Patents

Literature

383results about How to "To achieve the purpose of cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

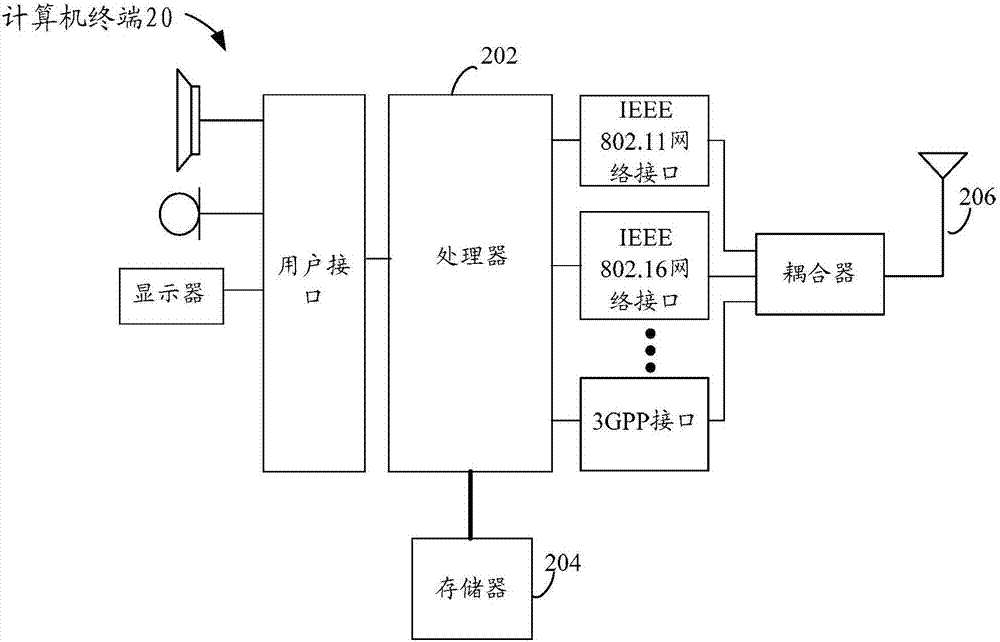

Power-supply controller of electric dust collector and long-range control system of the same

ActiveCN101152637AImprove accuracyFastTotal factory controlElectric supply techniquesElectrostatic precipitatorPower flow

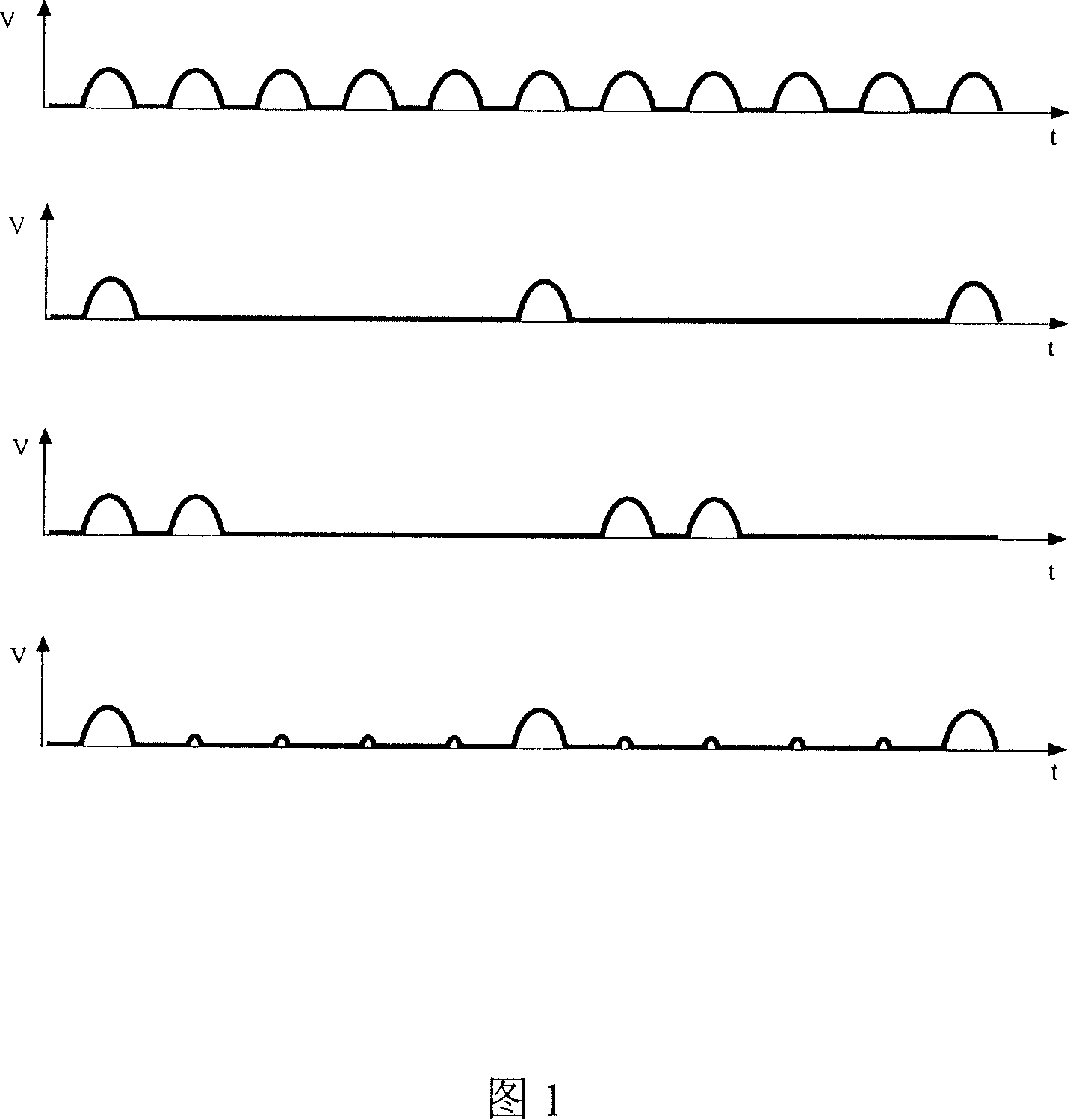

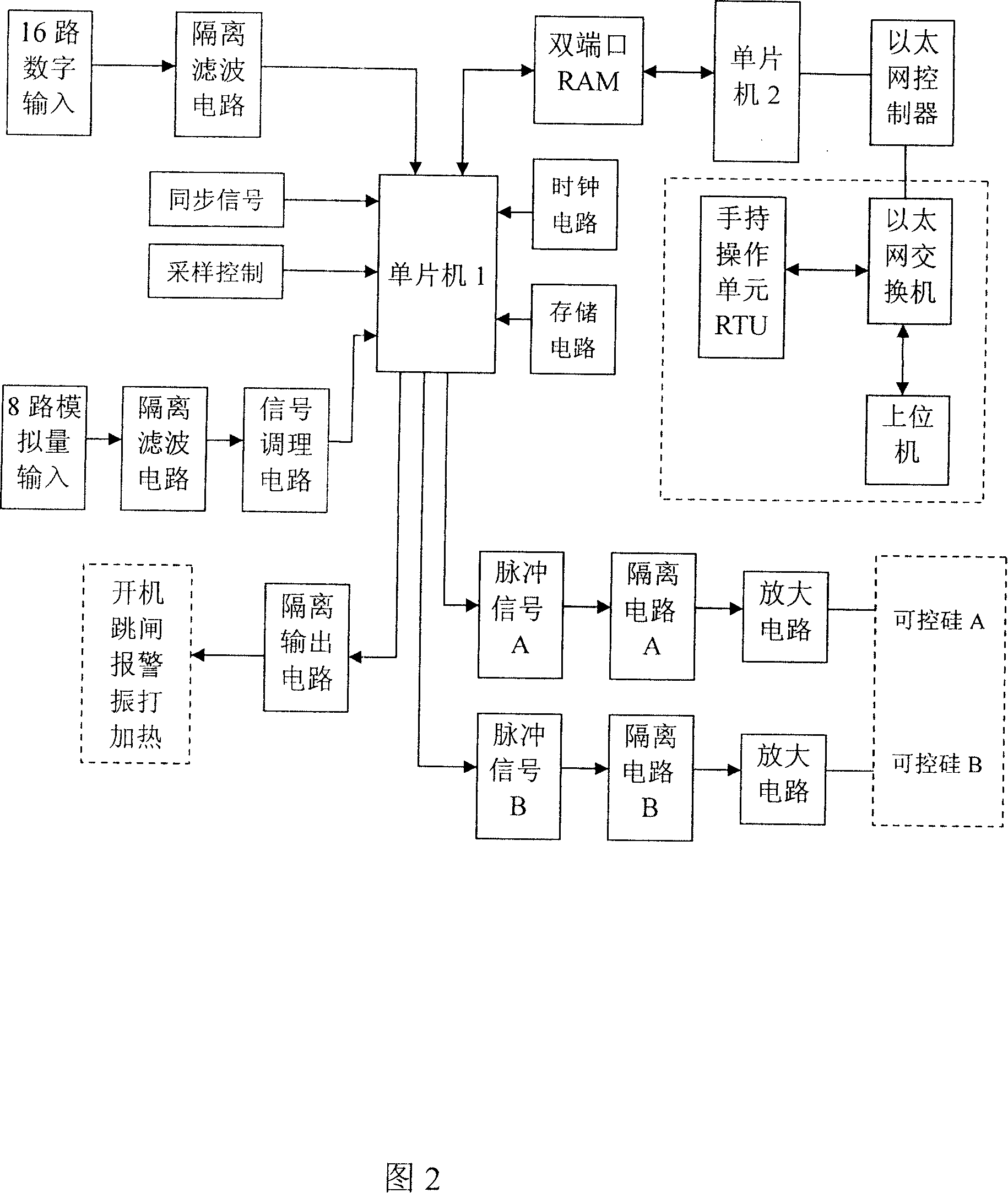

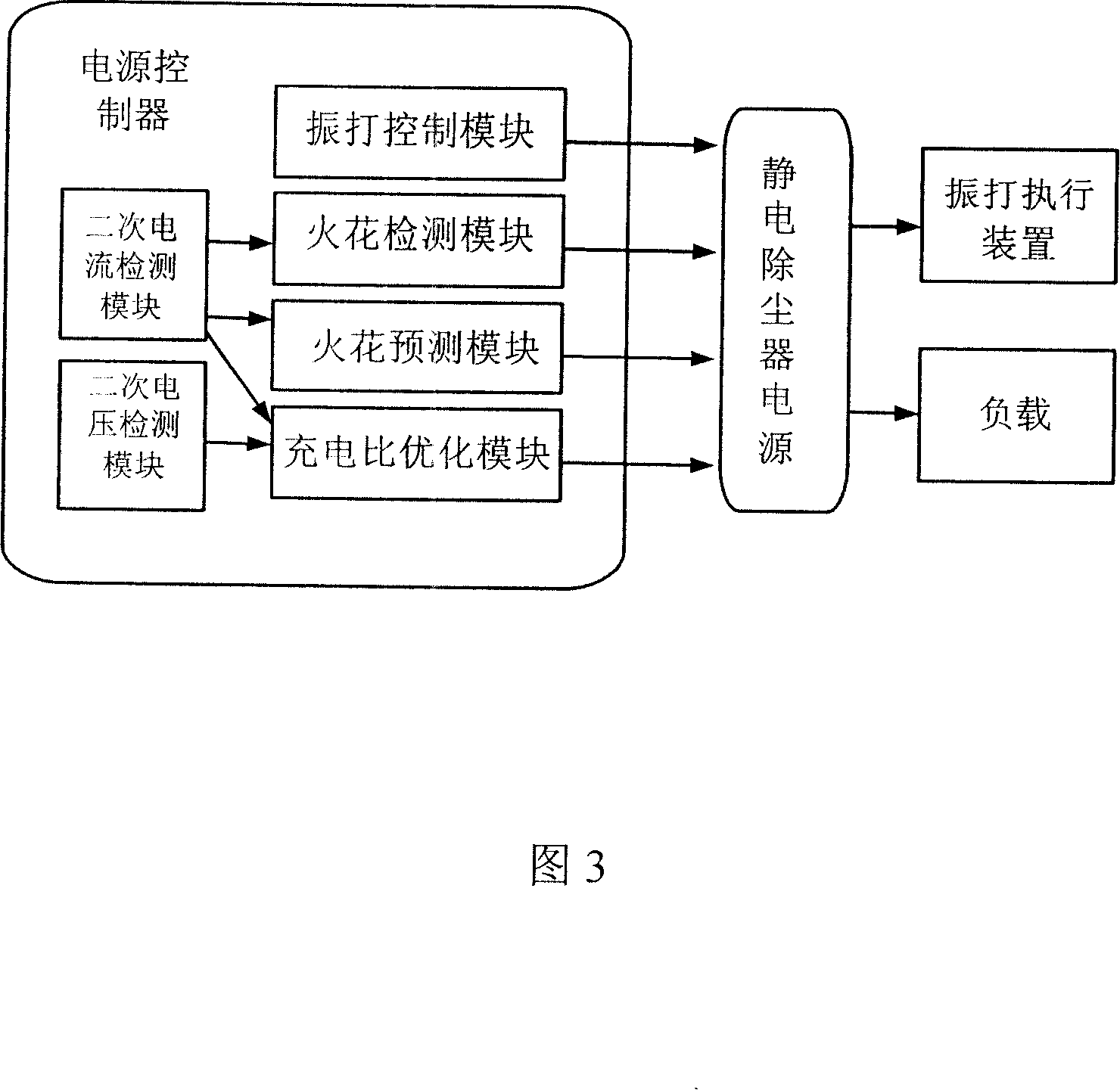

The invention provides a power controller of static dust collector and a remote control system for the controller. The controller comprises a rapping control module, a spark detecting module, a spark forecasting module and a charging ratio optimization module. The rapping control module is connected with the power of the static dust collector and a rapping executing device on a dust collecting plate in correct order to generate rapping period and rapping sustaining time required by various rapping modes as well as required constant voltage under various rapping modes; the spark forecasting module carries on second derivative analysis of second current waveform and determines generation of spark in advance; the spark detecting module carries on spectrum analysis of second current with sampling rate of 64 points to decide generation of small spark; the charging ration optimizing module calculates quality factor of a dust removing polar plate according to charging ratio, second current on one side of a load and second voltage and then charging ratio required by the power of the static dust collector is realized with hereditary screening method. In addition, the invention also realizes remote control on the power controller of the in-site static dust collector.

Owner:高峻峰

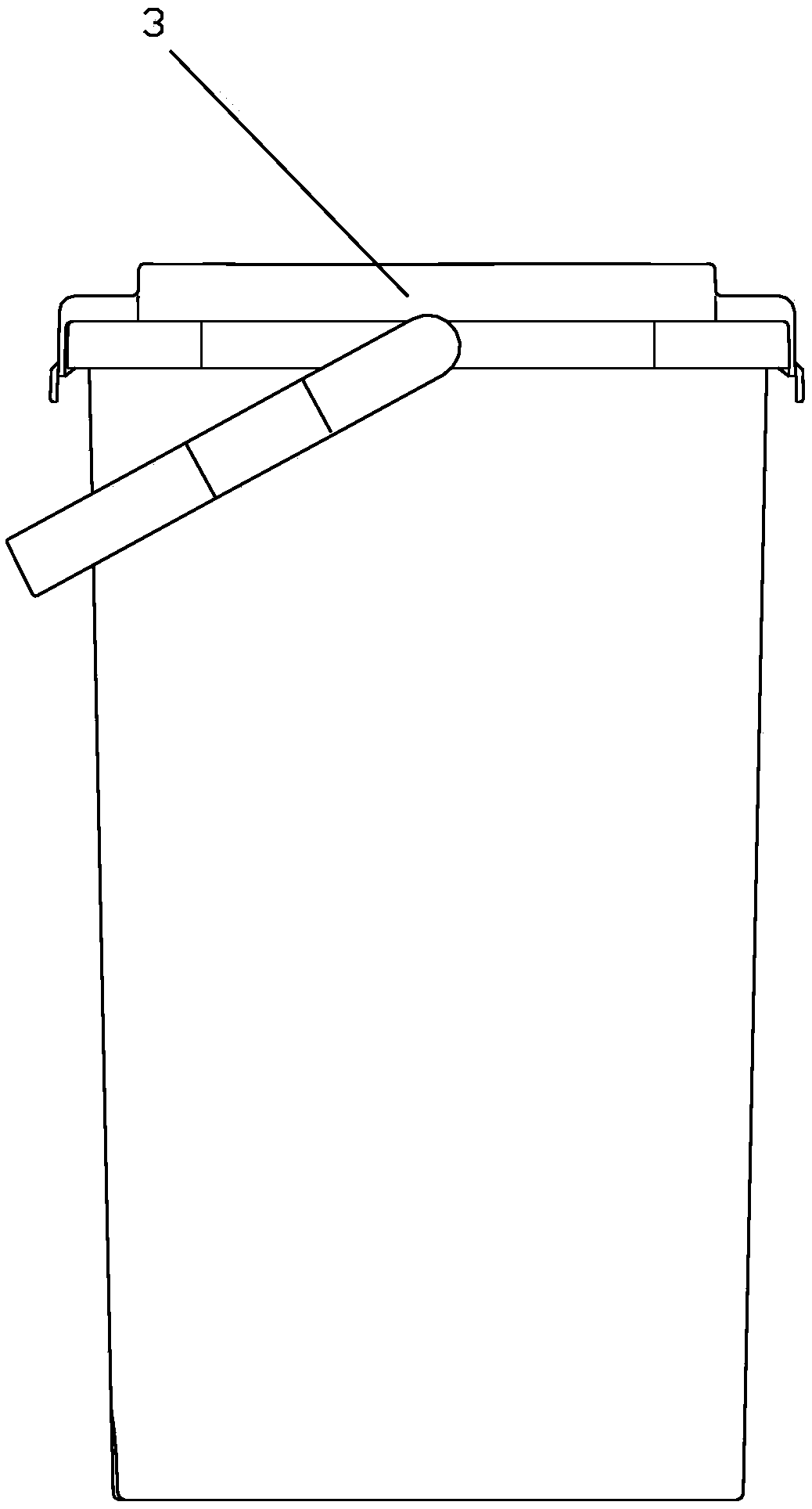

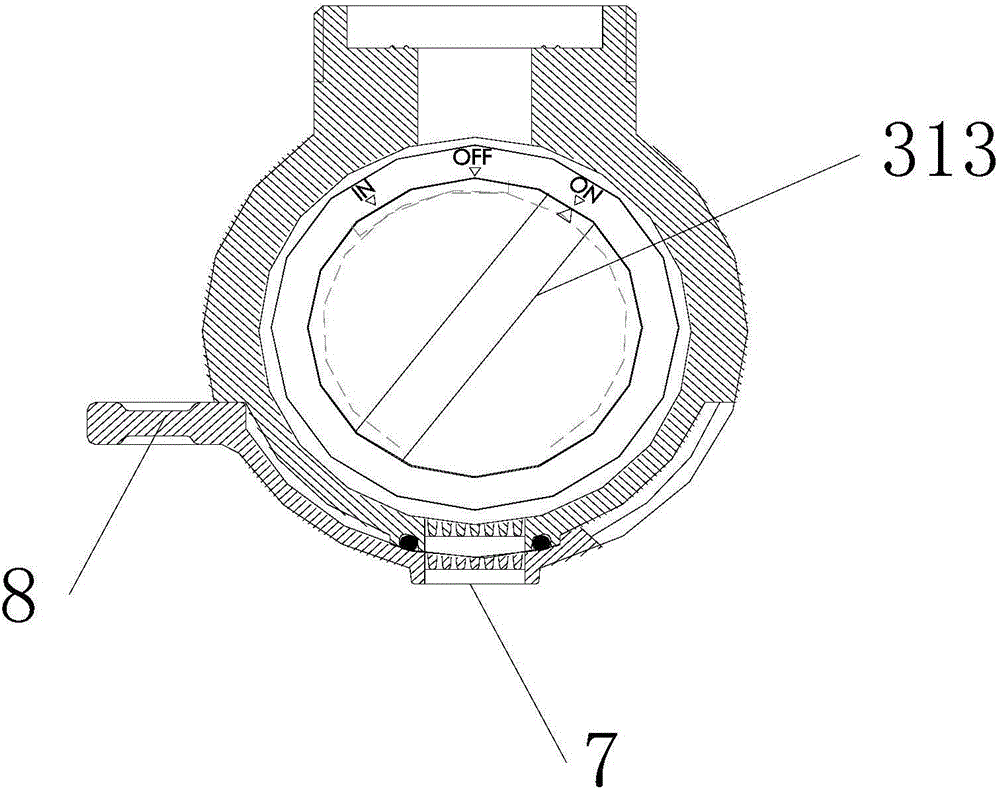

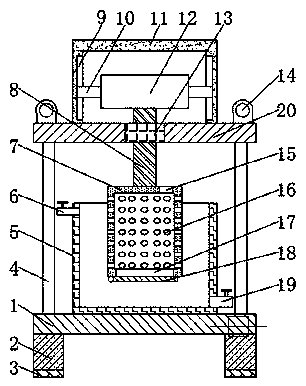

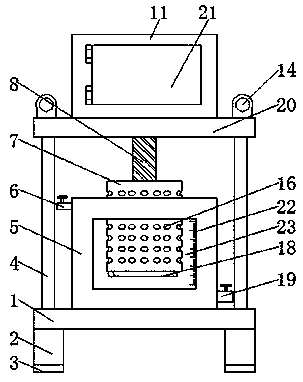

Collodion mop squeezing bucket

PendingCN109222803AEasy to carryTime-saving and labor-saving efficiencyCarpet cleanersFloor cleanersTorsion springEngineering

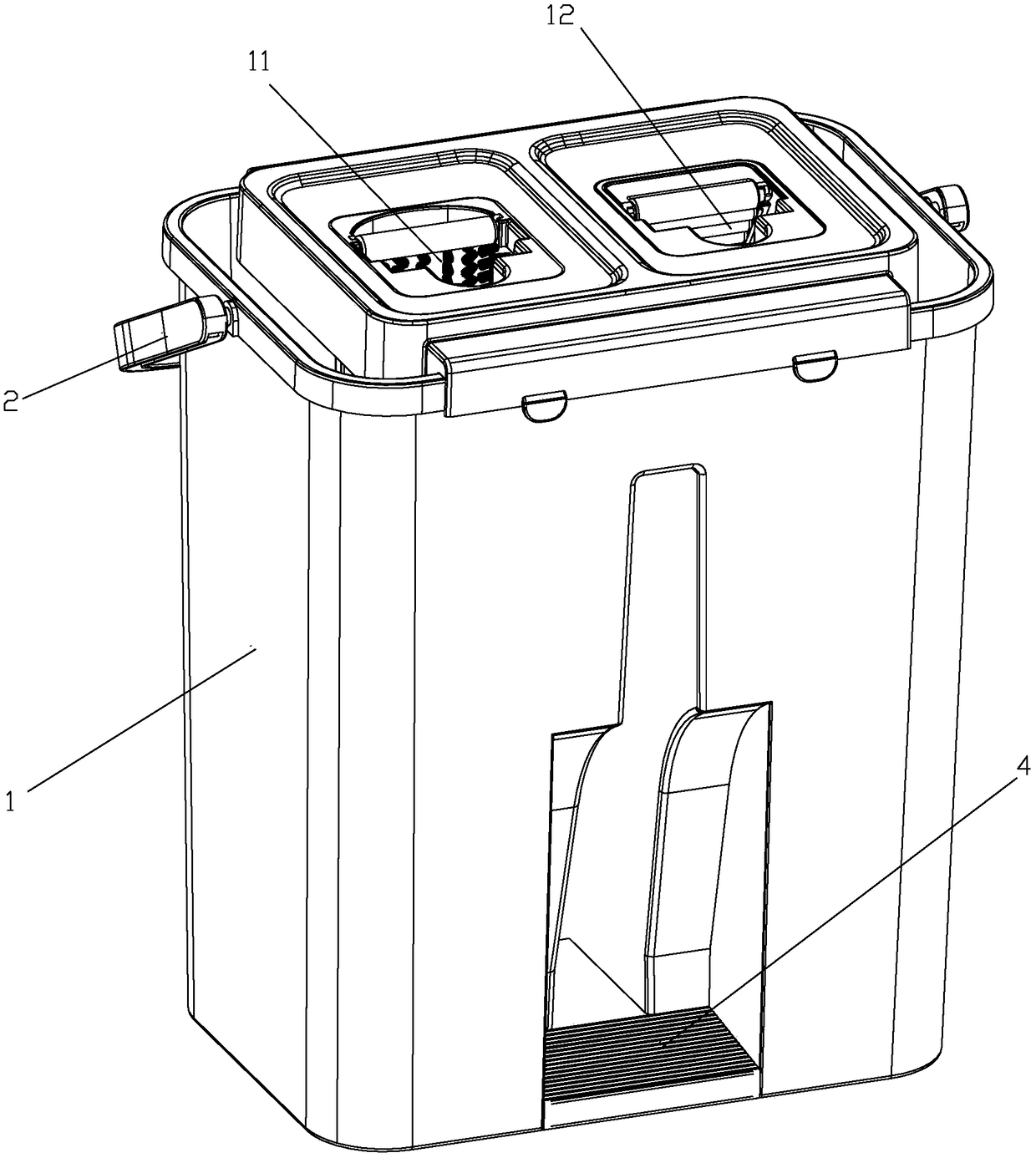

The invention belongs to the technical field of collodion mop cleaning bucket, and specifically provides a collodion mop squeezing bucket. By dividing the cleaning bucket into a cleaning portion and asqueezing portion which are independent, fresh water is contained in the cleaning department, extend the mop into the cleaning section and move it up and down, The mop is repeatedly contacted with clean water to achieve the purpose of cleaning, and then the mop is inserted into the extruded trunk and moved up and down, and the mop is extruded between the mop and the drum of the telescopic water-squeezing roller assembly of the extruded trunk port to achieve the purpose of drying, wherein the telescopic water-squeezing roller assembly can be rotated into the barrel and reset by a torsion spring. The rubber cotton mop is convenient to carry, can be washed and squeezed anytime and anywhere, and has high time-saving and labor-saving efficiency, in particular, can easily clean the hair dirt onthe bottom of the mop.

