Patents

Literature

54results about How to "Increase suction pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

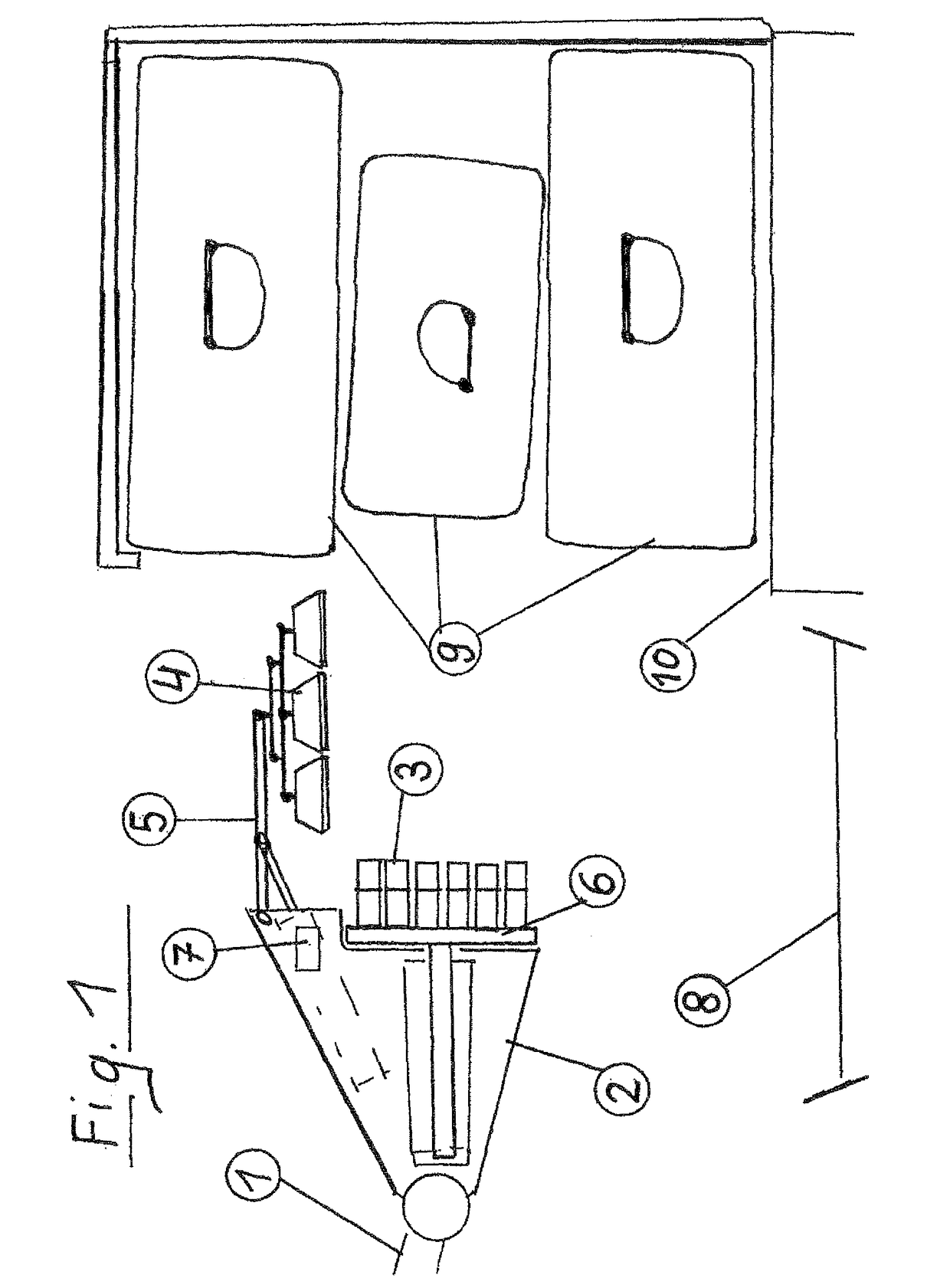

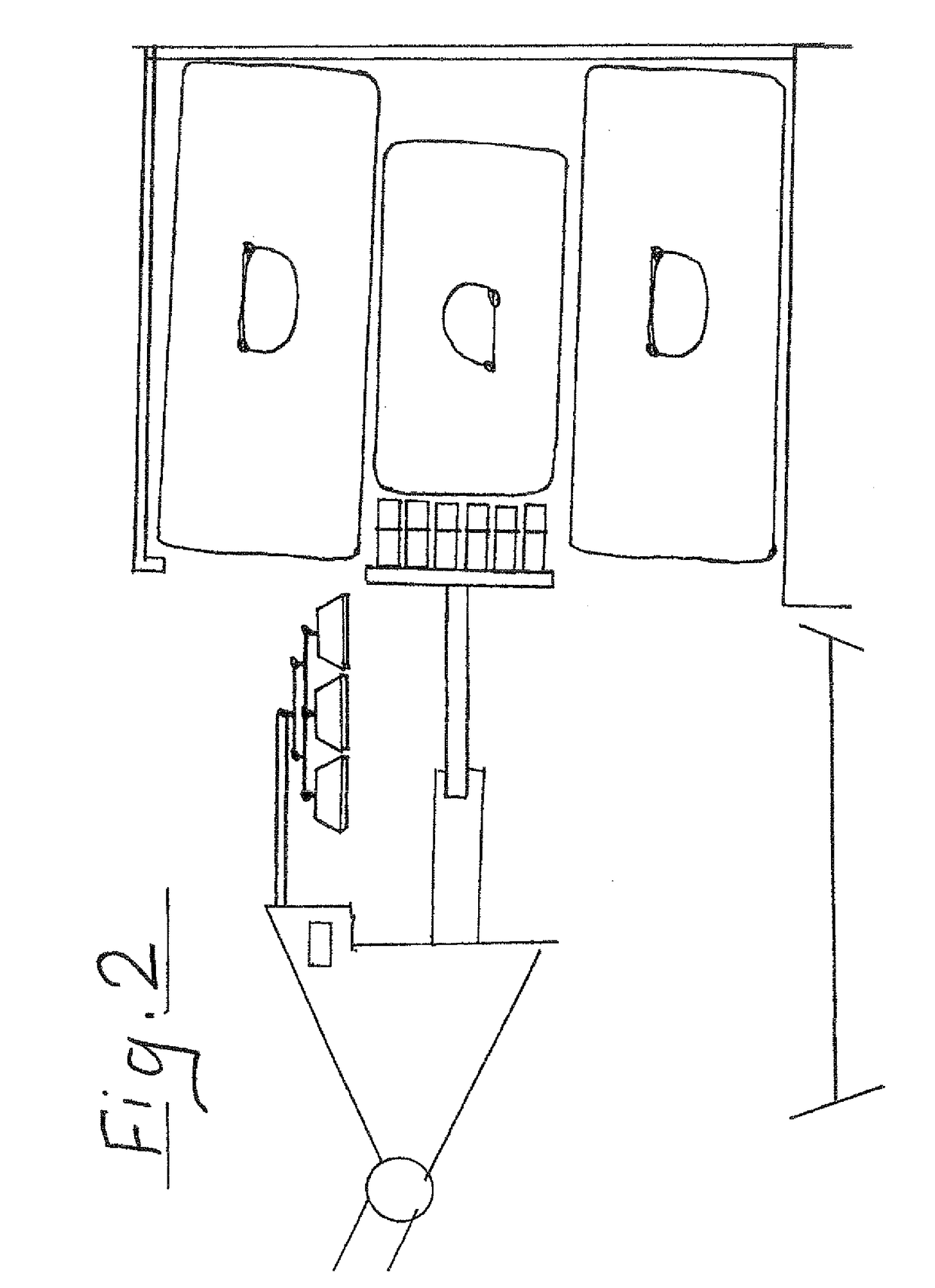

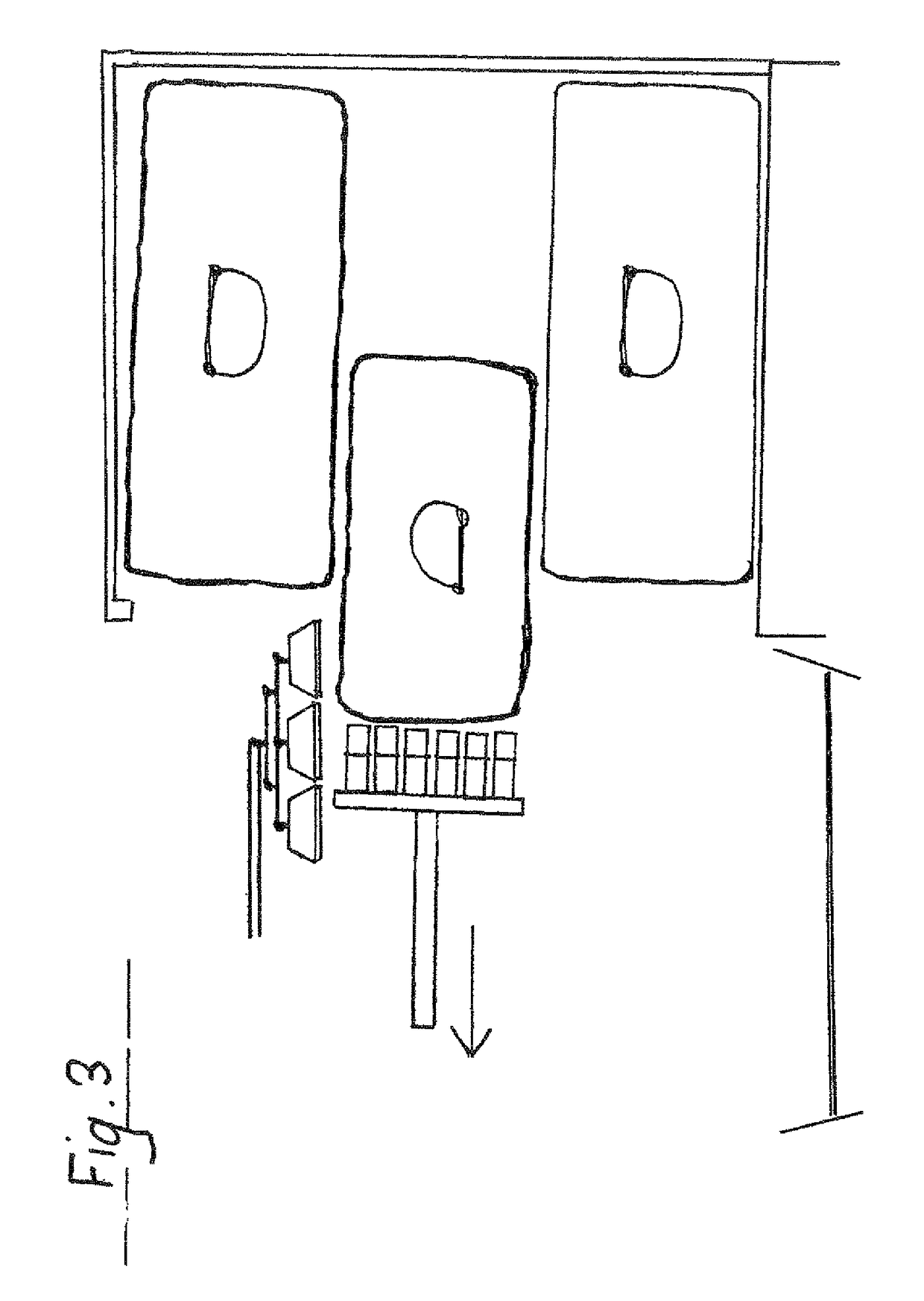

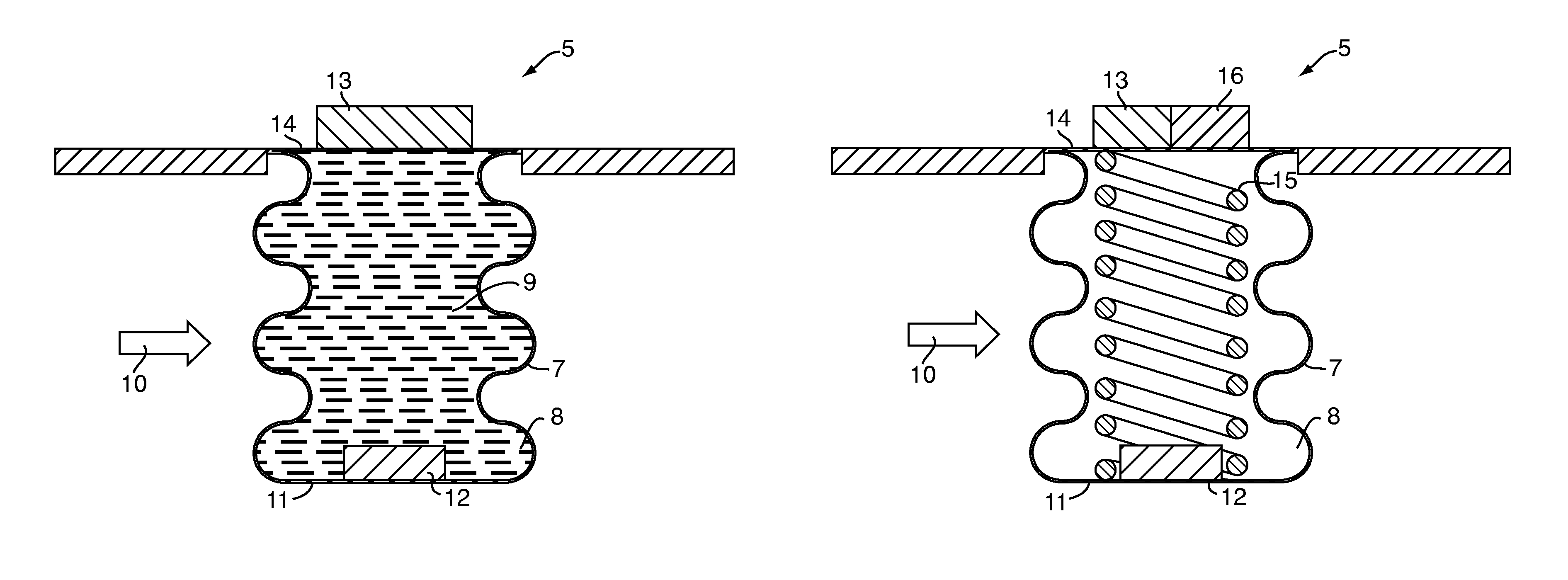

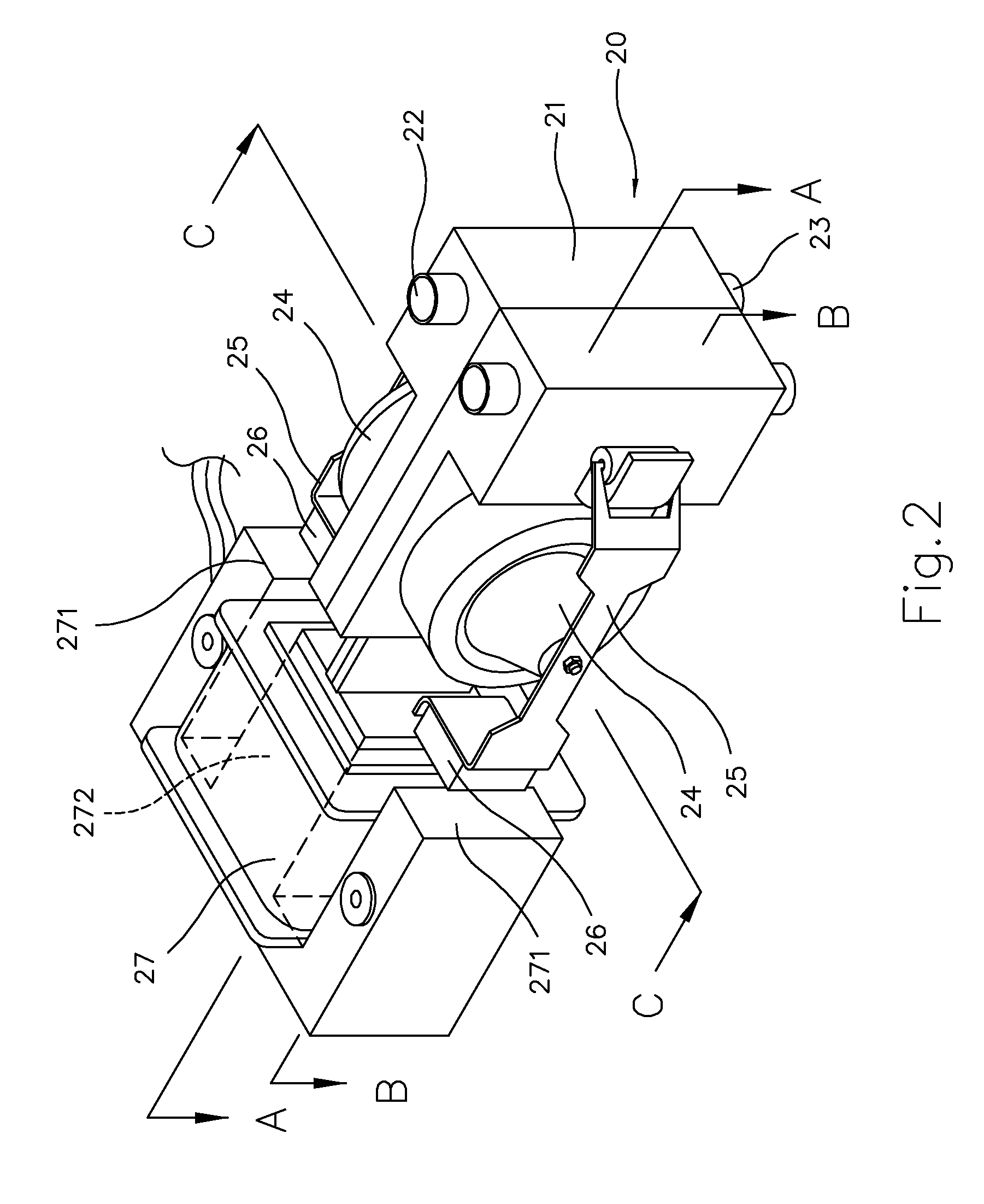

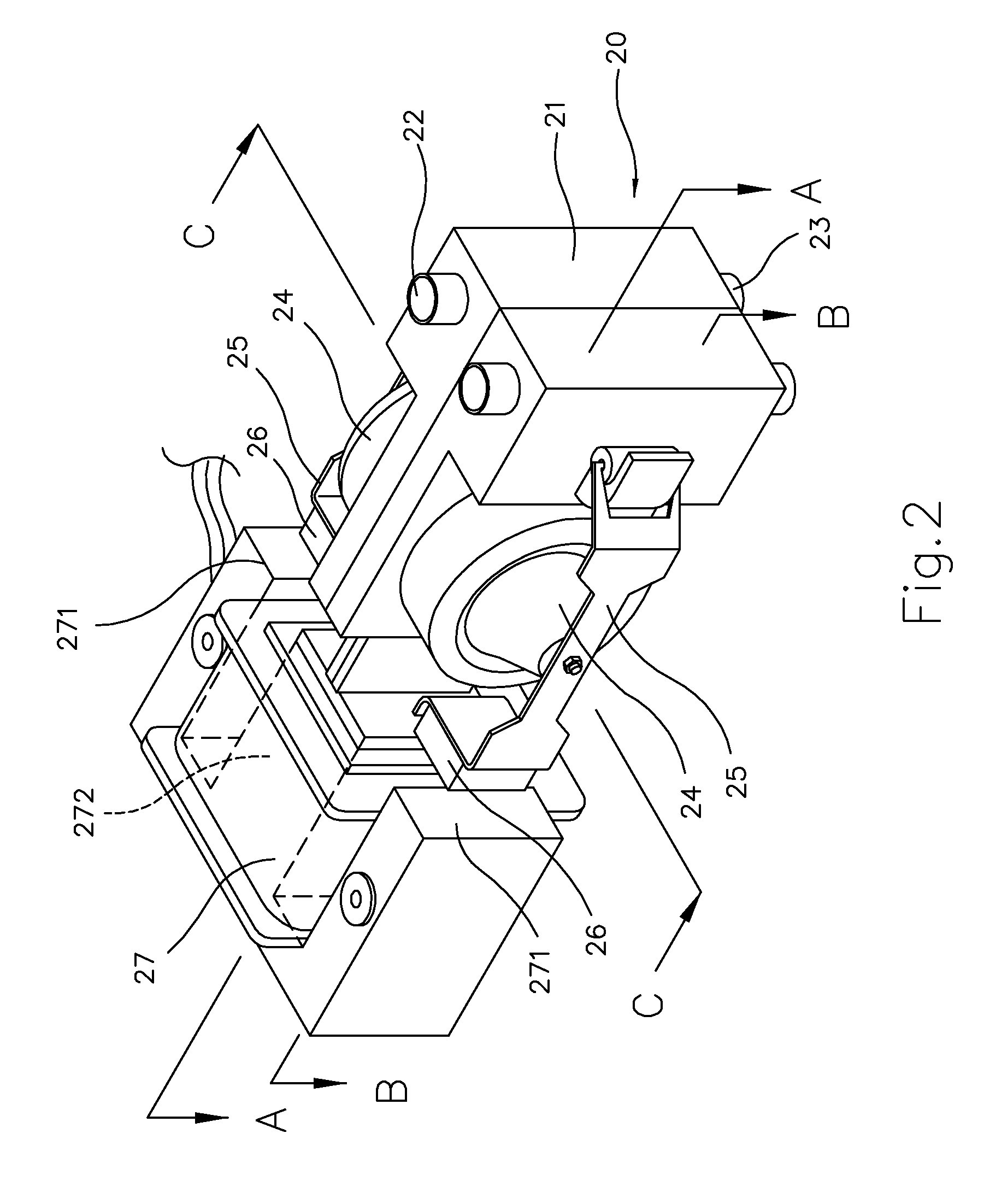

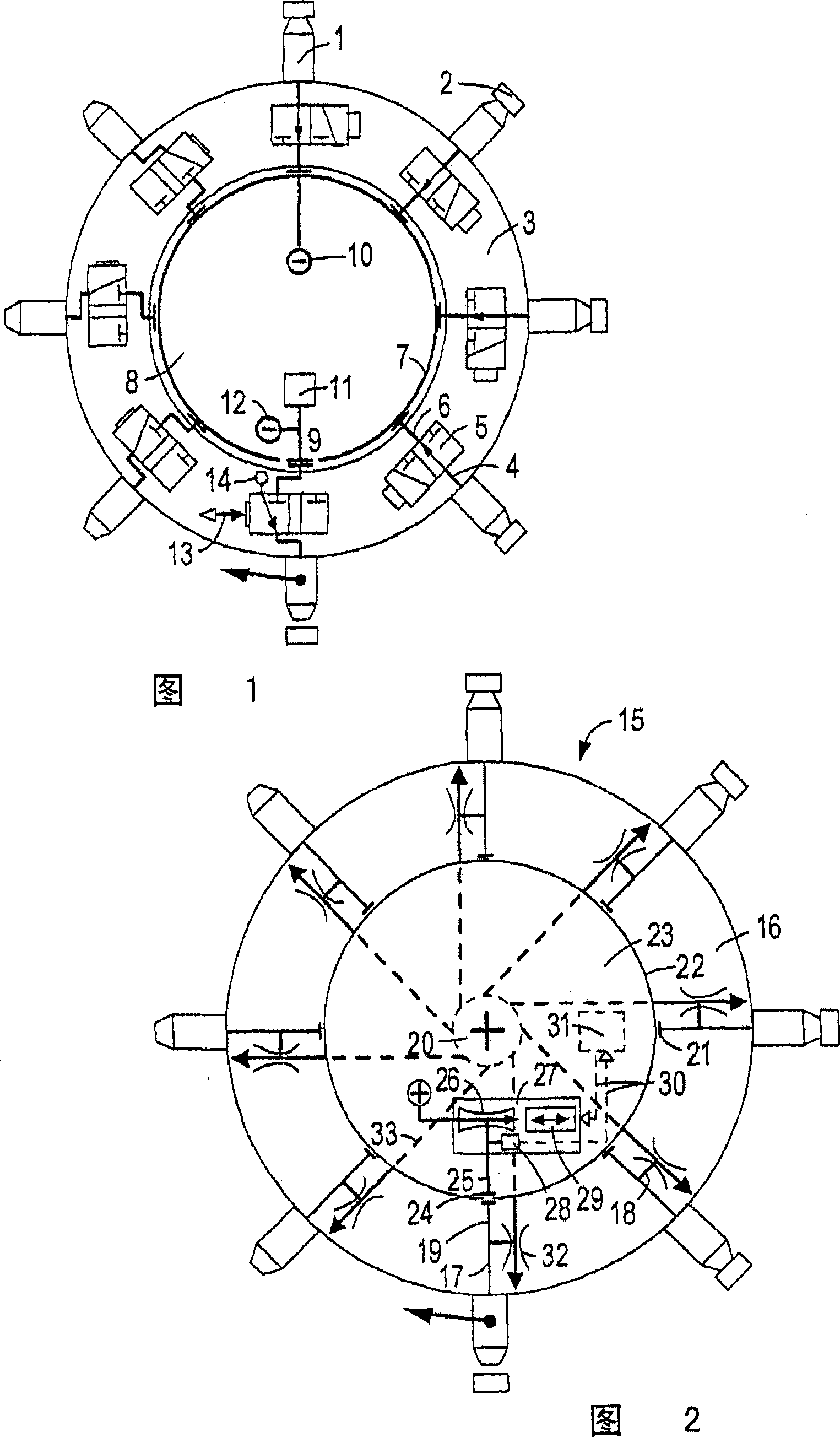

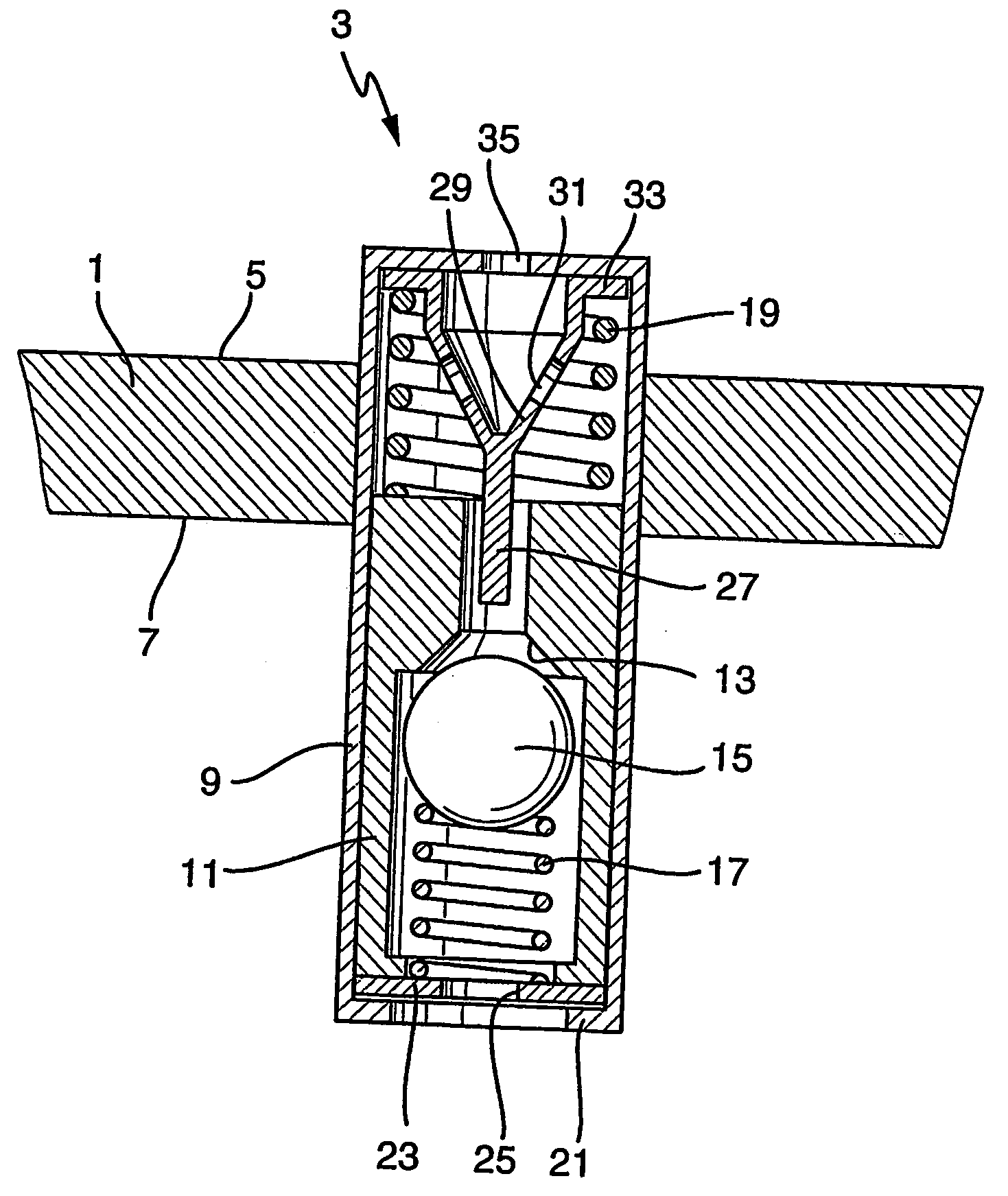

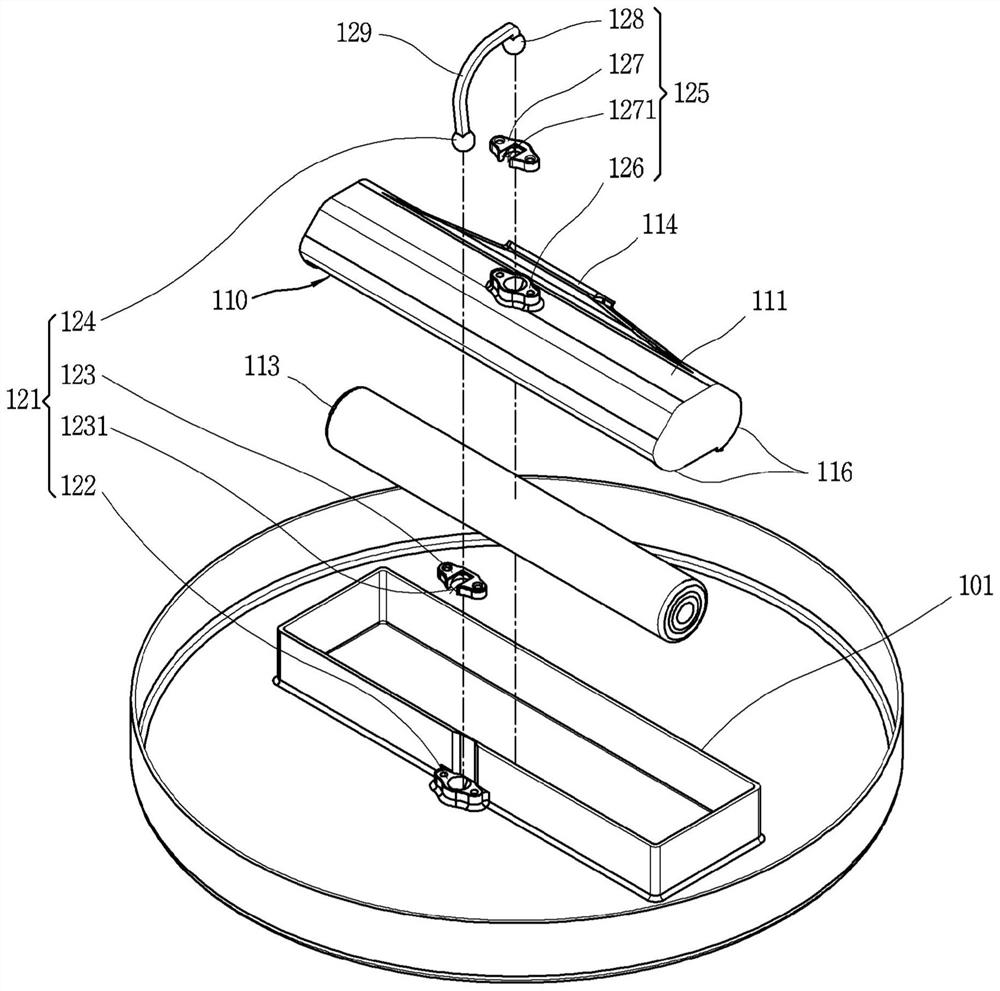

Method and apparatus for gripping and transferring pieces of luggage

ActiveUS8473094B2Increase suction pressureIncrease contact pressureDigital data processing detailsGripping headsEngineeringGrippers

