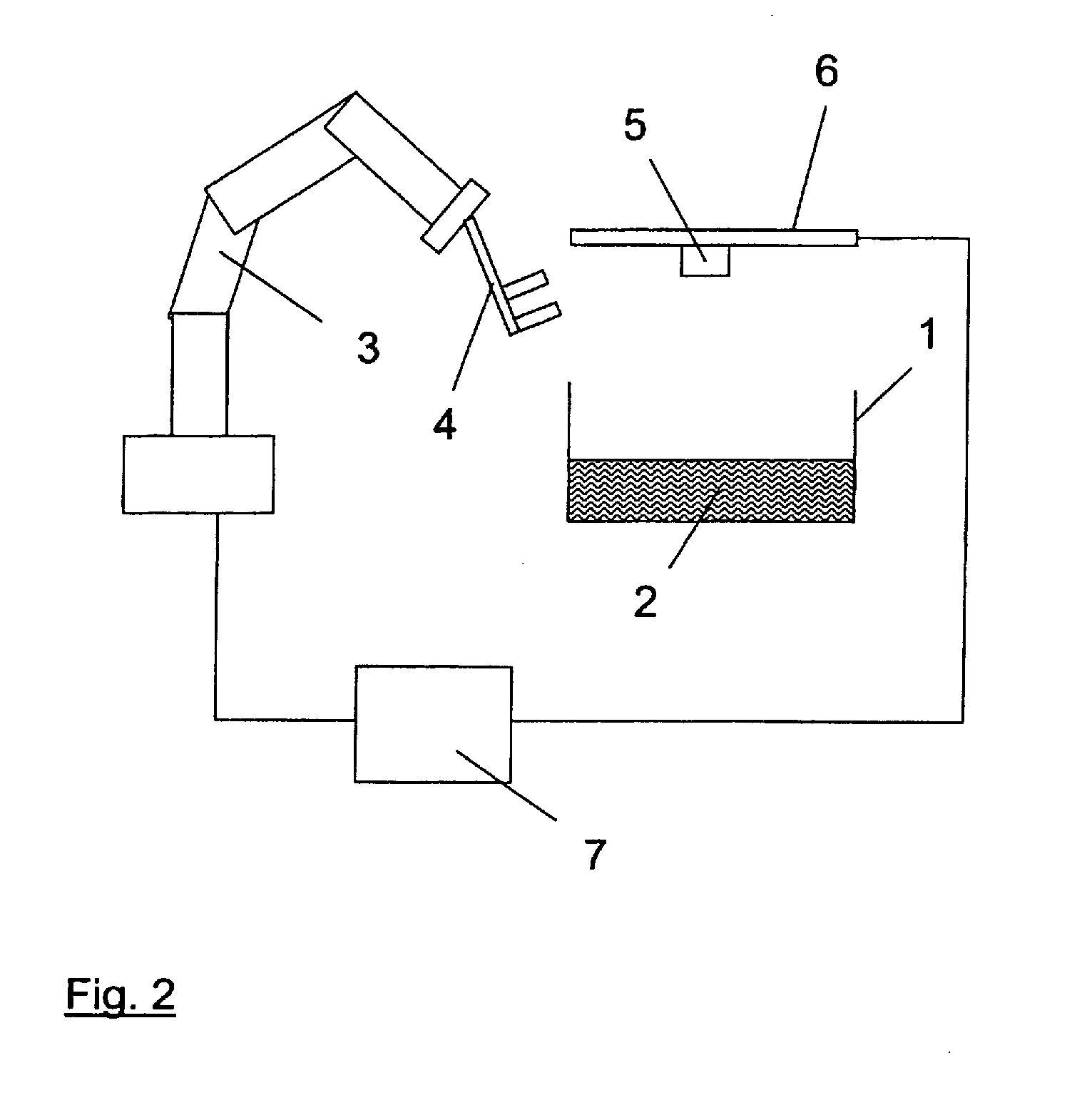

Method and apparatus for mounting a pneumatic tire

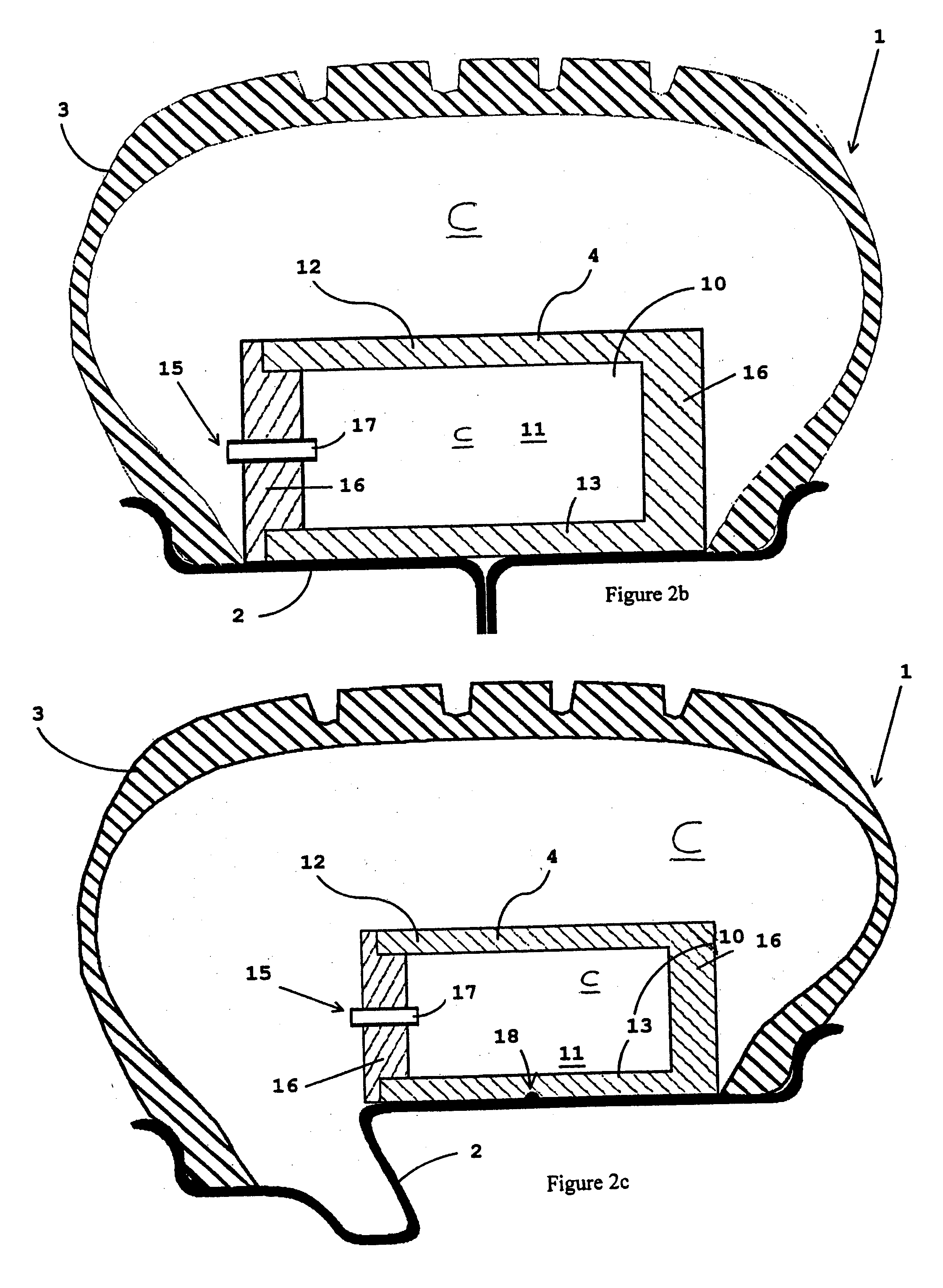

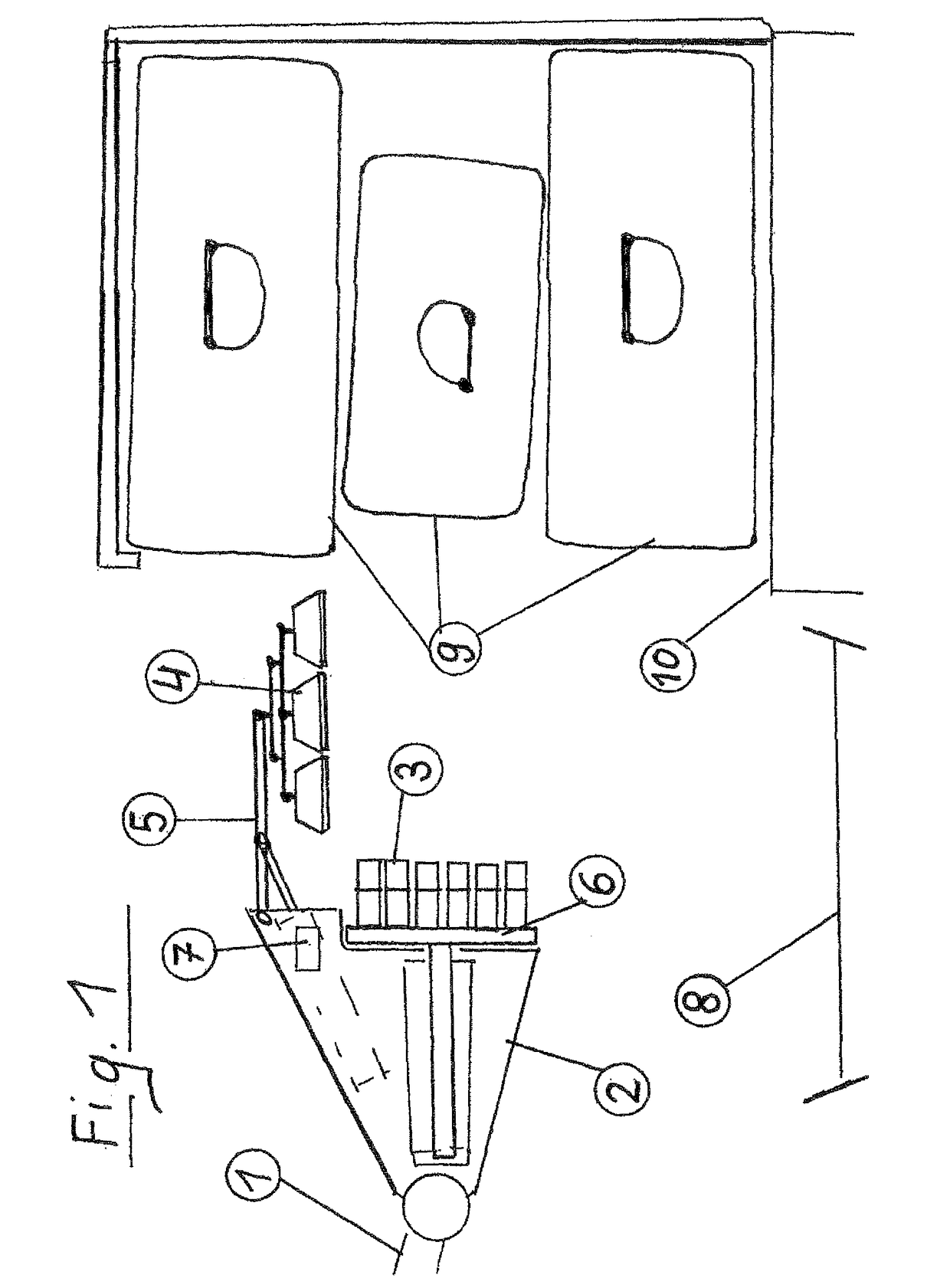

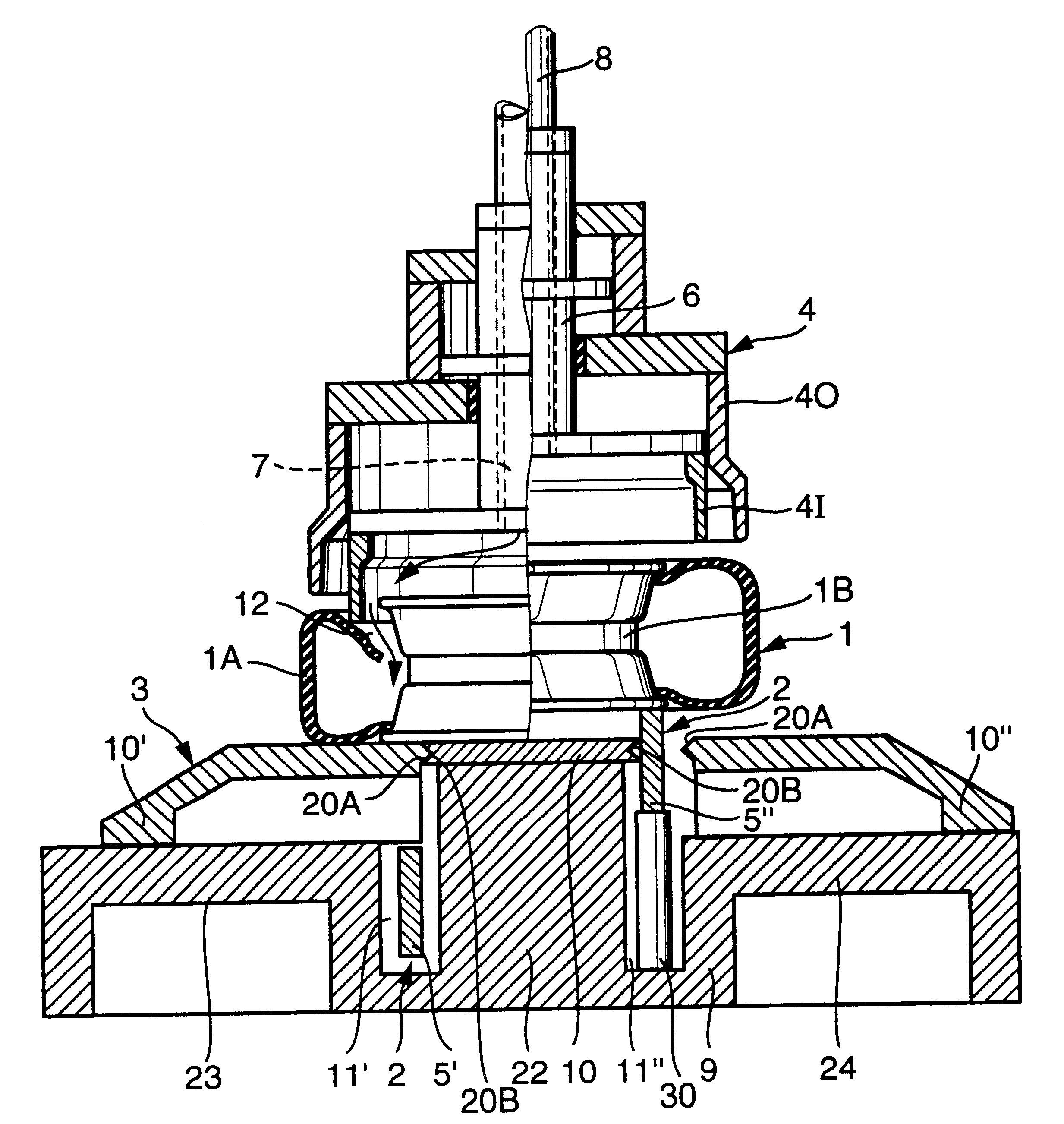

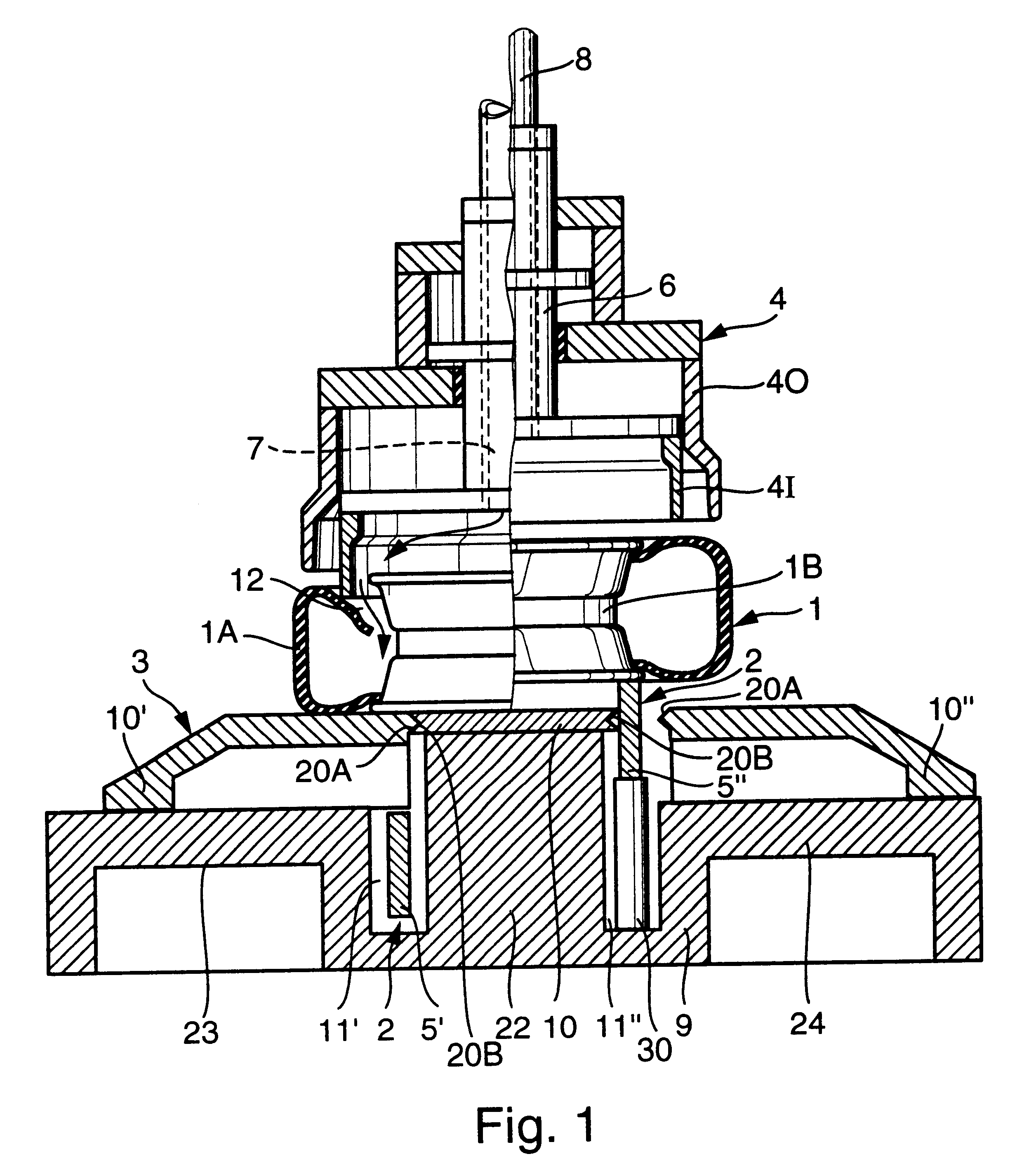

Method and apparatus for mounting a pneumatic tire Method for mounting a pneumatic tire (5) on a well base rim (26) of a motor vehicle wheel, in which the pneumatic tire (5) is grasped by means of a manipulator (1), brought up to a rim (26) held in a clamping device (27) and slipped with at least the one tire bead (20) facing the rim over a rim flange (28) by controlled movement of the manipulator (1). The apparatus suitable for this purpose comprises a manipulator (1) with an articulated arm (3) movable in three directions, which bears at its free end a gripper (2) for gripping and holding pneumatic tires (5), and a first mounting station (25) with clamping means (27) for releasably holding a rim (26), wherein the mounting station (25) is arranged within the working range of the manipulator (1).

