Dry ice jet cleaning method used for generator unit, dry ice solution formula and special device for dry ice jet cleaning method

A generator set and dry ice technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as the influence of generator equipment, damage to the generator set, and the need for thorough cleaning, so as to eliminate pollutants and prevent pollutants from adhering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A dry ice blasting cleaning method applied to generator sets is: using extremely low temperature dry ice particles of -78 ℃--48 ℃, using low-pressure gas as the carrier and power, and accelerating the dry ice particles to a speed of 200-273m / s. The gun sprays and hits the cleaned surface dirt in the generator set, causing the surface dirt to suddenly cool down and cause the surface to become brittle. At the same time, these extremely low temperature dry ice gases enter the cracked pollutants, using the energy of the high-speed moving solid dry ice particles The transformation makes the dirt and oil stains attached to the surface of the stator and rotor cores and end windings rapidly freeze, thereby condensing, embrittlement, and being stripped, and at the same time, it is removed with the airflow.

[0015] The following changes will occur during the cleaning process:

[0016] 1. "Energy Transfer". The dry ice hits the surface to be cleaned at high speed, the kinetic energy ...

Embodiment 2

[0020] A dry ice blast cleaning method applied to a generator set uses a dry ice solution weight percentage formula: 80 parts dry ice, 5 parts silicone oil, 15 parts water. When cleaning electrical equipment with insulation performance requirements, the generator set dry ice blasting The cleaning method is to add silicone oil to the dry ice and spray the surface to be cleaned at high speed. During the dry ice blasting cleaning process, when the contaminants are cleaned, the surface of the equipment will be covered with an insulating layer to prevent electrical equipment from being cleaned during the cleaning process. The condensation effect forms a build-up of water vapor on the surface of electrical equipment to protect the electrical equipment. At the same time, it can block the adhesion of contaminants to a certain extent during the subsequent operation of the equipment, and play a role in insulation protection.

Embodiment 3

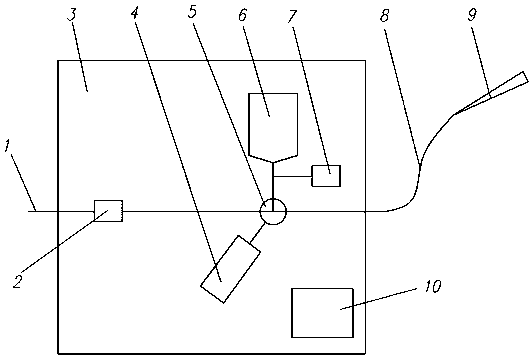

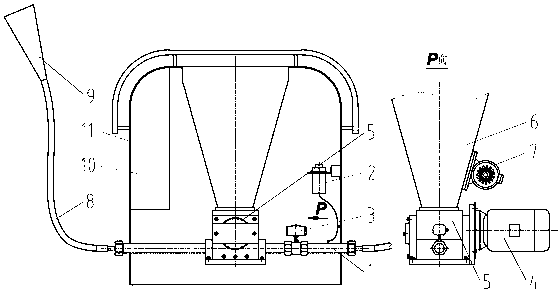

[0022] Such as figure 1 and figure 2 As shown, a special equipment for dry ice blast cleaning method applied to generator set, which includes low pressure air pipe 1, air pressure regulating valve 2, electric flow regulating valve 3, speed regulating motor 4, rotating ice wheel 5, dry refrigerator 6, vibration motor 7. Connect hose 8, nozzle 9, PLC control system 10 and cleaning cabinet body 11. The low-pressure gas in the workshop is connected to low-pressure air pipe 1 through a joint. Air pressure regulating valve 2 and electric flow regulating valve 3 are set on low-pressure air pipe 1, and The lower end of the refrigerator 6 is connected to the low-pressure air pipe 1 through the rotating ice wheel 5, and the rotating ice wheel 5 is connected to the speed regulating motor 4. A vibration motor 7 is provided under the dry refrigerator 6, and the outlet end 12 of the low-pressure air pipe 1 is connected to the nozzle 9 through a connecting hose 8 , The low pressure air pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com