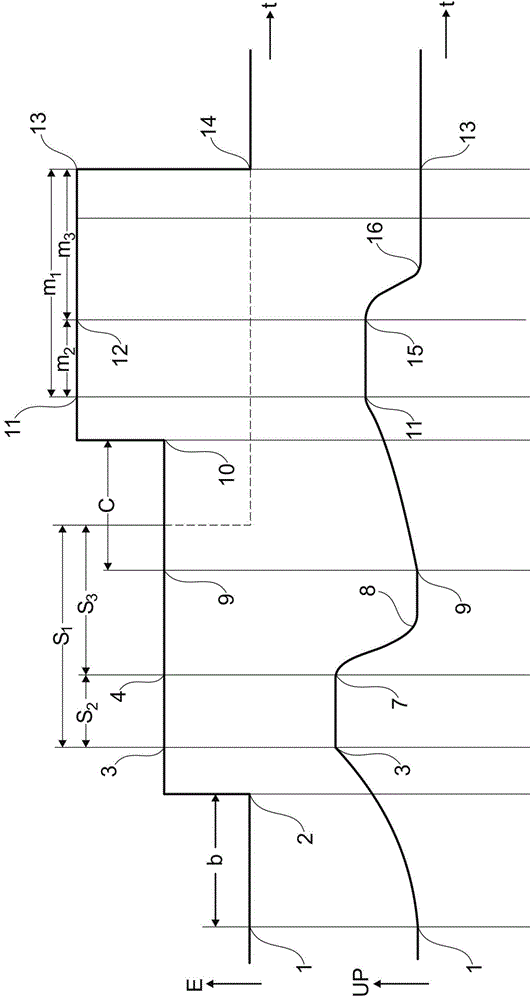

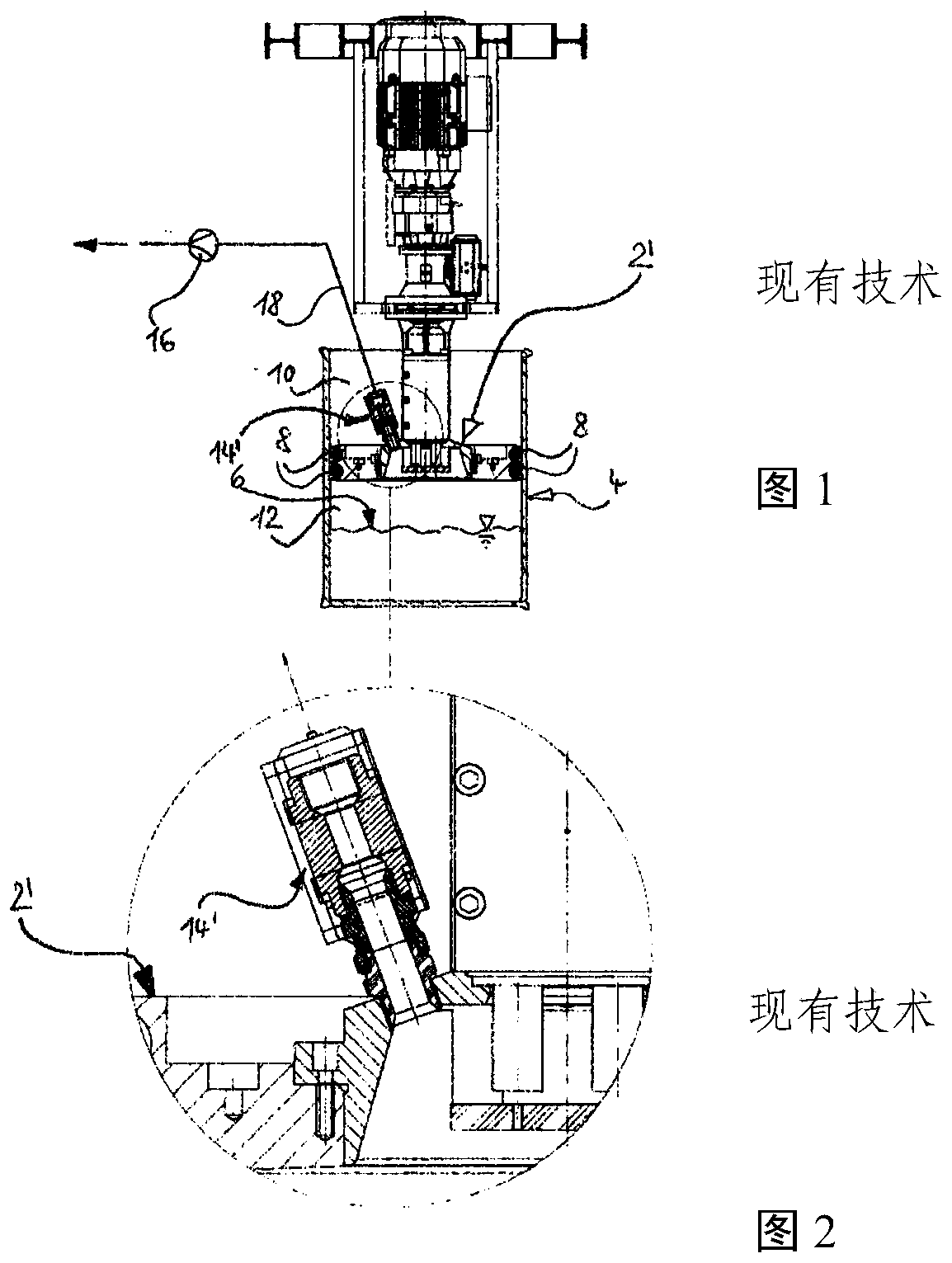

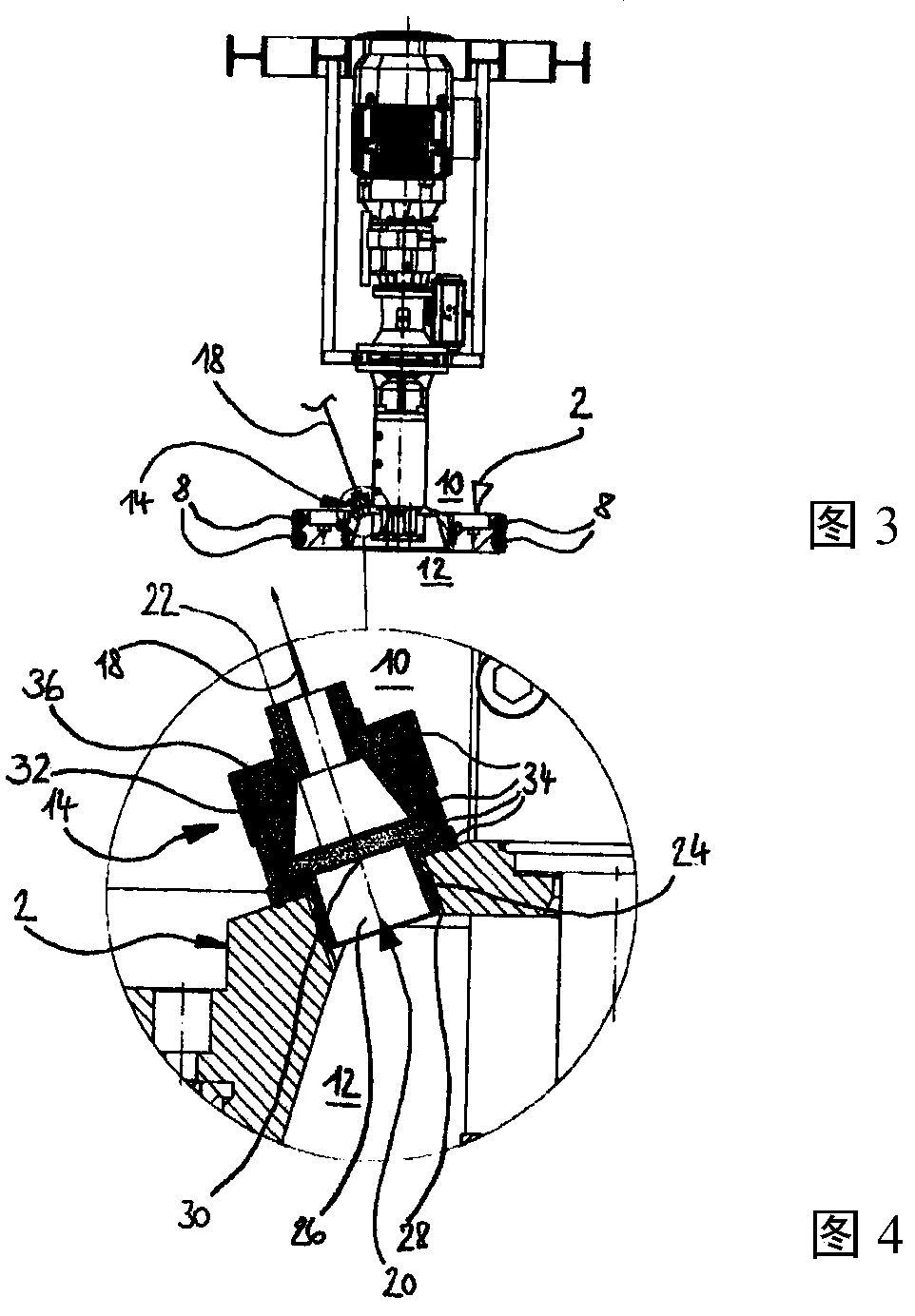

A method and an apparatus for automatically removing pieces of luggage that have different surface properties and dimensions and getting the pieces of luggage ready for further transport by means of a gripper that is hingedly connected to a robot arm is described. The method includes: a) moving the gripper and the container that is to be emptied close together; b) determining the first piece of luggage to be removed; (c) gripping the piece of luggage using a horizontal suction elements (3) and withdrawing the luggage horizontally; d) if the vertical suction elements (4) are not yet able to sufficiently grip the luggage, the vertical suction elements (4) are repositioned and turned off, the vertical suction elements (5) are repositioned, and then turned on to re-grip the piece of luggage.

Owner:GRENZEBACH MASCHINENBAU GMBH

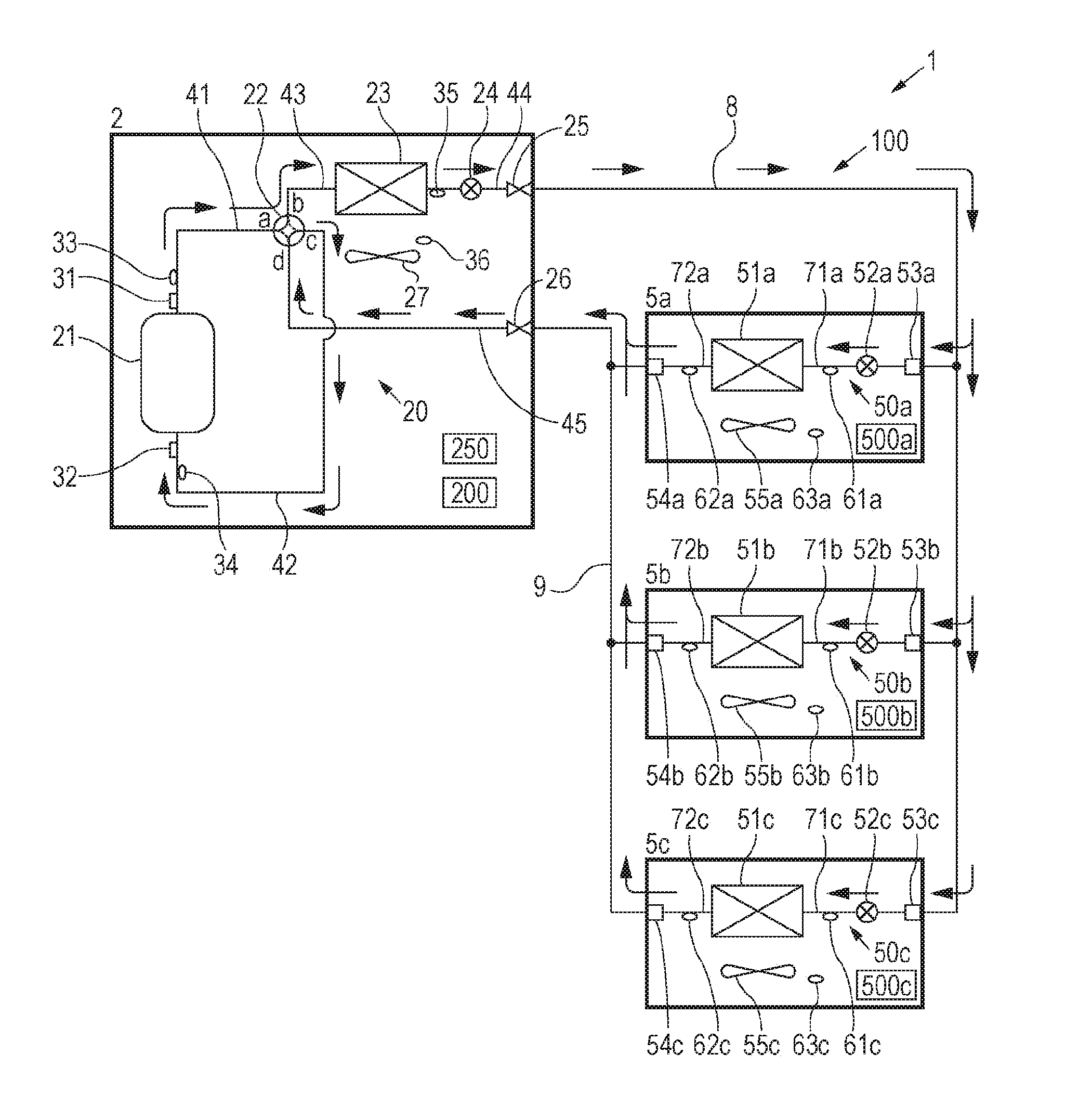

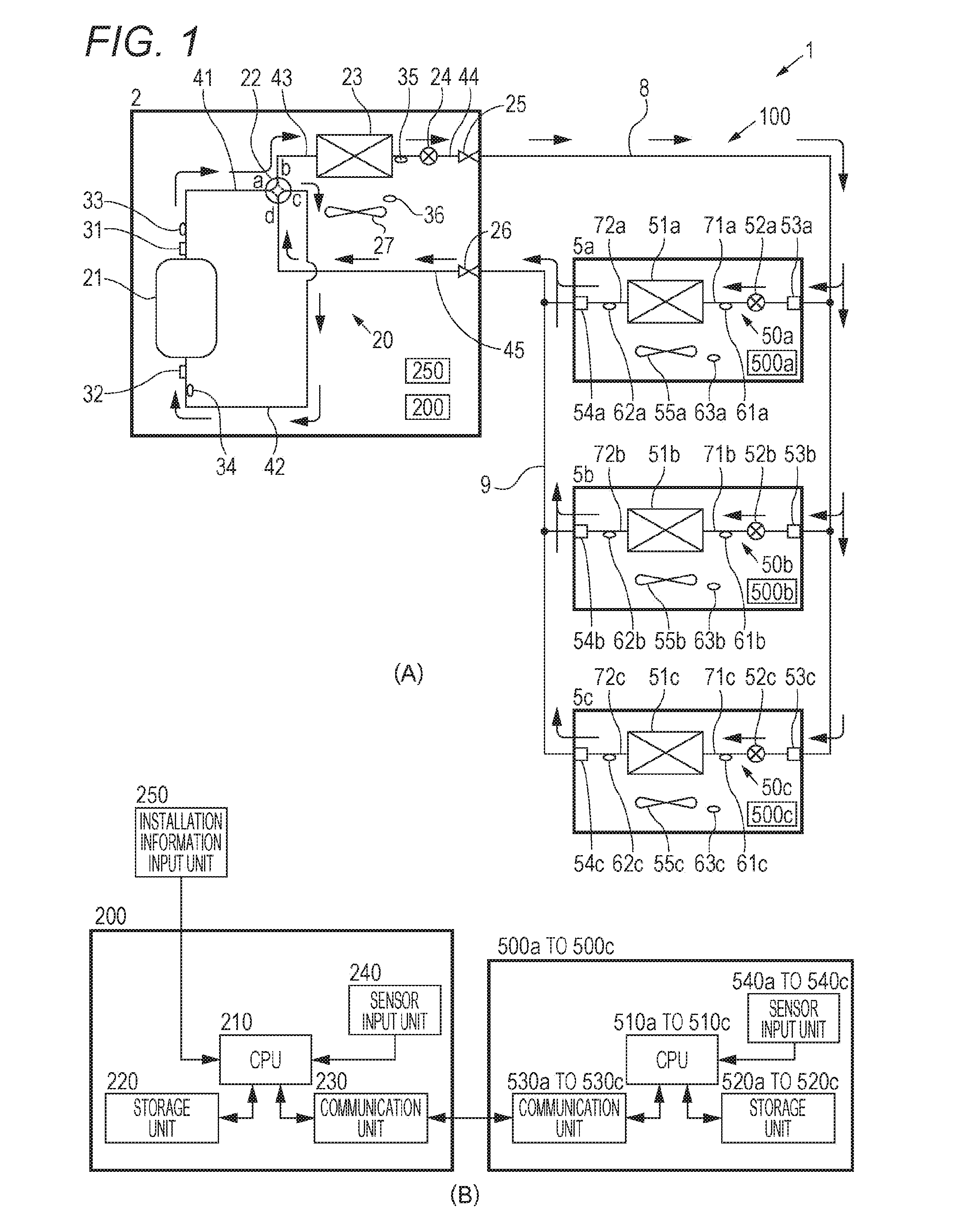

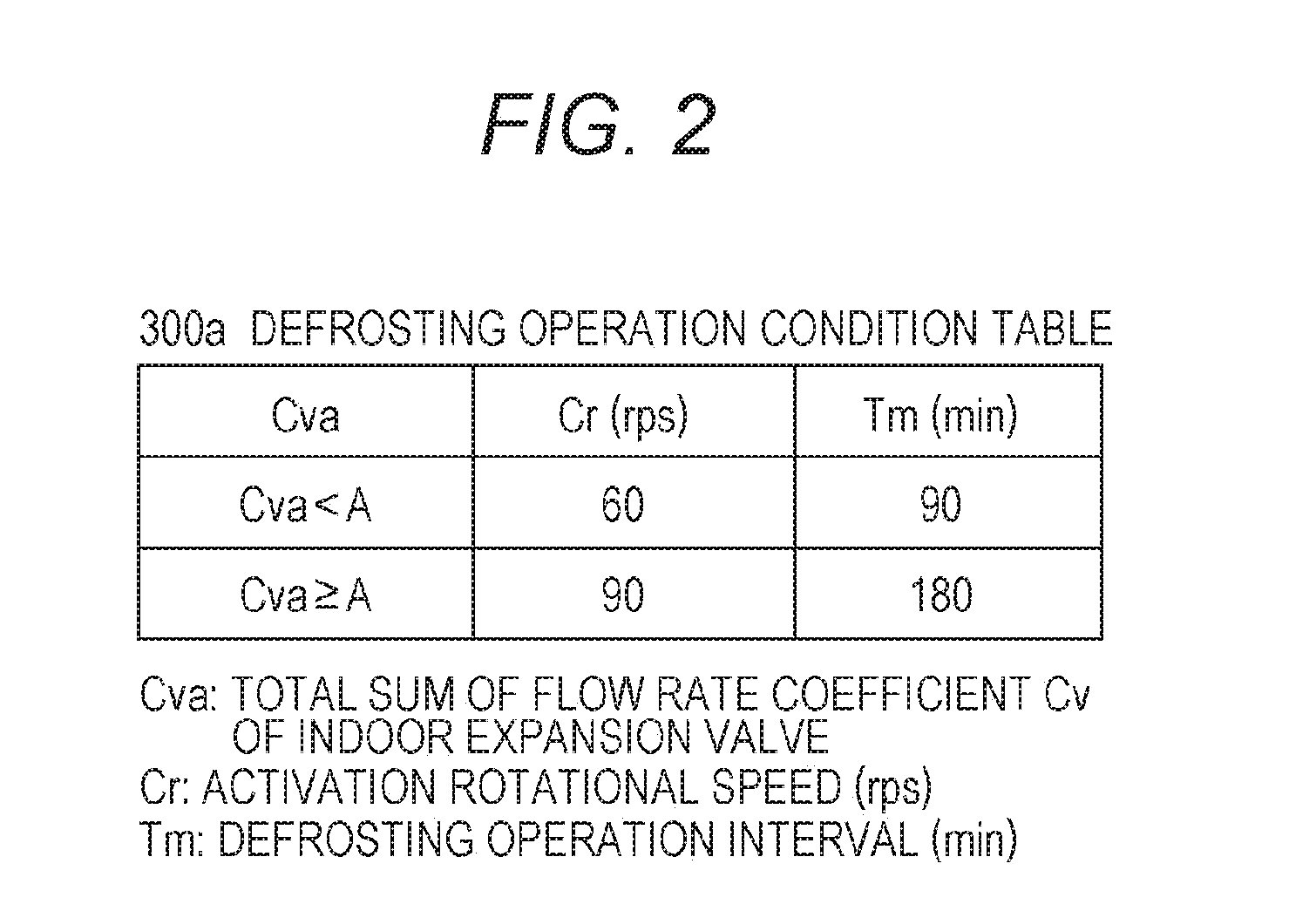

Air conditioner

ActiveUS20160223236A1Increase suction pressureAvoid damageMechanical apparatusCompression machinesEngineeringBiological activation

An outdoor unit control unit 200 has a defrosting operation condition table 300a that defines an activation rotational speed Cr in accordance with a total sum of flow rate coefficients Cva that is a total sum of flow rate coefficients Cv representing capacities of indoor expansion valves 52a to 52c. The outdoor unit control unit 200 calculates the total sum of the flow rate coefficients Cva by adding the flow rate coefficient Cv of each of the indoor expansion valves 52a to 52c, and refers to the defrosting operation condition table 300a, so as to determine the activation rotational speed Cr. Then, the outdoor unit control unit 200 activates a compressor 21 at the determined activation rotational speed Cr when starting a defrosting operation, maintains this activation rotational speed Cr for a predetermined time from the start of the defrosting operation, and drives the compressor 21.

Owner:FUJITSU GENERAL LTD

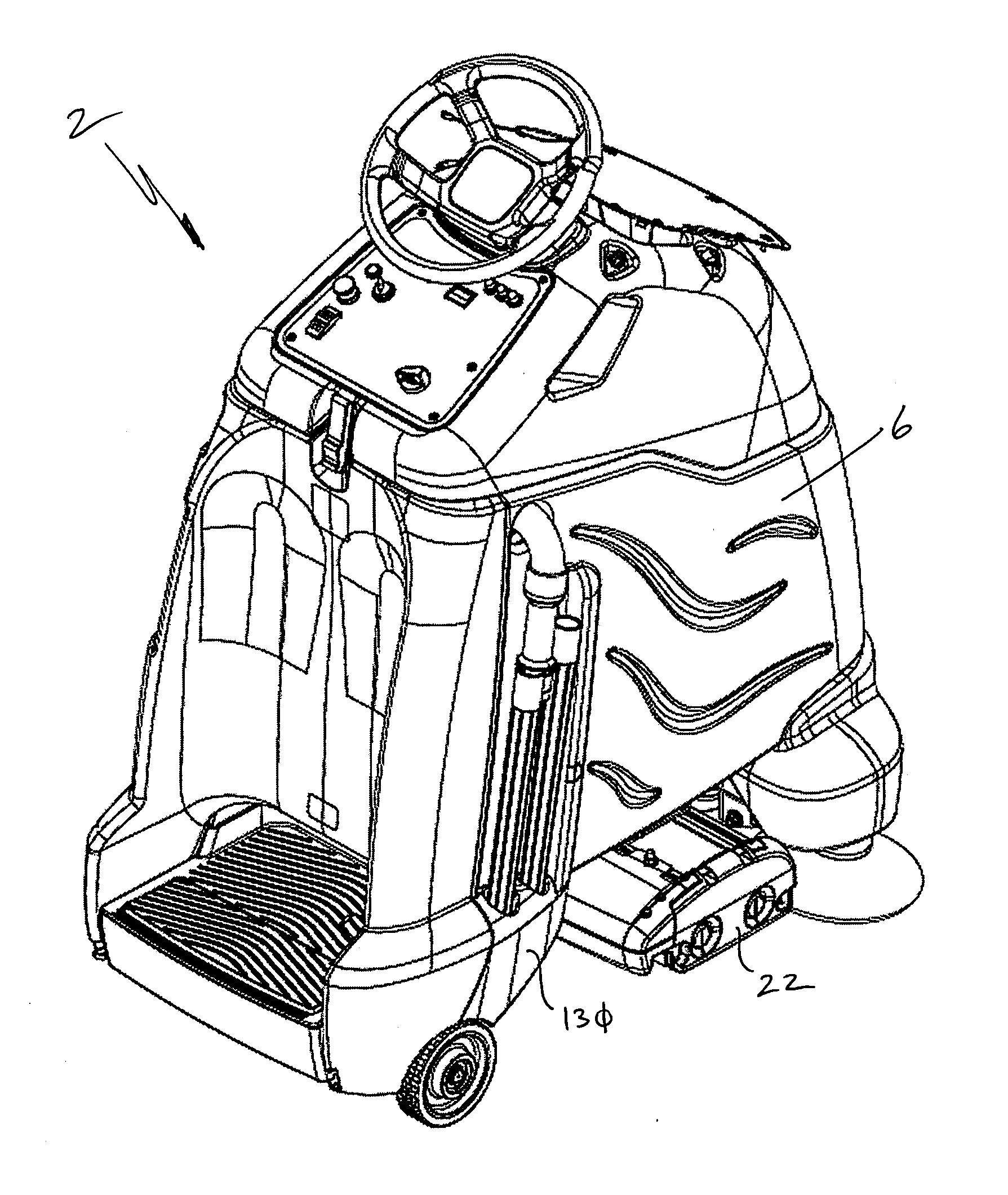

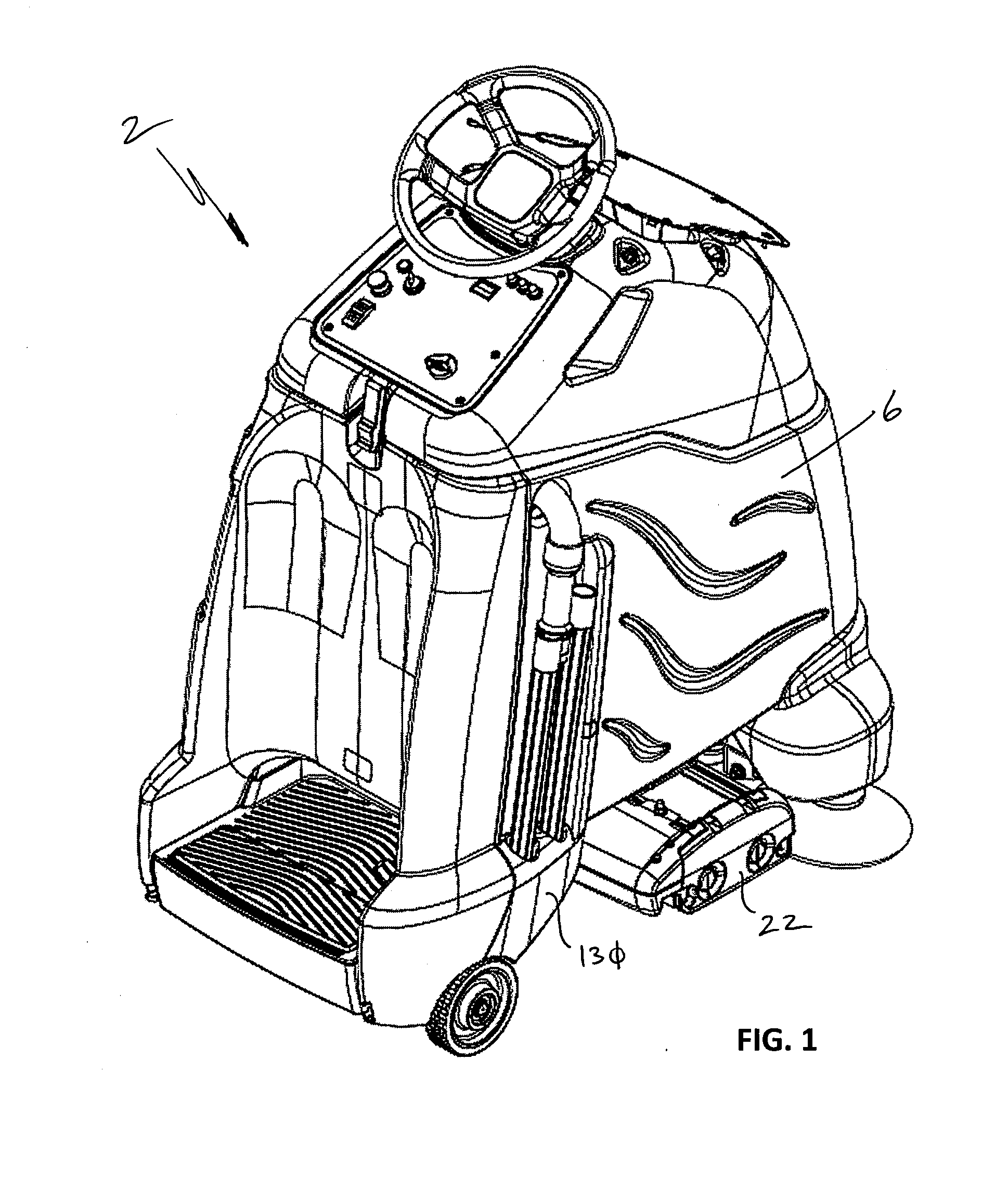

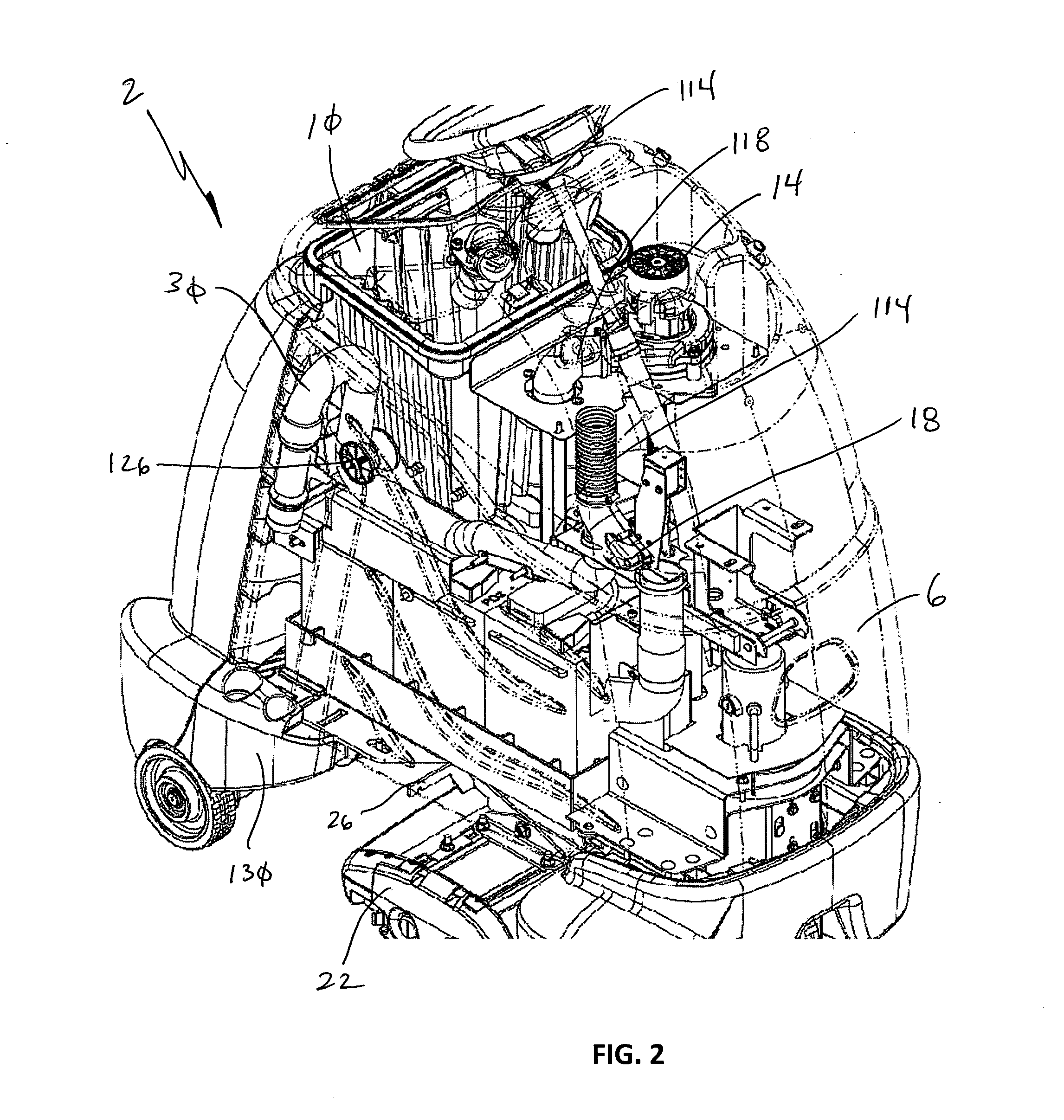

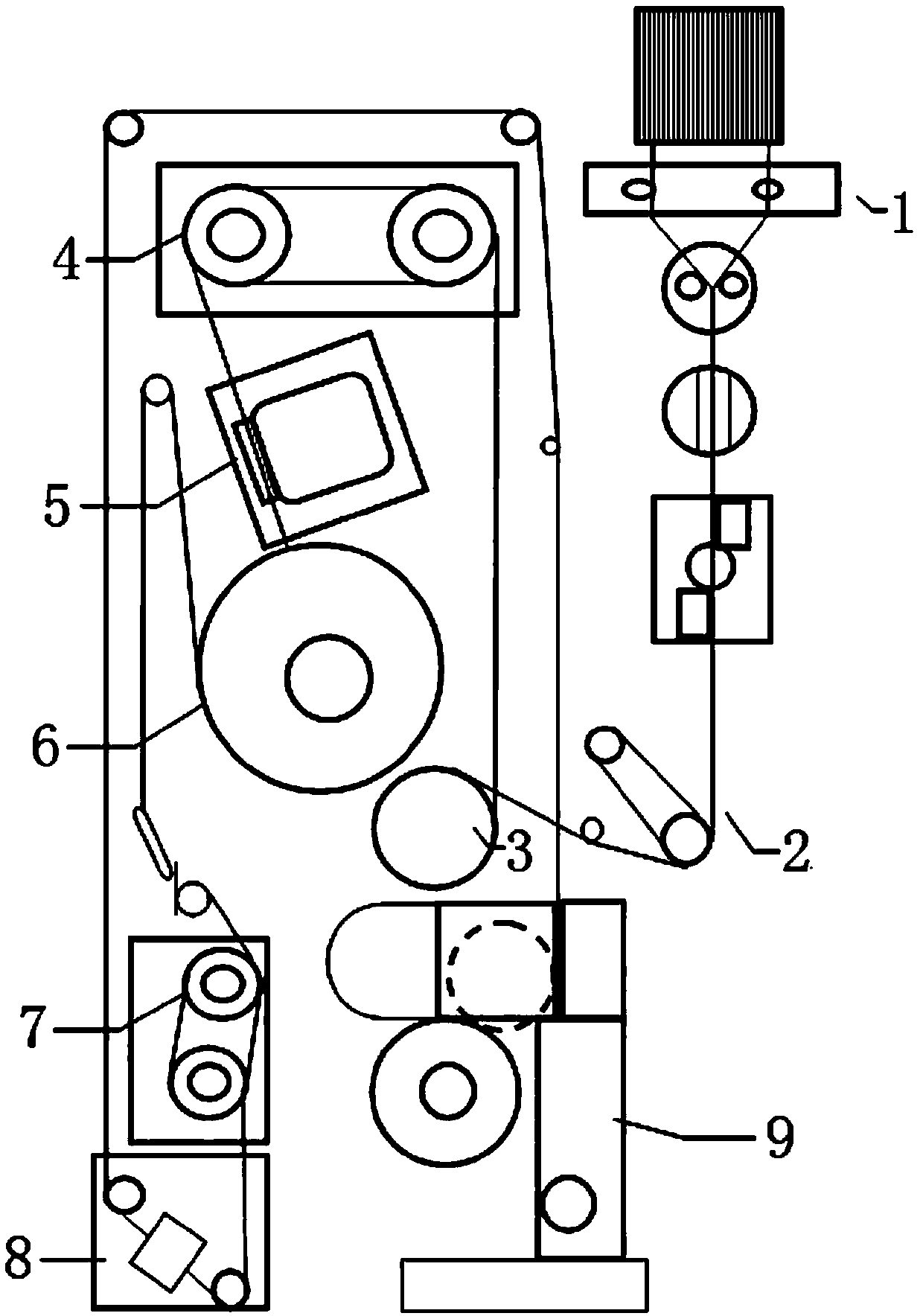

Floor cleaning apparatus employing a combined sweeper and vaccum assembly

InactiveUS20120096671A1Increase suction pressureIncrease airflowCleaning filter meansSuction filtersEngineeringAirflow

A floor cleaning device employing a brush assembly is provided. The brush assembly includes a front brush and a rear brush that spin about an axis line generally parallel to the surface being cleaned. The spinning rotation of the brush along with the configuration of the housing help provide an airflow path that sucks debris from the surface being cleaned. The debris is directed to a hopper wherein larger items are captured and smaller items are suctioned into a vacuum bag.