Owner:SCHENCK ROTEC GMBH

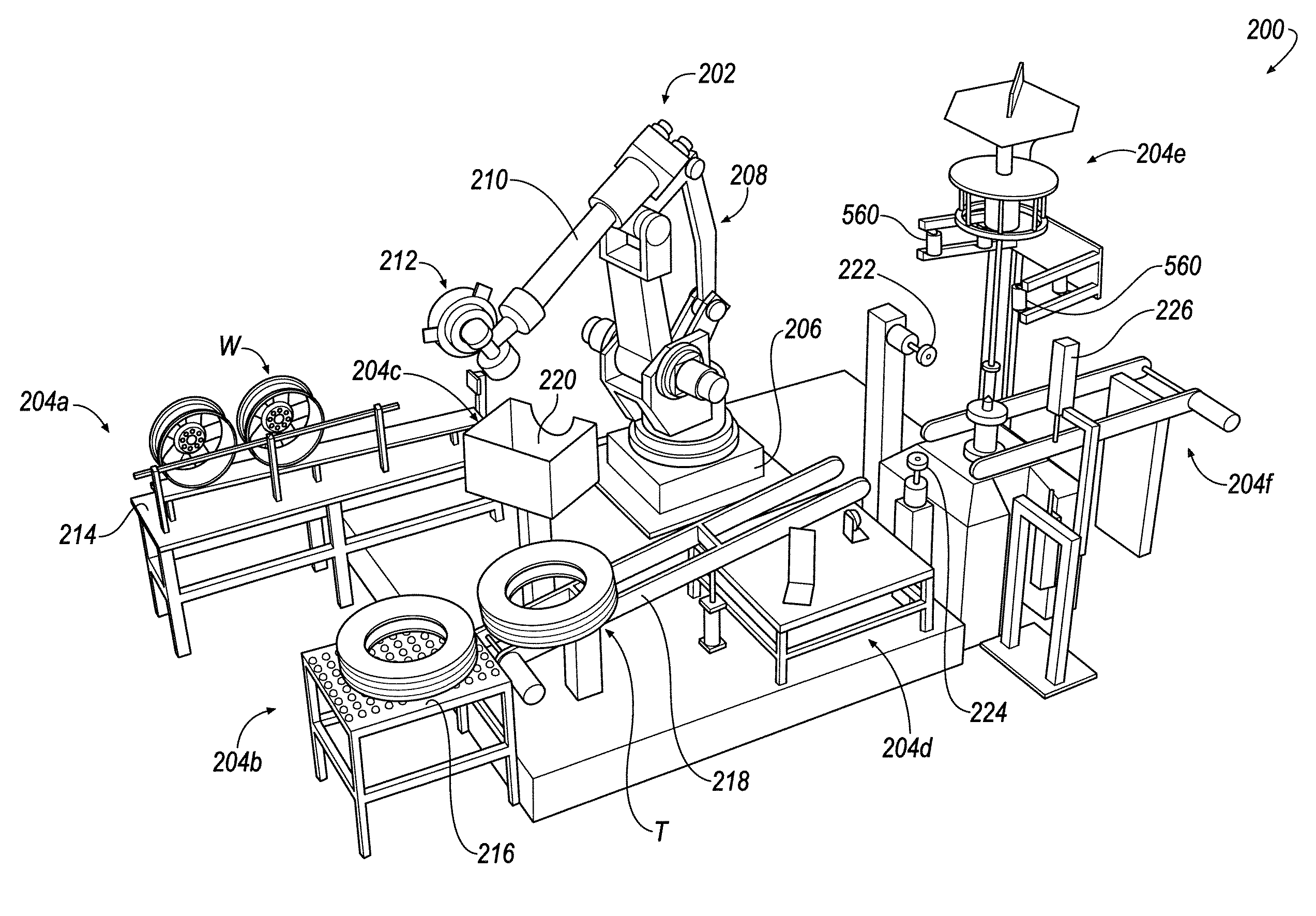

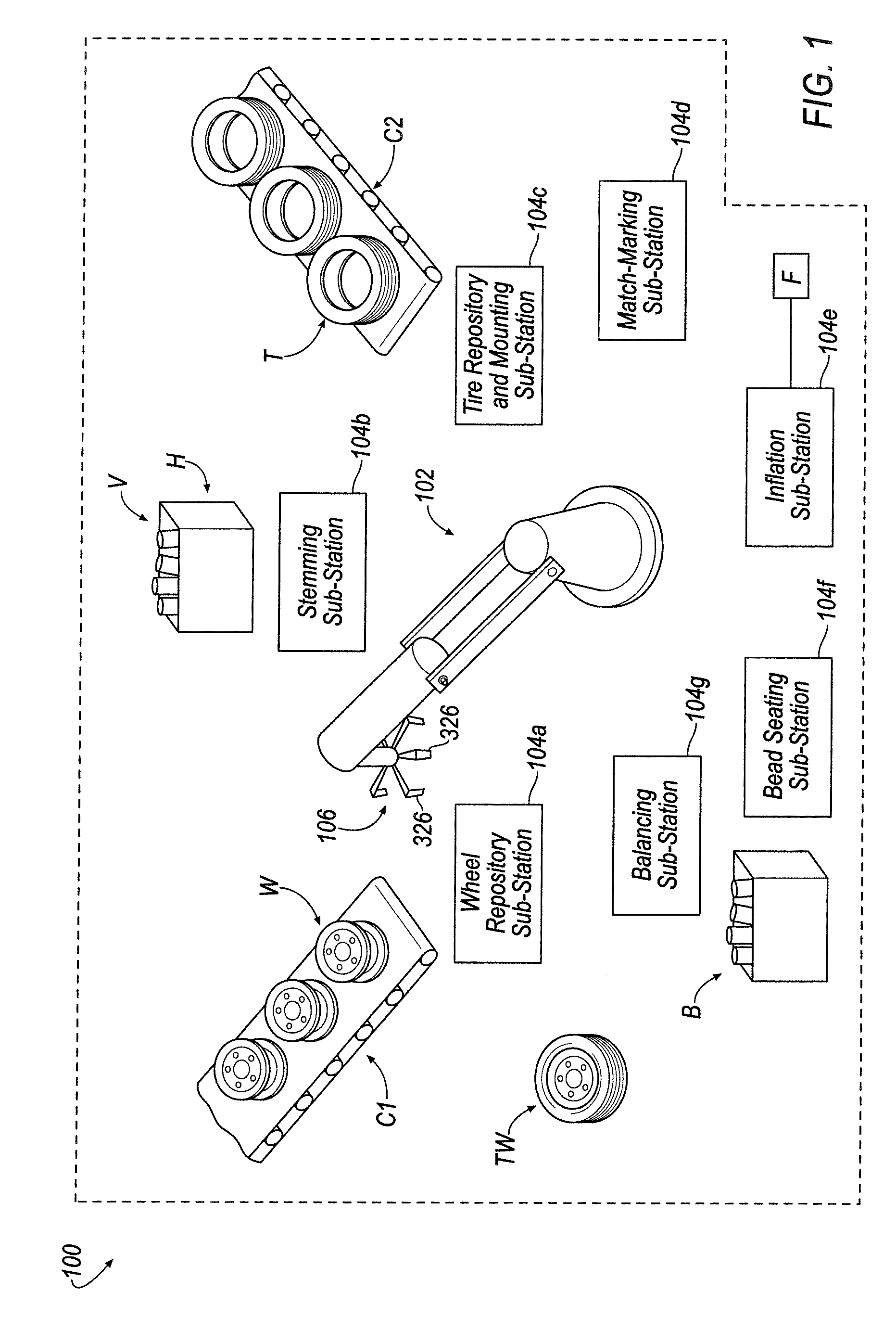

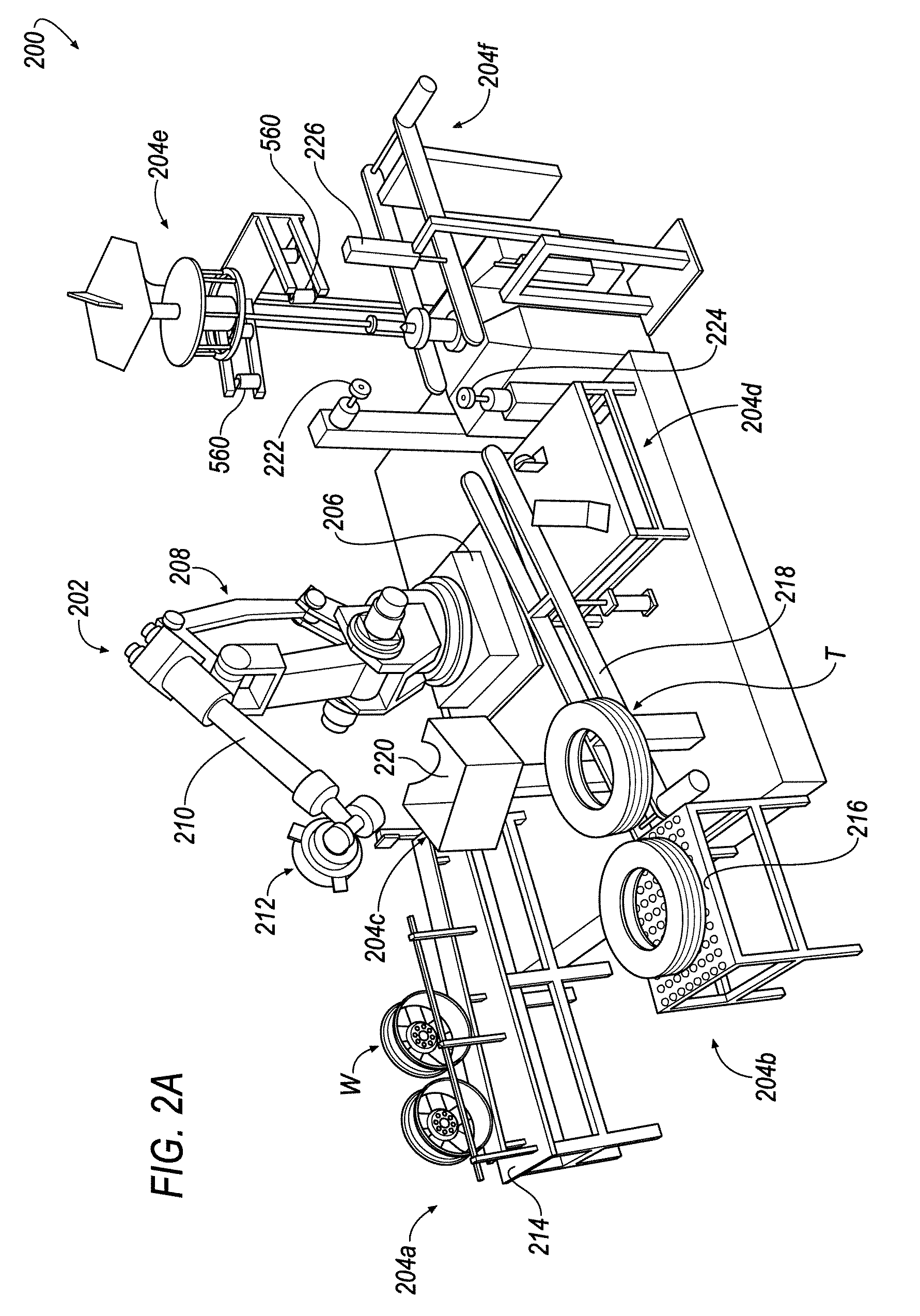

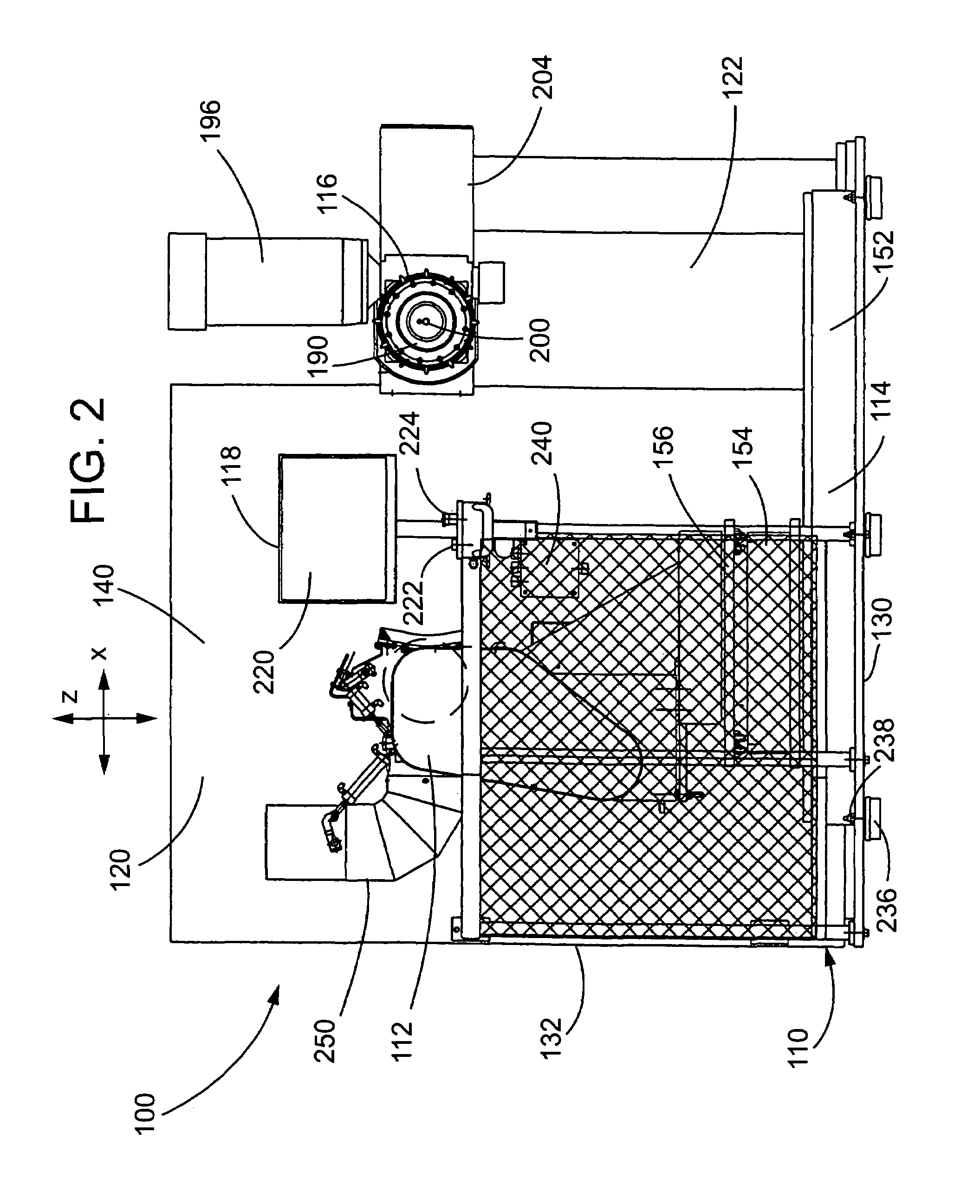

System and Method for Assembling a Tire and a Wheel

An apparatus for assembling a tire and a wheel is disclosed. The apparatus includes a single-cell workstation including a device that retains a wheel, and a plurality of sub-stations. The device moves the wheel to each of the plurality of sub-stations, without releasing the wheel, to assemble a tire-wheel assembly. A method is also disclosed.

Owner:ANDROID INDS OF MICHIGAN

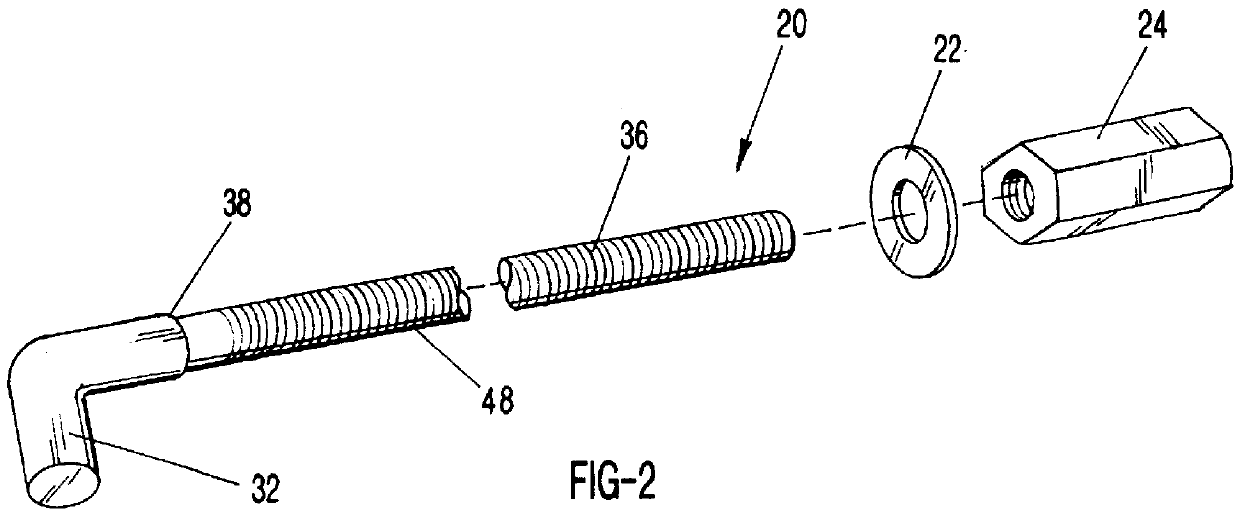

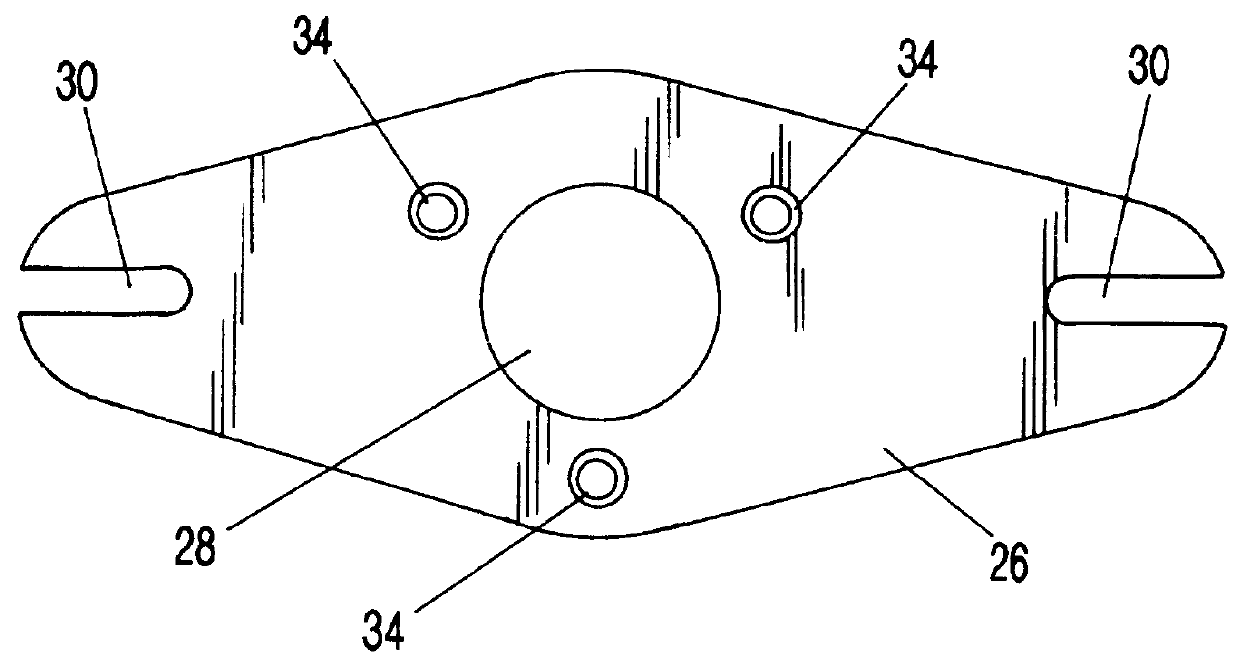

Wheel puller

InactiveUS6012211AImprove portabilityEasy to useWheel mounting apparatusMetal working apparatusEngineeringMechanical engineering

A wheel pulling apparatus and method for removing vehicle wheels by pushing against the mounting studs of a motor vehicle wheel assembly. The invention is designed to remove or break uni-mount wheels from large wheel assemblies. A push plate is positioned onto the wheel by at least one receiver. At least two threaded grappling hooks are affixed to the wheel, and the threaded portion of the grappling hooks are slid through slots in the push plate. Washers are inserted and nuts are tightened onto the threaded portion. The nuts are then alternately tightened causing the push plate to snug onto mounting studs and to pull the wheel from the wheel assembly.

Owner:OCHOA ROADRUNNER PRODS

Tire buffing apparatus

InactiveUS7040371B2Consistent texture profileIncrease productionRevolution surface grinding machinesTyresRaspEngineering

A tire buffer for buffing a tire casing as part of a retread operation can include a rasp pedestal having a rasp head and a texturing device. A moving assembly can be connected to the rasp pedestal for selectively moving the rasp pedestal along a pair of perpendicular axes. The rasp pedestal can rotate about a vertical axis. A tire hub assembly can be included for rotating the tire casing. The tire buffer can be operated at an operator station by interfacing with a control unit. The tire buffer can automatically buff a tire casing to achieve a predetermined tire casing profile and impart a texture thereto. The tire buffer includes a tire location mechanism and a tire measurement mechanism mounted to the rasp pedestal. The control unit can monitor an operating parameter of the rasp pedestal or the tire hub assembly during the buffing sequence, compare the actual value of the operating parameter to a predetermined target value of the parameter, and adjust an operating characteristic of the rasp pedestal, the tire hub assembly, or both such that the actual value of the operating parameter is urged toward the calculated target value of the operating parameter.

Owner:BANDAG INC

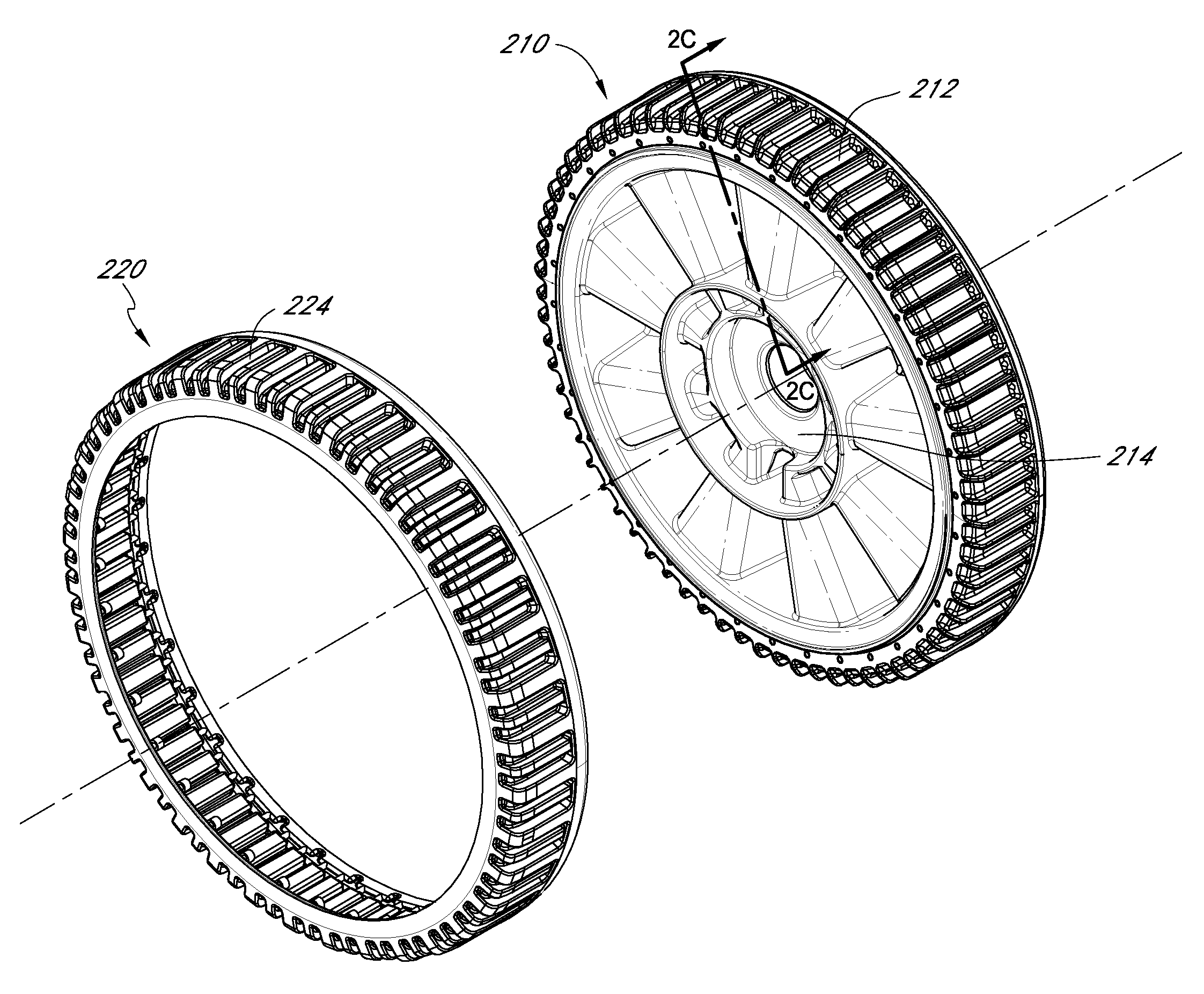

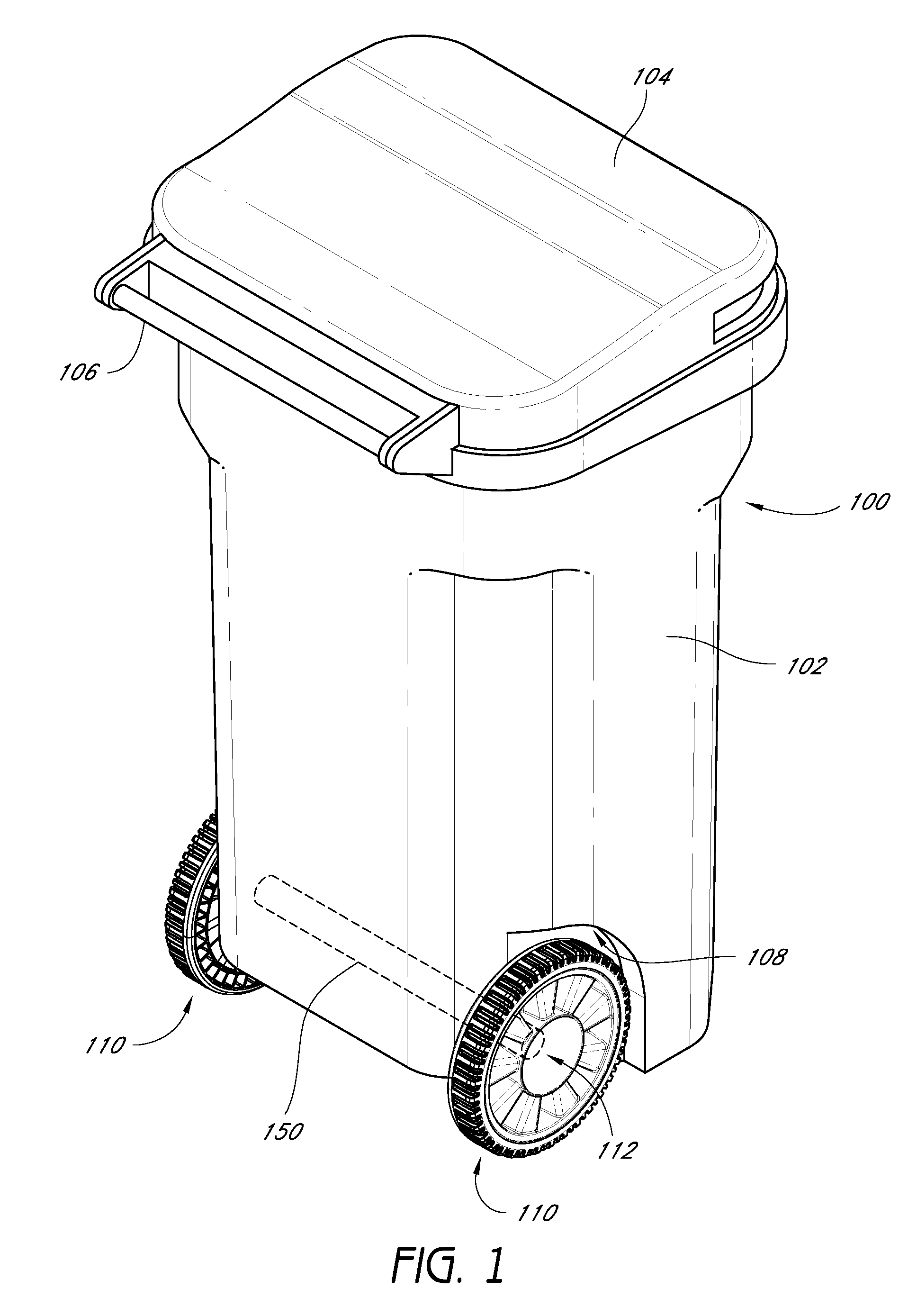

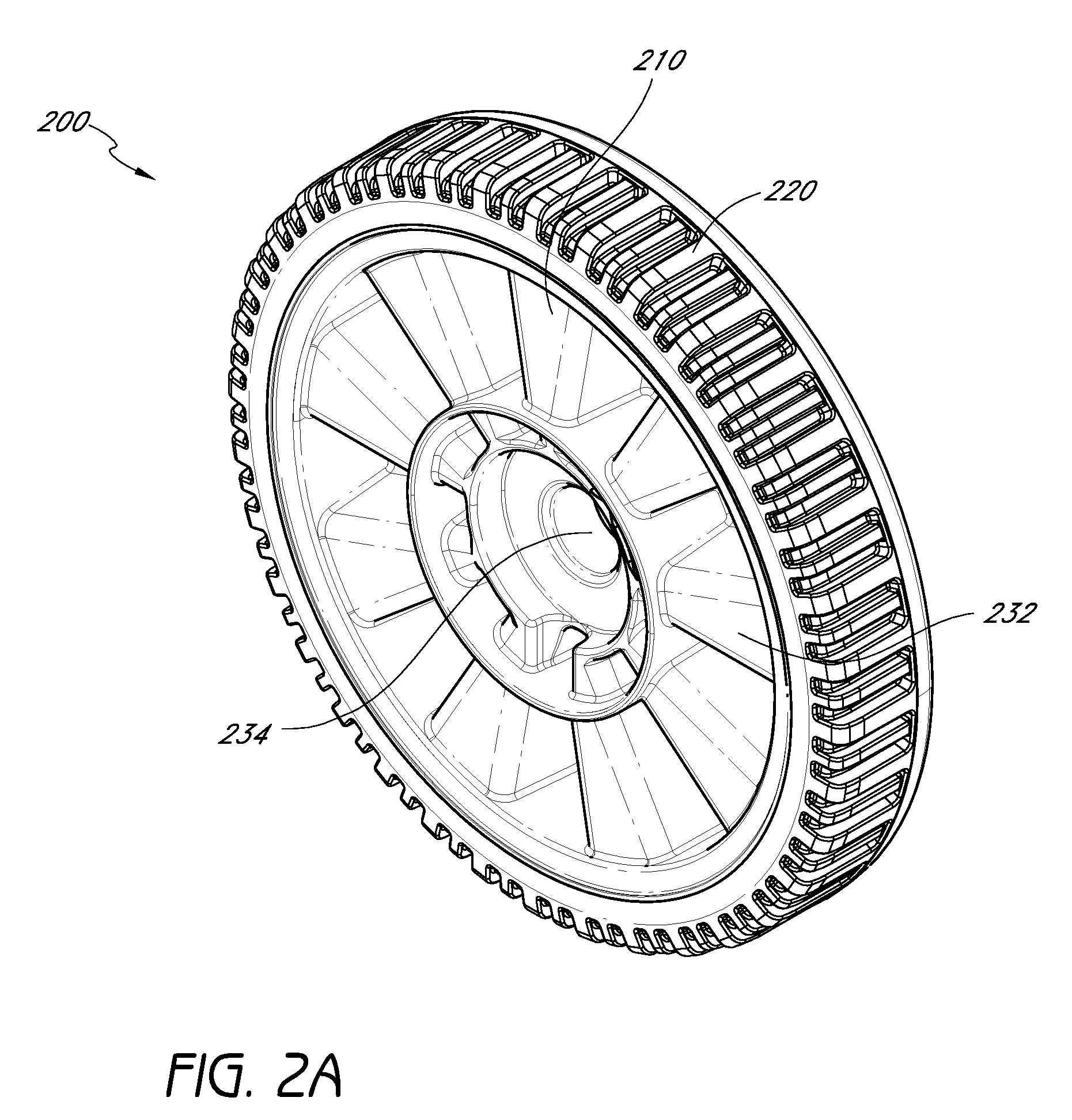

Wheel including tread

Wheels and methods of making wheels are disclosed including an inner portion and a tread mechanically coupled to the inner portion. The tread may be mechanically coupled to the inner portion on an inside and an outside of the wheel. The inner portion may include a rim including a plurality of apertures. The inner portion may be high density polyethylene and the tread may be thermoplastic elastomer.

