Roadway repairing machine for coal mine

A technology for repairing machines and roadways, applied in tunnels, conveyors, mining equipment, etc., can solve problems that affect workers' work efficiency, threat to cockpit safety, easy falling gravel, etc., and achieve the goal of improving safety and buffering The effect of enhancing the ability and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

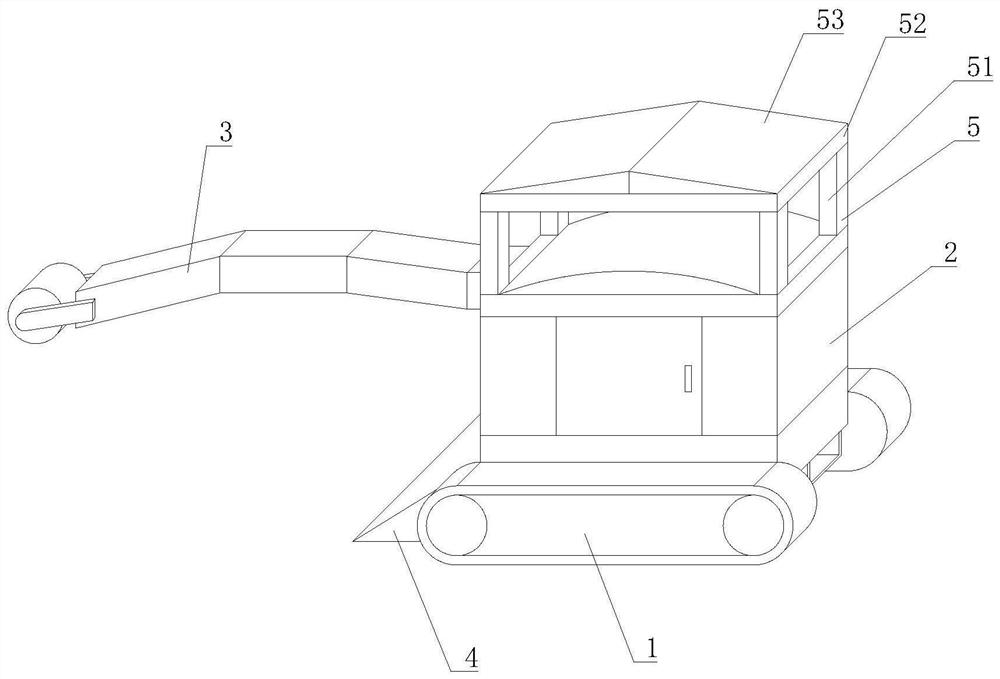

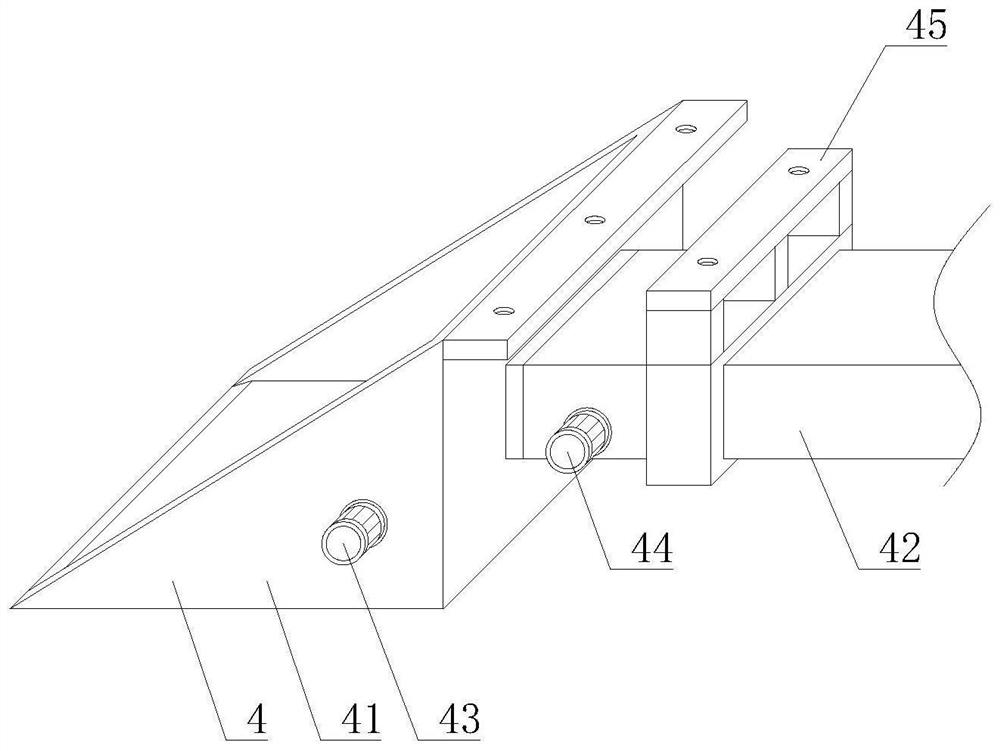

[0035] Such as Figure 1-9As shown, the present invention provides a roadway maintenance machine for coal mines, comprising a roadway maintenance machine body 1, a cockpit 2 is arranged on the top of the roadway maintenance machine body 1, and a maintenance mechanical arm is provided on the left side of the cockpit 2 3. The operator enters the cockpit 2 and controls the maintenance mechanical arm 3 through the roadway repair machine body 1 to realize the function of repairing the roadway. The bottom of the cockpit 2 is equipped with a coal mine transmission mechanism 4, and the cockpit 2 The top of the top is provided with a top protection mechanism 5. The coal mine transmission mechanism 4 includes a hopper 41 and a transmission channel 42. The hopper 41 is fixedly connected to the left side of the transmission channel 42. Through the design of the hopper 41, the roadway maintenance machine body 1 advances At this time, the coal mine can be shoveled into the inner cavity of t...

Embodiment 2

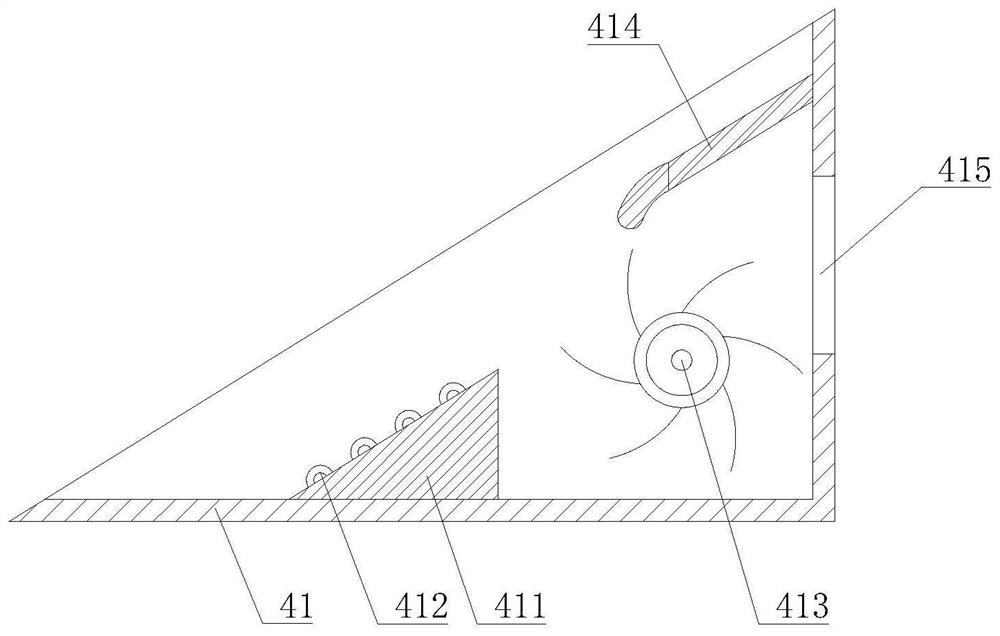

