Patents

Literature

48 results about "Dry-ice blasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry ice blasting is a form of carbon dioxide cleaning, where dry ice, the solid form of carbon dioxide, is accelerated in a pressurized air stream and directed at a surface in order to clean it. The method is similar to other forms of media blasting such as sand blasting, plastic bead blasting, or sodablasting in that it cleans surfaces using a media accelerated in a pressurized air stream, but dry ice blasting uses dry ice as the blasting medium. Dry ice blasting is nonabrasive, non-conductive, nonflammable, and non-toxic.

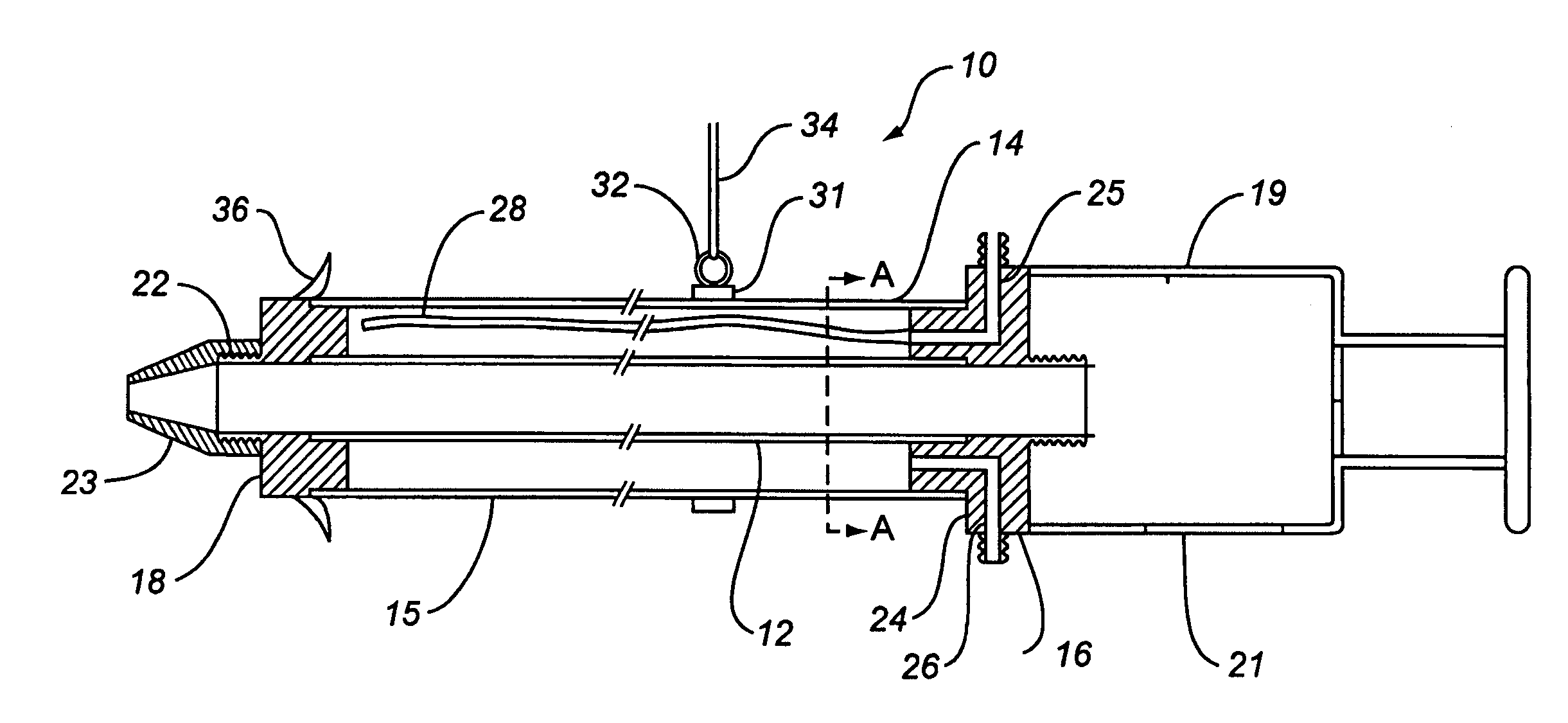

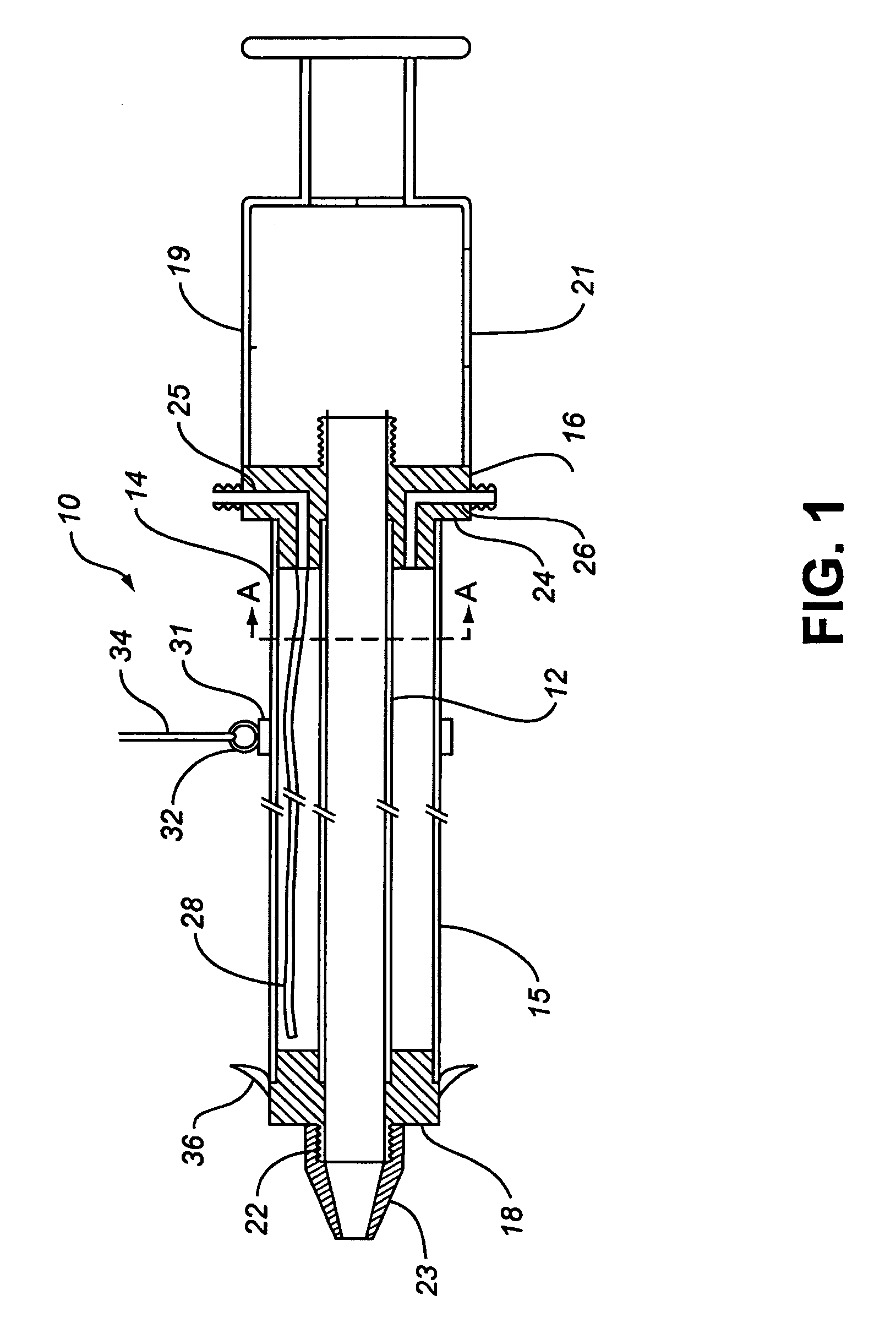

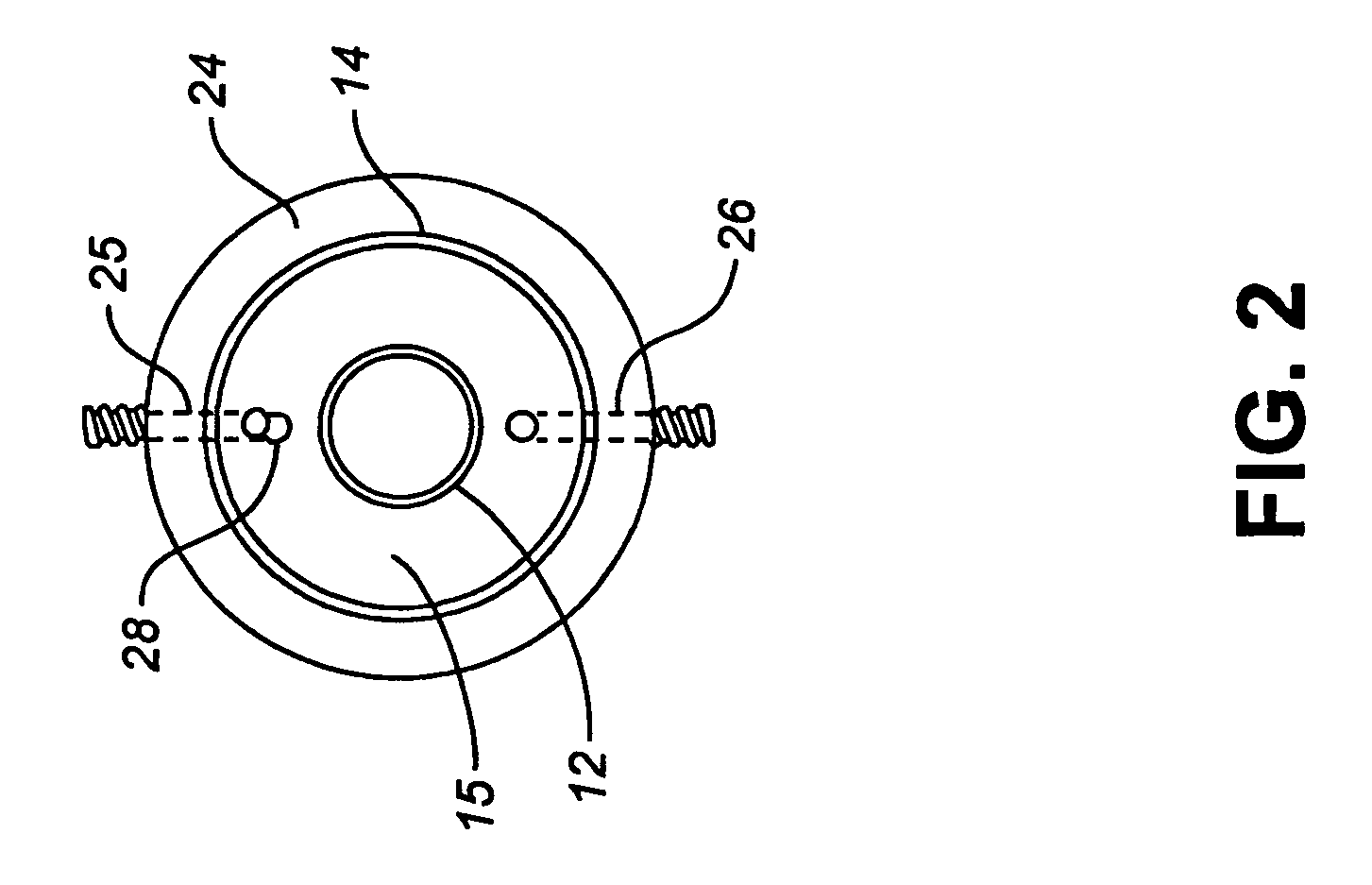

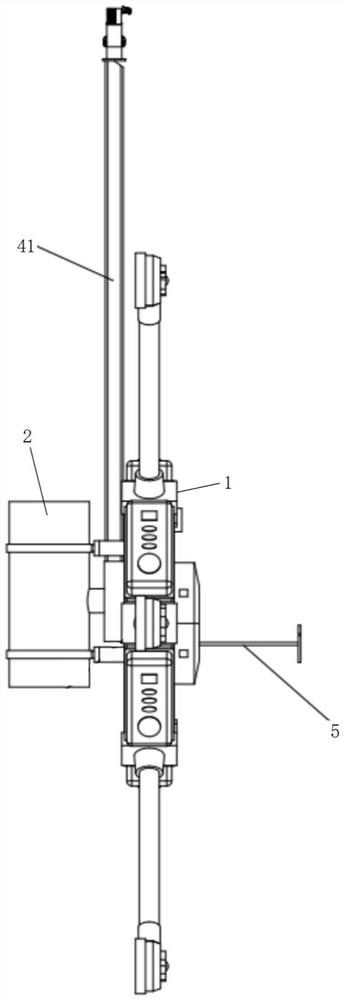

Dry ice blasting cleaning apparatus

The invention is an apparatus used for cleaning equipment including extremely high voltage energized electrical equipment using a dry ice blasting stream as the cleaning agent. The apparatus comprises a cleaning wand and a heating mechanism for impeding the formation of condensation and / or frost on the outer surface of the wand, thereby enabling the wand to operate for prolonged periods of time.

Owner:BRITISH COLUMBIA HYDRO & POWER AUTHORITY

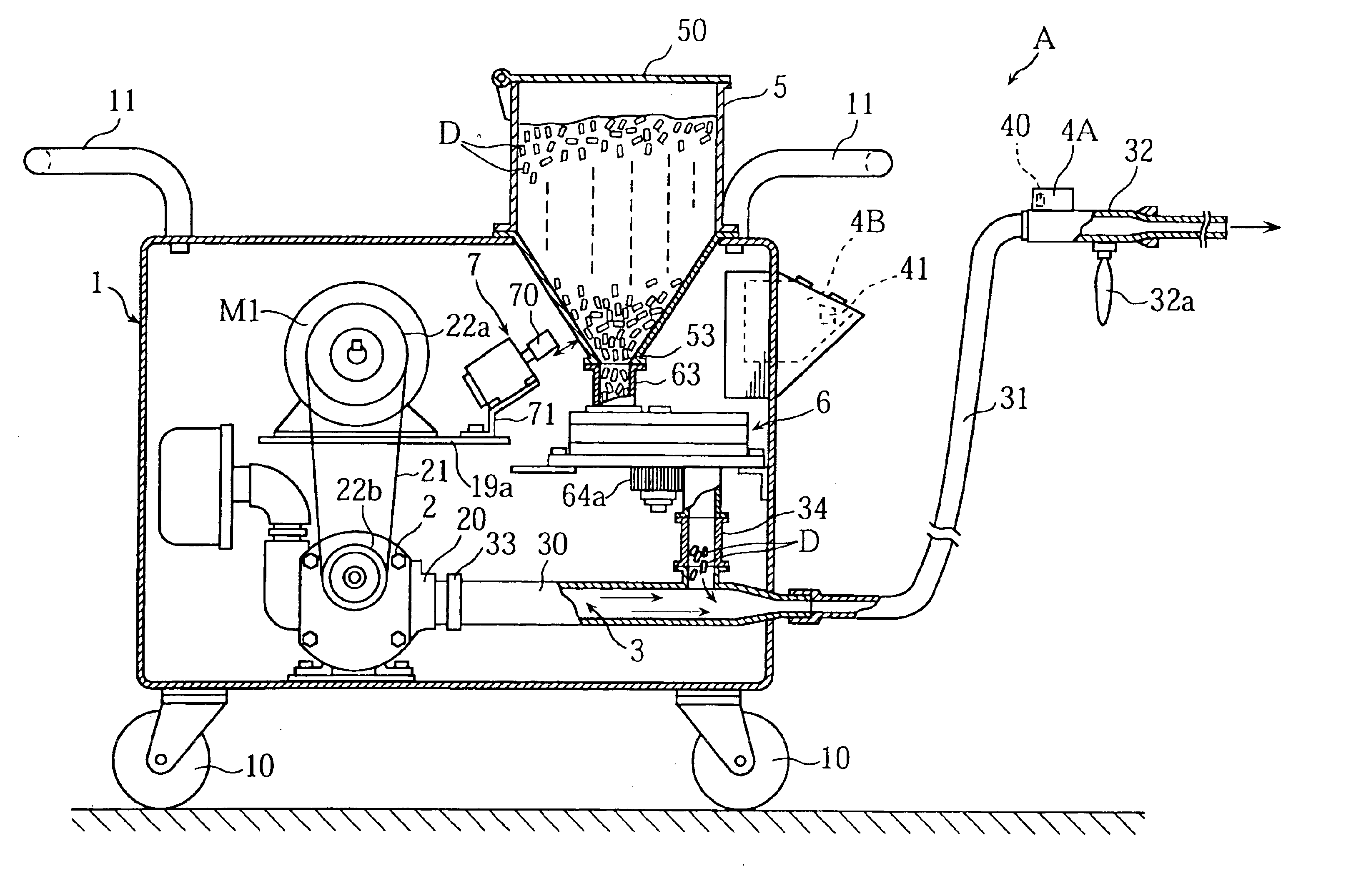

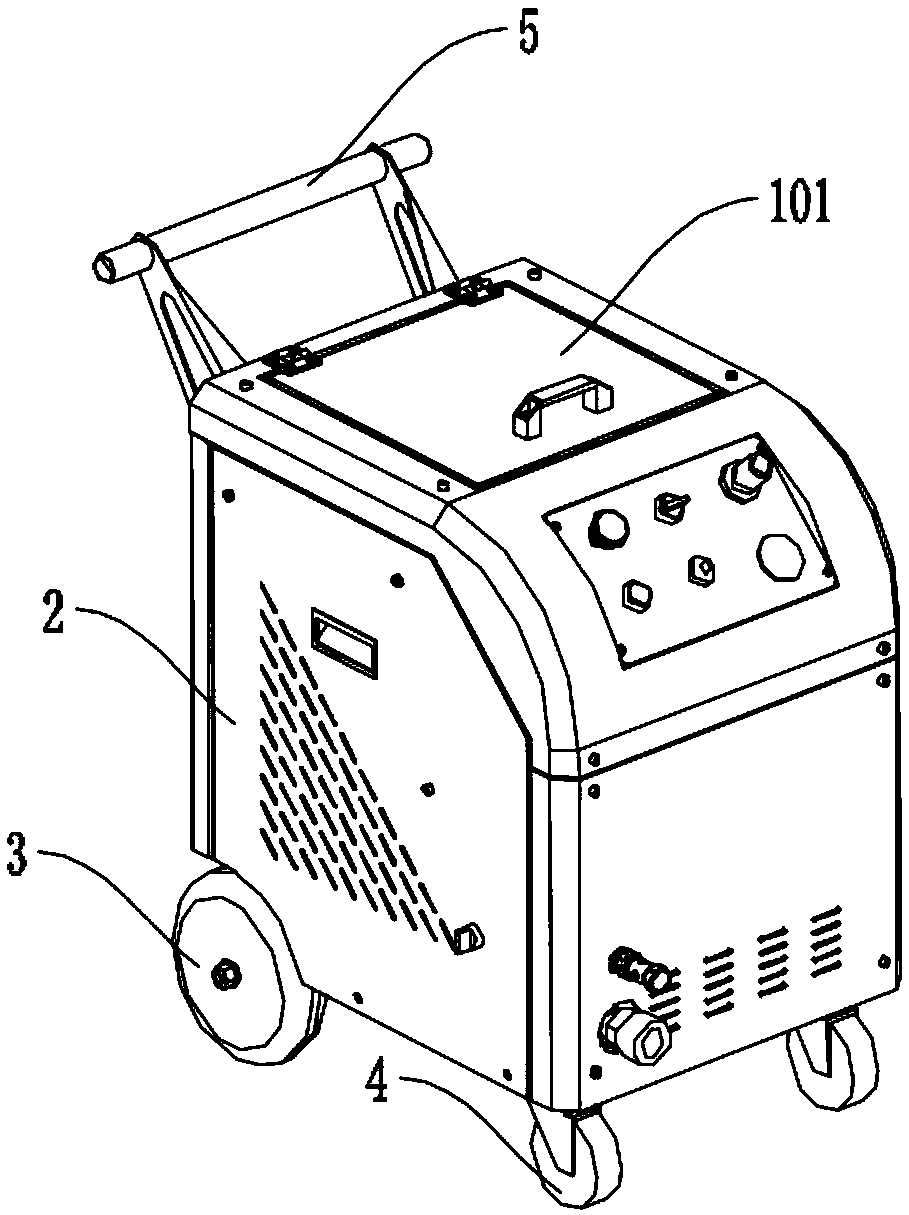

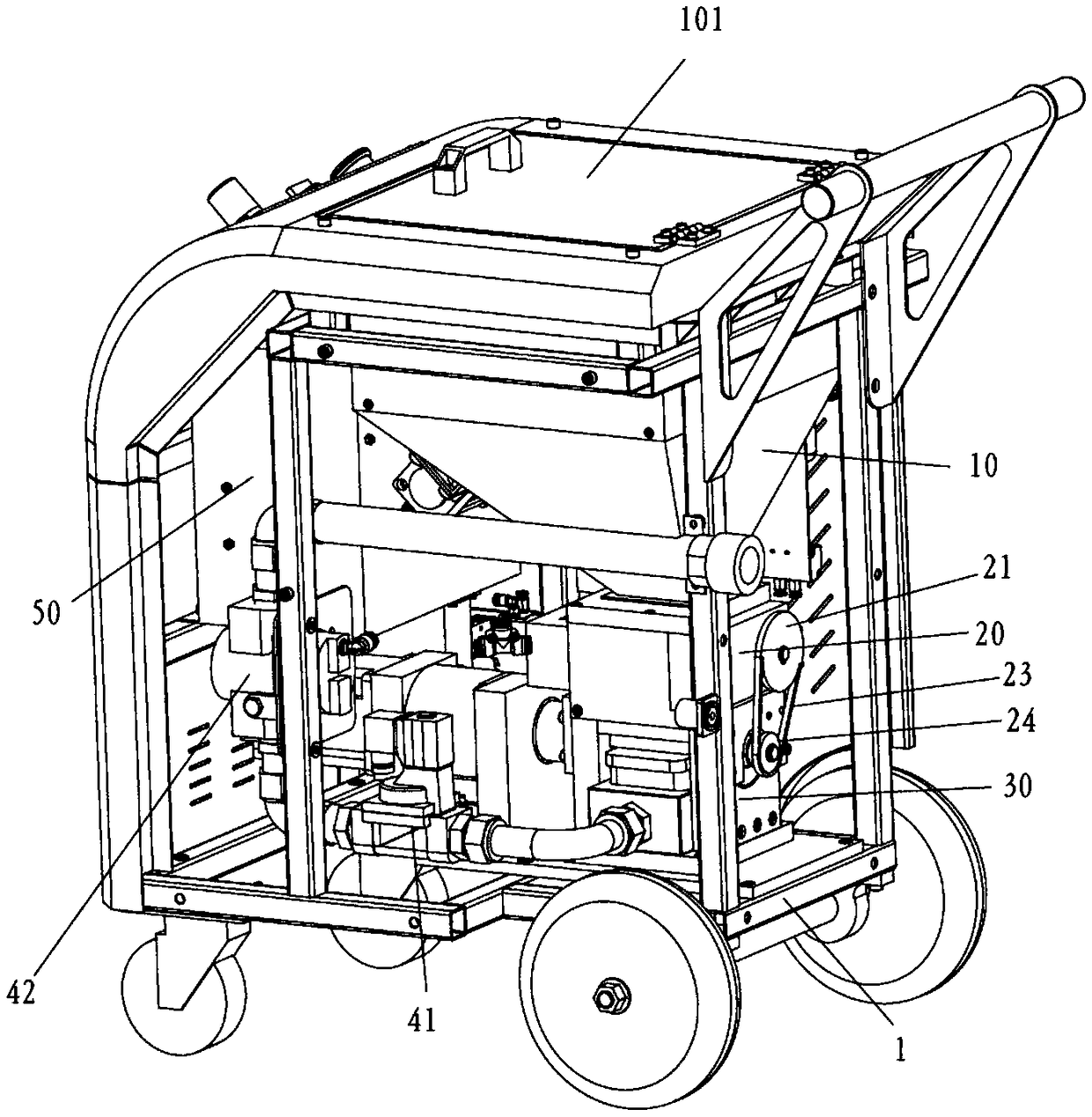

Dry-ice blast device

InactiveUS6890246B2Eliminates and alleviatesAbrasive feedersAbrasive machine appurtenancesEngineeringAir compressor

