Patents

Literature

142 results about "Shrinkage coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microcrystal bamboo charcoal purple sand composite pottery material and application thereof

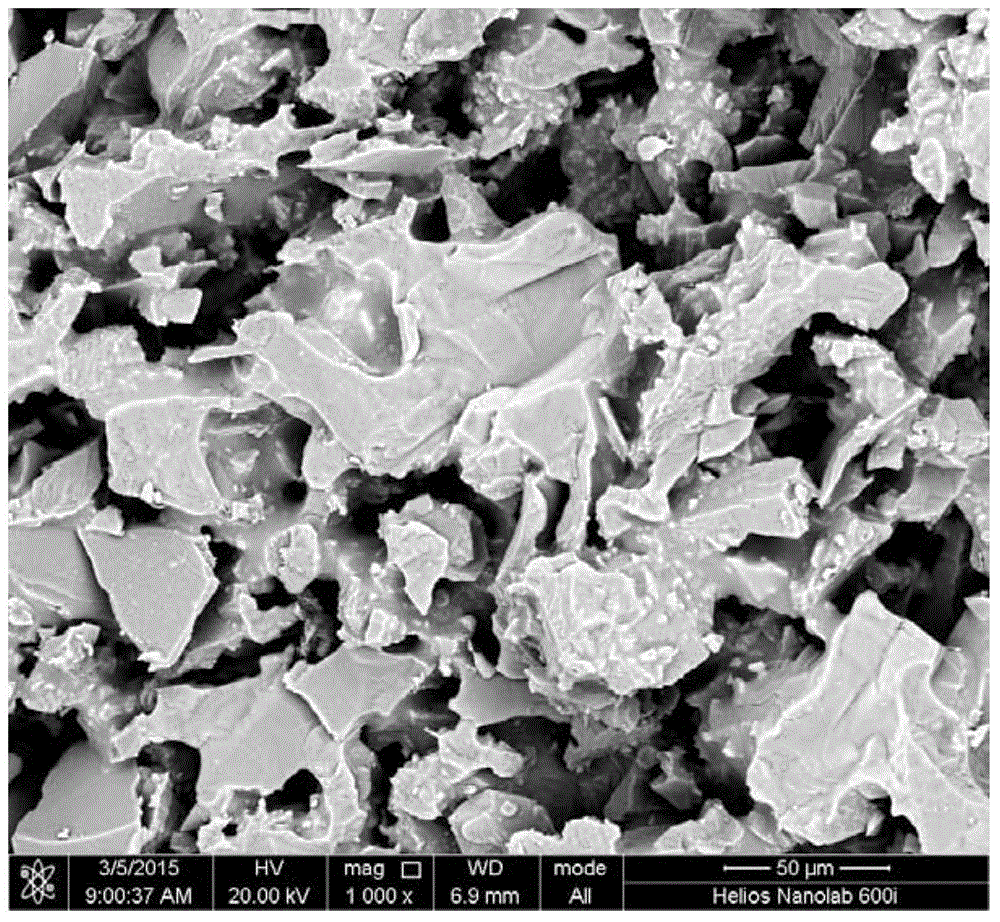

InactiveCN103467066AHigh porosityImprove thermal shock resistanceOther chemical processesCeramicwareHazardous substancePhenol

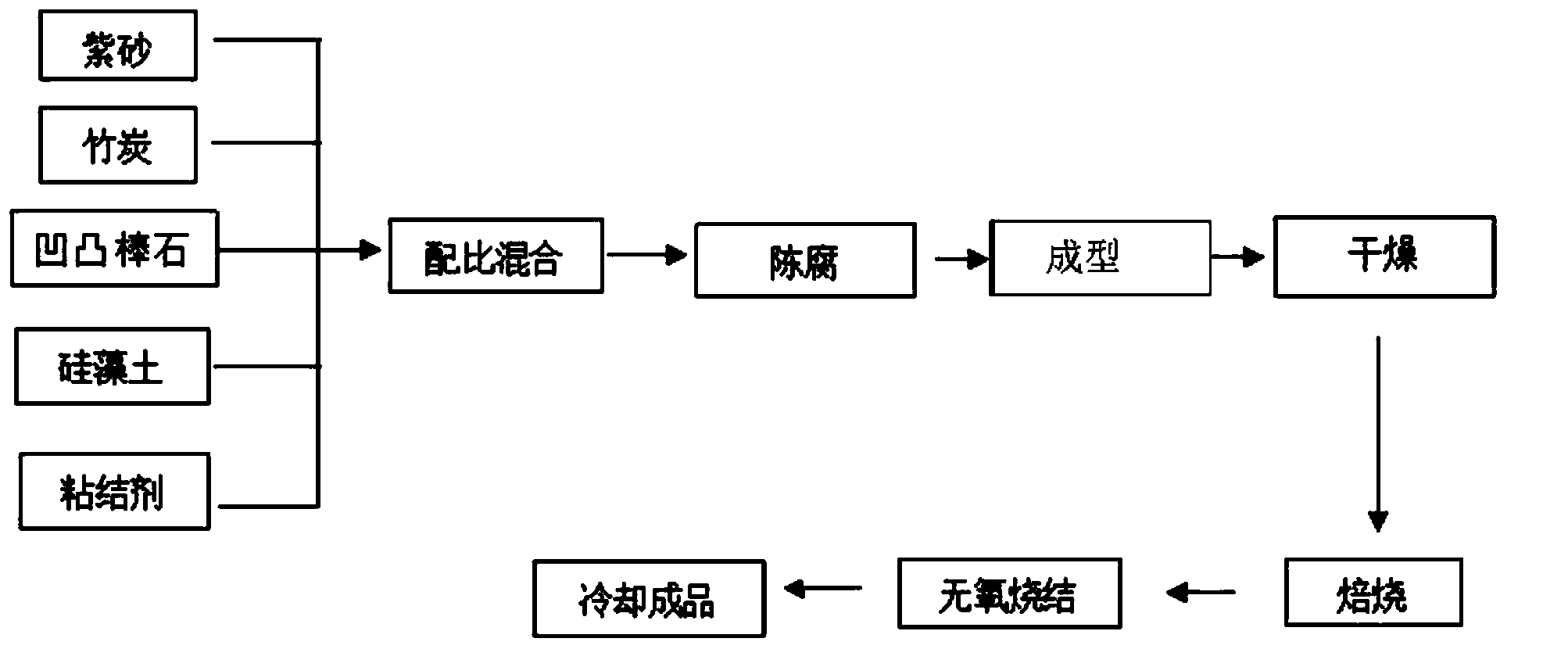

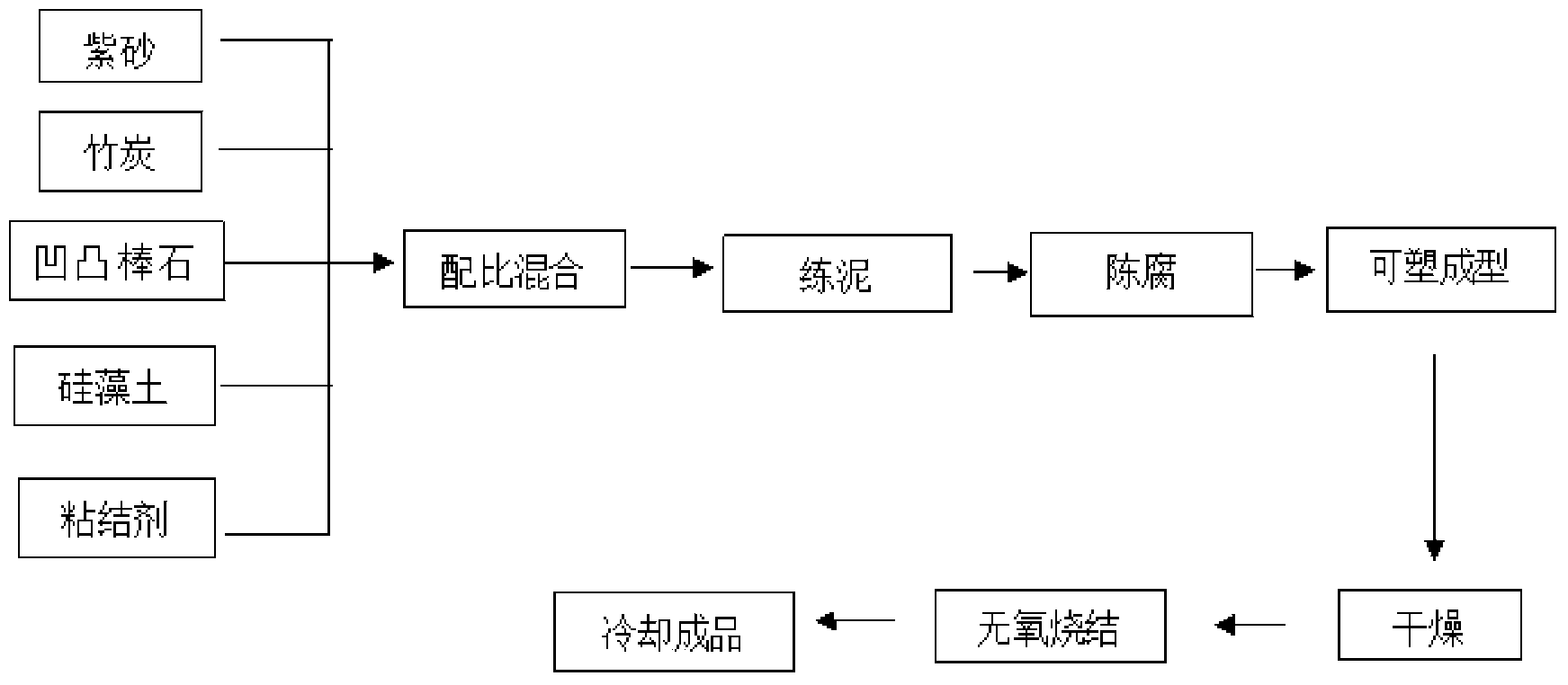

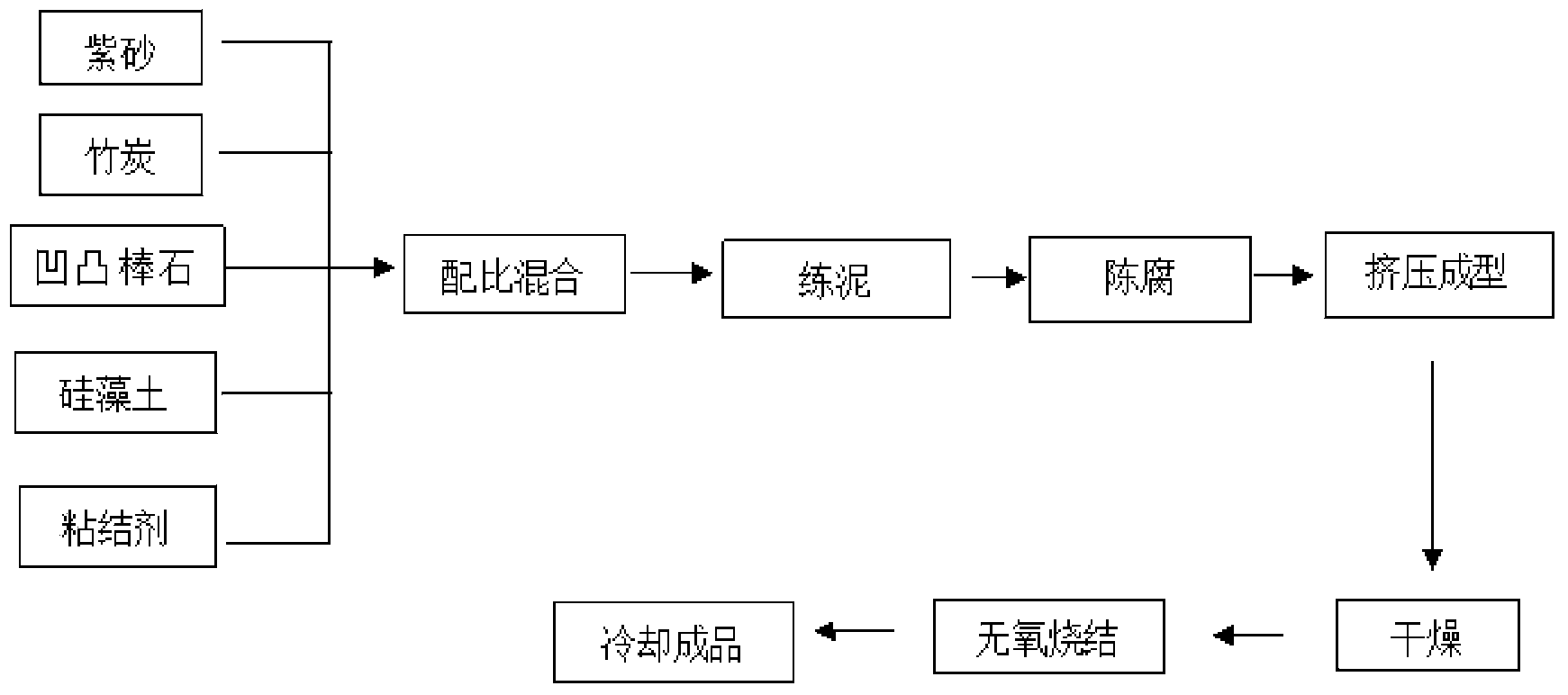

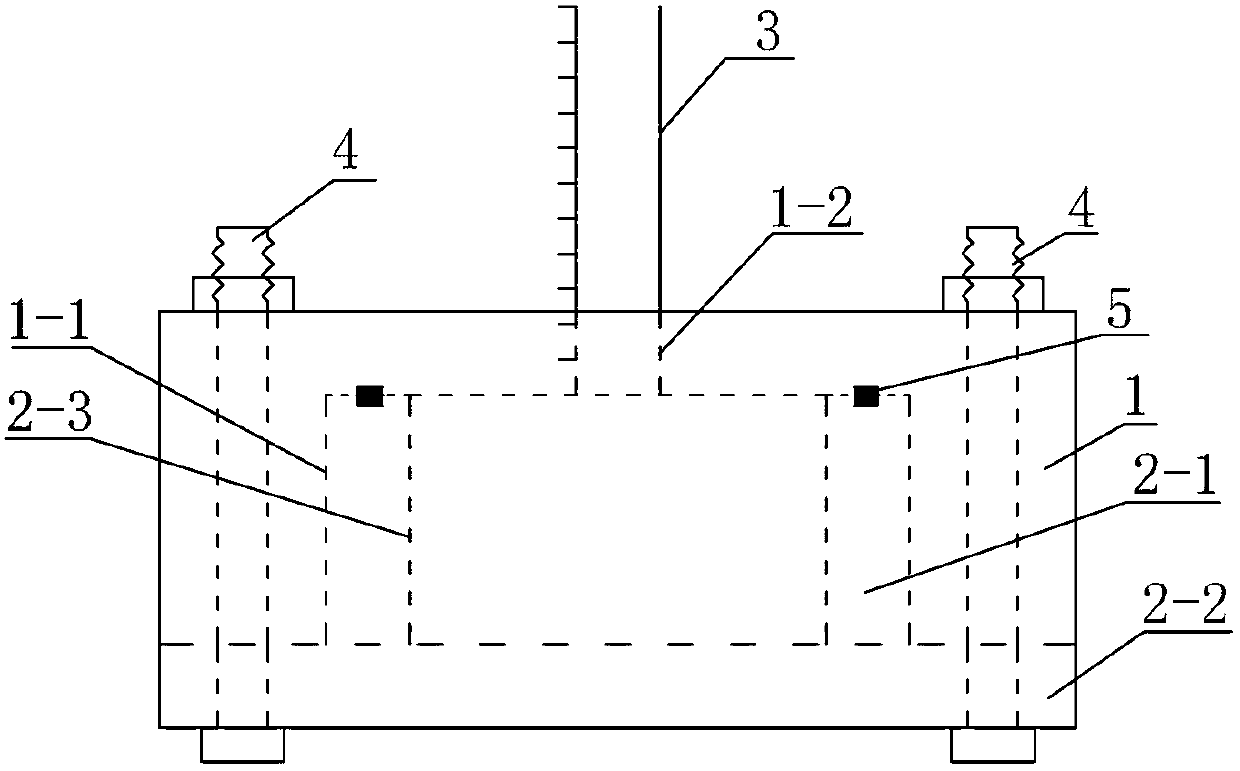

The invention relates to a microcrystal bamboo charcoal purple sand composite pottery material and application of the microcrystal bamboo charcoal purple sand composite pottery material. The microcrystal bamboo charcoal purple sand composite pottery material is composed of, by weight, 5-40% of microcrystal bamboo charcoal powder, 40-60% of purple sand powder, 10-30% of attapulgite, 5-30% of kieselguhr and 1-5% of binder in a mixing mode. The microcrystal bamboo charcoal purple sand composite pottery material can be used for manufacturing a microcrystal bamboo charcoal purple sand composite pottery, the steps for manufacturing the microcrystal bamboo charcoal purple sand composite pottery are specifically forming, air drying, drying, calcination and cooling, and therefore the microcrystal bamboo charcoal purple sand composite pottery can be obtained. According to the microcrystal bamboo charcoal purple sand composite pottery material and the application of the microcrystal bamboo charcoal purple sand composite pottery material, through different raw material ratios and calcination crafts, the manufactured microcrystal bamboo charcoal pottery after processing is low in firing shrinkage coefficient, high in bending strength and strong in adsorption of formaldehyde, phenol, sulfur dioxide, TVOC and other hazardous substances and can be manufactured into pottery materials of different water adsorption rates as required.