Owner:HUBEI LEARJA DAILY ARTICLE MFG

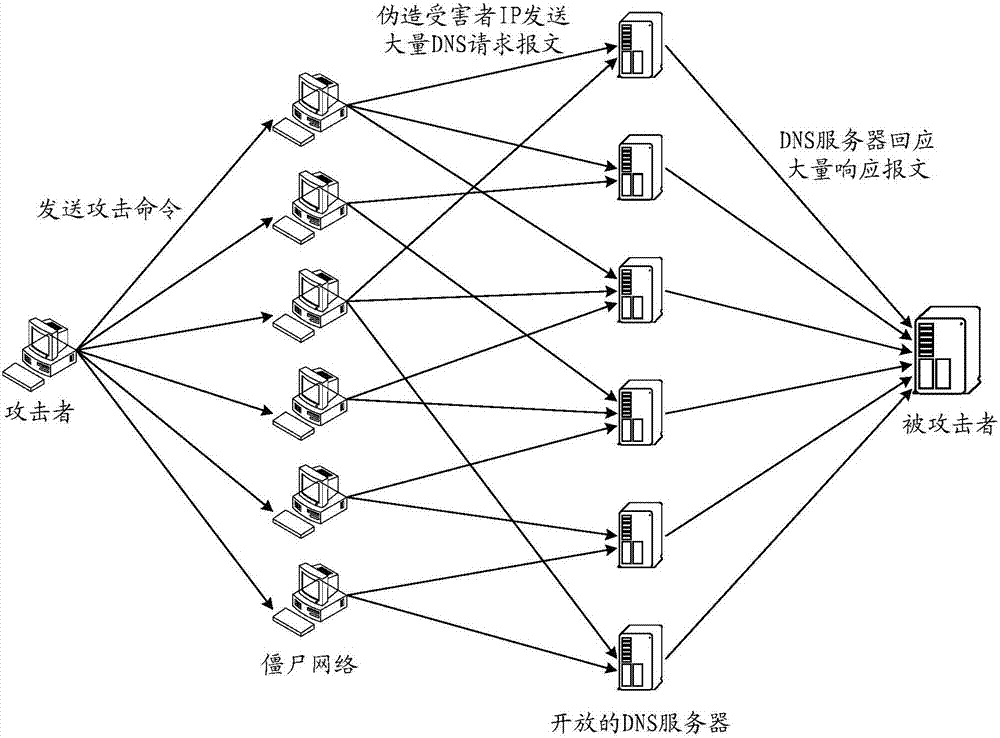

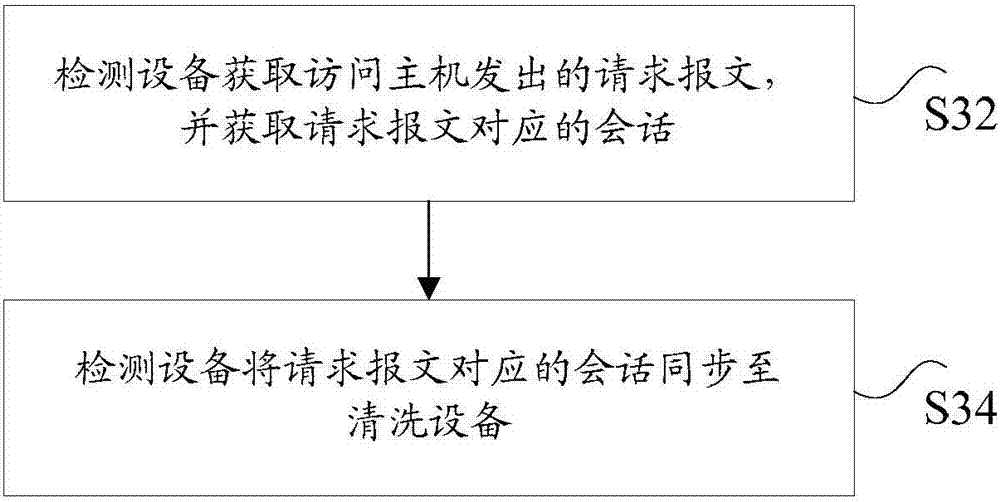

Reflection attack defending method, device and system

ActiveCN107241301ATo achieve the effect of defense reflection attackSolve leaking packetsTransmissionReflection attackCurrent technology

The invention discloses a reflection attack defending method, device and system. The method comprises the steps of receiving a response message; searching, according to the response message, whether a session matched with the response message exists; and determining, based on a searching result, whether the response message is an attack message. In the prior art, when deployment is carried out at a bypath of a cleaning device, the existing reflection attack defending method has the defects of package leakage and killing mistakes. Through adoption of the reflection attack defending method, device and system, the technical problems in the prior art are solved.

Owner:ALIBABA GRP HLDG LTD

Cleaning agent for removing pesticides and microorganisms from surfaces of fruits and vegetables

InactiveCN101979490AImprove cleanlinessGood dispersionSurface-active non-soap compounds and soap mixture detergentsOrganic acidPathogenic microorganism

The invention relates to a cleaning agent for removing pesticides and microorganisms from the surfaces of fruits and vegetables, which consists of organic acids, a surfactant, natural plant extracts, a synergist and water, wherein the organic acids at least contain one or more of a levulinic acid, a citric acid, a lactic acid and a malic acid. The cleaning agent is used for cleaning the fruits, the vegetables or other agricultural products before processing or eating, can remarkably remove the pesticides and kill the pathogenic microorganisms, has the advantages of environmental protection, high efficiency and the like, and is simple and convenient to use. When in use, the cleaning agent is diluted by 100 to 500 times and then the fruits and the vegetables are impregnated for 1 to 5 minutes.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN +1

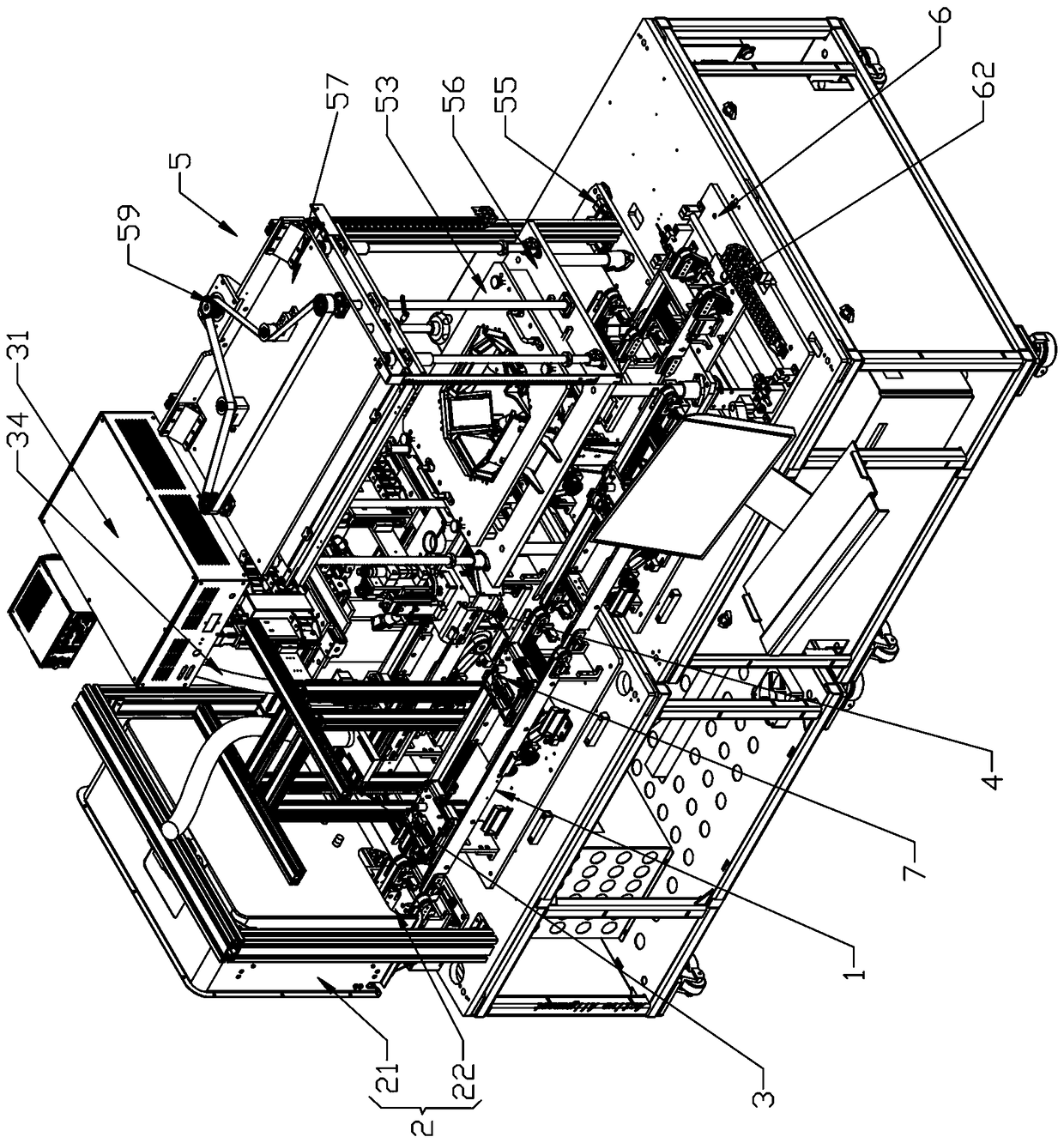

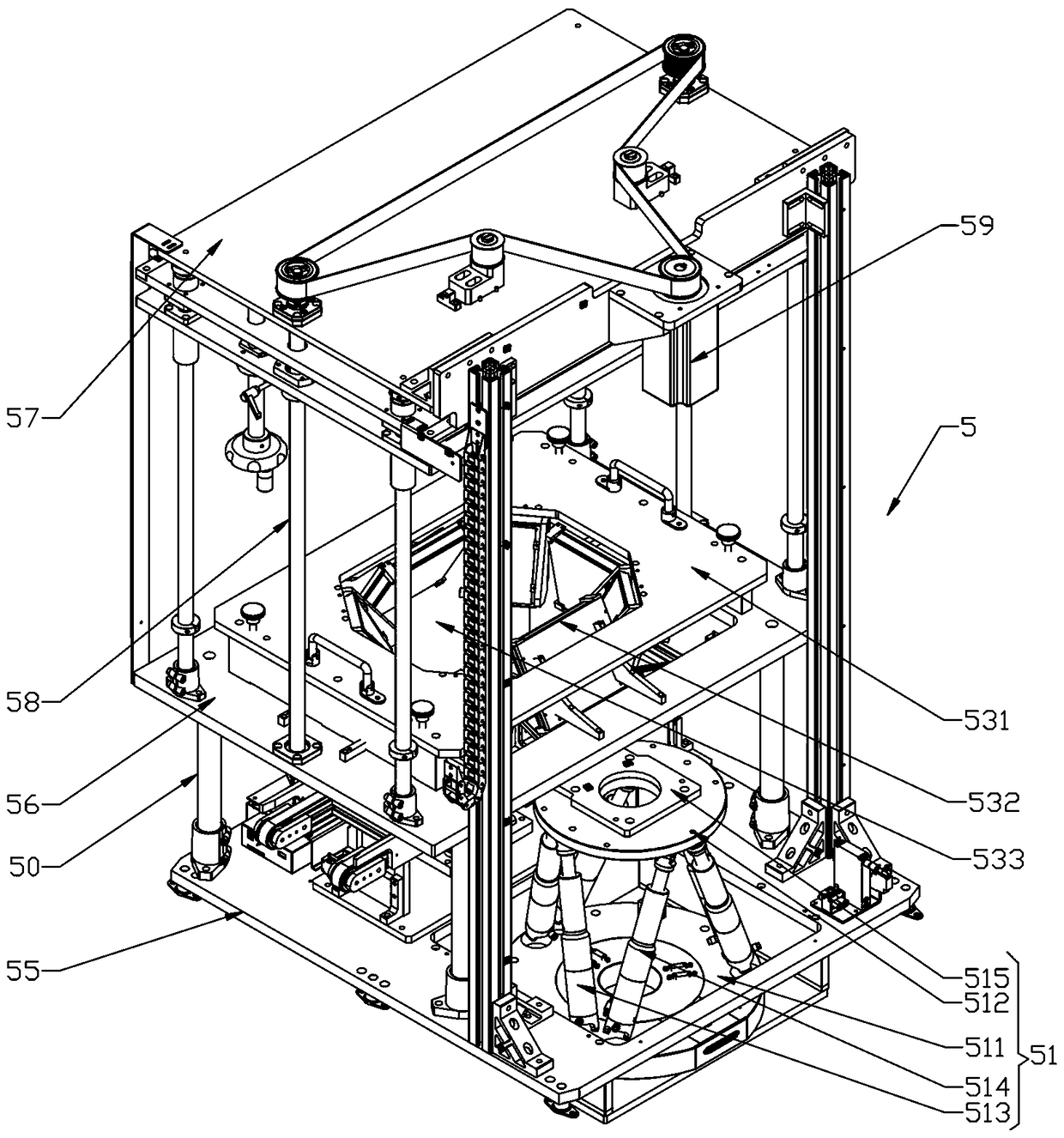

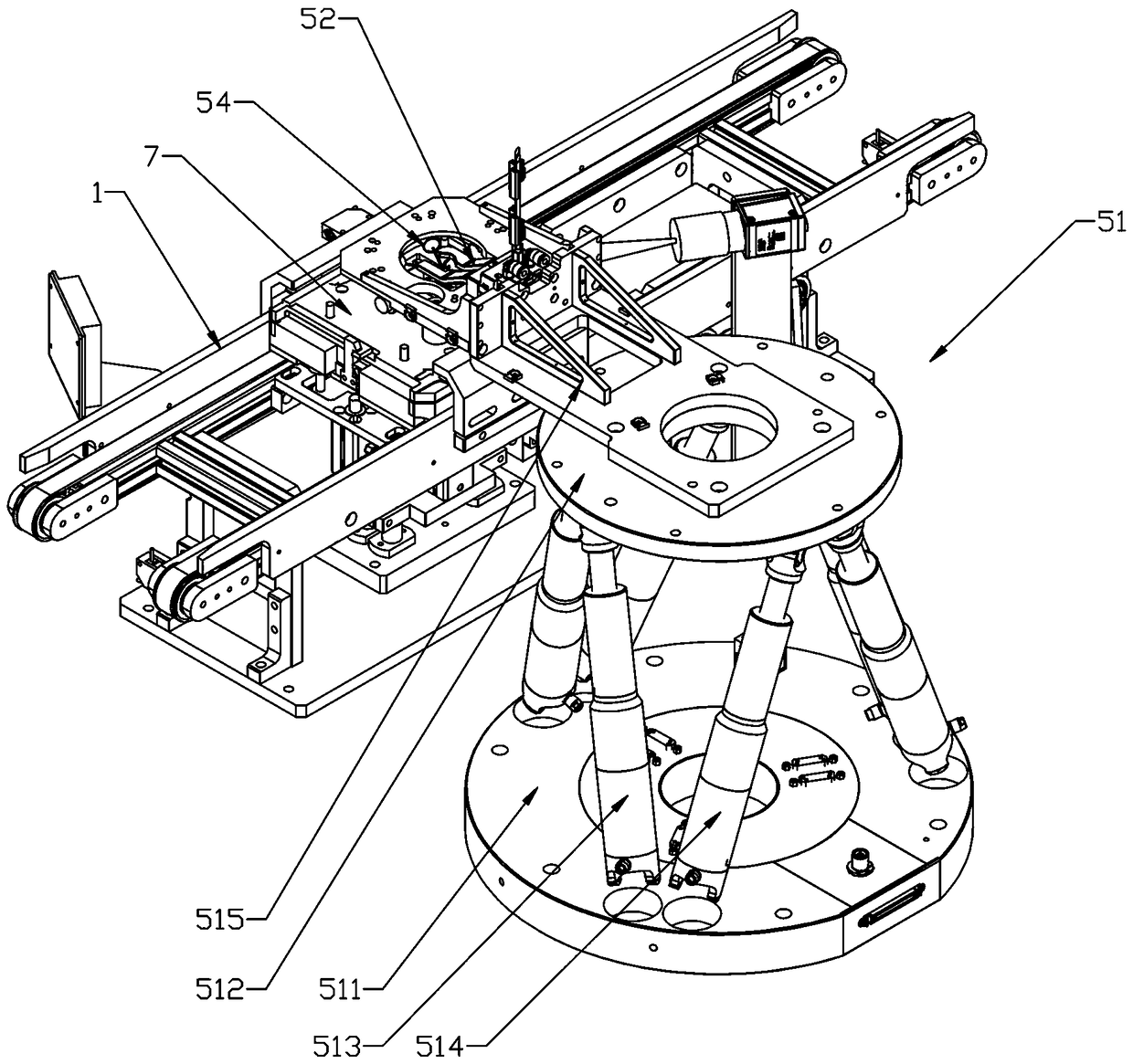

Return line type self-calibration camera assembly equipment

PendingCN108296751ASimple structureMeet the requirements of precise adjustmentPretreated surfacesCoatingsProduction lineEngineering

The invention discloses and provides return line type self-calibration camera assembly equipment which is simple in structure, can achieve modularization and has the stable, efficient and precise camera calibrating function. The return line type self-calibration camera assembly equipment comprises a belt production line, and a loading module, a plasma cleaning module, a glue dispensing module, a camera automatic calibrating module and an unloading return module which are arranged beside the belt production line in sequence; a carrier is arranged on the belt production line; the camera automatic calibrating module comprises a six-axle platform manipulator; a jaw of the six-jaw platform manipulator is positioned above the carrier; a turn-back mirror module is arranged above the jaw; the turn-back mirror module comprises a turn-back mirror fixed plate and multiple turn-back mirrors; a through groove is formed in the middle part of the turn-back mirror fixed plate; and the multiple turn-back mirrors are uniformly arranged at the lower part of the side wall of the through groove. The return line type self-calibration camera assembly equipment can be applied to the technical field of thecamera assembly industry.

Owner:ZHUHAI HUAYA MACHINERY TECH CO LTD

Mineral salt-based detergent special for fruits and vegetables

InactiveCN106281787AImprove securityEliminate concerns about secondary pollutionOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsAdditive ingredientPesticide residue

The invention relates to a detergent special for fruits and vegetables, made from an oxidant, an alkaline aid, a solubilizing aid and other aids, with the solubilizing aid acting as a main ingredient, wherein the content range of the oxidant is 5-90%, the content range of the alkaline aid is 5-50%, and the content range of the solubilizing aid is 5-40%; the alkaline aid and the solubilizing aid are significantly synergistic with oxidative ingredients, and deterging efficiency can be significantly improved; the content of the other aids is 0-30%, including a softener, an oxidation activator, a phase-transfer catalyst and the like; the detergent may come in powder, flake or particle, and can be diluted with water to 100-2000 times and to soak fruits and vegetables to effectively remove pesticide residue and harmful bacteria attaching to the surface; a multiple cleaning mechanism is used herein, cleaning effect can be effectively improved, and a wider pesticide range may be targeted; the detergent is environment-friendly and safe, is free of residue or secondary pollution, is free of phosphorus, and meets the demand of families and restaurants for cleaning fruits and vegetables.

