Method for removing film contaminants generated in the technological process and PECVD system

A process and pollutant technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve problems such as corrosion, base metal damage, improper cleaning time control, etc., to reduce maintenance time and improve Yield and production efficiency, convenient and fast cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

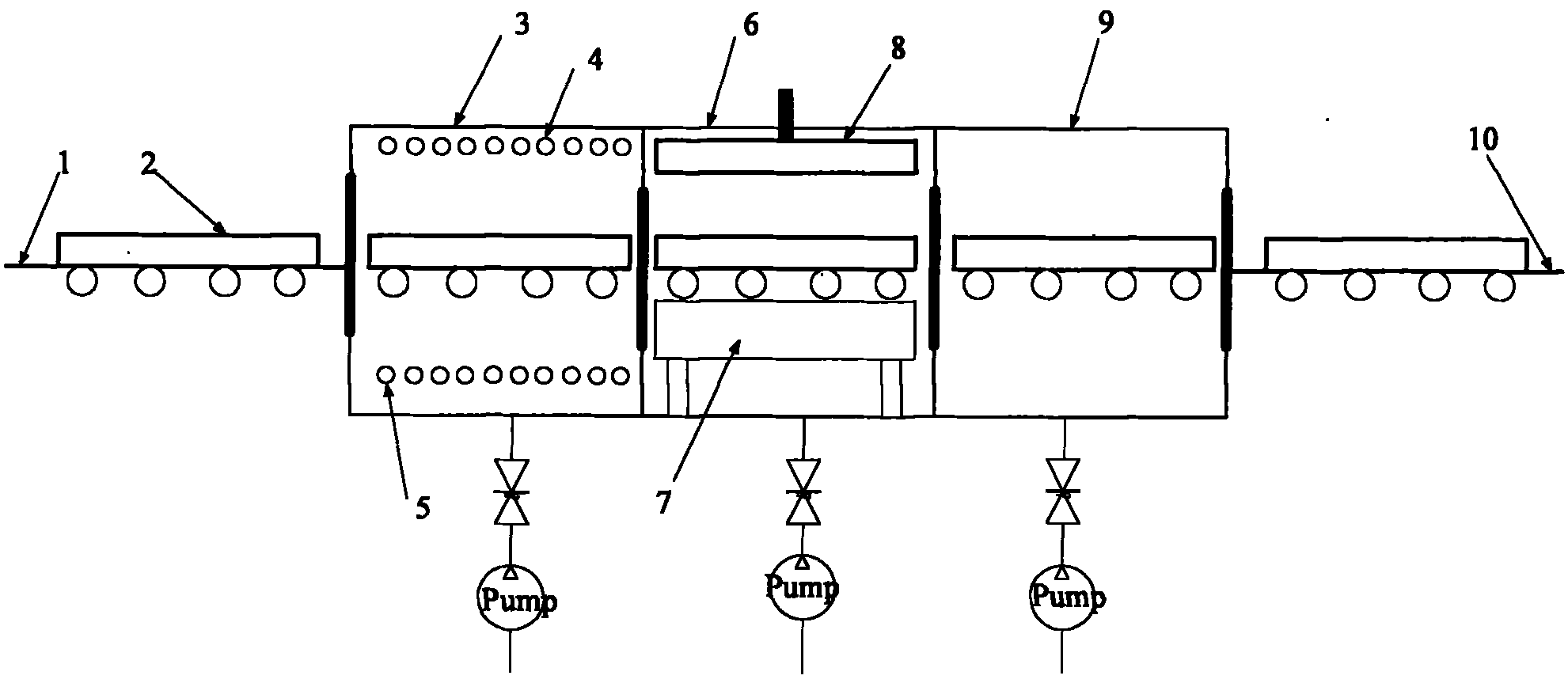