Owner:GEO PLASTICS

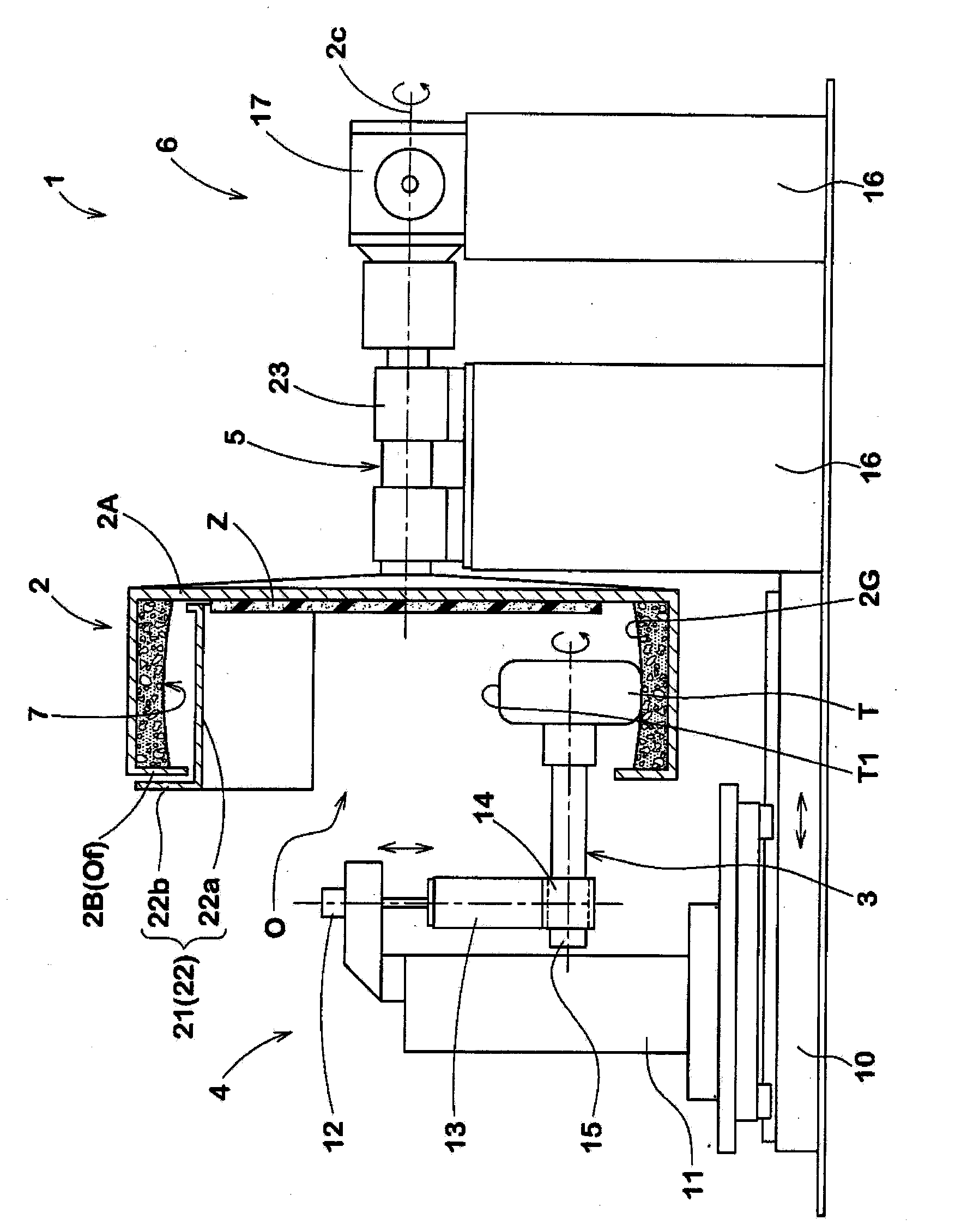

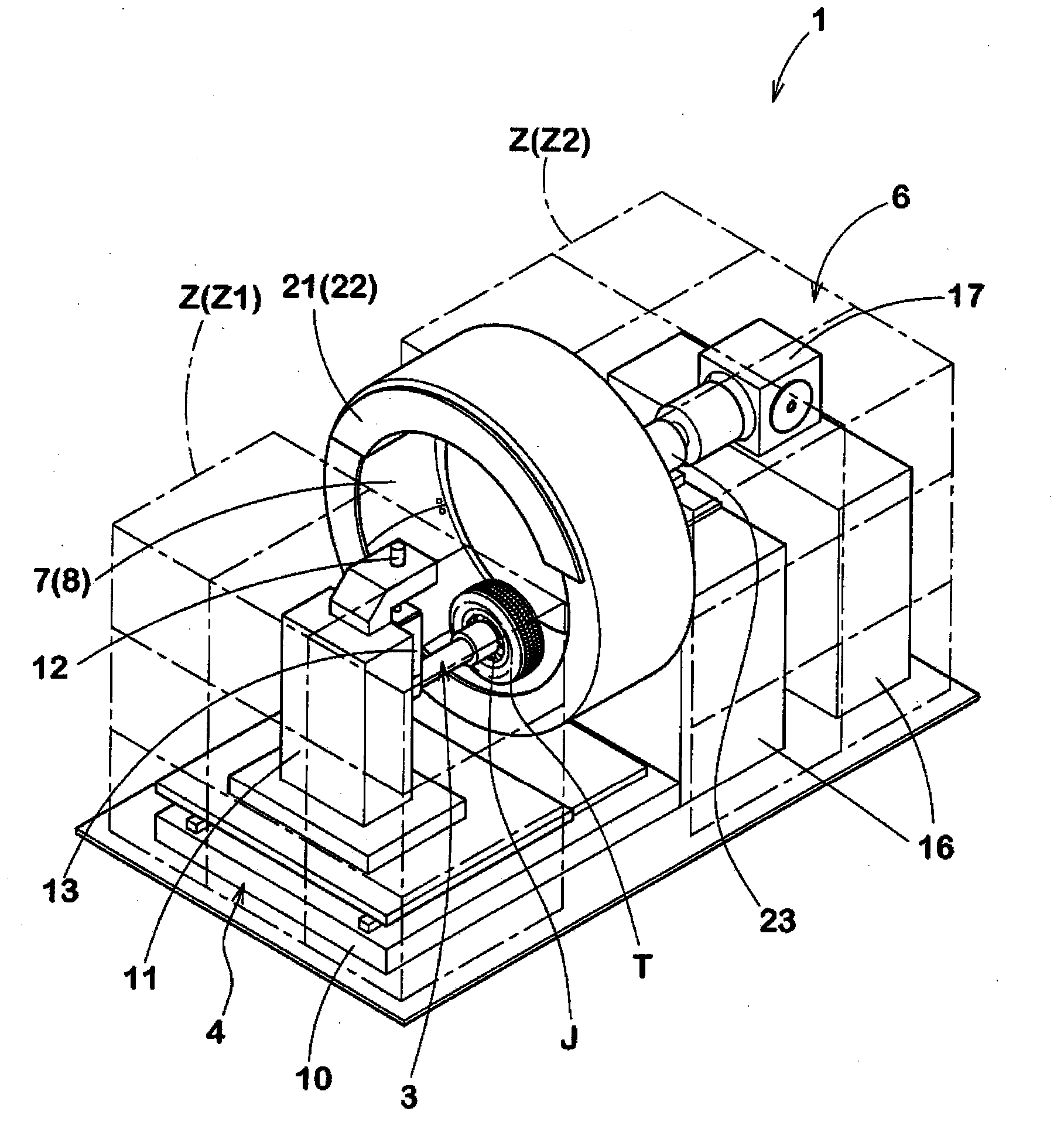

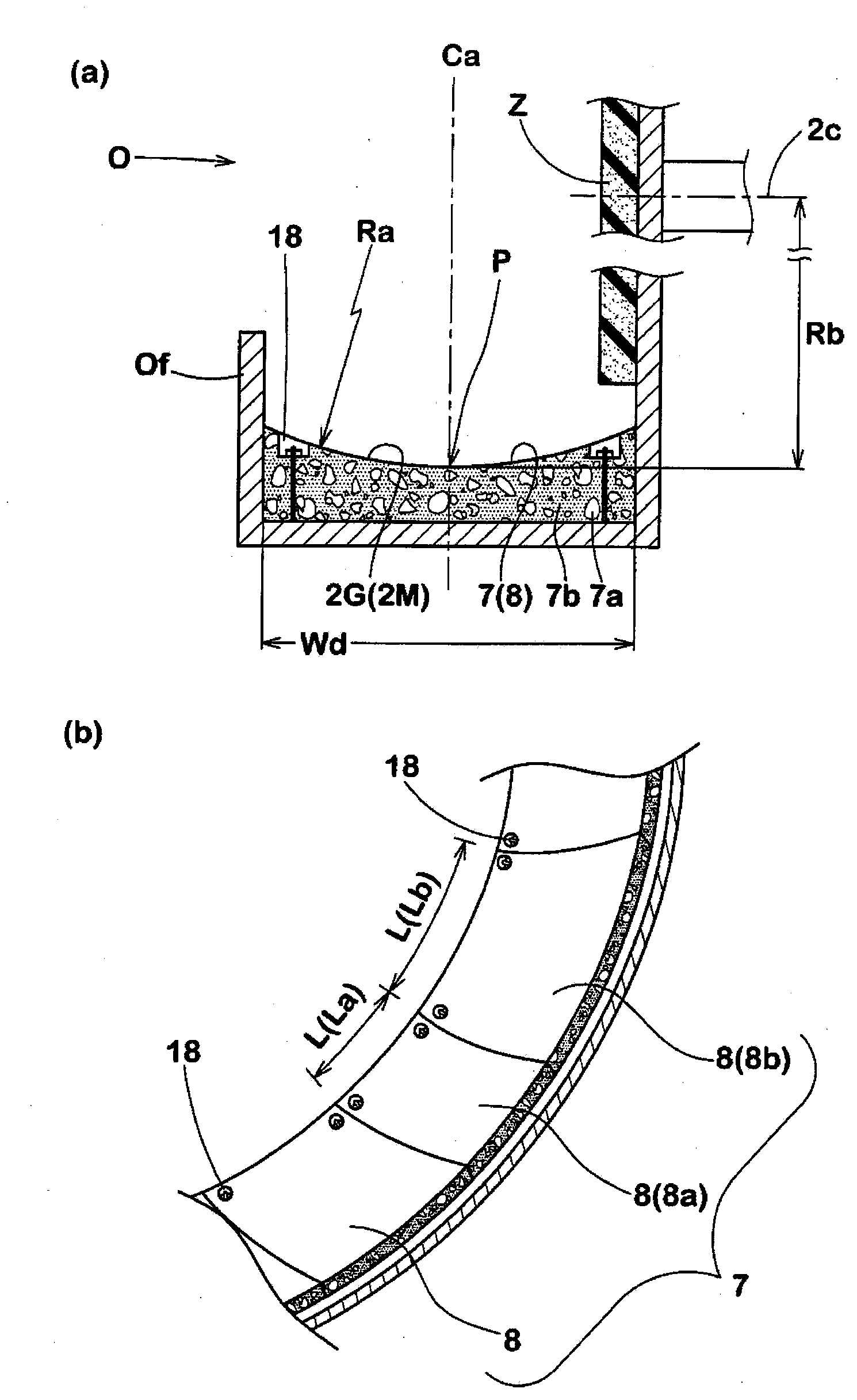

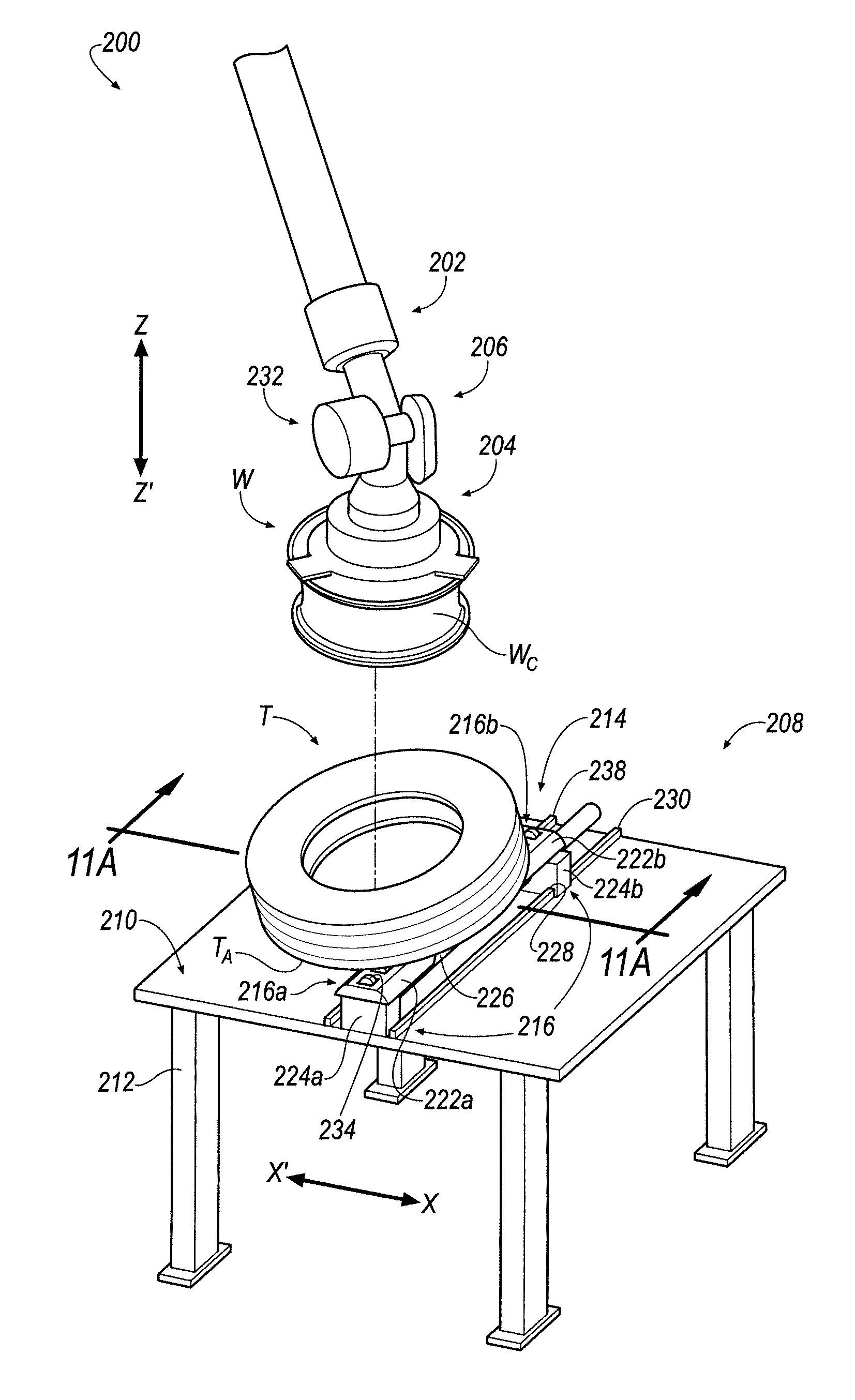

Tire bench testing apparatus and tire performance testing method using the same

The present invention provides a tire bench testing apparatus by which a test result having a higher correlation with a performance test result of a tire which is carried out in the field can be obtained in a room. The tire bench testing apparatus (1) carrying out the performance test of the tire in the room comprises a drum (2) which enables the tire (T) to be contacted and drive and can rotate; a supporting shaft (3) which keeps the tire (T) assembled in a rim (J) to be rotatable in a cantilever manner; a driving unit for rotating and driving the drum (2) or the supporting shaft (3). The drum (2) possesses an inner circumferential surface (2G), and the inner circumferential surface (2G) possesses a simulation road (7) on which the tire (T) can drive, and a smooth arc-shaped surface (2M) protruded towards a radial outside of the drum in a cross-section having the rotation axis (2c) of the drum.

