Patents

Literature

272results about How to "Reduce pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

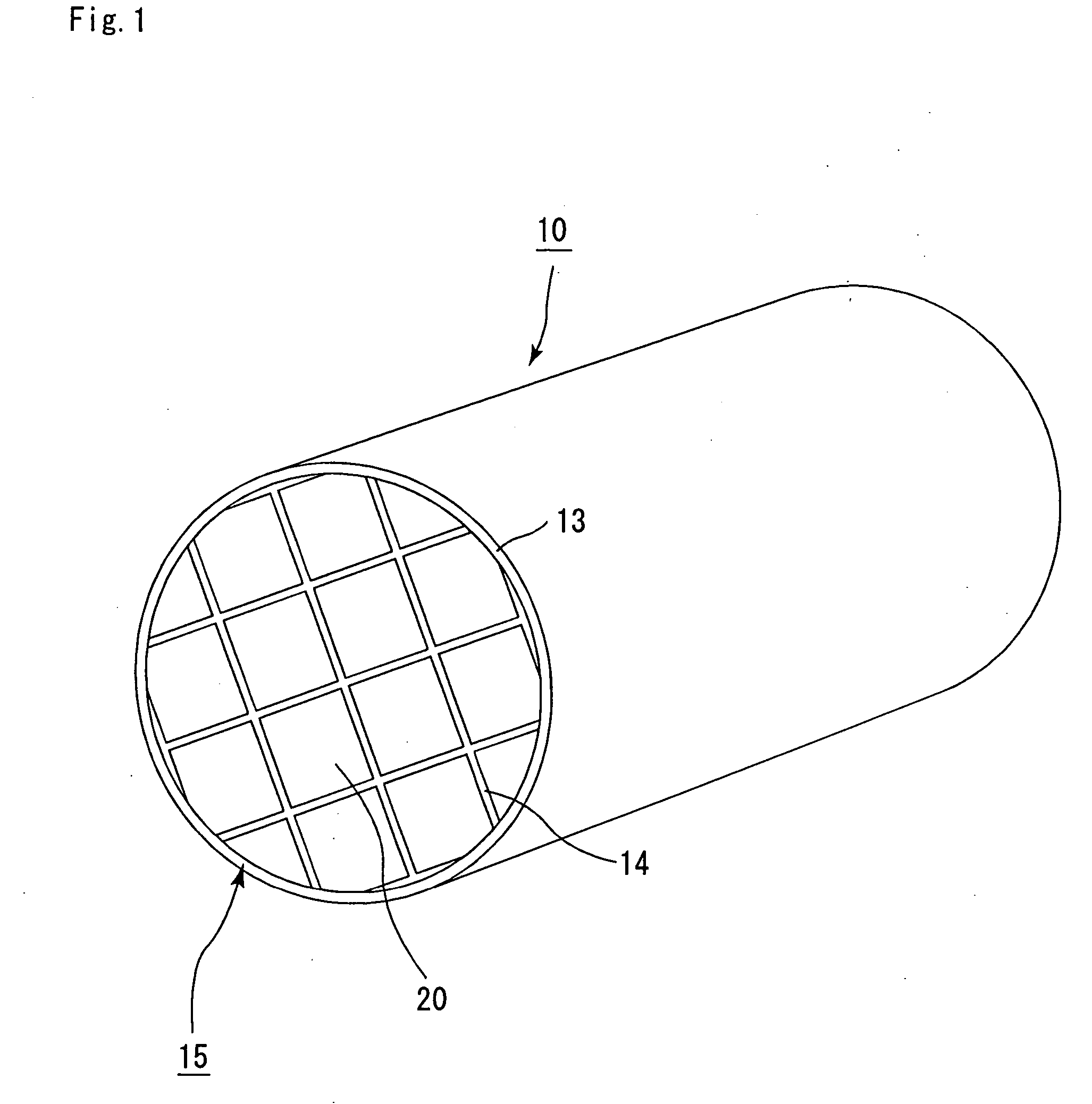

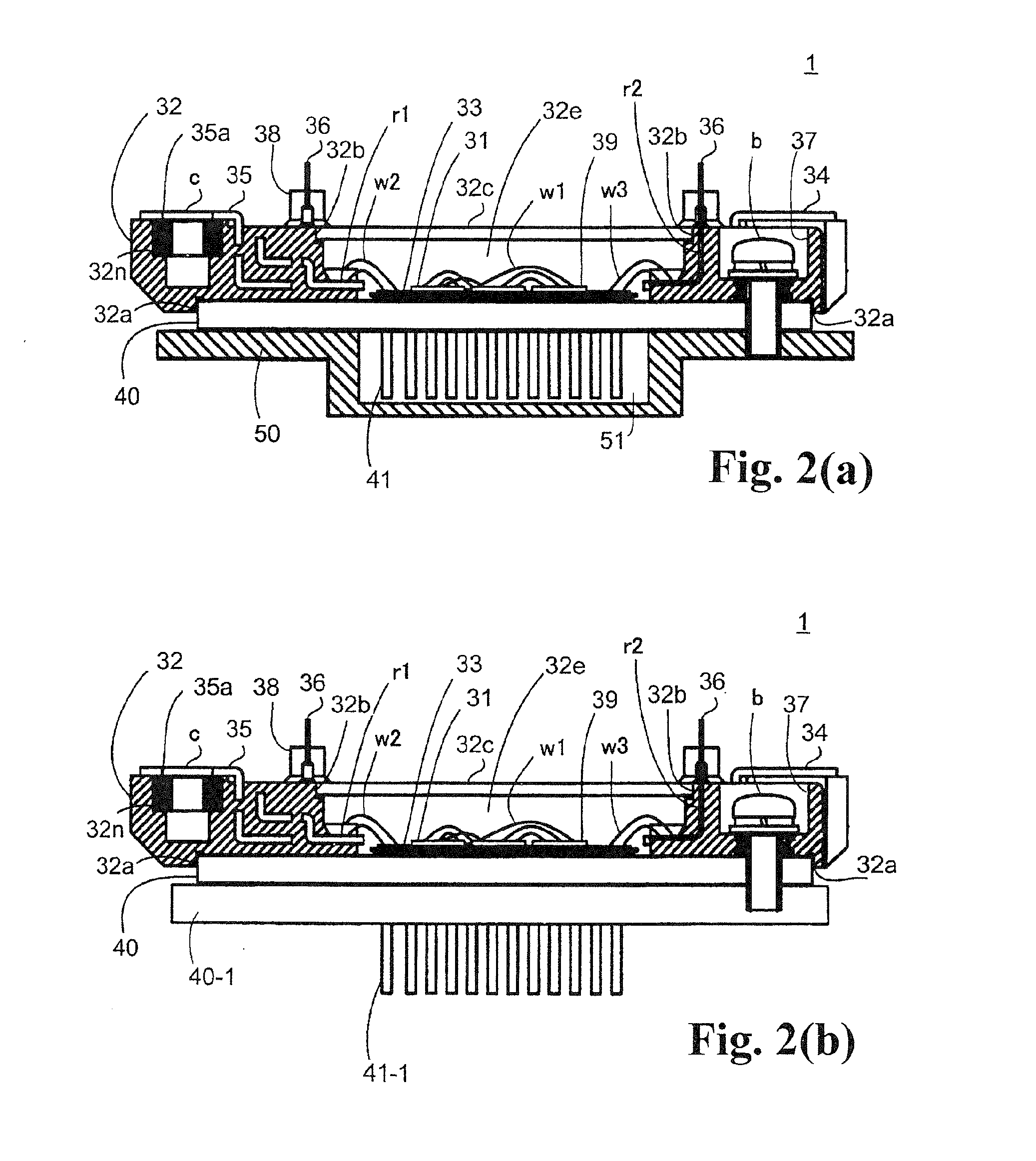

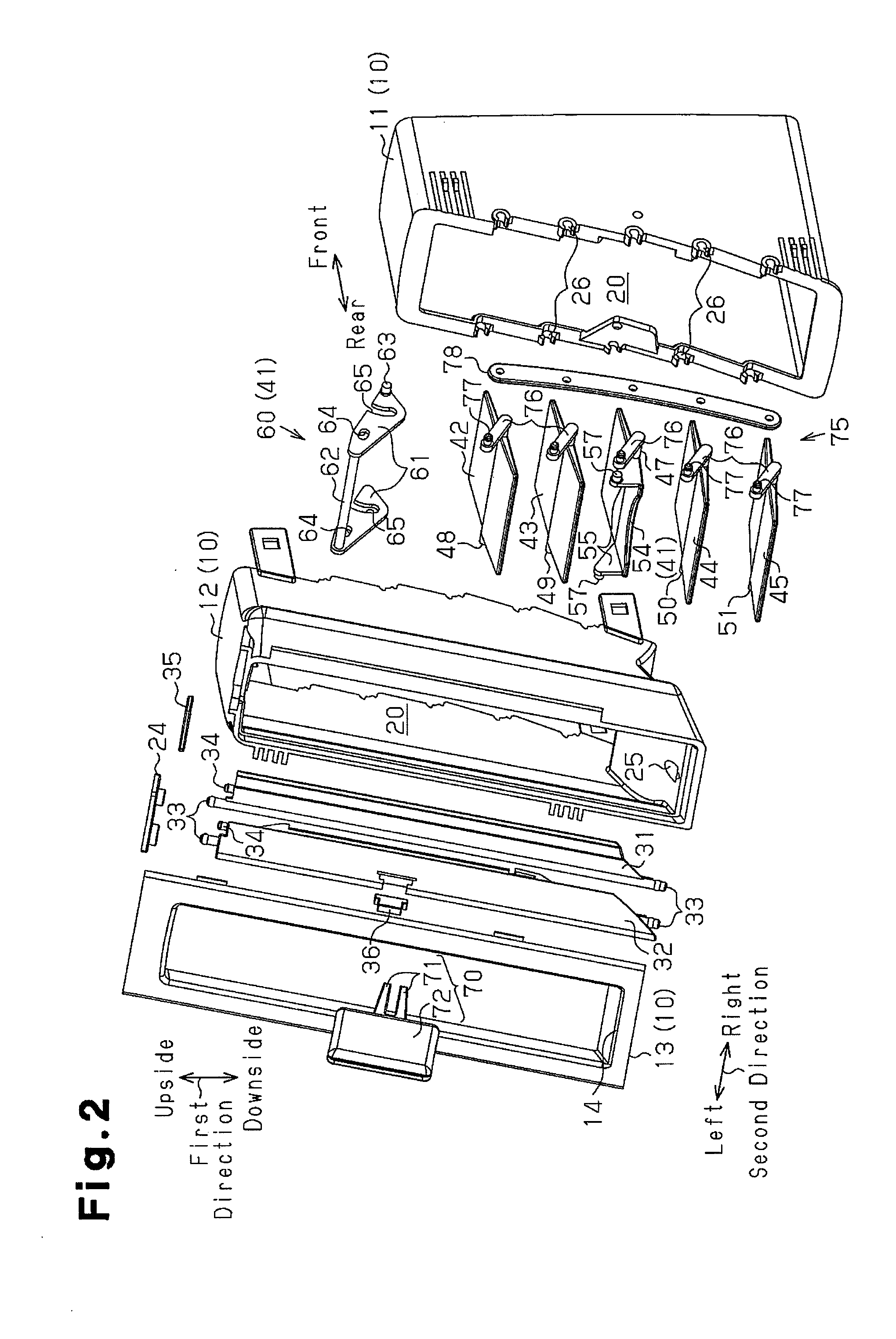

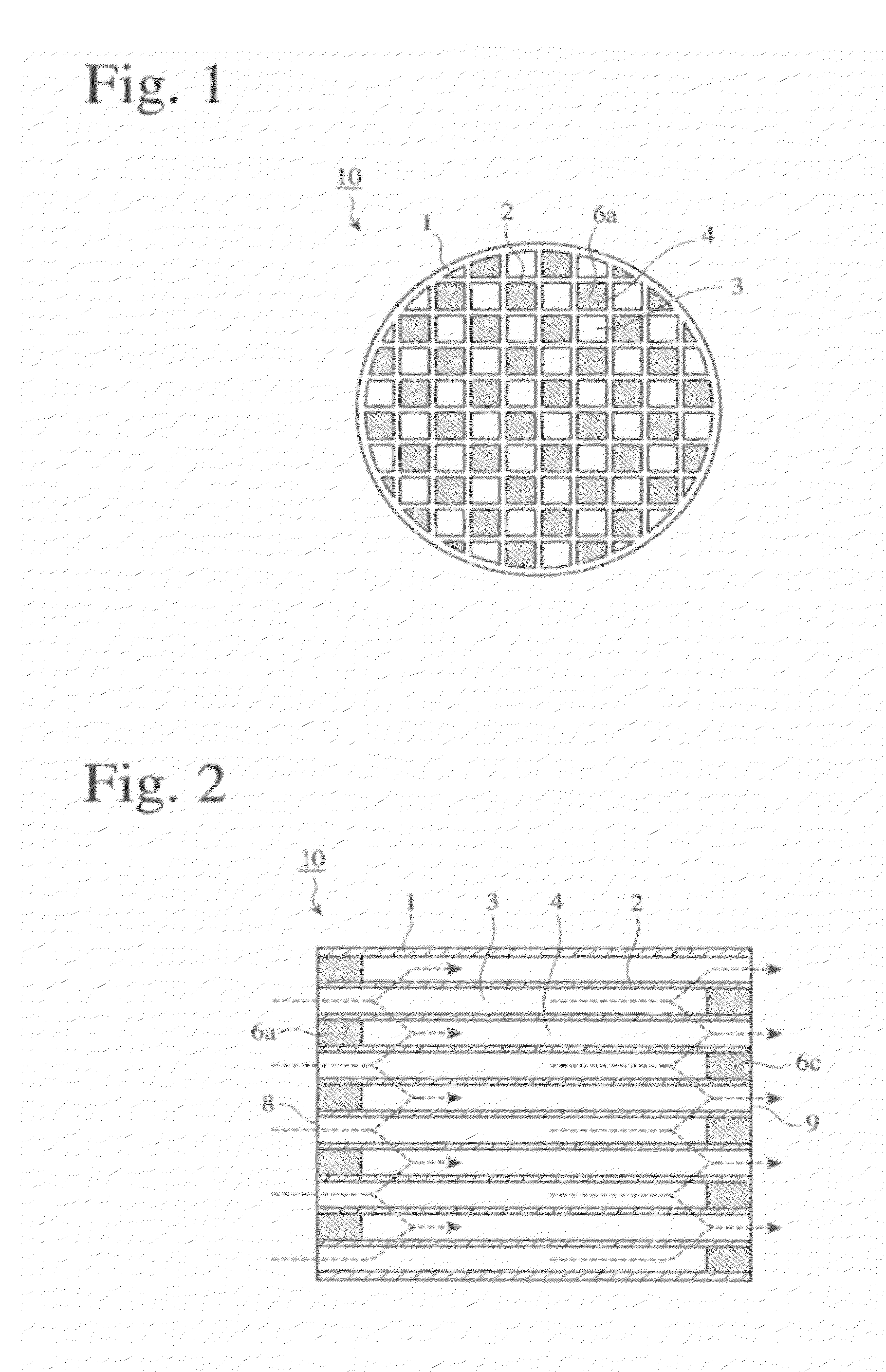

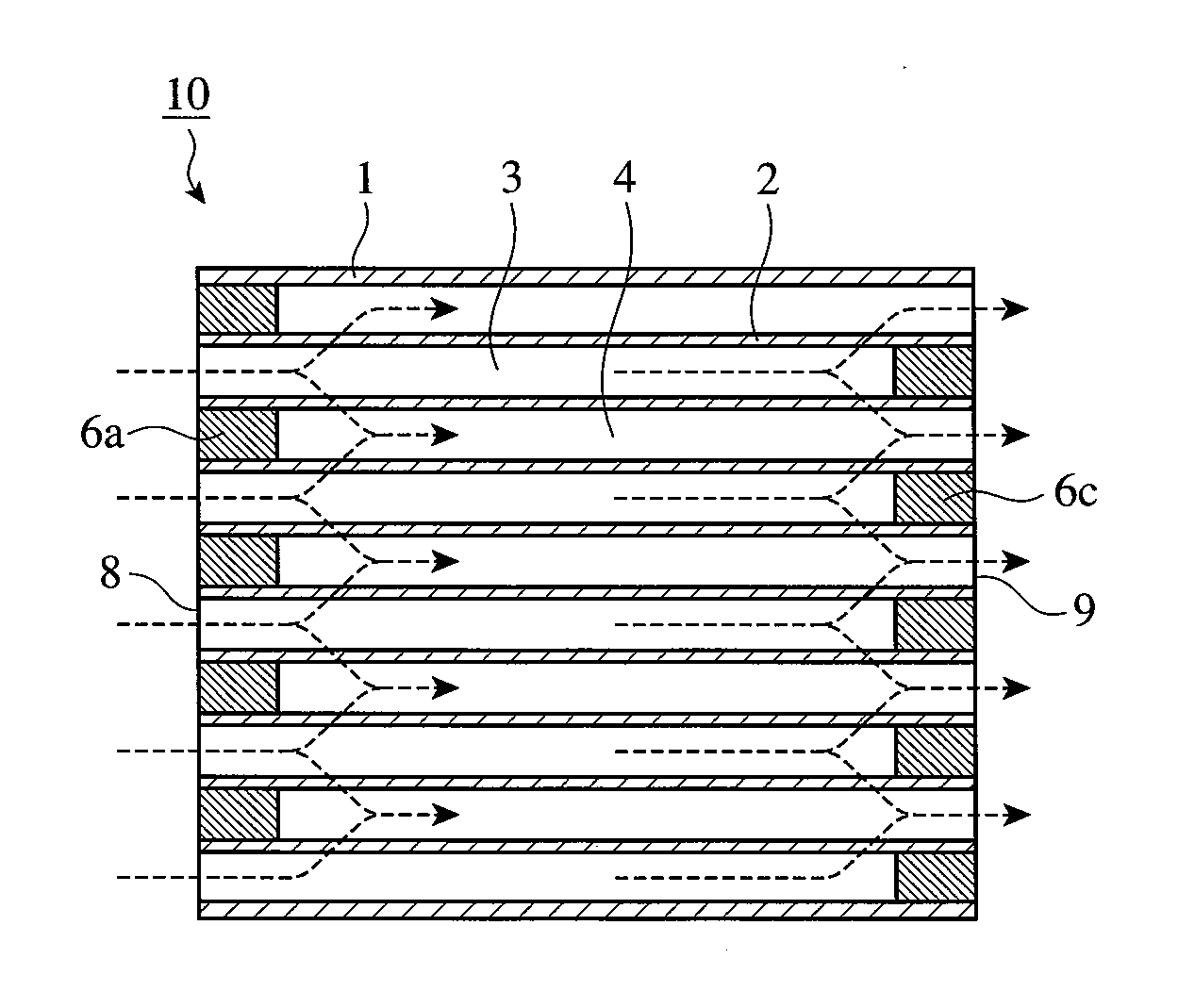

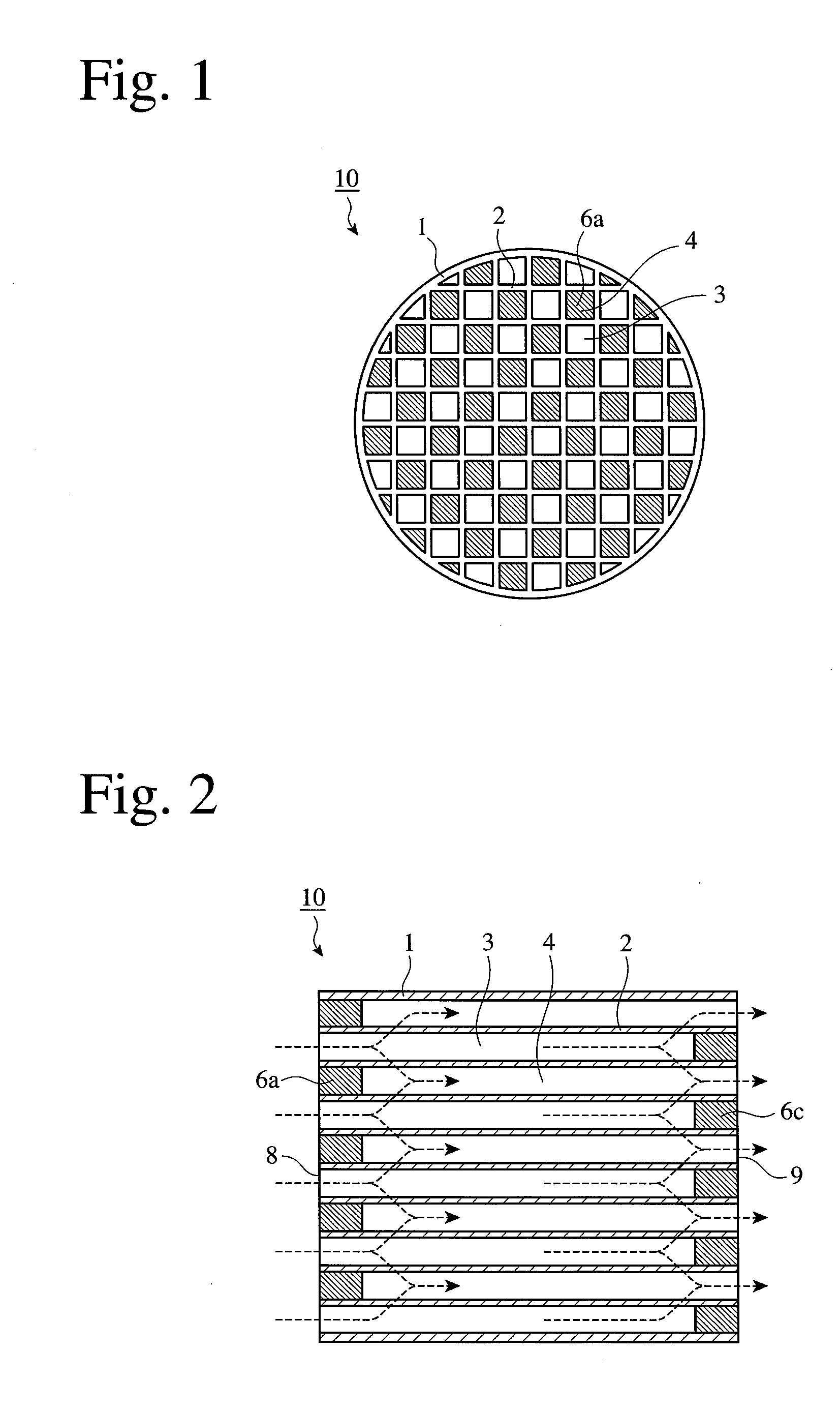

Spiral reverse osmosis membrane element, reverse osmosis membrane module using it, device and method for reverse osmosis separation incorporating the module

InactiveUS6656362B1Suppress lowering of performanceReduce pressure lossGeneral water supply conservationDialysis systemsMembrane configurationEngineering

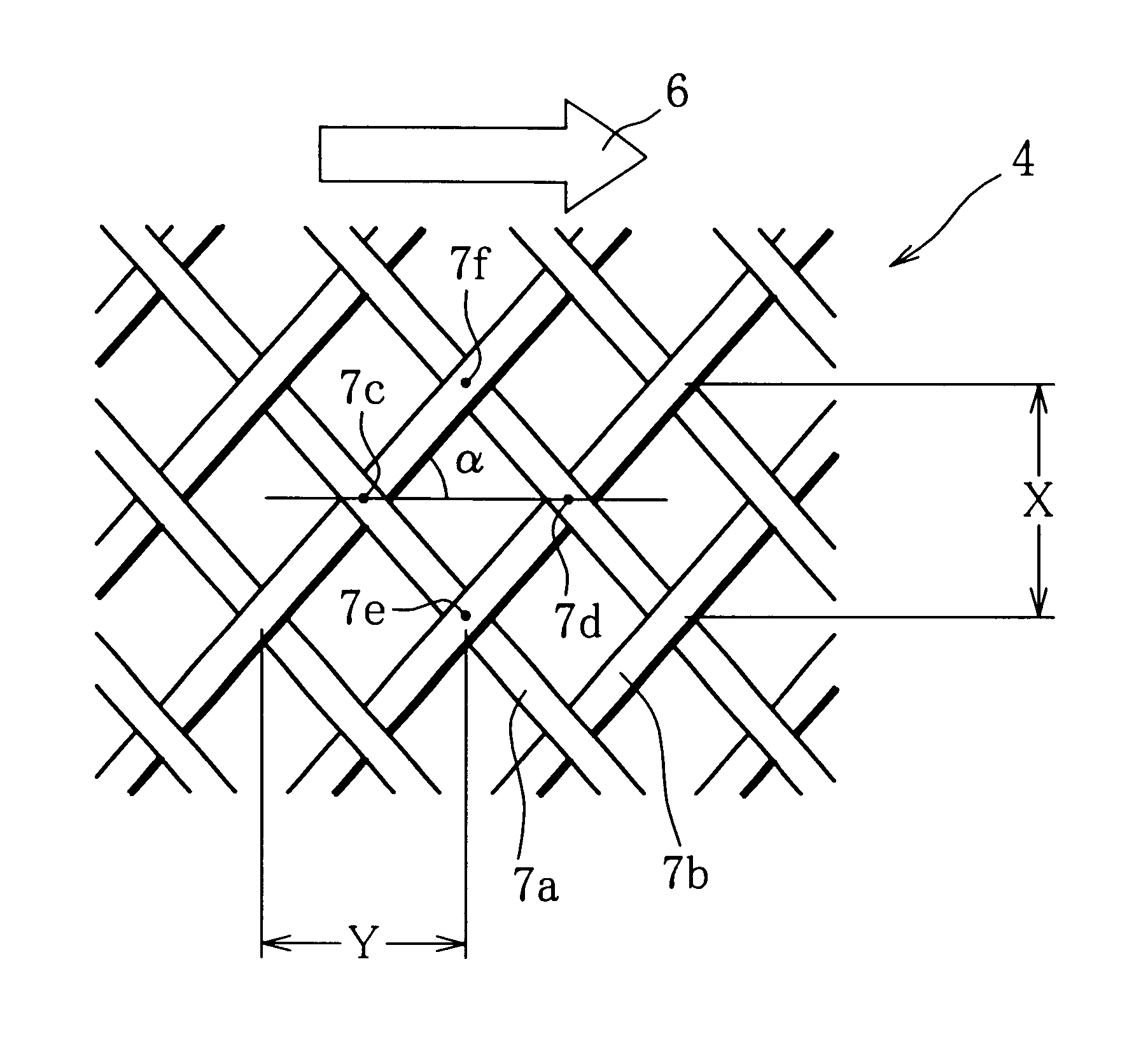

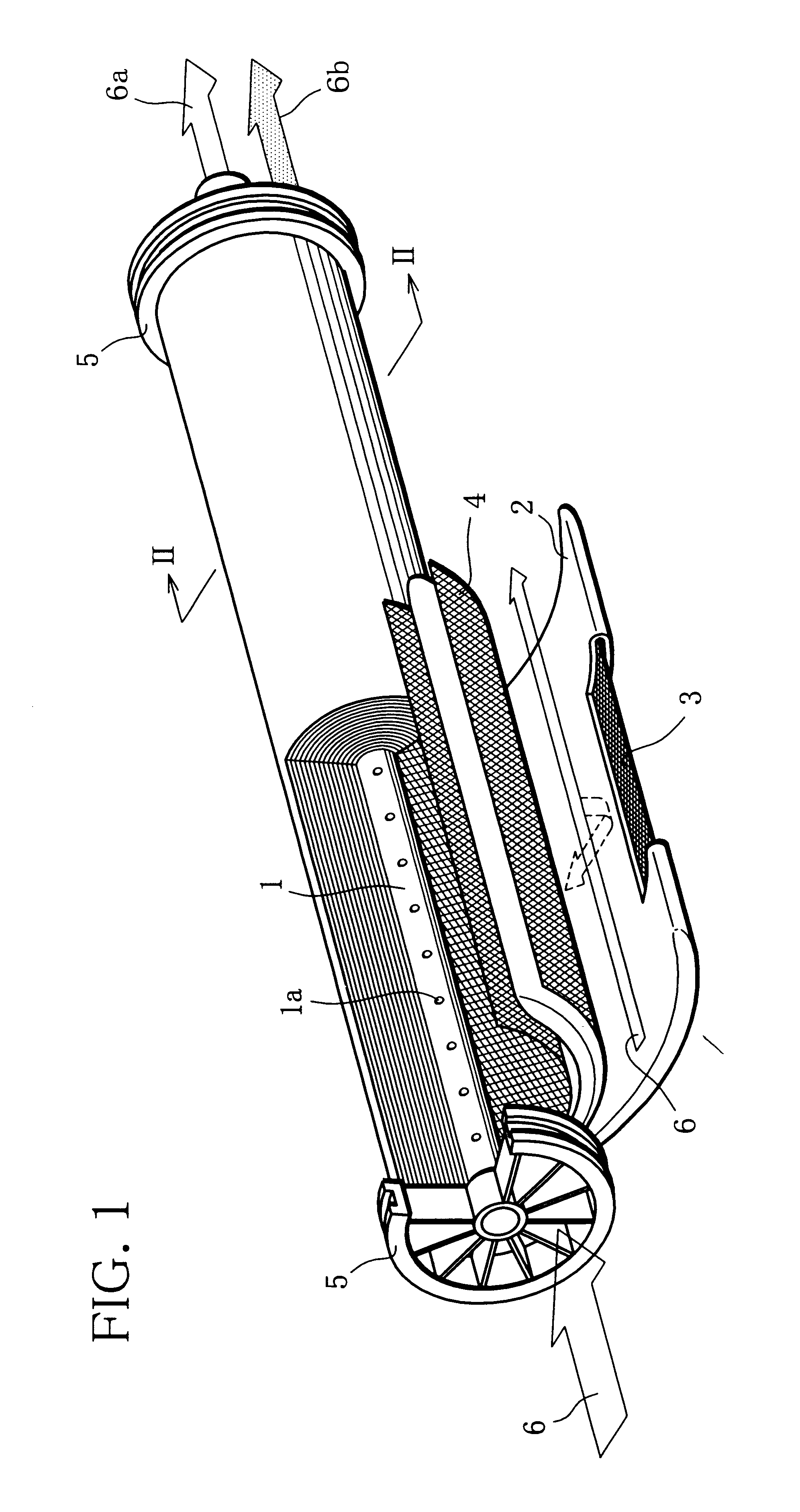

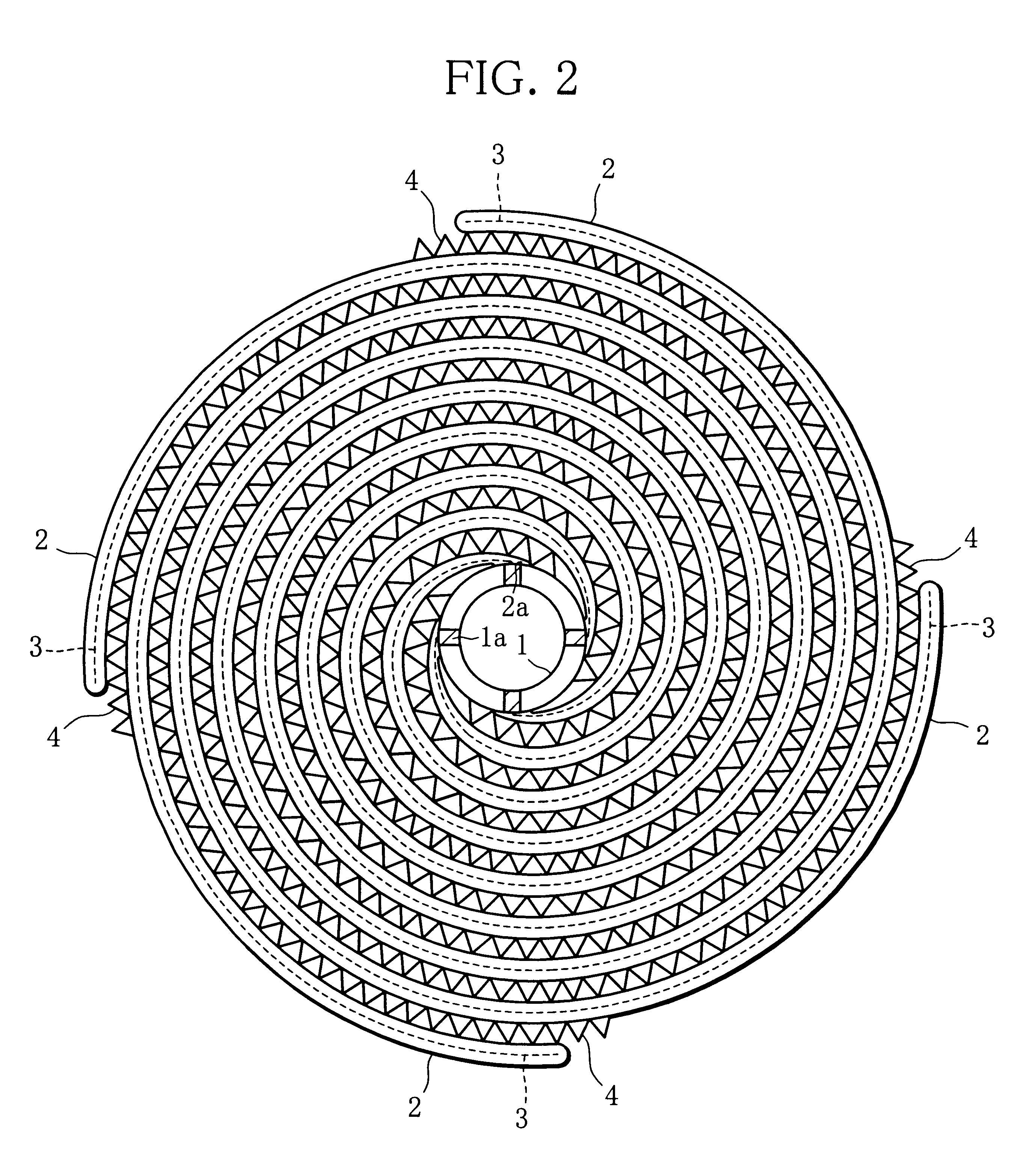

A spiral reverse osmosis membrane element of the present invention includes a plurality of bag-shaped reverse osmosis membranes, permeated liquid passage members arranged inside the reverse osmosis membranes, and a plurality of feed liquid passage members interposed between the reverse osmosis membranes, those membranes and passage members being wound around an outer surface of a hollow pipe in a manner that only the interiors of the reverse osmosis membranes communicate with through-holes formed in the surface of the hollow pipe. Each of the feed liquid passage members is a mesh member having series of quadrilateral meshes formed by a plurality of linear members crossing each other. Two opposite cross-points out of four cross-points of each of the quadrilateral meshes are in line in parallel with an axial direction of the hollow pipe. And relations 2 mm<=X<=5 mm and X<=Y<=1.8X are both satisfied where X denotes a distance between the cross-points in a direction perpendicular to the axial direction of the hollow pipe and Y denotes a distance between the cross-points in the axial direction of the hollow pipe.

Owner:TORAY IND INC

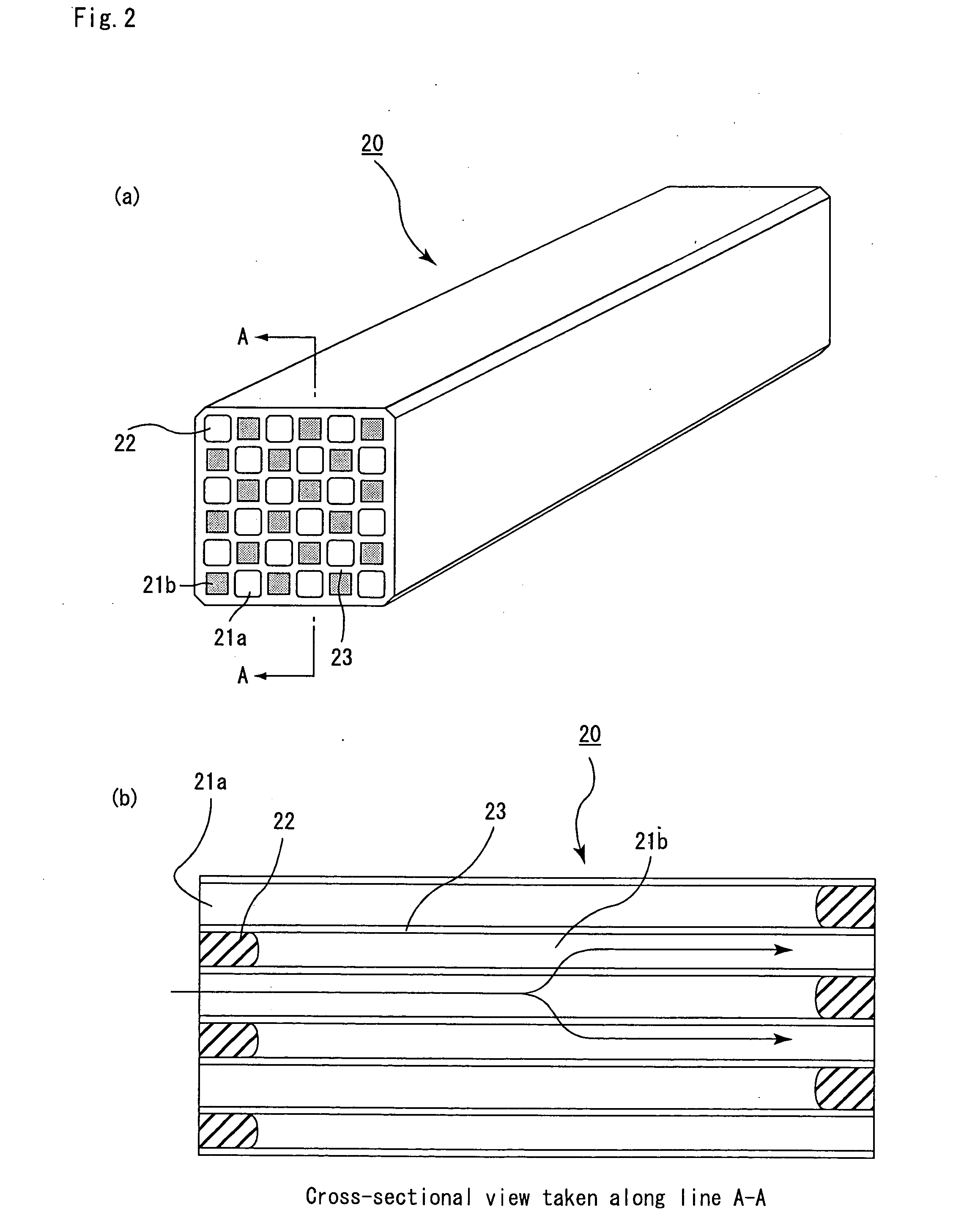

Honeycomb structural body

InactiveUS20060032203A1Reduce pressure lossApplied load reductionCombination devicesAuxillary pretreatmentParticulatesSurface roughness

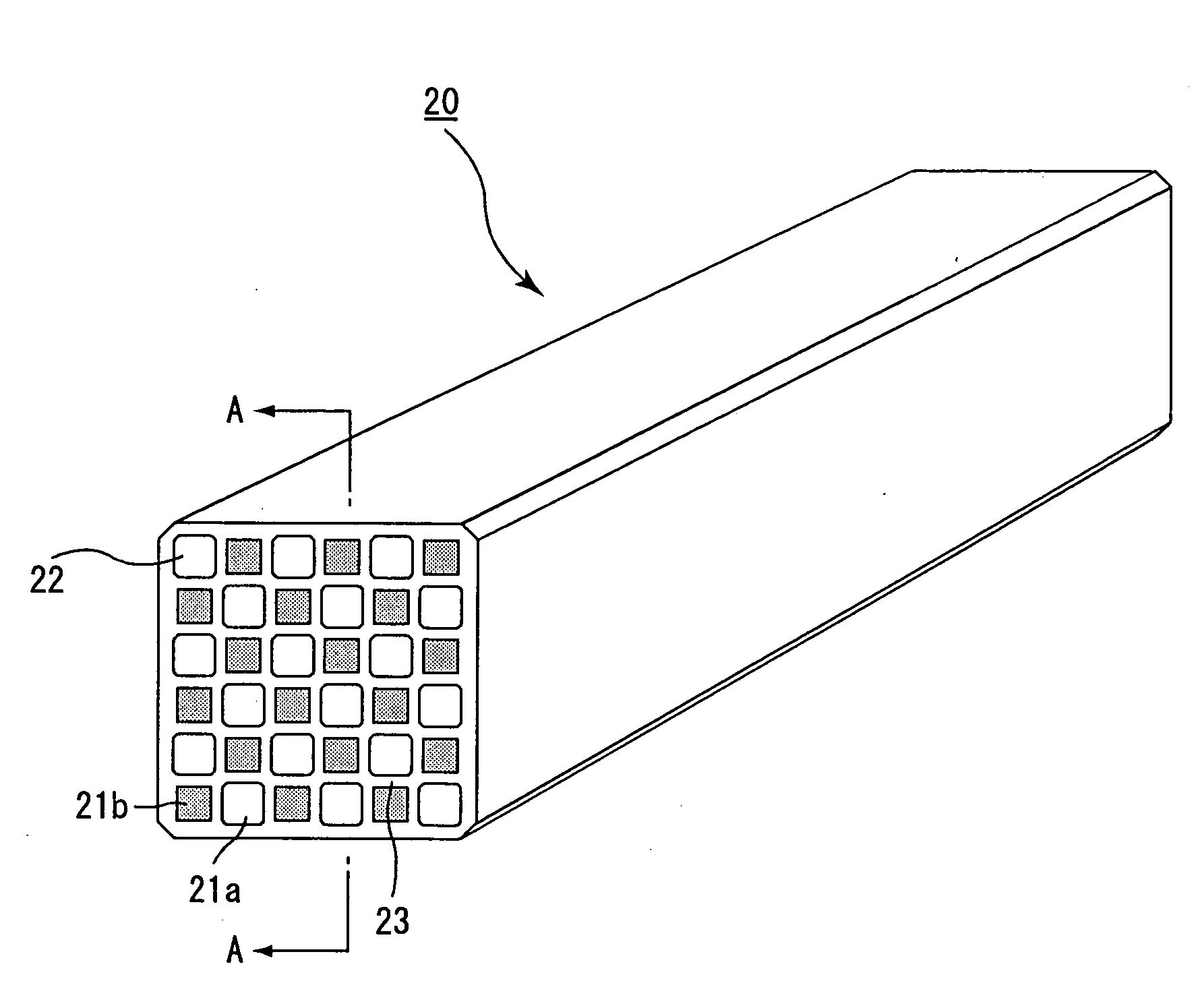

An object of the present invention is to provide a honeycomb structural body with a long service life, which can reduce a pressure loss to a low level upon collecting particulates and maintain the pressure loss at the low level for a long time even after regenerating processes. The honeycomb structural body includes a columnar porous ceramic block in which a large number of through holes are placed in parallel with one another in the length direction with a wall portion interposed therebetween. Herein, the large number of through holes are constituted by a group of large-capacity through holes, each of which is sealed at one end of the honeycomb structural body so that the total sum of the areas on a cross section perpendicular to the length direction is made relatively great, and a group of small-capacity through holes, each of which is sealed at the other end of the honeycomb structural body so that the total sum of the areas on the cross section is made relatively small, and a surface roughness Ry of the wall face of the through hole is set in a range from 10 to 100 μm.