Owner:KARCHER NORTH AMERICA INC

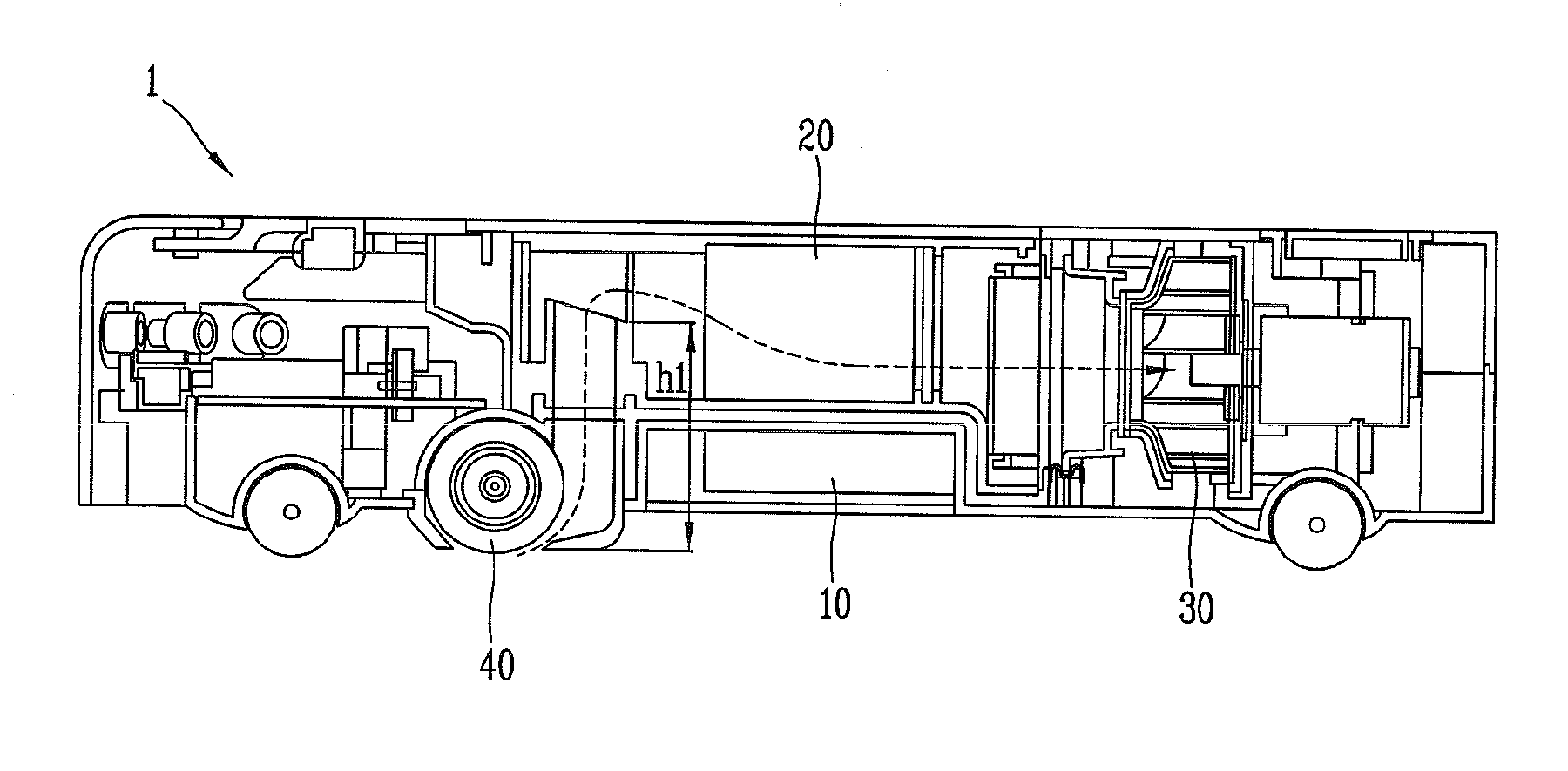

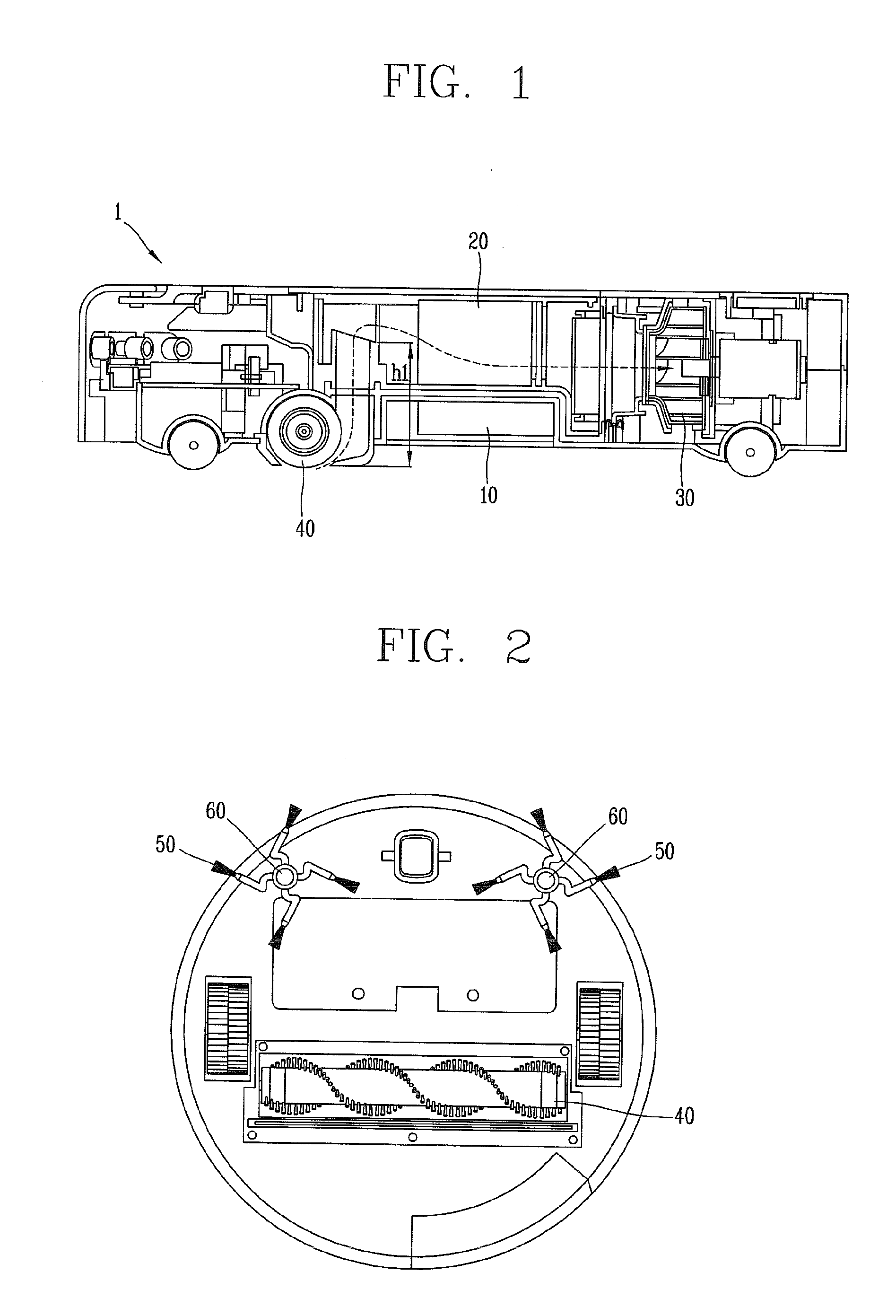

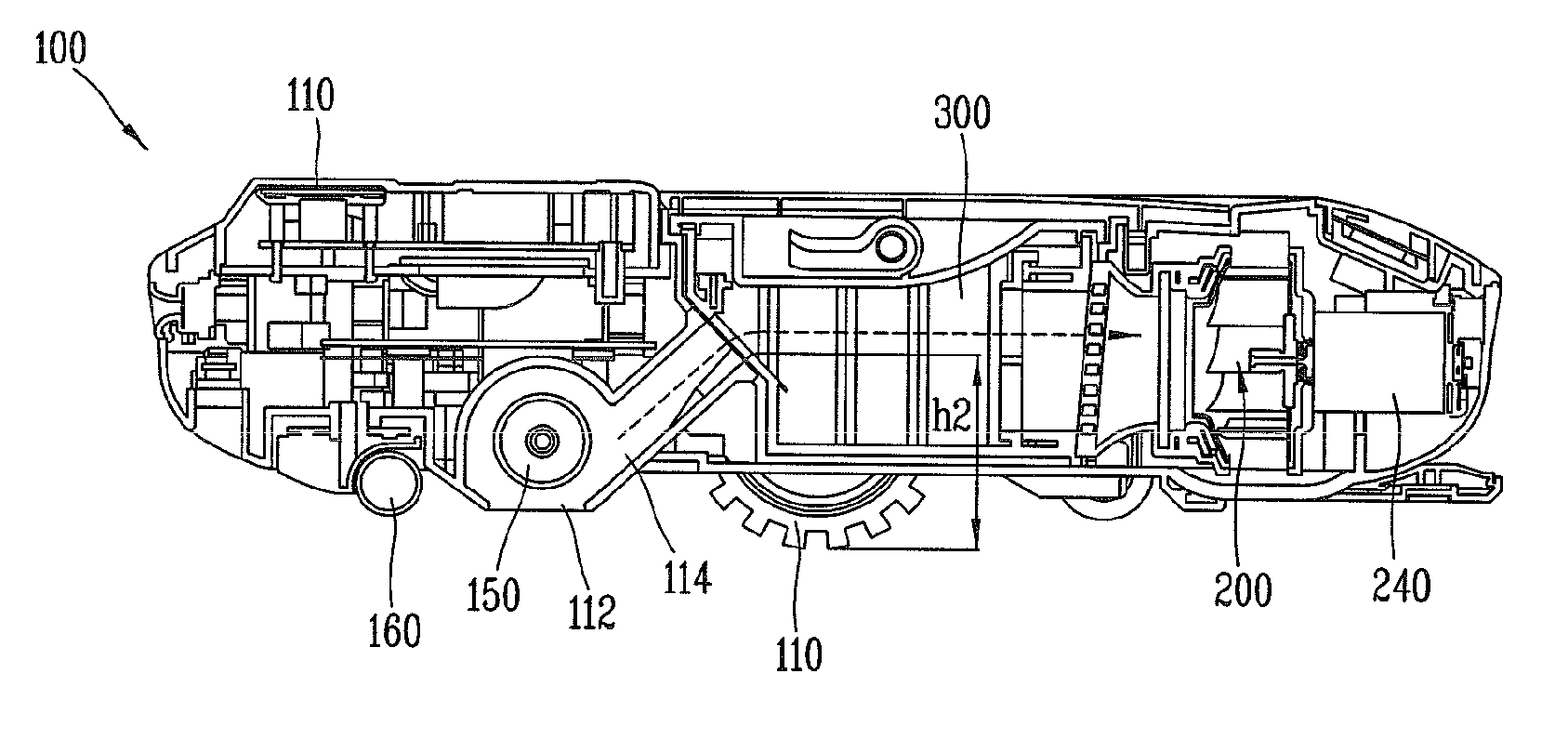

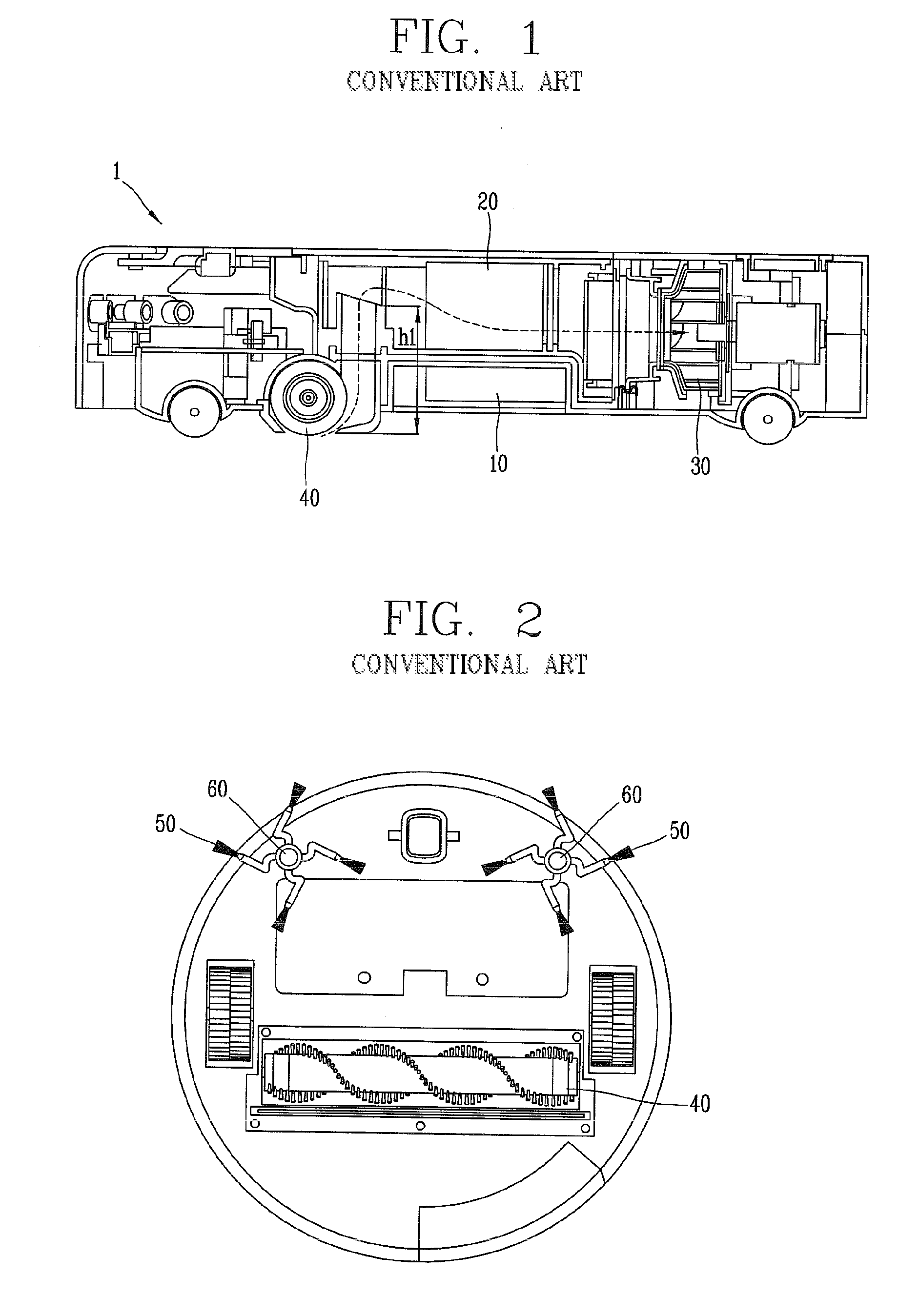

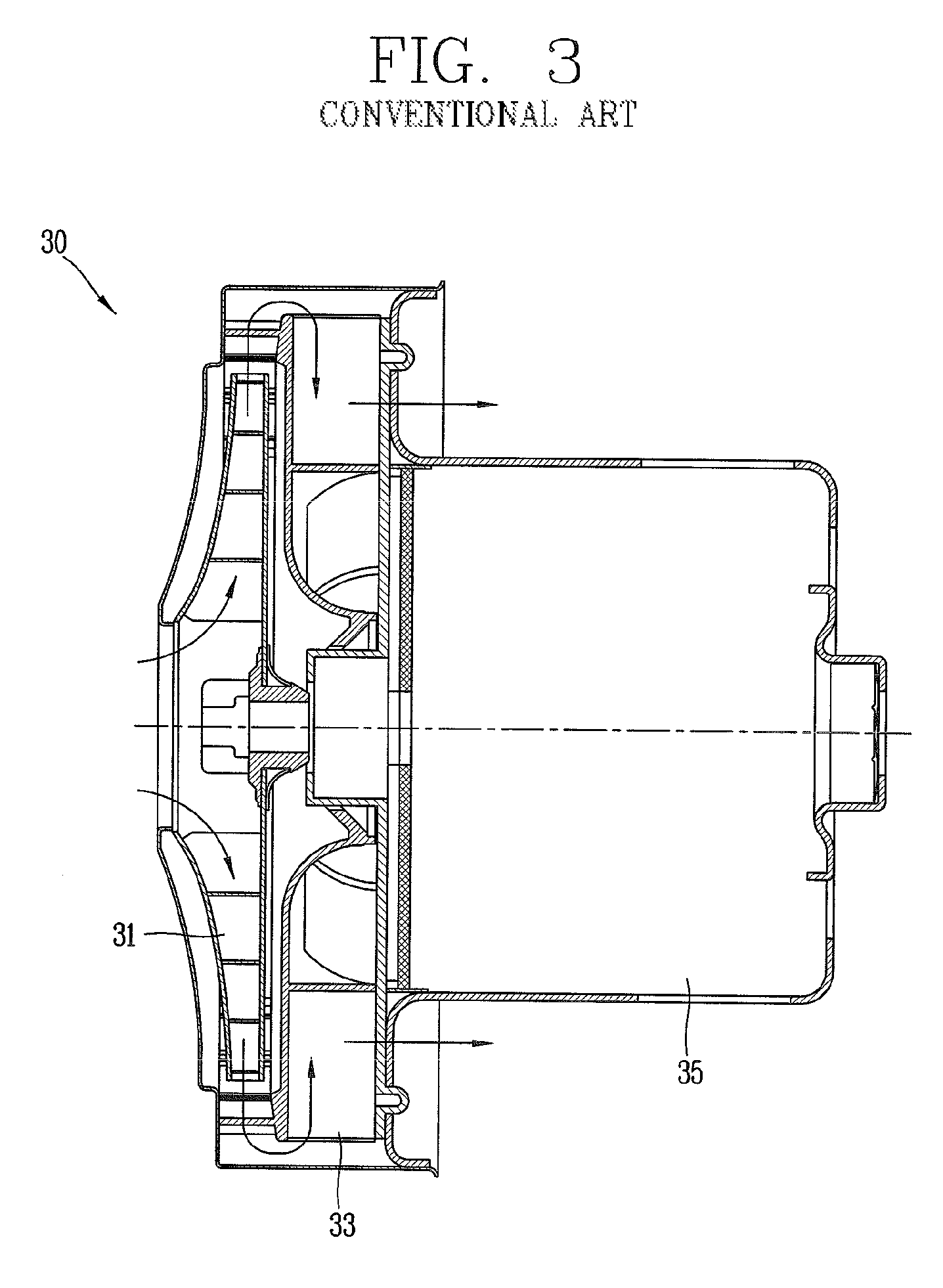

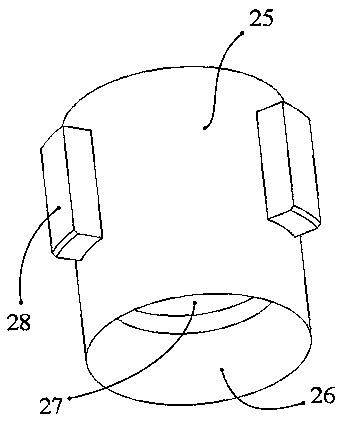

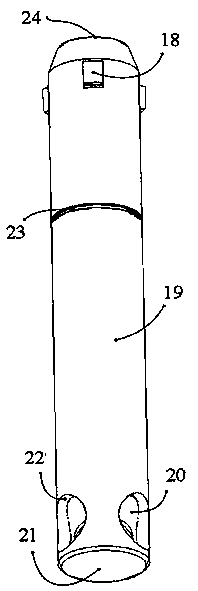

Robot cleaner

ActiveUS20110099747A1Increase suction pressureGreat suctionCleaning filter meansSuction filtersEngineeringRobot

A robot cleaner comprises a main body having a suction port at a bottom surface thereof, a pair of wheel assemblies disposed at both sides of the main body, and configured to move the main body, a dust box mounted to contact the bottom surface of the main body, and configured to collect dust sucked through the suction port, a filter unit configured to filter air discharged from the dust box, a suction fan configured to form a suction pressure on a suction channel defined by the suction port, the dust box and the filter unit, and a battery disposed at a side of the dust box.

Owner:LG ELECTRONICS INC

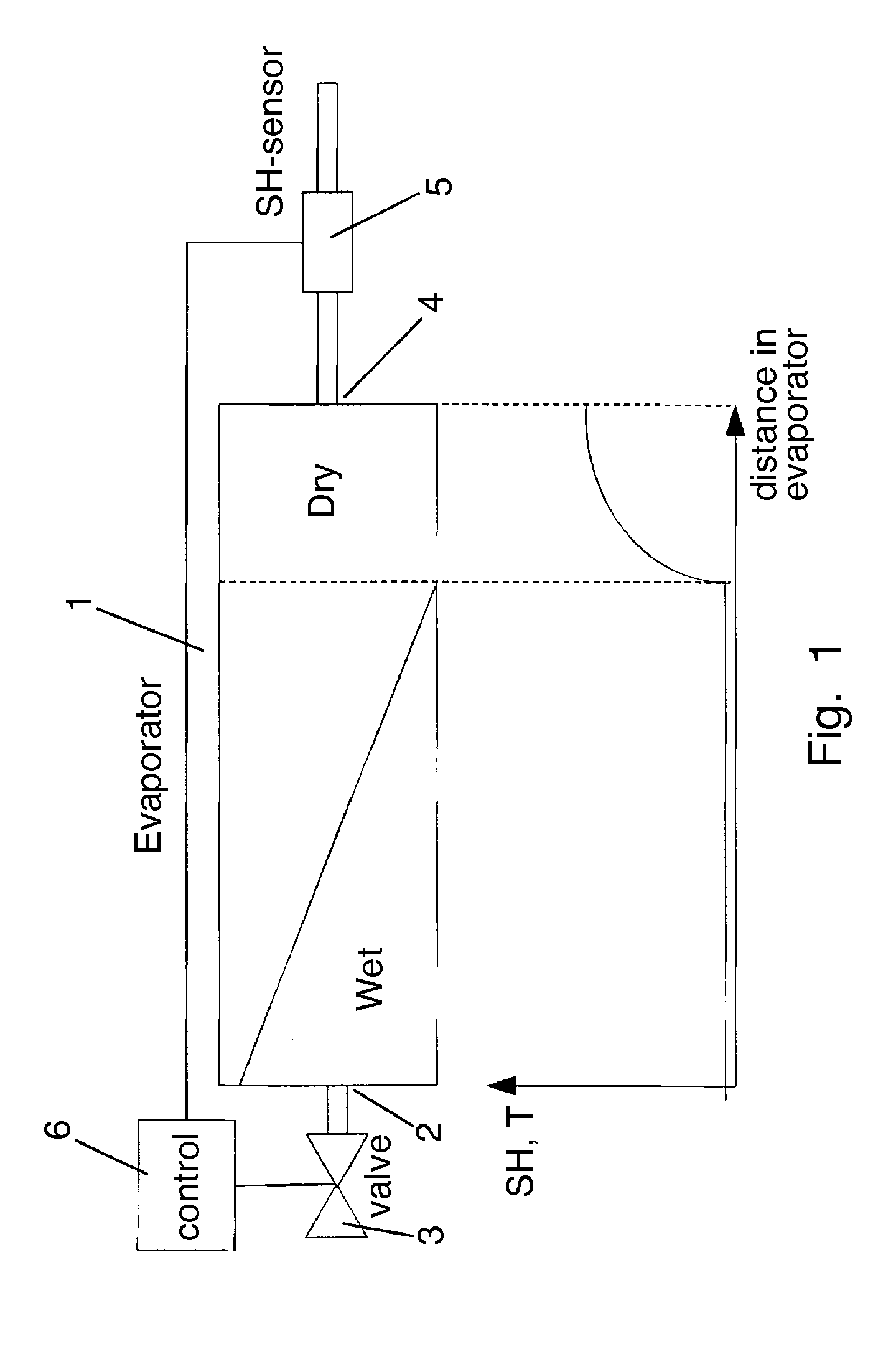

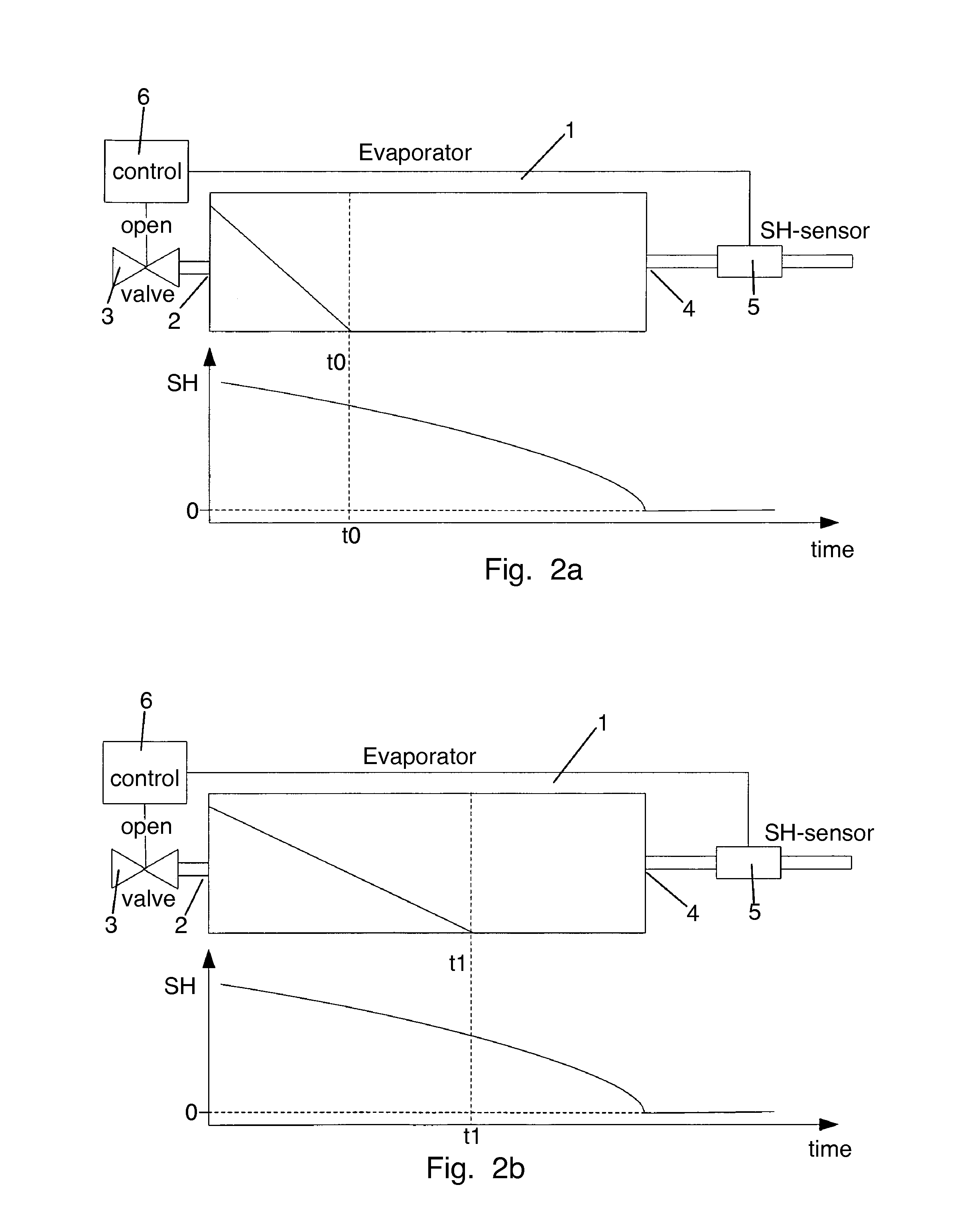

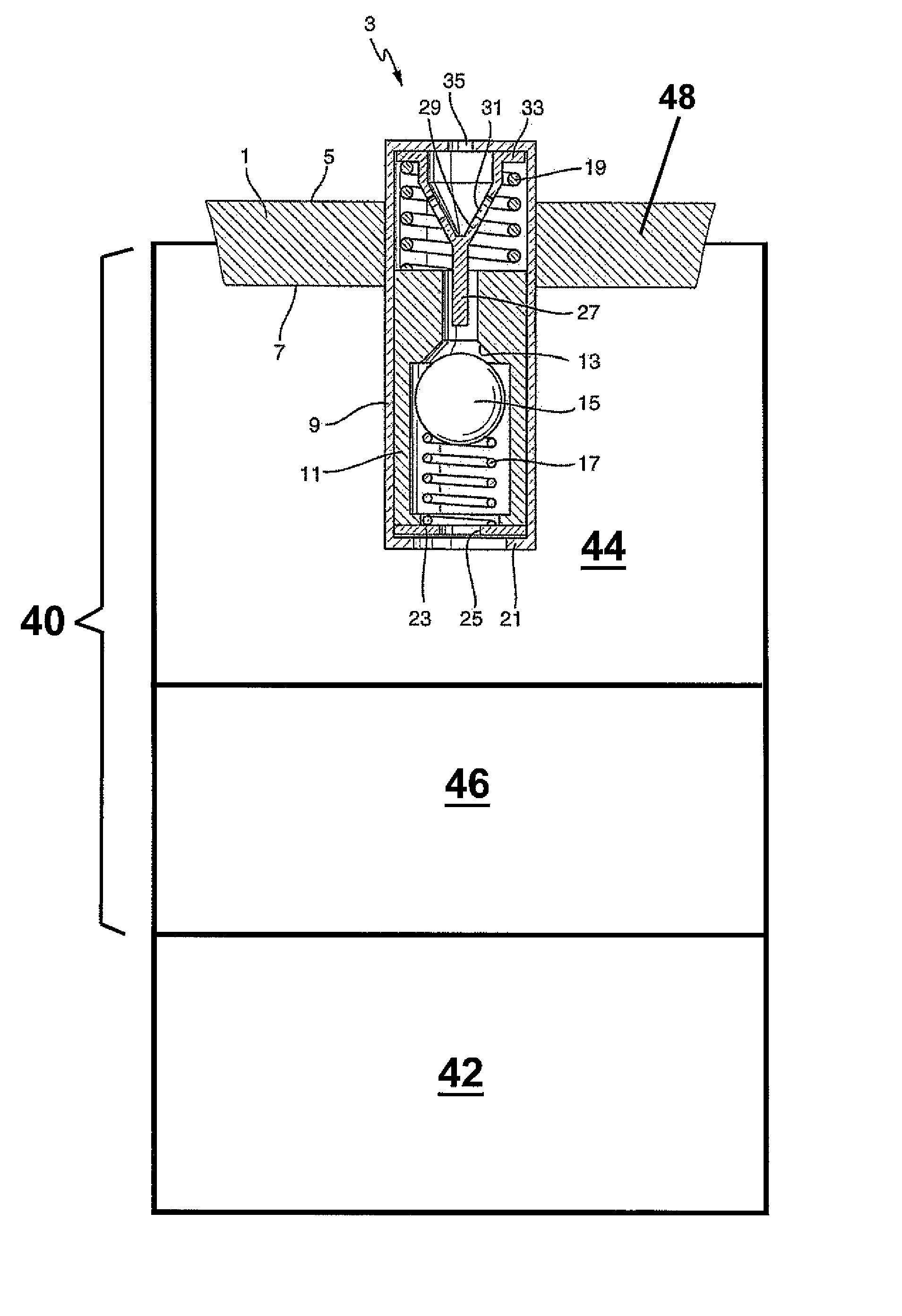

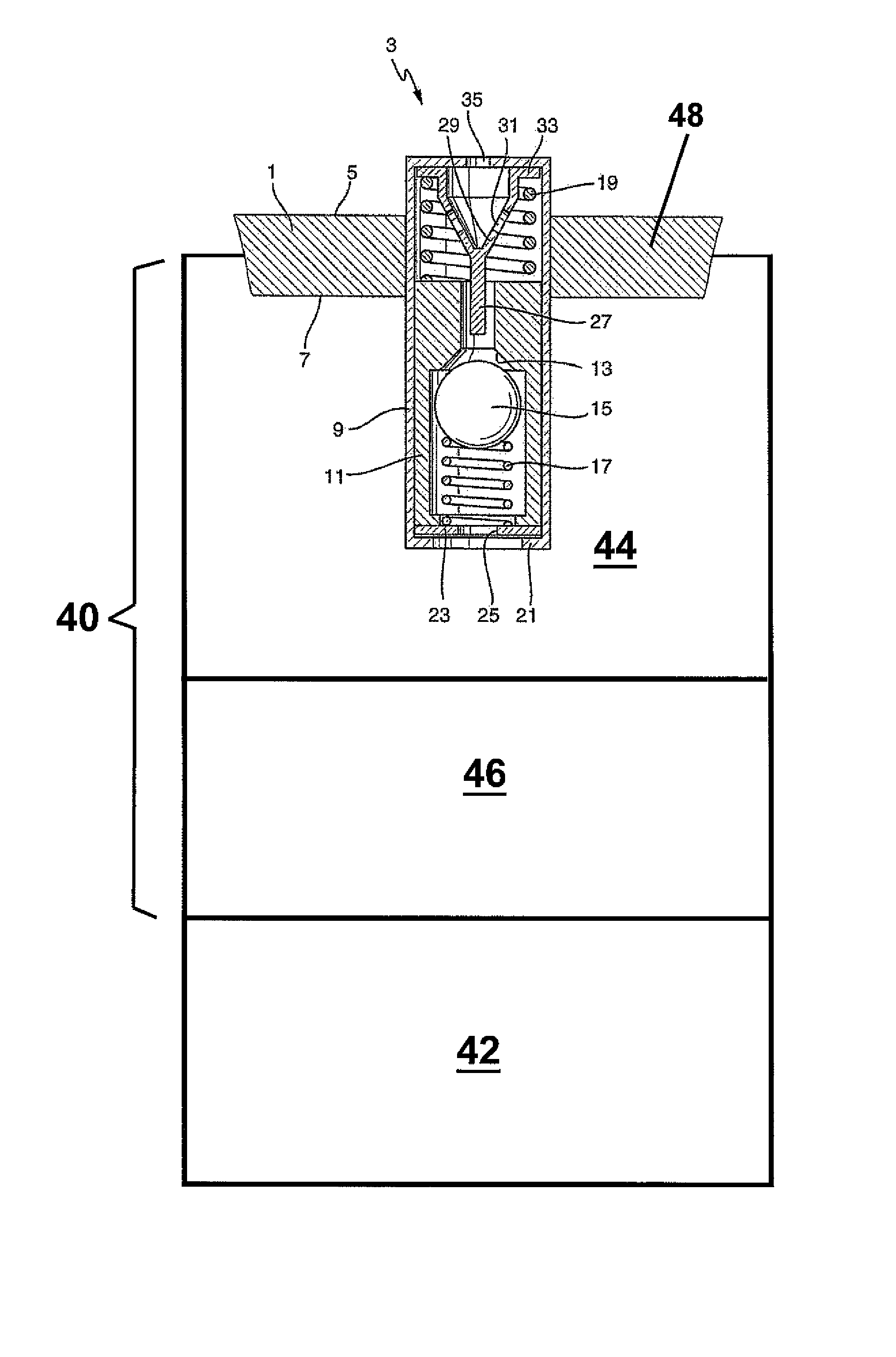

Method for calibrating a superheat sensor

InactiveUS8827546B2Reduce riskShorten speedThermometer detailsMechanical apparatusEngineeringRefrigerant

A method for calibrating a superheat sensor (5) for a refrigeration system is provided. The method comprises the following steps. Increasing an amount of liquid refrigerant in the evaporator (1), e.g. by increasing an opening degree of the expansion valve (3). Monitoring one or more parameters, e.g. the temperature of refrigerant leaving the evaporator (1), said parameters reflecting a superheat value of the refrigerant. Allowing the value of each of the parameter(s) to decrease. When the value(s) of the monitored parameter(s) reaches a substantially constant level, defining the superheat value corresponding to the constant level to be SH=0. The superheat sensor (5) is then calibrated in accordance with the defined SH=0 level. When the parameter(s) reaches the substantially constant level it is an indication that liquid refrigerant is allowed to pass through the evaporator (1), and thereby that the superheat of the refrigerant leaving the evaporator (1) is zero. Calibration can be performed on site, and it is therefore not necessary to calibrate the sensor (5) at the manufacturing facility. Thereby it is no longer required to match calibration information with a specific sensor.

Owner:DANFOSS AS

Method of optimizing internal negative pressure of vacuum device of textile machine for making cross wound bobbins

The invention relates to a method of optimizing internal negative pressure of a vacuum device of a textile machine for making cross wound bobbins. The vacuum device has a suction machine group. The textile machine comprises a plurality of workstations with diversified vacuum demands. To satisfy the vacuum demands, the negative pressure should not be lowered to a specified level satisfying a basic demand. The suction power of the suction machine group is adjusted through an adjusting mechanism in a way to provide a negative pressure greater than the specified level as a working requirement when a yarn with higher vacuum demands is reported to be broken during a yarn connecting period or a yarn is cut. According to the embodiments, a yarn head on the side of a winding bobbin is successfully found through the sensor. A success signal is sent to the adjusting mechanism of the vacuum device. Later, a request for higher vacuum demands for related workstation is deleted in the adjusting mechanism.