Owner:王萍 +2

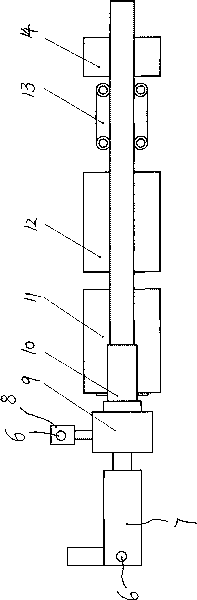

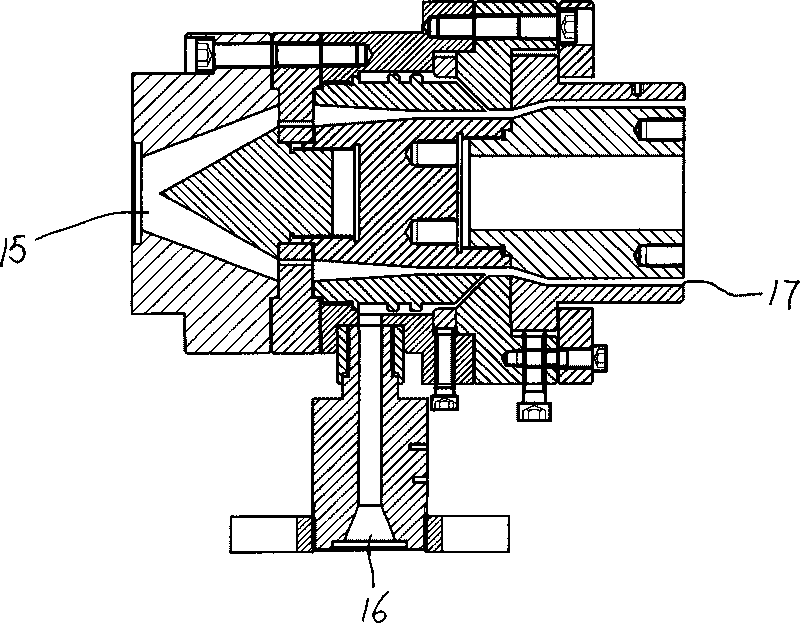

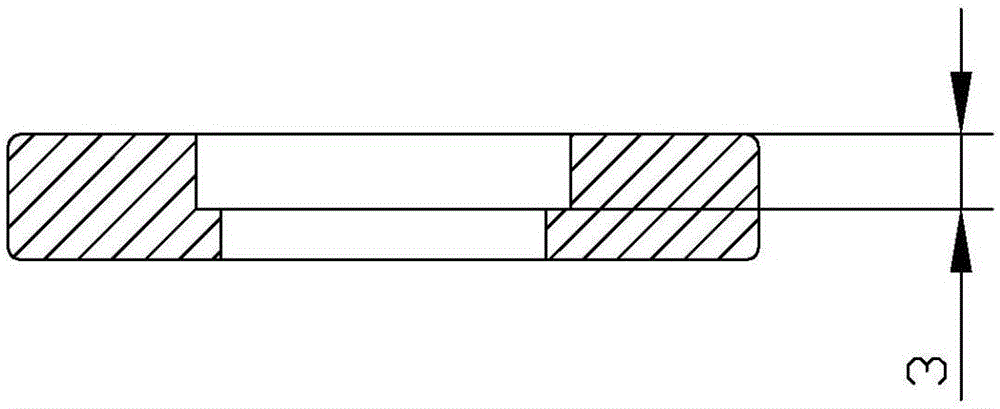

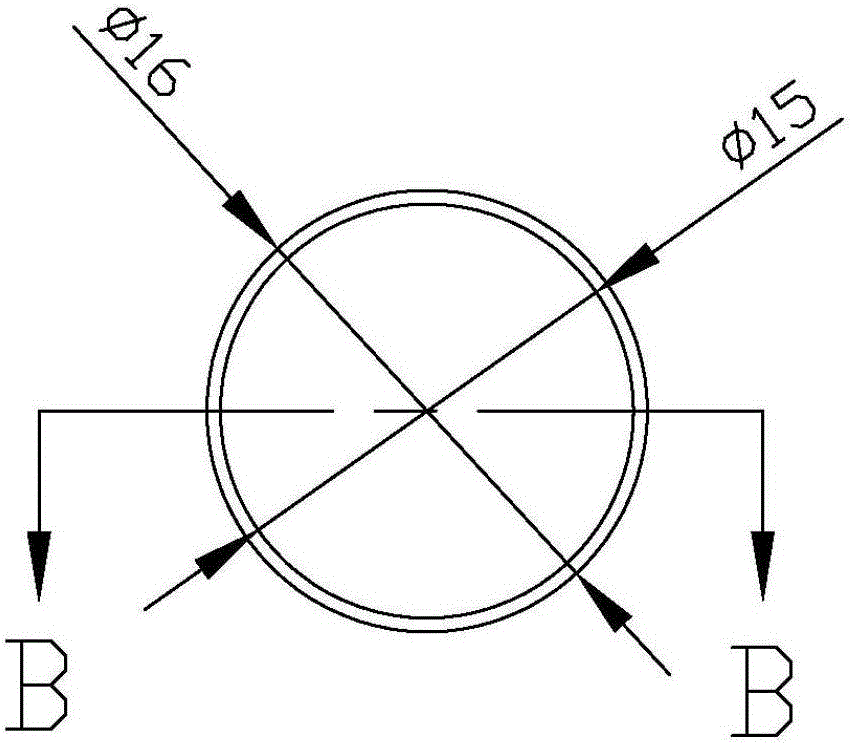

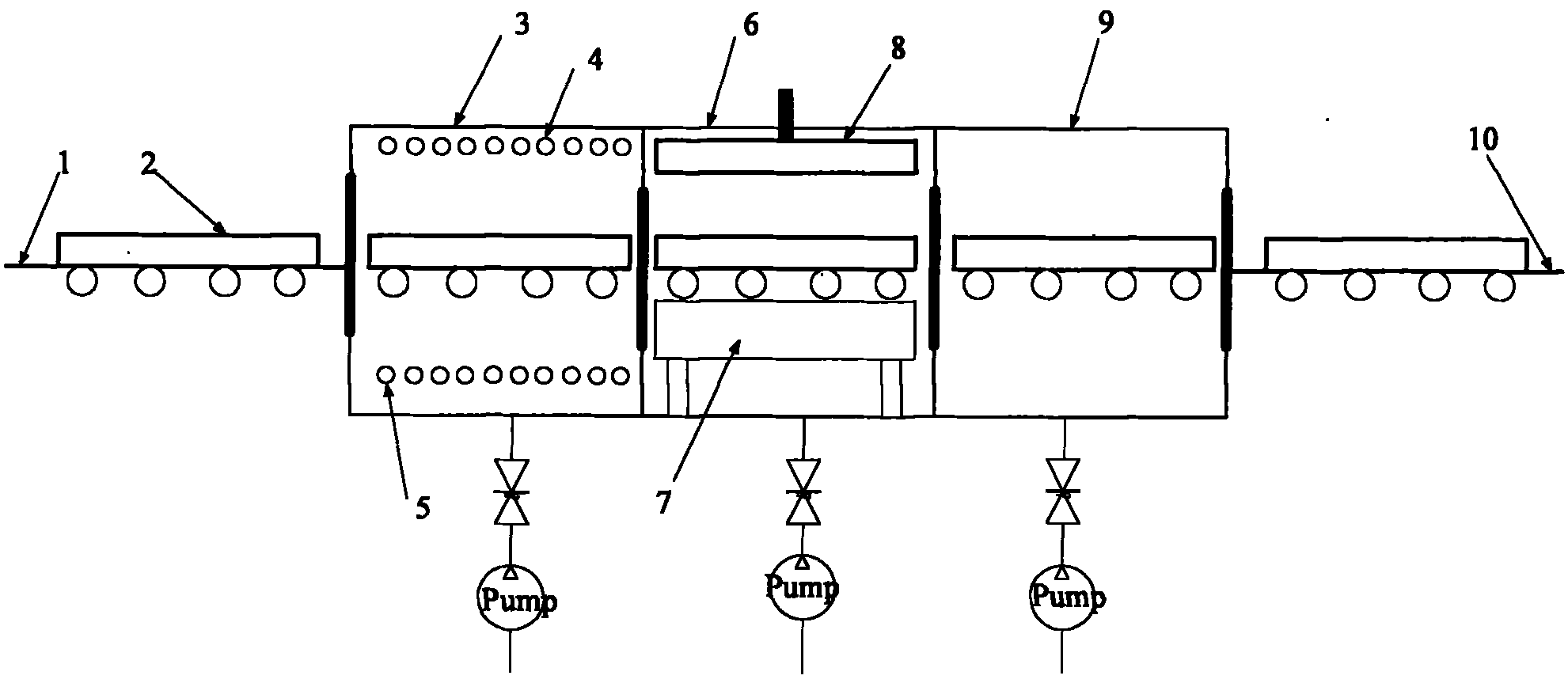

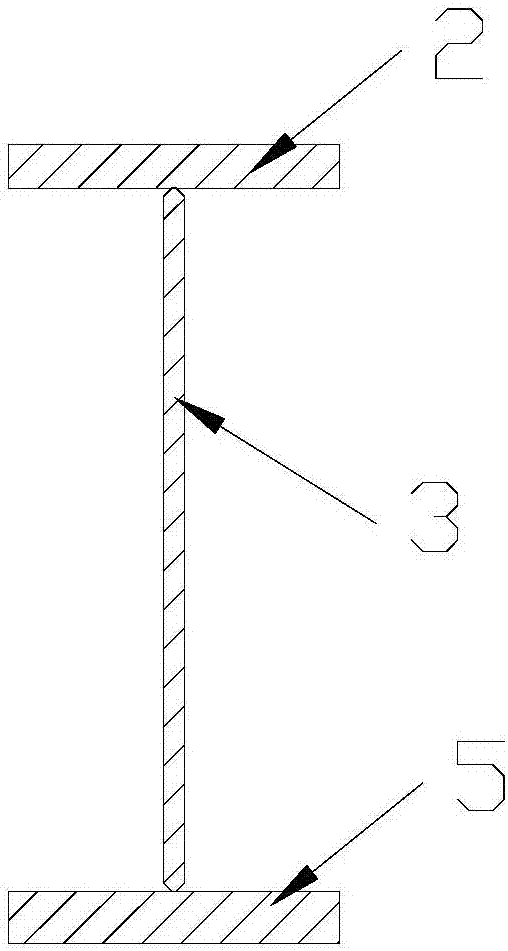

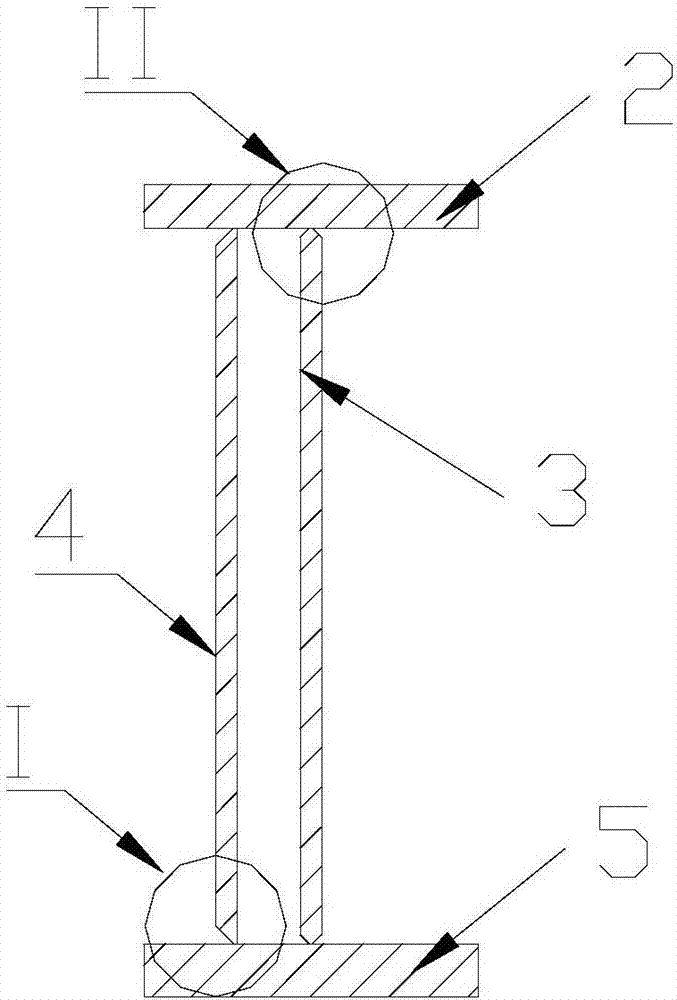

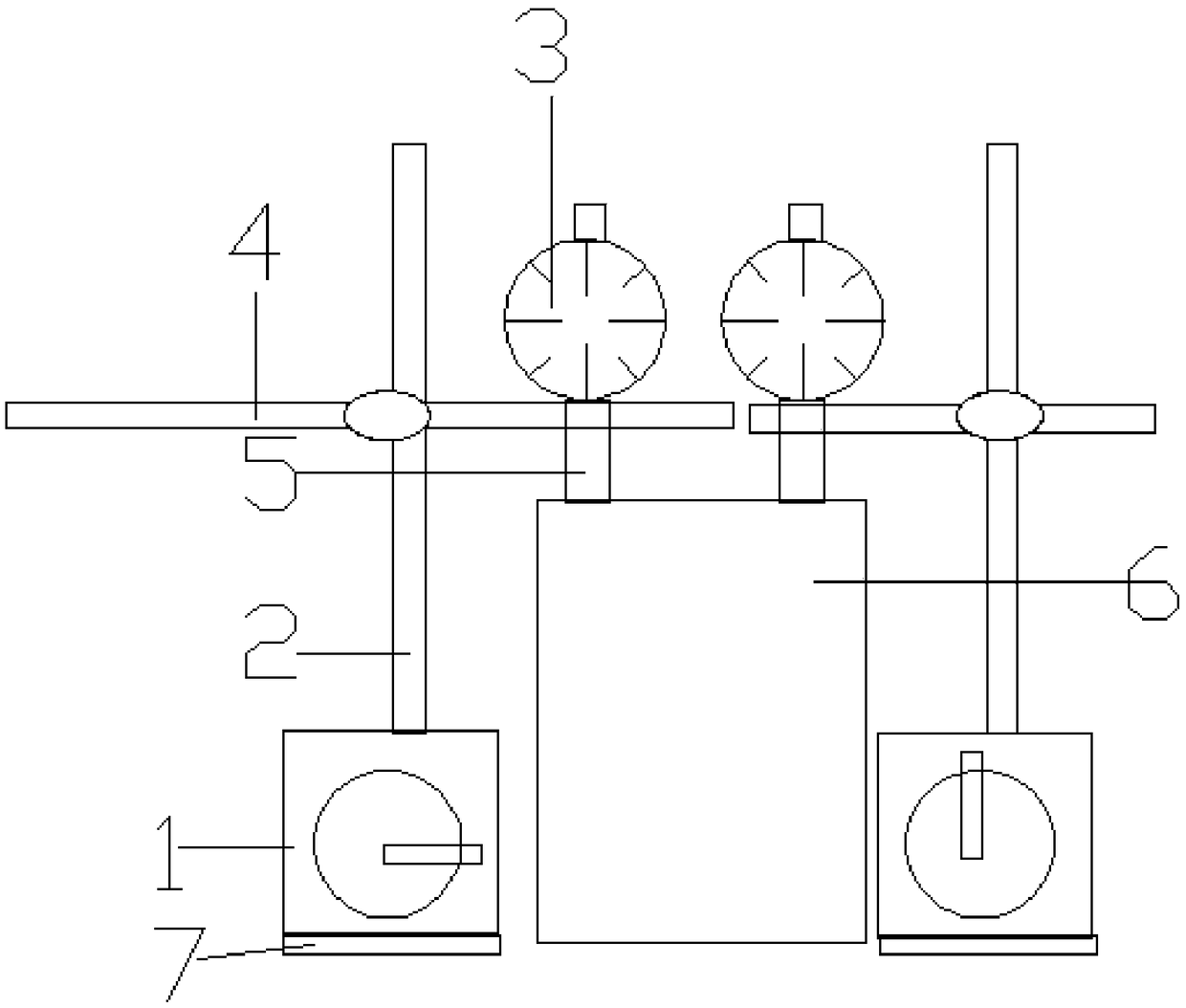

Asphalt volume expansion and shrinkage coefficient determinator and method

ActiveCN103278526ASolve the problem of linear expansion coefficientReduce low temperature crackingMaterial thermal coefficient of expansionAsphaltComputer science

The invention discloses an asphalt volume expansion and shrinkage coefficient determinator and method, and relates to a volume expansion and shrinkage coefficient determinator and method of a material, in order to solve the problems that when an existing device determines the asphalt volume expansion and shrinkage coefficient, the determined result accuracy cannot be ensured because of the influences by asphalt adhesion and the creep property, and only the linear coefficient of asphalt can be determined. The asphalt volume expansion and shrinkage coefficient determinator comprises a top cover, a base and a glass tube, wherein the base comprises a connector and a base plate; the connector is inserted and installed in a first groove, and the connector and the first groove are detachably connected with each other; the upper end surface of the connector and the bottom surface of the first groove are sealed; and a second groove forms an enclosed chamber. The determining method mainly comprises the following steps of: step 1, assembling the determinator; step 2, determining the volume expansion or shrinkage coefficient of an indicator; step 3, manufacturing an asphalt test element and determining the volume of the asphalt test element; step 4, determining the volume expansion or shrinkage coefficient of the asphalt test element; and step 5, calculating the volume expansion or shrinkage coefficient of the asphalt test element. The asphalt volume expansion and shrinkage coefficient determinator and method provided by the invention are used for determining the asphalt volume expansion and shrinkage coefficient.

Owner:HARBIN INST OF TECH

Forming method of hard alloy threaded hole

InactiveCN107695618AAvoid processing difficultyGuaranteed accuracyThread cutting machinesNumerical controlCompression molding

The invention discloses a forming method of a hard alloy threaded hole. The forming method of the hard alloy threaded hole is characterized by comprising the following steps of preparing materials, wherein PEG is used as a forming agent, raw materials are ground with ethyl alcohol, and after spray drying is conducted, a mixture is generated; conducting mold pressing, wherein compression molding isconducted on the mixture; conduct semi-machining, wherein through a numerical control milling machine or a lathe or a machining center, a dedicated cutter of a special material is used, accurate thread dimension calculation is conducted, and then a threaded hole of a fixed parameter is machined on the pressed blank; and conducting sintering, wherein the needed threaded hole is obtained through sintering formation finally. The forming method of the hard alloy threaded hole has the beneficial effects that through accurate pressed blank shrinkage coefficient control, inner threads are machined on the pressed blank, the machining difficulty existing when the alloy threaded hole is machined after sintering is avoided, and a scheme is provided for machining of the hard alloy threaded hole.

