Tire bench testing apparatus and tire performance testing method using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] In order to confirm the effect of the present invention, based on the JASO standard, the comprehensive value of the tire noise, the pitch noise (primary) and the ground contact shape when these noises are generated were obtained by using the bench test device of the present application, and were compared with each other. It is a test for comparing the test results of the above indicators when the real vehicle is running. Table 1 and Table 2 show the test results for different tire sizes. Common specifications are as follows.

[0079]

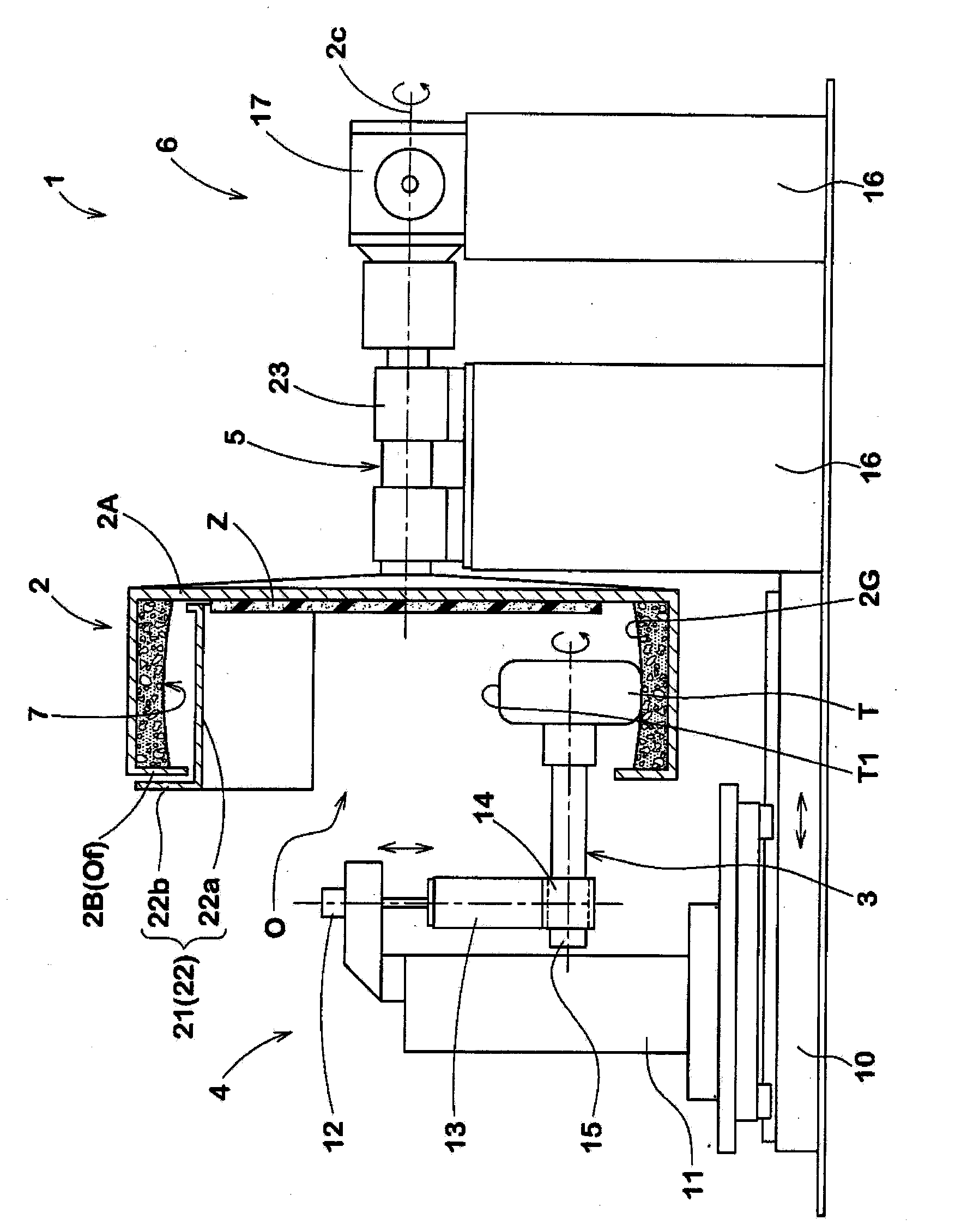

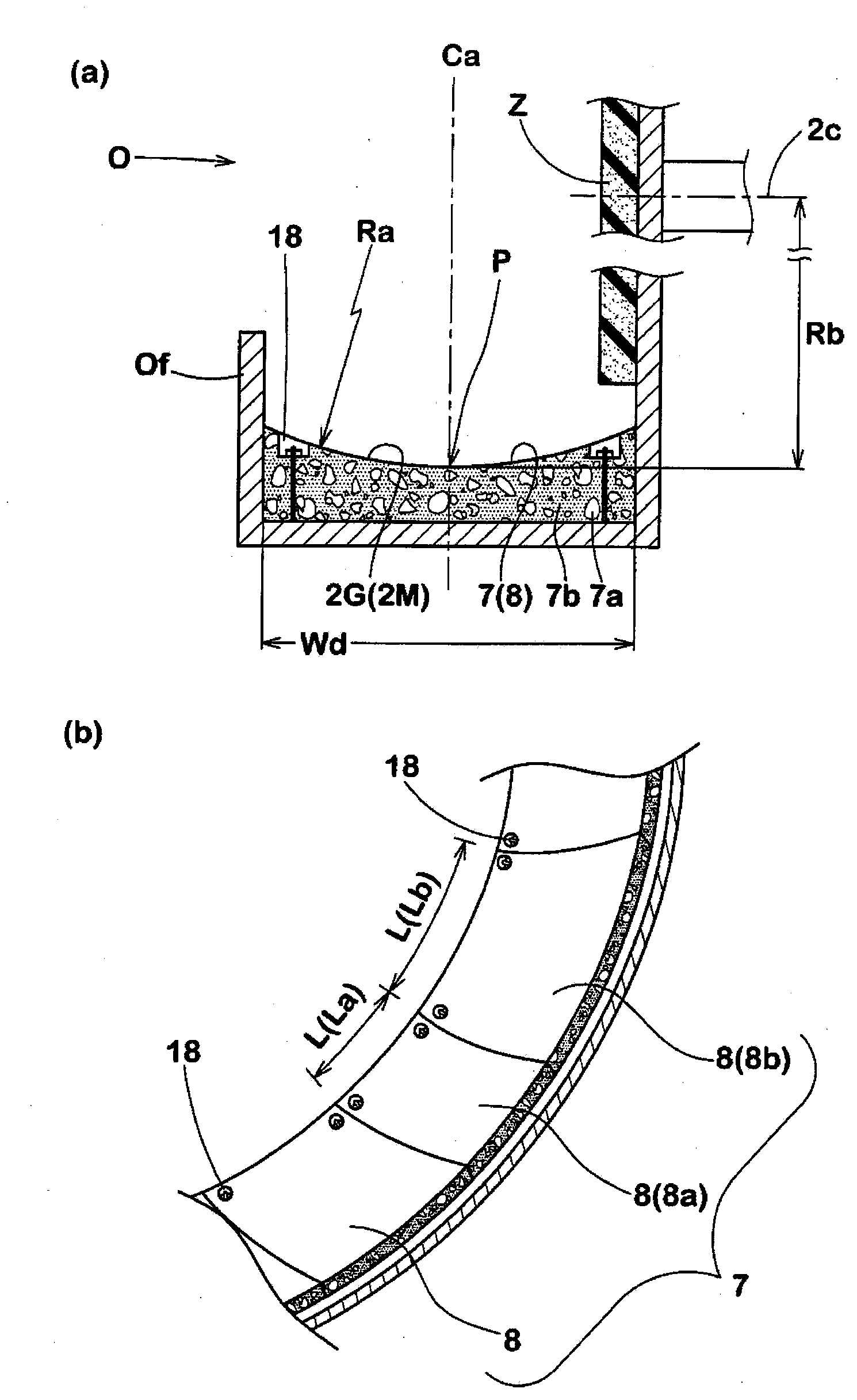

[0080] The position of the noise measuring instrument: on the vertical plane including the tire rotation axis, 1.0m away from the tire equator in the axial direction of the drum, and 0.25m upward from the lowest end of the inner peripheral surface of the drum (refer to Figure 7 (a), (b))

[0081] Specifications of noise measuring instrument: Noise meter based on JIS C1505 (precision noise meter)

[0082] Specifications of the simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com