Owner:IBIDEN CO LTD

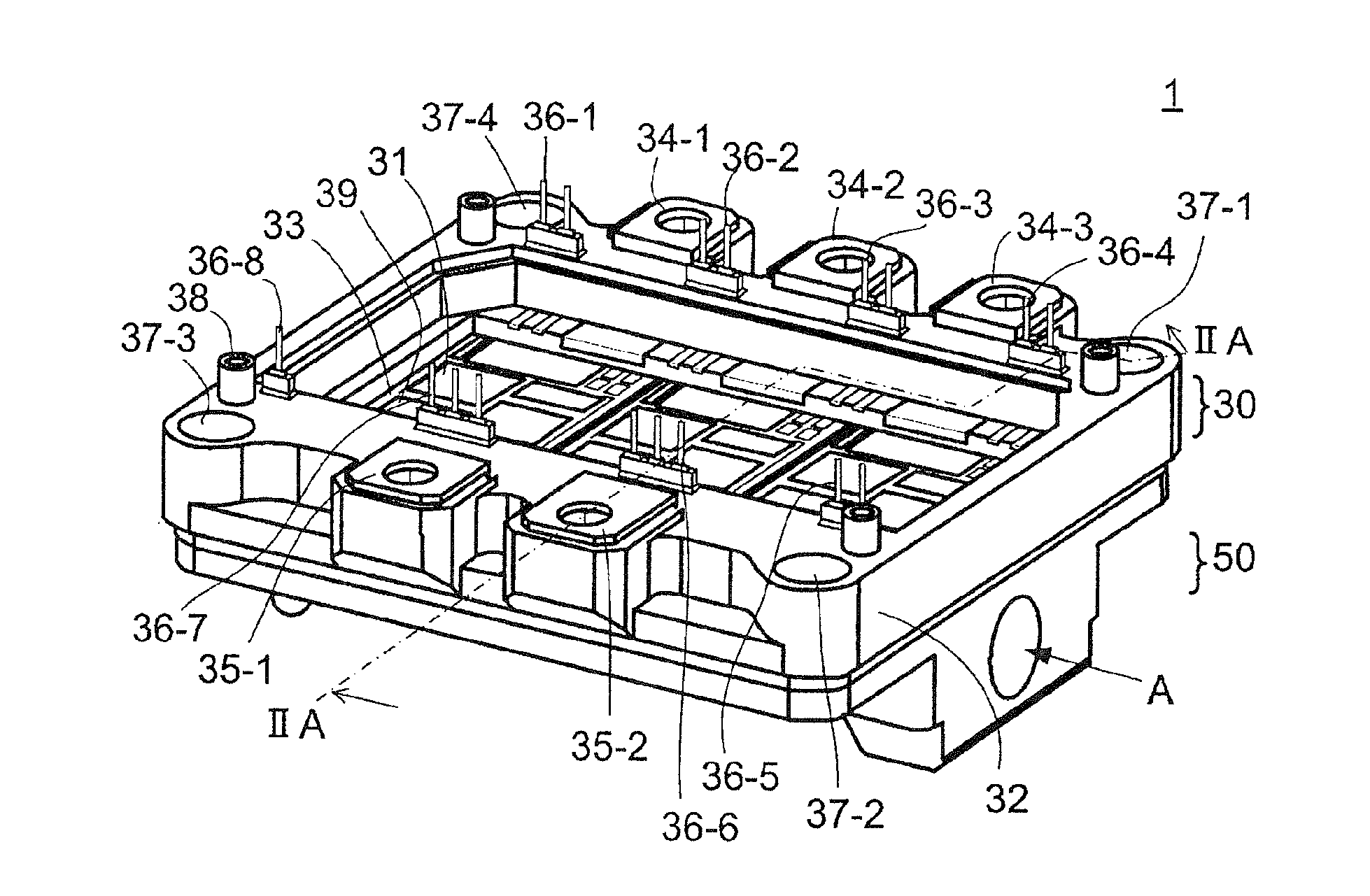

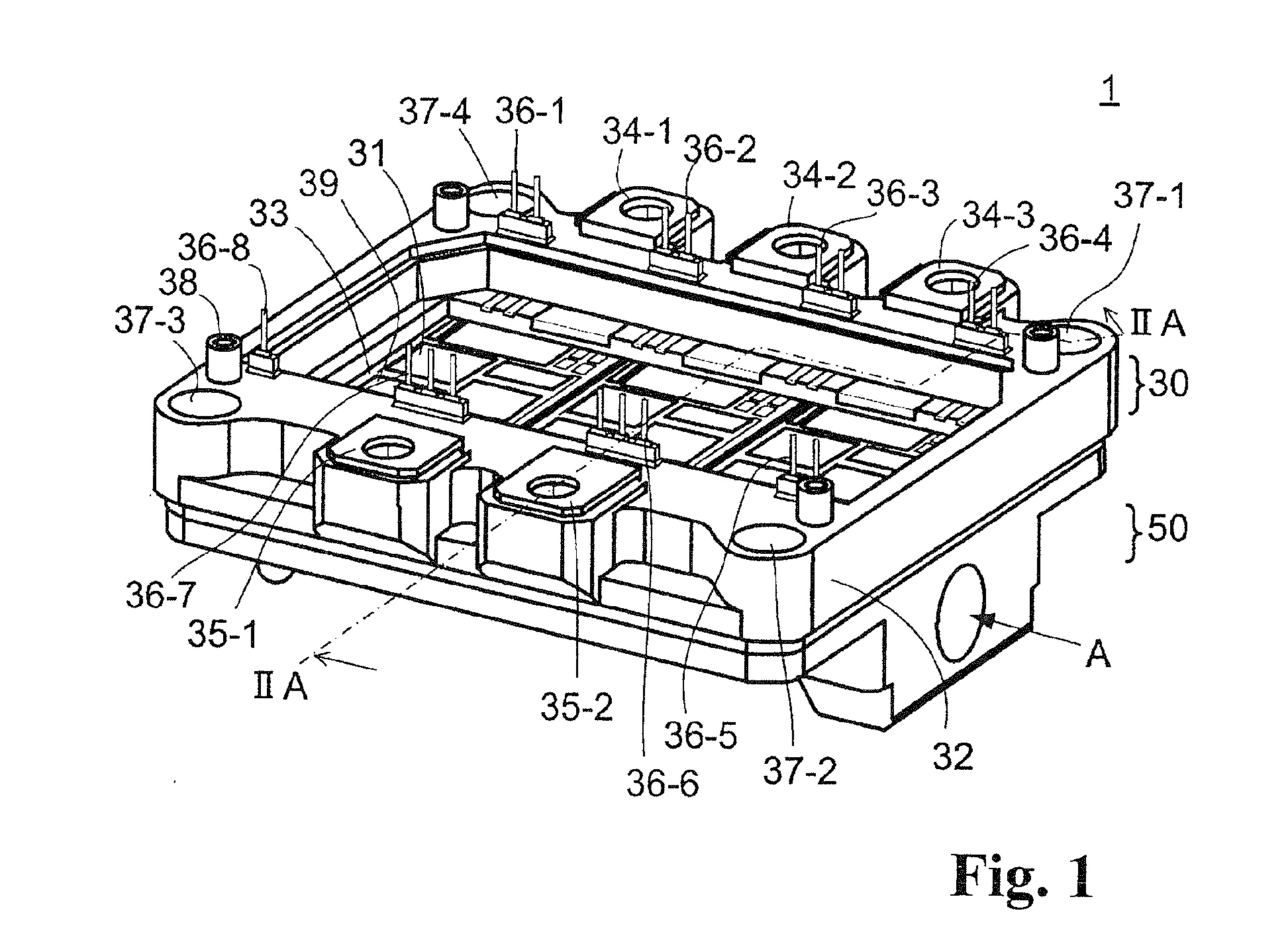

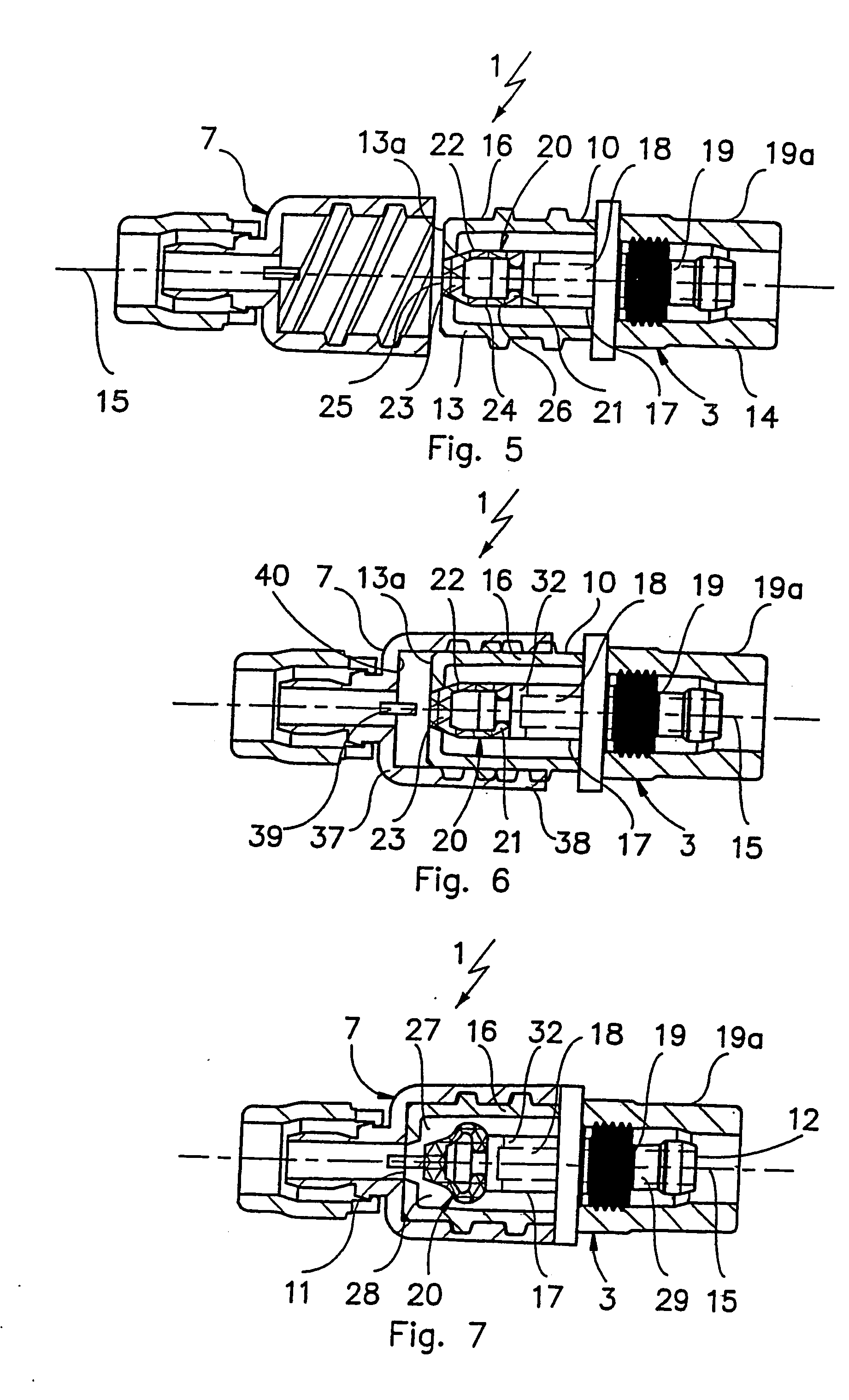

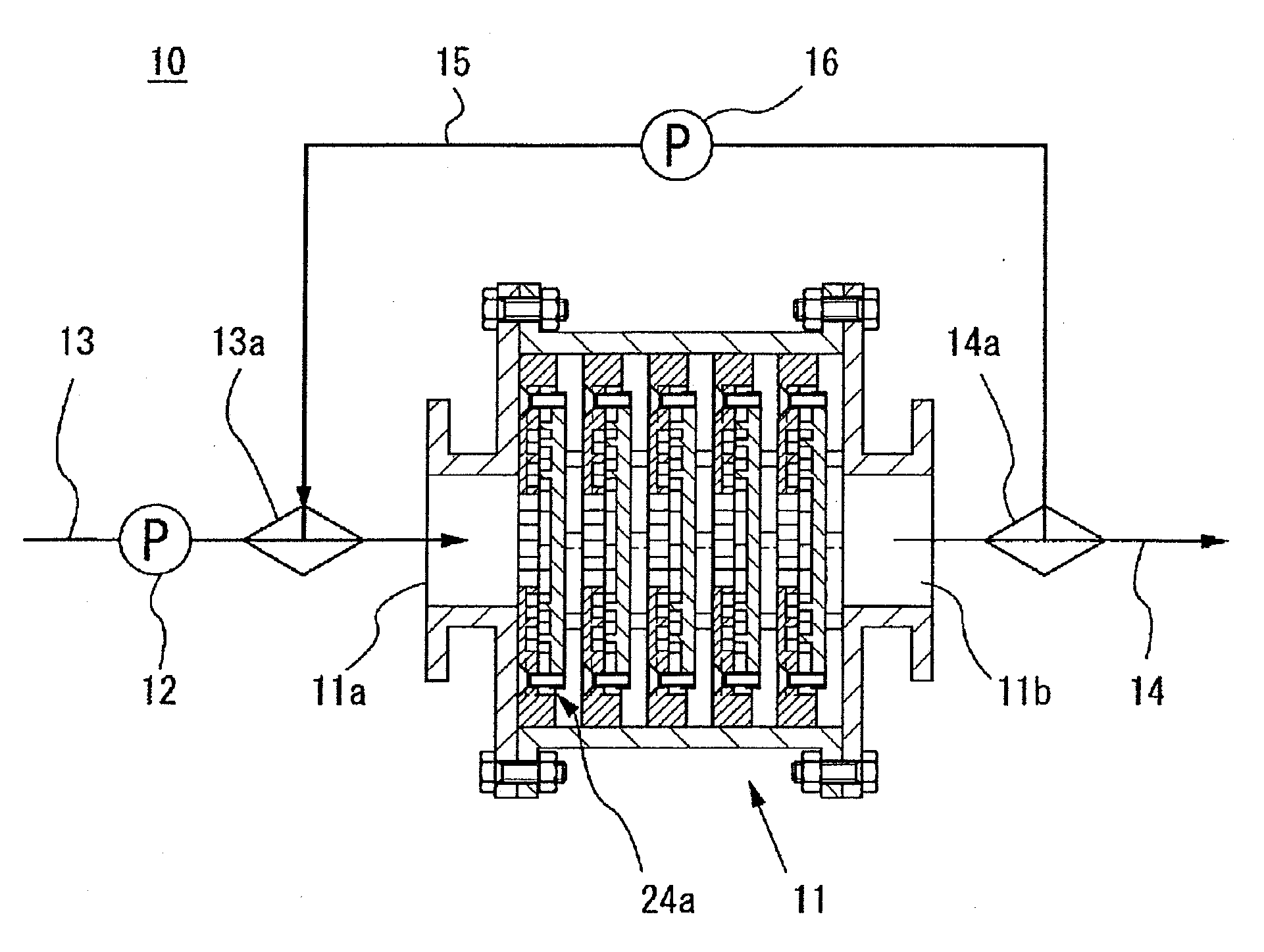

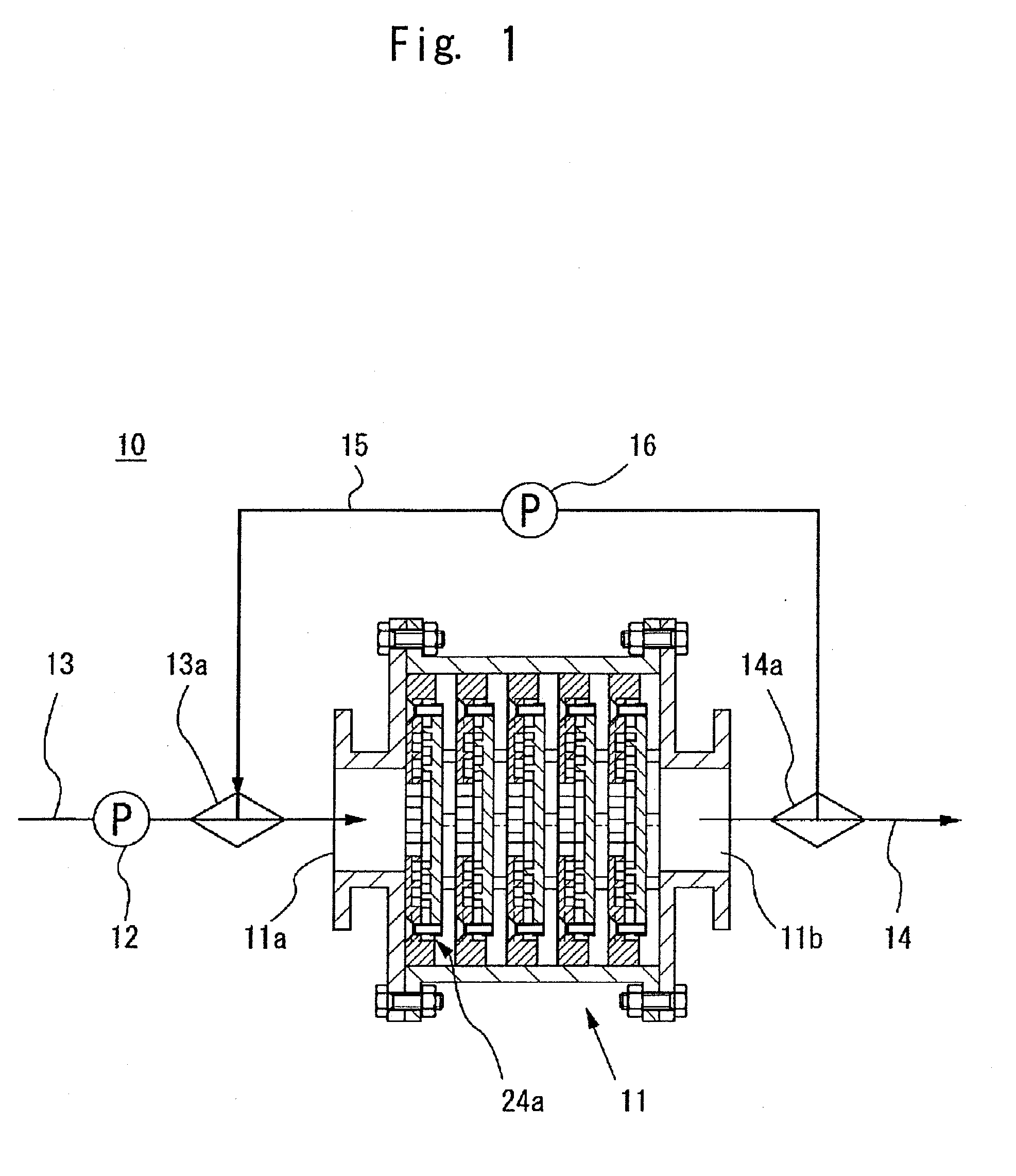

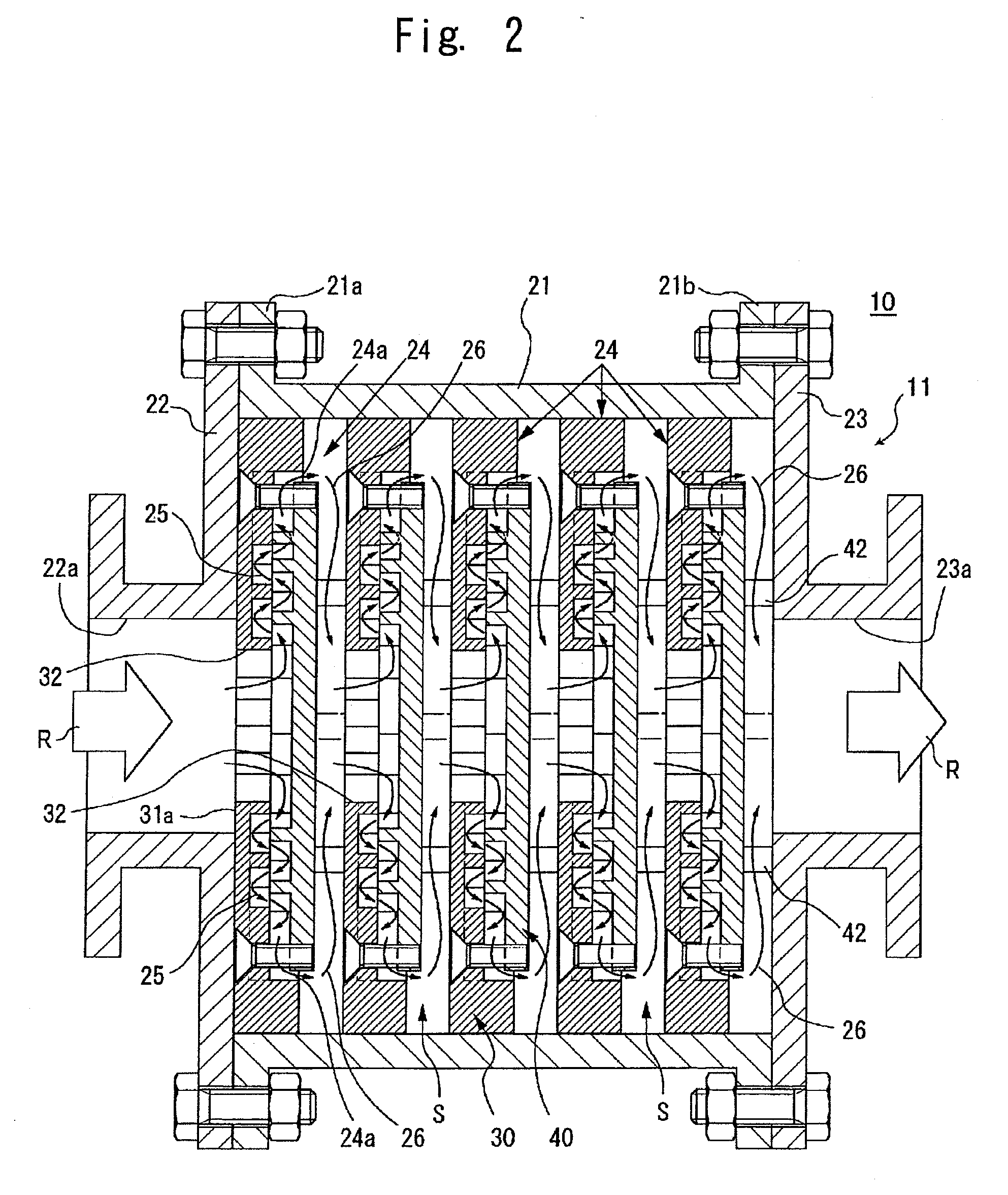

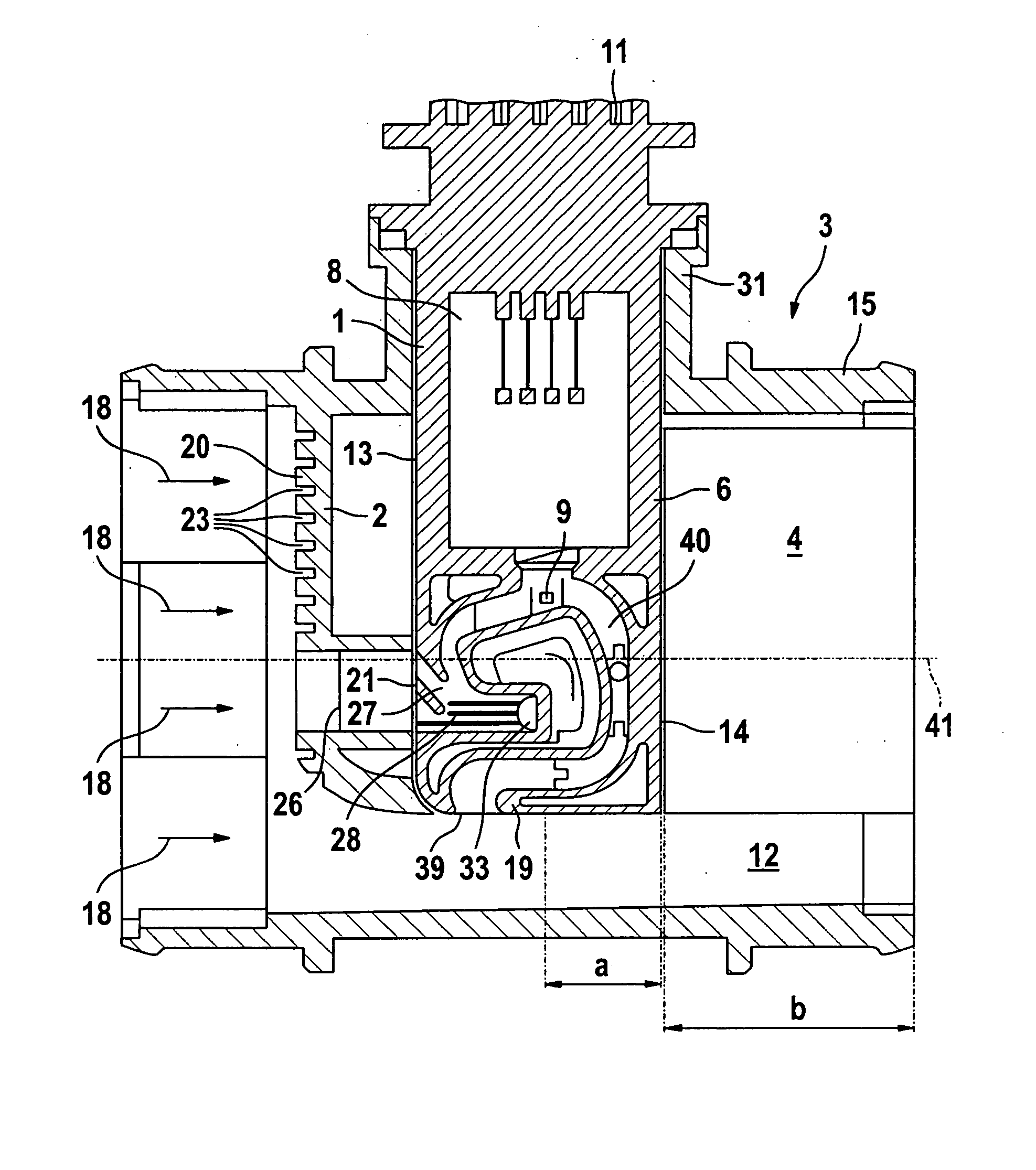

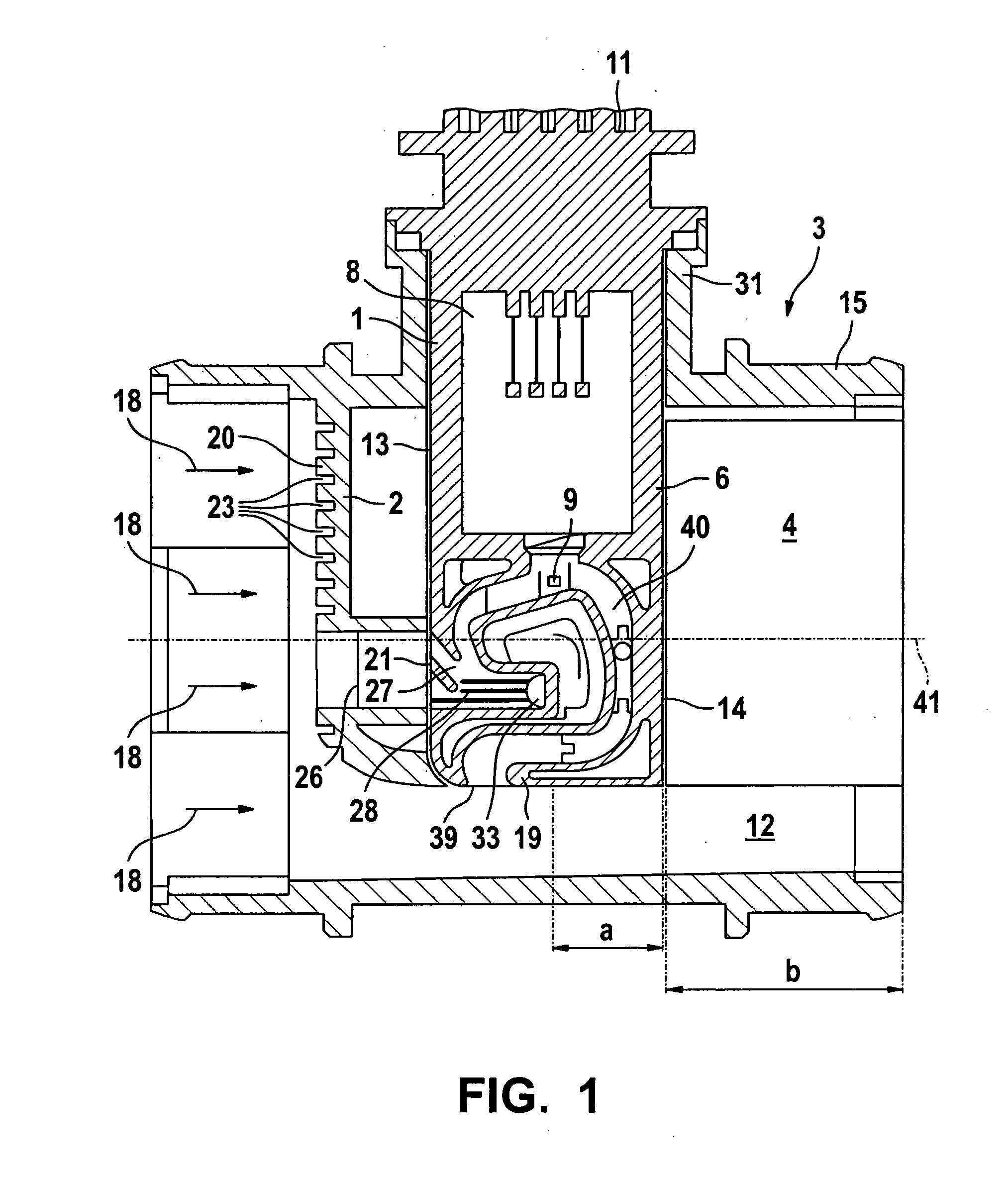

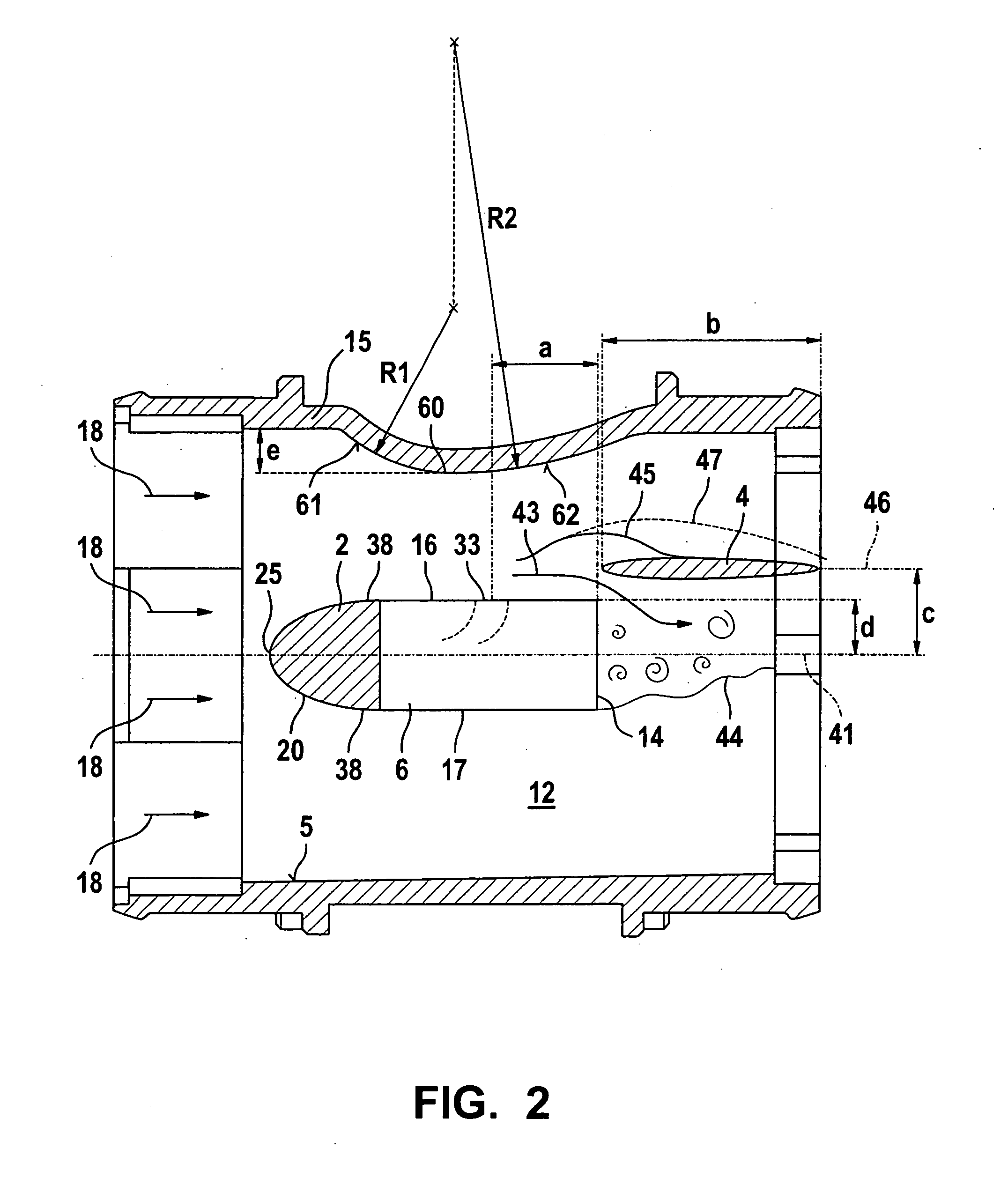

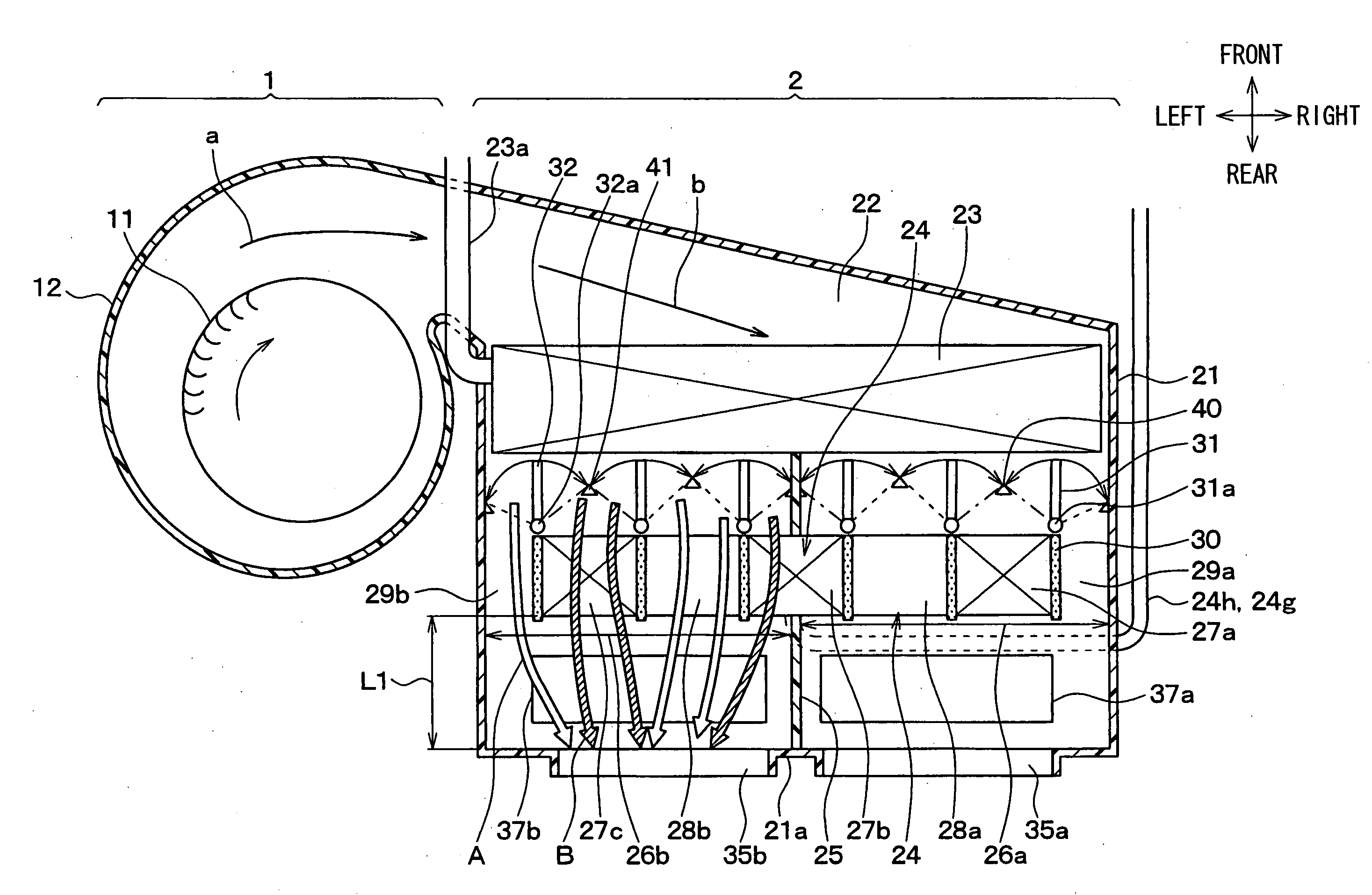

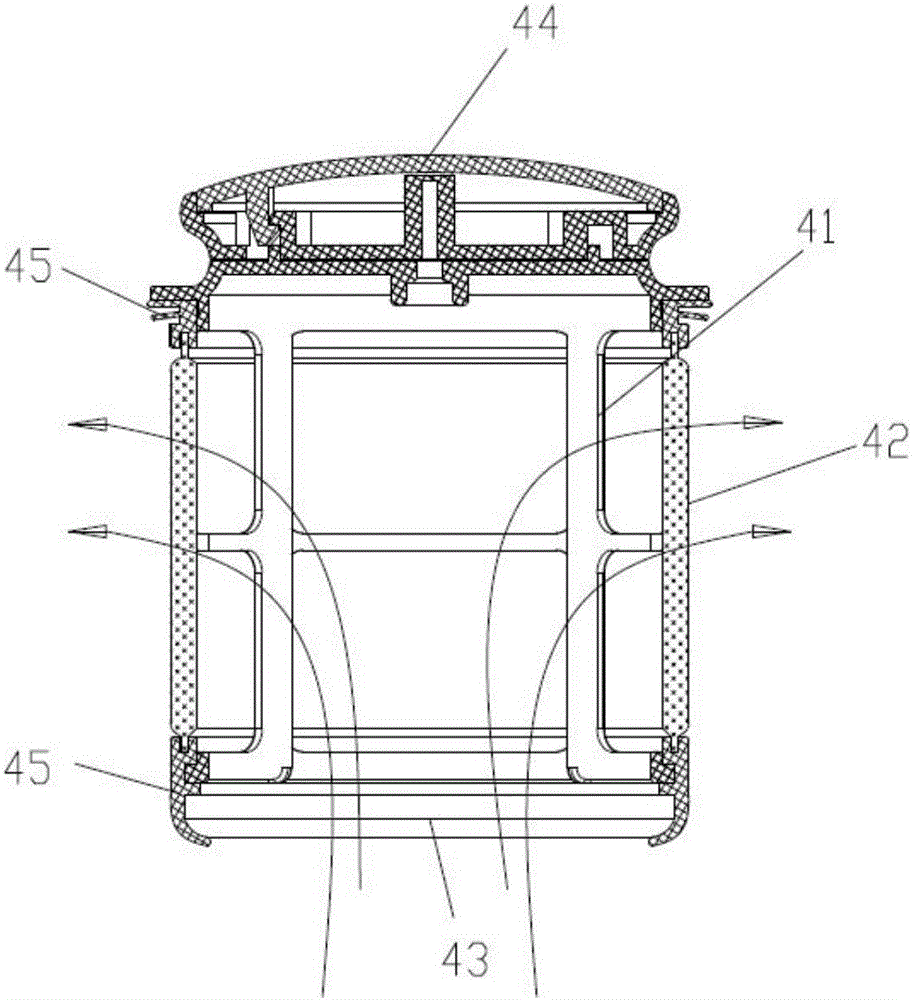

Semiconductor device and cooler thereof

ActiveUS20140376184A1Reduce pressure lossReduce power lossSemiconductor/solid-state device detailsSolid-state devicesHeat sinkCooling Units

A semiconductor device exhibits low pressure loss and is capable of cooling a plurality of power semiconductor chips evenly. This semiconductor device includes a semiconductor module and a cooler for cooling a power semiconductor element mounted in the semiconductor module. A cooling unit of the cooler has a first header part that has a first bottom surface disposed between a coolant inlet and an end portion of a first substrate on the coolant outlet side and inclined toward a bottom plane of cooling fins so that a coolant supplied from the coolant inlet flows toward the cooling fins; and a second header part that has a second bottom surface inclined from an end portion of the bottom plane of the cooling fins on the coolant outlet side so that the coolant discharged from the cooling fins flows to the coolant outlet.