Owner:彭晨

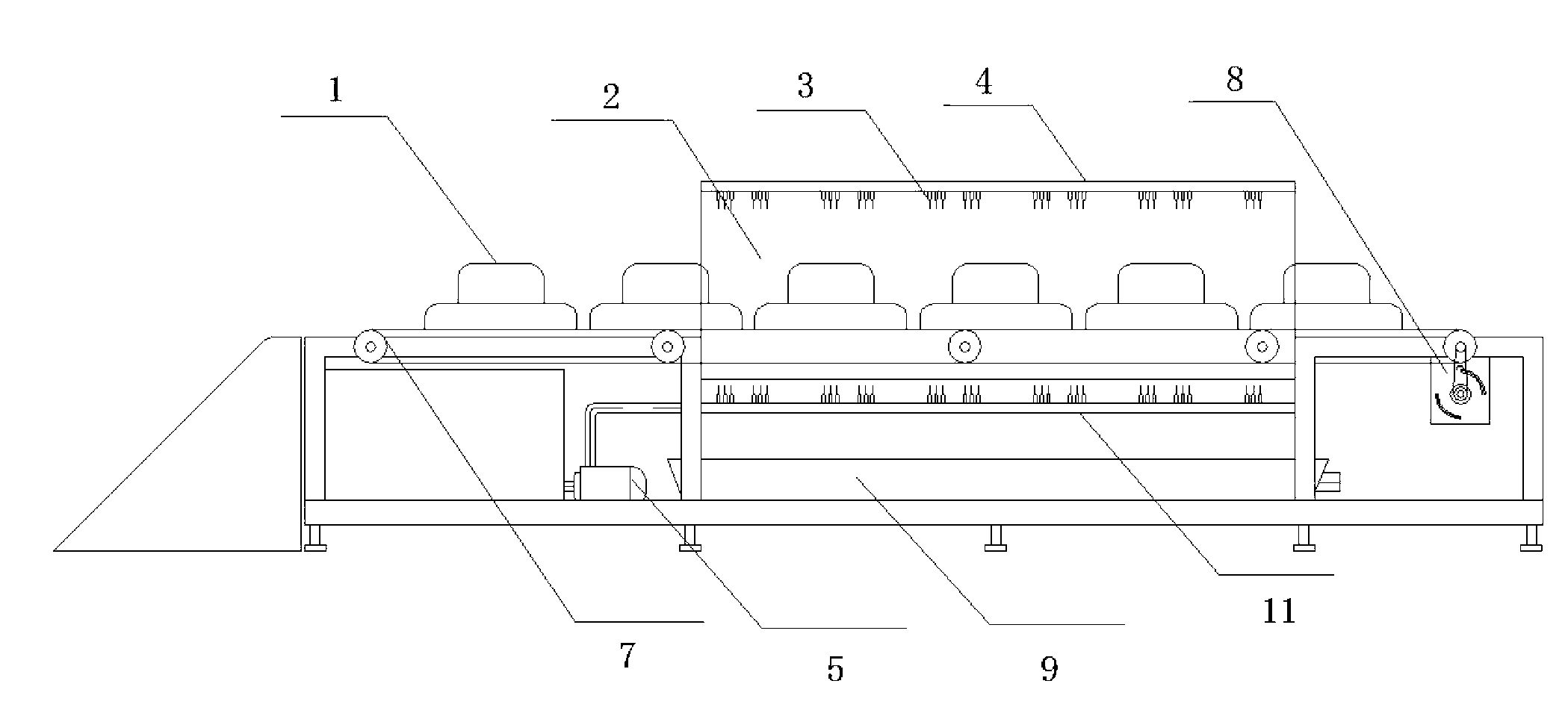

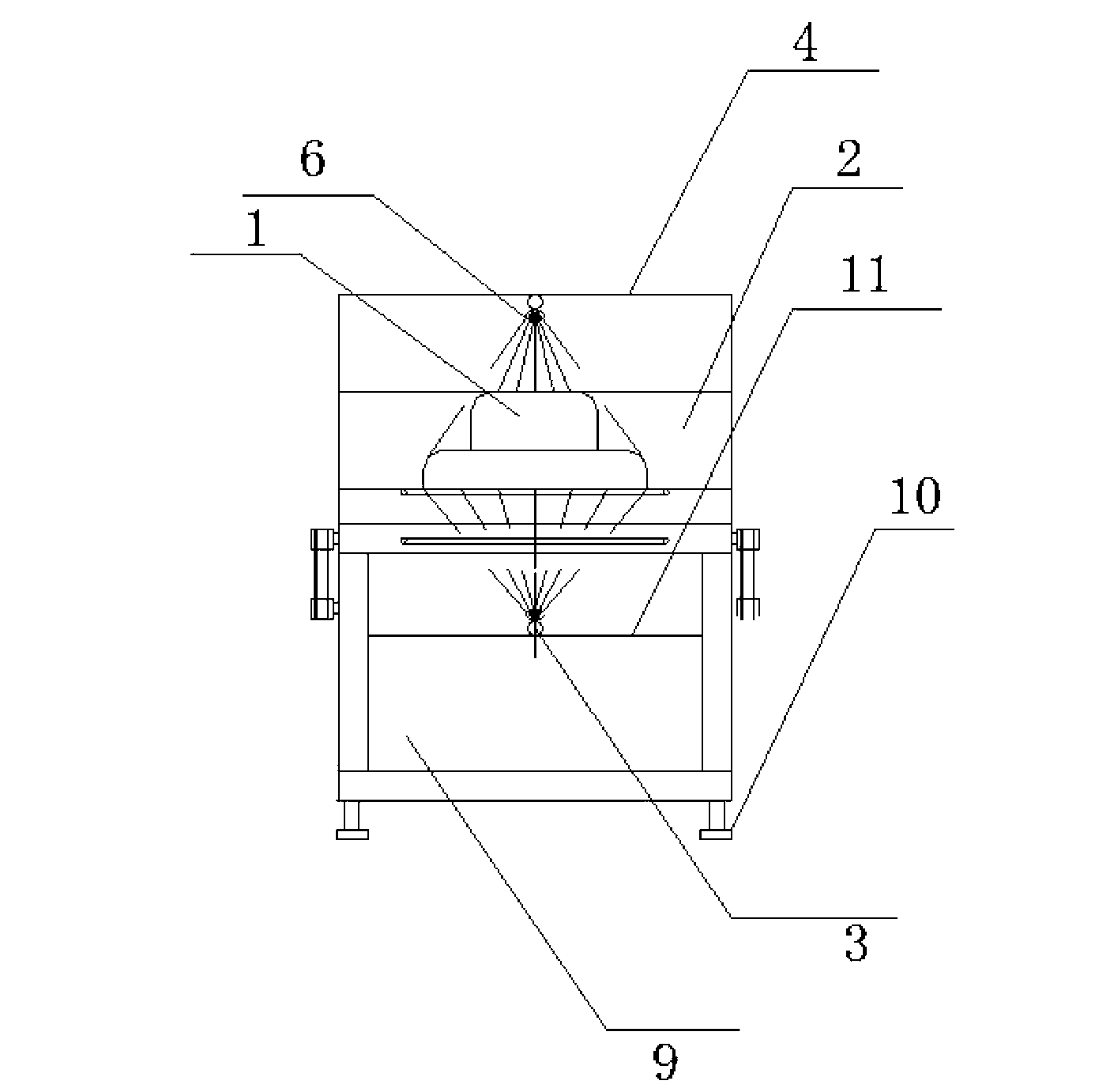

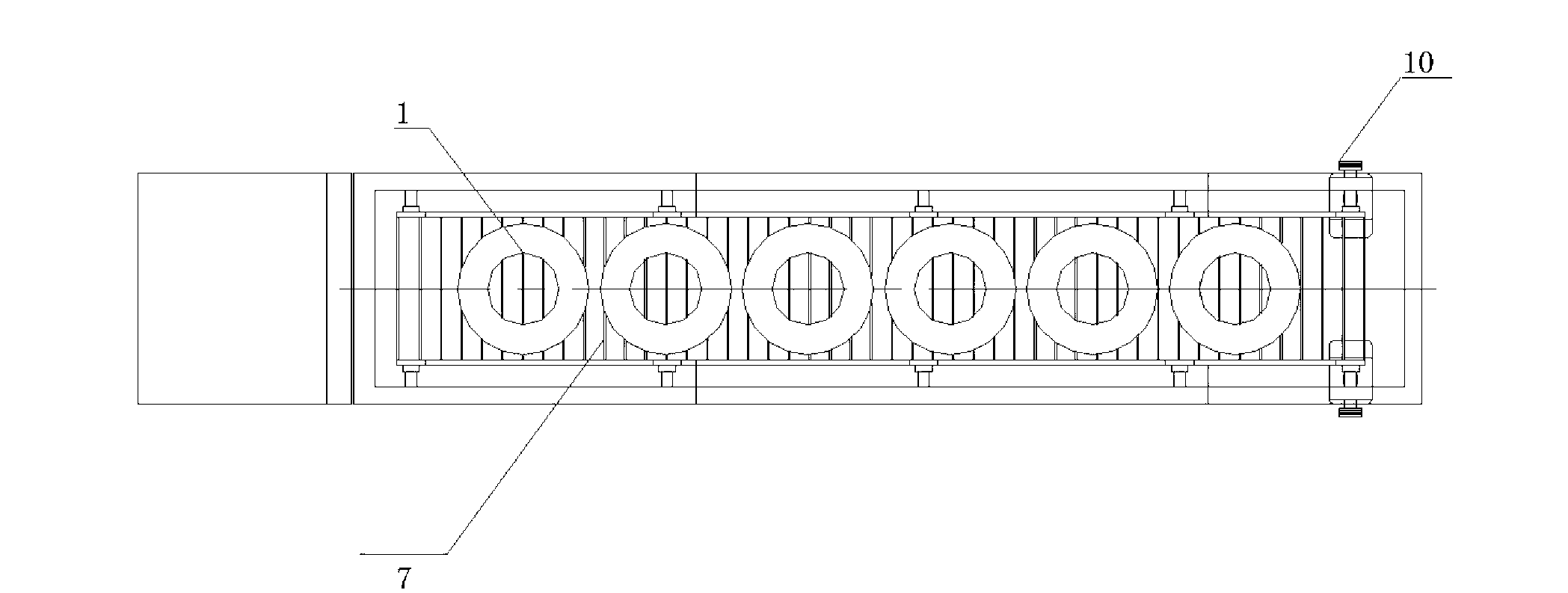

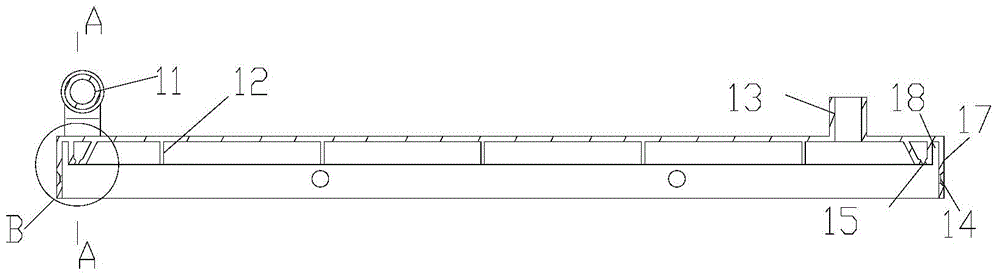

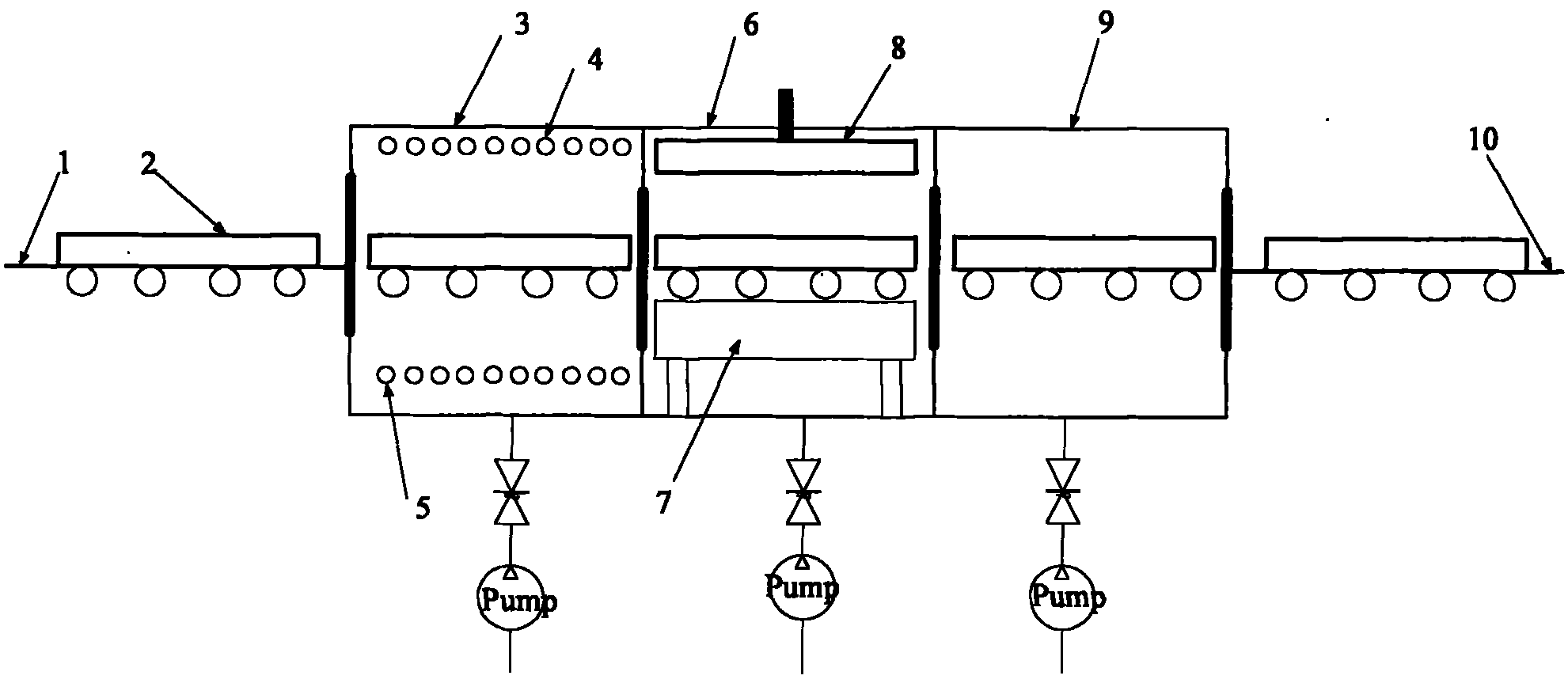

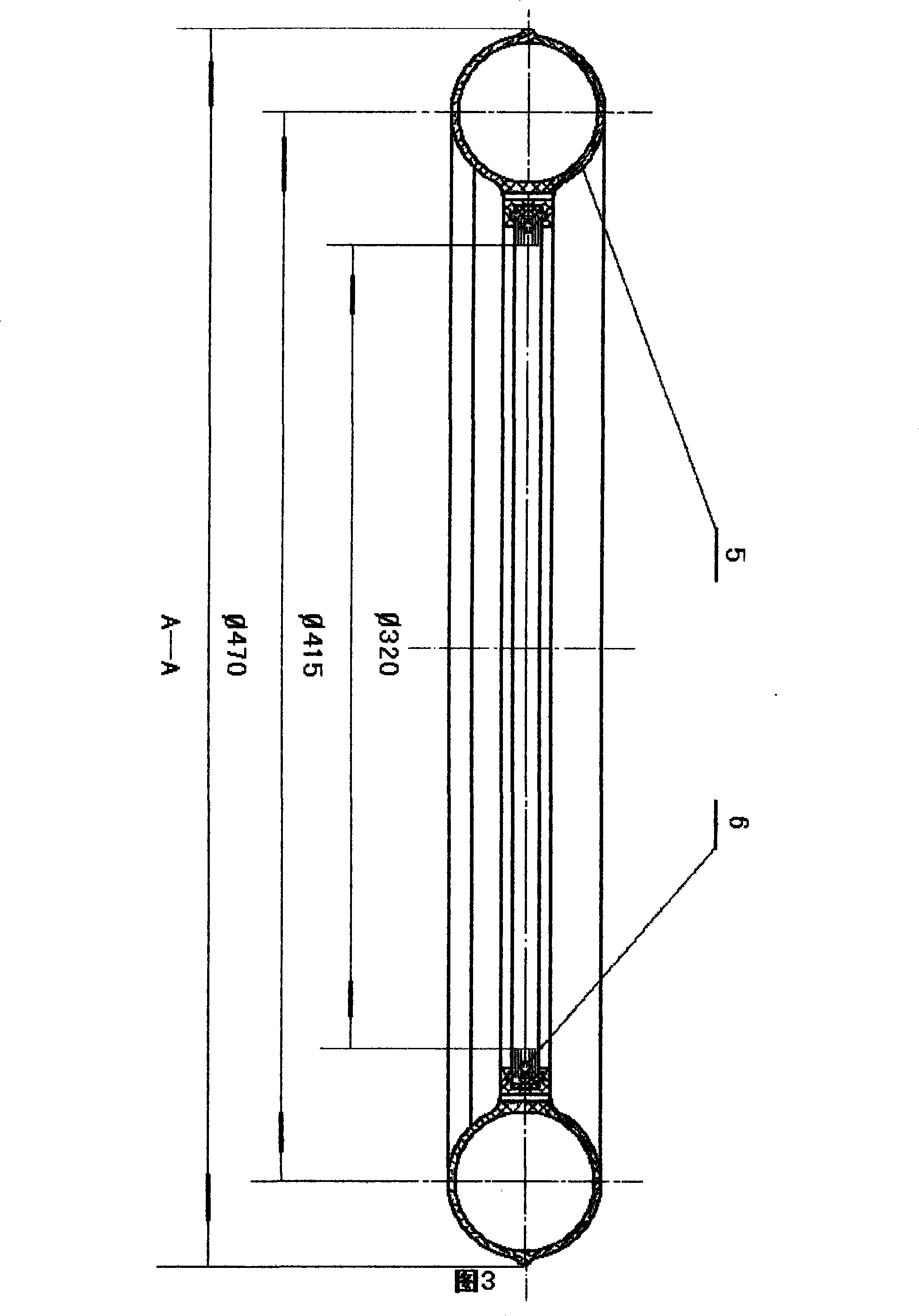

Automatic cleaning device of insulator for artificial contamination test

ActiveCN103056132ATo achieve the purpose of cleaningTime-consuming and labor-intensive solutionCleaning using toolsCleaning using liquidsTest efficiencyDual action

The invention provides an automatic cleaning device of an insulator for an artificial contamination test. The automatic cleaning device of the insulator for the artificial contamination test comprises a conveying mechanism, a water draining mechanism and a moving mechanism, wherein the bilateral sides of the conveying mechanism are provided with cleaning mechanisms and the water draining mechanism and the moving mechanism are arranged under the cleaning mechanisms. Under the dual function of the washing of high pressure water and long row brushes, the purpose of cleaning contaminants on the surface of the insulator is achieved through a conveying belt. Compared with the traditional method of cleaning the insulator manually, the automatic cleaning device of the insulator for the artificial contamination test has the advantages of having the function of automatically cleaning the insulator, being good in cleaning effect and high in efficiency; saving both time and labor; and greatly improving the test efficiency.