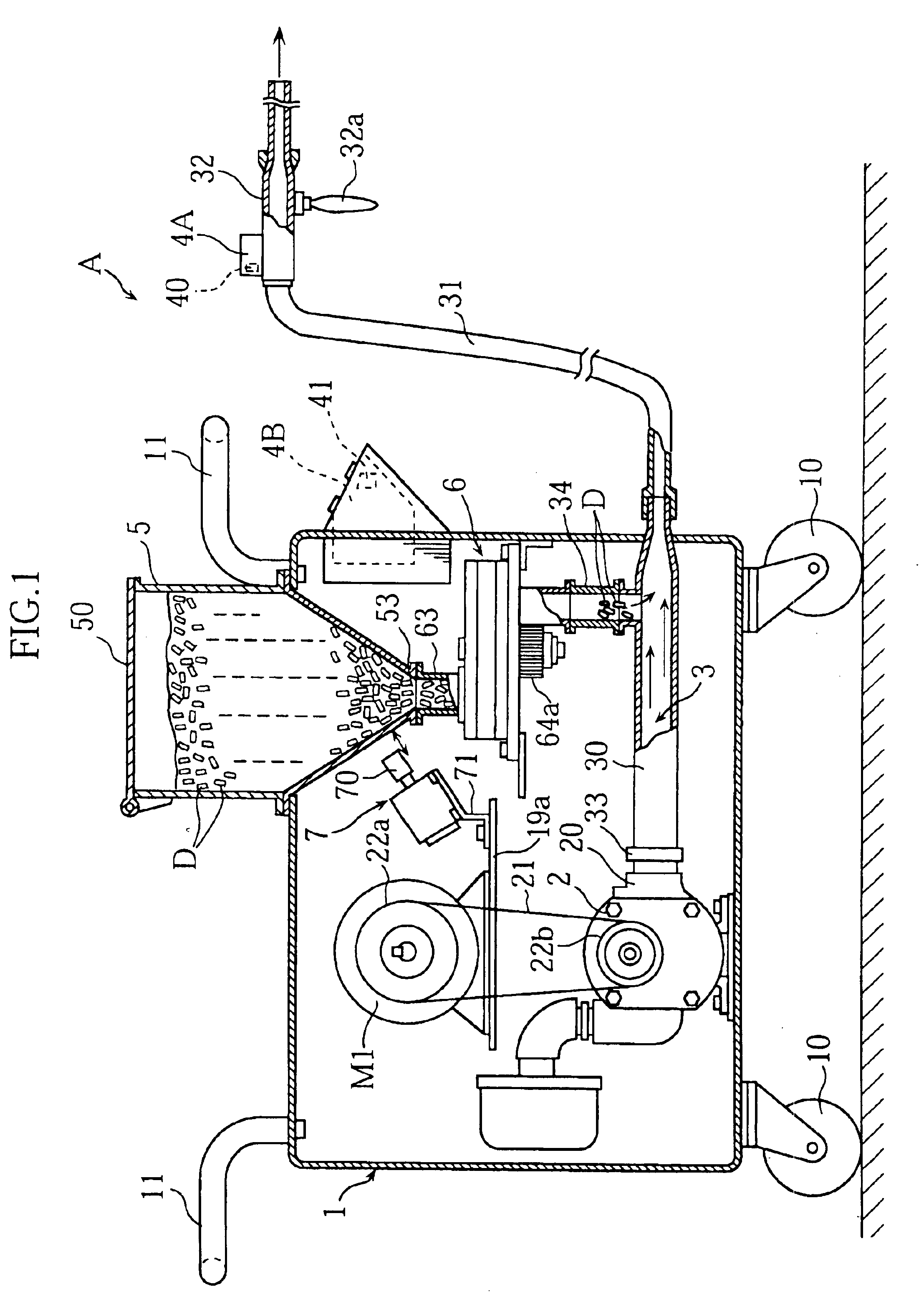

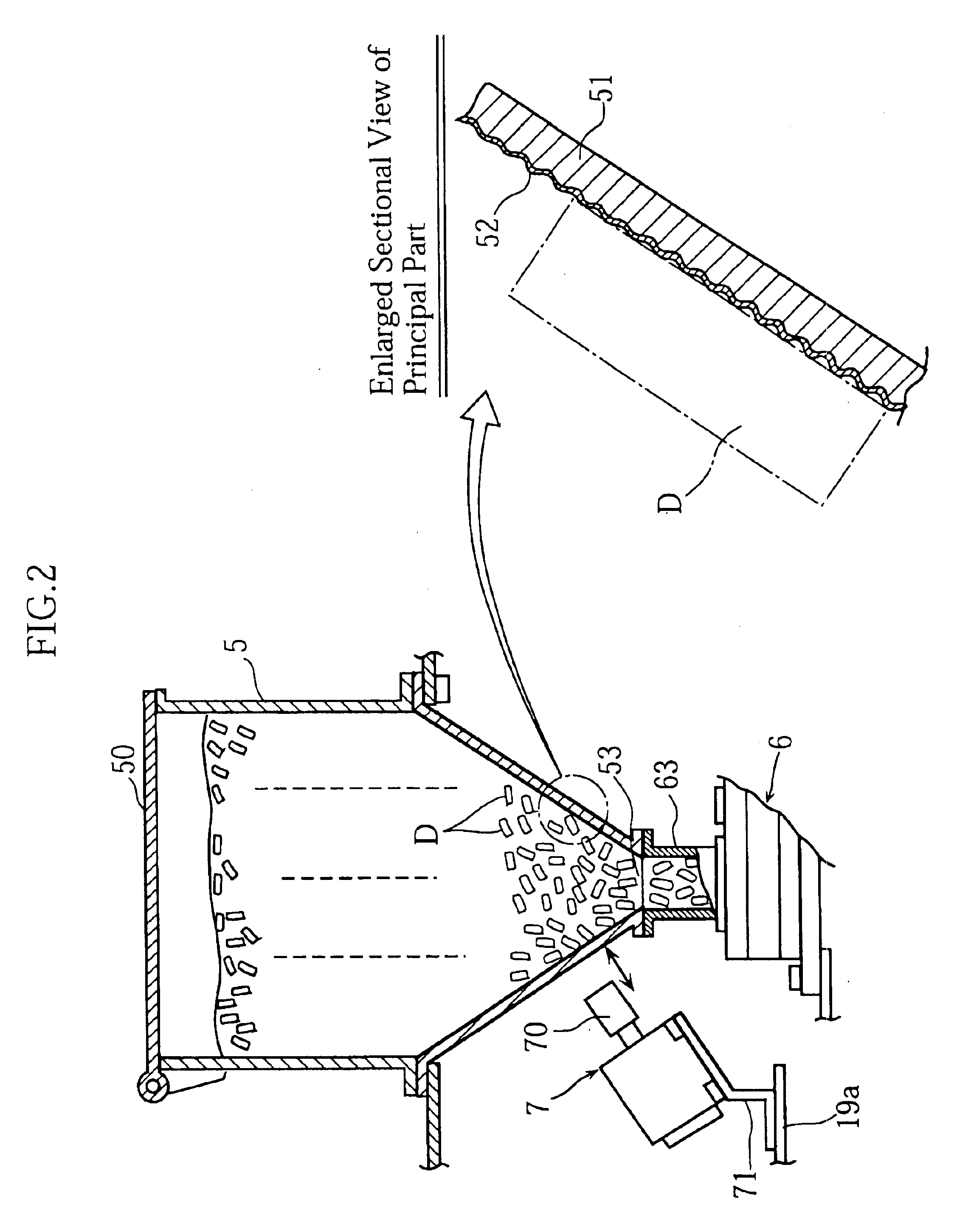

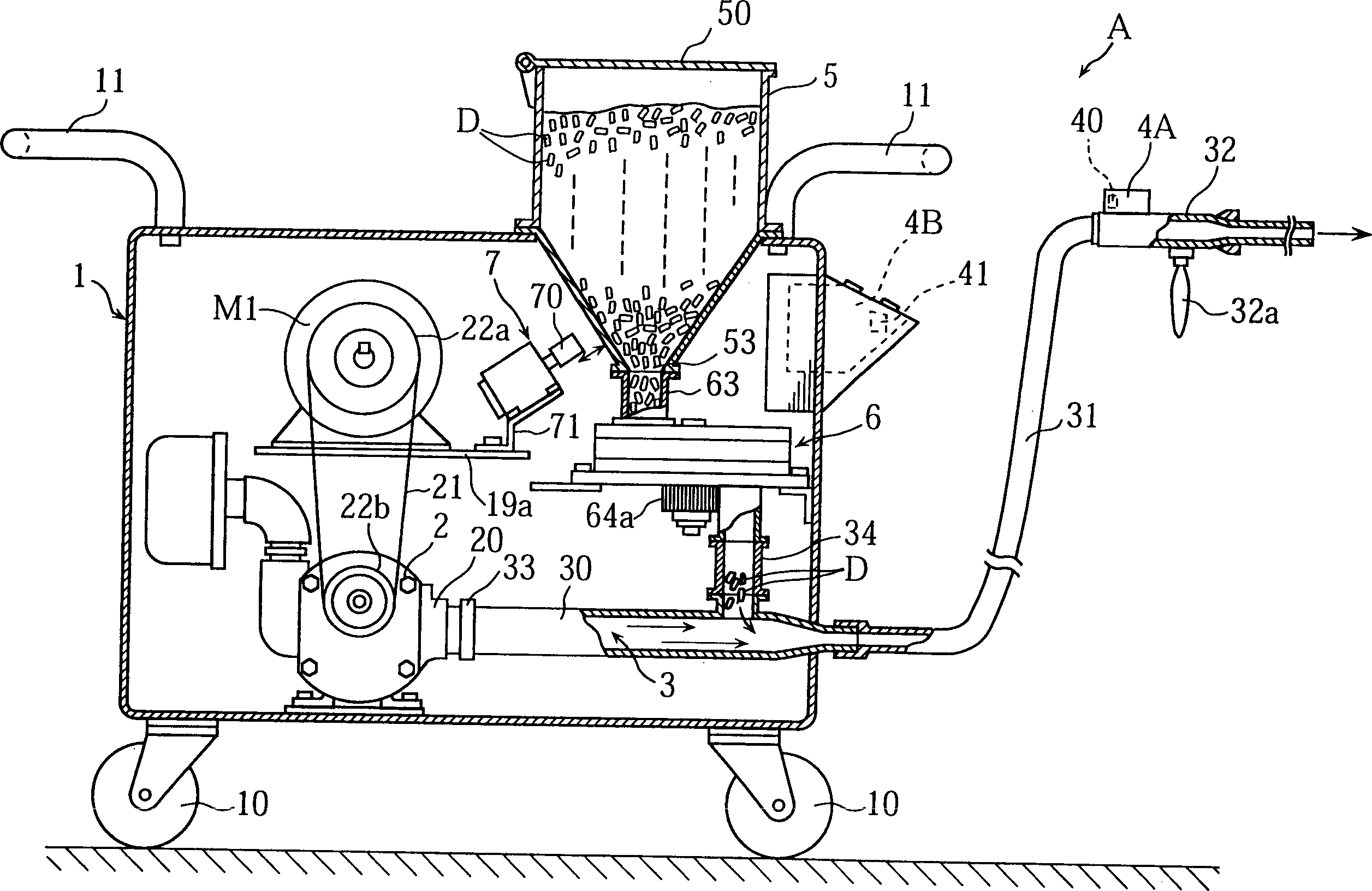

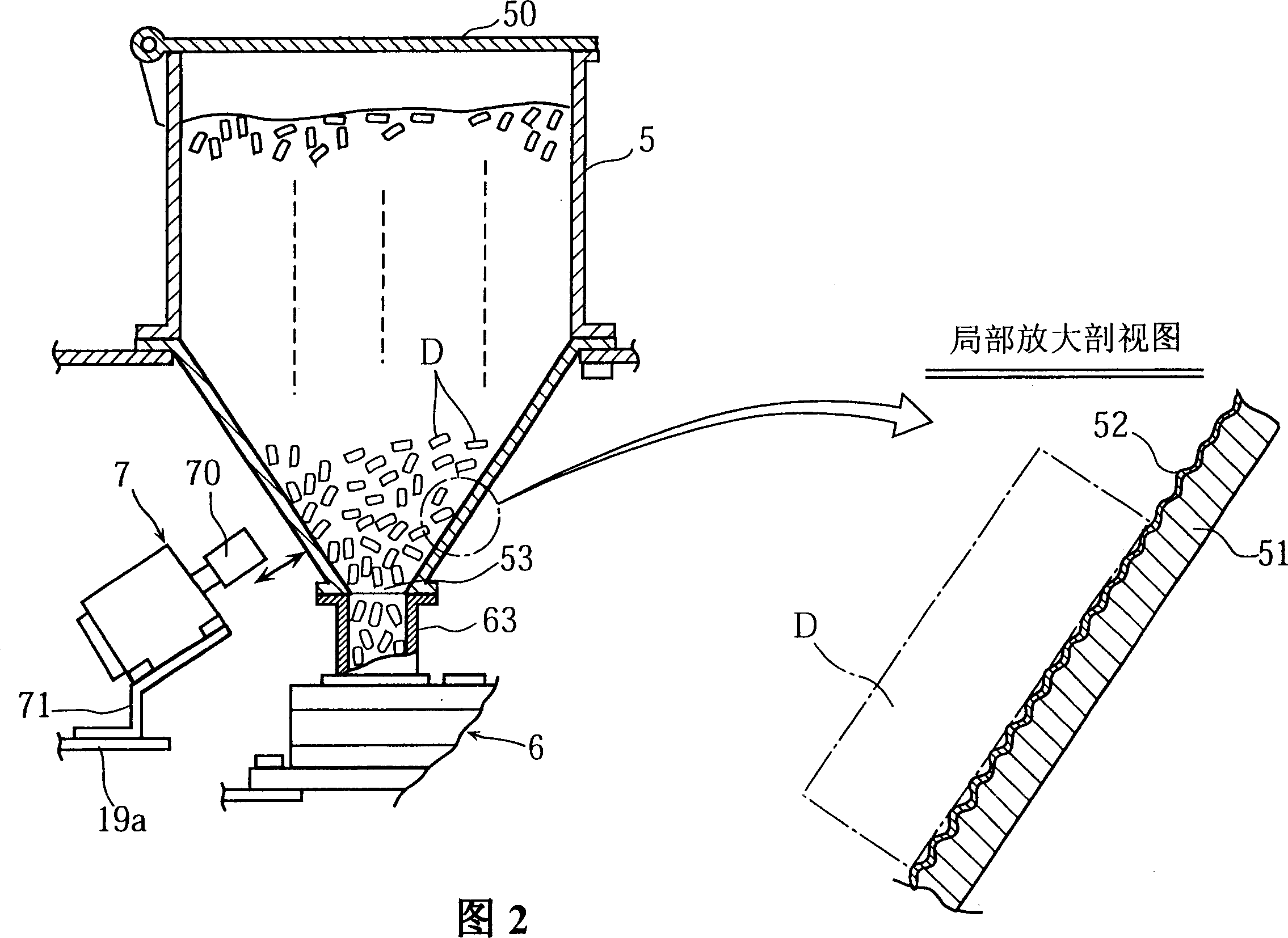

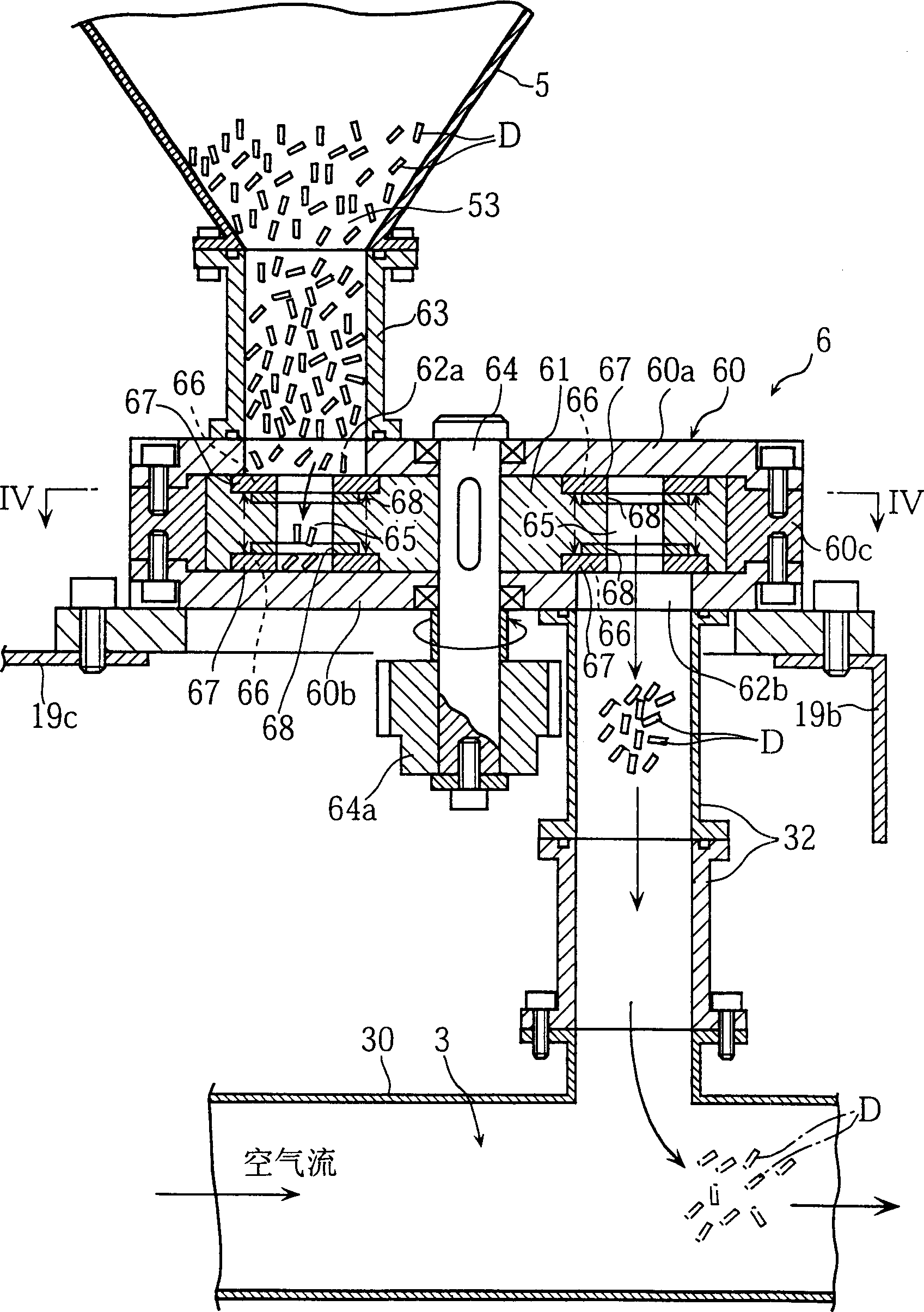

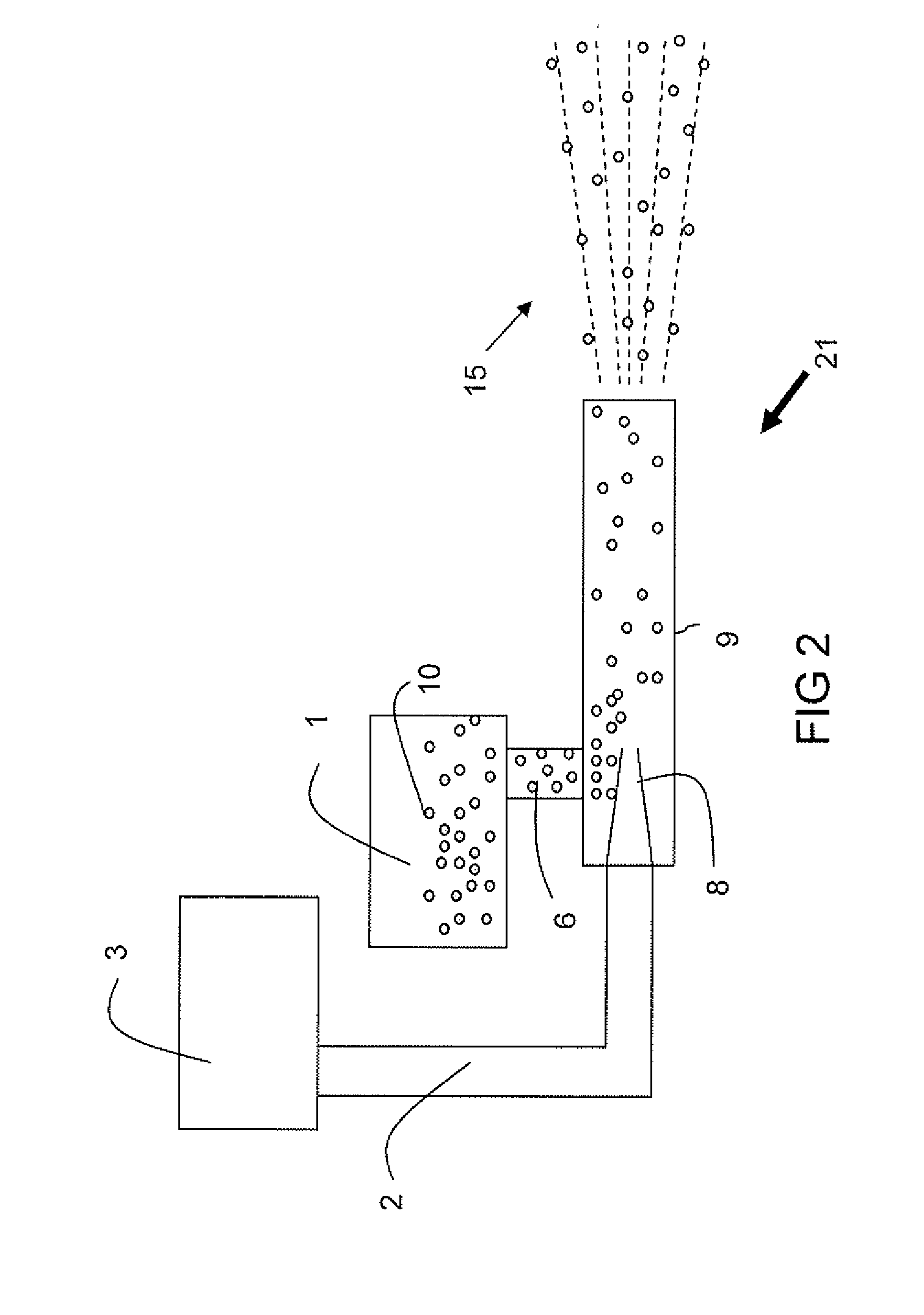

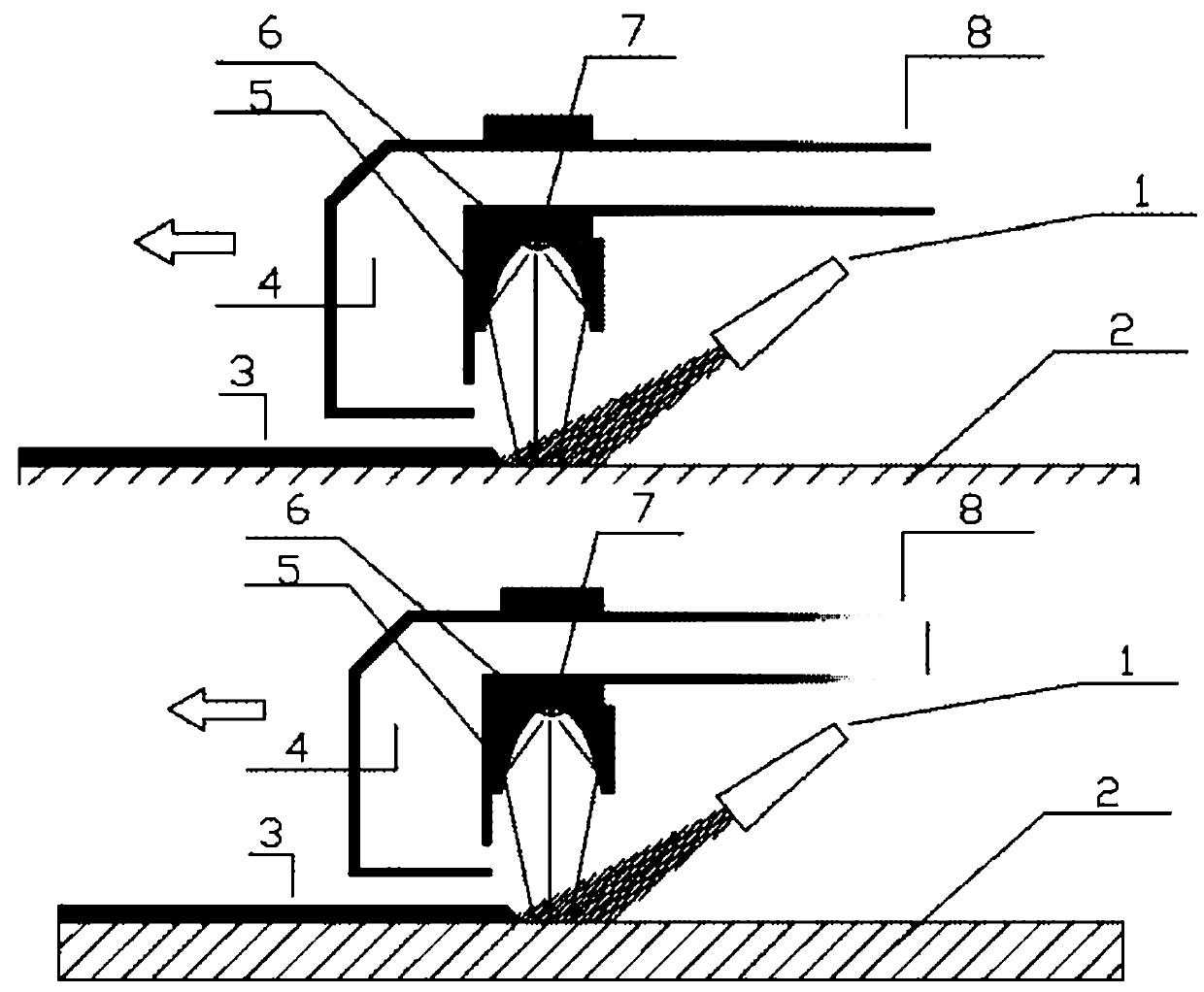

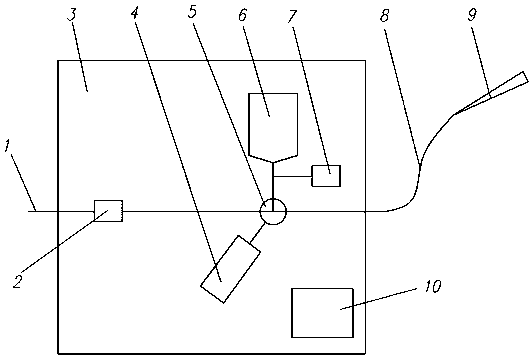

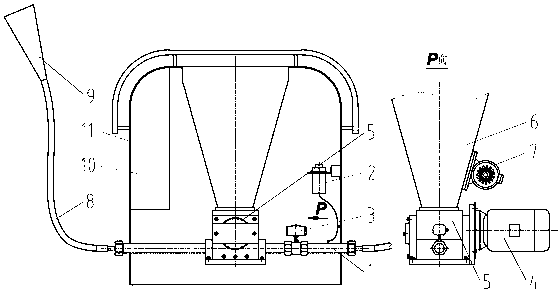

A dry-ice blast device (A) includes an air compressor (2) of a low pressure type as a source of the compressed air, the delivery pressure being 1.2-2.5 atm. Dry-ice particle feeder (5), (6) is provided for mixing dry-ice particles (D) into the air flow in the air flow path upstream from a nozzle (32). This enables low pressure blasting, which suppresses the abrasion of the dry-ice particles (D), decreases the noise, reduces the overall size and weight of the device and makes easy the handling of the device.

Owner:YAMAHARU EIKICHI

Dry-ice blast device

A dry-ice blast device (A) includes an air compressor ( 2 ) of a low pressure type as a source of the compressed air, the delivery pressure being 1.2-2.5 atm. Dry-ice particle feeder ( 5 ), ( 6 ) is provided for mixing dry-ice particles (D) into the air flow in the air flow path upstream from a nozzle ( 32 ). This enables low pressure blasting, which suppresses the abrasion of the dry-ice particles (D), decreases the noise, reduces the overall size and weight of the device and makes easy the handling of the device.