Owner:FUJI ELECTRIC CO LTD

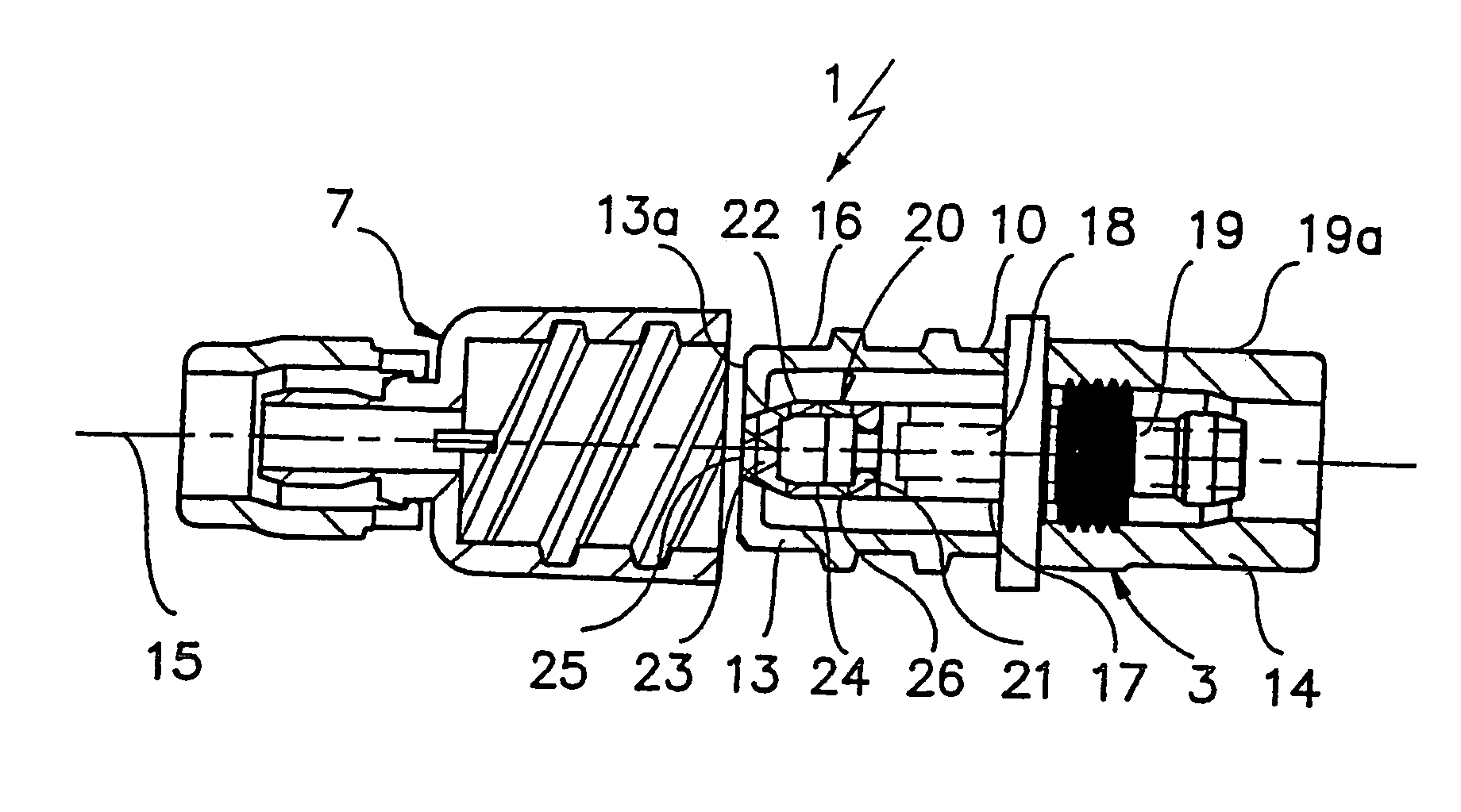

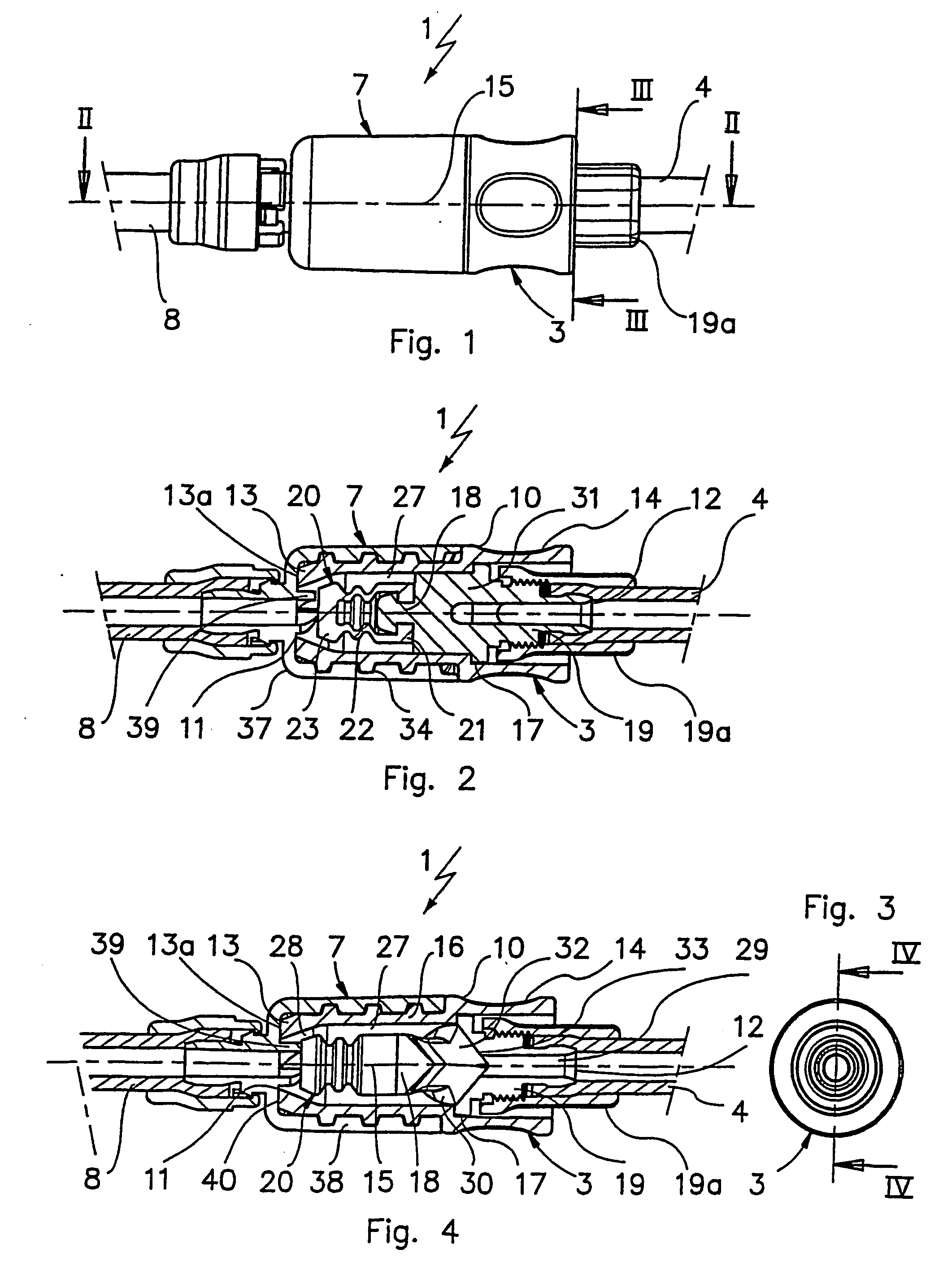

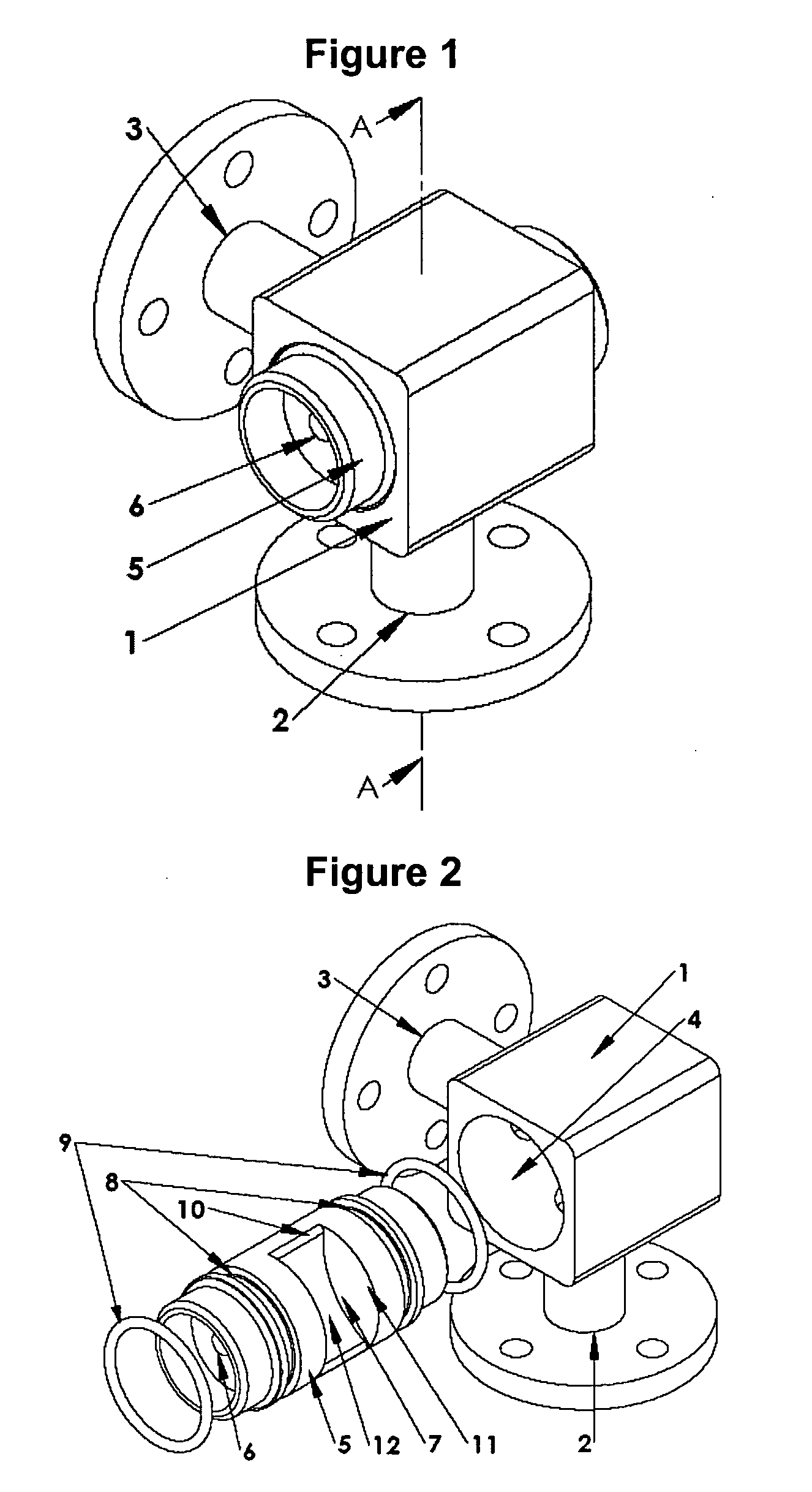

Connection element and connecting device for tubes

ActiveUS20050212292A1Reduce pressure lossLittle encouragementValve arrangementsInfusion devicesPeritoneal dialysisEngineering

A description is given of a connecting device for tubes for medical use having a connection element (7) comprising a main body designed to be attachable to the end of a first tube, and a shut-off element made of an elastically deformable material and at least partly housed inside the main body, to allow or prevent, as required, fluid communication through the main body. The shut-off element has a longitudinal axis of symmetry and is designed to deform symmetrically. Also described are a tube and a peritoneal dialysis line using the connection element described above.

Owner:GAMBRO LUNDIA AB

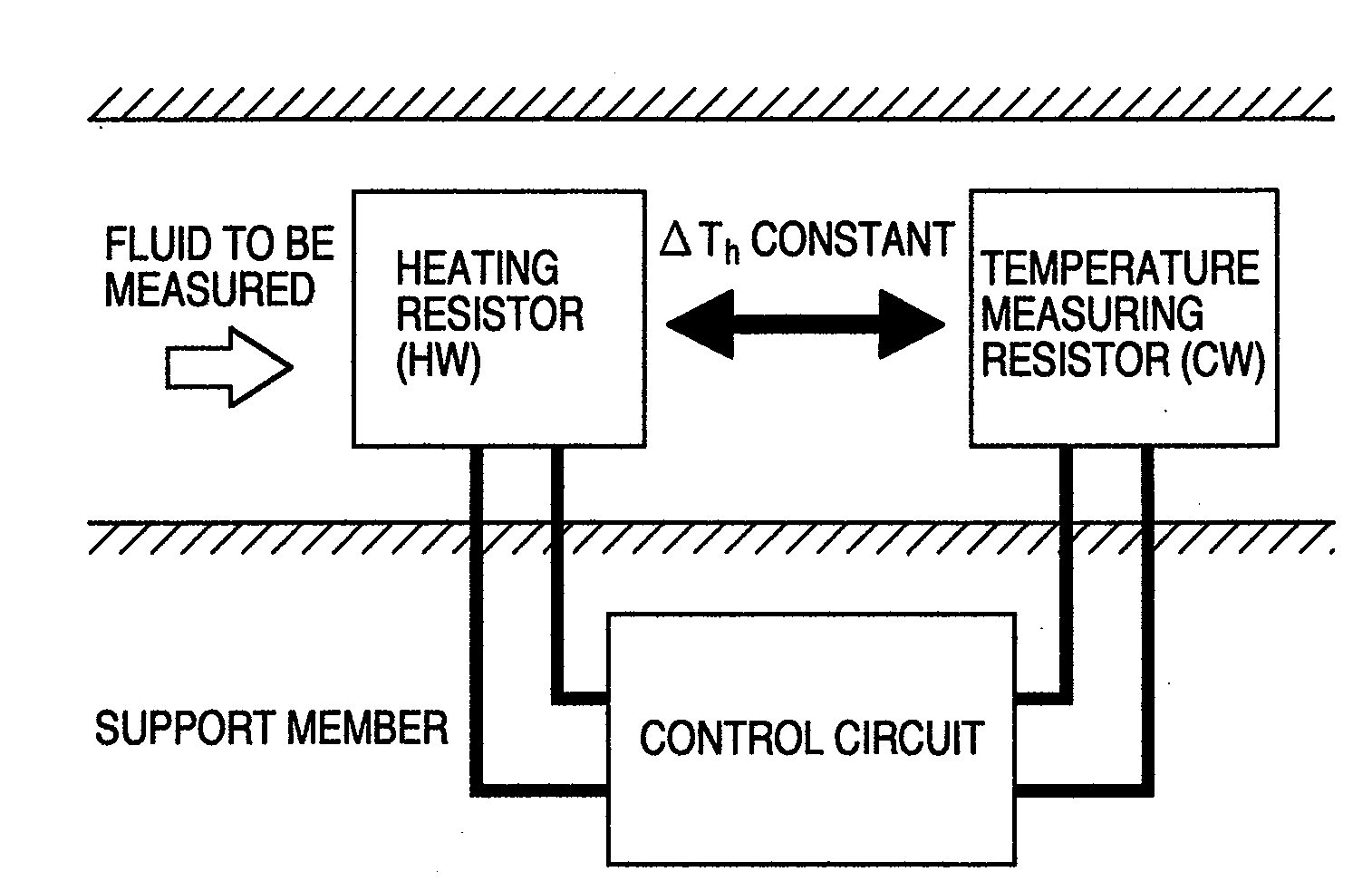

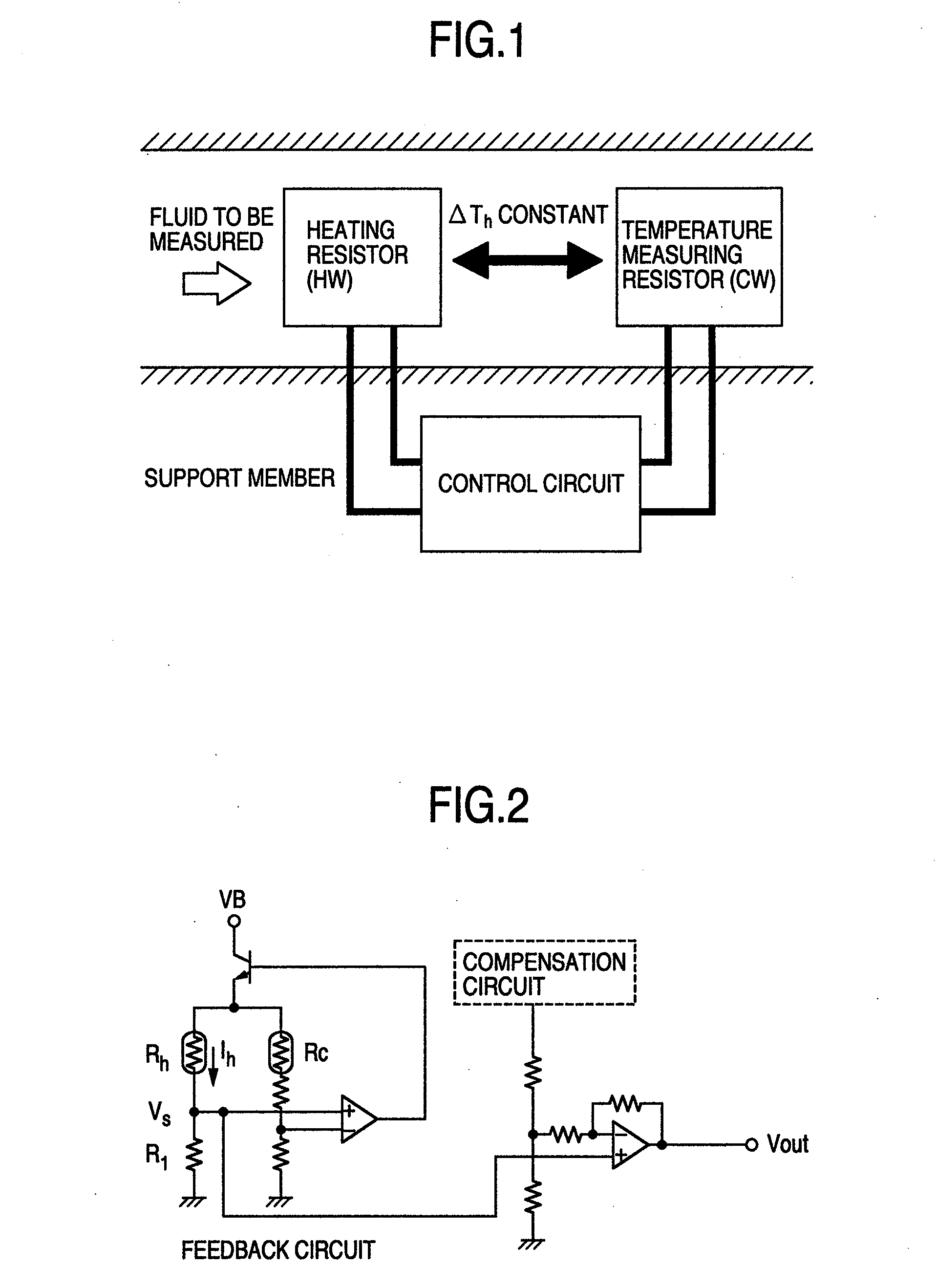

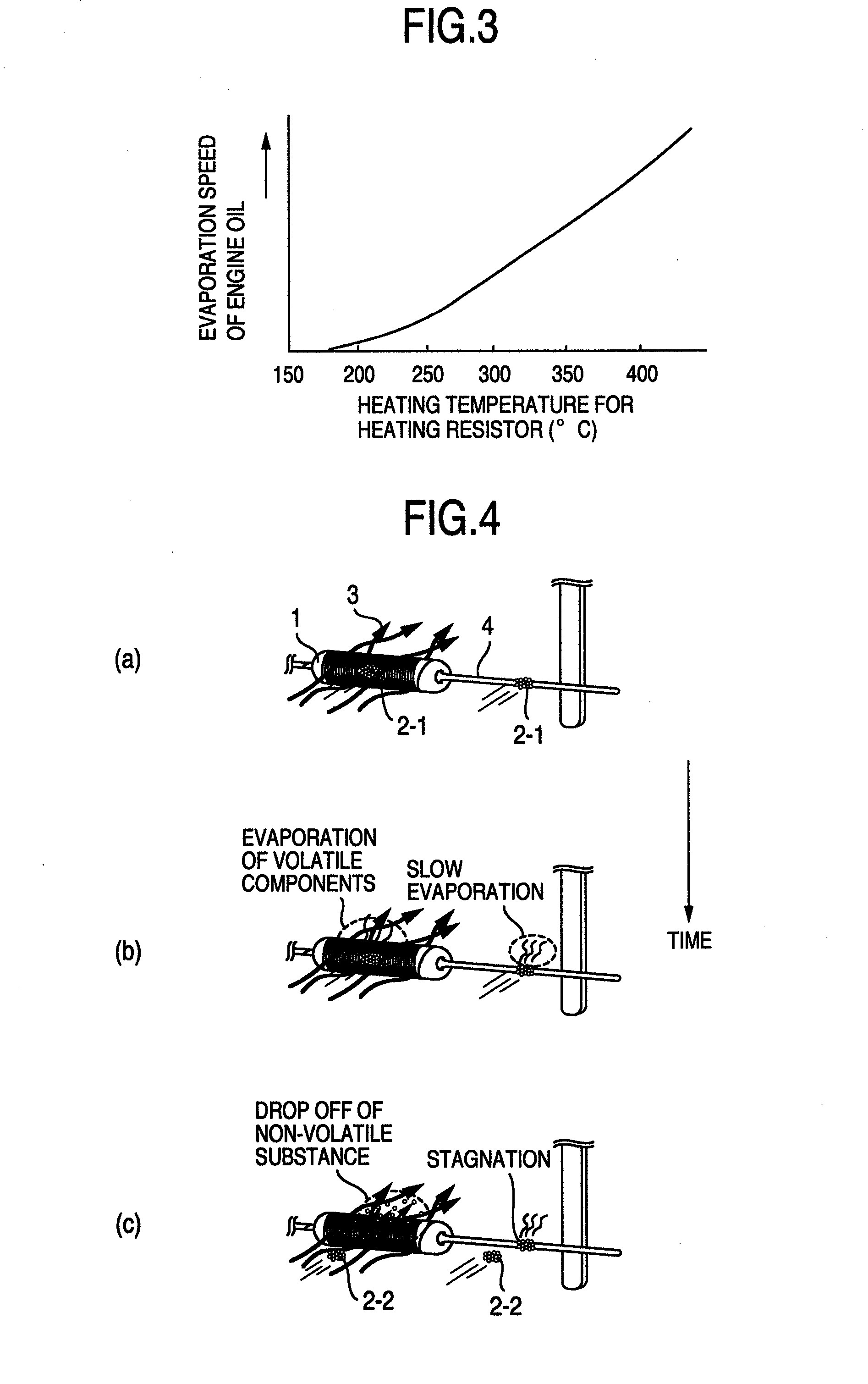

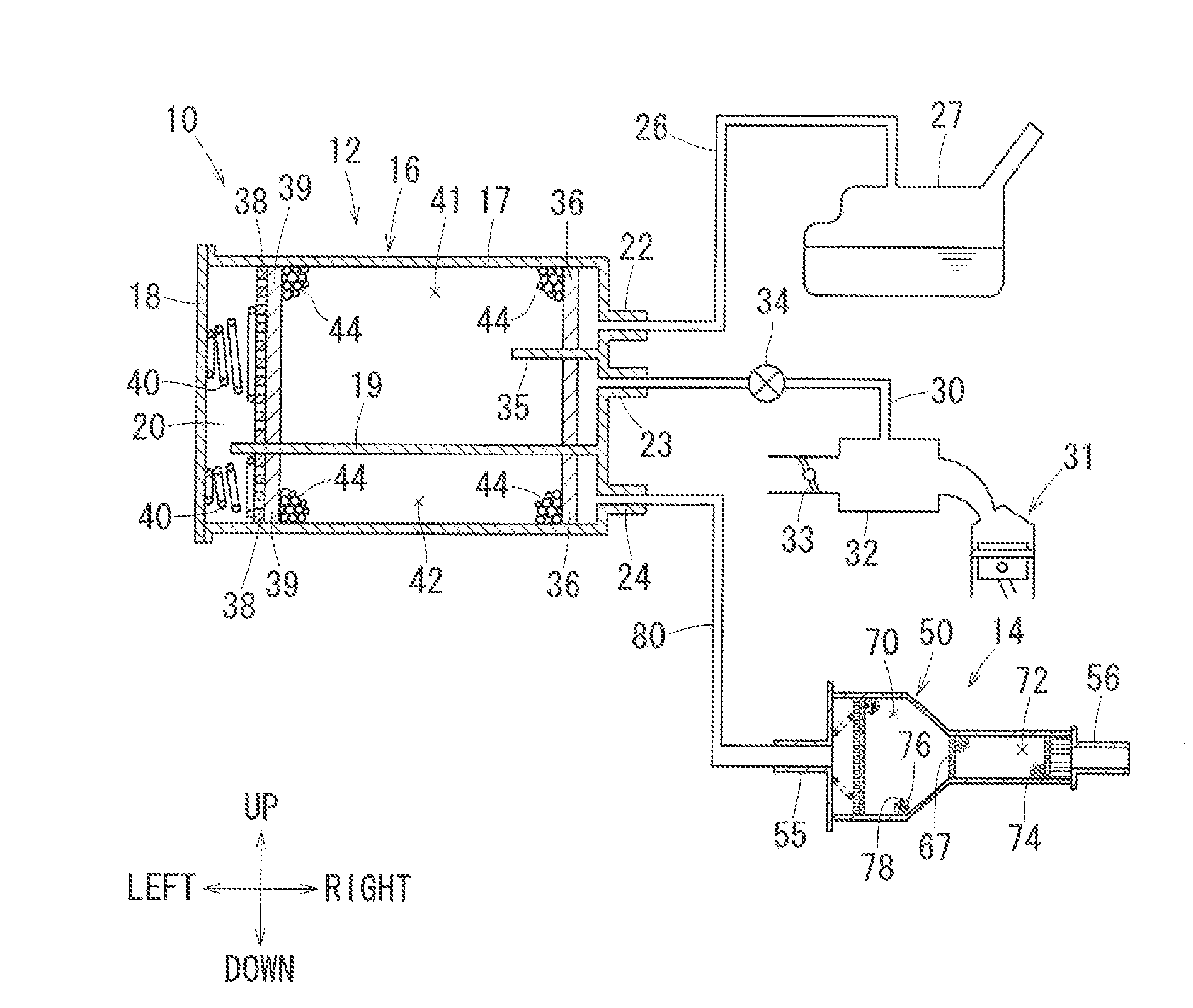

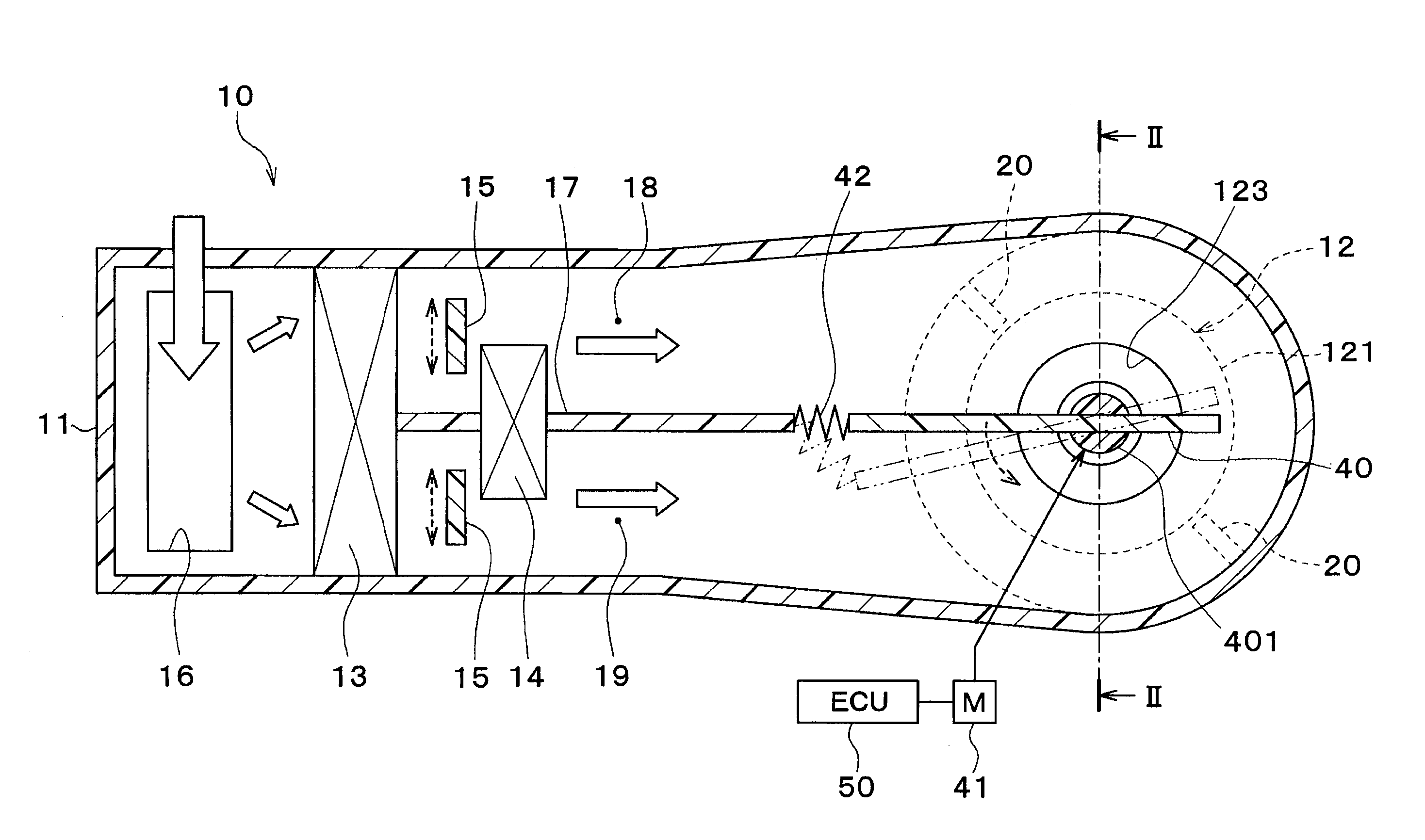

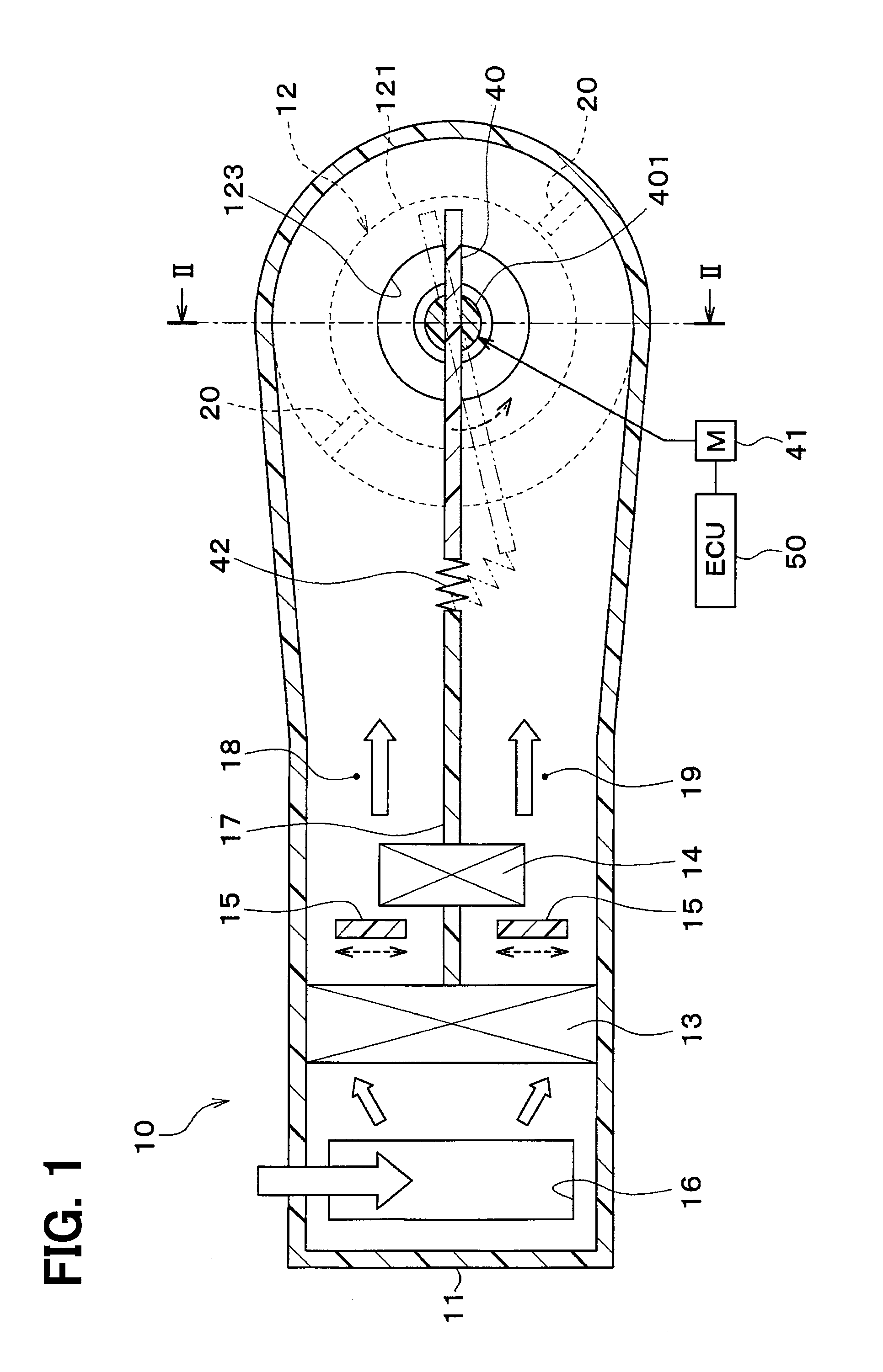

Thermal type flow meter and engine control system using the same

InactiveUS20080295590A1Small sizeFacilitate assurance of installation spaceVolume/mass flow by thermal effectsControl systemEngineering

A thermal type flow meter has a first heating resistor, a second heating resistor for blocking heat transfer from the first heating resistor to a console, a temperature measuring resistor interposed between the two heating resistors, and a controller for calculating a flow rate unrelated to temperatures of fluid from temperatures of the resistors and currents supplied to the heating resistors.

Owner:HITACHI LTD

Trap canister capturing fuel vapor

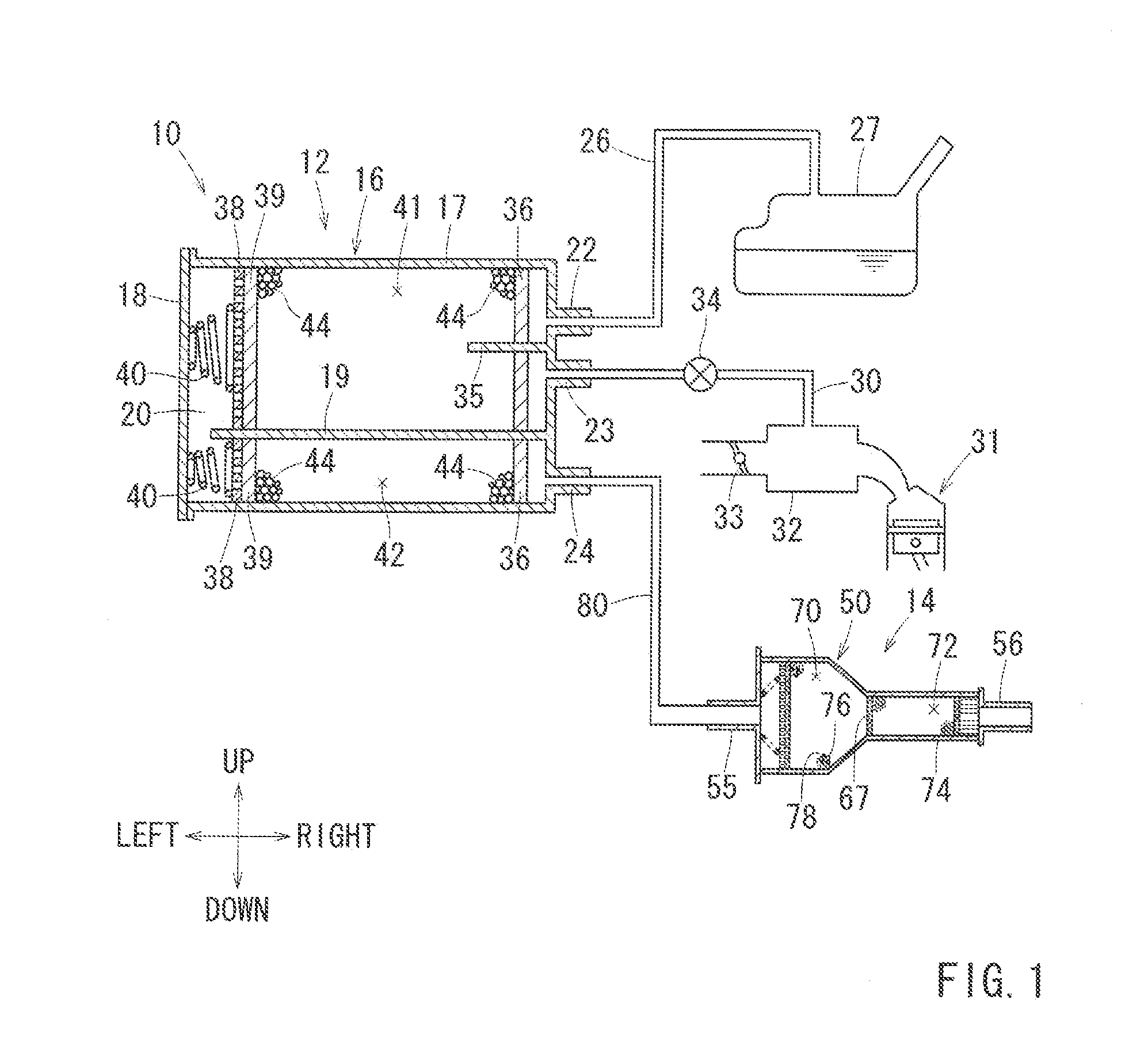

InactiveUS20130186375A1Reduce the amount of fuelReduce pressure lossNon-fuel substance addition to fuelMachines/enginesNuclear engineeringFuel vapor

A trap canister is configured to capture fuel vapor contained in breakthrough gas discharged from an adsorbent canister. The trap canister has a housing defining an adsorption chamber therein, a breathable partition member disposed in the housing and dividing the adsorption chamber into a first chamber and a second chamber, an adsorbent filled in the first chamber and the second chamber, and a latent heal storage material tilled in the first chamber in a mixed manner with the adsorbent. The first chamber is configured to receive breakthrough gas, while the second chamber is configured to communicate with the atmosphere. The first chamber has a cross-sectional area larger than that of the second chamber.

Owner:AISAN IND CO LTD

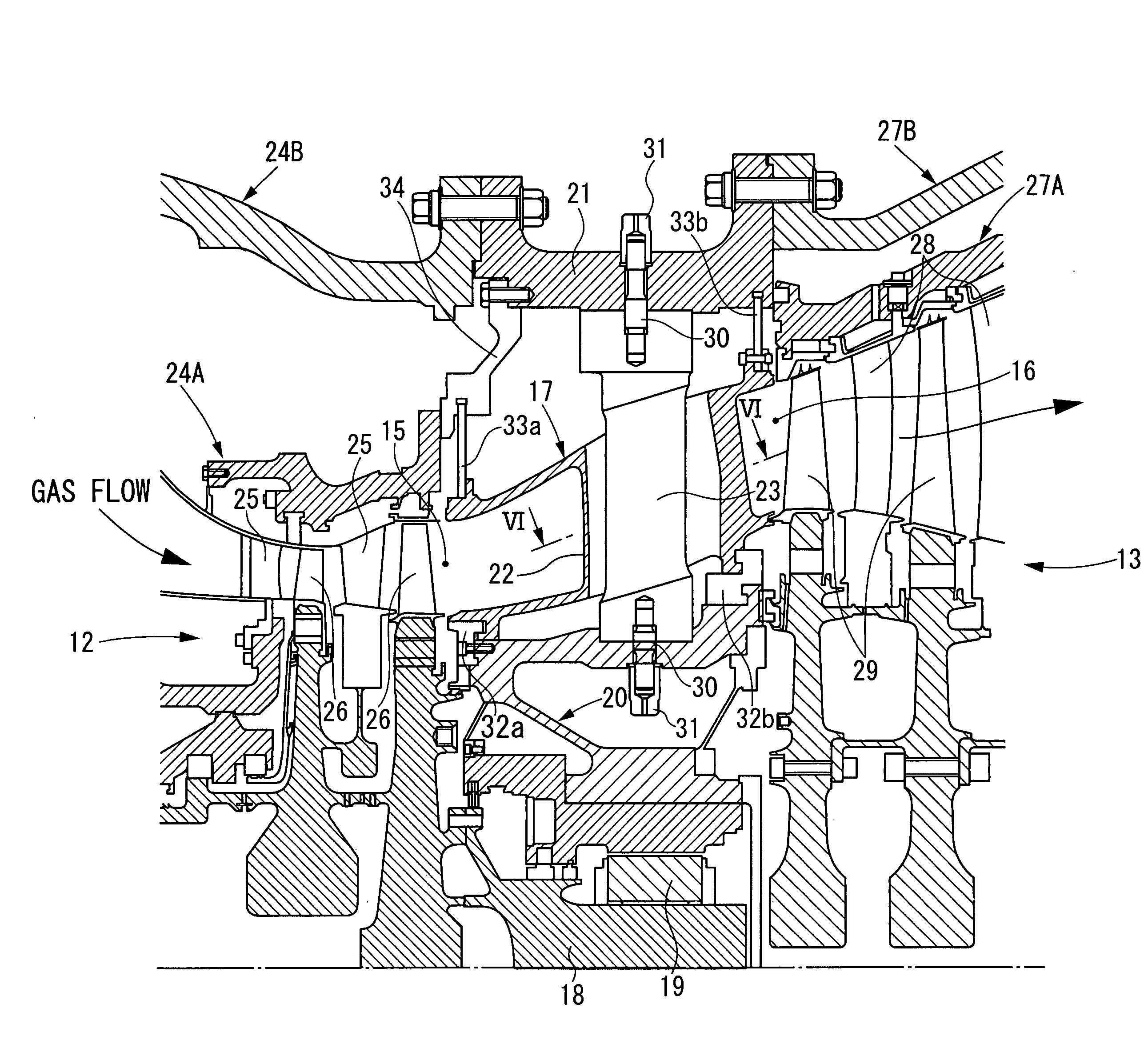

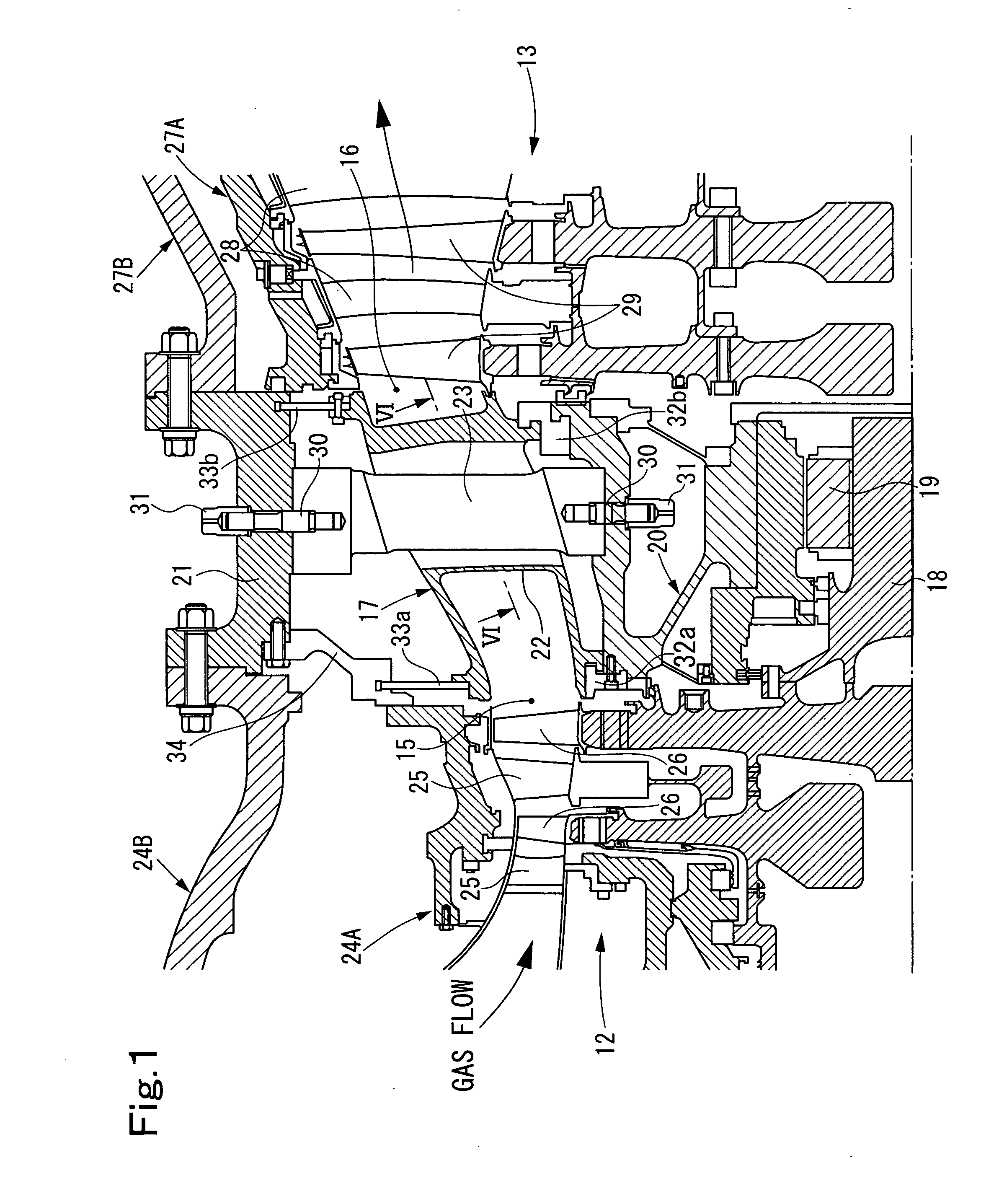

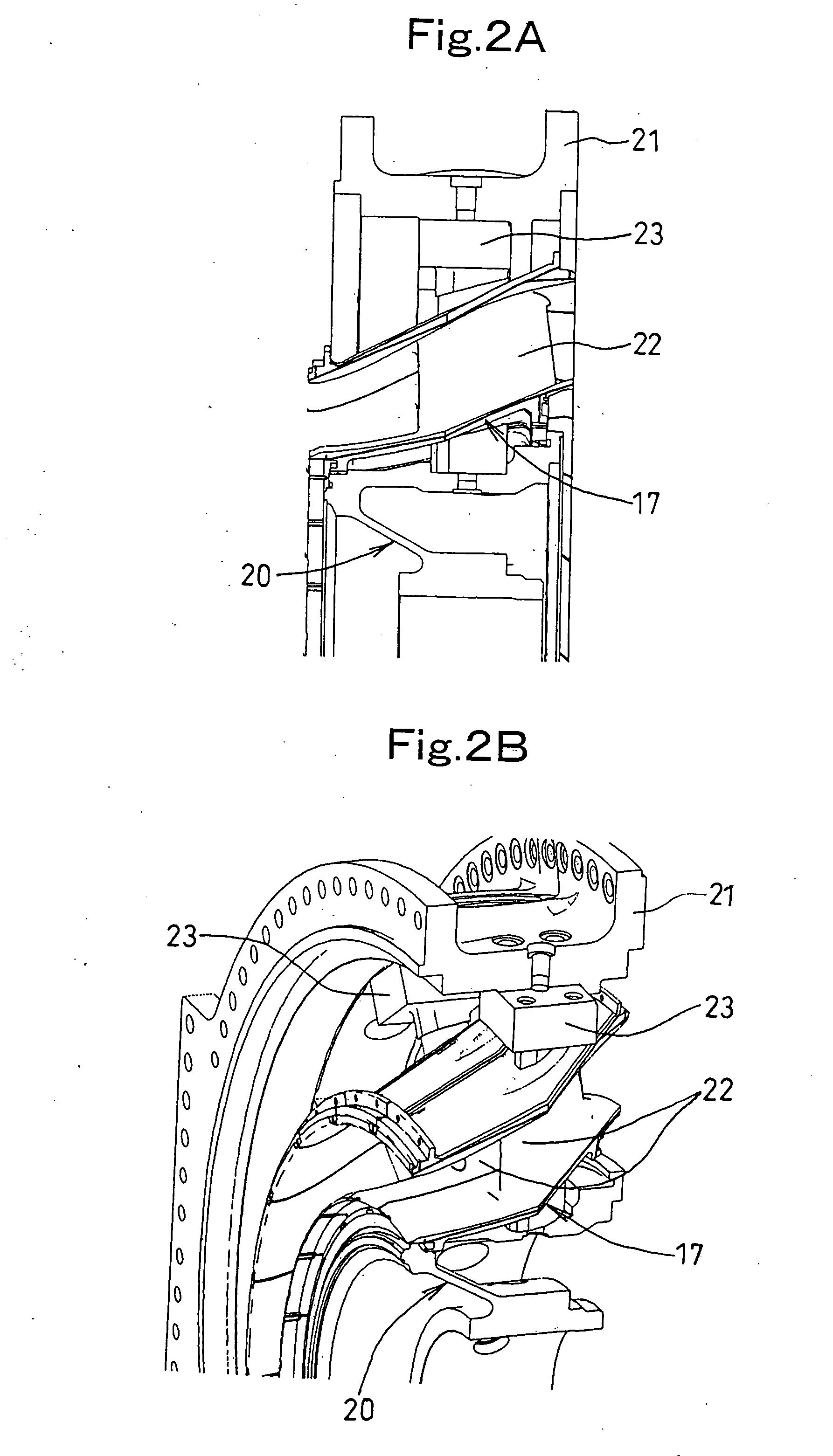

Two-shaft gas turbine

InactiveUS20100303608A1Improve performanceShorten the lengthCombination enginesEngine componentsEngineeringHigh pressure

A two-shaft gas turbine includes a high-pressure turbine having an annular gas-passage outlet, a low-pressure turbine having an annular gas-passage inlet, an annular intermediate duct that connects the gas-passage outlet to the gas-passage inlet, a bearing that supports a rotor of the high-pressure turbine and that is attached to a bearing case, and a plurality of struts that support the bearing case. The struts are arranged radially along the circumference of the bearing case so as to extend though the intermediate duct in a space between an outer peripheral surface of the bearing case and an inner peripheral surface of a casing wall that surrounds the intermediate duct. The intermediate duct has strut covers through which the struts extend and which function as first-stage stator blades for the low-pressure turbine.