Owner:九江金鹭硬质合金有限公司

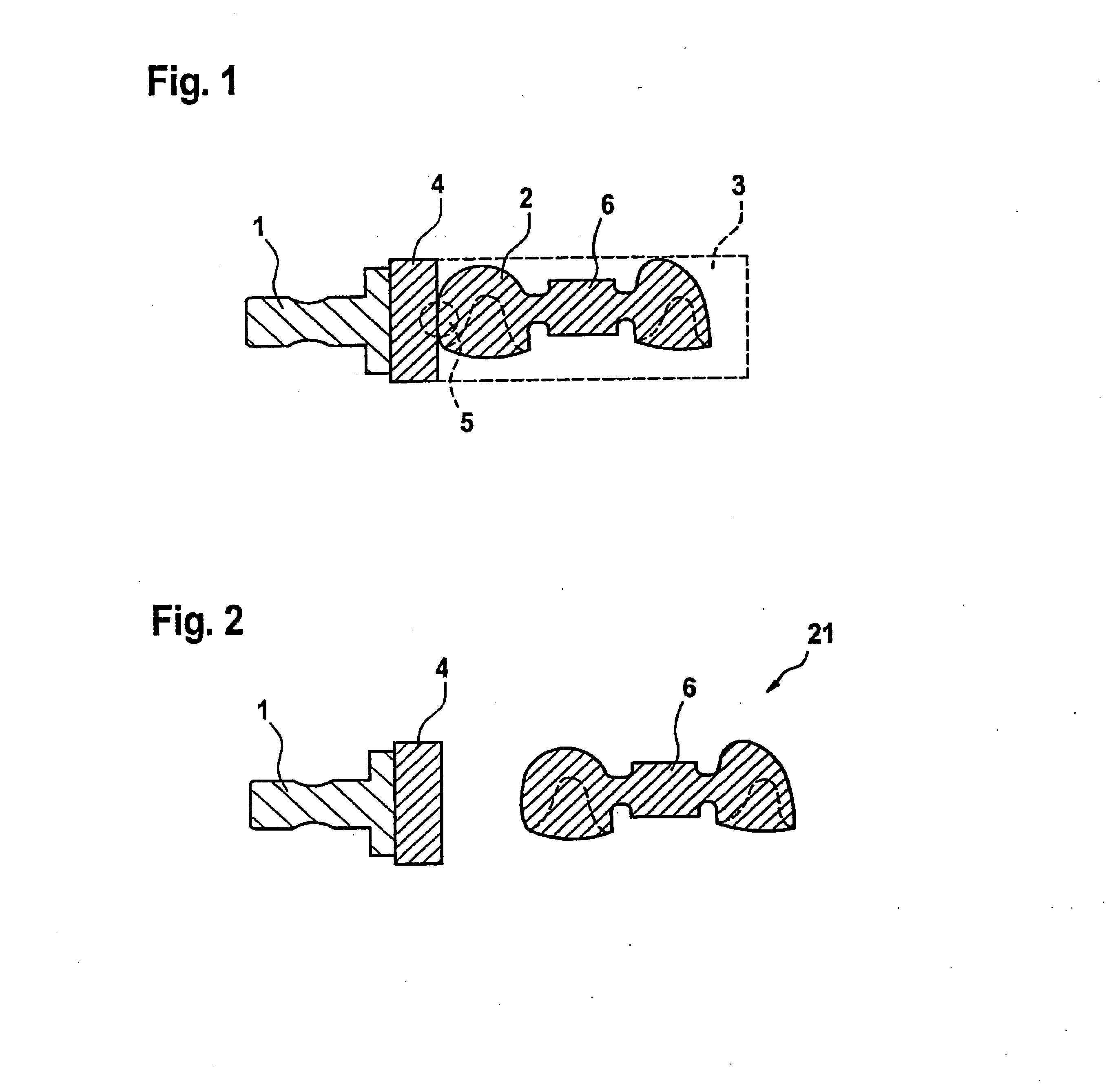

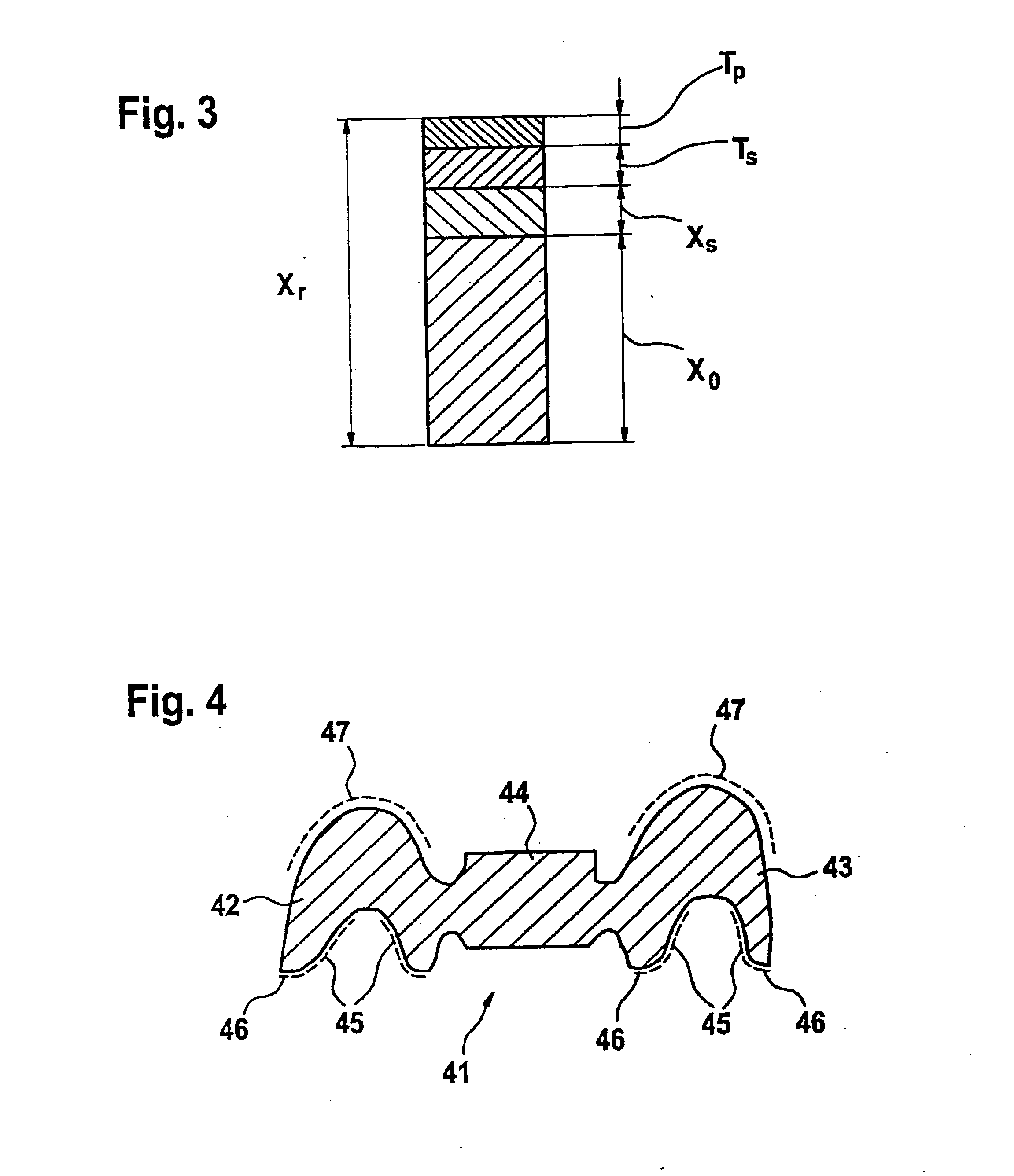

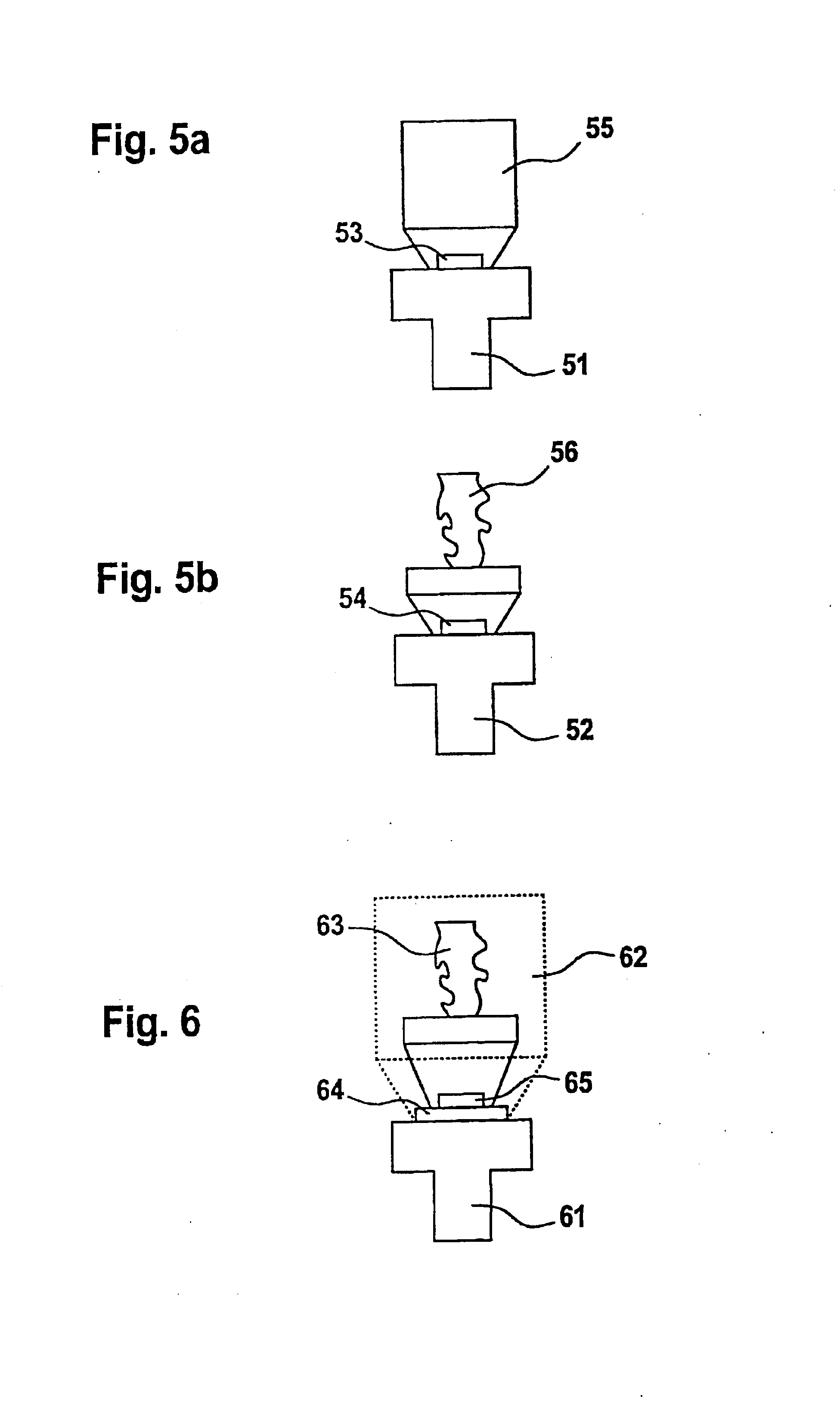

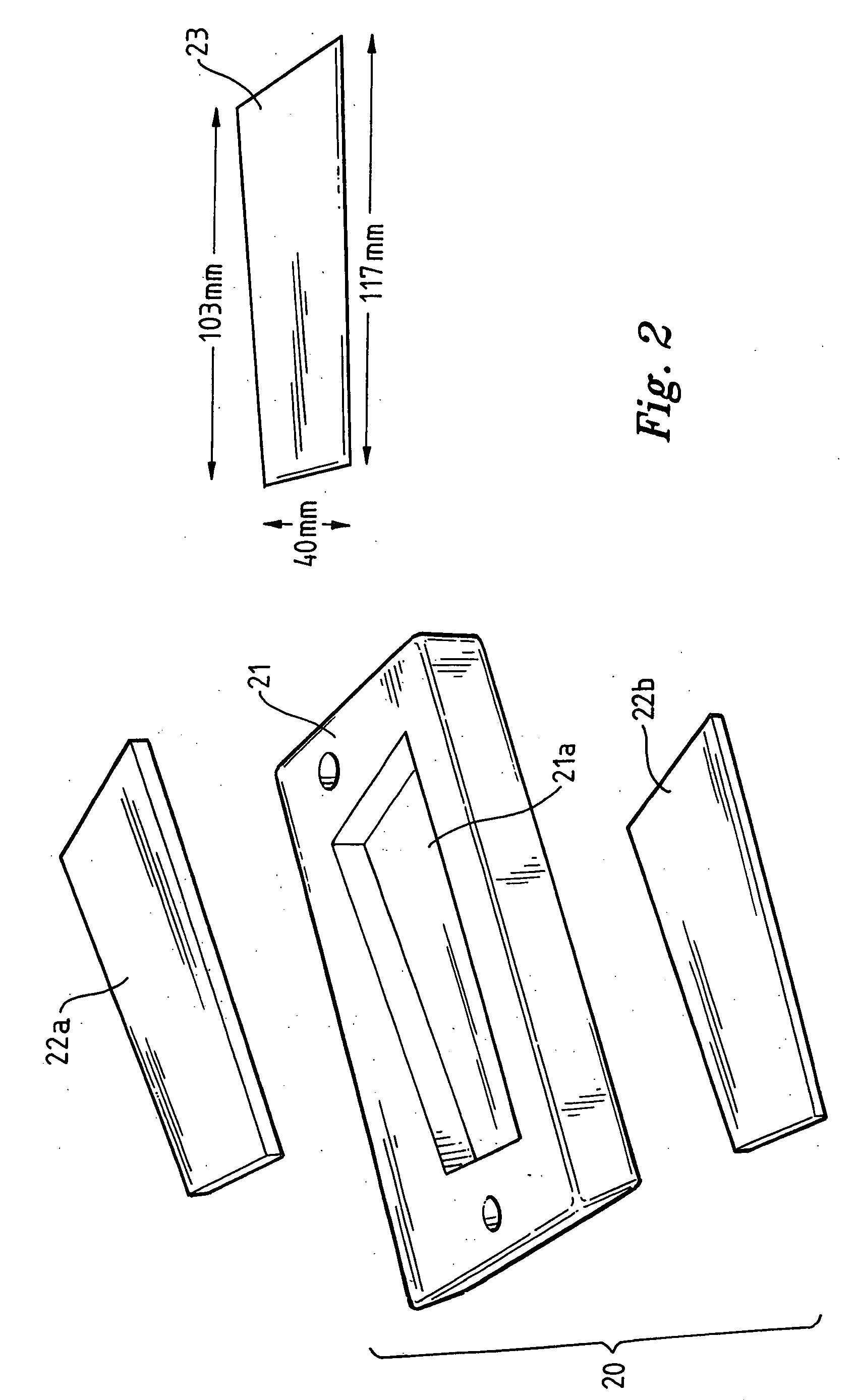

Method for production of a dental fitting body

InactiveUS20070172787A1Shorten the timeAccurate operationDental toolsDental prostheticsDenturesProsthesis

The invention relates to a method for the production of a tooth prosthetic piece (21), in particular, a skeleton, using a blank (3) for machining in a material ablating 3D-forming process, said blank being made from a material not yet having the final hardness, comprising a terminal hardening of the formed piece (2) produced during the forming process to give a formed piece (2′), with the final hardness, whereby the 3D forming process is divided into coarse machining process for the blank (3) and a precise finishing process for the formed piece (2′) with the final hardness, in order to give the final form of the tooth prosthesis piece (21). The invention further relates to a mount or mounting set for carrying out the method in said particular fashion, comprising connectors for mounting the blank and suited to the shrinkage factor of the fixed formed piece. A further aspect of the invention concerns a formed piece, which, in addition to the usual over-dimension, has a further over-dimension including the tolerance range for the material shrinkage and the machining process.

Owner:SIRONA DENTAL SYSTEMS

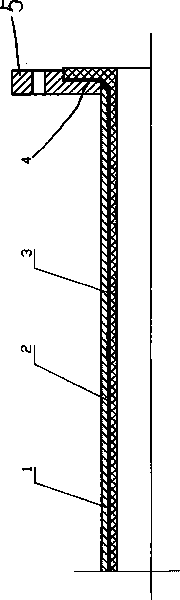

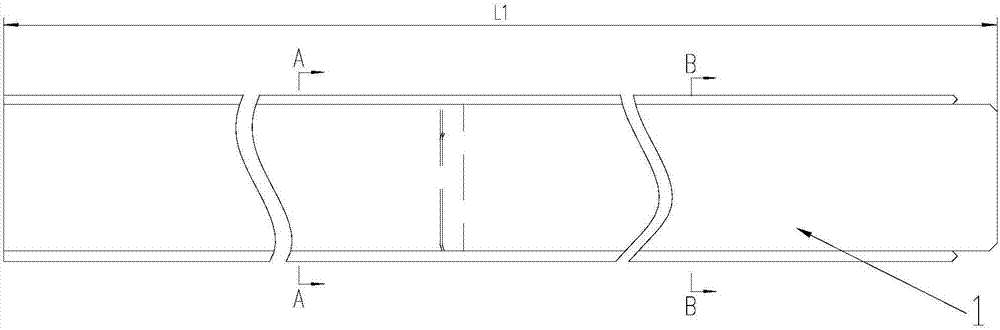

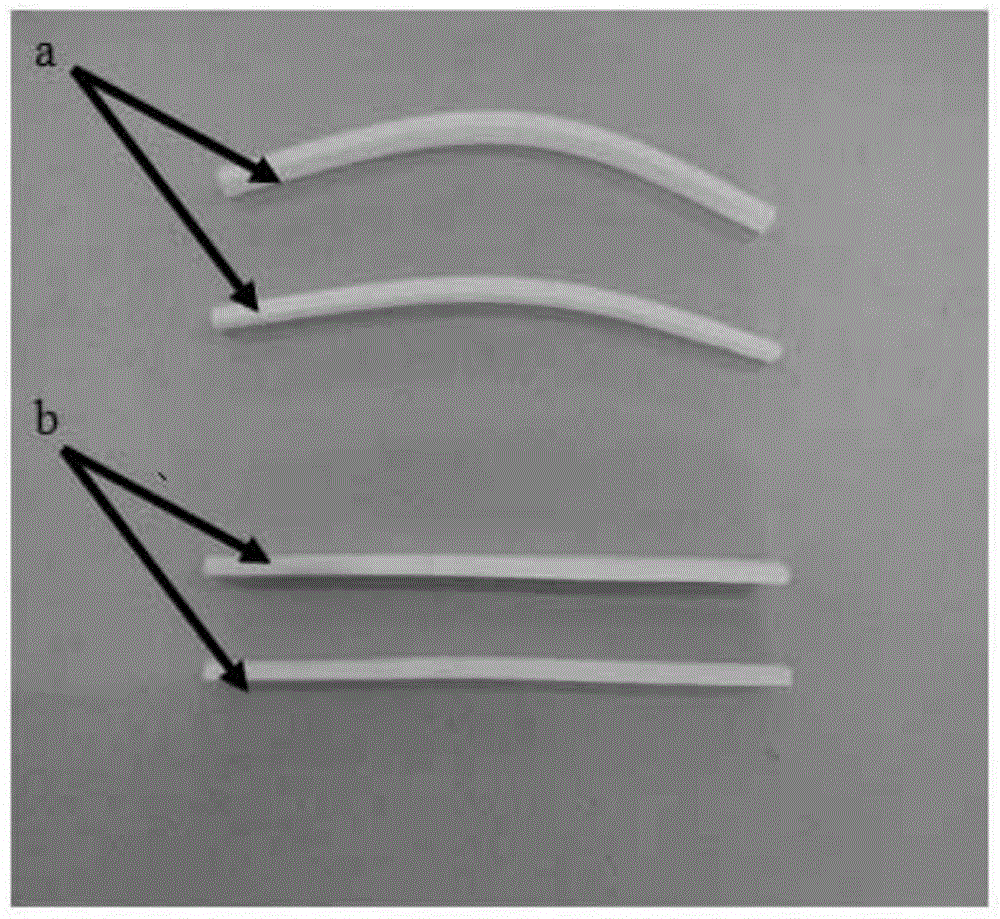

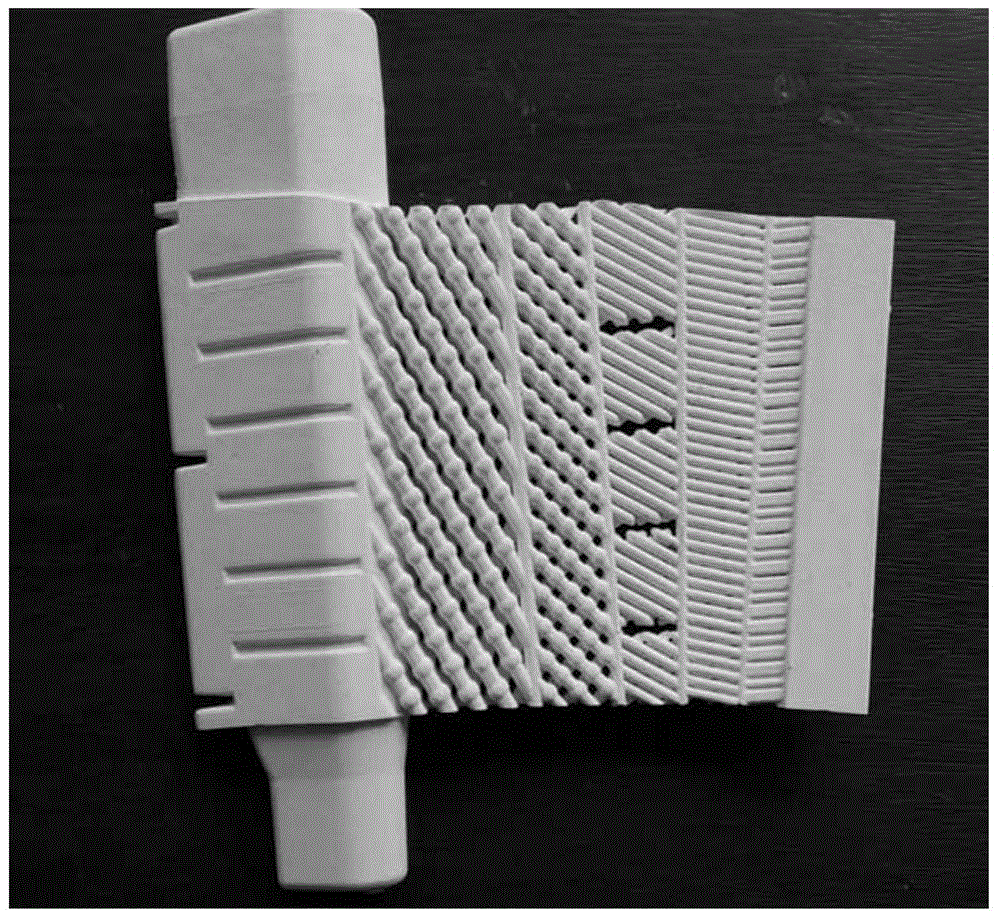

Mine wear-resistant composite metal plastic pipe, special preparation equipment thereof and preparation method thereof

InactiveCN101725774AImprove pressure bearing capacityLight weightLayered productsRigid pipesPolymer scienceWear resistant

The invention belongs to the technical field of pipes and discloses a mine wear-resistant composite metal plastic pipe, special preparation equipment thereof and a preparation method thereof. The mine wear-resistant composite metal plastic pipe has the main technical characteristics that: the wear-resistant composite metal plastic pipe comprises an outer wall steel pipe, wherein a high molecular weight polyethylene lining layer is arranged in the outer wall steel pipe; a maleic anhydride graft copolymerization modification low molecular weight polyethylene intermediate bonding layer used for bonding the high molecular weight polyethylene lining layer and the outer wall steel pipe into a whole is arranged between the high molecular weight polyethylene lining layer and the outer wall steel pipe; the end part of the outer wall steel pipe is provided with a flange plate with a trough; and the end part of the high molecular weight polyethylene lining layer is flanged and clamped into the trough. The mine wear-resistant composite metal plastic pipe uses the outer wall steel pipe as a pressure-bearing body with high pressure-bearing capability, uses the high molecular weight polyethylene lining layer as a wear-resistant and anti-corrosive layer to convey media such as slurry, paste, corrosive fluids and the like with different particle diameters, and uses the maleic anhydride graft copolymerization modification low molecular weight polyethylene intermediate bonding layer to composite the three layers of materials into a whole with the same expansion and shrinkage coefficients on the inner layer and the outer layer to overcome the defect that the pipe is blocked caused by plastic pipe end face deformation and steel-plastic delamination in the process of use.