Owner:SUMITOMO RUBBER IND LTD

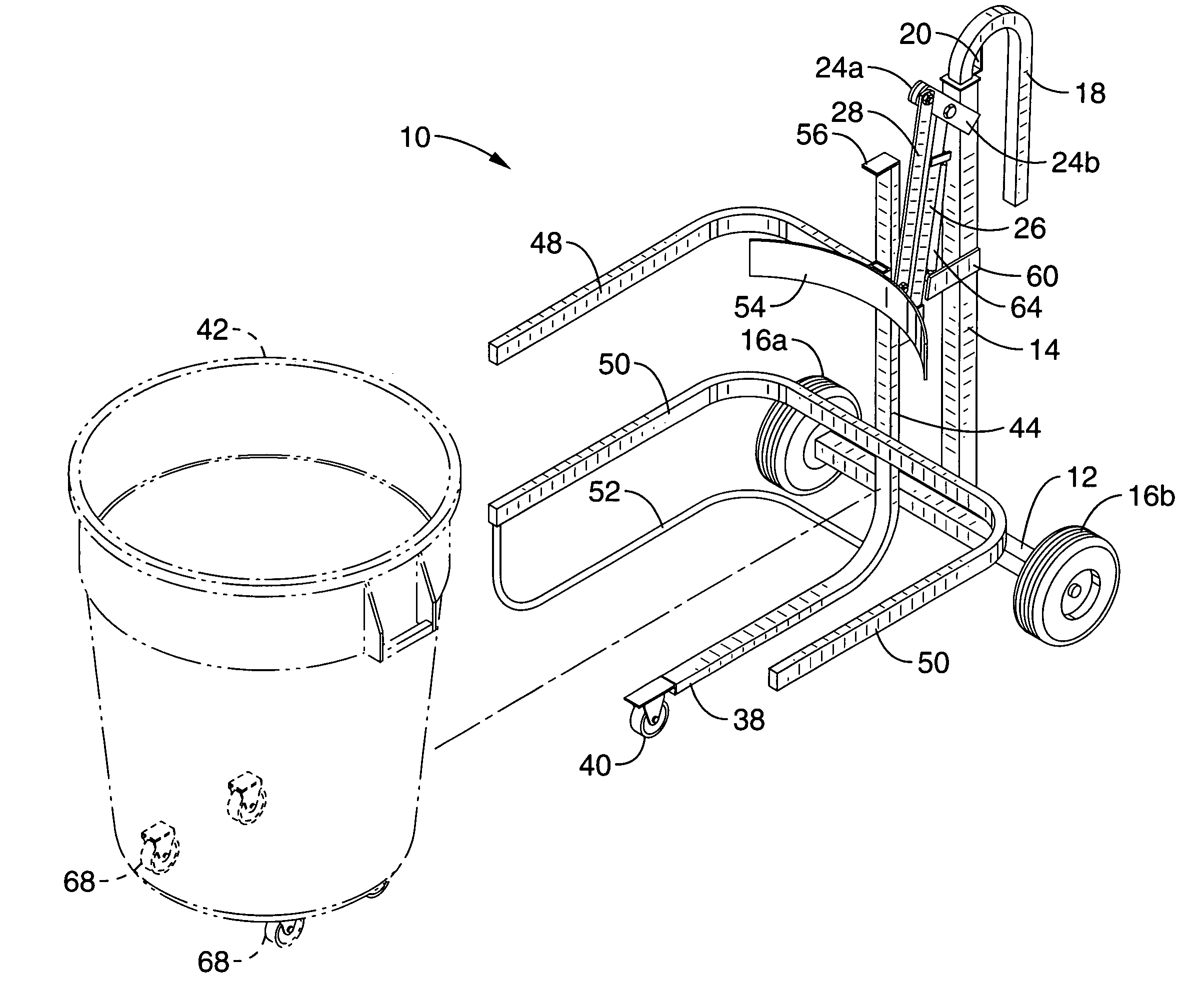

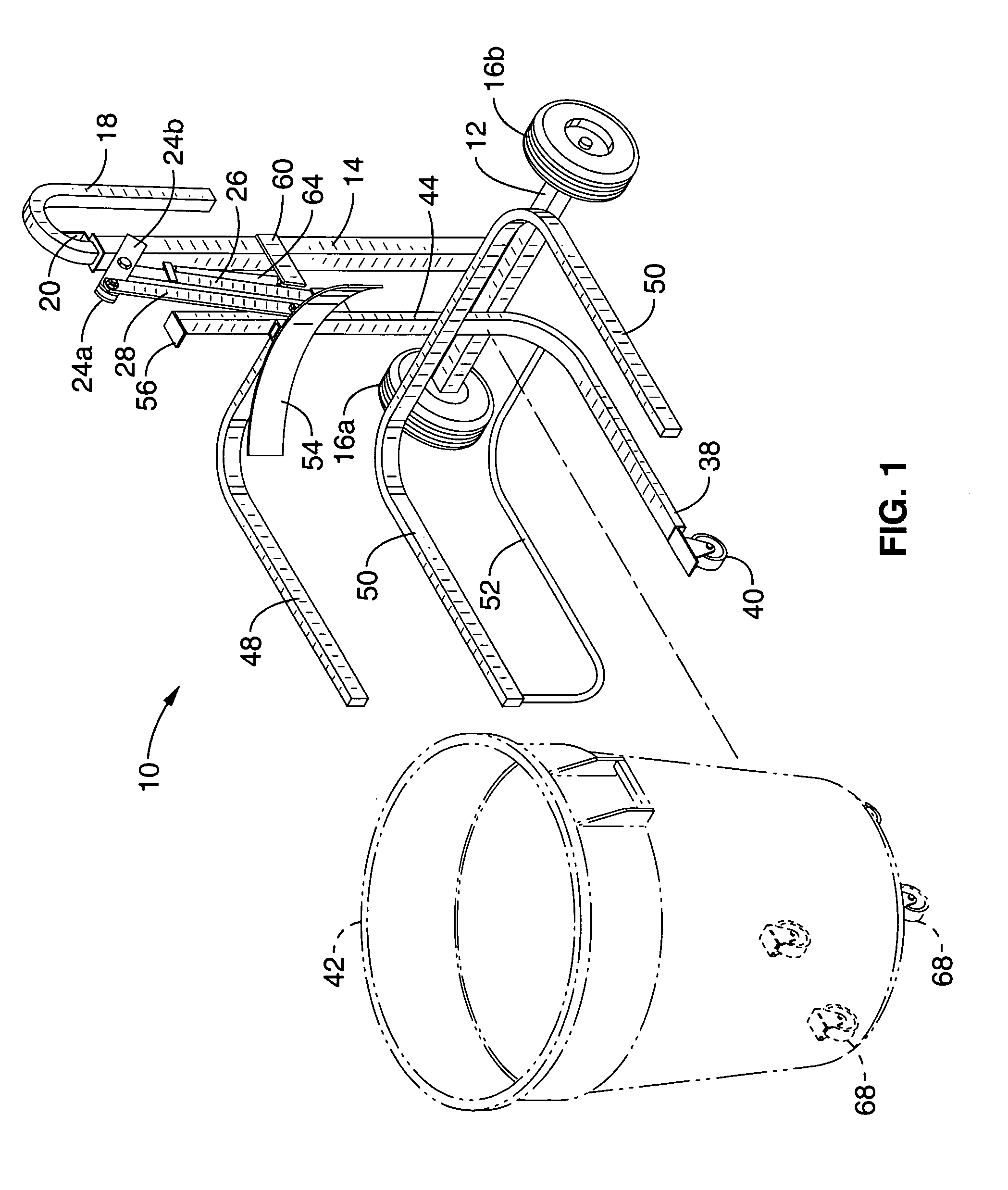

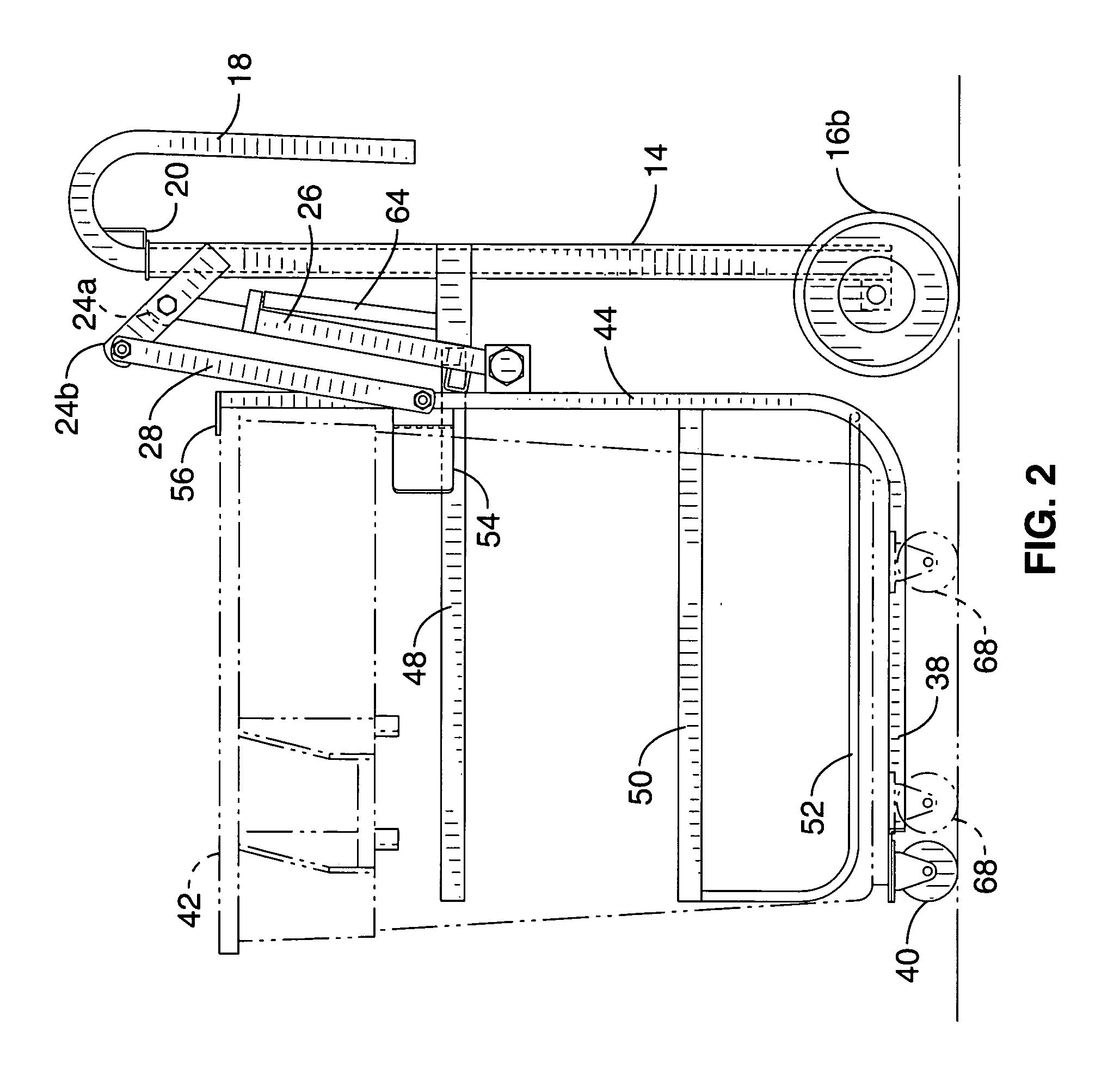

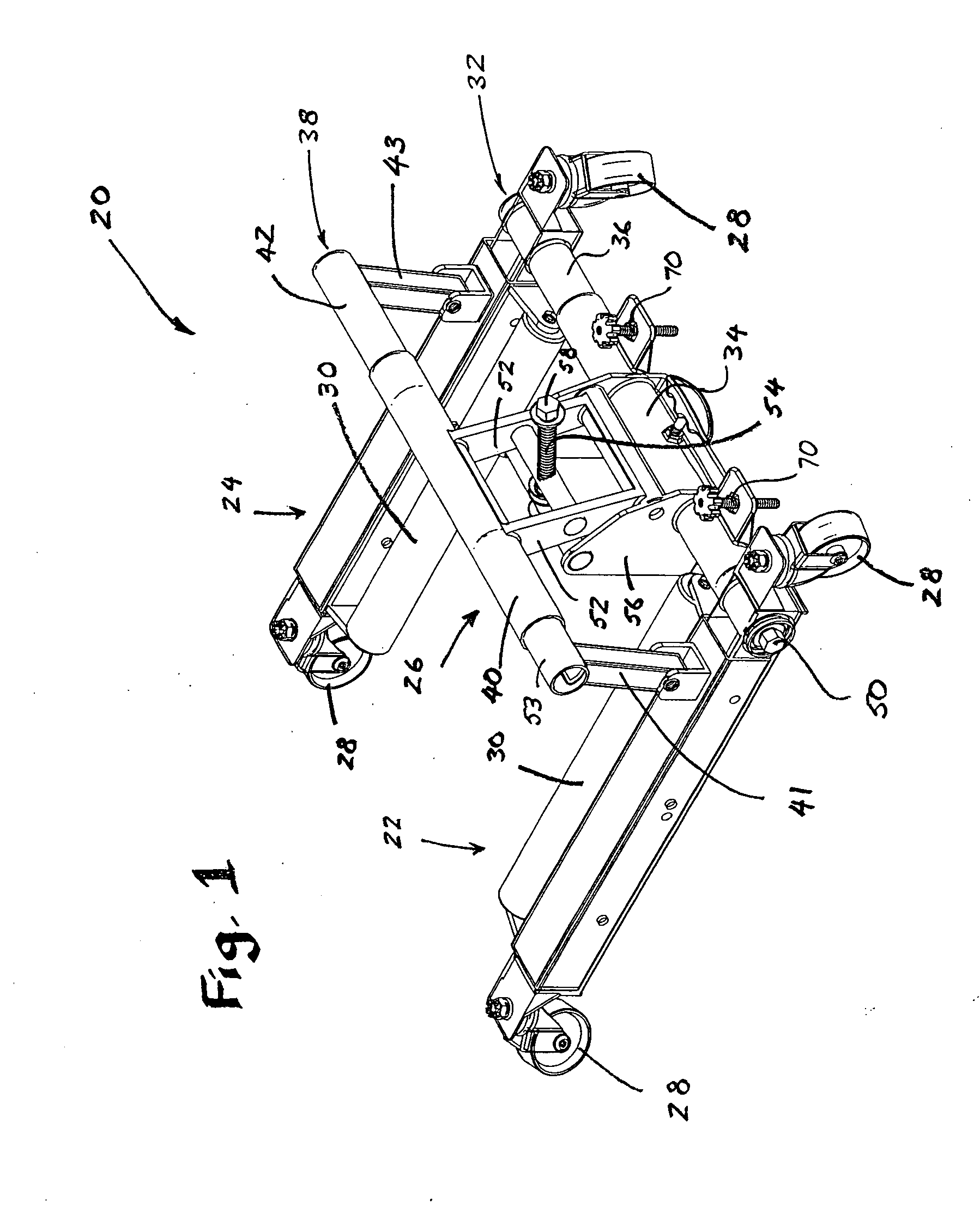

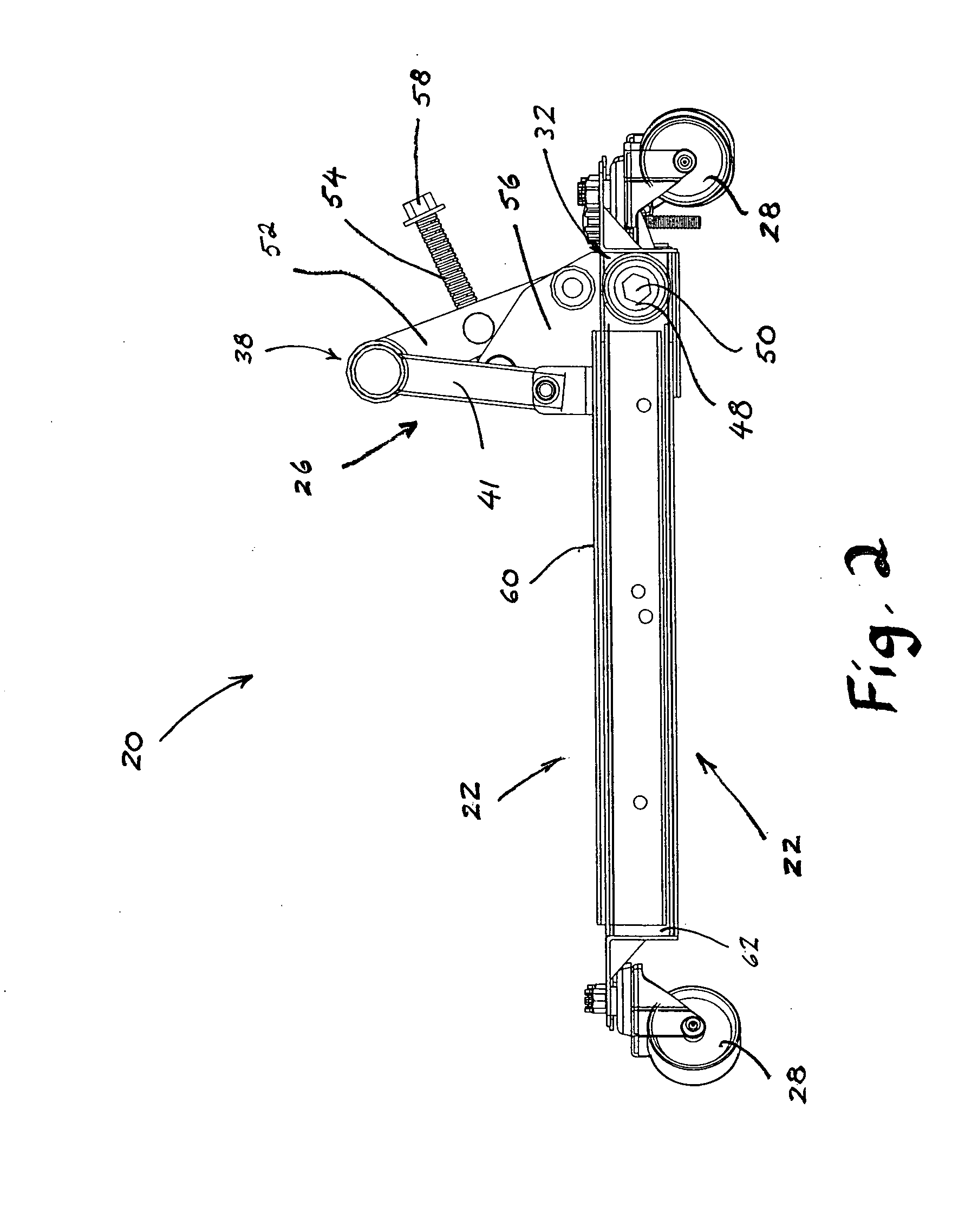

Refuse container transporter and lift

InactiveUS7018155B1Easy to engageLittle effortArticle unpackingSupporting partsLocking mechanismLitter

A lift apparatus for conveying, lifting and at least partially inverting a refuse container for emptying into a dumpster or a refuse receptacle. The apparatus preferably has a base with wheels and a handle to facilitate transport. In one embodiment, the handle telescopes vertically and is hook shaped and adapted for engaging the lip of a dumpster or garbage chute. A pair of offset pivot arms is pivotally mounted to the frame and to a bin carriage, into which a refuse receptacle may be received. Application of a pivoting force to the pivot arms lifts and at least partially inverts the bin carriage for emptying the refuse container. Preferably a damper is provided on bin carriage movement as well as a locking mechanism to prevent bin carriage movement while being conveyed. The device may be operated manually, or adapted with mechanical power output devices to simplify lifting.

Owner:SACRAMENTO UNIFIED SCHOOL DISTRICT

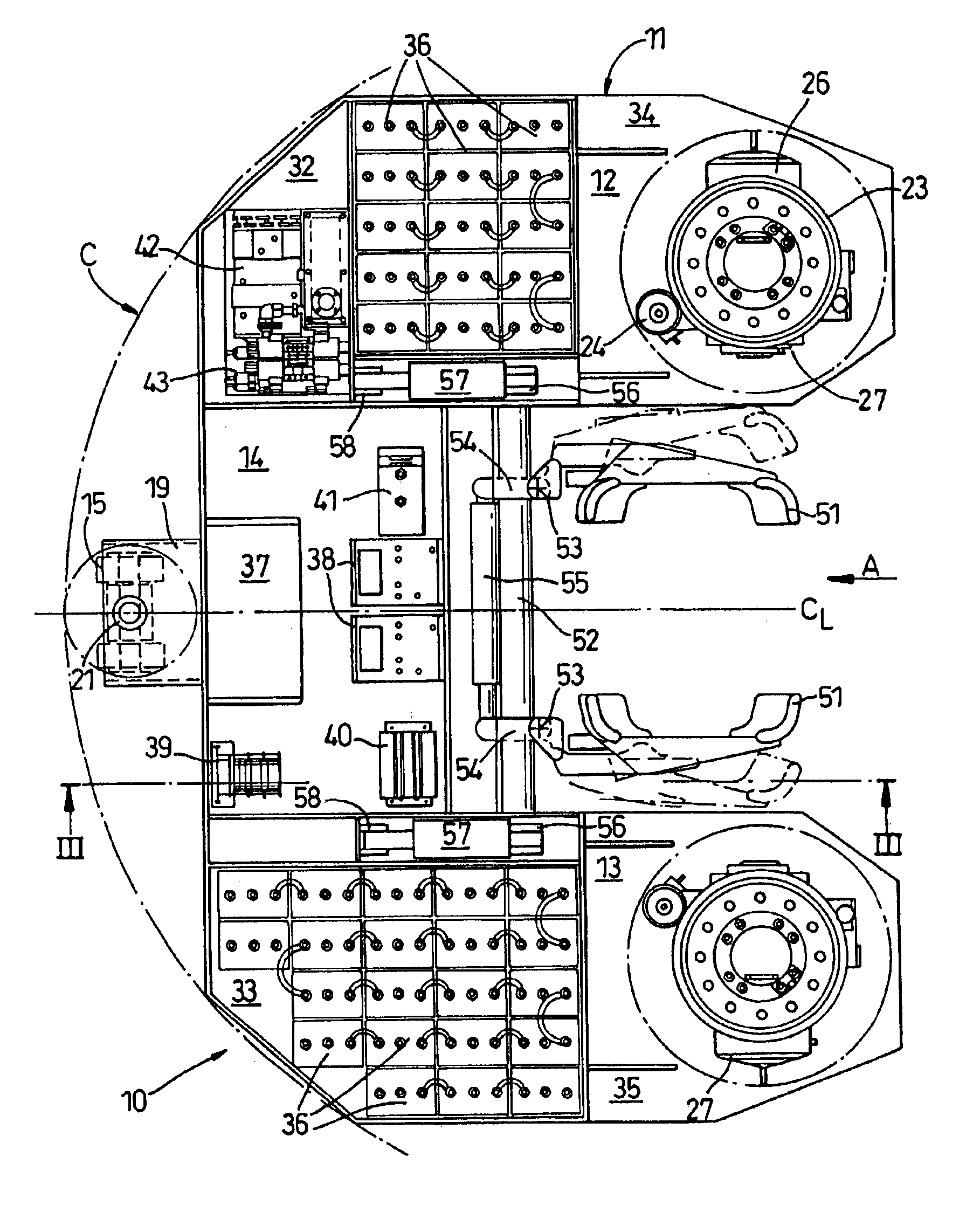

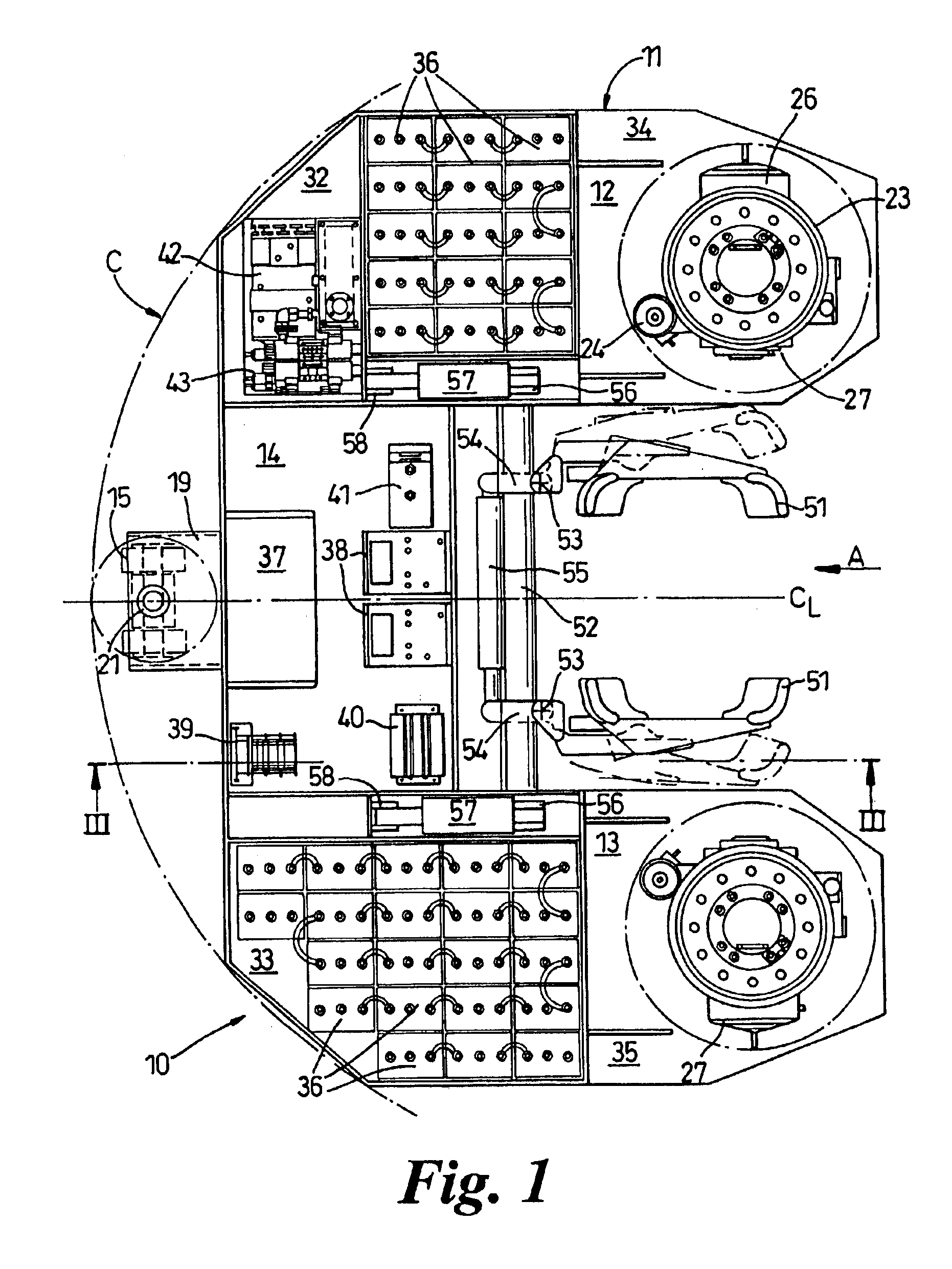

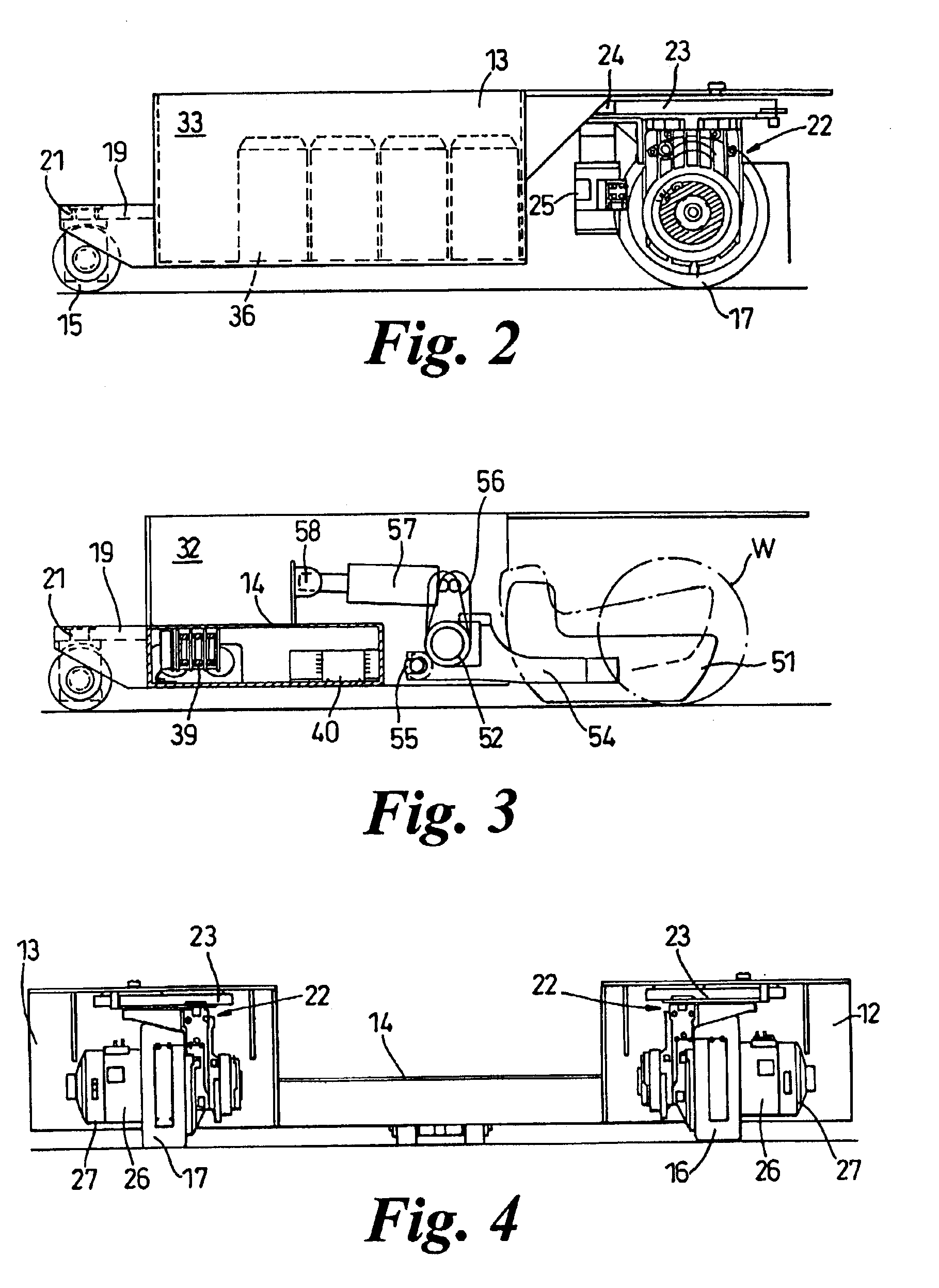

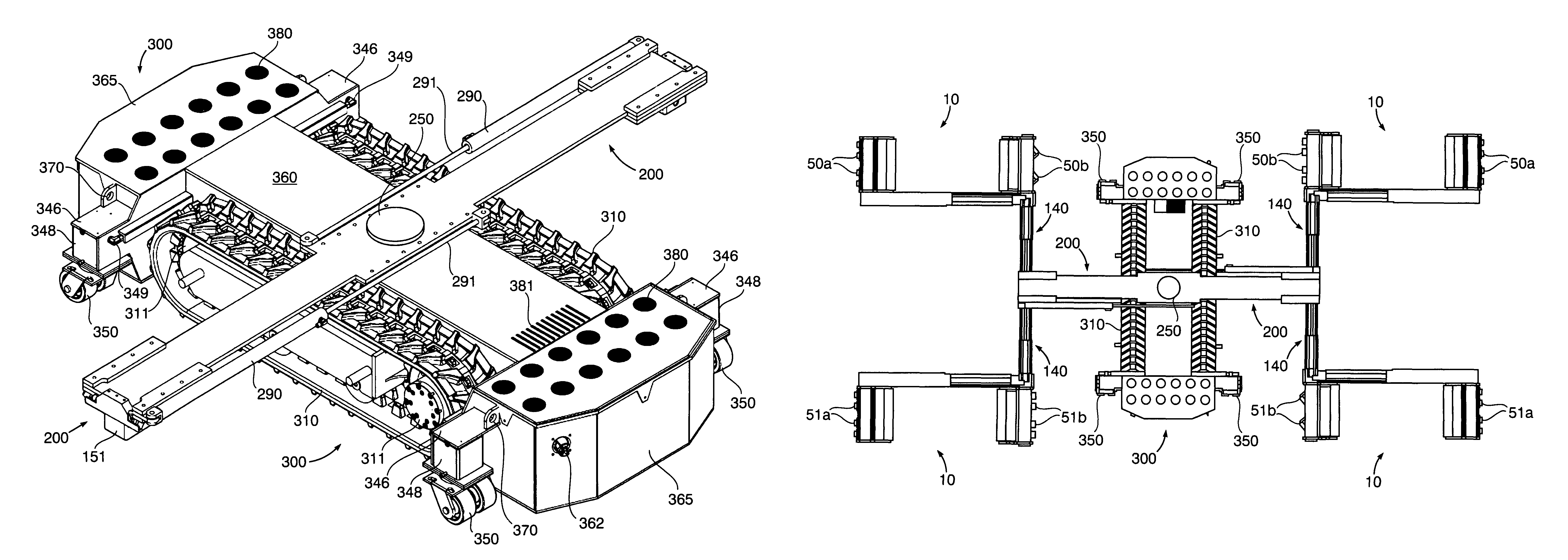

Aircraft handler

An aircraft handler (10) for use with an undercarriage of an aircraft, the handler being self-propelled and comprising a generally “U” shaped body (11) having arms (12 &13) linked by a bridge (14) at one end thereof with a pair of drive wheels (16 &17) located one at the free end of each arm, with at least one wheel(15) located adjacent the bridge(14). A pair of clamping jaws (51) are mounted on the body (11) between the drive wheels (16 &17) and the bridge (14)and jaws (51) have a lower profile than the arms (12 &17). The drive wheel (16 &17) are driven by DC electric motors powered by batteries stored in the arms.