Owner:MITSUBISHI HEAVY IND LTD

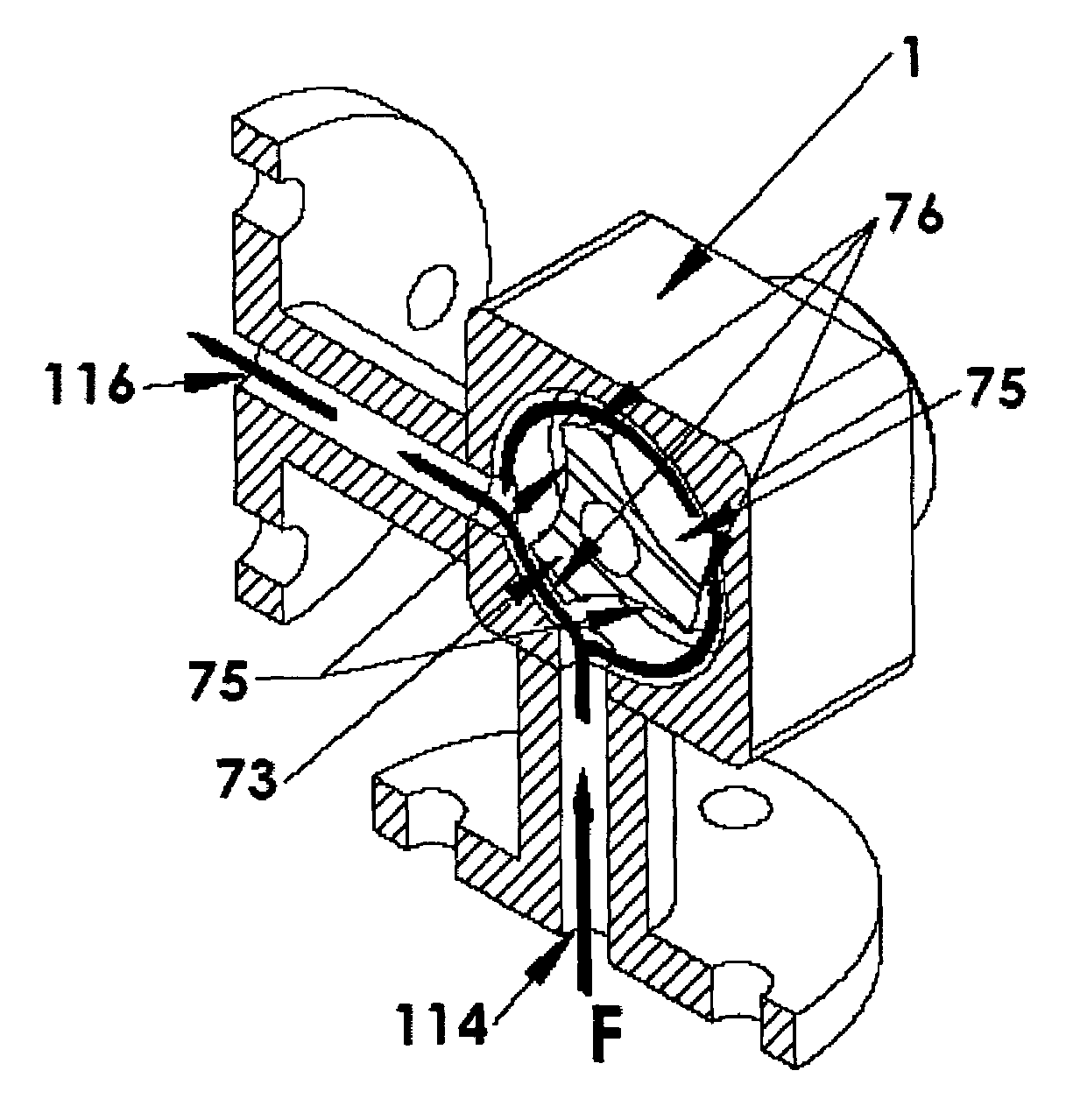

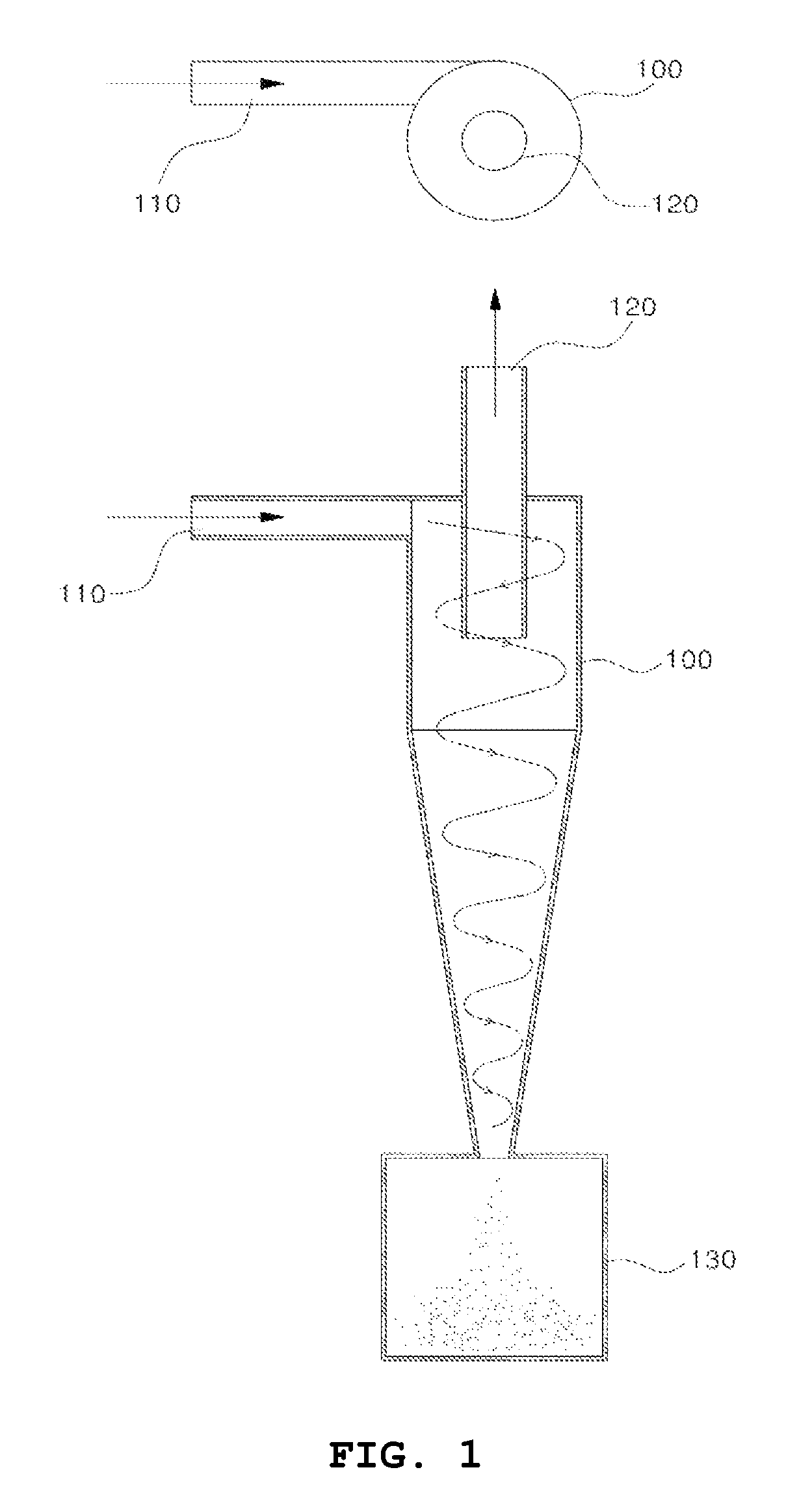

Static fluid mixer

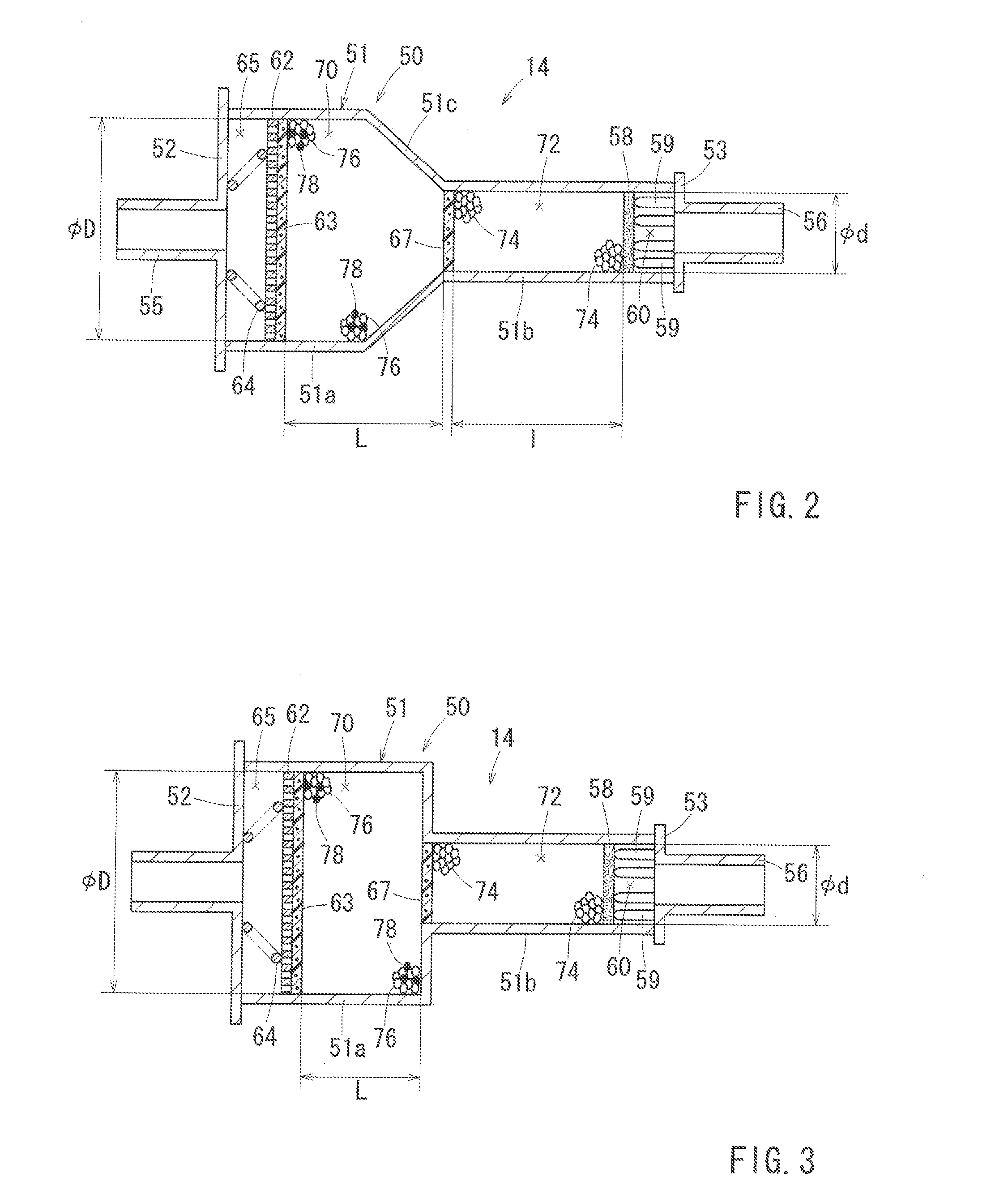

InactiveUS20100276820A1Reduce flow path resistanceReduce pressure lossFlow mixersMixing methodsEngineeringMechanical engineering

A static fluid mixer which can perform processing such as generation of ultrafine uniform bubbles and has small pressure loss. A static fluid mixer has mixing units having outflow openings for allowing fluid having passed through mixing flow paths to flow through the outflow openings. The mixing units are arranged in a tubular casing body at intervals in the axis direction of the casing body. Adjacent mixing units and the casing body forma flow path forming space. Each mixing unit has an annular outflow path communicating with the end of each mixing flow path. The annular outflow path is open in a ring-like form having a substantially constant width along the entire circumference. The opening at the end of the annular outflow path functions as an outflow opening connecting to the flow path forming space. In the outflow path forming space is formed a collection flow path into which liquid having passed through the mixing flow path collects after flowing from the entire circumference of the outflow opening which is open in the ring-like form and moving toward the axis of the casing body.

Owner:MG GROW UP CORP +1

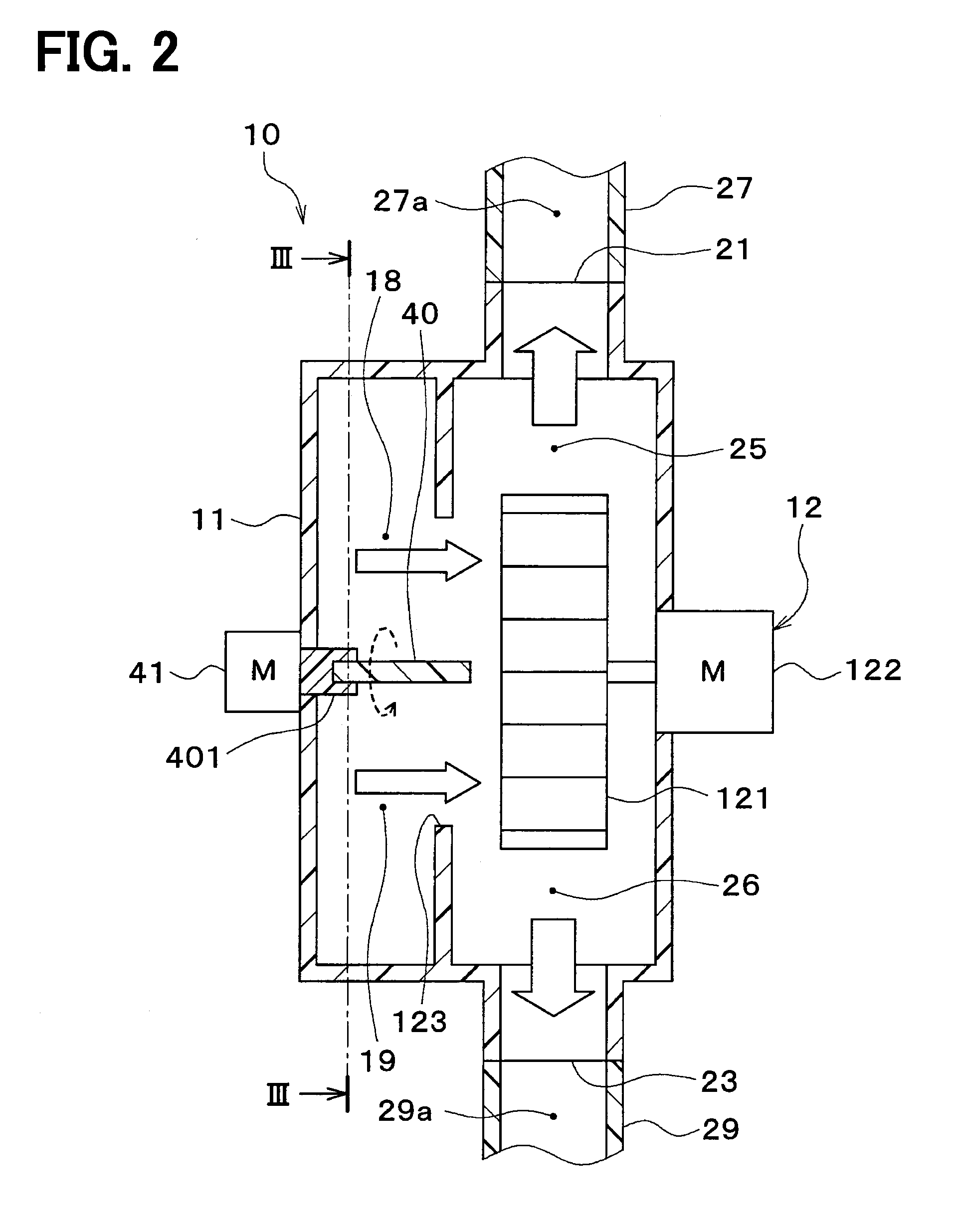

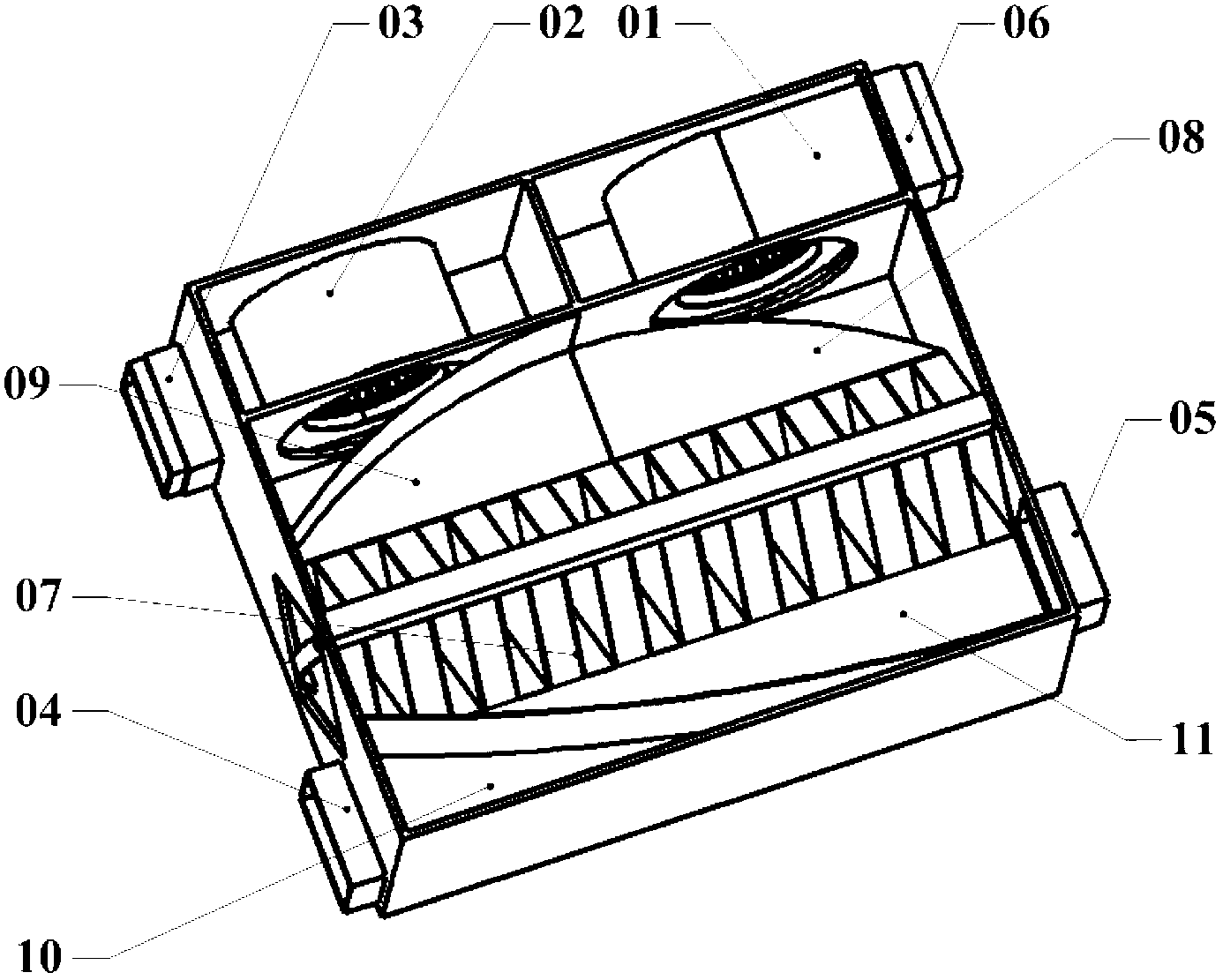

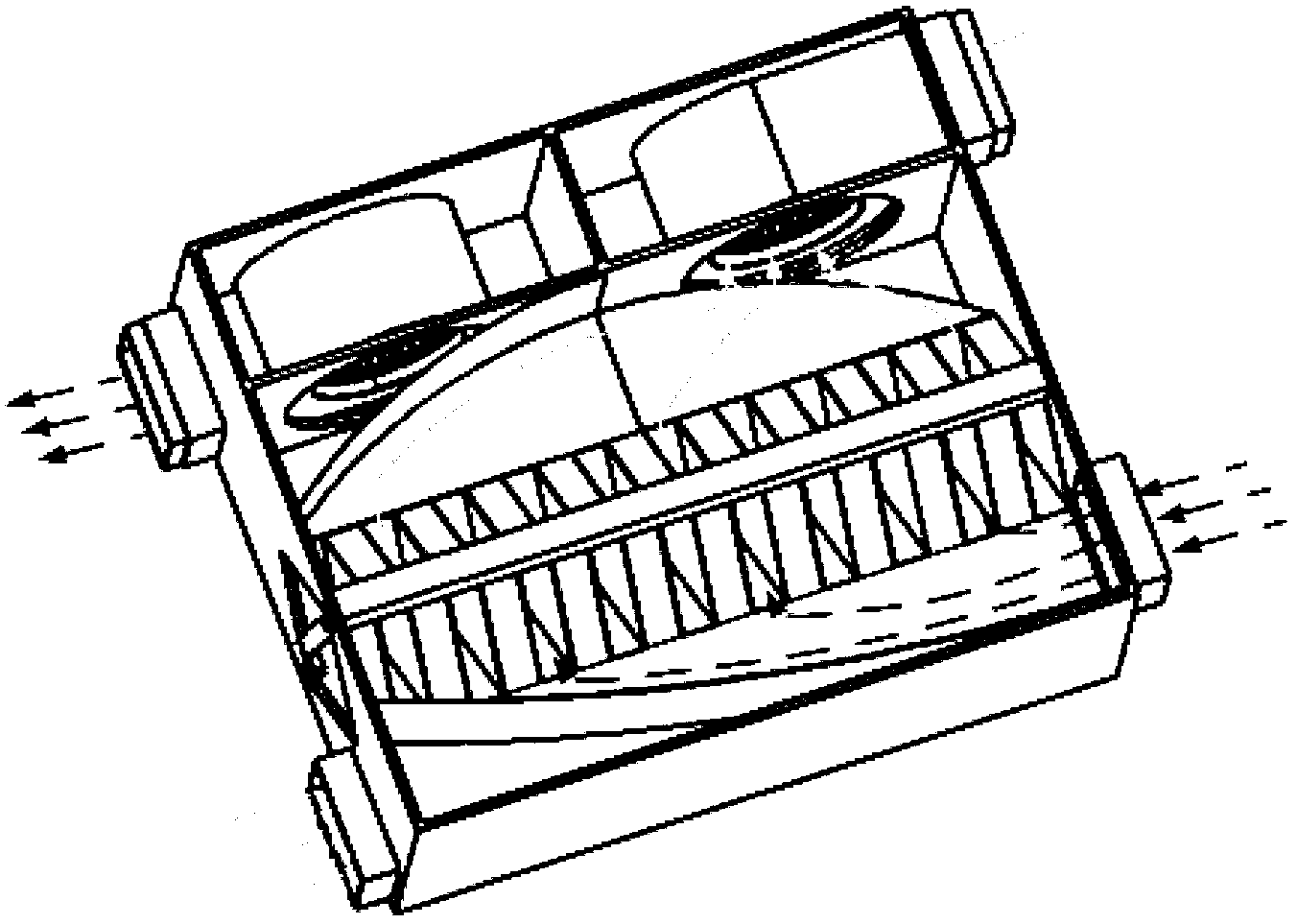

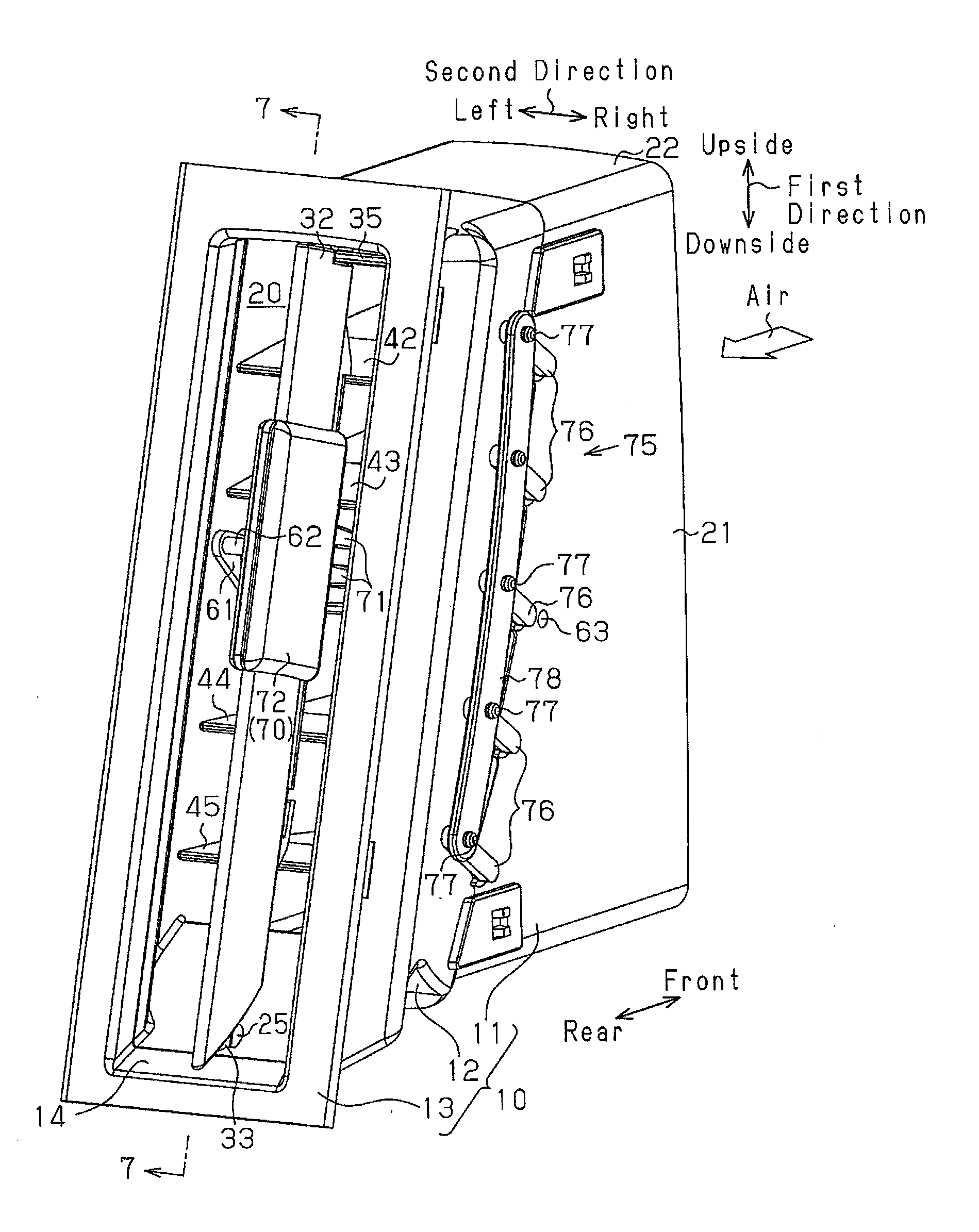

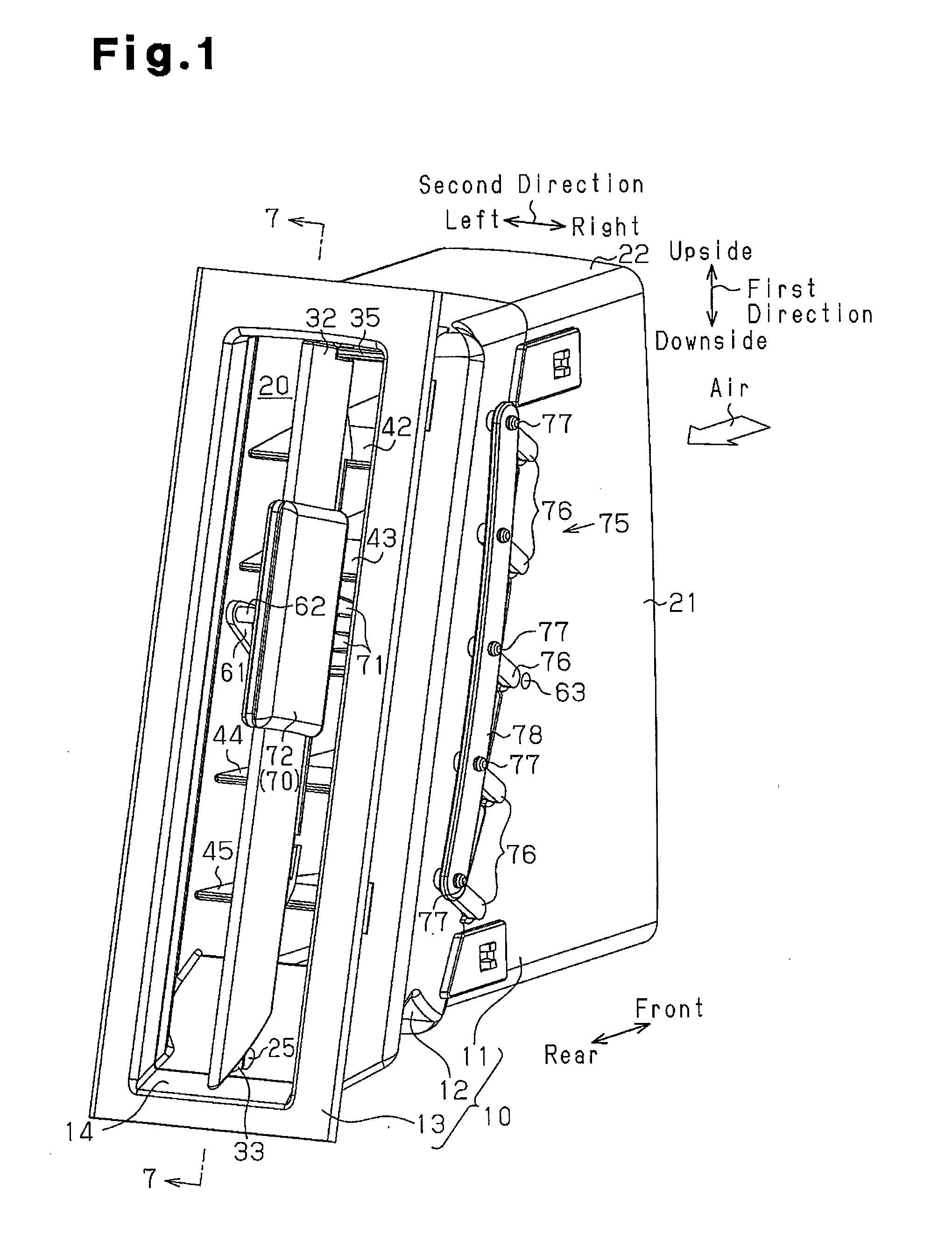

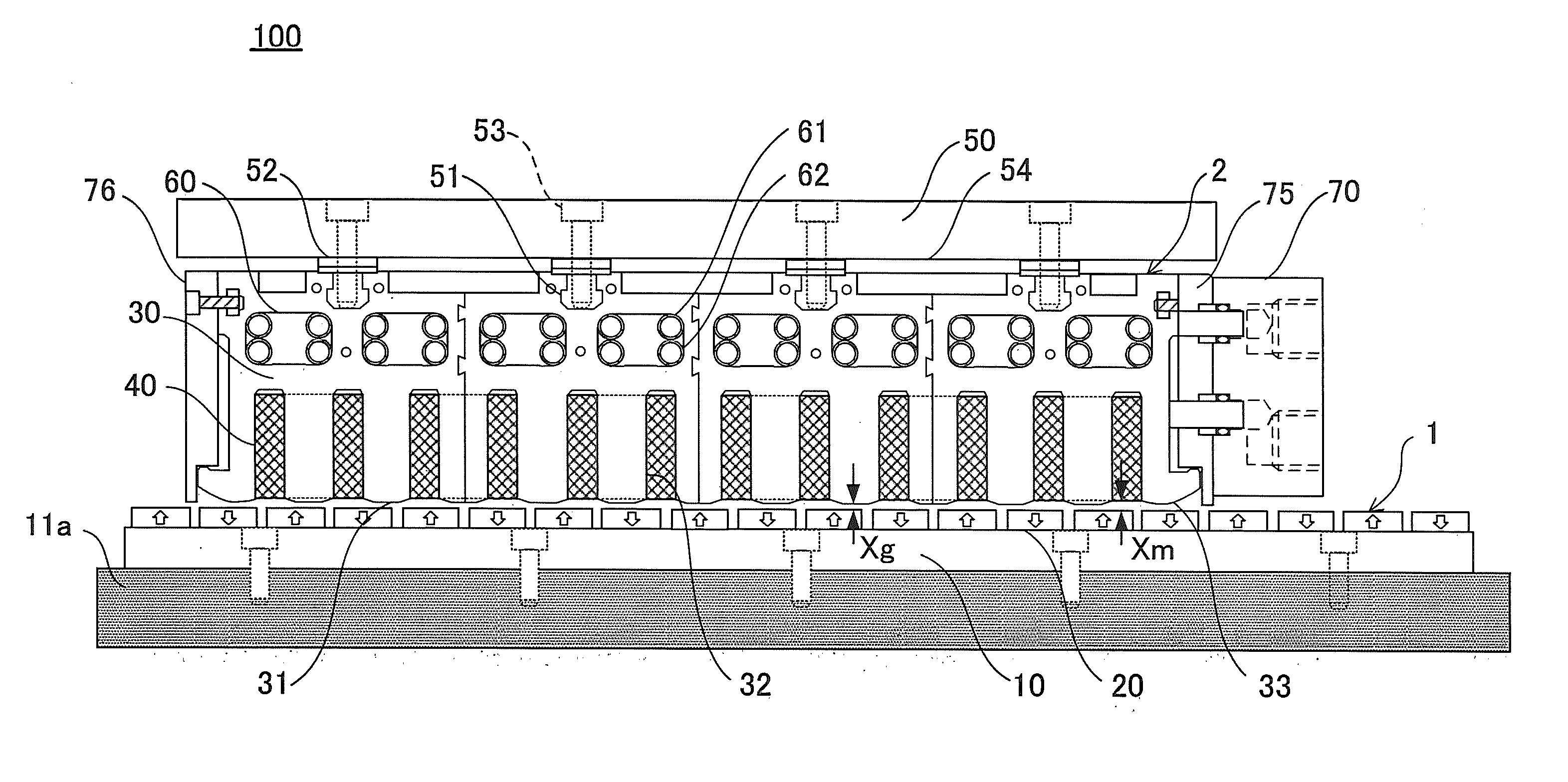

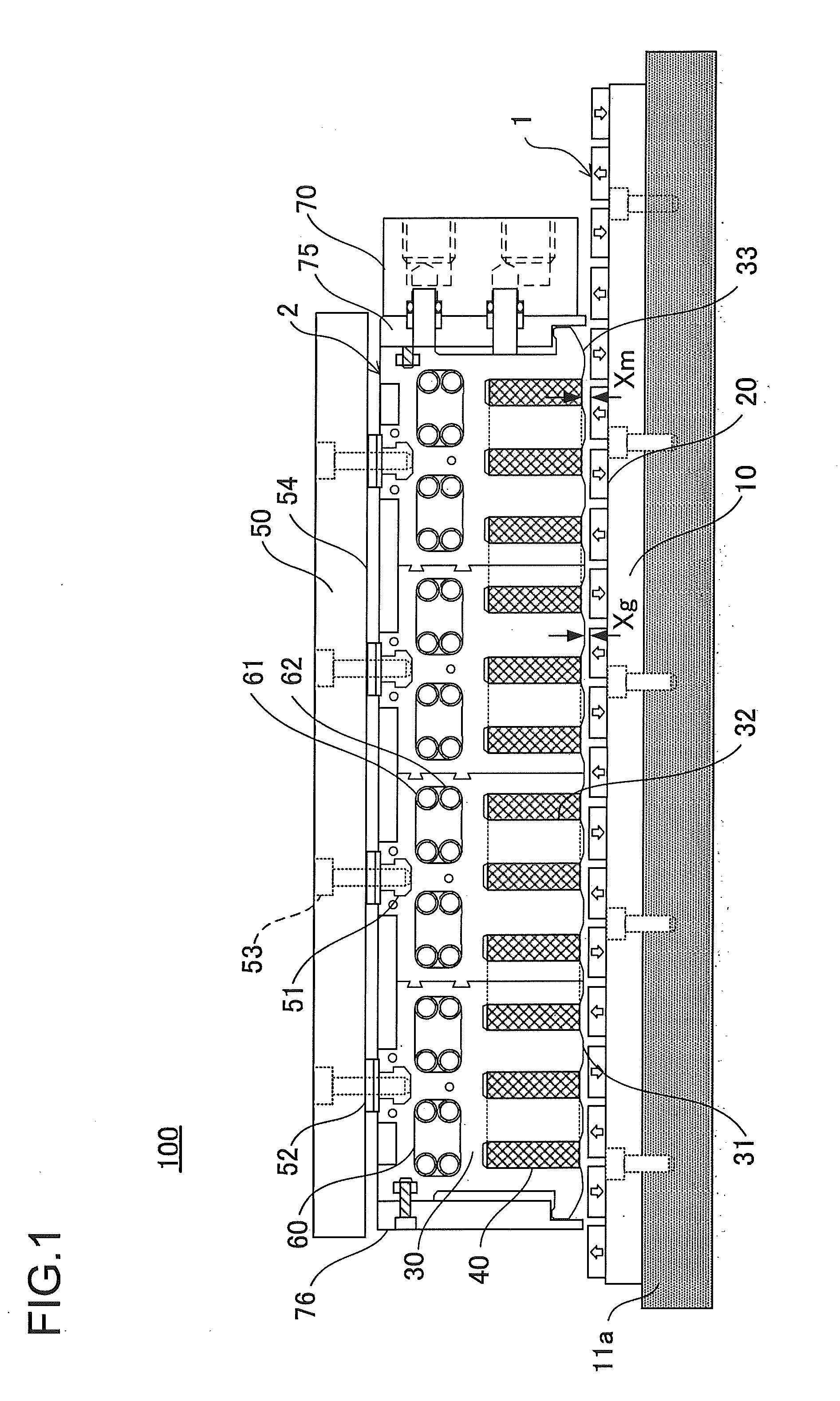

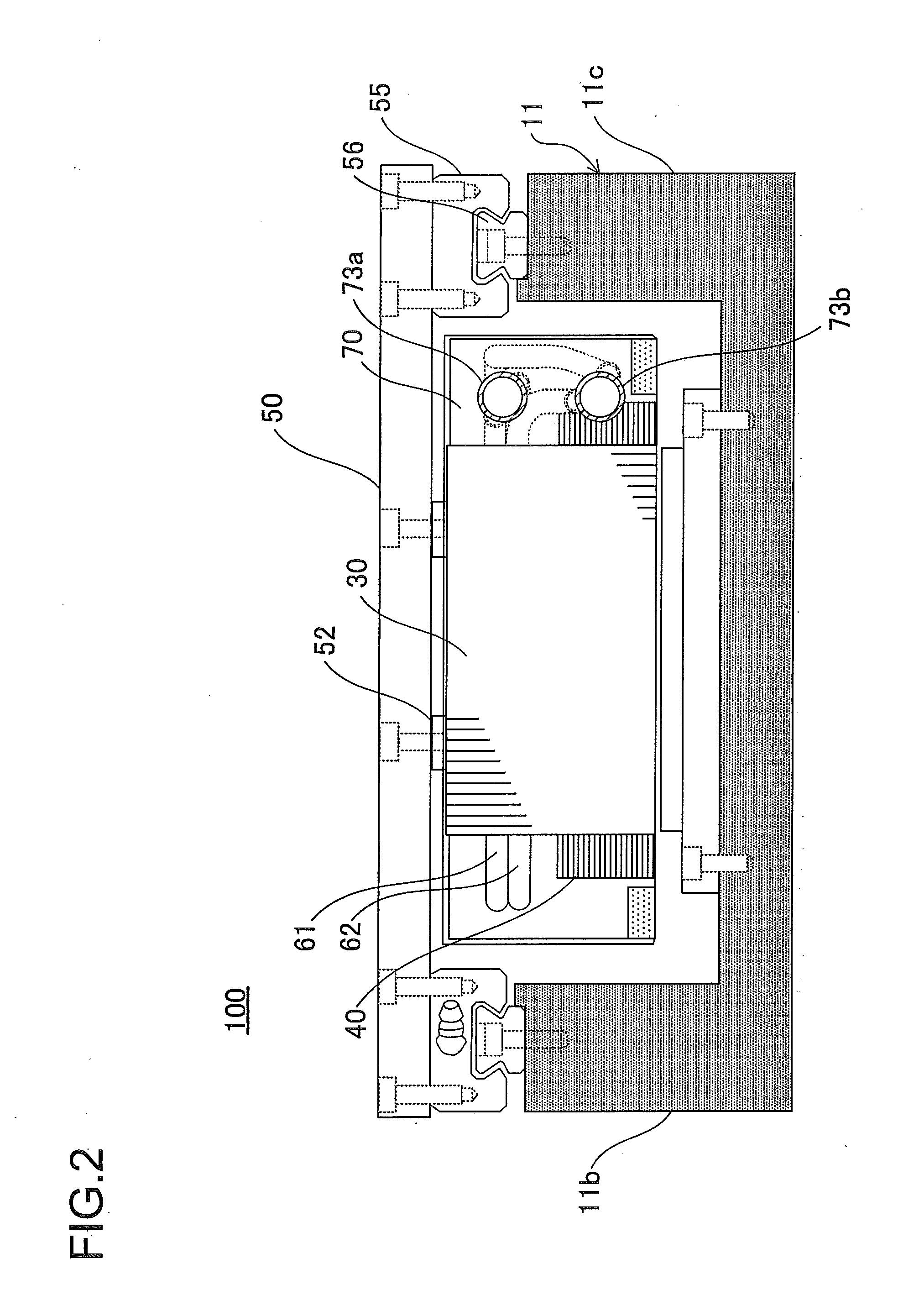

Air conditioning device

ActiveUS20160288609A1Reduce pressure lossAvoid mixing togetherAir-treating devicesLighting and heating apparatusEngineeringInhaled air

An air conditioning device includes a casing that provides multiple air passages, a blower fan that suctions an air from the multiple air passages and blows out the air in the casing, a suction side partitioning member that is disposed on a suction side of the blower fan in the casing and separates air flows from the multiple air passages from each other, and a blowing side partitioning member that is disposed on a blowing side of the blower fan in the casing and separates the air flows from the multiple air passages from each other. The suction side partitioning member and the blowing side partitioning member are disposed so that a relative position of the blowing side partitioning member to the suction side partitioning member is deviated in a rotation direction of the blower fan.

