Air-supported type film structure fireproof structure based on personnel safety and operation method

A technology of personnel safety and air-bearing, which is applied in the field of fire prevention of building structures and emergency evacuation under fire, which can solve the problems of slowing down the spread of open flames, restrictive places, and inability to use, etc., to achieve various types of disasters and strong operability , the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

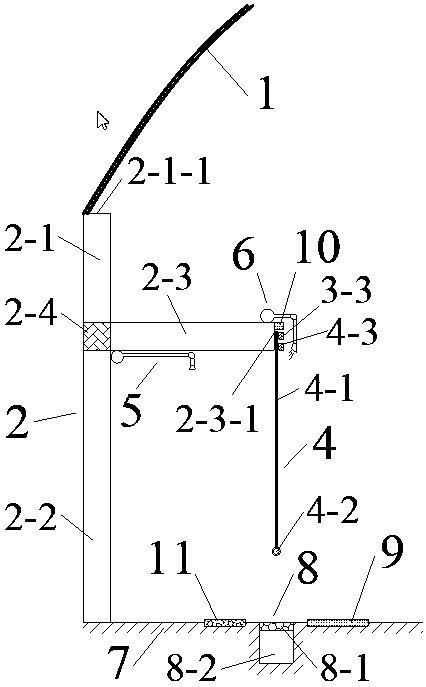

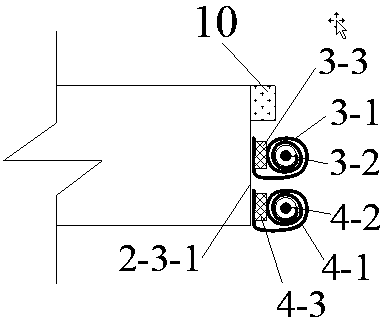

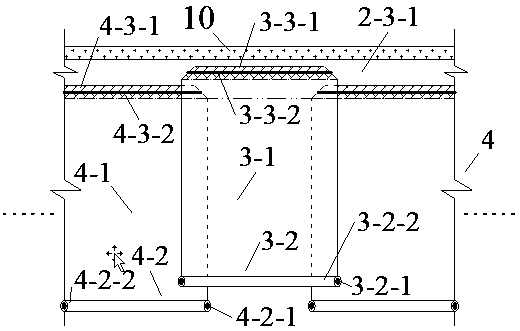

[0104] like Figure 1 to Figure 8 As shown, an air-supported membrane structure fireproof structure based on personnel safety includes an air-film roof 1, a ground 7, an airtight door 12, and an evacuation door 13, and also includes a smoke-proof foundation wall 2, a smoke-resistant vertical curtain I3, and a Smoke curtain II 4, air supply system 5, water cooling system 6, water storage ditch 8, refuge area indication sign 9, refuge area lighting indication sign 10, evacuation guide sign 11.

[0105] The smoke-proof foundation wall 2 includes the upper part 2-1 of the foundation wall, the lower part 2-2 of the foundation wall, the horizontal overhanging eaves 2-3 facing the room, and the upper part 2-1 of the connecting foundation wall, the lower part of the foundation wall 2-2 and the horizontal overhanging eaves 2- Node 2-4 of 3, the top surface of the foundation wall 2-1-1 is the top surface of the top part of the foundation wall 2-1, and the front end surface of the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com