Owner:DOUGLAS EQUIPMENT +1

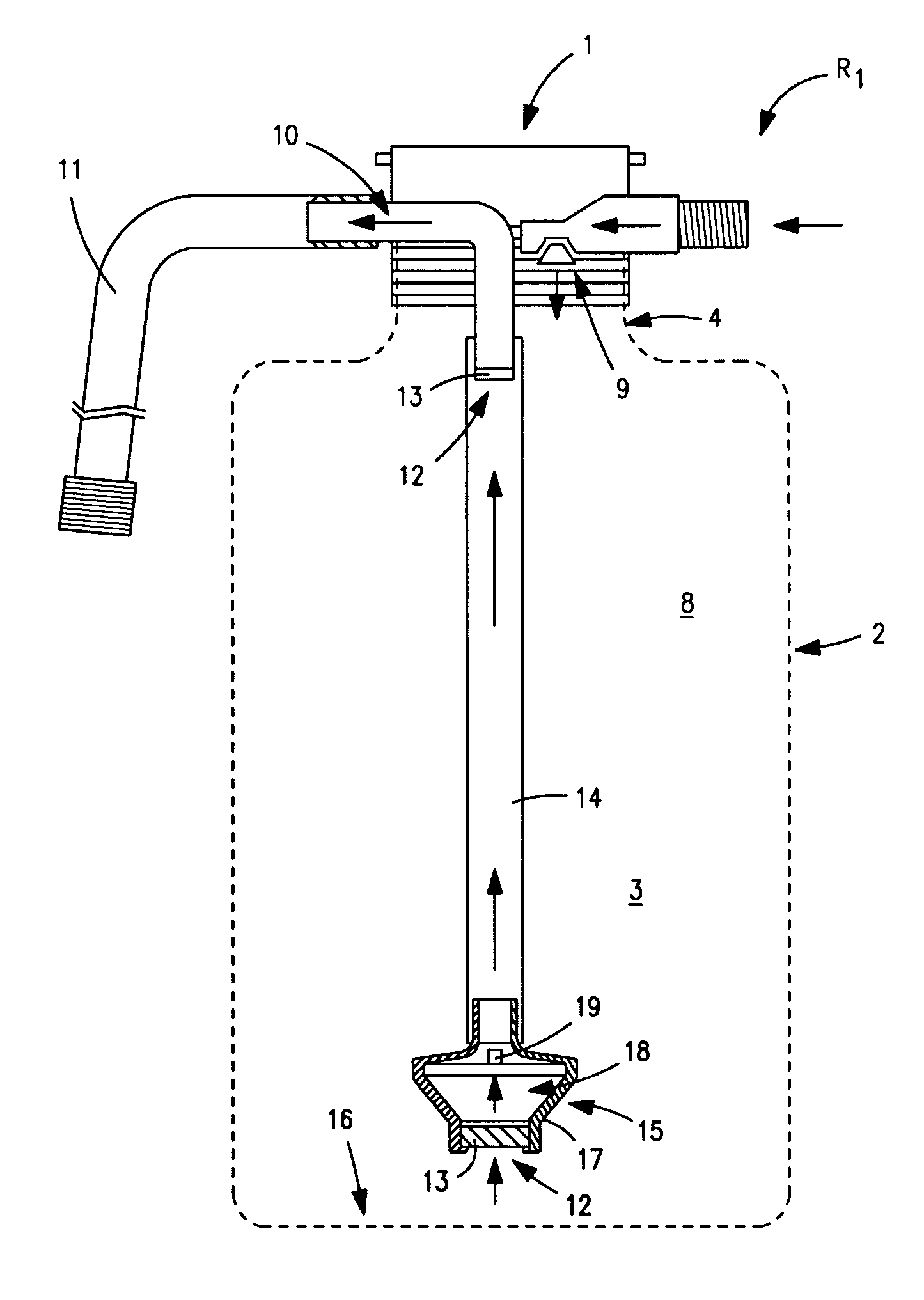

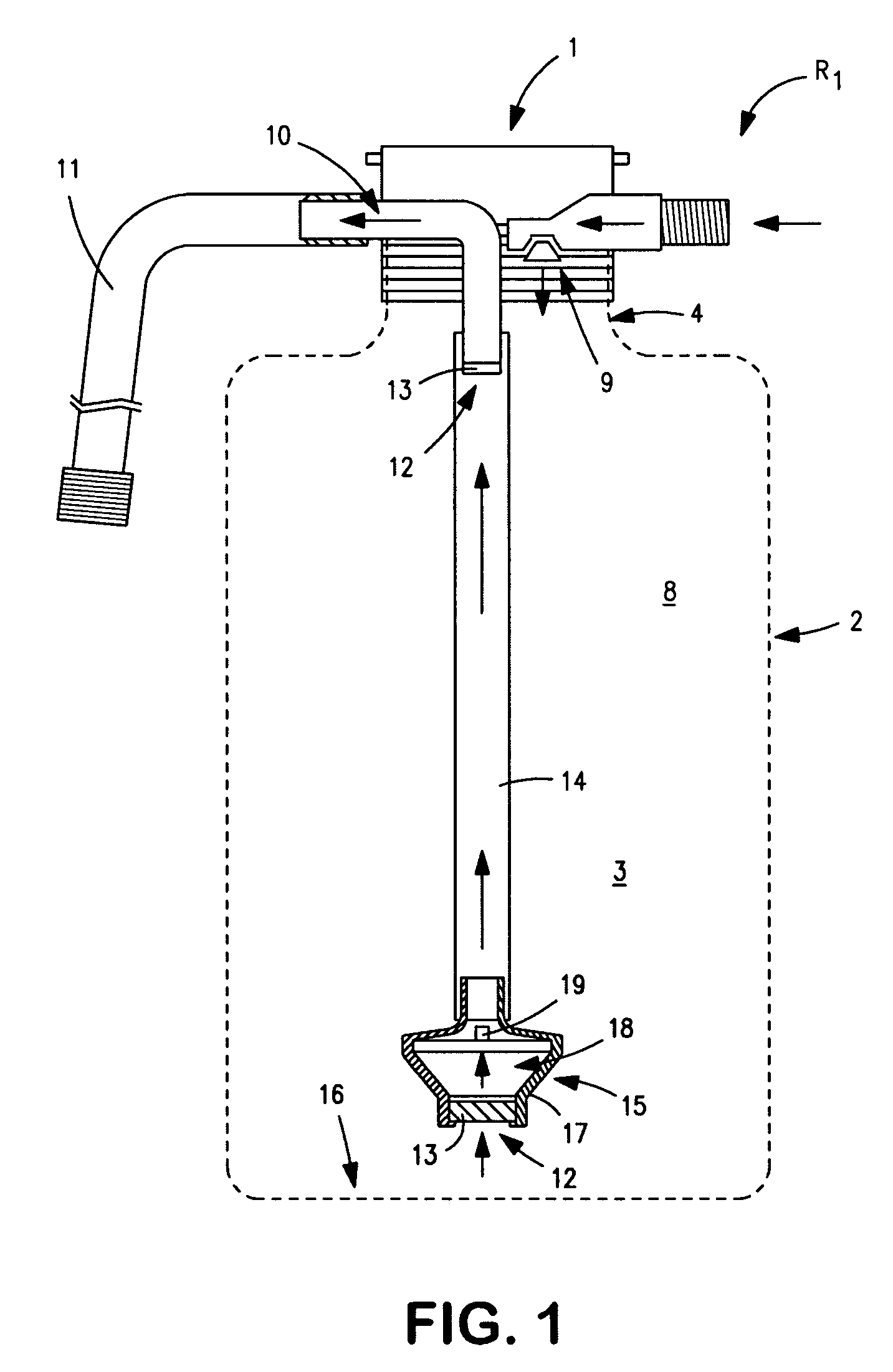

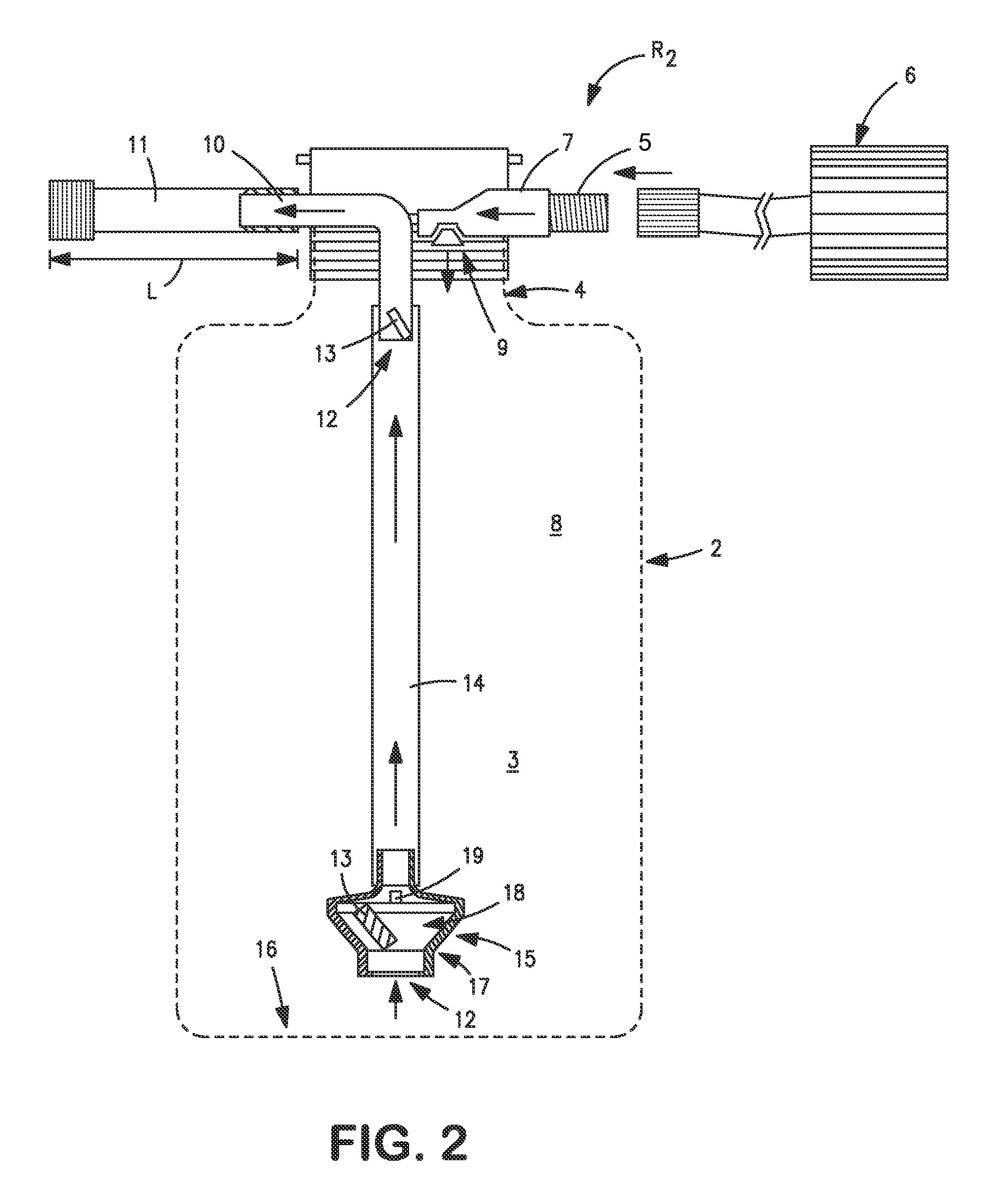

Device for discharging tire sealant from a container

A device for discharging tire sealant (3) from a container (2), the container (2) is connectable to a closure element (1). The pressure source (6) is able to be connected to the closure element (1) and, when a positive pressure is produced in the container (2), a removal opening (12) is able to be released in order to discharge tire sealant (3) from the container (2) into a tire.

Owner:ILLINOIS TOOL WORKS INC

Tire and tire rim assembly

Owner:CHEMTURA CORP

Apparatus for servicing a tired wheel

ActiveUS7089987B2Easy to controlEasy to operateStatic/dynamic balance measurementTyresMotor driveEngineering

An apparatus for servicing a tired wheel for motor vehicles, which comprises a tire assembling-disassembling machine provided with a rotatable motor-driven support (3) for supporting a wheel to be handled, sensor means (4, 5) for controlling both the position of, and the load on, the rotatable support (3), urging locking means (6) designed to act on the middle portion of the wheel-rim to make the wheel rigid in rotation with the rotatable support (3), detecting means (7, 7a, 7b) designed to measure the size of the wheel-rim, and program control means (EC).