[0037] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the bottom of the inner cavity of the hopper 41 is fixedly equipped with a triangular blocking table 411, and the top of the triangular blocking table 411 is rotatably connected with a rotating roller 412, The right side of the hopper 41 inner cavity is fixedly equipped with a baffle plate 414, the right side of the hopper 41 is provided with a through groove 415, and the inner cavity of the hopper 41 is provided with a centrifugal conveying mechanism 413, the centrifugal conveying mechanism 413 includes a rotating shaft 4131, and the rotating shaft 4131 is rotatably connected in the inner cavity of the hopper 41, the front of the rotating shaft 4131 is fixedly connected with the output shaft of the driving motor 1 43, the outer wall of the rotating shaft 4131 is fixedly equipped with a surrounding cylinder 4132, and the outer wall of the surroundi...

Embodiment 3

[0039] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a deflector 421 is fixedly installed on the top of the inner cavity of the transmission channel 42, and a drive shaft 422 is rotatably connected to the inner cavity of the transmission channel 42 , the front of the drive shaft 422 is fixedly connected with the output shaft of the drive motor 2 44, and the inner cavity of the transmission channel 42 is connected with the driven shaft 423, and the outer wall of the drive shaft 422 and the driven shaft 423 is connected with the transmission belt 424. The outer wall of 424 is fixedly equipped with a push paddle 425, and the rotation of the drive shaft 422 will drive the transmission belt 424 to move, and cooperate with the push paddle 425 to transport the coal to the back of the device. , the top of the anti-sticking plate 426 is fixedly connected with a connecting pipe 4261, and the end of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com