Owner:河北金菱管业股份有限公司

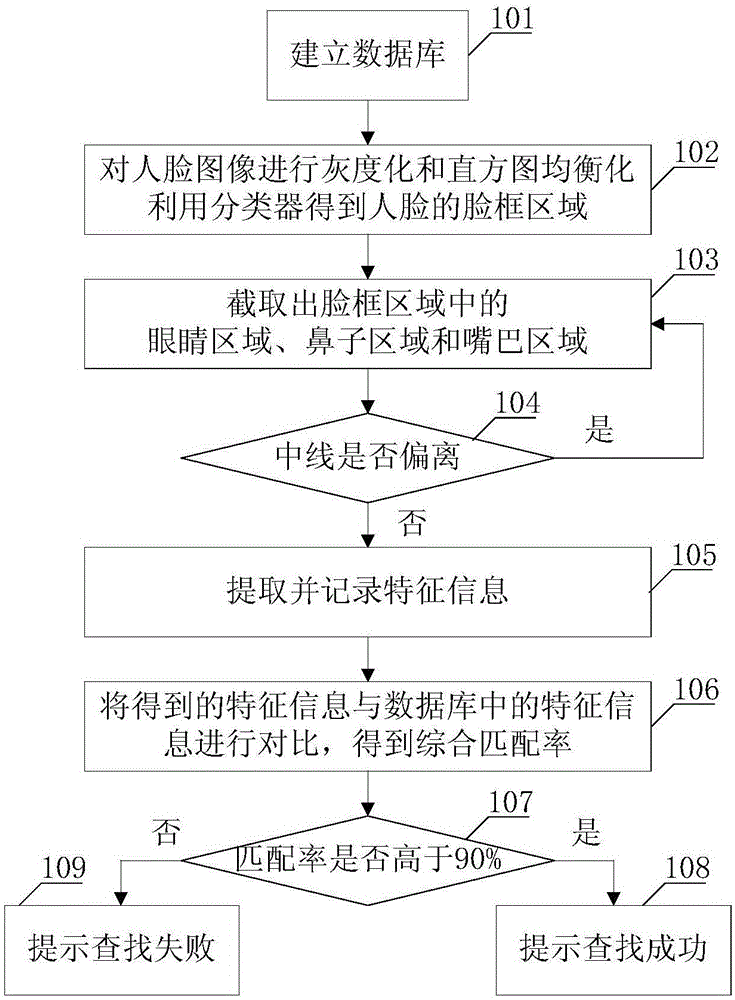

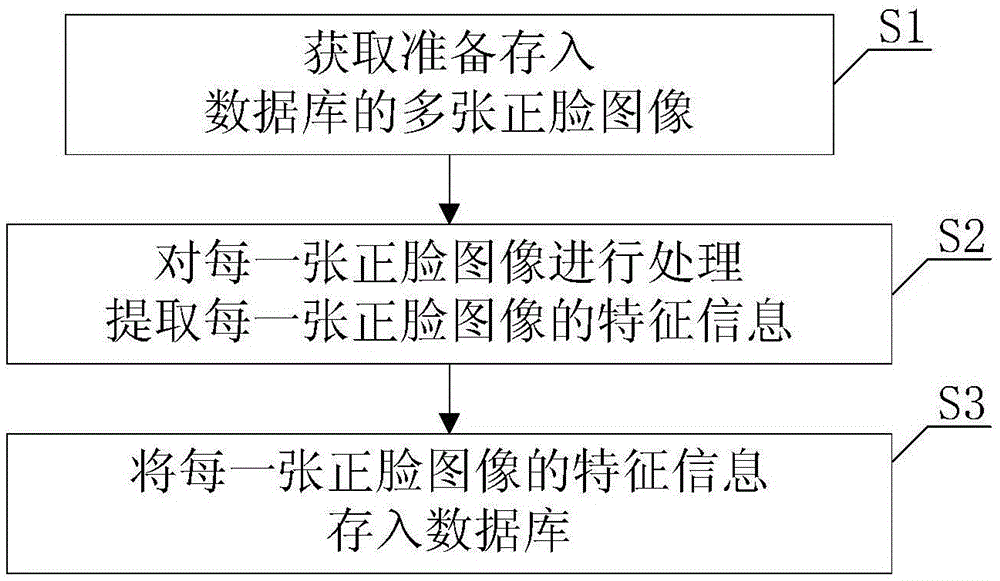

Hidden Markov model based face geometrical feature identification method

InactiveCN105160331AReduce rigidityLower conditionsCharacter and pattern recognitionHide markov modelHistogram equalization

The invention discloses a hidden Markov model based face geometrical feature identification method. The method comprises: performing graying and histogram equalization on a face image and obtaining a face frame region of a face by utilizing a classifier; setting a shrinkage coefficient of the face frame region, shrinking the face frame region, and intercepting an eye region, a nose region and a mouth region in the face frame region by utilizing the classifier; extracting and recording feature information; and comparing the obtained feature information with feature information stored in a database, to obtain the comprehensive matching rate. Comparative matching is performed by utilizing length and angle ratios of parts of the face, so that the influence caused by non-rigid and illumination conditions of the face is greatly reduced, the influence caused by change of the length and angle ratios of the parts of the face along with change of age and weight of people is avoided, and the accuracy and scientificity of matching are ensured.

Owner:镇江锐捷信息科技有限公司

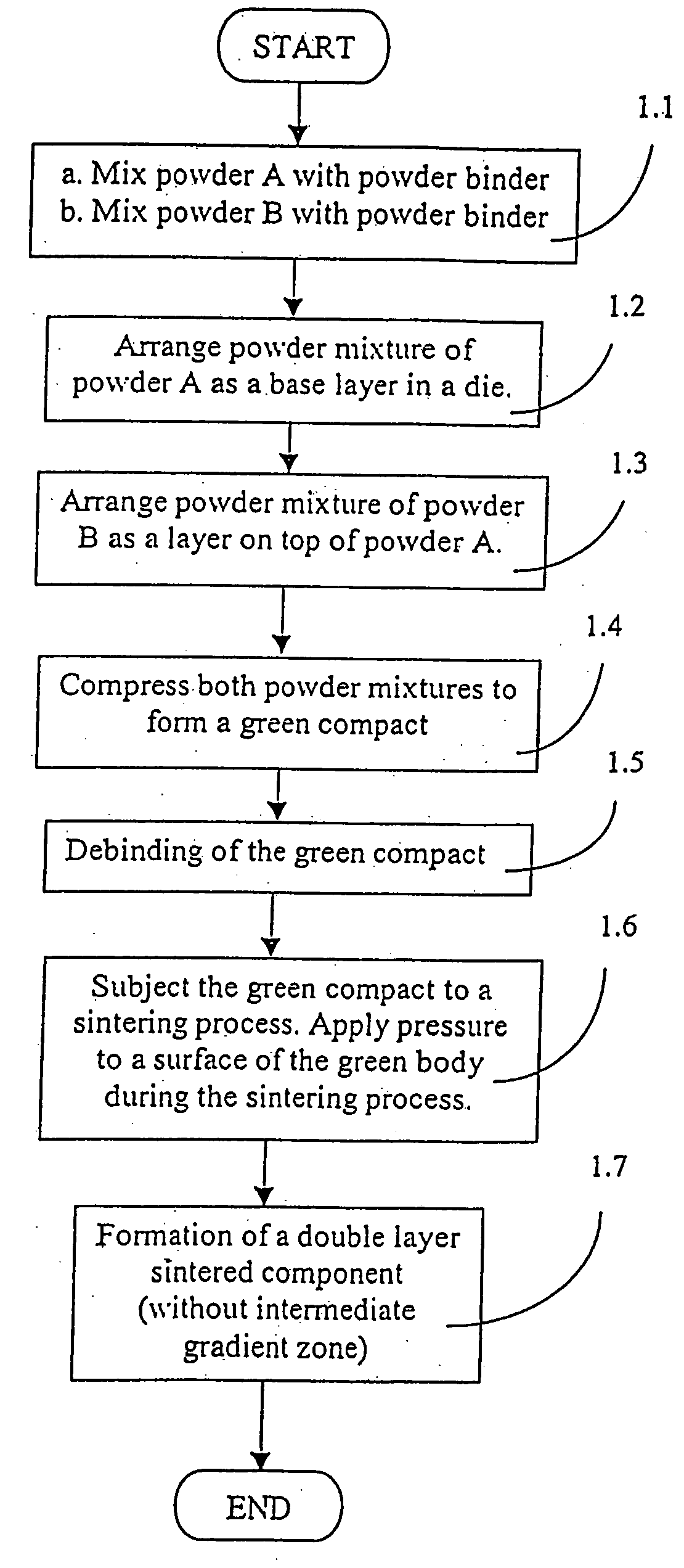

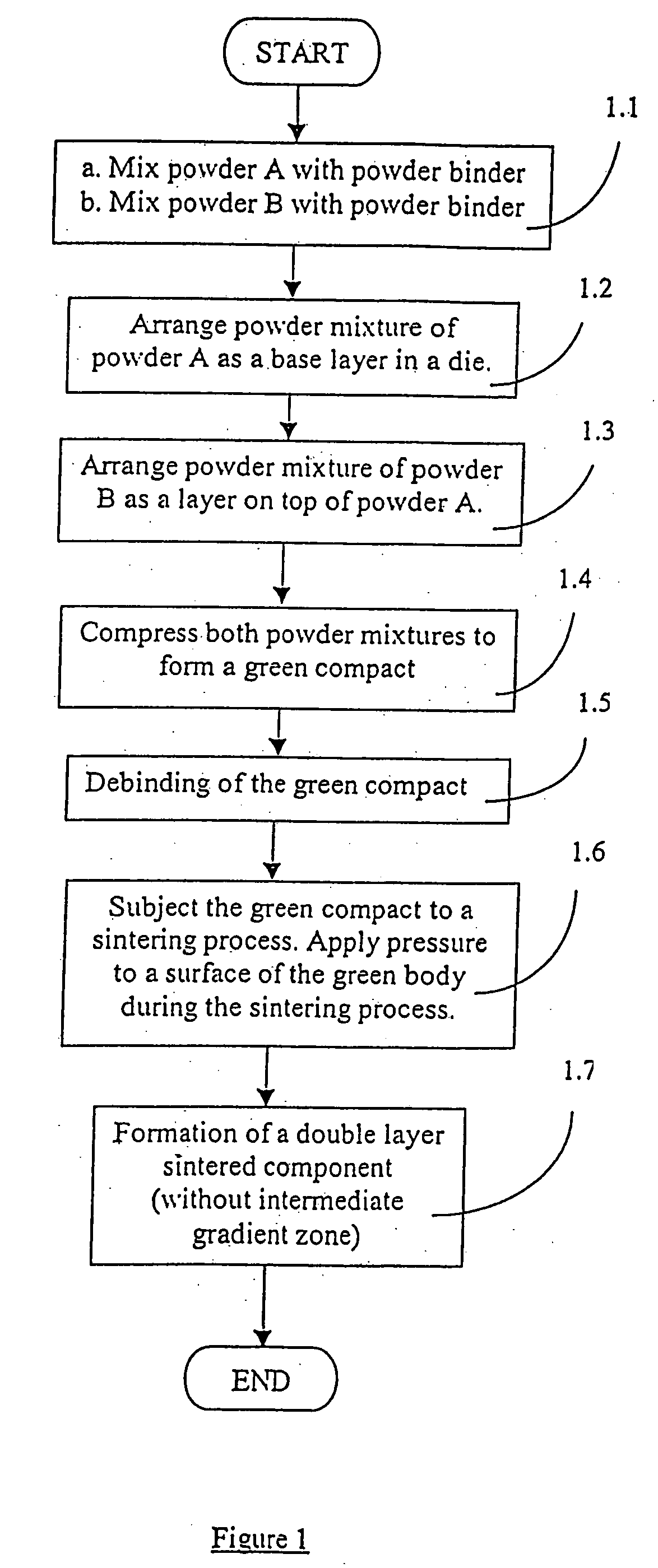

Double-layer metal sheet and method of fabricating the same

InactiveUS20050019199A1Reduces and prevents warpageReduce shrinkage differenceMetal sheetMetal powder

A method of bonding two powder components having different shrinkage factors, one of which is metal powder, is disclosed herein. In the preferred method, at step 1.1, each powder component is separately mixed with a powder binder to substantially match the other powder component's shrinkage factor. Then at steps 1.2 to 1.4, the powder component mixtures are compacted in a die set to form a green compact. Next at step 1.5, the green compact is debindered and at step 1.6, the green compact is sintered in a furnace while applying pressure on a surface of the green compact during the sintering process. In this way, the two powder components can be bonded directly without a need for an intermediate gradient zone and a double-layer metal sheet can be thus formed.

Owner:AGENCY FOR SCI TECH & RES

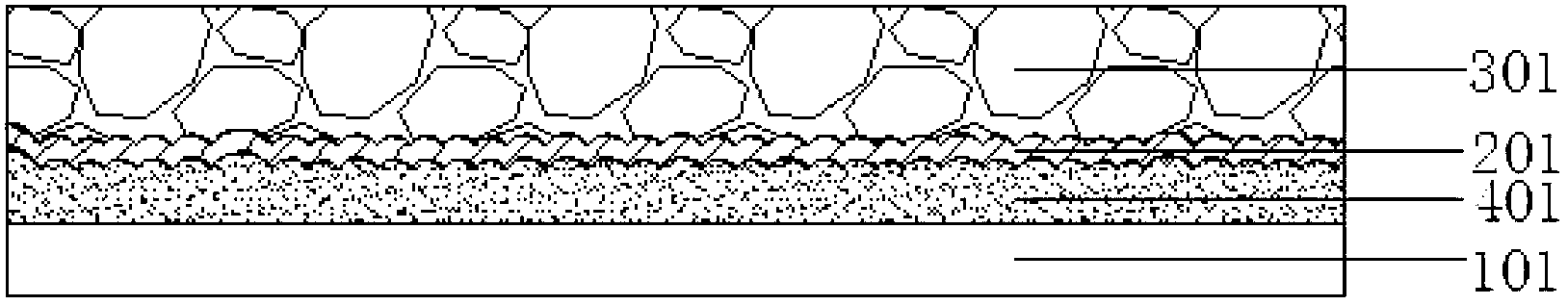

Microcrystal ceramic composite board as well as blank and preparation method of microcrystal ceramic composite board

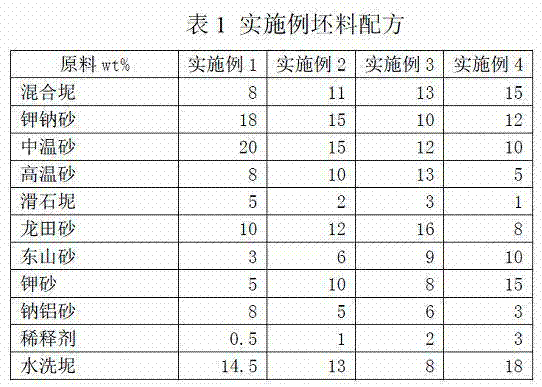

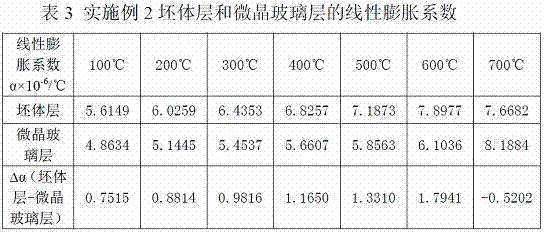

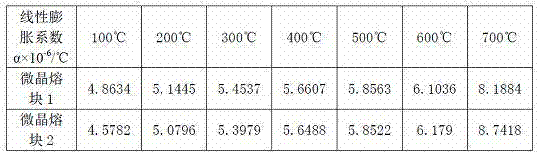

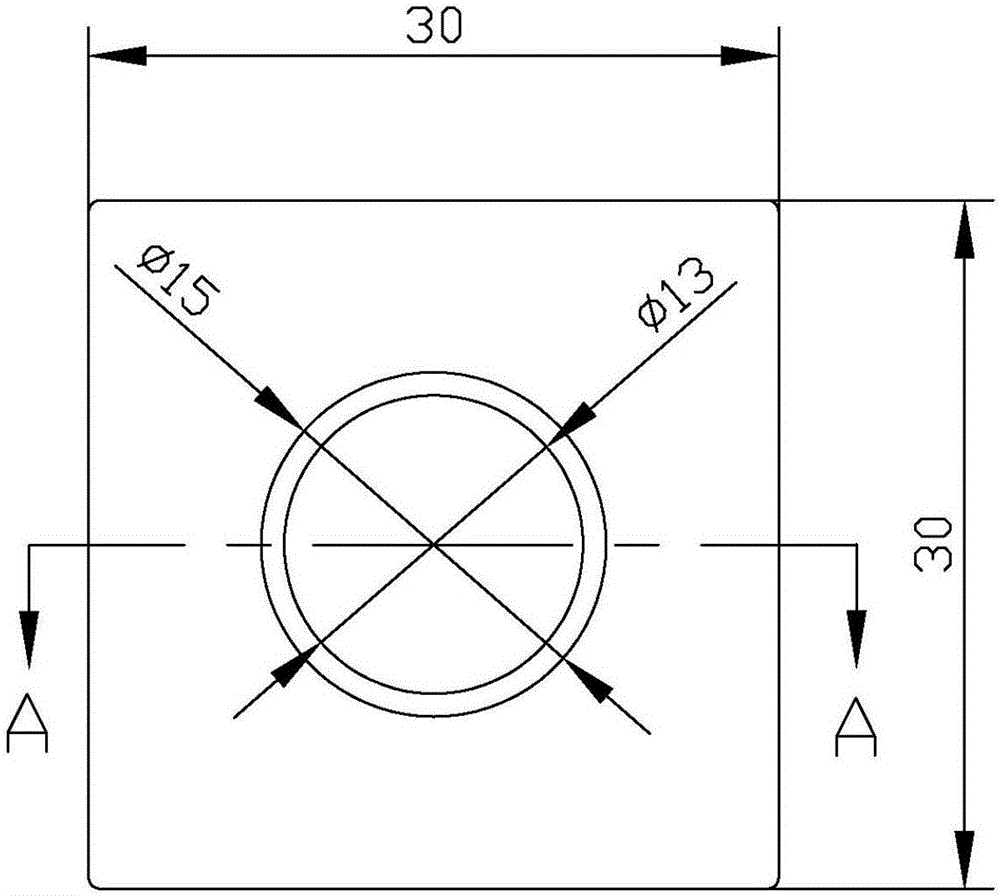

ActiveCN104743881AAlleviate problems such as flatness defectsCombined process improvementCeramic compositeFrit

The invention discloses a microcrystal ceramic composite board blank, a microcrystal ceramic composite board sintered by use of the blank and a preparation method of the microcrystal ceramic composite board. The blank is prepared from the following components in percentage by weight: 8-15% of mixed mud, 10-20% of potassium sodium sand, 10-20% of moderate-temperature sand, 5-15% of high-temperature sand, 1-5% of talcum mud, 8-16% of field sand, 2-10% of mountain sand, 5-15% of potassium sand, 3-8% of sodium aluminum sand, 0.5-3% of diluent and 8-18% of washing mud. The formula of the blank is adjusted and the process is further improved so that the linear expansion coefficient of the sintered blank can be within the range of 5.5-8*10<-6> / DEG C, and the difference with the liner expansion coefficient of a microcrystal frit commonly used at present can be basically controlled within the range of 0.6-1.8*10<-6> / DEG C; and as a result, the problems of flatness defect and the like due to unmatched expansion / shrinkage coefficients of the blank layer and the microcrystal glass layer in the sintering process are solved, the superior product rate is increased and the cost is saved.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

Method for embedding sapphire glass in zirconium oxide ceramics

The invention discloses a method for embedding sapphire glass in zirconium oxide ceramics. The method comprises the following steps that a zirconium oxide ceramic mould is enlarged according to the shrinkage coefficient of the zirconium oxide ceramics; injection forming is conducted by injecting zirconium oxide ceramic feed into the mould, and thus a zirconium oxide ceramic raw blank with an embedding part is formed; the surface of the embedding part of the zirconium oxide ceramic raw blank is coated with a layer of glass phase silicon oxide; and after the sapphire glass is placed in the embedding part, sintering is conducted in a sintering furnace. According to the method for embedding the sapphire glass in the zirconium oxide ceramics provided by the invention, binding force of the zirconium oxide ceramics and the sapphire glass is reinforced, so that the part decoration embedding effect of the zirconium oxide ceramics and the sapphire glass is achieved.