Owner:DENSO CORP

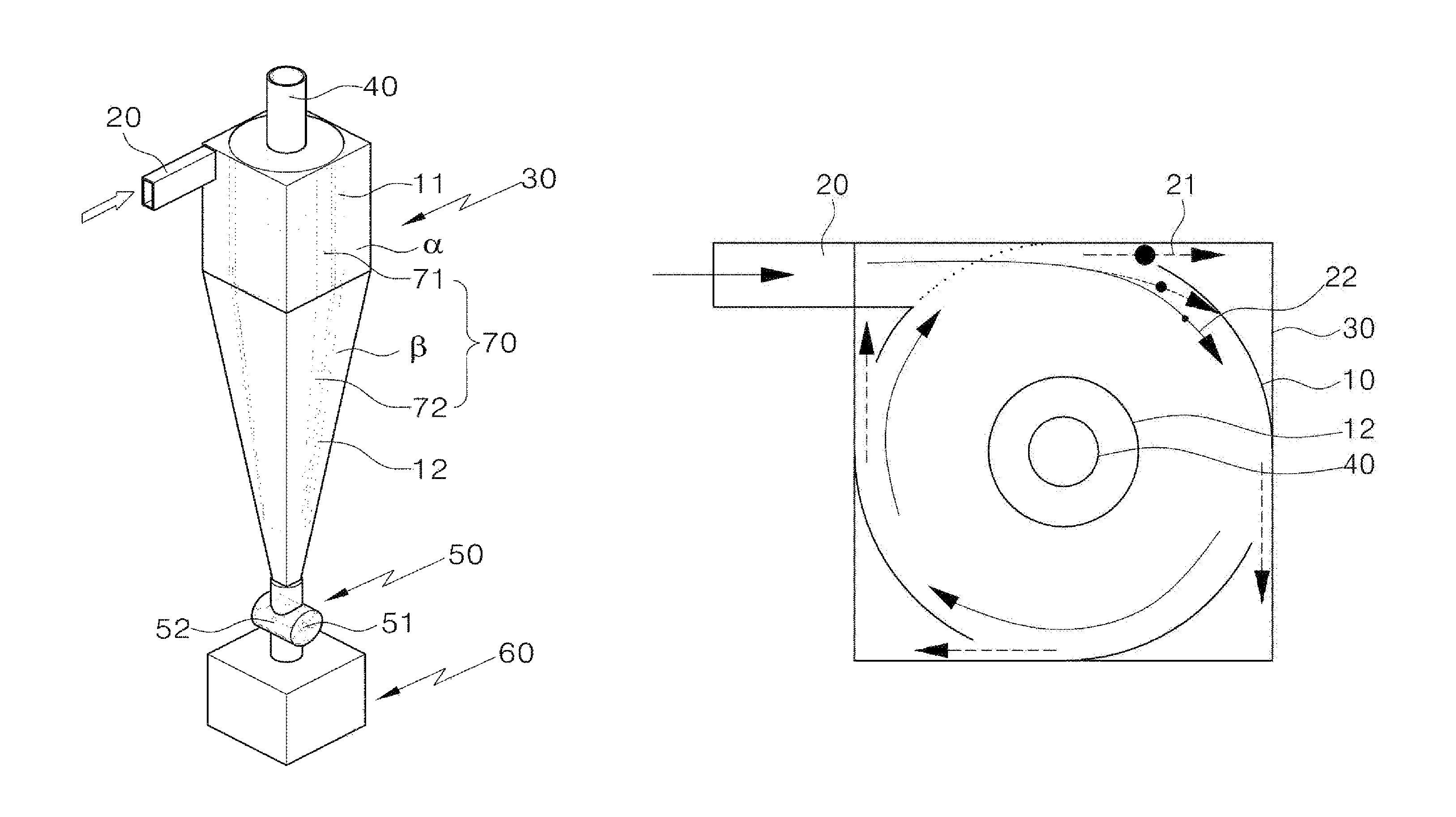

Rotary Valve for Industrial Fluid Flow Control

InactiveUS20090065724A1Reduce pressure lossReduce noisePlug valvesShaking/oscillating/vibrating mixersDry-ice blastingBiomedical engineering

A cylindrical rotary valve to control or affect fluid flow in processes where the fluid temperature must be maintained within a target range, the fluid pressure is varied and / or the amount of fluid flow is controlled comprising one or more of the following elements alone or in combination: (i) the use of a temperature control core in the valve shaft, (ii) the contoured or tapered shapes or the conduits (iii) the use of the valve to create predictable pulses or waves in the fluid being controlled, (iv) a modular system of valves where the valve body is fixed and the valve shaft is replaceable with a second valve shaft of different conduit shape, (v) a rotary valve with multiple inputs or multiple outputs for either mixing or diverting of input fluids, and (vi) the use of the valve in abrasive particulate blasting and in particular dry ice blasting.

Owner:MITTON VALVE TECH

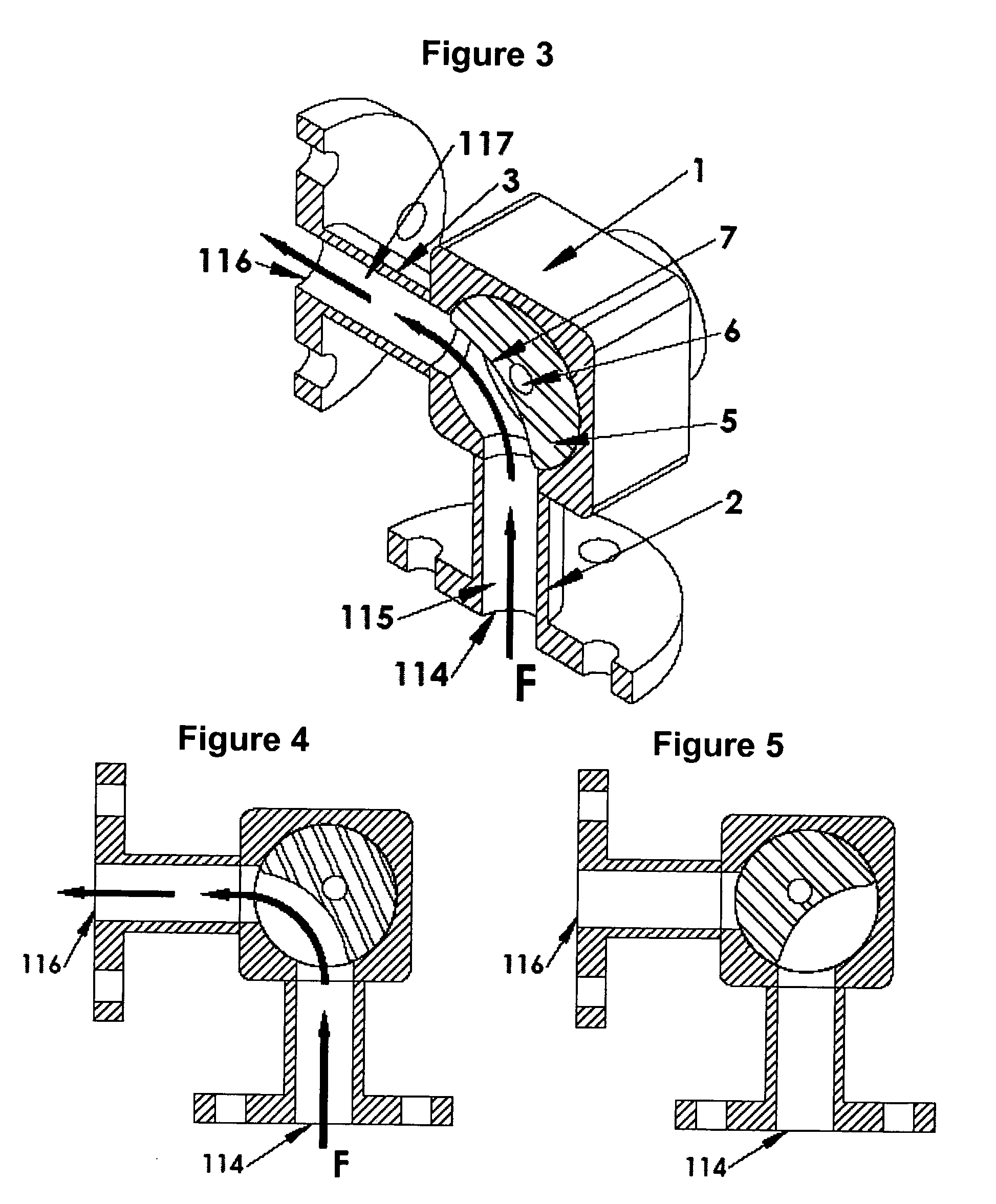

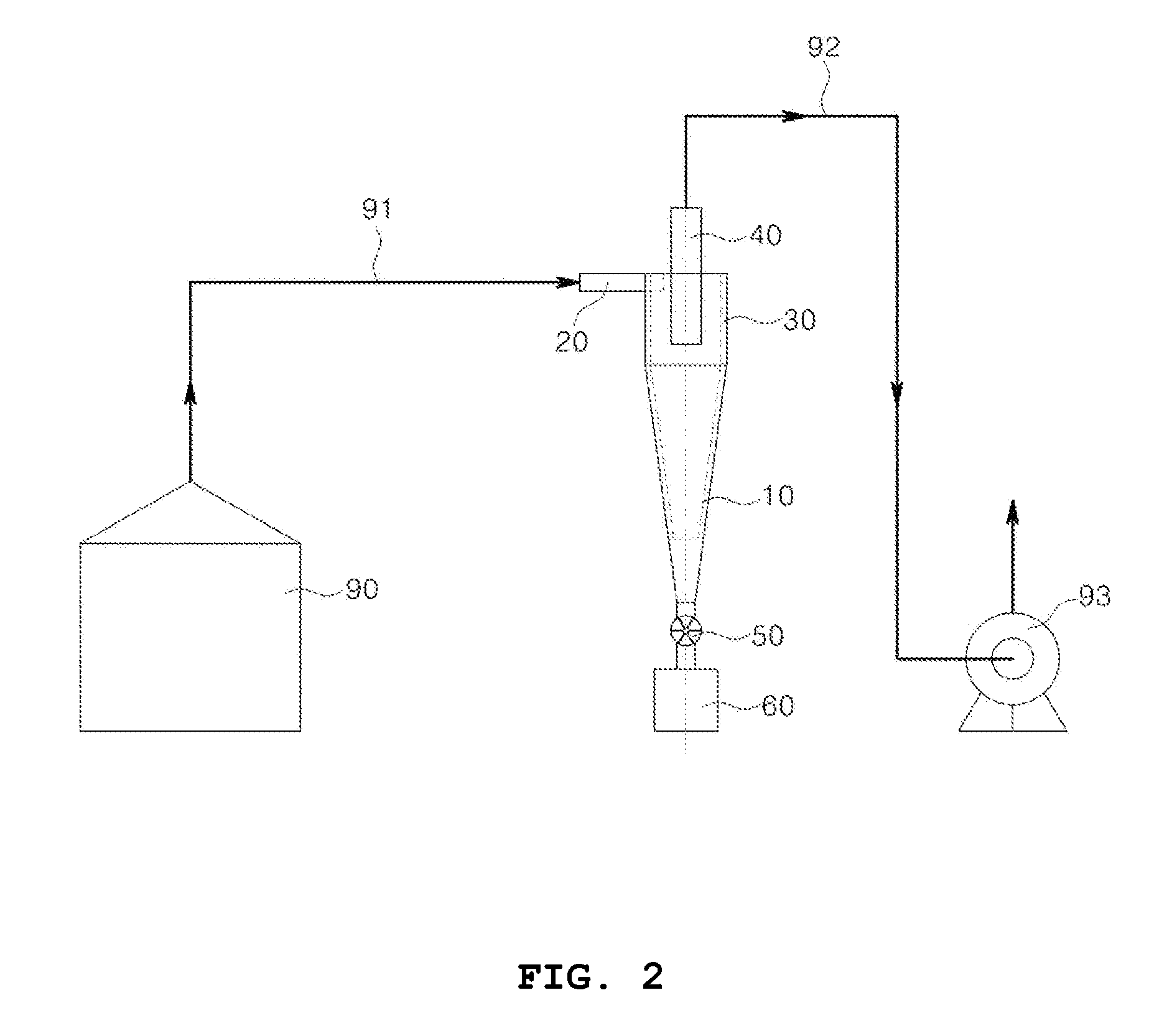

Cyclone dust collector

ActiveUS8657910B2Low pressure lossReduce flow rateCombination devicesSuction filtersCycloneCentrifugal force

Owner:KOREA INST OF ENERGY RES

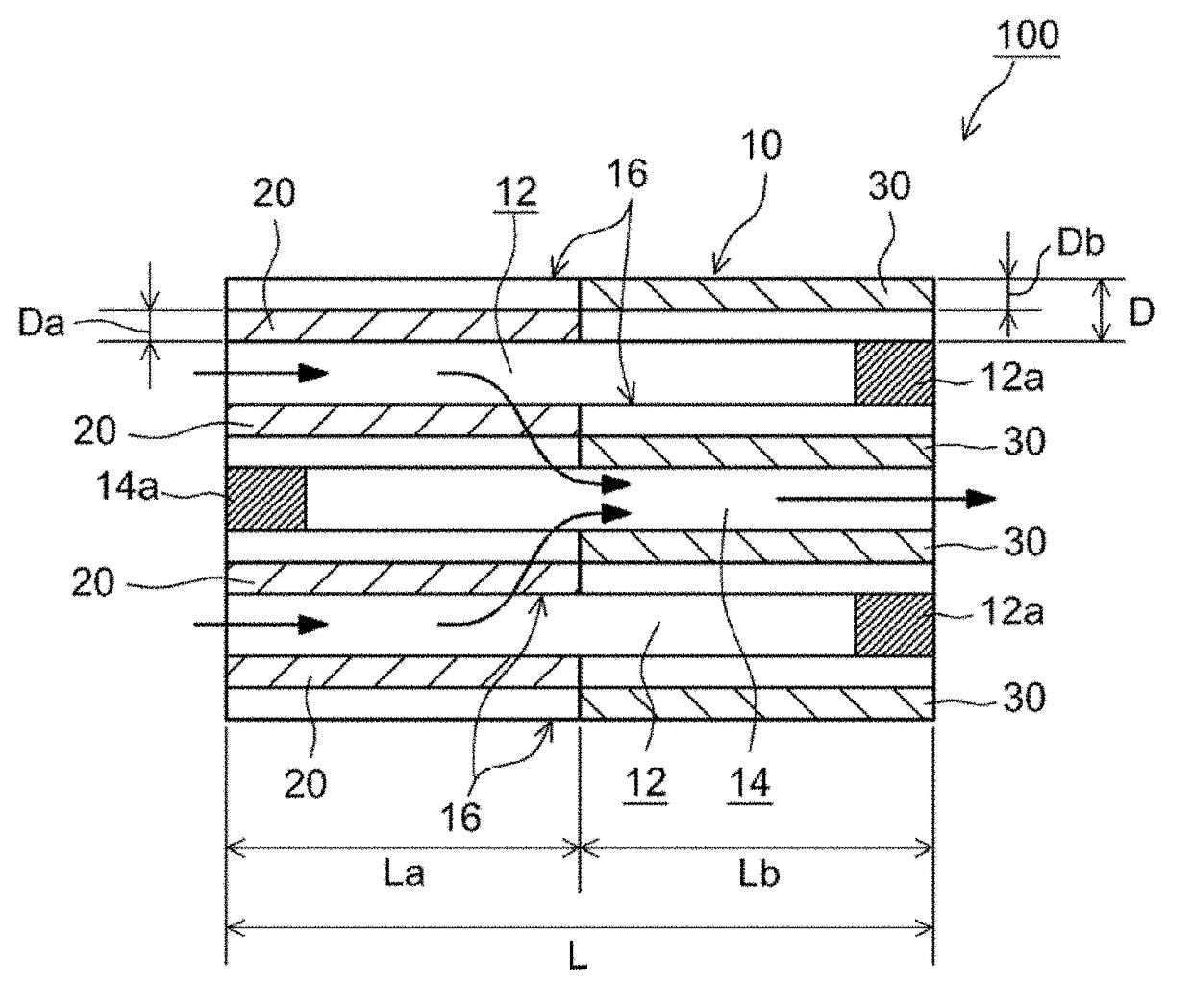

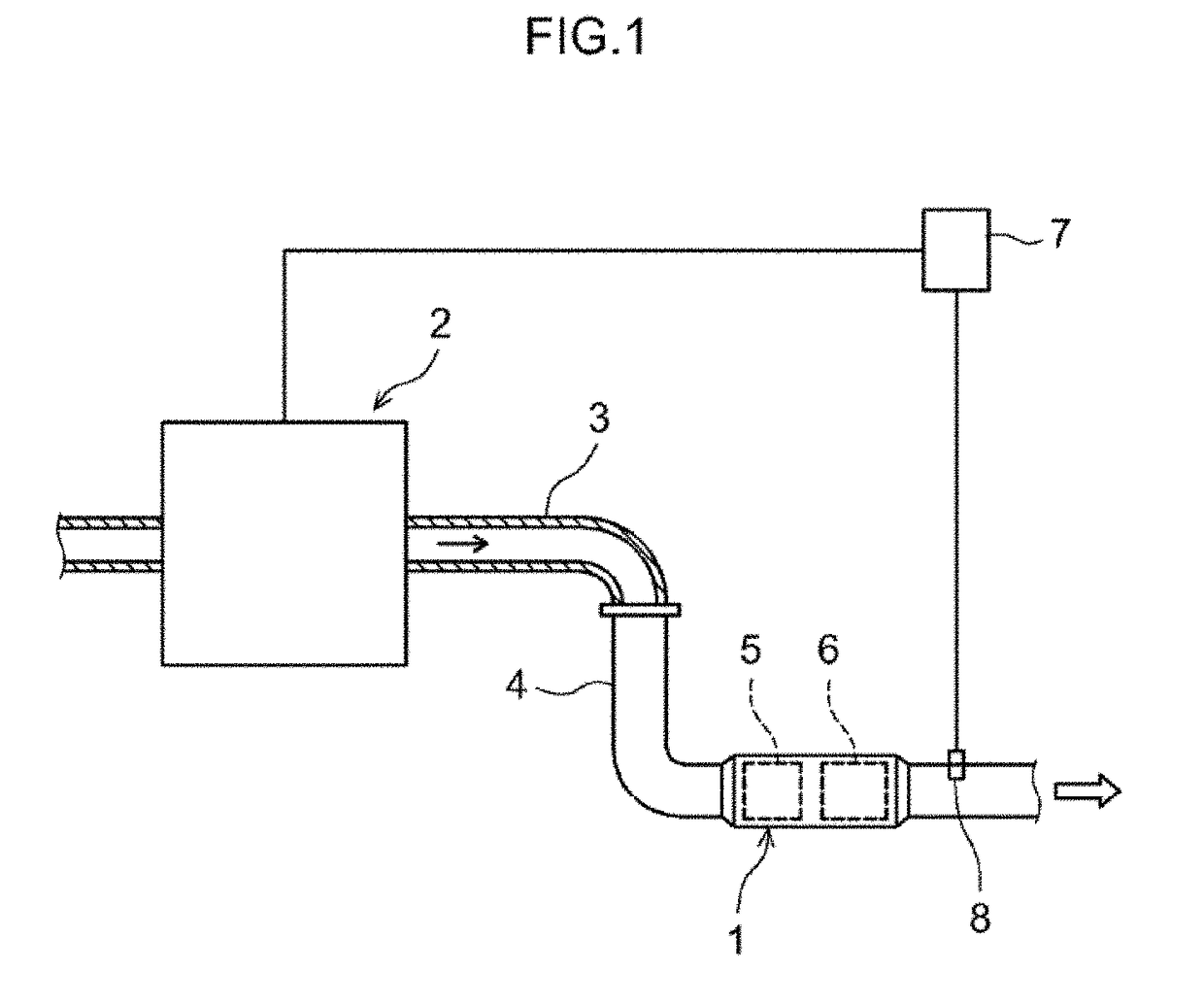

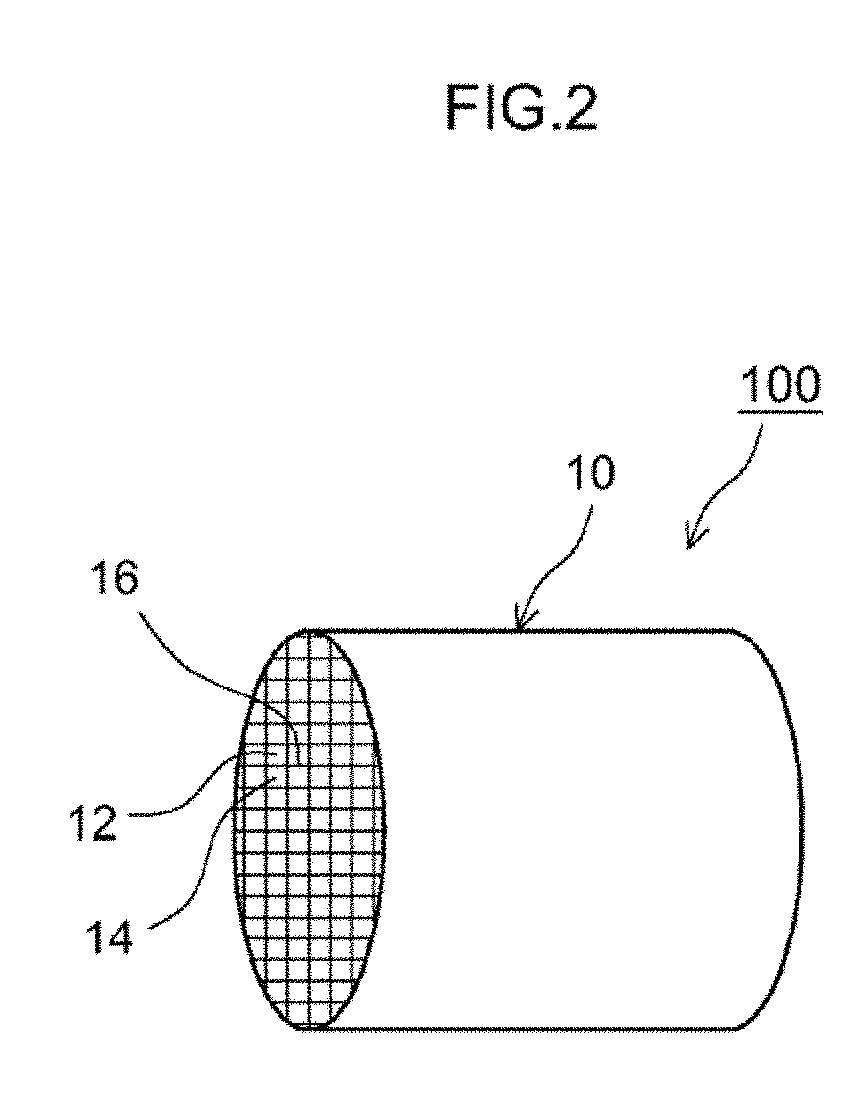

Exhaust gas purification device

ActiveUS20170296969A1Reduce pressure lossSmoothly flowInternal combustion piston enginesDispersed particle separationExhaust gasExhaust fumes

