Efficient dry ice spray gun

A high-efficiency, dry ice technology, applied in the direction of spraying devices, liquid spraying devices, cleaning methods and appliances, etc., can solve the problems of inaccessibility, inadequate insulation measures, low cleaning efficiency, etc., to maintain stability, facilitate lifting, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

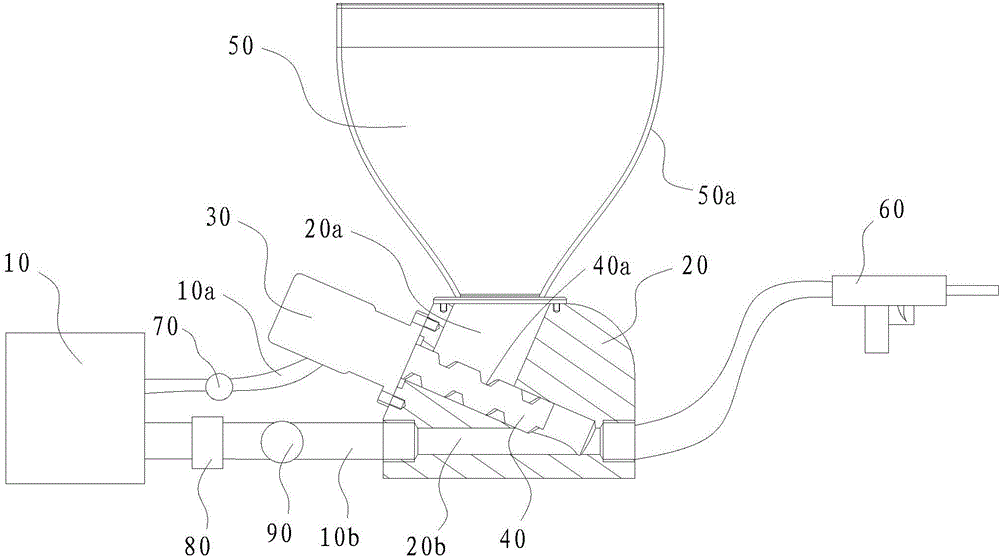

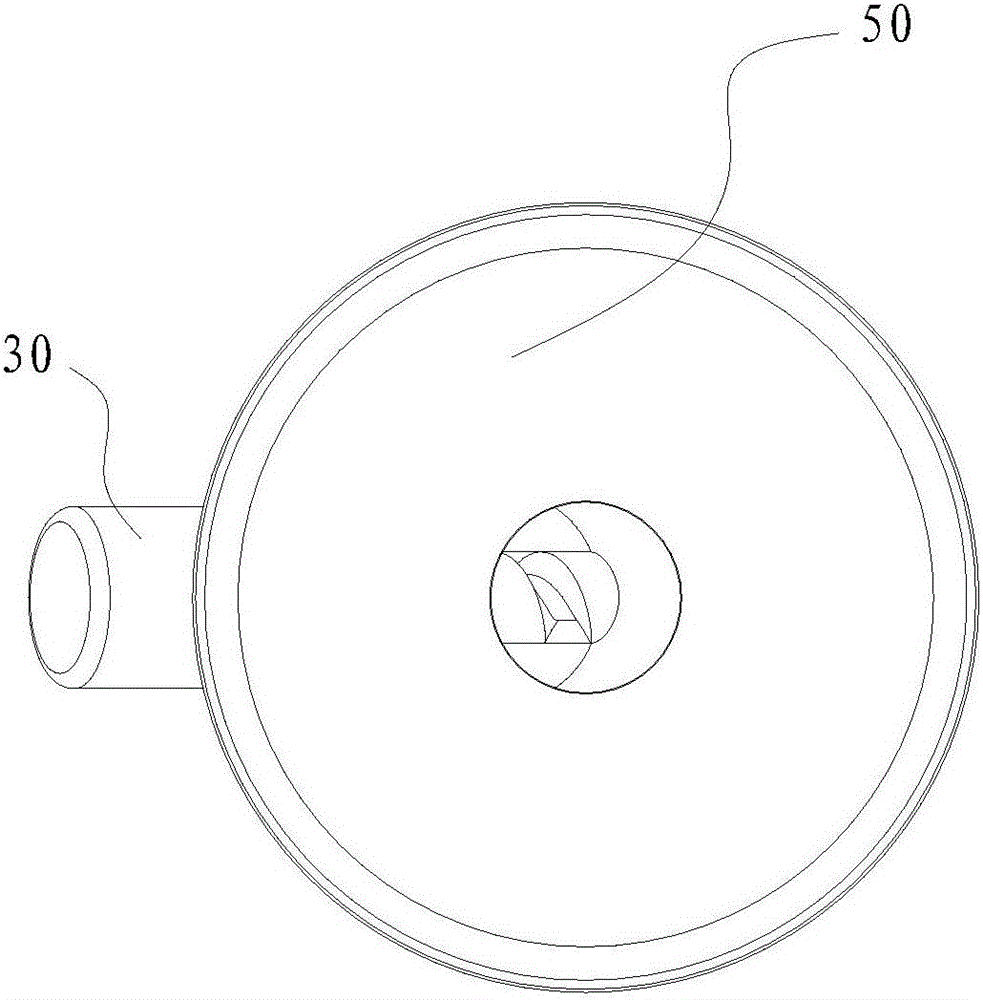

[0023] Such as figure 1 with figure 2 As shown, a high-efficiency dry ice spray gun includes an air compressor 10, an insulating box 20, an insulating air motor 30 supplied by the air compressor 10, an insulating screw 40 driven by the insulating air motor 30 to rotate, and an insulating screw 40 located on the The insulation hopper 50 on the top of the insulation box 20. The top of the insulating box 20 is provided with a dry ice inlet channel 20a corresponding to the bottom of the insulating hopper 50, and the interior of the insulating box 20 is provided with a compressed air channel 20b, one end of the compressed air channel 20b is connected to the air compressor 10, and the other is One end is connected to the spray gun 60 . The insulating screw 40 is obliquely arranged inside the insulating box 20, its lower end is located in the compressed air channel 20b, and its upper end is located at the bottom of the dry ice inlet channel 20a. 20b of the screw conveyor trough 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com