A kind of preparation method, device and application of modified PVC material with NTC effect

A technology of PVC material and preparation device, which is applied in the field of modified PVC material preparation, can solve the problems of inability to quickly replace the die head of the extruder, inconvenient operation, etc., and achieve the effects of preventing raw material overflow, convenient cleaning, and increasing airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below with reference to the accompanying drawings and embodiments.

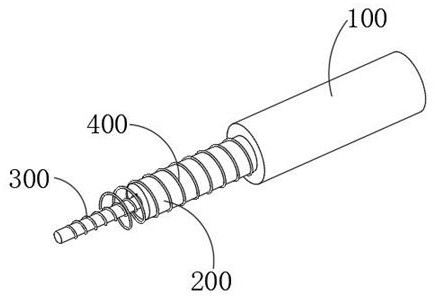

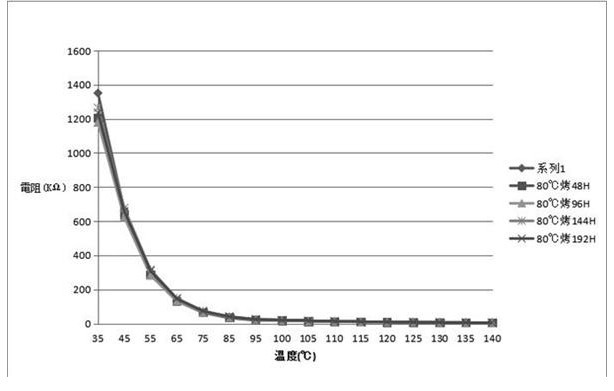

[0044] In the specific implementation process, such as Figure 4 and Figure 13 As shown, a method for preparing a modified PVC material with NTC effect comprises the following steps:

[0045] In step (1), the raw materials are weighed according to the mass percentage components of the corresponding components; the raw materials include the following components in mass fractions: 50-55 parts of polyvinyl chloride resin, 8-11 parts of calcium carbonate, 10 -13 parts of trimetyl ester plasticizer, 11-15 parts of polyester plasticizer, 2-4 parts of zinc stearate / calcium stearate compound, 1-3 parts of antimony trioxide, 4-7 parts of antimony trioxide part of the polymer amide complex, 4-7 parts of the silicon-based complex.

[0046] In step (2), the raw materials are placed in a vertical stirring cylinder, and the raw materials are mixed and stirred by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com