Owner:BUTLER ENG & MARKETING

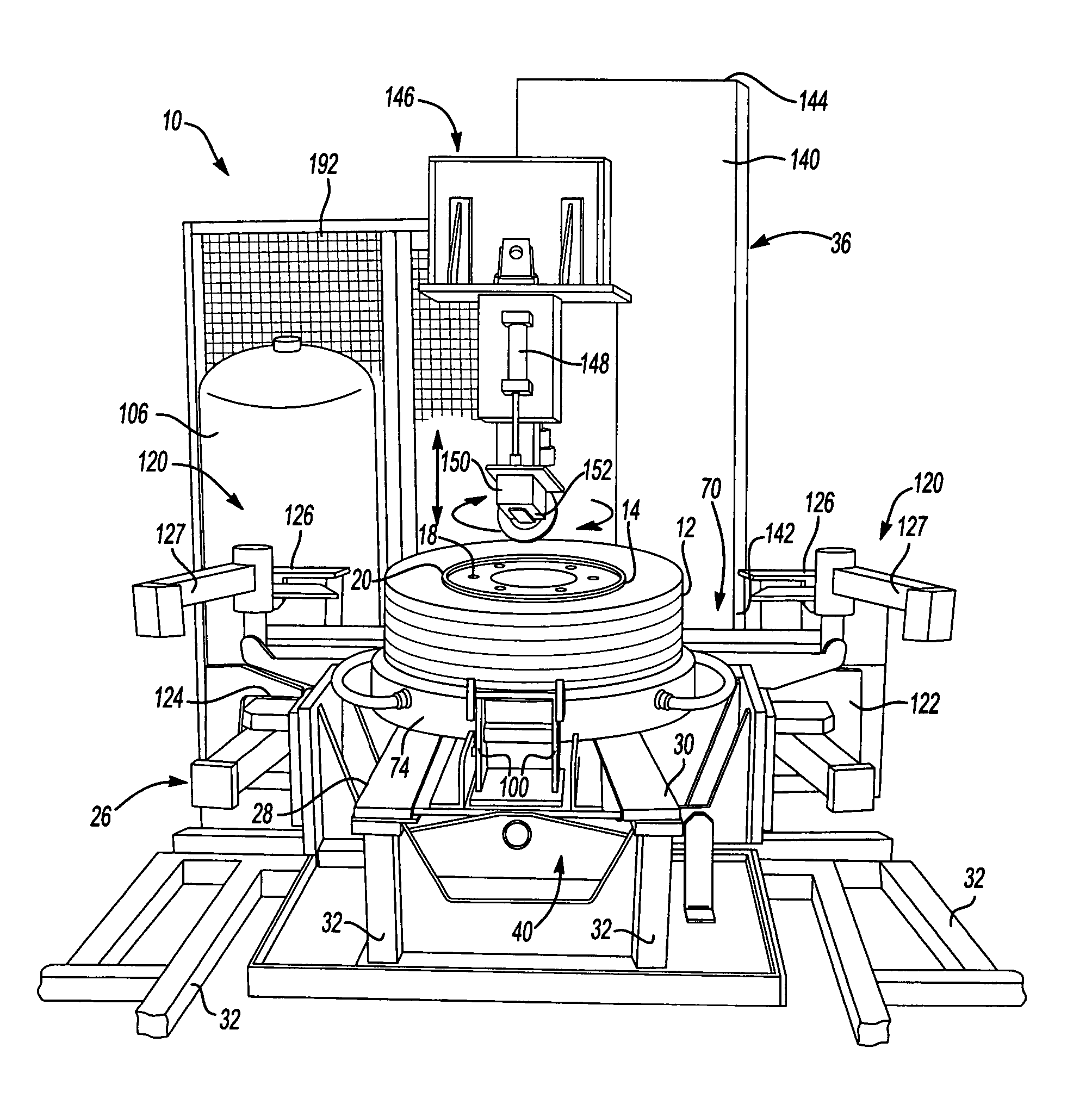

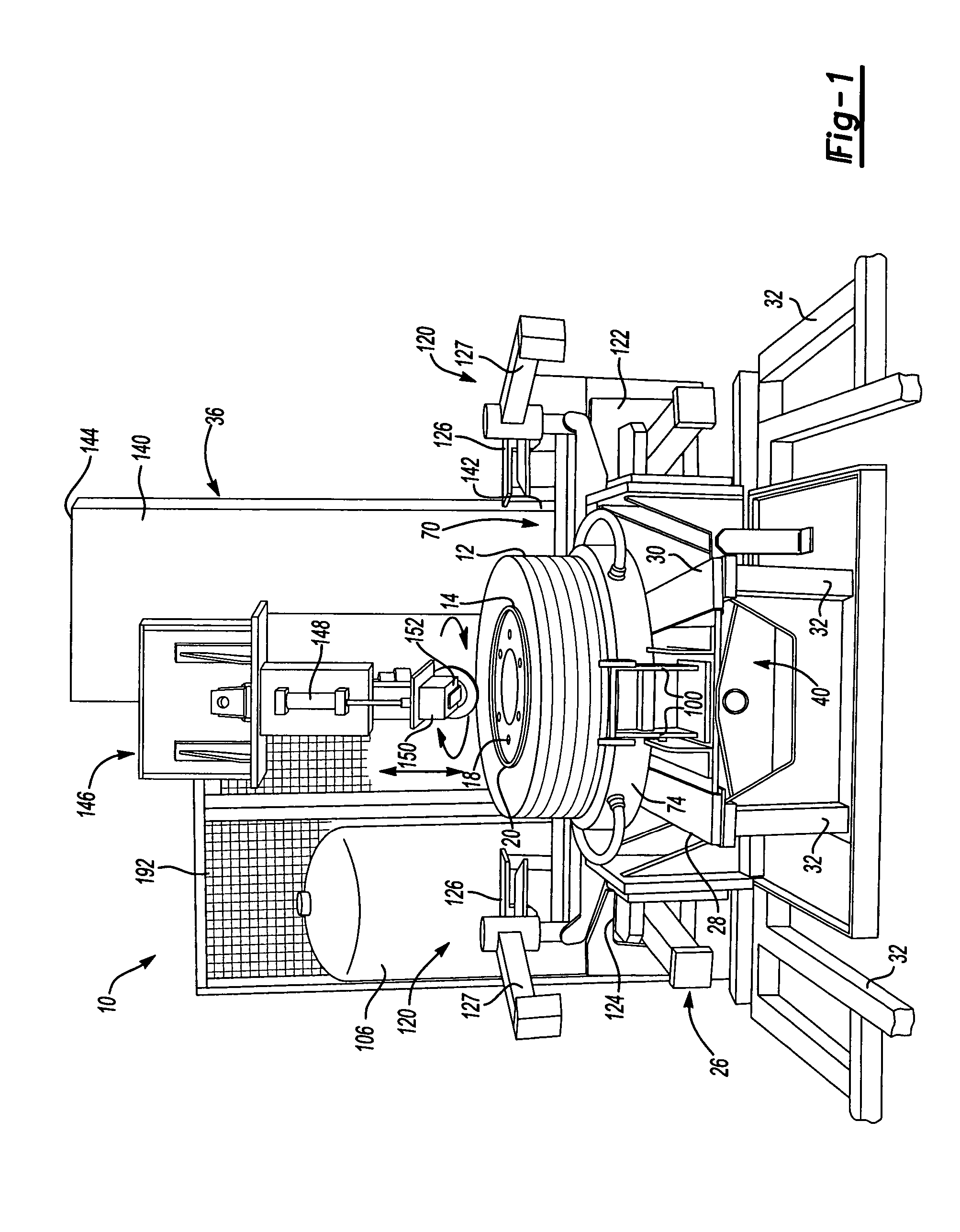

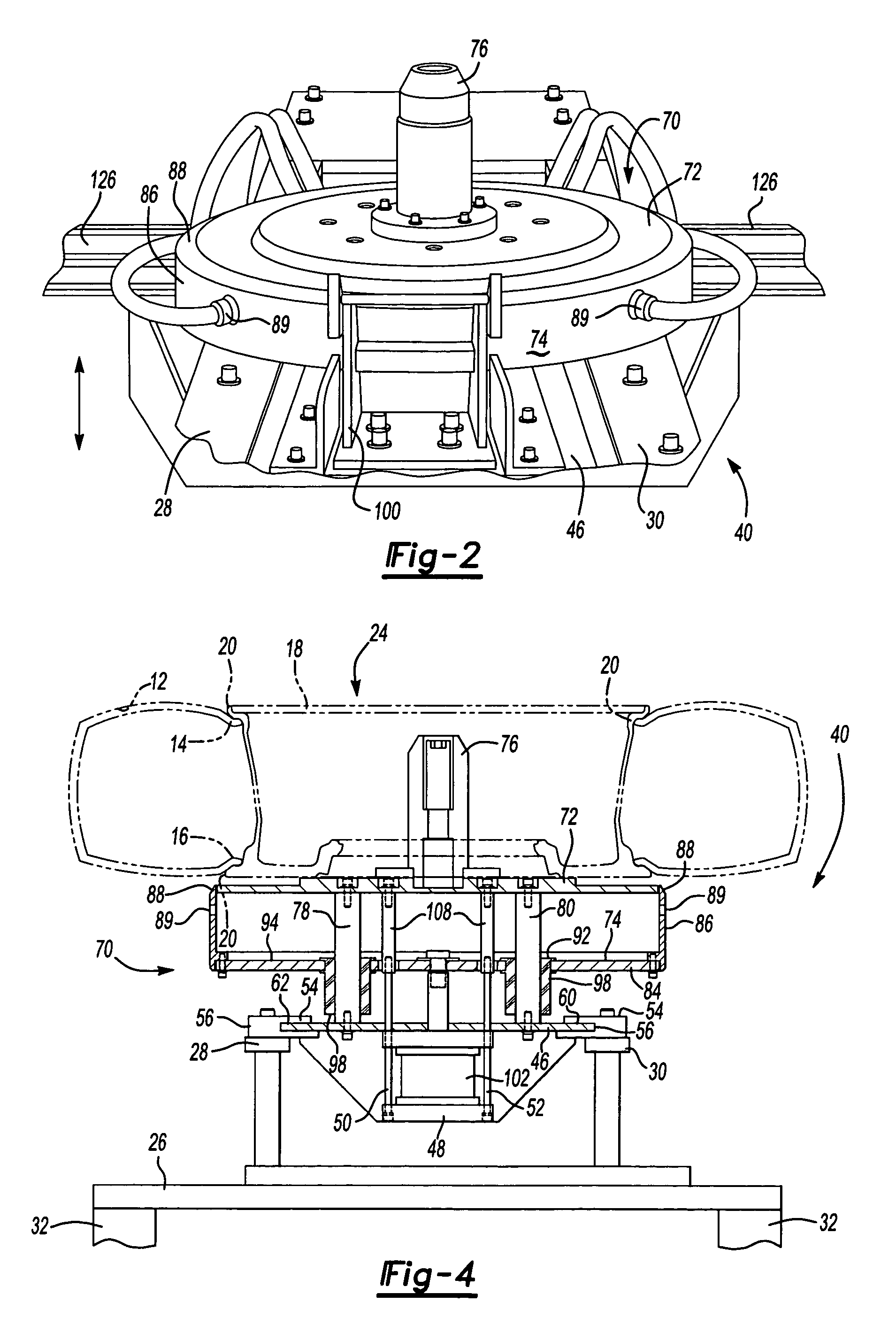

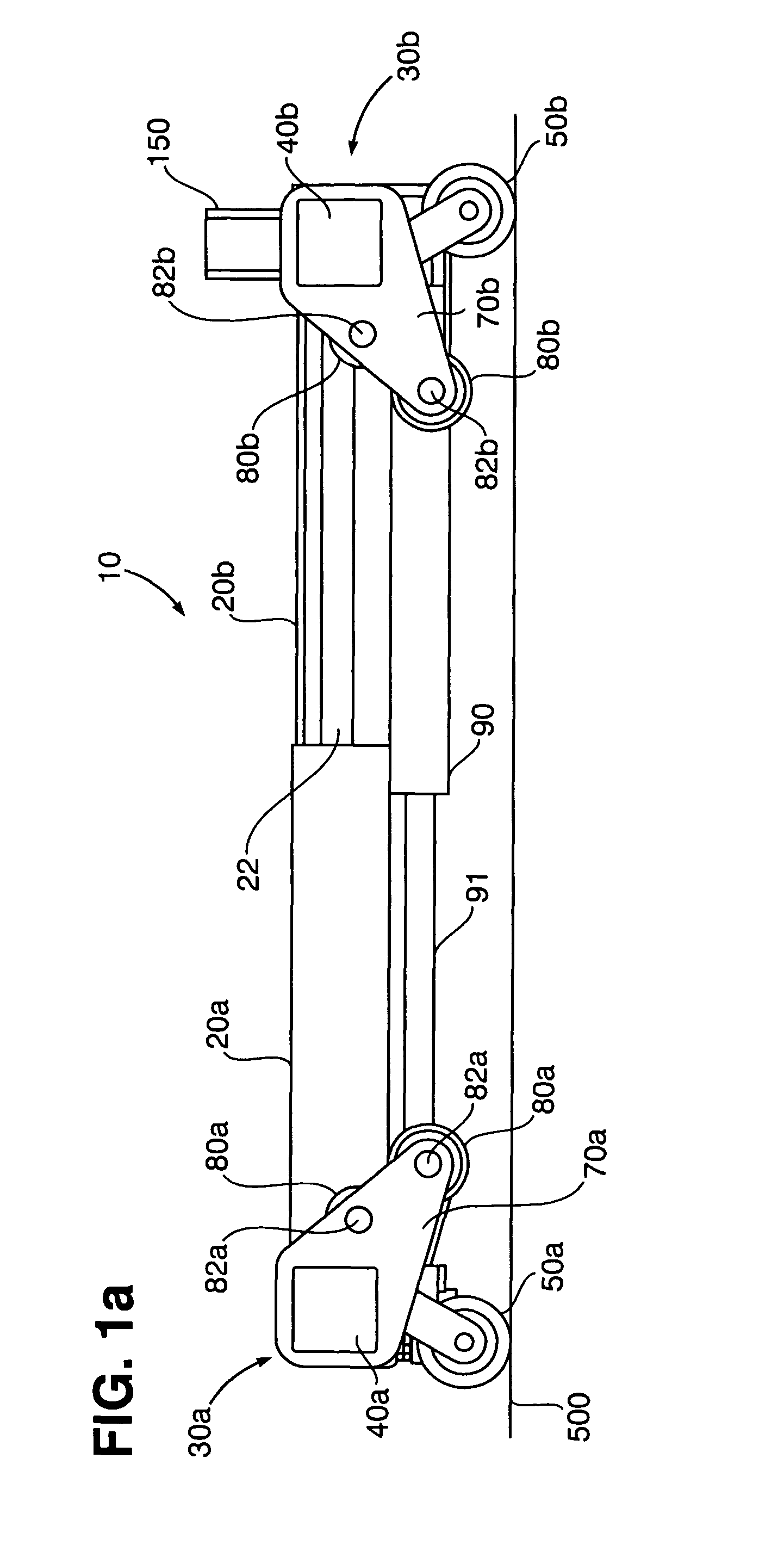

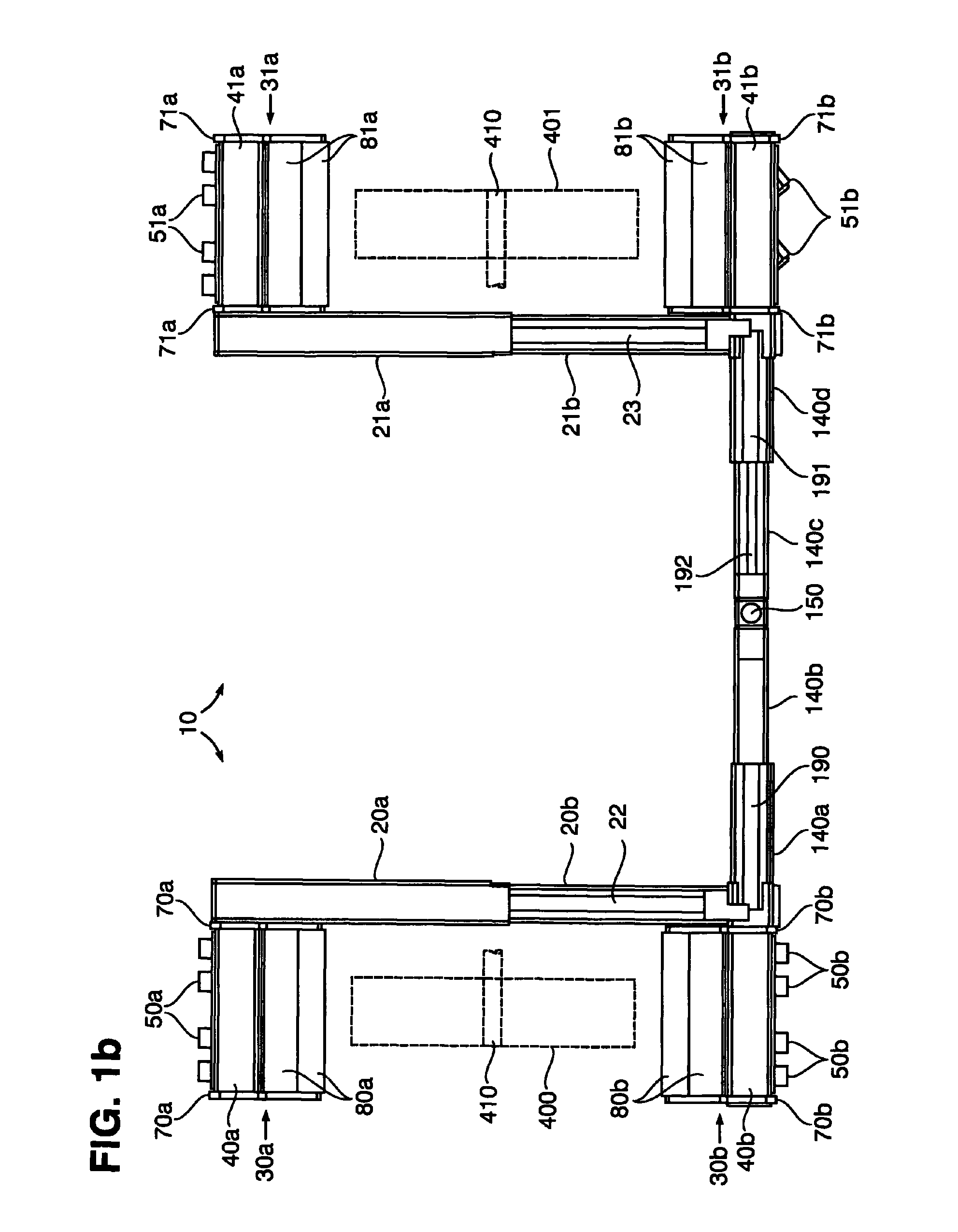

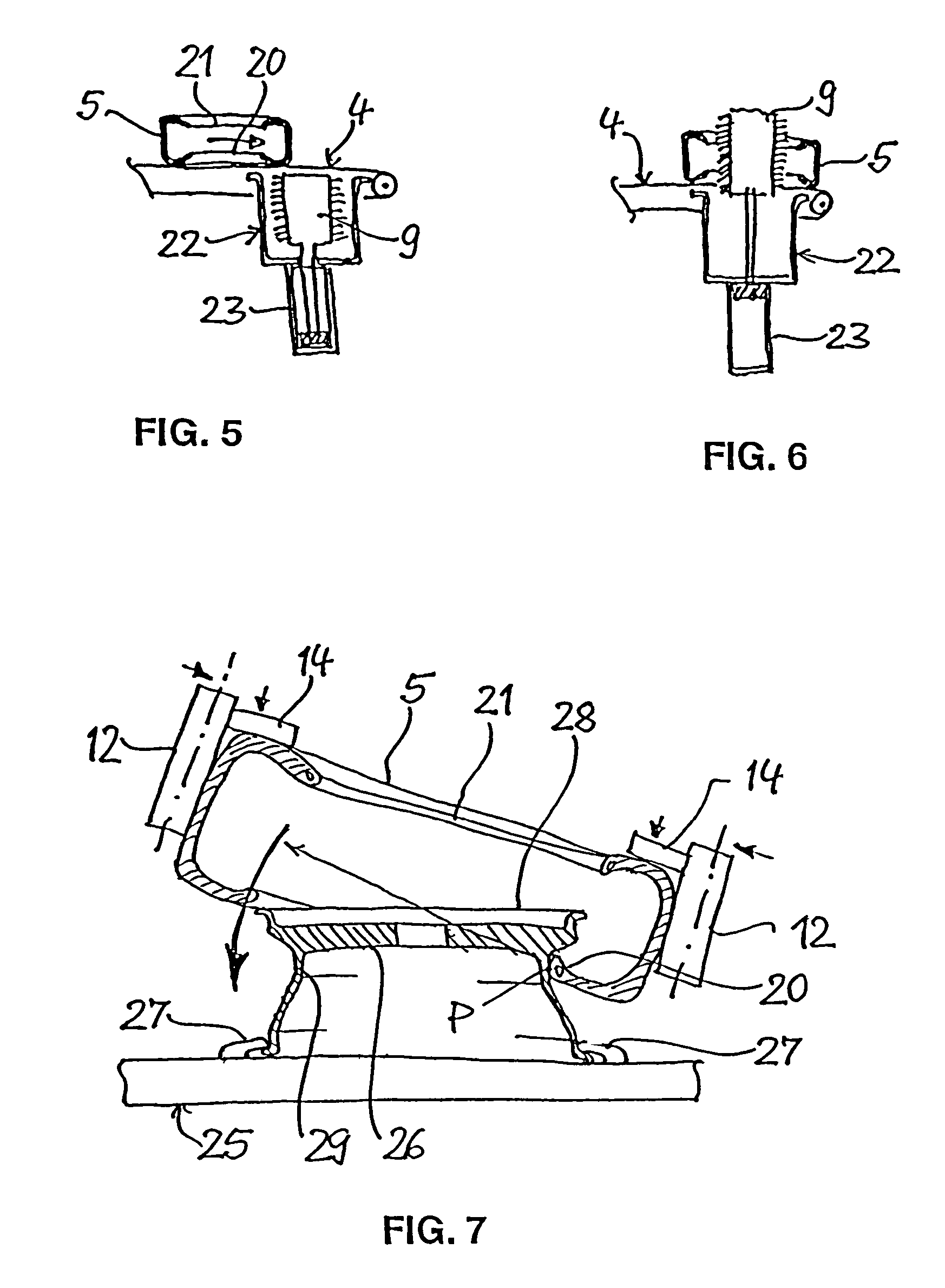

Apparatus for mounting and inflating a tire and wheel assembly

InactiveUS7044188B2High productRapidly inflating a tireTyre repairingEngineeringMechanical engineering

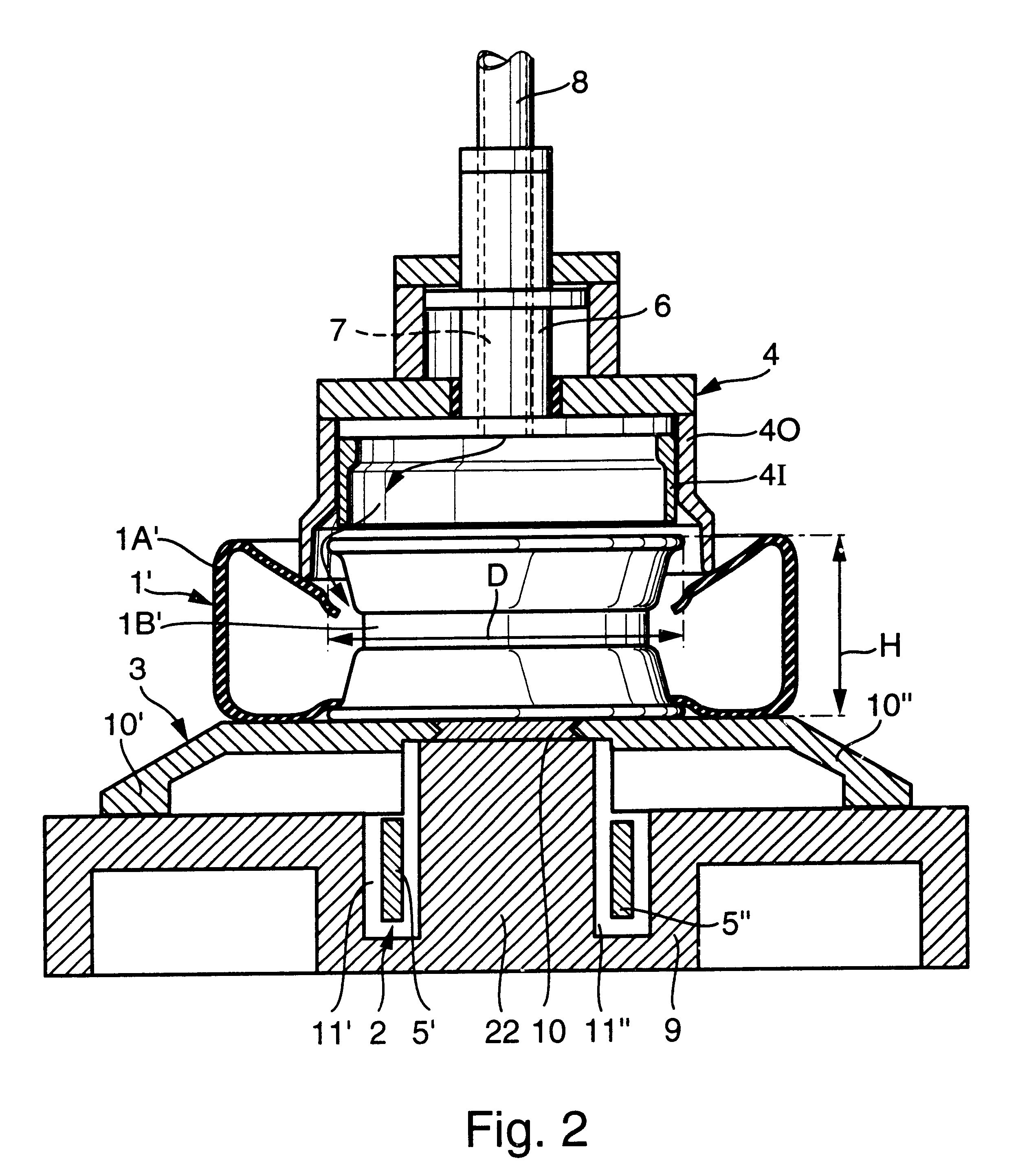

An apparatus (10) of the present invention is designed for assembling and inflating a tire (12) mounted on a wheel (18). A tool (36) of the apparatus (10) rotates around the tire (12) for forcing one of the beads of the tire (12) between the seats of the wheel (18). Inner (72) and outer (74) concentric members are operably connected relative to one another for inflating the tire (12) mounted about the wheel (18). An activator (102) is connected to the outer concentric member (74) for moving the outer concentric member (74) telescopingly relative to the inner concentric member (72) to form a fluid passage (104). A carriage mechanism (40) is connected,to the inner (72) and outer (74) concentric members for reversibly moving the same between an isolated position (42) and the tool (36).

Owner:DURR SYST INC

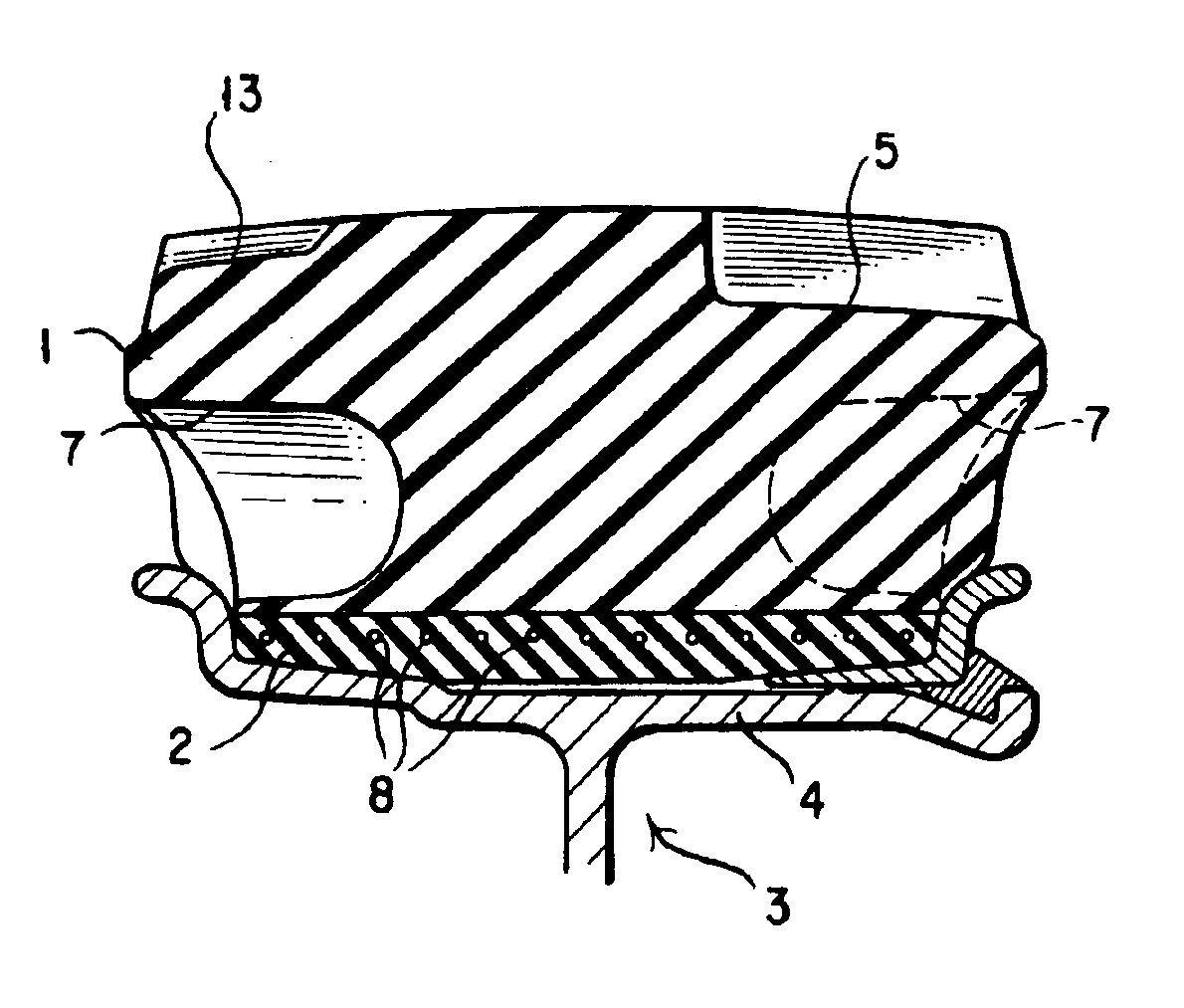

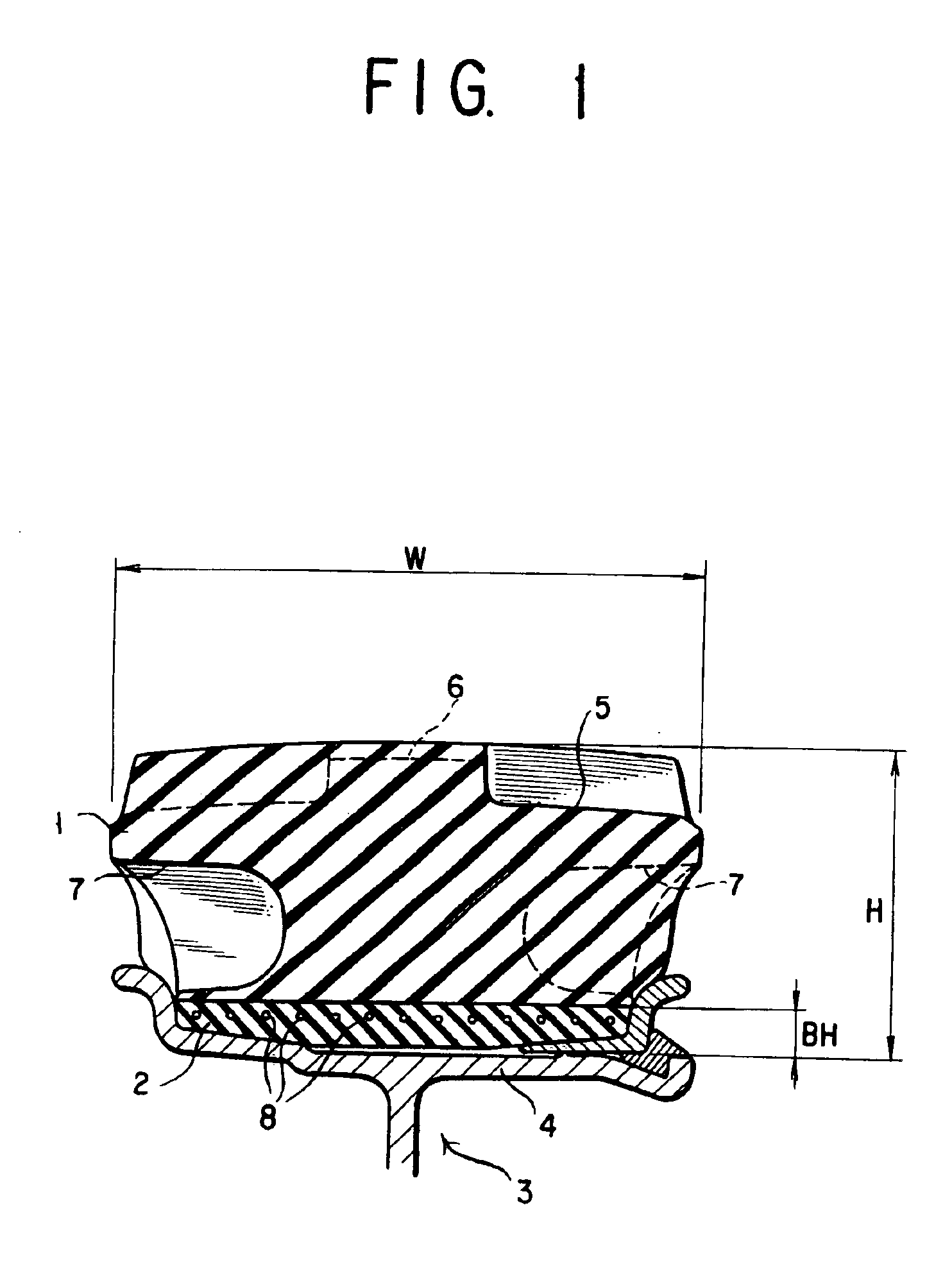

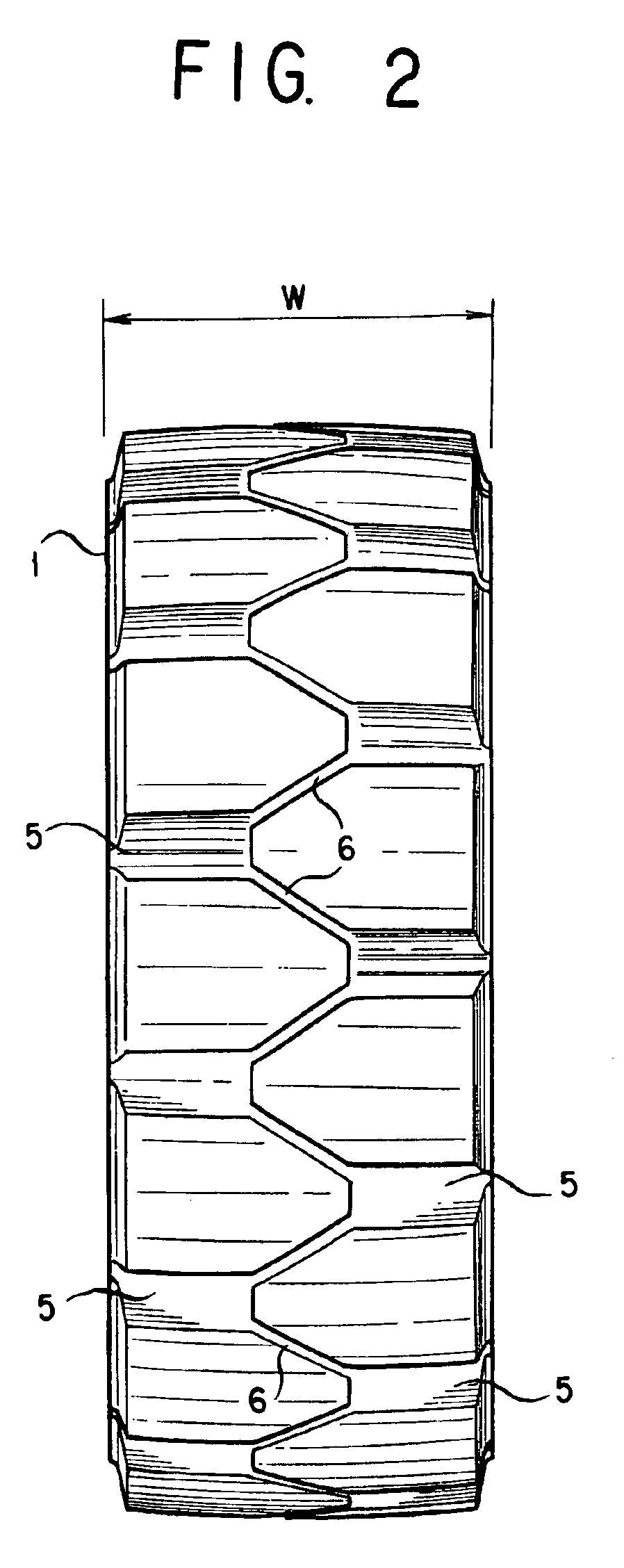

Cushion tire

InactiveUS6845796B2Improve fitImprove buffering effectWithout separate inflatable insertsNon-inflatable tyresRubber materialCushion

A cushion tire is formed from a rubber material without being provided with an airspace inside the tire. An aspect ratio, which is a ratio of a sectional height of a tire with respect to a width of the tire, is set to 15 to 80%. And a number of holes are formed in both bilateral side surfaces of the tire along a circumferential direction thereof.