Owner:SAURER GERMANY GMBH & CO KG

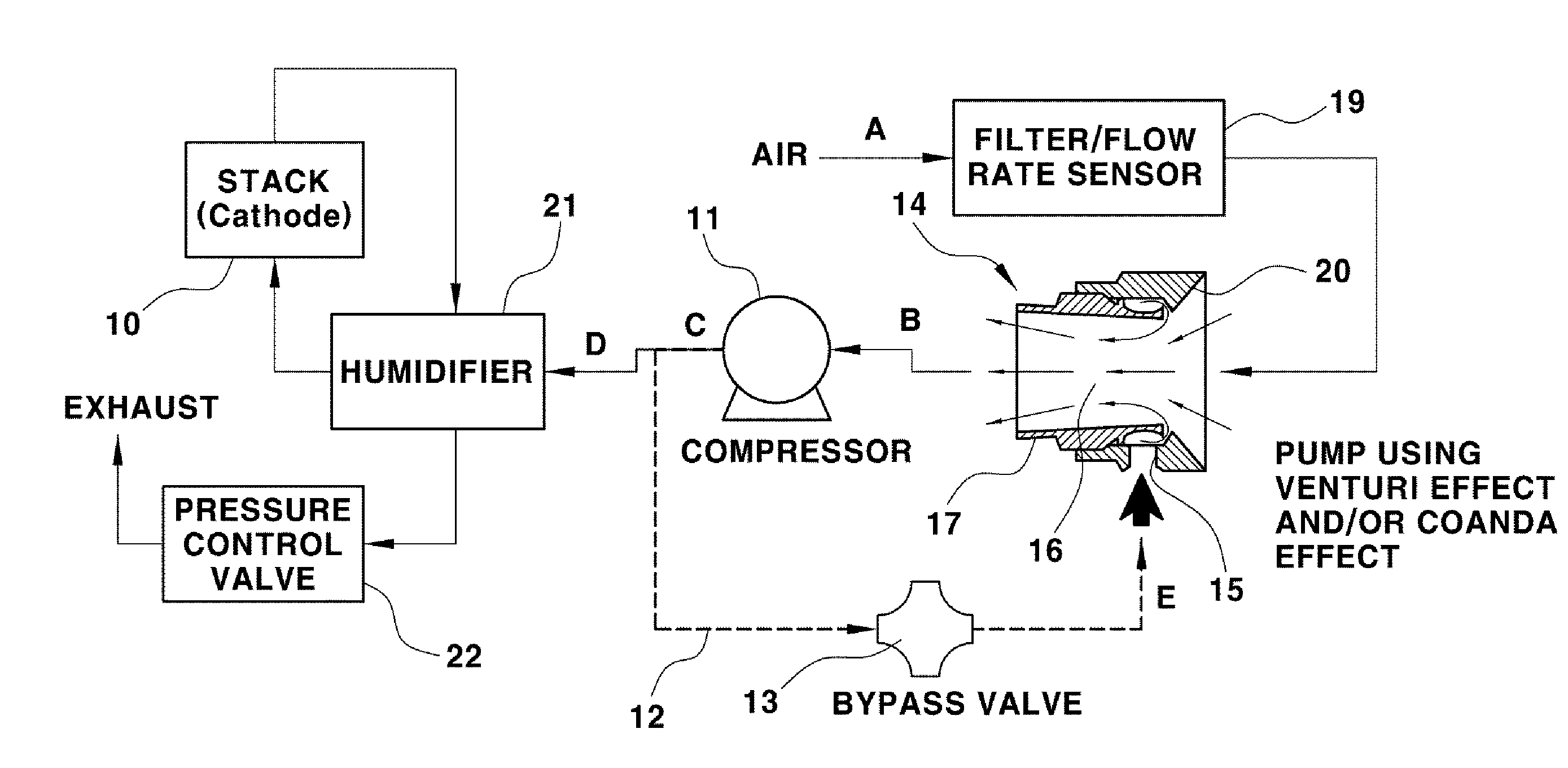

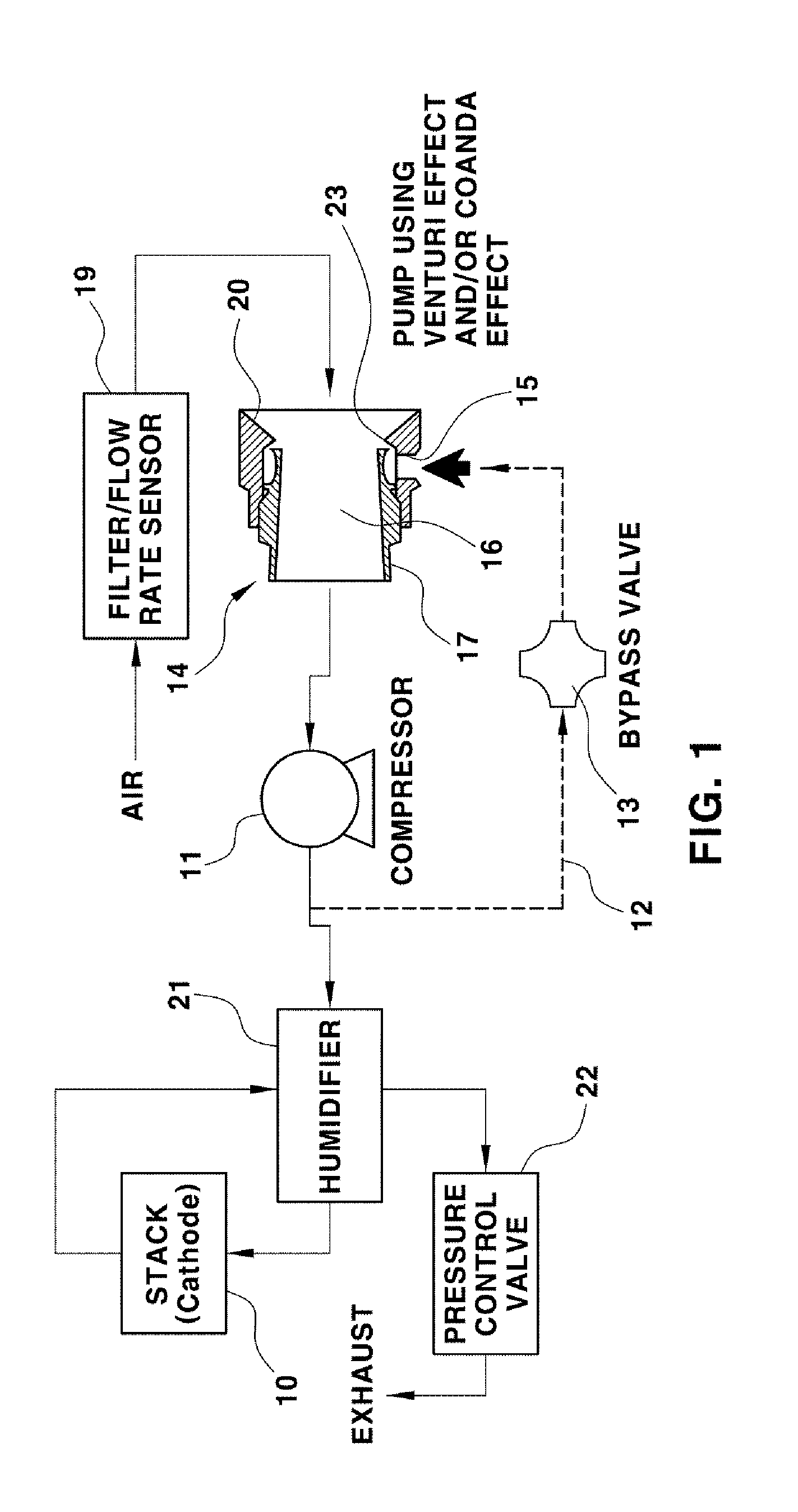

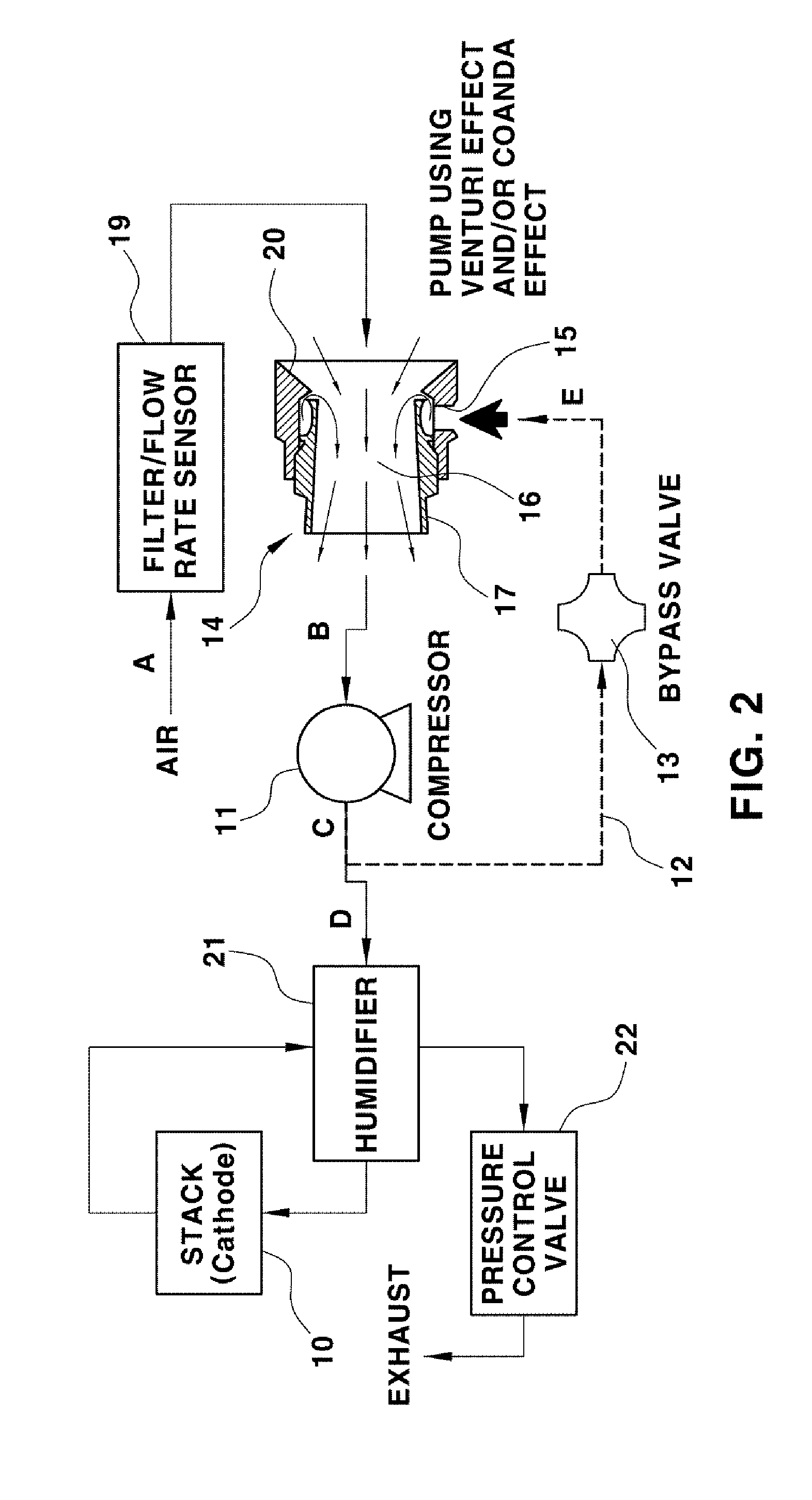

Air supply apparatus and method for fuel cell

ActiveUS20150188161A1Increase suction pressureImprove efficiencyReactant parameters controlFuel cellsHigh pressure

An air supply apparatus and method for a fuel cell, which supplies high-pressure air while avoiding a surge phenomenon of a turbo type compressor in a fuel cell system to which the turbo type compressor is applied is provided. In particular, a portion of air from an outlet of a compressor to an inlet of the compressor is recirculated to the supply of air supplied from the compressor to a stack. This recirculated air and external air introduced from the outside are mixed and supplied to the inlet of the compressor at a sufficiently high air pressure, allowing the compressor to avoid a surge region and enabling the supply of air with a high pressure and a low flow rate.

Owner:HYUNDAI MOTOR CO LTD

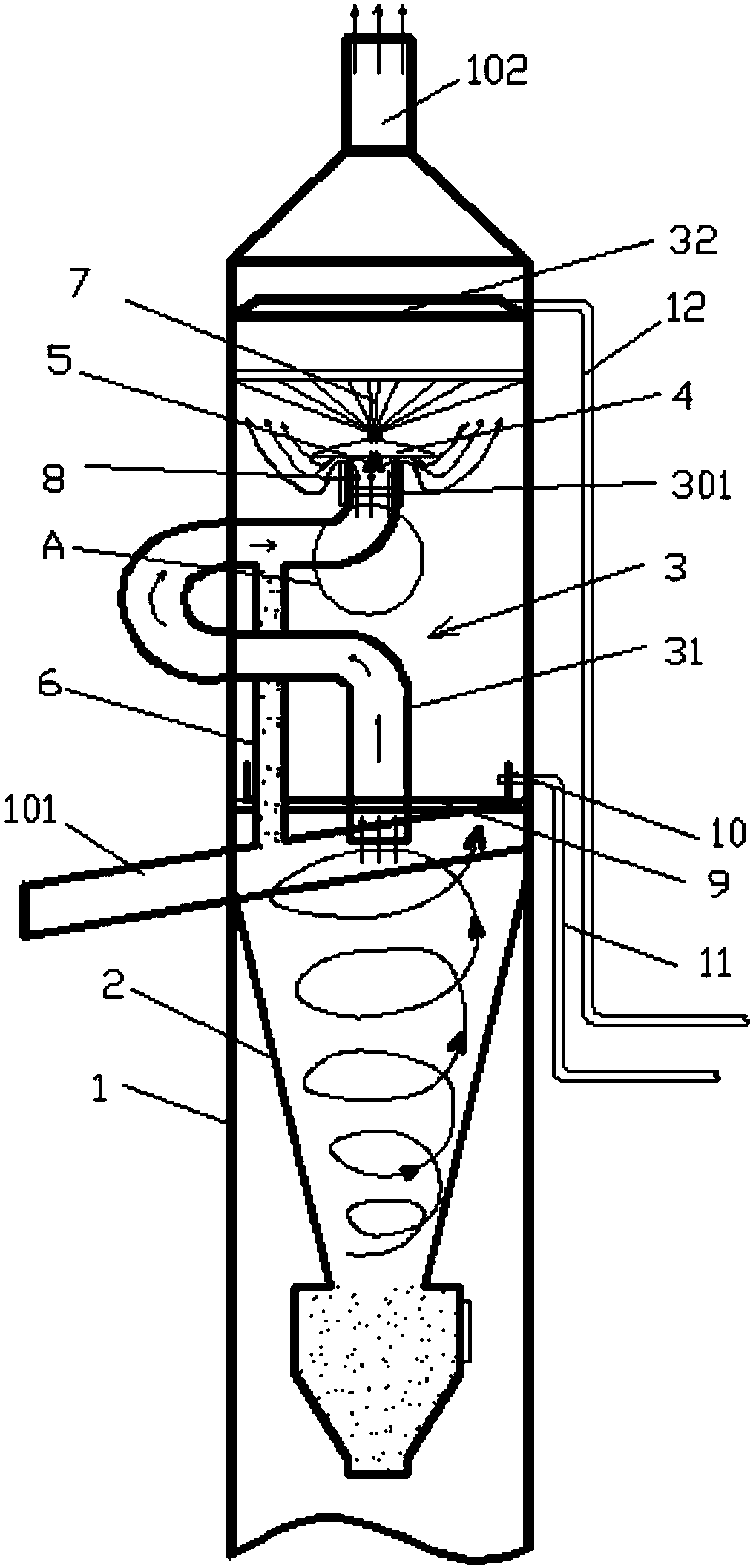

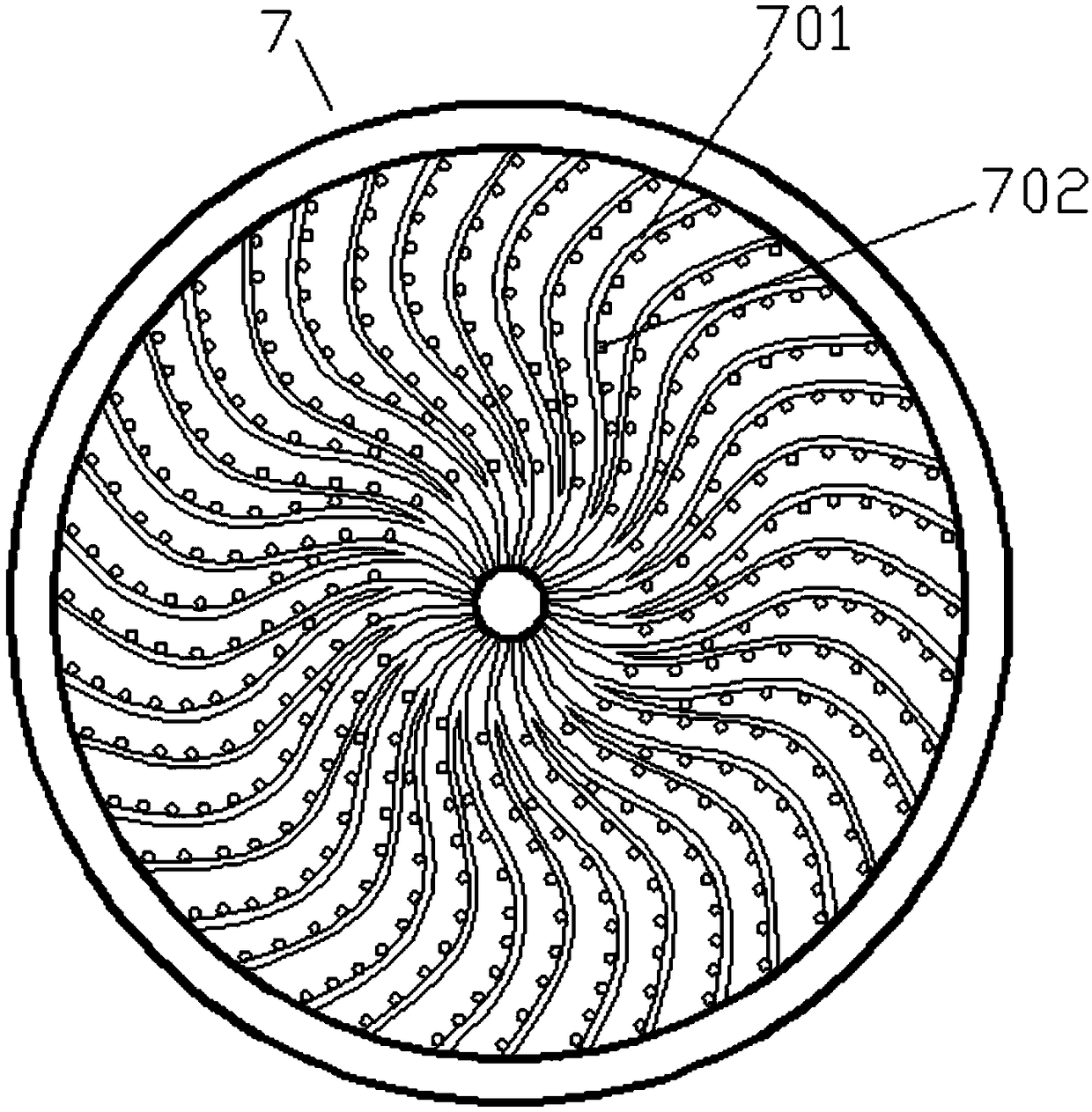

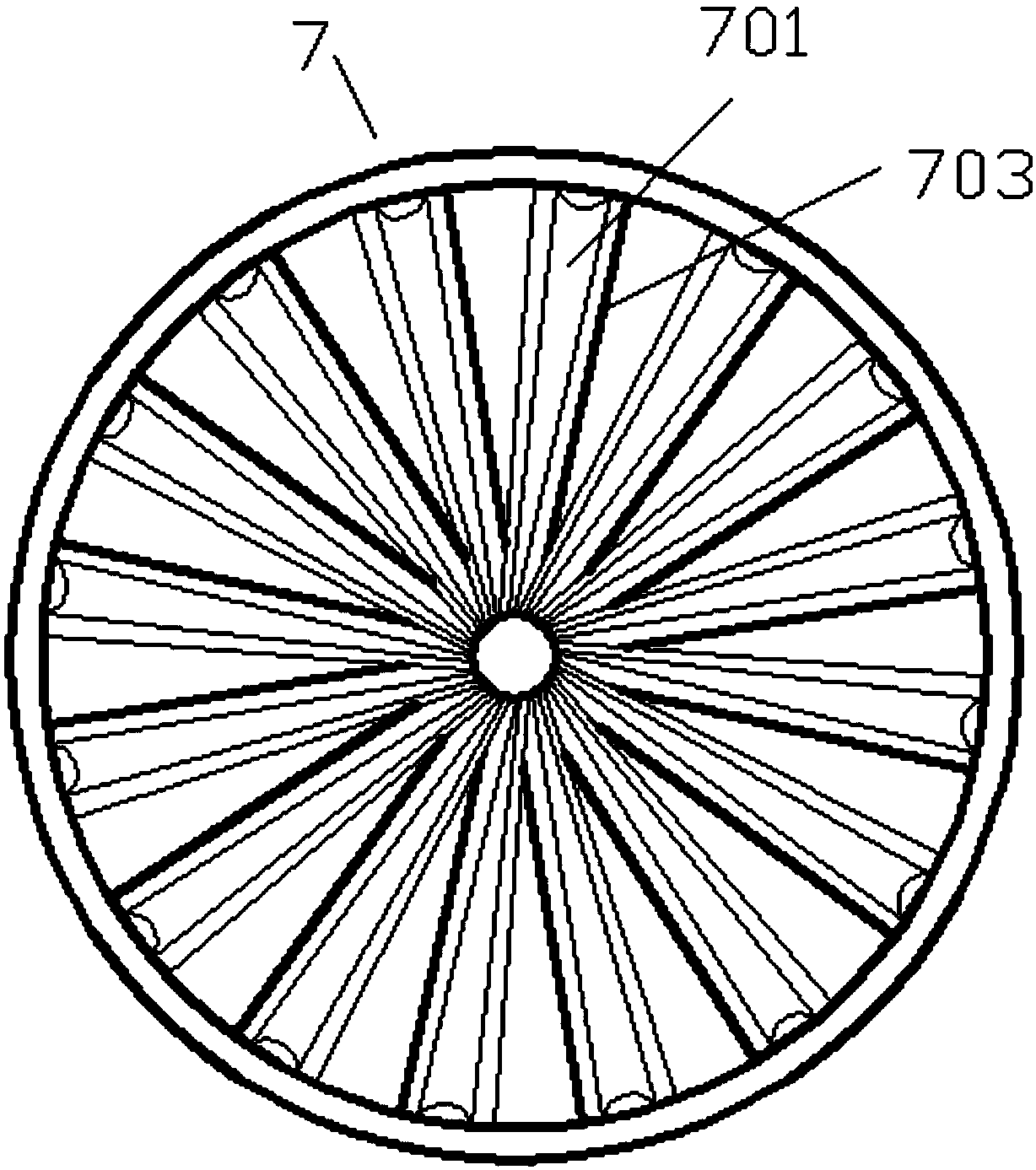

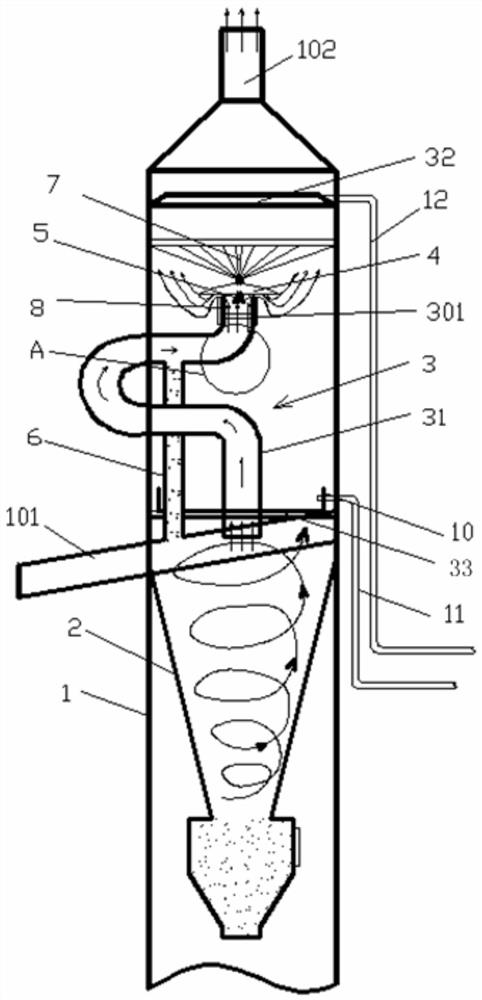

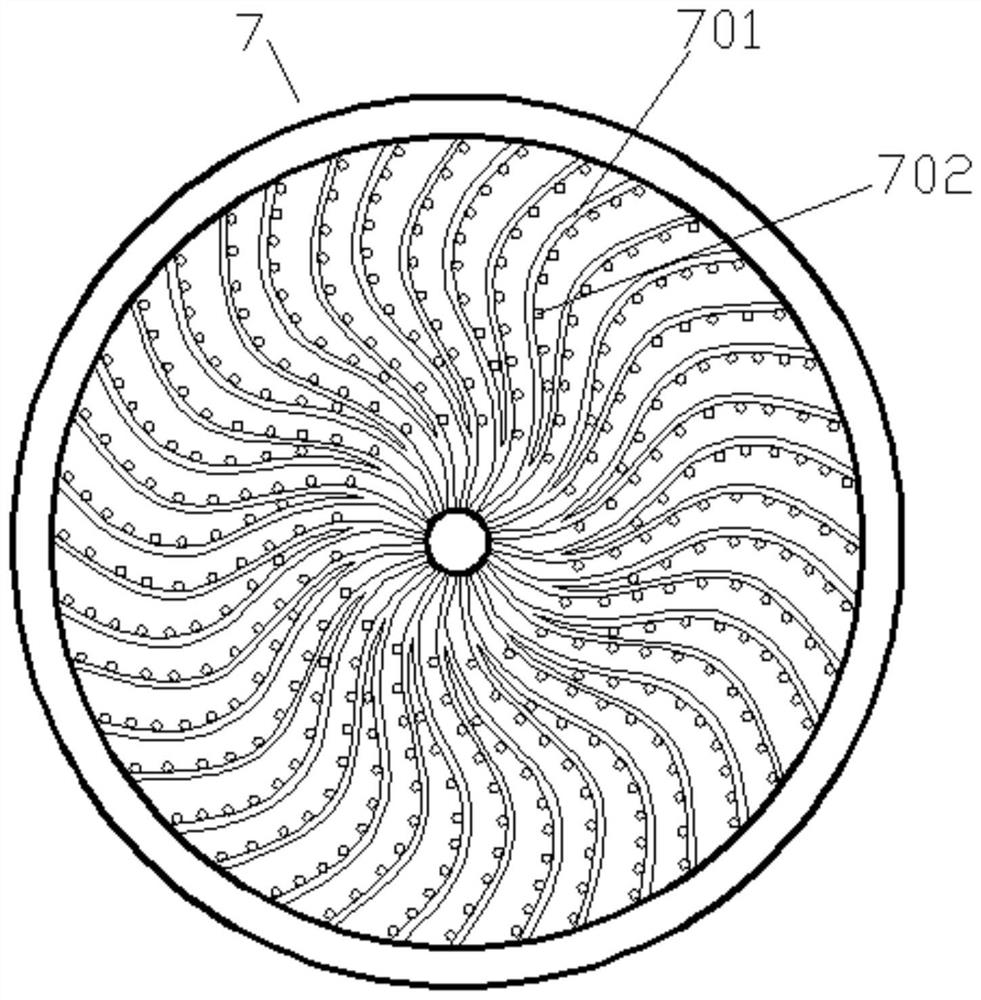

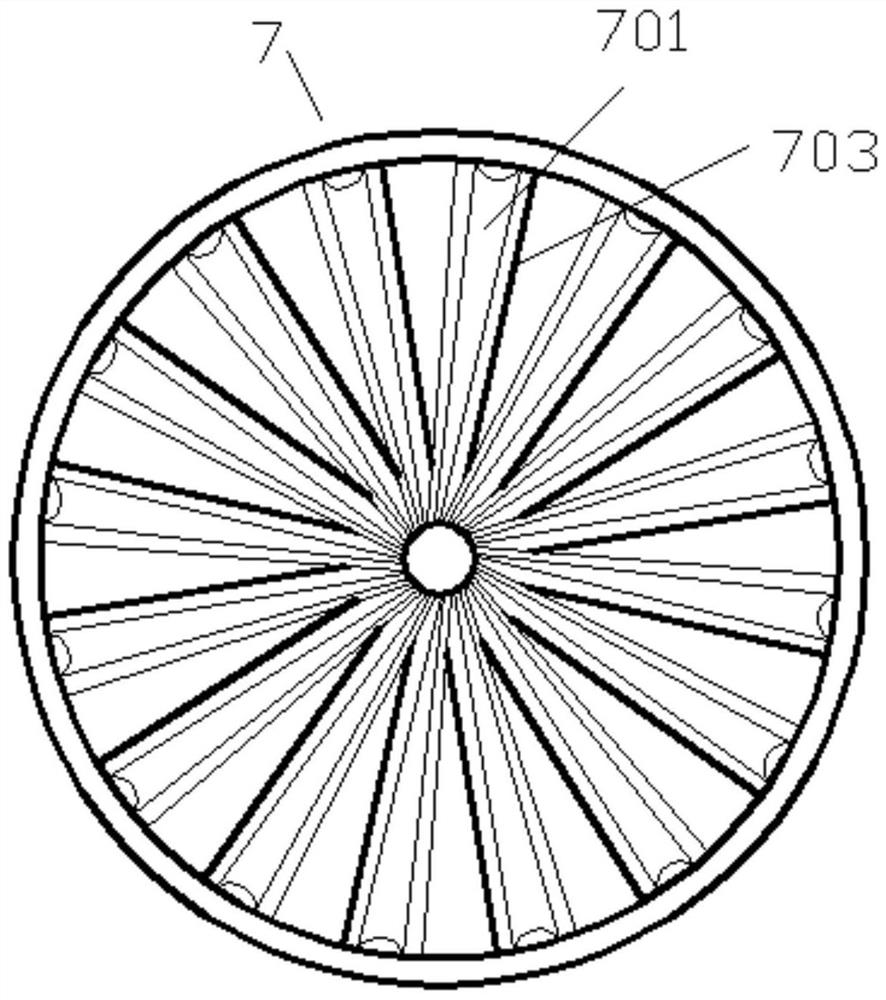

Integrated type dust-removal desulfurizing tower

The invention provides an integrated type dust-removal desulfurizing tower. A vertical lower part in an absorbing tower barrel body is provided with a cyclone dust collector; the upper end of the absorbing tower barrel body is provided with a dual-desulfurizing and dust-collecting device; the dual-desulfurizing and dust-collecting device comprises an intestine-shaped smoke gas guide and desulfurizing channel and a spraying frame; the lower end of the intestine-shaped smoke gas guide and desulfurizing channel is communicated with the cyclone dust collector to ventilate; the upper gas outlet port extends into the absorbing tower barrel body, and the horizontal section is provided with a vertical smoke gas recirculating dust-collecting channel which is communicated with a soot inlet; an umbrella-shaped smoke gas diffusing cover and a spray head are arranged above the gas outlet port; and a funnel-shaped smoke gas dispersing grid which is used for dispersing gas flow in the adsorbing towerbarrel body and recycling a desulfurizing agent sprayed by the spraying frame is mounted on the spray head in a communication mode. The integrated type dust-removal desulfurizing tower adopts a dust-collecting and desulfurizing vertical integrated design, is small in floor space, is compact in structure, is less in desulfurizing liquid, is high in desulfurizing efficiency, and is excellent in comprehensive performance.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

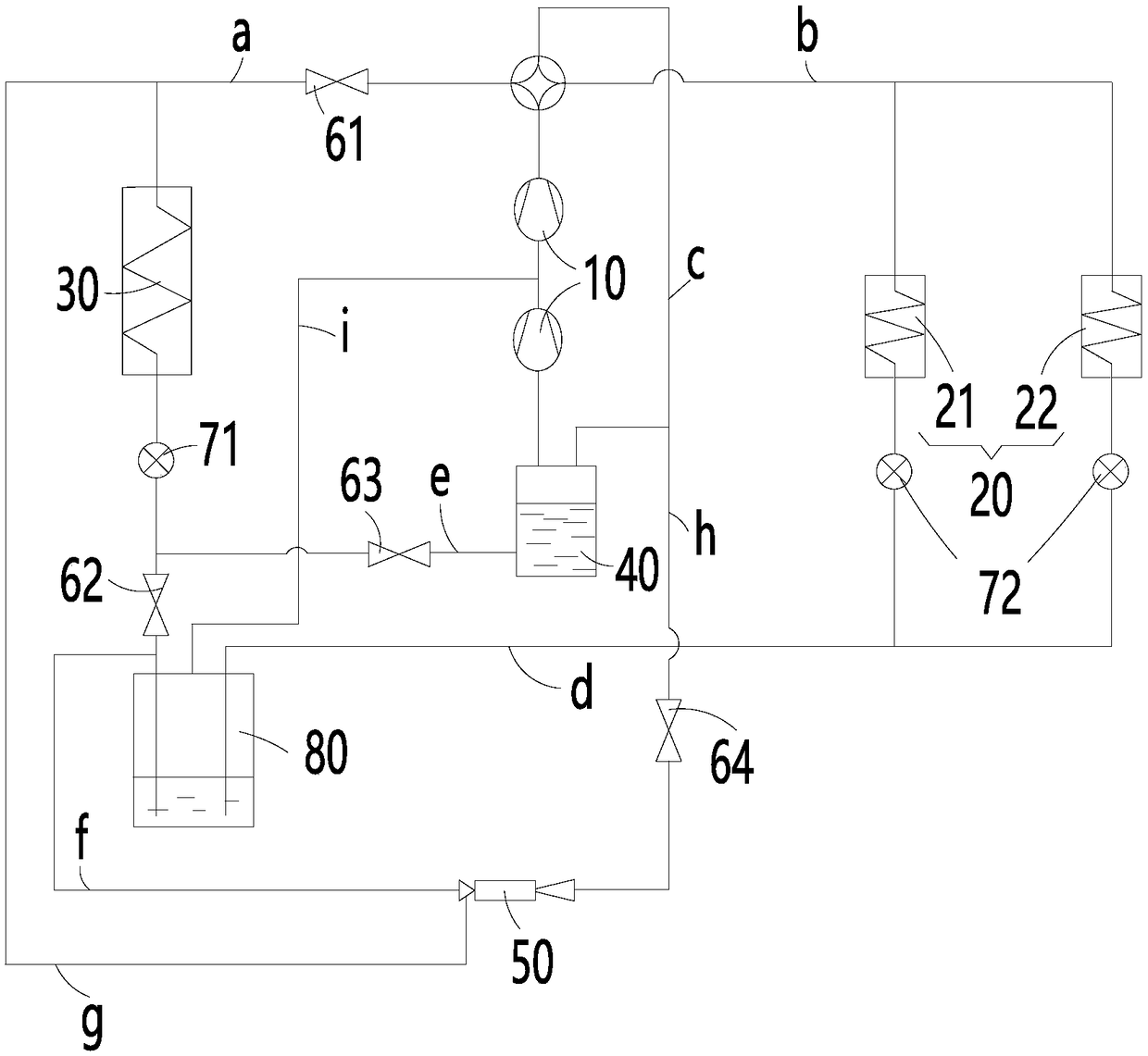

Air conditioning system

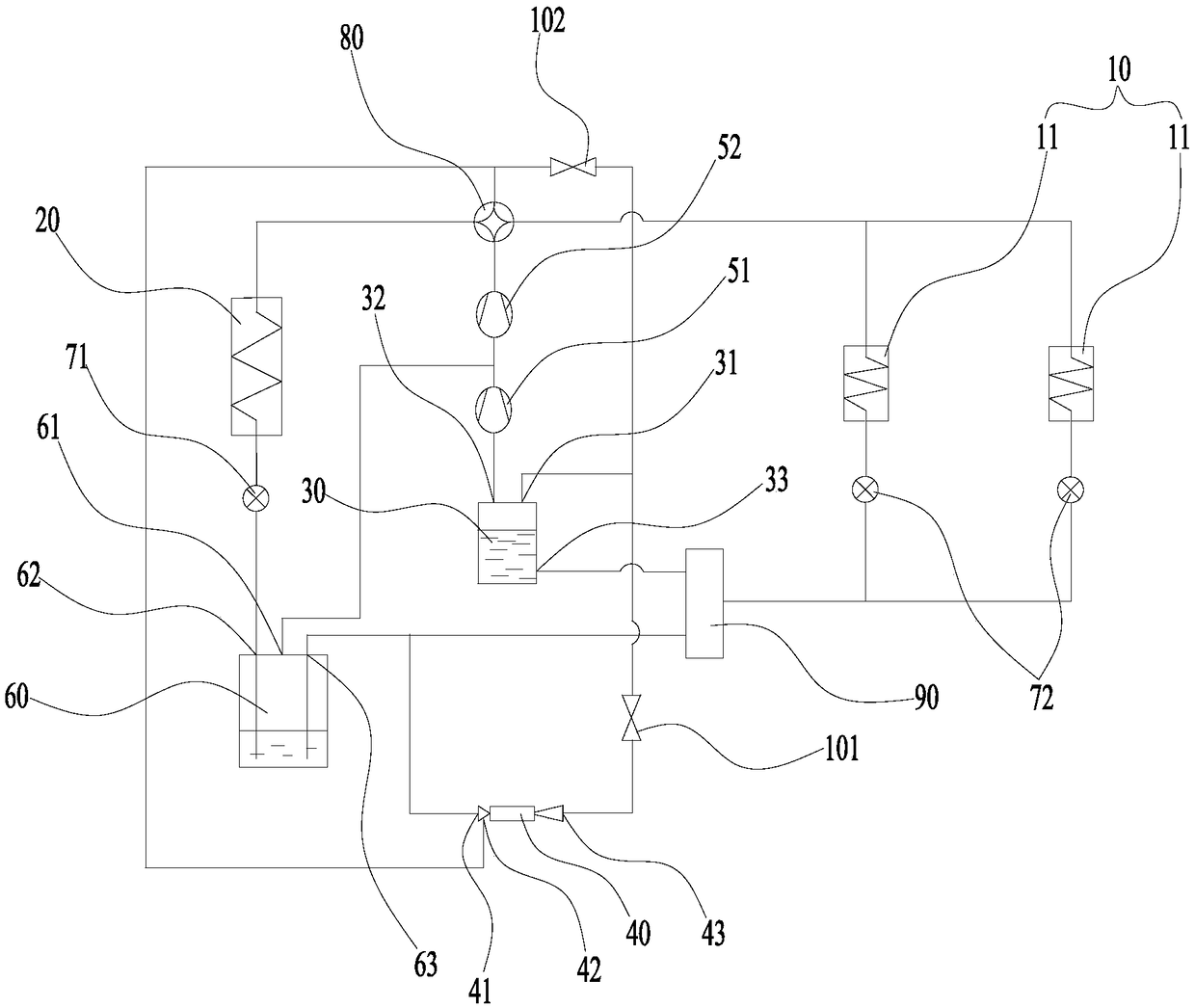

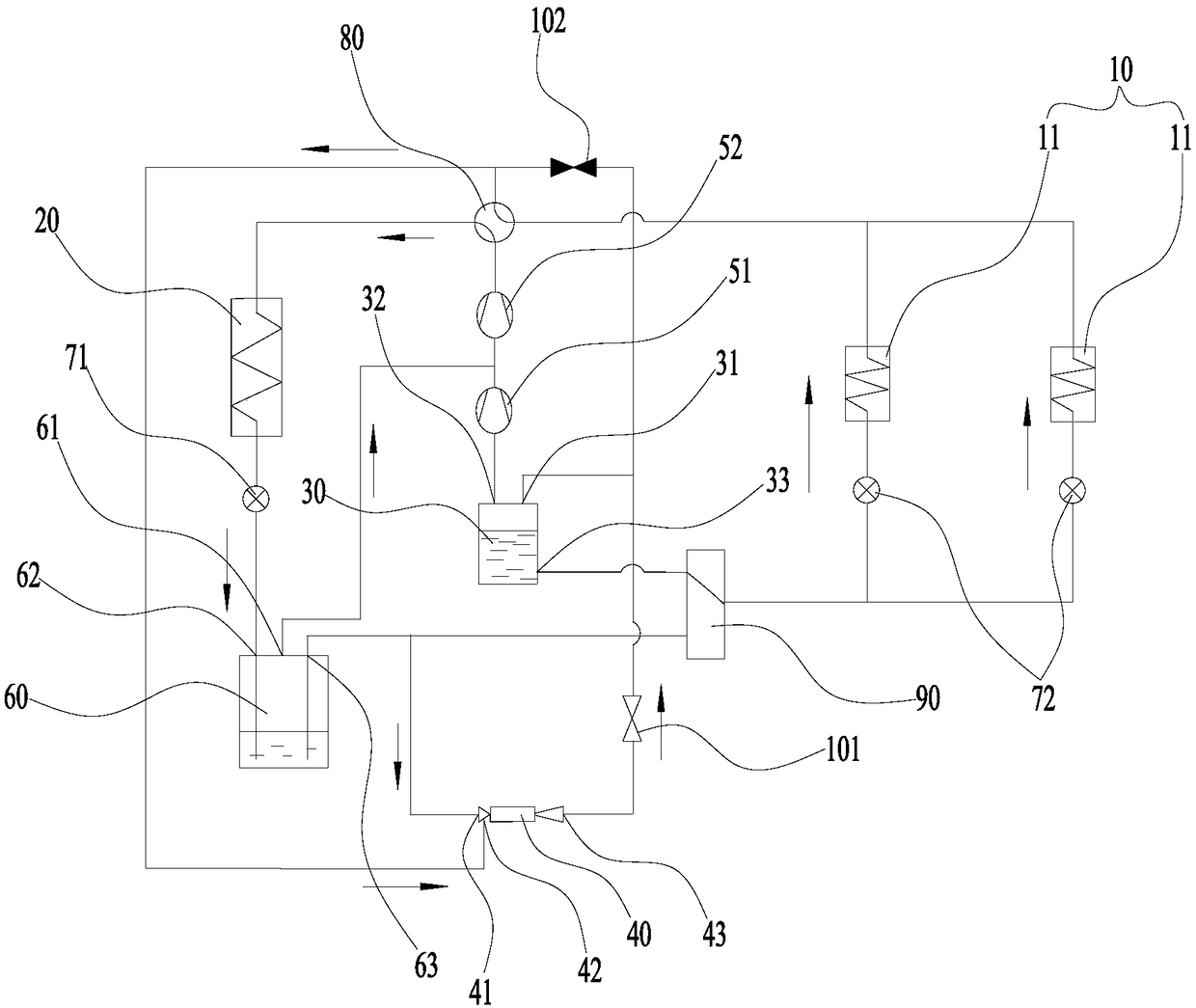

ActiveCN108800678AIncrease suction pressureEasy to meet high loadMechanical apparatusFluid circulation arrangementVapor–liquid separatorEngineering