Owner:CHINA ELECTRIC POWER RES INST +1

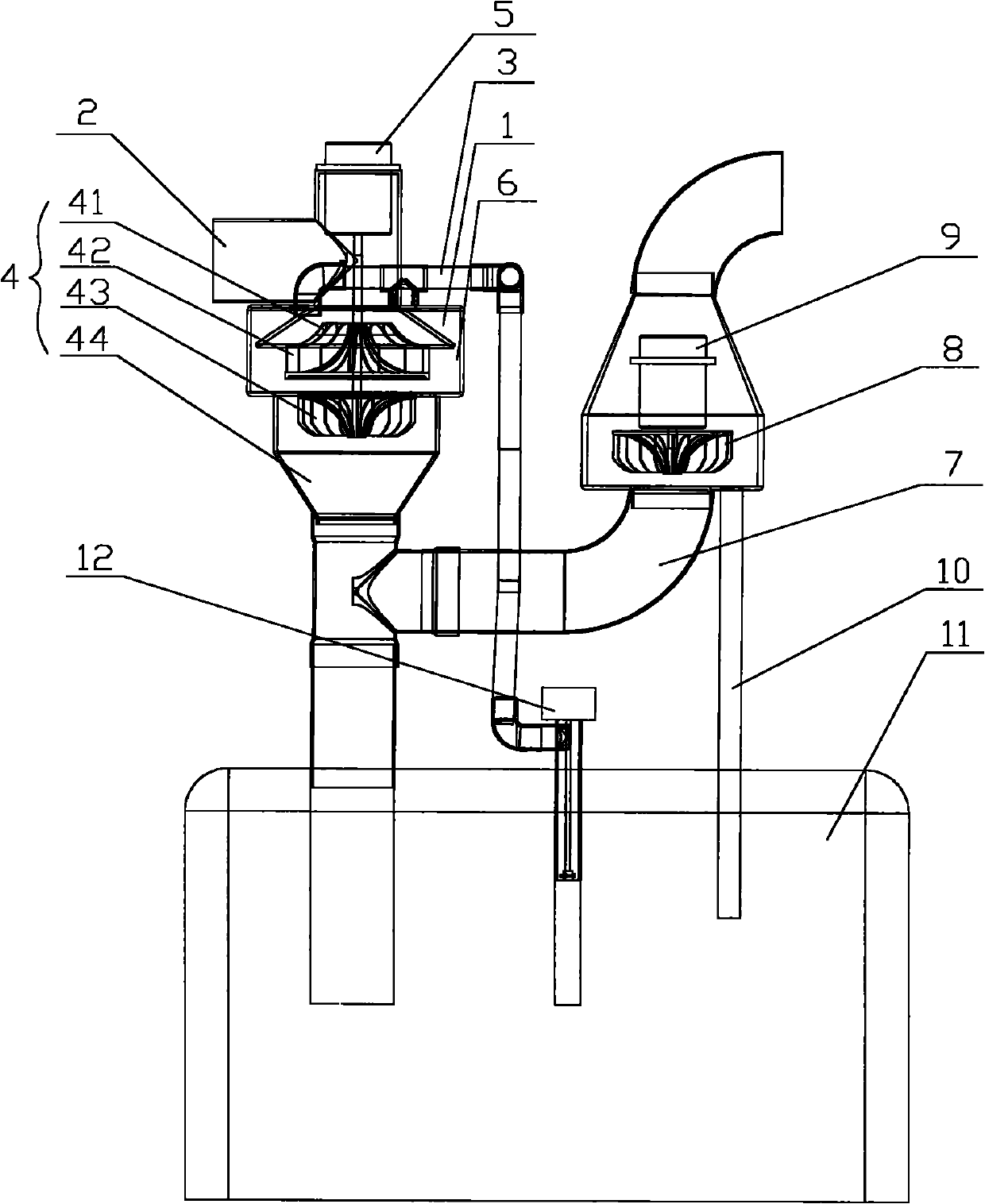

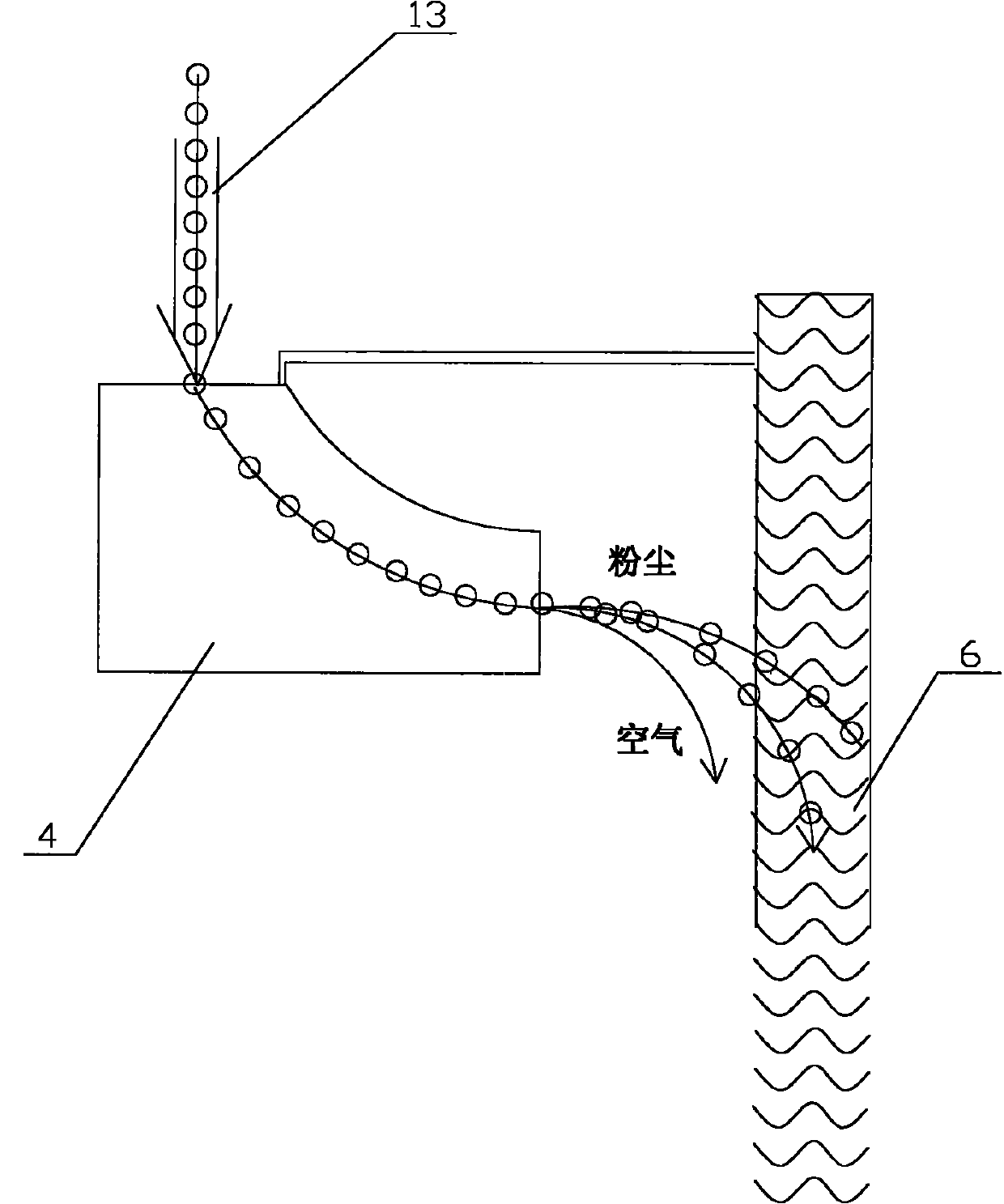

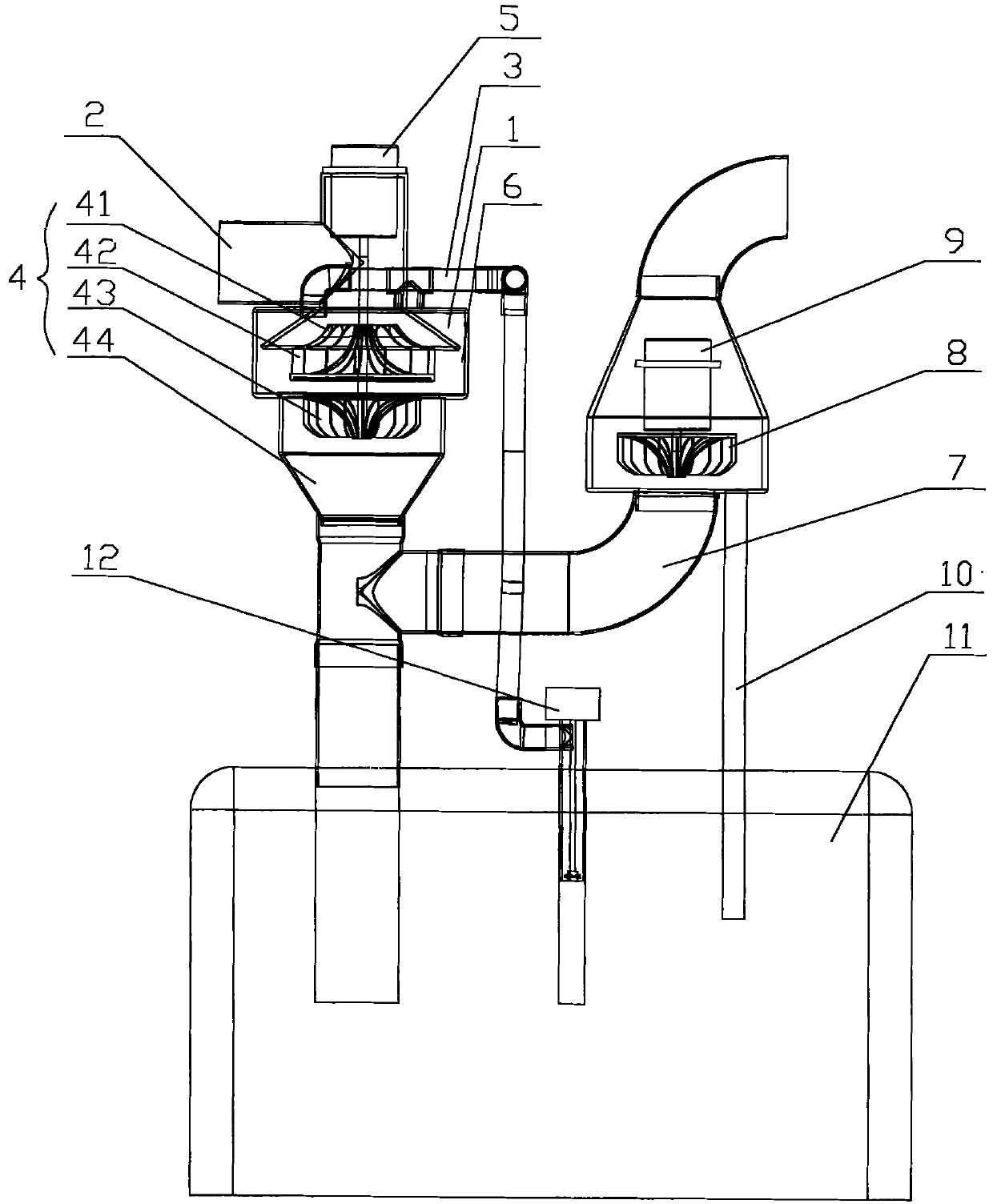

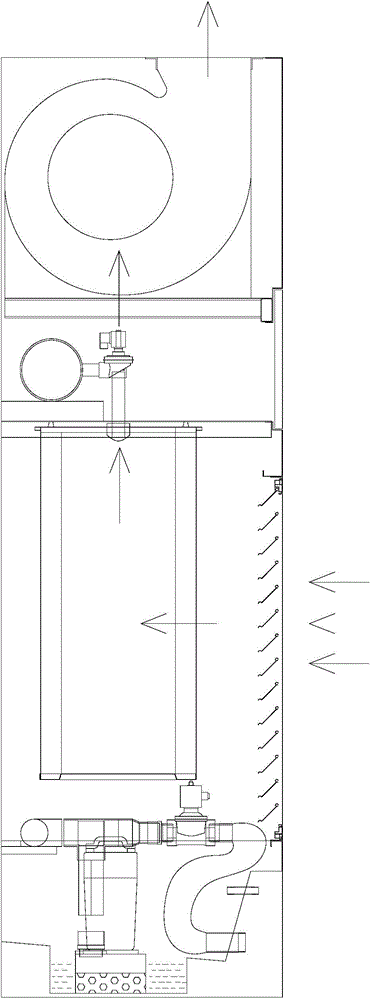

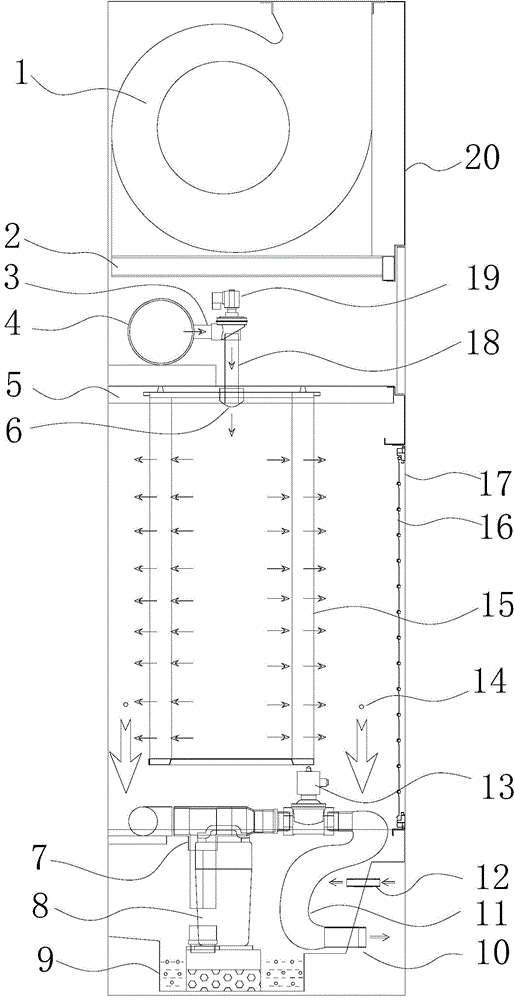

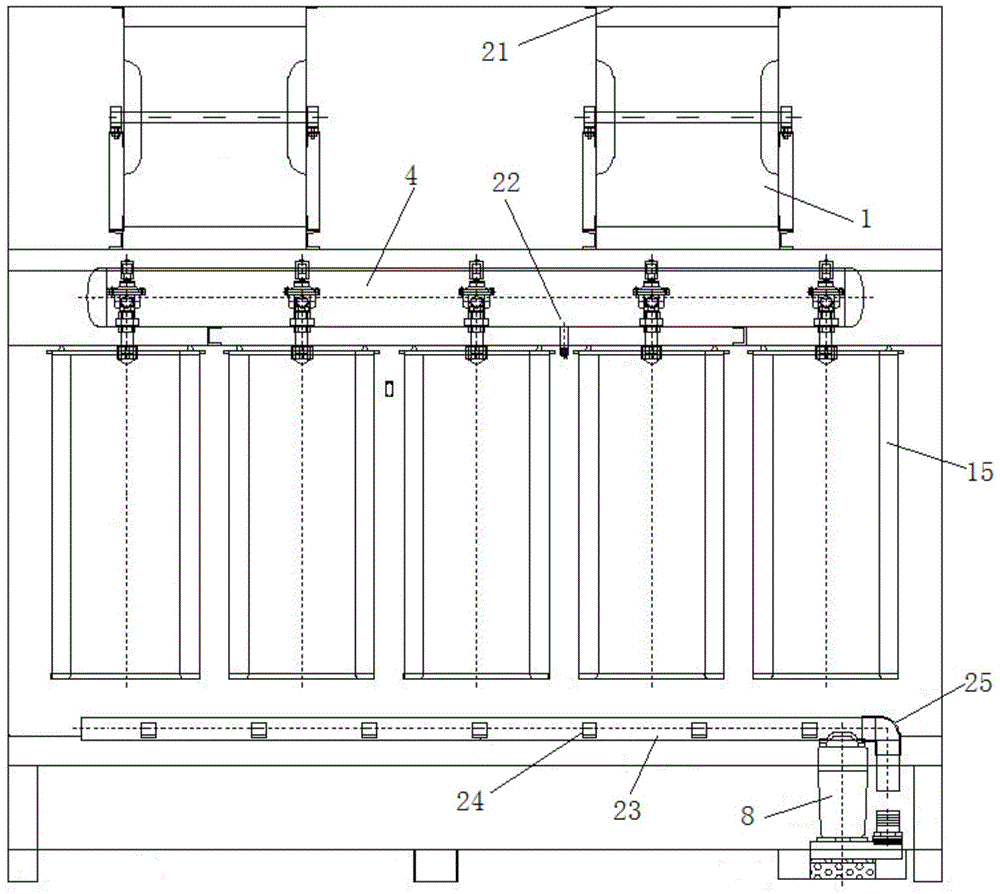

Cyclone water bath air cleaning device and cleaning method thereof

ActiveCN102000469AIncrease the diameterEasy to adjustUsing liquid separation agentWater bathsHigh concentration

The invention relates to the field of air purification, in particular to a cyclone water bath air cleaning device and a cleaning method thereof. The air with dust enters a centrifugal device through an air inlet pipe; extraneous water or circulating water forms a water curtain wall supported by the inner wall of the cavity of the device and coaxial with the centrifugal device under the action of the centrifugal device; the solid tiny dust or the liquid substance in the air with dust is instantaneously accelerated by the centrifugal device, then cut into the water curtain wall along the centrifugal direction and caught by the water curtain wall and flows out together with the water flow of the water curtain wall; the air is forced to turn quickly; and the dust removed air is led out through an air duct. The device has the function of treating high-flow and high-concentration dust by using small space; and the function has significance for places of gallery dust removal, working environment air purification, restaurant kitchen soot removal, commercial or household air cleaning and the like.

Owner:广州市合联科技发展有限公司

Transition-liquid-phase-assisted solid-phase connection method

InactiveCN105108257ATo achieve the purpose of "cleaning"Increase temperatureSoldering apparatusSolid phasesMetallurgy

The invention discloses a transition-liquid-phase-assisted solid-phase connection method. The method includes the steps that a middle layer material for transition liquid phase diffusion welding is placed at an interface to be connected, a transient liquid phase is formed on the surface to be welded through diffusion of melting point depressant elements in the middle material, forging force is applied, a liquefied phase on the surface of the material to be welded is extruded out of a joint region, a joint interface oxidation film of the material to be welded and a machining hardening layer are cleaned, and the requirement of a solid phase diffusion welding interface is met; after the liquid phase is extruded, certain pressure is kept, diffusion is further conducted, and a solid phase connection joint is formed. The transition-liquid-phase-assisted solid-phase connection method has the advantages that the oxidation film layer on the surface of the material to be welded and the machining hardening layer can be effectively removed through the liquid phase in the joint region, and the highly-required cleaning process of the surface to be welded before solid phase connection is conducted is avoided; meanwhile, the diffusion time for solid phase connection is shortened by removing the uneven layers on the surface of the joint, and welding efficiency is improved.

Owner:NANCHANG HANGKONG UNIVERSITY

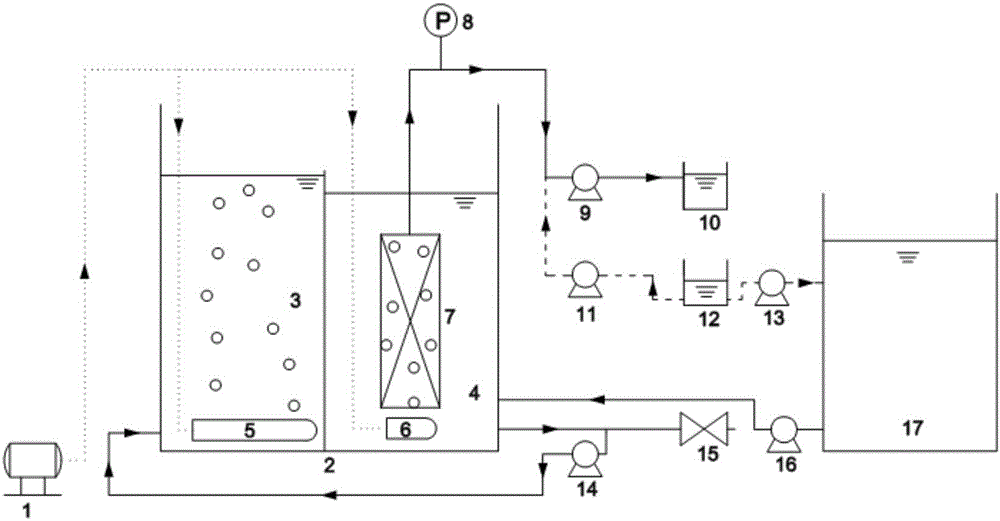

Ceramic membrane chemical cleaning system and method

InactiveCN106542631AEasy to cleanImprove oxidation efficiencySemi-permeable membranesSpecific water treatment objectivesWater treatment systemCeramic membrane

The invention relates to a ceramic membrane chemical cleaning system and method which are used for cleaning a ceramic membrane in a water treatment system. The chemical cleaning system comprises an online cleaning part, wherein the online cleaning part comprises a dosing pump and a sucking pump; the dosing pump is coupled onto the ceramic membrane arranged in a membrane pool by virtue of a pipeline, so as to inject a cleaning liquid into the ceramic membrane; the sucking pump is coupled onto the ceramic membrane by virtue of a pipeline, so as to discharge water from a back absorption membrane of the ceramic membrane; and the cleaning liquid on the ceramic membrane is discharged into the membrane pool in a sucking process. The system and method which are provided by the invention can be used for solving the problems of pollution of the ceramic membrane in a water treatment process, production of secondary pollutants by the cleaning liquid in a membrane cleaning process, secondary treatment of the membrane cleaning liquid, and the like.