Owner:山春荣吉

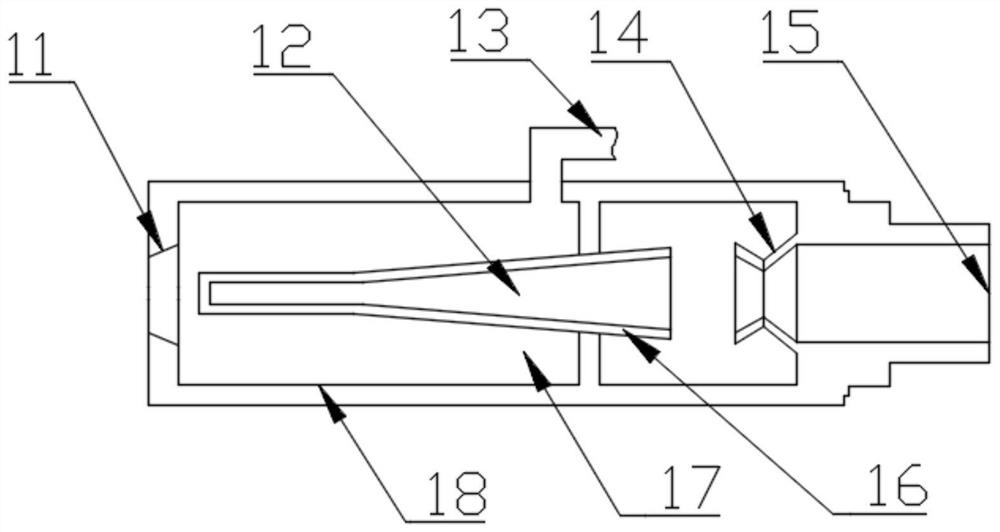

Dry ice blasting method and dry ice blasting device

InactiveCN104500068AOvercome potentially dangerous drawbacksWill not cause an explosionDisloding machinesUnderground miningToxic gasWater source

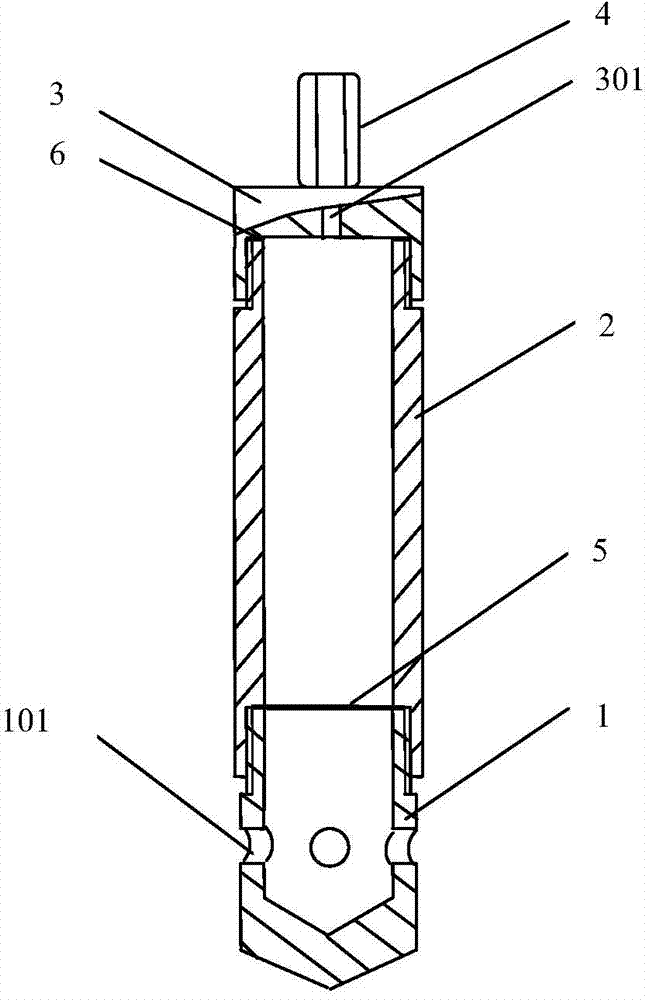

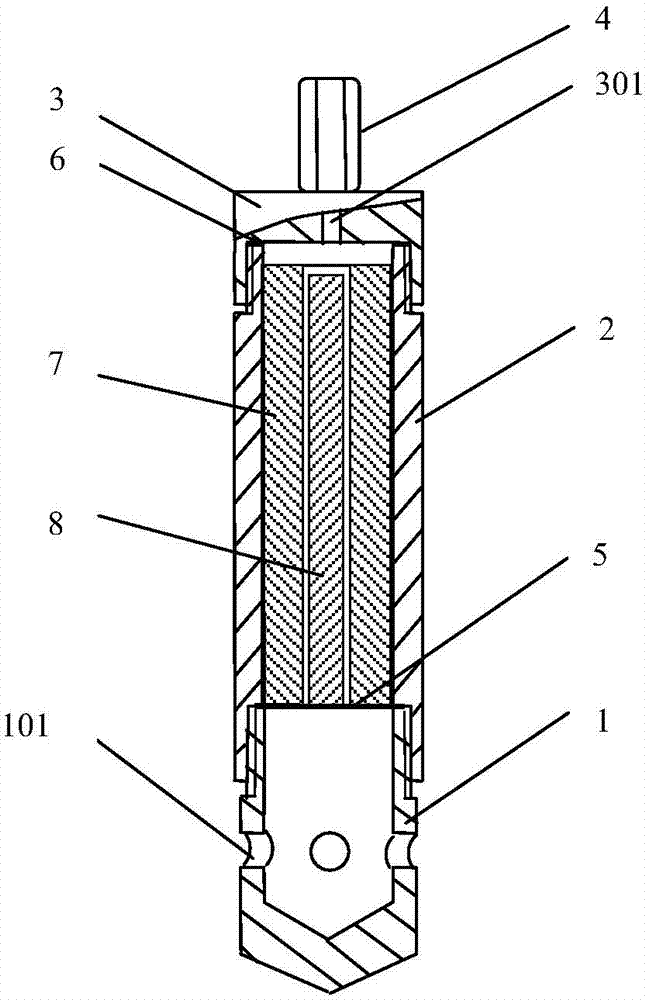

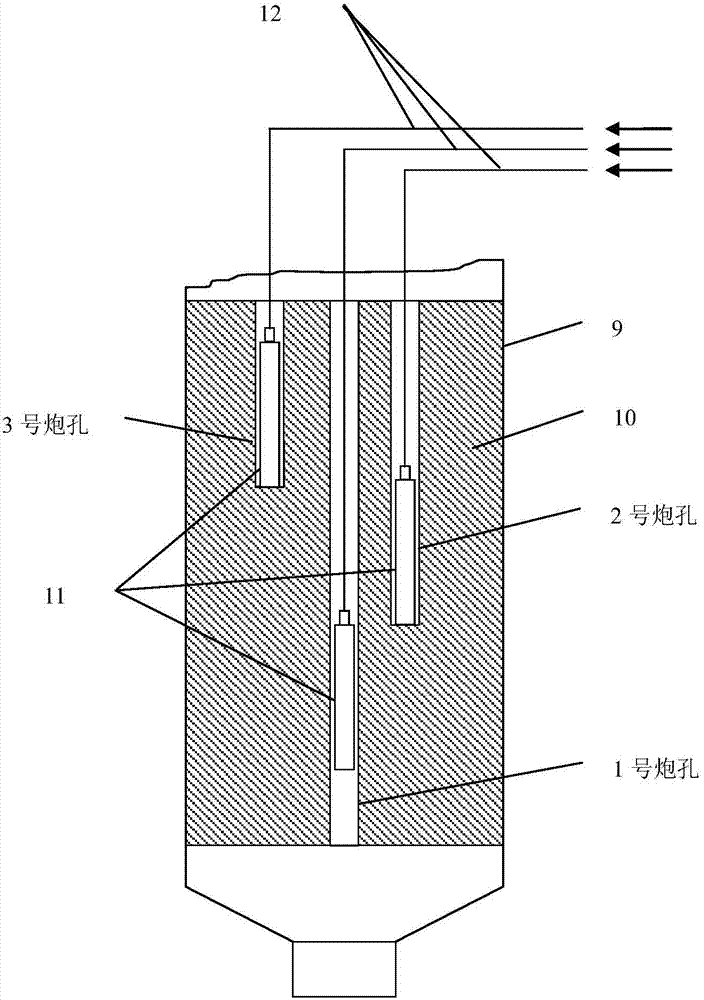

The invention relates to a dry ice blasting method and a dry ice blasting device, and belongs to the field of engineering blasting. The dry ice blasting device comprises a spray head, a cylinder body, a tail cover and a one-way valve, wherein the spray head is provided with an exhaust hole; the tail cover is provided with a water inlet hole; a sealing gasket is arranged between the cylinder body and the tail cover; a blasting sheet is arranged between the cylinder body and the spray head; and the tail cover is communicated with the one-way valve through the water inlet hole. The dry ice blasting method comprises the following steps: drilling in a coal bed; assembling the dry ice blasting device, and filling the dry ice blasting device with dry ice and a heating bag; connecting the dry ice blasting device with a water pipe, and placing into a blast hole; and communicating with a water source, and injecting water into the dry ice blasting device, wherein the heating bag inside the cylinder body fast releases heat when encountering water so as to urge the dry ice to be fast sublimated into carbon dioxide gas, when gas pressure exceeds the design pressure of the blasting sheet, the instant blasting of the blasting sheet is caused, and the carbon dioxide gas is fast discharged through the exhaust hole formed in the spray head to form impaction and expansion extrusion on the wall of the blast hole, so that the blasting is realized. The dry ice blasting method and the dry ice blasting device which are disclosed by the invention have the advantages of achieving the bursting at normal temperature, generating no flame or toxic gas and being suitable for a coal mine with gas and coal dust explosion risks.

Owner:CHINA UNIV OF MINING & TECH

Dry Ice Blasting With Ozone-Containing Carrier Gas

A surface of a target item is treated by directing a flow of solid carbon dioxide entrained in ozone towards it.

Owner:AIR LIQUIDE IND US LP

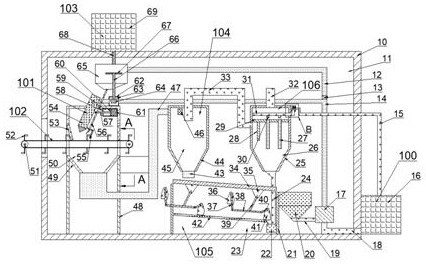

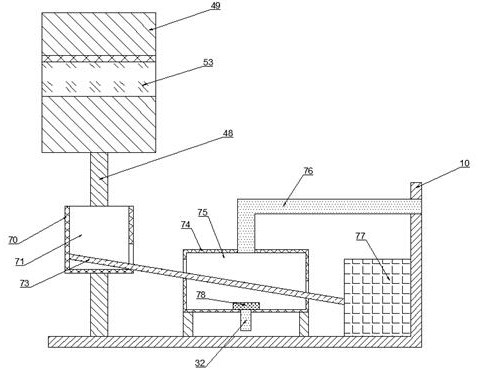

Heating dust suction and dry ice cleaning surface depainting treatment equipment and method

InactiveCN102380491AUnique thermodynamic propertiesAffect mechanical propertiesCleaning using gasesEpoxyAcrylic resin

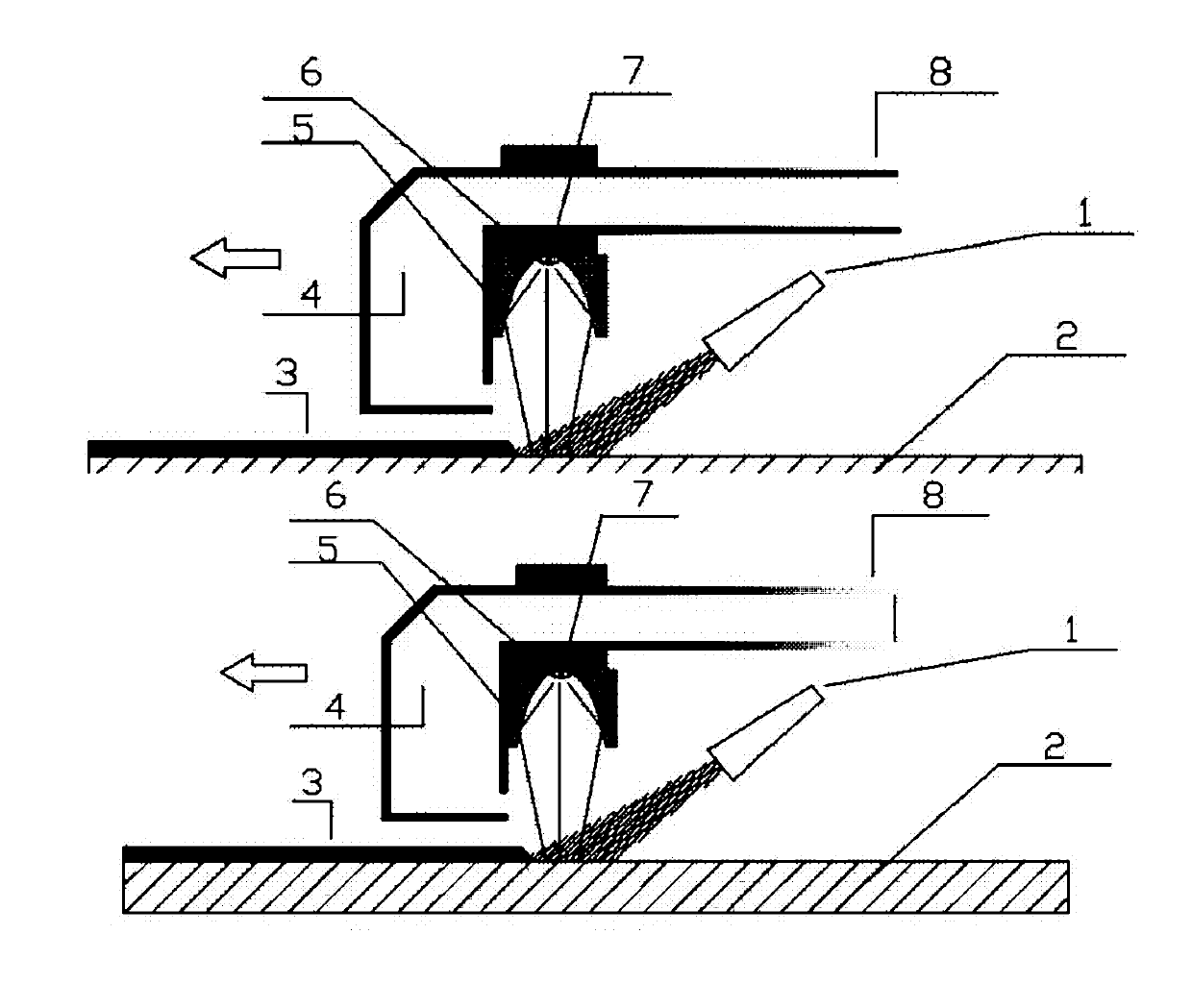

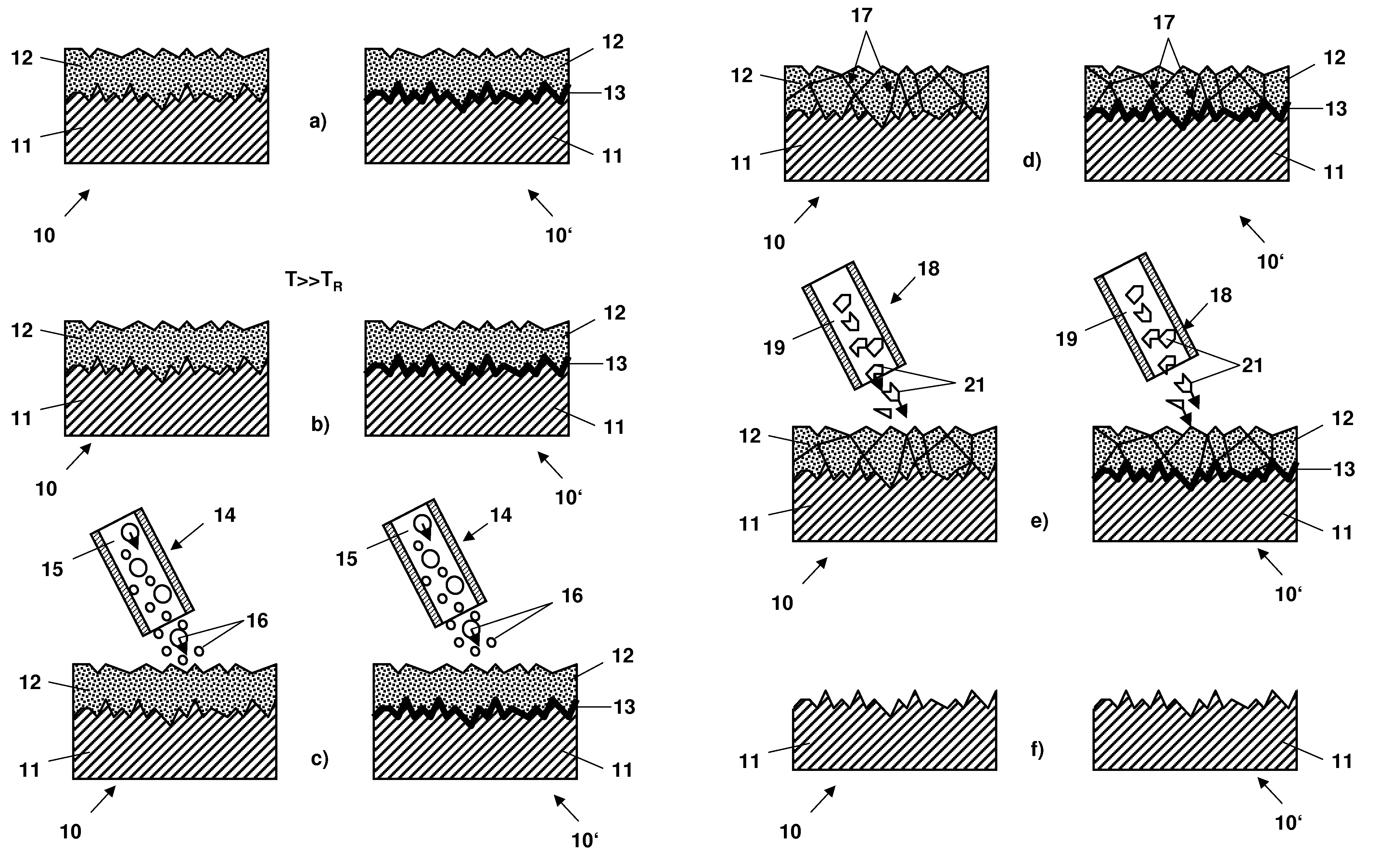

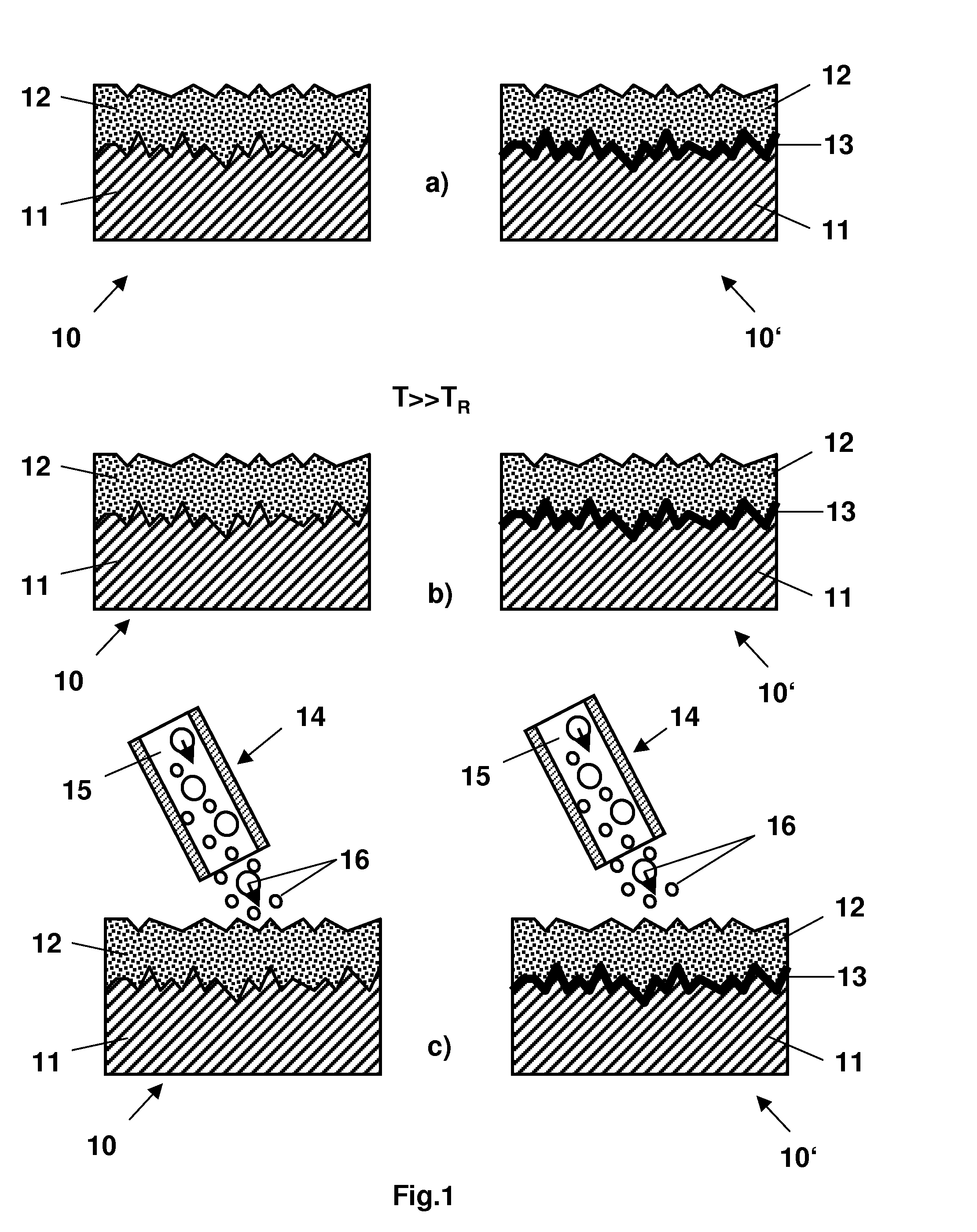

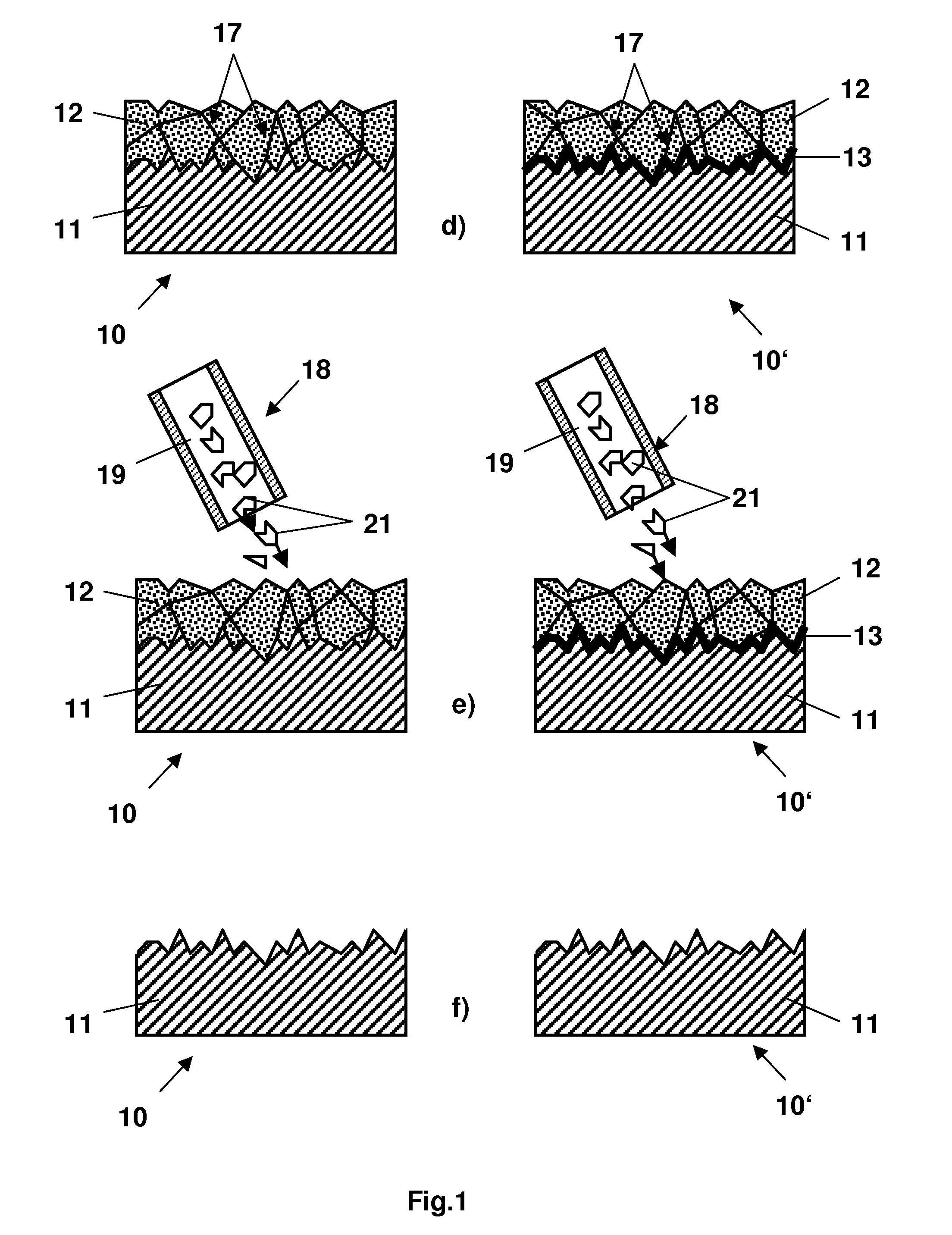

The invention relates to heating dust suction and dry ice cleaning surface depainting treatment equipment and a method, which belong to the technical field of surface treatment and are suitable for being used for removing paint films prepared from epoxy resin, polyurethane and acrylic resin materials, in particular to the depainting of metal paint films and composite materials on the surfaces of aircrafts, ships and armored vehicles. The equipment comprises a pulse dot light source heating device, a dry ice spraying device and a dust suction device, and when the equipment is used, a pulse dot light source carries out regional irradiation on the surface of an object to be depainted. Simultaneously, the irradiation region is depainted and cooled through low-temperature dry ice in high-speed air flows by the dry ice spraying device, and peeled paint fragments are directly recovered by the dust suction device without leaving residues in sites. The pulse dot light source heating device, the dry ice spraying device and the dust suction device are combined for depainting. Compared with the traditional physical depainting method, the method has the advantages that the cost is reduced, simultaneously, the efficiency is higher, in addition, no damage is caused on substrates, the environment is not polluted, and secondary contaminants are not generated.

Owner:迪普干冰制造(大连)有限公司

Method for treating a thermally loaded component

InactiveUS20080178907A1Improve efficiencyGood influenceBlade accessoriesElectrostatic cleaningMetallic substrateDry-ice blasting

A method for treating a thermally loaded component having a metallic substrate and at least partially coated on an outer side with a protective coating, is provided. The method includes the step of predamaging the protective coating before removing the protective coating from the substrate using dry ice blasting. The predamaging is performed so as to lead to an increase of efficiency of the removal process.

Owner:ALSTOM TECH LTD

Mold and microbial remediation using dry ice blasting

A method for cleaning noxious colonies of mold and other microbes out of buildings is disclosed, using “dry ice blasting”. This method involves pumping a gas stream containing small particles of dry ice (solidified carbon dioxide, or CO2) through a high-speed nozzle that can be directed at any surface that needs to be cleaned. This type of equipment previously has been used for cleaning charred surfaces and coating layers of soot and smoke off of wooden and other surfaces, in a building that has suffered a fire, but it has not previusly been used for mold remediation. It is highly effective for cleaning uneven surfaces, such as the surfaces of unfinished lumber, using a controllable a combination of pressure, velocity, and flow rates that can effectively soften, abrade, and blow away any surface layers that do not have the hardness of normal wood.

Owner:ARMSTRONG JAY T

Dry ice cleaning method for apparatus of coating by vaporization

InactiveCN1970176AReduce cleaning costsPromote environmental protectionVacuum evaporation coatingSputtering coatingVaporizationContamination

The cleaning with solid carbon dioxide for deposition equipment utilizes the temperature tolerance dramatic change of two materials resulted from the residue heat and solid carbon dioxide after heating the deposition under 100-200DEG C temperature, spraying solid carbon dioxide on the equipment surface, crushing the magnesia film left with solid carbon dioxide staying in the gaps between films left, condensing the contamination, and peeling off the residue film from the equipment with extreme inflation of the solid carbon dioxide. It features in the high voltage withstanding ability of 30,000-40,000 watts, without conductivity, with reduced washing cost of 3-5 times.

