Liquid conveying device

A technology for conveying devices and liquids, applied in water supply devices, waterway systems, drainage structures, etc., can solve the problems of complex anti-blocking alarm devices, inability to eliminate toxic gases, and inability to detect water inlet blockages, etc., to prevent sludge deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

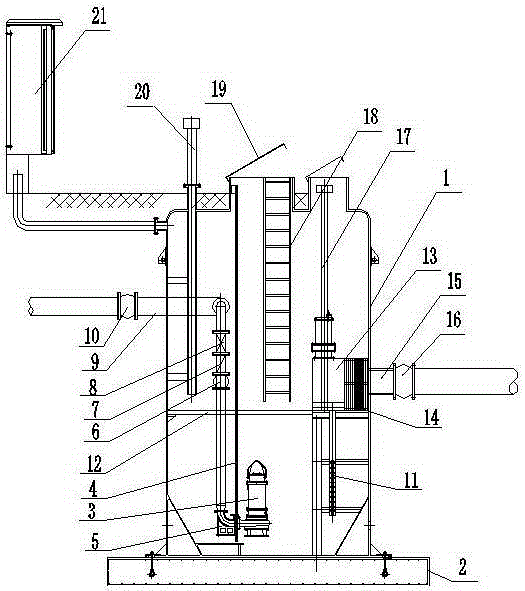

[0013] like figure 1 As shown, a liquid conveying device includes a wellbore 1, the wellbore 1 is fixed on a base 2, and a submersible sewage pump 3 is arranged on one side of the base 2, and the submersible sewage pump 3 is fixed on a submersible sewage pump guide rod and a lifting chain 4, The upper end of the guide rod of the submersible sewage pump and the lifting chain 4 are fixed on the top of the shaft 1; the submersible sewage pump 3 is sequentially connected to the valve flexible joint 6, check valve 7, gate valve 8, outlet pipe 9, and outlet pipe flexible joint 10 through the coupling base 5; the base 2 The other side is equipped with a liquid level control system and a detection system device 11. The working platform 12 on the upper part of the control system and detection system device 11 is located in the middle of the shaft 1; A fancy grid 14 is connected to the side of the type grid 13, and is connected with the flexible joint 16 of the water inlet pipe outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com