Owner:深圳市康源环境纳米科技有限公司 +1

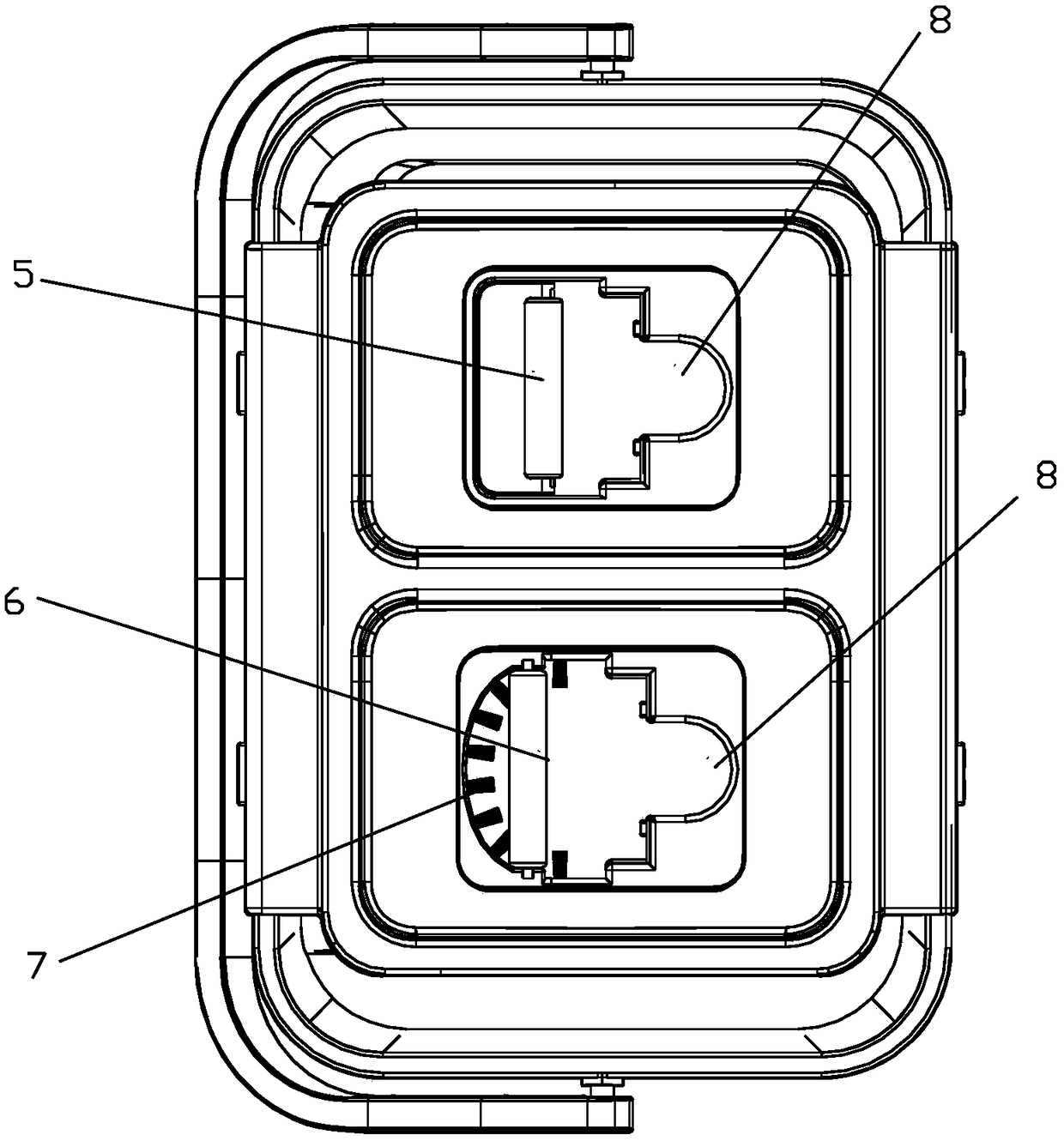

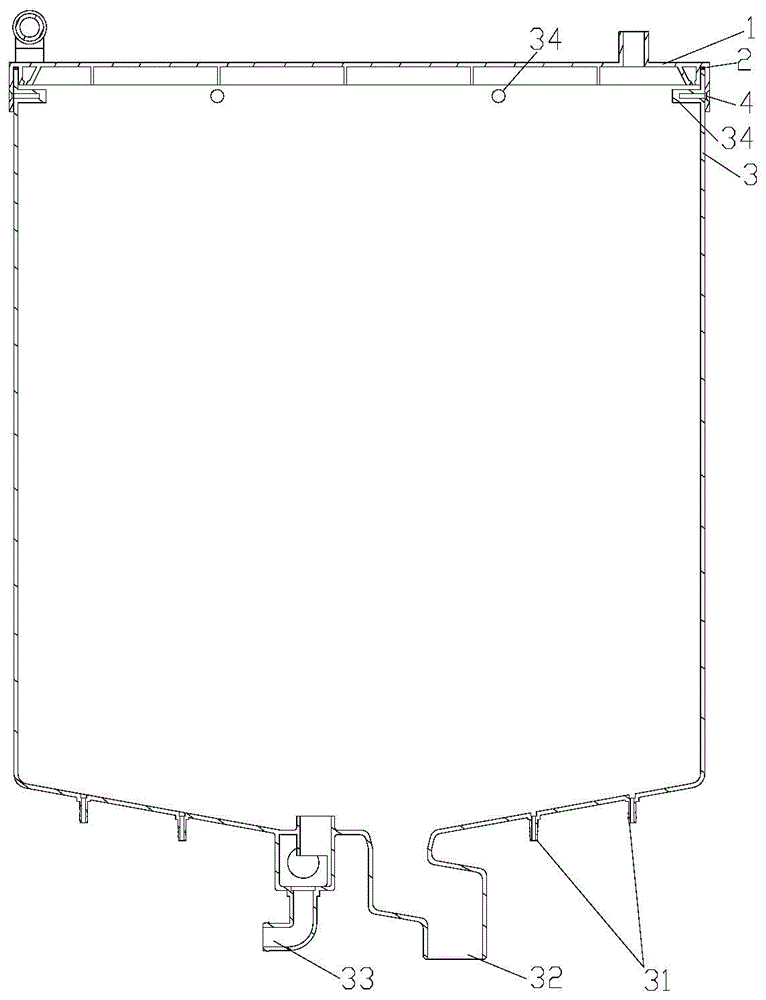

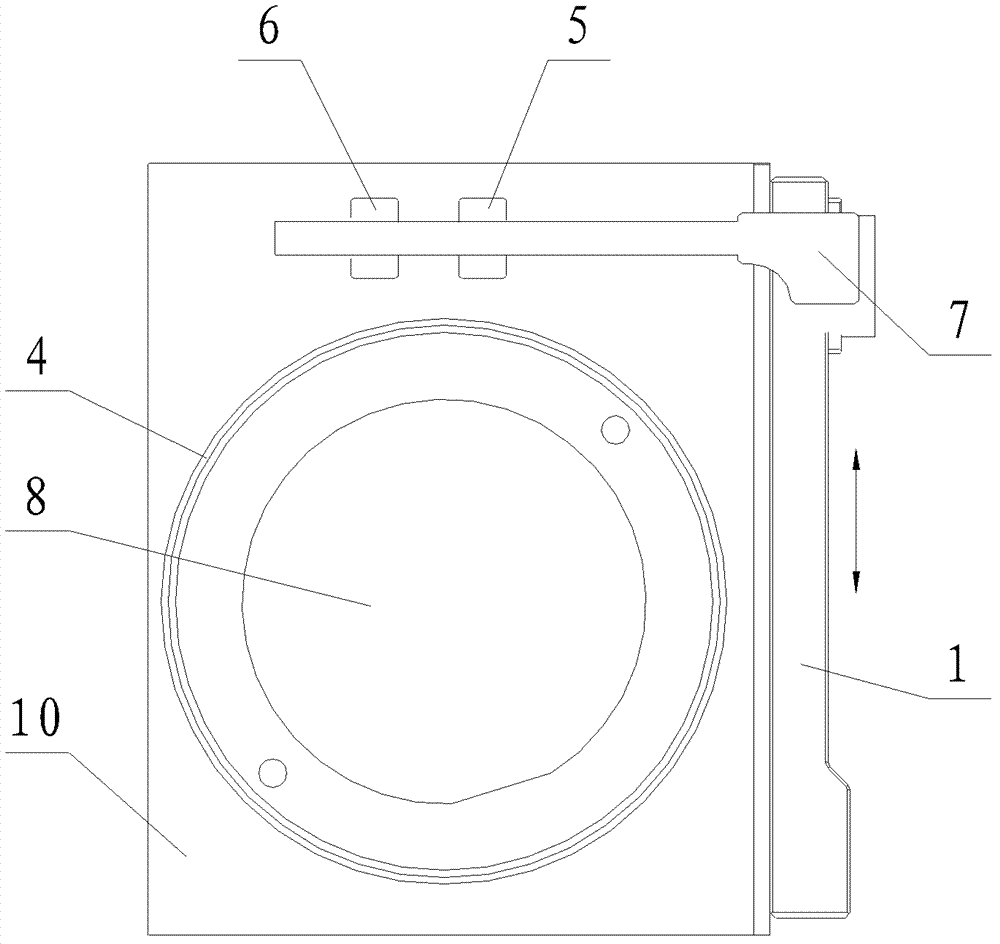

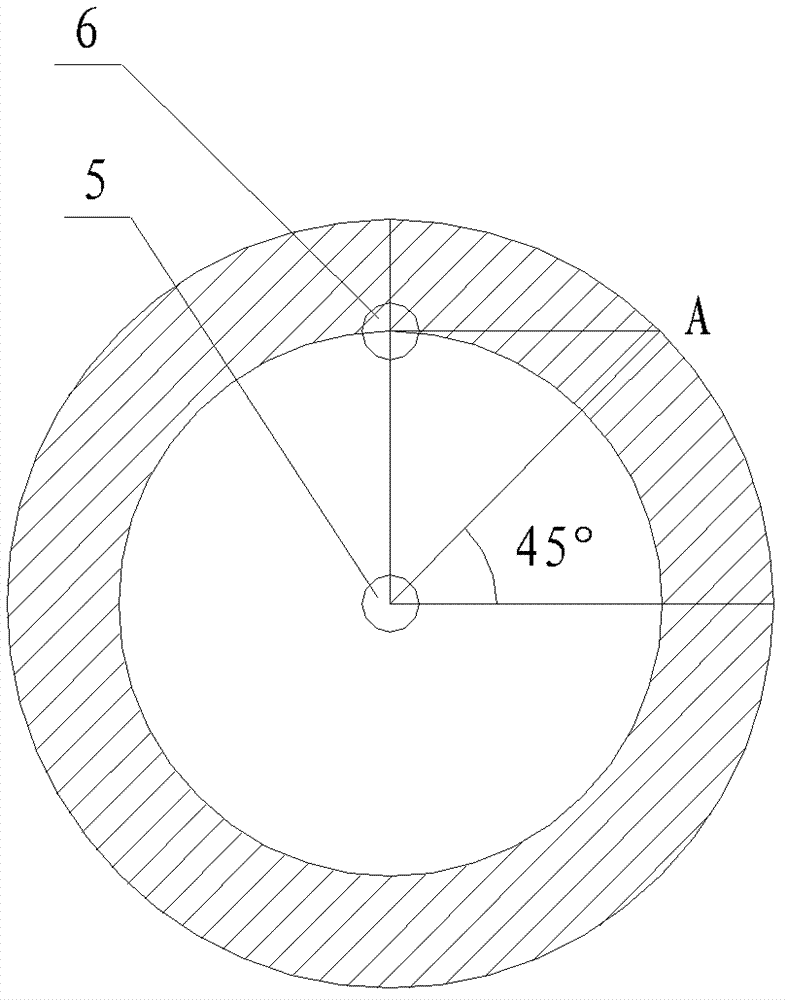

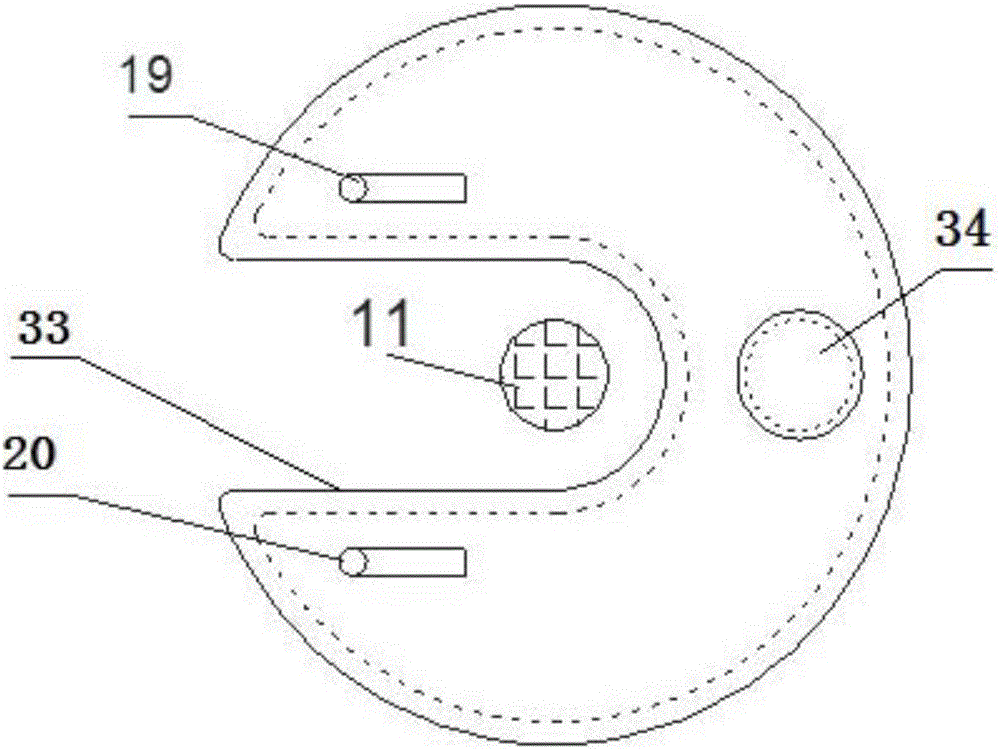

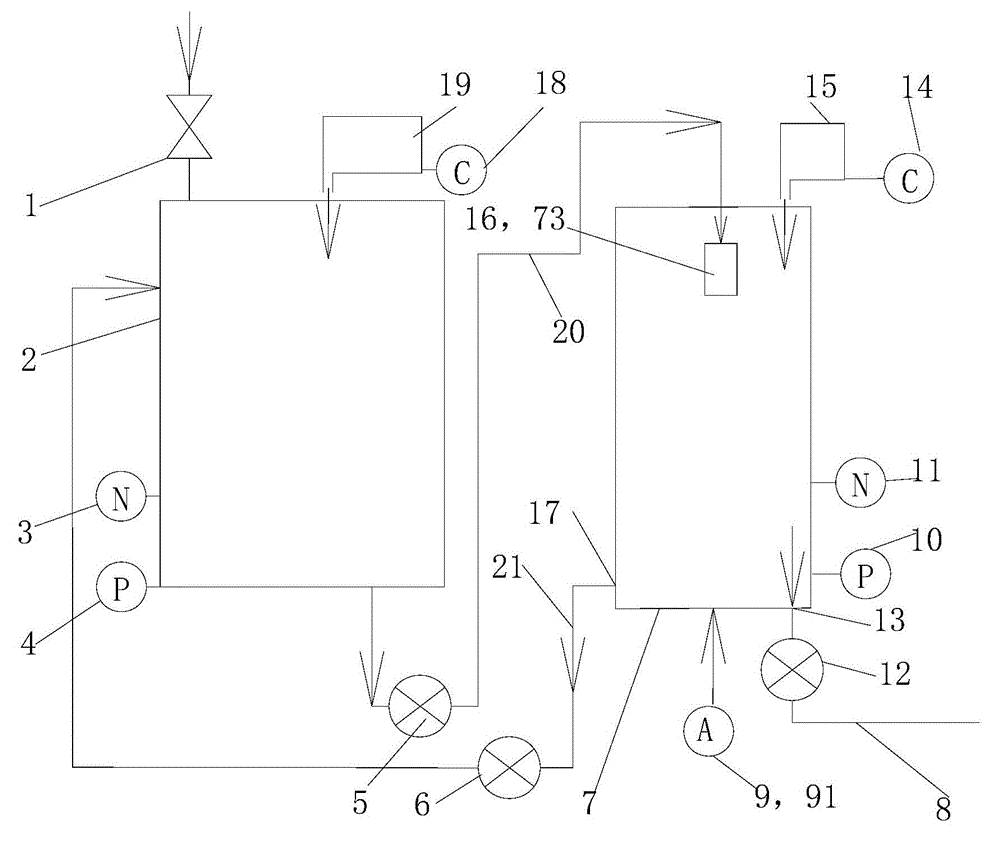

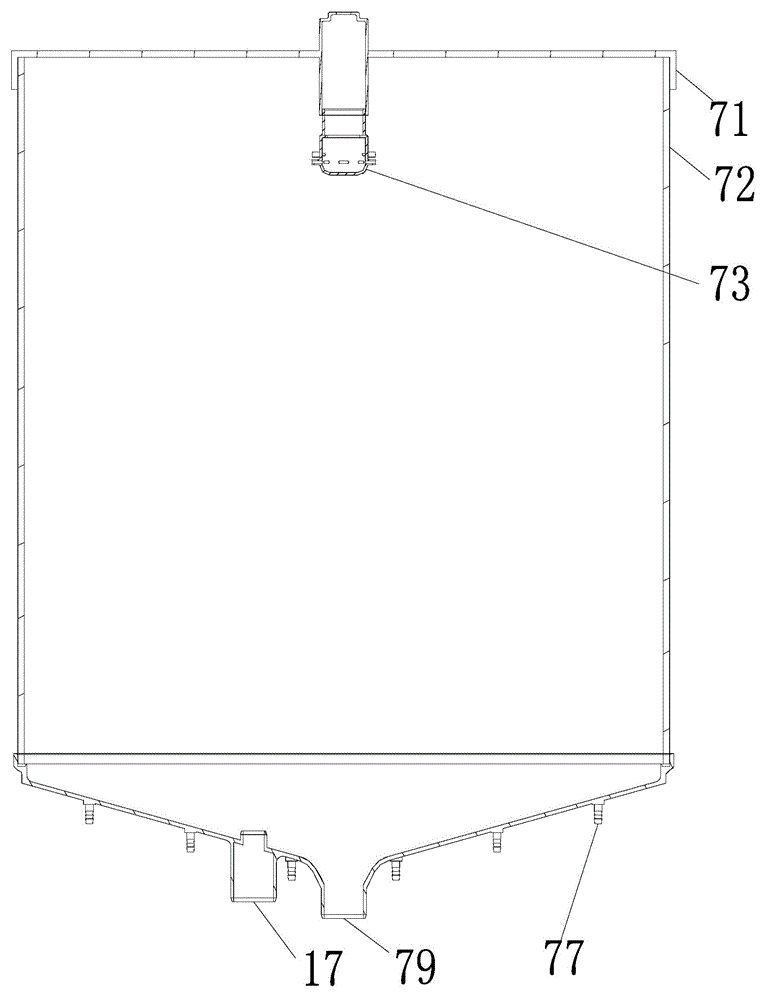

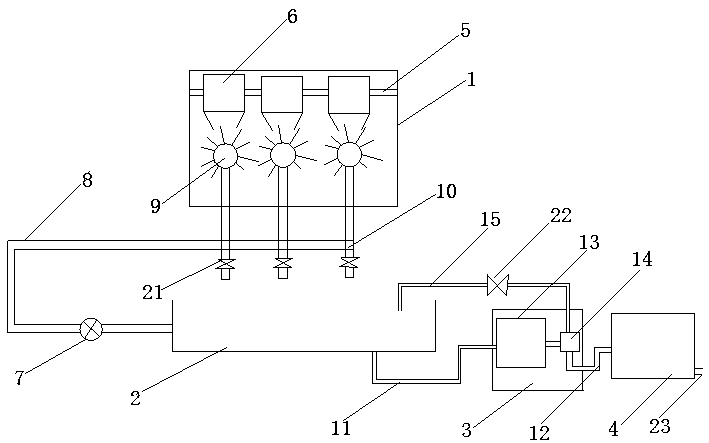

Flocculation container of washing machine

ActiveCN104652100ATo achieve the purpose of cleaningUniform water inflowOther washing machinesTextiles and paperFlocculationWater channel

The invention relates to a self-cleaning washing machine in the field of washing equipment, in particular to a flocculation container of the washing machine. The flocculation container comprises a flocculation barrel (3) and a flocculation barrel cover (1) which is buckled with an opening formed in the top of the flocculation barrel (3) in a combined mode. A water inlet (11), a water return opening (33), a sewage discharging outlet (32) and a putting inlet (13) are at least formed in the flocculation container; a water inlet structure is arranged on the flocculation barrel cover (1), and comprises an annular water channel (16), wherein spraying holes (15) which spray water to the inner wall of the flocculation barrel are formed in the bottom of the annular water channel (16), and the annular water channel (16) is communicated with the water inlet of the flocculation container. By the adoption of the flocculation container, the impact acting force applied by inlet water flow to flocculation in the flocculation barrel is reduced, and the phenomenon that the flocculation is dispersed is avoided; the purposes that the inner wall of the flocculation barrel is washed by the inlet water flow, and the flocculation container is cleaned through the inlet water flow are achieved.

Owner:HAIER GROUP TECHN R&D CENT +1

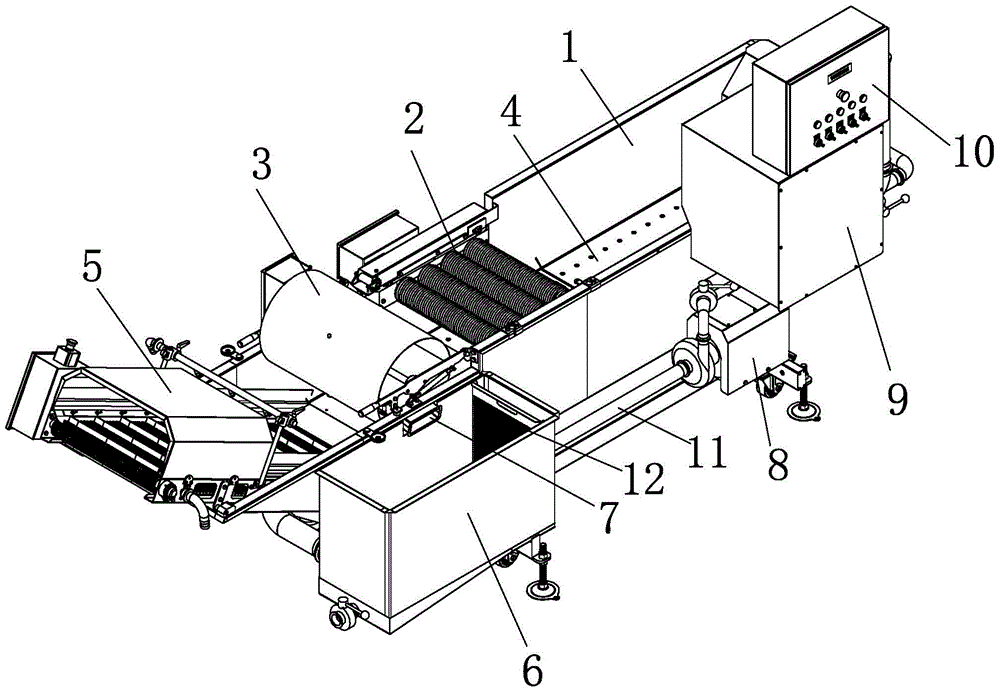

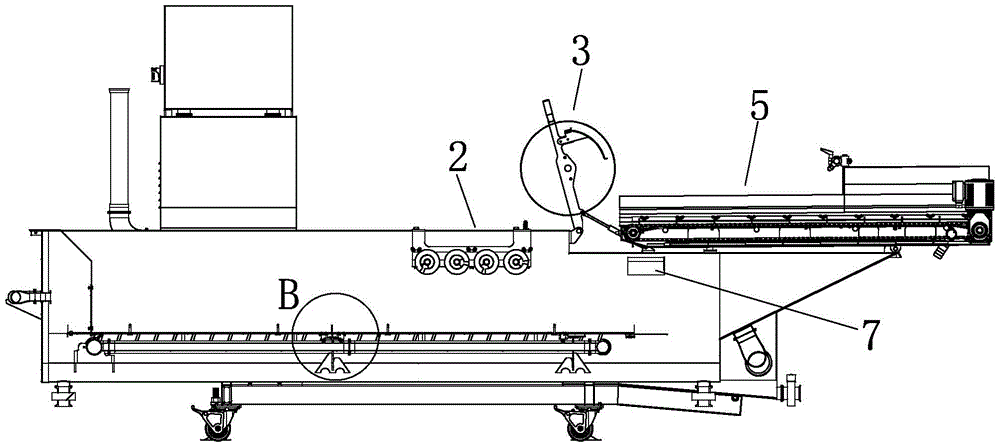

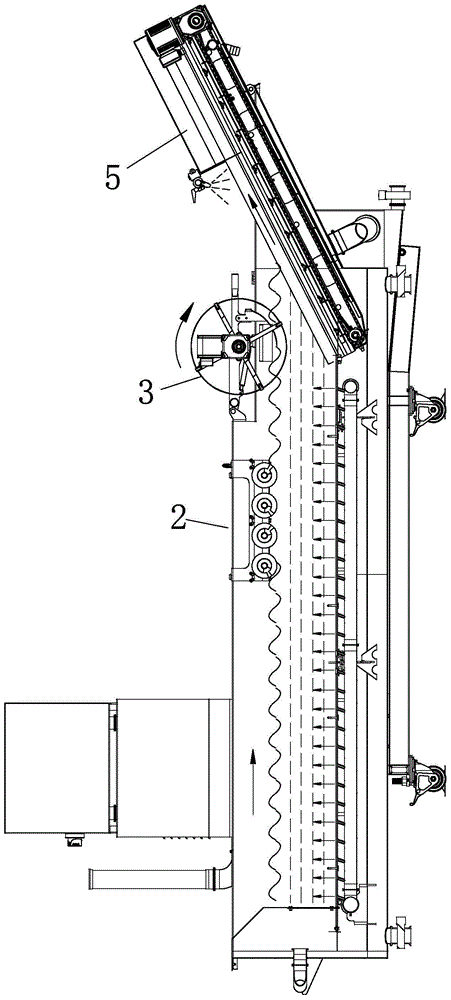

Food material turning and washing machine

PendingCN105686018AEfficient absorptionMechanical strength is not requiredFood treatmentCirculator pumpProcess engineering

The invention provides a food material turning and washing machine which solves the problems that in the prior art, because an existing food material turning and washing machine is not reasonable in design, food material washing is not complete and the turning and washing machine is difficult to wash. The food material turning and washing machine comprises a bottom frame, and a machine body and a draught fan which are fixed to the bottom frame. An electronic control box internally provided with control elements is fixedly connected with the top end of the draught fan. A precipitate removal device is arranged at the bottom of the machine body. The draught fan is connected with the precipitate removal device through a gas conveying pipeline. A hair removal device is hung on and fixed to the middle of the machine body. A conveying device is arranged on the front portion of the machine body. A floating object removal device is arranged between the conveying device and the hair removal device. The control elements are connected with the draught fan, a circulating pump, the hair removal device, the floating object removal device and the conveying device through wires respectively, the food material turning and washing machine is unique in design, washed food is high in cleanliness, and the device is high in work efficiency and practicability.

Owner:孙业国

Barley seedling clear juice powder processing method

InactiveCN104738430AEfficient removalQuality assuranceFood preparationMegasonic cleaningMaterial selection

The invention relates to a barley seedling clear juice powder processing method, and belongs to the technical field of foodstuff preparation. The barley seedling clear juice powder processing method comprises the steps of material selection, cleaning, soaking, ultrasonic cleaning and the like, and barley seedling clear juice powder which is balanced in nutrition and high in product purity can be produced. The barley seedling clear juice powder meets the nutritional requirements of different people.

Owner:JIANGSU ZHENYA FOOD CO LTD

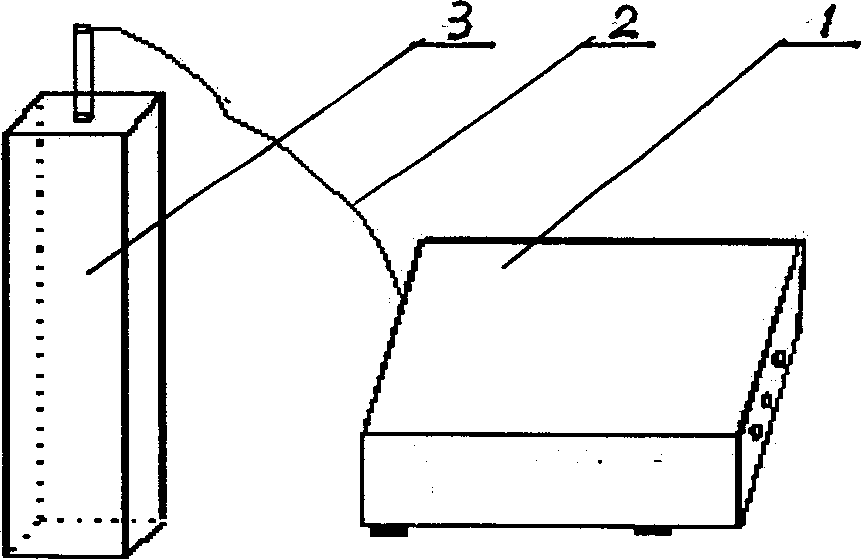

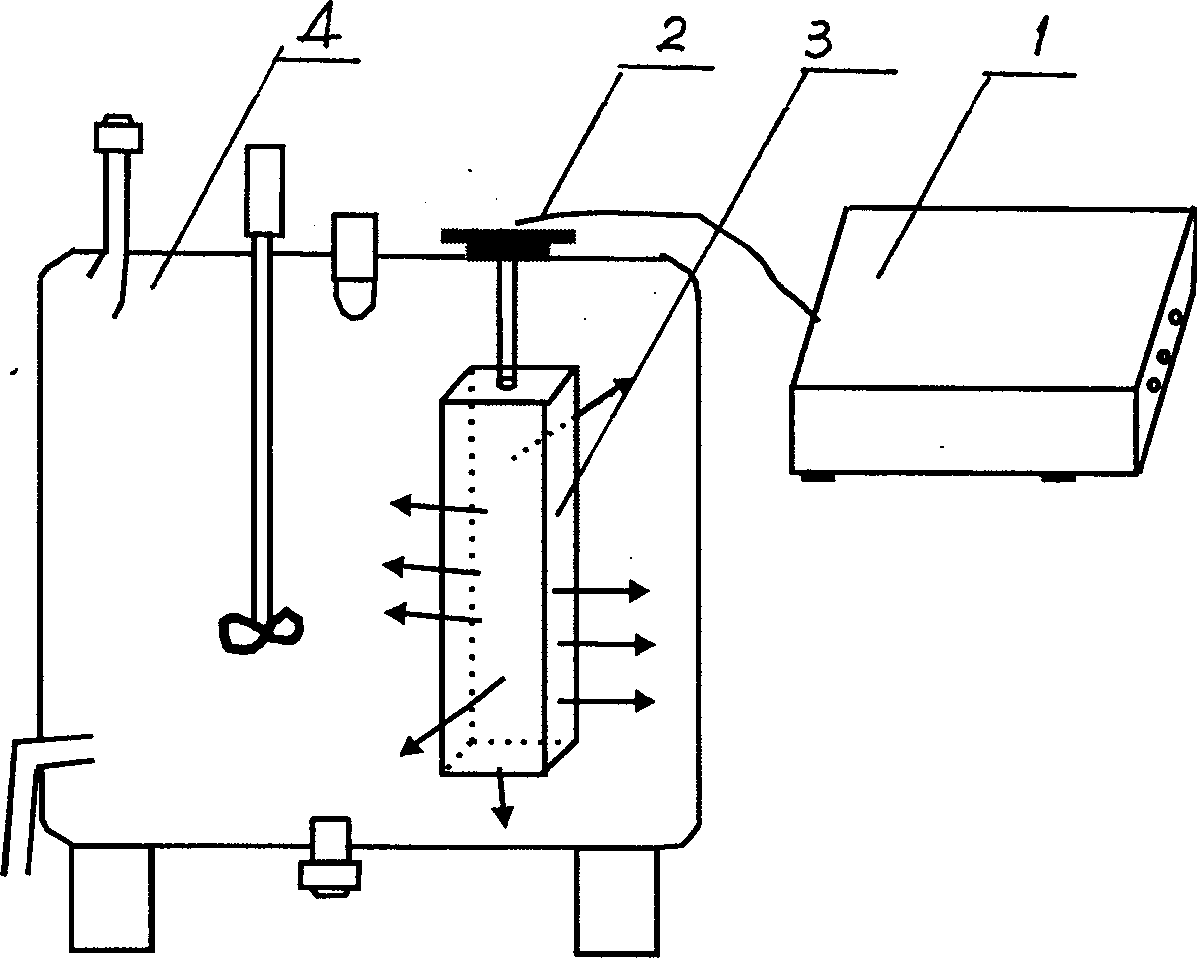

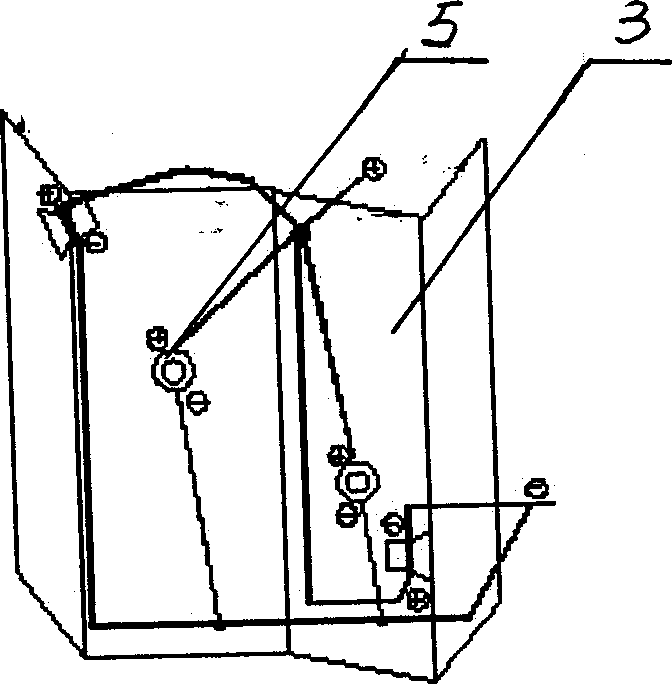

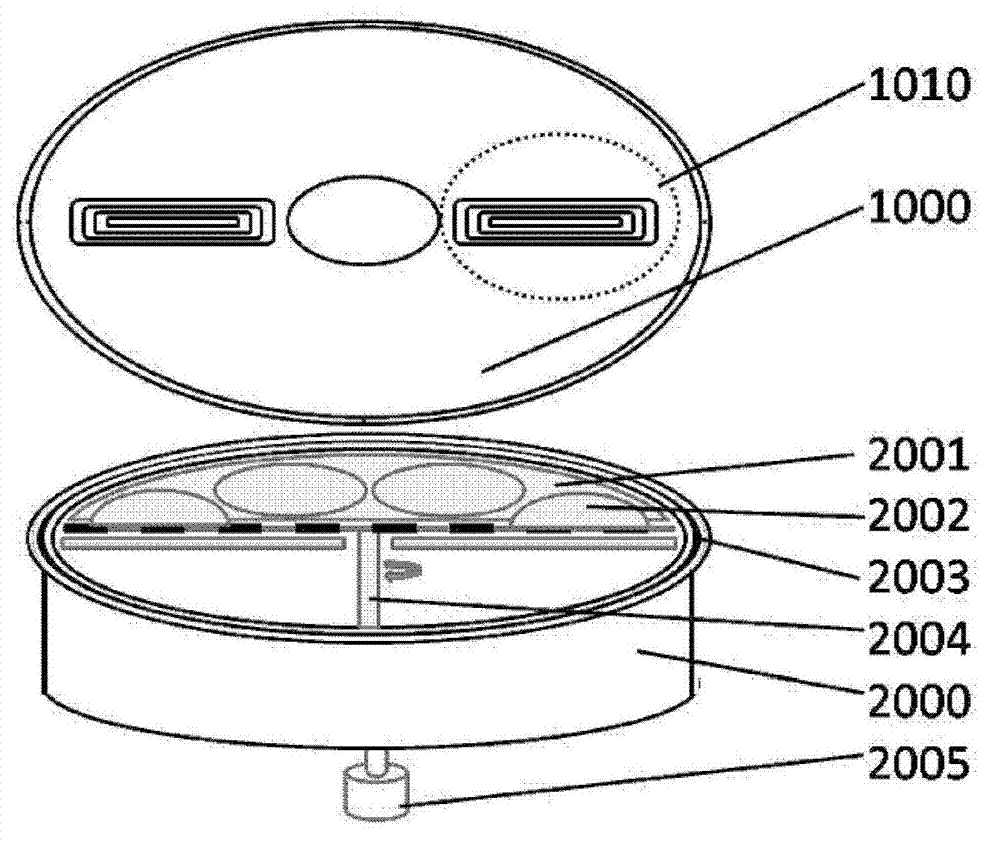

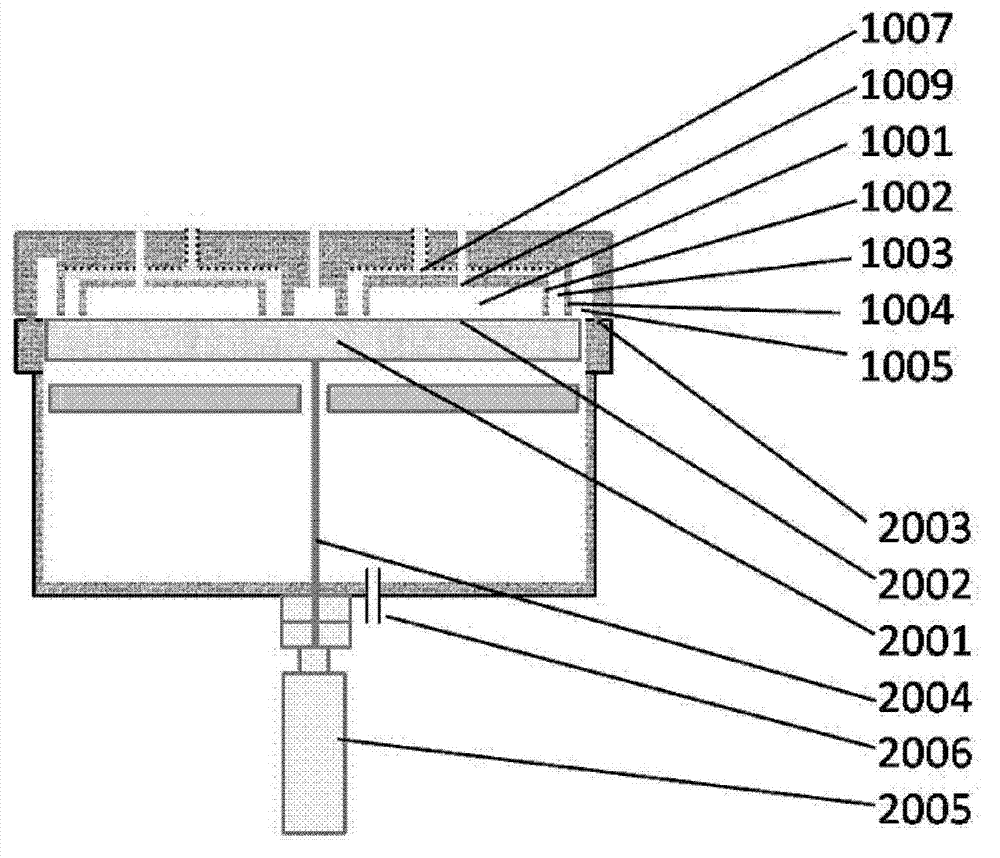

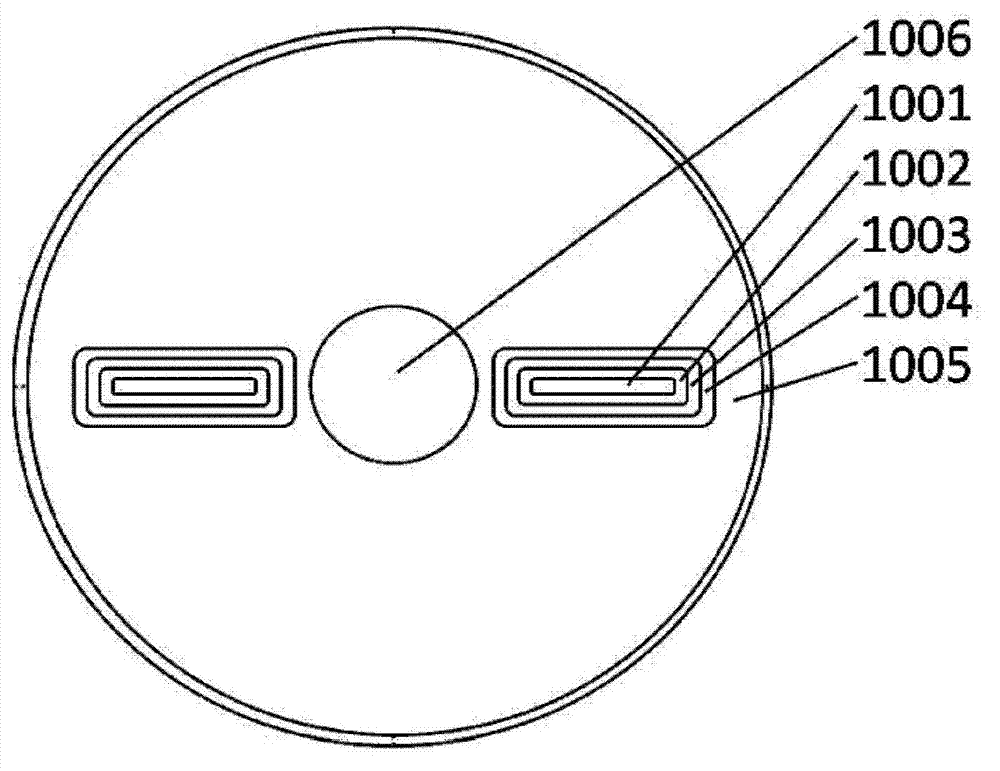

Ultrasonic wave cleaning processor

InactiveCN1422707ANo cleaning dead angleShorten the timeHollow article cleaningCleaning using liquidsMegasonic cleaningUltrasonic vibration

The present invention relates to an ultrasonic cleaning treatment equipment, it is formed from ultrasonic generator connected with ultrasonic vibration board via signal wire, on one surface of the described ultrasonic vibration board an ultrasonic transducer is mounted. In the presence of washing liquor of water, etc. proceed from central space of groove cavity container to be cleaned it can make ultrasonic wave stereo-irradiate all the inner walls of said container and produce cavitition function to implement high-quality cleaning operation under the moderate condition.