Owner:CATALER CORP

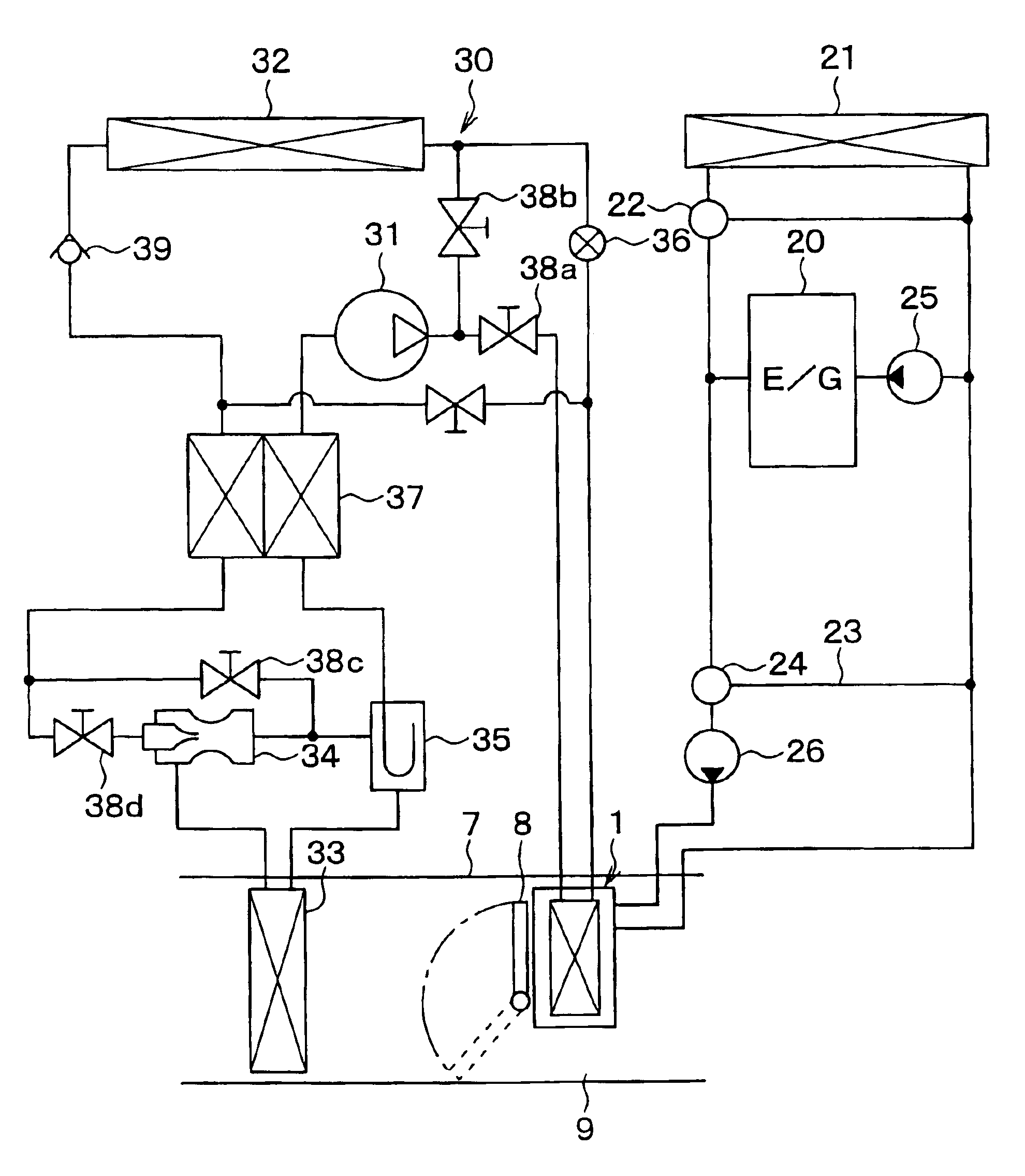

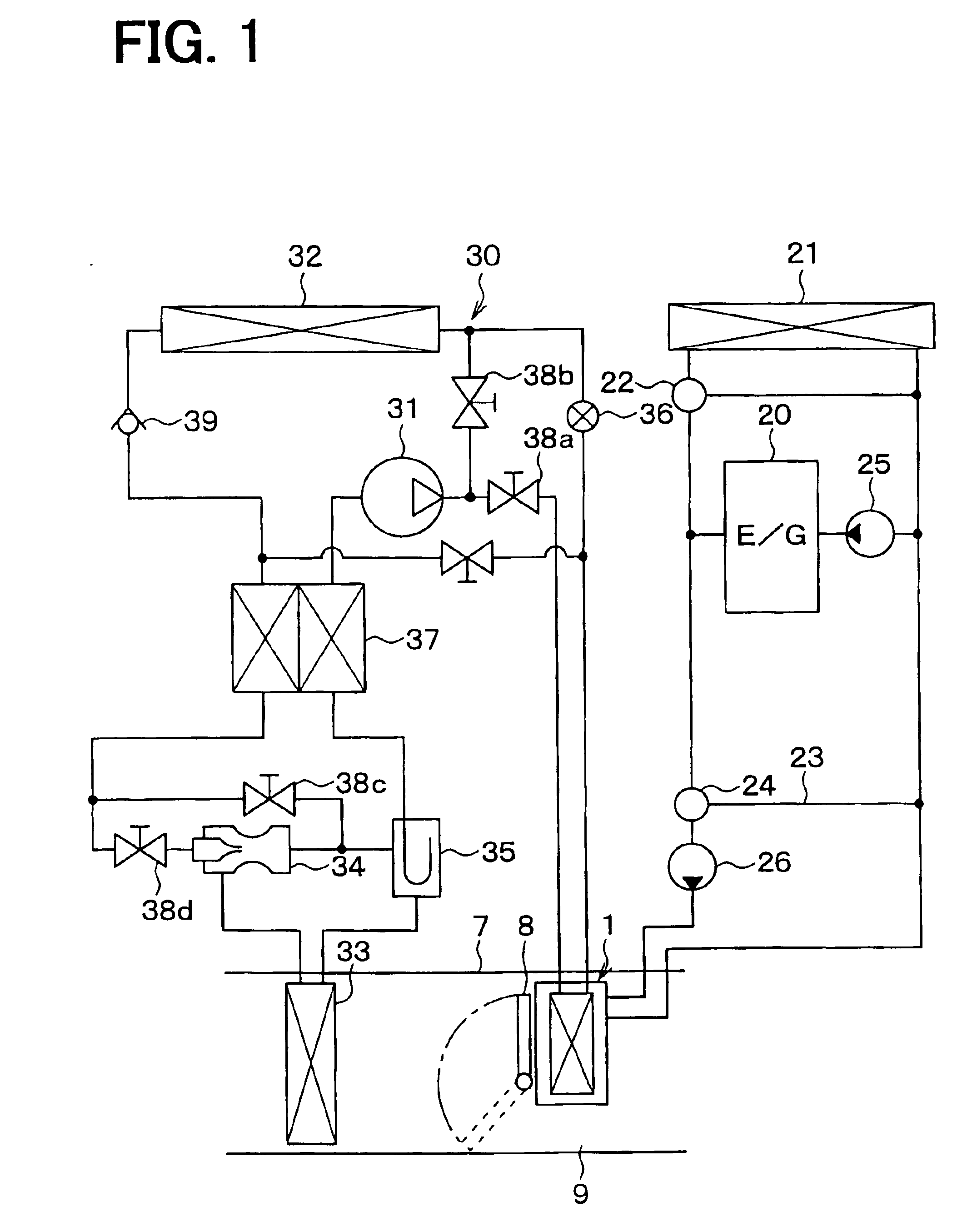

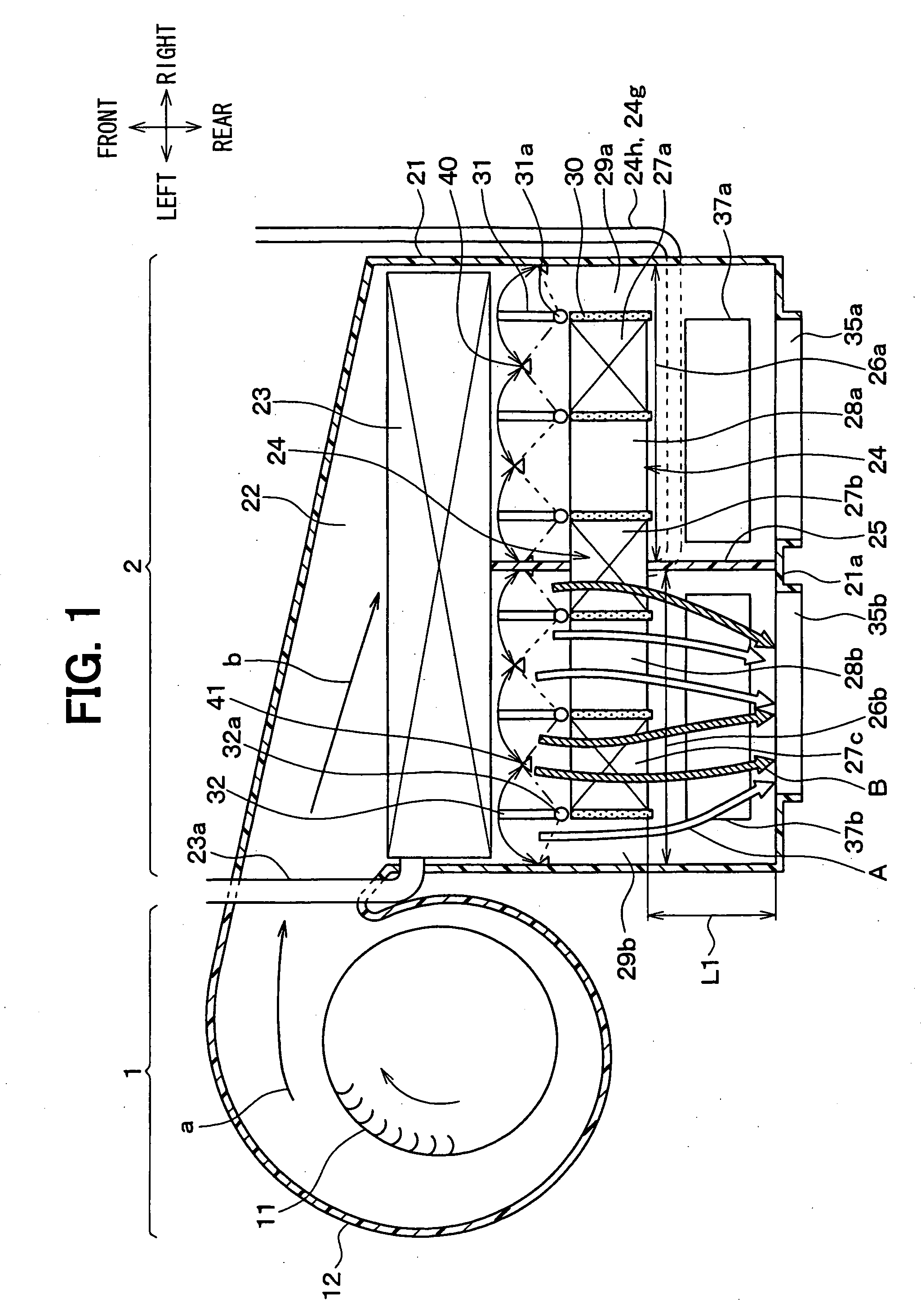

Car air conditioner

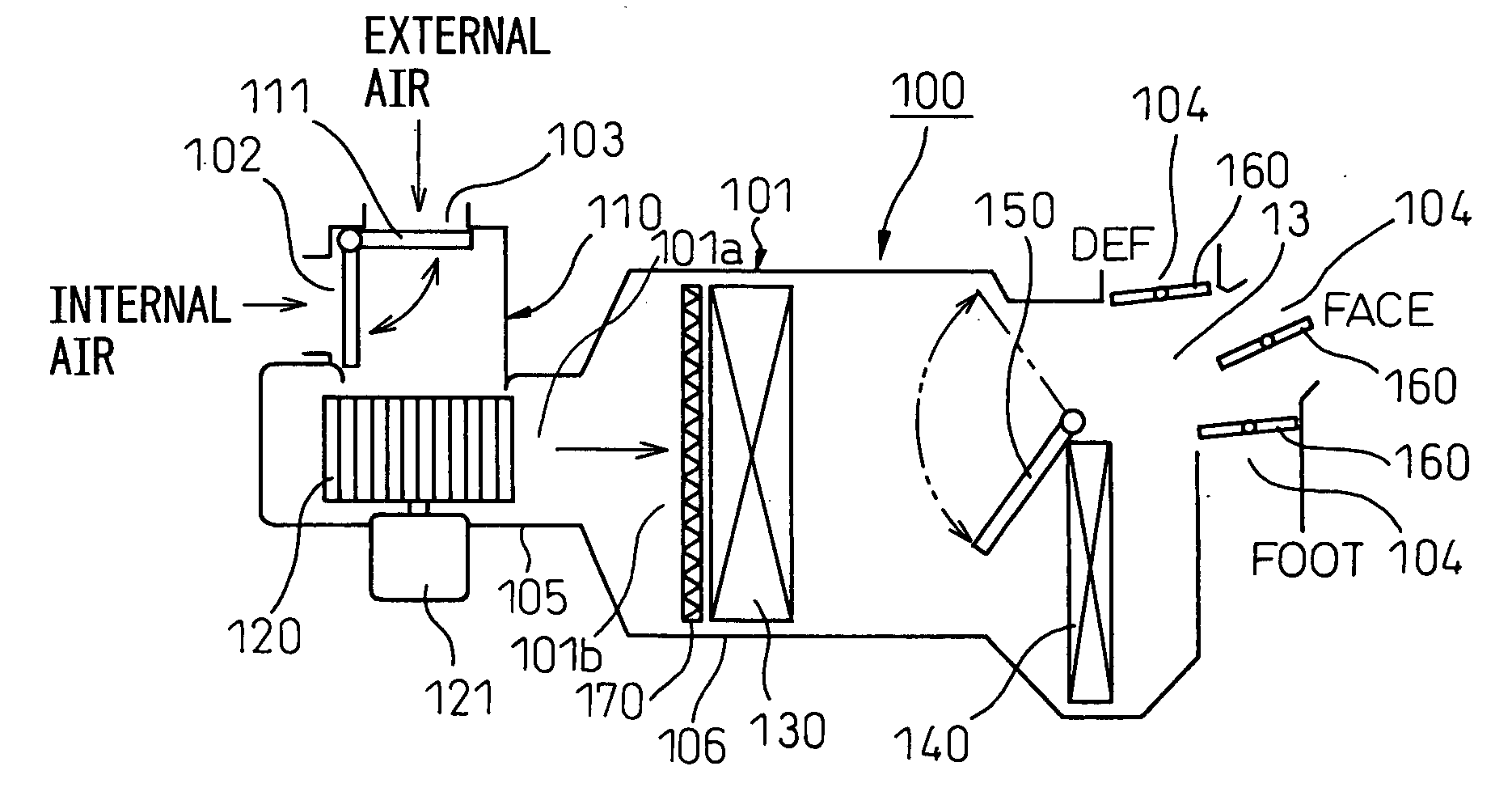

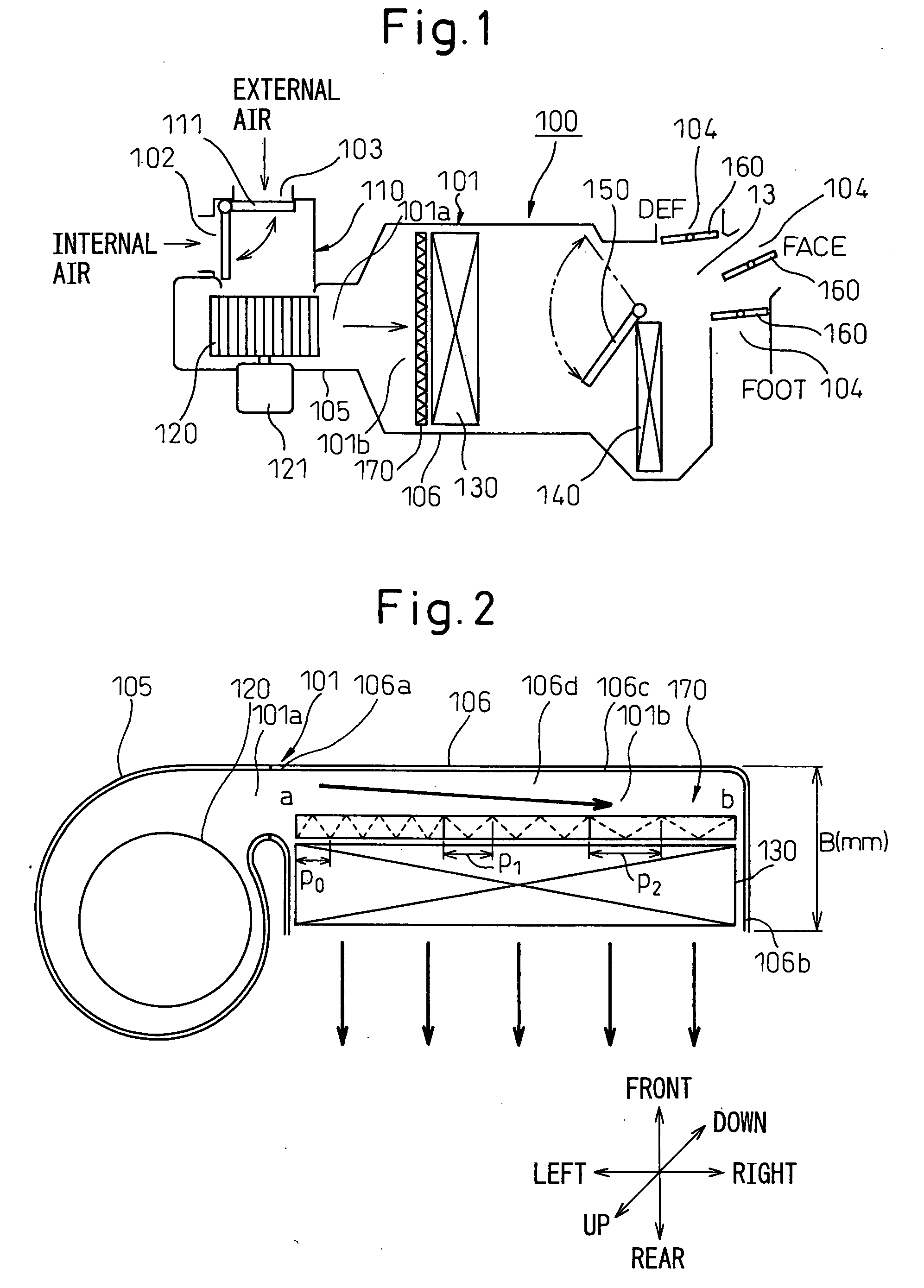

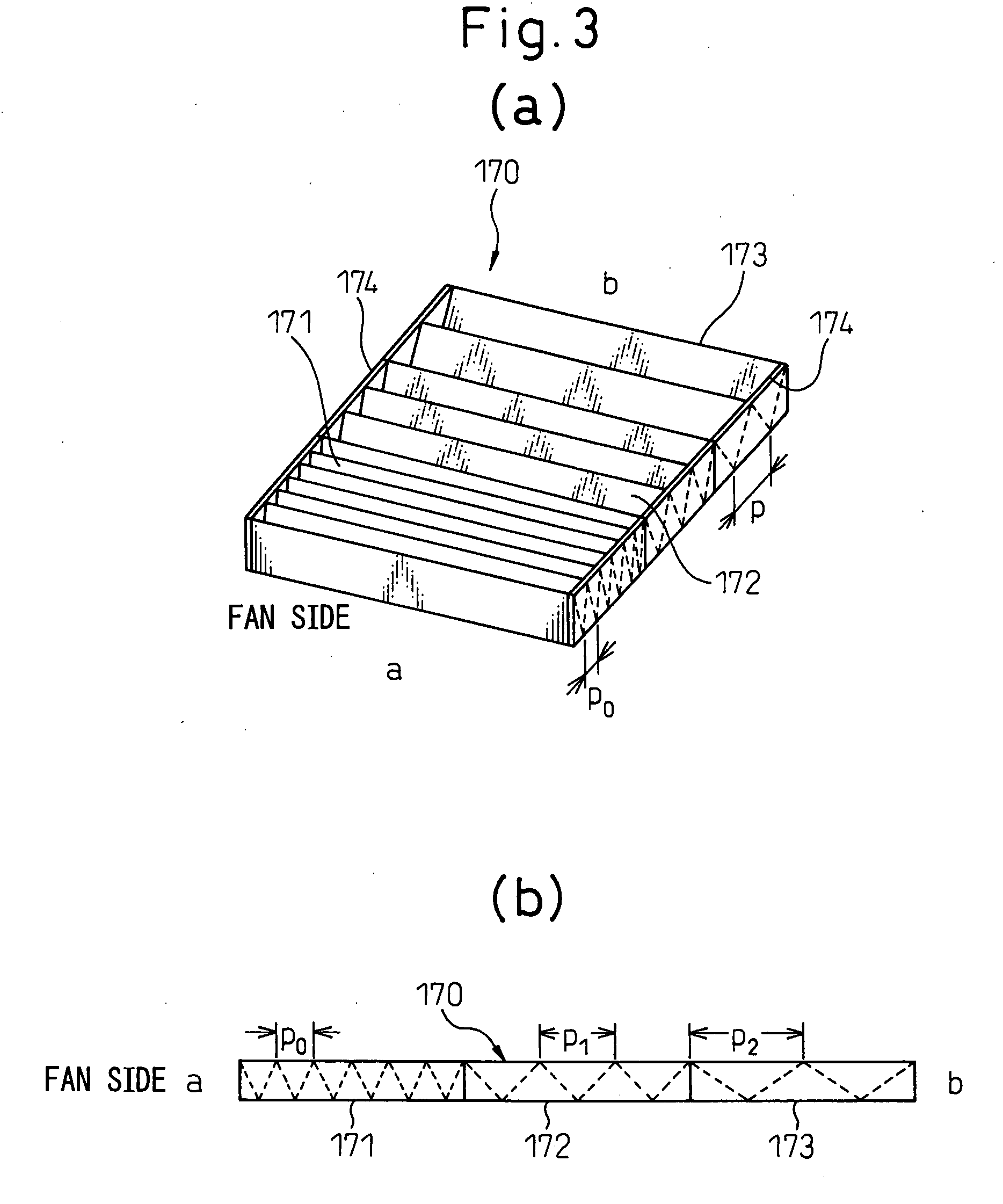

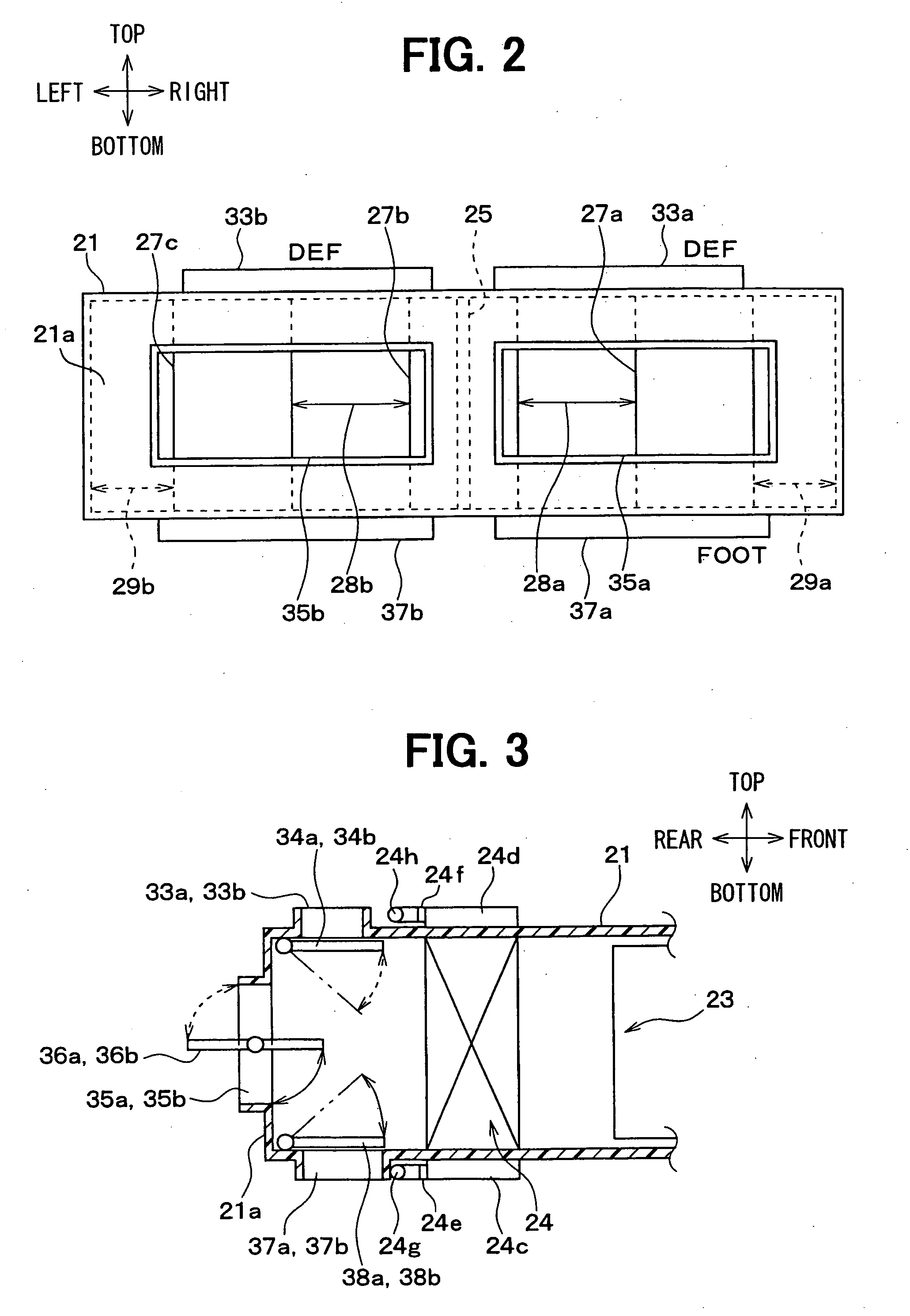

InactiveUS20070270095A1Decrease lengthReduce pressure lossGas treatmentAir-treating devicesAirflowEngineering

A construction of a filter 170 that allows air stream from a blower fan 120 to pass through a heat exchanger 130 arranged adjacent to the blower fan 120 after its flowing direction is changed by about 90 degrees. The filter 170 is disposed on the front surface of the heat exchanger on the upstream side of the air flow and has a construction such that airflow resistance of the filter gradually changes with respect to the flow velocity of air passing through the filter and in this way, flow velocity distribution of air passing through the heat exchanger becomes uniform. In this case, a fold pitch P of folds of the filter that is folded or a peak height h of the folds is changed in a plurality of steps or without any steps.

Owner:DENSO CORP

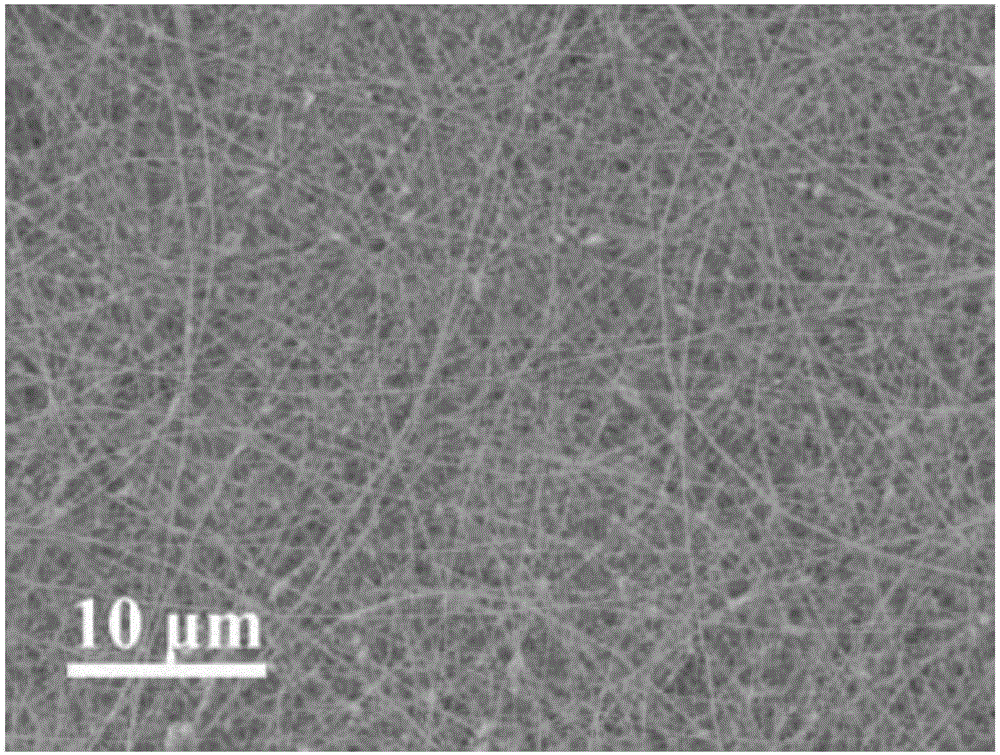

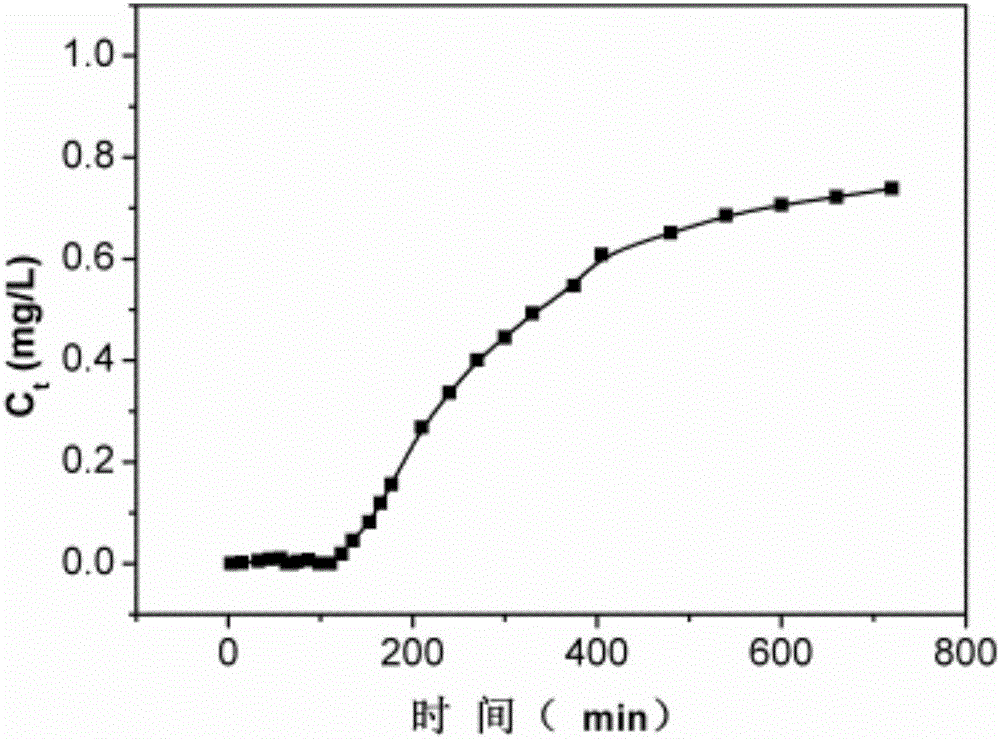

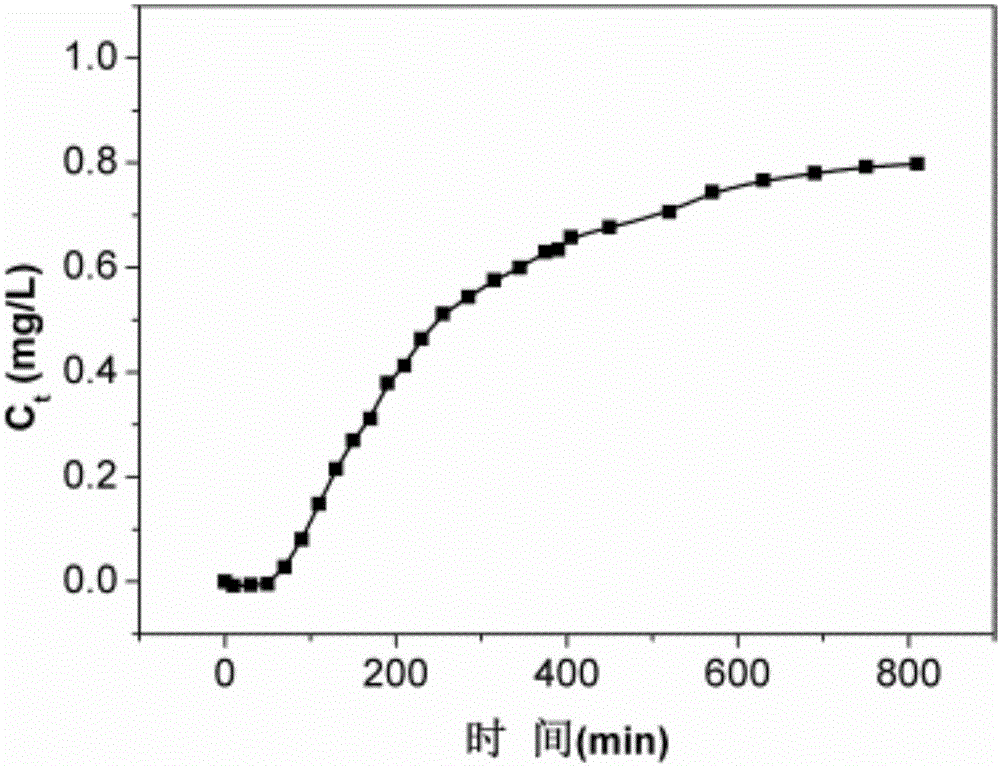

Chitosan nanofiber composite film for adsorbing and separating heavy metal ions and preparation method and application thereof

ActiveCN106311165AImprove the bonding strength of the interfaceIncrease the adsorption areaSemi-permeable membranesOther chemical processesIonWoven fabric

The invention relates to a chitosan nanofiber composite film for adsorbing and separating heavy metal ions and a preparation method and application thereof. The composite film is a chitosan electrospun nanofiber / non-woven fabric base composite film. The method for preparing the composite film comprises the following steps: performing electro-spinning on chitosan on a non-woven fabric base through an electrostatic spinning method, thereby obtaining a composite fiber film; and combining multiple composite fiber film layers in different manners, thereby preparing an adsorption and separation medium. The adsorption and separation medium is filled in a filter separator and can be used for dynamically adsorbing and filtering to remove heavy metal ions in water. The composite film disclosed by the invention is simple and convenient in preparation method, green, environmental-friendly, low in cost, easy to popularize and apply, high in heavy metal wastewater treatment efficiency and high in selectivity, can be used for purifying and treating heavy metals in industrial and domestic wastewater, and has important social and economical benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

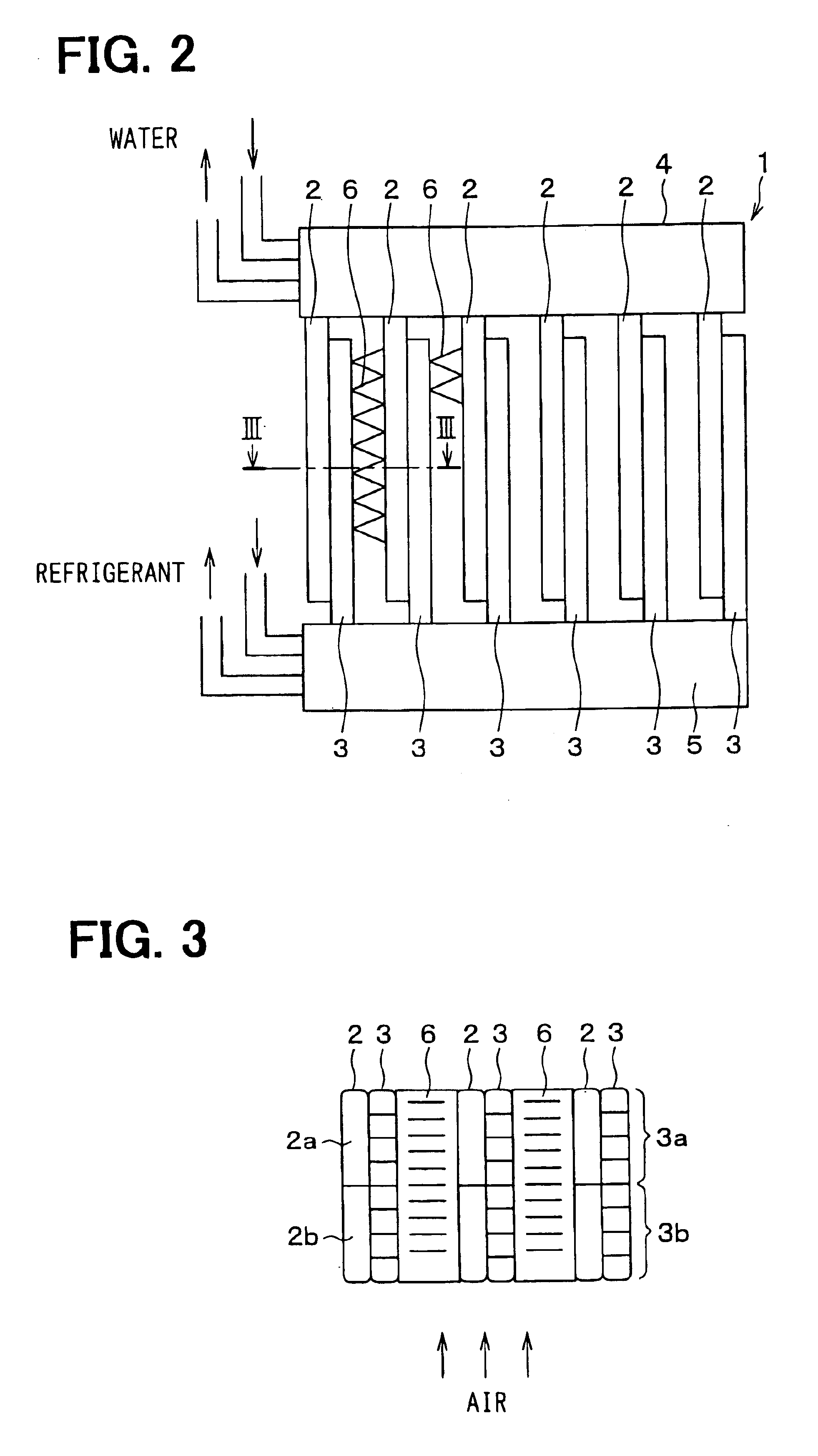

Heater with two different heat sources and air conditioner using the same

A heater for an air conditioner includes plural water tubes and plural refrigerant tubes which are arranged in parallel in an air flow direction. Therefore, the heater can heat air by using at least one of the heating sources while a pressure loss in the heater can be effectively reduced. For example, in a quick-heating mode, high-temperature refrigerant from a refrigerant cycle flows into the heater to heat the blown air, and low-temperature engine-cooling water from an engine bypasses the heater. In this case, thermal leakage from the refrigerant to the engine-cooling water is avoided.

Owner:DENSO CORP

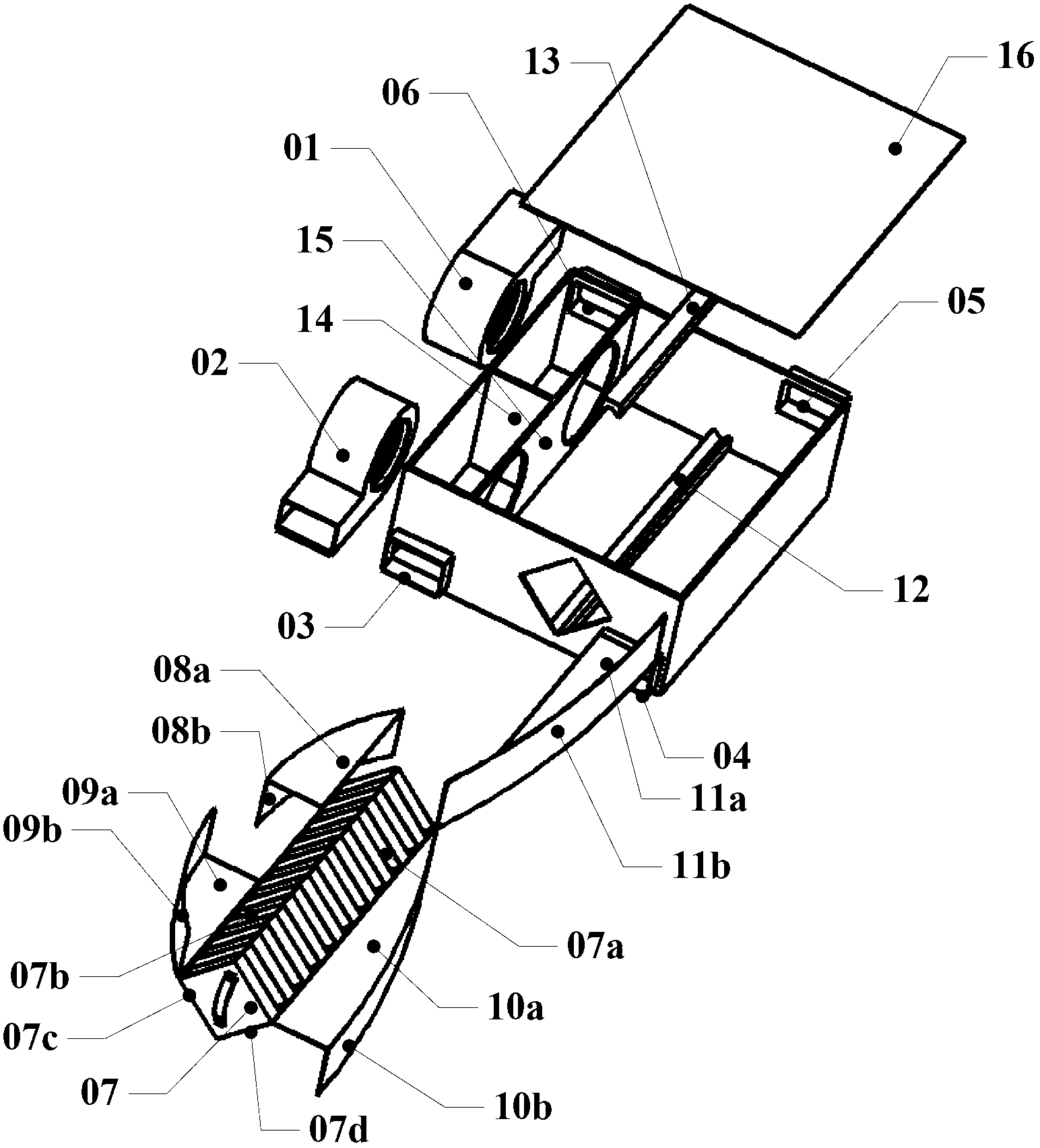

Air total heat exchanger for changing runner to improve efficiency

ActiveCN102840657AAvoid it happening againReduce pressure lossLighting and heating apparatusSpace heating and ventilation detailsHEAT/MOISTURE EXCHANGEEngineering

The invention relates to a novel air total heat exchanger which comprises a fresh air runner, a fresh air fan, an exhaust air runner, an exhaust fan and a total heat exchange core body. Fresh air and exhaust air are subjected to total heat exchange through a heat-moisture exchange membrane in the total heat exchange core body; inlets and outlets of the fresh air and the exhaust air of the total heat exchanger are laterally arranged relative to the total heat exchange core body; the fresh air inlet and the exhaust air outlet are arranged at the same end faces of different sides on the same horizontal plane; the fresh air outlet and the exhaust air inlet are arranged at the same end faces of the different sides on the same horizontal plane; the fresh air inlet and the exhaust air outlet are respectively arranged at the upper and lower layers (or lower and upper layers) at the same side of the total heat exchange core body; the fresh air outlet and the exhaust air inlet are respectively arranged at the lower and upper layers (or upper and lower layers) at the other same side of the total heat exchange core body, and diversion partition plates are arranged inside the fresh air runner and the exhaust air runner. Therefore, the air can be uniformly arranged on the total heat exchange core body; the total heat exchange efficiency is improved, and the air resistance is reduced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Air conditioning register

ActiveUS20140120826A1Reduce noise generationReduce pressure lossDucting arrangementsLighting and heating apparatusDrive shaftAir conditioning

An air conditioning register is provided that includes a case, a downstream fin, a specific upstream fin extending in a direction perpendicular to the downstream fin, and an operation knob. The specific upstream fin includes a fin main body pivotally supported by the case via an upstream fin shaft and a transmission body pivotally supported by the case via a pivot located further upstream than the upstream fin shaft. The fin main body and the transmission body are coupled to each other. The operation knob is mounted slidably on the downstream fin and includes a pair of fork portions sandwiching a transmission shaft portion of the transmission body therebetween. When the operation knob is operated to slide and thereby the transmission shaft portion is moved, the fin main body of the specific upstream fin is tilted.

Owner:TOYODA GOSEI CO LTD

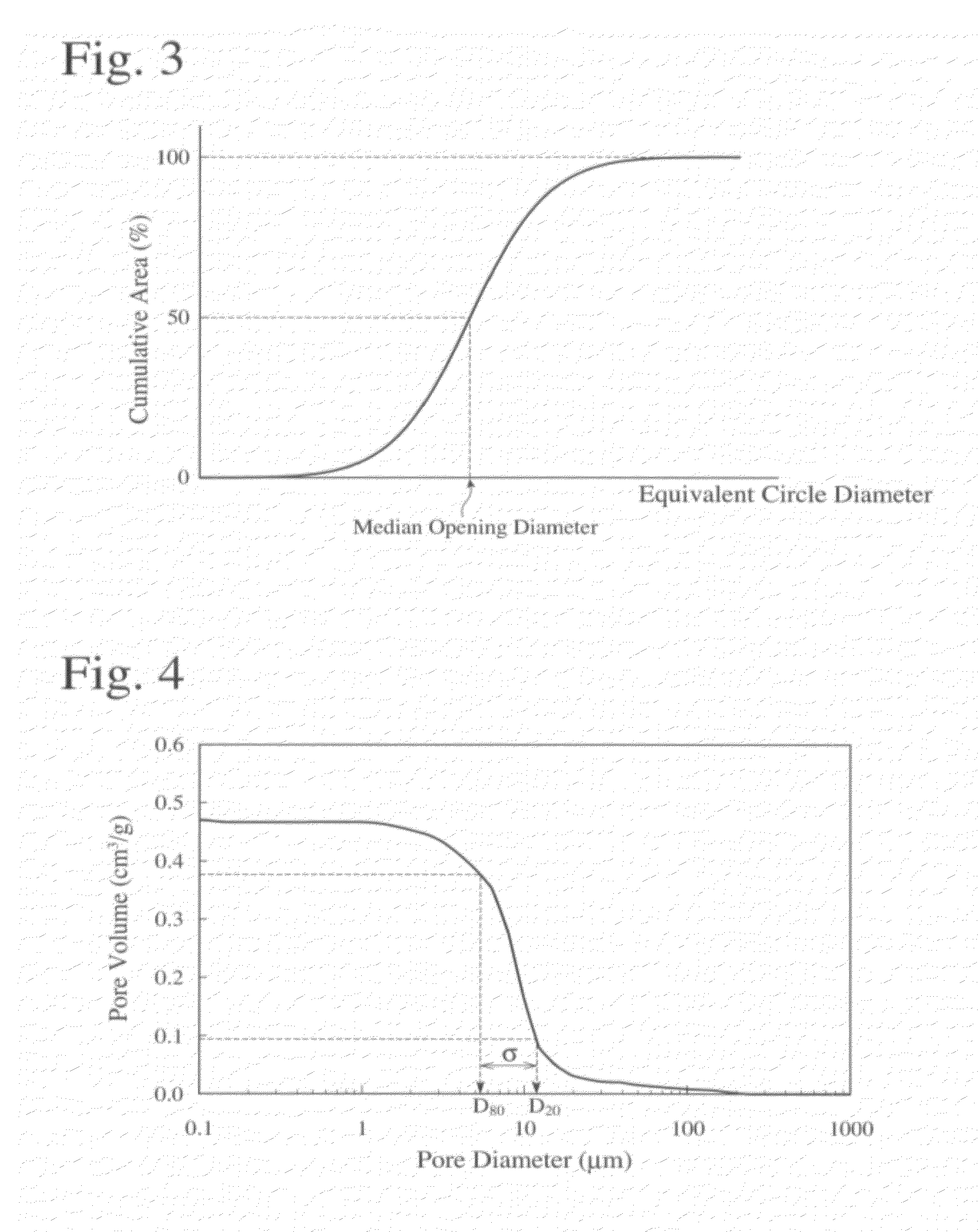

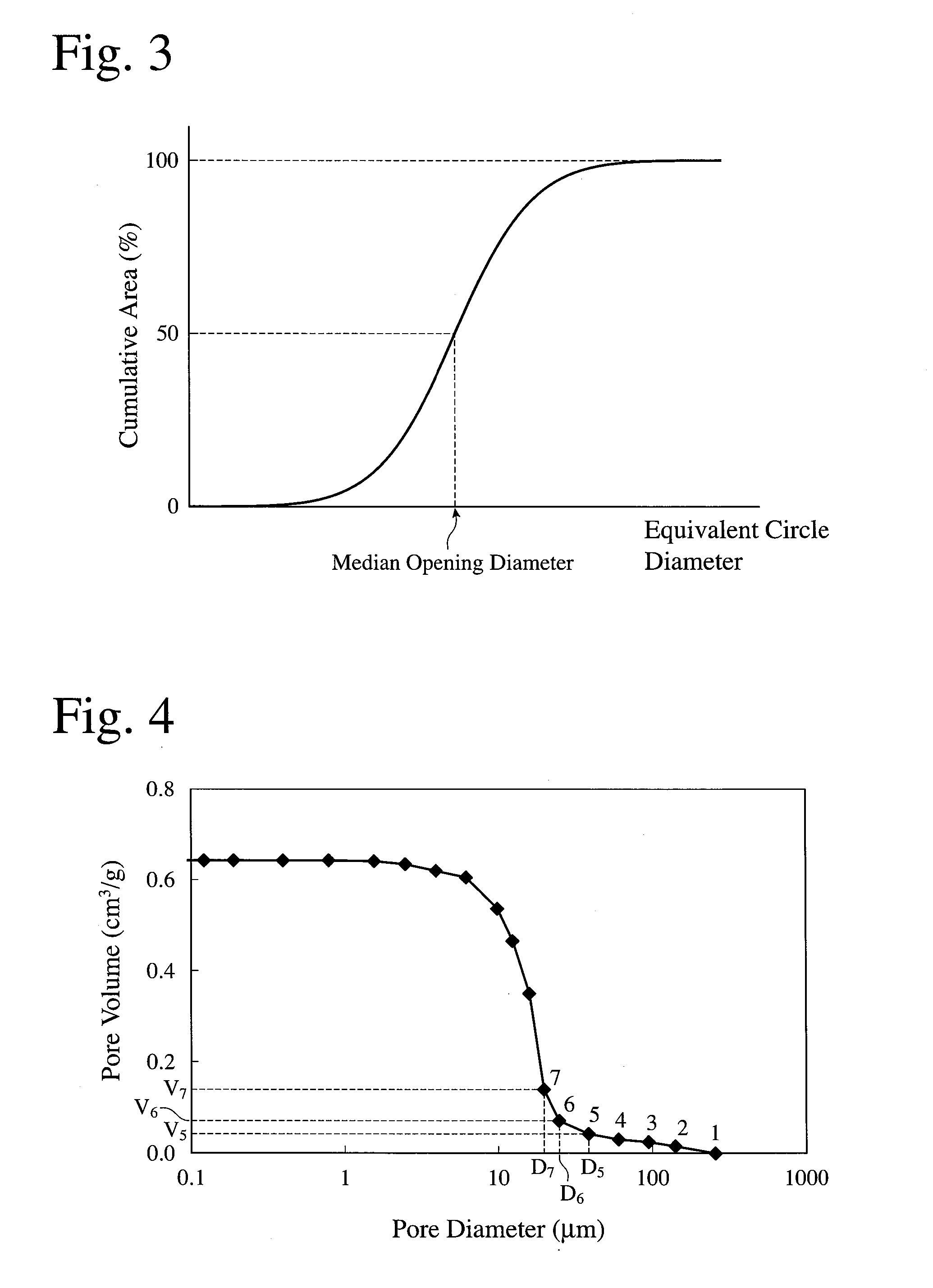

Ceramic honeycomb structure and its production method

ActiveUS20120148792A1Improved PM-capturing ratioReduce pressure lossInternal combustion piston enginesDispersed particle filtrationPorosityMetallurgy

A ceramic honeycomb structure having a large number of flow paths partitioned by porous cell walls, the cell walls having porosity of 40-60%; pores opening on the cell wall surface having an opening area ratio (the total opening area of pores opening on the cell wall surface per a unit area) of 15% or more; the median opening diameter of the opening pores being 10 μm or more and less than 40 μm, when the opening diameter of each pore opening on the cell wall surface is expressed by an equivalent circle diameter (a diameter of a circle having the same area as the opening area of each pore); the density of pores having equivalent circle diameters of 10 μm or more and less than 40 μm being 350 / mm2 or more; and the average circularity of pores having equivalent circle diameters of 10 μm or more and less than 40 μm being 1-2.