Owner:上海松下等离子显示器有限公司

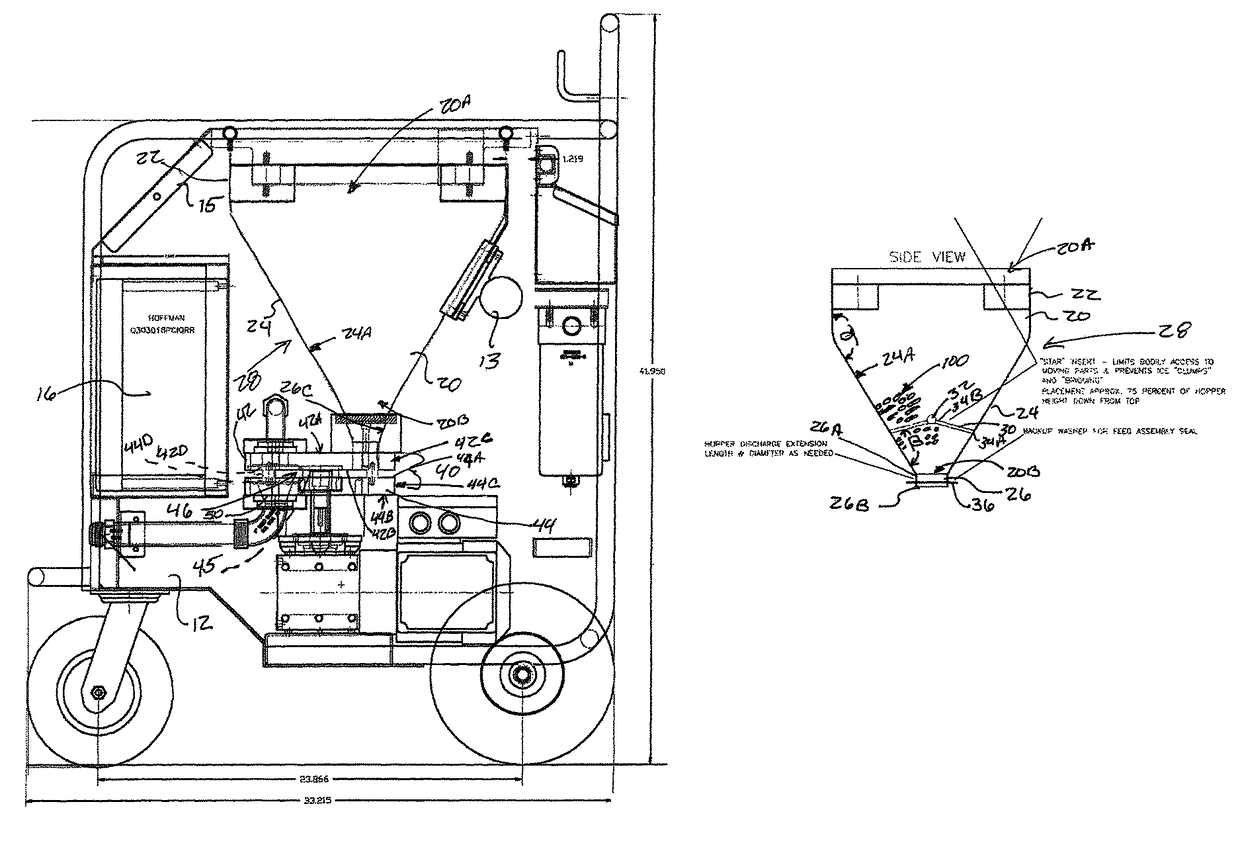

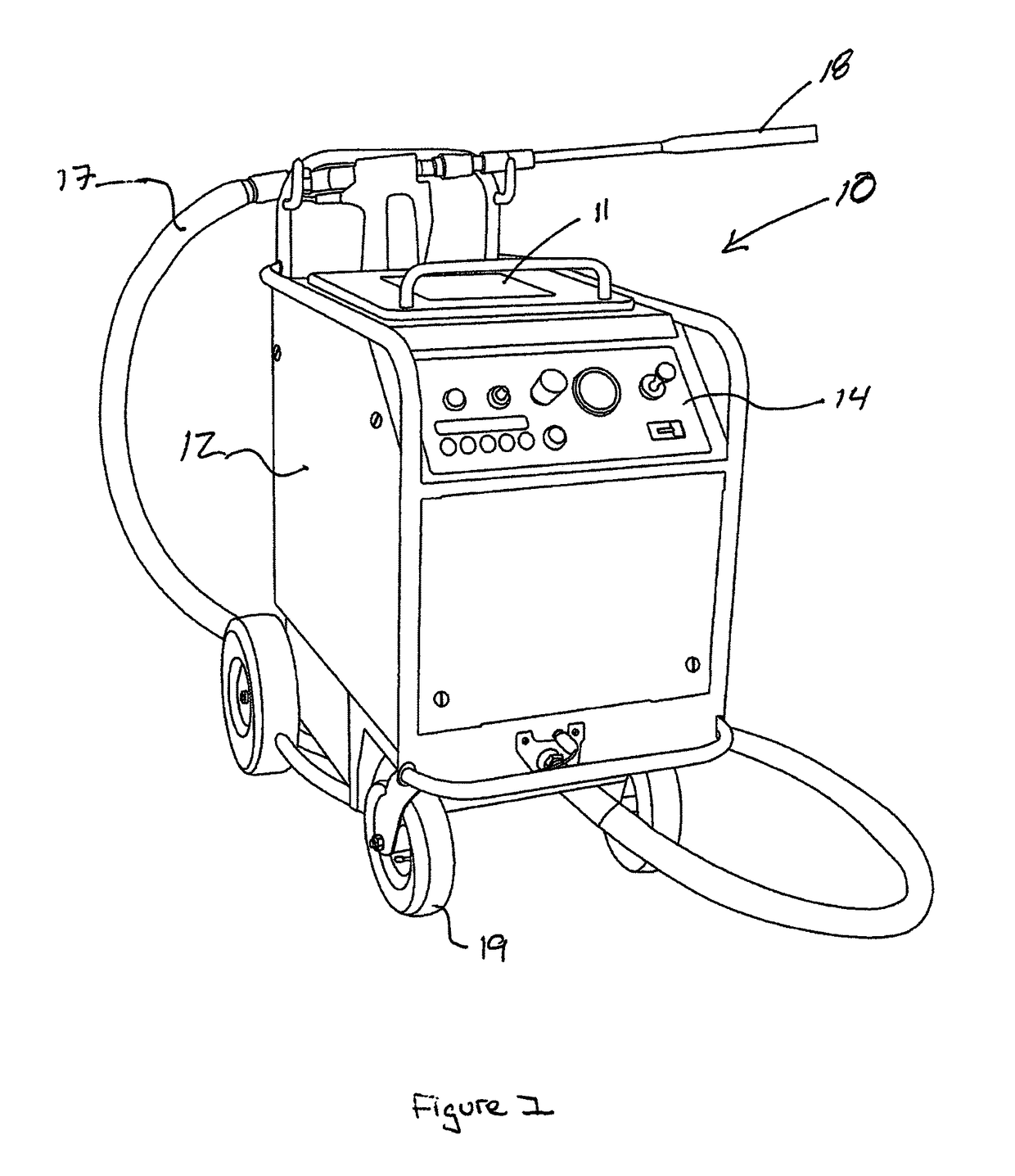

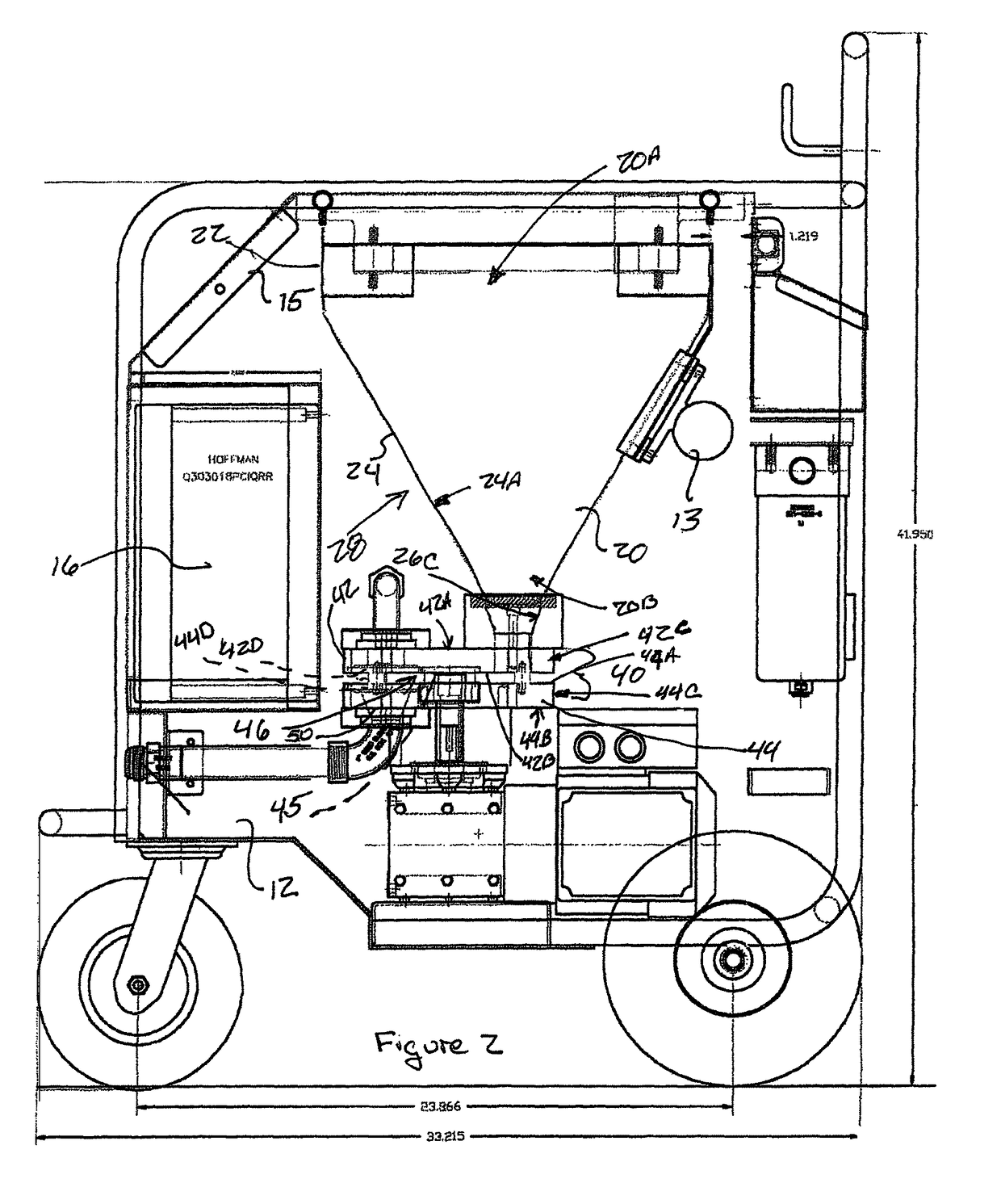

Dry ice blast cleaning system and method for operating the same

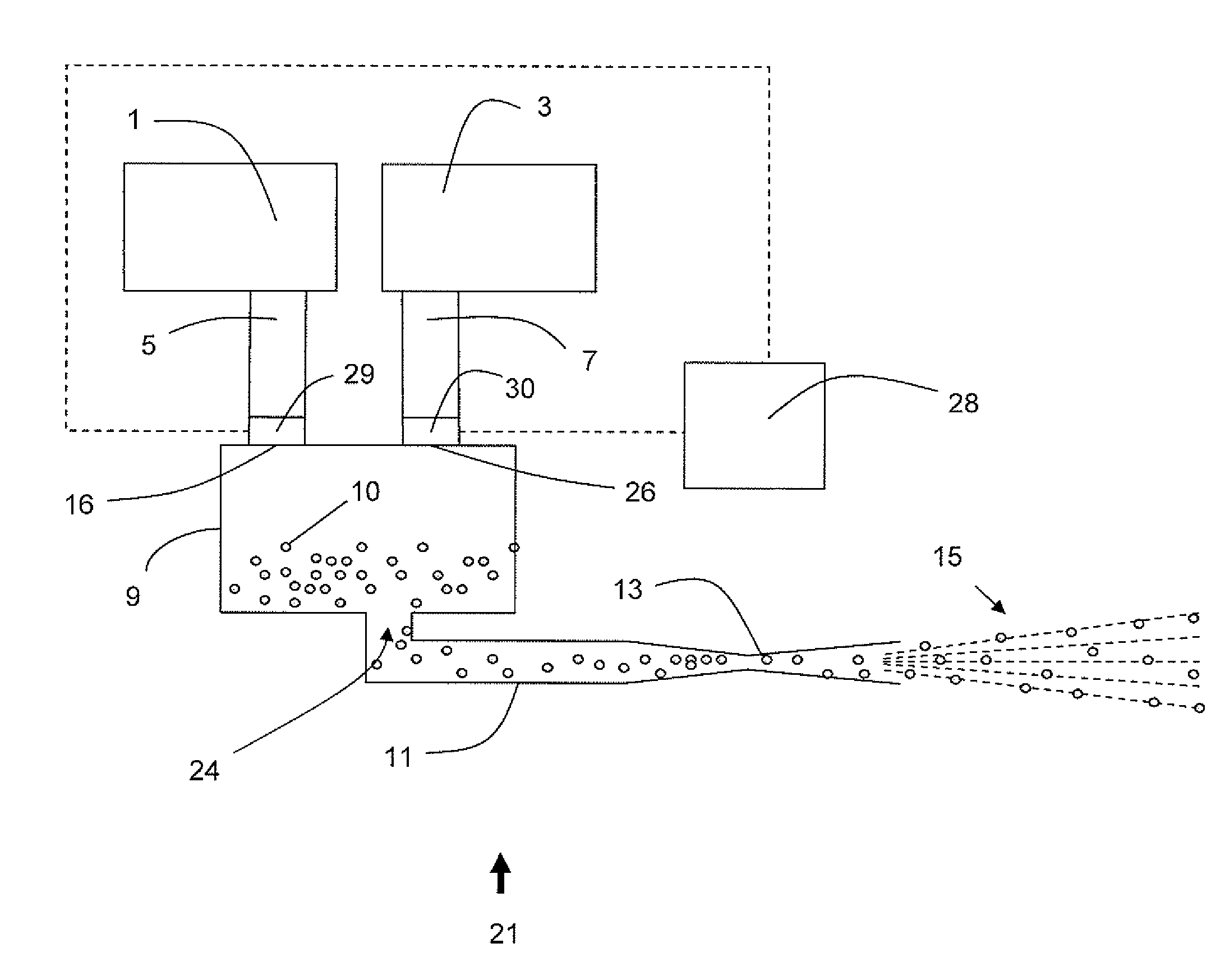

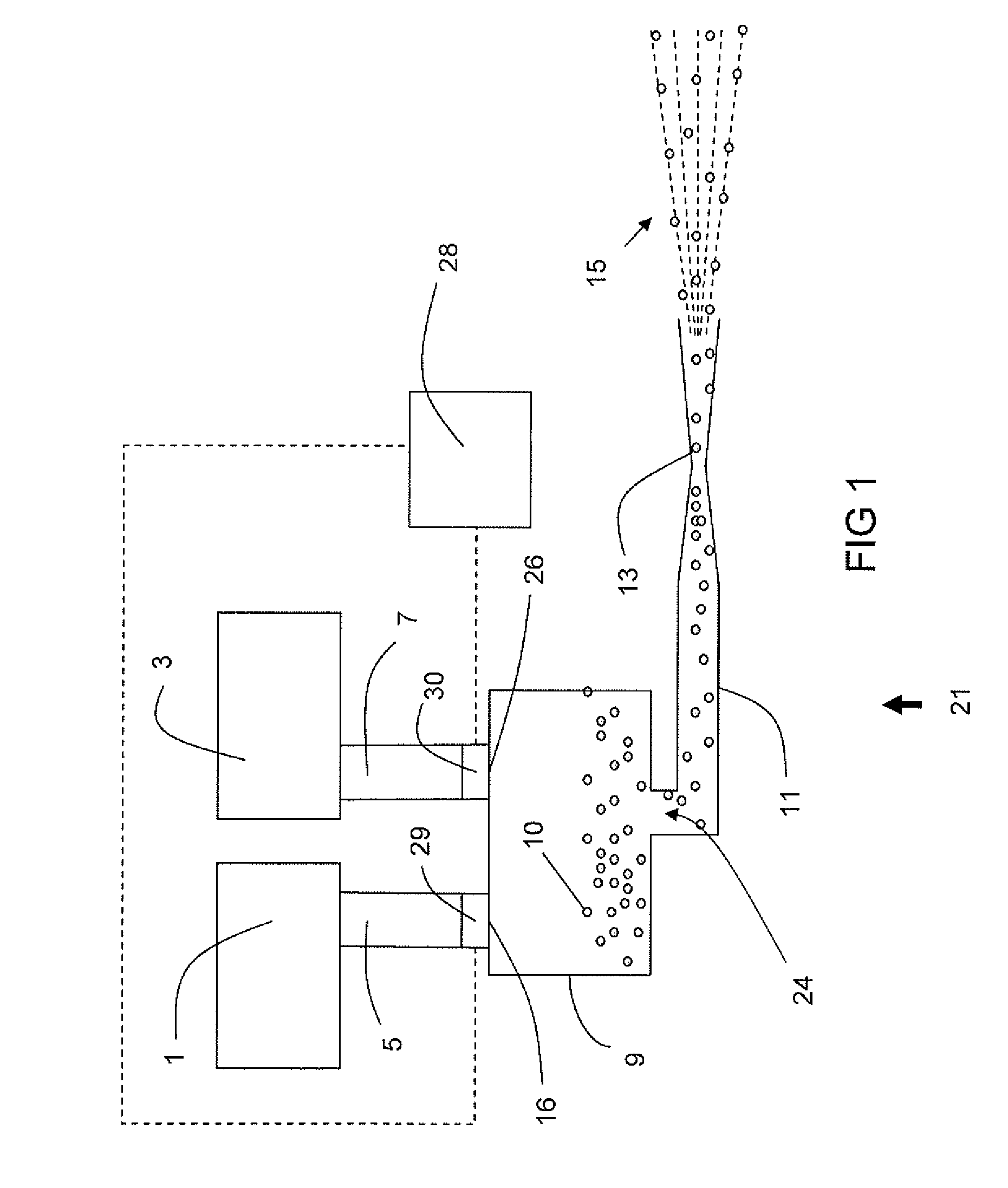

ActiveUS9700989B1Smooth inner surfaceBlast gunsAbrasive feedersProcess engineeringSupply and distribution

A dry ice blast cleaning system is disclosed. The system includes a dry ice feed apparatus, a mixing head, a supply of pressurized gas and a dispensing device. The apparatus has a hopper configured to store a supply of dry ice pieces with an anti-bridging device. A heat by-pass system is provided to heat the mixing head to prevent icing in the mixing head.

Owner:NU ICE AGE INC

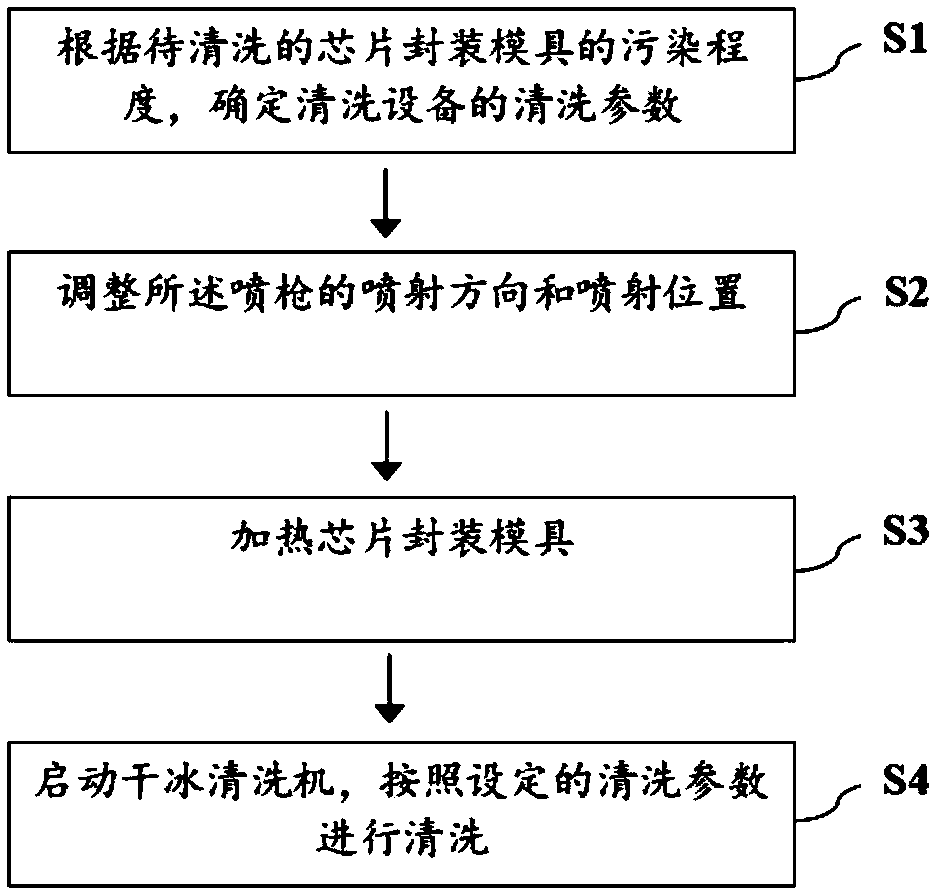

Control method for dry ice cleaning of chip packaging mold

InactiveCN109433741ACleaning parameter adjustmentEasy to cleanCleaning processes and apparatusEngineeringAir compressor

The invention provides a control method for dry ice cleaning of a chip packaging mold. The control method comprises the following steps that S1, according to the pollution degree of the chip packagingmold to be cleaned, cleaning parameters of cleaning equipment are determined, wherein the cleaning equipment comprises a dry ice cleaning machine, a spray gun used for jetting dry ice, and an air compressor used for providing compressed air for the dry ice cleaning machine, the air compressor is connected to an air inlet pipe of the dry ice cleaning machine, the spray gun is connected to an air outlet pipe of the dry ice cleaning machine, and the dry ice cleaning machine provides solid dry ice particles for the spray gun; S2, the spraying direction and the spraying position of the spray gun are adjusted; S3, the chip packaging mold is heated; and S4, the dry ice cleaning machine is started, and cleaning is carried out according to the set cleaning parameters. According to the control method, the cleaning efficiency of the chip packaging mold is improved, and the relatively high economic efficiency and market value are achieved.