Owner:FUKUYAMA GOMU KOGYO +1

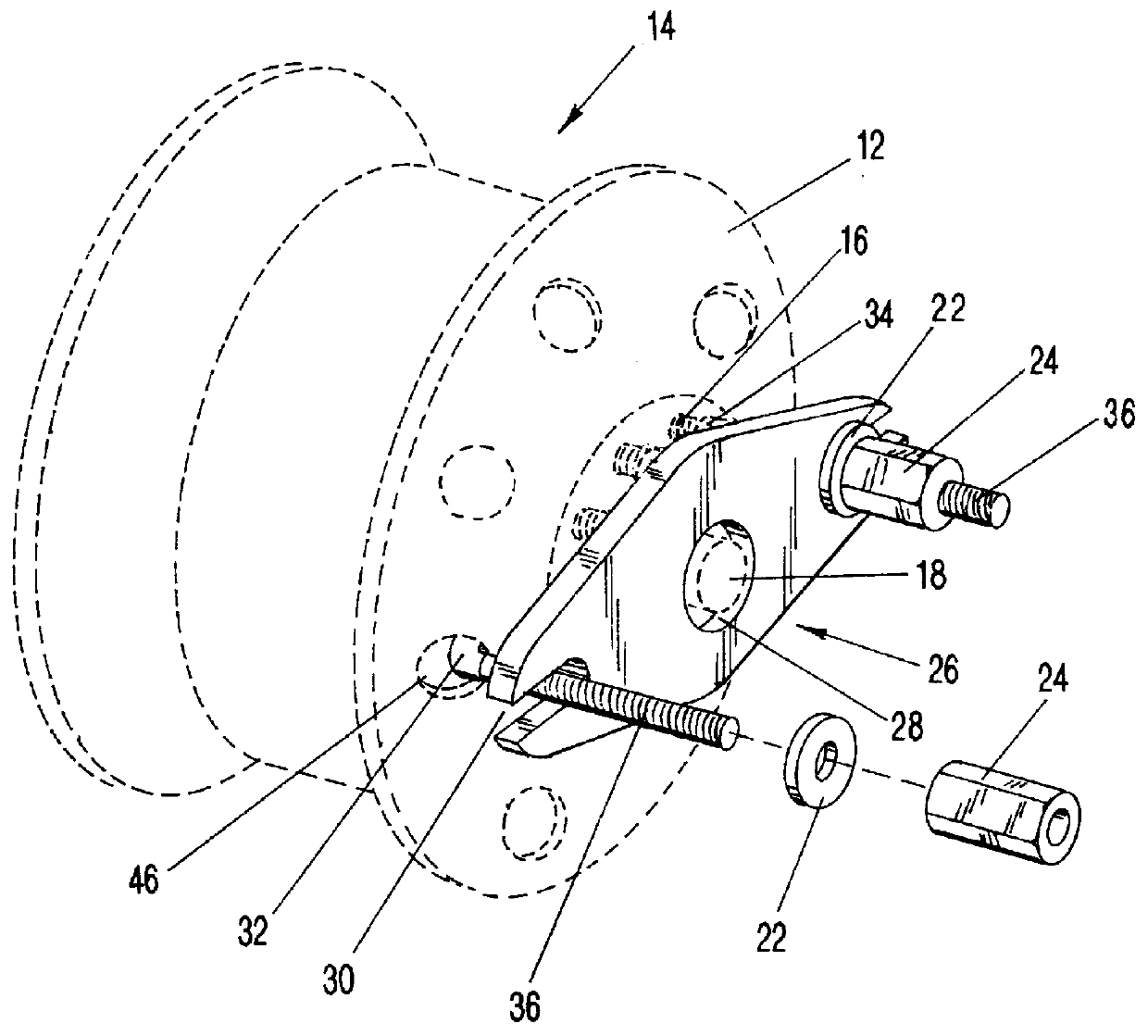

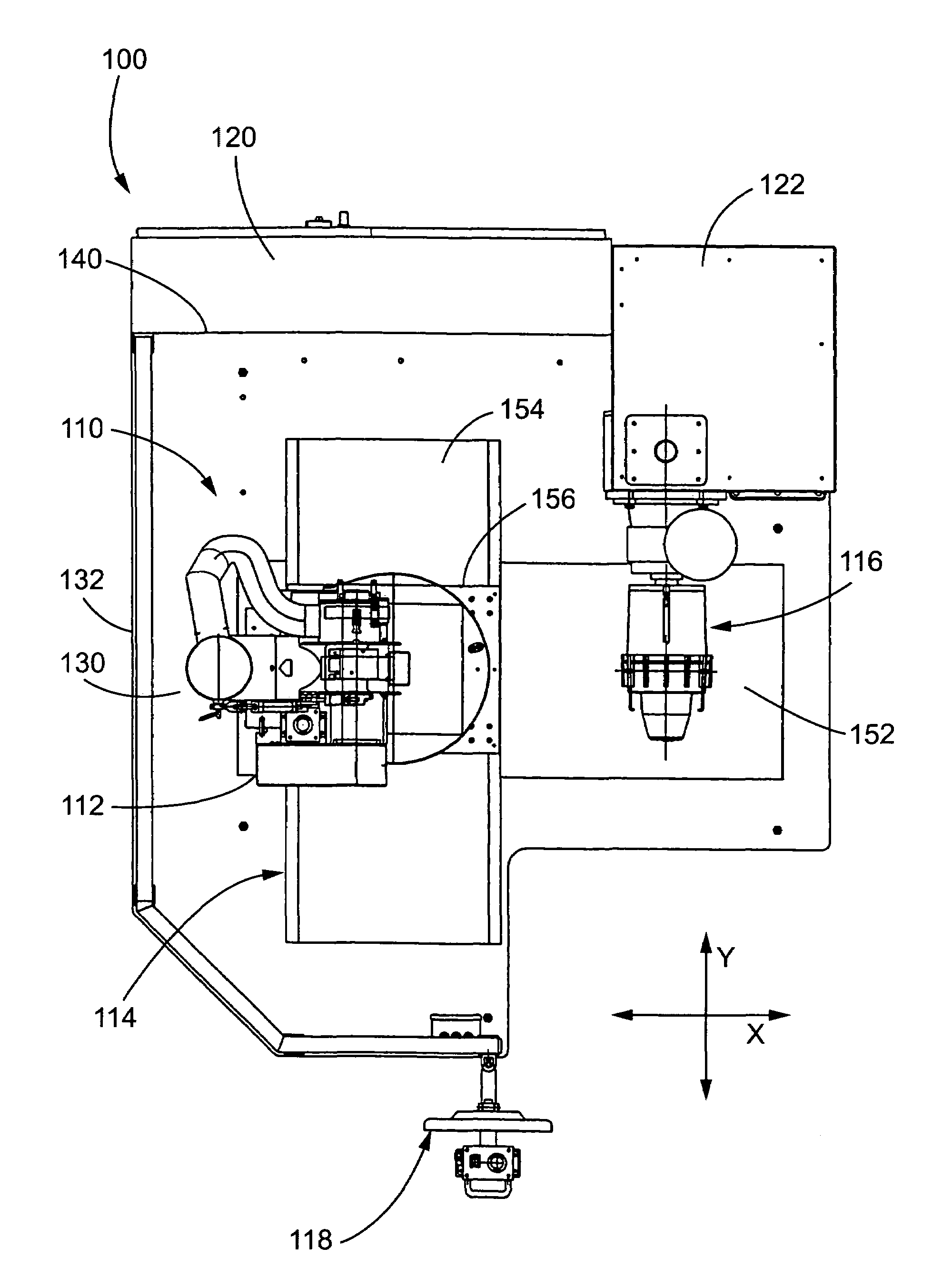

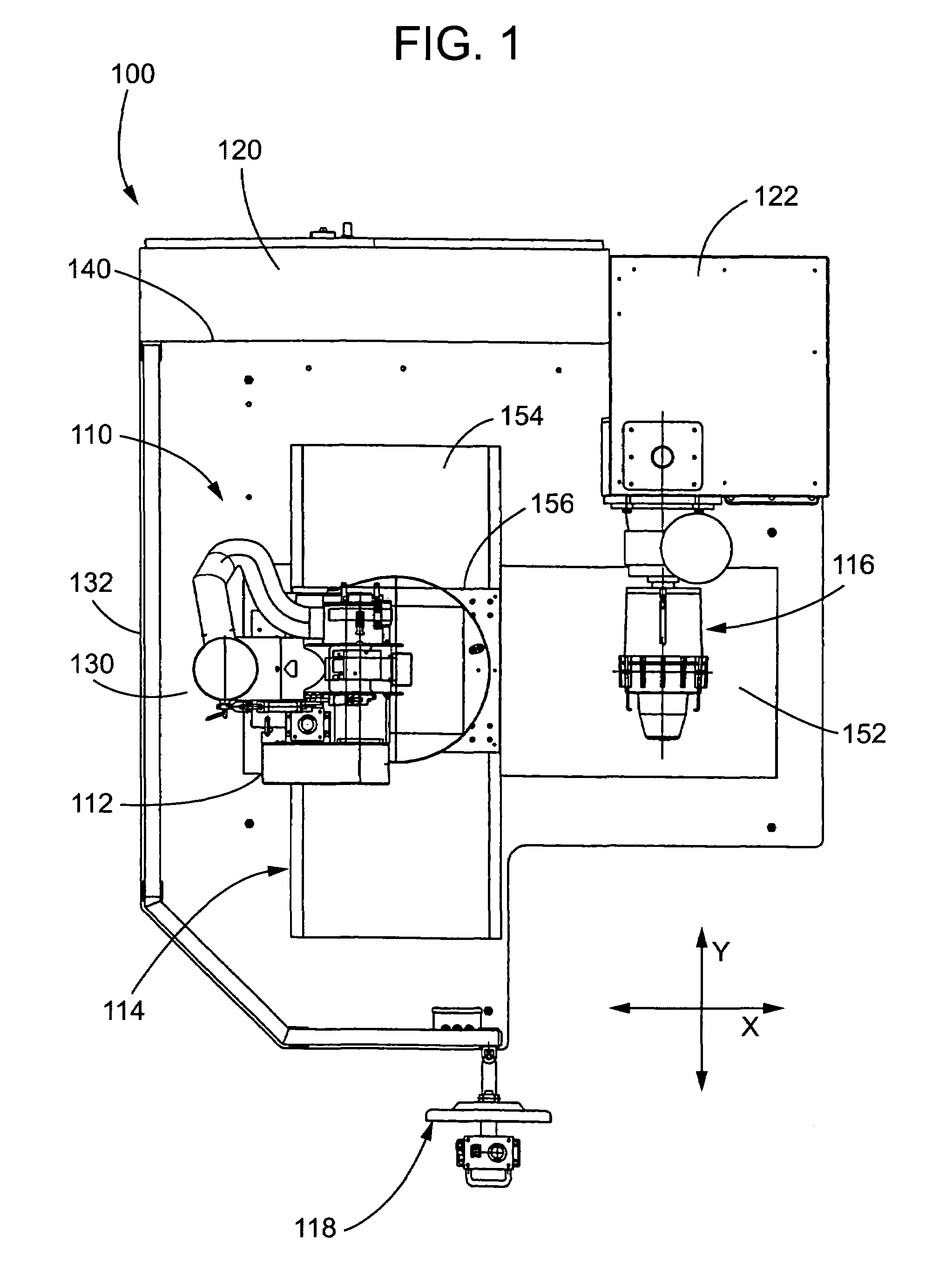

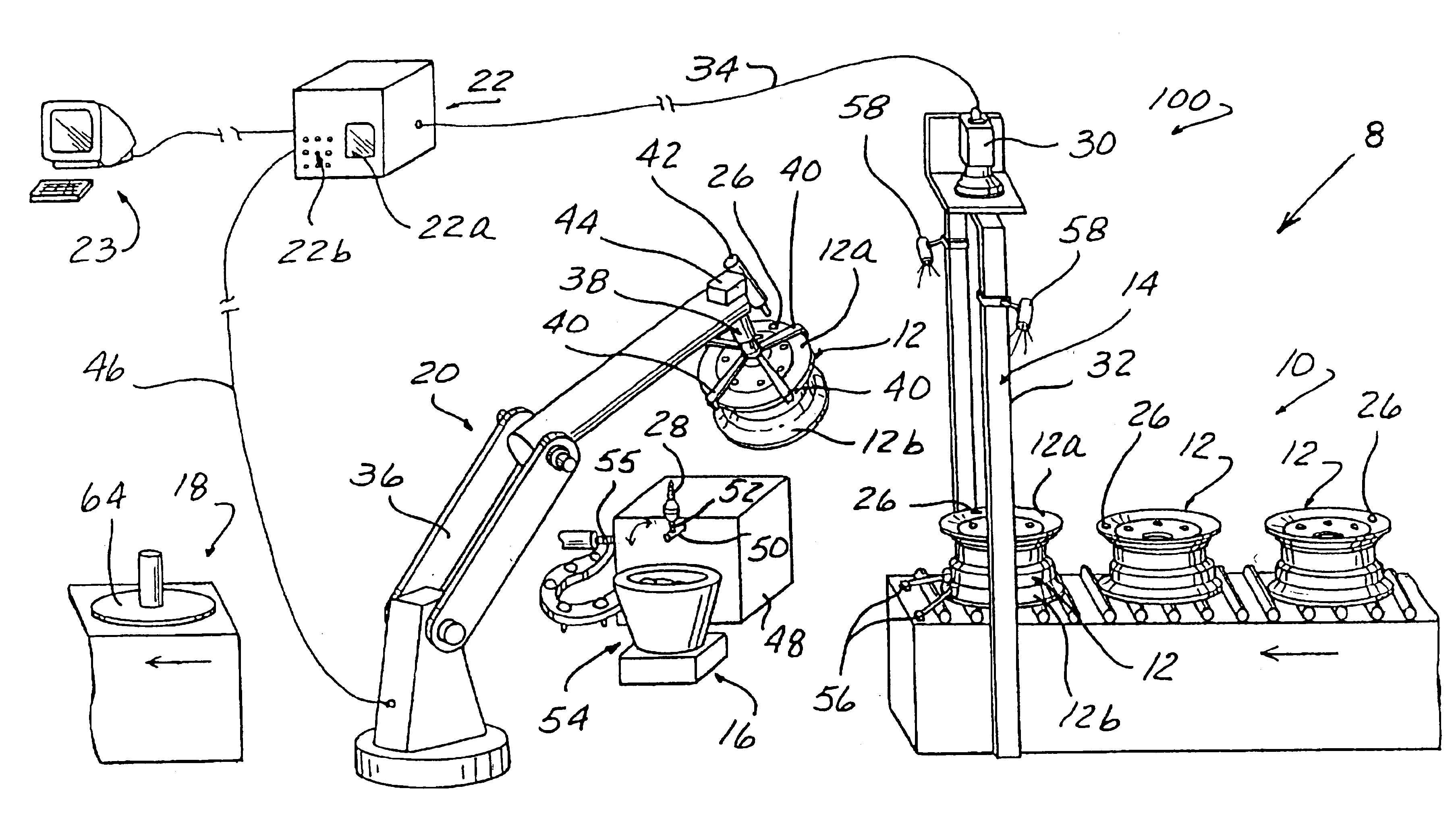

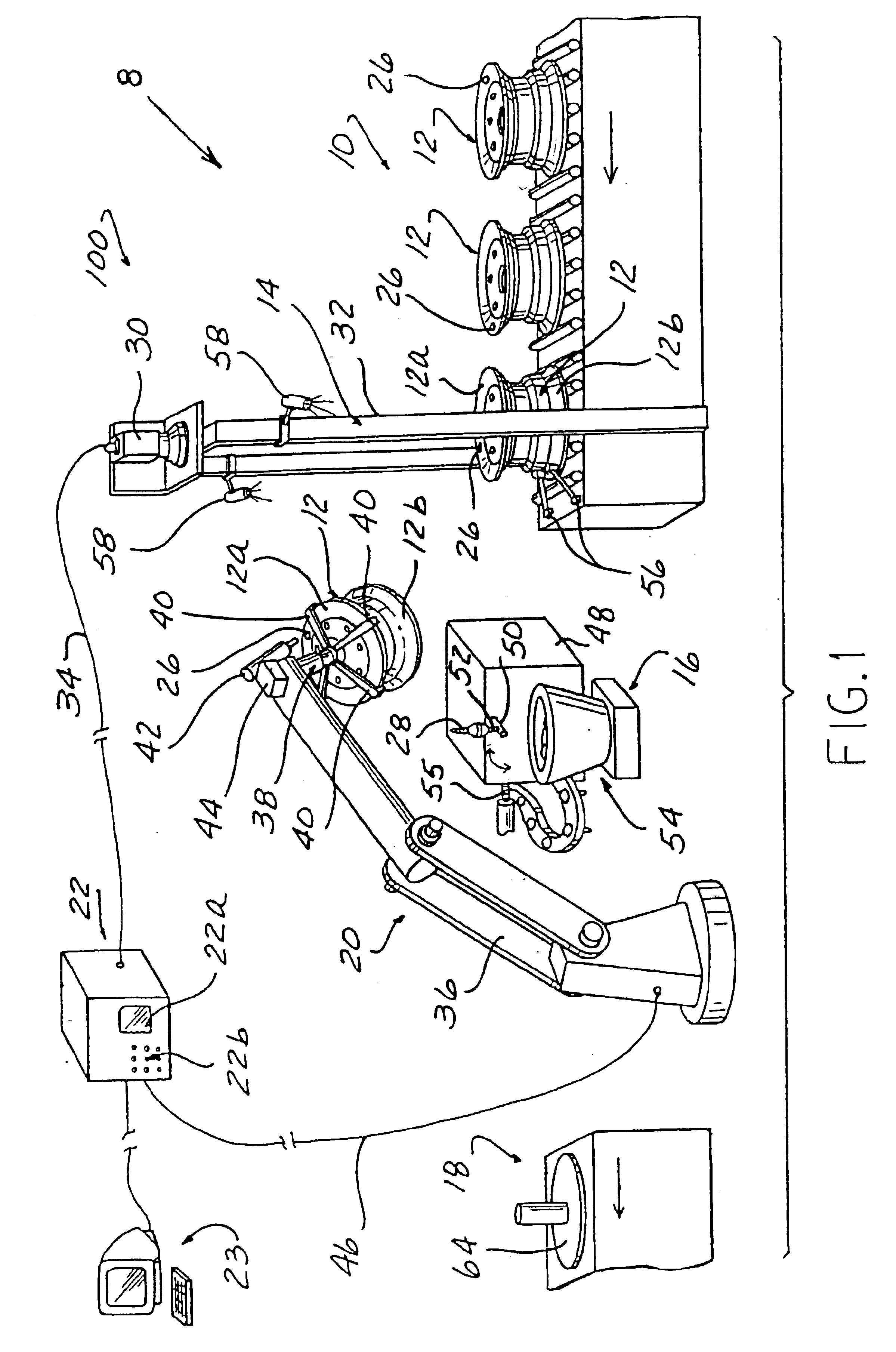

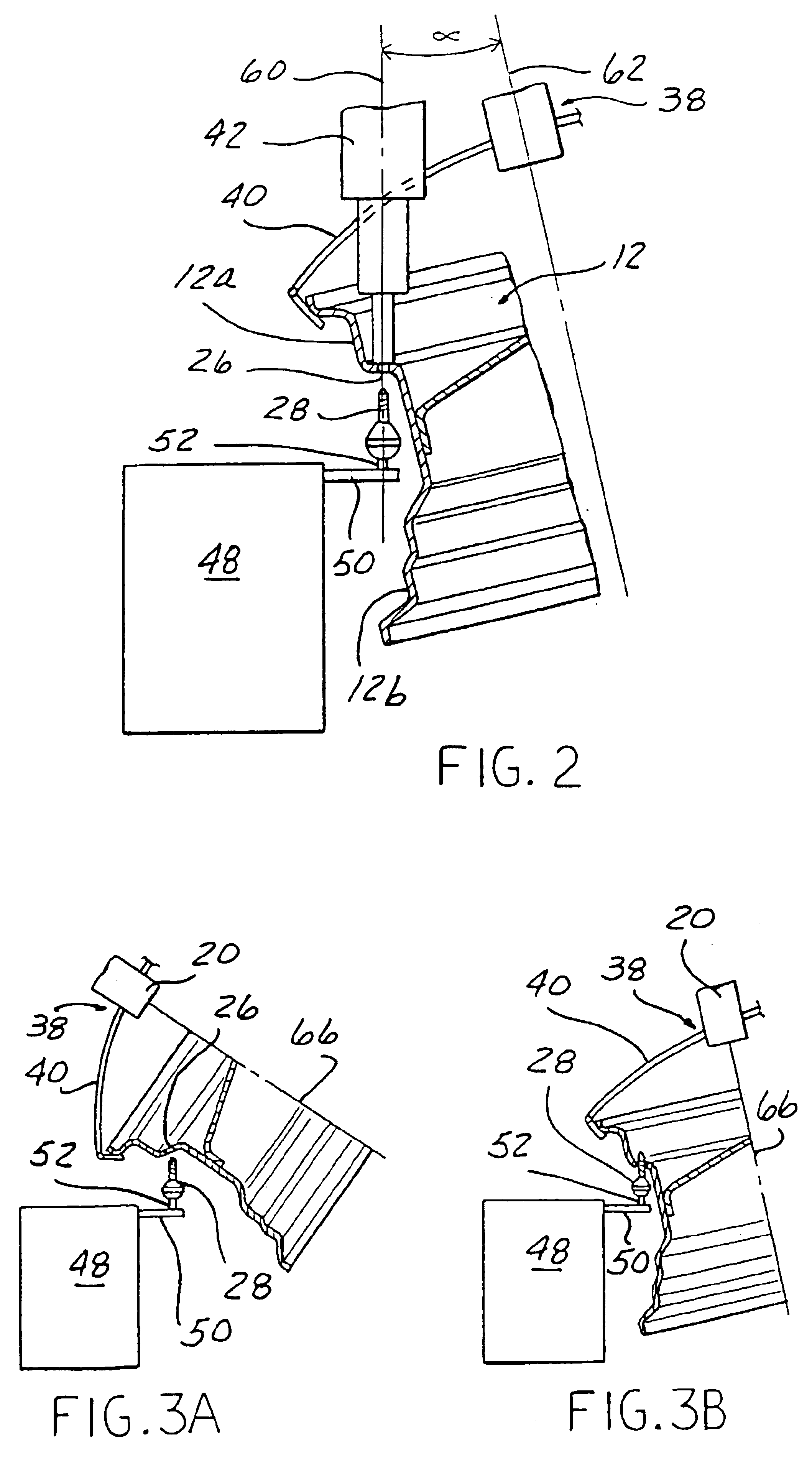

Robotic apparatus and method for mounting a valve stem on a wheel rim

InactiveUS6886231B2Accurate insertionIncrease volumeProgramme-controlled manipulatorAutomatic control devicesRotary stageElectronic control system

An apparatus and method for mounting a valve stem to the rim of an automotive vehicle wheel includes rims being supplied in series by a conveyor to a gauging station where the type and / or size of the rim and the location and alignment of an aperture for receiving the valve stem is determined by a machine vision system. An electronic control system directs a robotic manipulator to grasp either the valve stem or the rim, move the valve stem or the rim to a mounting station, position the valve stem or the rim with respect to the other such that the aperture in the rim is in coaxial alignment with the valve stem, and insert the valve stem through the aperture in the rim. If necessary, a power-actuated nut runner, mounted on the robotic manipulator or adjacent the mounting station, is used to tighten a nut over the valve stem. As an alternative to the machine vision system, the gauging station can use a rotating table which rotates the wheel about a central axis, and an “electric eye” optical sensor directing a beam of infrared light onto the rim. As the rim rotates through the beam, the presence or lack of a reflection of the light beam is used to detect the location of the aperture, and rotation of the table is stopped when the aperture is in alignment with the beam. A probe mounted on the gauging station can be extended to project into the aperture to confirm that the aperture is at the desired position and reposition the rim slightly to provide a precise positioning of the aperture.