Owner:DONGGUAN HUAJING POWDER METALLURGY

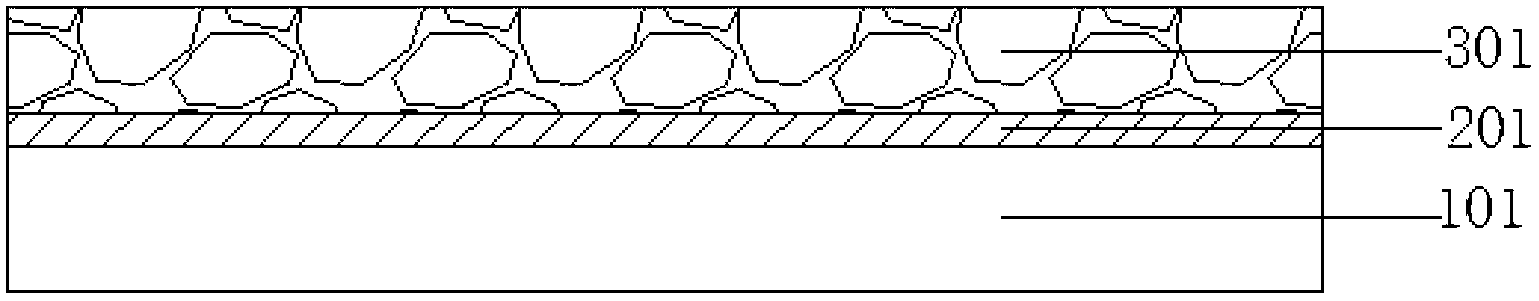

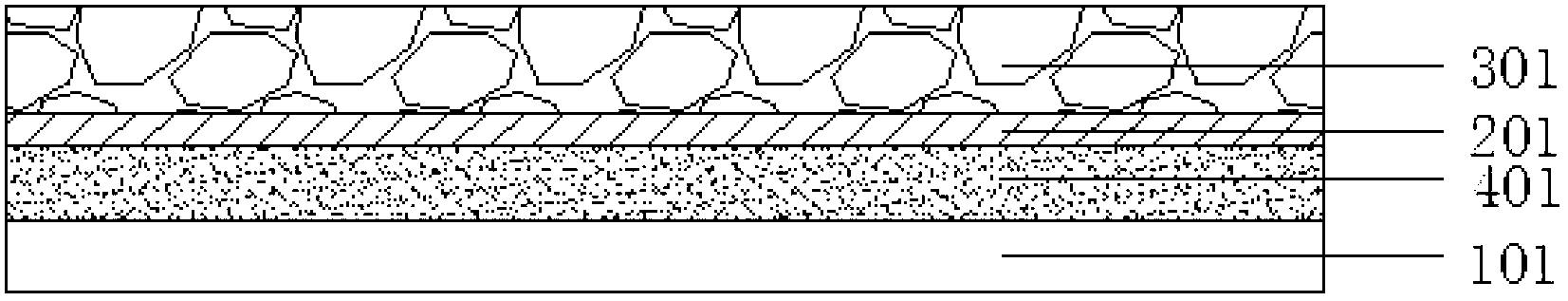

One-time sintering glass-ceramic composite board and preparation method thereof

The invention provides a one-time sintering glass-ceramic composite board and a preparation method of the one-time sintering glass-ceramic composite board, and belongs to the technical field of architectural ceramic production. The one-time sintering glass-ceramic composite board sequentially comprises a green body layer, a micro powder layer, a printing layer and a glass-ceramic layer from bottom to top. The micro powder layer is formed by stamping with the green body layer or spraying ball-milling slurry on the green body layer, the particle size of punch forming powder is smaller than or equal to 150 meshes, slurry used for spraying the ball-milling slurry is 325 meshes and screen residue is smaller than or equal to 0.3%, the expansion / shrinkage coefficient in the process of sintering the micro powder layer is between the expansion / shrinkage coefficient of the green body layer and the expansion / shrinkage coefficient of the glass-ceramic layer. According to the technical scheme, the problems of green body flatness defects caused by stress stretching and mismatching of the expansion / shrinkage coefficient of the green body layer and the expansion / shrinkage coefficient of the glass ceramic layer in the process of sintering can be solved. The matching rate of glass-ceramic clinkers for one-time sintering and green body raw materials is increased, the application range of the one-time sintering glass-ceramic composite board is increased, the influence on the superior product rate of products caused by instability of the green body raw materials is reduced, debugging frequency and debugging cycle are reduced, and therefore production is more stable.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

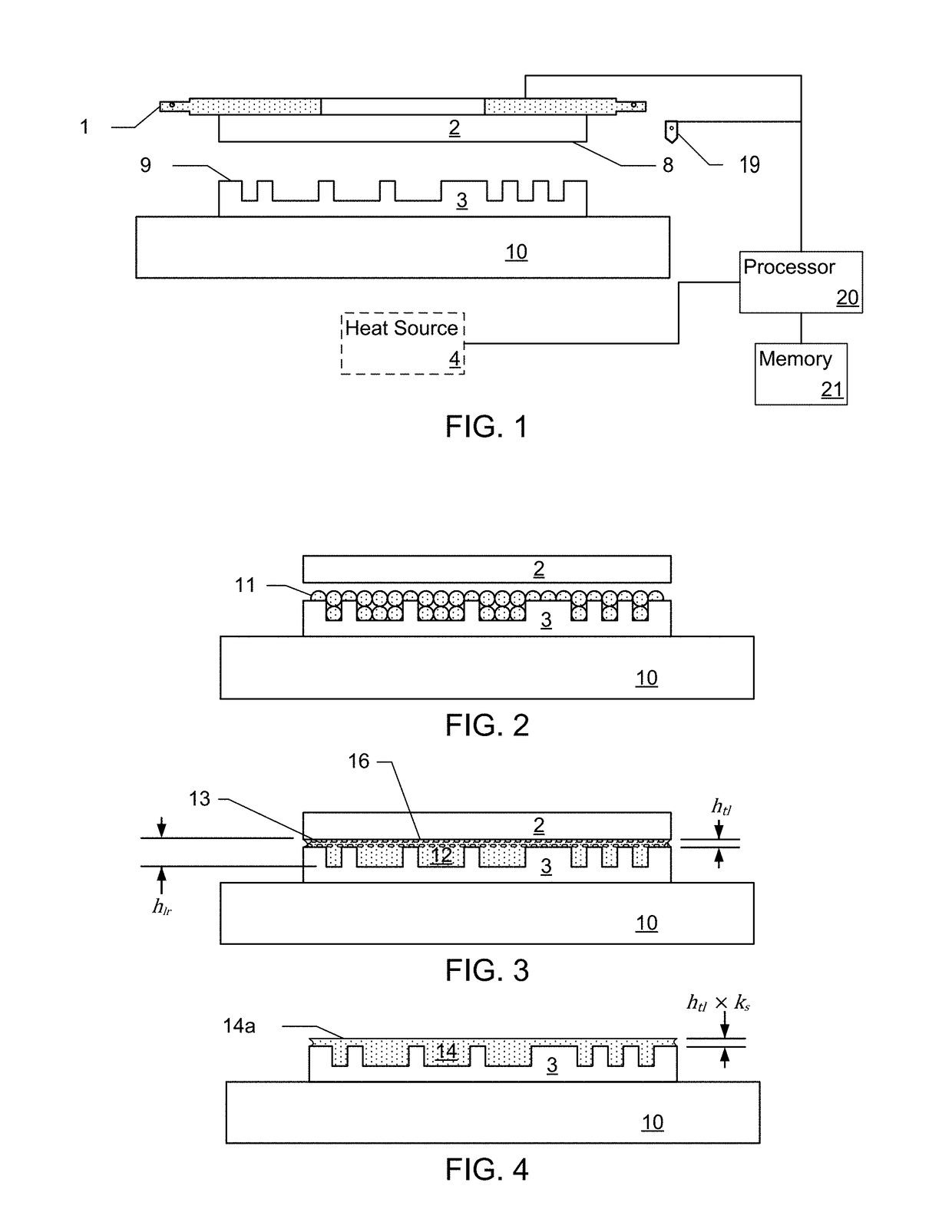

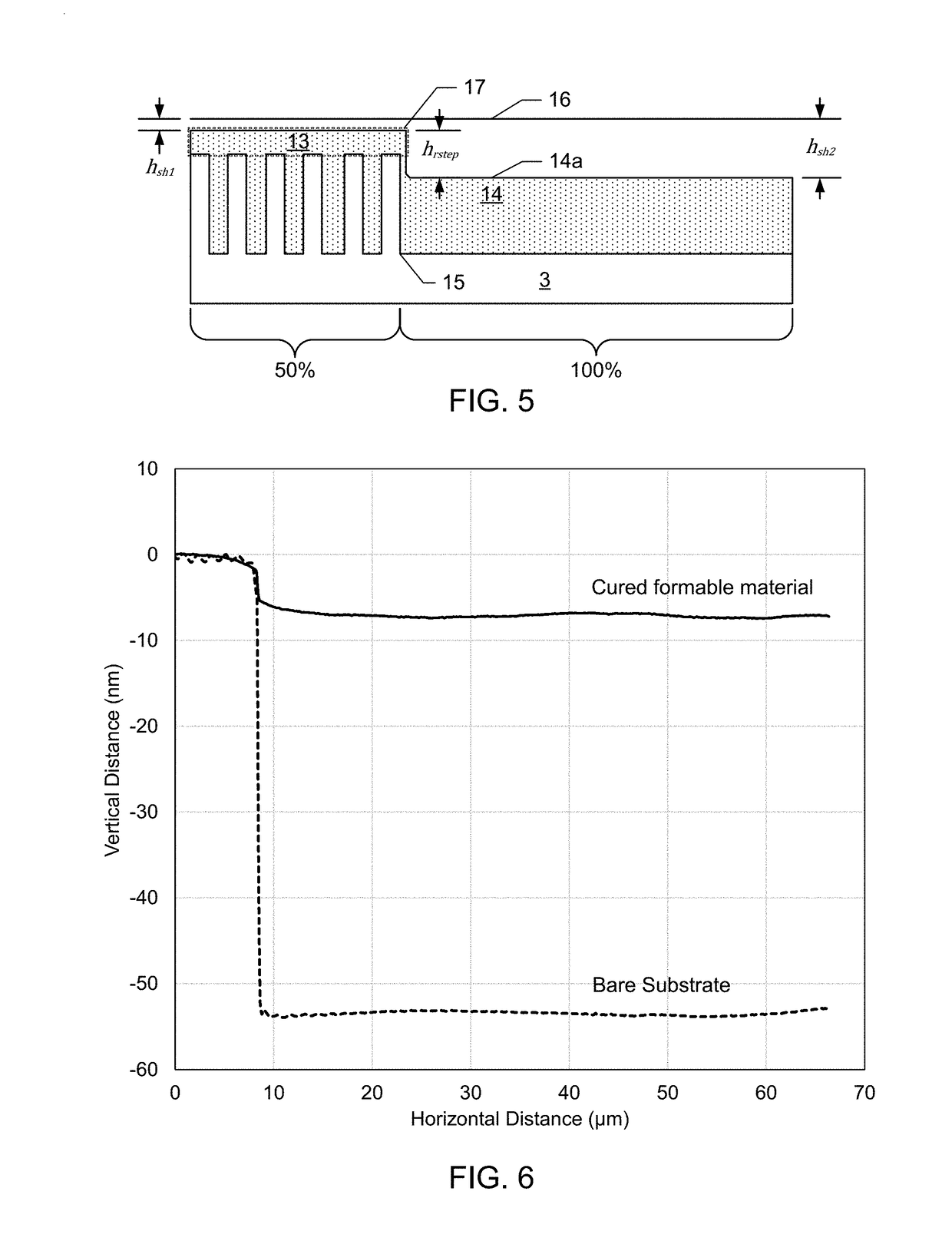

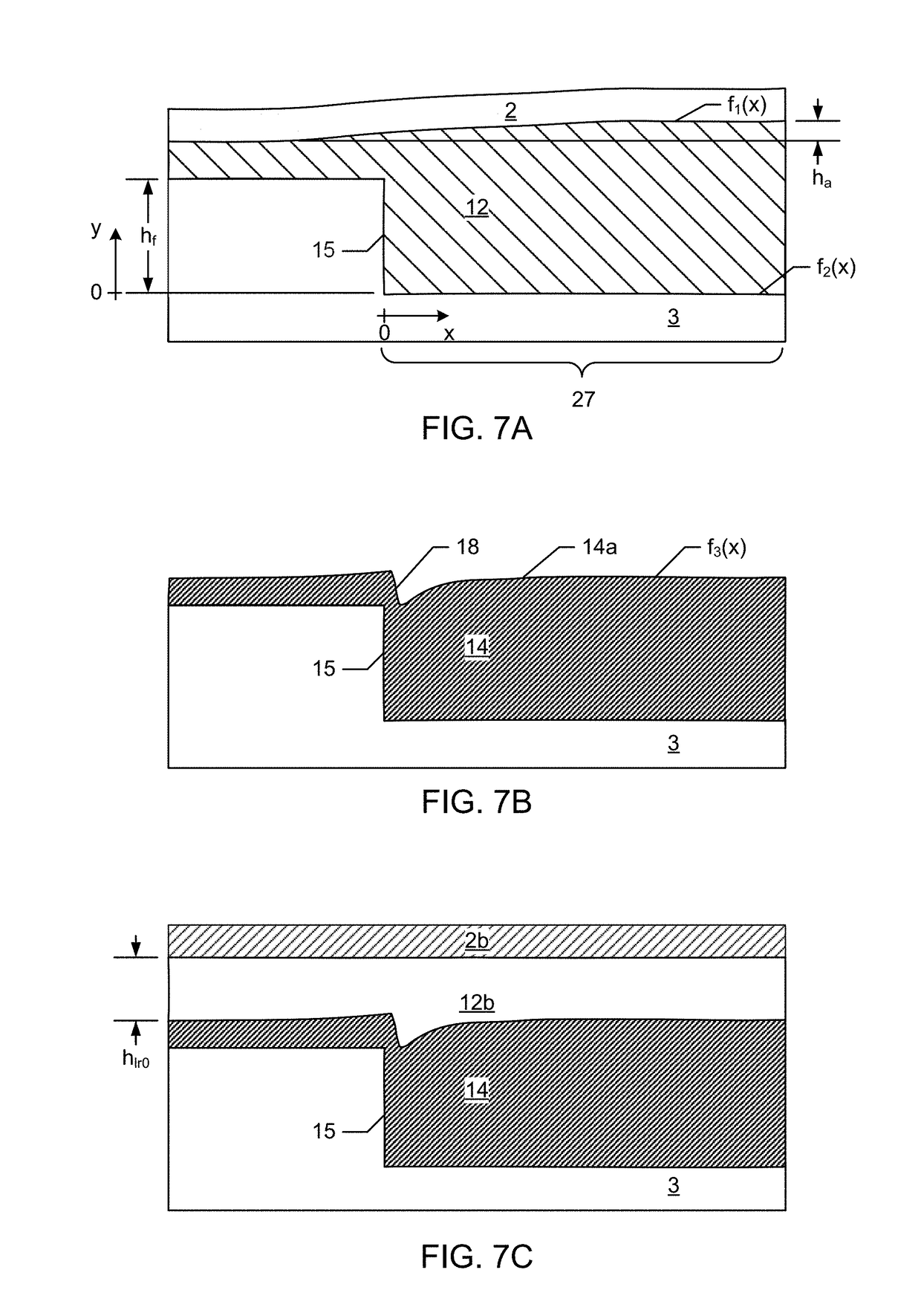

Planarization Process and Apparatus

ActiveUS20190080922A1Semiconductor/solid-state device testing/measurementPhotomechanical apparatusStep heightTopography

Methods and apparatus for planarization of a substrate. Material is dispensed onto the substrate that varies depending upon the substrate topography variation. A superstrate is brought into contact with the material, the material takes on a shape of the superstrate. The material is solidified. The superstrate is lifted away from the solidified material. Material has a first shrinkage coefficient. Second material is dispensed onto the solidified material with an average thickness. The average thickness is greater than a second material thickness threshold that is dependent upon step height of the substrate and the first shrinkage coefficient. The second material is then solidified.

