Method for operating a refrigerant circuit of a cooling system of a vehicle

A refrigerant circuit and refrigeration equipment technology, applied in heating/cooling equipment, refrigerators, refrigeration components, etc., can solve problems such as regulating supercooling, refrigerant escape, and high density of refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

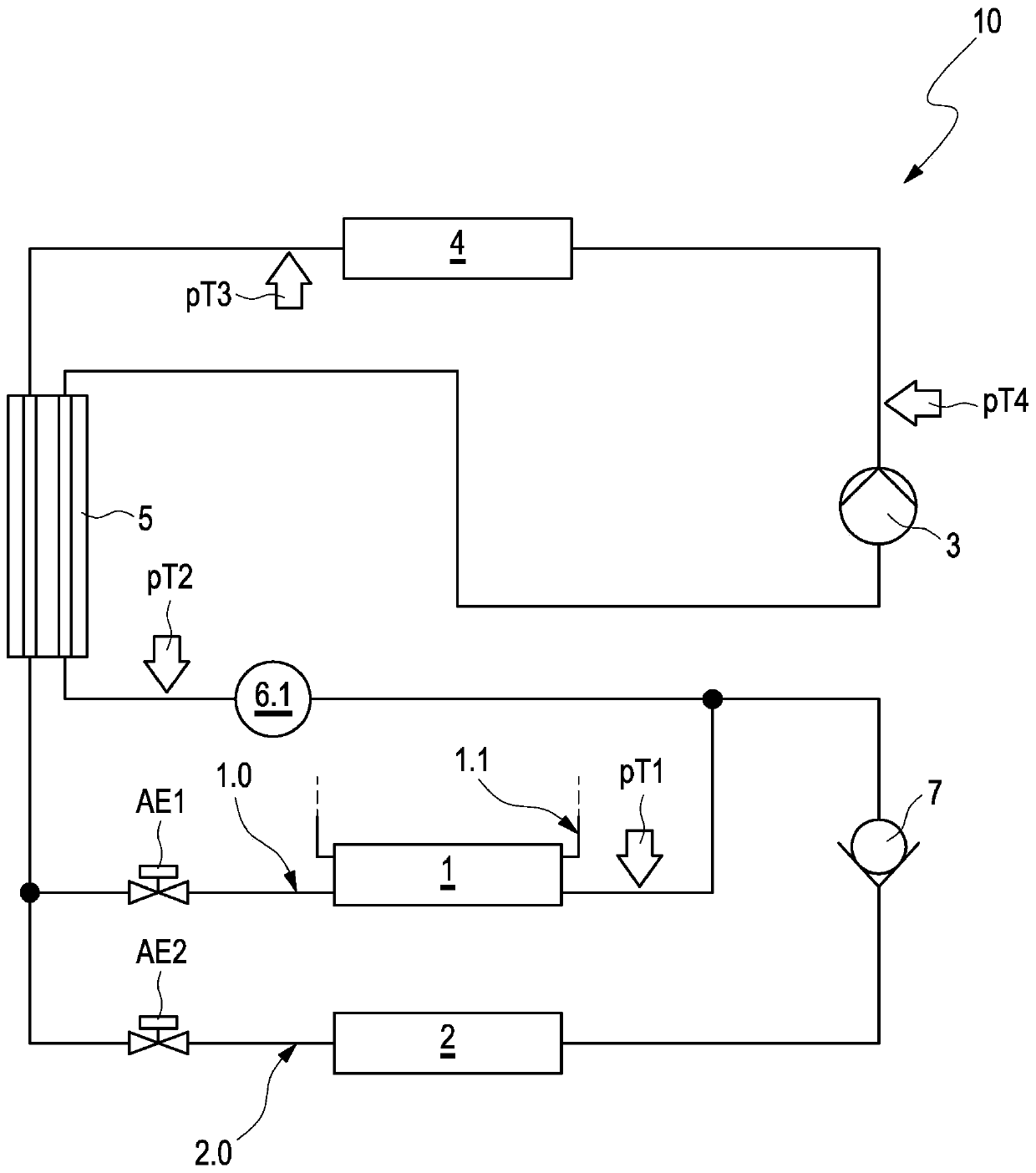

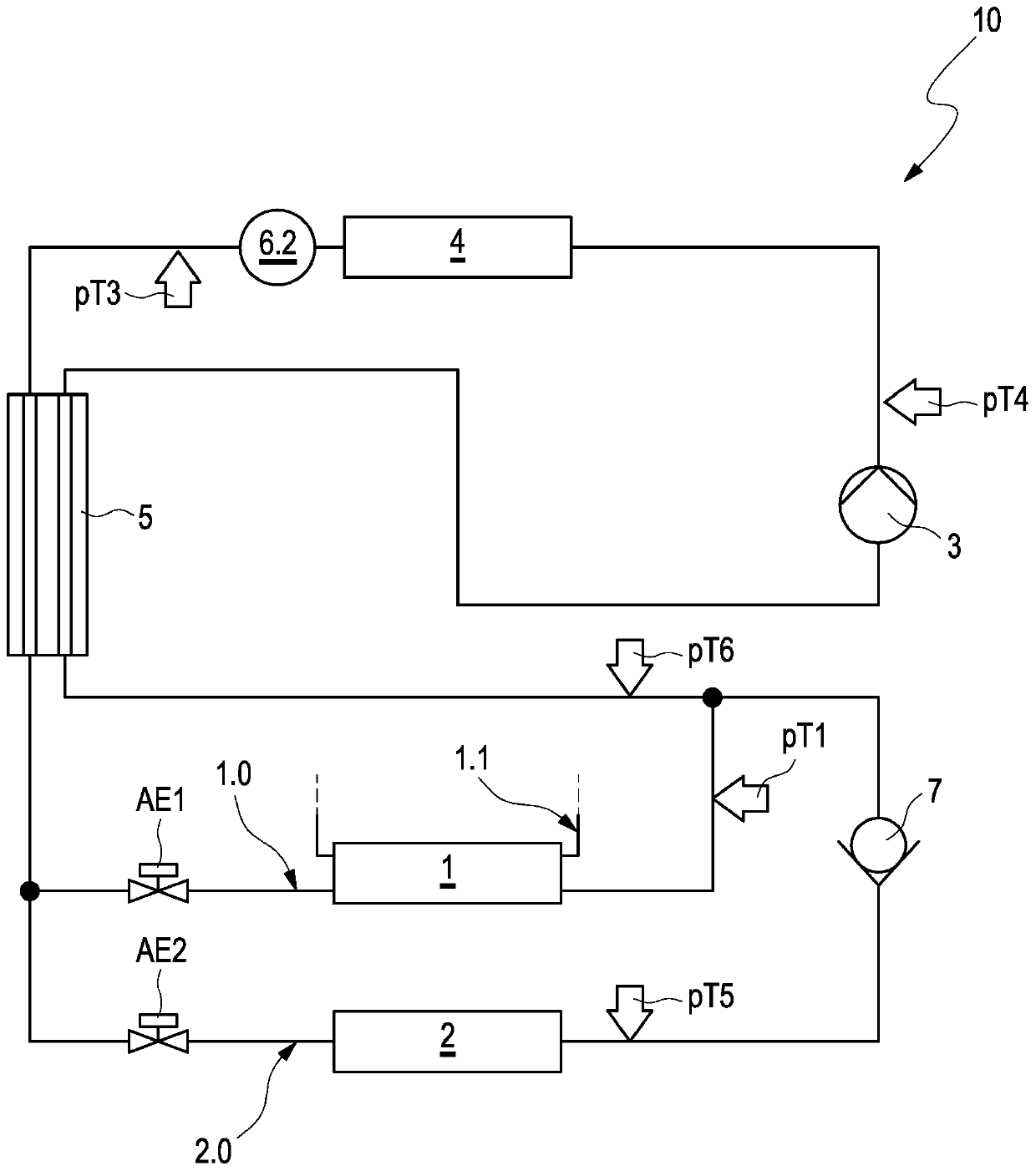

[0029] For simplicity, figure 1 with figure 2In each case, a refrigerant circuit 10 of a refrigeration system of a vehicle is shown, which refrigerant circuit is provided for pure AC operation (refrigeration system operation). Since the basic idea used to describe the method can be fully explained with a simple wiring concept and the functionality can be transferred directly to the heat pump-capable device and its inactive sectors, a functional expansion regarding the operation of the heat pump is omitted. The refrigerant circuits 10 are constructed with the same basic structure and differ in each case with regard to the arrangement of the refrigerant collectors as low-pressure or high-pressure refrigerant collectors. It should be mentioned here that the refrigerant collector arranged on the low-pressure side can be used for both subcritical and supercritical operating refrigeration equipment, while the high-pressure collector is mainly used for purely subcritical operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com