Owner:XIAMEN UNIV OF TECH

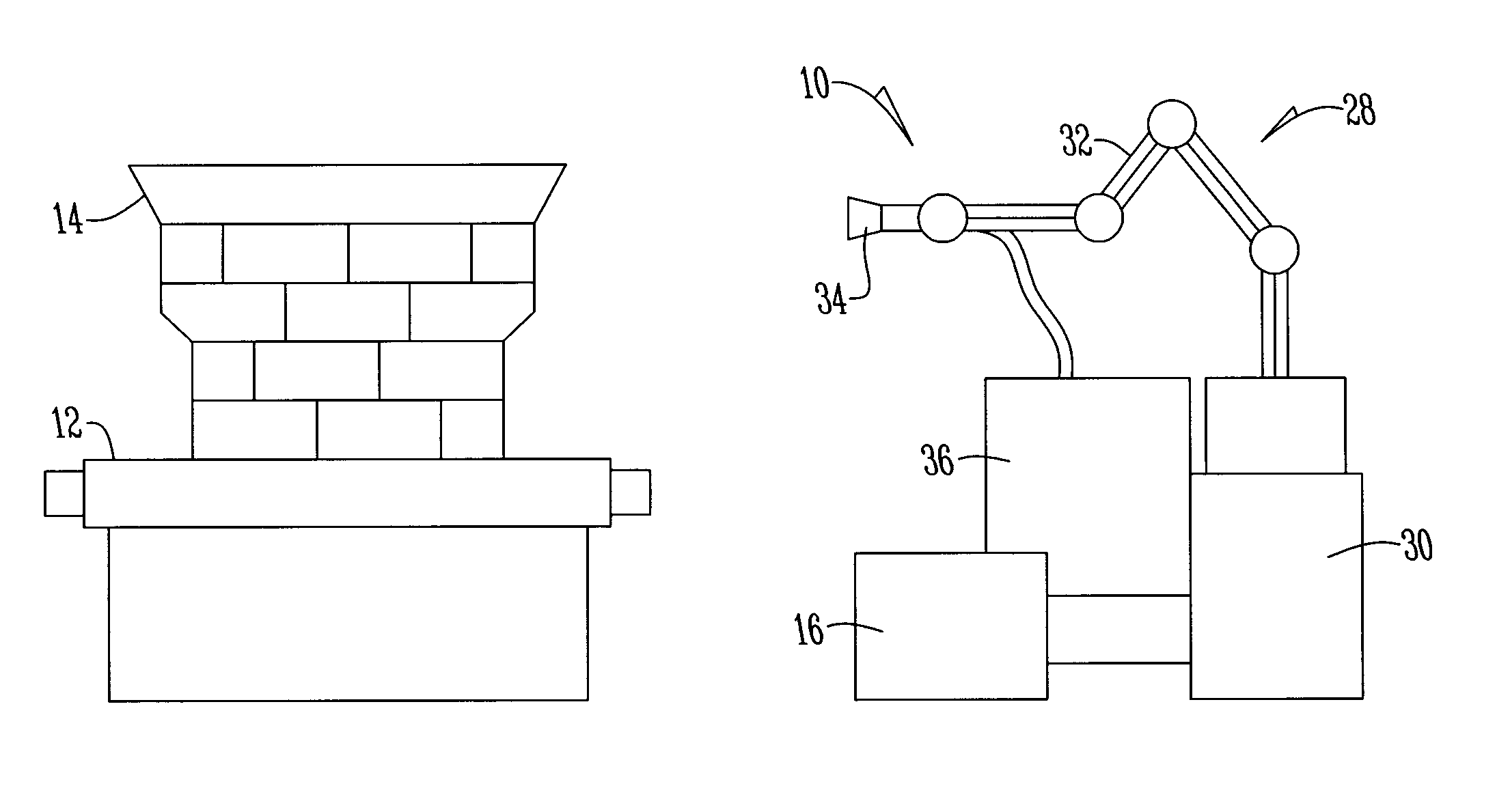

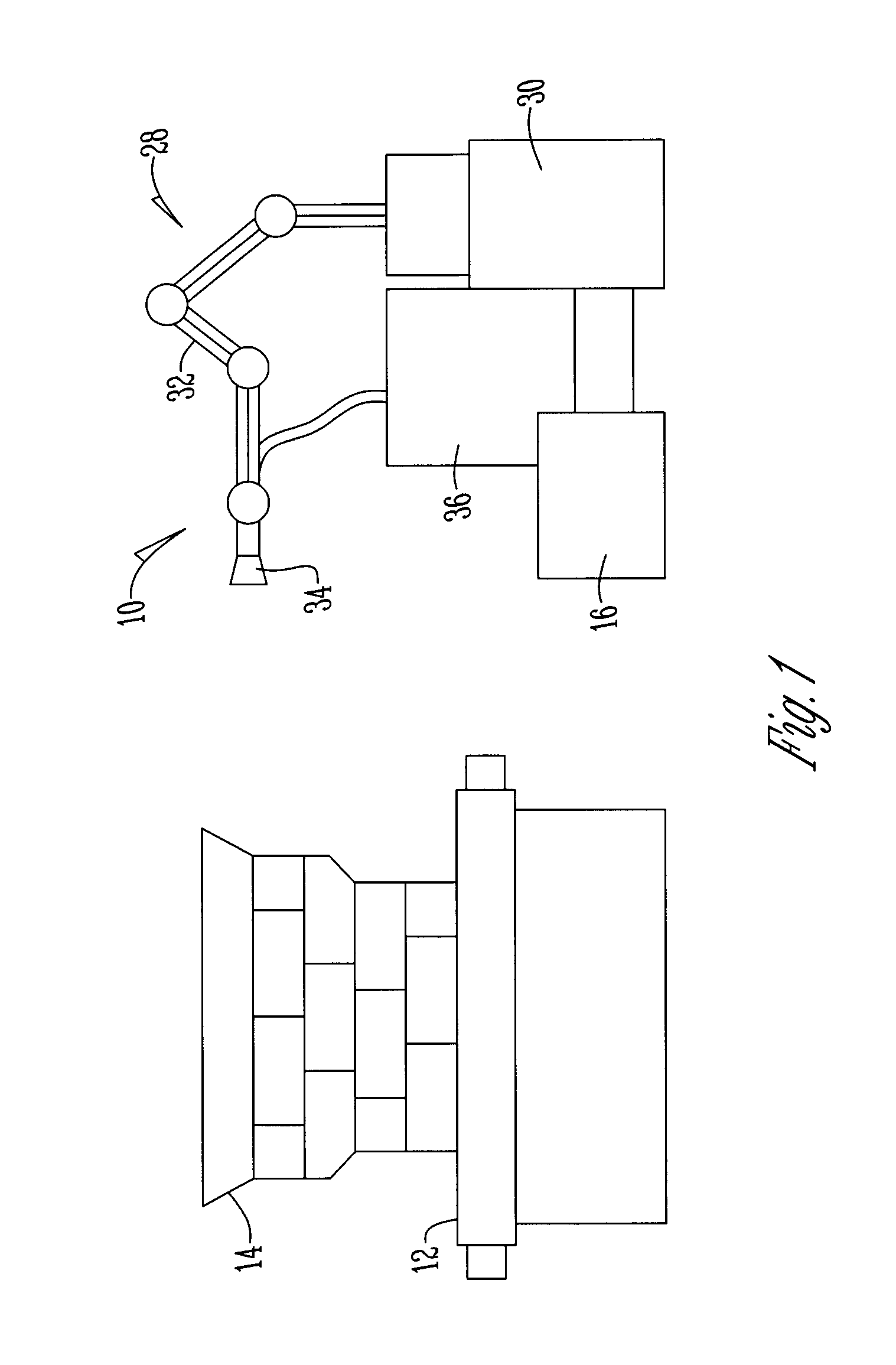

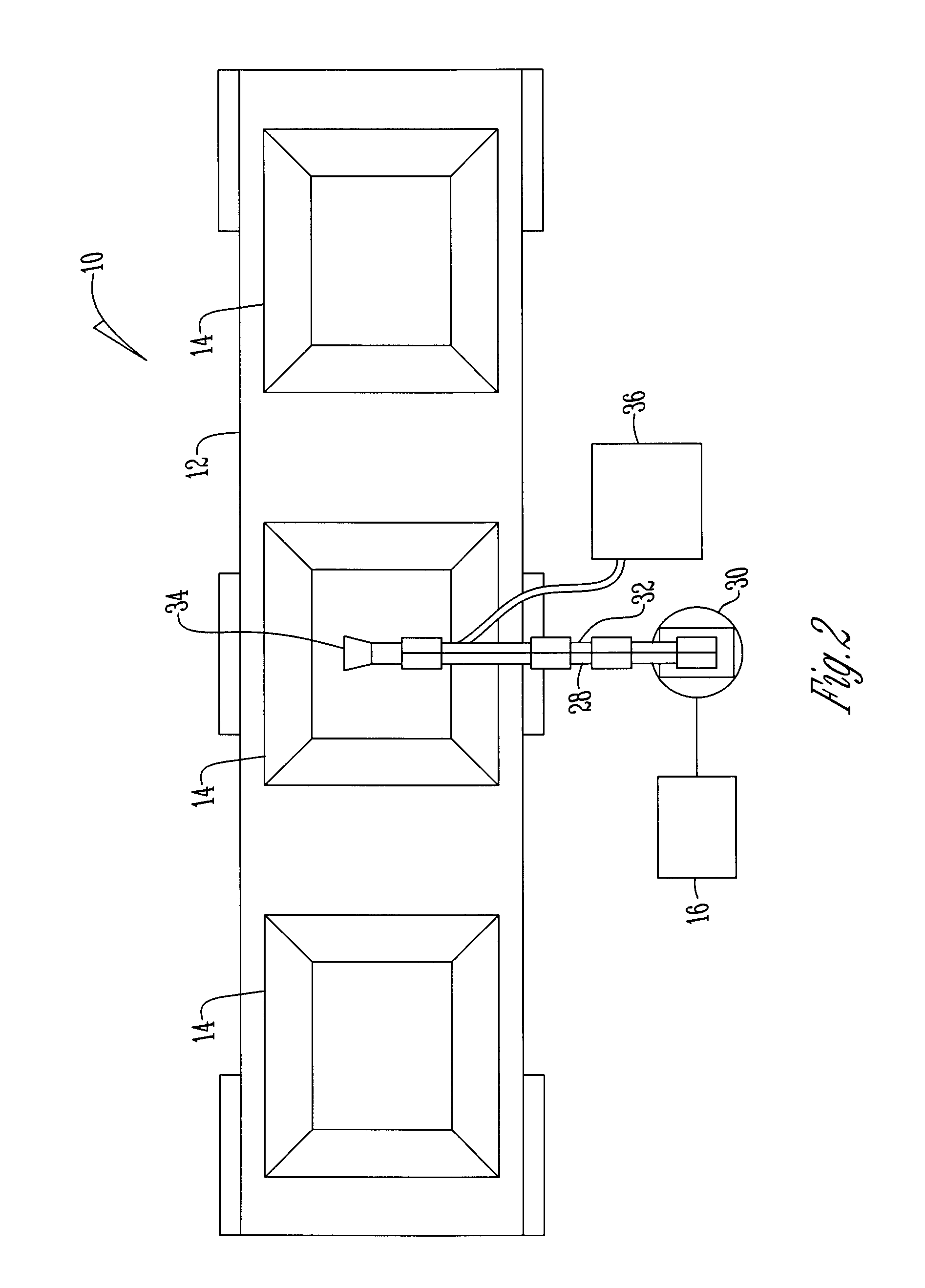

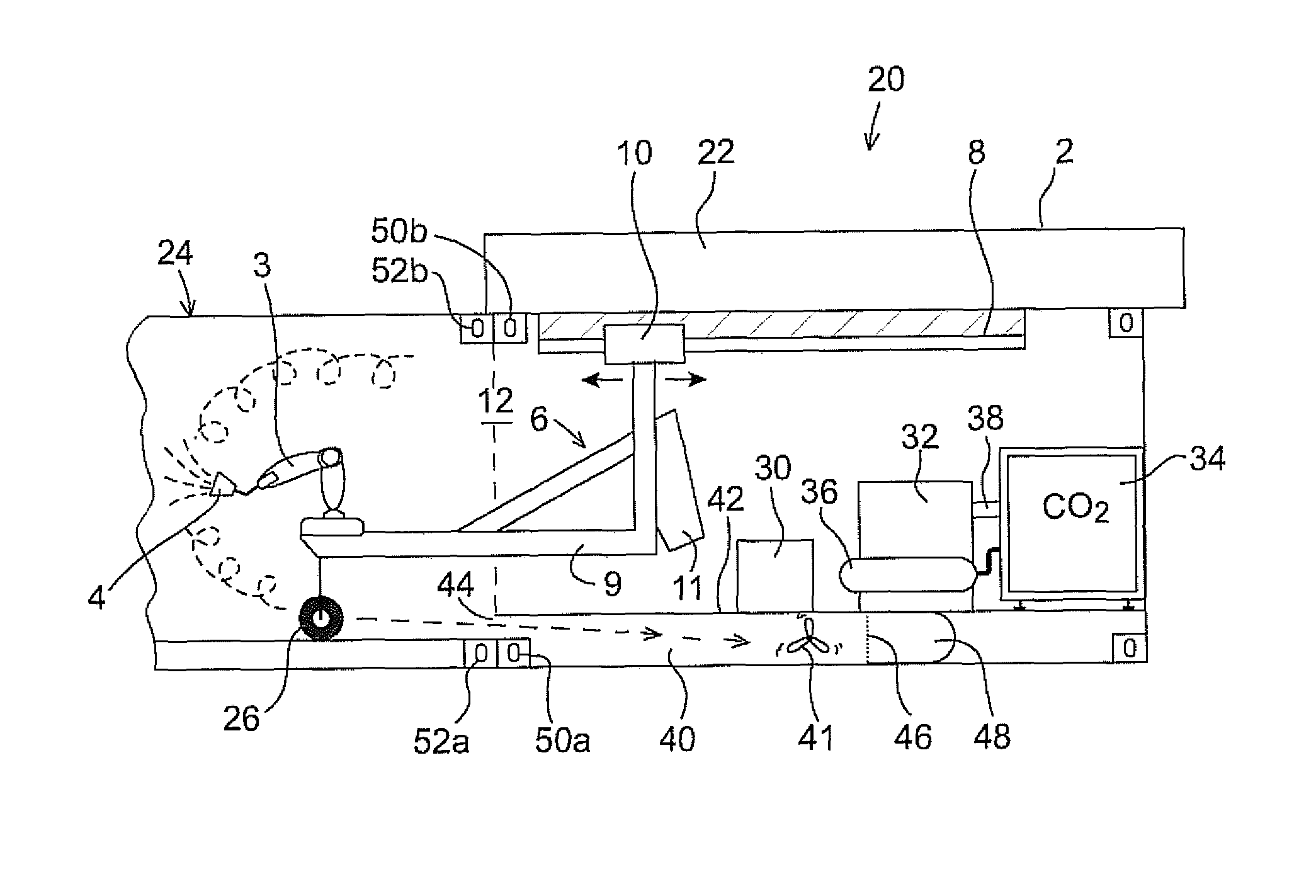

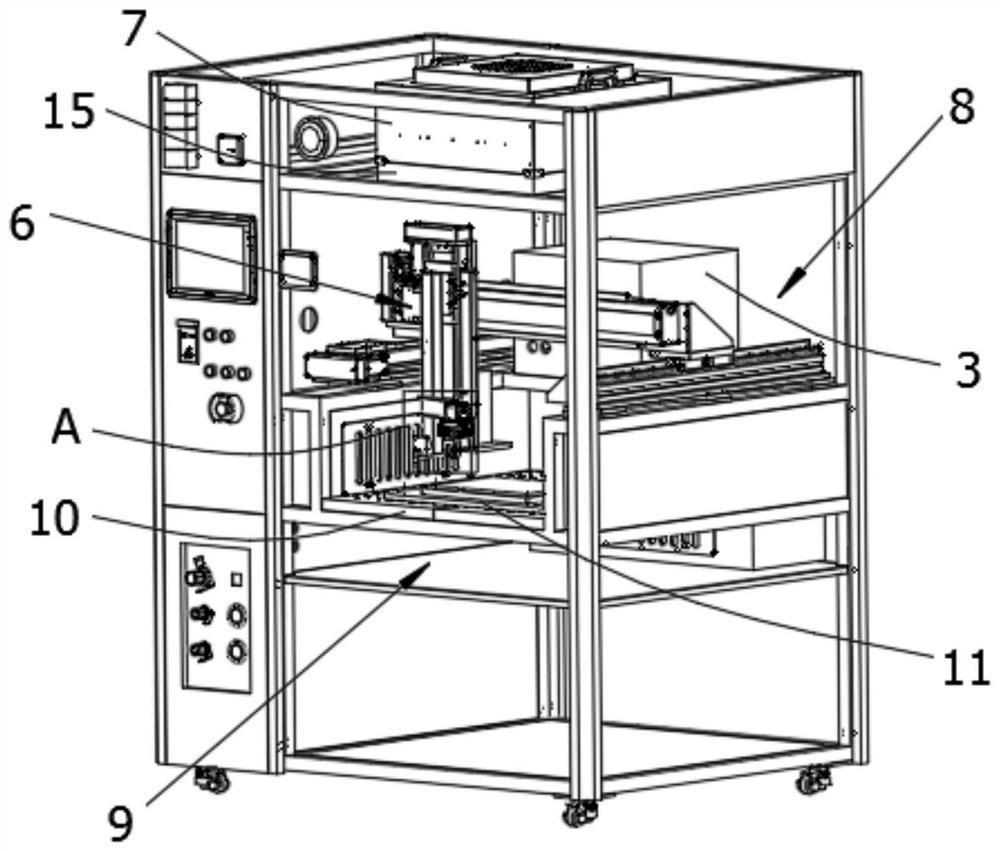

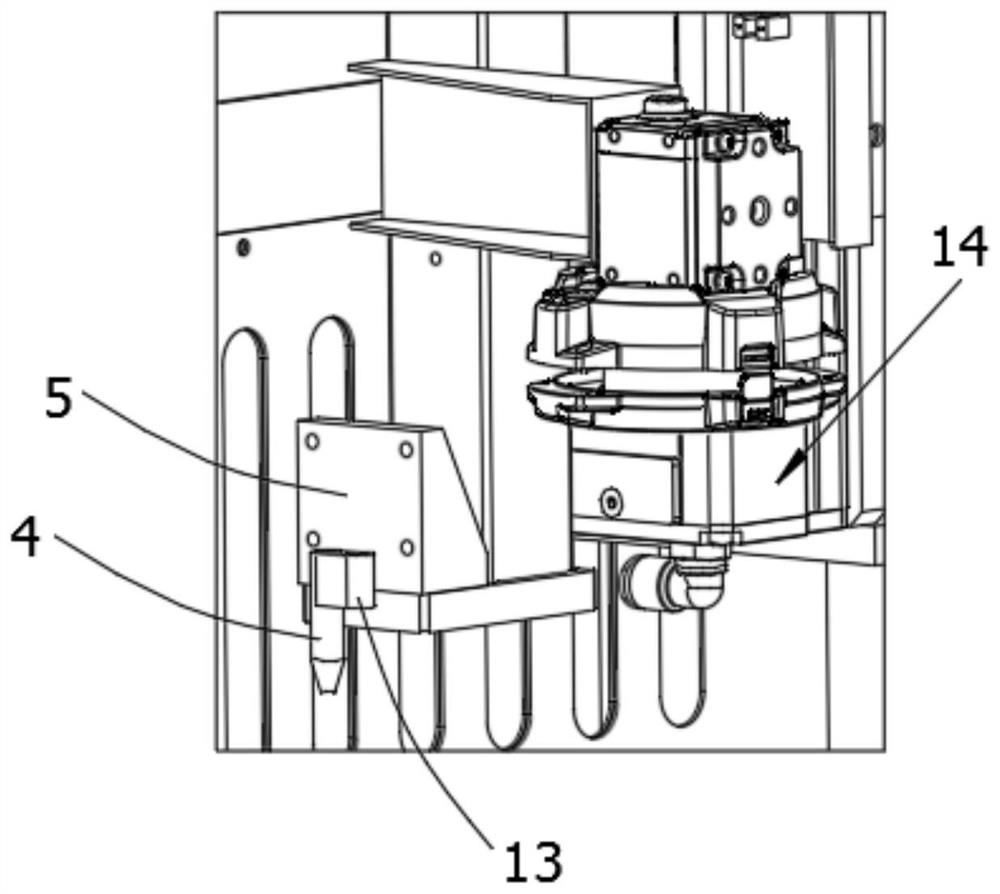

Dry ice blasting cleaning system and method of using the same

A cleaning system having at least one C02 blasting nozzle connected to a robotic arm to automatically and selectively clean an object transported on an assembly line.

Owner:K B C GRP INC

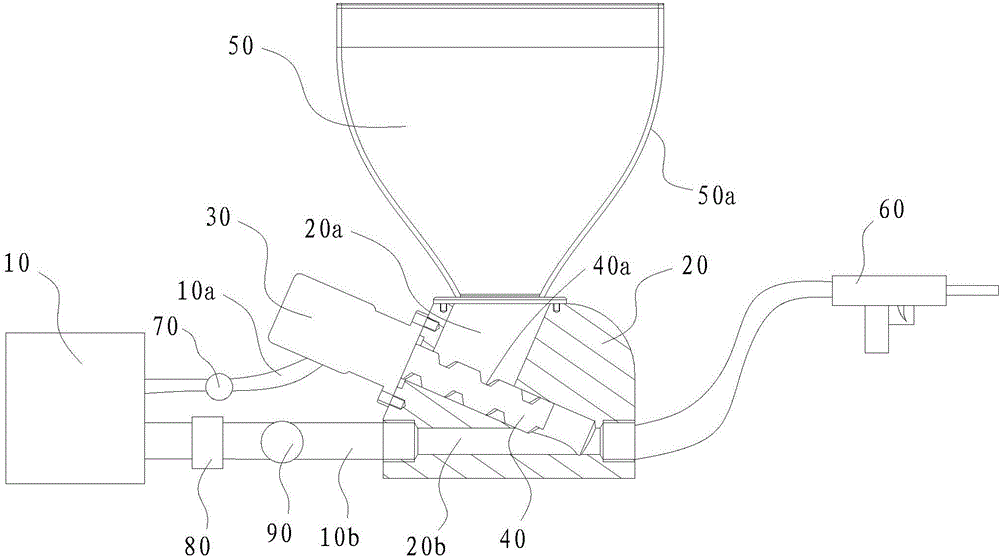

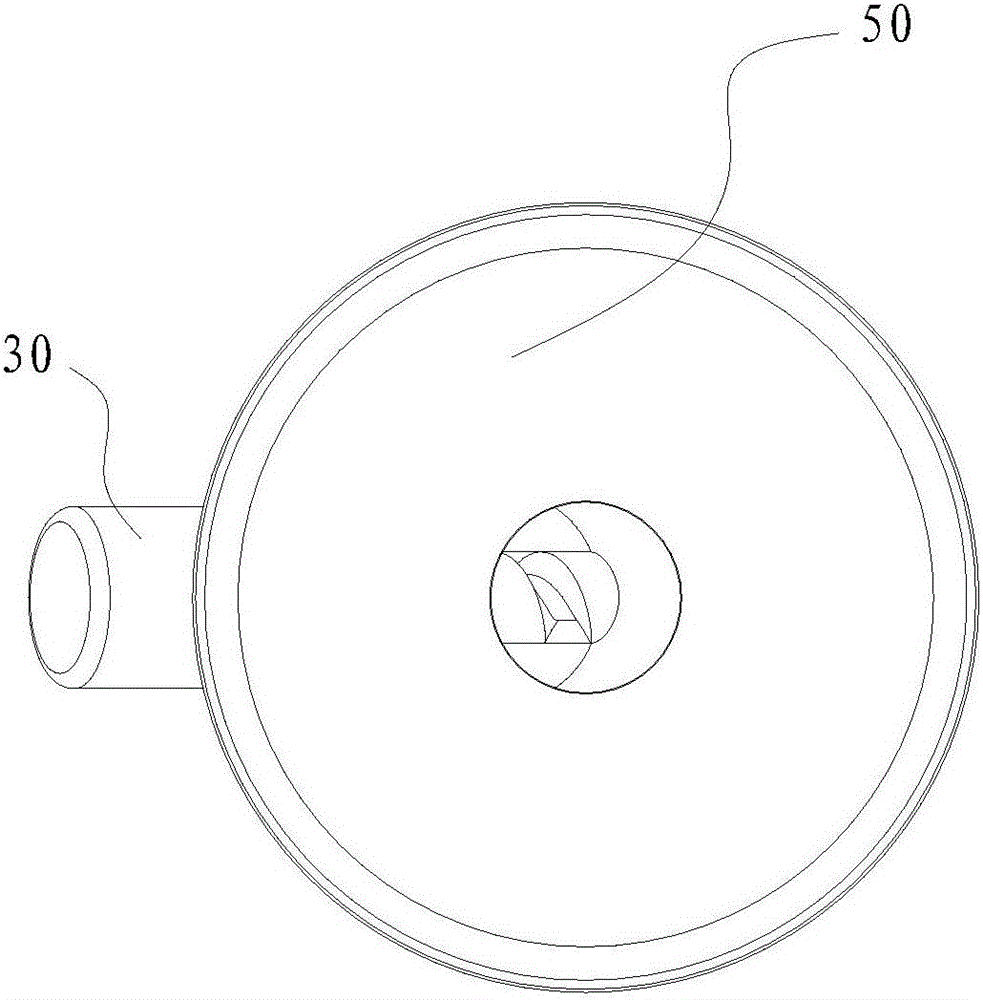

Efficient dry ice spray gun

InactiveCN106493013ASafe entryMeet cleaning tasksLiquid spraying apparatusCleaning processes and apparatusInlet channelGas compressor

The invention discloses an efficient dry ice spray gun. The efficient dry ice spray gun comprises an air compressor, an insulating box body, an insulating pneumatic motor, an insulating screw and an insulating hopper, wherein the air compressor supplies air to the insulating pneumatic motor, the insulating screw is driven by the insulating pneumatic motor to rotate, and the insulating hopper is arranged on the top of the insulating box body. A dry ice inlet channel corresponding to the bottom of the insulating hopper is arranged on the top of the insulating box body. A compressed air channel is arranged in the insulating box body. One end of the compressed air channel is connected with the air compressor, and the other end of the compressed air channel is connected with a spray gun body. The insulating screw is obliquely arranged in the insulating box body, the lower end of the insulating screw is located in the compressed air channel, the upper end of the insulating screw is located at the bottom of the dry ice inlet channel, and a spiral conveying groove penetrating the dry ice inlet channel and the compressed air channel is arranged on the insulating screw. According to the efficient dry ice spray gun, power drive is replaced with pneumatic drive, and the dry ice spray device is made of an insulating composite, so that the dry ice spray device is capable of safely entering the strong electromagnetic environment, and the cleaning requirement of specific occasions is met.

