Emulsified asphalt cement stabilized macadam

A technology for stabilizing crushed stone and emulsified asphalt with cement, applied in the field of road building materials, can solve problems such as failure to meet practical requirements, lack of systematic research on mechanical properties of stabilized crushed stone base materials, and pavement performance, and achieve modulus and compaction. The effect of excellent degree of compaction, high degree of compaction and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The mixture consists of the following raw materials (by weight):

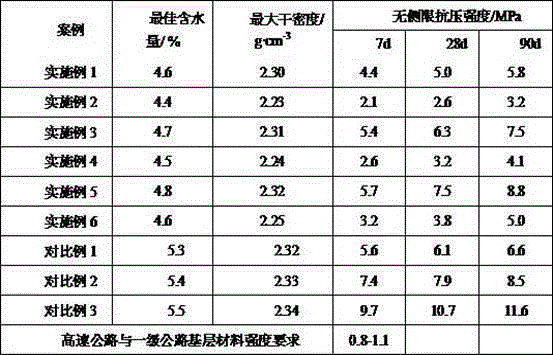

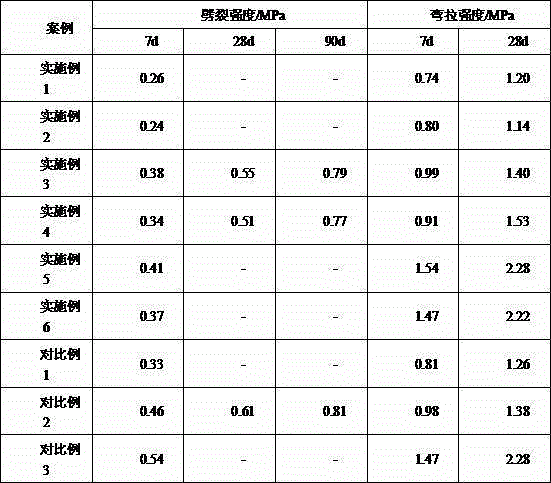

[0030] Gravel: 100; Cement: 3.5; Emulsified asphalt: 2. After weighing the raw materials according to the above ratio, add water to the mixture, and stir and mix evenly to obtain the roadbed material. The amount of water added is 4.9% of the weight of the gravel. Its performance indicators are shown in Table 1-Table 2.

Embodiment 2

[0032] The mixture consists of the following raw materials (by weight):

[0033] Gravel: 100; Cement: 3.5; Emulsified asphalt: 4. After weighing the raw materials according to the above ratio, add water to the mixture, and stir and mix evenly to obtain the roadbed material. The amount of water added is 4.7% of the weight of the gravel. Its performance indicators are shown in Table 1-Table 2.

Embodiment 3

[0035] The mixture consists of the following raw materials (by weight):

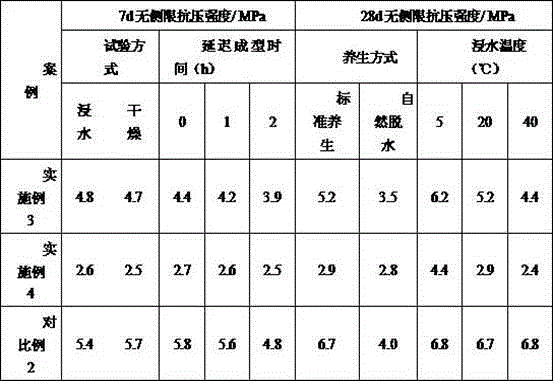

[0036] Gravel: 100; Cement: 4.5; Emulsified asphalt: 2. After weighing the raw materials according to the above ratio, add water to the mixture, and stir and mix evenly to obtain the roadbed material. The amount of water added is 5.0% of the weight of the gravel. Its performance indicators are shown in Table 1-Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com