Two-shaft gas turbine

a gas turbine and two-shaft technology, applied in the field of gas turbines, can solve the problems of increasing the size of the gas turbine, and achieve the effects of reducing the pressure loss in the gas passage and the length of the gas passage, and improving performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

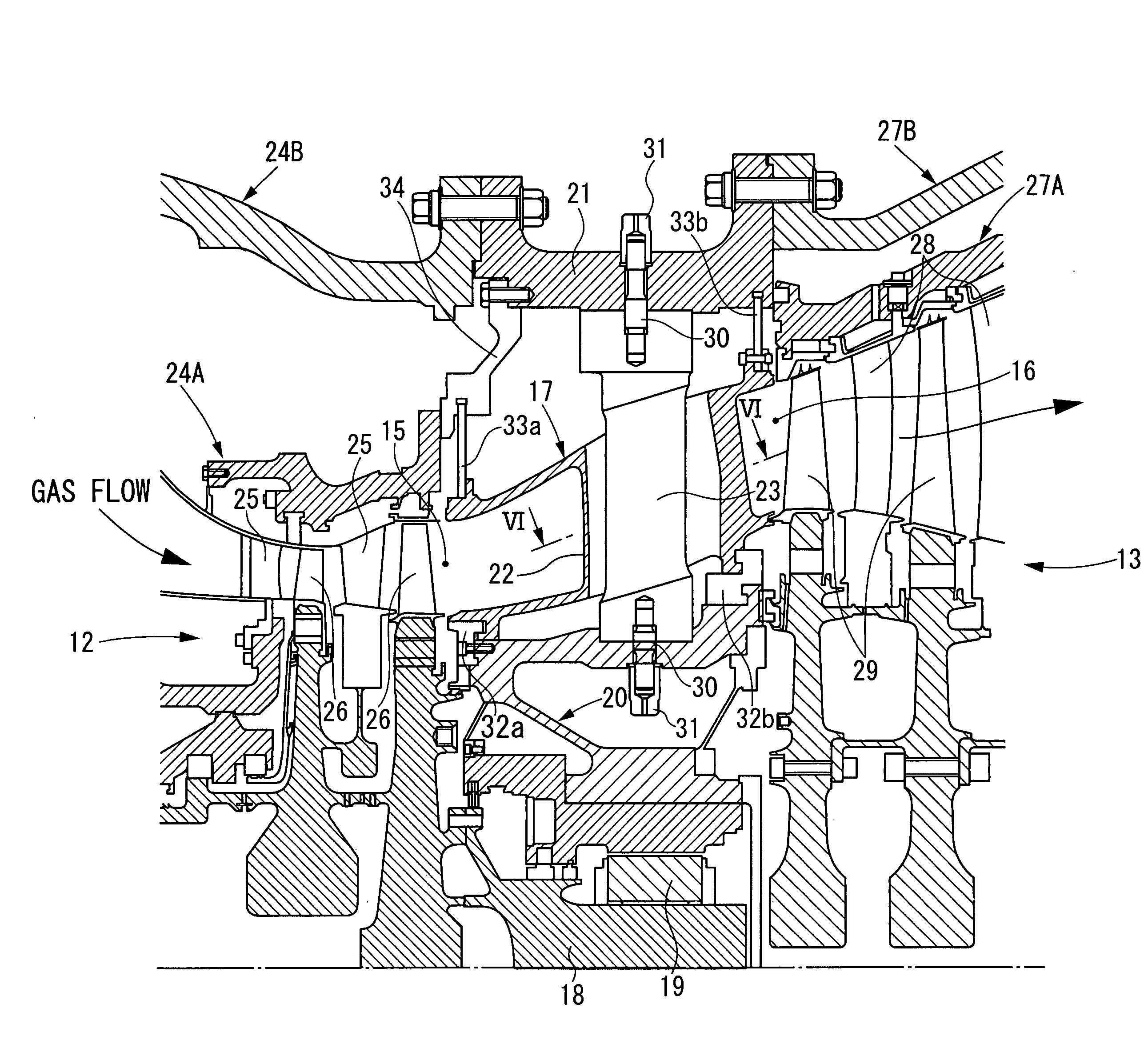

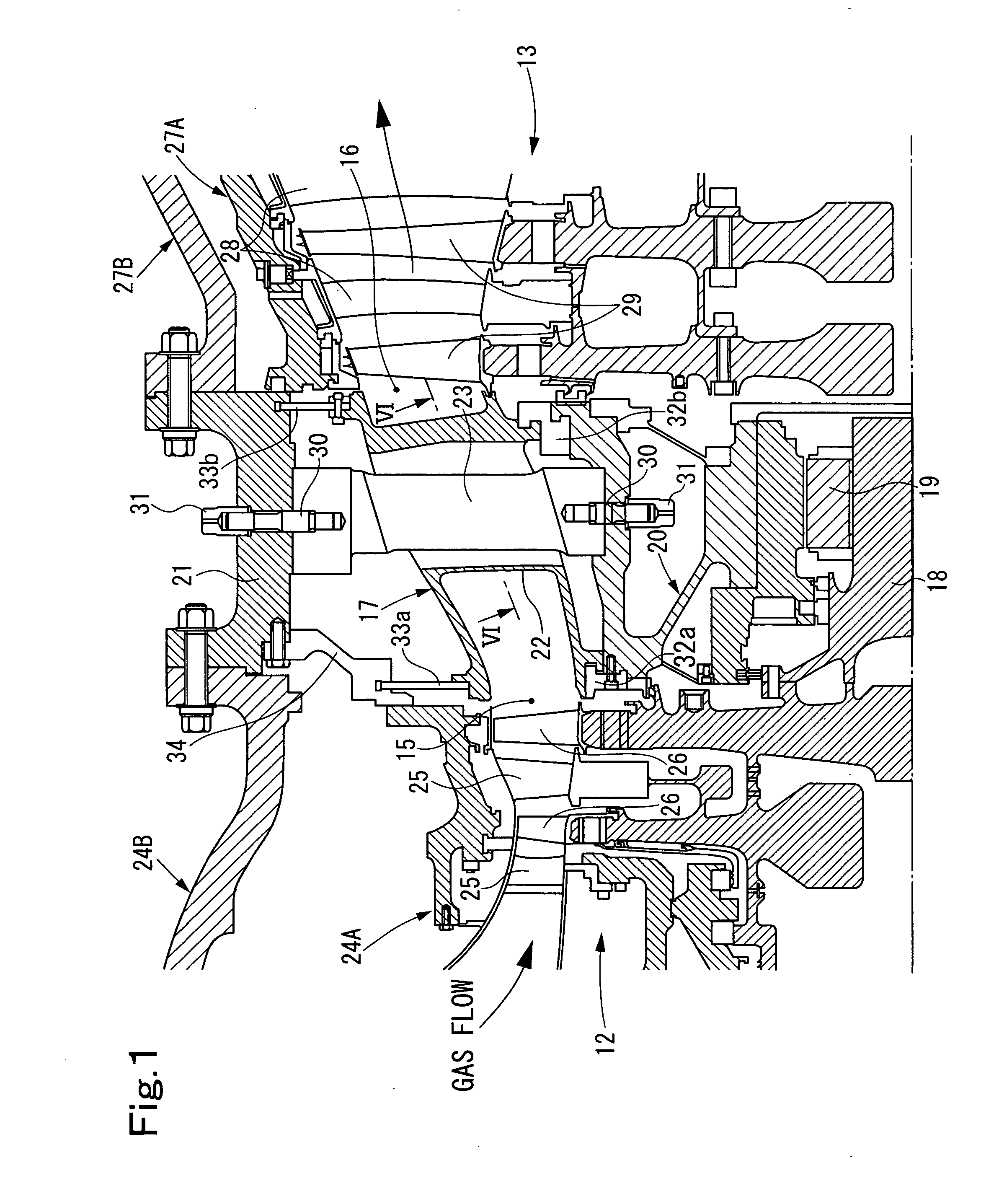

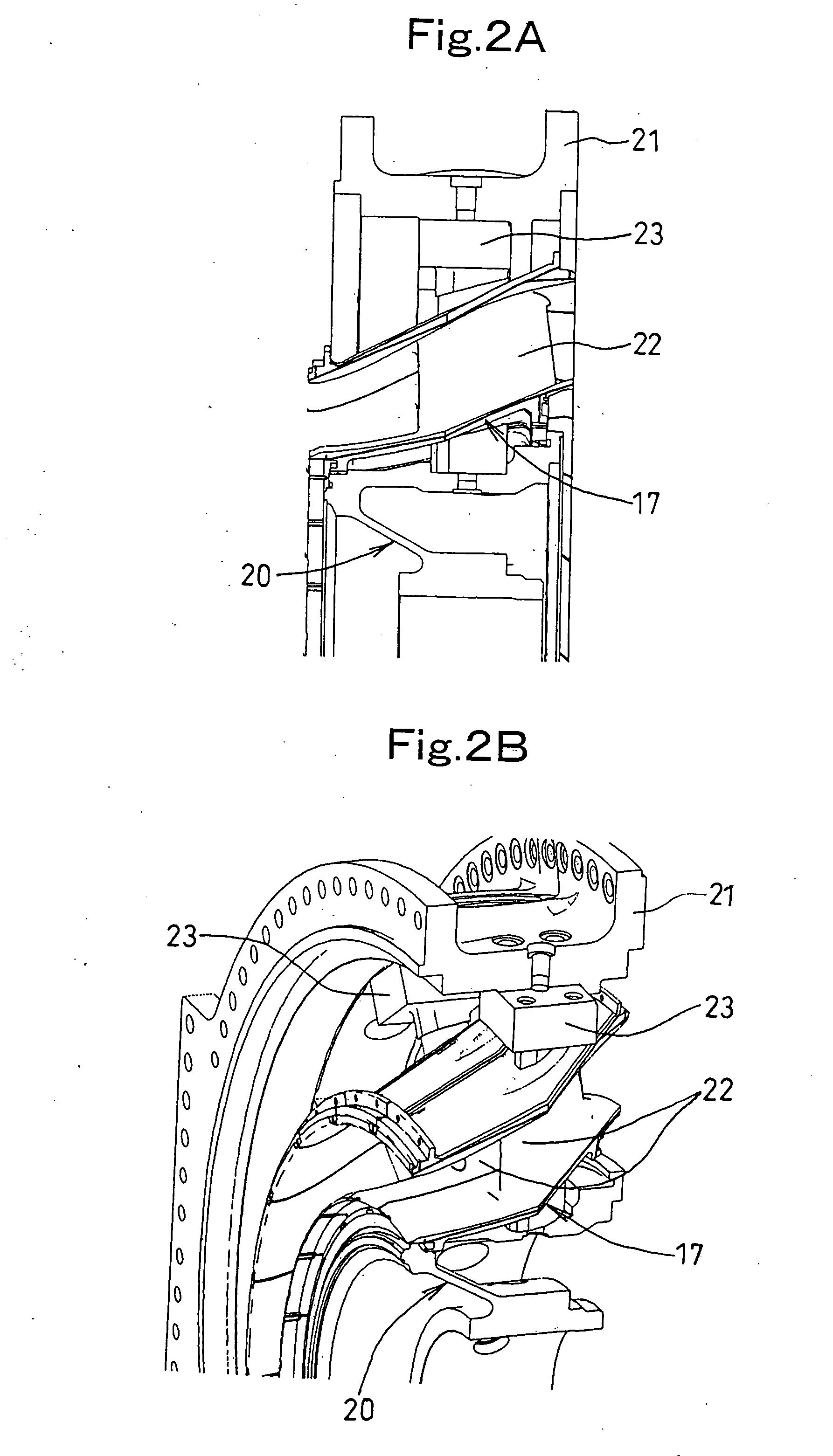

[0024]A two-shaft gas turbine according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0025]As shown in FIG. 5, a two-shaft gas turbine according to the present embodiment includes a compressor 10, a combustor 11, a high-pressure turbine 12 that functions as a gas generator, and a low-pressure turbine 13 that functions as a power turbine.

[0026]In this two-shaft gas turbine, air is compressed by the compressor 10 and is supplied to the combustor 11, where the compressed air is mixed with fuel that is separately supplied and the mixture of the compressed air and the fuel is combusted. Combustion gas is generated by combustion is supplied to the high-pressure turbine 12 and the low-pressure turbine 13. The high-pressure turbine 12 generates high-temperature, high-pressure combustion gas for driving the compressor 10 at, for example, 5,000 rpm and the low-pressure turbine 13 drives a generator 14 at, for example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com