Owner:CANON KK

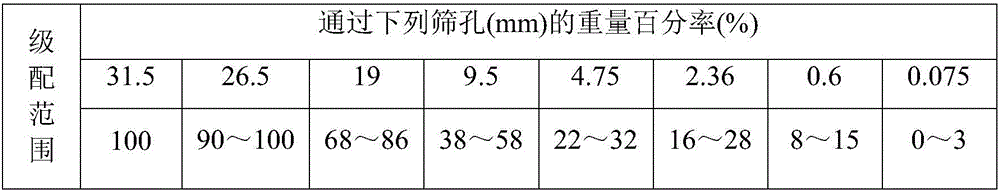

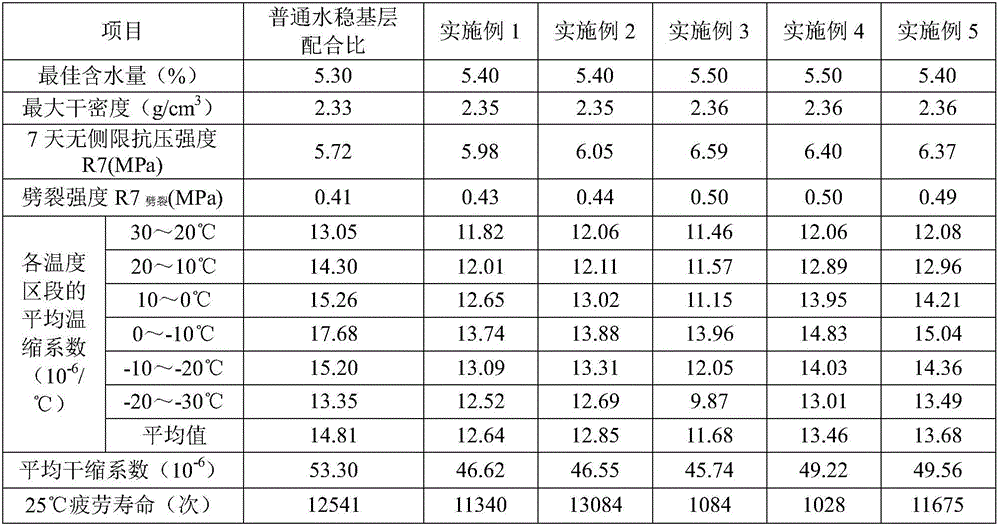

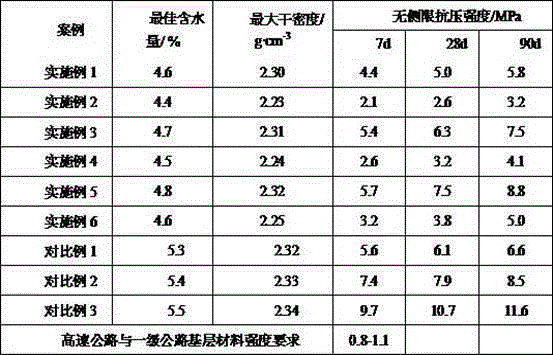

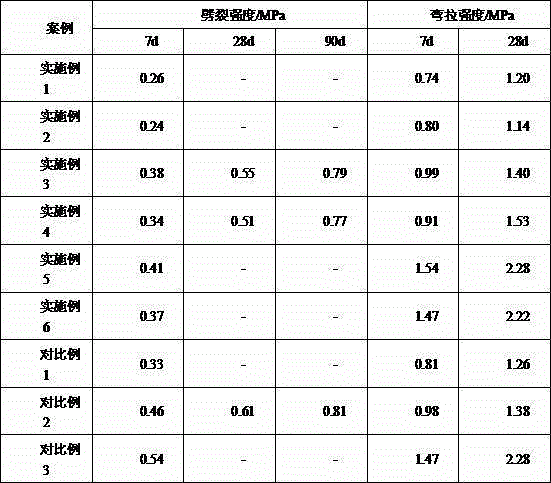

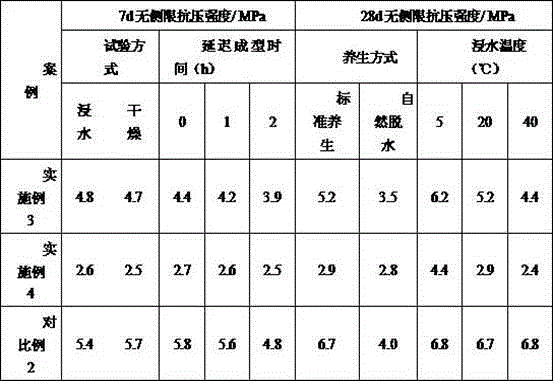

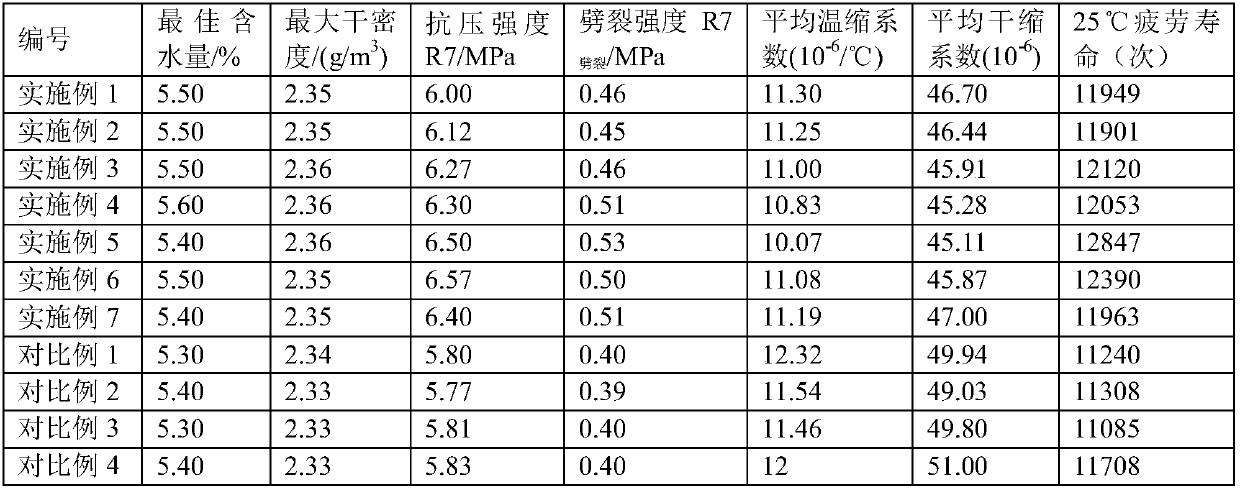

Anti-cracking mixture for cement-stabilized bases of roads in alpine high-altitude regions

The invention discloses a mixture for cement-stabilized bases, and particularly relates to an anti-cracking mixture for cement-stabilized bases of roads in alpine high-altitude regions, which consists of the following components in percentage by weight: 75 to 85 percent of aggregate, 5 to 10 percent of natural sand, 3 to 6 percent of cement, 5 to 10 percent of anhydrous sodium sulphate and 1.5 to 4 percent of aluminum sulfate; and the aggregate is characterized in that the aggregate crushing value is not greater than 28 percent, the flat and elongated particle content is not higher than 15 percent, and the plasticity index of the aggregate less than 0.6mm is less than 4 percent. The mixture for cement-stabilized bases which is disclosed by the invention is designed according to the alpine high-altitude characteristics, the average temperature shrinkage coefficient and the average dry shrinkage coefficient are effectively decreased, moreover, the requirement on the compressive strength, splitting strength and fatigue properties of the mixture can be met, the mixture can help to prevent the problem of the cracking of cement-stabilized bases in alpine high-altitude regions, the effect of reducing the number of reflection cracks of pavements in alpine high-altitude regions is remarkable, and the mixture is applicable to the construction of road bases in the Tibetan plateau region of China.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Method for reducing firing shrinkage coefficient of alumina ceramic material and product made by the same

The invention discloses a method for reducing the firing shrinkage coefficient of an alumina ceramic material and product made by the same. The firing shrinkage coefficient of the alumina ceramic material can be reduced by adopting metal aluminum powder instead of aluminum oxide powder so as to reduce the firing deformation rate of the product; the accurate control on size of alumina ceramic product can be implemented, and the post-processing cost of the product can be reduced by controlling the firing shrinkage coefficient to be tiny; the method for reducing the firing shrinkage coefficient of the alumina ceramic material is suitable for industrialized production.

Owner:JINGDEZHEN CERAMIC INSTITUTE

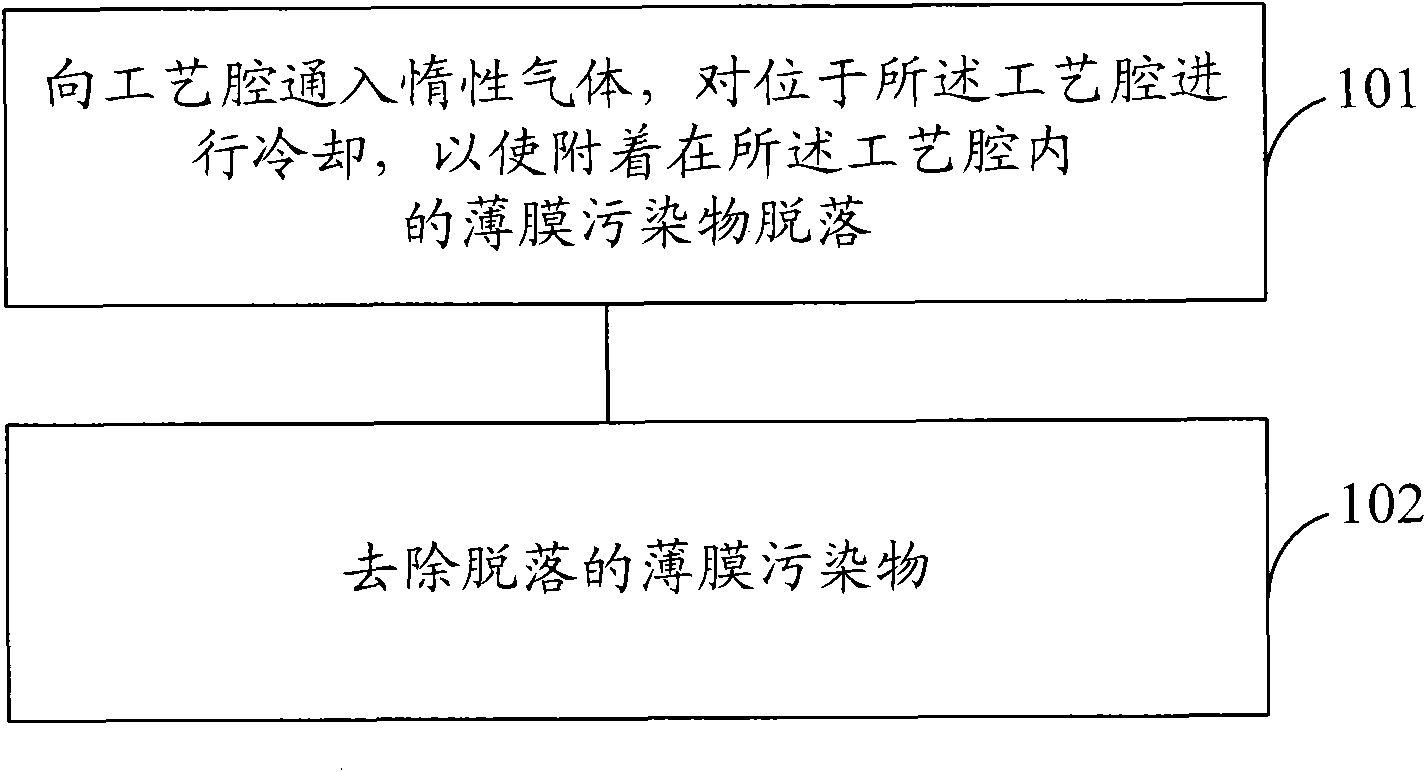

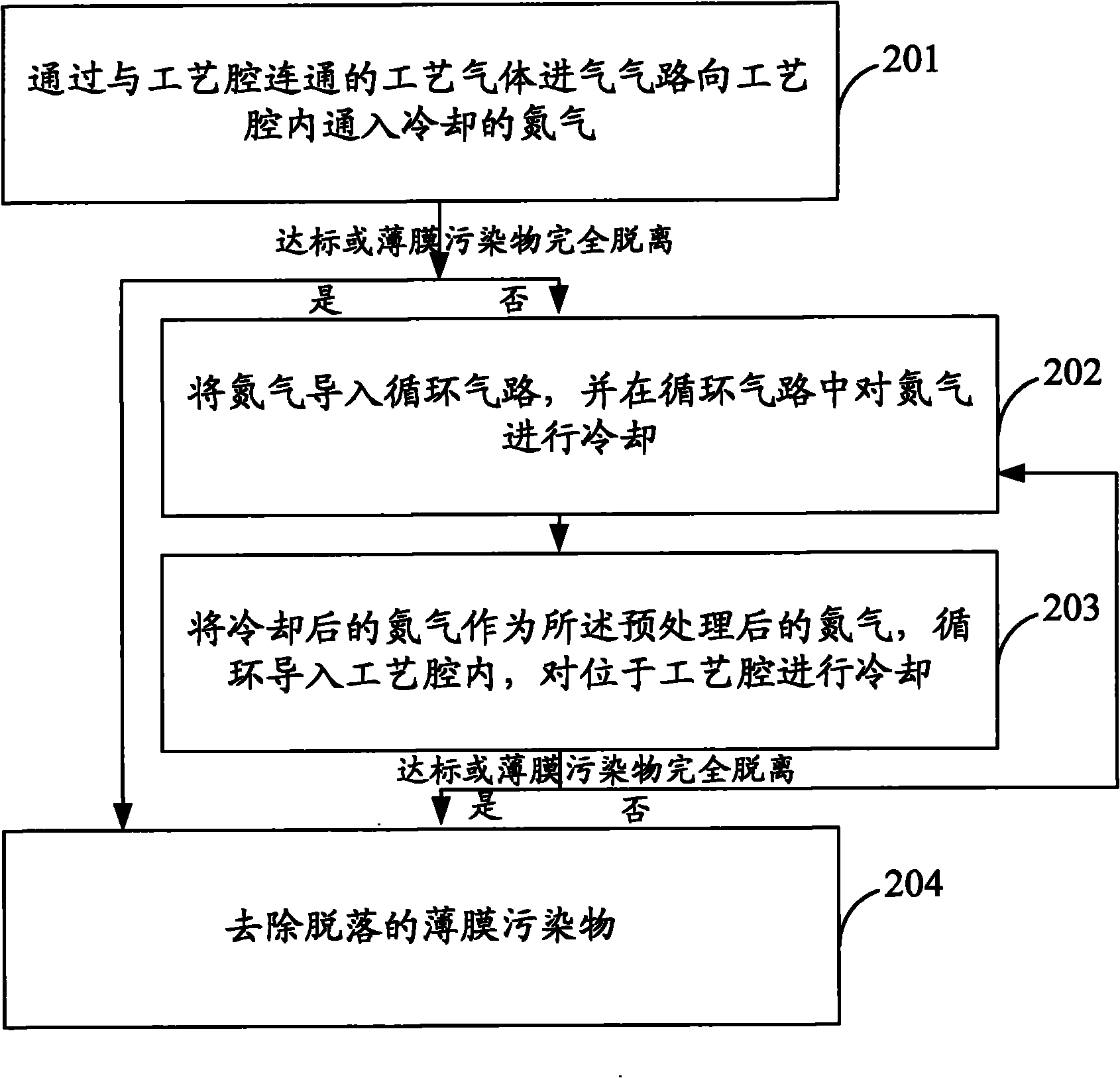

Method for removing film contaminants generated in the technological process and PECVD system

InactiveCN102108504AAchieve cleaningTo achieve the purpose of cleaningChemical vapor deposition coatingChemical agentShrinkage coefficient

The invention provides a method for removing film contaminants generated in the technological process and a plasma enhanced chemical vapor deposition (PECVD) system. The method for removing the film contaminants generated in the technological process is applied to a plasma enhanced chemical vapor deposition system, and comprises the following step of: cooling a part to which the film contaminants are attached, so that the film contaminants attaching to the part are separated from the part, wherein cold shrinkage coefficients of the part and the film contaminants are different. The film contaminants attaching to the part are removed by a physical means, a chemical agent is not needed for corrosion, and the aim of cleaning the part in the PECVD system without damage is fulfilled; moreover, the part is not needed to be detached, the cleaning process is convenient and quick, the maintenance time is reduced and the yield and production efficiency are improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Anti-sticking sand casting coating and preparation method thereof

InactiveCN108787996AHigh densityReduce voidsFoundry mouldsFoundry coresMulliteVolumetric Mass Density

The invention relates to an anti-sticking sand casting coating and a preparation method thereof, and belongs to the technical field of casting. According to the anti-sticking sand casting coating andthe preparation method thereof, a refractory aggregate is selected, an irreversible phase change is generated at a relatively low temperature and large expansion is generated, so that the surface of powder particles in a coating layer sintering shell is sintered more sufficiently, and the particles are in general adhesion due to surface fusion; the coating layer is in a glassy state, the gap of the coating layer is less, the density is higher, the shielding effects of element migration and diffusion are stronger, high-viscosity square quartz generated during high-temperature transformation canresist permeation of metal liquid, and the defect of mechanical sand sticking of castings can be prevented; and the line shrinkage coefficient differences between the glass state coating layer and the casting metal are also large after cooling, the cutting stress of the interface between the casting and the coating layer is increased, so that the coating layer and the casting are peeled off automatically, so that a casting with a smooth surface is obtained; and the thermal chemical stability of a generated mullite phase is high, the generated mullite phase is not easy to react with acid and alkaline oxides, and the prevention of the chemical sand sticking defects of castings is facilitated.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