Owner:魏华益

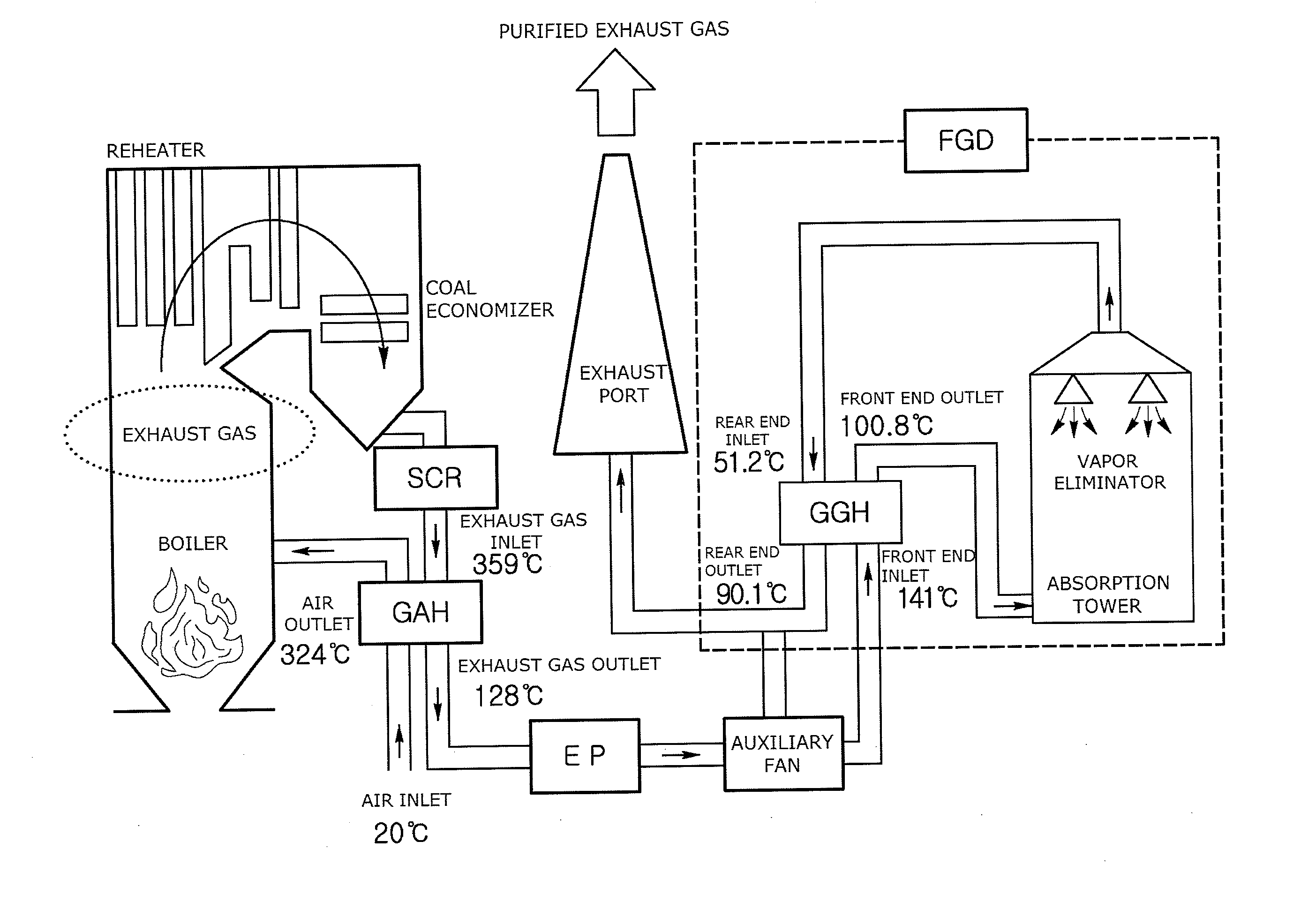

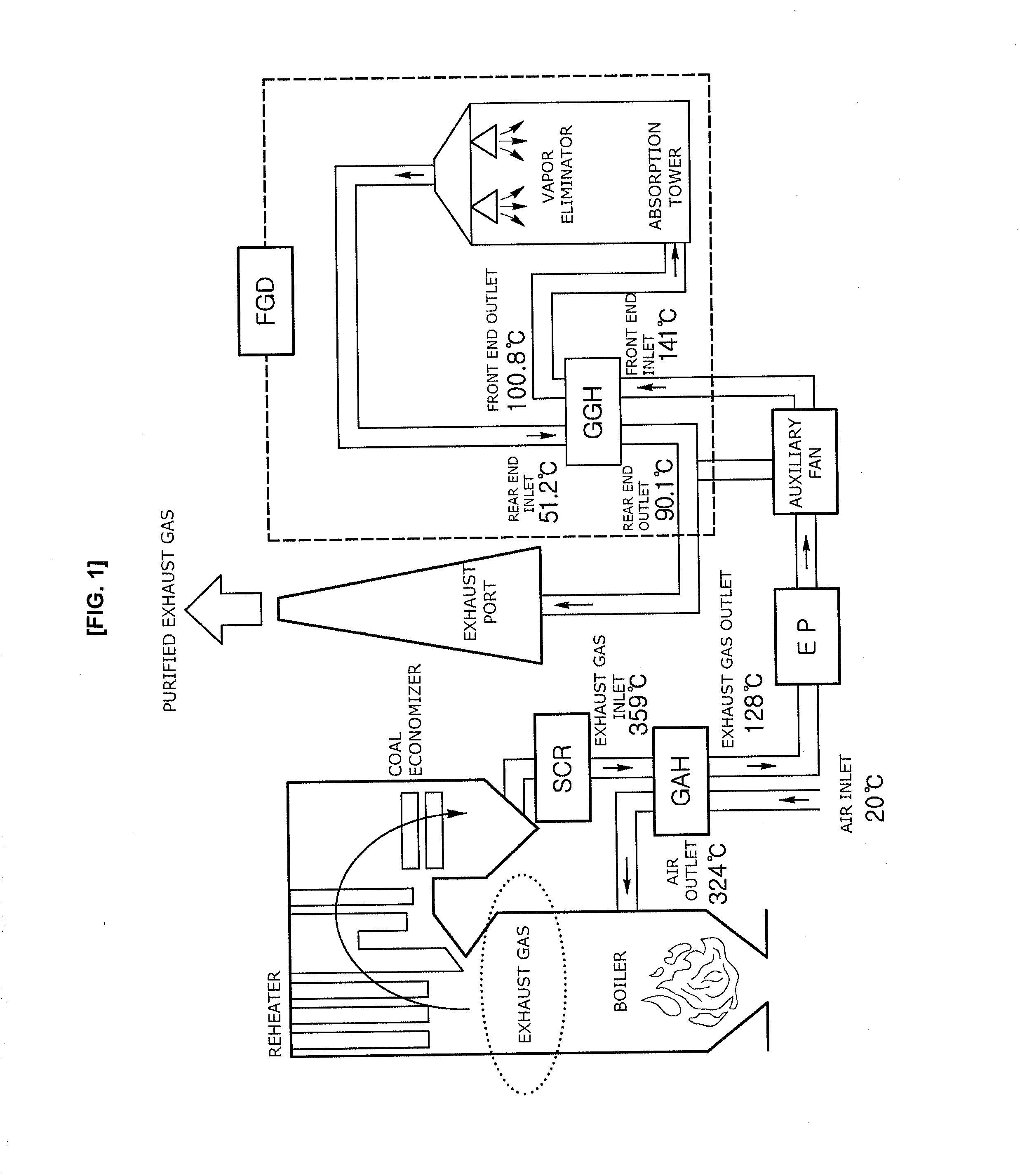

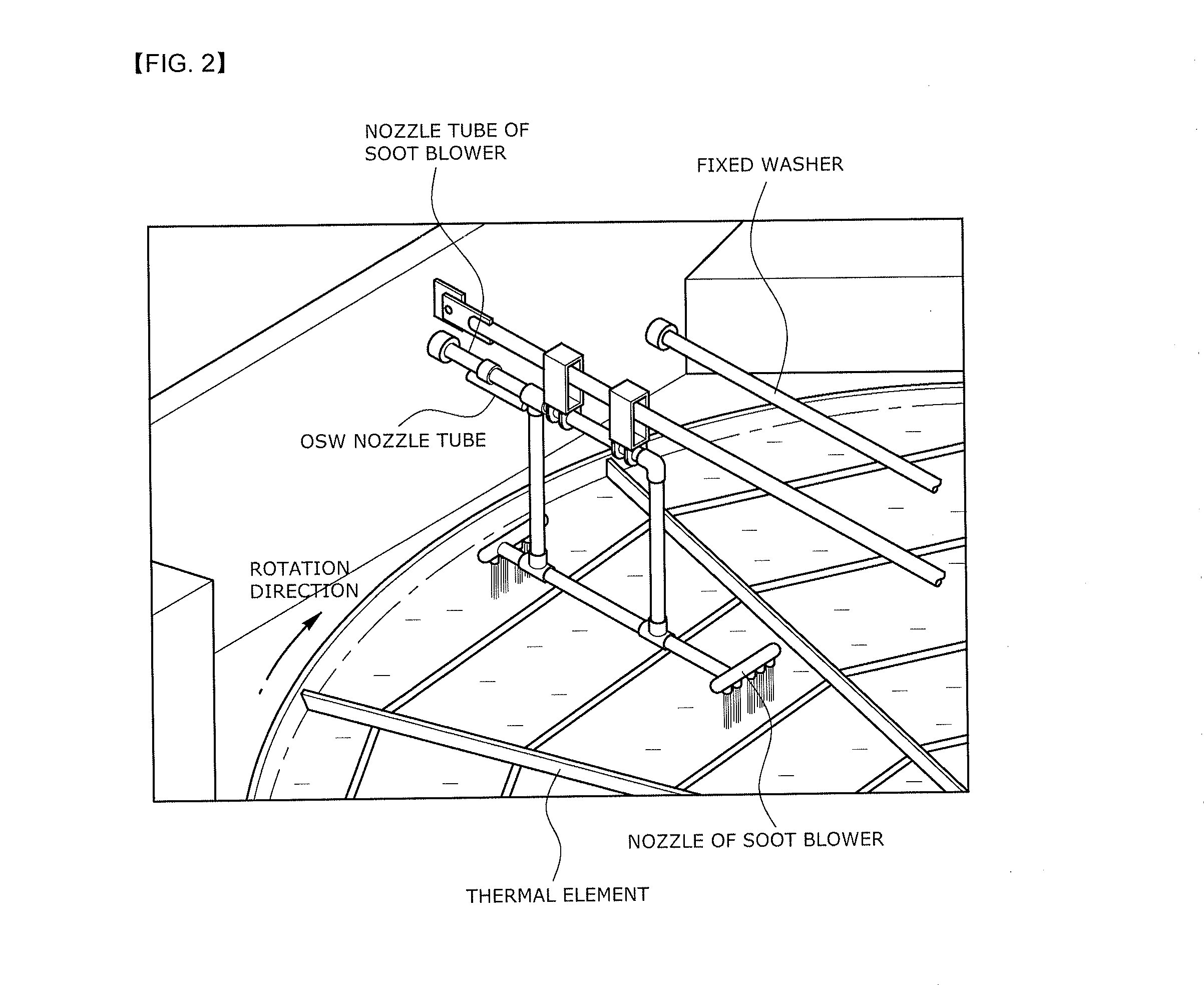

Complex cleaning system for heat exchanger

InactiveUS20170016686A1Reduce stressReduce water contentFlush cleaningRegenerative heat exchangersAir preheaterEngineering

The purpose of the present disclosure is to solve the problems of a difficult operation or occurrence of corrosion damage to equipment caused by the attachment of ammonium sulfate salt, which is generated when unreacted ammonia (NH3 slip) and sulfur trioxide (SO3) in exhaust gas are bonded with each other when a selective catalytic reduction (SCR) is used to eliminate nitrogen oxides that are contained in the exhaust gas generated during the combustion of a boiler or the like, to a heat exchanger of an air preheater (APH) or the like installed at the rear of an SCR device and blocks a passage of the exhaust gas such that the pressure inside the boiler is increased. To this end, a dry ice cleaning device is installed at the front of an exhaust gas inlet in an air preheater such that the blocking of a heat exchanger caused by ammonium sulfate salt or the like is removed by spraying dry ice pellets, and at the same time, high-temperature steam spraying device is installed at a cold end of the air preheater so as to spray the steam in the same direction as that of air supplied to a boiler, thereby removing contaminants more effectively. Furthermore, in order to effectively prevent blocking which occurs in a cold end of the air preheater, dry ice is sprayed to the front of an exhaust gas inlet of the air preheater and also, to the front of a supply air inlet of the air preheater which is an opposite direction thereof, such that a cleaning effect is increased.

Owner:GSCO

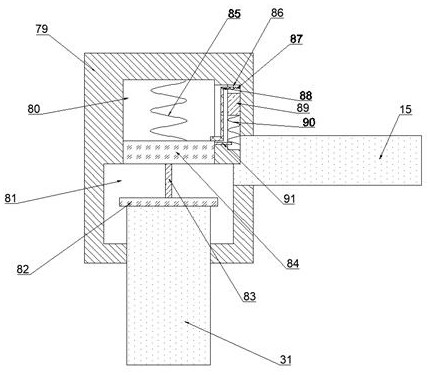

Efficient shot blasting equipment for removing rust and burrs of steel part

InactiveCN112497083AImprove reuse rateSimple stepsBlast gunsAbrasive feedersWorking environmentProcess engineering

The invention discloses efficient shot blasting equipment for removing rust and burrs of a steel part. The efficient shot blasting equipment for removing the rust and the burrs of the steel part comprises a shot blasting box and a pneumatic mechanism arranged on the right side of the shot blasting box, wherein a working cavity is formed in the shot blasting box. According to the efficient shot blasting equipment for removing the rust and the burrs of the steel part provided by the invention, a mode of directly adding dry ice fragment spraying on the rear side of a metal ball jet flow is used,rust removal and burr removal are integrated into one procedure, and traditional cleaning, drying and other procedures are not needed after dry ice spraying, so that the steps are greatly simplified,dry ice can be directly gasified after being used, and whether residues exist or not does not need to be manually detected; coarse and fine particles are separated in a vibration mode in subsequent separation equipment, so that the reuse rate of metal balls in a shot blasting machine is increased, rust, burrs and dust are collected in a unified mode, the cleaning cost is reduced, and the working environment quality is improved; and meanwhile, automation of the treatment process is achieved, so that the treatment efficiency is greatly improved, and labor force is saved.

Owner:石家庄闻索科技有限公司

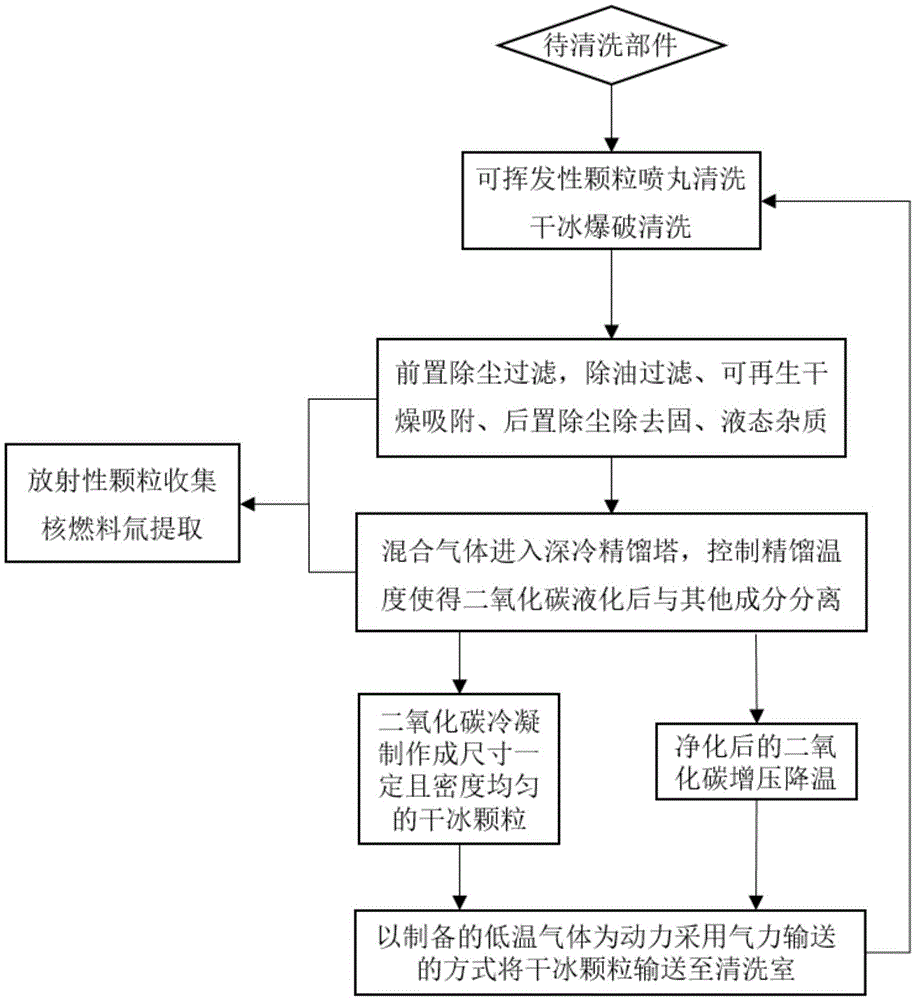

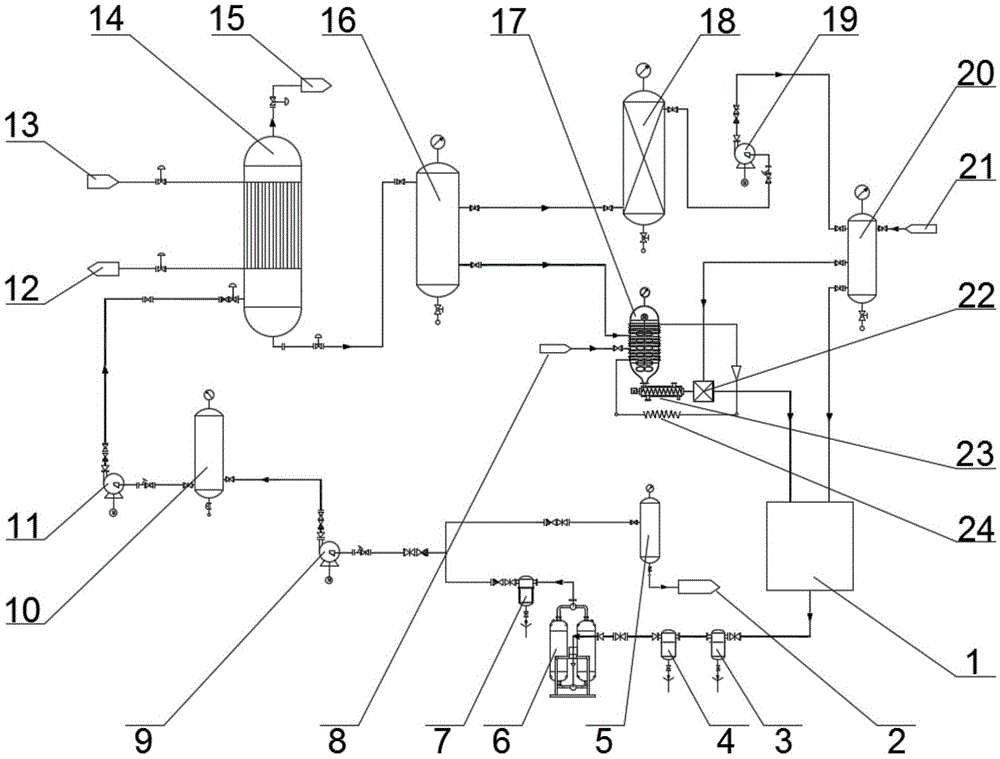

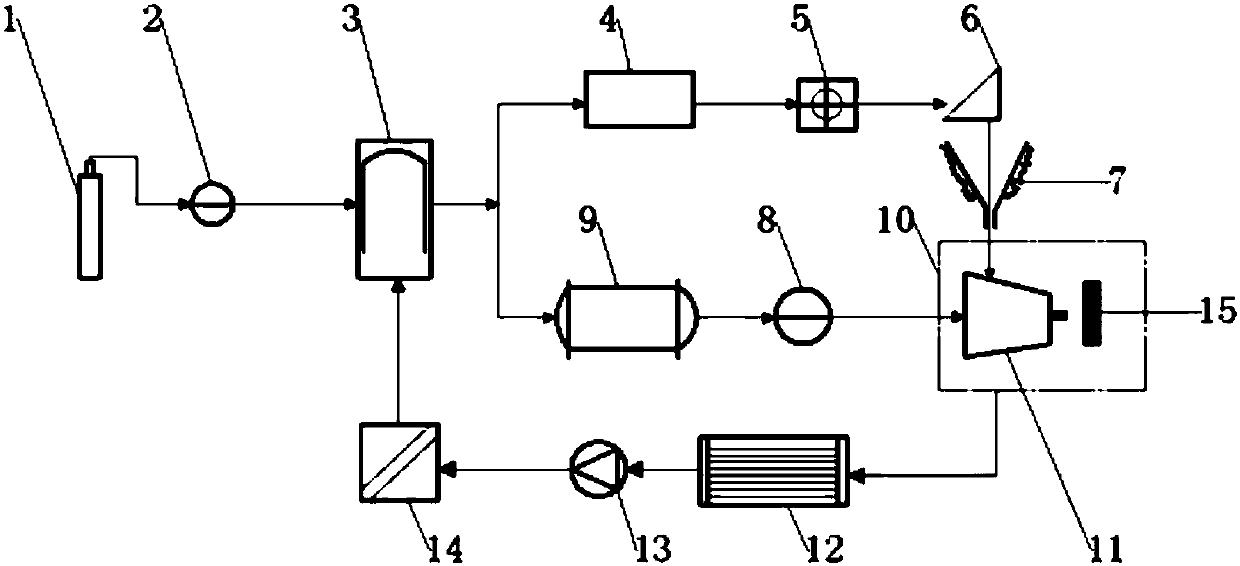

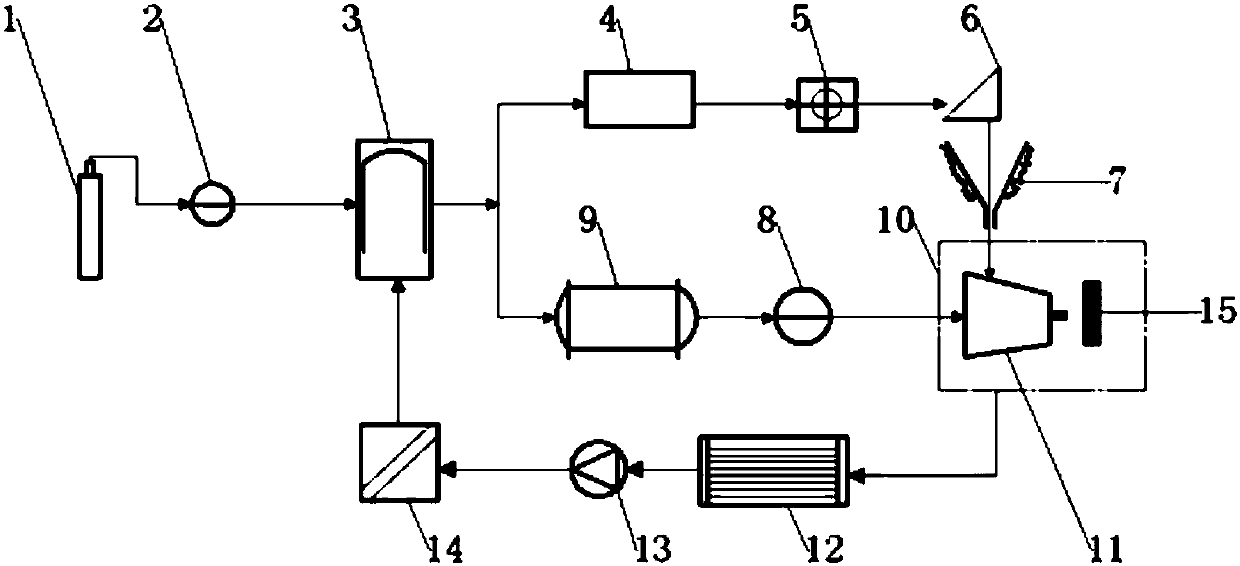

Method and device for purifying and recycling cleaning waste gas of hot cell of fusion reactor by cryogenic rectification

ActiveCN105632574ASolve processingSolve cleaningRadioactive decontaminationRadioactive gasSeparation technology

The invention relates to a method and a device for purifying and recycling cleaning waste gas of a hot cell of a fusion reactor by cryogenic rectification. The method comprises six technological processes including a decontaminating cleaning technology, a filtration and purification technology of solid and liquid-state impurities, a carbon dioxide cryogenic rectification separation technology, a low-temperature power gas preparation technology, a volatile granule regeneration technology and a long-distance pneumatic transmission technology. Radioactive particles and residual radioactive gases are collected in a sorting way together with or separated from a cleaning medium by utilizing the original cleaning waste gas. The effect that radioactive wastes in the hot cell are minimized can be realized. The radioactive particles and gaseous nuclear fuel are effectively collected while the cleaning waste gas is enabled not to pollute the environment as radioactive effluent, and an originally used cleaning medium is enabled to be recycled; on the basis, a carbon dioxide dry ice blasting cleaning scheme becomes a first selected option for cleaning a polluted radioactive surface in the hot cell; furthermore, the process scheme is simple in loop structure and easy to implement, thus being suitable for the remote control operation hot cell environment.

Owner:UNIV OF SCI & TECH OF CHINA

Method for regenerating TiN process Ti material part of film fabrication of semiconductor 8-inch wafer manufacturing

InactiveCN108672352AGood peeling and cleaning effectInjection parameters are easy to adjustCleaning using gasesCleaning using liquidsHigh pressure waterHigh pressure

The invention discloses a method for regenerating a TiN process Ti material part of film fabrication of semiconductor 8-inch wafer manufacturing. The method comprises the following steps (1) under normal pressure, after pure water or ultra-pure water is heated, hot water is fed into a high-pressure water pump and us sprayed on all parts of the surface of the Ti material part, and the water pressure is not less than 85 bar; (2) the Ti material part is dried by using hot air; (3) under normal pressure, as natural cooling is carried out, a dry ice jetting machine is used, dry ice particles are sprayed to all parts of the Ti material parts at a high speed, and the jetting speed is 870-1000 m / s; and (4) after dry-ice jetting is finished, the temperature naturally returns to the room temperature, and then washing is carried out. According to the method, the steps are concise, but the processing effect is magical, an excellent impurity falling and cleaning effect can be obtained in a relatively short time, moreover, the water flushing pressure and the dry ice quenching are both in the titanium material bearing range, and therefore, the regeneration of the Ti material photoelectric part becomes simple and feasible.

Owner:苏州珮凯科技有限公司

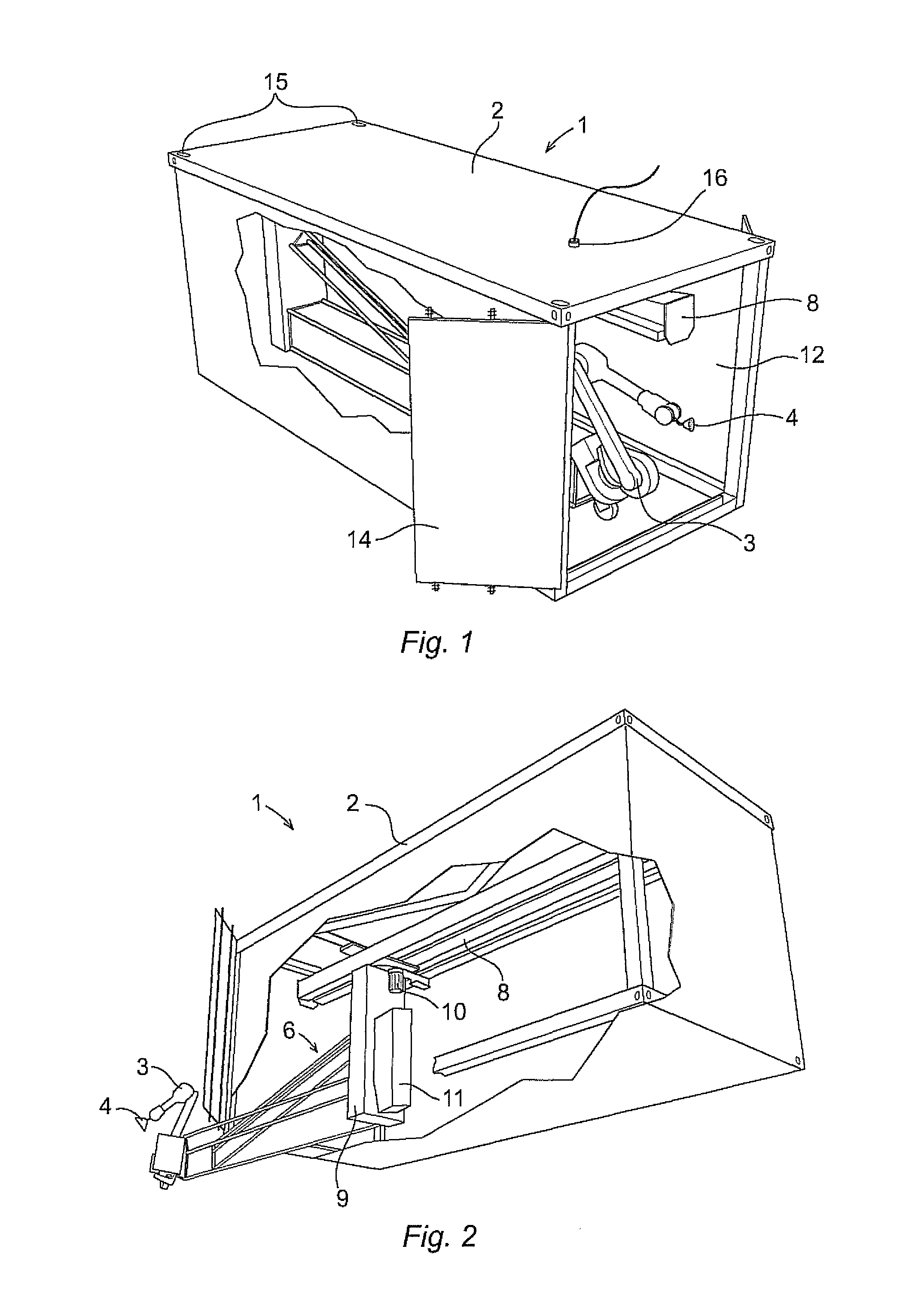

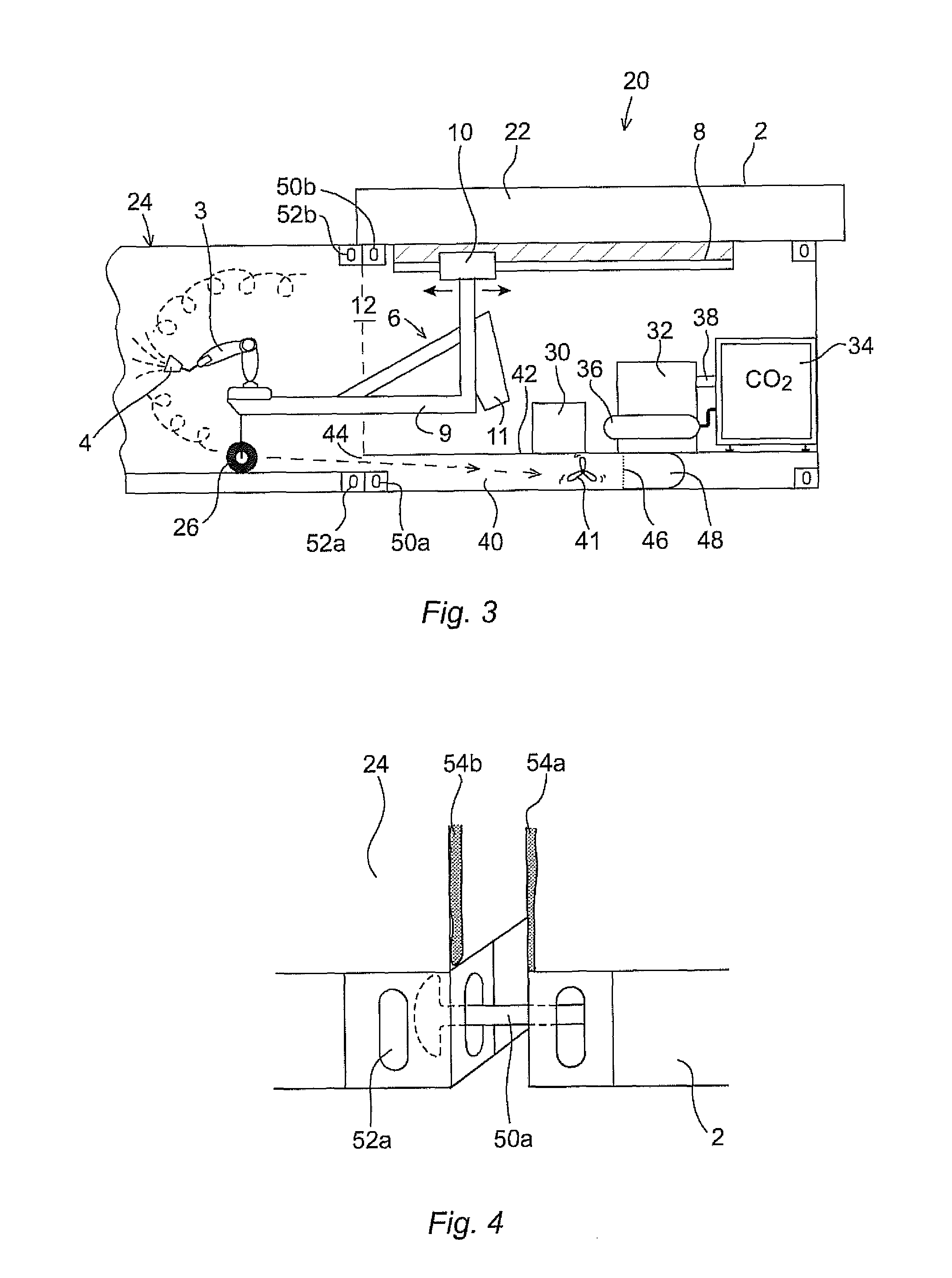

System, tool and method for cleaning the interior of a freight container

A tool and method for cleaning the interior of a freight container of ISO type. The tool having a framework, a robot movably connected to the framework and provided with a nozzle for supplying dry ice. The robot and the nozzle are adapted to clean the interior of the container by means of dry ice blasting. An actuating unit is arranged to move the robot between the framework and the interior of the container. The tool is a portable unit and has a size and a design that allows a truck adapted for gripping and carrying freight containers of ISO type to grip and carry the tool in order to move the tool to and from the container to be cleaned.