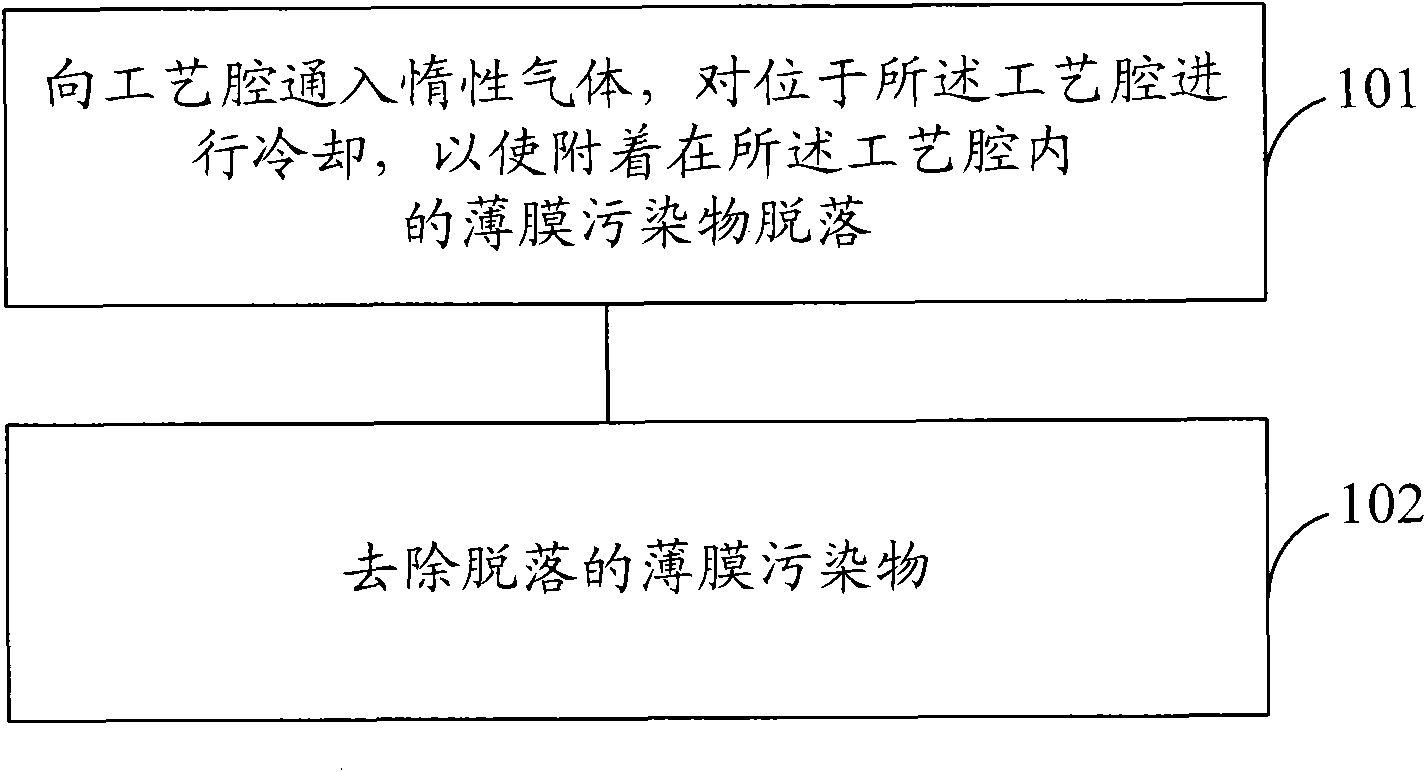

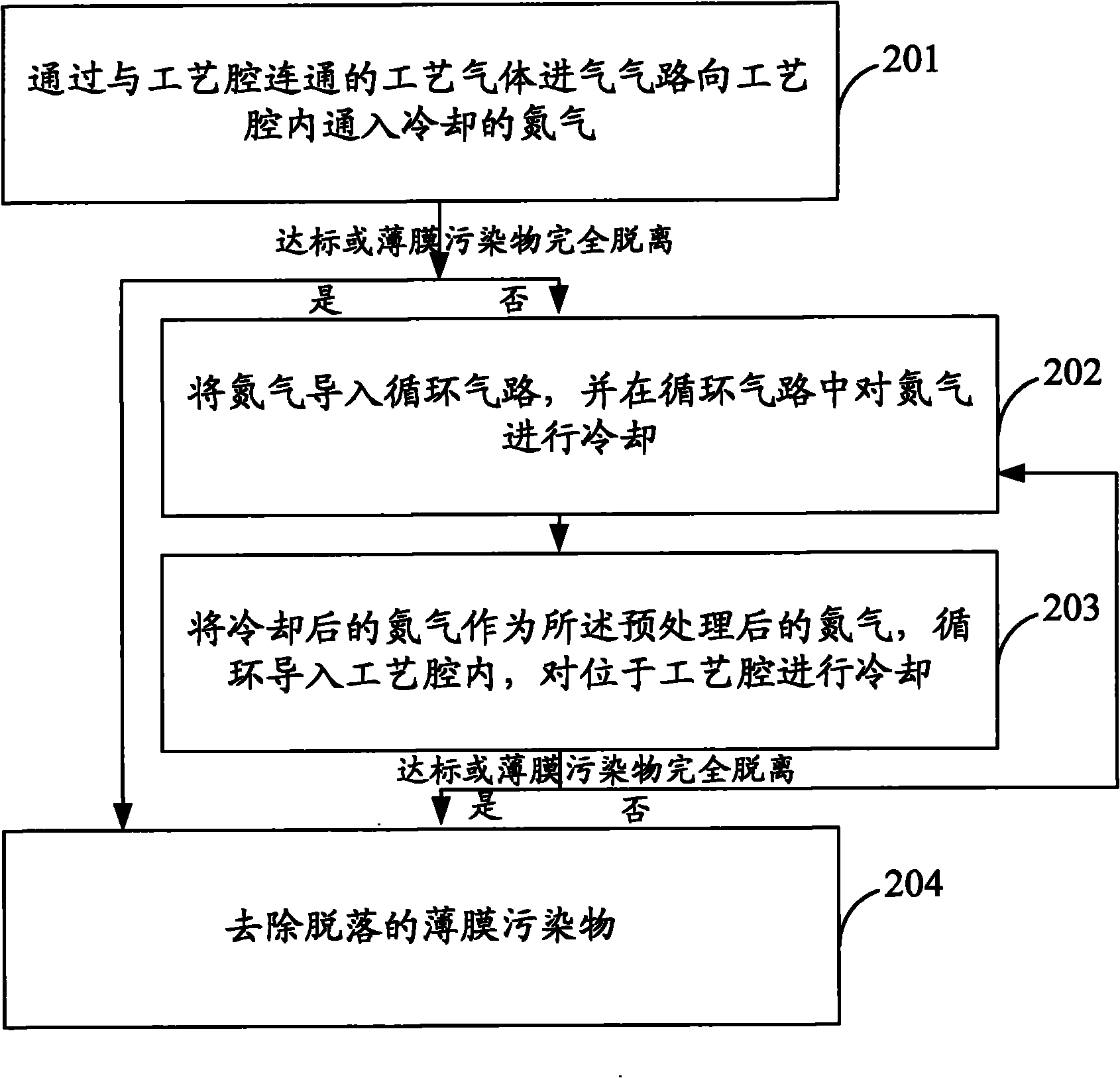

[0041] In order for those skilled in the art to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0042] In the prior art, some specific chemical solutions are used to remove the film pollutants attached to the inner wall of the process chamber and its internal devices such as the gas distribution plate. During the removal process, the chemical solution will have a certain corrosion effect on the process chamber. If the cleaning time is not properly controlled , will cause some damage to the base metal, and it is necessary to disassemble the gas distribution plate and other components from the process chamber and then clean them separately. The efficiency is low and the cleaning time is long, which reduces the output t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com