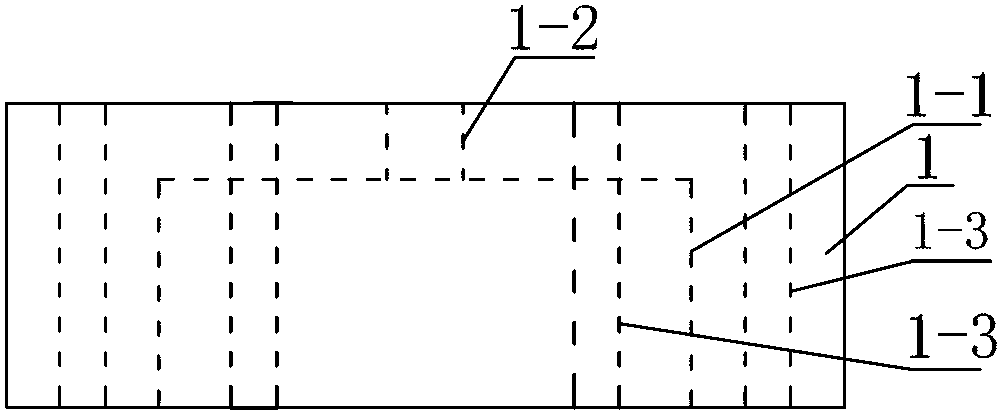

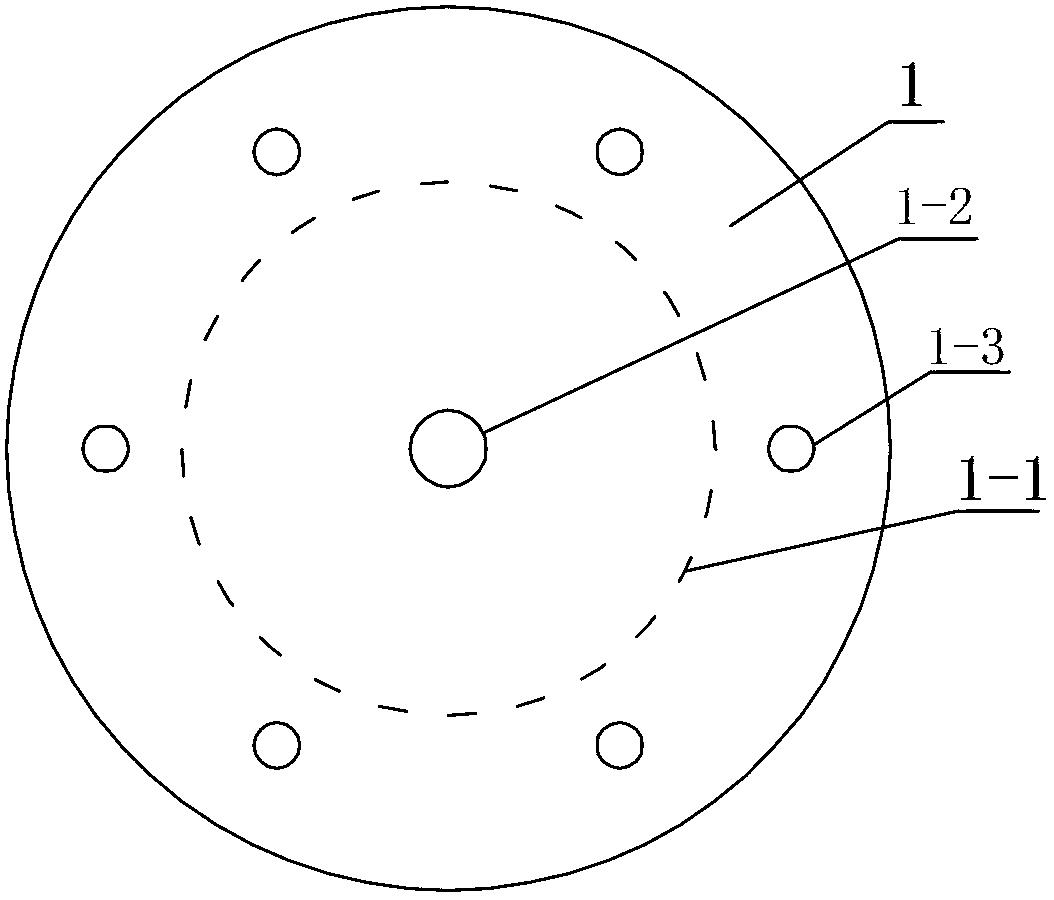

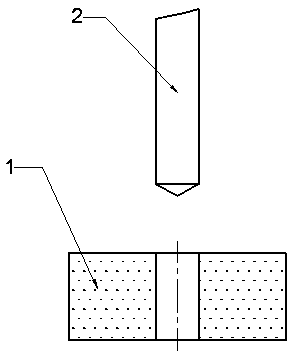

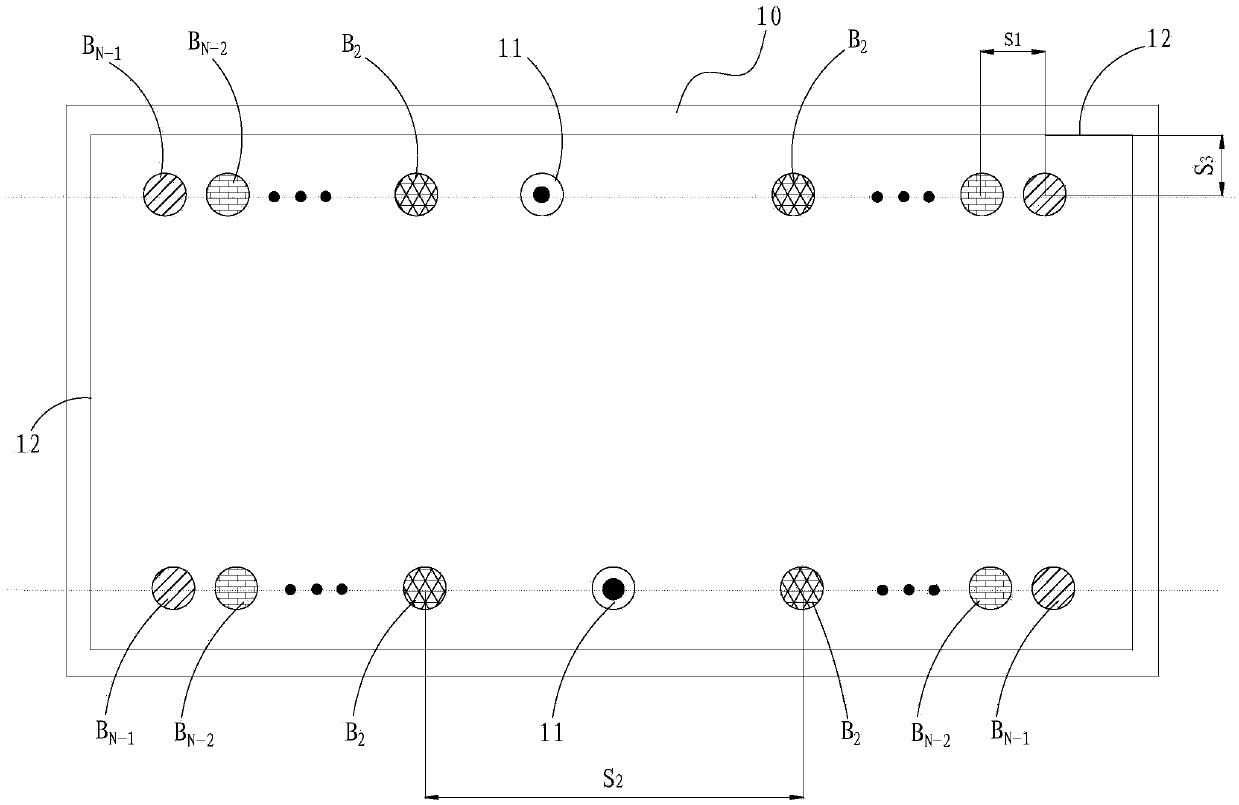

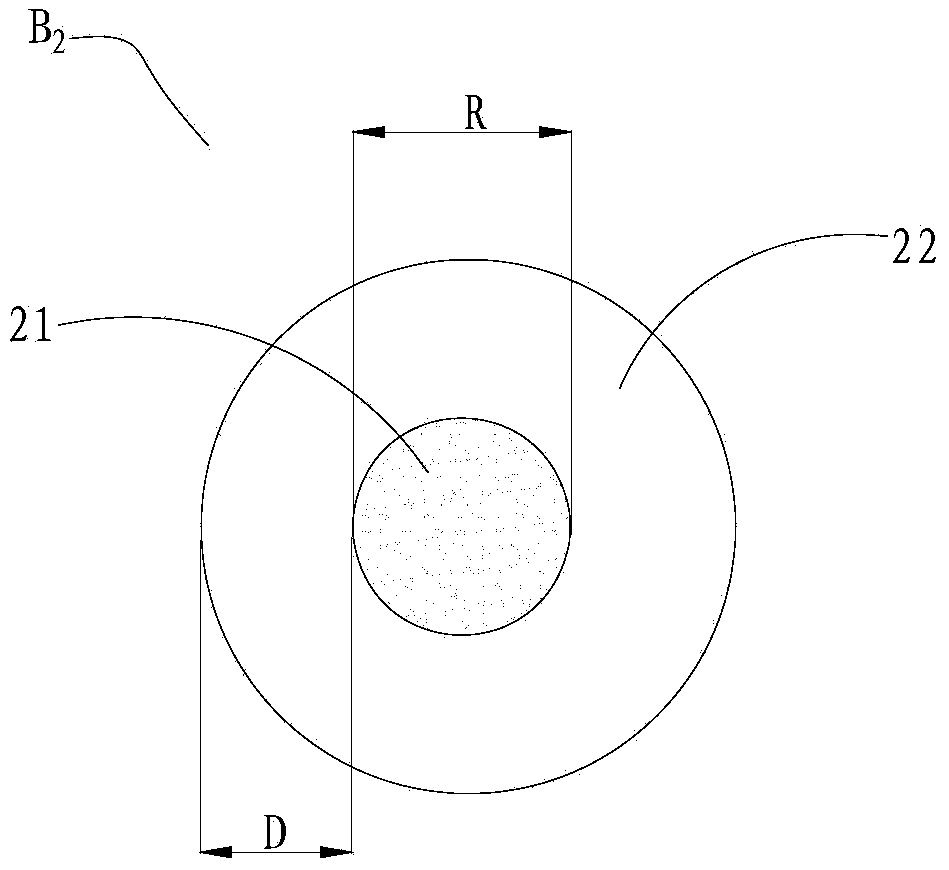

Multilayer circuit board expansion and shrinkage coefficient obtaining method and manufacturing method of multilayer circuit board

ActiveCN105376964AEasy alignmentExpansion and contraction coefficient is accuratePrinted circuit aspectsMultilayer circuit manufactureX-rayComputer science

The invention discloses a multilayer circuit board expansion and shrinkage coefficient obtaining method and a manufacturing method of a multilayer circuit board. The multilayer circuit board expansion and shrinkage coefficient obtaining method comprises the following steps: providing multiple inner plates to be pressed and an outer plate, adding more than three targets to the inner layers, and enabling the targets between the multiple inner layers to be arranged in a staggered mode; performing lamination processing on the multiple inner layers and the outer layer; obtaining target position information of the multiple inner plates through an X-Ray target drilling machine; and according to the target position information of the inner plates, obtaining an expansion and shrinkage coefficient b of the inner plates through calculation. According to the multilayer circuit board expansion and shrinkage coefficient obtaining method, the targets between each inner plate is arranged in a staggered mode, and after the targets between the inner plates are arranged in a staggered mode, the target position information of the N-2 inner layers can be simultaneously obtained through the X-Ray target drilling machine, such that the expansion and shrinkage coefficient of each inner plate can be obtained according to the target position information of each inner plate, and the alignment accuracy of line patterns between the inner plates can be improved.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Modified China fir composite wood

InactiveCN108098950AGood dimensional stabilityReduced impact toughnessPressure impregnationWood impregnation detailsPerformance indexComposite lumber

The invention provides modified China fir composite wood. The composite material has better dimensional stability. Impact toughness of modified China fir is reduced slightly, while other main mechanical performance indexes such as bending strength, bending elasticity modulus, parallel-to-grain compressive strength, hardness and the like are all increased. Fast growing China fir wood is treated with an aluminium sulfate solution and a water glass solution in sequence in experiments in order to improve properties of the fast growing China fir wood. Aluminium ions immersed into the wood are boundwith silicate ions, aluminium sulfate precipitates are generated in wood microfiber gaps and cells of tracheids (or fiber), so that the wood is filled with a large amount of inorganic matter, and theChina fir inorganic composite wood is obtained. Dimensional stability of the inorganic composite wood is improved substantially, anti-shrinkage coefficient can reach 34.21, and stability coefficientreaches 80% or higher.

Owner:哈尔滨正灏建筑设备安装工程有限公司

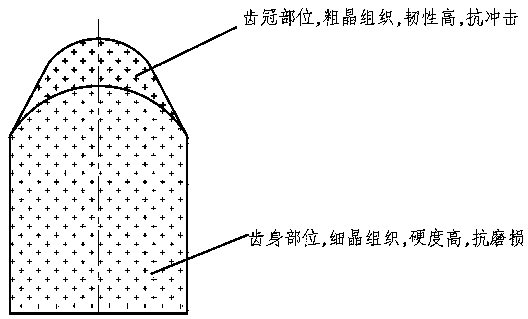

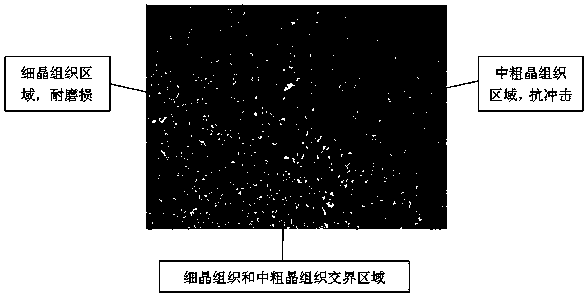

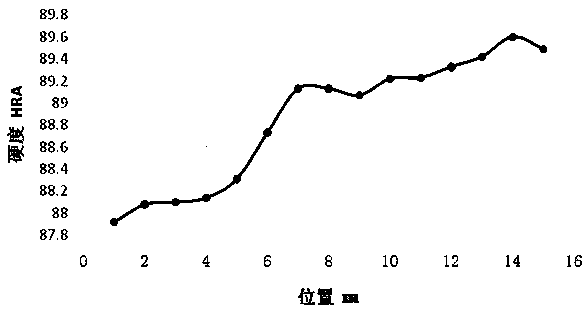

Macroscopic gradient hard alloy conical cylindrical tooth and preparation method thereof

ActiveCN110453128AHigh surface hardnessImprove surface wear resistanceTurbinesOther manufacturing equipments/toolsAlloySlow cooling

The invention discloses a macroscopic gradient hard alloy conical cylindrical tooth and a preparation method of the macroscopic gradient hard alloy conical cylindrical tooth. The method comprises thefollowing steps that a mixture A and a mixture B with different WC particle sizes, the same Co content and different carbon contents are respectively prepared; a die is designed according to the actual shrinkage coefficient, forward pressing is adopted, the mixture B is added into the die for pre-pressing, then the mixture A is added, and the mixtures are pressed into a mixed pressed blank; duringsintering, partial pressure sintering is carried out at the temperature of 1280-1430 DEG C, 20-60mba of argon gas is introduced, during cooling, slow cooling is carried out from 1430 DEG C to1350 DEGC, rapid cooling is carried out from 1350 DEG to 1250 DEG C, natural cooling is carried out from 1250 DEG C to room temperature, and the macroscopic gradient hard alloy conical cylindrical tooth is obtained after being discharged. The surface layer of the macroscopic gradient hard alloy conical cylindrical tooth has high toughness, the core has high hardness and wear resistance, and the service life of the conical cylindrical tooth is prolonged.

Owner:JINAN INSTITUTE OF METALLURGICAL SCIENCE CO LTD

Skin color-based inner face image segmentation method

ActiveCN106981066AStrong real-timeImprove recognition accuracyImage enhancementImage analysisSkin colorLogical operations

The present invention relates to a skin color-based inner face image segmentation method. The method comprises the steps of converting a front-face image in the white light from the RGB color space into the YCrBr color space, simultaneously constructing a skin-color clustering-based elliptical model for filtering a candidate image, and obtaining a skin-color mask; based on the skin-color mask, obtaining the candidate area of a human face as an external rectangle, and generating a preliminary elliptical segmentation region for segmenting an original image; constructing a shrinkage space for judging a mask, subjecting the shrinkage space and a skin-color distribution diagram in an elliptical area to logical operation so as to obtain non-skin pixels remaining in four directions, and adopting the obtained pixels as an adaptive shrinkage coefficient; according to the shrinkage coefficient, updating the elliptical segmentation region; repeating the iteration process until the number of iterations reaches an upper limit or the shrinkage coefficient is within a specified error range; stopping the iteration process and outputting a target image. The method of the present invention is not dependent on any library file, and is strong in real-time property, high in recognition precision, short in shrinkage time-consuming duration, and accurate in inner-face region fitting effect.

Owner:武汉嫦娥医学抗衰机器人股份有限公司

Emulsified asphalt cement stabilized macadam

The invention belongs to the technical field of road building materials and discloses emulsified asphalt cement stabilized macadam. The emulsified asphalt cement stabilized macadam is prepared from, by the weight ratio to macadam, 2-4 parts of mixed emulsified asphalt, 3.5-5.5 parts of mixed cement, 4.5-6.0 parts of water and 100 parts of macadam. The emulsified asphalt cement stabilized macadam has a hardness and softness feature and good water-damage-resistant performance, compared with common cement stabilized macadam, compression resistance and splitting strength of mixed materials are lowered, and flexural-tensile strength is approximate at the normal temperature of 20 DEG C and obviously improved at the low temperature of 5 DEG C. The dry shrinkage water-loss rate, dry shrinkage coefficient and dynamic modulus are lowered, and the limit strain capacity is increased; construction performance is excellent; compaction is easy, little segregation is generated, strength variability is small, and bad influences of delay forming and dry maintenance are weakened; the requirements for mechanical strength of pavement bases of high-grade highways and urban roads can be met, and base shrinkage cracks can be effectively reduced or prevented.

Owner:TONGJI UNIV

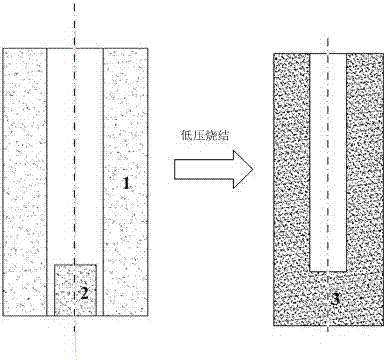

Manufacture method for superfine hard alloy blind hole bars

The invention relates to a manufacture method for superfine hard alloy blind hole bars. Soft straight-hole superfine hard alloy bar billets are manufactured in an extruding forming mode, soft solid bar billets are manufactured in an extruding or mould pressing mode, the diameter of each soft solid bar billet is smaller than that of a straight hole of each soft straight-hole superfine hard alloy bar billet, the shrinkage coefficient of each soft solid bar billet is smaller than that of each soft straight-hole superfine hard alloy bar billet, the soft solid bar billets are cut off according to the fixed length, then put into the hole at one end of each soft straight-hole bar billet to be fixed, placed into a low-pressure sintering furnace to be sintered, the holes of the soft straight-hole bar billets are larger than the shrinkage coefficient of each soft solid bar billet in during sintering, prestress produced in the sintering process enable the soft straight-hole bar billets and the soft solid bar billets to be densified through metallurgical bonding, and the superfine hard alloy blind hole bars different in diameter and depth are manufactured. The manufactured superfine hard alloy blind hole bars are used for manufacturing automobiles and aviation machinery and non-standard and efficient hard alloy overall inner-cooling drill bits for machining other mechanical device parts.

Owner:武汉新锐合金工具有限公司

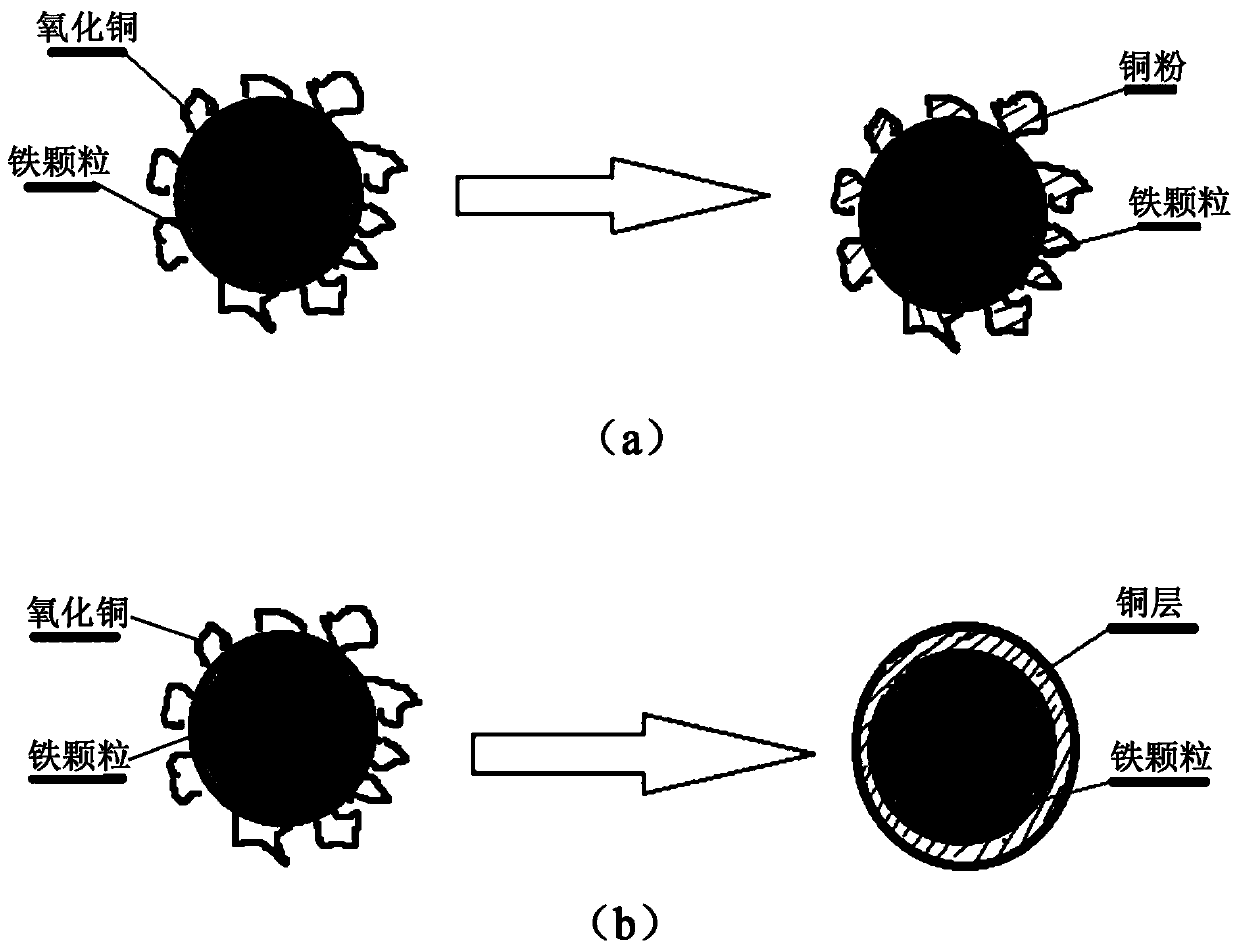

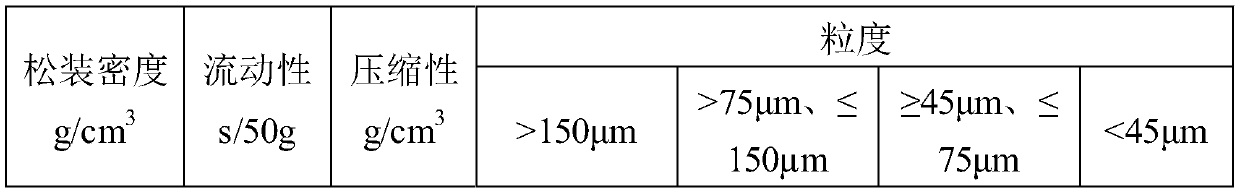

Copper-coated iron powder and preparation method thereof

ActiveCN110369730AExcellent performance indexReasonable particle size distributionTransportation and packagingMetal-working apparatusIron powderPerformance index

The invention provides a copper-coated iron powder and a preparation method thereof. The preparation method comprises the following steps of fully mixing copper oxide powder and iron powder to obtainmixed material powder; in protective atmosphere composed of reducing gases, rising the temperature of the mixed material powder to T1 and keeping heat preservation, then rising the temperature of themixed material powder to T2 and keeping heat preservation, going on to rise the temperature of the mixed material powder to T3 and keeping heat preservation, cooling the mixed material powder to 40 DEG C or below, and obtaining a cooled product, wherein the T1 is larger than or equal to 250 DEG C and smaller than 600 DEG C, the T2 is larger than or equal to 600 DEG C and smaller than 690 DEG C, and the T3 is larger than or equal to 690 DEG C and smaller than 820 DEG C. The cooled product is crushed and screened to obtain copper-coated iron powder. The copper-coated iron powder includes the product prepared with the preparation method. The copper-coated iron powder and the preparation method thereof have the beneficial effects that the preparation method is easy and convenient to carry out,and is free of pollution in the preparation process, various performance indexes of the copper-coated iron powder are excellent, the size distribution is reasonable and easy to control, the mobilityof a powder body is good, the powder is high in oxidation resistance, and a sintered product is small in shrinkage coefficient.