The invention provides an air conditioning system which comprises a refrigerant cycle. The refrigerant cycle comprises an indoor heat exchanger, an outdoor heat exchanger and a gas-liquid separator. The gas-liquid separator is provided with a separator inlet, a separator gas outlet and a separator liquid outlet. The air conditioning system is characterized in that the air conditioning system further comprises an injector, and the injector is provided with an injector main inlet, an injector lateral inlet and an injector outlet; during refrigerating of the air conditioning system, the outdoor heat exchanger communicates with the injector main inlet, the indoor heat exchanger communicates with the injector lateral inlet, and the injector outlet communicates with the separator inlet; and during heating of the air conditioning system, the indoor heat exchanger communicates with the outdoor heat exchanger, and the outdoor heat exchanger communicates with the separator inlet. According to the technical scheme, the problems that in the prior art, the load requirement and the high and low pressure ratio of a compressor of an air conditioning system are large, the compressor needs to keep high frequency for operation, and use reliability is low can be effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

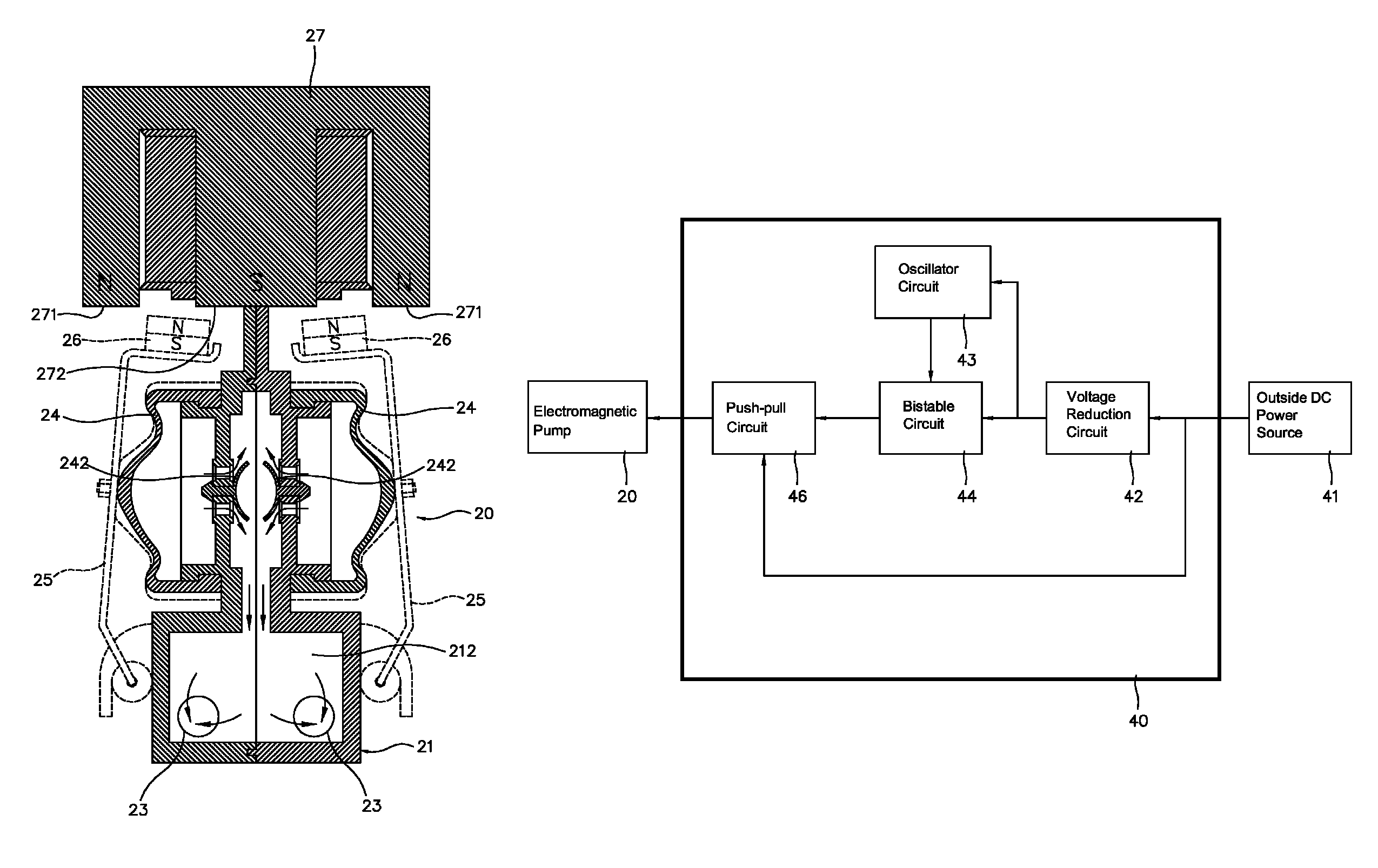

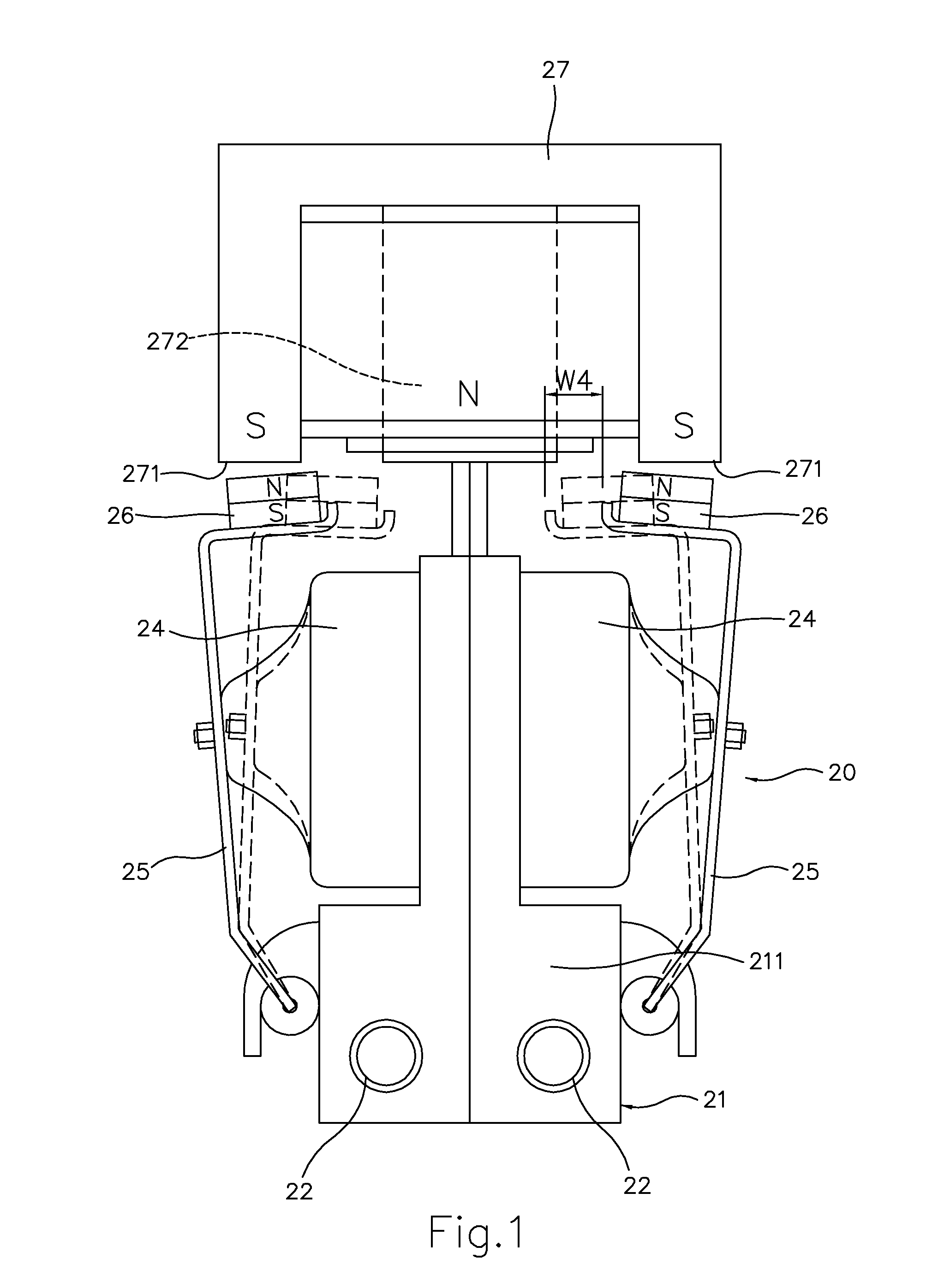

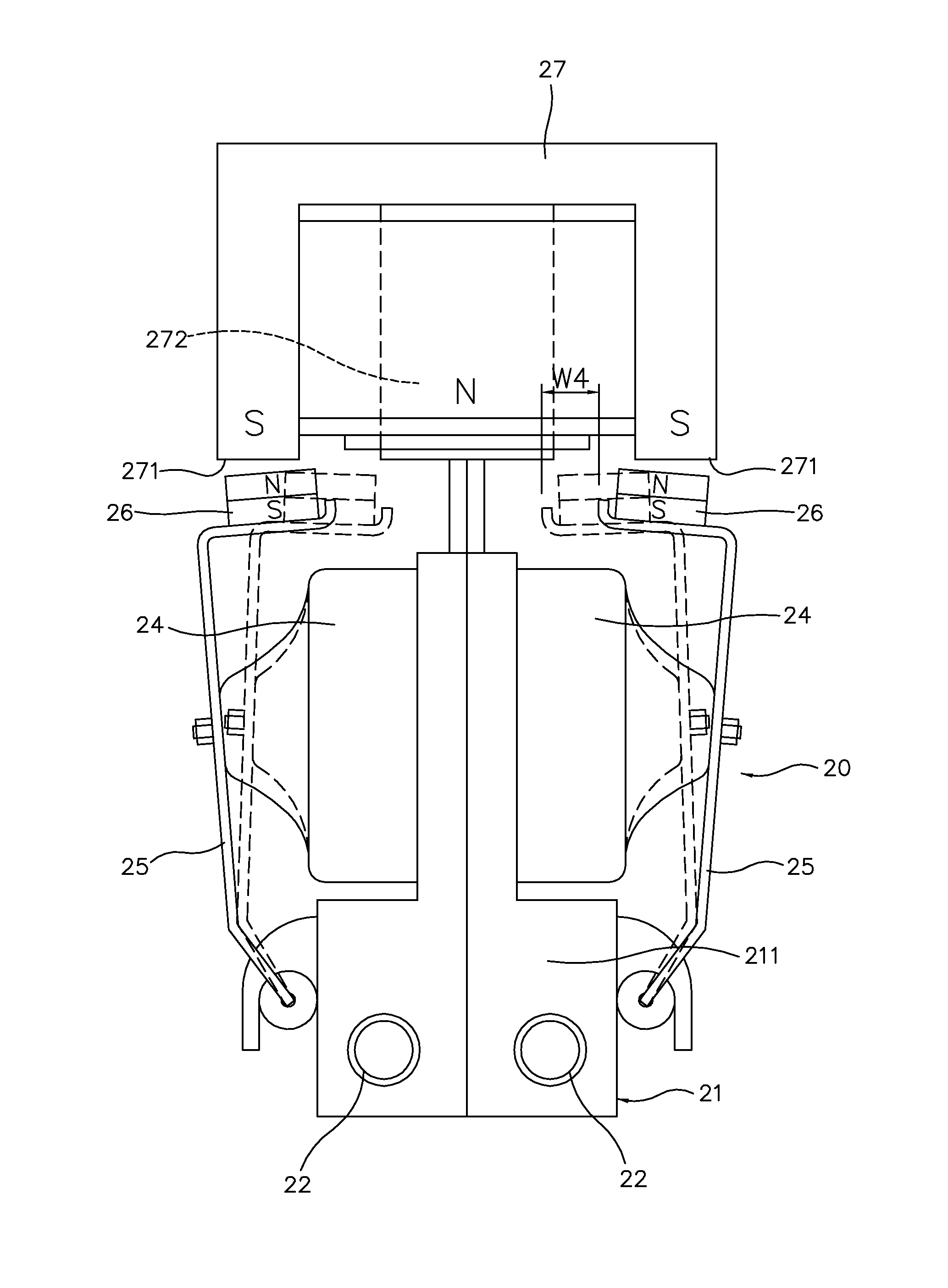

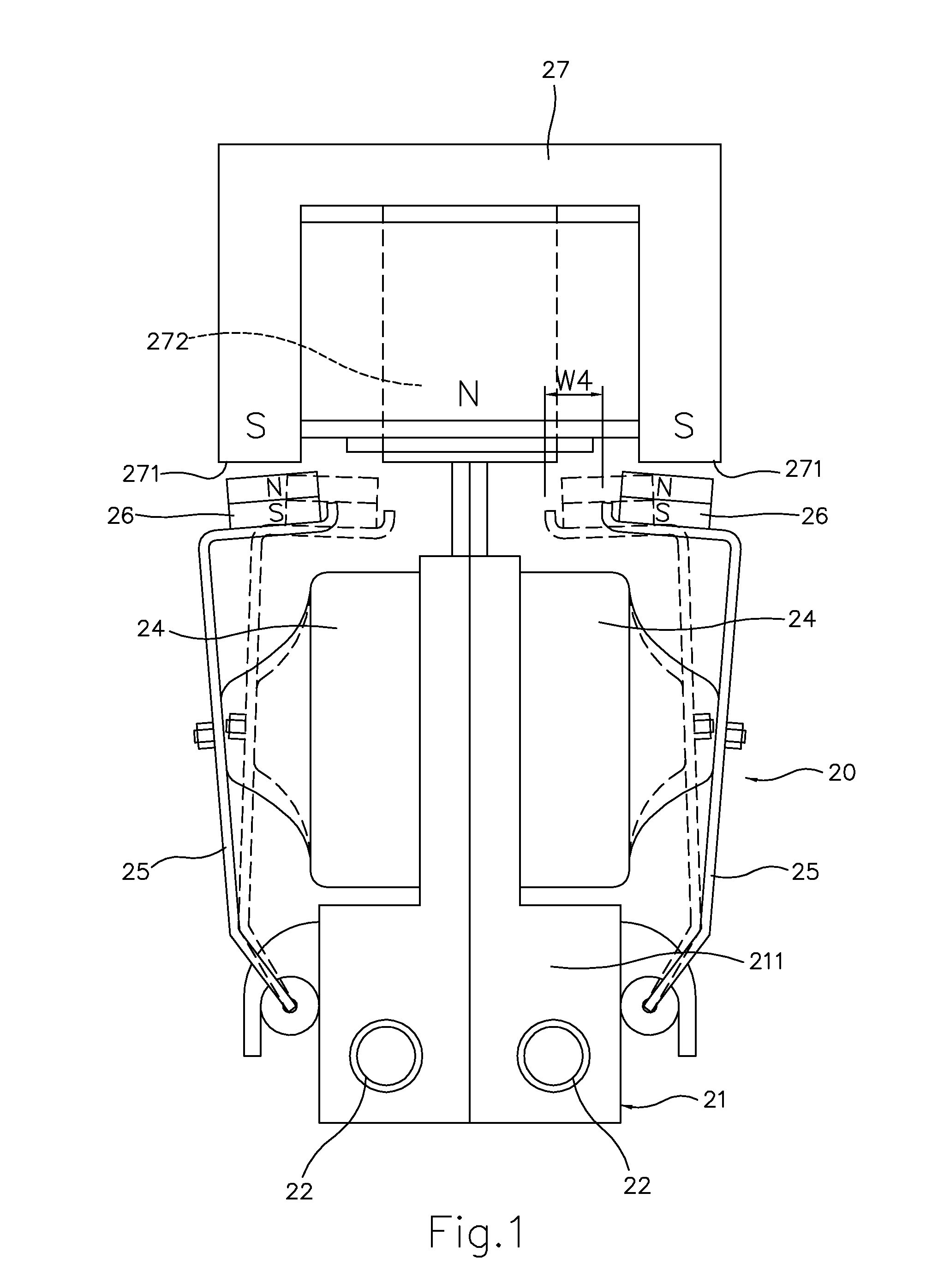

Electromagnetic pump with frequency converter circuit

InactiveUS8480382B2Reduce power consumptionLess overall consumptionMotor/generator/converter stoppersDC motor speed/torque controlBistable circuitsFrequency changer

An electromagnetic pump has a frequency converter circuit for driving the electromagnetic pump, wherein the frequency converter circuit comprises an oscillator circuit, a bistable circuit and a push-pull circuit. The oscillator circuit oscillates to transform DC into a single-phase oscillating signal. The bistable circuit splits the single-phase oscillating signal into a N-phase stimulus signal and a S-phase stimulus signal. The push-pull circuit amplifies and transports the N-phase stimulus signal and the S-phase stimulus signal to the electromagnetic pump to make the swing arms of the electromagnetic pump swinging effectively, wherein the swing speed, the swing frequency and the swing amplitude of the swing arms vary with the change of the oscillation frequency of the oscillator circuit. Thereby, the suction pressure and the discharge pressure of the electromagnetic pump could further be adjusted higher or lower, wherein said frequency converter circuit comprises a modulation circuit, which could change the swing speed of the swing arms swinging outwardly or inwardly to further increase or decrease the suction pressure or the discharge pressure.

Owner:CHIOU JACKEY

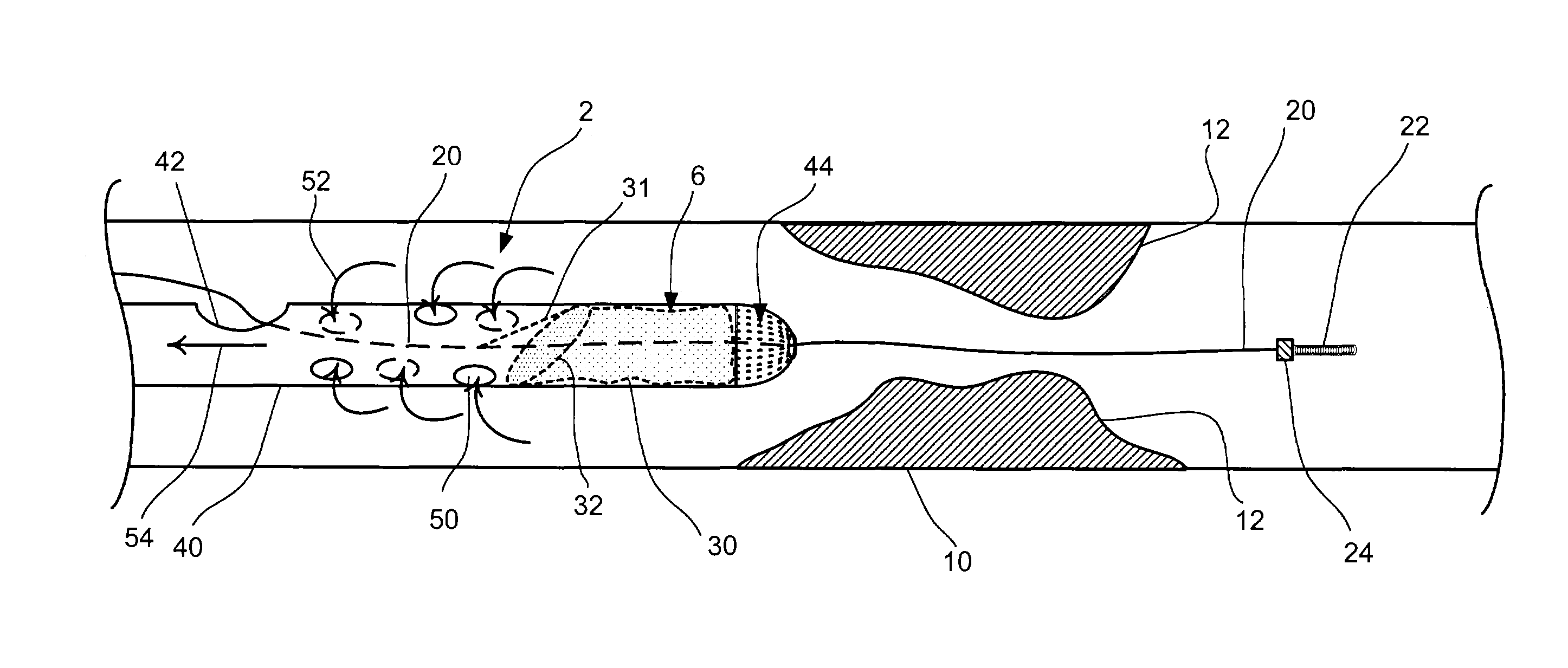

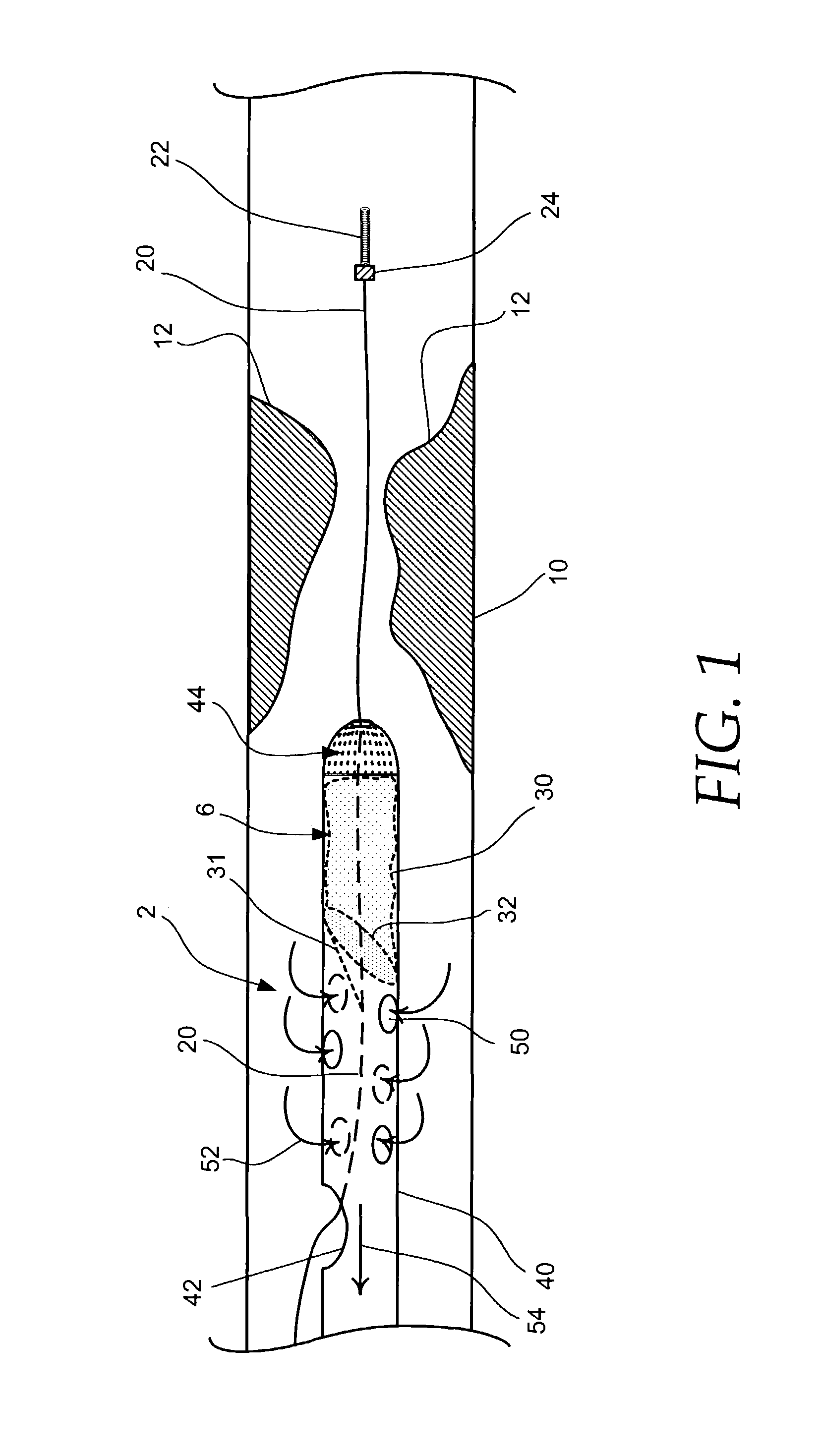

Embolic protection aspirator

ActiveUS9301829B2Minimize collection of debrisIncrease suction pressureStentsSurgeryFiltrationFilter retrieval

Owner:BOSTON SCI SCIMED INC

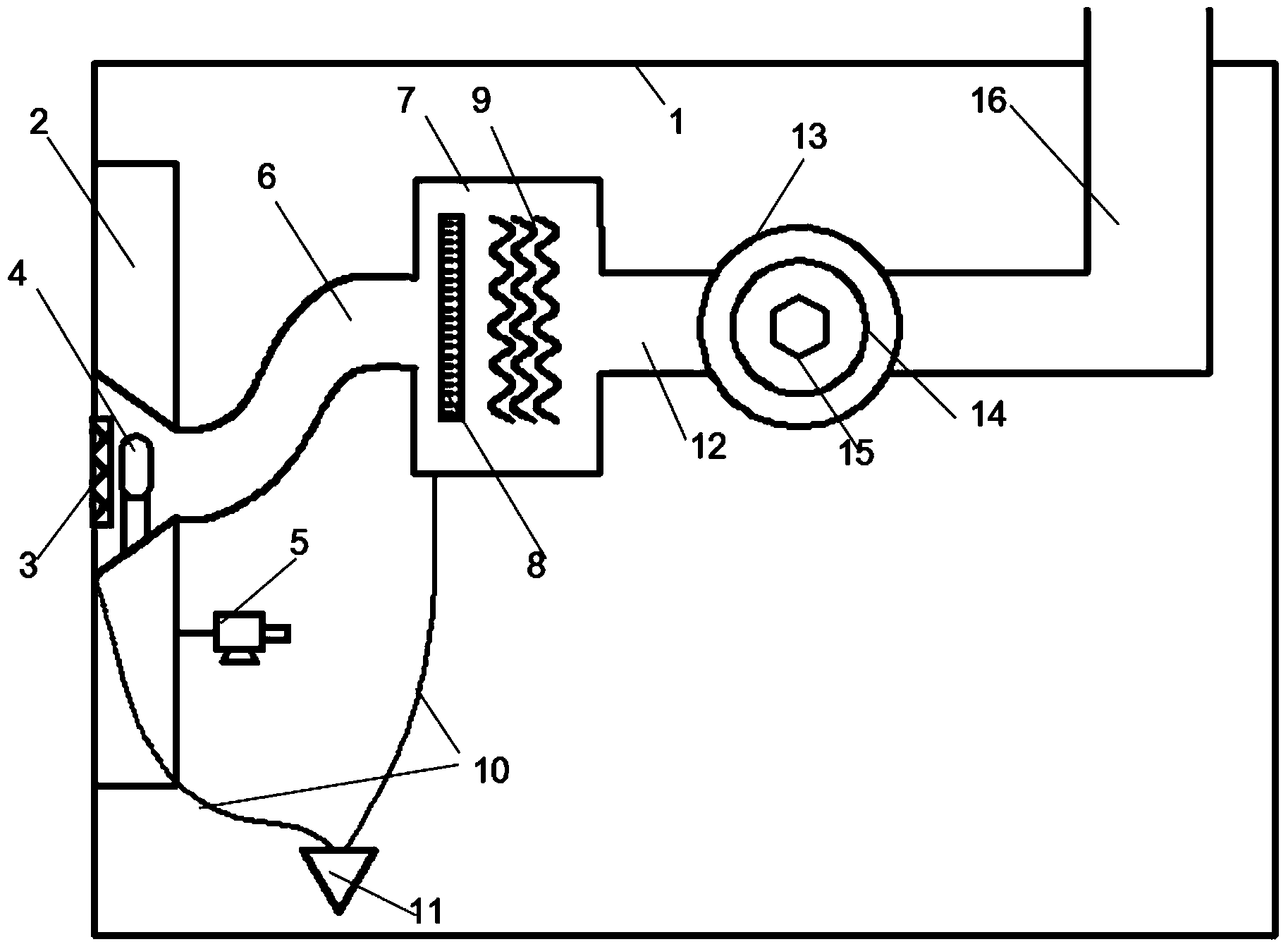

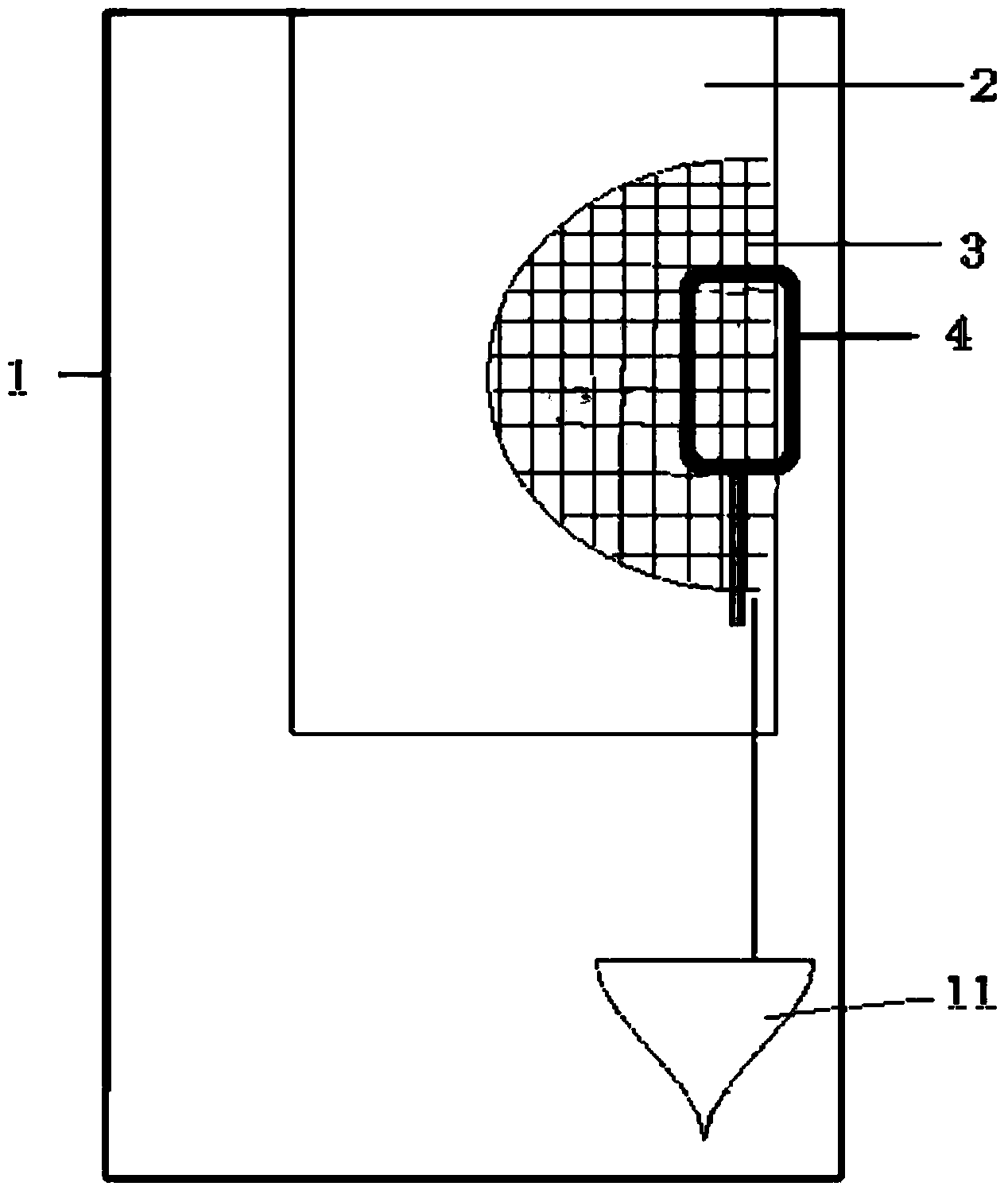

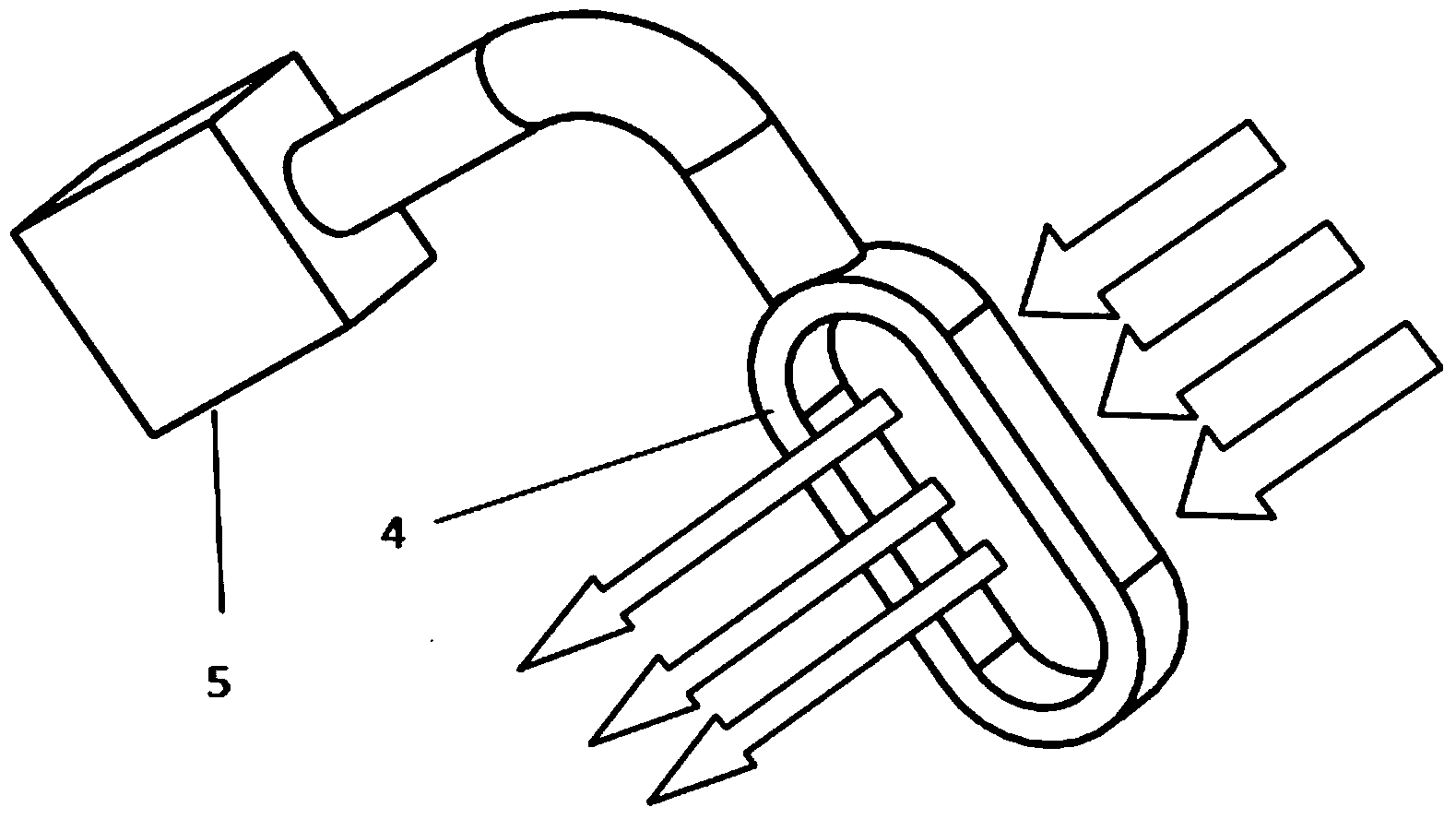

Air multiplication-based condensation adsorption ionization purification cooking fume treatment system

InactiveCN103953956ALow energy consumptionImprove dirty suctionDomestic stoves or rangesLighting and heating apparatusIonizationFlue gas

The invention discloses an air multiplication-based condensation adsorption ionization purification cooking fume treatment system which comprises a case (1) and an exhaust channel, wherein a suction device, a condensation adsorption recovery device and a flue gas ionization purification device are sequentially arranged in the case (1) from the left to right; and the suction device is connected with the condensation adsorption recovery device through an Archimedes spiral channel (6). According to the system, harmless emission of the treated flue gas is realized, the environment is protected, and the system can be applied to household cooking fume treatment.