Owner:BURKE E PORTER MACHINERY

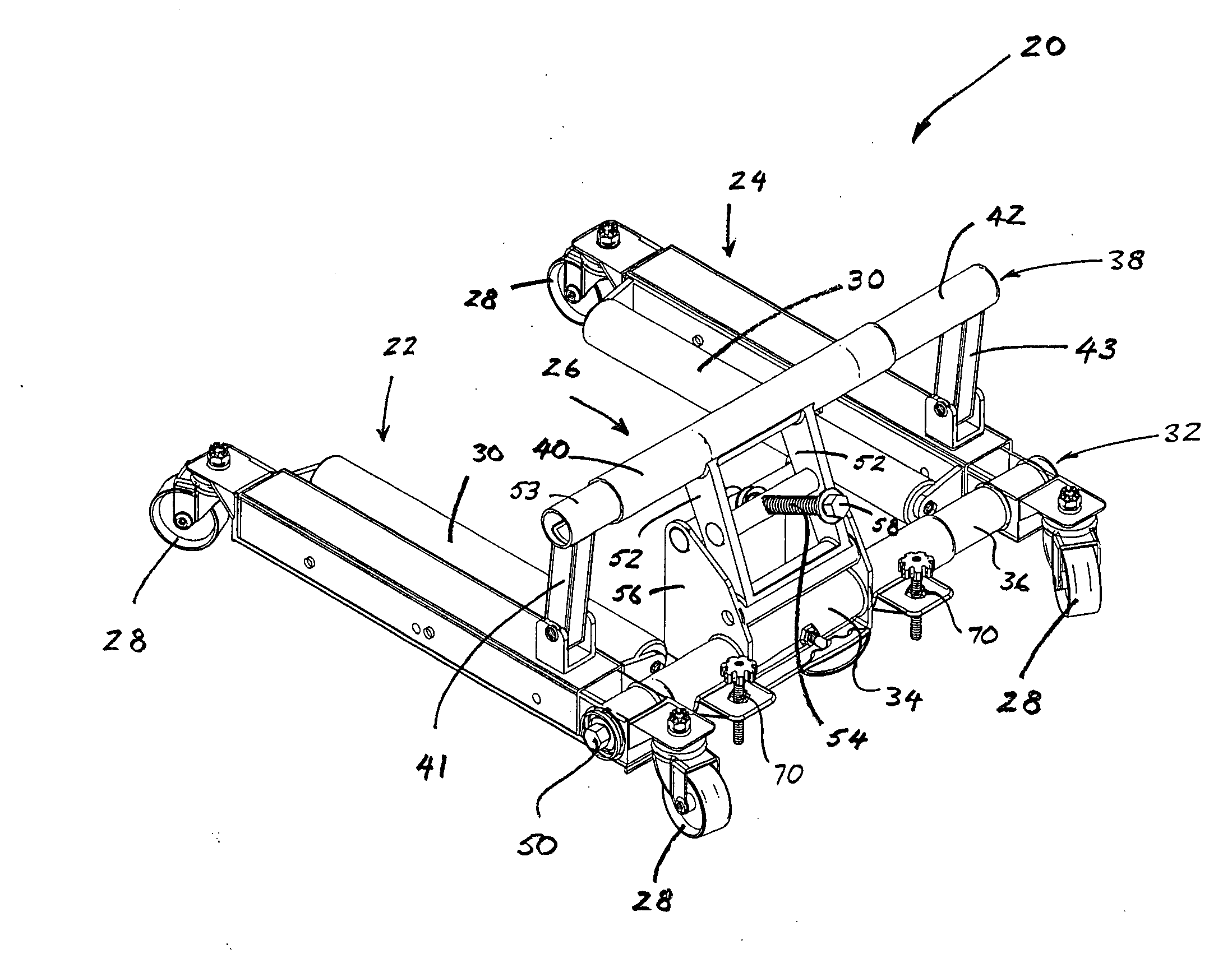

Wheeled-vehicle dolly

A dolly is particularly adapted to lift, support and maneuver a four-wheel vehicle. The dolly comprises an adjustable, generally U-shaped frame assembly for each vehicle tire. The frame assembly has pairs of reciprocally opposed first and second frame members adapted to be positioned adjacent opposite sides of a tire and to lift the vehicle by way of the tires. A castering wheel assembly supports the vehicle on a ground surface. The frame assembly is pivotably mounted on a tractor.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

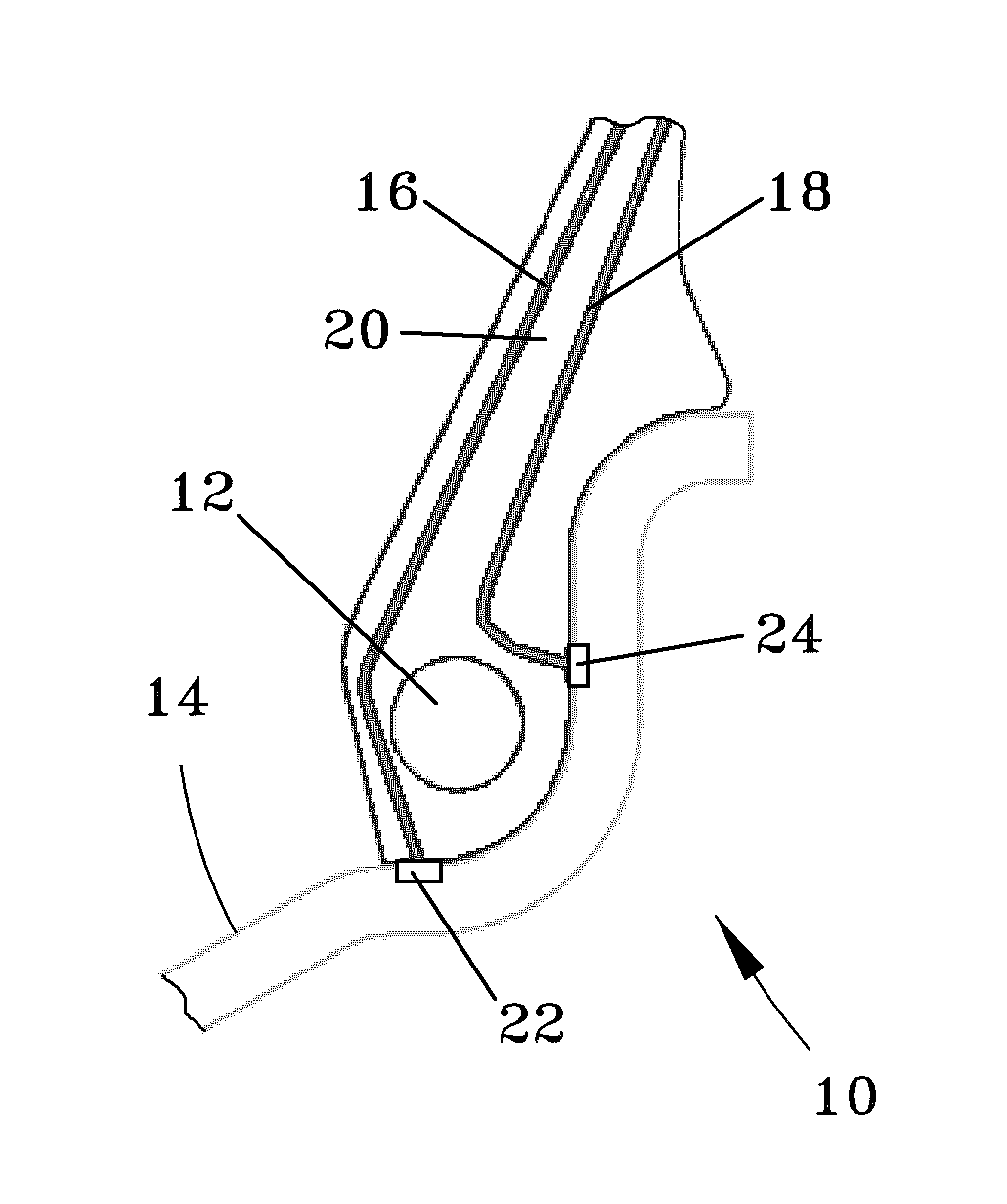

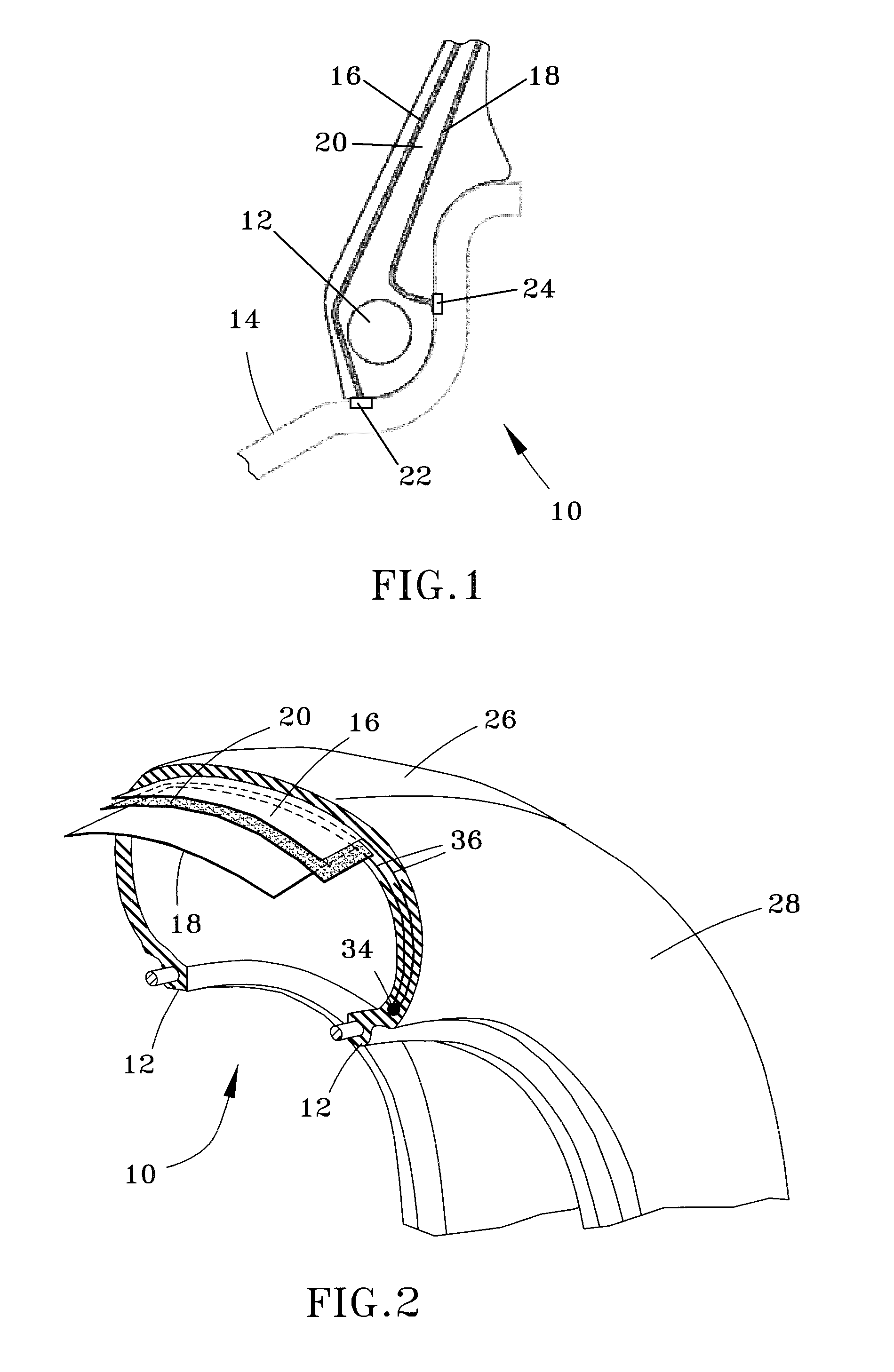

Structures with integral life-sensing capability

InactiveUS20070131035A1Continuous monitoringRemoval from serviceVehicle testingTesting/calibration apparatusElectricityElectrical resistance and conductance

A structure subjected to stresses that can lead to structural failure. The structure includes first and second conductive layers and an intermediate layer therebetween formed of a dielectric, semiconductive, or resistive material, such that the first, second, and intermediate layers form in combination an electrical element, namely, a capacitive or resistive element. The electrical element is located within the structure so as to be physically responsive to transitory and permanent distortions of the structure resulting from extrinsic and intrinsic sources. The structure further includes applying an electrical potential to at least one of the first and second conductive layers so as to generate an electrical signal from the electrical element, sensing changes in the electrical signal generated by the electrical element in response to the electrical element physically responding to the transitory and permanent distortions, and transmitting the changes in the electrical signal to a location remote from the structure.

Owner:PURDUE RES FOUND INC

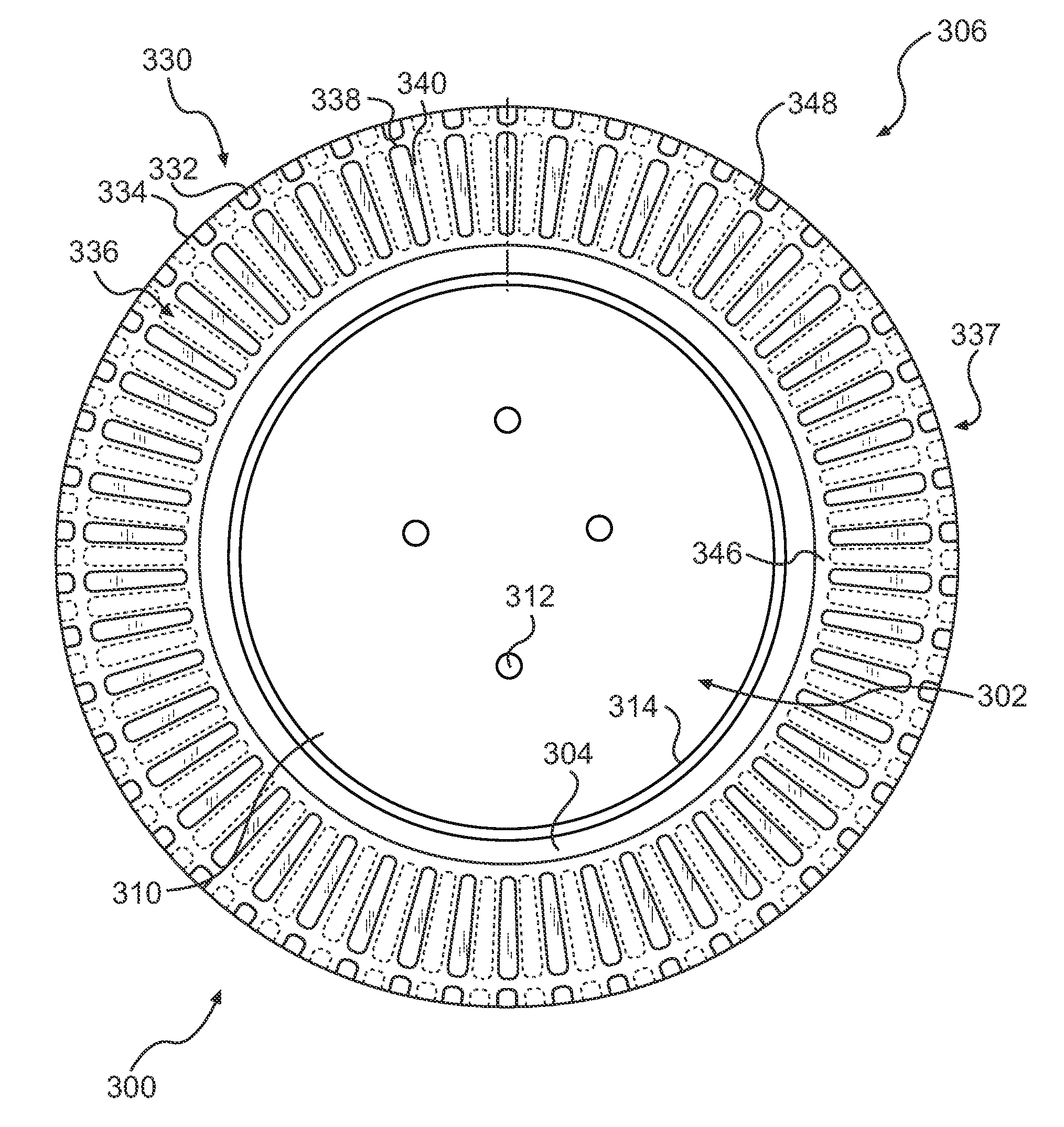

Tire filing method and apparatus adaptable to different sizes of tires

InactiveUS6467524B2Check valvesPackaging under special atmospheric conditionsEngineeringMechanical engineering

A pneumatic tire filling station includes a support and seal arrangement on which one side wall of the tire is supported and sealed, and a tire filling bell that presses and seals against the opposite side wall of the tire and then supplies pressurized air into the tire. The filling bell includes outer and inner rings that are concentrically slidable relative to each other. One of the rings is selected for the filling operation depending on the size of the tire. The support and seal arrangement includes plural plate members that are joined and sealed together to form a continuous support and seal surface, or moved laterally apart to allow a transport apparatus to carry and support the mounted tire from underneath. The tire filling station is adaptable to different models and sizes of mounted tires even in a mixed process flow, in an automated manner.

Owner:SCHENCK ROTEC GMBH

Automatic tyre removal and mounting device and tyre removal machines equipped therewith

InactiveUS6619362B2Eliminate operationEasy to provideTyre repairingMechanical engineeringEngineering

Owner:NEXION SPA

Automobile jack and wheel dolly

InactiveUS20080101898A1Easy to adjustChange lengthWheel mounting apparatusLifting framesJackscrewLift system

A wheel dolly is disclosed that is suited to serve as both an automobile jack, capable of holding large loads aloft for extended periods, relying on only mechanical systems and eliminating hydraulic systems. In a further aspect, the wheel dolly of the present invention does not include extended arms, handles, or levers for pumping or rotating the lifting mechanisms. Each lifting element terminates in only a single nut exposed to the user. Preferably, each nut of each lifting system has the same plan dimensions as the other, thus providing the advantage of allowing the user to operate the dolly with a driver and only one socket.

Owner:ALLTRADE TOOLS

Sealed tubeless tire bicycle wheel

InactiveUS20050210675A1Good handling characteristicsImprove featuresWithout separate inflatable insertsWith separate inflatable insertsTubeless tireAutomotive engineering

Pneumatic tires adapted to use on bicycles have a number of criteria that need to be evaluated. For high performance bicycle riding, such as in mountain bike races, it is advantageous to optimize performance. Standard tires with tubes have ease of repair in the replacement of a punctured tube, have the ability to maintain pressure for long periods, and do not require special adaptation of the rim for sealing.

Owner:PRICE CHAD NATHANIEL +1

System and Method for Mounting a Tire and a Wheel

A system for mounting a tire and a wheel is disclosed. The system includes a robotic arm pivotably-connected to an end effector. The system also includes a tire-supporting portion including a support surface and a pair of wheel-engaging and tire-manipulating portions disposed upon the support surface. The pair of wheel-engaging and tire-manipulating portions includes a first wheel-engaging and tire-manipulating portion fixedly-disposed relative the support surface and a second wheel-engaging and tire-manipulating portion movably-disposed relative the support surface.

Owner:ANDROID INDS OF MICHIGAN

Method and apparatus for vehicle service system with imaging components

ActiveUS7355687B2More procedureEasy to processAngle measurementStatic/dynamic balance measurementService systemAutomotive engineering

An improved vehicle wheel service system for servicing a vehicle wheel assembly, configured with one or more imaging sensors to accurately measure distances, dimensions, and characteristics of features associated with a vehicle wheel assembly undergoing a service.

Owner:HUNTER ENG

Method for mounting a pneumatic tire

ActiveUS7699087B2Low structure complexitySimply set up and optimizedTyre repairingTire beadManipulator

Method for mounting a pneumatic tire on a well base rim of a motor vehicle wheel, in which the pneumatic tire is grasped by means of a manipulator, brought up to a rim held in a clamping device and slipped with at least the one tire bead facing the rim over a rim flange by controlled movement of the manipulator.

Owner:SCHENCK ROTEC GMBH

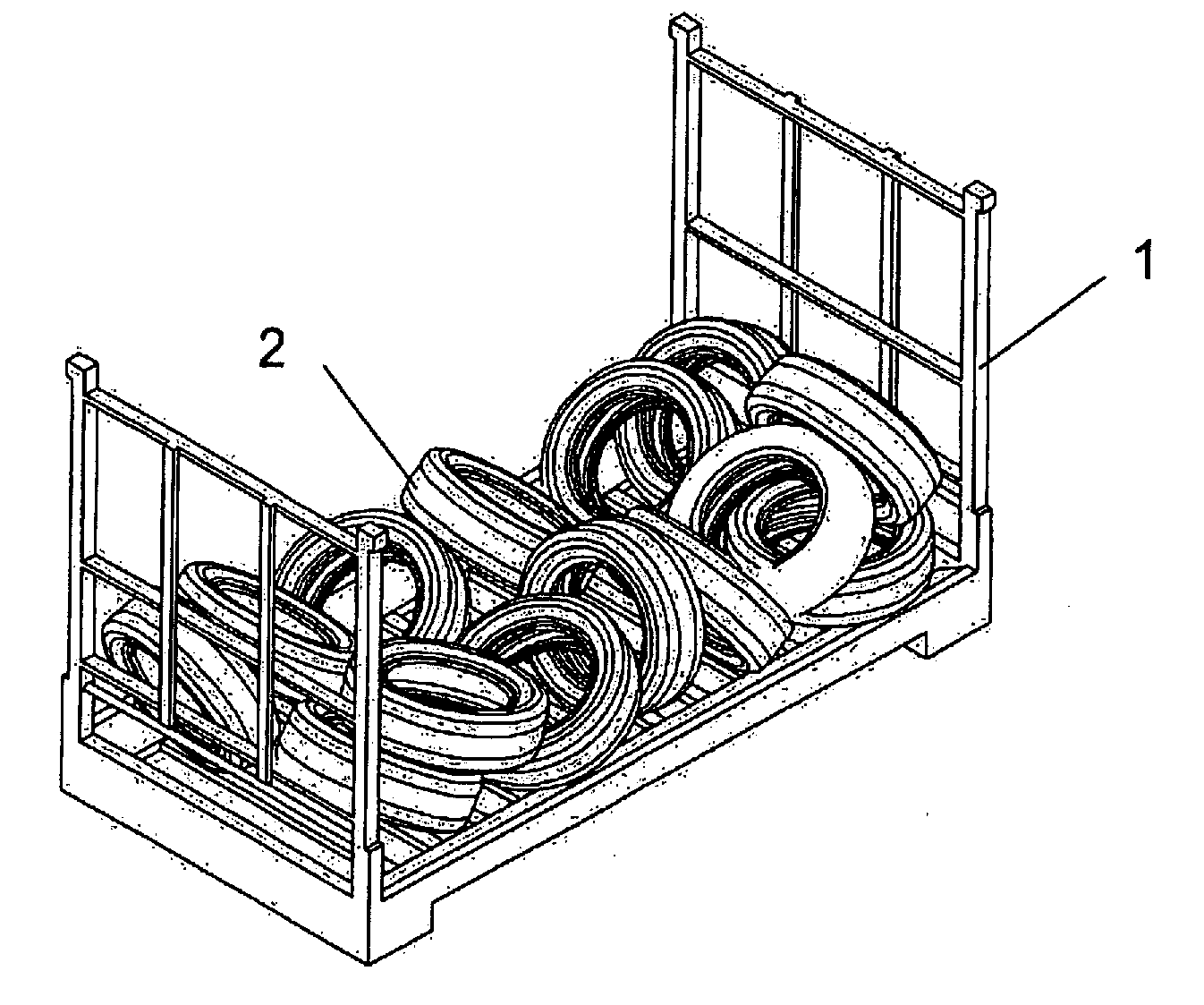

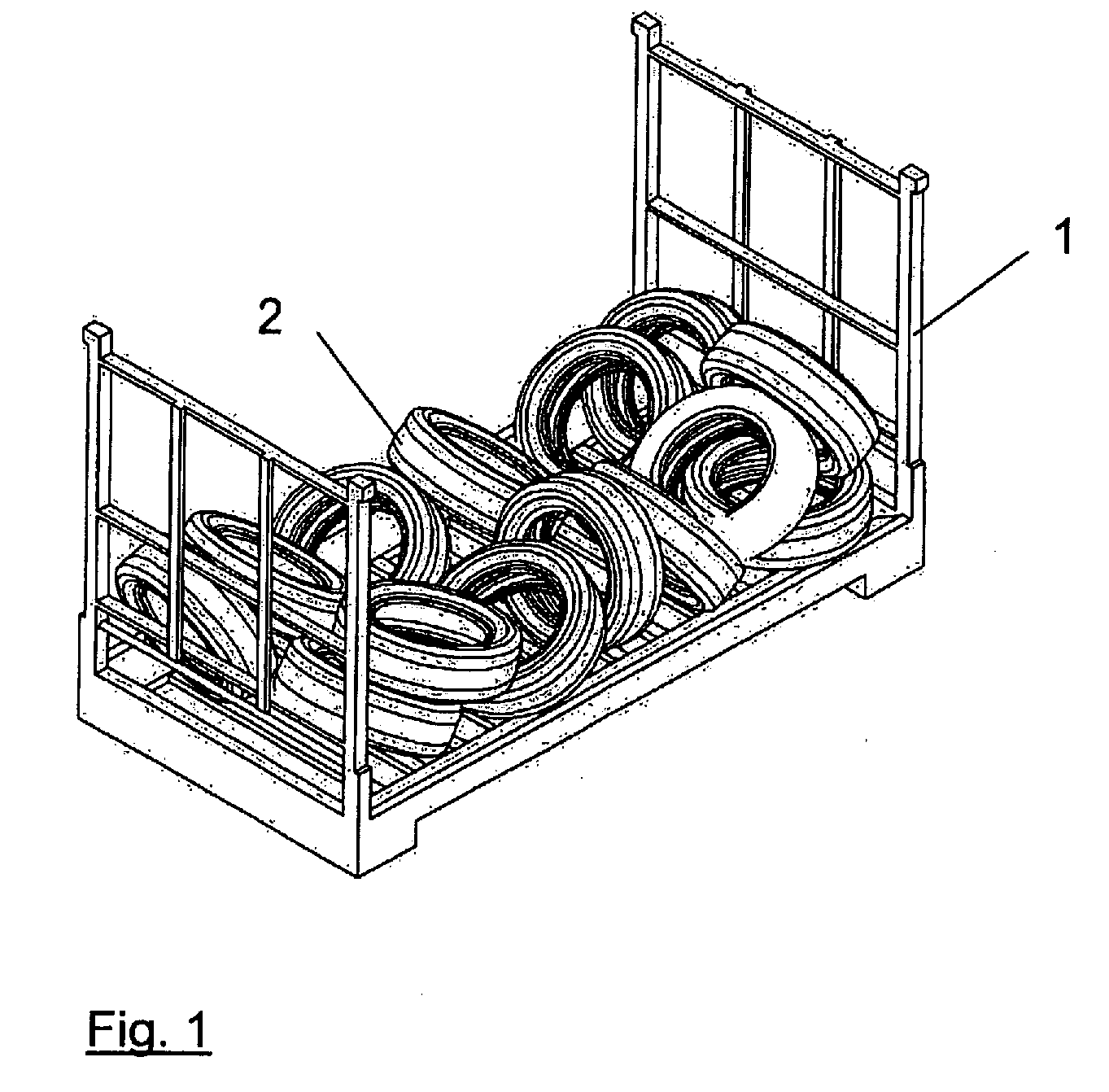

Method And System For Depalletizing Tires Using a Robot

InactiveUS20100272547A1Easy to detectImprove reliabilityProgramme-controlled manipulatorDigital data processing detailsCollision freeIndustrial robot

In a method and system for depalletizing tires using a robot, wherein the tires are randomly located on a carrier, the position and orientation of outer tires on the carrier are detected using a sensor, and a processor, using a signal from the sensor, determines a tire that can be gripped by a gripping tool of an industrial robot, and calculates a movement path for the gripping tool for that tire. If the calculated path is not collision-free, another tire from among the outer tires is selected, and a movement path for depalletizing that tire is determined. The procedure is repeated until a collision-free movement path for a tire from among the outer tires is established. The gripping tool is then guided according to this collision-free movement path to depalletize the tire having the collision-free path associated therewith.

Owner:KUKA ROBOTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com