Owner:SOUTH CHINA UNIV OF TECH

Cleaning machine with twin-jet nozzle

ActiveCN103094148AMeet cleaning needsTo achieve the purpose of cleaningSpraying apparatusSemiconductor/solid-state device manufacturingReciprocating motionSemiconductor chip

The invention relates to the equipment which is used for cleaning the chip in the workpiece process of semiconductor chips, in particular to a cleaning machine with a twin-jet nozzle used for optimizing the washing of the surface of the chip. The cleaning machine comprises a nozzle electric cylinder, a spindle motor, a supporting stage, a shell body, a nozzle arm, a spindle and a workbench. The spindle motor is installed on the workbench and one end of the spindle is connected with an output end of the spindle motor and the other end of the spindle motor is installed inside the shell body of the workbench. The other end of the spindle is connected with the supporting stage used for fixing and rotating the chip. The nozzle electric cylinder is installed on one side of the workbench and one end of the nozzle arm is connected with the nozzle electric cylinder and is in reciprocating motion through the drive of the nozzle electric cylinder. The other end of the nozzle arm is located above the chip and the other end of the nozzle arm is provided with the twin-jet nozzle corresponding to the chip. The cleaning machine with the twin-jet nozzle can meet the cleaning demand to the hilt through the control of the position of the nozzle and the characteristic of the rotation of the chip in the cleaning process and achieve the cleaning goal that all particles on the surface of the chip are cleared away.

Owner:SHENYANG KINGSEMI CO LTD

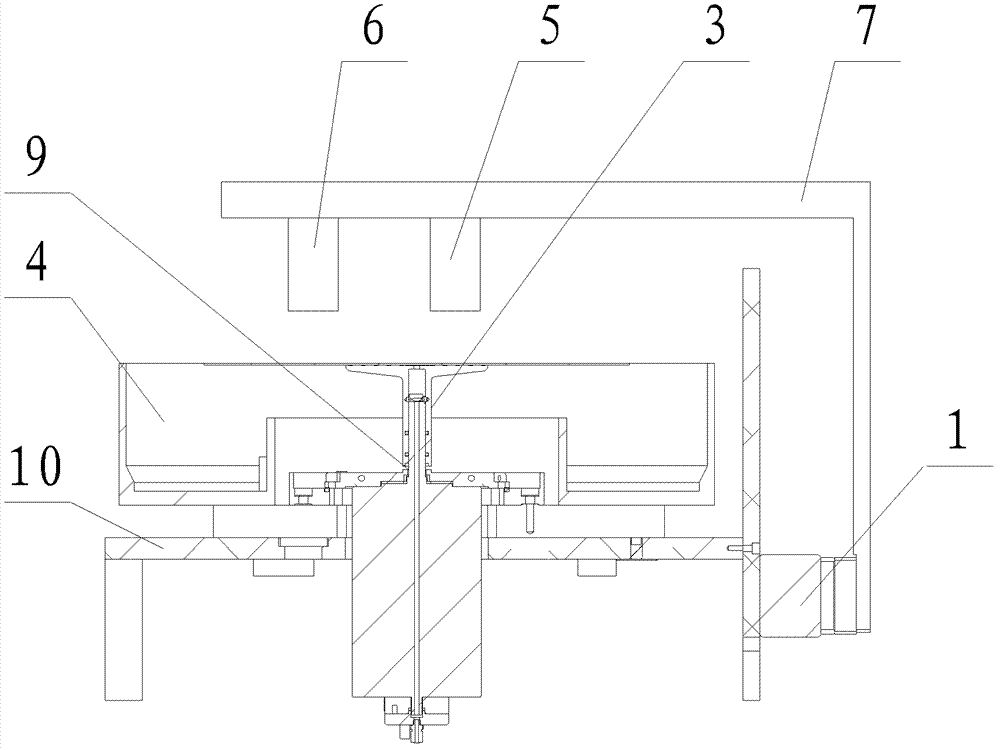

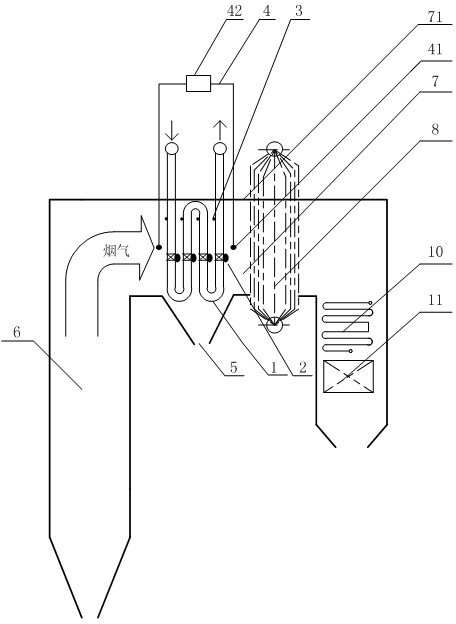

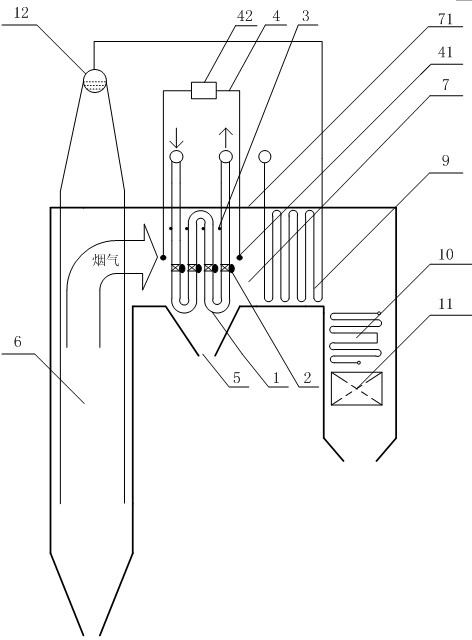

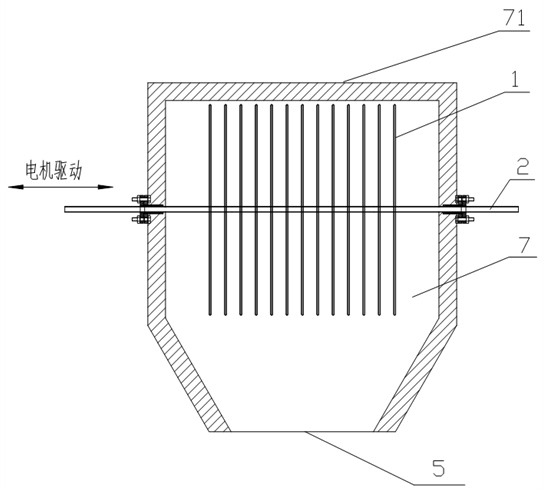

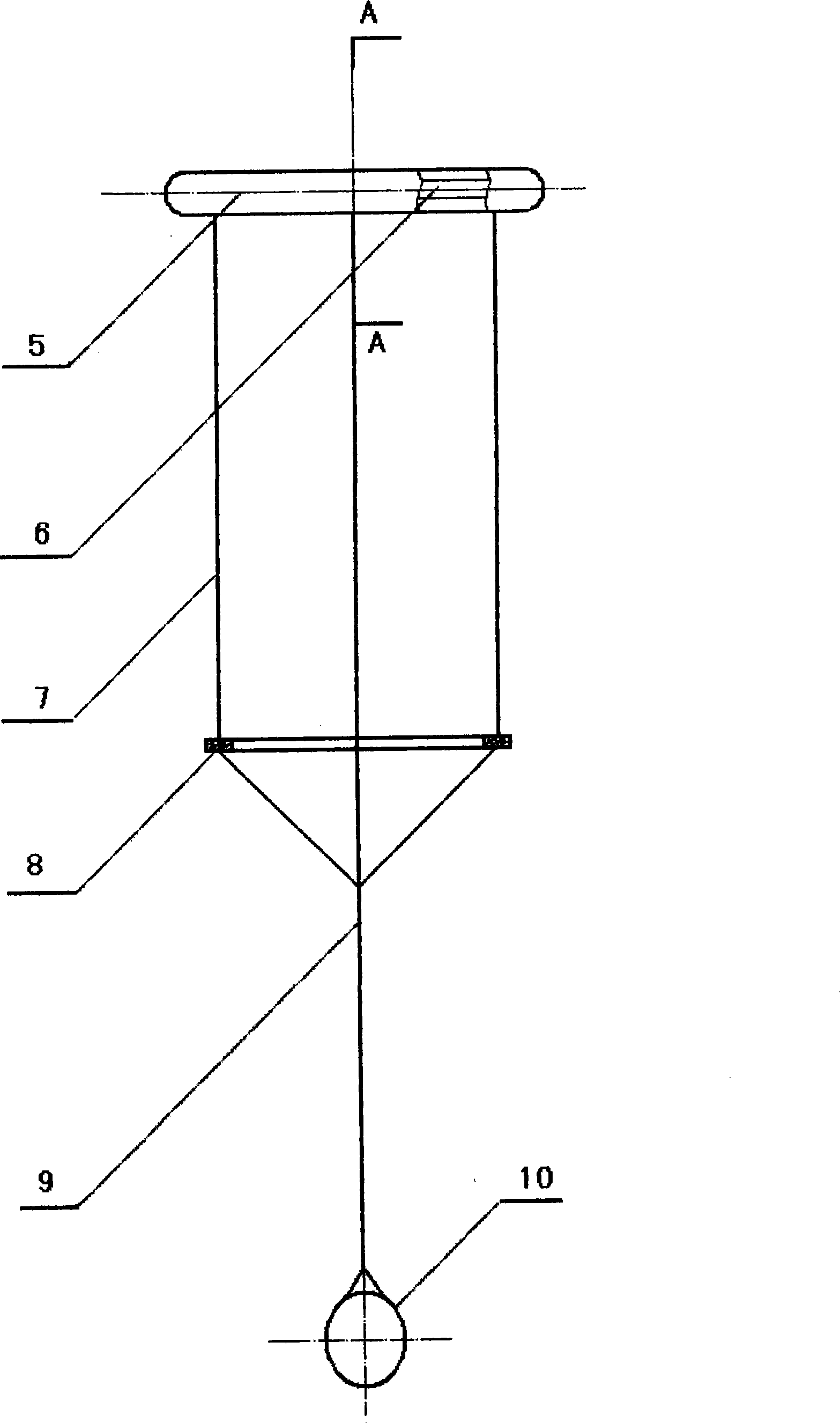

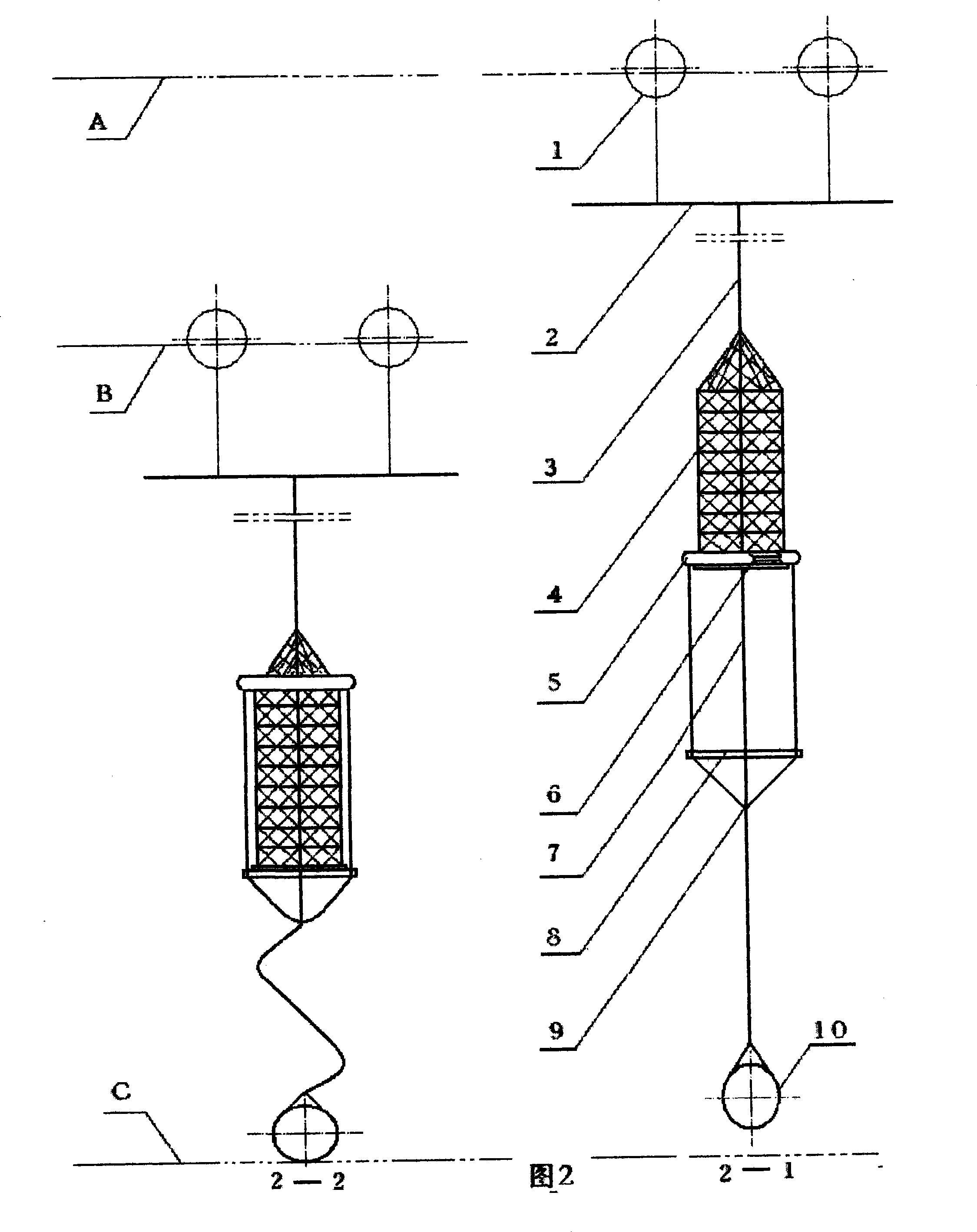

Deashing device and method for waste incineration boiler and biomass boiler

The invention provides a deashing device and method for a waste incineration boiler and a biomass boiler. The deashing device is characterized by comprising a metal hose (1), a push rod (2), a temperature measuring device (3), a differential pressure measuring device (4) and an ash discharge port (5); and a horizontal flue (7) at the exit of a boiler furnace (6) is surrounded by a horizontal flue furnace wall (71) and is hollow. The method comprises the following steps: flue gas leaves the furnace (6) and flows through the metal hose (1) arranged in the horizontal flue (7) so that ash deposition in the flue gas can be blocked by the metal hose (1); when the drop changes of the temperature and the resistance measured by the temperature measuring device (3) and the differential pressure measuring device (4) exceed threshold values, the push rod (2) starts to do reciprocating motion and drives the metal hose (1) to deform, so that the ash deposition deposited on the surface of the metal hose (1) can fall off from the surface due to the deformation and can be discharged from the ash discharge port (5). The deashing device provided by the invention has a simple structure; in addition, the deashing device and method have the advantages of high deashing efficiency, low cost and wide application range.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD +1

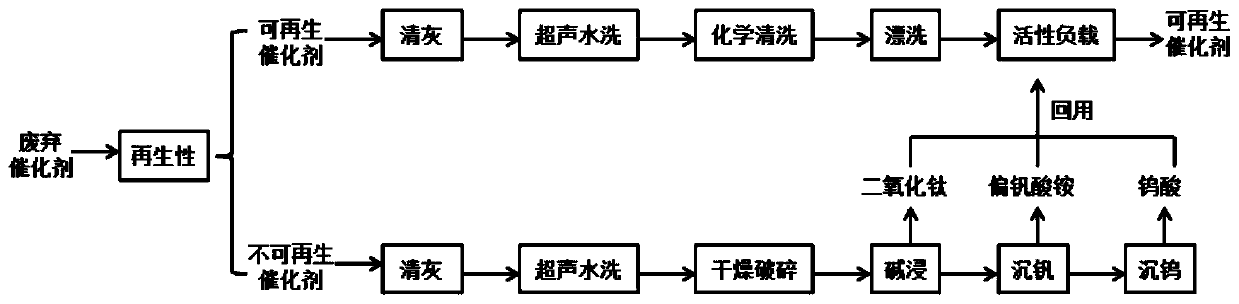

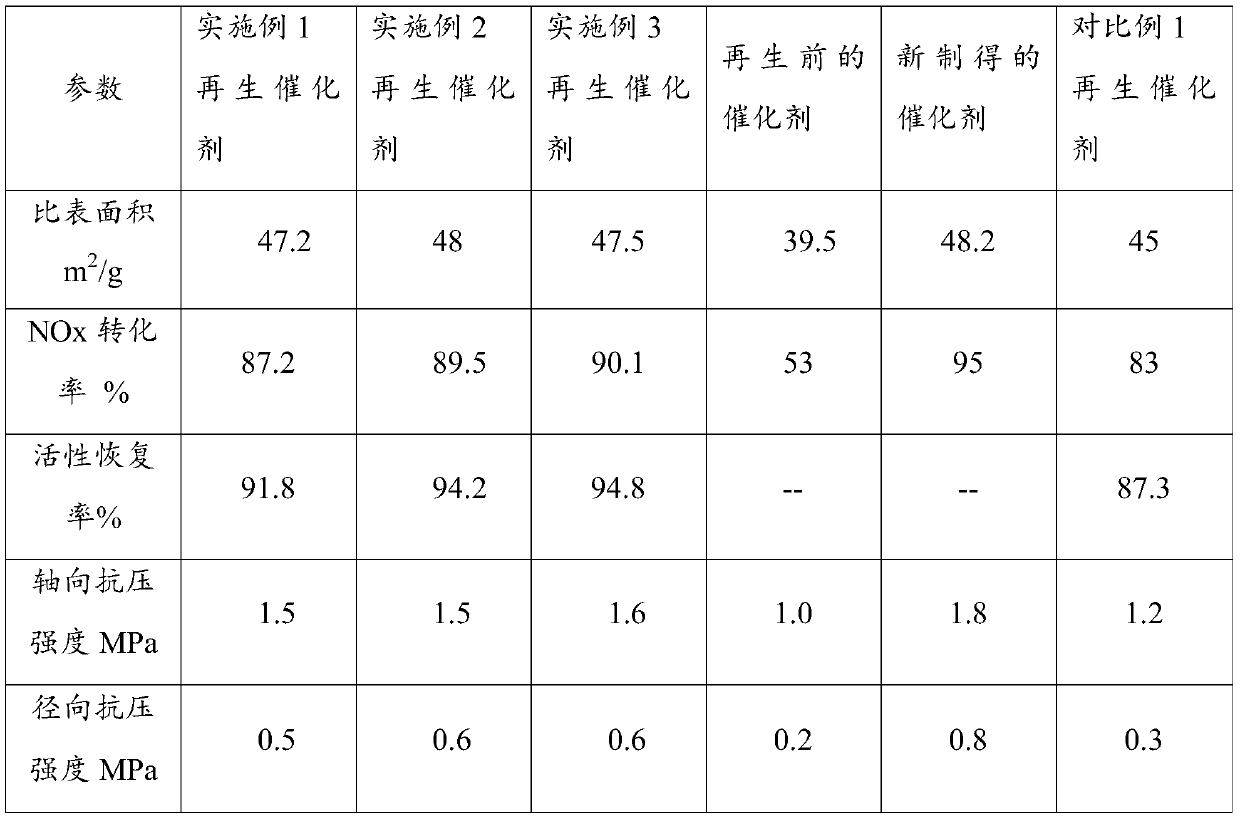

Regeneration and recovery method of waste SCR denitration catalyst

PendingCN110721754AImprove mechanical strengthPoor regenerative abilityCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsProcess engineeringPtru catalyst

The invention provides a regeneration and recovery method of a waste SCR denitration catalyst. Microwave heating treatment of the active loaded reversible inactivated SCR denitration catalyst is carried out to prepare a regenerated SCR denitration catalyst, wherein a regeneration liquid used during active loading comprises Ti<4+>, V<5+> and W<6+> which are respectively recovered from the irreversible inactivated SCR denitration catalyst. The regeneration and recovery method of the waste SCR denitration catalyst adopts microwave heating to effectively improve the mechanical strength of the regenerated catalyst, so repeated regeneration of the catalyst is facilitated, the dispersion uniformity of active components on the surface of the catalyst is improved, and the denitration activity of the regenerated catalyst is improved; and the Ti<4+>, V<5+> and W<6+> are respectively recycled, so that the recycled Ti<4+>, V<5+> and W<6+> can be used as supplements of the regeneration liquid in theregeneration process to form closed loop circular economy, and surplus products can be sold as products, thereby resources of the waste denitration catalyst are comprehensively recycled.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD +1