Owner:ROBOTICS

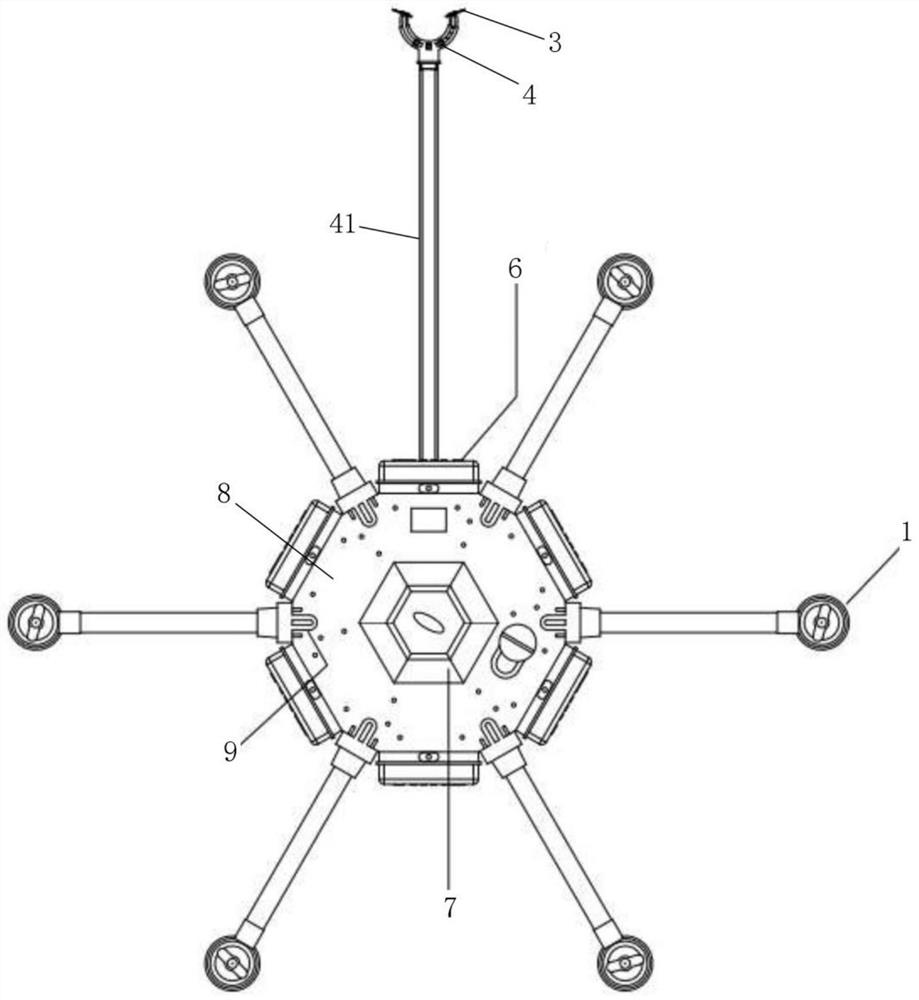

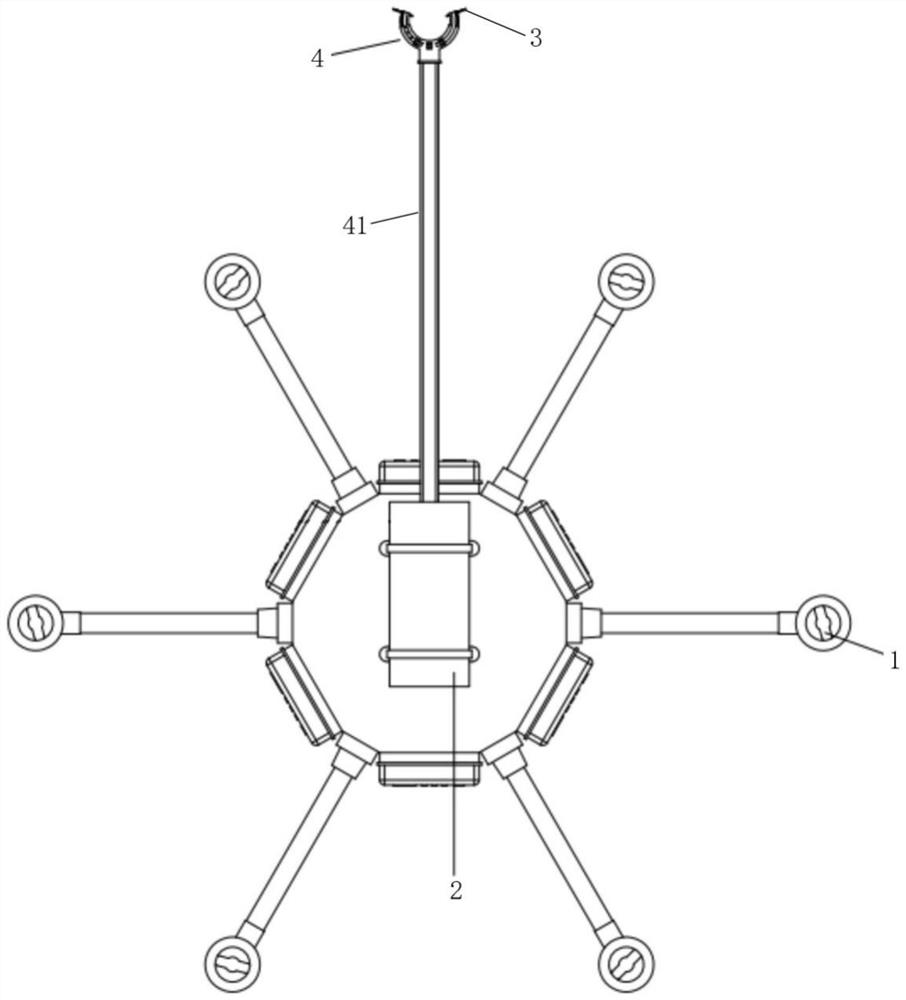

Unmanned aerial vehicle dry ice cleaning system for power grid insulator

PendingCN113967641AReduce the impactImprove securityAircraft componentsCleaning processes and apparatusSpray nozzleUncrewed vehicle

The invention discloses an unmanned aerial vehicle dry ice cleaning system for a power grid insulator. The system comprises an unmanned aerial vehicle body, wherein a dry ice supply device and one or more dry ice spraying nozzles connected with the dry ice supply device are installed on the unmanned aerial vehicle body, and the dry ice spraying nozzles are installed on the unmanned aerial vehicle body through an adjusting device in a spraying angle mode. The system has the advantages of high safety coefficient, high cleaning efficiency, simplicity in operation, convenience in use, good cleaning effect and the like.

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD MAINTENANCE CO +2

Ultrahigh-pressure supercritical carbon dioxide current-carrying dry ice cutting device and method

PendingCN109986318ARealize cutting and disintegrationImprove dismantling efficiencyUltra high pressureRadioactive waste

The invention belongs to the technical field of nuclear facility decommission and particularly relates to an ultrahigh-pressure supercritical carbon dioxide current-carrying dry ice cutting method. The method comprises the following steps that 1, supercritical carbon dioxide is prepared; 2, ultrahigh-pressure supercritical carbon dioxide current-carrying dry ice is sprayed; and 3, carbon dioxide is recycled. According to the method, cutting and disintegrating of metal rubbish on the nuclear facility decommission site can be achieved, the cutting efficiency is improved, the treatment amount ofsecondary radioactive waste is reduced, and safety of personnel, the public and environment is ensured.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

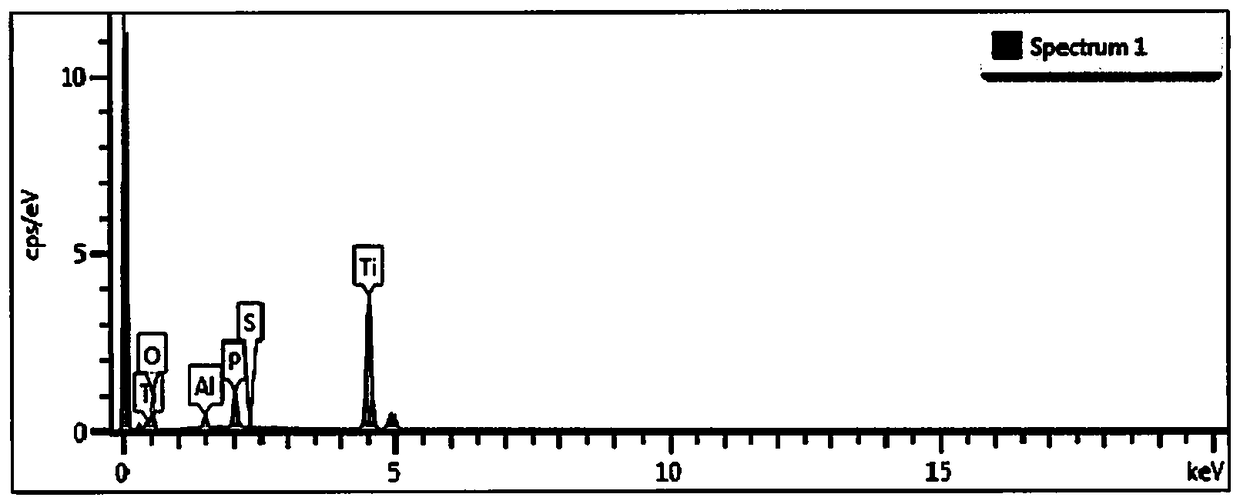

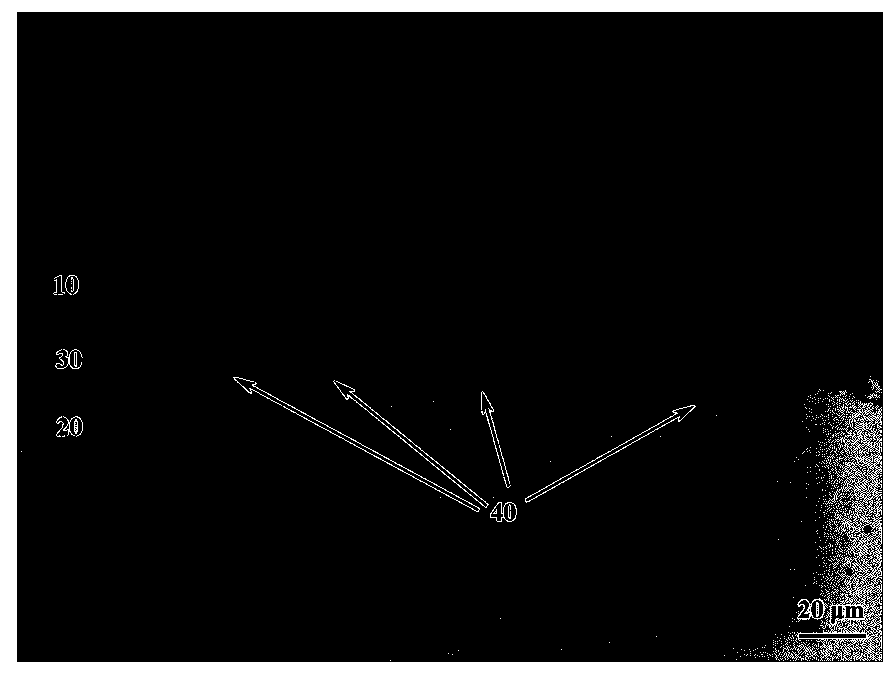

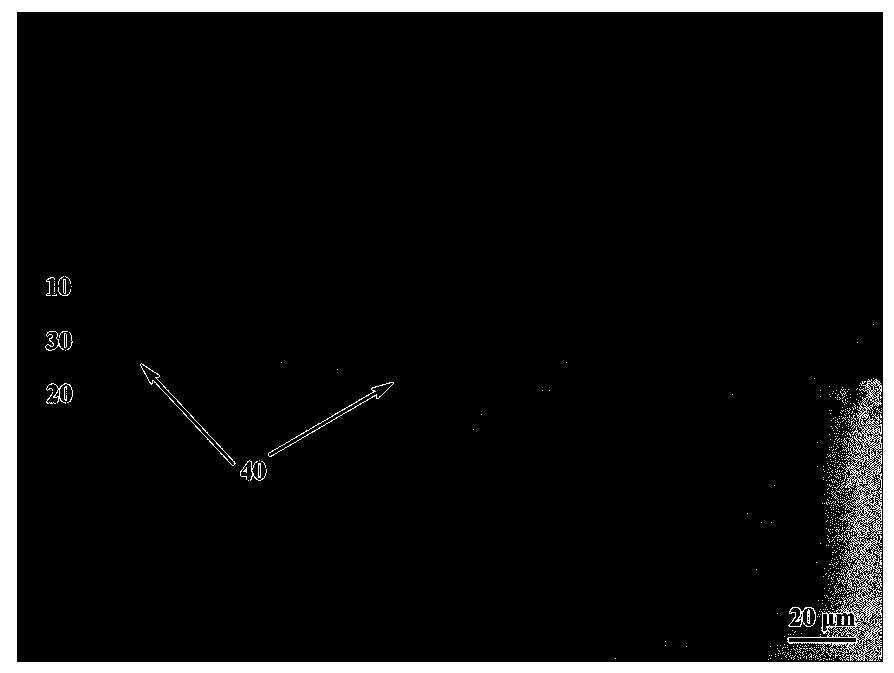

Novel pretreatment method for anodic oxidation process

InactiveCN108441925AReduce pollutionQuality improvementSurface reaction electrolytic coatingPretreatment methodBiological activation

The invention provides a novel anodic oxidation pretreatment method, and relates to treatment methods for biomedical materials, in particular to surface pretreatment before anodic oxidation for titanium and titanium alloy preparation. The novel pretreatment method comprises the step that carbon dioxide ice particle jet treatment is conducted on the surface of a matrix, specifically, (1-1) carbon dioxide ice particles are treated by changing the size of the carbon dioxide ice particles or by changing both the size and shape of the carbon dioxide ice particles, and (1-2) the carbon dioxide ice particles are sprayed onto the surface of the matrix, so that the surface of the matrix is purified and coarsened. According to the novel pretreatment method, an existing carbon dioxide jet cleaning process is improved, an existing sand-blasting / centrifugal grinding process is replaced, and even the activation procedure can be omitted; by using the carbon dioxide ice particle jet cleaning techniquefor treatment, it is found that the quantity of broken abrasive particles left on the surface of the matrix is greatly reduced, and interface pollution is basically eliminated. Obvious broken abrasive particle residues on an interface are avoided while the surface of the matrix is purified and coarsened, and thus, secondary interface pollution is greatly reduced; and the quality and bonding strength of the film interface are improved, and the service life of the film interface is prolonged.

Owner:北京理贝尔生物工程研究所有限公司

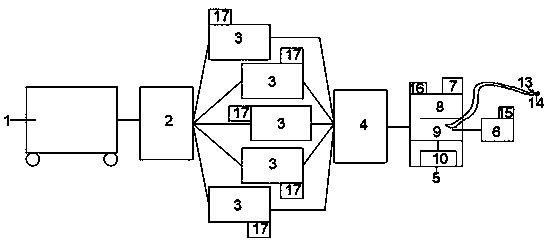

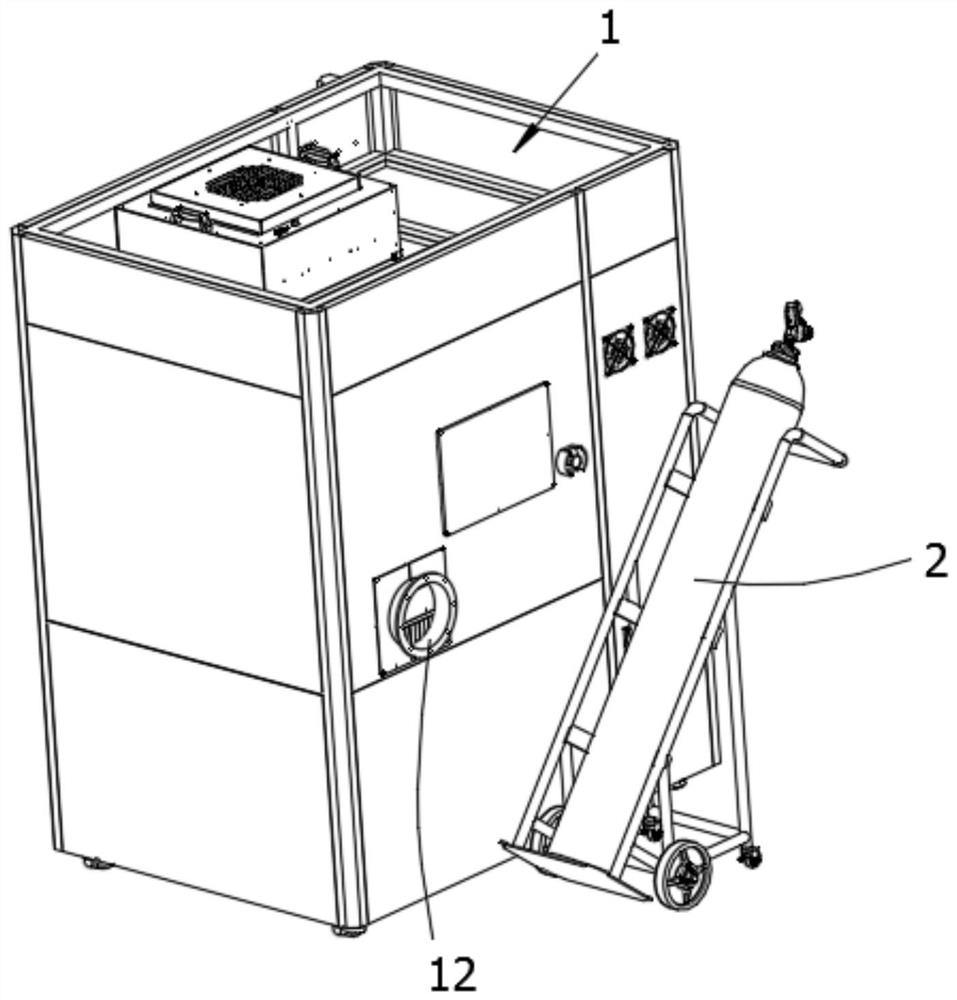

Dry ice cleaning device

The invention discloses a dry ice cleaning device which comprises a carbon dioxide storage tank car. The carbon dioxide storage tank car is connected with a dry ice granulator through a liquid inlet pipe; the dry ice granulator is connected with multiple dry ice preserving bins; dry ice in the multiple dry ice preserving bins is conveyed to a dry ice jet cleaner through a conveyor belt; dry ice quantity detectors are arranged on the multiple dry ice preserving bins; the dry ice jet cleaner is connected with a drier and comprises a feed inlet; the feed inlet is connected with a dry ice storingcavity; a dry ice smasher is arranged under the dry ice storing cavity and is connected with an electromotor and an air compressor; an ejector is connected onto the dry ice jet cleaner through a pipeline, and comprises a valve and a rotating nozzle; a data detector is arranged on the dry ice jet cleaner; and the data detector and the dry ice quantity detector are connected with a computer throughnetwork. The dry ice cleaning device provided by the invention is simple in structure; the adopted drier can be used for removing moisture in a high-pressure gas; and the adopted nozzles can rotate at360 degrees without dead angles.

Owner:伊婕

Dry ice cleaning equipment for semiconductor element

PendingCN112657944AImprove broken rateTo achieve the effect of cleaning impurities on the surface of the productCleaning using gasesThermodynamicsSpray nozzle

The invention discloses dry ice cleaning equipment for a semiconductor element. The dry ice cleaning equipment comprises an equipment frame body, a dry ice generating mechanism, a dry ice spraying mechanism, a dry ice purifying mechanism and a cleaning chamber, wherein the dry ice generating mechanism, the dry ice spraying mechanism, the dry ice purifying mechanism and the cleaning chamber are mounted on the equipment frame body; the dry ice generating mechanism comprises a liquid carbon dioxide storage tank and a dry ice generator; the dry ice spraying mechanism comprises a dry ice nozzle boss for mounting a dry ice spray nozzle, and a manipulator for driving the dry ice nozzle boss to move; the dry ice purifying mechanism comprises an air intake fan and an air exhaust fan, the air intake fan communicates with the cleaning chamber, and the air exhaust fan communicates with the cleaning chamber; and the cleaning chamber is divided into an upper-layer cleaning part and a lower-layer material collecting part by a screen plate, a containing plate where a product can be placed is fixed on the screen plate, the cleaning chamber is provided with an air outlet, and the air outlet communicates with the air exhaust fan. According to the dry ice cleaning equipment, impurities such as burrs and particles on the surface of the semiconductor element are crushed by the dry ice particles, so that the surface of the semiconductor meets the requirement of high cleanliness.

Owner:苏州睿智源自动化科技有限公司

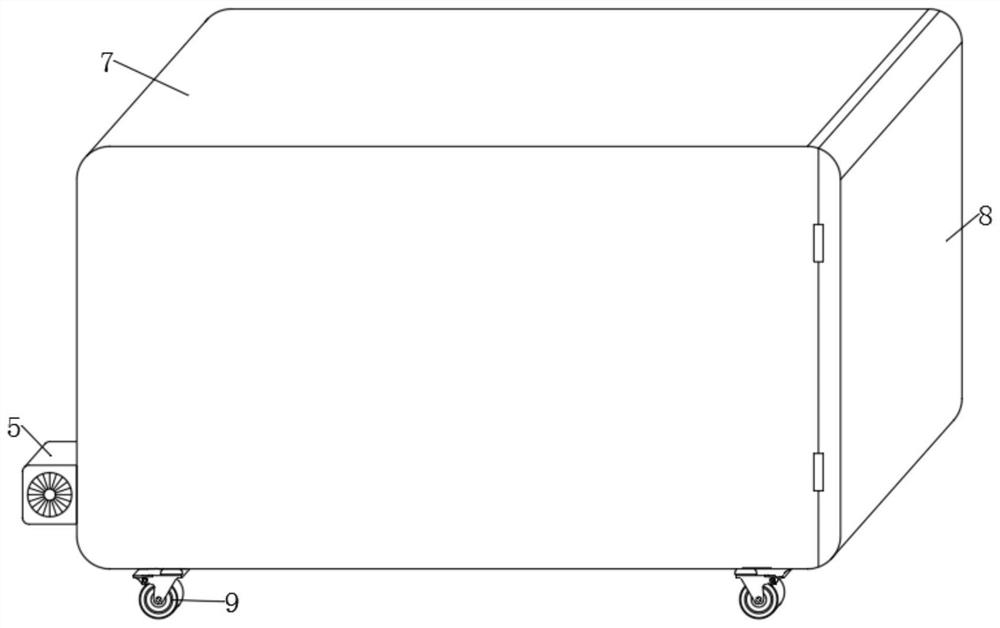

Dry ice jet cleaning method used for generator unit, dry ice solution formula and special device for dry ice jet cleaning method

InactiveCN110721963APromote sheddingBlocking adhesionCleaning processes and apparatusIceboxEngineering

The invention discloses a dry ice jet cleaning method used for a generator unit, a dry ice solution formula and a special device for the dry ice jet cleaning method. The cleaning method comprises thesteps that dry ice particles with the extremely low temperature of -78--48 DEG C are adopted to be accelerated with low-pressure air as a carrier and power, and jetted out of a jetting gun at the speed of 200-273 m / s to hit against dirt on a to-be-cleaned surface in the generator unit. The special device comprises a low-pressure air pipe, an air pressure adjusting valve, an electric flow regulating valve, a variable-speed motor, a rotary ice wheel, a dry ice tank, a vibration motor, a connecting hose, a spray nozzle, a PLC system and a cleaning machine case. The dry ice jet cleaning method hasthe advantages of being simple in operation, high in cleaning efficiency, environmentally friendly, high in installation adaptability and suitable for cleaning of all large, middle and small generators, saving energy and having no special requirements for a place.