Owner:WUHAN UNIV OF TECH

Robot cleaner

ActiveUS8667638B2Great suctionIncrease suction pressureCleaning filter meansSuction filtersEngineeringRobot

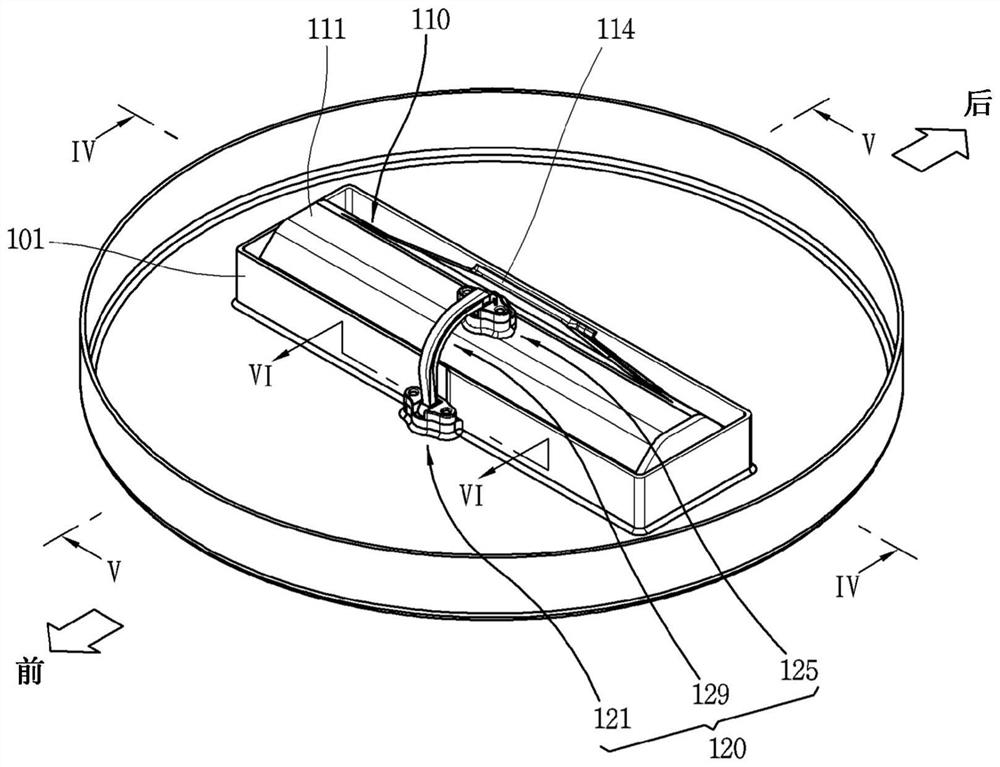

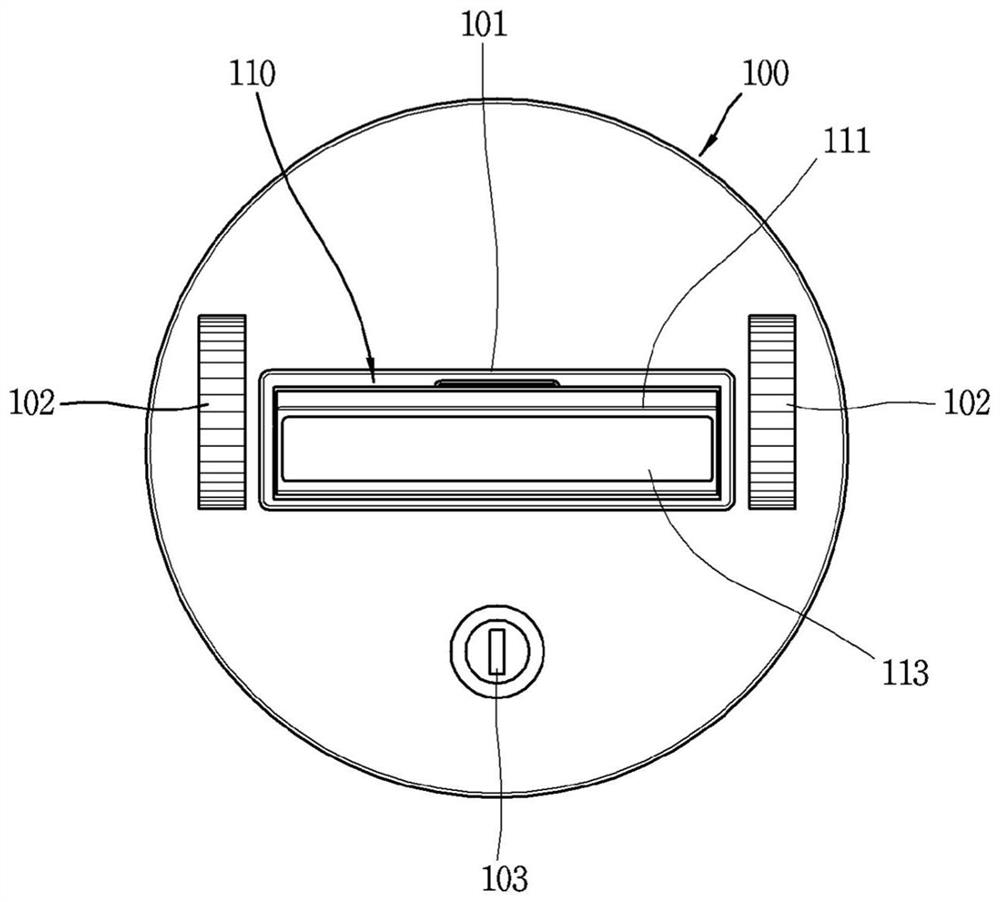

A robot cleaner comprises a main body having a suction port at a bottom surface thereof, a pair of wheel assemblies disposed at both sides of the main body, and configured to move the main body, a dust box mounted to contact the bottom surface of the main body, and configured to collect dust sucked through the suction port, a filter unit configured to filter air discharged from the dust box, a suction fan configured to form a suction pressure on a suction channel defined by the suction port, the dust box and the filter unit, and a battery disposed at a side of the dust box.

Owner:LG ELECTRONICS INC

Electromagnetic Pump with Frequency Converter Circuit

InactiveUS20120082574A1Reduce power consumptionLess overall consumptionMotor/generator/converter stoppersDC motor speed/torque controlFrequency changerBistable circuits

An electromagnetic pump has a frequency converter circuit for driving the electromagnetic pump, wherein the frequency converter circuit comprises an oscillator circuit, a bistable circuit and a push-pull circuit. The oscillator circuit oscillates to transform DC into a single-phase oscillating signal. The bistable circuit splits the single-phase oscillating signal into a N-phase stimulus signal and a S-phase stimulus signal. The push-pull circuit amplifies and transports the N-phase stimulus signal and the S-phase stimulus signal to the electromagnetic pump to make the swing arms of the electromagnetic pump swinging effectively, wherein the swing speed, the swing frequency and the swing amplitude of the swing arms vary with the change of the oscillation frequency of the oscillator circuit. Thereby, the suction pressure and the discharge pressure of the electromagnetic pump could further be adjusted higher or lower, wherein said frequency converter circuit comprises a modulation circuit, which could change the swing speed of the swing arms swinging outwardly or inwardly to further increase or decrease the suction pressure or the discharge pressure.

Owner:CHIOU JACKEY

Production method of BCF nylon 66 medium-low denier yarn and BCF nylon 66 medium-low denier yarn

InactiveCN109518288AEasy to disassembleEasy to cleanArtificial thread manufacturing machinesStretch-spinning methodsBreaking strengthYarn

The invention belongs to the technical field of nylon 66 spinning production, and relates to a production method of a BCF nylon 66 medium-low denier yarn, which comprises the following steps of: a, spinning and cooling; b, firstly oiling tows through an oiling agent nozzle; c, drafting the tows after oiling in step b between a first roller and a second roller; d, feeding the drawn tows in step c into a deforming machine for heating deformation, arranging a suction pipe at the rear part of a deformation nozzle of the deforming machine, wherein the suction pipe is convenient to disassemble and clean, and the suction direction of the suction pipe is perpendicular to the direction of a filament path of the tows; e, cooling and shaping the deformed tows in step d on a cooling drum; f, punchingnetwork points on the tows cooled and shaped in step e; g, sending the tow punched with the network points in the step f into a winding machine to be wound into a bobbin, and winding to obtain the finished yarn. The BCF nylon 66 medium-low denier yarn has a fineness of 400 to 700 dtex, and the BCF nylon 66 medium-low denier yarn is prepared by using the method. The method solves the problems of serious filament, low breaking strength, large elongation and the like of the prior medium-low denier yarn.

Owner:SHEN MA INDUSTRY CO LTD

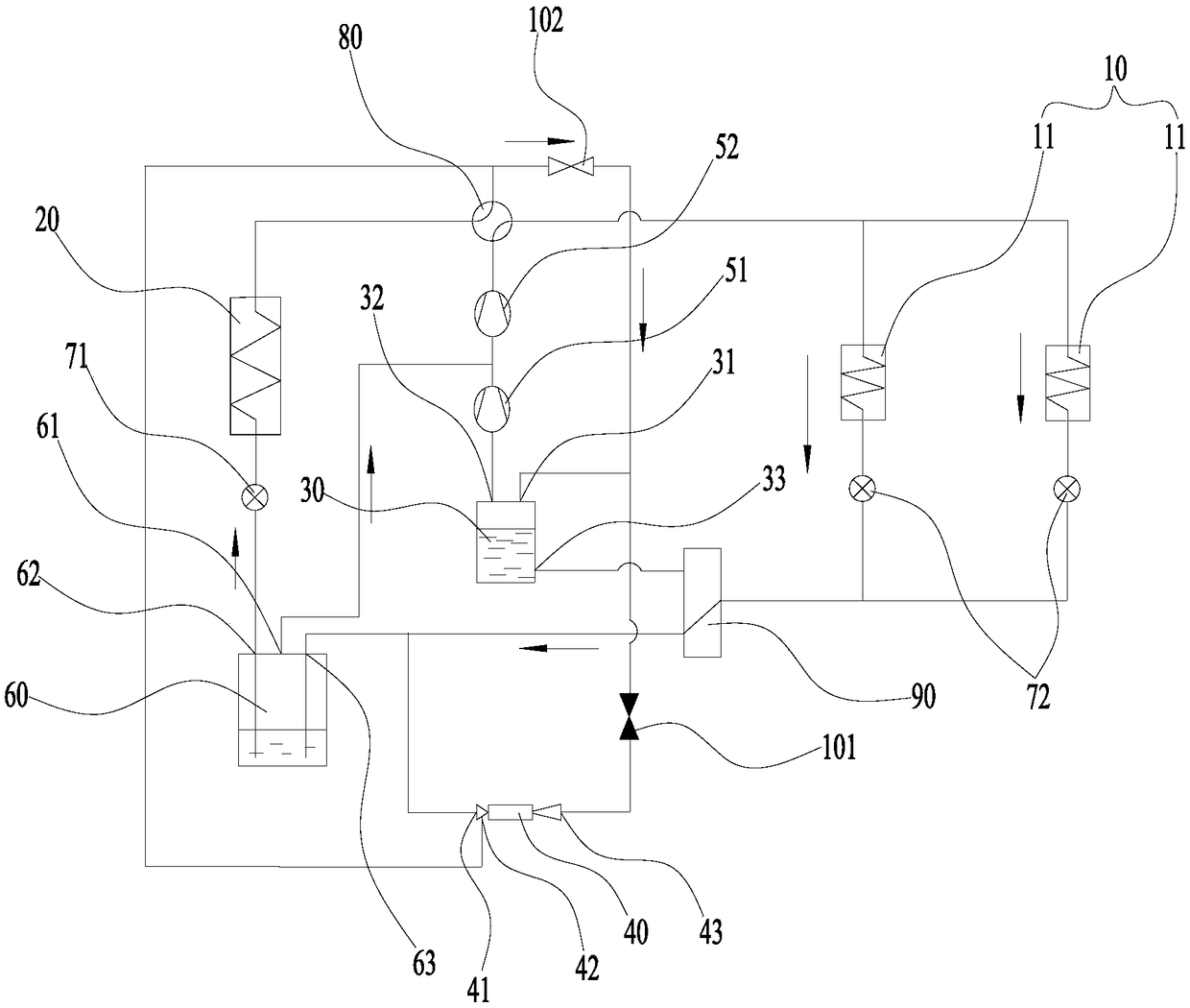

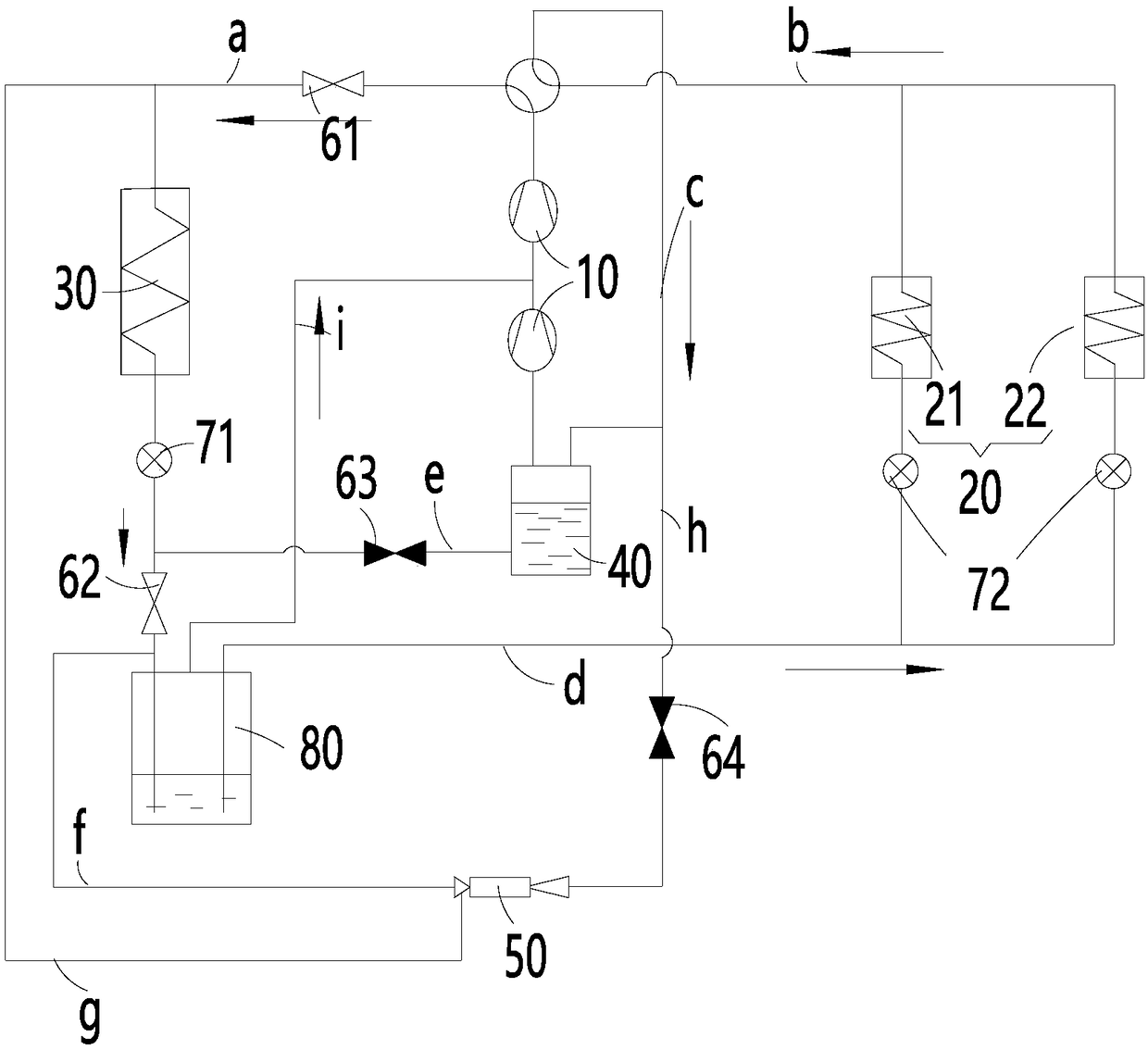

Air conditioner system

PendingCN108800393AIncrease suction pressureIncrease heating capacityMechanical apparatusFluid circulation arrangementVapor–liquid separatorBusiness efficiency

The invention provides an air conditioner system which comprises a compressor, a four-way valve, an indoor heat exchanger, an outdoor heat exchanger, a gas-liquid separator and an ejector. A liquid outlet of the gas-liquid separator is connected with the outdoor heat exchanger through a fifth pipeline, the indoor heat exchanger is connected with a first inlet of the ejector through a sixth pipeline, the outdoor heat exchanger is connected with a second inlet of the ejector through a seventh pipeline, and an outlet of the ejector is connected with an input port of the gas-liquid separator through an eighth pipeline. By the adoption of the technical scheme, during heating, expansion work of a refrigerant is utilized through the ejector, the pressure of the air suction end of a compressor isimproved through the ejector, and the heating capacity and energy efficiency ratio of the air conditioner system in the low-temperature working conditions are improved, so that the requirements of theair conditioner system for the high load and the high pressure ratio are met, and the heating capacity and energy efficiency ratio of the air conditioner system in the low-temperature environment areimproved.

Owner:GREE ELECTRIC APPLIANCES INC

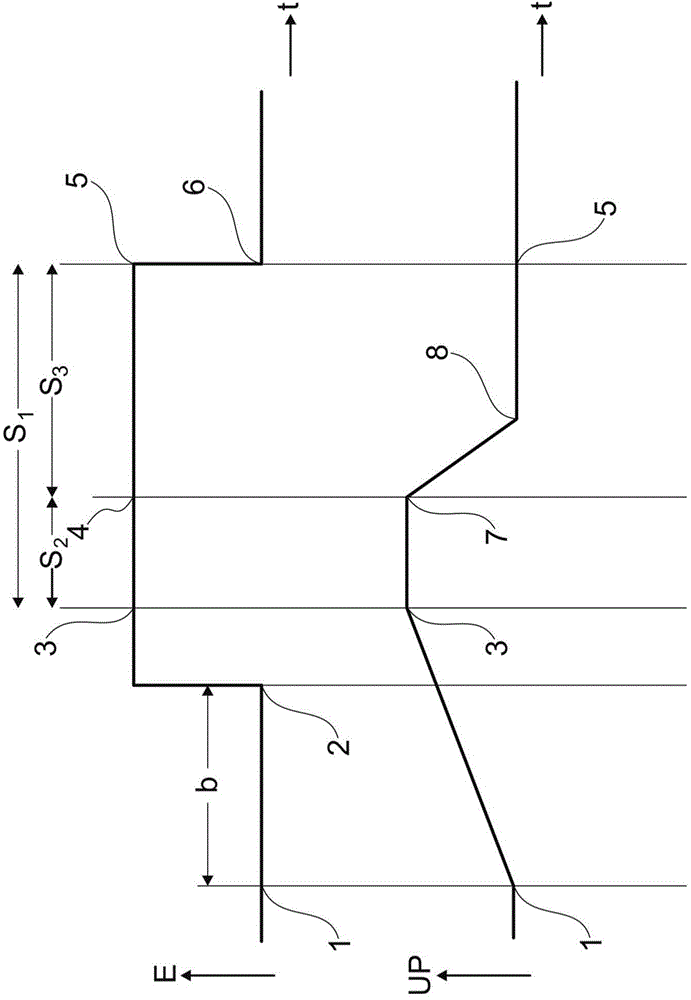

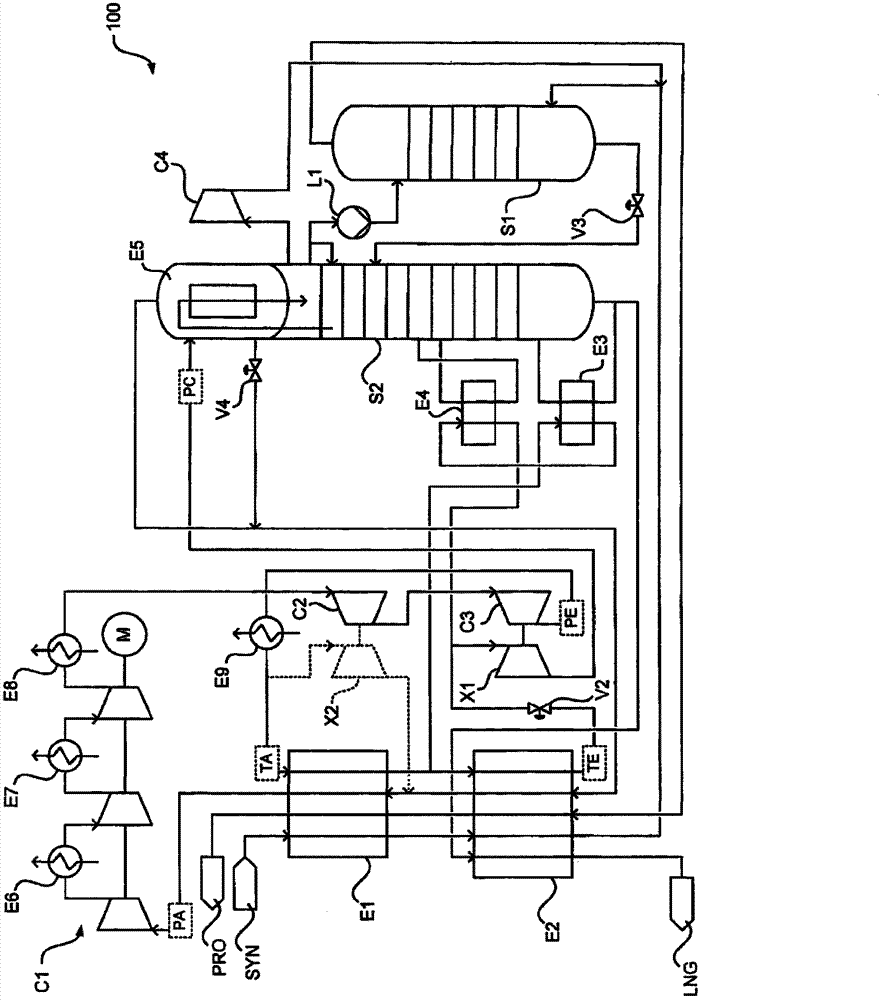

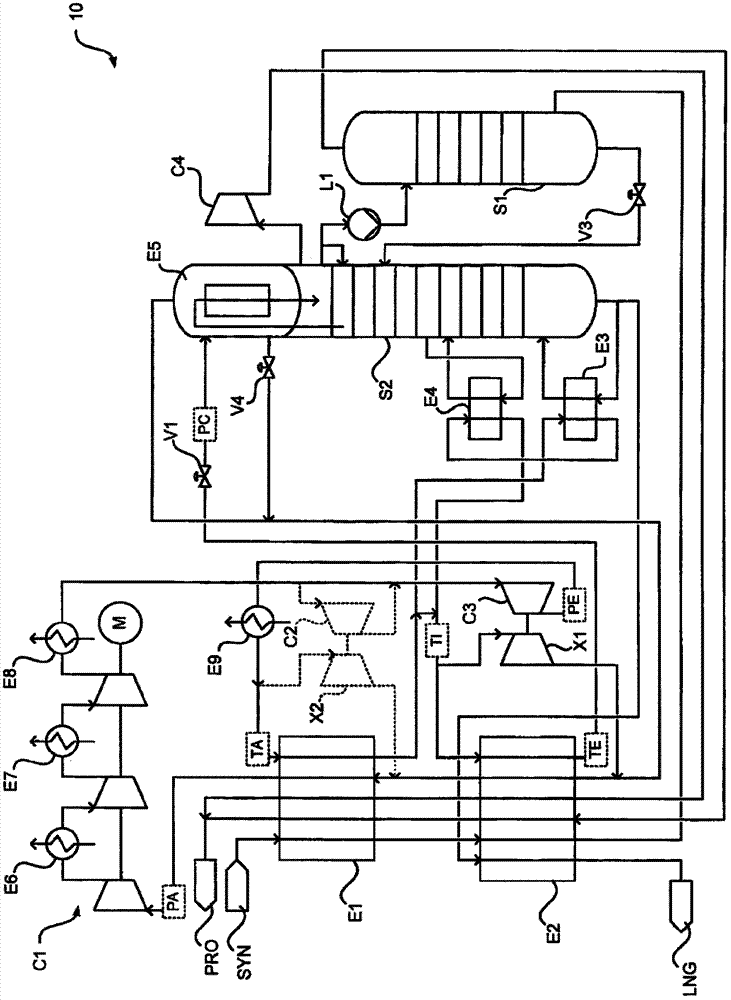

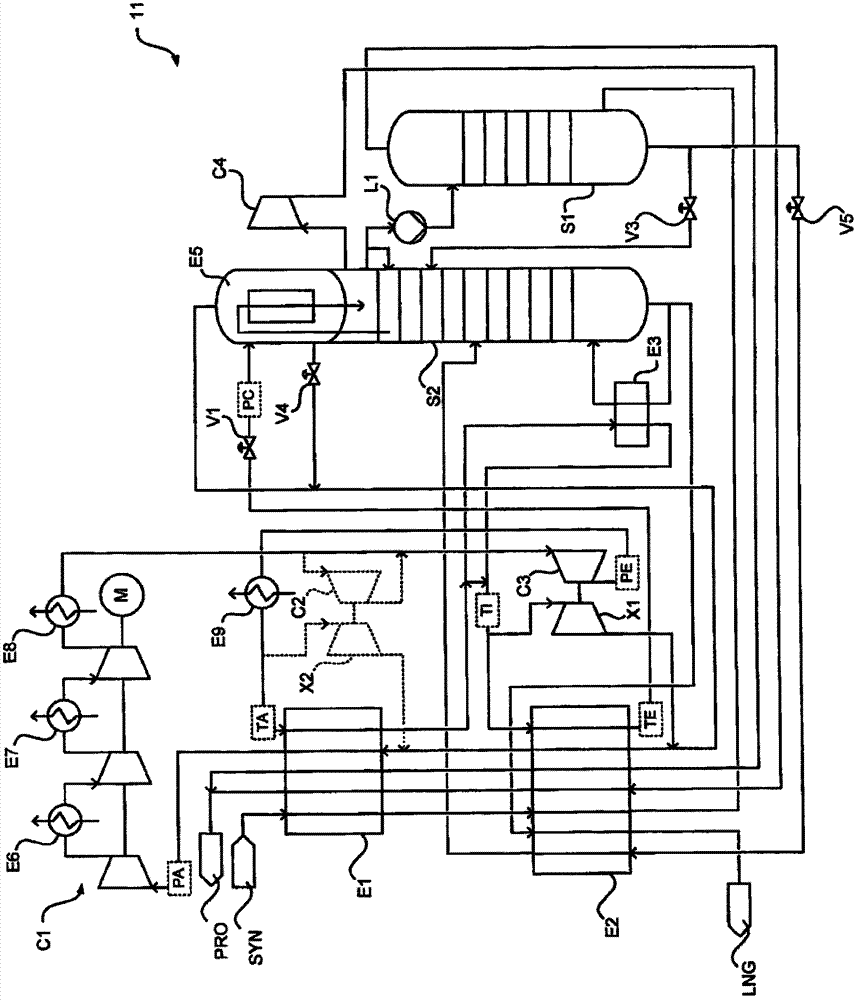

Method and equipment for separating methane from synthesis gas

InactiveCN103776238AImprove separation efficiencyLow costSolidificationLiquefactionEngineeringProcess engineering

The invention proposes a method for separating methane (LNG) from a methane-containing synthesis gas (SYN) in low temperature separation equipment (10). The low temperature separation equipment includes a refrigerant circuit having at least one expander (X1) and at least one separating column (S2) having a condenser (E5), and A portion of compressed and cooled refrigerant from the refrigerant circuit is supplied to the at least one expander (X1) and the condenser (E5) respectively. A primary portion of the refrigerant which is cooled to an intermediate temperature (TI) from a starting temperature (TA) is supplied to the at least one expander (X1). A secondary portion of the refrigerant which is firstly cooled to an intermediate temperature (TI) from a starting temperature (TA) and then cooled to a lower final temperature (TE) is supplied to the condenser (E5). The invention also relates to equipment (10, 11, 12) used for implementing the method according to the invention.