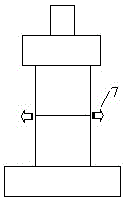

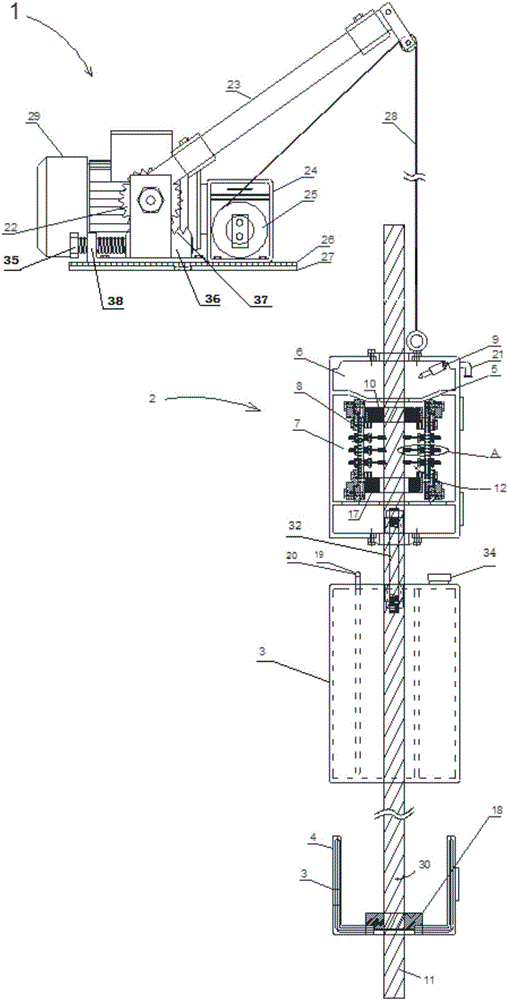

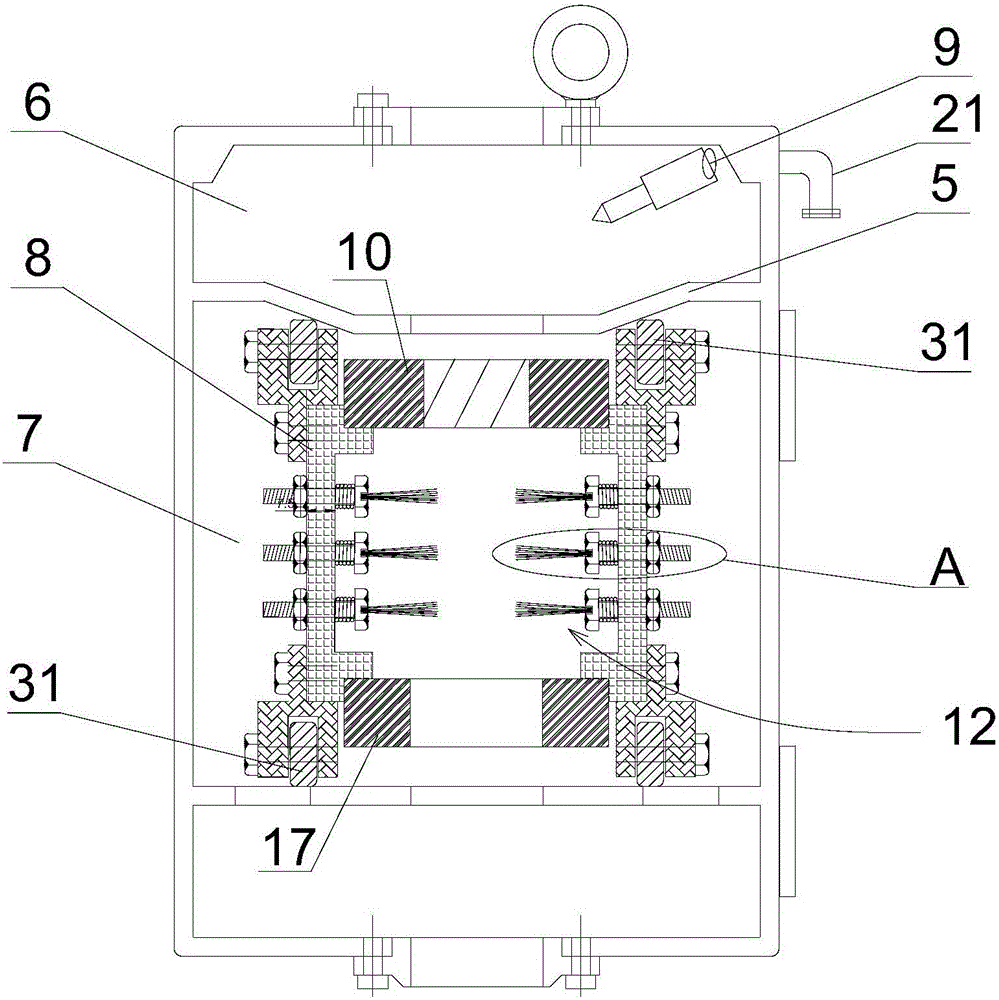

Automatic cleaning mechanism for steel wire ropes

ActiveCN105921443AAvoid safety hazardsTo achieve the purpose of cleaningCleaning using toolsCleaning using liquidsCopper wireAlternating current

The invention discloses an automatic cleaning mechanism for steel wire ropes. The automatic cleaning mechanism for steel wire ropes comprises a lifting device (1) and a cleaning device (2), and the lifting device and the cleaning device are arranged independently. The lifting device is connected with the top of the cleaning device through a suspension steel wire rope (28) of the lifting device, and can drive the cleaning device to move up and down. The cleaning device comprises a cleaning cavity (7). A brush drum (8) is arranged in the cleaning cavity (7), and a target steel wire rope (11) penetrates through the brush drum. An upper nylon rotating ring (10) is arranged on the top of the brush barrel. The inner round twisting surface of the upper nylon rotating ring (10) is attached to the outer round twisting surface (30) of the target steel wire rope. A plurality of copper wire brushes (12) aligned to the target steel wire rope are arranged on the inner wall of the brush drum. Since the lifting device and the cleaning device are arranged independently, alternating current and a cleaning agent are not crossed, and safety is achieved; gaps of the target steel wire rope can be cleaned through the copper wire brushes; the suspension steel wire rope is exposed, human intervention can be carried out, the risk that the cleaning mechanism falls down when the rope breaks off is reduced, and safety is improved.

Owner:江苏省太湖地区水利工程管理处

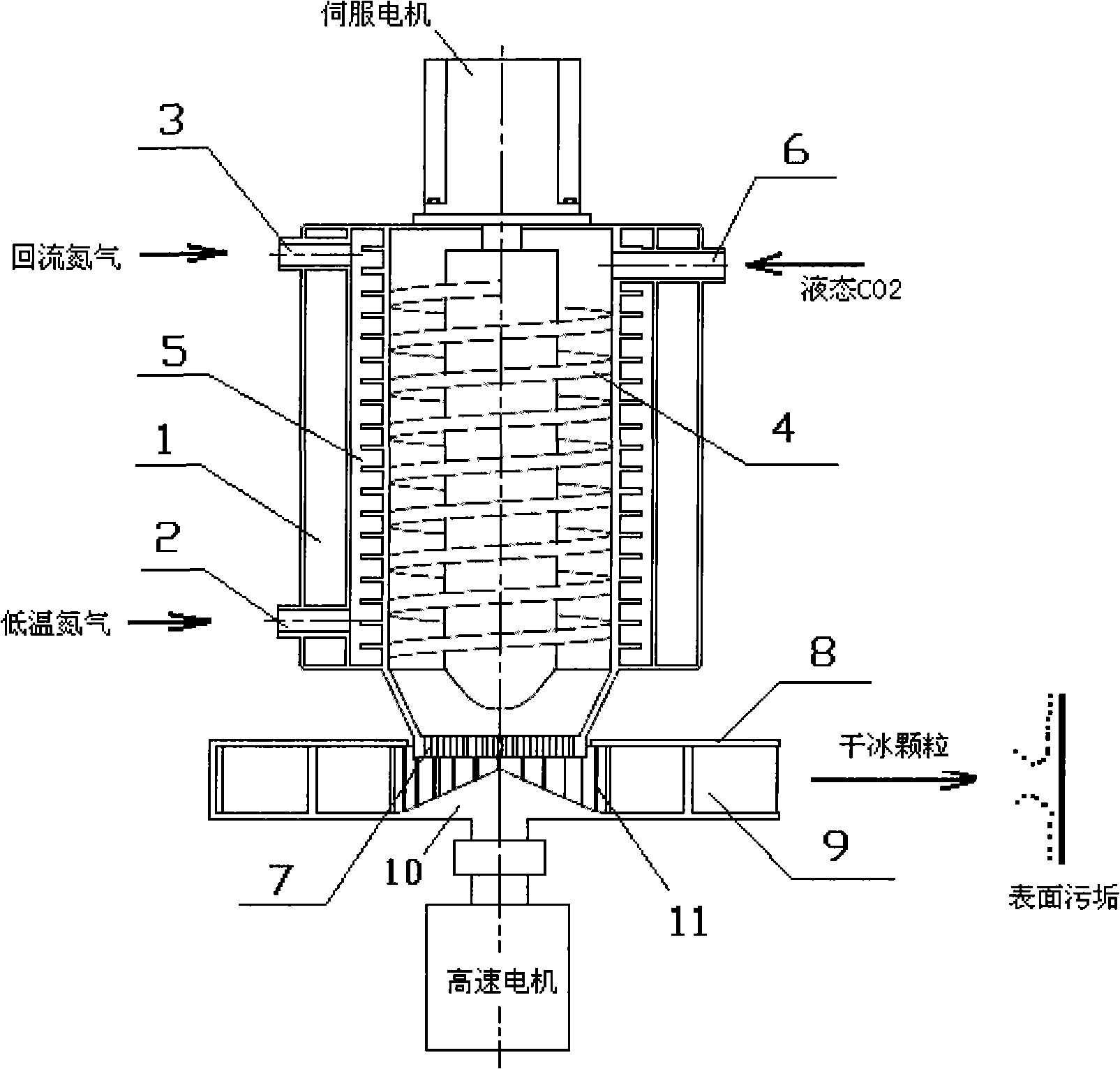

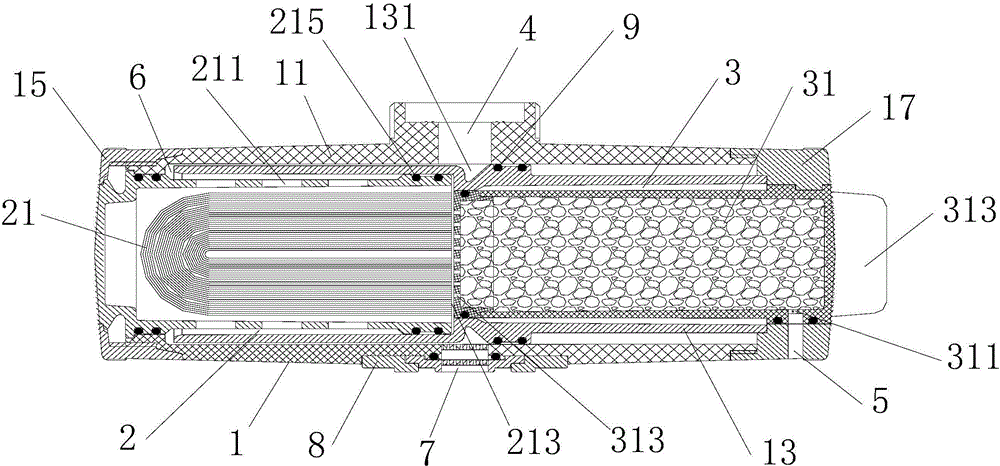

Screw extrusion centrifugal acceleration dry ice pill cold jet cleaner

InactiveCN101513638AIncrease jet speedIncrease the effective areaCarbon compoundsCleaning processes and apparatusDry iceEngineering

The invention discloses a screw extrusion centrifugal acceleration dry ice pill cold jet cleaner comprising a cylindrical dewar vessel, an inlet and an outlet are provided on the cylindrical dewar vessel, a spiral feeder is arranged in the inner cavity of the cylindrical dewar vessel, which periphery is provided with a heat exchanger, the inner cavity of the cylindrical dewar vessel is communicated with the liquid CO2 feed port. A bottom plate with an opening is installed at a discharge port on the lower end of the cylindrical dewar vessel, a box body is arranged below the bottom plate, an opening is provided on the side wall of the box body, a rotable disc is horizontally arranged in the box body and is connected with a centrifugal blade which is disposed right below the bottom plate. Compared with the existing technology, the invention increases the dry ice forming efficiency and outlet jetting speed, expands the effective area for cleaning the dry ice, is especially suitable for performing clean operation onto the huge device which is inconvenient to move and disassemble; the dry ice forming and acceleration process are integrated into one system, accordingly, the invention is convenient to move and use, and is low in system noise.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Filter core type deduster and control method thereof

InactiveCN104083974APrevent blowbackHigh precisionCombination devicesDispersed particle filtrationWaste managementDirt

The invention relates to a filter core type deduster and a control method thereof. The filter core type deduster comprises a cabinet, a fan and a dirt accumulating tank, wherein the fan is arranged on the top of the cabinet through a fan support plate, the dirt accumulating tank is arranged at the bottom of the cabinet, a filter core is arranged between the fan and the dirt accumulating tank and is fixed in the cabinet through a filter core installing plate, the bottom end of the filter core is enclosed, the top end of the filter core is provided with a through hole, a blowing blasting head is installed in the through hole and is connected with a pulse valve through a blowing pipe, a cylinder is arranged between the filter core installing plate and the fan support plate and is connected with the pulse valve through a cylinder air outlet pipe, one side of the cabinet is provided with a dust absorbing port, and the dust absorbing port is provided with, from interior to exterior, an air inlet gauze and an air inlet shutter. The filter core type deduster can completely remove dust in dust-containing air and allows dust filtering to be more thorough, ash in the filter core can be easily removed, the filter core is hardly to obstruct and has high filtering efficiency, so the filter core type deduster can be widely applied to removal of industrial dust.

Owner:柏司得环保科技(上海)有限公司

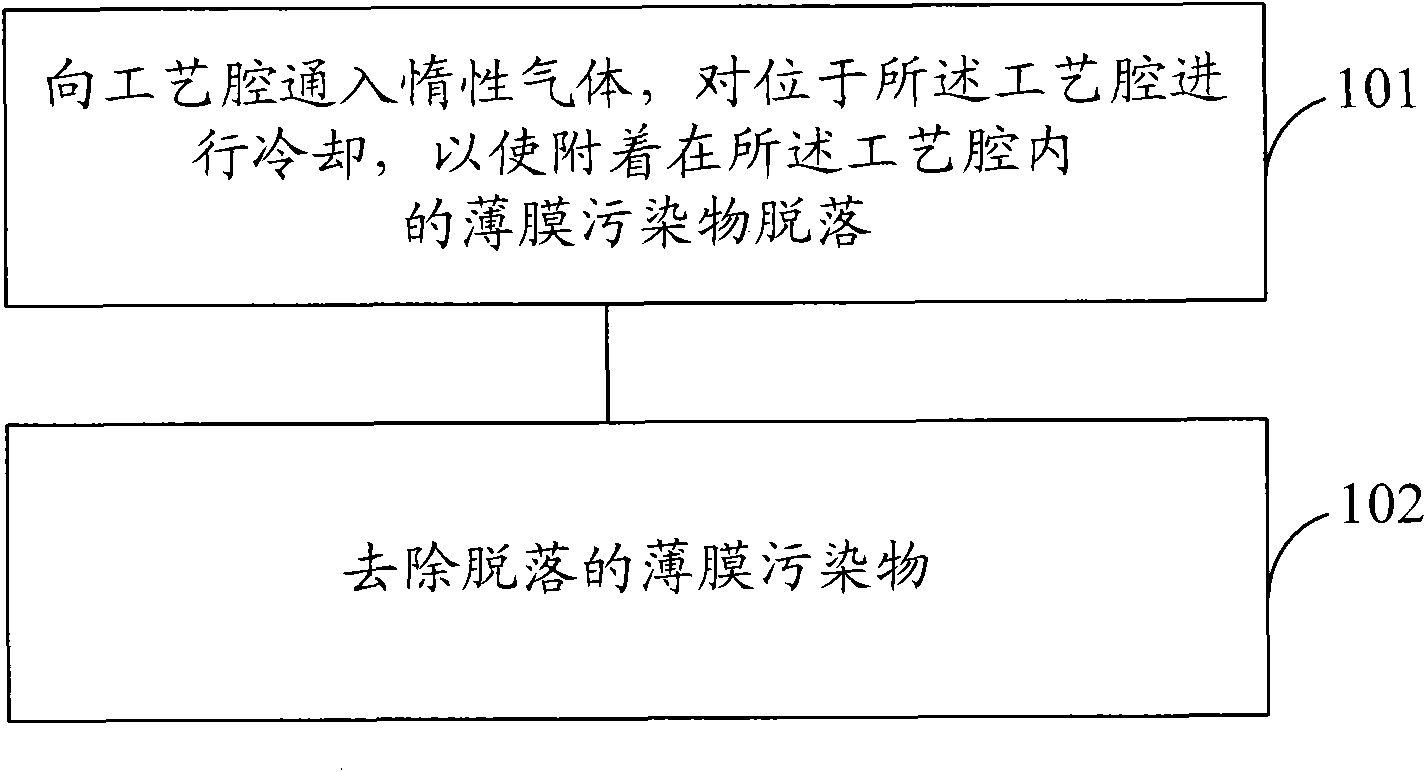

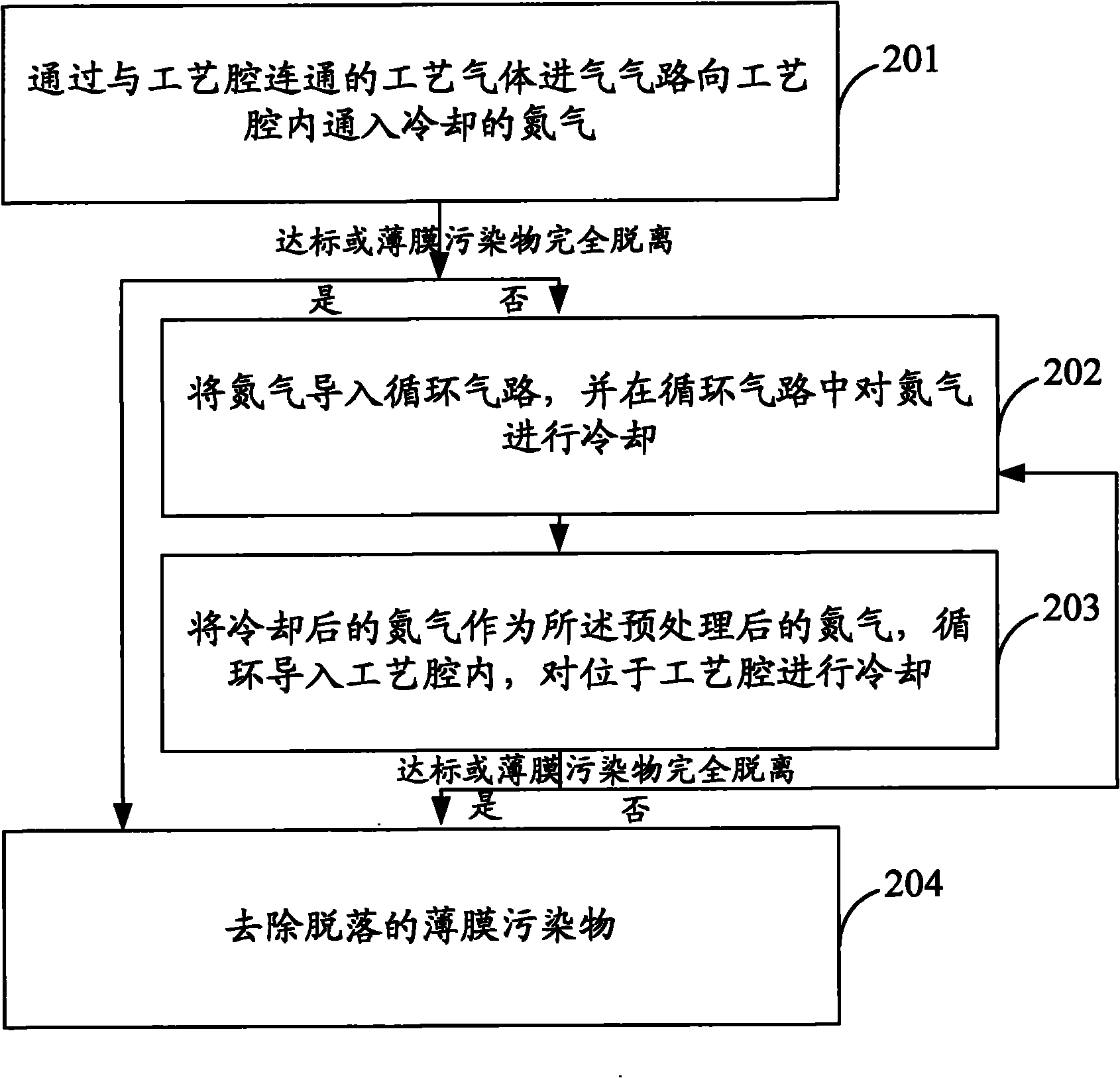

Method for removing film contaminants generated in the technological process and PECVD system

InactiveCN102108504AAchieve cleaningTo achieve the purpose of cleaningChemical vapor deposition coatingChemical agentShrinkage coefficient

The invention provides a method for removing film contaminants generated in the technological process and a plasma enhanced chemical vapor deposition (PECVD) system. The method for removing the film contaminants generated in the technological process is applied to a plasma enhanced chemical vapor deposition system, and comprises the following step of: cooling a part to which the film contaminants are attached, so that the film contaminants attaching to the part are separated from the part, wherein cold shrinkage coefficients of the part and the film contaminants are different. The film contaminants attaching to the part are removed by a physical means, a chemical agent is not needed for corrosion, and the aim of cleaning the part in the PECVD system without damage is fulfilled; moreover, the part is not needed to be detached, the cleaning process is convenient and quick, the maintenance time is reduced and the yield and production efficiency are improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Tide wave and stream wave type ,esh-cage underwater automatic cleaning method and device

InactiveCN101361470ARealize up and down movementTo achieve the purpose of cleaningClimate change adaptationHollow article cleaningSea wavesUnderwater

The invention discloses a submersed automatic cleaning method of a mesh cage of a tidal wave type and a vagrant type, and a device, relating to the agricultural sea floating raft mesh cage breeding, which is the automatic cleaning to the mesh cage. The tidal wave type: an annular hollow float is rearranged on the mesh cage, the float is assembled with a strip bush to form a component, namely, an annular hollow float mesh brush, the lower part of the mesh cage is matched with a hanging object, the part can move up and down by virtue of the change of tide and the floating up and down of sea weave; the vagrant type: the hollow part of the component is filled with water and the proportion thereof is slightly less than 1, the component is then sheathed on the mesh cage. When flowing, the component flows freely to the top of the mesh cage. With the continually changing of the tide towards big, the included angle between the axis line of the mesh cage and sea level changes into a certain small angle, the component moves to the bottom of the mesh cage along the axis direction under the effect of the tide. When the sea wave lifts up the mesh cage, the movement velocity is faster than the component, a relative movement occurs between the two. The two types can achieve the cleaning of the mesh cage. The method has the beneficial effects of saving energy, reducing exhaust, saving labor and protecting environment.

Owner:大连敖龙水产技术推广有限公司

Atomic layer deposition equipment

InactiveCN103114277ANo stacking effectTo achieve the purpose of cleaningChemical vapor deposition coatingSingle processEngineering

The invention discloses atomic layer deposition equipment which is an openable and closable closed cavity comprising a cover plate and a main cavity, wherein the inner surface of the cover plate is provided with an air path unit; the air path unit comprises a plurality of airflow channels; the plurality of airflow channels are spaced through spacing layers, and each airflow channel is communicated with a plurality of air holes arranged on the outer surface of the cover plate; the main cavity comprises a rotatable loading disc and a transmission system; the transmission system drives the rotatable loading disc to rotate; the rotatable loading disc is provided with a groove used for placing a wafer; the plurality of airflow channels at least include a first airflow channel and a second airflow channel; the first airflow channel is used for accessing a reaction source gas; and the second airflow channel is used for exhausting the unreacted reaction source gas. The atomic layer deposition equipment disclosed by the invention can increase the speed of atomic layer epitaxy, save the single process time and enhance the growth rate of the atomic layer epitaxy by increasing the rotation speed of the loading disc.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

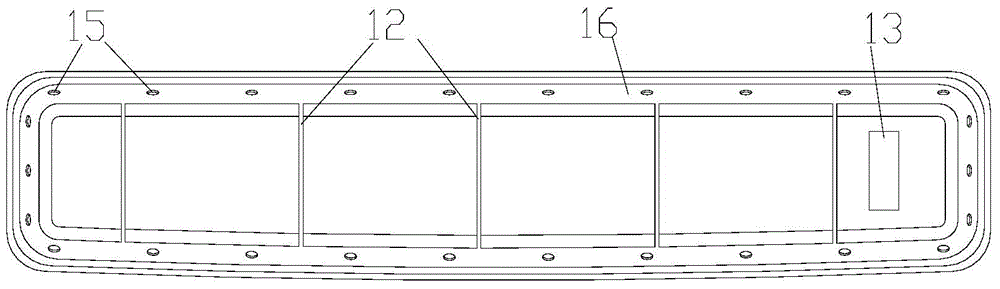

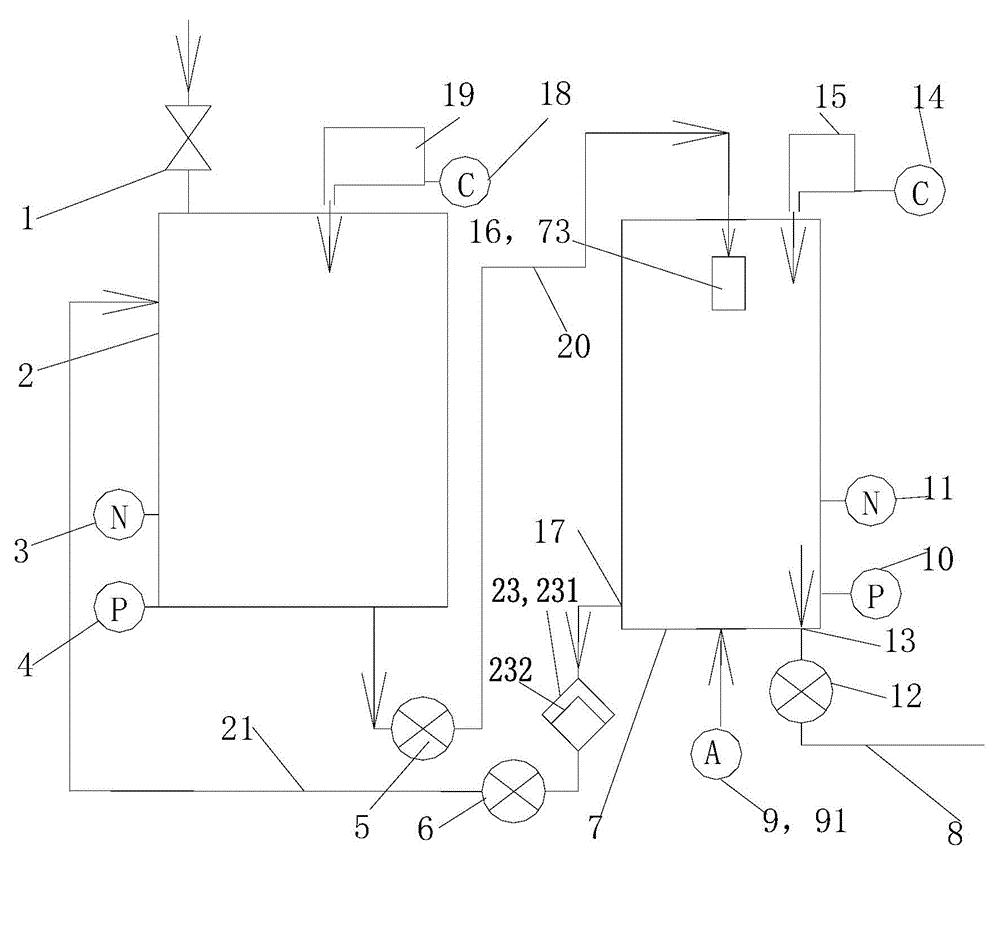

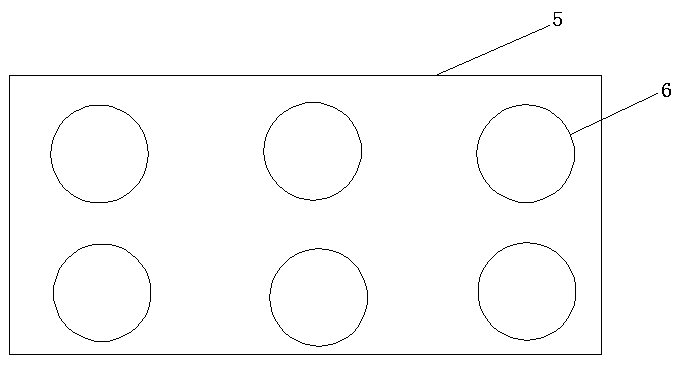

Water-inlet structure of flocculation container for washing machine and washing machine

