Production method of BCF nylon 66 medium-low denier yarn and BCF nylon 66 medium-low denier yarn

A production method and technology of medium and low denier, applied in the field of BCF nylon 66 medium and low denier yarns, can solve the problems such as the difficulty of stable deformation spinning of BCF nylon yarns, and achieve good spinnability, less clogging and low failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

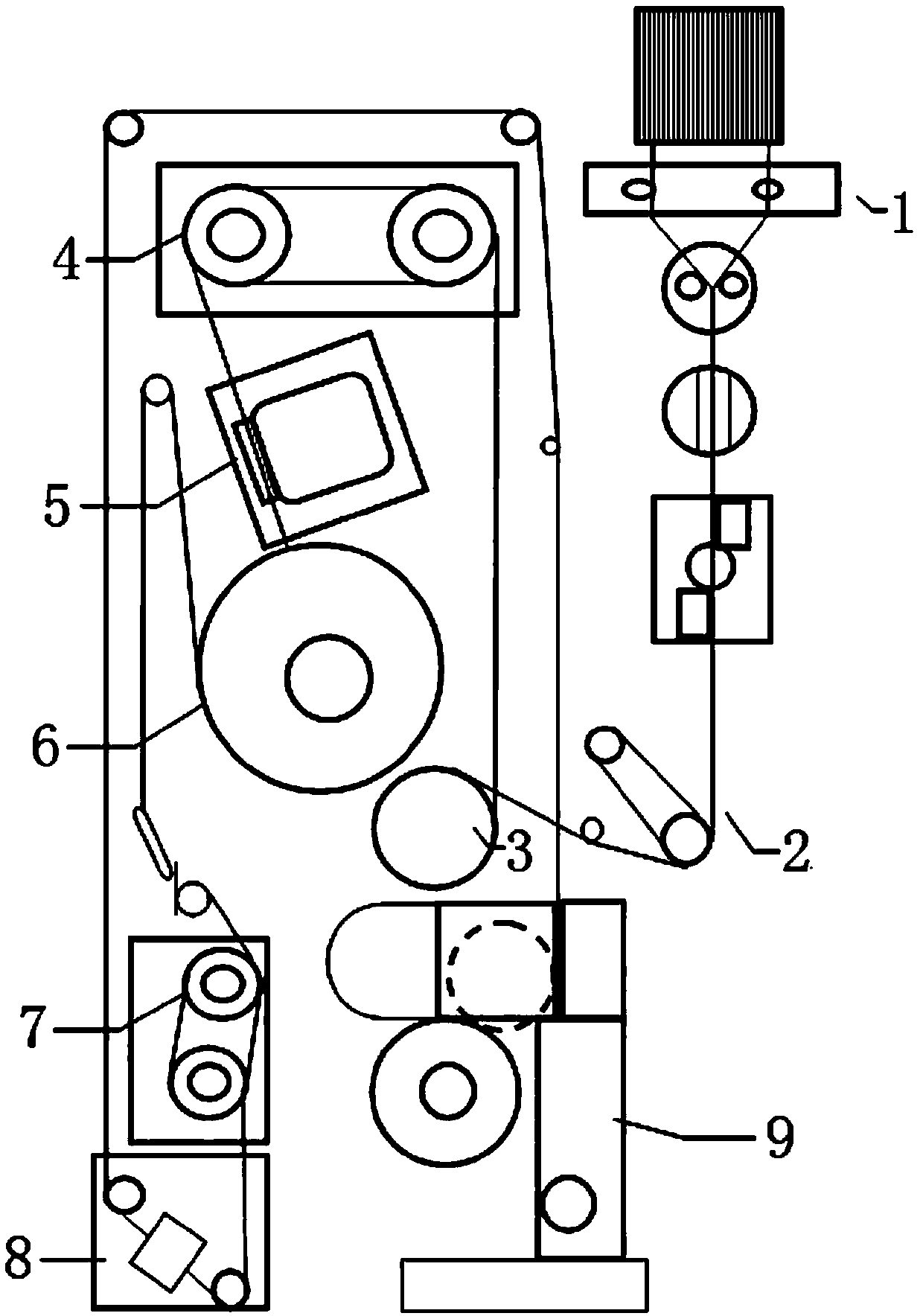

[0032] Embodiment 1: see figure 1 , the production method of low denier yarn in BCF nylon 66 of the present invention, the detailed steps of this production method are as follows:

[0033] a. Spinning and cooling: Add the dried nylon 66 chips into the screw extruder, extrude and melt to become spinnable nylon 66 melt, and send the spinnable nylon 66 melt into the spinning box Spinning, the spinning method adopts the commonly used ordinary spinning process, and the tow coming out of the spinning box is cooled and formed;

[0034] B, oiling: the tow after cooling and forming in step a is oiled through the oil agent nozzle, and the oil agent adhesion is 0.8% of the tow quality;

[0035] c, drafting: the tow after oiling in step a is drawn between the first roll and the second roll after the pre-drawing roll, the temperature of the first roll is 60 degrees, the temperature of the second roll is 20 °C, and the draft ratio is 2.8; The roll speed is 956 m / min, and the second roll s...

Embodiment 2

[0045] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0046] The production method of low denier yarn in BCF nylon 66 of the present invention, the detailed steps of this production method are as follows:

[0047] a. Spinning and cooling: Add the dried nylon 66 chips into the screw extruder, extrude and melt to become spinnable nylon 66 melt, and send the spinnable nylon 66 melt into the spinning box Spinning, the spinning method adopts the commonly used ordinary spinning process, and the tow coming out of the spinning box is cooled and formed;

[0048] b, oiling: the tow after cooling and forming in step a is oiled through the oil agent nozzle, and the oil agent adhesion is 1.0% of the tow quality;

[0049]c, drafting: the yarn after oiling in step b is drafted between the first roll and the second roll after the pre-drawing roll, the temperature of the first roll is 70 degrees, the temperature of the second roll is 205, and the draft ratio is 2.8. T...

Embodiment 3

[0059] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0060] The production method of low denier yarn in BCF nylon 66 of the present invention, the detailed steps of this production method are as follows:

[0061] a. Spinning and cooling: Add the dried nylon 66 chips into the screw extruder, extrude and melt to become spinnable nylon 66 melt, and send the spinnable nylon 66 melt into the spinning box Spinning, the spinning method adopts the commonly used ordinary spinning process, and the tow coming out of the spinning box is cooled and formed;

[0062] B, oiling: the tow after cooling and forming in step a is oiled through the oil agent nozzle, and the oil agent adhesion is 0.9% of the tow quality;

[0063] c, drafting: the tow after oiling in step a is drafted between the first roll and the second roll after the pre-drawing roll, the temperature of the first roll is 70 degrees, the temperature of the second roll is 200, and the draft ratio is 2.77. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com