Owner:株洲湘水机电有限责任公司

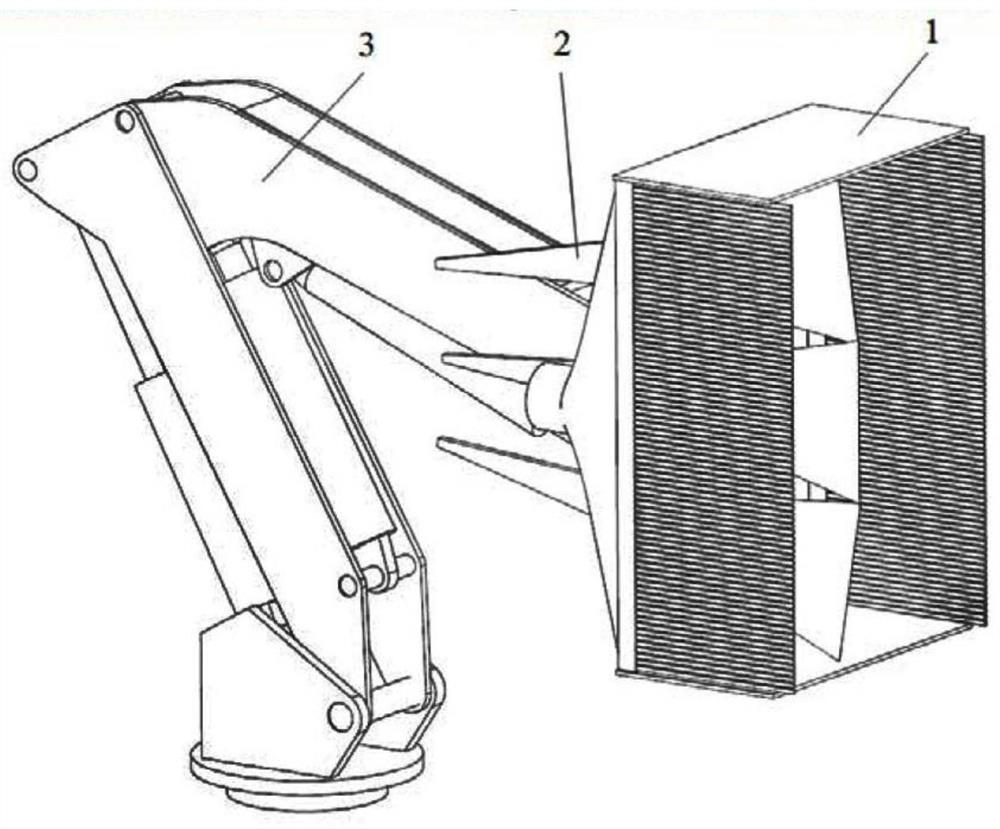

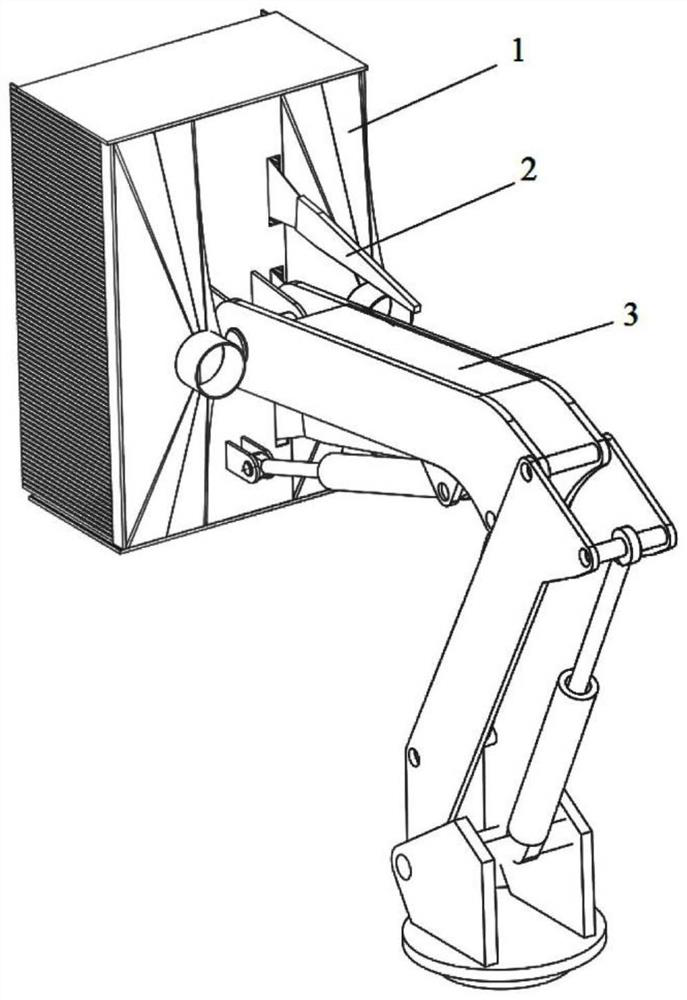

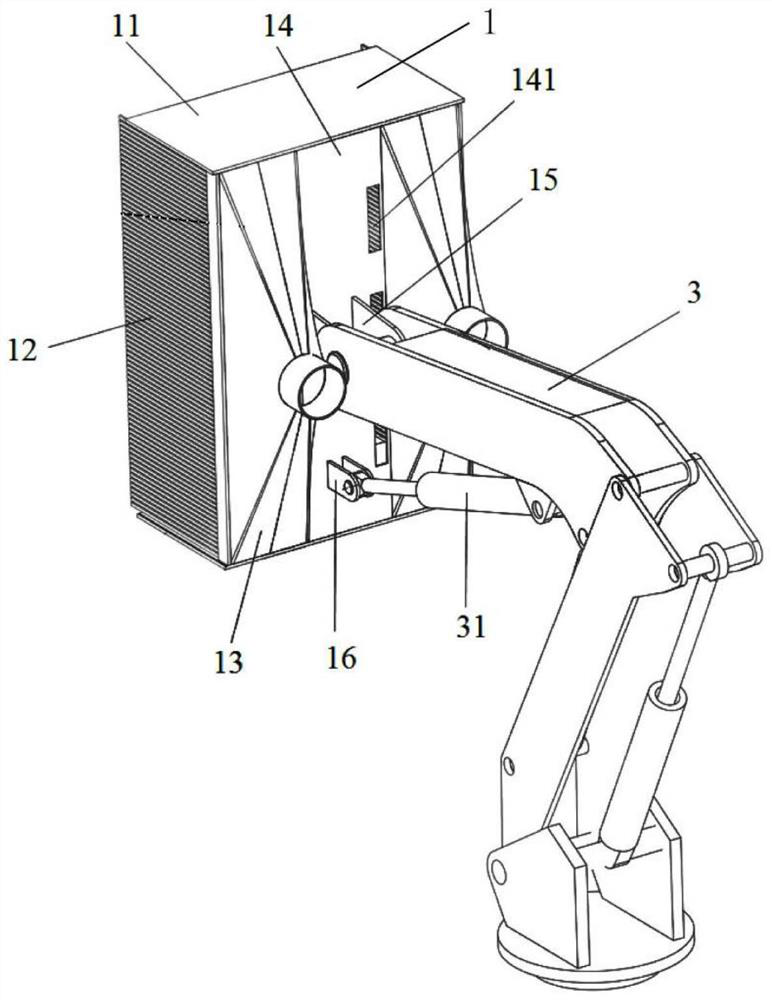

Tunnel wall cleaning device

The invention relates to a tunnel wall cleaning device which comprises a dry ice spraying assembly (2), the dry ice spraying assembly (2) is fixedly connected to a cover body (1), and the back of the cover body is connected with a mechanical arm (3). The cover body (1) can prevent dust from flying in a cleaning area during cleaning; a row brush plate (12) is arranged on the cover body (1), when an electrical equipment installation area on the tunnel wall is cleaned, bristles on the row brush plate (12) can achieve a sweeping function and can avoid obstacles; through the design, the cover body (1) can be close to the tunnel wall face as much as possible through the mechanical arm (3) in the cleaning process, and dust raising is prevented. The problem that in the prior art, a high-pressure air blowing cleaning mode is large in dust raising amount is solved.

Owner:CRCC HIGH TECH EQUIP CORP LTD

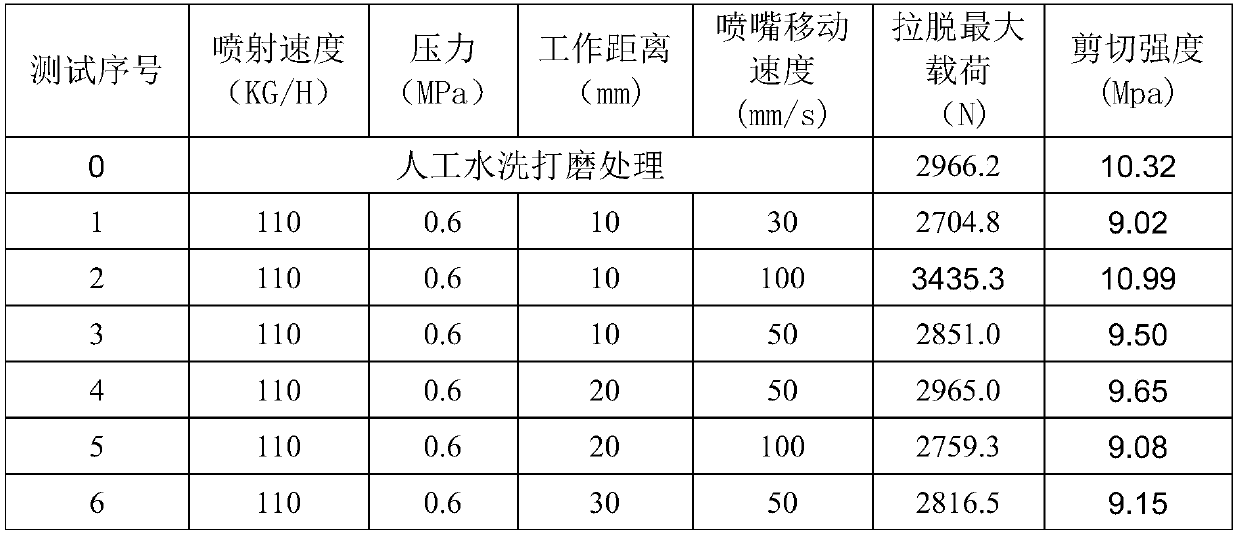

Cleaning technology for surface demoulding agent of carbon fiber composite product

The invention discloses a cleaning technology for a surface demoulding agent of a carbon fiber composite product. The cleaning technology for the surface demoulding agent of the carbon fiber compositeproduct comprises the following steps of spraying dry ice onto the surface of the composite product by a dry ice spraying device to remove the demoulding agent from the surface of the composite product. According to the cleaning technology for the surface demoulding agent of the carbon fiber composite product, the demoulding agent can be effectively removed, the removal efficiency is improved, and the product surface quality after removing the demoulding agent can be effectively guaranteed.

Owner:苏州华特时代碳纤维有限公司

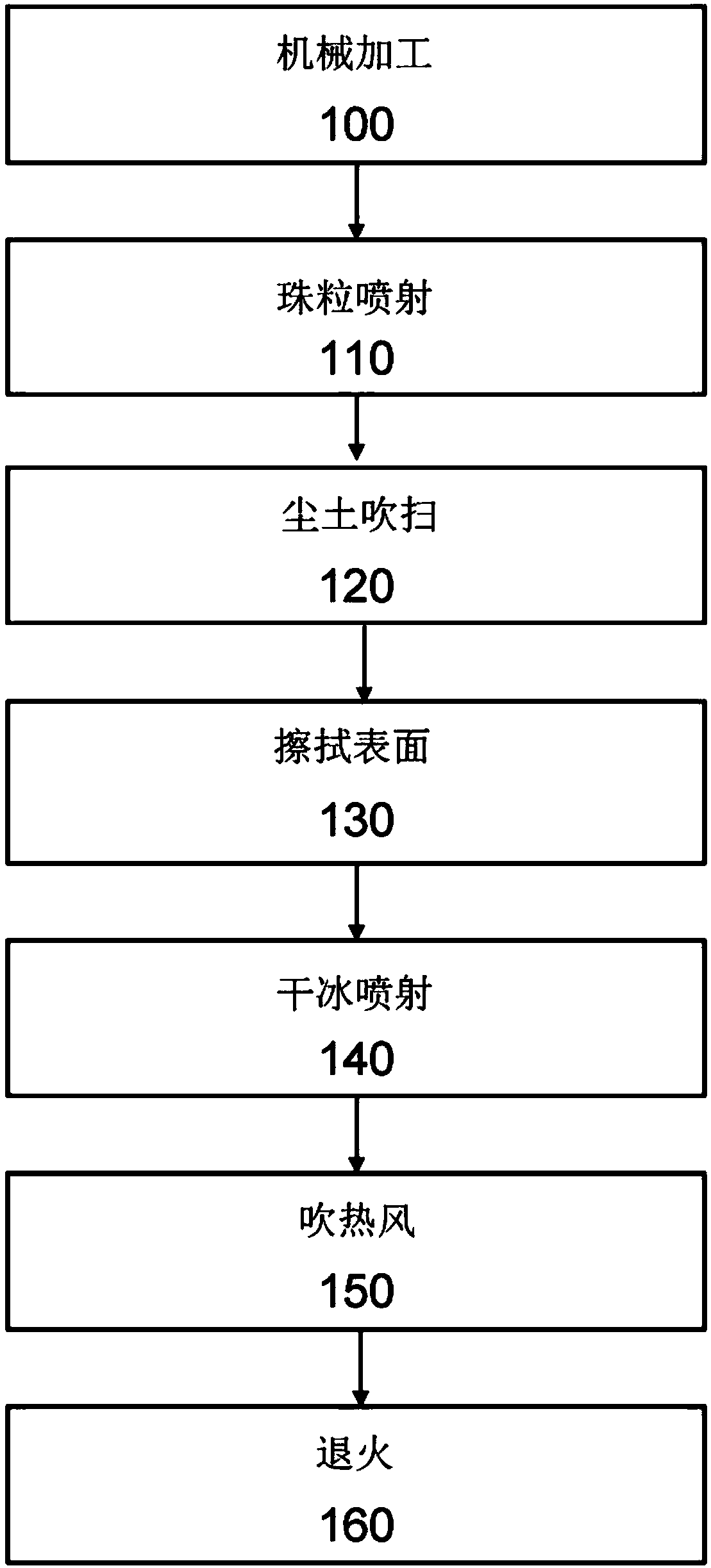

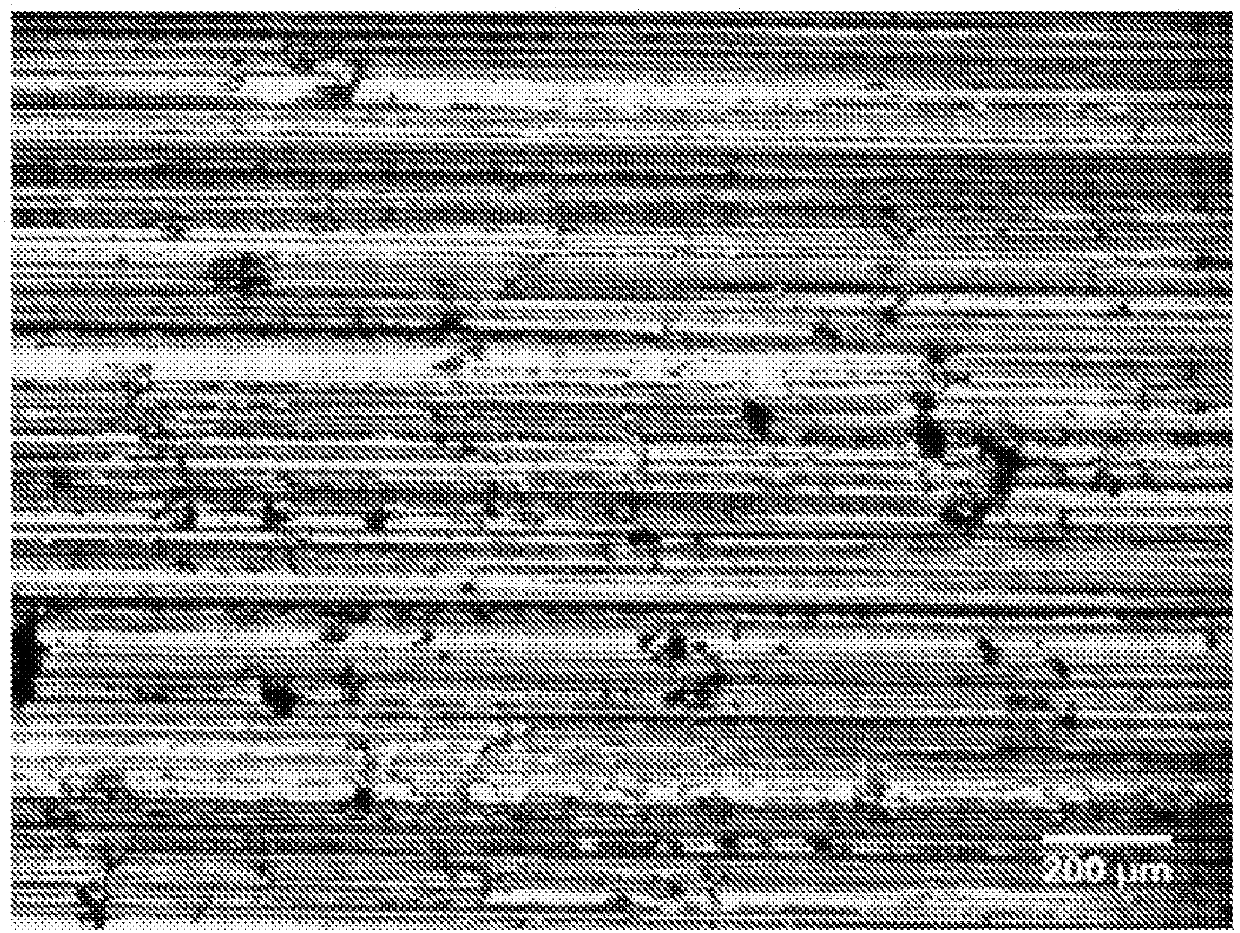

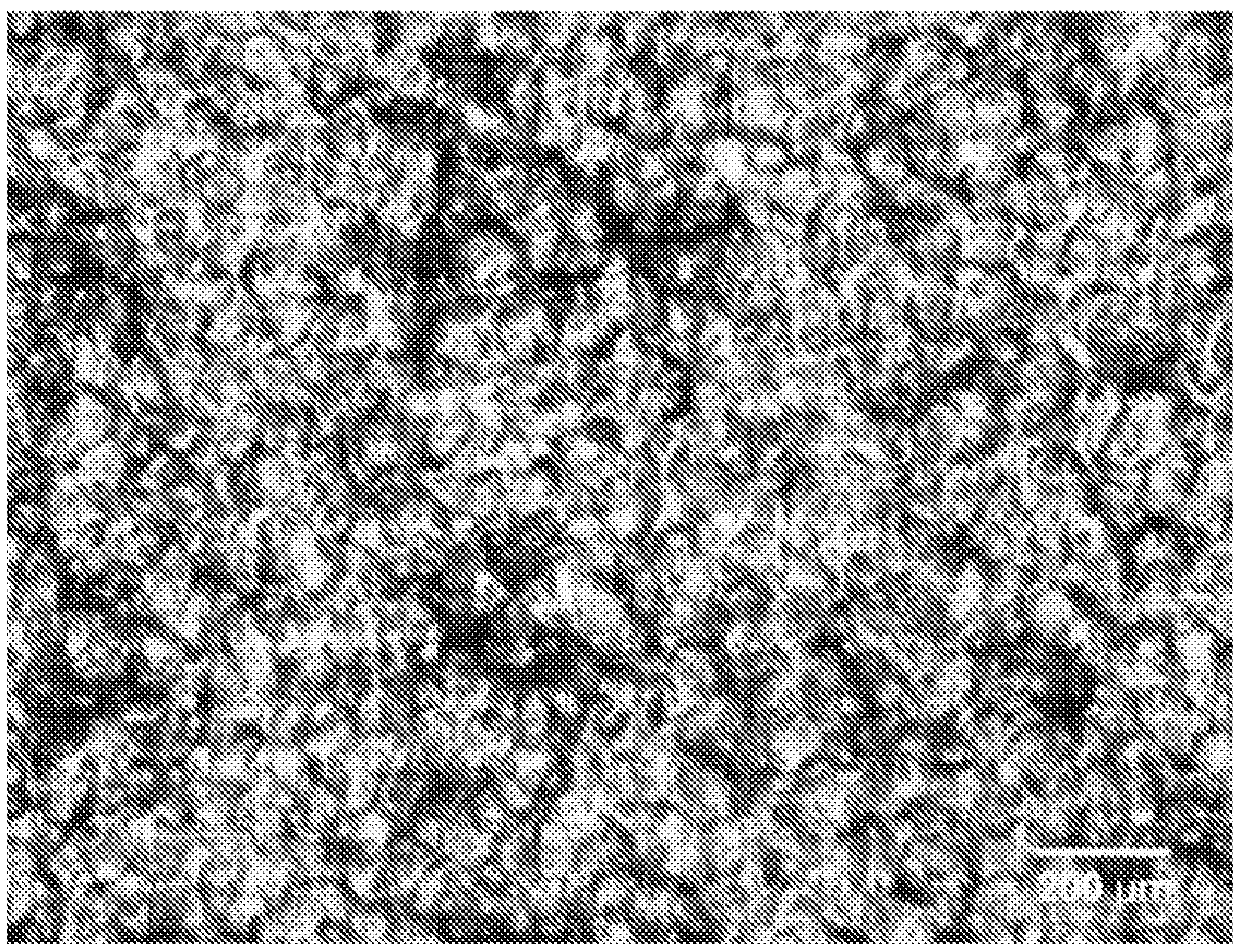

Methods for surface preparation of sputtering target

Methods for finishing a sputtering target to reduce particulation and to reduce burn-in time are disclosed. The surface of the unfinished sputtering target is blasted with beads to remove machining-induced defects. Additional post-processing steps include dust blowing-off, surface wiping, dry ice blasting, removing moisture using hot air gun, and annealing, resulting in a homogeneous, ultra-clean,residual-stress-free, hydrocarbon chemicals-free surface.

Owner:MATERION

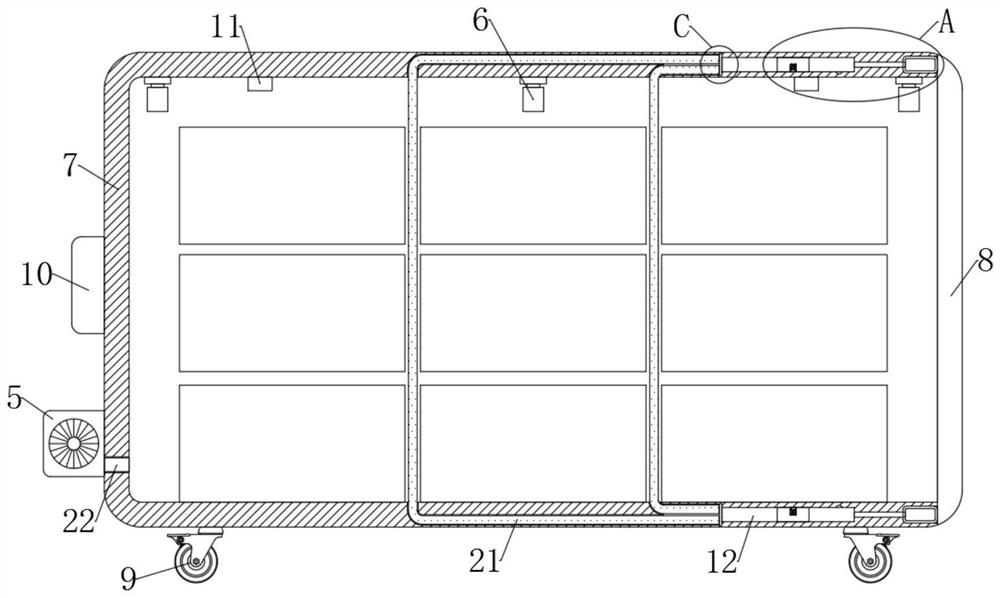

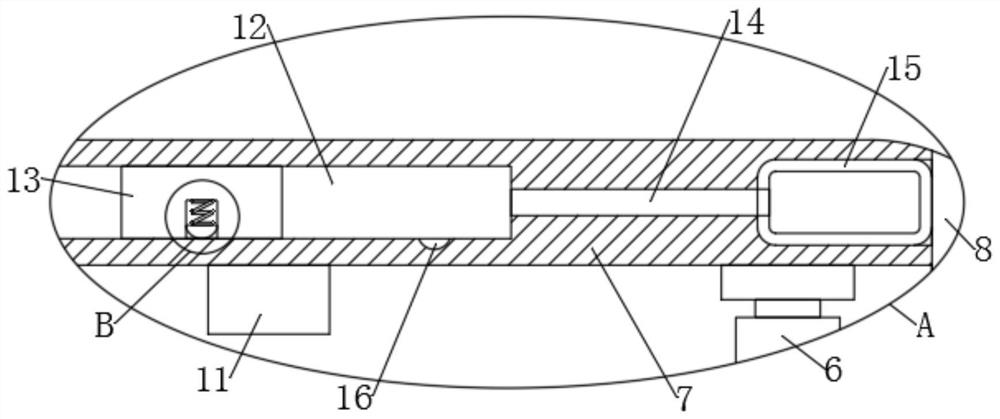

An economical cargo device for smart aviation based on the Internet of Things

ActiveCN112373897BRealize intelligent fire prevention systemReal-time monitoring of temperatureShock-sensitive articlesContainers preventing decayAviationThe Internet

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

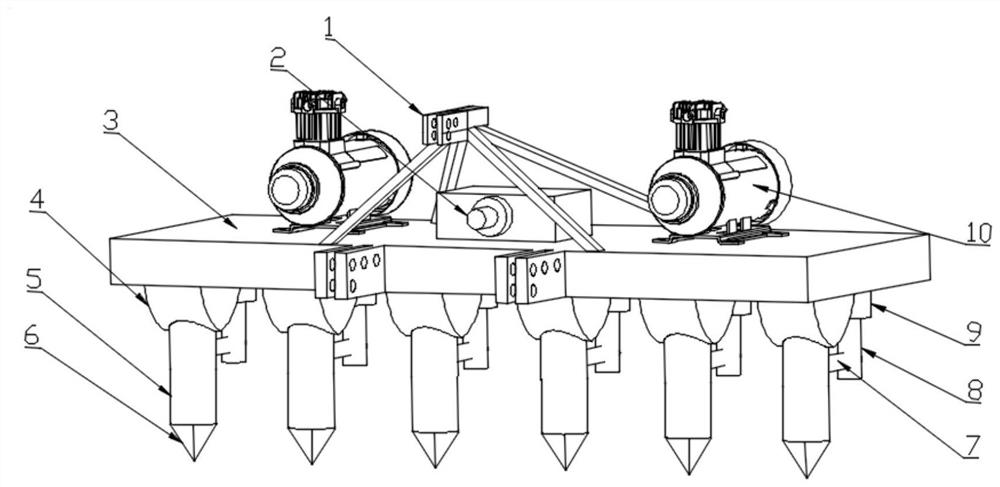

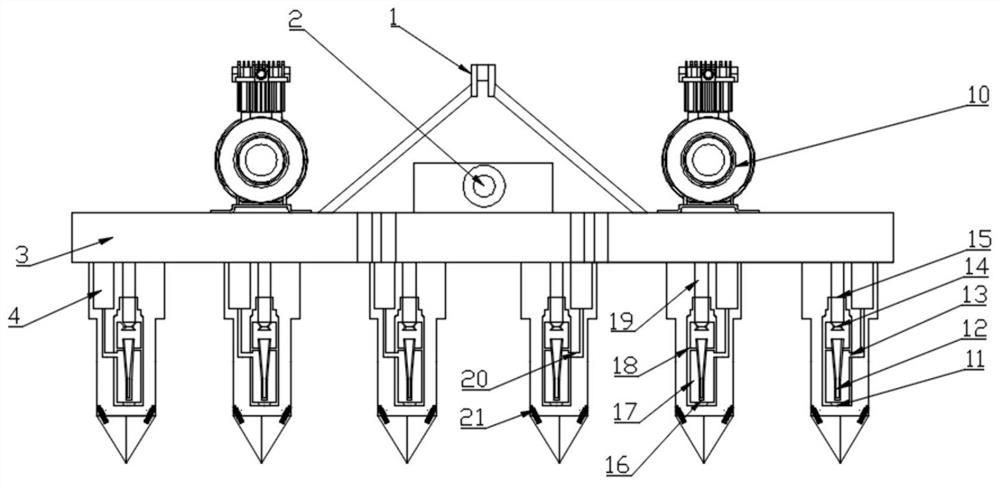

Dry ice powder blasting cultivation device and working method

PendingCN114514805AHigh strengthImprove toughnessSoil-working equipmentsAgriculture gas emission reductionAgricultural engineeringStructural engineering

The invention discloses a dry ice blasting cultivation device and a working method, and relates to the technical field of agricultural equipment.The dry ice powder storage device communicates with a telescopic pipe, and an opening and closing head is arranged below the telescopic pipe; the outer wall of the telescopic pipe is connected with one end of a connecting rod, the other end of the connecting rod is connected to a hydraulic mechanism, and the hydraulic mechanism works to drive the telescopic pipe to move up and down. A conical-column-shaped resonance body support is arranged in the telescopic pipe, and an air inlet, a powder inlet and a powder outlet are formed in the conical-column-shaped resonance body support; gas enters a Laval pipe arranged in the cone-column-shaped resonant body support through the gas inlet, enters the cone-column-shaped resonant cavity through an outlet in the outlet end of the Laval pipe and then flows out. Dry ice powder enters from the powder inlet, is converged with gas at the outlet of the conical-cylindrical resonant cavity, and is sprayed out from the powder outlet; the dry ice powder is sprayed out through the powder outlet, and the elastic piece works to open the opening and closing head under the action of impact force. The effect of shallow ploughing and soil loosening can be achieved.

Owner:JIANGSU UNIV

Stage smoke onsite manufacturing platform used for dry ice spraying

ActiveCN109011656AGuaranteed validityGuaranteed on-site effectStage arrangementsEngineeringAtmosphere

The invention relates to a stage smoke onsite manufacturing platform used for dry ice spraying. The platform comprises a dry ice spraying device, a movement driving device, a hemisphere type camera, and an overall analysis device. The dry ice spraying device is arranged on one side of a stage main place and used for spraying dry ice towards the stage main place so as to provide stage smoke effectsand create atmospheres for performance on the stage main place. The movement driving device is arranged under the dry ice spraying device, and used for carrying out the dry ice spraying device to drive the dry ice spraying device to move. The hemisphere type camera is used for carrying out immediate image shooting on the stage main place so as to acquire and output a corresponding stage main place image. The overall analysis device is connected with the hemisphere type camera and used for receiving the stage main place image and determining an overall segmentation threshold corresponding to the stage main place image according to distribution conditions of pixel values of each pixel point in the stage main place image. According to the invention, the cost performance of the stage dry icespraying is improved.

Owner:ZHEJIANG DAFENG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com