Method and equipment for separating methane from synthesis gas

A separation equipment, synthesis gas technology, applied in lighting and heating equipment, cold treatment separation, refrigeration and liquefaction, etc., can solve problems such as high cost and low efficiency, achieve high effectiveness, reduce equipment costs, and improve effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

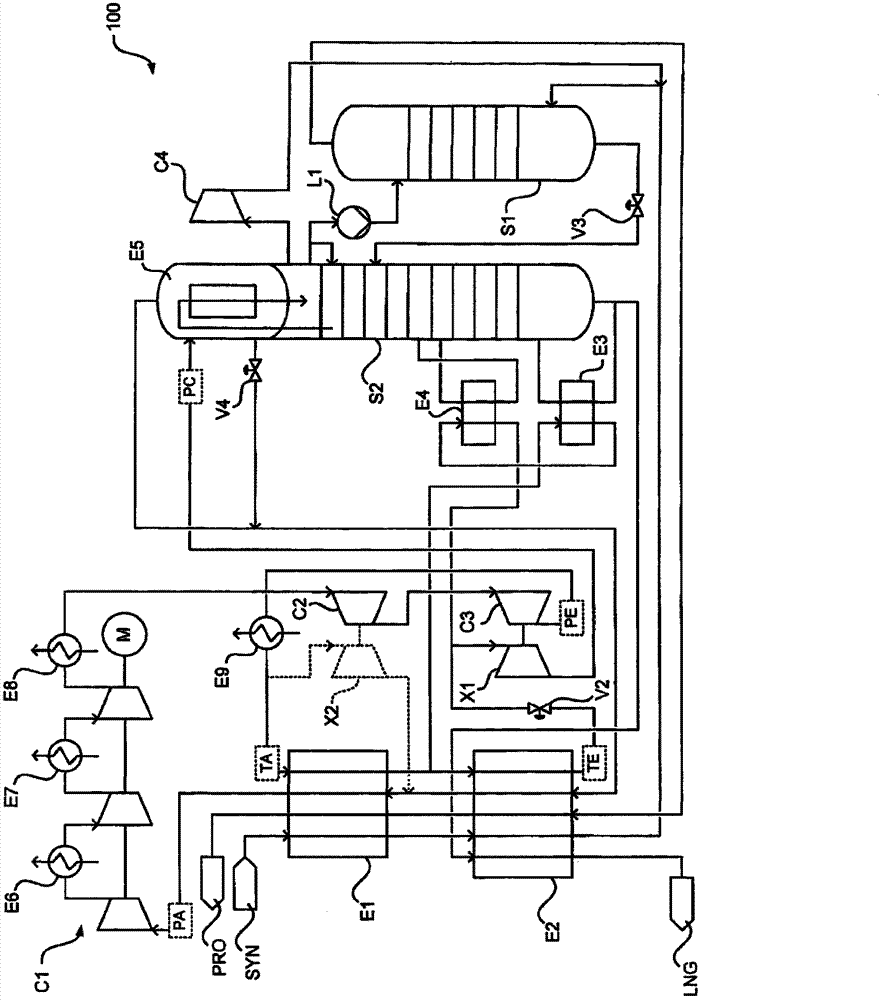

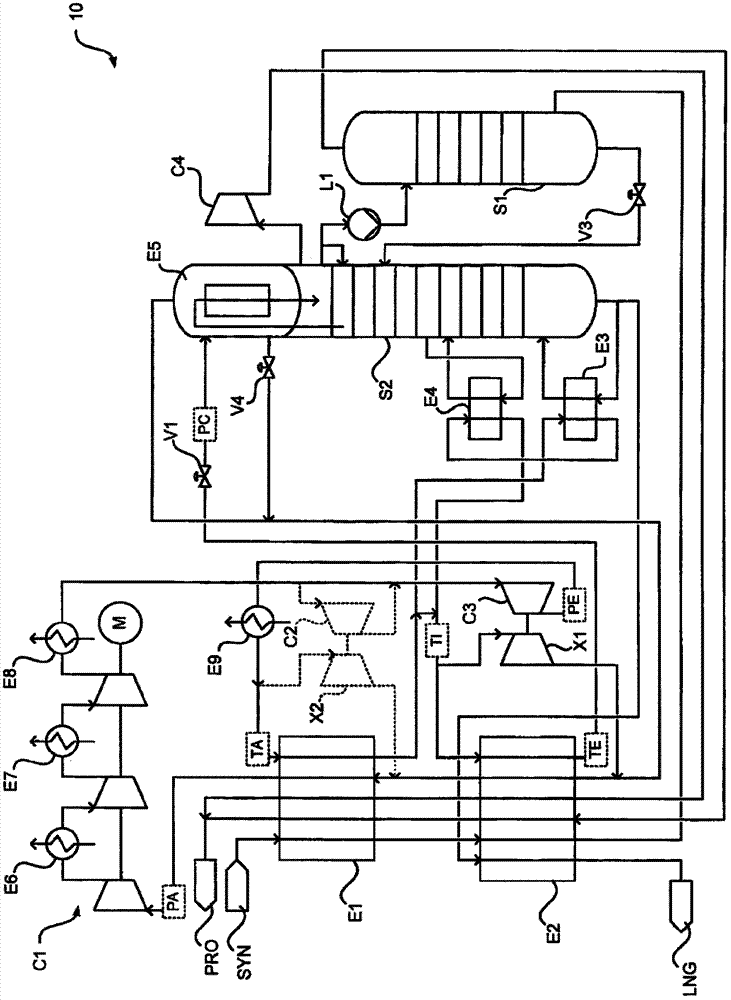

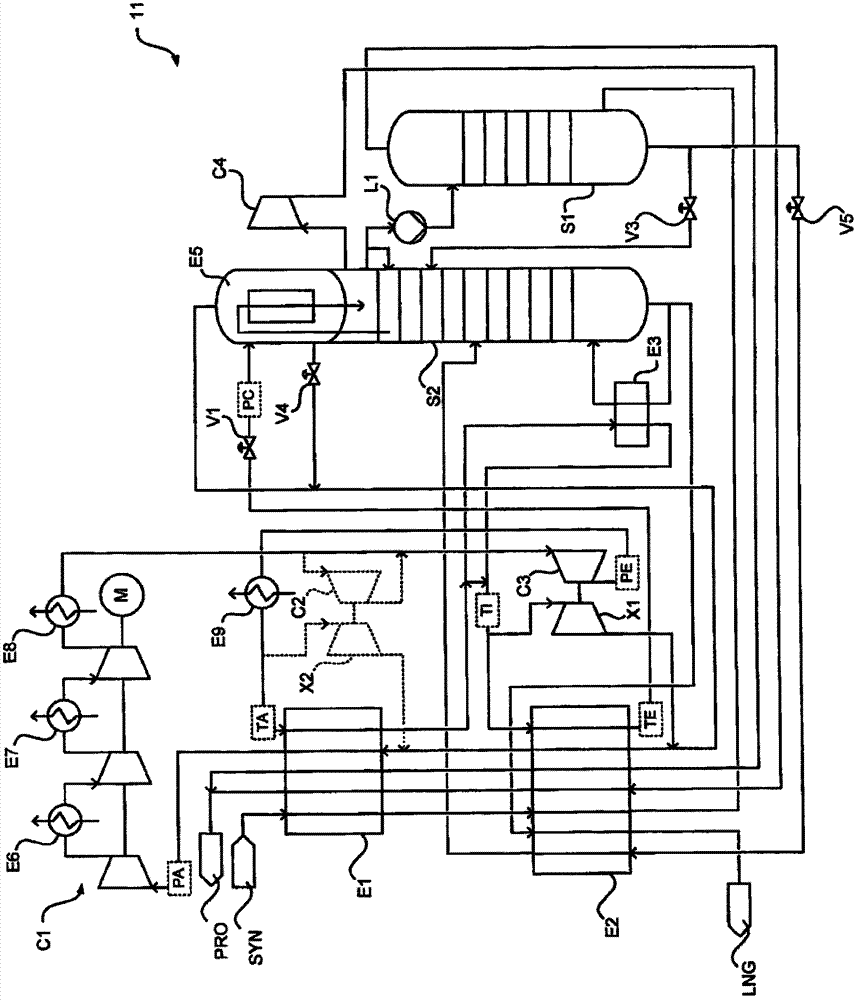

[0044] figure 1 Shown is a plant not according to the invention for the separation of methane from methane-containing synthesis gas. The device is denoted as a whole by the reference number 100 .

[0045] The plant 100 has a first separation column S1 and a second separation column S2. The first separation column S1 and the second separation column S2 work under different pressures. The pressure difference is, for example, 5 to 30 bar, especially 10 to 20 bar. The pressure of the second separation column S2 can be limited to 25 to 30 bar to ensure a pressure difference between the gaseous and liquid phases of at least 240 kg / m 3 , especially at least 270kg / m 3 .

[0046] The methane-containing synthesis gas SYN is cooled in the first heat exchanger E1 to a temperature of, for example, -60 to -110° C., in particular -80 to -95° C., and in the second heat exchanger E2 to, for example, -120° C. to a temperature of -170° C., especially -130 to -160° C., which is then fed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com