Owner:HITACHI METALS LTD

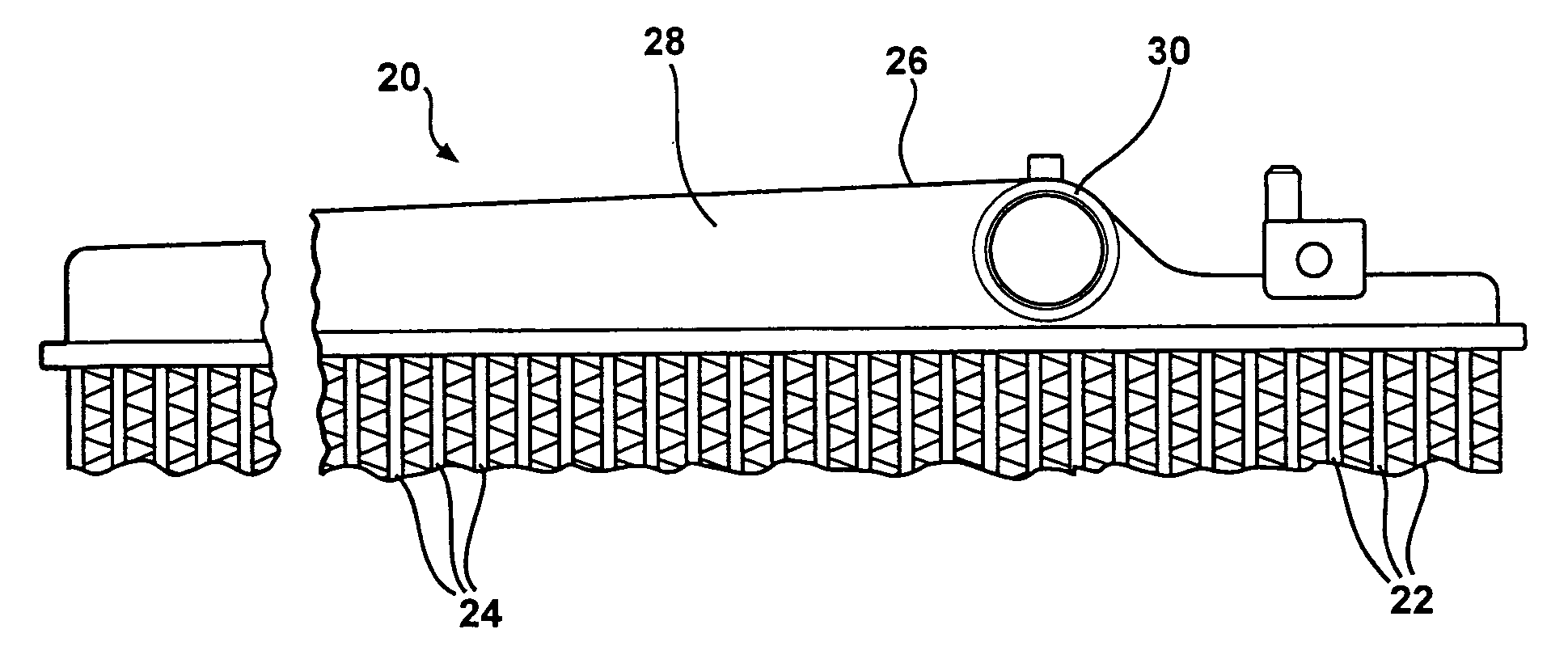

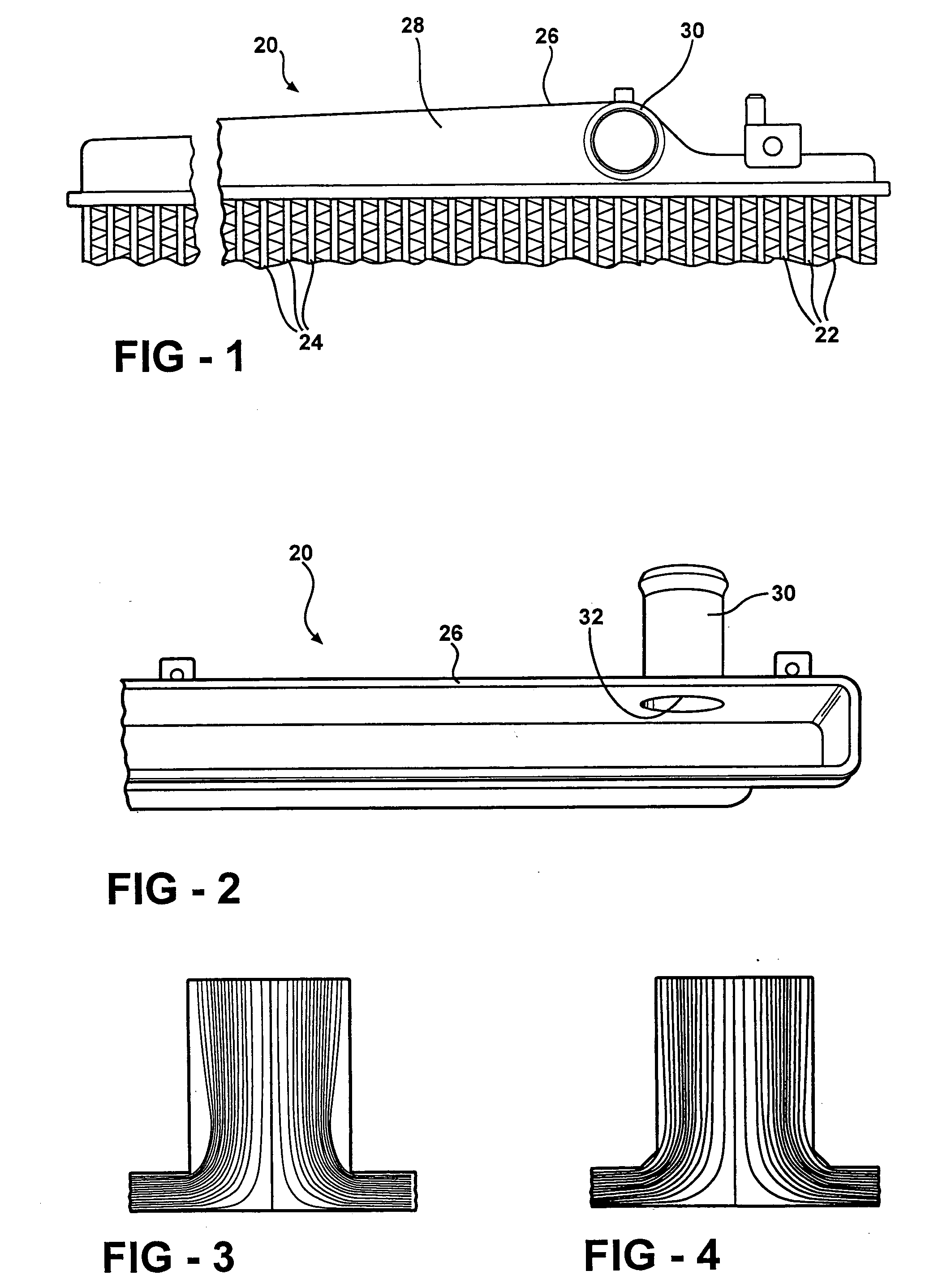

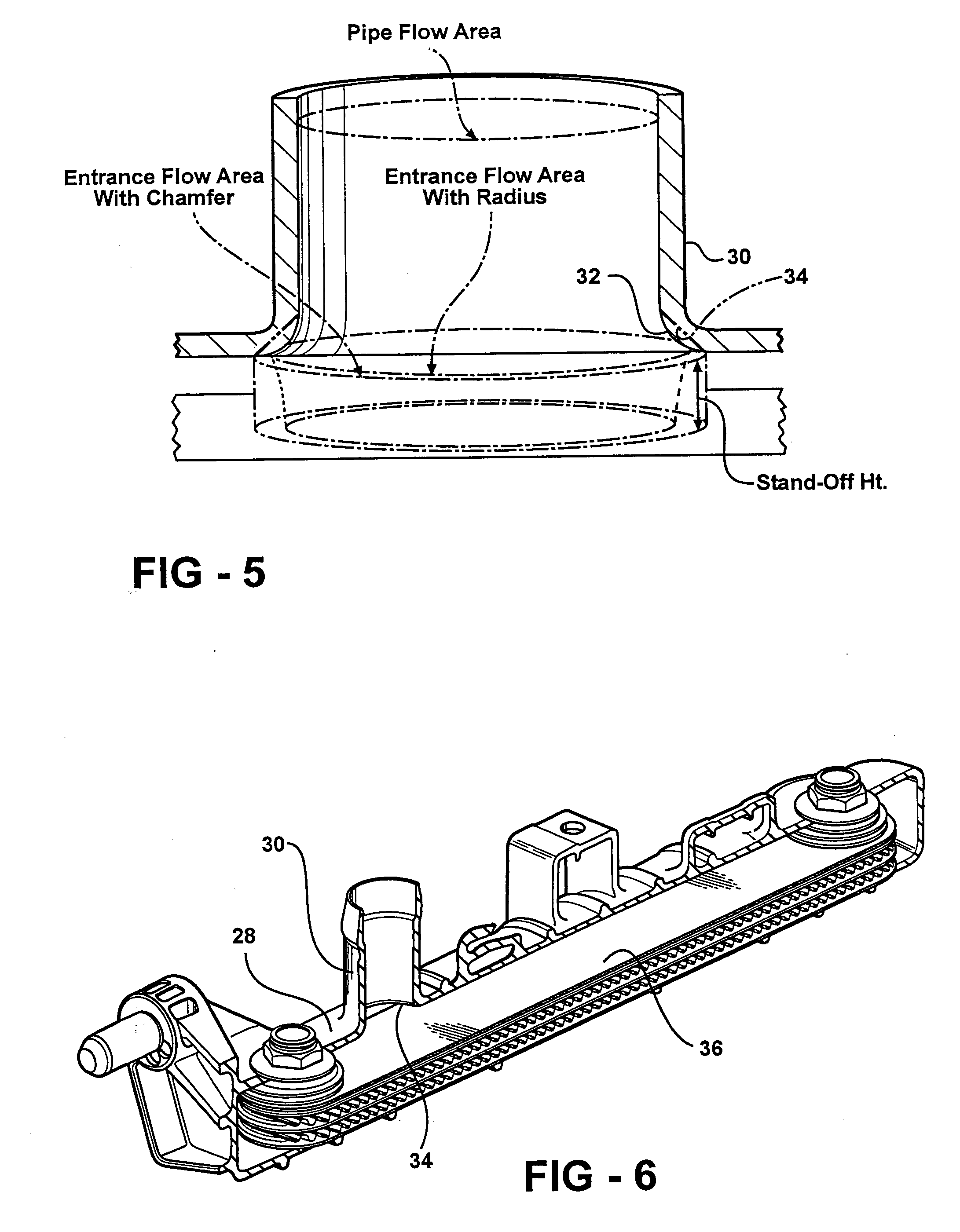

Sheet metal pipe geometry for minimum pressure drop in a heat exchanger

InactiveUS20070017664A1Reduces coolant pressure dropReduce pressure lossHeat exchanger casingsPlate heat exchangerEngineering

A heat exchanger joint between a pipe and a header wall defines an endless transition for conveying the heat exchange medium closely over a control surface of a radius or a chamfer between the interior surface and the pipe to reduce turbulence and pressure loss. The radiused or chamfered flow control surface expands radially as it opens axially into the interior surface of the header wall.

Owner:DELPHI TECH INC

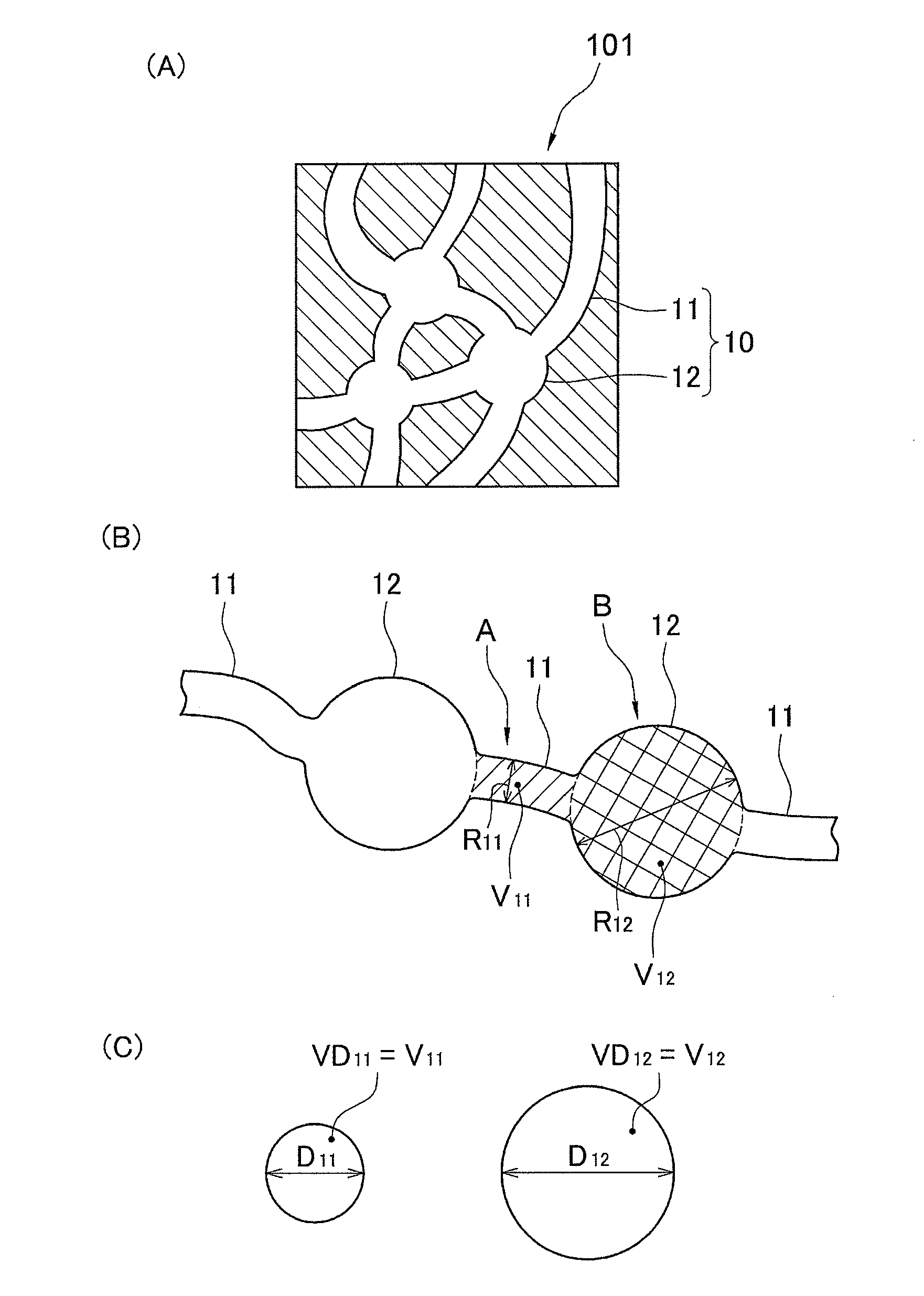

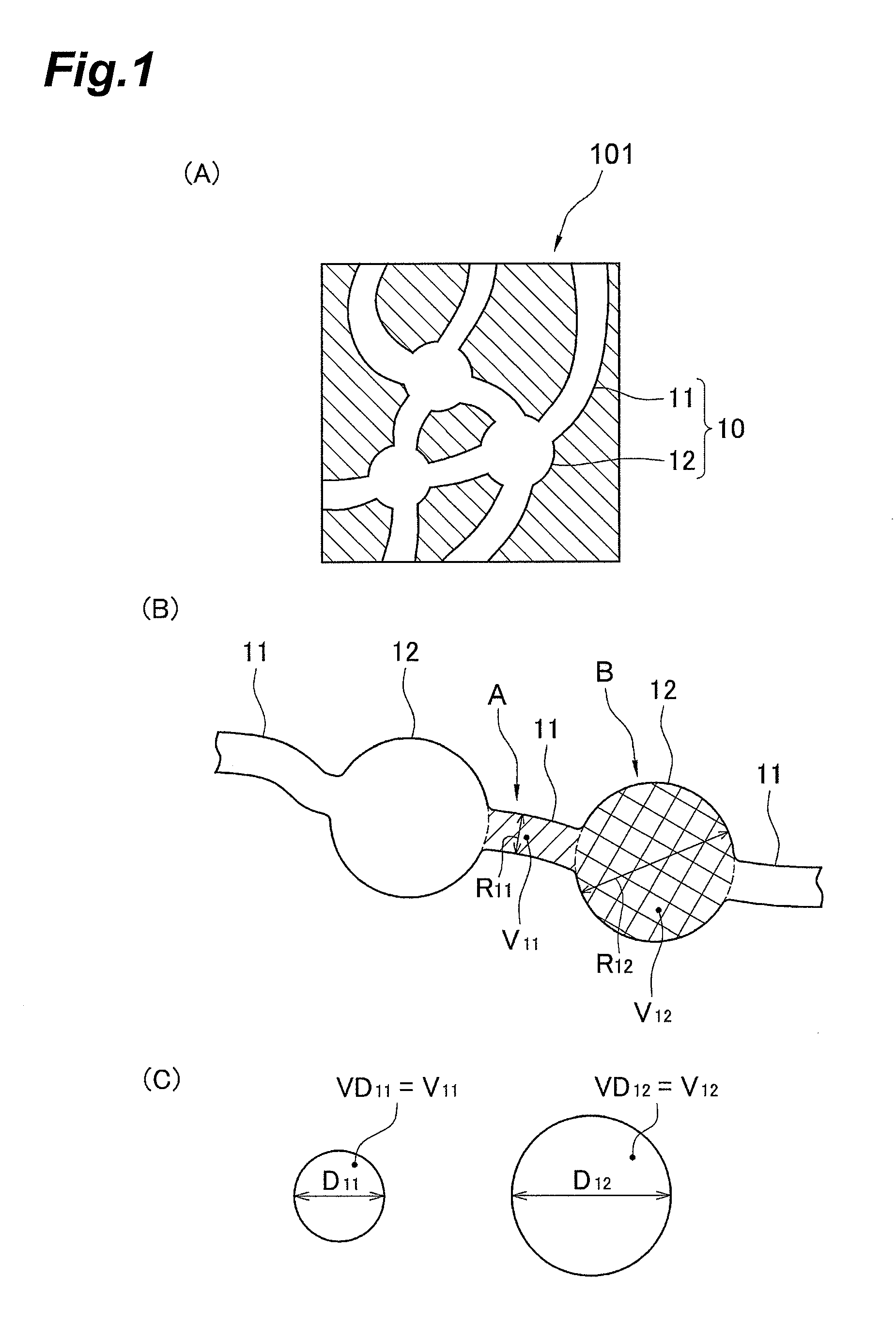

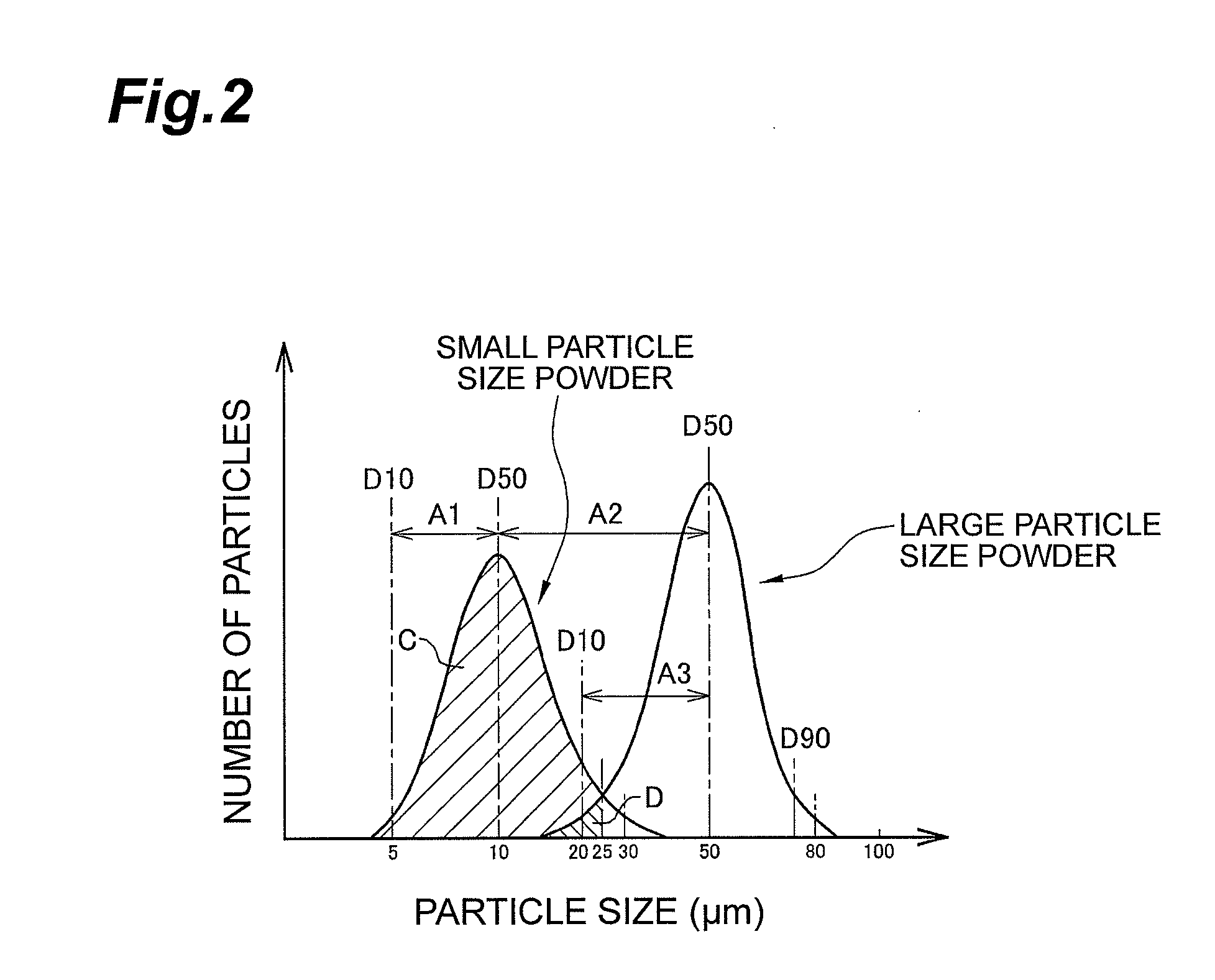

Process for production of honeycomb structure, honeycomb structure, and particulate filter

InactiveUS20130062275A1Reduce pressure lossPrevent leakagePhysical/chemical process catalystsDispersed particle filtrationMetallurgyShell molding

A method of manufacturing a honeycomb structure comprises a step of forming a molded article by molding a raw material containing a ceramic powder and a pore-forming agent; and a step of manufacturing a honeycomb structure by sintering the molded article, wherein the pore-forming agent is powder formed of a material that disappears at a sintering temperature or less where the molded article is sintered, the powder is obtained by mixing a small particle size powder and a large particle size powder, a median particle size of which a ratio of a cumulative mass with respect to a total mass of the small particle size powder is 50% is 5 to 20 μm, a median particle size of which a ratio of a cumulative mass with respect to a total mass of the large particle size powder is 50% is 30 μm or more, and a ninety-percentage particle size of which a ratio of a cumulative mass with respect to a total mass of the large particle size powder is 90% is 80 μm or less.

Owner:SUMITOMO CHEM CO LTD

Device for determining at least one parameter of a medium flowing in a conduit

ActiveUS20060021429A1Inhibition of flow separationReduce total pressure lossElectrical controlVolume/mass flow by thermal effectsEngineeringInternal combustion engine

Devices are previously known for determining at least one parameter of a medium flowing in a conduit, in particular for determining the air mass flow in the intake section of an internal combustion engine, having a conduit part and a sensor device that has a bypass part. In order to avoid a flow detachment at the side walls of the bypass part, it is provided that a flow vane, running at least approximately parallel to a side wall, provided with a separation opening, of the bypass part, be provided in a conduit part behind a separation opening, seen in the main flow direction, and that the conduit part be provided, in the area of the bypass part, with at least one projection that protrudes from an inner wall of the conduit part towards the bypass part.

Owner:ROBERT BOSCH GMBH

Ceramic honeycomb structure and its production method

ActiveUS20120317947A1Improve PM-capturing ratioReduce pressure lossGas treatmentInternal combustion piston enginesPore distributionOn cells

A ceramic honeycomb structure having a large number of flow paths partitioned by porous cell walls, the cell walls meeting the conditions; (a) the cell walls having porosity of 55-80%, (b) the cell walls having a median pore diameter D50 (measured by mercury porosimetry) of 5-27 μm, (c) pores open on cell wall surfaces having an opening area ratio of 20% or more, (d) pores open on cell wall surfaces having a median opening diameter d50 (determined from equivalent circle diameters on an area basis) of 10-45 μm, (e) the density of pores open on cell wall surfaces having equivalent circle diameters of 10 μm or more and less than 40 μm being 350 / mm2 or more, (f) the maximum inclination of a curve of a cumulative pore volume relative to a pore diameter (determined from a pore distribution measured by mercury porosimetry) being 1.6 or more, and (g) a ratio D50 / d50 of the median pore diameter D50 to the median opening diameter d50 being 0.65 or less.

Owner:HITACHI METALS LTD

Heat exchanger and air conditioner

InactiveUS20070125521A1Reduce pressure lossIncrease the degree of mixingAir-treating devicesRailway heating/coolingEngineeringHeat exchanger

A heating heat exchanger includes plural tubes which are arranged in parallel and through which a thermal fluid for heating air flows, and plural fins which are joined to the tubes. The tubes and the fins are arranged to form plural heating parts equal to or more than three in which air is heated, and at least two bypass passages each of which is provided between adjacent heating parts, through which the air passes without exchanging heat with the thermal fluid. Furthermore, first and second tank parts for distributing the thermal fluid to and for collecting the thermal fluid from the tubes are arranged at two longitudinal ends of the tubes and extend to across an area where the bypass passages and the heating parts are provided. In addition, the bypass passages and the heating parts are arranged in an arrangement direction perpendicular to an air flow direction.

Owner:DENSO CORP

Linear motor

ActiveUS20140054979A1Prevent increase total lengthReduce pressure lossMagnetic circuit stationary partsCooling/ventillation arrangementRefrigerantEngineering

An armature of a linear motor includes a plurality of cooling pipe storage holes formed along a longitudinal direction of a core, and a plurality of cooling pipes stored vertically in the cooling pipe storage holes and having a meander shape. The cooling pipes vertically adjacent to each other are arranged such that inlets and outlets of the cooling pipes are alternately connected in parallel to a refrigerant inlet and a refrigerant outlet in order to allow a refrigerant to flow in the reverse direction.

Owner:SANYO DENKI CO LTD

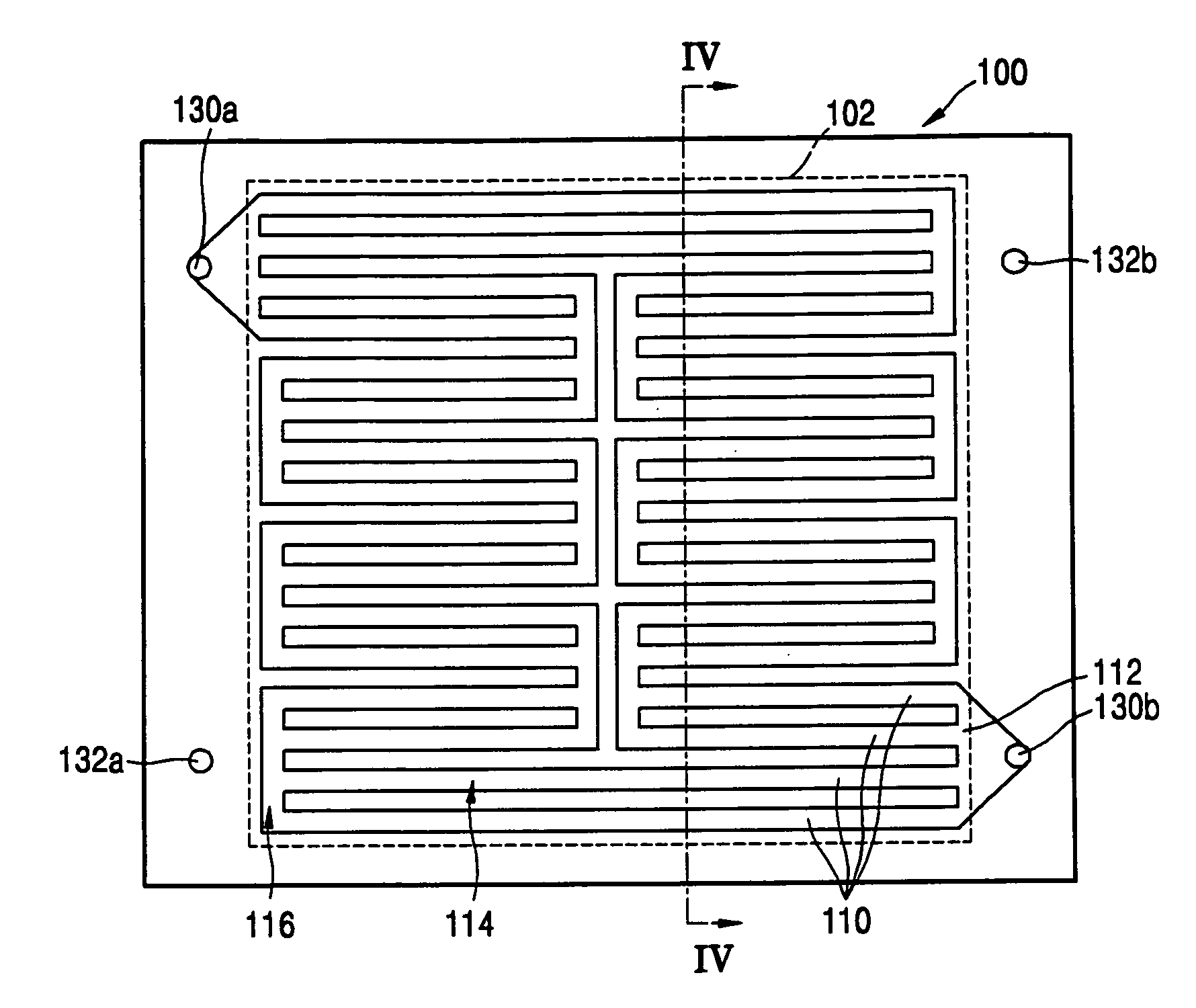

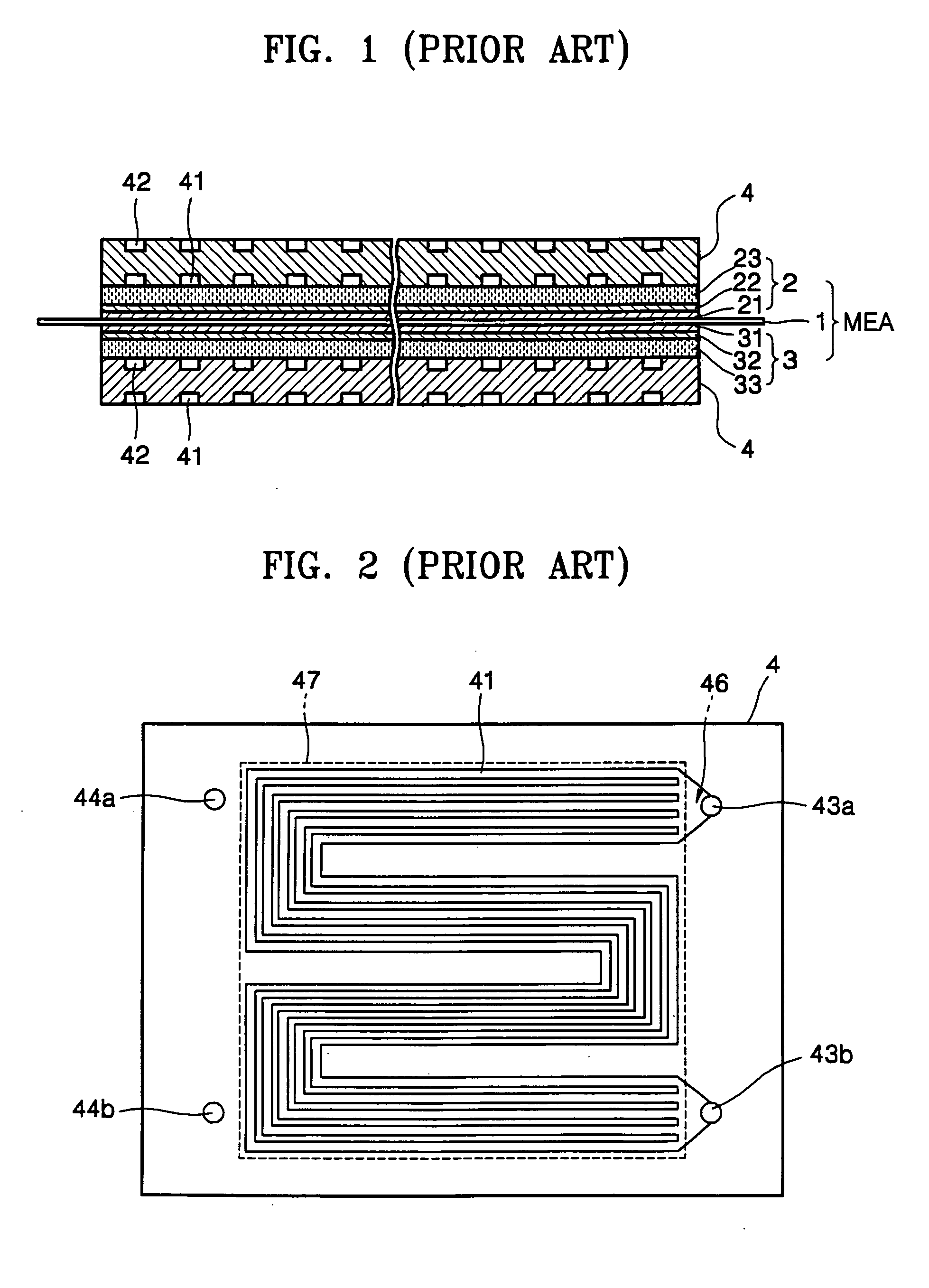

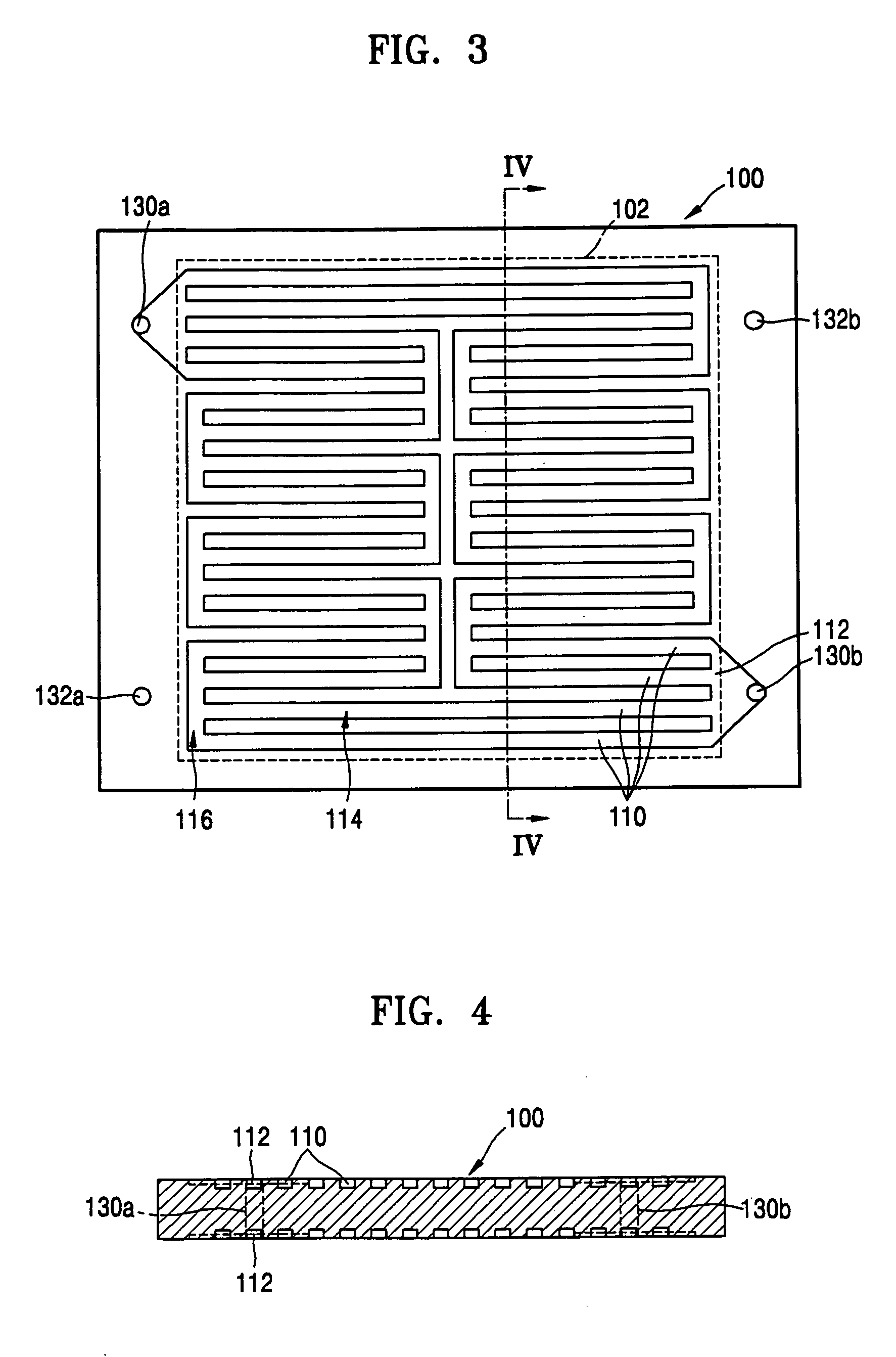

Bipolar plate and direct liquid feed fuel cell stack

InactiveUS20060115705A1Decrease the concentration gradientReduce pressure lossFuel cells groupingElectrode carriers/collectorsFuel cellsElectrical and Electronics engineering

A bipolar plate and a direct liquid feed fuel cell stack are provided. The bipolar plate includes a manifold that is coupled with the fuel / oxidant path holes and a plurality of flow channels that are coupled with the manifold. The flow channels are divided into a plurality of groups, where the flow channel of each group forms a serpentine flow path and a length of each flow channel is substantially the same.

Owner:SAMSUNG SDI CO LTD

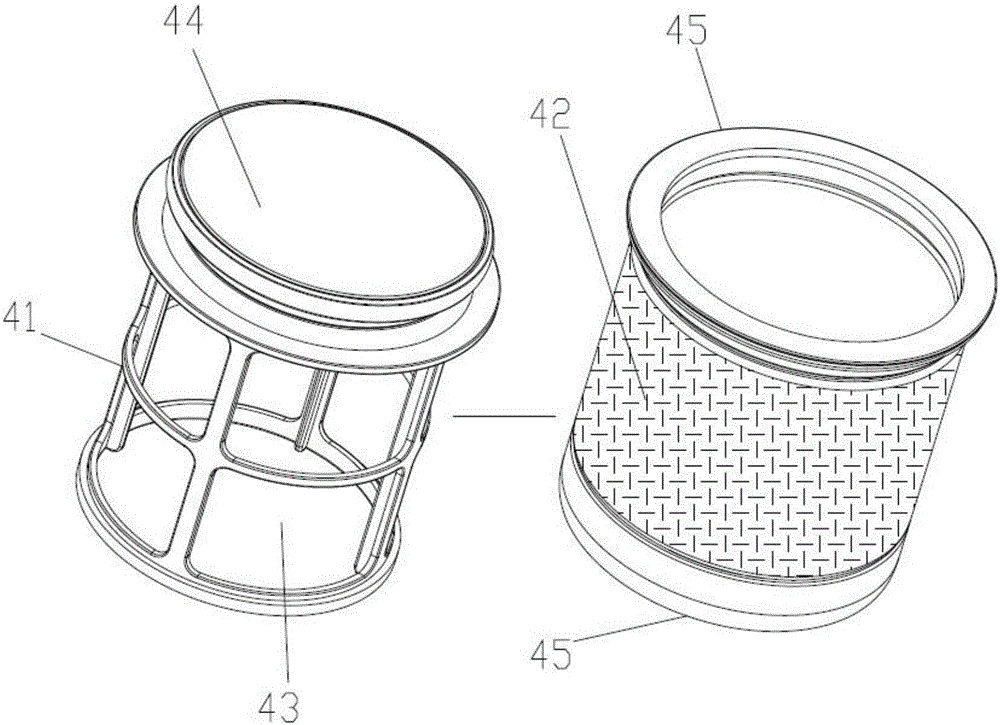

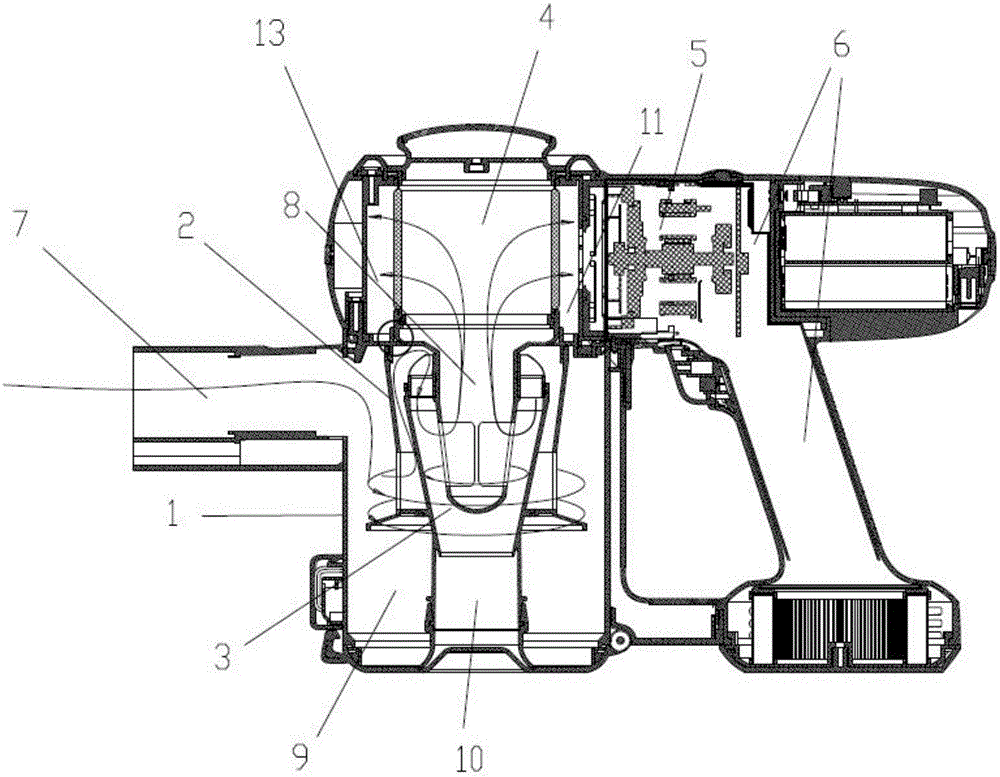

Dust cup filter and dust collector provided with same

ActiveCN106388698AShorten the flow pathIncrease wind areaSuction filtersSuction handlesFiltrationEngineering

The invention discloses a dust cup filter. A cyclone dust-gas separating device is arranged in a dust cup, the dust cup filter is arranged above the cyclone dust-gas separating device, dust and gas enter from a gas inlet of the dust cup, pass through the cyclone dust-gas separating device in the dust cup and then enters into the interior of the filter upwards, and gas is discharged along an air outlet air channel of the dust cup after filtration of the interior of the filter toward the exterior. The dust cup filter disclosed by the invention has the advantages that an air passing area is increased more effectively by changing the structural form of the filter, filtration efficiency is improved, the filter is detachably arranged at the top of the dust cup and can be cleaned after being taken upward directly, a dust cup cover does not need to be opened, and operation is easy.