Owner:LINDE AG

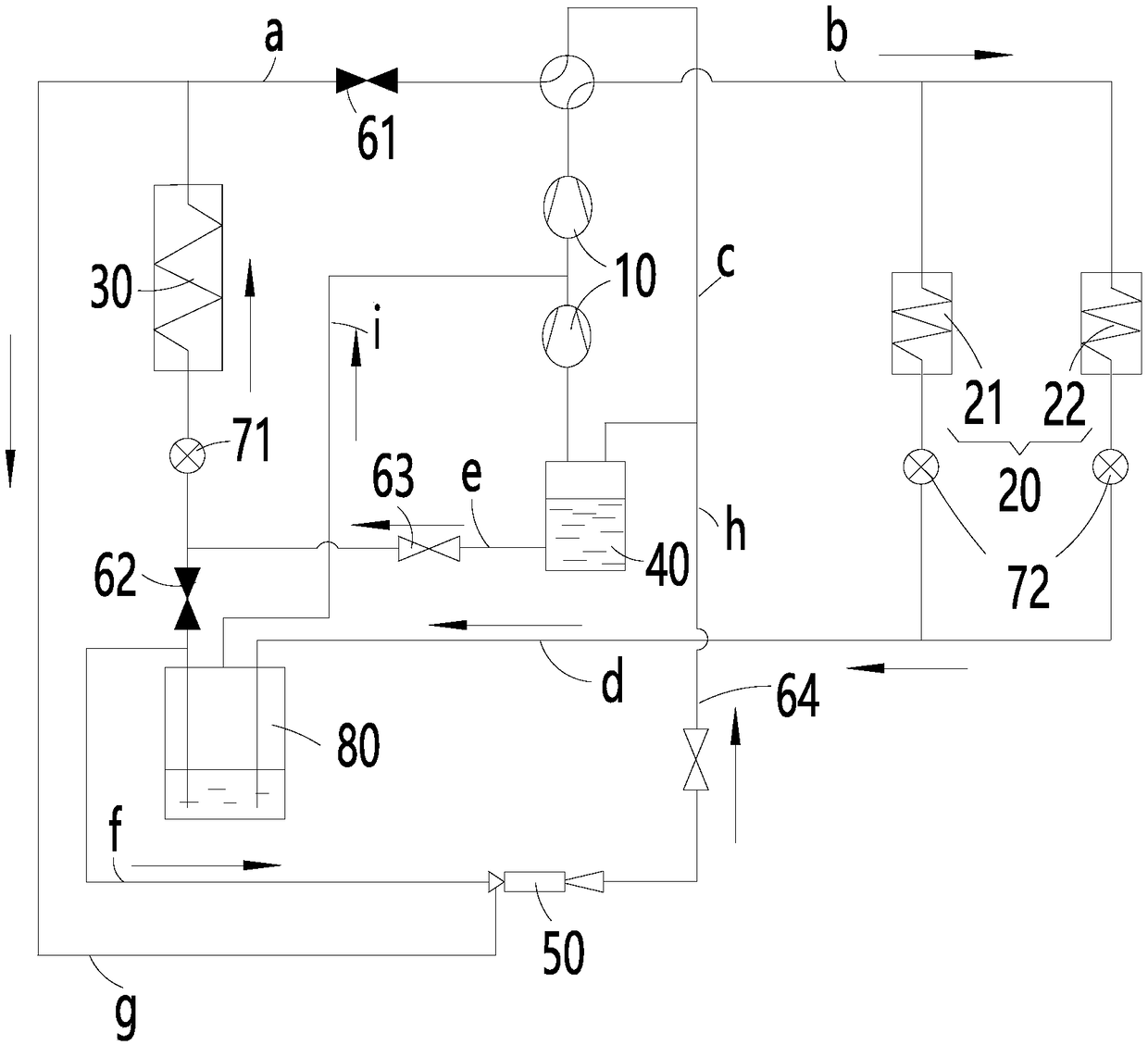

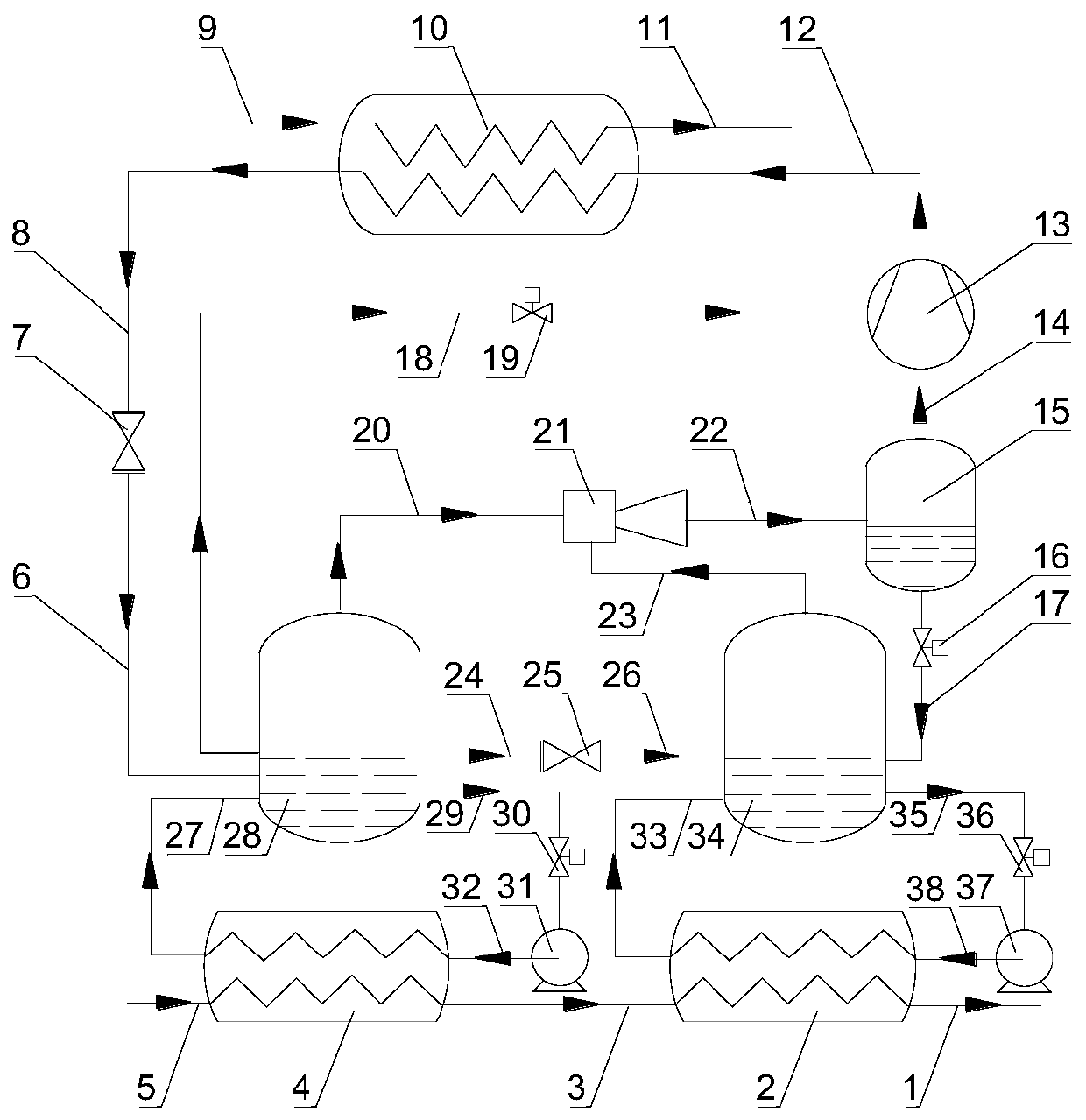

Water working medium injection type heat pump system realizing cascaded recovery of waste heat and working method thereof

ActiveCN110186220AFree from destructionEffective protectionMechanical apparatusHeat pumpsEngineeringHigh pressure water

The invention provides a water working medium injection type heat pump system realizing cascaded recovery of waste heat and a working method thereof. The heat pump system comprises a high-pressure water vapor generation system, a low-pressure water vapor generation system, a water vapor injection system and a water vapor compression heat supply system, wherein the high-pressure water vapor generation system and the low-pressure water vapor generation system are connected through a waste heat connection pipe (3); the high-pressure water vapor generation system and the water vapor injection system are connected through a high-pressure gas storage tank (28); the low-pressure water vapor generation system and the water vapor injection system are connected through a low-pressure gas storage tank (34); the water vapor injection system and the water vapor compression heat supply system are connected through the high-pressure gas storage tank (28) and a medium-pressure gas storage tank (15); and the high-pressure water vapor generation system and the water vapor compression heat supply system are connected through the high-pressure gas storage tank (28).

Owner:上海诺通新能源科技有限公司

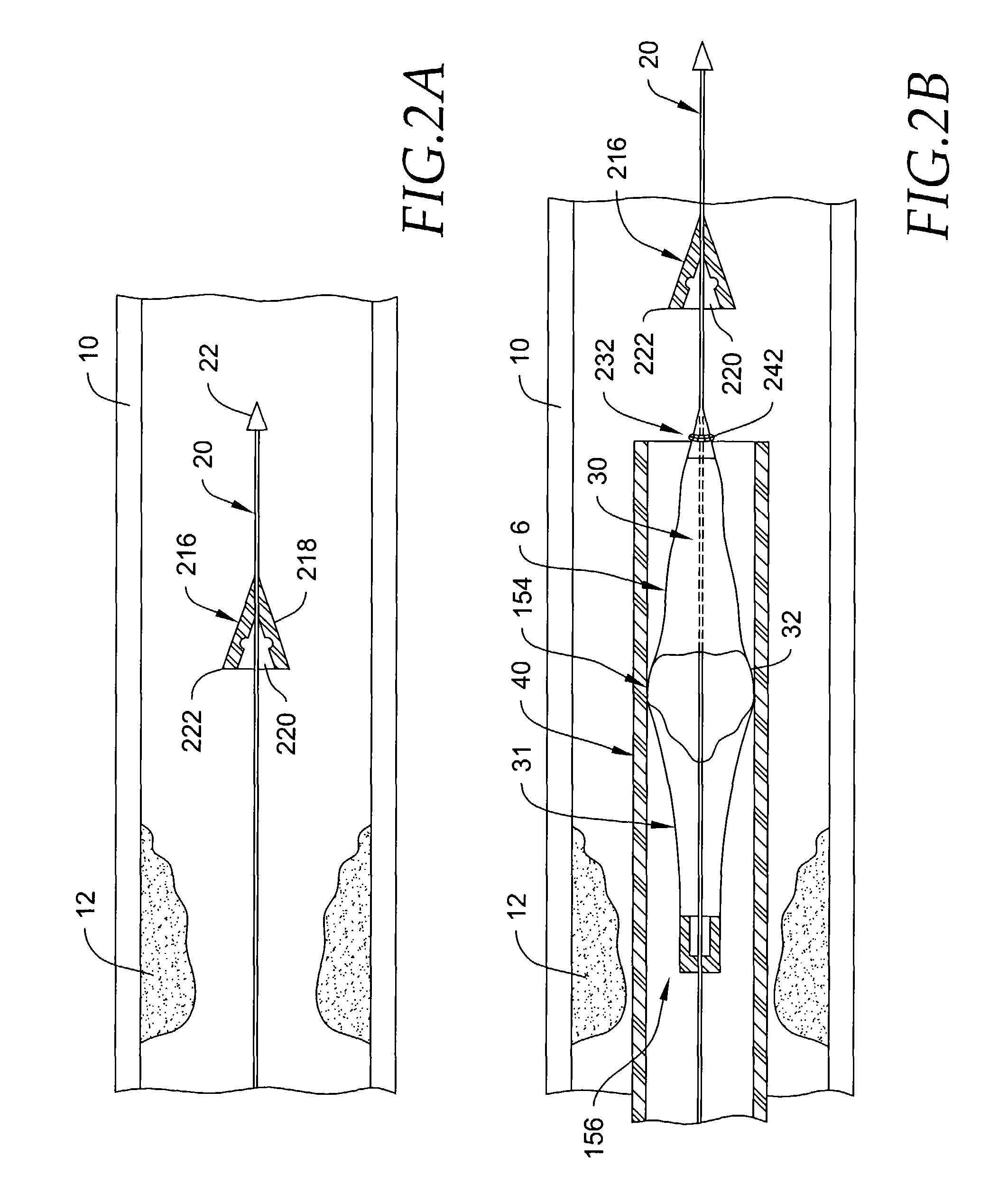

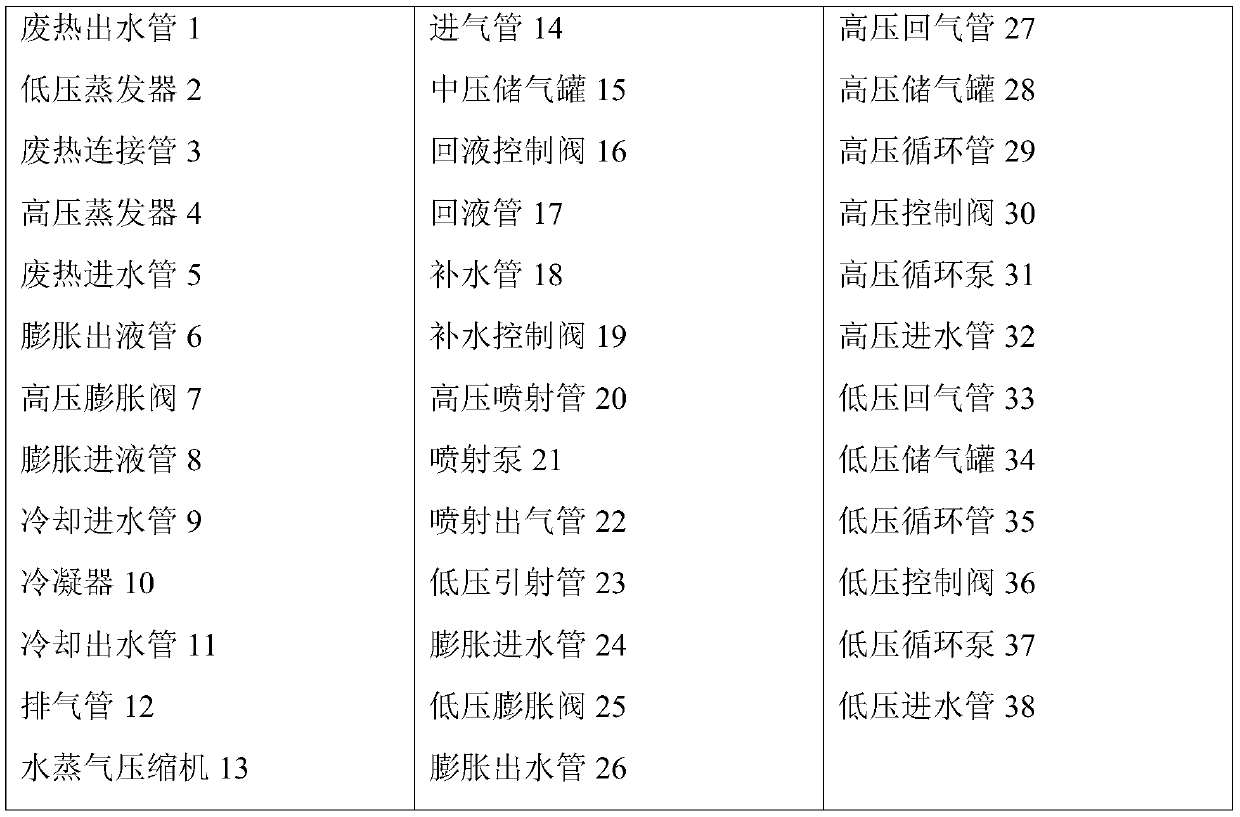

Assembly head comprising a stepped-drive rotating rotor and a pneumatic pressure control device

InactiveCN101128108ACompression ratio has no effectIncrease suction pressureElectrical componentsOvervoltageEngineering

Owner:ASM ASSEMBLY SYST GMBH & CO

Hydraulic power steering system with charging valve and air cushion in the tank

InactiveUS20090095563A1Overcome disadvantagesSuction pressureAccumulator installationsEqualizing valvesAtmospheric airPositive pressure

A hydraulic power steering system which includes a tank and a power steering pump which takes in a pressure medium from an intake area which is decoupled from the prevailing atmospheric pressure on the side of the tank wall and delivers it under pressure to the power steering system. A valve device builds up a pre-pressure in the intake area and prevents a negative pressure and a positive pressure from building up on the interior of the oil tank.

Owner:IXETIC BAD HOMBURG

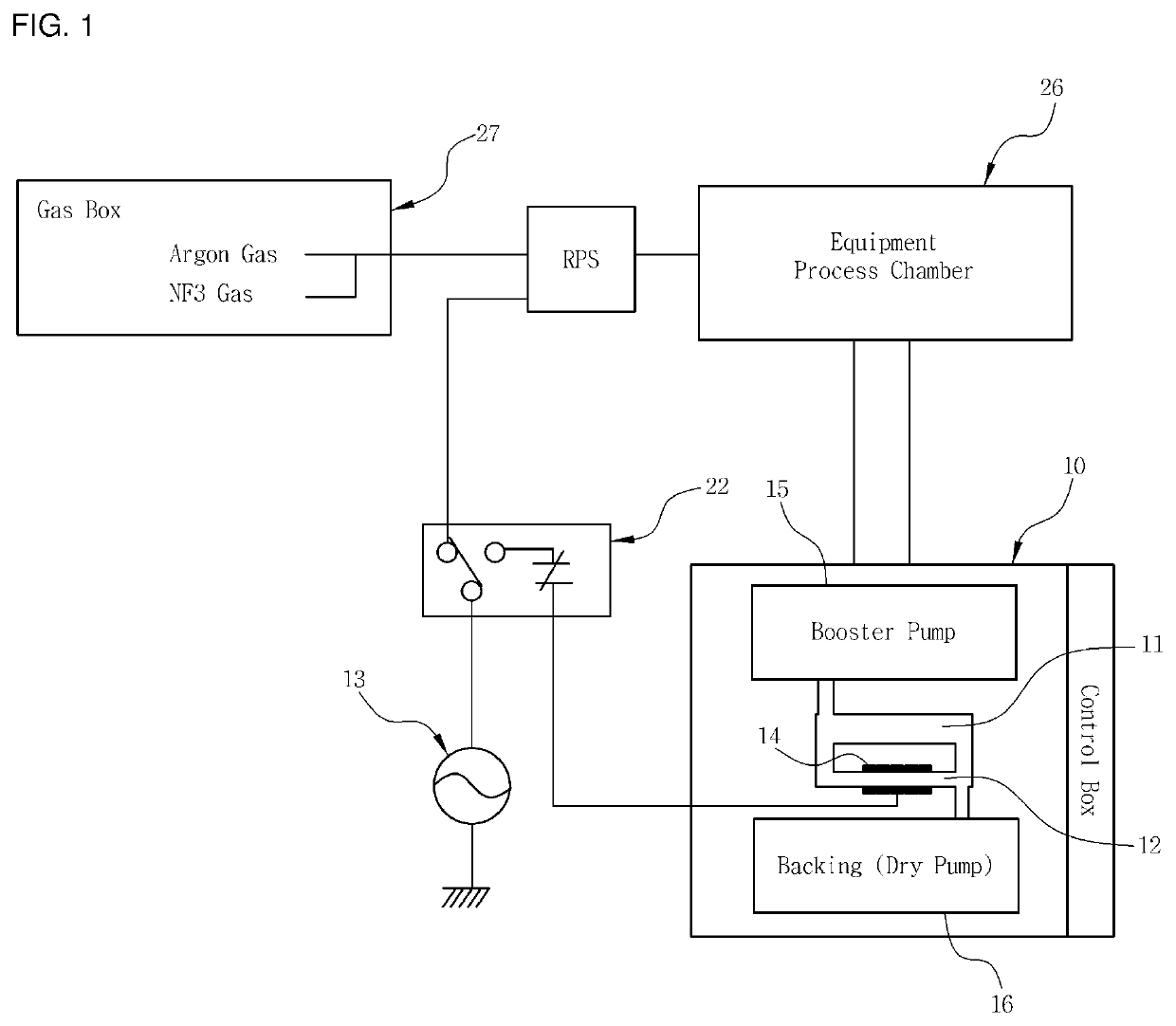

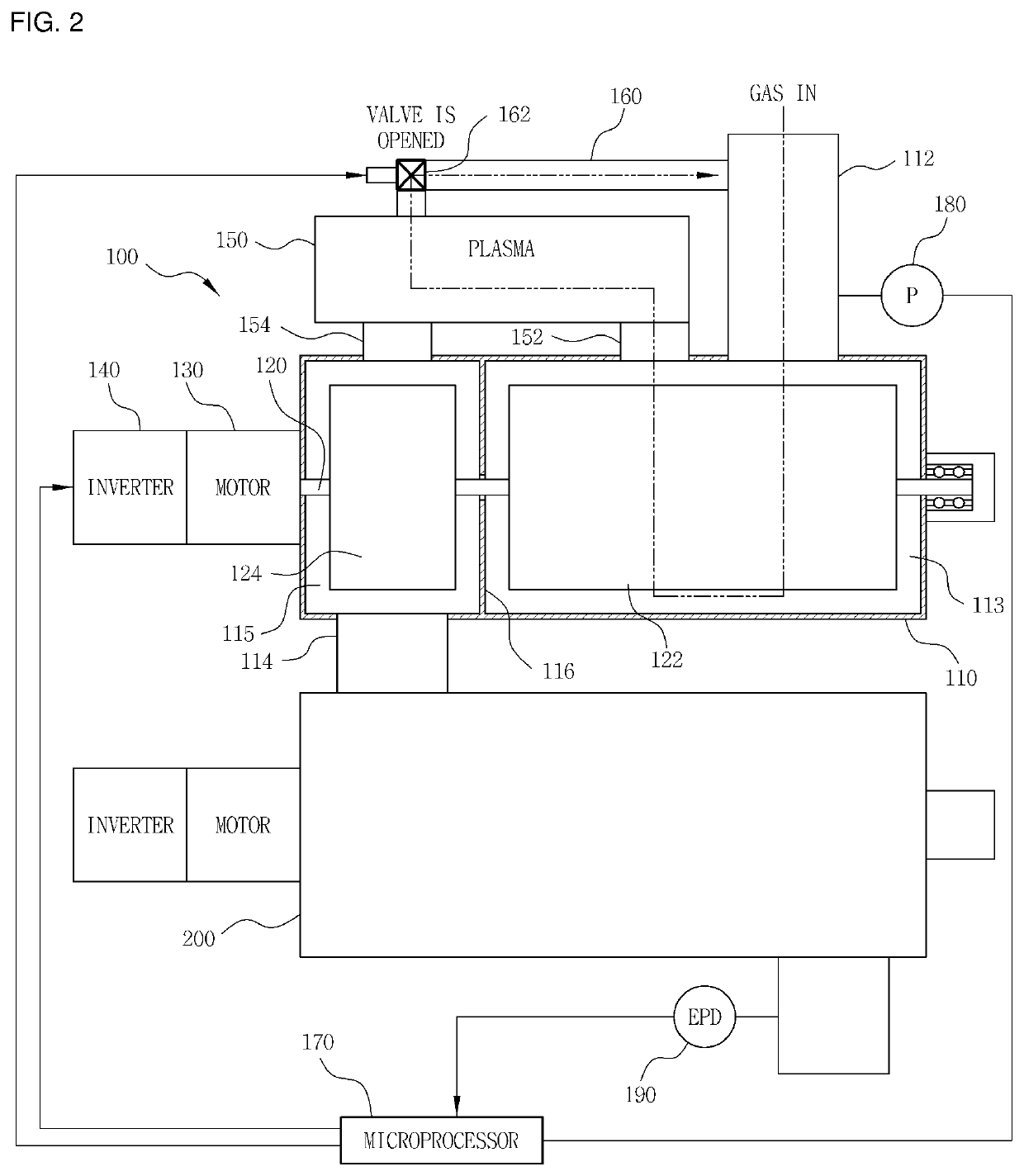

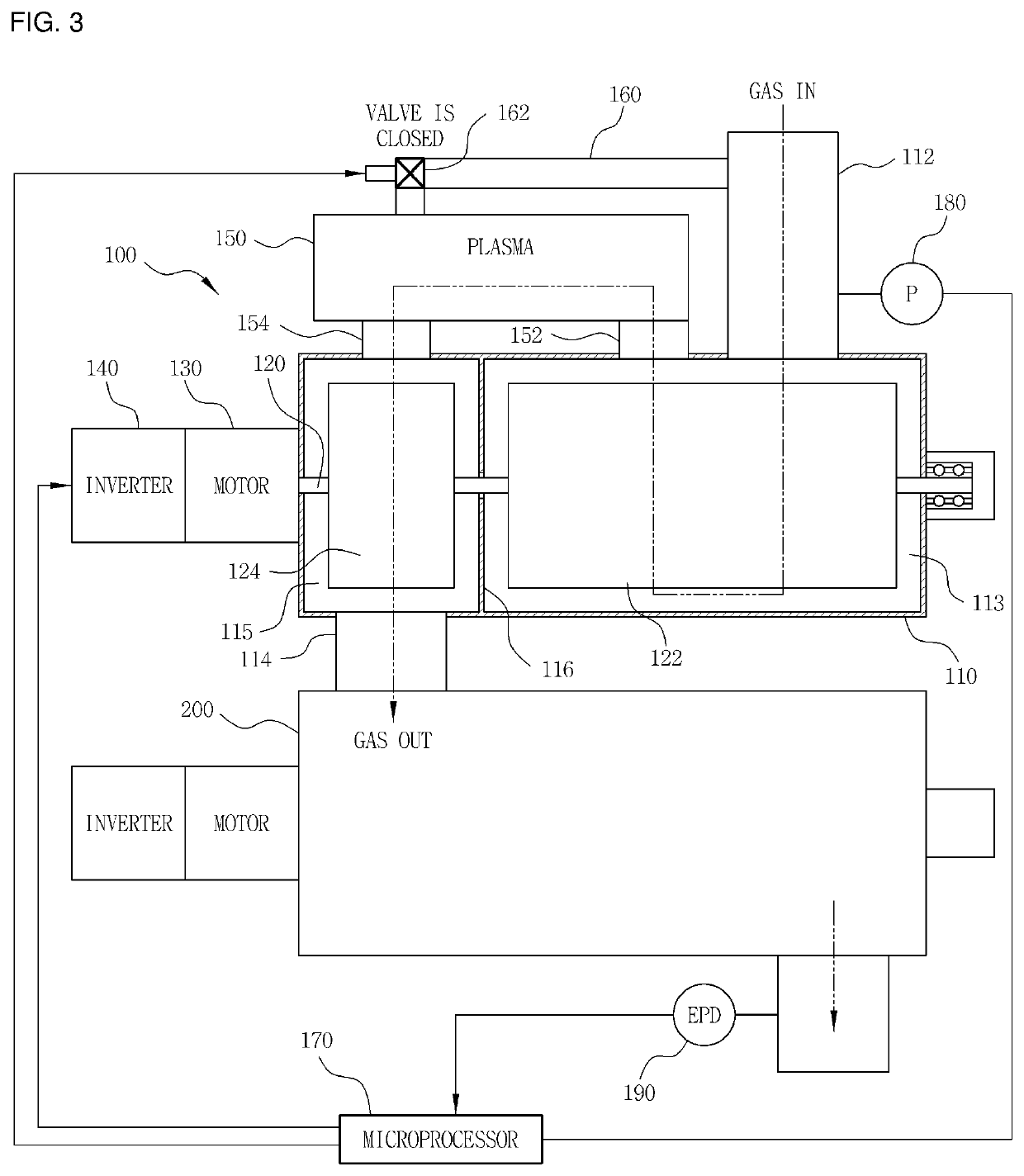

System and method for treating exhaust fluid from semiconductor manufacturing equipment

PendingUS20220097000A1Improve removal efficiencyExtended reaction timeRotary/oscillating piston combinations for elastic fluidsPump componentsThermodynamicsElectric machine

Disclosed is a system for treating exhaust fluid from semiconductor manufacturing equipment in which cleaning gases decomposed by a plastic apparatus alternately flow towards a front rotor region (a main rotor unit) and a rear rotor region (a subsidiary rotor unit) of a booster pump and then flow towards a dry pump, and thus uniformly react with process byproducts present throughout the whole area in a vacuum pump including the booster pump and the dry pump so as to improve removal efficiency of the process byproducts. Further, the retention time of the cleaning gases decomposed by the plasma apparatus in the vacuum pump is increased by adjusting the pressure in the pump with the rotational speed of a motor, and thus the reaction time of the cleaning gases with the process byproducts is increased, so as to further improve removal efficiency of the process byproducts, such as SiO2 powder.

Owner:PLAN

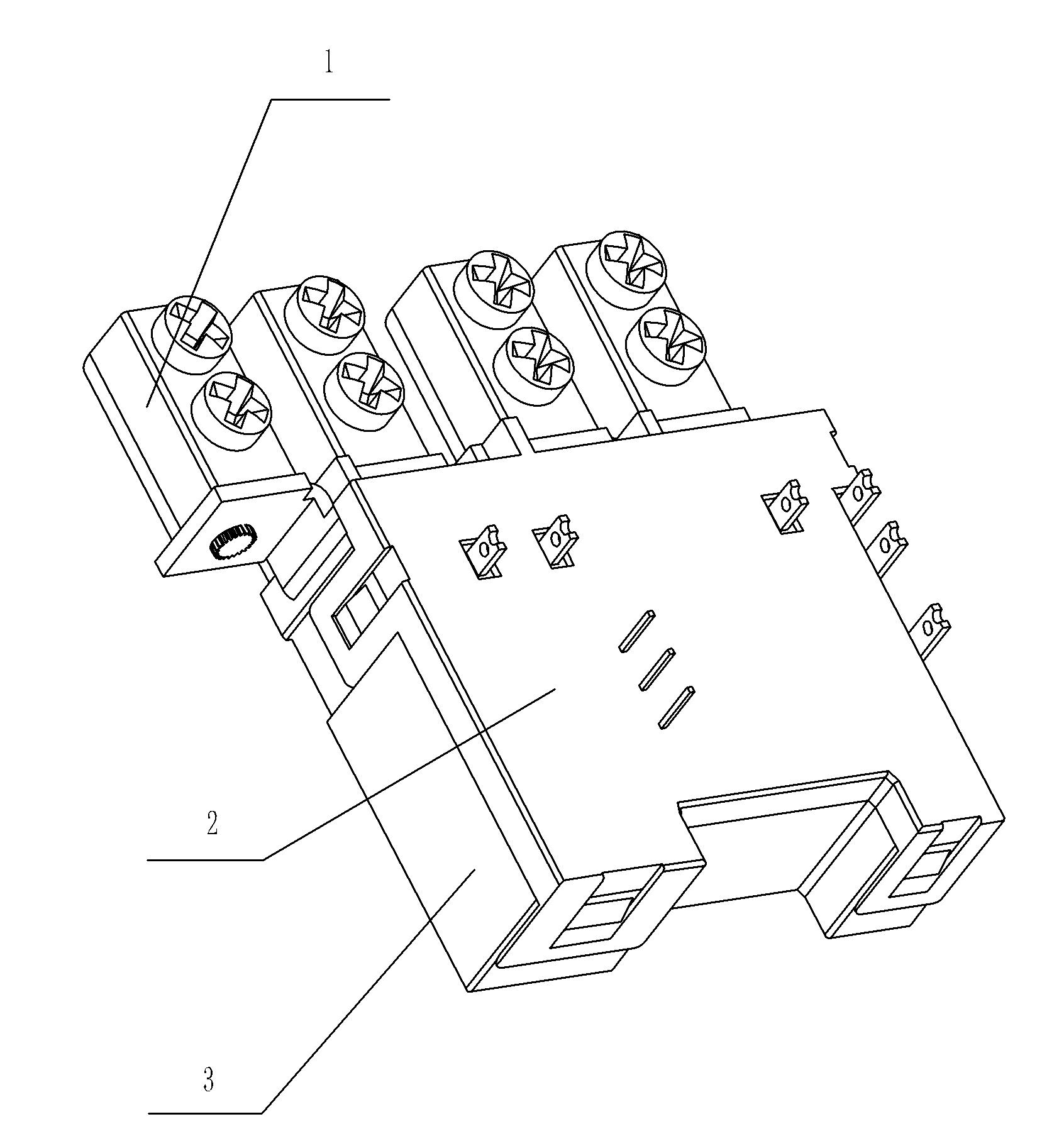

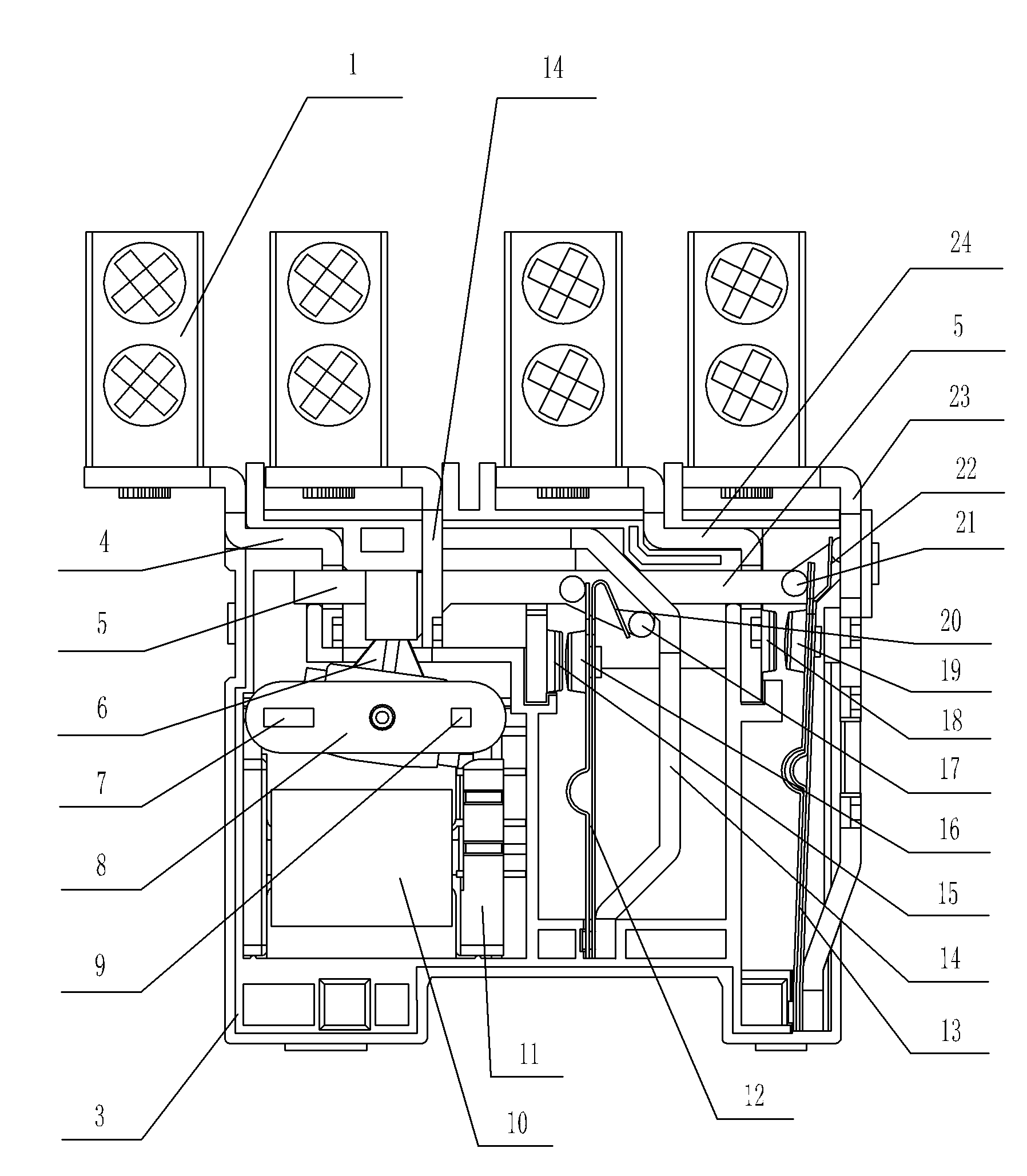

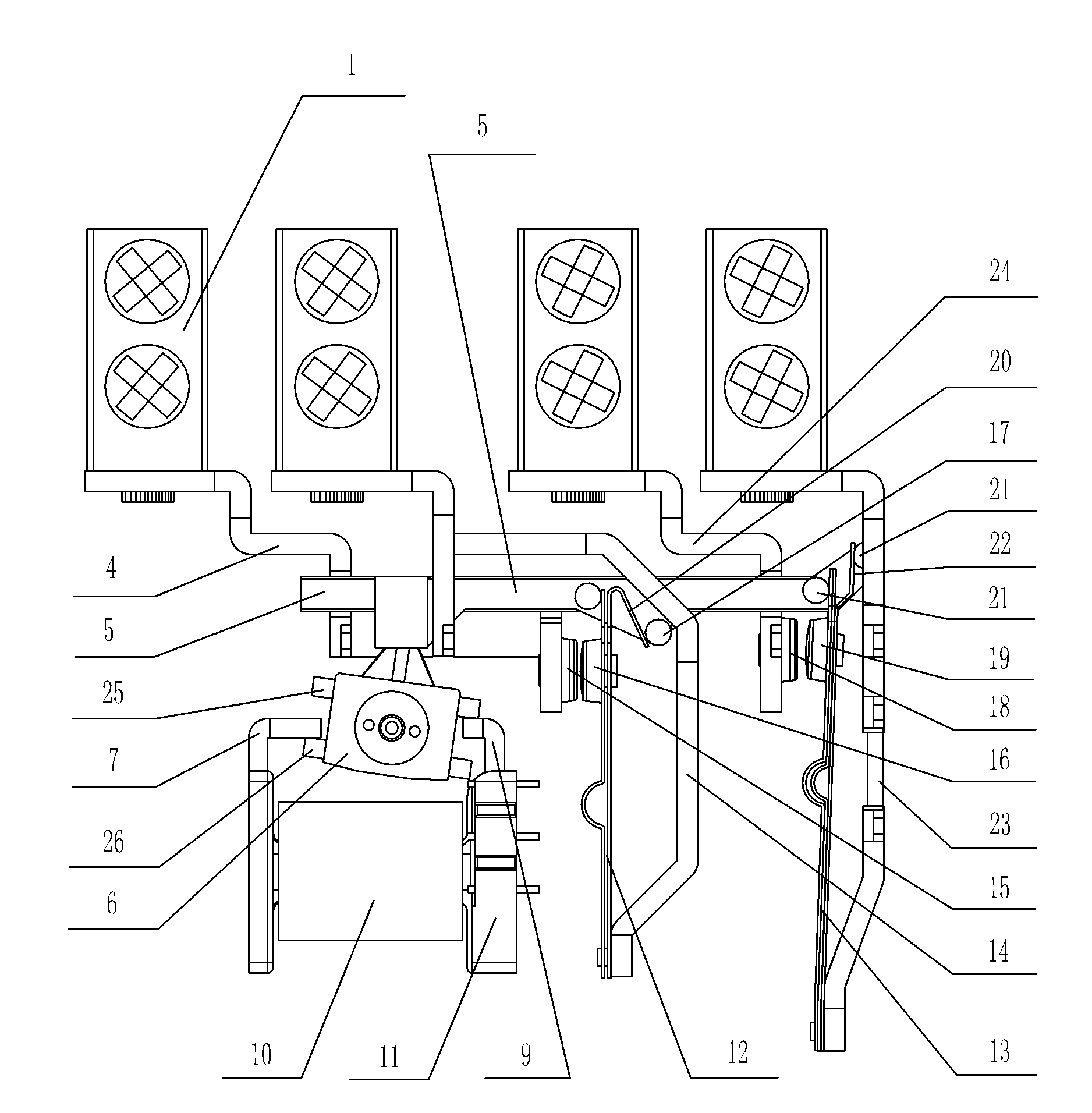

Relay

InactiveCN101834095AReduce power-on timeLow calorific valueElectromagnetic relay detailsEngineeringMechanical engineering

The invention discloses a relay, comprising a base, a rear cover, a movable contact spring I, a movable contact spring II, a framework, a coil connected on the framework, a static contact spring I, a movable leading-out spring I, a static contact spring II and a movable leading-out spring II, wherein the static contact spring I, the movable leading-out spring I, the static contact spring II and the movable leading-out spring II are sequentially connected on the base from left to right; the base is connected with the rear cover, the static contact spring I is connected with a static contact I, the lower part of the movable contact spring I is connected with the movable leading-out spring I, the upper part of the movable contact spring I is connected with a movable contact I capable of being sucked on the static contact I, the static contact spring II is connected with a static contact II, the lower part of the movable contact spring II is connected with the movable leading-out spring II, the upper part of the movable contact spring II is connected with a movable contact II capable of being sucked on the static contact II, the polarity of the coil can be changed, the framework is positioned at the left of the movable contact spring I, and a retention mechanism, which can retain the movable contact spring I and the movable contact spring II in the state that the coil is power on after the coil is power off, is arranged between the framework and the movable contact spring I as well as the movable contact spring II. The invention can save electric energy and prolong the service life of the coil.