Owner:四川容克斯科技有限公司

Method for determining welding shrinkage of H-type longitudinal beam

ActiveCN107957979AMeet the design requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a method for determining the welding shrinkage of an H-type longitudinal beam. The method comprises the steps that the length, cross section area, weld area and welding shrinkage of a preset number of welded H-type longitudinal beams are counted; based on a shrinkage calculation formula, the welding shrinkage coefficient of each welded H-type longitudinal beam is calculated; averaging operation is conducted on the welding shrinkage coefficients of the preset number of welded H-type longitudinal beams, and a first welding shrinkage coefficient is obtained; the length, cross section area and weld area of an H-type longitudinal beam to be machined are determined, the first welding shrinkage coefficient is used as the welding shrinkage coefficient of the H-type longitudinal beam to be machined, and the welding shrinkage of the H-type longitudinal beam to be machined is calculated out based on the shrinkage calculation formula. By means of the method, the welding shrinkage of the H-type longitudinal beam can be precisely determined, so that the blanking length of a corresponding part is determined, and it is unnecessary to conduct cutting machining after weldingto enable the length of the longitudinal beam to meet a design requirement.

Owner:SANJIANG VOLAT SPECIAL VEHICLE

Preparation method of graded cemented carbide

The invention discloses a preparation method of graded cemented carbide. The preparation method comprises the following steps: an alloy inner core and an annular alloy pressing blank are manufactured, wherein the shrinkage coefficient of the annular alloy pressing blank is larger than that of the alloy inner core, the alloy inner core is embedded in the annular alloy pressing blank in a sleeving manner, and the alloy inner core is in interference fit with the annular alloy pressing blank to form an embedding part; the embedding part is placed in a sintering furnace for first-time sintering, vacuumizing is performed, inert gas is injected, the sintering temperature is 1200-1300 DEG C, the sintering time is 1-3 hours; vacuumizing is performed again for second-time sintering at the sintering temperature of 1380-1470 DEG C with the sintering time of 1-2 hours, cooling to room temperature is carried out, therefore sintering is completed. The preparation method of graded cemented carbide provided by the invention has the advantages as follows: powder with more than two grades is used to be compressed respectively to form pressing blanks with different shrinkage coefficients, and the charging method by enabling two products to be embedded in a sleeving manner is adopted, therefore the outer diameter of the inner part is in fit with the inner diameter of the outer part after sintering, gradient cemented carbide with different grades at the inner part and the outer part is prepared, and the method can be also used for increasing the outer diameter of products.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

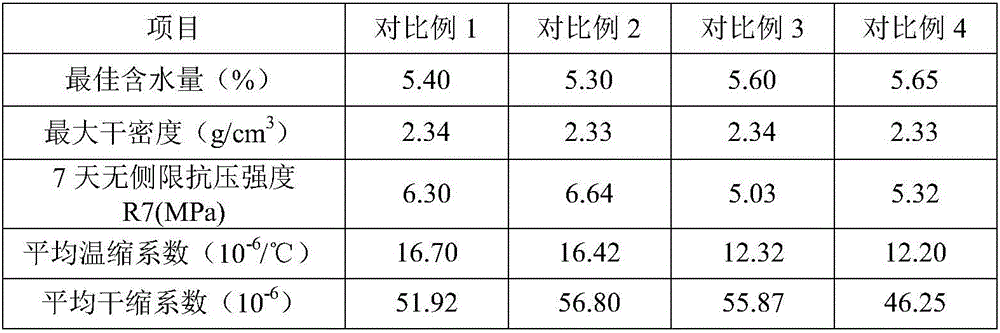

Cement-stabilized macadam base and construction method thereof

ActiveCN110055846AImprove fatigue resistanceImproved ability to compensate for shrinkageRoadwaysRoad surfaceFatty acid

The invention relates to the technical field of highway pavement laying, in particular to a cement-stabilized macadam base. The cement-stabilized macadam base is prepared from the following compositions in parts by weight: 78-87 parts of coarse aggregates, 5-13 parts of fine aggregates, 4-9 parts of high belite cement, 0.2-0.8 part of a calcium sulphoaluminate-calcium oxide compound expansion agent and 5-15 parts of water, a waterproof reinforcing agent is sprayed on the surface layer of the cement-stabilized macadam base, and the waterproof reinforcing agent is prepared from the following rawmaterials in percentage by weight: 1-3% of a fatty acid water-proofing agent, 50-70% of a styrene-acrylic emulsion, 15-30% of asbestos powder and 10-25% of water; and the invention further relates toa construction method of the cement-stabilized macadam base. According to the base obtained through construction, compared with the prior art, the mechanical strength is improved, the average temperature shrinkage coefficient and the average dry shrinkage coefficient are both decreased, and the comprehensive performance is improved.

Owner:河北交规院瑞志交通技术咨询有限公司

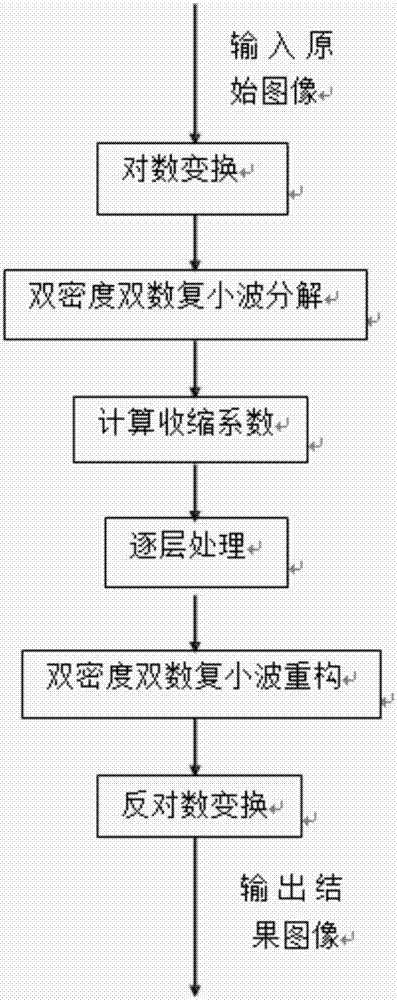

Image denoising method

InactiveCN107993211AQuality improvementStrong retentionImage enhancementImage analysisAnti-aliasingWavelet reconstruction

The invention discloses a remote sensing image denoising method. The method comprises the following steps of logarithm transformation, double-density dual-number complex wavelet decomposition, shrinkage coefficient calculation, layer-by-layer processing, double-density dual-number complex wavelet reconstruction, inverse-logarithm transformation and image output. Double-density double-tree complexwavelet transformation, the Bayesian theory and the quantum-derived idea are combined, and double-density double-tree complex wavelet transformation has translation invariance and the anti-aliasing characteristic, is more approximate to continuous wavelet transformation and has higher directivity, so that a mutual promotion effect is achieved after double-density double-tree complex wavelet transformation is combined with the quantum-derived method, the contradiction between spot removing smoothing and detail maintaining is better solved, the quality processed images is improved, an image speckle removing method is simple and effective, the image detail maintaining capability is high, a better visual effect is achieved, high-frequency signals and noise of the images are effectively distinguished, the self-adaptability of local filtering is enhanced, and image edge details are kept to a greater extent.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI +1

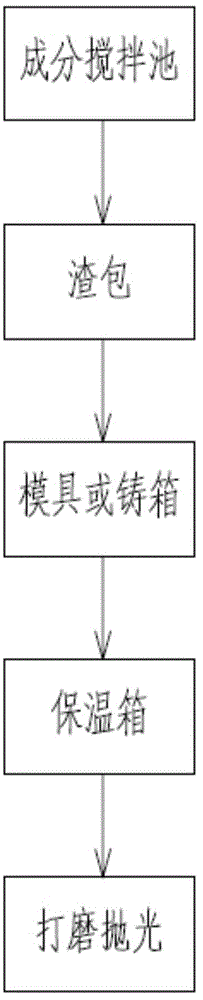

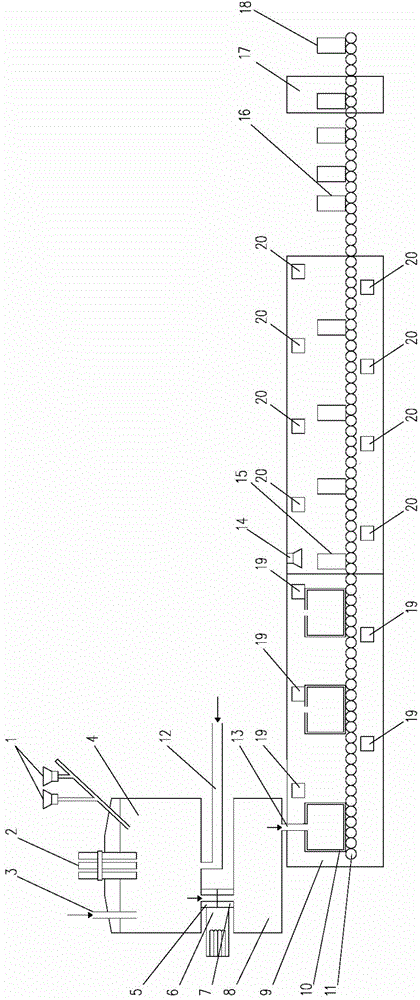

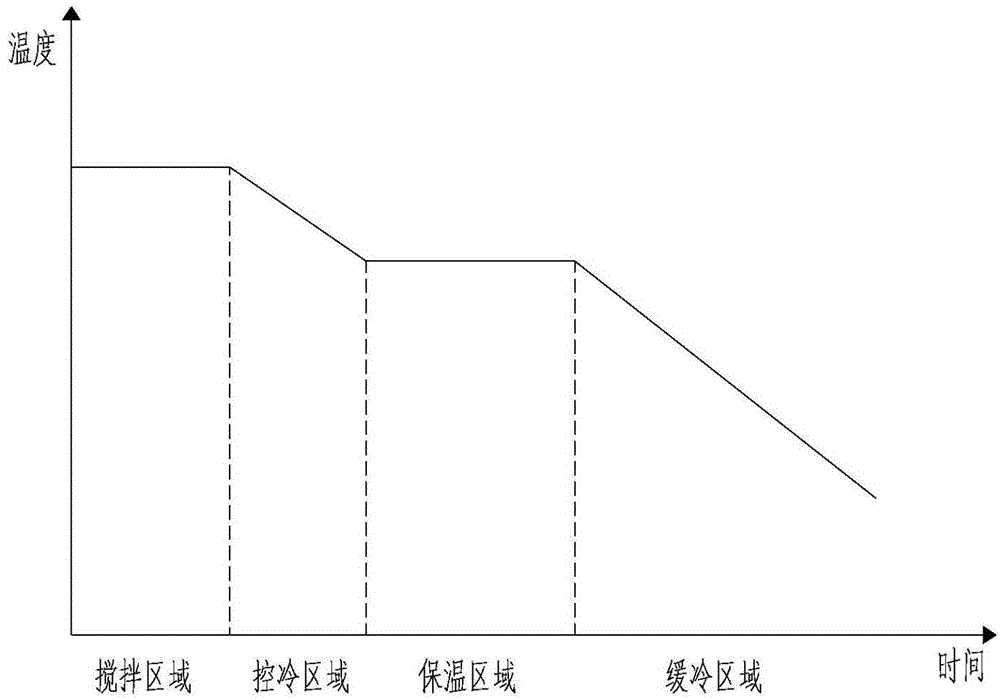

Temperature-controllable mold casting process method and equipment for producing cast stone through blast furnace slag

The invention belongs to the field of metallurgical and inorganic nonmetallic materials, and provides a temperature-controllable mold casting process method and equipment for producing cast stone through blast furnace slag. The process method comprises the following steps: (1) transferring the blast furnace slag into a component hardening, tempering and stirring pond by keeping the temperature of the blast furnace slag to be in a temperature interval of a tap hole of a blast furnace, adding a corresponding modifier and a corresponding colorant, and performing uniform stirring; (2) putting the slag into a mold through a slag hole for mold casting forming, or putting the slag into a casting box for amorphous mold casting treatment; (3) putting a de-molded product into a heat insulation box, spraying an enamel material, performing surface coloring treatment, and performing step-by-step cooling in the heat insulation box to room temperature so as to obtain a formed product; (4) polishing the surface of the formed product to obtain a finished cast stone product. According to the method and the equipment, blast furnace slag and waste resources are fully utilized. The produced cast stone is multi-purpose, is suitable for large-scale production, and has the characteristics of stable color quality, abrasion resistance, pressure resistance, acid-base resistance, small expansion and shrinkage coefficients and the like.

Owner:UNIV OF SCI & TECH BEIJING

Improved alumina ceramic core and preparation method thereof

The invention discloses an improved alumina ceramic core and a preparation method thereof and aims to solve the problems that an existing ceramic core has low firing porosity, low room temperature strength, high shrinkage cofficient, high high-temperature deflection and difficulty in core stripping and cannot be used in a high-temperature environment and later core stripping is difficult. The improved alumina ceramic core is prepared from ceramic slurry and a plasticizer, wherein the ceramic slurry is formed by mixing corundum powder, mullite, quartz powder, activated graphite, magnesium oxide and oleic acid; the plasticizer is formed by mixing paraffin, beewax and polyethylene. The method comprises preparation of the plasticizer, preparation of the ceramic slurry, preparation of a prefabrication material and preparation of the improved alumina ceramic core. The firing shrinkage coefficient of the non-strengthened improved silica ceramic core is 0.58% and is reduced by 2.52%; meanwhile, the high-temperature deflection of the improved alumina ceramic core after high-temperature reinforcement is 0.23 mm and reduced by 6.77 mm.

Owner:HARBIN INST OF TECH

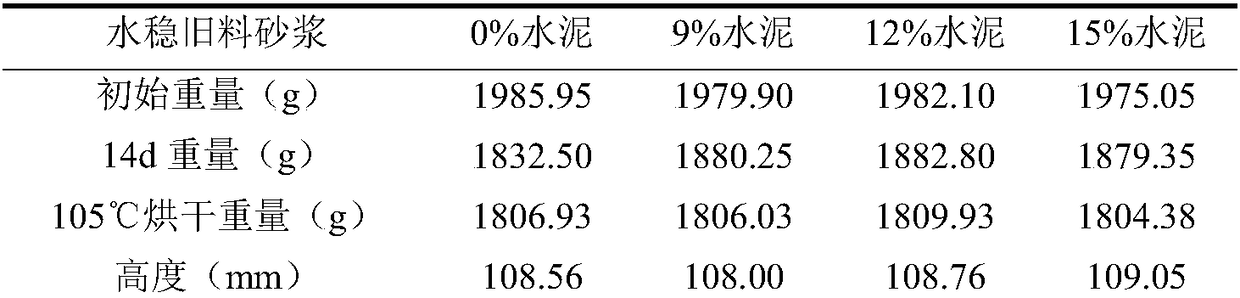

Method for determining dry shrinkage coefficient of cement stabilized macadam

The invention relates to a method for determining the dry shrinkage coefficient of cement stabilized macadam. The method comprises the following successive steps: step 1, determining the grading, optimum moisture content and maximum dry density of the cement stabilized macadam and determining the dosage of cement; step 2, calculating the dosage and water content of cement in a cement mortar test piece; step 3, making the test piece, and subjecting the shaped cement mortar test piece to maintenance; step 4, after completion of maintenance, placing the test piece in a dry shrinkage chamber to measure dry shrinkage amount and water loss rate; and step 5, calculating the dry shrinkage strain and dry shrinkage coefficient of the cement mortar test piece according to the measured water loss rateand dry shrinkage amount, and evaluating the dry shrinkage performance of the cement-stabilized graded macadam.

Owner:HENAN ZHONGYUAN EXPRESSWAY +1

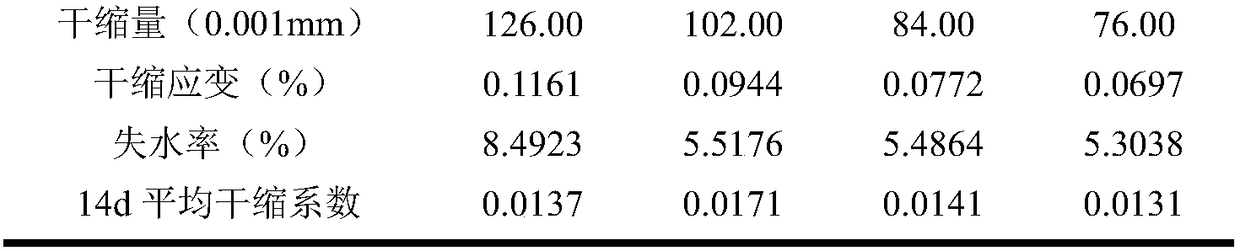

Optimizing method and system based on throughput rate and packet loss control CWND

ActiveCN104378307AImprove search speedImprove throughputError prevention/detection by using return channelData switching networksPacket lossTime delays

The invention provides an optimizing method and system based on the throughput rate and a packet loss control CWND. The method includes the following steps of calculating an actual instant throughput rate for data messages receiving ACK, calculating a smooth throughput rate according to the instant throughput rate, judging the changing state of the smooth throughput rate B, correspondingly controlling the increase mode of the CWND, entering a Recovery mode if packet loss happens at any moment, and reducing the CWND in the Recovery mode according to the CWND shrinkage coefficient. By means of the method and system, the purpose of calculating the CWND under the severe environment that time delay changes are large under the wireless communication environment and bandwidths fluctuate is achieved in a concentrated mode, and the best throughput rate is ensured.

Owner:BEIJING QINGWANG TECHNOLOGY CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com