Owner:KINGCLEAN ELECTRIC

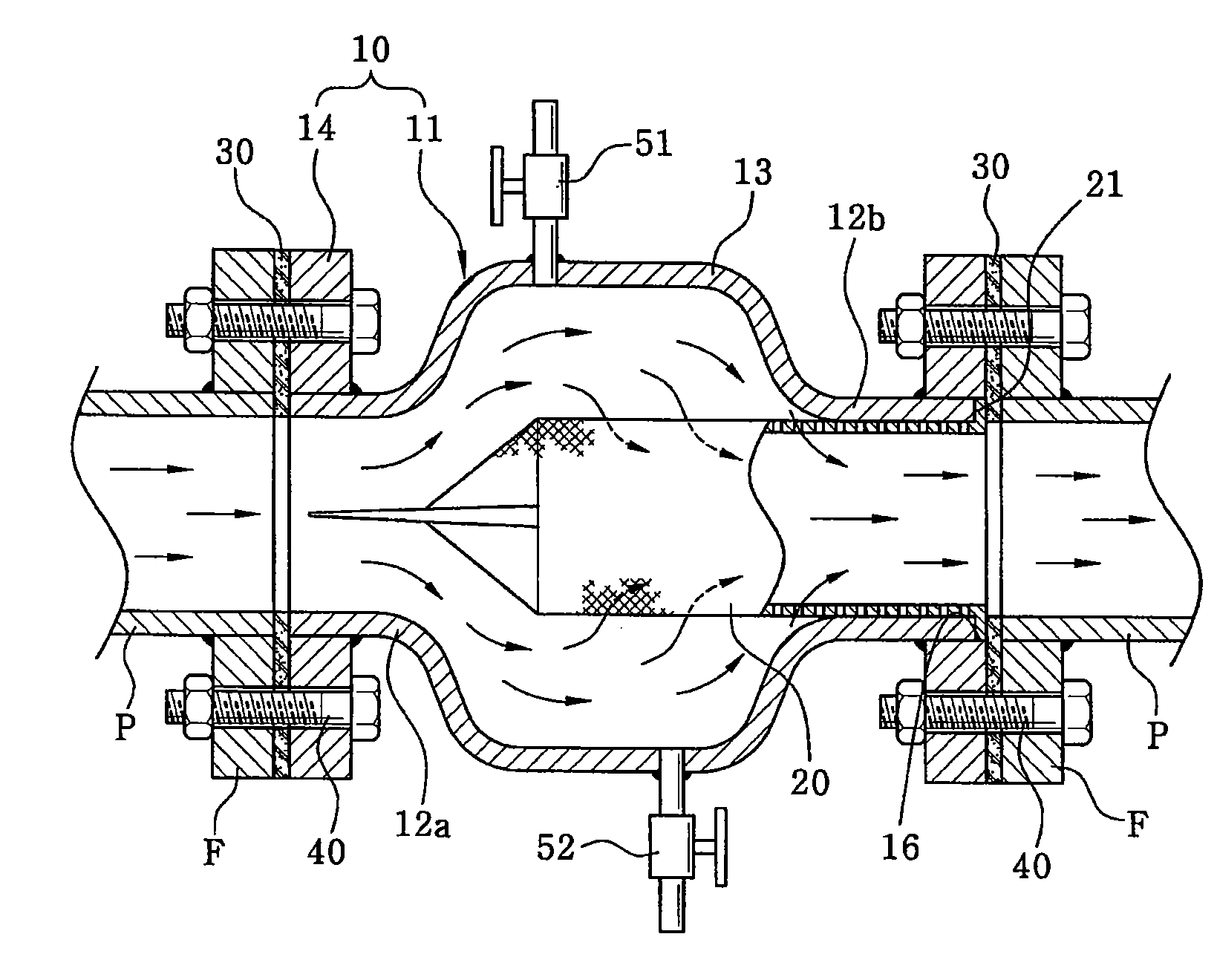

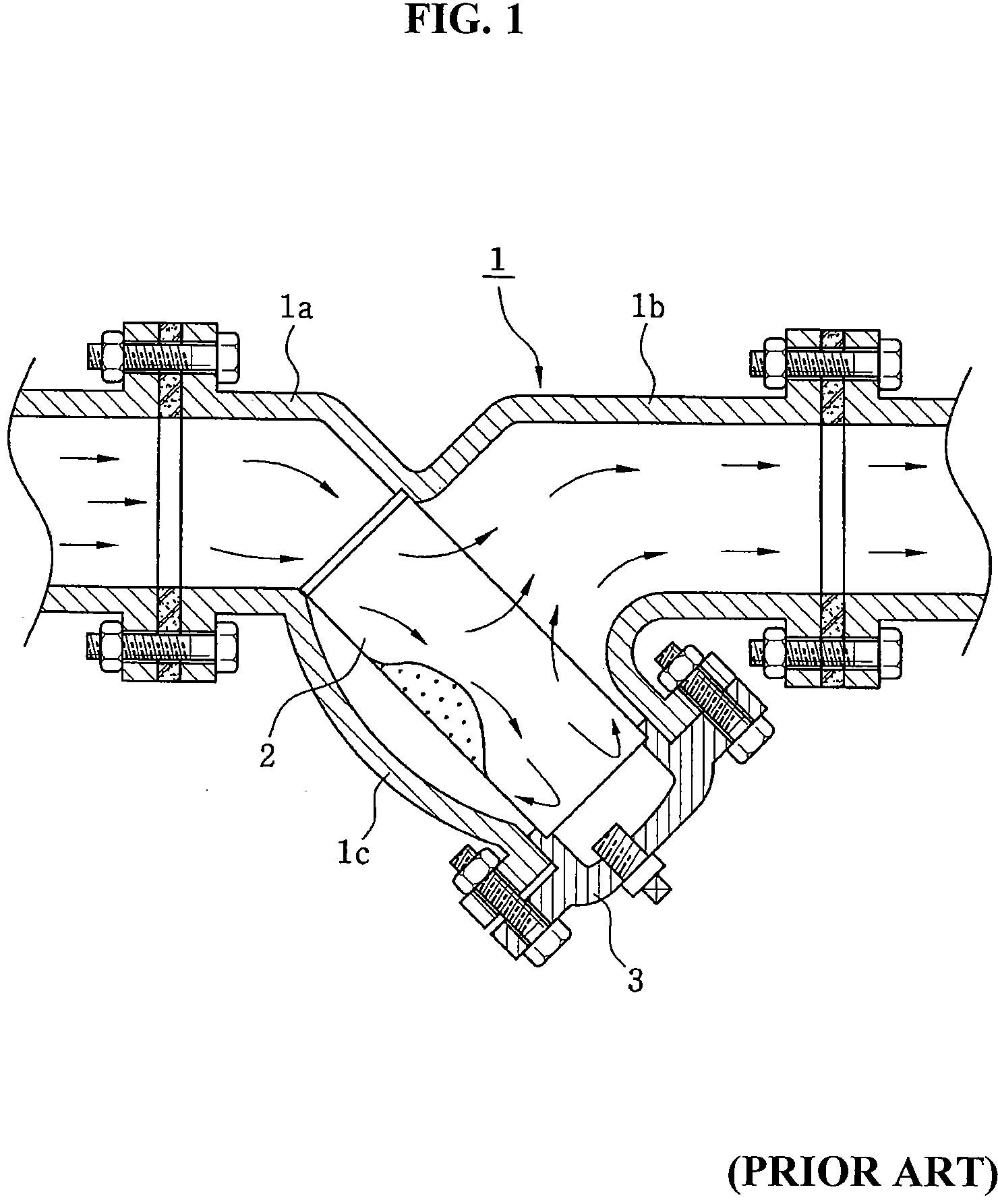

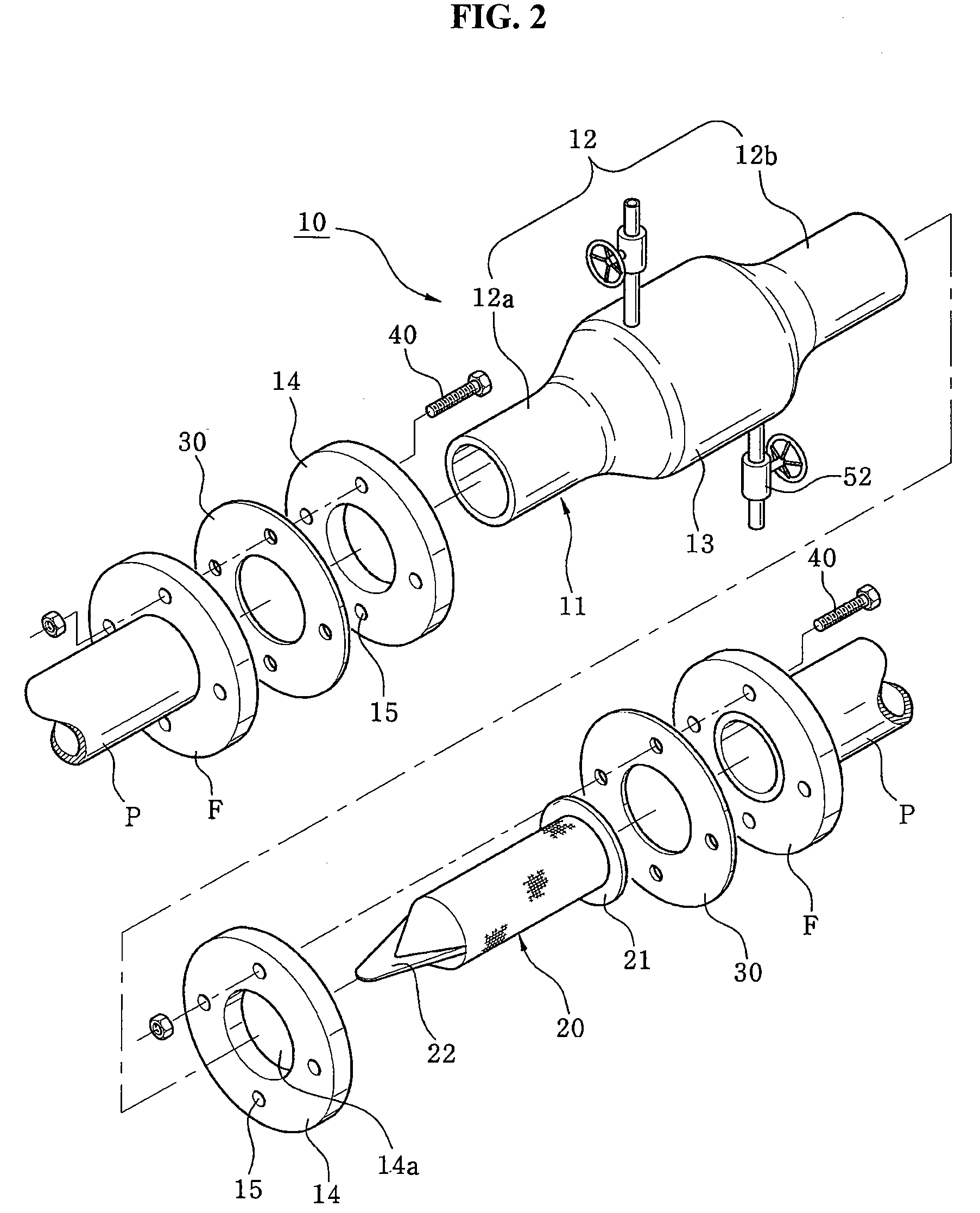

In-line strainer

InactiveUS20100116732A1Gentle and stable fluid flowReduce pressure lossMembrane filtersCartridge filtersEngineeringFlange

The present invention relates to an in-line strainer including: a body formed of a linear pipe having an enlarged part formed increased in diameter in the middle portion thereof, and a fastening flange mounted at the both ends thereof in such a manner as to be connected coaxially to a pipeline by means of a gasket; and a mesh screen having a generally conical shape at the front end portion thereof and a generally cylindrical shape at the back end portion thereof in such a manner as to be coupled to the body, the mesh screen being inserted from the outlet port of the body and being disposed concentrically into the enlarged part of the body in such a manner as to place the front end portion thereof into the enlarged part of the body, having a predetermined space from the inlet port of the body.

Owner:KMC

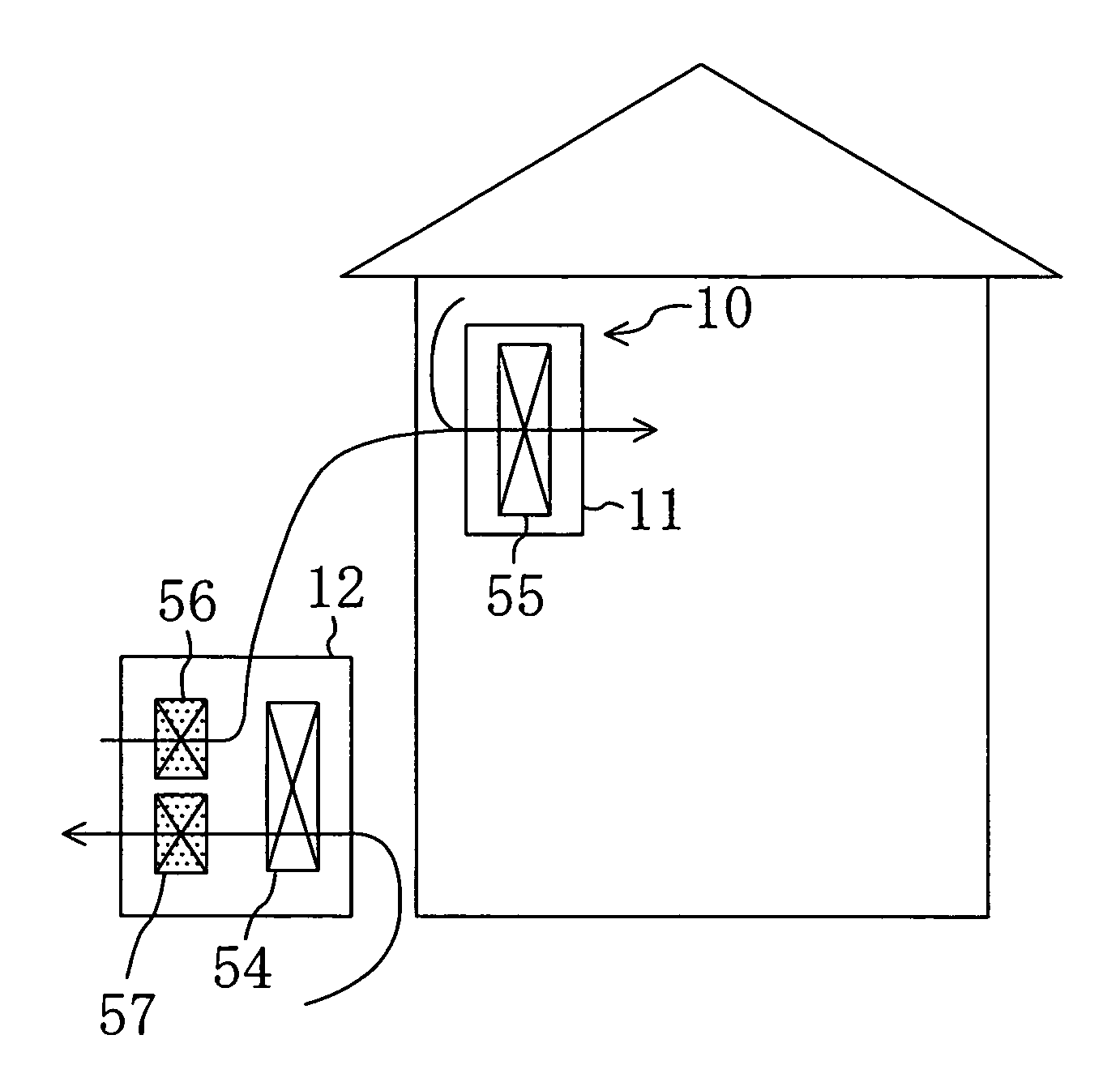

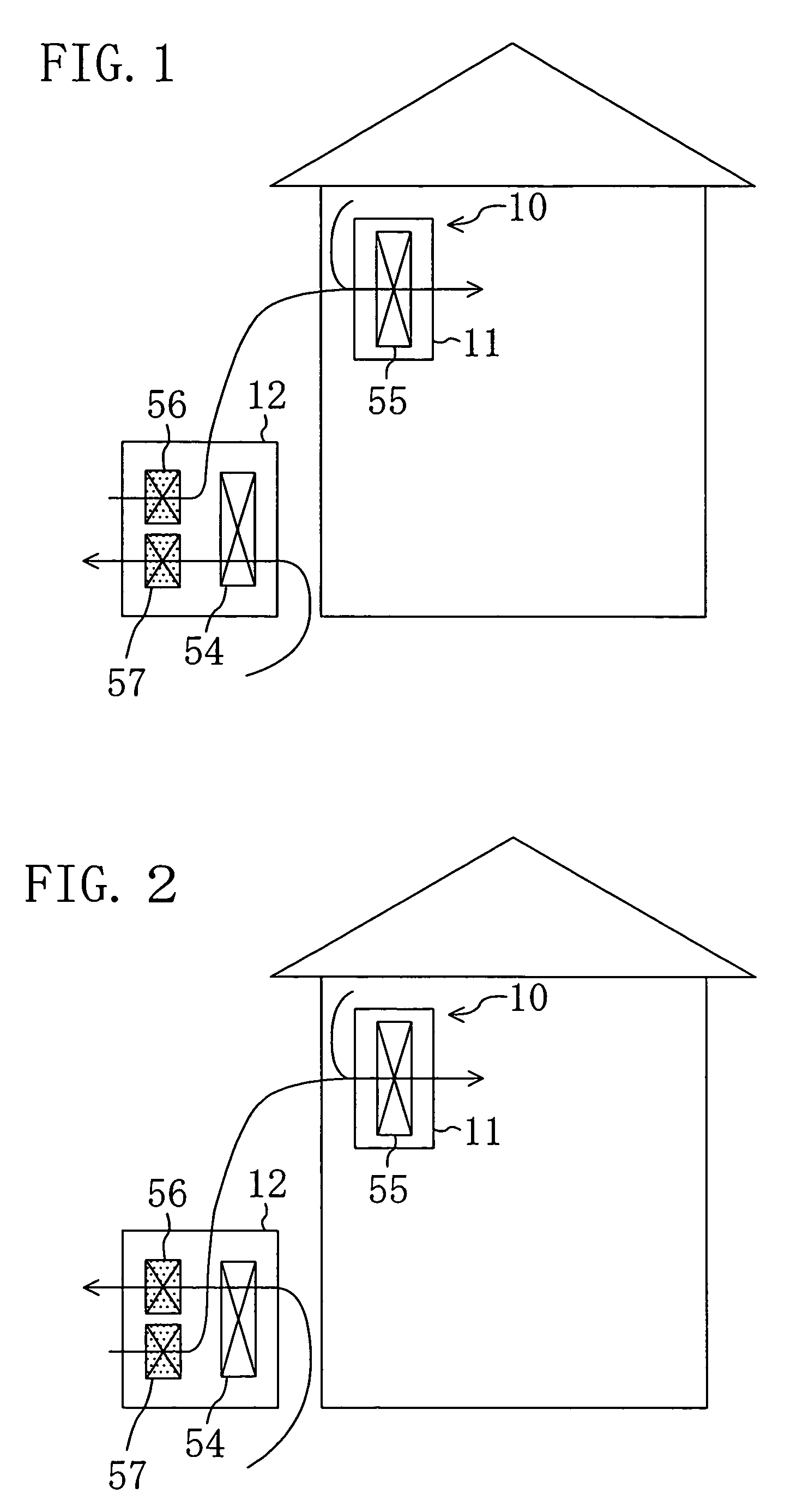

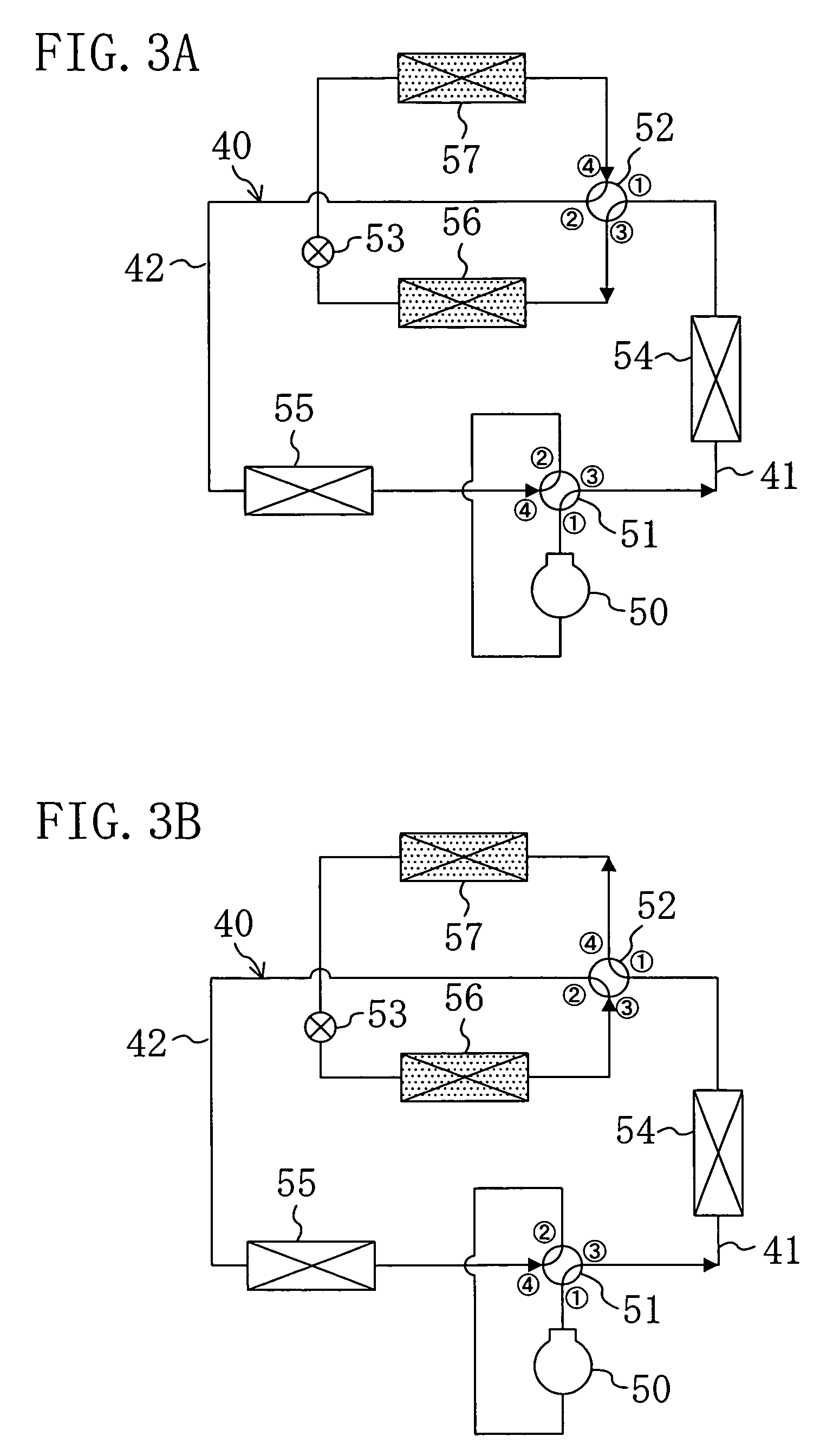

Air conditioning system

InactiveUS7930896B2DownsizedReduce pressure lossGas treatmentSpace heating and ventilation safety systemsRefrigerantEvaporator

A refrigerant circuit (40) is provided with an outdoor heat exchanger (54), an indoor heat exchanger (55) and two adsorption heat exchangers (56, 57). The indoor heat exchanger (55) is disposed in an indoor unit (11), while the outdoor heat exchanger (54) and the two adsorption heat exchangers (56, 57) are disposed in an outdoor unit (12). Moisture in outdoor air taken in the outdoor unit (12) is adsorbed by the adsorbent in the adsorption heat exchanger (56, 57) serving as an evaporator and the air is dehumidified. The dehumidified air is cooled by the indoor heat exchanger (55) serving as an evaporator and the air is supplied to the room space.

Owner:DAIKIN IND LTD

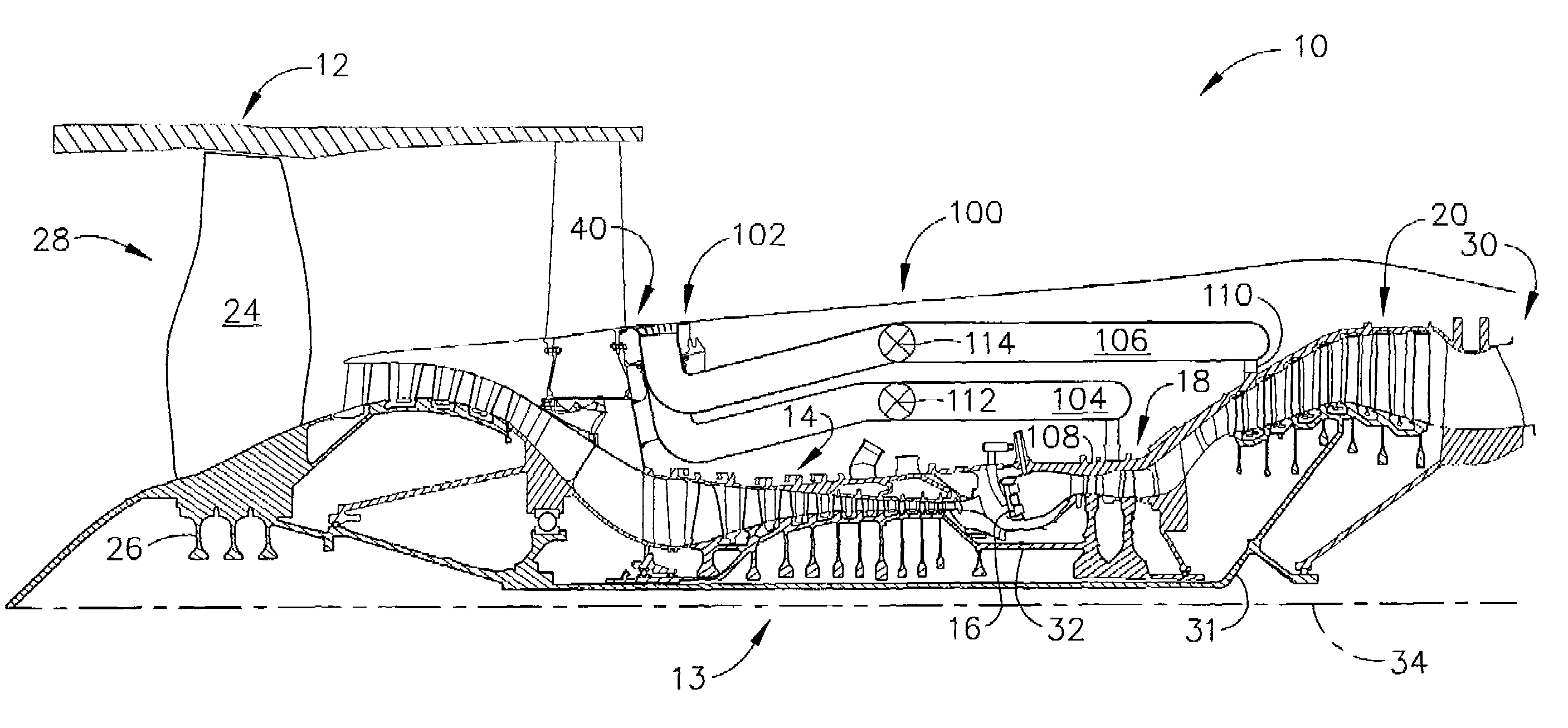

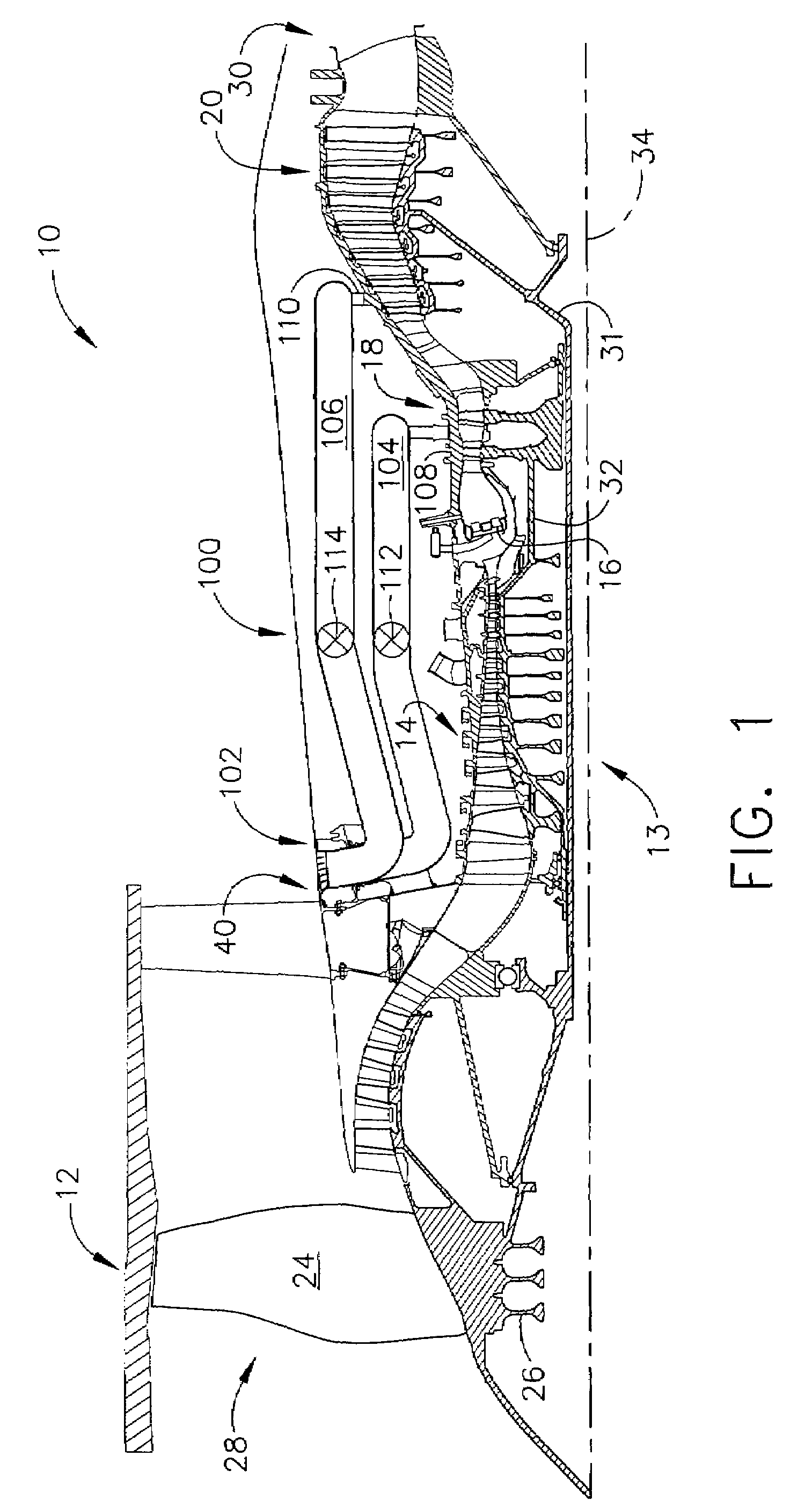

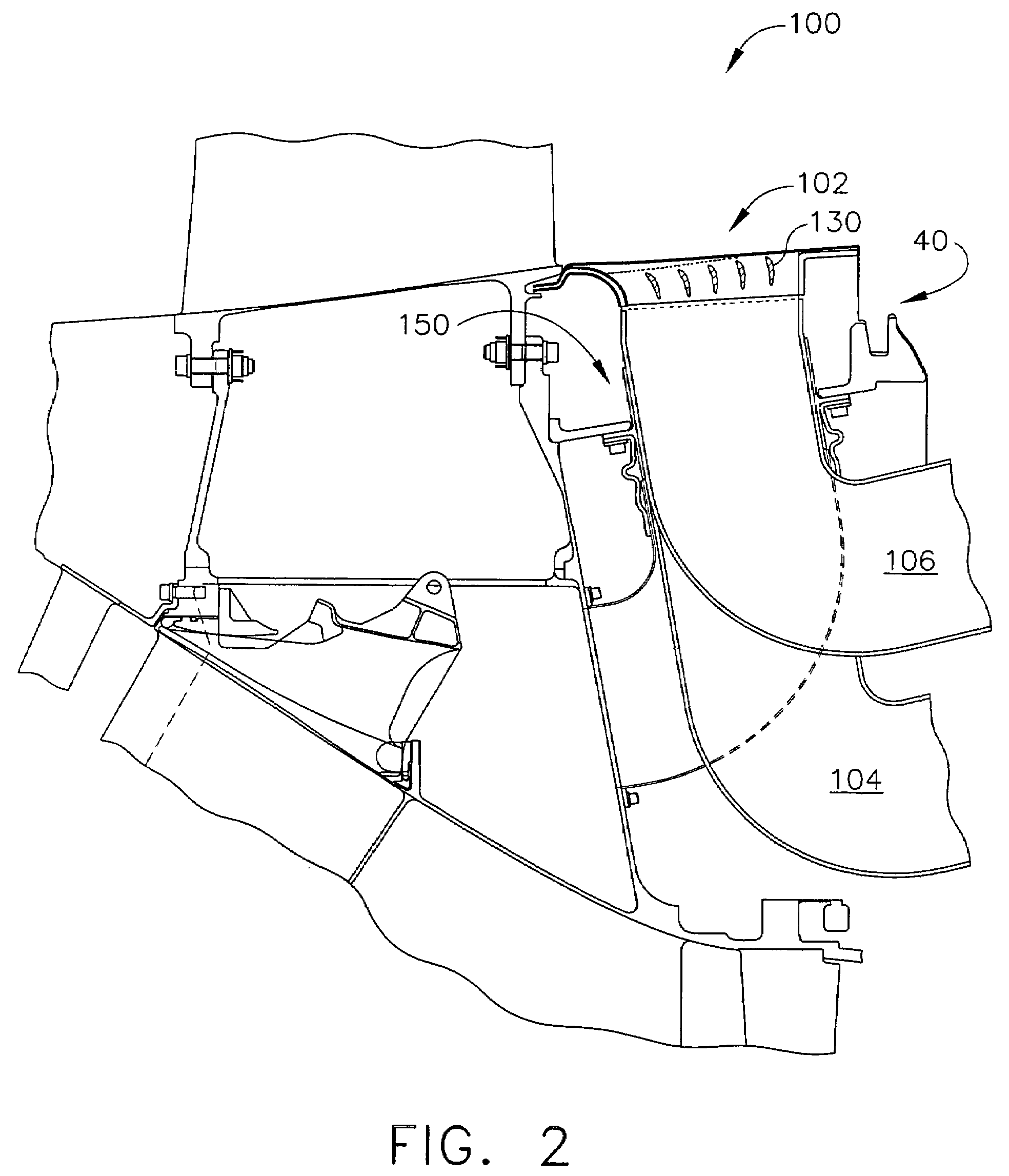

Method and apparatus for operating gas turbine engines

ActiveUS7717667B2Reduce total pressure lossReduce pressure lossLeakage preventionPump controlControl systemHigh pressure

A method for operating a gas turbine engine is provided. The gas turbine engine includes a fan, a high pressure turbine coupled downstream from the fan, and a low pressure turbine downstream from the high pressure turbine. The method includes channeling a portion of air discharged from the fan through a clearance control system including an inlet assembly that includes a plurality of louvers, and directing air from the inlet assembly into a first pipe and second pipe coupled to the inlet assembly such that pressure losses associated with the airflow are facilitated to be reduced.

Owner:GENERAL ELECTRIC CO

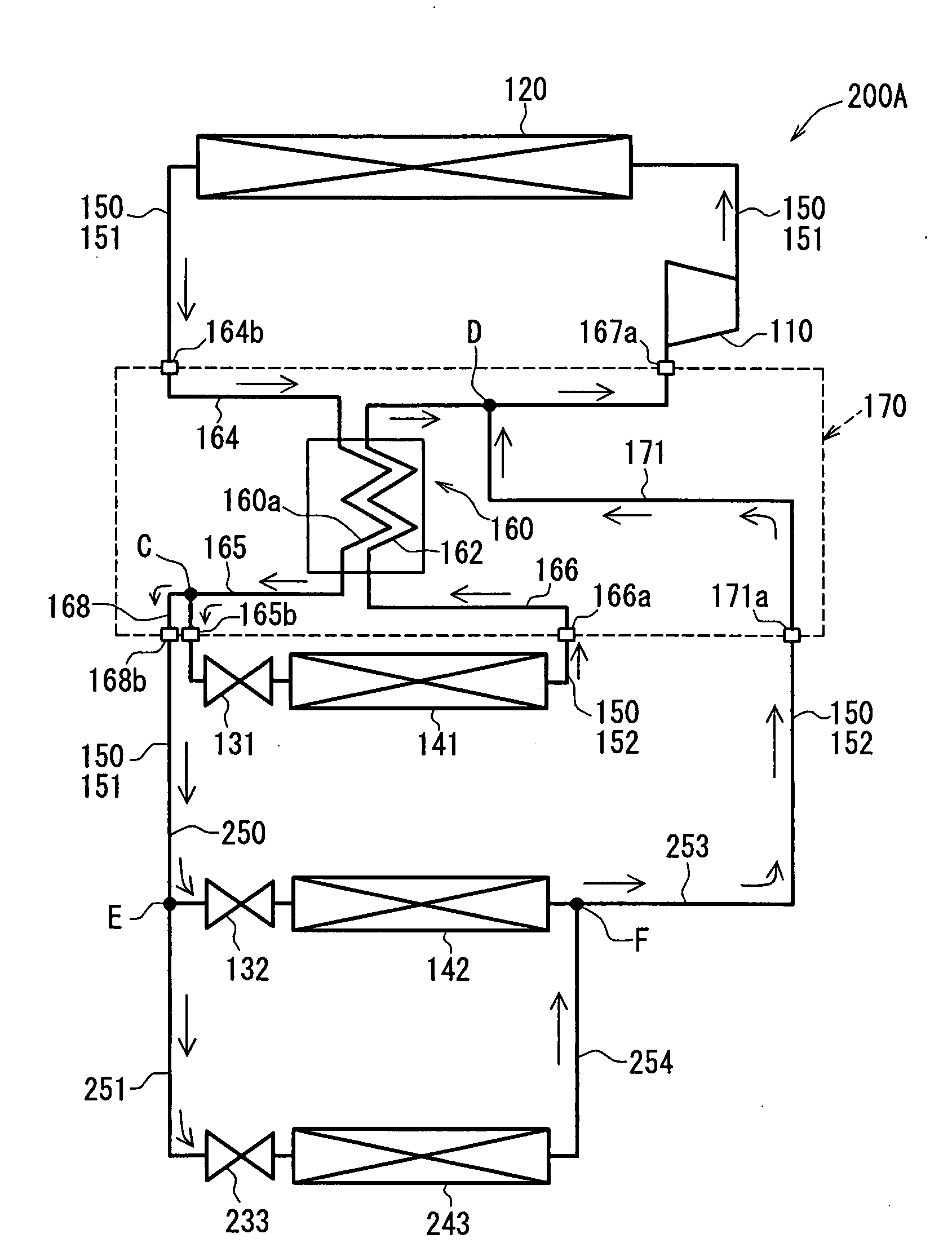

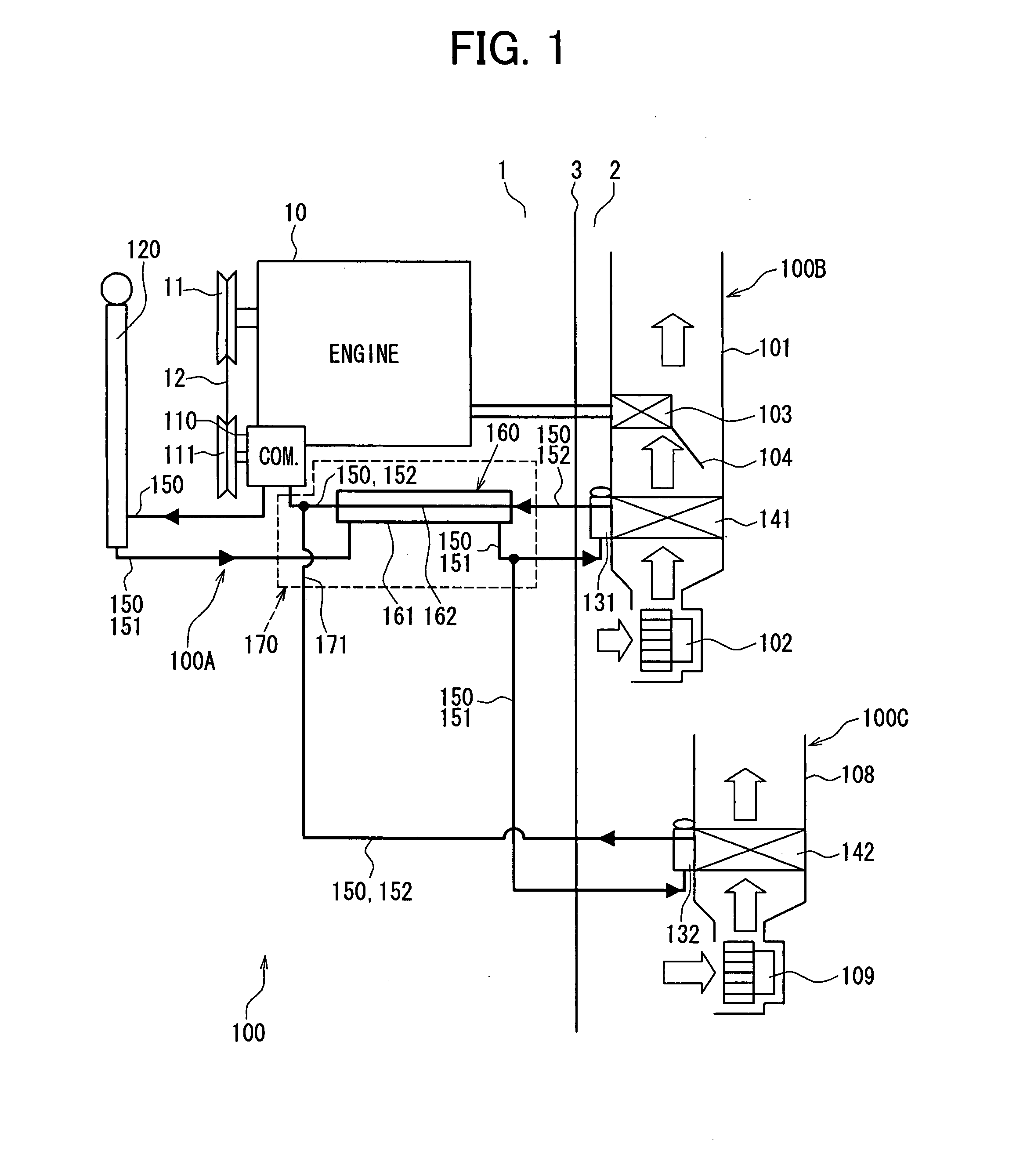

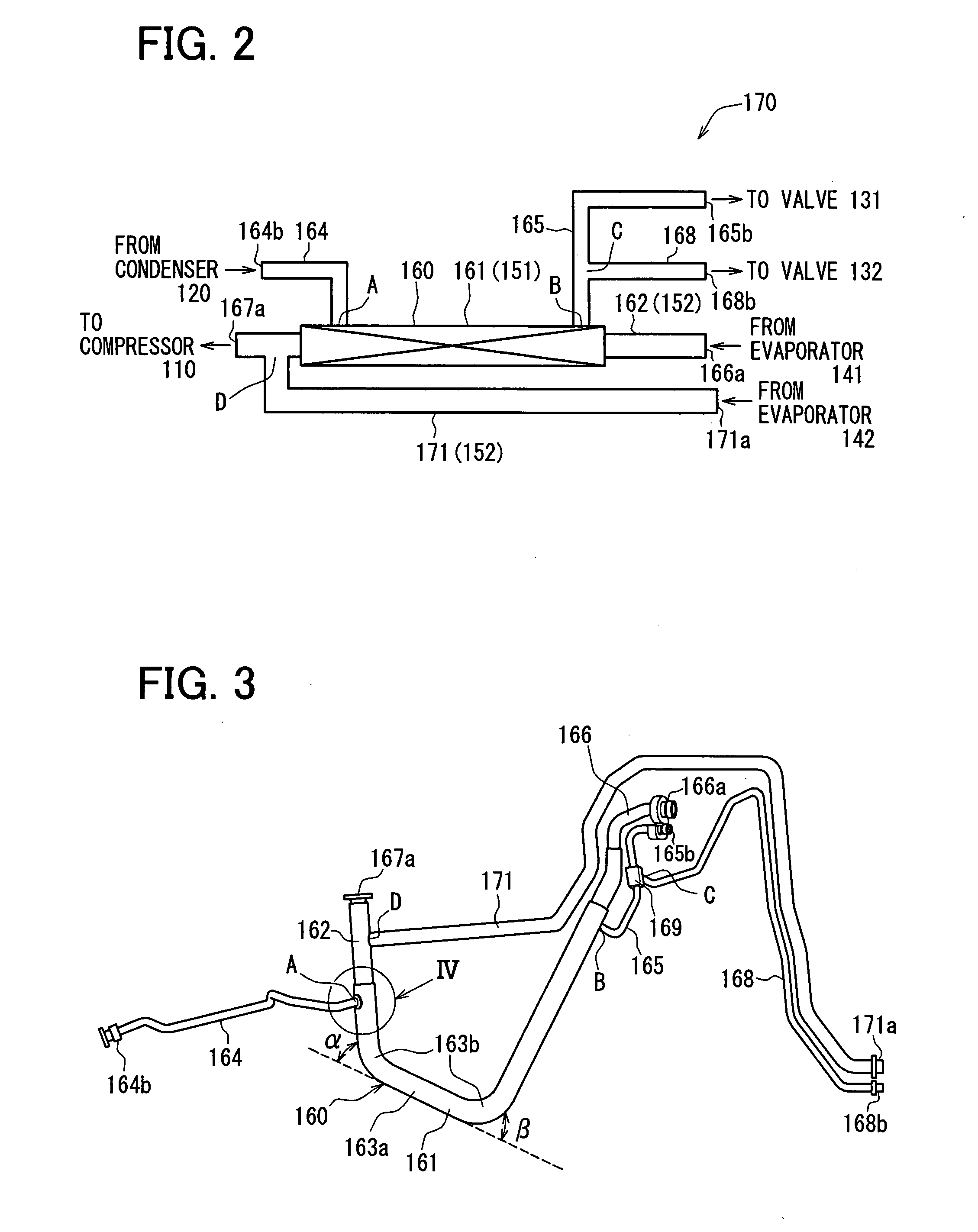

Piping structure with inner heat exchanger and refrigeration cycle device having the same

InactiveUS20070251265A1Reduce pressure lossReduce total pressure lossCompression machines with several evaporatorsVehicle heating/cooling devicesPipingRefrigerant

A piping structure for a refrigerant cycle device includes an inner heat exchanger, and a bypass pipe through which refrigerant flows while bypassing the inner heat exchanger. The inner heat exchanger has a first flow passage in which high-pressure refrigerant before being decompressed flows and a second flow passage in which low-pressure refrigerant after being decompressed flows. The refrigerant cycle device includes plural low-pressure side heat exchangers, and the plural low-pressure side heat exchangers are located such that refrigerant from a part of the low-pressure side heat exchangers flows through the second flow passage of the inner heat exchanger, and refrigerant from the other part of the low-pressure side heat exchangers flows through the bypass pipe while bypassing the inner heat exchanger.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com