Owner:NINGBO TIANBO GANGLIAN ELECTRONICS

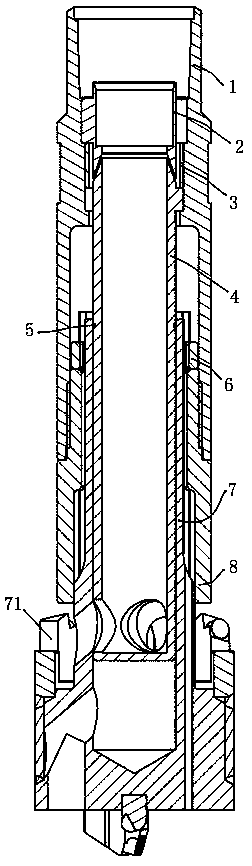

Bidirectional reverse circulation continuous deslagging drilling tool

InactiveCN111577163AIncrease suction pressureReduce pressure lossDrill bitsDrilling rodsSlagClassical mechanics

The invention discloses a bidirectional reverse circulation continuous deslagging drilling tool. The bidirectional reverse circulation continuous deslagging drilling tool comprises an outer pipe (1),wherein a suction core pipe (4) is arranged in the outer pipe (1); a radial lug on the upper portion of the suction core pipe (4) and the bottom of a positioning ring (3) are clamped and pressed abovea necking step on the inner wall of the outer pipe; a supporting lug seat of an injection ring (2) is pressed on the top surface of the positioning ring (3); a spline connecting sleeve (8) is in threaded connection with the inner wall of the lower portion of the outer pipe (1); a bidirectional reverse circulation drill bit body (7) is in sliding connection with the spline connecting sleeve (8) through a spline; the lower section of the suction core pipe (4) is inserted into a core hole of the bidirectional reverse circulation drill bit body (7); and a sealing ring (5) is embedded between theouter wall of the suction core pipe (4) and the inner wall of the core hole of the bidirectional reverse circulation drill bit body (7). The bidirectional reverse circulation continuous deslagging drilling tool has the technical effects that the deslagging capability and the deslagging stability of reverse circulation hole forming are improved, during drill withdrawing, a hole wall is trimmed, collapsed coal slag is also discharged, and drilling accidents such as drill locking and hole spraying caused by accumulation of a large amount of coal slag in a drill hole of a soft coal seam are avoided.

Owner:CHONGQING UNIV

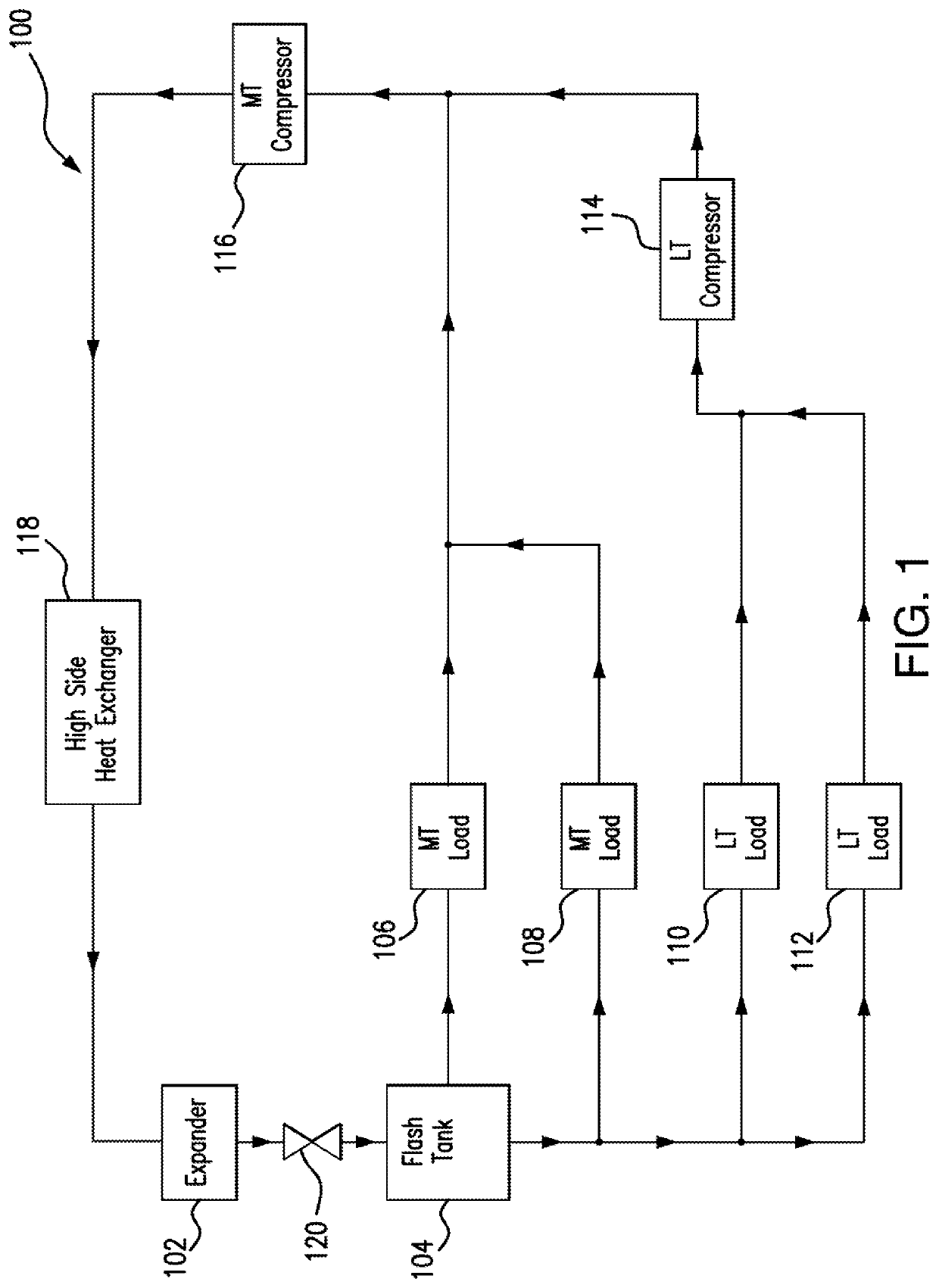

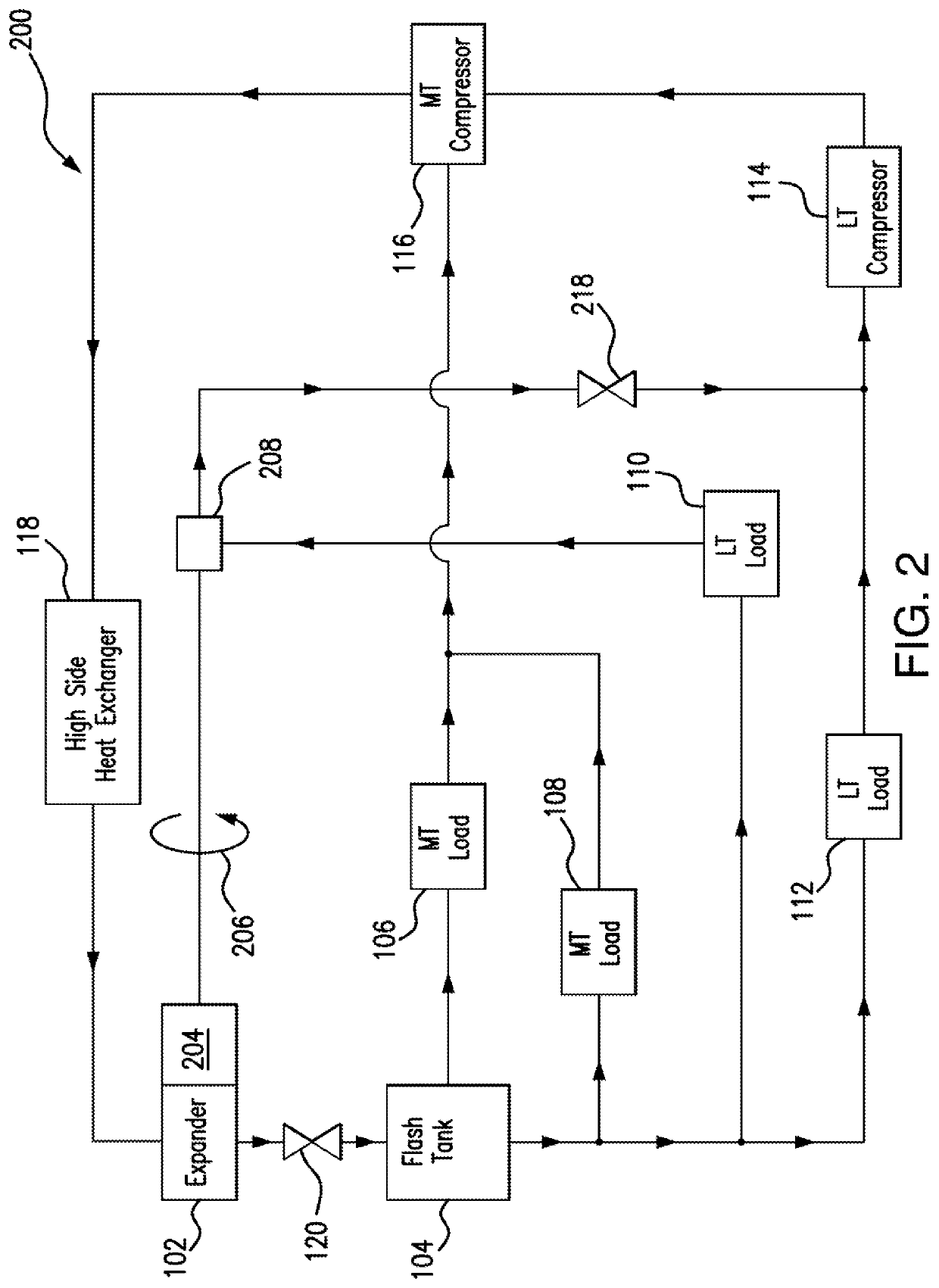

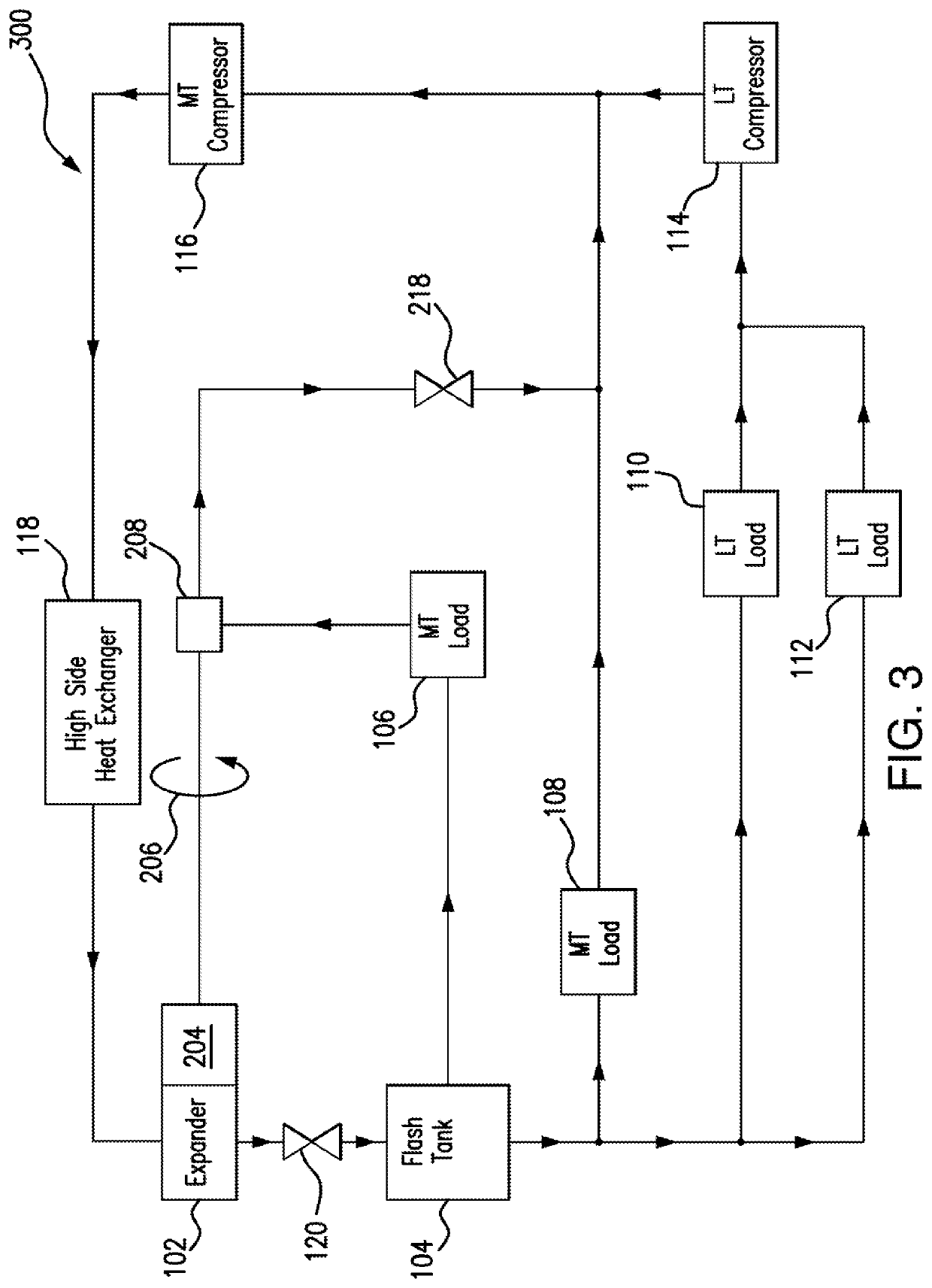

Cooling System

ActiveUS20200217562A1Concentrated heatingIncrease suction pressureCompressorMechanical apparatusRefrigerantVALVE PORT

An apparatus includes a first expander, a flash tank, a first load, a first work recovery compressor, a valve, and a first compressor. The first expander expands a refrigerant. The flash tank stores a refrigerant from the expander. The first load uses the refrigerant from the flash tank to cool a space proximate the first load. The work recovery compressor compresses the refrigerant from the first load and is driven by the first expander. The valve reduces the pressure of the refrigerant from the work recovery compressor below a threshold. The first compressor compresses the refrigerant from the valve.

Owner:HEATCRAFT REFRIGERATION PRODS

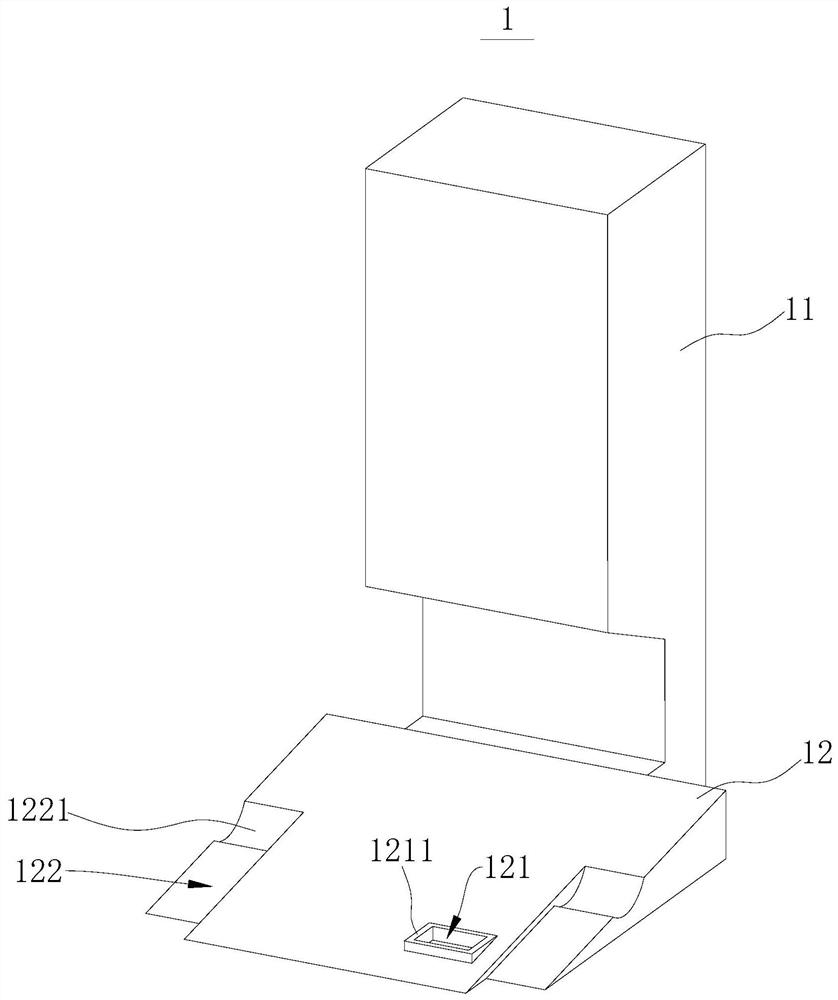

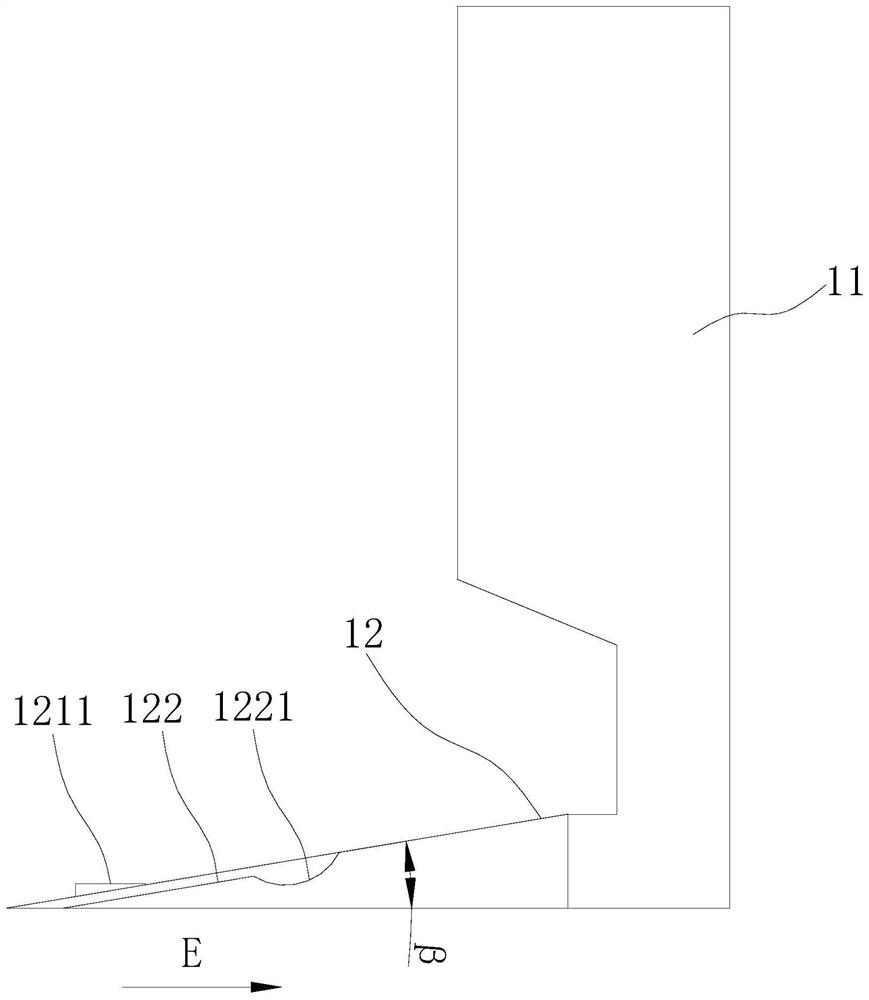

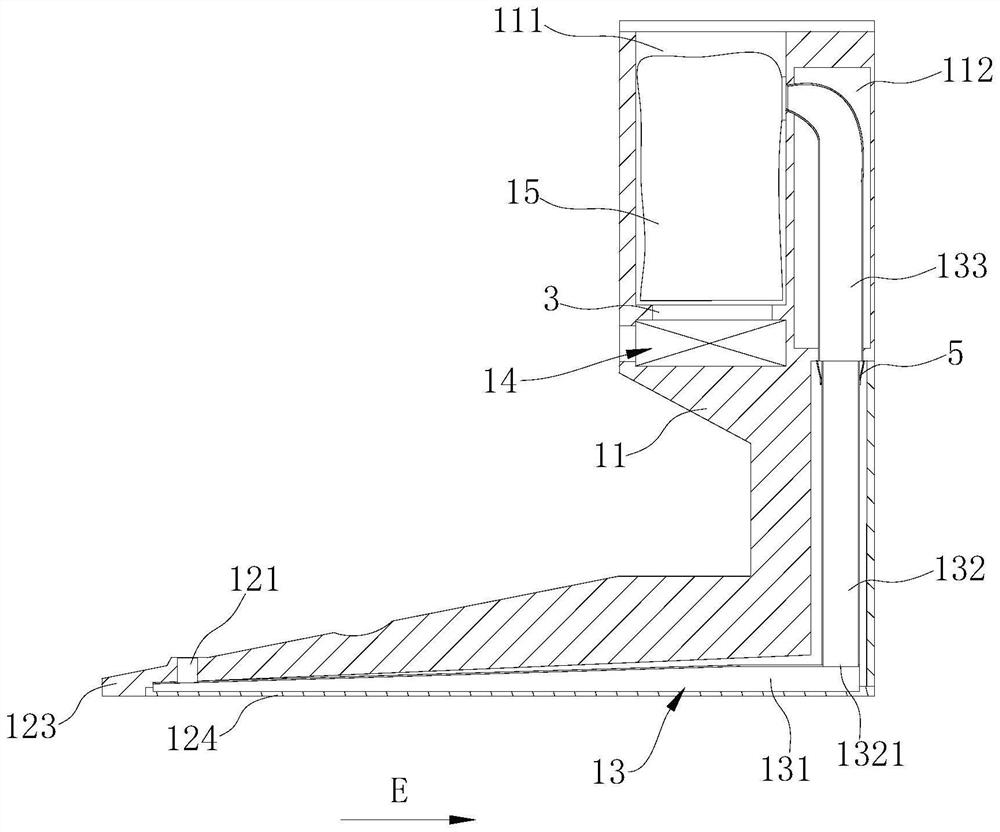

Sweeping machine dirt collecting base station

InactiveCN114271735AImprove emptying efficiencyRealize positioning docking connectionMachine detailsFloor sweeping machinesMechanical engineeringIndustrial engineering

The invention discloses a dirt collection base station of a sweeping machine, and relates to the technical field of sweeping machines, the dirt collection base station comprises a main body, a bearing platform, a suction pipeline and a negative pressure suction assembly, the bearing platform is arranged below the main body and forms an inclination angle with the horizontal plane, and the height of the surface of the bearing platform is gradually increased in the direction close to the main body; a suction inlet and a positioning track are arranged on the bearing platform; one end of the suction pipeline is communicated with the suction inlet, the other end of the suction pipeline is communicated with the inner cavity of the main body, the suction pipeline is arranged in the bearing platform, and the longitudinal section height of the flow cavity of at least one part of the suction pipeline is gradually increased in the direction close to the main body. The dirt collection base station of the sweeping machine has the advantages of being compact in structure, high in positioning efficiency of the mobile sweeping machine, high in emptying efficiency, reasonable in structural design and convenient and fast to assemble.

Owner:上海禅睿实业有限公司

Device for sealing and evacuating a container containing a paste-like liquid

ActiveCN110494680AAvoid enteringAvoid lostEngine sealsPositive displacement pump componentsEngineeringVacuum pump

Owner:乌多塔勒

Robotic vacuum cleaner

ActiveCN114727733AImprove driving abilityIncrease suction pressureAutomatic obstacle detectionTravelling automatic controlEngineeringMechanical engineering

A robotic vacuum cleaner includes: an autonomously moving vacuum cleaner body; a suction nozzle mounted so as to be able to ascend / descend or swing relative to the vacuum cleaner body; and a support member for supporting the suction nozzle so that the suction nozzle can ascend / descend or swing. Accordingly, driving performance is improved due to easy handling of a changing floor height, and an operation capable of assisting a vacuum cleaner in climbing across an obstacle may be achieved. In addition, even when the floor height changes greatly, the cleaning performance can be improved by maintaining the surface pressure of the suction nozzle and increasing the suction pressure.

Owner:LG ELECTRONICS INC

Hydraulic power steering system with charging valve and air cushion in the tank

InactiveUS8657590B2Suction pressureIncrease suction pressureAccumulator installationsEqualizing valvesAtmospheric airPositive pressure

A hydraulic power steering system which includes a tank and a power steering pump which takes in a pressure medium from an intake area which is decoupled from the prevailing atmospheric pressure on the side of the tank wall and delivers it under pressure to the power steering system. A valve device builds up a pre-pressure in the intake area and prevents a negative pressure and a positive pressure from building up on the interior of the oil tank.

Owner:IXETIC BAD HOMBURG

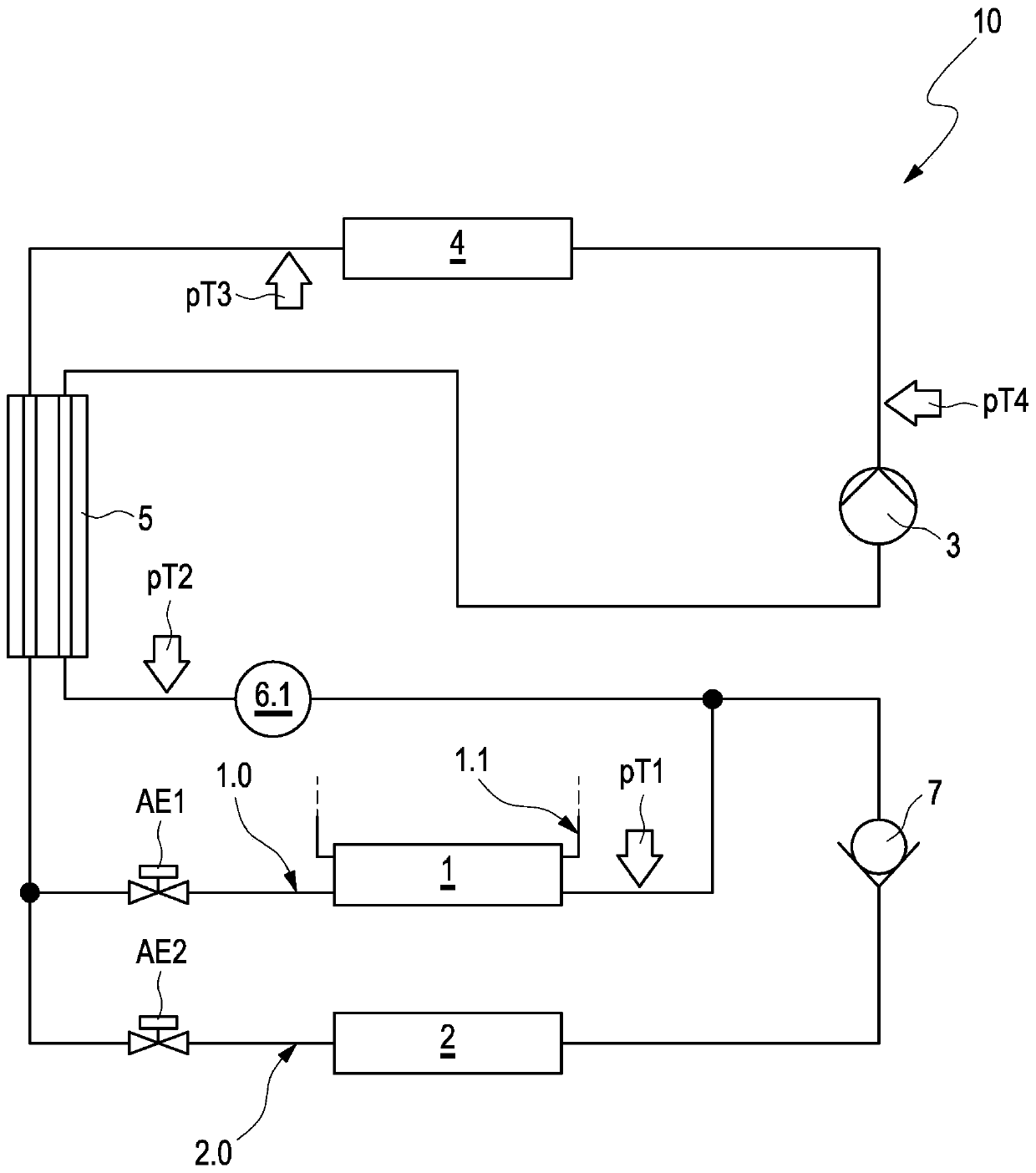

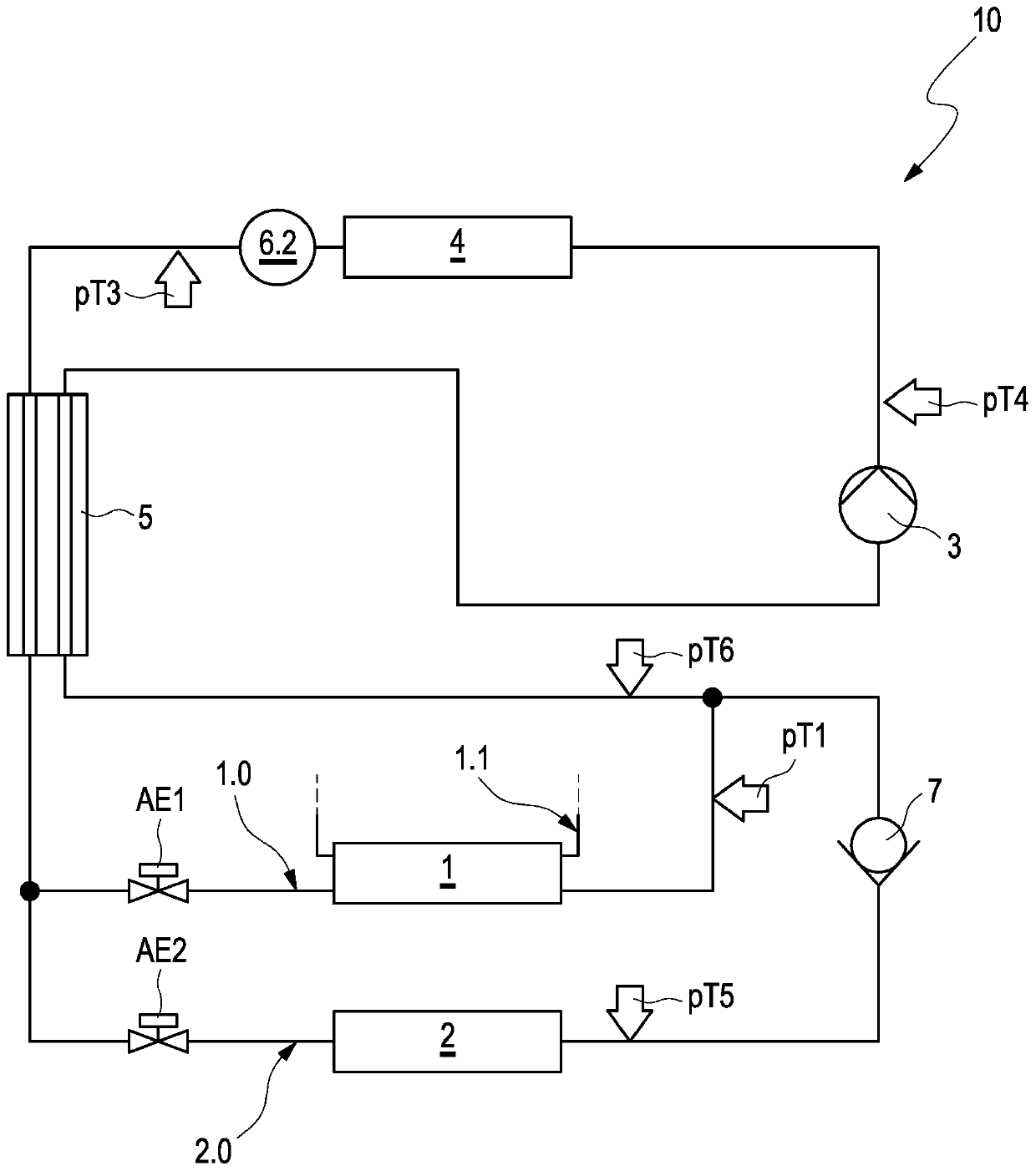

Method for operating a refrigerant circuit of a cooling system of a vehicle

ActiveCN111520937AIncrease suction pressureMechanical apparatusCompression machines with several evaporatorsChillerRefrigeration plant

A method of operating a refrigerant circuit (10) of a cooling system of a vehicle in cooling system mode is disclosed, the refrigerant circuit having a chiller branch (1.0) which includes a chiller (1) and a first expansion element (AE1) connected upstream from it and being thermally coupled to a coolant circuit (1.1); at least one interior evaporator branch (2.0) connected in parallel with the chiller branch (1.0), comprising an interior evaporator (2), a second expansion element (AE2) connected upstream from it, and a segmentation element connected downstream from the interior evaporator (2), being adapted to prevent a backflow of refrigerant into the interior evaporator; a refrigerant compressor (3); and a condenser or gas cooler (4), wherein the cooling system mode is carried out in single chiller mode by closing the second expansion element (AE2) and aspirating the refrigerant from the interior evaporator by the starting or already started refrigerant compressor (3).

Owner:AUDI AG

Integrated dust removal and desulfurization tower

An integrated dust removal and desulfurization tower is provided. The vertical lower part of the absorption tower body is a cyclone dust collector, and the upper end is equipped with double desulfurization and dust reduction devices; the double desulfurization and dust reduction devices include intestinal flue gas drainage, desulfurization channels and spray racks Among them, the lower end of the intestinal flue gas drainage and desulfurization channel is connected to the cyclone dust collector, the upper gas outlet port extends into the absorption tower body, and the horizontal section is provided with a vertical flue gas recirculation and dust reduction channel connected to the flue dust inlet; above the gas outlet port Equipped with an umbrella-shaped flue gas diffuser and a nozzle; connected to the nozzle, a funnel-shaped flue gas dispersion grid is installed to disperse the air flow in the absorption tower cylinder and to recover the desulfurizer sprayed by the spray rack. The dust reduction and desulfurization vertical integration design of the present invention occupies a small space, has a compact structure, consumes less desulfurization liquid, has high desulfurization efficiency, and has superior comprehensive performance.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com