ActiveCN105297356AIncrease flow rateIncrease coverageOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention relates to a water-inlet structure of a flocculation container for a washing machine. The top of the flocculation container is provided with an inwardly-protruding water-inlet spray head, in which multiple water-spray holes are arranged. The water-spray holes having different hole diameters are correspondingly arranged based on the distance among the water-spray holes and the side wall of the flocculation container. Water flows at different speed are sprayed out of the water-spray holes having different hole diameters and can be flushed to the side wall of the flocculation container. The water-inlet structure of the flocculation container for the washing machine has following beneficial effects: by the above device, all water inlet flows sprayed out of the water-spray holes having different hole diameters can be flushed to the inner wall of the flocculation container such that water inlet flows of the flocculation container are used for flushing the inner wall of the flocculation container; and the purpose of utilizing water inlet flows to clean the flocculation container is fulfilled. The invention further relates to a washing machine provided with the above water-inlet structure of the flocculation container. The washing machine is simple in structure and significant in effect and is suitable for promotional use.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

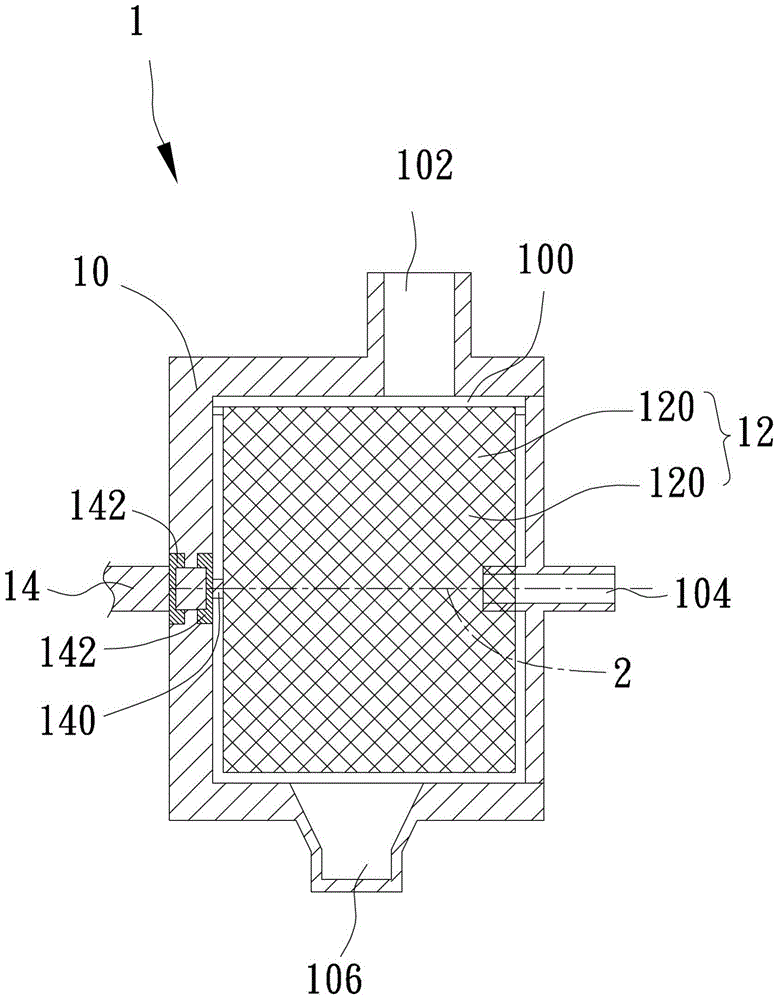

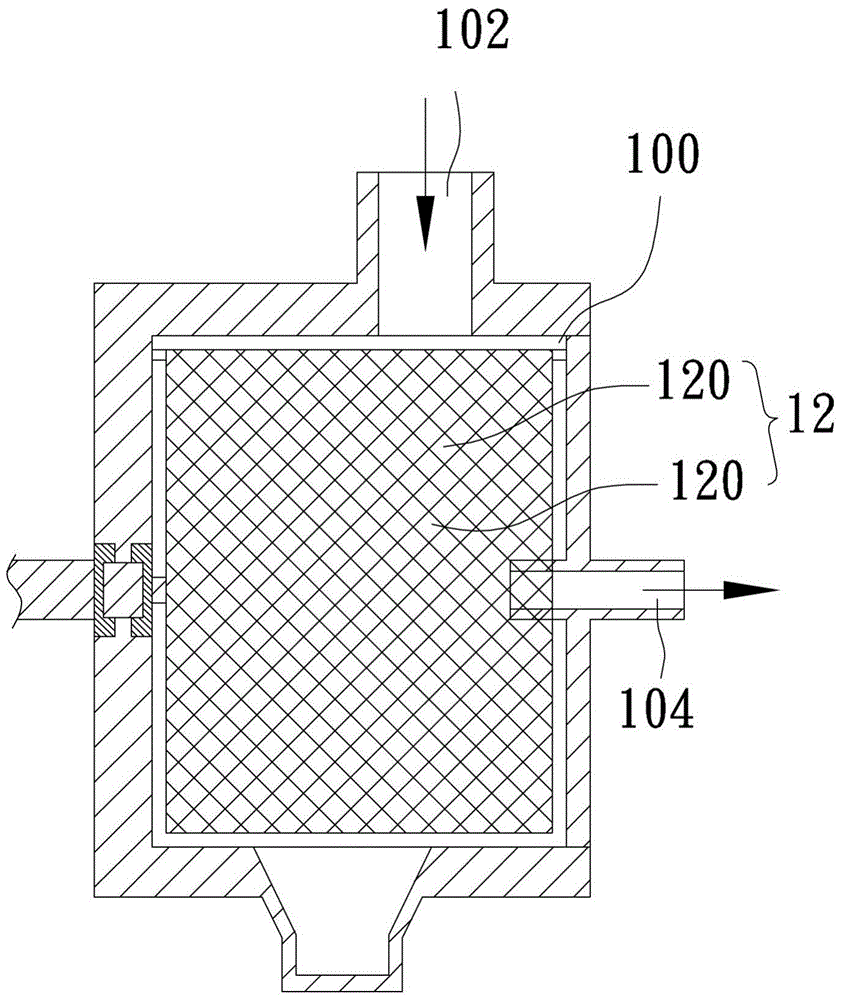

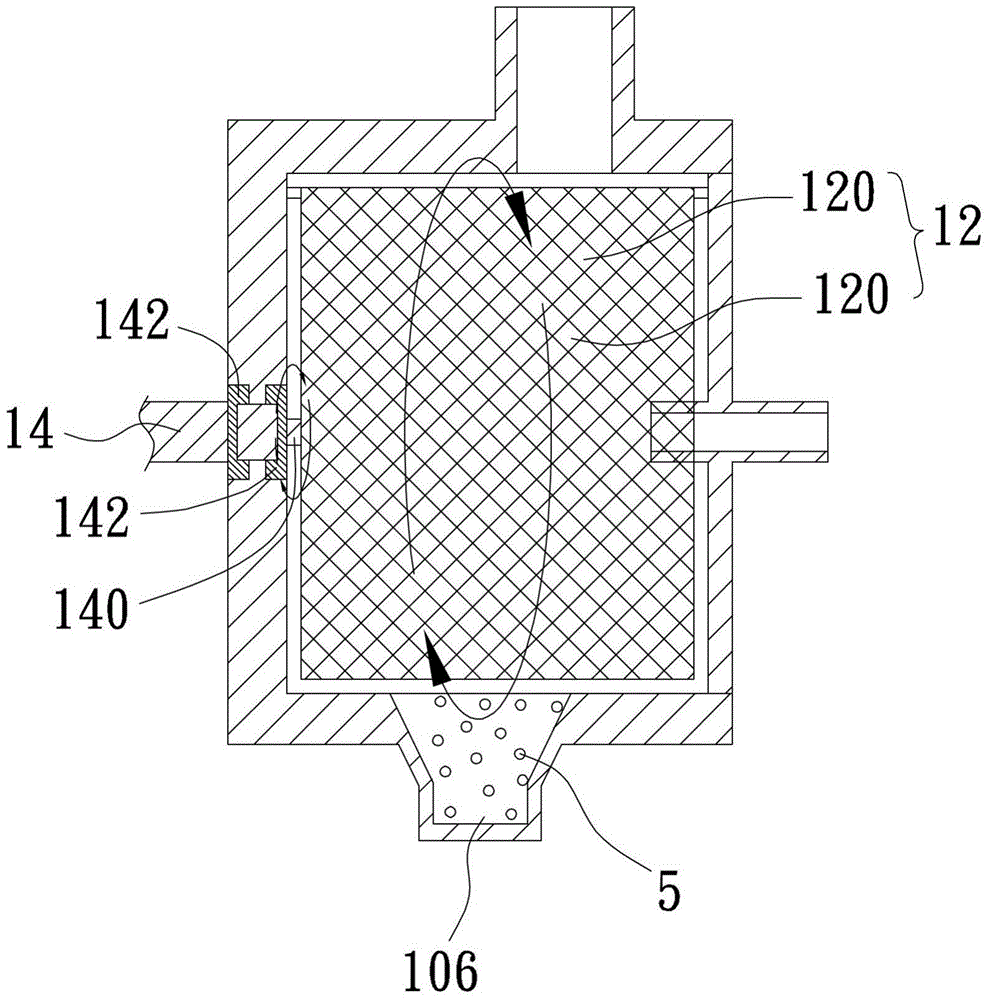

Front filter device of vacuum pump

InactiveCN104096428AReduce the probability of failureReduce manufacturing costDispersed particle filtrationHigh concentrationCoupling

The invention relates to a front filter device of a vacuum pump, and belongs to the field of filter equipment. The device mainly comprises a filter barrel, a filter screen and an actuator, wherein a cavity, an air inlet, an air outlet and a dust collecting area are formed in the filter barrel; the filter screen is around a shaft center and is mounted in the cavity; a rotating shaft which is connected with the filter screen and can be used for rotating the filter screen is mounted on the actuator, and a coupler which is mounted on the filter barrel and is used for sealing the rotating shaft and the actuator is arranged on the rotating shaft. Therefore, the device capable of being used for generating high-concentration particles is used for filtering the high-concentration particles, and the filtered particles are separated from the filter screen by centrifugal force by rotating the filter screen, so that the purposes of cleaning and reusing can be achieved without dismounting the filter screen.

Owner:HANBELL PRECISE MACHINERY

Electric insulating oil sample bottle cleaning device

PendingCN109731852AEliminate distractionsClean thoroughlyHollow article cleaningCleaning using liquidsOil separationOil water

The invention discloses an electric insulating oil sample bottle cleaning device, and belongs to the technical field of insulating oil treatment. The electric insulating oil sample bottle cleaning device comprises a cleaning tank, a recovery tank, a water-oil separation device and a waste liquid recovery device, wherein the recovery tank is located below the cleaning tank; a fixing plate and a cleaning device are fixed in the cleaning tank; a plurality of insulating oil bottles are arranged on the fixing plate in an inverted mode; the insulating oil bottles are cleaned by the cleaning device by using of the cleaning liquid in the recovery tank; the recovery tank is connected to the oil-water separation device through a first conveying pipeline; and the oil-water separation device is connected to the waste liquid recovery device through a second conveying pipeline. By means of the electric insulating oil sample bottle cleaning device, multiple electric insulating oil bottles are cleaned, and the interference of the electric insulating oil sample bottles on an electric insulating oil experiment is eliminated, so that the working intensity and environmental pollution are greatly reduced.

Owner:国网河南省电力公司南召县供电公司

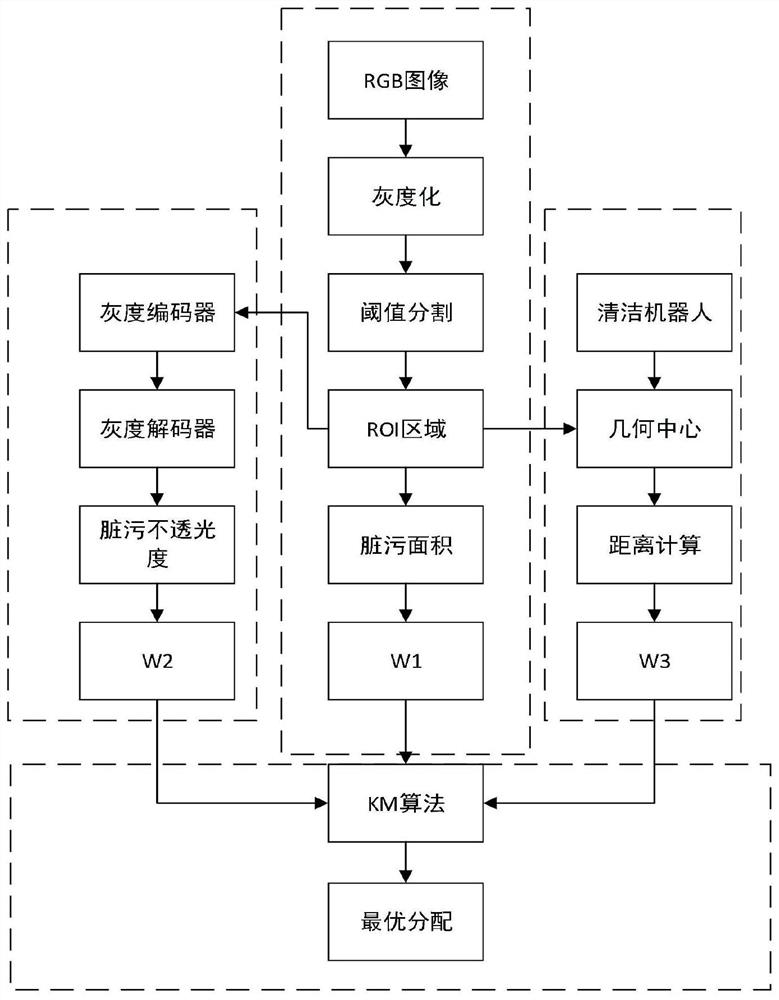

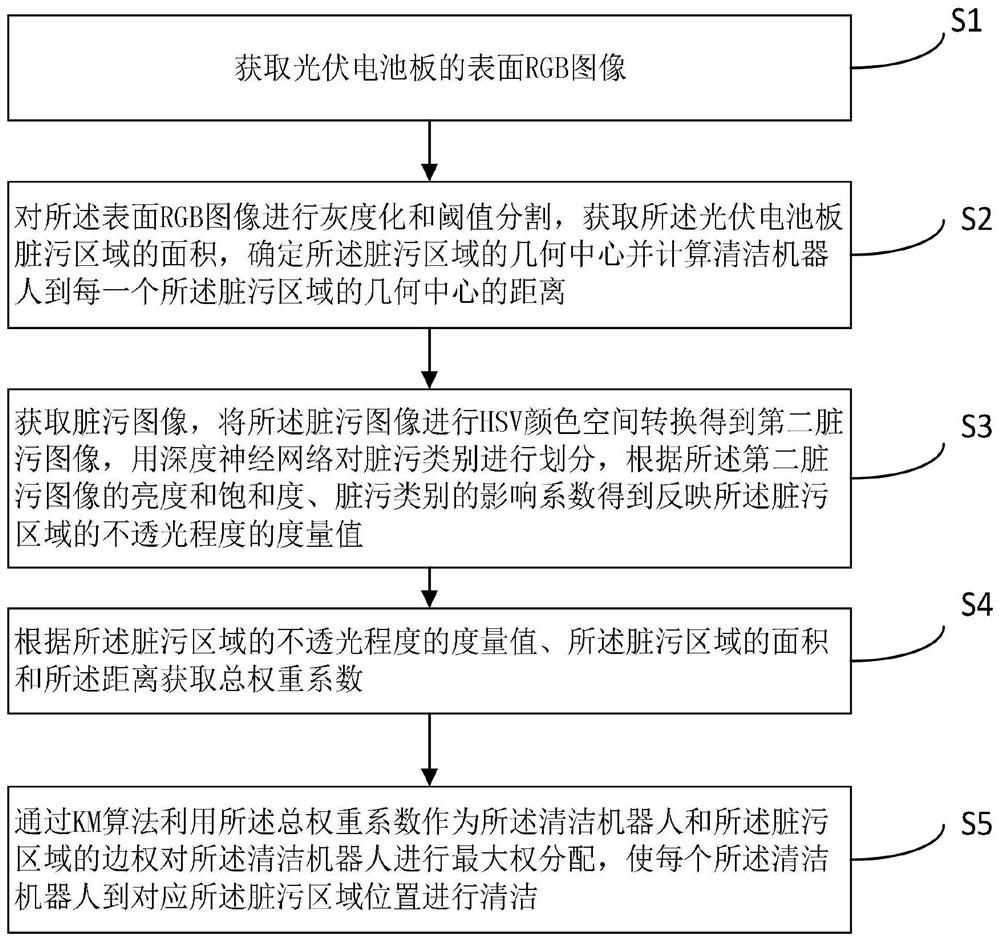

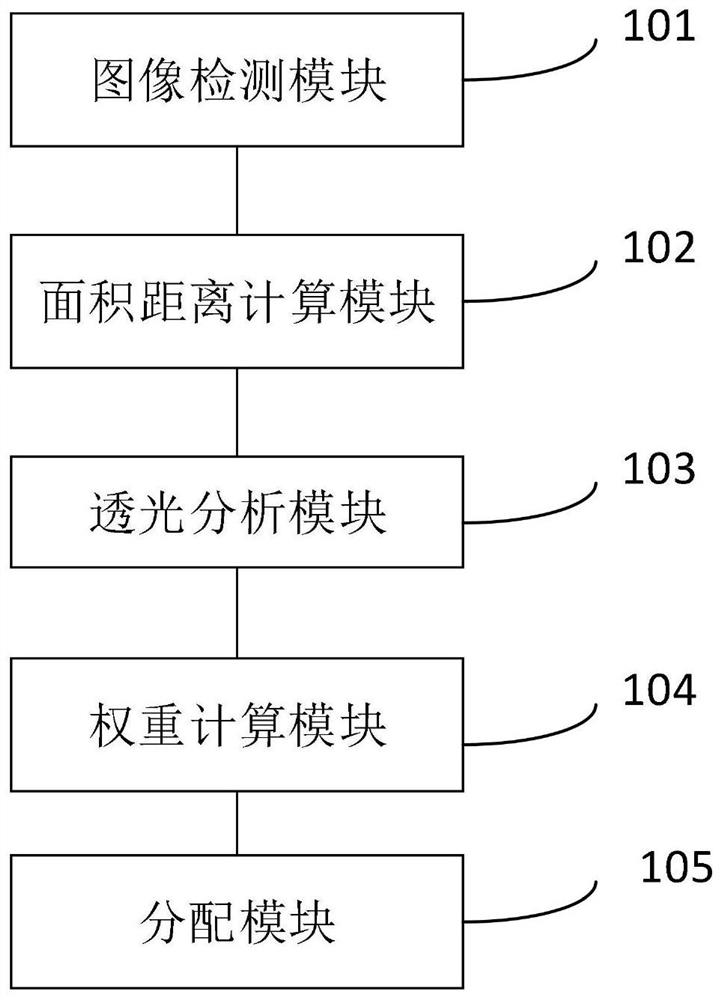

Multi-robot cooperative cleaning method and device on photovoltaic module based on artificial intelligence

InactiveCN112588764AEfficient cooperationTo achieve the purpose of cleaningImage enhancementImage analysisCells panelAlgorithm

The invention relates to the technical field of artificial intelligence, in particular to a multi-robot cooperative cleaning method and device on a photovoltaic module based on artificial intelligence. The method comprises the following steps of acquiring a surface RGB image of a photovoltaic cell panel, performing graying and threshold segmentation, acquiring the area of a smudgy area of the photovoltaic cell panel, and calculating the distance; acquiring a smudginess image, performing HSV color space conversion to obtain a second smudginess image, dividing smudginess categories, and obtaining a measurement value reflecting the light-proof degree according to the brightness and saturation of the second smudginess image and the influence coefficient of the smudginess categories; acquiringa total weight coefficient according to the measurement value of the light-proof degree of the smudgy area and the area and the distance of the smudgy area; and using the total weight coefficient as the edge weight of the cleaning robot and the smudgy area to carry out maximum weight distribution on the cleaning robot, so that each cleaning robot can reach the corresponding position to carry out cleaning. According to the multi-robot cooperative cleaning method and device on the photovoltaic module based on artificial intelligence provided by the invention, task area route distribution can becarried out on the smudgy area, so that the cleaning robot can be guided to carry out cleaning efficiently and rapidly.

Owner:李振环

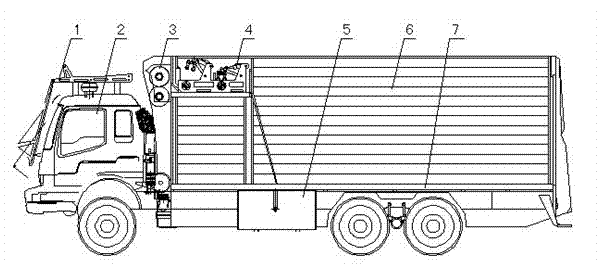

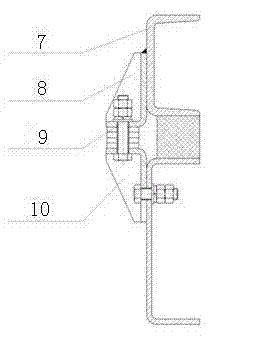

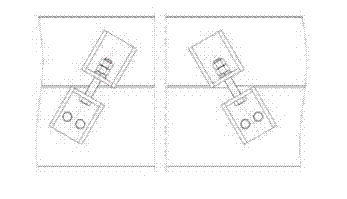

Water hose rolling module of long-distance water supply system

ActiveCN103083847ATo achieve the purpose of cleaningLarge working spaceFire rescueEngineeringWorking space

The invention discloses a water hose rolling module of a long-distance water supply system. A guide rail is mounted at the top of a headstock; a chassis is mounted below an entire body; a box body is mounted in back of the headstock; water band washing equipment is mounted between the top of the headstock and the box body; a water hose rolling system is mounted inside the box body beside the water hose washing equipment; a water tank is mounted at a left part below the box body; and a secondary beam is mounted on the right side of the water tank below the box body. With the adoption of the technical scheme provided by the invention, the water hose rolling module is used for providing strong and powerful power for an entire car; the entire body is firm and reliable, so that the security can be ensured; a tent covers a box top and can be quickly uncovered when a water hose is rolled and unrolled, so that the working space of operators can be expanded, a water hose rolling and unrolling process is convenient and fast; and meanwhile, the water hose rolling module is randomly flexible to move in work, and the purpose of washing the water hose further can be realized.

Owner:JIANGSU ZHENXIANG VEHICLE EQUIP

Backflushing type tap water purifier

InactiveCN105268233AInnovative design ideasEasy to cleanStationary filtering element filtersPistonFiltration

The present invention relates to water purification equipment, and discloses a backflushing type tap water purifier, which comprises an outer cavity, wherein both ends of the outer cavity are opened, the inner cavity is divided into a left chamber and a right chamber, a first filtration core and a second filtration core are respectively sleeved inside the left chamber and the right chamber, the second filtration core and the right chamber form sliding matching so as to form a piston type structure, the side wall of the first filtration core is provided with a first water inlet for entering of tap water, the adjacent surfaces of the first filtration core and the second filtration core are correspondingly provided with a first water outlet and a second water inlet, the first water outlet and the second water inlet are communicated, the second filtration core is provided with a water purification hole for removing purified water, the outer cavity is provided with a tap water inlet and a tap water outlet, the tap water outlet is correspondingly provided with a tap water switch, and both ends of the outer cavity are provided with a left end cover and a right end cover for sealing the inner cavity. According to the present invention, the backflushing type tap water purifier has characteristics of novel design idea, easy operation, and effective filtration core dirt removing.

Owner:孙银焕

Bean sprout washing equipment

Owner:WUXI SUYA FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com